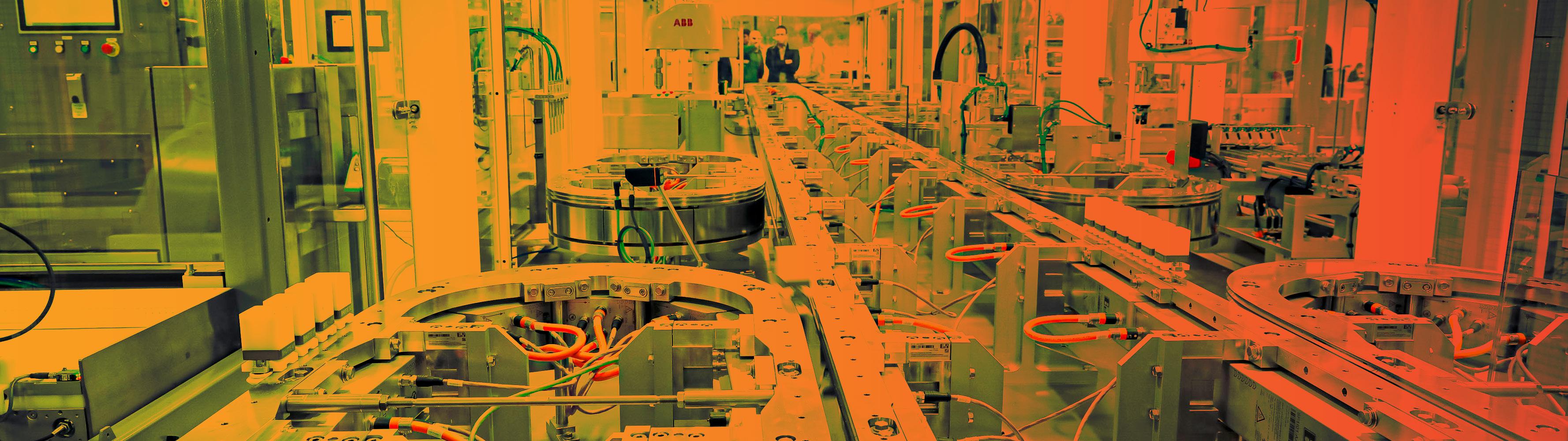

TRANSFORMING MANUFACTURING THROUGH DIGITAL TECHNOLOGY ADOPTION

DMI is a Government of Ireland initiative established to deliver worldclass digital manufacturing transformation solutions to Irish-based manufacturers.

our mission

An industry-led national organisation that enables Irishbased manufacturers to access, adopt and accelerate new digital technologies solving real-world challenges and driving future competitiveness.

our vISION

To position the Irish discrete manufacturing base at the forefront of digital transformation and to ensure that Ireland is recognised internationally as having a vibrant, collaborative, competitive and digitally enabled industry base, ideally suited to delivering the next generation of manufacturing.

our PURPOSE

Global Manufacturing is entering a new era of digitalisation: Industry 5.0. This represents the single most significant shift in the industry since the introduction of computers.

The Manufacturing Sector in Ireland is a key contributor to Ireland’s economic resilience, recovery and ongoing success. Employing c. 270,000 people nationally, representing 12% of total employment and accounting for a third of Irish GDP, the sector is also strategically important to the balanced regional development of Ireland.

DMI is a strategic, national intervention to sustain, upskill and digitise the Irish-based manufacturing sector, and to deliver transformative innovations for the manufacturing value chain in Ireland and across the globe.

1

our values

Delivering the next generation of digital manufacturing through inclusive, collaborative industry partnerships.

OPEN TO ALL

We are committed to supporting all manufacturers, both SMEs and MNCs, regardless of their size or level of technological maturity.

BENEFITS-DRIVEN COLLABORATION-BASED

Our success will be based around tangible benefits and real-word solutions focusing entirely on impact over output.

Our ambition is to create an ecosystem for industry partners to share experiences, learn best practice and collaborate in the innovation of new, impactful solutions.

3

OUR WORK

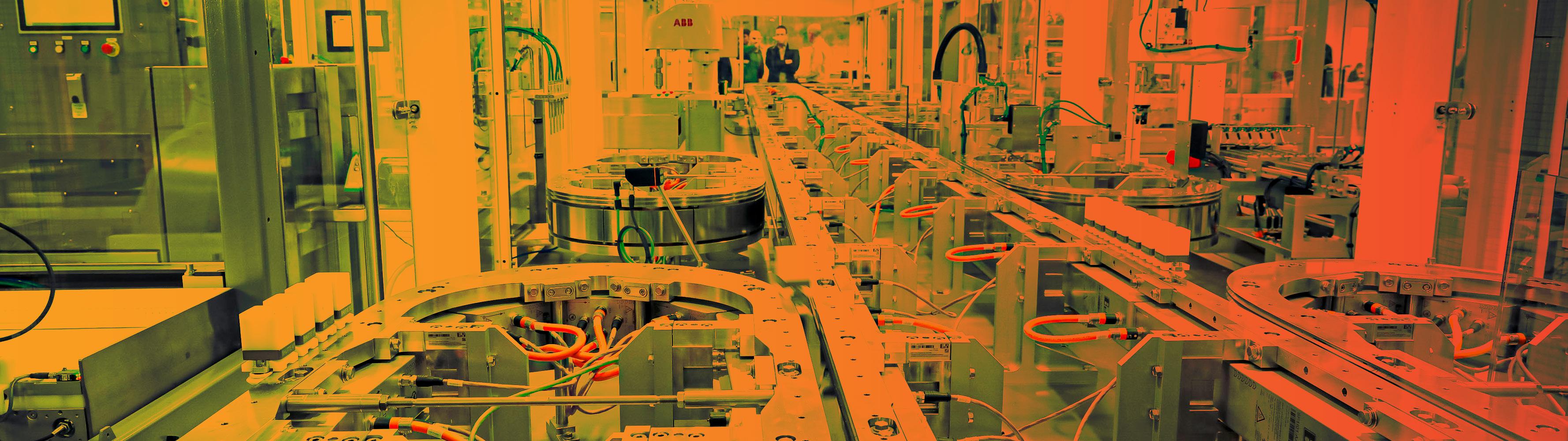

We take leading-edge technologies to pilot and deploy them in a manufacturing environment Delivering a unique proposition to support the next wave of manufacturing success in Ireland

Digital Manufacturing Ireland delivers an exemplary physical and virtual environment via the ‘Digital Factory’ for manufacturers to test, develop and scale digitallyenabled solutions to solve industry challenges safely, before deployment in a live environment.

With a specific focus on enabling and creating efficiencies in manufacturing processes, DMI can support ALL manufacturers, including both MNCs and SMEs, to reduce overheads and maximise the potential of their operations and competitiveness.

Furthermore, Digital Manufacturing Ireland informs and drives cultural change and upskilling through research, targeted workshops, specialist training and access to experts leveraging leading technology and best-practice in human-centric manufacturing.

5

DMI facilitates the establishment of collaboration groups that offer Centres of Excellence (CoEs) across the manufacturing ecosystem. The goal of these CoEs is to develop solutions to real world manufacturing challenges through a uniquely collaborative process.

The CoEs make use of the core expertise and infrastructure of DMI (project managers, collaboration managers, data scientists, and digital assets) in addition to seconded resources from collaboration partners to form focused and results-driven industry collaboration groups.

collaboration groups

Industry 5.0 Lighthouse Network

The primary purpose of the Industry 5.0 Lighthouse Network (I5.0LN) is to identify solutions to common challenges through a unique collaborative industry-led group process. The deployment of digital technologies to deliver transformation improvement in the operations of I5.0LN member organisations is a core objective.

The delivery of these collaborative solutions showcases the Irish operations as exemplar lighthouse sites globally, informing and guiding other sites within these organisations in the deployment of Industry 5.0 technologys.

visual cognitive-manufacturing group

The long-term aspiration of the Visual Cognitive-Manufacturing Group (VCMG) is for Ireland to become a global leader in the research, development and deployment of computer vision and A.I. solutions within the manufacturing domain.

The scope of the VCMG will be manufacturing companies with an initial focus on MedTech and supply chain (Pharma), supported by technology companies specialising in Vision and the use of AI technology.

Through an ecosystem of international experts and collaborators, we are futureproofing the way manufacturing teams interact with technology.

5 7

digital capabilities

transformation strategy:

Supporting organisations to make their digital step-change, building an enterprise transformation strategy.

innovative technology adoption:

Enabling state-of-the-future technology adoption and integrating it into the existing manufacturing footprint.

manufacturing operations and supply chains:

Working with manufacturer’s teams during the transformation process –staying with them to ensure successful adoption.

human centric manufacturing:

Helping manufacturers transition their workforce (and wider supply chain) into one that embraces transformative strategic change.

operations readiness:

Supporting the successful deployment of new technology across the enterprise.

sustainable deployment:

Delivering sustainable gains, consistent improvement, using new digital metrics, resulting in enterprise-wide embedded cultural behaviour change.

Delivering transformative services that create social and economic value, and operational efficiencies through digitisation, culture change and up-skilling

9

Digital Assets

Digital Factory

A 1,200 square meter physical production space with a control layer providing connection to the data layer and digital twin. Here we collaborate with clients and see the impact and benefit of digital transformation - using data testing to inform processes of ideation.

Digital twin

Digital twin is a model-based representation of a physical production environment, a physical product and a real supply chain. Our digital twin allows us to demonstrate the value of working in a virtual world in tandem with physical assets.

Digital transformation space

Visitors can explore the art-of-the-possible in advanced manufacturing through local and international case studies, technology exemplars, and user stories in this collaborative space.

Digital manufacturing suite

World-Class facilities boasting an exemplary physical and virtual digital factory environment

– the largest of its kind for manufacturing in Ireland

DMI matches its digital capabilities and expertise with a suite of physical and digital assets, including the digital factory, digital twin, digital transformation space, digital manufacturing suite and the external interface layer. Combined, these resources offer partners and clients the capabilities and digital transformation environment critical to manufacturing transformation success.

The world of digital manufacturing can be further explored here where the global technology innovators have partnered with DMI to make fully functional and integrated digital tools available to Irish-based manufacturers.

The suite will focus on transformation across the full value chain from digital product and production design to virtual reality maintenance, training and cyber security. Here visitors can see how the adoption of innovative manufacturing technologies can help their organisation prepare for the future.

external interface layer

The external interface layer allows DMI to share and interact with clients, partners, academia, research organisations and manufacturing experts. Here we publish live data models and virtual interfaces that allow industry participants to interact with our physical and digital assets, where they can test our datasets.

8 12

Our mission is to drive world-class, industry-led digital manufacturing adoption in Ireland

org