Proud to Power Progress:

Partnering with Hyundai Motor Group Metaplant America in Georgia

BankSouth is proud to have been selected as the on-site banking services partner for Hyundai Motor Group Metaplant America, Hyundai’s first dedicated electrified vehicle (EV) plant in the U.S. and the largest economic development project in Georgia’s history.

Scan to Learn More About This Partnership

Publisher’s Letter

As we close out another dynamic quarter in manufacturing, technology, and industry leadership, this issue of Industry Today turns its focus to the forces reshaping how we build, power, and sustain the world around us. Progress this meaningful doesn’t happen in isolation - it’s forged at the intersection of innovation, collaboration, and bold thinking. And in this issue, we’re proud to highlight organizations that embody exactly that.

We begin with Hyundai, where the future of mobility is unfolding in real time. At the Hyundai Metaplant (HMGMA), AI is more than a buzzword — it’s a catalyst for genuine innovation, enabling smarter operations and a more resilient approach to manufacturing.

From mobility to machinery, Wheeler Machinery demonstrates that transformation also comes from operational versatility. Whether it’s appraising, moving, selling, or auctioning heavy equipment, Wheeler shows how service-first solutions can amplify productivity across industries.

Our economic development section highlights two regions shaping America’s competitive landscape. The Lehigh Valley Economic Development Corporation illustrates why food and beverage manufacturers, and increasingly advanced manufacturing sectors, are choosing this thriving East Coast hub for sustainable growth. And in Chicago, the World Trade Center network reinforces the importance of global connectivity, offering U.S. metros a steady platform for engagement even as international trade grows more volatile.

In our feature articles, we explore the frontier of human ingenuity. DEEP’s Project Vanguard heralds the first new subsea human habitat in 40 years, opening the door to new scientific, environmental, and industrial possibilities beneath the ocean’s surface. Discovery Education shares how companies can build stronger, more meaningful relationships with classrooms, preparing students for future-ready careers. And Mitsubishi Electric America Foundation underscores a message we can’t afford to ignore: the workforce of tomorrow must be inclusive, equitable, and built with intention.

We’re also proud to feature cutting-edge perspectives on reshoring, as industry expert Harry Moser highlights the U.S. companies achieving award-winning success through smart planning, total cost of ownership analysis, and strategic investment in workers and technologies. In energy and resources, Myriad Uranium Corp. revisits Wyoming’s Copper Mountain and reveals how modern assays are unlocking overlooked uranium reserves, a critical element in America’s push for secure, domestic fuel sources.

And finally, Saint-Gobain North America reminds us that talent development begins long before the factory floor. Their Sustaining Futures, Raising Communities initiative invites students into the world of modern manufacturing, helping them envision a place where their skills, curiosity, and ambition can thrive.

Together, these stories paint a portrait of an industry moving with purpose. Whether improving communities, strengthening supply chains, or pioneering new frontiers, every organization in this issue reflects a foundational truth: manufacturing is, and always has been, about building a better future.

Thank you for joining us in that mission. We hope you find inspiration, insight, and forward momentum in the pages ahead.

— Susan Poeton, Publisher

www.industrytoday.com spoeton@industrytoday.com

Publisher: Susan G. Poeton

Senior Editor: David Soyka

Contributing Editor: Lorie Greenspan

Associate Publishers:

James Ballam, Renata Ginter, Jonathan Listig, Brian McMillan

Digital Marketing & Operations

Coordinator: Melissa Burge

Marketing Director: Alice Anne Coakley

Art Director: Seema Mazhar

Contributing Designers: Jorge Leandro Rodrigues

472 Meeting Street, Ste C-156, Charleston, SC 29403, USA Ph. 973.218.0310

Contents Table of CONTENTS

04 COMPANY PROFILES

ECONOMIC DEVELOPMENT

HYUNDAI METAPLANT (HMGMA) META DYNAMICS

At HMGMA, AI fuels real innovation - machines helping humanity and driving a stronger, more resilient future.

WHEELER MACHINERY

WHEELER DEALER

74

If you need it moved, appraised, sold, or auctioned, Wheeler Machinery can do that – and more.

LEHIGH VALLEY ECONOMIC DEVELOPMENT CORPORATION

WHY FOOD & BEVERAGE MANUFACTURERS SAVOR THE LEHIGH VALLEY

50

From food to advanced manufacturing, Lehigh Valley’s makers are fueling sustainable progress for the East Coast and beyond.

WORLD TRADE CENTER CHICAGO BUILDING THE INFRASTRUCTURE FOR PERMANENT GLOBAL GROWTH

34

As trade volatility grows, World Trade Centers offer U.S. metros a stable, global hub for business growth and investment.

CONTENTS

DEEP: PROJECT VANGUARD

A NEW ERA OF UNDERWATER LIVING BEGINS

DEEP has unveiled Vanguard – the first new subsea human habitat of its kind in 40 years.

DISCOVERY EDUCATION

HOW COMPANIES BUILD STRONG CLASSROOM CONNECTIONS

Strategies for companies to build effective classroom connections.

MITSUBISHI ELECTRIC AMERICA FOUNDATION

THE FUTURE OF MANUFACTURING? INCLUSIVE WORKFORCES

How Mitsubishi Electric America Foundation is preparing the next generation of manufacturing workers.

MOSER ON MANUFACTURING

AWARD WINNING RESHORING SUCCESS STORIES: MEET OUR HIGH-PERFORMING TEAMS

Industry leaders are reshoring by planning smartly, using TCO, and investing in U.S. workers, facilities, and advanced technologies.

MYRIAD URANIUM CORP.

UNLOCKING AMERICA’S URANIUM SUPPLY

At Wyoming’s Copper Mountain, modern assays reveal overlooked uranium as the U.S. works to rebuild a secure fuel supply.

SAINT-GOBAIN NORTH AMERICA

INSPIRING TOMORROW’S MANUFACTURING LEADERS, TODAY

Saint-Gobain’s Sustaining Futures, Raising Communities workforce development program shows students career paths in manufacturing.

META DYNAMICS

They call it artificial intelligence but its impact on the world is anything but insincere. At Hyundai Motor Group’s Metaplant America (HMGMA) the innovation is real and the machines are not turning against humanity but helping the world to move into a robust future. Lorie Greenspan reports.

Electrified is a good way to describe Hyundai Motor Group’s Metaplant America (HMGMA), located outside of Savannah, Georgia. It is Hyundai Motor Group’s first dedicated mass-production

Electrified Vehicle (EV) plant. The operation brims with intelligent activity, turning meta manufacturing on its head while utilizing the next wave of advances in automotive processes: order collection, procurement, logistics and

production are all optimized utilizing AI and data.

HMGMA boasts that its innovative manufacturing system creates a human-centered work environment where robots assist human work-

ers to build more than 500,000 vehicles per year. Its first vehicle was the 2025 IONIQ 5 and its second will be the 2026 IONIQ 9. HMGMA will eventually produce models for Kia and Genesis, which are part of the HMG family.

Pictured: Euisun Chung, Executive Chair Hyundai Motor Group, left, joins Georgia Gov. Brian Kemp during the grand opening of the Hyundai Motor Group Metaplant America in March, 2025 in Ellabell, Ga.

“Hyundai Motor Group Metaplant America not only represents the Group’s advanced manufacturing capabilities and commitment to innovation, but also our investment in relationships with our partners and communities right here in Georgia,” said Euisun Chung, Executive Chair of Hyundai Motor Group. “With the rich history of craftsmanship and manufacturing

in this community, together with the talented workforce at HMGMA we are building the future of mobility with America, in America.”

The company’s plans for its Metaplant date to 2022 when it sought to build its first dedicated fully electrified vehicle and battery manufacturing facilities in the United States. HMG chose the 2,900-acre site in Bryan County, Georgia,

When Hyundai Motor Group Metaplant America (HMGMA) selected BankSouth as its on-site banking partner, the choice reflected more than convenience—it signaled confidence in a Georgia-born institution built on innovation, community trust, and employee empowerment. As Hyundai establishes its first dedicated electrified vehicle (EV) manufacturing plant in the U.S. and the largest economic development project in Georgia’s history, its partnership with BankSouth demonstrates the critical role of financial wellness in workforce satisfaction and retention.

At the center of HMGMA’s decision was a core priority: improving the day-to-day lives of Meta Pros by reducing financial stress, expanding financial access, and providing convenient, trusted resources right where employees work. The partnership is designed not only to support the plant’s operations, but to meaningfully enhance the employee experience, an essential focus for HMGMA as it builds a sustainable, people-centered culture.

Why BankSouth Was the Right Fit

See Inside Front Cover

For more than 75 years, BankSouth has been part of Georgia’s economic fabric. Its selection by Hyundai was driven by shared values of progress, innovation, and community investment. As Harold Reynolds, Chairman and CEO of BankSouth, noted, “Supporting one of Georgia’s most significant economic projects aligns with our mission to drive progress and innovation while serving the financial needs of businesses and individuals.”

BankSouth’s presence inside the Metaplant, complete with an in-plant branch and multiple ATMs - ensures Hyundai’s employees (“Meta Pros”) have direct, easy access to full-service banking. This means Meta Pros can manage finances during their workday without the burden of travel, scheduling challenges, or added personal time - helping reduce stress and increase financial confidence, especially for employees new to the region or entering the workforce for the first time.

Beyond convenience, this model delivers on-site access to personalized financial tools, home lending expertise through BankSouth Mortgage, and education for long-term financial health. Laura Moore, BankSouth’s Savannah Regional Market President, emphasized this people-first approach: “Our goal is to empower Meta Pros with the knowledge and tools for lasting financial success.”

Extending the Model: BankSouth@Work

The success of the Hyundai collaboration mirrors BankSouth’s broader BankSouth@Work program, an employer-focused initiative designed to bring comprehensive financial services directly to the workplace. For large organizations, especially those with distributed or shift-based workforces, BankSouth@Work bridges the gap between personal finance and professional life.

The benefits extend far beyond basic banking. BankSouth can offer employees access to checking and savings accounts, financial literacy resources, mortgage and home loan programs, and mobile-first digital banking solutions, all customized for the company’s needs. The result: improved employee engagement, reduced financial stress, and a deeper sense of employer support.

A Partnership That Sets a Standard

As Hyundai invests billions in its Georgia Metaplant and creates thousands of jobs, BankSouth’s integration represents a model for how localized financial institutions can enhance major corporate ecosystems. The partnership demonstrates how a regional bank, deeply rooted in community values, can support the workforce of a global enterprise, proving that “big impact” doesn’t require “big bank.”

HMGMA’s Chief Administrative Officer Brent Stubbs highlighted the partnership’s community impact, calling BankSouth “part of the fabric of our community for over 75 years.” The trust embedded in that statement is exactly what makes the BankSouth@Work model so appealing to other organizations seeking to boost workforce wellbeing through credible, accessible financial partnerships.

In an era when companies compete for both talent and loyalty, BankSouth’s approach - meeting employees where they are, literally, may be its most powerful product yet. For more information visit banksouth.com

BANKSOUTH RENDERING FOR THE HMGMA BRANCH

for the area’s quality of life, strong regional connectivity, global logistical connections and infrastructure, and existing workforce training programs. Now fully operational, the site employs more than 8,500 workers; more than 6,900 jobs will be created at off-site suppliers.

To date, the economic development agreement is Georgia’s largest in state history and totals more than $7.5 billion.

“Hyundai Motor Group Metaplant America is a once-in-a-generation opportunity, made possible by our commitment to working with job creators to build fruitful partnerships for decades. Collaborations between HMGMA and Georgia’s universities and technical colleges, including Georgia Quick Start’s on-site

training facility, are preparing Georgians for high-quality jobs of today and tomorrow, while our award-winning infrastructure, such as our ports connects companies to markets around the nation and globe,” said Governor Kemp, highlighting the positive impact of the plant on the state’s economy as well as its role in advancing innovative manufacturing and cultivating a skilled labor pool in Georgia.

The megasite consists of the Metaplant, LG Battery Joint Venture (known as HLA Greenpower) and five affiliates including Hyundai Mobis, Hyundai Glovis, Hyundai Transys, Hyundai Steel and Hyundai Material. There are nineteen suppliers located offsite. Such energy is pulsating in its sheer capacity

for innovation. But there’s more.

Miles of meta pros

With 11 cavernous buildings and a massive 7.5 million square feet of space, HMGMA is one of the most technologically advanced manufacturing facilities in the world. The Metaplant employs more than 850 robots and almost 300 Automated Guided Vehicles (AGV) working alongside employees, who the company calls Meta Pros.

The amount of meta knowledge, both human and robotic, at HMGMA can fill a digital encyclopedia – each wave of innovative meta data

feeds into a comprehensive strategy of precision automotive manufacturing.

The factory is also environmentally friendly; its meta pros park in nearly 1,900 spaces beneath solar roofs that provide up to 5 percent of the plant’s electricity. The bulk of finished vehicles are shipped by rail rather than truck, trimming fossil-fuel emissions and the automaker’s carbon footprint.

As part of an AI-based procurement and logistics system, the AGVs automatically allocate and ferry parts to their proper workstations for just-in-time delivery, saving space, time, and money otherwise used to stockpile parts.

When you leave the HMGMA plant, you can tell people that you have, beyond a doubt, met a pro.

History in the Automotive Making

One of the more unique and cutting-edge features of HMGMA are the Spots, robotic quadrupeds designed by Hyundai-owned Boston Dynamics that use 360-degree vision and “athletic intelligence” to sniff out poten-

tial defects on car welds. The Atlas humanoid robots, also from Boston Dynamics, can crawl, cartwheel, and move in sync with their human counterparts, utilizing RGB cameras on their 360-degree swiveling heads in an effort to sense their environments, avoid collisions, and manipulate and move parts in factories. In addition, HMGMA’s welding shop houses 475 industrial robots that assemble the bodies in white. Such robotic deftness and ability to secure

Pictured: The Grand Opening celebration was attended by Hyundai Motor Group Executive Chair Chung, Governor Brian P. Kemp, U.S. Representative Buddy Carter, Hyundai Motor Group Vice Chair Jaehoon Chang, Hyundai Motor Company President and CEO José Muñoz, Kia Corporation President and CEO Ho Sung Song, company officials, state and local leaders, HMGMA Meta Pro employees, and other distinguished guests.

accuracy allows the installation of such items as bulky doors on the assembly line without a bump or scratch. The robotic factory worker frees people for the more intricate craftsmanship that goes into the technical and design innovation of Hyundai’s vehicles.

One of the biggest features of the site is its hydrogen ecosystem. HMGMA has deployed Hyundai Motor XCIENT heavy-duty hydrogen fuel-cell electric trucks for clean logistics operations. A total of 21 XCIENT trucks are currently in operation, representing more than a third

of the Glovis America truck fleet at HMGMA, which transport vehicle parts from suppliers across the region to the 2,906-acre Megasite where HMGMA is located on a daily basis.

This industry-leading initiative represents a significant step forward in HMGMA’s leadership efforts to both reduce its carbon footprint and actively promote sustainable practices in daily logistics operations.

Overall, the Metaplant’s technical advances represent an historic achievement that will thrive in the annals of automotive construction,

representing a leap in manufacturing efficiency – the possibilities afforded through AI breakthroughs in our current age are what the invention of the assembly line was to the 1910s.

Landmark investment

In other areas, the Group has enabled further growth related to joint battery ventures

with LG Energy Solution and SK totaling a $12.6 billion investment. This represents the largest single investment in the state’s history. The Group’s total investments in Georgia are expected to create nearly 40,000 direct and indirect jobs, and $4.6 billion in individual earnings every year, according to the Center for Automotive Research.

Pictured: HMG entered into a landmark agreement with the State of Georgia in May 2022 to establish a cutting-edge electric and hybrid vehicle production and battery manufacturing facility in Ellabell, Georgia, located 20 miles outside of historic Savannah. HMGMA has the capacity to initially produce 300,000 vehicles annually.

HMGMA exemplifies the Group’s dedication to fostering economic growth, driving technological advancements, and delivering sustainable solutions to the U.S. market. To date, the Group has invested more than $20.5 billion in the U.S. in the service of these goals, creating or supporting over 570,000 jobs nationwide.

A total of $6 billion will be allocated to enhance the Group’s parts and logistics business, as well as establishing an Electric Arc Furnace-based integrated steel mill in the U.S. through its affiliate, Hyundai Steel, with an annual steel production capacity of 2.7 million tons. The mill will supply high-quality automotive steel plates to HMGMA when commercial

steel production begins in 2029.

“It’s a historic moment that our state-of-theart smart plant is officially open,” said Oscar Kwon, CEO of HMGMA. “It is as important for us to create a comfortable and welcoming work environment for our Meta Pros, as it is for us to create an energy-efficient and technologically advanced plant. It is essential for our Meta Pros to be happy, comfortable and safe in their work environment for long-lasting careers at HMGMA.”

Hyundai Motor America: Who Are They?

Hyundai Motor America has been in the U.S.

Pictured: Hyundai Motor Group Metaplant America (HMGMA) hosted a Grand Opening celebration, as part of Hyundai Motor Group’s commitment to investment in the U.S. The ceremony marked the completion of the largest economic development project in Georgia’s history, just two and a half years after breaking ground.

market for 37 years. The sales volume grew from 168,000 units in 1986 to near 800,000 units in 2016. HMA’s Alabama plant has been producing U.S.-made vehicles since 2005. The annual production volume increased from 91,000 units in 2005 to shy of 400,000 units in 2013 and 2014. HMA’s U.S.-based assembly plant produced about 45 percent of HMA’s vehicles sold in the U.S. market. Globally, Hyundai Motor Group ranks third, with more than 6.8 million units sold in 2022.

Hyundai Motor Company contributed nearly 4.0 million units of vehicles sold worldwide.

Hyundai Motor America offers U.S. consumers a technology-rich lineup of cars, SUVs, and

electrified vehicles, while supporting Hyundai Motor Company’s Progress for Humanity vision. Hyundai has significant operations in the U.S., including its North American headquarters in California, the Hyundai Motor Manufacturing Alabama assembly plant, the all-new Hyundai Motor Group Metaplant America, and several cutting-edge R&D facilities. These operations, combined with those of Hyundai’s 850 independent dealers, contribute $20.1 billion annually and 190,000 jobs to the U.S. economy, according to the company’s economic impact report.

For more information, visit www.hyundainews.com.

INSPIRING TOMORROW’S MANUFACTURING LEADERS, TODAY

Saint-Gobain’s Sustaining Futures, Raising Communities workforce development program shows students career paths in manufacturing.

By Mark Rayfield, President and CEO of Saint-Gobain North America and CertainTeed.

For over a century and a half, manufacturing has been at the center of the US economy, providing a livelihood for millions of American families and inspiring major innovations that shape the world we live in. The industry remains vital in the 21st century, currently employing over 13 million Americans in manufacturing careers. However, we now face an existential challenge that threatens the growth and innovation manufacturing has always provided – a shortage in the manufacturing workforce. As an integral component of the US and global economy, we must work together to develop the future of the manufacturing workforce. It is in all our interest to ensure the industry has the people and tools it needs to continue to thrive, and to open career paths in manufacturing for all.

A study by Deloitte and the Manufacturing Institute highlights that over the next decade the manufacturing sector will require over 3.8

million jobs. Unfortunately, with our current challenges, nearly 1.9 million of those jobs in manufacturing careers could go unfilled. This would leave us without the necessary teams to make key materials for our homes, automobiles,

airplanes and the products we use every day, putting our country’s growth at risk of coming to a halt. How do we overcome these manufacturing workforce development challenges? As leaders in the industry, we have a responsibility

to communicate how valuable and rewarding a career path in manufacturing can be to generations of workers who have been encouraged to avoid this sector. We must inspire a renewed interest and understanding of the field.

The manufacturing sector will require over 3.8 million jobs by 2030. Without action, 1.9 million could go unfilled.

This is an area where we must make progress. If we can show our young people the advantages and benefits of manufacturing careers at an early age, it is more likely they will pursue a career path in manufacturing fields. We need more engagement with those in K through 12 to educate students on what modern manufacturing looks like and the competitive wages and benefits a manufacturing career in the industry could bring. Those who have been on a career path in manufacturing can tell you that manufacturing jobs today are light years from what they used to be. With technological advancements such as AI and robotics, World Class Manufacturing techniques, and updated environmental, health and safety guidelines, the popular image in media of manufacturing careers as dirty and dangerous could not be further from the truth.

Getting the message out to those who we want and need to be the future leaders of the field is key. From executives to operators on the line, everyone must step outside the plant and engage with students directly. According to a study from the Manufacturing Institute, of students enrolled in CTE courses, most have had no contact with potential future employers, and only 12 percent have had an opportunity to visit a manufacturing site. This is a statistic that should get our attention. If students are not exposed to the field through manufacturing

workforce development programs, we cannot expect them to consider manufacturing as a career. It is past time to proactively work to build the pipeline for the next generation and ensure there are clear pathways available from the classroom to the manufacturing floor.

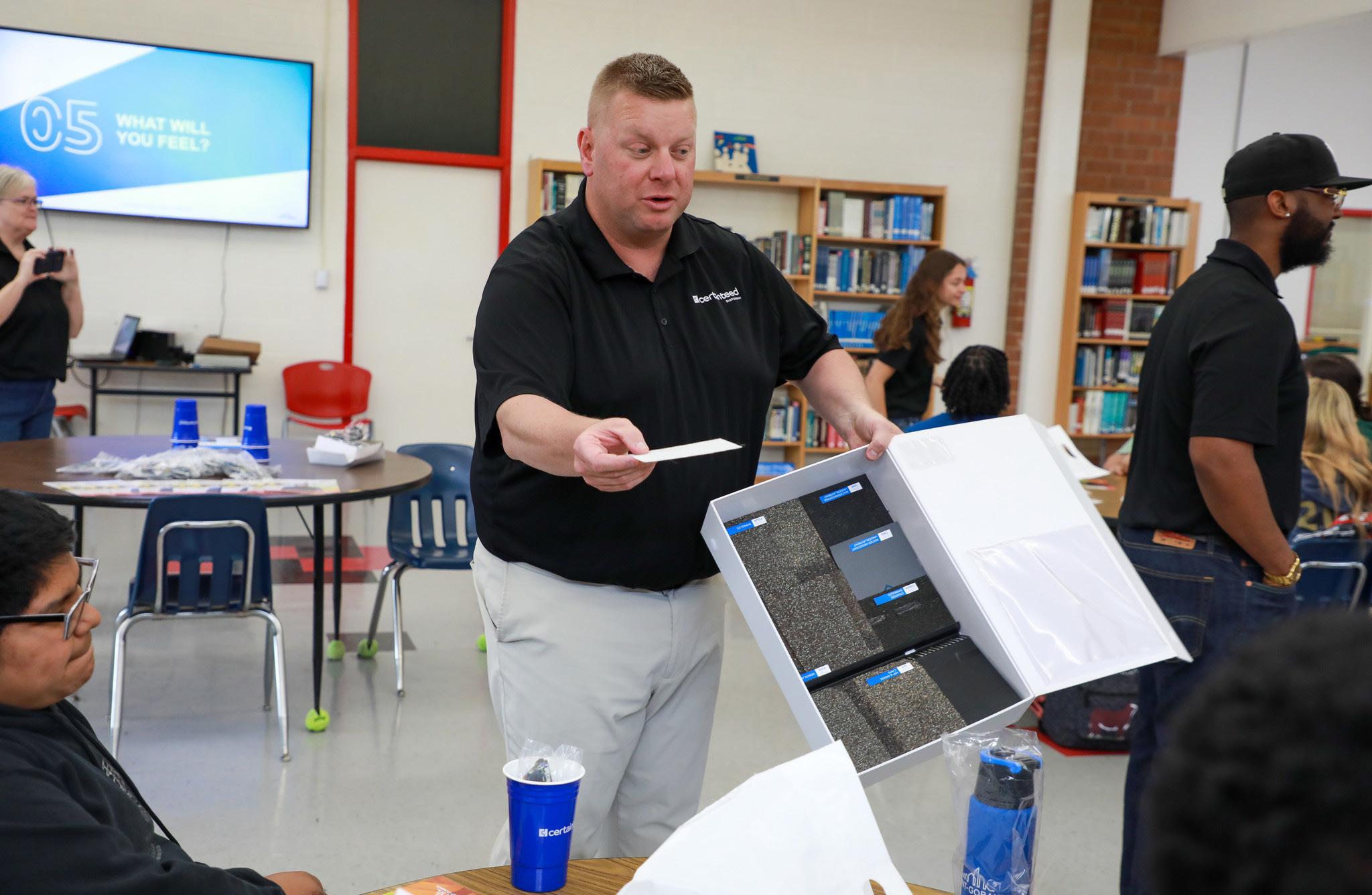

This is what has spurred Saint-Gobain North America to get into the classroom and launch Sustaining Futures, Raising Communities, a

Pictured: Students receive safety training before plant tour at Saint-Gobain’s CertainTeed Roofing plant in Oxford, North Carolina.

manufacturing workforce development program aimed at introducing high school students directly to the field and showcasing the robust manufacturing career paths available in this modern industry. Partnering with high schools across the United States, our aim is to help students explore all a career path in manufacturing has to offer through an interactive classroom curriculum focused on real experiences. The program also offers direct access to the plant setting with visits to Saint-Gobain manufacturing facilities. Our goal is to expand

this program across the United States and Canada to students of all ages.

Piloted this summer in Oxford, North Carolina and Shakopee, Minnesota, we are already seeing what showcasing manufacturing careers can do to spur interest in our field. At both pilot sites, students displayed an increased interest in a career path in manufacturing following the classroom visit and plant tour. And for many, old stereotypes and myths about the industry were debunked. As we expand this manufacturing workforce development pro-

gram, we hope and expect this progress to continue.

According to the National Association of Manufacturers, manufacturing in the United States alone would constitute the eighth-largest economy in the world, with over $2.60 trillion in value. While the world today may be increasingly digital, manufacturing still makes it run. The components that make up the chips in our smartphones and the vehicles that transport our food to the grocery store still need to be produced. Building the future of this vital industry is a must-win. Those who have spent their lives in manufacturing careers know the

Mark Rayfield

Mark Rayfield is President and CEO of Saint-Gobain North America and CertainTeed. Leaders in light and sustainable construction, Saint-Gobain manufactures building and high-performance solutions for construction and industrial markets. SaintGobain operates over 140 manufacturing facilities with over 18,000 employees across the United States and Canada.

industry can provide professional career opportunities in hometowns, big cities and everywhere across the globe. By sharing how SaintGobain North America is leading, it is my hope that we can inspire other manufacturing organizations to evaluate their progress and take proactive steps in building the workforce and career paths in manufacturing for the future. Join us and let’s solve the talent equation for the industry. Let’s continue the success story of American manufacturing.

Pictured: Saint-Gobain’s Sustaining Futures, Raising Communities program brings visibility to the manufacturing industry through both a classroom curriculum and plant tours.

OUR HIGH-PERFORMING

he National Metalworking Reshoring Award

T AWARD WINNING RESHORING SUCCESS STORIES MEET

The National Metalworking Reshoring Award honors companies that have contributed to the reshoring trend by effectively reshoring products, parts, or tooling made primarily by metal forming, fabricating, casting, or machining, including additive

RESHORING

HIGH-PERFORMING TEAMS

manufacturing. The award is made possible by: the Reshoring Initiative; the Precision Metalforming Association (PMA); AMT – The Association For Manufacturing Technology;

These industry-leading companies are rewiring domestic supply chains for success. They are successfully reshoring through careful planning, doing the math with TCO, and investing in American workers, facilities and new technologies.

By Harry Moser, Founder/ President, Reshoring Initiative®

SME; the National Tooling and Machining Association (NTMA); and the Fabricators and Manufacturers Association (FMA). This year Marlin Steel and GE Appliances were honored with the award for their leadership, reshoring and investment in U.S. manufacturing.

Tracking Successful Reshoring

The Reshoring Initiative has been tracking successful reshoring since 2010. With accurate calculations and planning, reshoring makes good economic sense for about 30% of what is now imported. We would like to share with you how these award-winning companies reshored successfully. Meet our Reshoring Award Winners.

GE Appliance — 2025 Reshoring Award Co-Winner

Reshoring is nothing new for GE Appliance. GE Appliance, a subsidiary of China-based Haier Group after an acquisition from General Electric in 2016, has been investing in its U.S. manufacturing operations for well over a decade.

The company began its reshoring journey with a 2012 announcement of a five-year, $1 billion investment to reshore and revitalize its U.S. manufacturing. Eight hundred million dollars of the investment was allocated to Appliance Park in Louisville, Kentucky creating new assembly lines for hybrid water heaters and

refrigerators previously made offshore.

GE Appliance’s “Zero Distance” Strategy

GE Appliance was honored with the 2025 Reshoring Award for leadership and continued investment in U.S. manufacturing. In June 2025, the company announced a $490 million investment to reshore production of washers and washer/dryers from China. This move is expected to create 800 new full-time jobs in 2027.

It was the first phase of a more than $3 billion plan to shift production of refrigerators, gas ranges, and water heaters out of China and Mexico over the next five years. As part of the investment, the company will partner with high schools and technical schools to train the next generation of manufacturing leaders, offering apprenticeship programs and providing upskilling to legacy employees to develop new skills to adapt to new technologies.

“This award is proof that when you invest in American workers and factories, you strengthen supply chains and fuel the resurgence of U.S. manufacturing,” said Bill Good, Vice President of Supply Chain at GE Appliances.

Pictured: Bill Good, vice president of supply chain at GE Appliances left, Harry Moser, president of the Reshoring Initiative right; right: Harry Moser, president of the Reshoring Initiative left, Drew Greenblatt, president, Marlin Steel right.

GE touts a customer-centric “zero distance” strategy to bring product development and manufacturing closer to the consumer through reshoring. “We’ve had a strategy that making appliances in America makes sense; it’s an economic thing, and it’s also how we can serve our customers in a better, more efficient way,” said CEO Kevin Nolan.

Marlin Steel — 2025 Reshoring Award Co-Winner

Drew Greenblatt, President and CEO of Marlin Steel, accepted the 2025 Reshoring Award in recognition of leadership in reshoring and domestic manufacturing resilience.

Marlin Steel reshored multiple production lines from diverse industries including; medical device, food processing, and aerospace. Marlin earned the Award by repeatedly demonstrating that automation, engineering, quality, and delivery can enable reshoring even of high-volume commoditized products. It did so by offering engineered solutions to previously commoditized applications, thus making price no longer the driving factor. Drew Greenblatt’s guiding philosophy is, “How can we engineer our products to solve problems?”

Where numbers meet know-how

One example involves a reshoring decision by

a U.S.-based buyer who previously sourced from Mexico. That buyer shifted production of 1500 custom wire racks to Marlin’s facility in Indiana, with final powder coat painting completed in Michigan. These racks had historically been manufactured in Mexico, but were reshored to the United States to improve turnaround time, simplify logistics,

and increase product consistency. Seven engineers from locations in Maryland, Indiana, and Massachusetts played a critical role. Their engineering capabilities, coupled with advanced fabrication and welding technologies, delivered faster prototyping, tighter process control, and improved responsiveness. It’s been proven that when a company separates its engineering and manufacturing, innovation declines. If the U.S. is going to be a home to innovation, it’s best to keep engineering and manufacturing together. Marlin Steel’s key reshoring successes demonstrate that even commodity-level components can be reshored when paired with precision and consistency.

Sumitomo Drive Technologies Wins 2024 National Metalworking Reshoring Award

Sumitomo Drive Technologies, a brand of Sumitomo Machinery Corporation of America, earned the award for its success in bringing manufacturing to the United States through foreign direct investment and to Mexico via nearshoring.

Pictured left top: Harry Moser (left), presents the 2024 Reshoring Award to Joe Gopi (right), director of manufacturing at Sumitomo Drive Technologies; left below: Anthony Bracale, director, sales and marketing at Hobson & Motzer; right: Harry Moser presenting “Manufacturing is Cool” t-shirts as bonuses to executives from Hardinge, Inc.

“This award reflects our commitment to customer satisfaction and building a strong, resilient supply chain,” Joe Gopi, Director of Manufacturing, remarked.

Reshoring Booms, Hobson & Motzer Wins 2023 National Metalworking Reshoring Award

Hobson & Motzer, a Connecticut-based precision machining and assembly contract manufacturer, received the 2023 Reshoring Award for reshoring a family of high precision stamped, machined, and assembled components for a medical device company. They successfully replaced a Taiwanese supplier due to having the resources and technology necessary

to scale and deliver consistent quality. This case embodies several of the strongest benefits and drivers of reshoring:

• Quality and efficient, effective cooperation of engineering and manufacturing enhanced by proximity.

• Overcoming one of the biggest barriers to reshoring — availability of skilled workforce — with four apprenticeship programs and plans to add more.

Hardinge Wins 2022 National Metalworking Reshoring Award

Hardinge Inc., a multinational machine tool and accessories builder, now operating as Kellenberger and Forkardt Hardinge, has

been manufacturing machine tools in the U.S. since the 1890’s. Hardinge received the 2022 Award for shifting the manufacturing of its milling and turning machine center solutions from its Taiwan plant to its plant in Elmira, New York.

President and General Manager of Turning & Milling, Ryan Ervin, Chief Marketing Officer and Vice President of Sales; David Bassett, Senior Director Continuous Improvement, Quality, Export Compliance; and Chandra

Urs, President – Turning & Milling were on hand to receive the award.

Acme Alliance Wins 2021 National Metalworking Reshoring Award

Acme Alliance was chosen for its record of reshoring products for its customers. In one case, their reshoring fixed a quality problem and cut the customer’s inventory by 94 percent. Acme also has successful facilities in Brazil and China. By not shipping from those facilities to

Pictured above: From left: Matt Thavis, director of business development at Acme Alliance, Mauri Mendes, president of Acme Alliance-Lovejoy Industries, and JR Kinnett, general manager at Acme Alliance, are congratulated by Harry Moser, founder and president of the Reshoring Initiative, for winning the 2021 National Metalworking Reshoring Award; right: Chelsea Moxlow Lantto, Director of Manufacturing, Trenton Forging; Bill Berry, Owner of Die-Tech & Engineering.

the U.S., Acme has proven that reshoring is not only possible but the right business choice.

“We truly believe being close to our customers is the most important strategy,” said Mauri Mendes, president of Acme Alliance-Lovejoy Industries.

Trenton Forging and Die-Tech

& Engineering are the 2020 winners of the third annual National

Metalworking Reshoring Award

Trenton Forging won the award for two key factors: 1. For supplying components previously imported from Japan by a Japanese machining company doing business in the U.S., and 2. For demonstrating substantial investment in automation and processing, as well as quality innovation, which are essential in a high-wage country like the U.S.

“The factors that came into play the most were

things like duty, freight, inventory carrying cost, lead and delivery times,” said Trenton Forging Director of Manufacturing, Chelsea Moxlow Lantto.

A key factor in the selection of mold and diemaker Die-Tech & Engineering, was the fact that its sector faces particular competitive challenges in the U.S. —where wage rates are higher — due the complexity and labor-intensive nature of mold and die making. The company was also recognized for its five-day turnaround of a critical component during the height of the Covid pandemic.

“Some of the products we’ve worked on in the last year are office furniture products, some consumer products, but most interesting perhaps, was a very short lead time effort to tool up for ventilators that couldn’t have been done logistically in a time frame that was needed,” said Die-Tech Owner Bill Perry.

Sherrill Manufacturing/Liberty Tabletop wins 2019 National Metalworking Reshoring Award

New York-based Sherrill Manufacturing was chosen because its success demonstrates that it is feasible to reshore completely lost product categories, including everyday products such as flatware. When Oneida Ltd. ceased operations, all U.S. flatware production had been lost, primarily to Asia. Sherrill Mfg. took over the Oneida flatware factory, launched prod-

ucts under the Liberty Tabletop brand, and found a more efficient way to market those products.

Mitchell Metal Products wins First National Reshoring Award

Mitchell Metal Products was selected after using reshoring to complete more end products with less lead time. In 2016, they manufactured a cultivator handle subassembly, increasing the production volume from 4,500

Harry Moser, Founder/President, Reshoring Initiative®

Click here to access the full list of Reshoring resources offered by the Reshoring Initiative. To report your reshoring successes or to get help with reshoring, contact Harry Moser, Founder and President, Reshoring Initiative, harry.moser@ reshorenow.org, 847-867-1144.

units made overseas to 30,000 units made in Wisconsin.

Are you thinking about reshoring?

We encourage companies to implement the top priorities for reindustrialization revealed by the Reshoring Survey — build a strong talent pipeline, use total cost of ownership, and prepare for geopolitical risk. Click here to access the full list of Reshoring resources offered by the Reshoring Initiative. To report your reshoring successes or to get

Pictured left: Harry Moser presents the National Metalworking Reshoring Award to Greg Owens, CEO of Sherrill Manufacturing; right: Harry Moser (left) presents the first National Reshoring Award to Tim Zimmerman of Mitchell Metal Products, in front of their award-winning cultivator handle subassembly.

help with reshoring, contact Harry Moser, Founder and President, Reshoring Initiative, harry.moser@reshorenow.org, 847-867-1144. Have you reshored a metal component or product? Apply here for the National Metalworking Reshoring Award today.

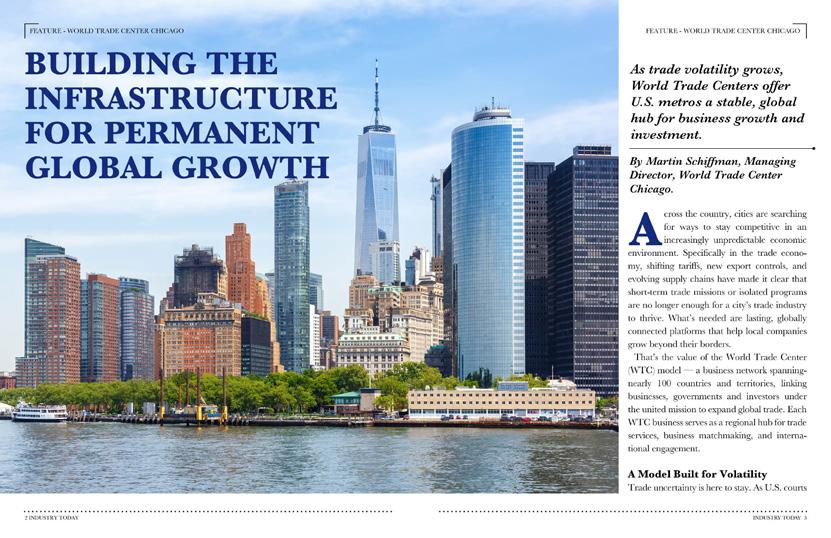

BUILDING THE INFRASTRUCTURE FOR PERMANENT GLOBAL GROWTH

As trade volatility grows, World Trade Centers offer U.S. metros a stable, global hub for business growth and investment.

By Martin Schiffman, Managing Director, World Trade Center

Chicago.

Across the country, cities are searching for ways to stay competitive in an increasingly unpredictable economic environment. Specifically in the trade economy, shifting tariffs, new export controls, and evolving supply chains have made it clear that short-term trade missions or isolated programs are no longer enough for a city’s trade industry to thrive. What’s needed are lasting, globally connected platforms that help local companies grow beyond their borders.

That’s the value of the World Trade Center (WTC) model — a business network spanningnearly 100 countries and territories, linking businesses, governments and investors under the united mission to expand global trade. Each WTC business serves as a regional hub for trade services, business matchmaking, and international engagement.

A Model Built for Volatility

Trade uncertainty is here to stay. As U.S. courts

revisit the legality of tariffs and countries adjust to new geopolitical alignments, businesses of every size must adapt quickly. Large corporations often have the resources to absorb these shocks. Smaller firms — especially manufacturers, exporters, and suppliers — do not.

A WTC license through World Trade Centers Association (WTCA) provides the permanent infrastructural hub that these smaller and midsized businesses need: a global network for sourcing, exporting, and investment attraction; professional service support to navigate regula-

tory shifts; and a neutral venue that connects public and private interests to ensure the continued flow of international trade.

Chicago as a Case Study

Chicago, one of the world’s great logistics and

innovation hubs, already holds a WTC license but has yet to activate it due to the fragmented nature of the city’s economic development ecosystem. The timing could not be more critical

Pictured: The Bean: Downtown Chicago — where art, commerce, and global trade intersect.

Martin Schiffman Managing Director, World Trade Center Chicago

Martin Schiffman is the Managing Director of World Trade Center Chicago and President of Schiffman Consulting Corp. He specializes in urban economic development, having planned and developed over $1 billion in urban reclamation and value-added projects.

Since 1989, Mr. Schiffman has studied global markets and cities across North America, Europe, the Middle East, and Asia in connection with the World Trade Centers Association, providing insight into how World Trade Centers can drive local economic growth through trade and investment. In addition to his current role as a license holder for the inactive World Trade Center Chicago, Martin also helped establish and remains actively involved in leading the World Trade Center of Greater Philadelphia.

for a city like the Windy City to activate this tool specifically to aid the community’s small businesses in their efforts to grow beyond their own borders. While peer cities such as Kansas City, Philadelphia, and Toronto have leveraged their WTC businesses to drive trade-led growth, Chicago risks being left behind.

A functioning WTC Chicago would give the region’s small and mid-sized businesses yearround access to international partners and trade best practices, while amplifying existing state and local economic development programs. The goal isn’t to construct another landmark tower — it’s to establish a coordinated ecosystem for global business expansion.

Some may argue the city already conducts trade missions and diplomatic outreach. But

Pictured: River: Flowing through the heart of downtown, the Chicago River connects the Great Lakes to global markets — an enduring reminder of the city’s role in moving goods and ideas worldwide.

these efforts—while well-intentioned—are sporadic, costly, and rarely deliver lasting results. A WTC business, by contrast, is a standing hub that is activated all year through the support of staff support and events. It would allow Chicago to showcase its most innovative products and services to international buyers every day, not just once or twice a year.

Imagine WTC Chicago as the international front door for Illinois’ SMEs and MWBEs. Picture a permanent showcase of local products, accessible to investors and trade partners worldwide. This isn’t about constructing a tower; it’s about creating a hub of services and partnerships that strengthen—not duplicate— existing business support systems.

Why It Matters for Cities Everywhere

Small and mid-sized businesses in Chicago and beyond are often the least equipped to

navigate abrupt economic policy changes, currency fluctuations, or new compliance requirements. Larger corporations can absorb shocks, hire legal teams, and shift sourcing strategies quickly. Smaller companies cannot. A WTC business provides exactly the infrastructure they need: permanent trade services, yearround connections to 300+ WTC businesses, and neutral ground for forging strategies above the partisan fray.

Cities that invest in this kind of permanent economic and trade infrastructure will be better equipped to weather policy swings, supply chain shocks, and geopolitical uncertainty. Chicago’s next step can serve as a model for others: activating its WTC license not just for its own gain, but as proof that when cities commit to global engagement, they build economic resilience from the ground up.

Time to Lead

Global trade is not optional. The S&P 500 derives 40% of revenues from international sales; small-cap companies average 20%; and the U.S. attracts 38% of global cross-border investment. Having a functioning WTC business is not a luxury. It’s a necessity.

It’s time for Chicago and cities like it to stop treating trade as the domain of multinationals and recognize it as the most powerful tool we have to create jobs, grow GDP, and expand opportunity across every neighborhood.

HOW COMPANIES BUILD STRONG CLASSROOM CONNECTIONS

Strategies for companies to build effective classroom connections.

By Catherine Dunlop, Senior Vice President of Corporate Partnerships, Discovery Education.

The global workforce is undergoing a significant shift. By 2030, more than 170 million new jobs are projected worldwide, and the U.S. manufacturing sector alone anticipates 4 million openings in the next decade.

Yet, despite this growth, the talent pipeline is under strain. The manufacturing industry could face a shortage of 1.9 million skilled workers by 2033 if current trends persist. This gap isn’t just in manufacturing: employers across industries cite consistent skills gaps, a fact compounded by the continued impact of emerging technologies, like AI.

Classrooms have the potential to address the skilled worker shortfall. How? Let me explain:

K-12 education is appropriately focused on academic achievement in line with state and national standards; but today’s economy and the rapidly evolving world demands more. Employers increasingly value adaptable, skilled individuals who can apply knowledge to realworld challenges and market needs.

However, 83% of students report they

cannot link classroom learning to future employment. This disconnect not only impacts workforce readiness but also student engagement. Research shows that 92% of students find lessons more enjoyable when they see real-world relevance, a powerful motivator for learning. Connecting careers to the classroom addresses both issues. For example, when students understand how math relates to engineering or how communication skills matter in health-

care, school becomes a gateway to opportunity. Career-connected learning fosters confidence, builds purpose, and equips students with durable skills like problem-solving, collaboration, communication, and other competencies employers

consistently rank as critical for success.

In my role, I partner with global brands who want to help build an impactful workforce. Together, we prepare students for the future through innovative, real-world learning opportunities that nurture curiosity. Here are two strategies companies can take to build relations with schools.

Strategy 1: Classroom Connections with Employee Volunteers

Students cannot aspire to careers they don’t know exist. Career fairs, industry partnerships, and virtual experiences broaden horizons beyond the familiar. Meeting professionals helps students picture themselves in those roles.

With Career Connect schools gain a direct-toclassroom virtual volunteer experience where corporate employees meet with students to explain their jobs.

For students, these interactions reinforce classroom lessons by connecting the dots between possible careers and the actual people with the career. These interactions also cultivate mentorship opportunities and professional fluency, giving students practice in networking and communication long before their first job interview. As the platform offers virtual-based interactions, students all over the country are able to meet with industry professionals from anywhere, ensuring all students can access the benefits of career connections.

Catherine Dunlop

Senior Vice President of Corporate Partnerships

Catherine Dunlop is an accomplished growth and partnerships leader with more than 25 years of experience building high-performing teams and driving revenue across mission-driven and technology-focused organizations. In her new role, Dunlop designs and implements strategies connecting PreK-12 education and the public/private sector, forging connections with corporate and community partners that infuse real-world content into school curricula. Together with her colleagues, Dunlop is nurturing curiosity in classrooms around the world through cutting-edge technology solutions and immersive, hands-on experiences focused on critical topics such as workforce readiness, STEM, environmental education, financial literacy, and more.

Prior to joining Discovery Education, Dunlop held leadership positions at Bonterra and Network for Good, creators of tech solutions supporting non-profit fundraising and engagement. At both organizations, she built meaningful partnerships across the philanthropic sector driving growth and impact. In addition, Dunlop has led strategic partnerships with companies including Walmart, Google, Facebook, and Patagonia, helping to advance their philanthropic goals.

For companies, many prospective employees prioritize working for companies that support employees’ overall well-being. Offering volunteerism opportunities can improve how applicants see a company’s culture. According to a Deloitte volunteerism survey, 70% of U.S. workers “agree that companies who sponsor volunteer activities have a more pleasant work atmosphere.” Organizations such as Genentech, American Society of Mechanical Engineers, Lockheed Martin, ProLogis, DuPont, Nucor, Trane, Capital Power, The Home Depot, and many others all use Career Connect to build

employee engagement through volunteerism.

Strategy 2: Translating Work Tasks into Classroom Learning

Another way for companies to effectively connect with classrooms is to transform the day-today work experiences of professionals in diverse fields into resources for educator lessons plans. This type of work bridges industry to classrooms to inspire the next generation.

There are multiple pathways for how this can take shape, but let me highlight two:

• Immersing Students in Learning: Verizon

took their power of connectivity and technology to create TimePod Adventures, which immerses K-12 students in the universe through state-of-the-art, life-size Augmented Reality (AR). Accessible on a browser, Chromebook, or mobile device, students need only internet access and audio, meaning more students are able to enjoy AR. Guided by an AI-powered assistant and featuring grade-band specific lesson plans available in English and Spanish, TimePod Adventures support educators in developing new skills and encourages students to take control, explore incredible environments, and solve complex challenges. Plus, accompanying professional development resources help educators quickly dive into new and innovative techniques and teaching strategies, all while teachers earn additional teaching credentials.

• Addressing Teen Driver Safety: In 2023, Honda launched the multi-year safety imitative – Honda Safety Driven – as a multi-to help address the nearly one-third of annual traffic fatalities in the U.S. involving drivers under the age of 25. Having already reached nearly one million students, the national safety education initiative uses real-world applications and practices of STEAM, aiming to empower students to use safe driving skills as a roadmap to become responsible decision-makers. The latest classroom resources bring Honda Racing Corporation engineers alongside IndyCar driver and Indy 500 winner Scott Dixon and

champion motocross riders Jett and Hunter Lawrence of the Honda HRC Progressive racing team to teach students about safety.

Students Need You, Now

The future of work is being built now. By connecting careers to the classroom, we can inspire the next generation, meet critical workforce needs, and create a more resilient economy. Programs that help integrate industry expertise into classroom instruction help students see and practice what they can be.

Investing in education is a long-term strategic investment in both business and society.

Corporate partnerships can create a stronger talent pipeline, improve employee skills and retention, and accelerate innovation.

The question isn’t whether we can afford to make these connections. It’s whether we can afford not to. If we miss the opportunity to act, the cost will be measured in lost potential. Millions of students will leave school without the confidence, skills, and vision to shape their futures. They’ll enter a world of opportunity without the tools to seize it. This isn’t just about education; it’s about ensuring every learner has a chance to thrive in a rapidly changing economy.

WHY FOOD & BEVERAGE MANUFACTURERS SAVOR THE LEHIGH VALLEY

From food to advanced manufacturing, Lehigh Valley’s makers are fueling sustainable progress for the East Coast and beyond.

By Kristin Cahayla-Hoffman, Vice President of Business Development & Attraction, Lehigh Valley Economic Development Corporation.

BEVERAGE SAVOR VALLEY

Long a powerhouse of industrial manufacturing, Lehigh Valley, PA has become a major hub for producing beverages and food, including some of the world’s most iconic brands, for people and pets.

Lehigh Valley is a dynamic, two-county region in eastern Pennsylvania that is among the fastest

growing in the Northeast and encompasses the cities of Allentown, Bethlehem, and Easton. Ranked among the Top 15% of U.S. manufacturing markets by Gross Domestic Product, the Lehigh Valley has over 700 manufacturers churning out 16% of the regional GDP, which is well above the national average.

Those manufacturers include global food and beverage brands such as Coca-Cola, Ocean Spray, Boston Beer Co., Nestle Purina, Freshpet, Bimbo Bakeries, and Bakerly/Norac. They are joined by regional and local standouts such as Just Born, maker of the iconic Peeps marshmallow candies.

Since 2010, manufacturing employment in the Lehigh Valley has surged three times as fast as the U.S., 28.8% compared to 9.6%.

The food and beverage industry, in particular, has seen remarkable growth, with employment increasing by 76% over that time.

That growth is driven by strategic advantages of location, workforce, and heritage.

Located within a day’s drive of one-third of the U.S. population, the region provides immediate proximity to major consumer markets along the East Coast and the Midwest along with the Ports of New York/New Jersey and Philadelphia. An extensive freight rail network includes an intermodal facility just 15 minutes from Lehigh Valley International Airport, Pennsylvania’s second-largest air cargo hub that is undergoing a major expansion.

Lehigh Valley’s location advantages make it

an ideal hub for companies looking to speed goods to market, a leading commercial real estate economist said in September at the Office and Industrial Property Summit of the Philadelphia chapter of the Society of Industrial and Office Realtors® (SIOR).

“If you want to beef up the speed at which your goods are getting to consumers, this is a great market to do that,” Adrian Ponsen, Senior Economist at Cushman & Wakefield, said at the summit, held in Bethlehem. Ponsen presented data showing the Lehigh Valley is the No. 1 metro area in the U.S. for proximity to population within a four-hour

truck drive, being able to reach just shy of 50 million people.

A skilled workforce of 1.8 million is replenished annually with more than 10,000 graduates from 11 colleges and universities, and another 1,000 graduates from three career and technical education high schools.

A unique apprenticeship program, the Industrial Training and Education Consortium (iTEC) trains workers for careers in advanced manufacturing, based on the German apprenticeship model.

Initiatives like the annual “What’s So Cool About Manufacturing” video contest inspire middle school students to explore manufacturing careers while highlighting companies in their communities, including those in the food and beverage industry.

This modern strength is rooted in a long local tradition. The region’s food production heritage dates to the mid-1700s, when Moravian

Pictured: Since 2010, Lehigh Valley manufacturing jobs have grown 3× faster than the U.S.—food and beverage up an impressive 76%.

settlers in Bethlehem established a self-sustaining economy that integrated farming, craft production, and trade — laying the foundation for the region’s enduring link between agriculture and manufacturing.

This legacy continues today.

In 2023, Just Born, which makes Mike & Ike and Peanut Chews, in addition to Peeps, celebrated 100 years in the Lehigh Valley. CocaCola has operated a syrup plant in the region since 1997. Nearly half of all dog and cat food production jobs in Pennsylvania are in the Lehigh Valley.

Building on this rich history, the Lehigh Valley continues to attract significant new investments. Major investments from this year alone include:

• Kerry Group, an Irish-based food manufacturer, is building a multi-million-dollar facility for coffee roasting and extraction, creating 61 new jobs. The state is investing $516,880 to support the operation, which includes plans for future expansion.

• Bazzini, America’s oldest nut company, expanded by leasing a 150,000-square-foot production facility. Bazzini was founded in New York City in 1886 and has provided peanuts to Yankee Stadium since 1923. It moved its headquarters and main manufacturing operations to the Lehigh Valley in 2011, in Upper Macungie Township.

Pictured: Global and local food giants like Freshpet, Coca-Cola, Nestlé, and Just Born call the Lehigh Valley home.

• Ecopax, a leading manufacturer of sustainable food packaging solutions, is expanding its footprint in Bethlehem with the addition of a new 104,238-square-foot facility, which will complement its existing 315,643-square-foot manufacturing and warehousing center.

• Kervan USA, a Turkish candy producer, is establishing a $20 million U.S. headquarters and manufacturing facility. Plans call for about 40 new employees to be hired, bringing Kervan USA’s Lehigh Valley workforce to about 50.

“This location made perfect sense, both proximity to the ports and the workforce,” said

Kristin Cahayla-Hoffman

Gokhan Kacmaz, Chief Financial Officer of Kervan USA. “We saw a big opportunity. All this made the Lehigh Valley a great location to make this investment.”

Innovation thrives in the Lehigh Valley through nationally recognized research institutions such as the Rodale Institute, pioneers in organic agriculture, and Penn State Extension, which applies agricultural science to real-world industry practices. The Lehigh Valley also stands out for its concentration in cold storage, with employment concentration that’s 6.1 times the national average—highlighting its

Ms. Cahayla-Hoffman leads LVEDC’s business attraction, expansion, and retention initiatives. This includes implementing strategic marketing campaigns to attract companies from targeted industry sectors to the Lehigh Valley and reaching out to existing companies to understand their successes and challenges and support them in staying and growing here. She came to LVEDC in 2022 after more than a decade of experience in corporate real estate at Air Products. Ms. Cahayla-Hoffman also worked as a financial analyst at Air Products and a senior economic support analyst at Mack Trucks. She is a graduate of Muhlenberg College and has an MBA from Lehigh University. She is a board member of the International Asset Management Council (IAMC), a leading industrial real estate trade association. - Email: kcahayla@lehighvalley.org

expertise in temperature-controlled logistics and reinforcing its leadership in food production and distribution.

So, what’s next? The region will continue to invest in its people by providing advanced workforce programs tailored to the evolving needs of the manufacturing sector. A key asset

will be iTEC, a partnership of industry, education, and community organizations.

We’ll stay attuned to commercial real estate trends and deliver the resources food and beverage companies need to thrive, including developing a skilled workforce.

As one of the nation’s most dynamic manufacturing markets, the Lehigh Valley continues to blend tradition with transformation—where a centuries-old foundation in food production now fuels a modern ecosystem of making and moving goods. In the Lehigh Valley, companies don’t just make products, they make progress, driving sustainable growth for the East Coast and beyond.

A NEW ERA OF UNDERWATER LIVING BEGINS

UNDERWATER

DEEP has unveiled Vanguard – the first new subsea human habitat of its kind in 40 years.

By Norman Smith, Chief Technology Officer at DEEP.

For as long as I can remember, I’ve been drawn to the challenge of sustaining human life in places we weren’t adapted to survive. I engineered hardware for NASA’s human spaceflight programs, but the work I lead today at DEEP – designing, building, and testing subsea human habitats – is the realization of the dreams that set me on the path to becoming an engineer.

Jacques Cousteau was one of my childhood heroes, and his pioneering spirit shaped my imagination. Yet the ocean, despite covering most of our planet, remains an overlooked frontier. Vast regions are unexplored, full of mysteries waiting to be uncovered.

At DEEP, I see an opportunity to pick up where Cousteau (and others) left off. An opportunity to give humans sustained access to the ocean on a scale we’ve never achieved before.

That’s why recently unveiling Vanguard in Miami, Florida, meant so much to me. It’s our pilot subsea human habitat and the first new one of its kind to be built in nearly 40 years. We designed it for a crew of four to live and work

underwater for seven days or more, and it represents a major step forward in how we explore and understand the marine environment.

With Vanguard, with have created a comfortable, functional living space for ocean scientists, conservationists, and explorers. By allowing teams to live and work submerged in the ocean realm for extended periods, we can dramatically expand what’s possible. That means more comprehensive research and real-time observation of marine ecosystems. This capability has the potential to transform everything from coral reef restoration and climate monitoring to astronaut training for future space missions.

Vanguard is also a cornerstone of DEEP’s expansion into the United States. It reflects our $100 million commitment to establishing a permanent engineering and development hub in Florida and a manufacturing facility in Houston, Texas.

And if, like me, you grew up watching Jacques Cousteau and imagining what it would be like to live beneath the waves, this is a meaningful milestone – because that dream is now one step closer to becoming reality.

The next step in making humans aquatic

DEEP is on a mission to make humans aquatic. In practice, that means enabling people to live

Pictured: Inside Vanguard’s dive center; previous spread: Through the hatches inside Vanguard.

Norman Smith

Norman Smith has more than 35 years of experience launching complex technology products. Before joining DEEP, these products were for manned space flights with NASA and for deep-water equipment at Oceaneering International. He was previously Executive Vice President of Engineering at a microgrid power company providing low-emission backup power to hyperscale data centers.

for days, weeks, or even months at the bottom of the ocean, giving researchers and divers more time to explore, make new discoveries, and carry out conservation work.

The first stage of the journey is Vanguard, which has been built in Sebastian, Florida. Not only will this be DEEP’s first underwater living space, it will also be the biggest development in subsea habitation in 40 years.

Vanguard is the beginning of a roadmap that

will include many habitats and a long-term vision of habitats in installed in oceans all over the world. We can bring in technologies that are available now that were never available in Jacques Cousteau’s day.

The 1960s were the heyday of underwater habitats. That decade saw Cousteau’s Conshelf missions in the Mediterranean and the Red Sea, as well others including the US Navy’s Sealab experiments, overseen by pioneering physician and navy diver Captain George Bond, and Germany’s Helgoland habitat.

These projects demonstrated the concept of saturation diving. This is where a diver stays at depth until their body’s tissues adjust to all the gases, like nitrogen, that they are capable of absorbing at that pressure. At this point the diver is said to be ‘saturated’. Although they will still need to go through a period of decompression to avoid the bends on their way back to the surface, once a diver reaches saturation, they can stay at depth indefinitely without adding to that decompression time.

Projects like Conshelf, Sealab, and Helgoland proved that humans can live indefinitely on the ocean floor in practice, not just in theory. They were followed by other habitat missions in the 1970s. Some of these extended the underwater habitat concept to Arctic waters, while others expanded the scope of research.

Then, in 1986, the Aquarius habitat was built

Pictured: Bunk inside Vanguard’s living chamber.

in Texas, later being deployed in the Florida Keys in 1993. And for the next 30 years, Aquarius flew the flag for subsea habitat missions, being used by scientists to further our knowledge of the ocean, as well as by NASA for its astronauts’ extreme environment training.

But the appetite to build laboratories under the sea has been relatively quiet to non-existent in recent decades.

Made in America

DEEP’s U.S. expansion has allowed us to team up with other specialists in subsea engineering, like Florida-based Triton Submarines.

DEEP is also working with aerospace and subsea engineering experts Bastion Technologies, based in Houston, Texas, and Unique Group, a global leader in diving and marine services.

We’re really excited to expand DEEP into the U.S. We’ve been able to tap into the engineering capabilities and development opportunities that are in the U.S., as well as deepen our relationships with the scientific community, defense community, and the space industry.

What’s it like in Vanguard?

Vanguard is roughly the size of a shipping container. It has been designed for a crew of four people to undertake medium-duration missions of seven or more days, at depths of up to 50 meters.

Vanguard comprises a pressurized living chamber, where the crew will work, eat, and sleep, a dive center, where divers will change in and out of dive gear, and a moon pool, which is basically an unobstructed opening in the floor

KEY FACTS ABOUT VANGUARD

• Space for a crew of four aquanauts

• Designed for medium-duration missions of seven days or more

• Designed to operate at depths up to 50 meters

• Operates at ambient pressure (i.e. the same pressure as the sea outside)

• Designed to withstand the subsurface effects of a category 5 hurricane

• Will be the first subsea habitat classed by DNV, a leading international certification an classificatio agency for underwater technology

that gives free access to the ocean. The pressure inside Vanguard will be the same as that of the ocean outside (a.k.a. ambient pressure), preventing any water from coming in. Vanguard is capable of being deployed to ocean depths of 50 meters configured with heliox as the breathing gas, and 20 meters with air.

The living chamber and dive center will be attached to a foundation, securely mounted to the ocean floor, while a buoy on the surface will be tethered to the habitat to provide compressed air, power, and a communications link.

Vanguard is set to be the first underwater habitat to be classed by DNV, a leading international certification and classification agency for underwater technology. This will mark a new global standard in subsea safety.

Vanguard differs from previous subsea habitats in other ways. Whereas earlier habitats were functional and basic accommodations, DEEP is paying much more attention to human comfort.

As a team of engineers, we’re used to regularly working with astronauts, aquanauts, manufacturers and subject matter experts. Now we’re also working with architects and designers detailing the interior spaces, outfitting, and even choosing upholstery fabrics.

The Vanguard project is a chance to get feedback from the crew and make improvements to everything from how the bathrooms are designed to what food is available (living in denser, pressurized air affects divers’ sense of taste).

What’s next?

Once installed on location (to be announced in the coming weeks) and acceptance testing is complete, our mission operations team will run through a series of training and proficiency drills on Vanguard and then (big celebration!) we will be ready for our first missions.

But building the first new underwater habitat in four decades is just the start of the story. As the name suggests, Vanguard is planned to be the first of many subsea habitats built by DEEP.

The learnings from Vanguard will inform the design of Sentinel, a much larger, modular habitat architecture that’s next on the drawing board.

We’re building an entire ecosystem for subsea habitation.

Find out more at deep.com or follow on social @deepengineered.

Pictured: Vanguard subsea human habitat at unveiling event in Miami.

UNLOCKING AMERICA’S URANIUM SUPPLY

At Wyoming’s Copper Mountain,

modern assays reveal overlooked uranium as the U.S. works to rebuild a secure fuel supply.

By Thomas Lamb, CEO, Myriad Uranium Corp.

The U.S. uranium gap and why it matters

Nuclear power is the largest source of carbon-free, around-the-clock electricity in America. Yet nearly all of the uranium fueling those reactors comes from outside the country. In 2023, U.S. plants relied on about 32 million pounds of imported uranium and only around 50,000 pounds produced domestically. That means about 99 percent of the fuel supply was imported, leaving the country exposed when it comes to energy security and climate goals.

The market is responding. Uranium contract prices have climbed to their highest levels since 2008 as utilities look for stability. Spot prices have strengthened from the 30s to above 80 dollars, while long-term contracts are holding around 80 dollars per pound. This reflects a tighter market and a clear push from utilities to lock in secure supply.

The federal government is also stepping up. Programs like the Department of Energy’s

HALEU initiative are designed to rebuild a domestic fuel cycle for next-generation reactors. Efforts to speed up licensing for nuclear projects are also underway. These moves come as artificial intelligence data centers and advanced manufacturing drive a surge in electricity demand.

Globally, uranium demand is expected to rise about 28 percent by 2030 and more than double by 2040. Meanwhile, there are no easy or rapid ways to increase global supply. For the United States, therefore, bringing reliable domestic production online is about more than energy. It is also about national security, grid reliability, and industrial competitiveness.

A legacy district gets a modern look

One of the best examples of this opportunity is in Wyoming’s Copper Mountain district. In the 1970s, Union Pacific drilled roughly 2,000 boreholes, found seven deposits, and even created a six-pit mine plan. When uranium prices collapsed after 1979’s Three Mile Island incident, the project was shelved. What was left behind was a rich archive of drill logs, engineering work, and mine plans, data that today can be re-analyzed with far better tools.

Myriad Uranium, with its partner Rush Rare

Pictured: An aerial view of a drill rig in action at the Canning Deposit, Copper Mountain; previous spread: View of a drill rig in action at the Canning Deposit, Copper Mountain.

Metals, is doing exactly that. We are digitizing these historical records, applying modern geophysics, and most importantly, running laboratory chemical assays to check the accuracy of probe results (gamma and neutron probes are the first-line instruments used to assess uranium deposits). Our early work has focused on the

U.S. uranium by the numbers

In 2023, U.S. nuclear plants purchased more than 51 million pounds of uranium, with 99 percent coming from foreign suppliers. Domestic production was only about 50,000 pounds that year, rising to about 677,000 pounds in 2024. Global uranium demand is projected to rise 28 percent by 2030 and more than double by 2040. At Copper Mountain in Wyoming, Union Pacific drilled about 2,000 boreholes in the 1970s and designed a sixpit mine plan. Today, new chemical assays show grades 50 to 60 percent higher than probe results, highlighting the potential of legacy U.S. uranium projects.

Canning deposit, which was at the center of Union Pacific’s original mine plan.

Finding the “invisible” pounds

Why is this so important? The probes used in the 1970s and even today often undercount uranium in certain geological settings. When we recently compared probe readings to new chemical assays, the differences are striking. In some cases, assays are showing grades 50 to 60 percent higher than the probe data suggested.

Pictured: Chief Geologist George van der Walt explaining the nature of mineralization in core from the Canning Deposit at Copper Mountain; right: Inspecting reverse circulation drill chips from the Canning Deposit at Copper Mountain; A section of mineralized core from the Canning Deposit at Copper Mountain; Proprietary historical data set for Copper Mountain.

Entire zones that looked unremarkable before now appear to host significant mineralization.

This is what we mean when we talk about “invisible uranium.” It is mineralization that was always there but simply not captured by the default tools. .

In 2024 and 2025, our work program has combined the application of advanced new methods and innovative thinking with confirmation drilling at Canning. The goal is to validate the historical results, refine targets, and build a clearer picture of the opportunity.

The opportunity appears to be one of America’s largest in the uranium space. In 1982, the U.S. Department of Energy released a report that assessed Copper Mountain’s uranium endowment could be 246 million pounds. Myriad and its partner Rush hold roughly 70 percent of the acreage relevant to this. The Department of Energy assessed that an even broader area around Copper Mountain could contain 656 million pounds. It is important to note that Copper Mountain’s historic estimates and the Department of Energy’s assessments are not current resources or reserves under NI 43-101 standards. They must be verified through modern work. Myriad continues to advance the project through verification drilling and ongoing scientific work.

Why Wyoming matters

Wyoming remains America’s leading uranium jurisdiction. It has active production, existing

processing facilities, and regulators who are familiar with uranium projects. That combination makes it an attractive place to invest in new exploration.

Copper Mountain benefits from decades of past work, road access, and a district-scale land package. A Plan of Operations submitted in 2025 outlines a multi-year drilling program that will allow us to confirm mineralization and bring the data into compliance with modern standards.

Pictured: A view over part of the Copper Mountain project area; right: A piece mineralized rock from Copper Mountain.

About the author

A demand picture changing faster than expected

For years, utilities expected electricity demand to remain flat. That is no longer the case. AI data centers, electric vehicles, and new manufacturing facilities are creating a surge in demand for reliable, clean power. Nuclear energy is one of the few options that can provide this at scale. That shift is showing up in the market. Utilities are signing longer-term contracts at stronger prices. Federal programs are encouraging investment in the fuel cycle. There is also renewed interest in restarting reactors and extending the lives of existing plants. All of this