Proposed Structural Drawings

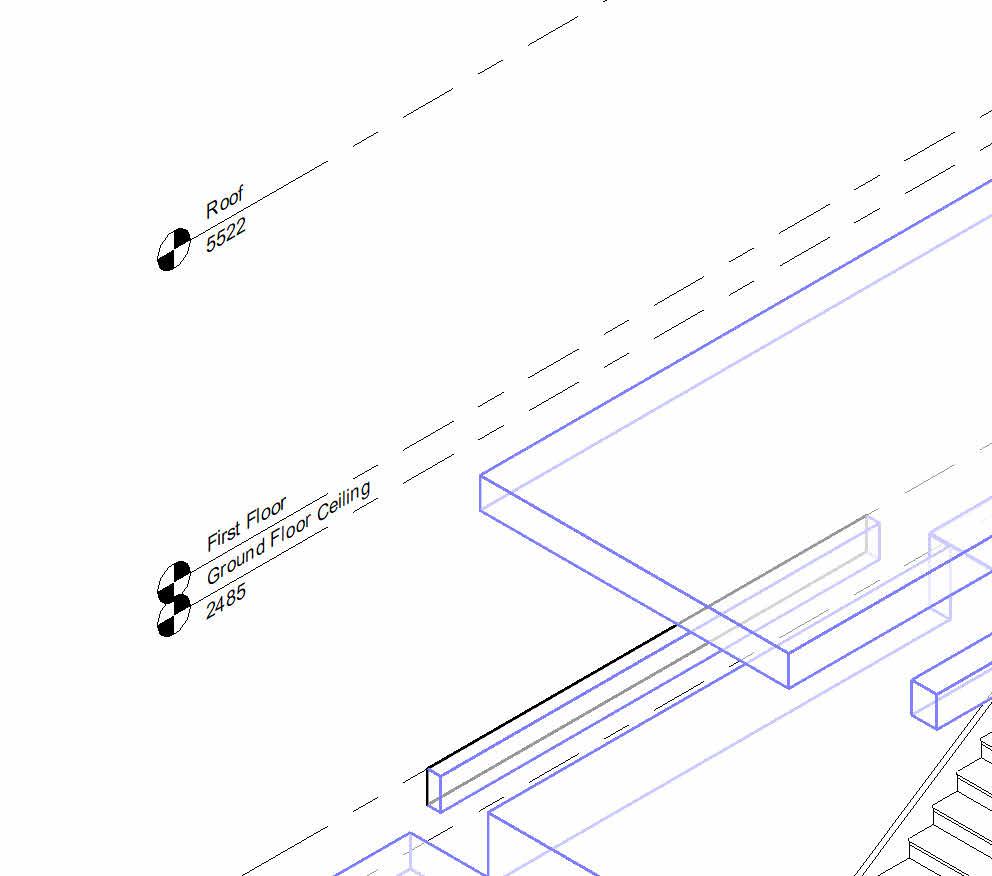

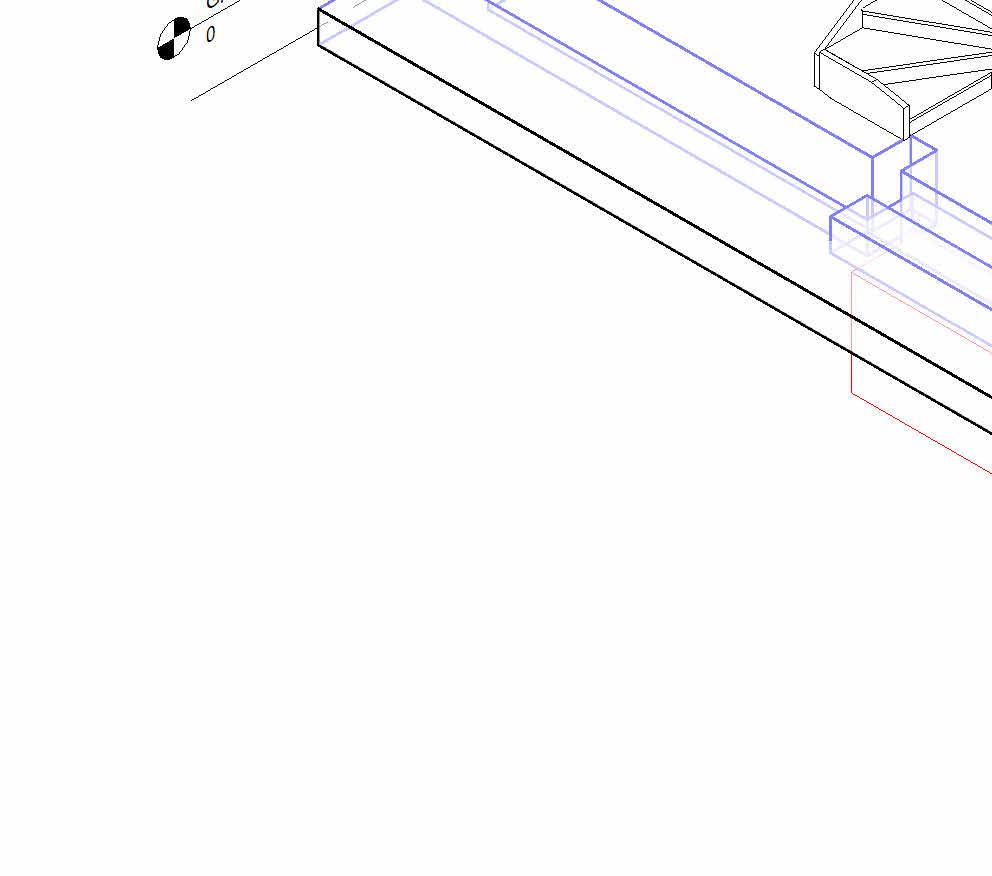

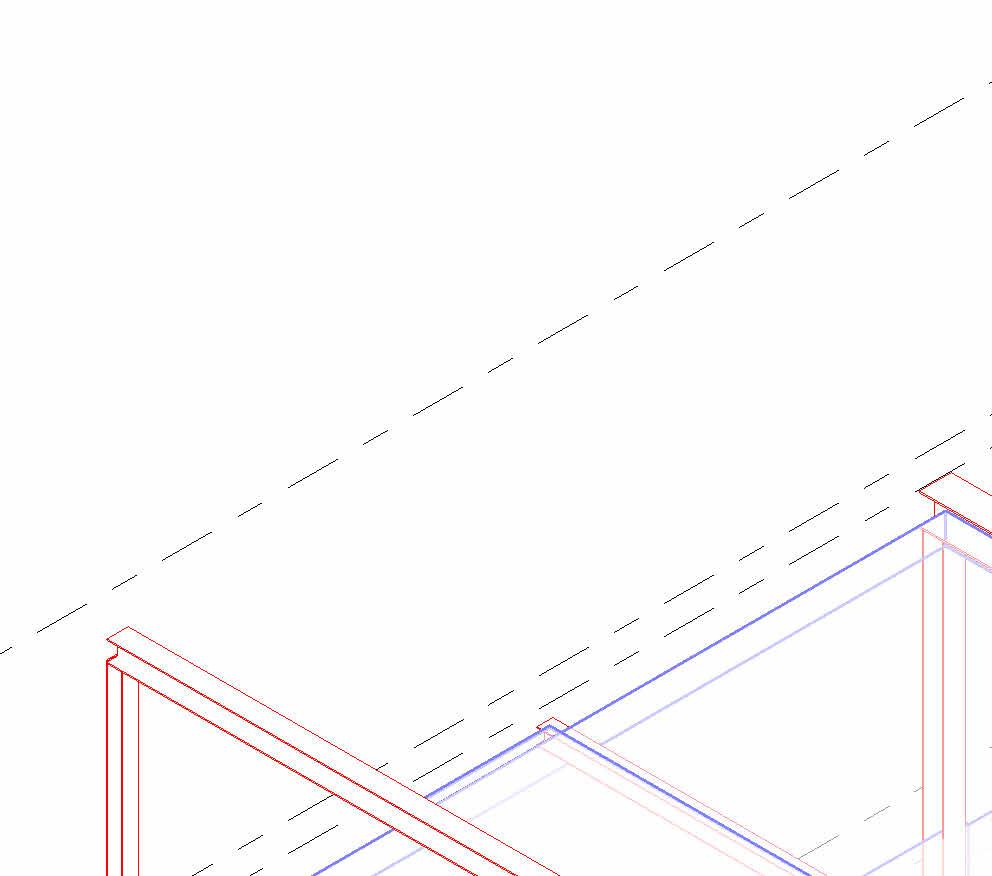

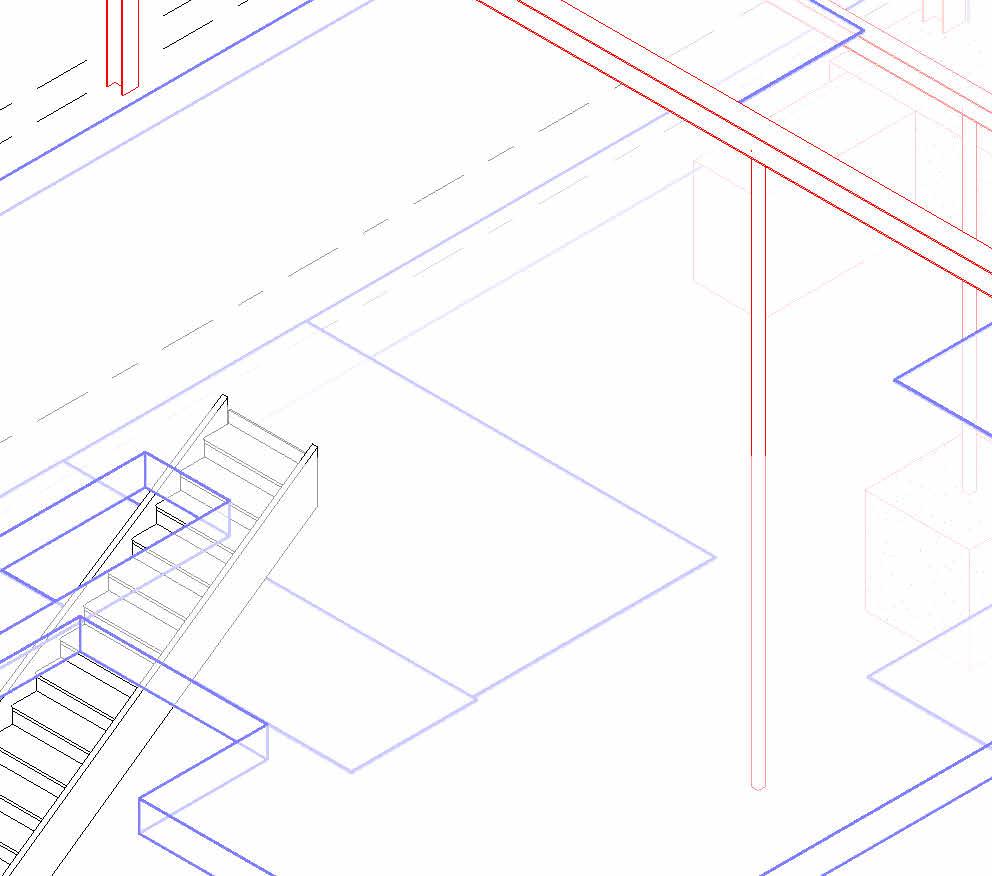

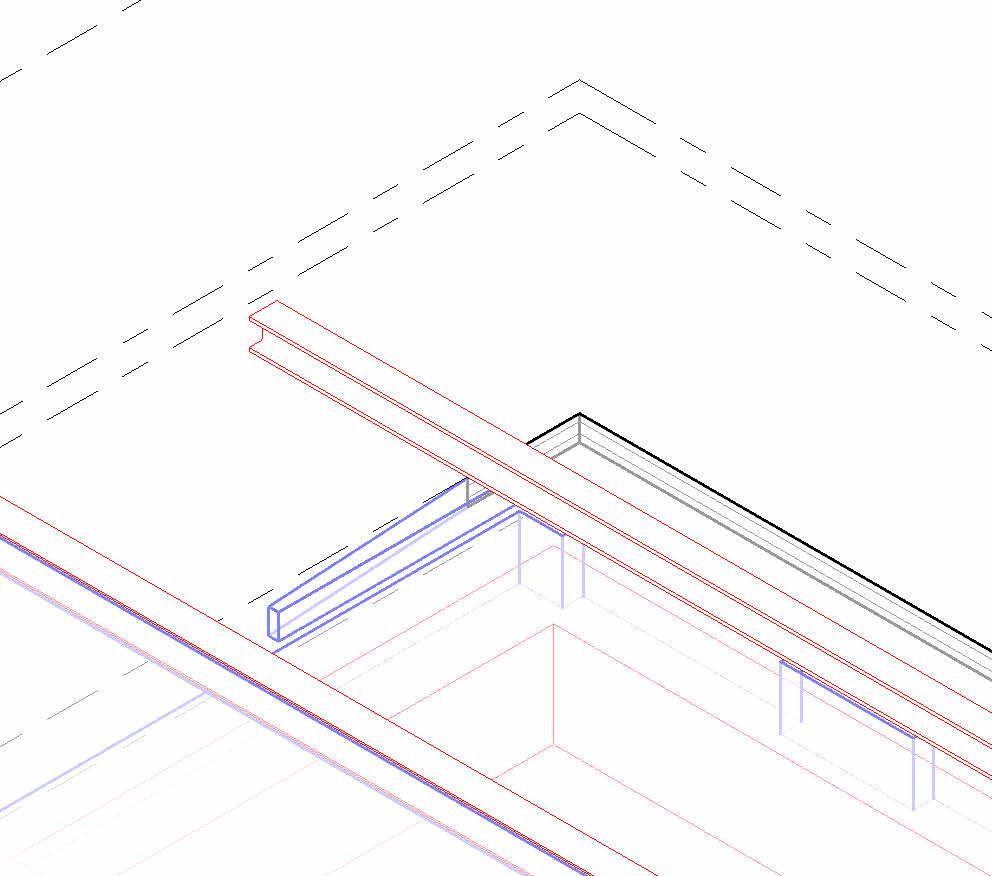

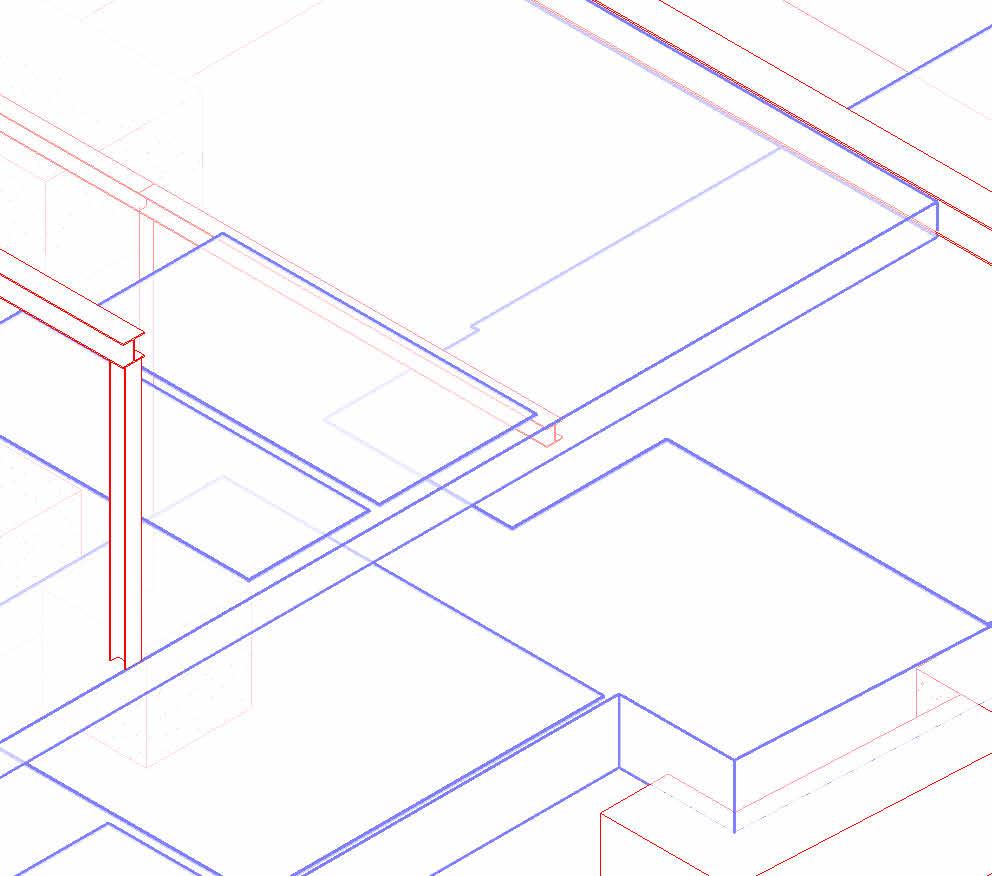

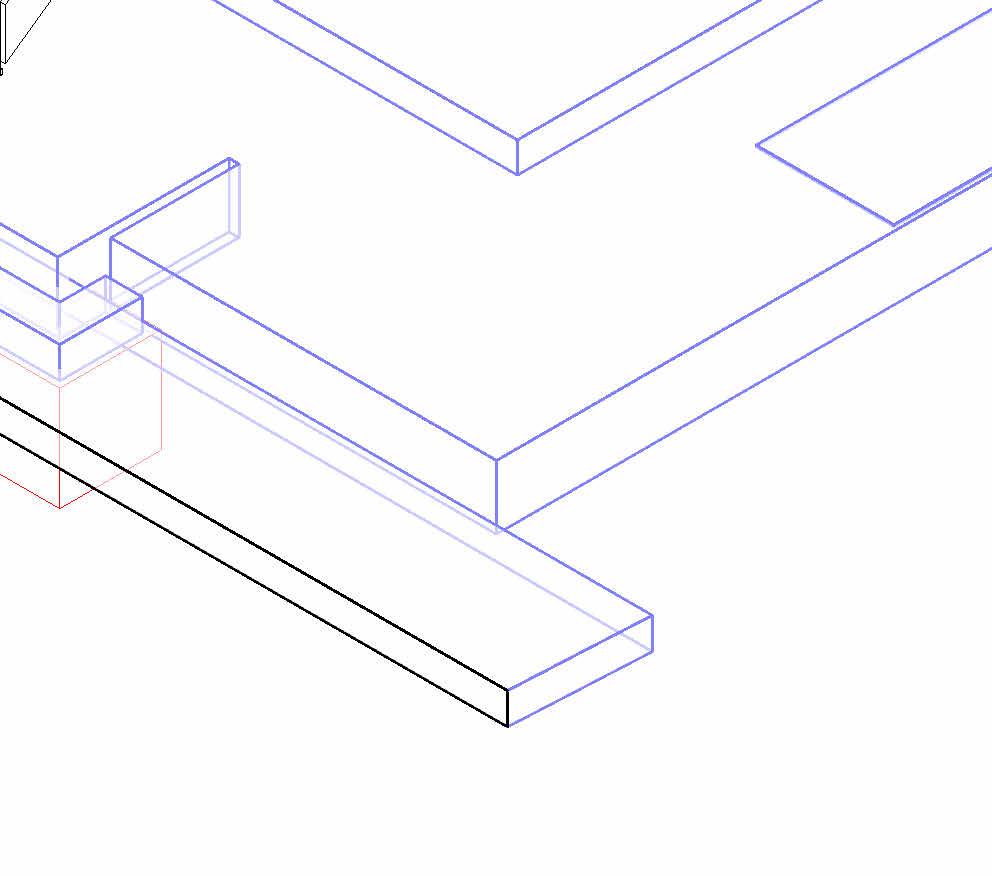

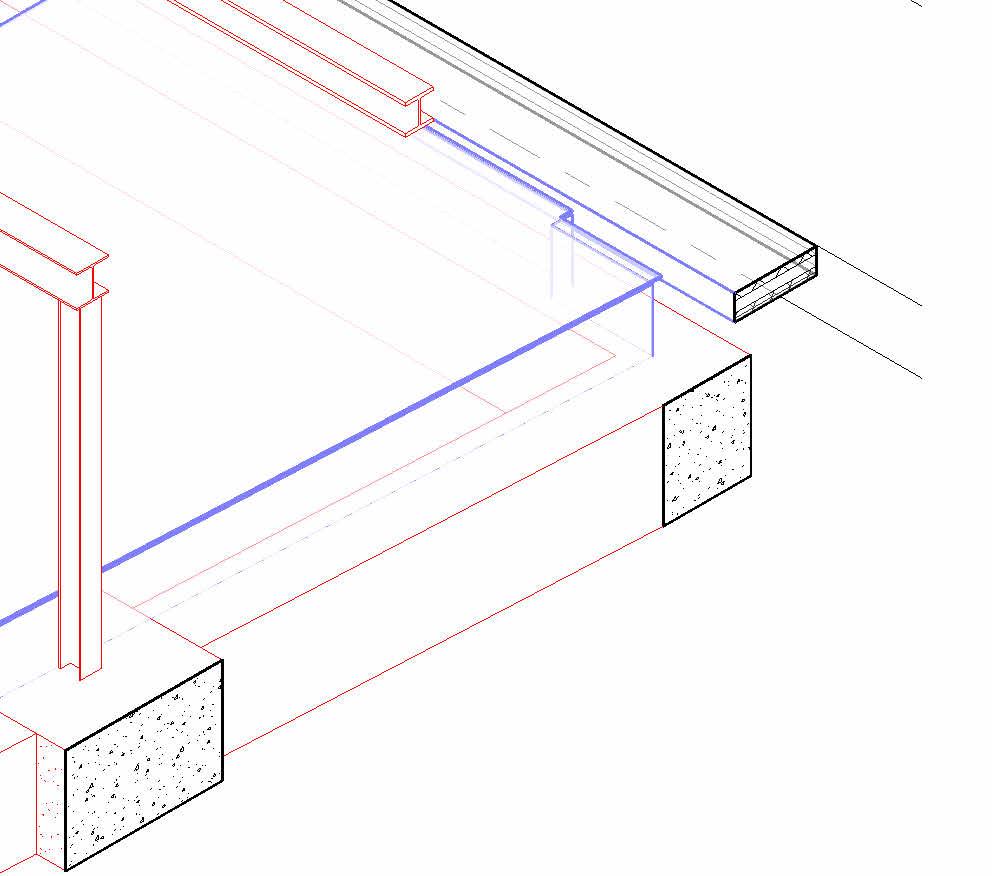

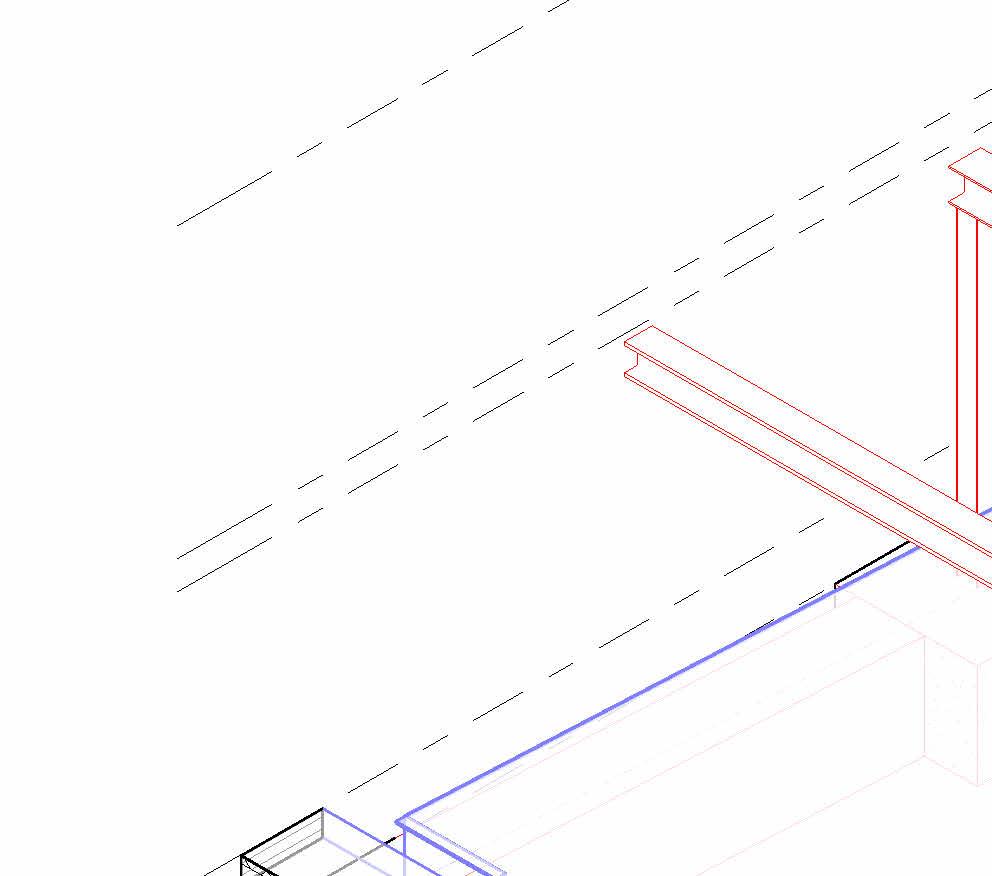

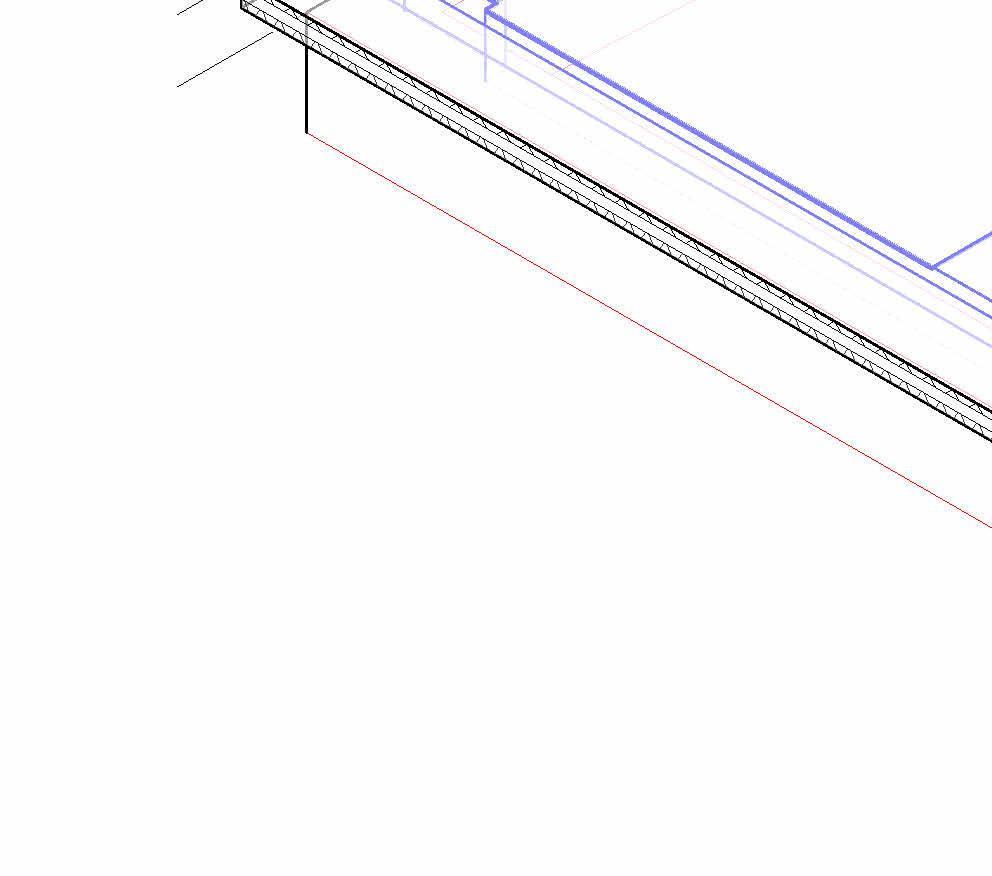

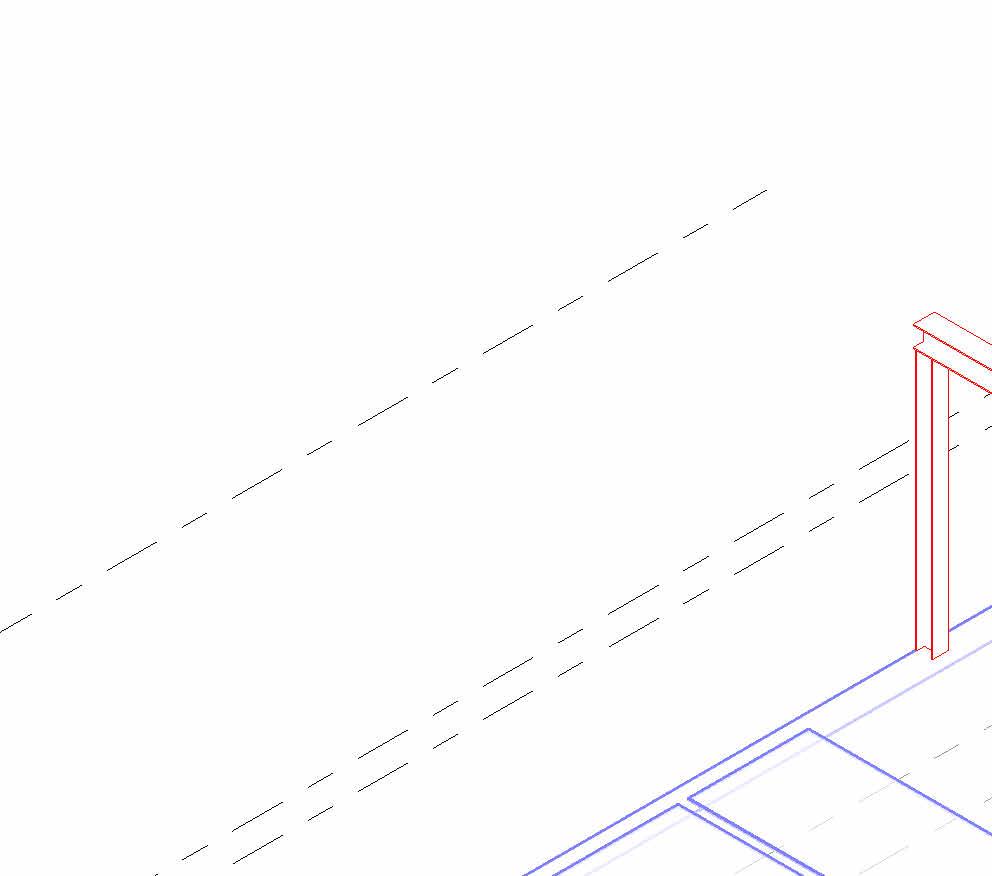

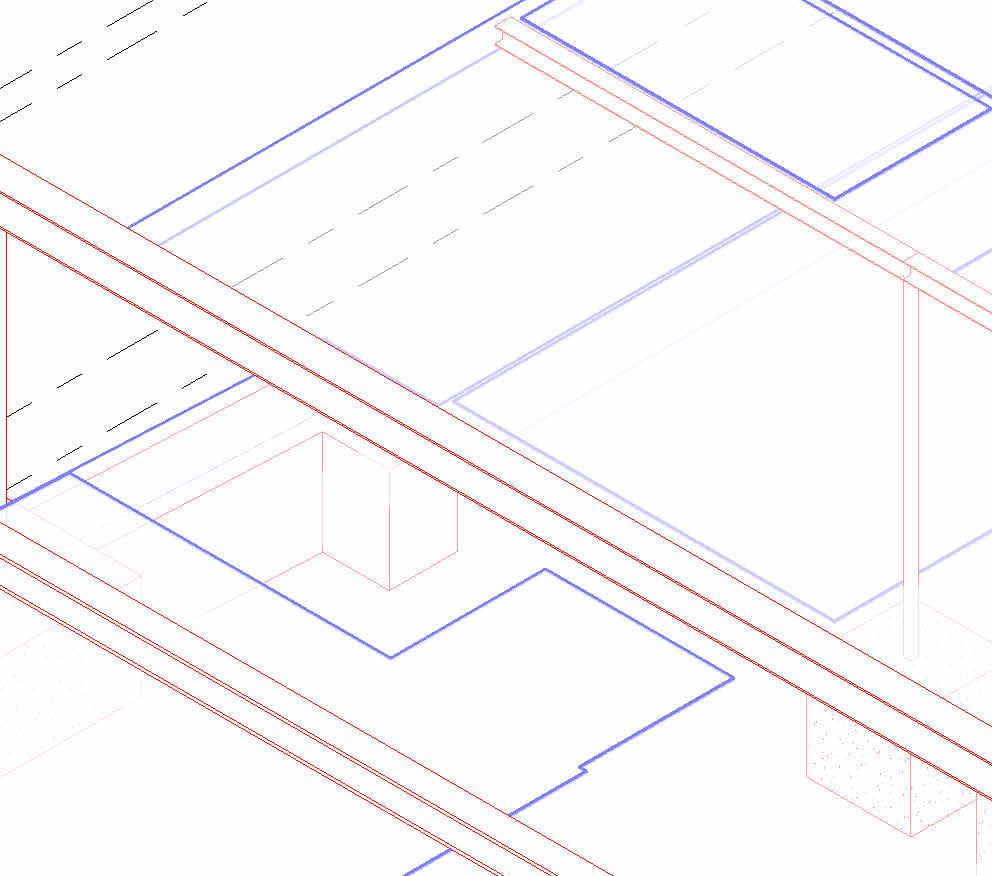

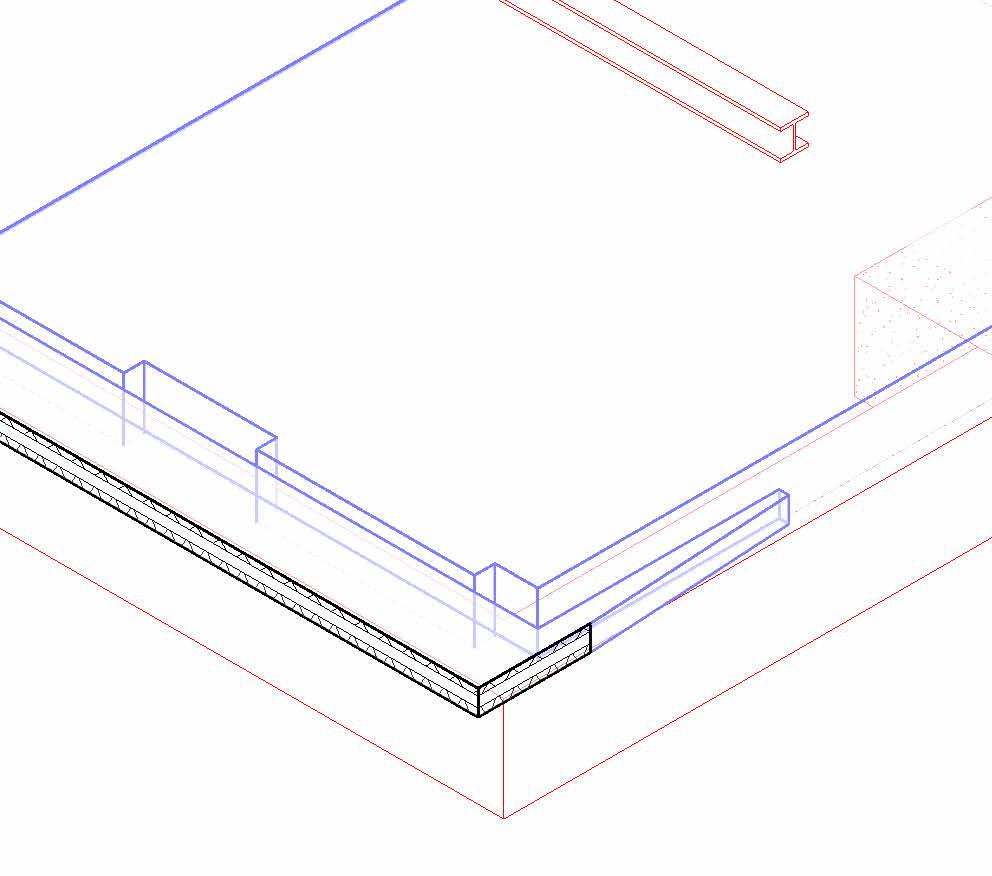

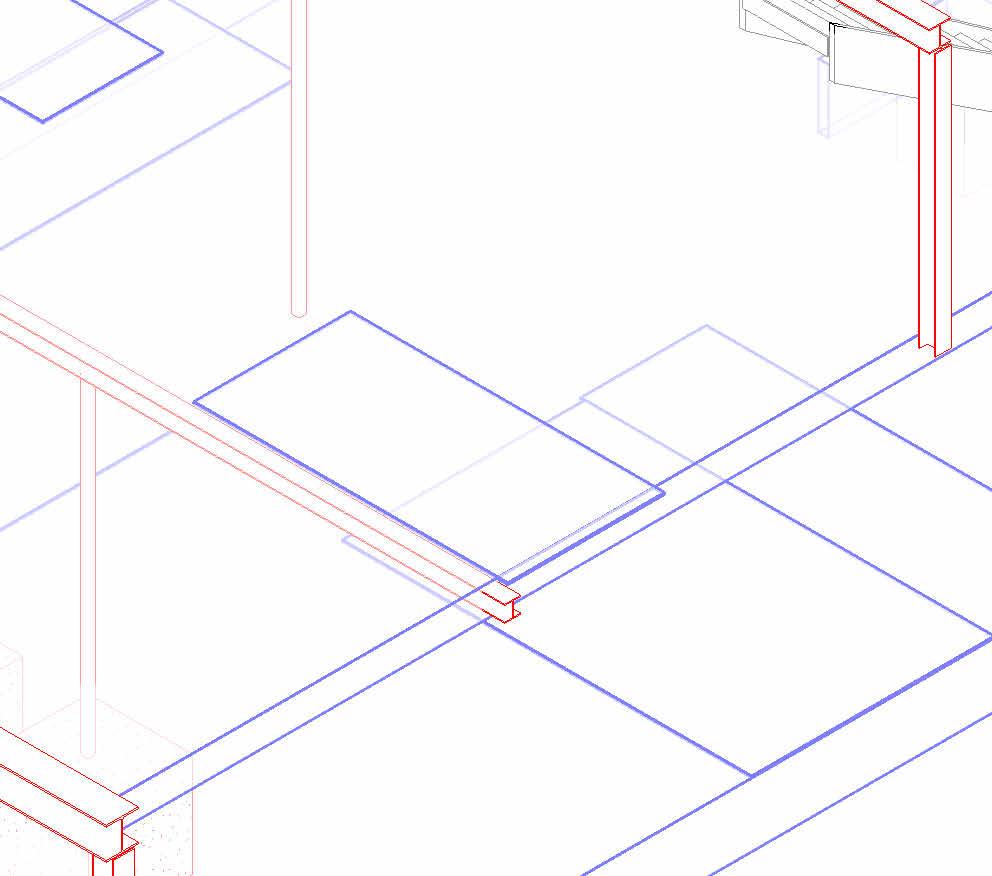

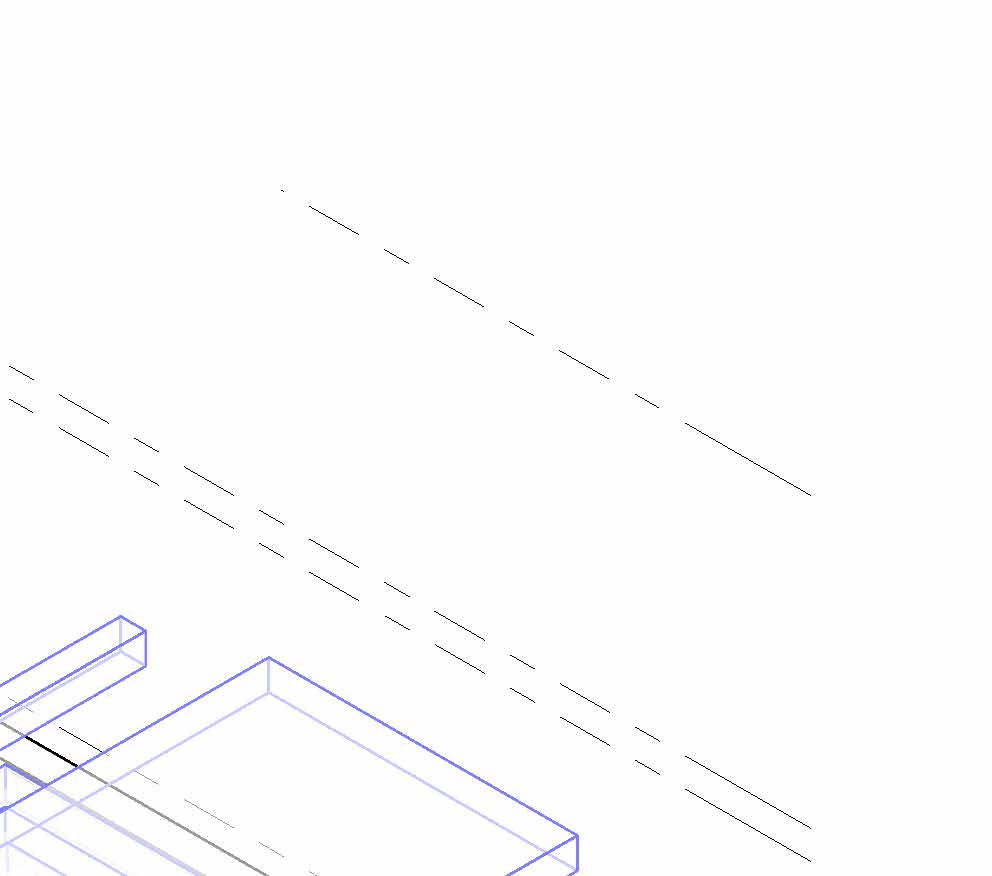

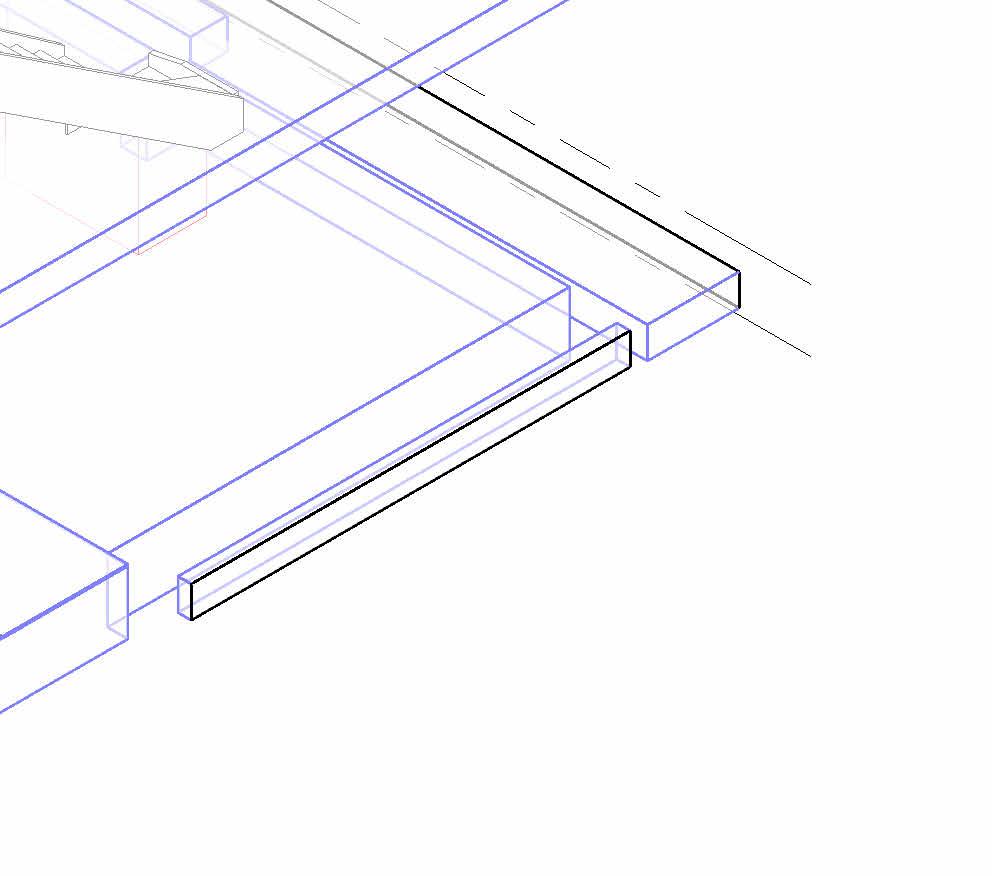

C10UC152x152x30

C1UC203x203x46

C12SHS80x80x8

C2UC203x203x46

C2UC203x203x46

1.0 GENERAL

1.1 DO NOT SCALE DRAWINGS. THE CONTRACTOR IS TO CHECK ALL DIMENSIONS ON SITE BEFORE CARRYING OUT ANY WORKS.

1.2 THIS SPECIFICATION TOGETHER WITH THE STRUCTURAL ENGINEER'S DRAWINGS AND CALCULATIONS ARE TO BE READ IN CONJUNCTION WITH ARCHITECT'S AND ALL OTHER CONSULTANT'S DRAWINGS AND SPECIFICATIONS, WHICH SHOULD BE USED TO VERIFY LAYOUT, SETTING OUT, FINISHES ETC.,. ANY DISCREPANCIES ARE TO BE REPORTED TO THE ARCHITECT BEFORE PROCEEDING WITH THE WORKS.

1.3 THE CONTRACTOR MUST ENSURE THAT THE CLIENT HAS AGREED ALL NECESSARY PARTY WALL NOTICES PRIOR TO CARRYING OUT WORKS UNDER, ON OR ADJACENT TO PARTY WALL.

1.4 SETTING OUT DETAILS ARE SHOWN ON THE ARCHITECT'S DRAWINGS UNLESS NOTED OTHERWISE ON THE DRAWINGS.

1.5 THE CONTRACTOR IS TO INFORM THE ARCHITECT AND STRUCTURAL ENGINEER IF THE EXISTING FABRIC, INCLUDING FOUNDATIONS, IS OPENED UP AND FOUND TO BE INADEQUATE, UNSUITABLE TO SUPPORT THE PROPOSED WORKS, OR AT VARIANCE FROM THE DETAILS SHOWN ON THE DRAWINGS.

1.6 ITEMS NOTED ON THE DRAWINGS "TO BE VERIFIED ON SITE" ARE TO BE EXPOSED BY THE CONTRACTOR FOR INSPECTION BY THE STRUCTURAL ENGINEER AT THE EARLIEST OPPORTUNITY.

1.7 HOLES OR CHASES MUST NOT BE CUT THROUGH ANY STRUCTURAL MEMBERS WITHOUT THE WRITTEN CONSENT OF THE STRUCTURAL ENGINEER.

1.8 NOTHING INCLUDED OR OMITTED FROM THIS OUTLINE SPECIFICATION WILL RELIEVE THE CONTRACTOR OF HIS DUTY TO CARRY OUT THE WORKS IN ACCORDANCE WITH CURRENT STANDARDS OF SAFETY AND GOOD BUILDING PRACTICE.

2.0 TOLERANCES

2.1 ALL TOLERANCES ARE TO BE AGREED WITH THE ARCHITECT, AND THE CONTRACTOR WILL BE RESPONSIBLE FOR ENSURING THAT SUFFICIENT TOLERANCES ARE PROVIDED AND INTEGRATED THROUGHOUT ALL ELEMENTS OF THE WORKS.

2.2 THE CONTRACTOR IS TO TAKE ACCOUNT OF TOLERANCES DETAILED ELSEWHERE IN THE DRAWINGS, APPENDED SPECIFICATIONS, AND BRITISH STANDARDS WHEN COMPLYING WITH THE ABOVE CLAUSE

3.0 MATERIALS AND WORKMANSHIP

3.1 ALL ARTICLES, MATERIALS AND GOODS SHALL BE NEW AND OF GOOD QUALITY, SUITABLE FOR THE REQUIRED PURPOSE AND SHALL CONFORM TO THE APPROPRIATE BRITISH STANDARD WHERE SUCH EXISTS. WHERE REFERENCES TO THE ABOVE ARE MADE IT SHALL BE INFERRED THAT THE LATEST EDITION APPLIES, TOGETHER WITH SUBSEQUENT AMENDMENTS, UNLESS OTHERWISE SPECIFIED.

4.0 TEMPORARY WORKS AND STABILITY

4.1 THE CONTRACTOR IS ENTIRELY RESPONSIBLE FOR MAINTAINING THE STABILITY OF ALL EXISTING BUILDINGS AND STRUCTURES, WITHIN AND ADJACENT TO THE WORKS, AND OF ALL THE WORKS FROM THE DATE OF POSSESSION OF THE SITE UNTIL PRACTICAL COMPLETION OF THE WORKS.

4.2 THE CONTRACTOR SHALL DESIGN, INSTALL AND MAINTAIN ALL NECESSARY TEMPORARY WORKS AND SHALL ADVISE BOTH THE ARCHITECT AND STRUCTURAL ENGINEER AT LEAST TEN WORKING DAYS FROM COMMENCEMENT OF THE WORKS, OF HIS PROPOSALS FOR TEMPORARY SUPPORTS AND SEQUENCE OF CONSTRUCTION FOR THE WORKS. THESE PROPOSALS SHALL BE SUPPORTED BY DESIGN CALCULATIONS IFREQUESTED.

4.3 THE DESIGN OF TEMPORARY WORKS SHALL INCLUDE AN ASSESSMENT OF THE LOADS TO BE RESISTED AND IS TO BE UNDERTAKEN BY A COMPETENT PERSON. DUE REGARD SHALL BE GIVEN TO LATERAL STABILITY AS WELL AS TO THE SUPPORT OF VERTICAL LOADS. TEMPORARY SHORING TO VERTICAL ELEMENTS (EG. PARTY WALLS) TO BE DESIGNED TO RESIST A MINIMUM OF 5% OF DEAD LOAD, SUPPORTED BY THE PARTICULAR ELEMENT, ABOVE ANY LEVEL OF THE POINT OF CONTACT OF THE SHORING.

4.4 THE CONTRACTOR IS TO FAMILIARISE HIMSELF WITH THE BUILDING AND ITS STRUCTURE SO THAT HE IS AWARE OF THE NATURE AND MAGNITUDE OF THE LOADS TO BE SUPPORTED.

4.5 PARTICULAR CARE IS TO BE TAKEN TO ENSURE THAT TEMPORARY PROPS REMAIN ADEQUATELY SEATED AND TIGHTENED SO THAT SUPPORT TO THE STRUCTURE ABOVE IS NOT ALLOWED TO YIELD DURING BUILDING OPERATIONS.

4.6 THE CONTRACTOR IS TO ENSURE THAT TEMPORARILY PROPPED STRUCTURE IS ADEQUATELY WEDGED, PINNED OR PACKED OFF THE PERMANENT WORKS PRIOR TO REMOVAL OF ANY TEMPORARY SUPPORTS.

4.7 THE CONTRACTOR SHALL ENSURE THAT ANY COMPLETED OR PARTIALLY COMPLETED STRUCTURAL ELEMENT IS NOT OVERLOADED. DETAILS OF DESIGN LOADS MAY BE OBTAINED FROM THE STRUCTURAL ENGINEER.

4.8 ALL TEMPORARY WORKS TO SUPPORT THE SIDES OF EXCAVATIONS FOR NEW FOUNDATIONS SHALL BE DESIGNED IN ACCORDANCE WITH BS 8000 PART 1: 1989 AND ANY OTHER APPROVED DOCUMENTS.

4.9 EXCAVATIONS SHALL IN NO CIRCUMSTANCES ENCROACH WITHIN 45° OF THE BOTTOM NEAR SIDE OF ANY EXISTING FOOTING.

5.0 DEMOLITION

5.1 DEMOLITION IS TO BE CARRIED OUT TO AND IN ACCORDANCE WITH BS 6187: 1982, HEALTH AND SAFETY EXECUTIVE GUIDANCE NOTE GS 29/1 PARAGRAPH 32, AND ANY OTHER RELEVANT STATUTORY UNDERTAKINGS OR REGULATIONS.

5.2 DEMOLITION IS TO BE UNDERTAKEN IN THE REVERSE ORDER OF CONSTRUCTION. NO PART OF THE STRUCTURE IS TO BE LEFT IN AN UNSUPPORTED CONDITION OVERNIGHT OR FOR LONG PERIODS.

5.3 DEMOLITION IS TO BE UNDERTAKEN IN A MANNER WHICH AVOIDS EXCESSIVE NOISE AND NUISANCE. ALL WORK IS TO BE WELL-WATERED TO MINIMISE DUST. ALL MATERIAL IS TO BE CARTED AWAY FROM SITE AS SOON AS PRACTICABLE.

6.0 EXCAVATING AND FILLING

6.1 TRIAL PITS TO BE CARRIED OUT TO INDICATE UNDERLYING SOIL.

6.2 GROUND WATER LEVEL ON THE SITE IS NOT KNOWN.

6.3 INSPECT ALL AVAILABLE DRAWINGS AND MAKE ENQUIRIES ABOUT EXISTING SERVICES ON SITE. VERIFY POSITIONS AND DEPTH OF ALL SERVICES BEFORE COMMENCEMENT OF WORK ON SITE. SERVICES WHICH ARE BEING RETAINED DURING ANY PHASE OF THE WORKS ARE TO BE PROTECTED.

6.4 BEFORE STARTING WORK VERIFY WITH THE ARCHITECT WHICH EXISTING FENCES, GATES, WALLS, PAVED AREAS, TREES, SHRUBS, HEDGES, BUSHES AND ANY OTHER SITE FEATURES ARE TO BE REMOVED. MATERIALS ARISING ARE TO BE REMOVED FROM SITE.

6.5 WORKMANSHIP FOR EXCAVATING TO COMPLY WITH BS 8000: PART 1, SECTIONS 3.1, 3.2 AND 3.3.

6.6 WHERE AN EXCAVATION ENCROACHES BELOW A LINE DRAWN AT AN ANGLE OF 45° FROM THE HORIZONTAL FROM THE NEAREST FORMATION LEVEL OF ANOTHER HIGHER EXCAVATION, THE LOWER EXCAVATION, ALL WORK WITHIN IT AND BACKFILLING THERETO MUST BE COMPLETED BEFORE THE HIGHER EXCAVATION IS MADE.

6.7 MAKE ADVANCE ARRANGEMENTS WITH THE BUILDING CONTROL OFFICER AND/OR ARCHITECT FOR INSPECTION OF FOUNDATIONS AND TRENCHES REQUESTED AT THE BEGINNING OF THE WORKS.REMOVE THE LAST 150mm OF EXCAVATIONS JUST BEFORE INSPECTION. TRIM EXCAVATIONS TO REQUIRED PROFILES AND LEVELS, AND REMOVE ALL LOOSE MATERIALS. UNLESS OTHERWISE INSTRUCTED SEAL FORMATIONS WITHIN 4 HOURS OF INSPECTION WITH CONCRETE OR OTHER SPECIFIED FILL.

6.8 BACKFILL ANY EXCAVATIONS FOR FOUNDATIONS TAKEN DEEPER THAN REQUIRED WITH LEAN MIX CONCRETE. EXCAVATIONS OTHER THAN FOUNDATIONS TAKEN DEEPER THAN REQUIRED MAY BE BACKFILLED WITH WELL GRADED GRANULAR MATERIAL.

6.9 HARDCORE TO BE GRANULAR MATERIAL, FREE FROM HARMFUL MATTER, WELL GRADED, PASSING A 75mm BS SIEVE AND ONE OF THE FOLLOWING: - CRUSHED CONCRETE, BRICK OR TILE, FREE FROM OLD PLASTER. - GRAVEL. SPREAD AND LEVEL BOTH BACKFILLING AND GENERAL FILLING IN LAYERS NOT EXCEEDING 150mm. THOROUGHLY COMPACT EACH LAYER WITH A VIBRATORY ROLLER, VIBRATING PLATE COMPACTOR, VIBRO- TAMPER, POWER RAMMER OR OTHER SUITABLE MEANS APPROPRIATE TO THE AREA BEING WORKED.

6.10 HARDCORE UNDER GROUND BEARING CONCRETE SLABS TO BE AS ABOVE AND NOT LESS THAN 150mm THICK, UNLESS NOTED OTHERWISE ON THE DRAWINGS. EXCAVATE EXTRA MATERIAL AS NECESSARY. INCREASE THICKNESS OF HARDCORE AS NECESSARY TO MAKE UP LEVELS FROM STRIPPED SITE LEVELS TO UNDERSIDE OF SLABS.

6.11 SURFACES OVER HARDCORE TO RECEIVE SHEET OVERLAYS OR CONCRETE TO BE BLINDED WITH SUFFICIENT SAND OR FINE GRAVEL TO FILL INTERSTICES AND PROVIDE A CLOSE SMOOTH SURFACE (50mm MIN THICKNESS), UNLESS NOTED OTHERWISE ON THE DRAWINGS. PERMISSIBLE DEVIATIONS ON SURFACE LEVEL TO BE + 0-15mm.

6.12 MINIMUM VOID UNDER SUSPENDED GROUND FLOORS TO BE 225mm FOR PRECAST CONCRETE AND 300mm FOR TIMBER FLOORS. SUSPENDED IN-SITU CONCRETE FLOORS SHALL BE CAST OVER A SUITABLE VOID FORMER TO PROVIDE A VOID OF 150MM UNDER THE SLAB, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

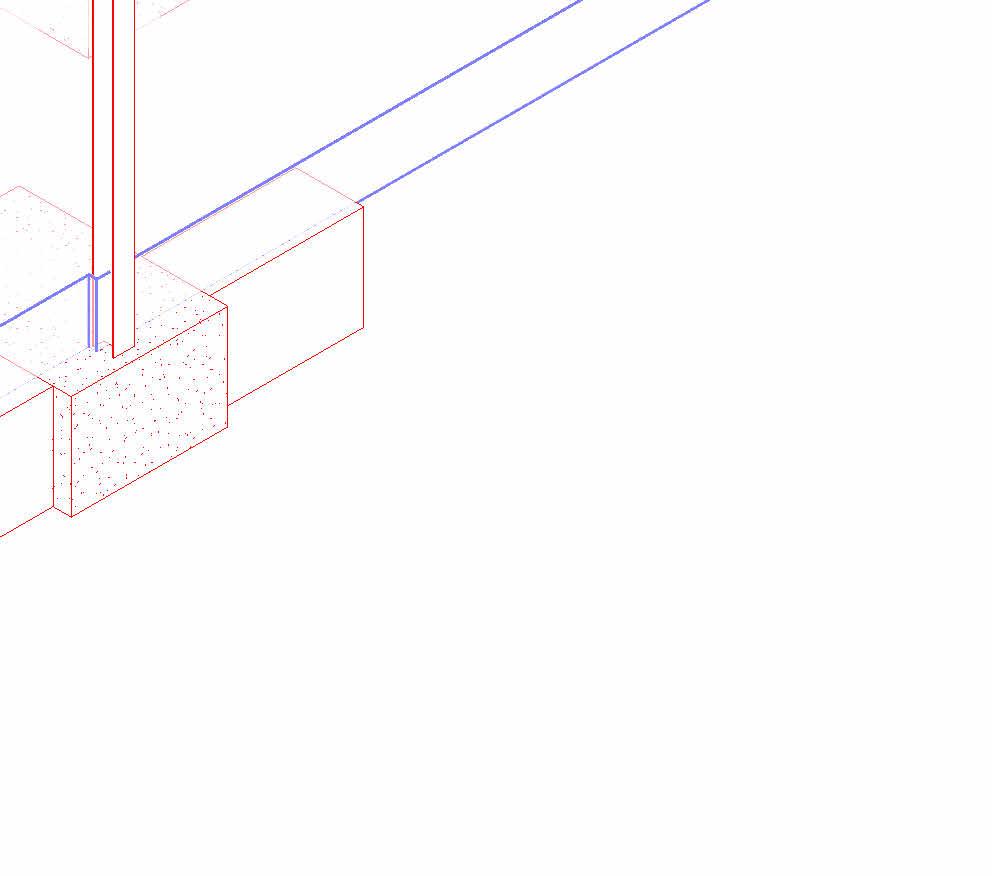

7.0 FOUNDATIONS

7.1 FOUNDATIONS ARE TO BE CAST TO THE PROFILES INDICATED ON THE DRAWINGS. THEY ARE TO BE CAST SYMMETRICALLY ABOUT PIERS, STANCHIONS OR WALLS, UNLESS NOTED OTHERWISE ON THE DRAWINGS. ALL FORMATION LEVELS FOR FOUNDATIONS TO BE AGREED WITH BUILDING INSPECTOR ON SITE.

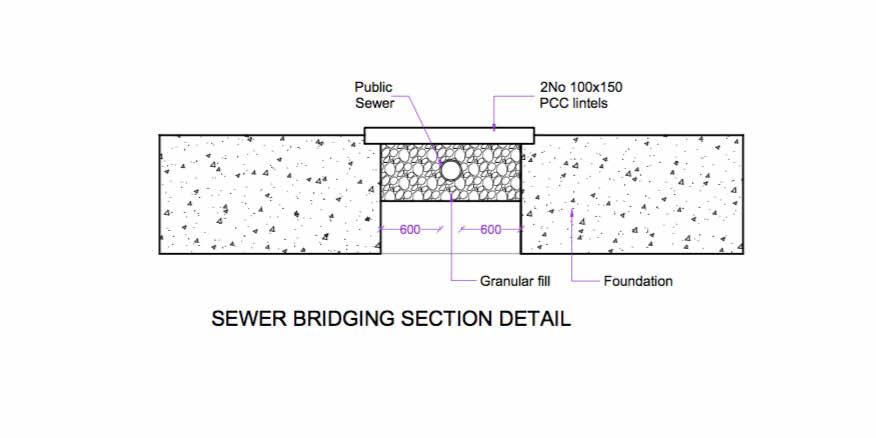

7.2 NEW FOUNDATIONS HAVE BEEN DESIGNED TO IMPOSE A SAFE BEARING PRESSURE OF 100kN/m2 ON CLAY 1100mm BELOW FINAL EXTERNAL GROUND LEVEL. THE CONTRACTOR IS TO ENSURE THAT ALL NEW FOUNDATIONS BEAR A MINIMUM OF 150mm ONTO FIRM CLAY. WHERE POOR GROUND CONDITIONS ARE ENCOUNTERED OR THE BUILDING CONTROL OFFICER REQUESTS AMENDMENTS THE STRUCTURAL ENGINEER IS TO BE NOTIFIED IMMEDIATELY.

7.3 WHERE TREE ROOTS ARE ENCOUNTERED, FOUNDATIONS ARE TO EXTEND 600MM BELOW THE LAST TRACE OF ANY ROOT ACTIVITY.

7.4 FOUNDATIONS SITED WITHIN A ZONE 1.25 X MATURE TREE HEIGHT FOR HIGH WATER DEMAND TREES, 0.75 X MATURE TREE HEIGHT FOR MODERATE WATER DEMAND TREES AND 0.50 X MATURE TREE HEIGHT FOR LOW WATER DEMAND TREES WHICH ARE TO REMAIN OR TO BE REMOVED, OR OVER TREES AFTER REMOVAL, ARE TO BE PROTECTED AGAINST CLAY HEAVE AS FOLLOWS:

(i) TRENCH FILL FOUNDATIONS

PROVIDE COMPRESSIBLE MATERIAL AGAINST INSIDE FACE OF ALL EXTERNAL WALL FOUNDATIONS GREATER THAN 1.5M DEEP TO GIVE A 35mm VOID. THE COMPRESSIBLE MATERIAL IS TO BE POSITIONED 500mm ABOVE THE BOTTOM OF THE FOUNDATION.

(ii) PIER AND GROUND BEAM FOUNDATIONS

PROVIDE COMPRESSIBLE MATERIAL AGAINST FACES OF ALL PIER FOUNDATIONS GREATER THAN 1.5m DEEP TO GIVE A 35mm VOID. THE COMPRESSIBLE MATERIAL IS TO BE POSITIONED 500mm ABOVE THE BOTTOM OF THE FOUNDATIONS. ALSO, PROVIDE COMPRESSIBLE MATERIAL OR VOID FORMER BELOW ALL GROUND BEAMS AND AGAINST THE INSIDE FACE OF EXTERNAL GROUND BEAMS TO GIVE A 150mm AND 35mm VOID RESPECTIVELY.

(iii) PILE AND GROUND BEAM FOUNDATIONS

PROVIDE COMPRESSIBLE MATERIAL OR VOID FORMER BELOW ALL GROUND BEAMS AND AGAINST THE INSIDE FACE OF THE EXTERNAL GROUND BEAMS TO GIVE A 150mm AND 35mm VOID RESPECTIVELY. PILES ARE TO BE DESIGNED IN ACCORDANCE WITH THE PERFORMANCE PILING SPECIFICATION.

7.5 WHERE CONSTRUCTION JOINTS IN TRENCH FILL FOUNDATIONS ARE UNAVOIDABLE THEY SHOULD NOT BE POSITIONED NEAR A RETURN IN THE FOUNDATION. CONSTRUCTION JOINTS SHOULD BE FORMED USING 4 NO. 20mm DIAMETER AND 1200 LONG HIGH TENSILE DOWEL BARS CAST 600mm INTO ADJACENT SECTIONS.

7.6 THE CONTRACTOR IS TO ENSURE THAT THE BUILDING CONTROL OFFICER IS NOTIFIED FOR HIS INSPECTION OF THE BOTTOM OF ALL FOUNDATIONS PRIOR TO CONCRETING

8.0 INSITU CONCRETE

8.1 MATERIALS AND WORKMANSHIP ARE TO COMPLY WITH BS 8110.

8.2 CONCRETE FOR NEW FOUNDATIONS IS TO BE DESIGNATED MIX FND 2 TO BS 5328. "SUITABLE FOR CLASS 2 SULPHATE CONDITIONS"

8.3 CONCRETE FOR REINFORCED CONCRETE STRUCTURES, INCLUDING GROUND BEARING SLABS, IS TO BE DESIGNATED MIX RC35 TO BS 5328.

8.4 CONCRETE FOR THE ENCASEMENT OF STEEL BEAMS AND FOR PADSTONES IS TO BE GEN3 TO BS 5328 WITH 10mm MAXIMUM AGGREGATE AND 260 kg/m3 OF CEMENT

8.5 READY MIX CONCRETE IS TO BE USED UNLESS OTHERWISE ALLOWED BY THE STRUCTURAL ENGINEER. THIS MUST BE OBTAINED FROM A PLANT WHICH HOLDS A CURRENT CERTIFICATE OF ACCREDITATION UNDER THE QUALITY SCHEME FOR READY MIX CONCRETE. DETAILS OF CEMENT TYPE, AGGREGATE GRADING AND SOURCES, WITH CHLORIDE AND SULPHATE CONTENT OF MIXES TO BE SUBMITTED TO THE STRUCTURAL ENGINEER FOR HIS APPROVAL PRIOR TO ORDERING ANY CONCRETE.

8.6 THE USE OF SITE MIXED CONCRETE FOR STRUCTURAL ELEMENTS MAY ONLY BE USED FOLLOWING THE WRITTEN APPROVAL OF THE STRUCTURAL ENGINEER. BATCHING AND MIXING EQUIPMENT WILL NEED TO COMPLY WITH BS 1305 AND BS 4251.

8.7 THE CONTRACTOR IS RESPONSIBLE FOR THE DESIGN AND INSTALLATION OF ALL FORMWORK. DESIGN AND STRIKING OF THE FORMWORK IS TO BE IN ACCORDANCE WITH BS 8110.

8.8 DO NOT PLACE CONCRETE WHEN THE AMBIENT AIR TEMPERATURE IS LESS THAN 5°C.

8.9 ALL HOLES SHALL BE FORMED AND ALL INSERTS CAST IN AT THE TIME OF POURING CONCRETE. NO PART OF THE CONCRETE WORKS SHALL BE DRILLED OR CUT AWAY WITHOUT THE APPROVAL OF THE STRUCTURAL ENGINEER.

8.10 REINFORCEMENT SHALL BE:

(i) PLAIN BARS TO BS 4449, GRADE 250 (MILD STEEL), PREFIX R ON DRAWINGS AND SCHEDULE. OR (ii) DEFORMED BARS TO BS 4449, OR BS 4461, GRADE 460 (HIGH YIELD) TYPE 2, PREFIX T ON DRAWINGS AND SCHEDULES. MESH TO BS 4483.

8.11 REINFORCEMENT SHALL BE FIXED ADEQUATELY USING TYING WIRE OR STEEL CLIPS. CONCRETE COVER IS TO BE AS SPECIFIED ON THE DRAWINGS. CHAIRS AND SPACERS ARE TO BE PROVIDED BY THE CONTRACTOR AS NECESSARY TO MAINTAIN THE SPECIFIED COVER.

8.12 UNLESS NOTED OTHERWISE ON DRAWINGS, ALL REINFORCEMENT IS TO BE LAPPED 50D (WHERE D IS DIAMETER OF THE SMALLER BAR).

8.13 THE RATE OF SAMPLING FOR COMPRESSIVE TESTING OF CONCRETE S TO BE AGREED WITH THE STRUCTURAL ENGINEER PRIOR TO COMMENCEMENT OF ANY CONCRETE WORKS

8.14 USE MECHANICAL VIBRATION TO FULLY COMPACT CONCRETE FOR STRUCTURAL ELEMENTS. COMPACT CONCRETE TO FULL DEPTH (UNTIL AIR BUBBLES CEASE TO APPEAR ON THE TOP SURFACE), ESPECIALLY AROUND REINFORCEMENT, CAST-IN ACCESSORIES, INTO CORNERS OF FORMWORK AND AT JOINTS.

8.15 BEFORE PLACING STRUCTURAL CONCRETE (NOT BLINDING) ON HARDCORE OR OTHER ABSORBENT SUBSTRATES LAY BUILDING PAPER TO BS 1521 CLASS 3 OR POLYTHENE SHEET 250 MICRONS THICK. LAP EDGES 150MM. THIS IS NOT A DPM - SEE ARCHITECT'S DETAILS FOR THIS.

8.16 STRIKE FORMWORK WITHOUT DISTURBING, DAMAGING OR OVERLOADING STRUCTURE, AND WITHOUT DISTURBING PROPS. NOTWITHSTANDING OTHER CLAUSES IN THIS SPECIFICATION AND ANY CHECKING OR APPROVALS BY THE CA, THE RESPONSIBILITY FOR SAFE REMOVAL OF ANY PART OF THE FORMWORK AND ANY SUPPORTS WITHOUT DAMAGING THE STRUCTURE RESTS WITH THE CONTRACTOR.

8.17 MINIMUM PERIODS: THE FOLLOWING PERIODS (IN DAYS) FOR RETAINING FORMWORK IN POSITION BEFORE STRIKING APPLY TO CLASS 42.5 OR SULFATE- RESISTING PORTLAND CEMENT CONCRETE WITH NO CEMENT REPLACEMENT MATERIALS OR ADMIXTURES:

SUBMIT DETAILS OF PROPOSED PERIODS FOR MIXES USING ADMIXTURES OR OTHER TYPES OF CEMENT.

MINIMUM PERIODS: ALTERNATIVE METHODS OF DETERMINING MINIMUM PERIODS FOR RETAINING FORMWORK IN POSITION MAY BE SUBMITTED FOR APPROVAL. ACCEPT RESPONSIBILITY FOR COST OF CHECKING OF PROPOSALS BY CA AND FOR ANY TESTING.

8.18 FORMED FINISHES

BASIC FINISH: NO PARTICULAR REQUIREMENTS, EXCEPT THOSE FOR TOLERANCES AND FULL COMPACTION. FINISH TO RECEIVE ASPHALT TANKING: PRODUCE AN EVEN FINISH WITH A SHEET MATERIAL (E.G. PLYWOOD), SUITABLE TO RECEIVE ASPHALT, AND ACCEPTABLE TO ASPHALT CONTRACTOR. AVOID EXCESSIVE USE OF RELEASE AGENTS. ABRUPT IRREGULARITIES TO BE NOT GREATER THAN 3mm. GRADUAL IRREGULARITIES, EXPRESSED AS A MAXIMUM PERMISSIBLE DEVIATION FROM A 1mm STRAIGHT EDGE, TO BE NOT GREATER THAN 3mm. BLOWHOLES LESS THAN 10mm IN DIAMETER WILL BE PERMITTED BUT OTHERWISE SURFACE TO BE FREE FROM VOIDS, HONEYCOMBING, SEGREGATION AND OTHER LARGE DEFECTS.

8.19 TOLERANCES

UNLESS SHOWN OTHERWISE ON THE DRAWINGS, THE MAXIMUM PERMITTED DEVIATIONS OF DIMENSIONS AND LEVELS IN THE COMPLETED STRUCTURE FROM THOSE SHOWN ON, OR CALCULABLE FROM, THE DRAWINGS ARE SET OUT BELOW.

THE FIGURES GIVEN INCLUDE, BUT ARE NOT LIMITED TO, SUCH VARIABLES AS:

a) POSITION ON PLAN OF ANY POINT OF THE STRUCTURE FROM NEAREST GRID LINE.

b) VERTICALLY.

c) CROSS SECTION AND OTHER LINEAR DIMENSION OF MEMBER.

d) CLEAR HORIZONTAL AND VERTICAL DIMENSIONS BETWEEN MEMBERS.

e) BOW AND CAMBER OTHER THAN SPECIFIED CAMBER

f) TWIST (THE DISTANCE OF ANY CORNER FROM A PLANE CONTAINING THE OTHER THREE CORNERS).

g) SQUARENESS OF CORNERS (THE LONGER OF TWO ADJACENT SIDES SHALL BE TAKEN AS THE BASE LINE). DEVIATION IS

h) RELATED TO THE LENGTH OF THE SHORTER SIDE.

9.0 MASONRY

9.1 WORKMANSHIP IS TO COMPLY GENERALLY WITH BS 5628 PARTS 1 & 3. BRICKWORK TO BE BS 3921. BLOCKWORK TO BE TO BS 6073.

9.2 NEW BRICKWORK ABOVE DPC IS TO BE A MINIMUM OF CLASS 3 CLAY BRICKS (20 N/mm2) SET IN 1:1:6 MORTAR UNLESS NOTED OTHERWISE ON THE DRAWINGS.

9.3 NEW BLOCKWORK ABOVE DPC IS TO BE OF MINIMUM STRENGTH OF 10.4N/mm2 SET IN 1:1:6 MORTAR, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

9.4 BRICKWORK AND BLOCKWORK ARE TO BE LAID PROPERLY BONDED AS AGREED WITH THE ARCHITECT AND FULLY BONDED INTO EXISTING WORK OR AS SPECIFIED OTHERWISE ON THE DRAWINGS. ALL PERPENDS MUST BE FULLY FILLED WITH MORTAR.

9.5 NEW FACING BRICKWORK BELOW DPC IS TO BE MINIMUM FL DURABILITY BRICKS SET IN 1:3 MORTAR WITH SRPC, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

9.6 ALL OTHER MASONRY BELOW DPC IS TO BE CLASS B ENGINEERING BRICKS, SET IN 1:3 MORTAR WITH SRPC OR AS NOTED OTHERWISE ON THE DRAWINGS.

9.7 DO NOT LAY MASONRY WHEN THE AMBIENT AIR TEMPERATURE IS LESS THAN 5°C.

9.8 CAVITY WALL TIES SHALL BE STAINLESS STEEL DOUBLE TRIANGLE TYPE TIES TO BS 1243, FOR CAVITIES OF 75mm OR LESS, SPACED AT 450mm c/c VERTICALLY, 900CRS HORIZONTALLY STAGGERED, AND AT 225mm c/c VERTICALLY 150mm FROM ALL OPENINGS, CORNERS, MOVEMENT JOINTS AND REVEALS. MINIMUM EMBEDMENT TO BE 50mm INTO EACH MASONRY LEAF. CAVITIES OF GREATER THAN 75MM WIDTH TO HAVE STAINLESS STEEL VERTICAL TWIST TIES AT SIMILAR CENTRES.

9.9 MOVEMENT JOINTS IN FACING BRICKWORK ARE TO BE FORMED BY BUILDING IN 'AEROFIL' JOINT FILLER BY SERVICISED LTD, AS THE WORKS PROCEED ENSURING NO PROJECTIONS INTO CAVITIES. IN JOINTS TO BE POINTED WITH SEALANT, POSITION FILLER ACCURATELY AT THE RECOMMENDED DISTANCE FROM THE FACE OF WALL. LEAVE JOINTS OPEN FOR AS LONG AS POSSIBLE BEFORE SEALING WITH APPROPRIATE SEALANT TO ARCHITECTS' SPECIFICATION.

9.10 WHERE PINNING UP TO SOFFITS IS REQUIRED, COMPLETELY FILL THE JOINT AT THE TOP OF LOADBEARING WALLS WITH 1:3 CEMENT/SHARP SAND DRY PACK MORTAR, WELL RAMMED INTO POSITION USING TEMPORARY SHUTTERING.

9.11 CARRY UP WORK WITH NO PORTION OR SECTION OF WALL MORE THAN 1.2m ABOVE ANOTHER AT ANY TIME, RAKING BACK BETWEEN LEVELS. DO NOT CARRY UP WORK HIGHER THAN 1.5m IN ONE DAY. 9.12 SPACING OF MOVEMENT JOINTS IN BRICKWORK AND BLOCKWORK ARE NOT TO EXCEED 12.0m AND 6.0M, RESPECTIVELY.

9.13 PROVIDE STAINLESS STEEL BED JOINT REINFORCEMENT, "BRICKTOR" BY BRC, AT 225mm AND 450mm VERTICAL CENTRES ABOVE EXTERNAL DOORS & ALSO ABOVE AND BELOW WINDOWS. BED JOINT REINFORCEMENT TO EXTENT 500mm MINIMUM PAST DOOR / WINDOW LINE.

10.0 STRUCTURAL TIMBER

10.1 NEW TIMBER IN THE WORKS IS TO BE SELECTED STRUCTURAL TIMBER NOT INFERIOR TO EUROPEAN REDWOOD/WHITEWOOD GRADE SC3 TO BS 5268: PART 2, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

10.2 NEW TIMBER IN THE WORKS IS TO BE VACUUM IMPREGNATED WITH PRESERVATIVE TO BS 5268: PART 5 AND THE MANUFACTURER'S RECOMMENDATIONS. CUT ENDS ARE TO BE THOROUGHLY TREATED WITH BRUSH APPLIED COATS OF APPROPRIATE PRESERVATIVE BEFORE FIXING. ALL PRESERVATIVES ARE TO BE TO THE ARCHITECT'S APPROVAL.

10.3 STRUCTURAL TIMBERS MAY ONLY BE DRILLED OR CUT FOR SERVICES AS NOTED BELOW. NOTCHES IN THE JOISTS ARE TO BE AT THE TOP AND LOCATED BETWEEN 0.1 AND 0.25 OF THE SPAN FROM THE SUPPORT. NOTCH CANNOT BE DEEPER THAN 0.125 OF THE JOIST DEPTH. HOLES IN THE JOISTS ARE TO BE ALONG THE CENTRE WITH MAXIMUM DIAMETER OF 0.125 OF THE JOIST DEPTH.

10.4 SIZES OF NEW STRUCTURAL TIMBERS NOTED ON THE DRAWINGS ARE SAWN BASIC SIZES. 10.5 ALL SCREWS, NAILS, TIMBER CONNECTORS, JOIST HANGERS, STEEL STRAPS ETC., ARE TO BE GALVANISED. JOIST HANGERS, STRAPS, CONNECTORS ETC., SHALL BE PURPOSE MADE AND OF MANUFACTURE OR PERFORMANCE STATED ON THE DRAWINGS. ALL SUCH ITEMS ARE TO BE FIXED IN ACCORDANCE WITH THE MANUFACTURER'S RECOMMENDATIONS, UNLESS SHOWN OTHERWISE ON THE DRAWINGS.

10.6 ALL EXISTING TIMBERS ARE TO BE INSPECTED AT THE BEGINNING OF THE WORKS BY A SPECIALIST SUB- CONTRACTOR FOR ROT AND INFESTATION. DETAILS OF REPLACING OR STRENGTHENING ANY DEFECTIVE TIMBERS RECOMMENDED BY THE SPECIALIST ARE TO BE AGREED ON SITE.

10.7 TRIMMERS TO OPENINGS IN FLOORS AND CEILING CONSTRUCTION SHALL BE JOINTED TO THE TRIMMING JOISTS WITH JOIST HANGERS UNLESS NOTED OTHERWISE ON THE DRAWINGS. 10.8 DOUBLE UP JOISTS UNDER NEW PARTITIONS RUNNING PARALLEL TO THE JOIST SPAN. DOUBLED JOISTS ARE TO BE BOLTED TOGETHER AT 600mm c/c USING M12 BOLTS AND OVERSIZE WASHERS, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

PROVIDE SOLID NOGGINS UNDER NEW PARTITIONS RUNNING PERPENDICULAR TO THE JOIST SPAN.

10.9 IN ALL NEW TIMBER FLOORS FULL DEPTH NOGGINS 50mm WIDE ARE TO BE PROVIDED ALONG LINES OF SUPPORT AND AT MID SPAN FOR SPANS EXCEEDING OVER 2500mm AND AT 1/3 AND 2/3 SPAN POSITIONS FOR SPANS EXCEEDING 4500mm, UNLESS NOTED OTHERWISE ON THE DRAWINGS. IN EXISTING FLOORS NEW NOGGINS ARE TO BE PROVIDED AS SHOWN ON THE DRAWINGS.

11.0 STEELWORK

11.1 ALL WORKMANSHIP IS TO COMPLY WITH BS 5950: PART 2 AND THE STRUCTURAL STEELWORK SPECIFICATION BY BRITISH STEEL.

11.2 ALL STRUCTURAL STEEL SECTIONS ARE TO BE GRADE S275 JR TO BS 5950, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

11.3 ERECTING STEELWORK: SET OUT AND ERECT TO BS 5950 : PART 2. PROVIDE ALL TEMPORARY ERECTION BRACING NECESSARY TO ENSURE STABILITY OF THE BUILDING DURING ERECTION. REMOVE WHEN IT IS SAFE TO DO SO, TIMING TO BE AGREED WITH THE MAIN CONTRACTOR. DO NOT DISTORT STEELWORK AND DO NOT EXCEED STRESS LIMITS DURING ERECTION UNLESS OTHERWISE APPROVED.

11.4 ALL BOLTS ARE TO BE GRADE 8.8 PRECISION BOLTS TO BS 3692. BOLTS TO HAVE A CLASS 1 SHERARDISED FINISH TO BS 4921.

11.5 ALL WELDING IS TO COMPLY WITH BS 5135. SITE WELDING SHALL NOT BE PERMITTED EXCEPT WITH THE WRITTEN APPROVAL OF THE STRUCTURAL ENGINEER.

11.6 ALL WELDS ARE TO BE 6MM FILLET WELDS OR FULL STRENGTH BUTT WELDS, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

11.7 THE STEEL FABRICATOR IS TO OBTAIN DIMENSIONS FROM SITE. SETTING OUT DIMENSIONS ARE TO BE OBTAINED FROM THE ARCHITECT'S DRAWINGS.

11.8 ALL STEELWORK IS TO BE THOROUGHLY POWER BRUSHED CLEAN DOWN TO BRIGHT STEEL IN ORDER TO REMOVE ALL MILL SCALE, RUST, OIL, GREASE ETC., AND PAINTED WITH TWO COATS ALKYD BASED HIGH BUILD ZINC PHOSPHATE BEFORE ERECTION, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

ENDS OF BEAMS WHICH ARE BUILT INTO THE INNER LEAF OF A CAVITY WALL OR INTO SOLID BRICK WALLS ARE TO BE PAINTED WITH AN ADDITIONAL COAT ON SITE OF HB BITUMEN PAINT TO DRY FILM THICKNESS OF 175 MICRONS .

CONTRACTOR TO ENSURE THAT ALL COATING MATERIALS TO BE USED ARE RECOMMENDED BY THEIR MANUFACTURERS FOR THE PARTICULAR SURFACE AND CONDITIONS OF EXPOSURE, AND THAT THEY ARE COMPATIBLE WITH EACH OTHER.

11.9 FIRE PROTECTION TO ALL STEELWORK IS TO BE TO THE ARCHITECT'S DETAILS.

11.10 STEELWORK THAT IS TO BE CONCRETE ENCASED IS TO BE CLEANED AS NOTED ABOVE AND LEFT UNPAINTED. WRAP STEELWORK WITH D98 MESH PRIOR TO CONCRETING. PROVIDE A MINIMUM 50MM OF CONCRETE TO THE STEEL BEAM, WITH THE MESH PLACED CENTRALLY WITHIN THE CONCRETE. SEE CONCRETE SPECIFICATION FOR MIX REQUIREMENTS.

11.11 ALL STEELWORK THAT IS BURIED IN THE GROUND TO HAVE A MINIMUM OF 100 MM CONCRETE ENCASEMENT AND MESH AS NOTED ABOVE. REFER TO CONCRETE SPECIFICATION FOR FOUNDATION CONCRETE MIX REQUIREMENTS.

11.12 ENSURE THAT INSIDES OF HOLLOW SECTIONS ARE DRY AND CLEAR OF DEBRIS, BEFORE SEALING ENDS AND OPENINGS.

11.13 THE FINISH OF ANY STEELWORK THAT IS TO REMAIN VISIBLE OR IS OF AN ARCHITECTURAL NATURE MUST BE AGREED WITH THE ARCHITECT PRIOR TO MANUFACTURE. ALL WELDS IN AREAS NOTED ABOVE ARE TO BE GROUND SMOOTH.

11.14 ALL FABRICATION DRAWINGS TO BE SUBMITTED TO ENGINEER, ALLOWING 10 WORKING DAYS FOR CONSIDERATION.

11.15 EXTERNAL STEELWORK IS TO GALVANIZED IN ACCORDANCE WITH ITEM 11.18 BELOW.

11.16 ALL STEELWORK IN CAVITIES TO BE BLASTED CLEAN TO SA2.5 OF BS7079:PART A1:1989 AND FINISHED WITH 125 MICRONS OF 'LEIGH'S PAINTS' 'EPIGRIP M555 SHEEN PROTECTIVE FINISH' EPOXY ZINC PHOSPHATE.

11.17 TOLERANCES: THE TOLERANCES FOR THE ERECTED STEELWORK AT ANY LEVEL ARE RELATED TO THE MAJOR GRID LINES AND DATUM PROVIDED BY THE CONSTRUCTION MANAGER AT THAT LEVEL. THE TOLERANCES FOR THE ERECTED STEELWORK SHALL BE AS FOLLOWS:

POSITION OF CENTRE LINE OF COLUMN AND COLUMN BASE ± 3mm

LINEAR DIMENSIONS UP TO 9m ± 6mm

LINEAR DIMENSIONS UP TO 18m ± 10mm

PLUM OF COLUMN CENTRE LINE WHICH IS WITHIN THE POSITIONAL TOLERANCE: -IN ANY STOREY HEIGHT -IN ANY TWO STOREY HEIGHT -OVERALL HEIGHT

6mm

8mm

10mm

LEVEL OF BASE OF FIRST ERECTED COLUMN ± 5mm

LEVEL OF BEAM AT JUNCTION WITH COLUMN MEASURED FROM THE TRANSFERRED BENCH MARK

LEVELS OF UPPER OR LOWER SURFACES OF TWO OR MORE BEAMS MEETING AT A COLUMN

DIFFERENCE IN LEVEL OF ENDS OF A BEAM OR TRUSS TOLERANCES ARE: -UP TO 9m -UP TO 18m

8mm

3mm

THE CONTRACTOR SHALL NOTE THE TOLERANCES OF THE SETTING-OUT GRID AND DATUMS IN ARRIVING AT ANY ABSOLUTE VALUES OF HEIGHT OR DISTANCE BETWEEN STEELWORK COMPONENTS. 11.18 GALVANIZING PLUS DECORATIVE COATING ALL EXPOSED STEELWORK IS TO BE GALVANISED. UNLESS NOTED OTHERWISE ON DRAWINGS. EXPECTED PERIOD TO FIRST MAINTENANCE: GREATER THAN 18 YEARS IN POLLUTED INLAND ENVIRONMENT.

PREPARATION: BLAST CLEANING TO BS 7079:PART A1, PREPARATION GRADE SA2 (FOR ROUGHNESS) USING CHILLED IRON GRIT GRADE G24, FOLLOWED BY ACID PICKLING. GALVANISING: TO BS729, MINIMUM AVERAGE COATING THICKNESS 85 MICRONS. PREPARATION FOR PAINTING: THOROUGHLY DEGREASE (USING AN EMULSIFYING AGENT), LIGHTLY ABRADE (BY HAND USING WIRE-WOOL OR BY LIGHTLY BLASTING WITH A FINE GRADE NON-METALLIC ABRASIVE) FOLLOWED BY RINSING WITH FRESH CLEAN WATER. RESIDUE OF GREASE AND/OR INSUFFICIENT ABRASION: REPEAT PREPARATION LOCALLY AND RE-APPLY MORDANT WASH.

SHOP PRIMER: APPLY ONE COAT EPOXY MI0 (E.G. W & J LEIGHS EPIGRIP K267). DRY FILM THICKNESS: 50 MICRONS.

DECORATIVE TOP COATS: APPLY TWO COATS ACRYLIC URETHANE SHEEN (E.G. W & J LEIGH'S RESISTEX M237). DRY FILM THICKNESS: 40 MICRONS EACH COAT.

COLOUR: AS SPECIFIED BY ARCHITECT.

FINISH: IF GLOSS FINISH IS REQUIRED THEN THE SECOND TOP COAT SHOULD BE REPLACED WITH AN ACRYLIC URETHANE ENAMEL. (E.G W E J LEIGH'S RESISTEX M437)

12. LINTELS

12.1 PRECAST CONCRETE LINTELS ARE TO BE BS 5977: PART 2 BY TARMAC 'TOPFLOOR', TELEPHONE 01335 360601. SIZES AND TYPES ARE AS INDICATED ON THE DRAWINGS. END BEARING LENGTHS ARE TO BE AT LEAST 150MM ON NEW MASONRY AND 225MM ON EXISTING MASONRY, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

12.2 GALVANISED STEEL LINTELS ARE TO BE BS 5977: PART 2 BY CATNIC COMPONENTS LTD, PONTYWINDY ESTATE, CAERPHILLY, MID GLAMORGAN, CF8 2WJ, TELEPHONE 0222-885-955. SIZES AND TYPES ARE AS INDICATED ON DRAWINGS. END BEARING LENGTHS ARE TO BE AT LEAST 150MM ON NEW MASONRY AND 225MM ON EXISTING MASONRY, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

12.3 THE CONTRACTOR SHALL OBTAIN THE STRUCTURAL ENGINEER'S OR ARCHITECT'S WRITTEN CONSENT, PRIOR TO COMMENCEMENT OF THE WORK, TO THE USE OF LINTELS BY ALTERNATIVE MANUFACTURERS TO THOSE LISTED ABOVE.