1Introduction

1.1ProblemDefinition

Likeotherlean-steerplatforms(suchasbikes,skis,andsurfboards),skateboardsareinherently unstable.Muchlikeaninvertedpendulum,gravitywillcausethemtofalloverunlesstheyare perfectlyupright.Tocounteractthis,arestorativeforceisneededtobalancetheforceofgravity andreturntheridertoanuprightposition.Thisforcecomesfromturning,whichcausestherider toexperiencecentripetalacceleration,pullingthemupright.Thesetwocounteractingforcesallow theridertoreachastableequilibriumatacertainleanangle.Thisprincipleisknownas”optimal lean-steerphysics”andisthegoverningprinciplebehindmostlean-steervehicles,withonenotable exception:theskateboard.

Theturningradiusofaskateboardisdeterminedentirelybytheboard’stilt.However,the centripetalaccelerationexperiencedwhileturningisaffectedbybothvelocityandturningradius. Thismeansthatskateboardriderscannottakeadvantageofoptimallean-steerphysics,asthesame amountoftiltproducesvastlydifferentcentripetalaccelerationsatdifferentspeeds.Additionally, theboardbecomesmuchmorereactiveathighspeeds;aslighttiltintheboard’sanglecauses significantacceleration,whichcanthrowtheriderofftheboardorleadtoissueslikespeedwobble.

1.2ValueProposition

Oursolutionproposesaturningmechanismforskateboardsthatenablesriderstousethefull leaningrangeoftheboardatallspeedsbydynamicallyadjustingtheturningradiusinresponseto changesinspeedandtiltangle.Bydoingso,wecanimprovethecontroldynamicsofskateboards athigherspeeds,whichcanotherwiseposesafetyconcernsandtechnicallimitationsforriders. Thekeyobjectivesoftheproposedsolutionincludedesigningatestrigtocharacterizeskateboard stabilitywithrespecttodifferentboardandriderparametersandimplementingsensing,control, andactuationsystemsthatenableriderstousethefullleaningrangeoftheboardatallspeeds.

Thepotentialreal-worldapplicationsofthissolutionincludetransportation,purerecreation, andprofessionalskateboarding.Theadvantagesofourproposedsolutioninthemarketarethat itprovidesacombinationof(1)afullleaningrangeoftheboardand(2)anactuatedturning mechanismthatdynamicallyadjuststheturningradiusbasedontiltangleandvelocitytomore closelyalignwithleansteerphysics.Currently,thereareproductsinthemarketthataddress(1), suchasWaterborneSkateboards,and(2),suchasdampingsystemsforskateboards(JeremyFox US8752849B1)[1],butdonotaddressboth.

Incitieswithpublictransportationinfrastructure,theproposedsolutionaimstotacklethefirst mile/lastmile(FM/LM)problem.Thefirstmilereferstotheinitialpartofanindividual’strip fromthestartingpoint,oftentheirhomeorworkplace,tothepublictransportstation,whilethe lastmileisthefinalpartoftheindividual’stripfromthetransportationstationtotheirultimate destination.Anoptimizedleansteerskateboard,whichourprojectaimstocreate,willenable riderstocompletethefirstandlastpartsoftheirjourneyatafasterpaceandlowercost,thereby increasingtheadoptionofpublictransportation.

1.3SocietalContext

Fromasocietalperspective,theproposedsolutionhasthepotentialtoencouragetheadoption ofelectricskateboardsbypedestriansandincreasetheaccessibilityofroadinfrastructurethrough micro-mobility.Withnonoiseandlowemissions,therewouldbesubstantialenvironmentalbenefits.Thiswouldleadtoimprovedairqualityincitiesbyreducingcommuter-associatedpollution.

Furthermore,theproposedsolutionwouldaddresstheFM/LMdilemmaandchangehowpeople approachpublictransportation,resultinginmoreefficientandequitablepublictransportation. AccordingtorecentCensusBureaufindings,justover46%ofallpublictransportationcommuters prefertotakebusesinsteadofotherformsoftravel[2].However,transitstopsoftenonlyprovide transportationtohigh-trafficlocations,leavingmanycommuterstowalkthefirstorlastlegoftheir trip.Theproposedsolutionprovidesamodeoftransportationthatcanbridgethisdistance.This micro-mobilitycontributestoeasingtrafficbyofferinganalternativetousingpersonalvehicles. Thecostoftheproposedsolutionwouldalsohelpindividualssavemoneyonthecostofbuyinga car,maintenance,andparking.Peoplewouldhaveaquickerandmoreefficientoptionthanwalking alongwayorgettingstrandedfarfromworkorhome.

Thedownsidetotheproposedsolutionisthattheindividualswouldpreferridingskateboards ontheroadsincetherideismorestableathigherspeeds.However,trafficlawsforskateboardingon theroadaren’taswelldefinedasbicycleorin-lineskatingwhichencouragesriskybehaviorsuchas notfollowingstopsignsorhelmetrules.Therefore,itposesriskstotheridersaswellasthedrivers whomightnotbeawareofthespeedcapableofelectricskateboards.Moreover,iftheindividuals chosetorideonpavements,itposesrisksagaintotheridersaswellasthepedestrianswhomightnot havesurroundingawareness.Theproposedsolutioncanalsoencouragetheproductionoflithium whichcanbeenvironmentallydevastatingwhenmined.

2Ideation

Weexploredmanydifferentavenuesthatwouldallowustoaccomplishthisdynamicchange oflean-steerratios.LSDwantedasolutionthatwascompatiblewithcurrentskateboards,which ledustofocusoncreatingatrucksystemthatwouldbemountabletoanyskateboardusingthe standardskateboardbolt-holepattern.

Figure1:FirstMileLastMileProblem

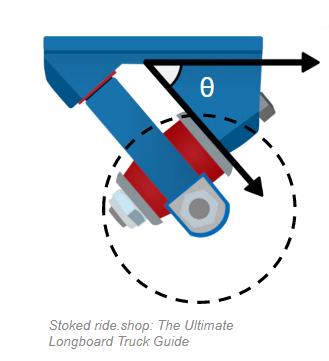

2.1BaseplateAngle

Currently,skateboardriderscanoptforreducingtheresponsivenessoftheskateboard’sturning totheirleaningbybuyingtrucksofdifferentbaseplateangles.Baseplateanglereferstotheangle ofthehangerrelativetotheboard.Thebaseplateanglewillrangefrom0to90◦.Thelowerthe baseplateangle,thelessresponsivethetruckswillbe,whilehigherbaseplateanglesresultinmore responsiveridesandrequireincreasedridersensitivity.However,changingthebaseplateangledoes notaddressthemainproblem.Lowerbaseplateangleswillreducetherider’sexperienceofspeed wobble,however,thelean-steerphysicsofthesystemremainsnotideal.Furthermore,thischangeis notdynamic.Thebaseplateangledoesnotchangewithspeed.Wedidexploredynamicbaseplate angleadjustmentasasolutionbutdeterminedthatwewouldneedtopushfurthertofindanidea thatsolvedthemainproblemathand.

2.2ElectricalvsMechanical

LSD’scurrentmechanicaldesign(Fig. 4a)allowstheridertobetteroptimizelean-steerphysics atpredeterminedspeedsbyhavinginterchangeableinserts(Fig. 4b).Thisdesignhighlightedthe problemwewereobserving:Purelymechanicalsolutionsonlysolvedlean-steerphysicsatchosen speedswithoutdynamicallychangingthroughouttheride.

Forelectronicsolutions,weexploredideasregardingbaseplateangleadjustmentwithspeed,a 3-barlinkageactuatedbyamotor,andagearsystemactuatedbyamotor.Wefoundthateach ideabroughtitsowncomplicationsfromnotsolvingtheproblemdirectly,togearstrippingunder load.However,wewereabletodeterminethatwewouldneedtoseparateleaningfromsteeringto effectivelytacklethisproblem.Wegivetherideraccesstothefullleaningrangeoftheboardatall times,andthroughacontrolsystemwecandeterminetheturningradius;dynamicallyadjusting thelean-steerratiowithspeedthroughthecontrolsystem.However,deformationunderloadwas stillanapparentproblem.

2.3FullActuation

Actuatingthehangersthatcontroltheturningradiusoftheboardwasadiscussionwehad manytimesasateamandwithLSD.Thesolution’scomplexitywasincreasingrapidlyandwe neededthesimplestwaytoactuatethehangerstoreduceanyfurtherincreaseincomplexity.We decidedtouseasteppermotorforthepositionalaccuracyitprovidesandthetorque-to-sizeratio thatitoffers.Therewouldbeamotormountedonbothtrucksandtheywillworktogethertoturn theboardbyprovidingtheirrespectivehangerangles.

2.3.1Gears

Whenexploringhangeractuation,motor-actuatedgearswerethefirstavenueweexplored. Strippingofthegearsbecameamajorconcern.Askateboardexperiencesheavyloadsunderuse. Incurrenttruckdesignsdisturbancesareusuallyhandledbytherideranddampenedbyabushing. Gearactuationwouldeliminatealldamping.Inregularusetheboarddoesexperiencewearand deformation,however,thisdeformationisneverdetrimentaltothefunctionalityoftheboard.We neededasystemthatwouldtoleratemoderatedeformationandmaintainfunctionality.

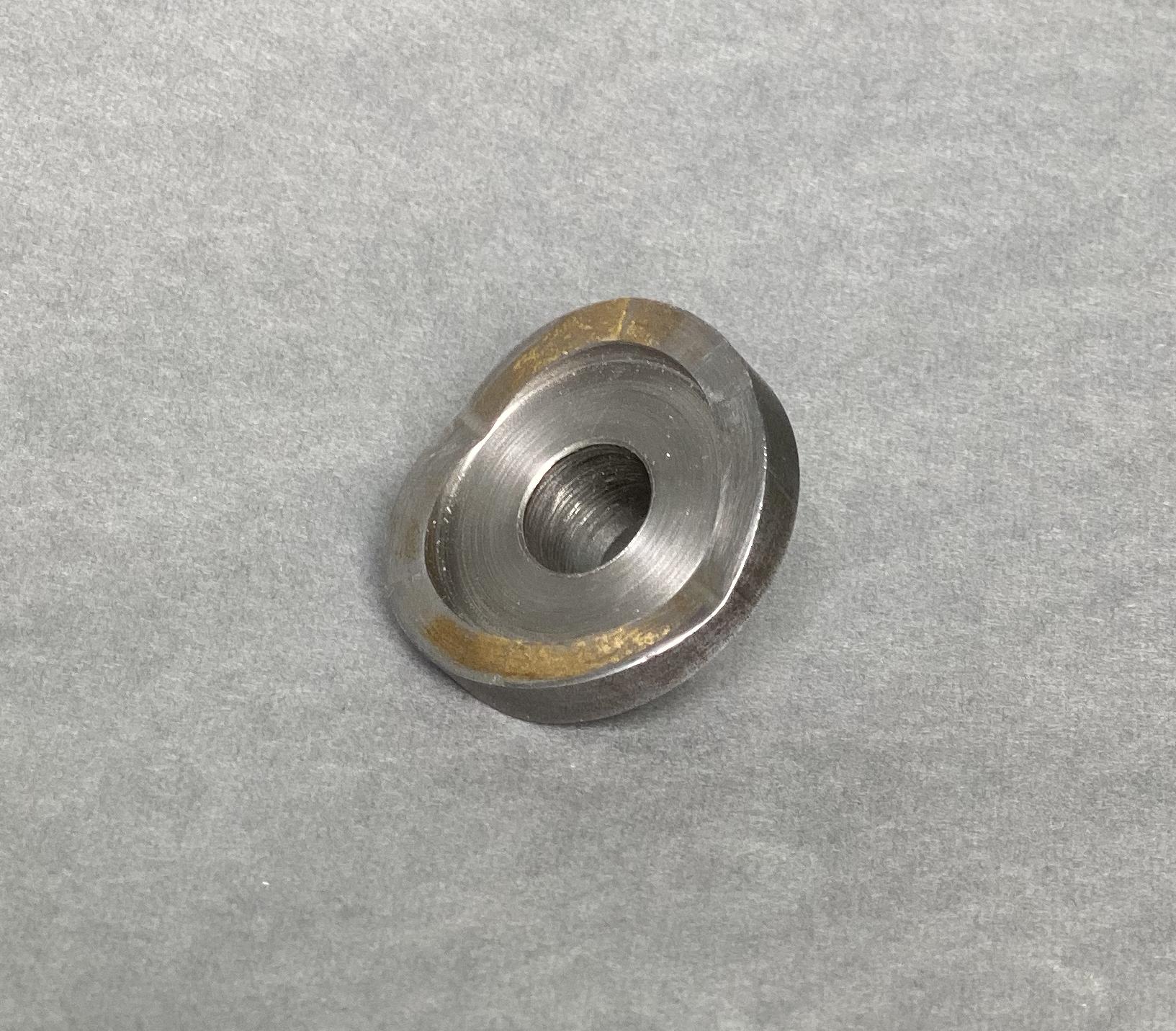

2.3.2CamActuation

AlongwithLSDwedecidedthatusingthesteeringguidecamprofilefromtheircurrentmechanicaldesign(Fig.4b)allowsustomaintainturningfunctionalitydespitemoderatedeformation

fromthefollowers,andprovidesresistancetodisturbancessuchasvibrationsandpebbleswhen riding.Thecamprofileprovidesagearreductionwhichfurtherimprovesthelikelihoodthatthe motorwouldbeabletotoleratelargedisturbancesduringaride.

3Deliverables

3.1TestRig

Bydecouplingleaningandsteering,weremovetherider’sabilitytodirectlysteertheboard mechanically.Thiscarriessignificantrisks,especiallysincethetechnologyisstillinitsinception. Anycodingerrors,sensorfailures,orelectricalfailureswouldleavetheuserunabletosteerthe boardmechanically.Furthermore,wewouldseethegreatestimprovementsfromthestandard mechanicalskateboardtoourproposedactuatedtrucksathigherspeeds.Asaresult,beforewe startedtodevelopthetrucks,wecreatedatestingapparatusthatallowsustotestaskateboardat thesehigherspeedswhilemimickingahuman’sweightandinteractionwiththeboard.

3.1.1MechanicalDesign

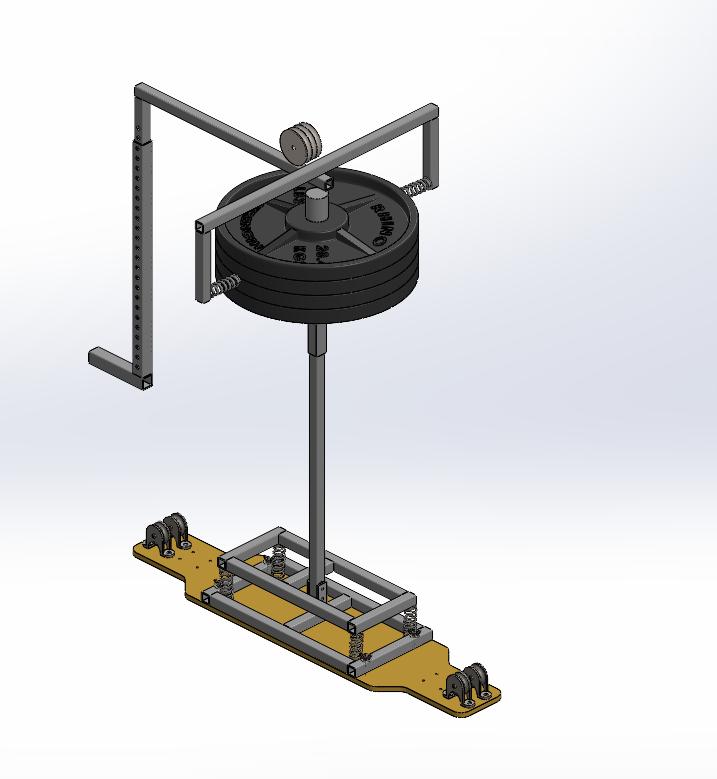

Asstatedpreviously,thistestingapparatusneedstomimicahumanrider.Anormalskateboard willexperiencegeneraloscillationsifpushedinastraightline.Therefore,weneedtoprovideour testrig’s”human”rider–affectionatelynamedJerry–themeanstocorrectfortheseoscillations independently.Ahumanwilldothisbyusingtheirabdominalstostayupright,andtheirankles tosteertheboardbackontrack.Furthermore,thistestrigneededthecapabilityofbeingdriven andtestedatmoderatelyhighspeeds.

Ourapproachwasasfollows:Toachievethespeedsnecessaryforeffectivetesting,acarmust beused.Assuch,theremustbeacomponentofthetestingapparatusthatcanbesecuredtoacar toguideittothesespeeds.However,rigidmountingwouldresultinskeweddataasthearmwould involuntarilypreventtheboardfromoscillatingnaturally.Wemustcreateacar-mountedsystem thatcanonlylightlyguidethetestingrigtostayupright.Thisprovidesagreatpointofcontact forthe”abs”.Wecreatetwoseparatecomponents,onethatattachestoacarandanotherthat attachestoaboard.Theboardattachmentwillholdthebody,orthemainweight,thatactsas theinvertedpendulumandfunctionsasthe”ankle”,whilethecarattachmentwillholdthebody uprightviasurgicaltubingtoactastheabs.

Therider’sanklewillbesimulatedusing4springs.Thespringsarerelativelystiffbutareonly slightlylessrigidthanthetruckbushings.Thisallowsthespringstofollowasimilarstiffnessto thebushingsasmoreleaningisrequiredandsubsequentlymoreforce.Thisresultsinneitherthe bushingsnorthespringsfullyengagingbeforetheotherengages.Twospringsinthefrontandback willhelpsimulatetheweightdistributionofariderinaccelerationanddeceleration.Forfurther guiding,thespringsareheldincupsandsecuredwithscrewstoallowthemtoengageinextension andcompression–reducingtherequiredspringconstantbyhalf.

Pulleysareaddedtothetruckattachmentandboardtoallowforasafetybail.Ifthetesting rigoscillatesorwillpotentiallyfall,aropewillbeallthatisrequiredtolifttheboardawayfrom thestreet.Apulleyreductionof3isshowninthemodelsuchthatasingleindividualshould beabletolifttheboardwithrelativeease.Heightadjustabilityofthecarattachmentwasalso addedtoaccountfordifferentsuspensionheightsofcarsthatmaybeused.Acustomsurgical tubingattachmentfortheweightbarwascreatedforeaseofmountingandcustomtensioningata moment’snotice.

3.1.2ElectricalDesignandSensors

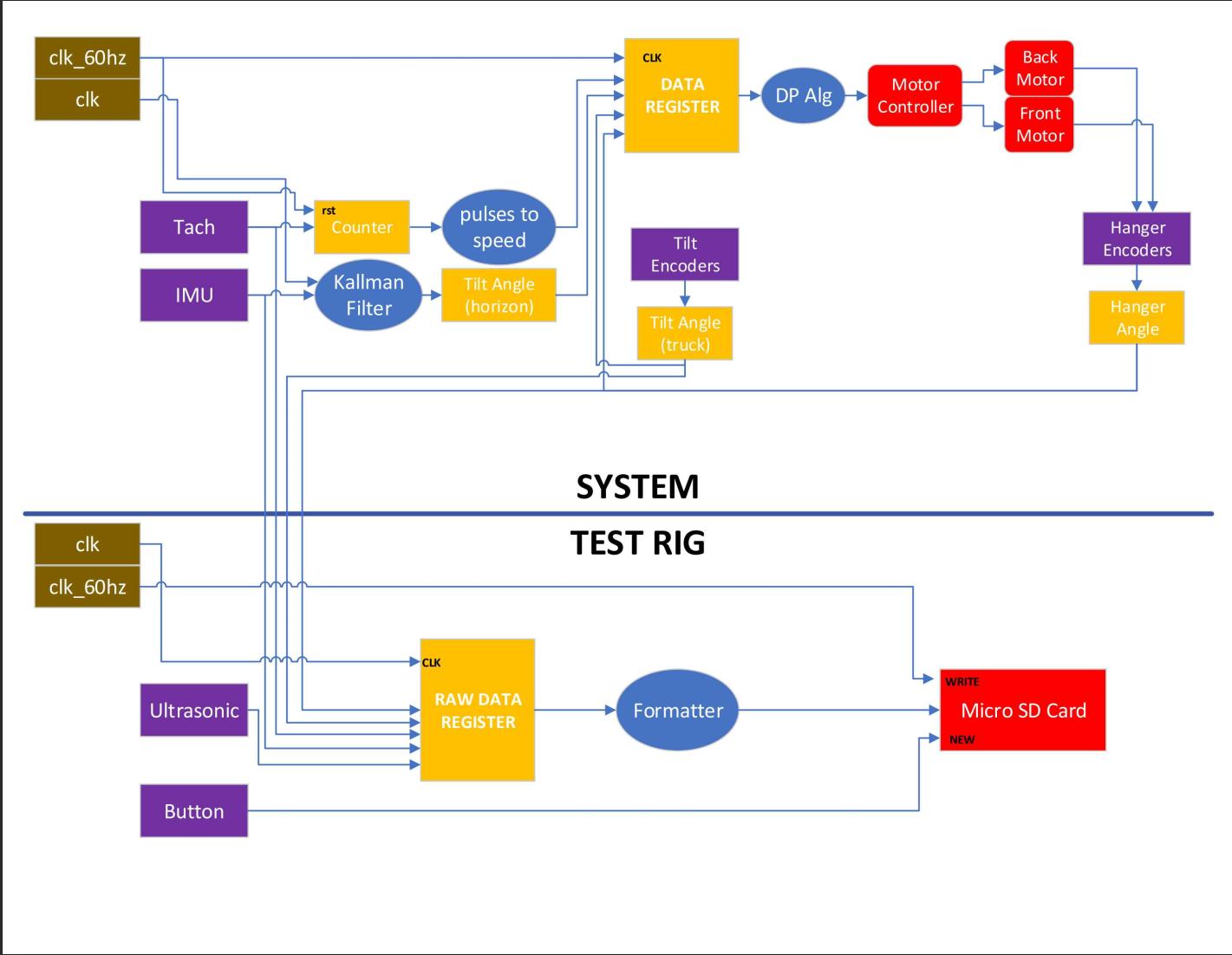

Theelectricalportionofthetestingrigmustcollectdatafrombothitsownsensorsalongwith sensordatafromthetruckdesignbeingtested.Forthisreason,datamustbepassedbetweentwo Teensys–oneonthetest-rigandoneonthetruck–totrackandvalidatethesystem’sperformance.

Thissortofdatahandshakingcanbeseeninappendix C.5.Thetwopartsoftheoverall environmenthavetheirownsensors,buttheseandthealgorithmsthatrunonthemmustbe tracked.ThisdataisthenwrittentoanSDcardonboardthetestingrig’sTeensy.

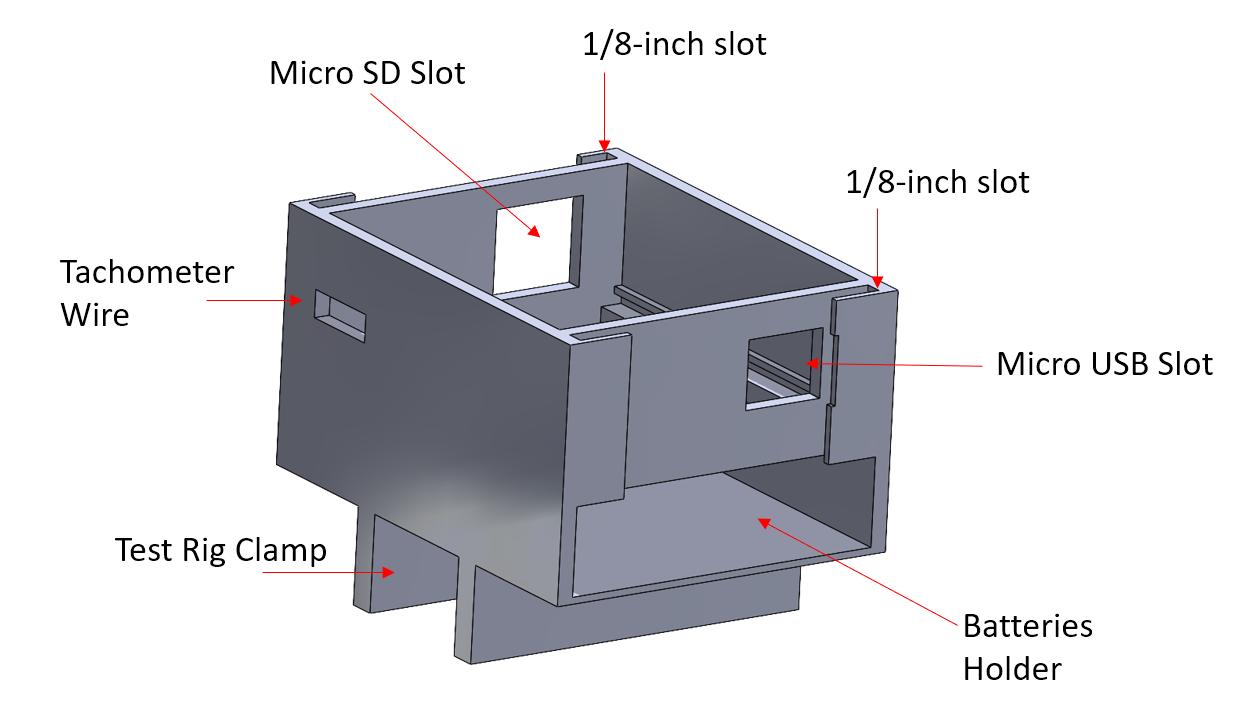

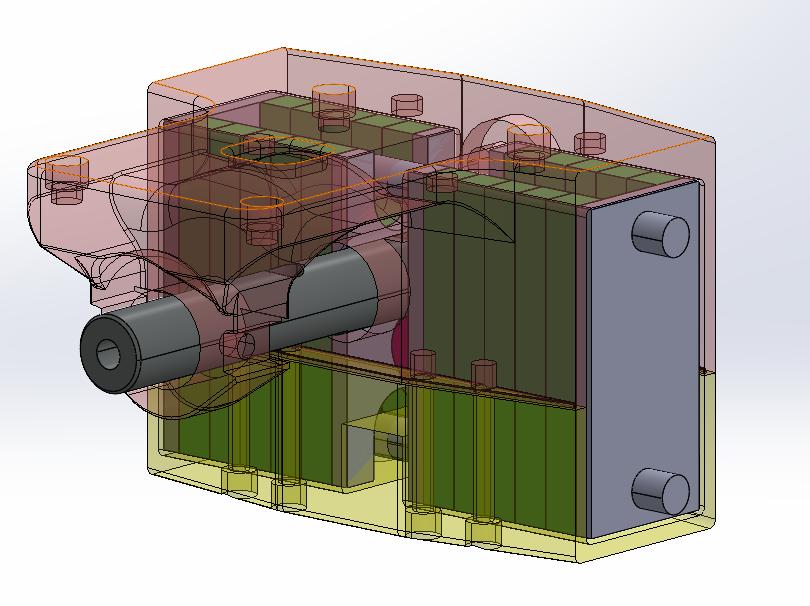

Thehousingforthetestingrigisseenbelowinfigure 3.

(a)HousingCAD

(b)HousingonTestingRig

Figure3:TestRigHousing

Forthisspecifichousing,thetopisanacrylicsheetthatislaser-cuttofitabuttonthatcreates newfiles,debuggingLED,andpowertoggleswitch.Thetwo1/8inacrylicsheetsonthesideallow ustoaccessthebatterycompartment,micro-SD,andmicro-USBwithoutpenalizingwaterand dustresistance.Thishousingsafelyclampstothetestrigwiththetwolegsatthebottom.The housingadditionallyhasaone-wayclamptosecurelyplacetheelectroniccircuitboard.Thesystem ismademorewater-resistantbyusinghotgluetosealthetopandthetachometerslot.

3.1.3SoftwareImplementation

Thesoftwareforthetestrigis,onthewhole,verysimple.Theaforementionedappendix C.5 showsablockdiagramincludingthesoftwareflowforthetestrig.Themostimportantconsideration isthatthesystemwritesanewbatchofdatatotheSDcardona60hzclockcycle.Inorderto achievethis,itmustreadthroughtheserialreceivingbufferspecifictohardwareSerialreceiver1.

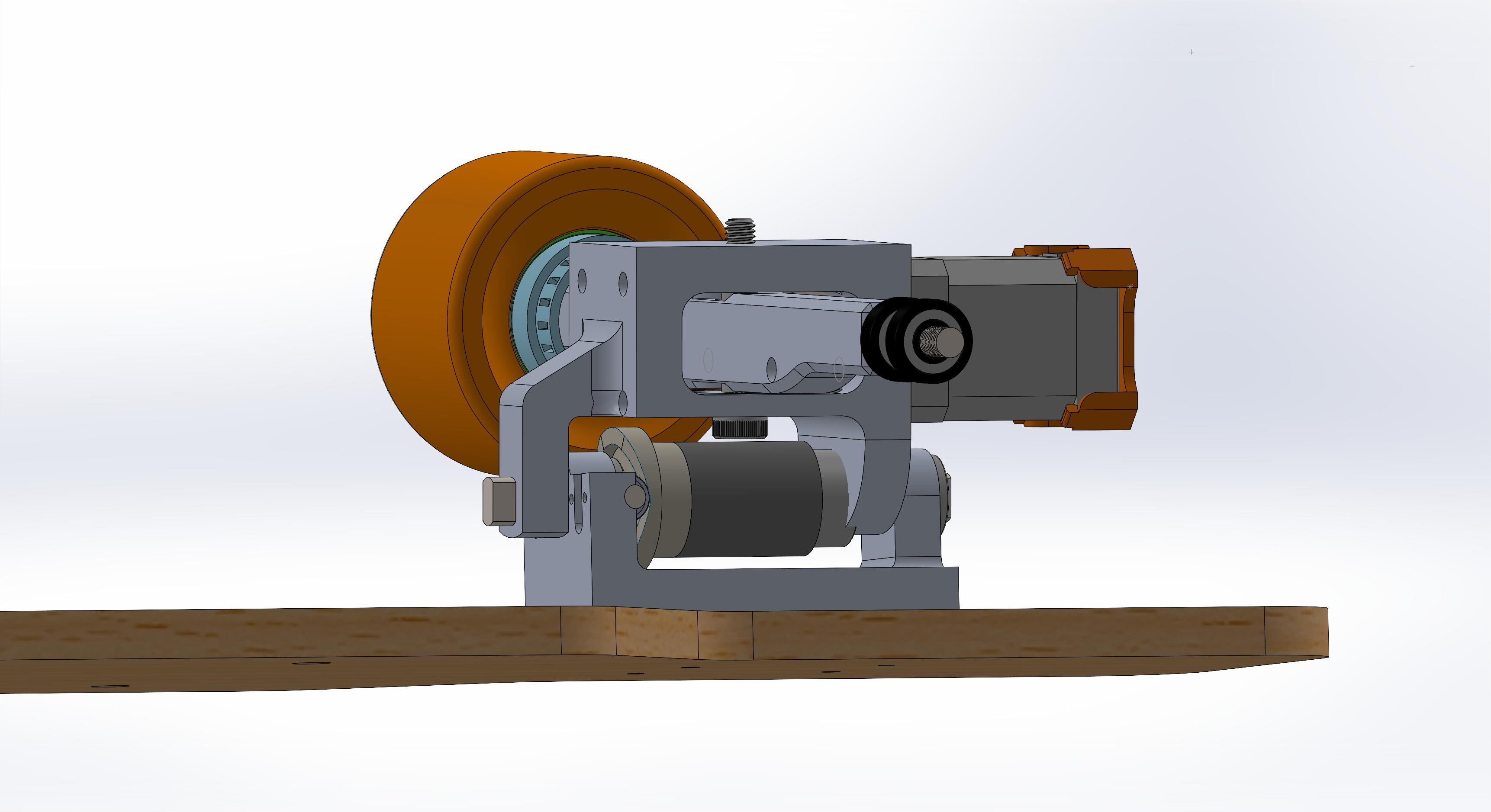

Figure2:SolidWorksoftestingrig

Whatthismeansisthatthetestrigishighlyadaptabletoanyfuturedesign.Anarbitrary futuredesignmustthereforehavesomemeansofcommunicatingtothetestrigviaUARTover Serial1,whichhasitsRXandTXpinsonTeensypins0and1.Thisisimportanttoconsidershould sensorchoiceandimplementationbealtered.Generallyspeaking,datashouldbecommunicated inCSVformatfromaunitundertesttothetestrig.ThisisbecauseCSVisacompactwayto communicatethedata,anditiseasytoappendtestrigvalidationdata(liketheultrasonicsensor’s reading,orothersifimplemented)forsubsequentwritingtotheSDcard.

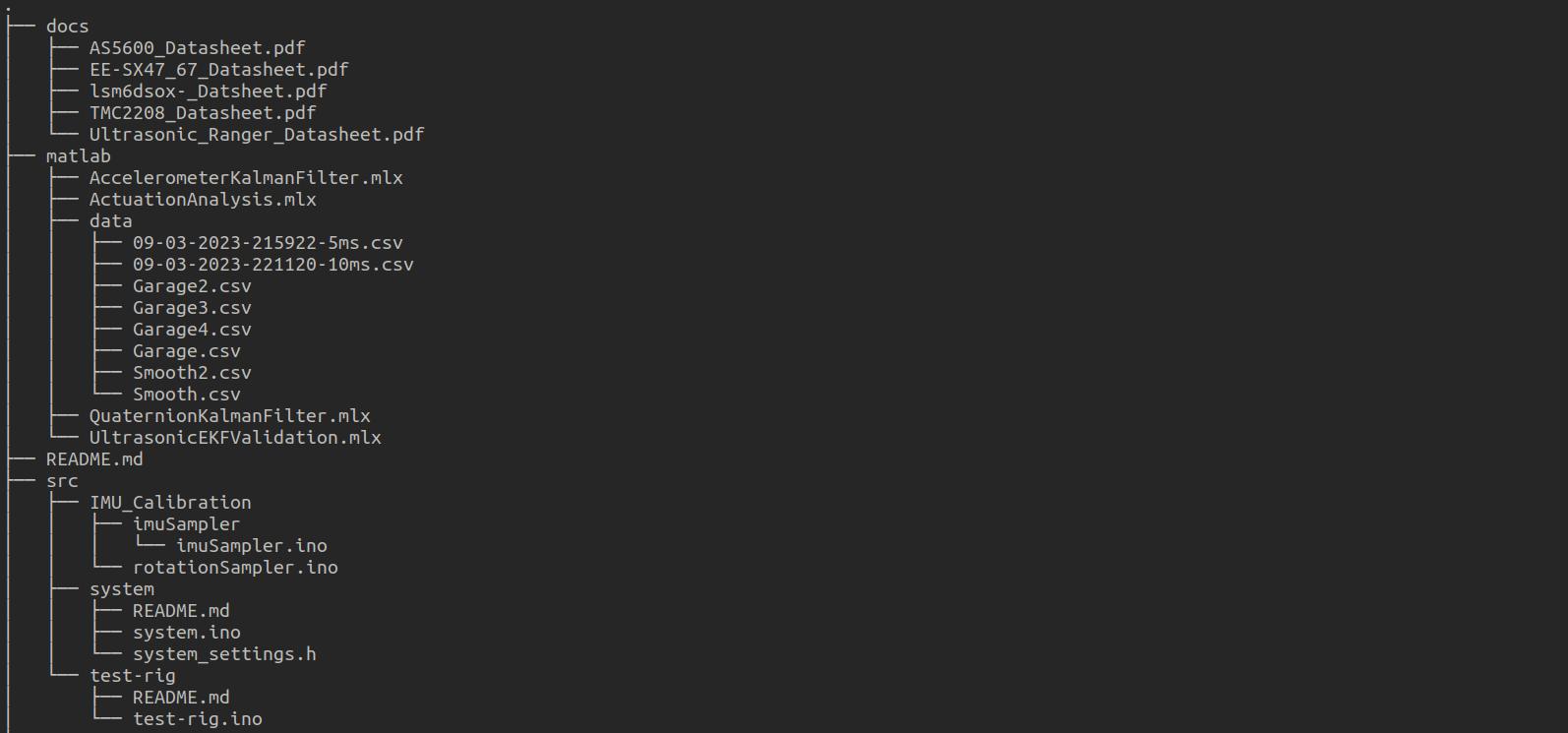

Thisisdescribedmorein-depthintheactualcodethroughcomprehensivecomments.ArepositoryofallcodewillbedeliveredtoLSDinazipfilealongwiththisreport.Thecodespecificto thetestrigispresentinthetest-rigsubdirectoryseeninfigure 11

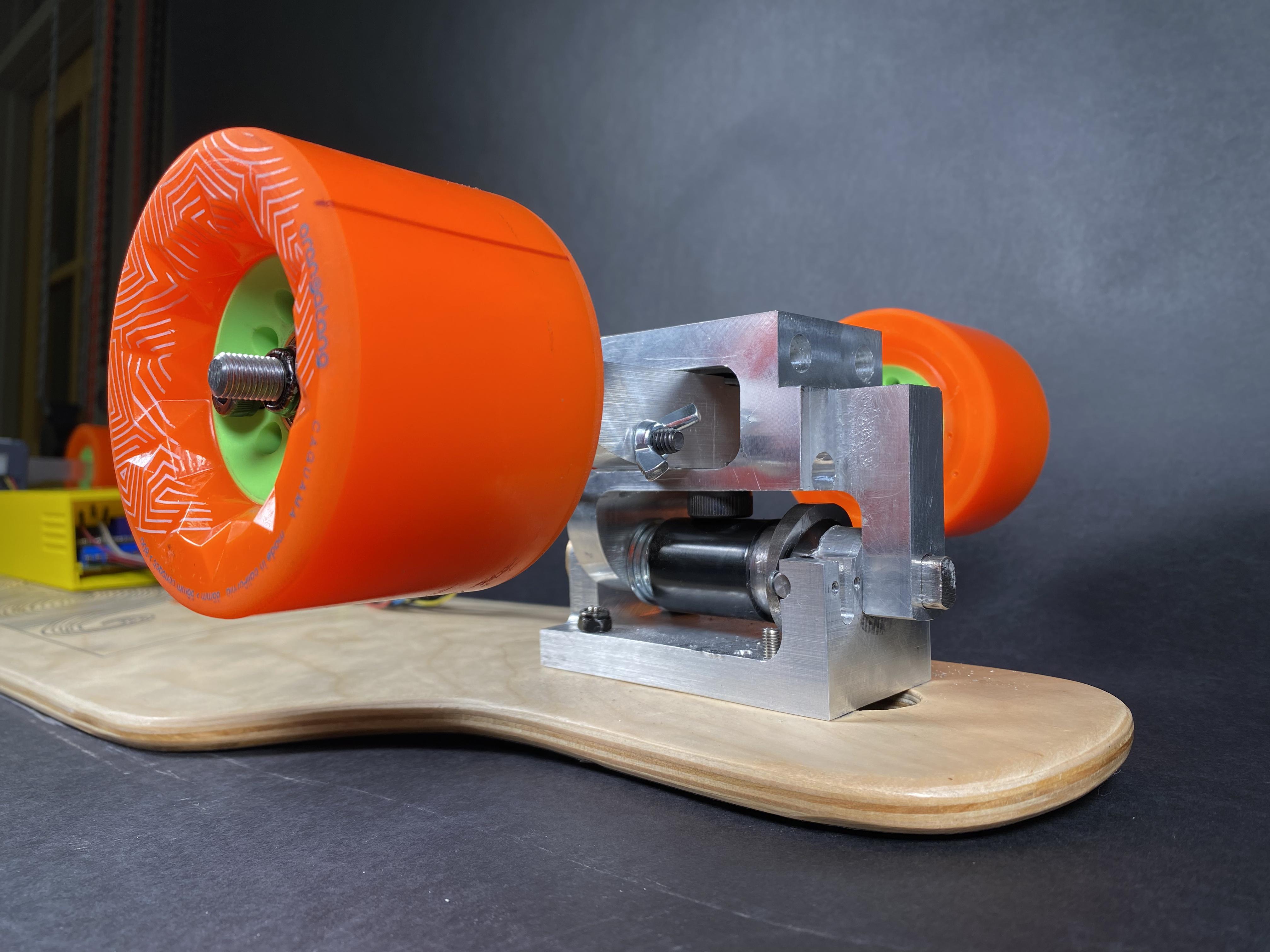

3.2TruckMechanics

LeanSteerDifferencecametouswithapurelymechanicaldesignforatruckthatwould allowcustomizablelean-steerratioinserts.Thisletstheriderbetteroptimizelean-steerphysics atapredeterminedspeed.However,atspeedslowerandhigherthanoptimal,theriderwould needtooverorunder-steer,respectively.Thistruckdesignwasourstartingpoint.Thedynamic adjustabilityoflean-steerphysicswouldbecontrolledbyamotor,andcontrolalgorithm.

Figure4:AbovearethemaincomponentsofLeanSteerDifference’soriginalmechanicalunpinned truck.

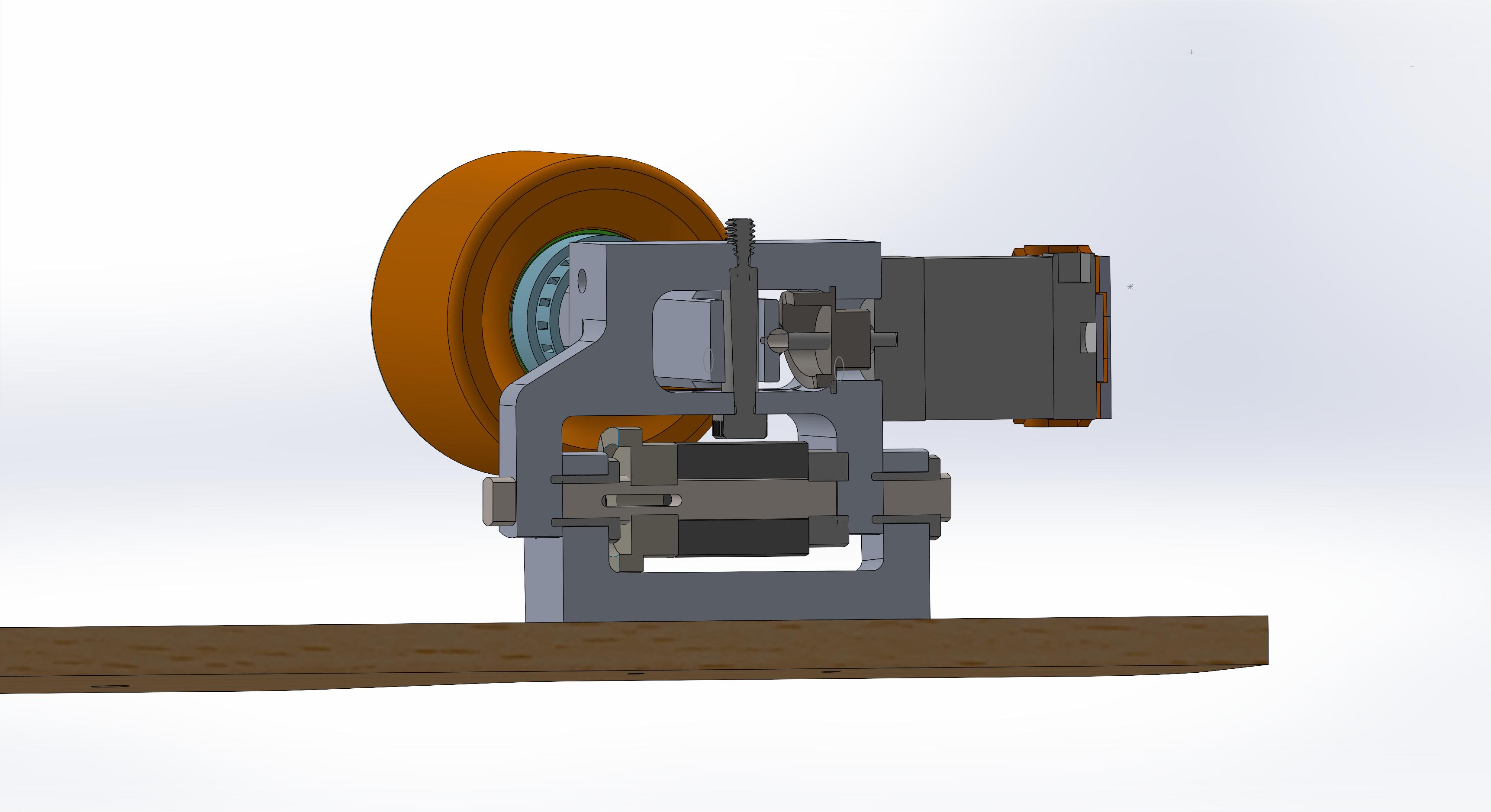

3.2.1ReturntoCenter(RTC)

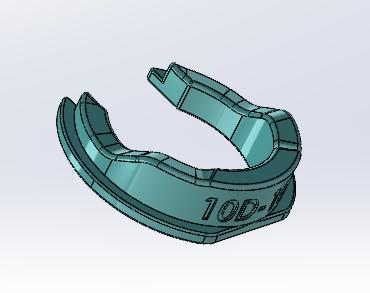

LeanSteerDifferencebroughtusaredesignconceptofthereturntocentercreatedbyHelix DesigninManchester,NH.ThedesignwasbasedonOriginalSkateboards’truckandfollowsthe sameconceptbutusesahigh-constantspringratherthanurethane.TheconceptbyHelixDesign usesashallowcamprofilethatwillcompressaurethanecylinderastheboardtilts.Wewouldneed tofabricatetrucksinordertoproperlytestthedynamictrucks,soweoptedtocreateaprototype oftheconcepttoverifythetorqueitwasproducingbeforeredesigningandfabricating.Thenew designhadmuchfewerpartsandalowerprofile,whichwefavoredbecausetheadditionofamotor resultedinalackofspaceundertheboard.

Bymountingitonatestshaftandusingatorquewrenchwewereabletovalidatethetorque producedbythecamdesigntopeakingat29.5oz-inoftorquewithnoinitialcompressionofa

(a)Fullmechanicalunpinned truck

(b)SteeringGuide

(c)ReturntoCenter

95AurethanecylinderwithanODof11/8”andIDof0.5”(Appendix C.2).Withtheaddition ofthenewRTCcam,thisprojectnowhas2camprofiles;thefirstisassociatedwiththeturning ofthehangerandisseeninFigure. 4b.Toreduceconfusion,wehaveusedthefollowingnaming convention:RTCcamprofileisnowcalledthe”Tulip”andthetruckhangercamremainsthe ”cam”.

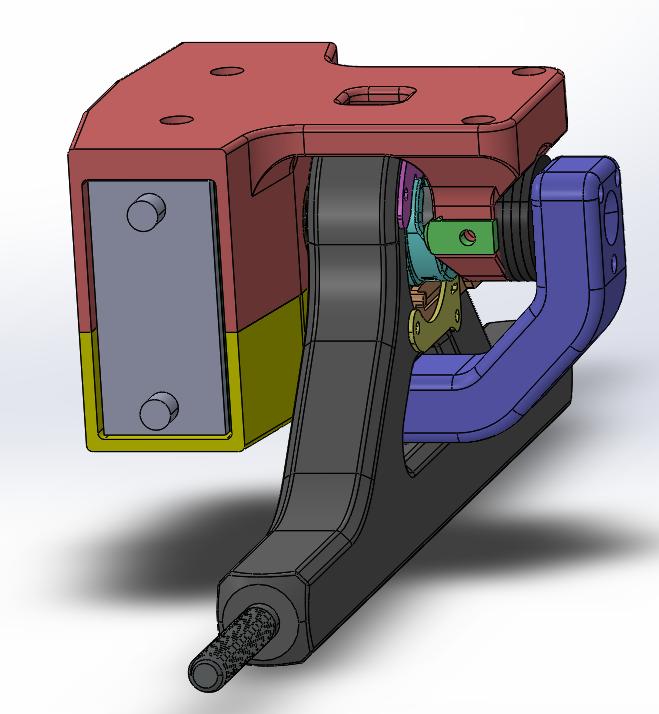

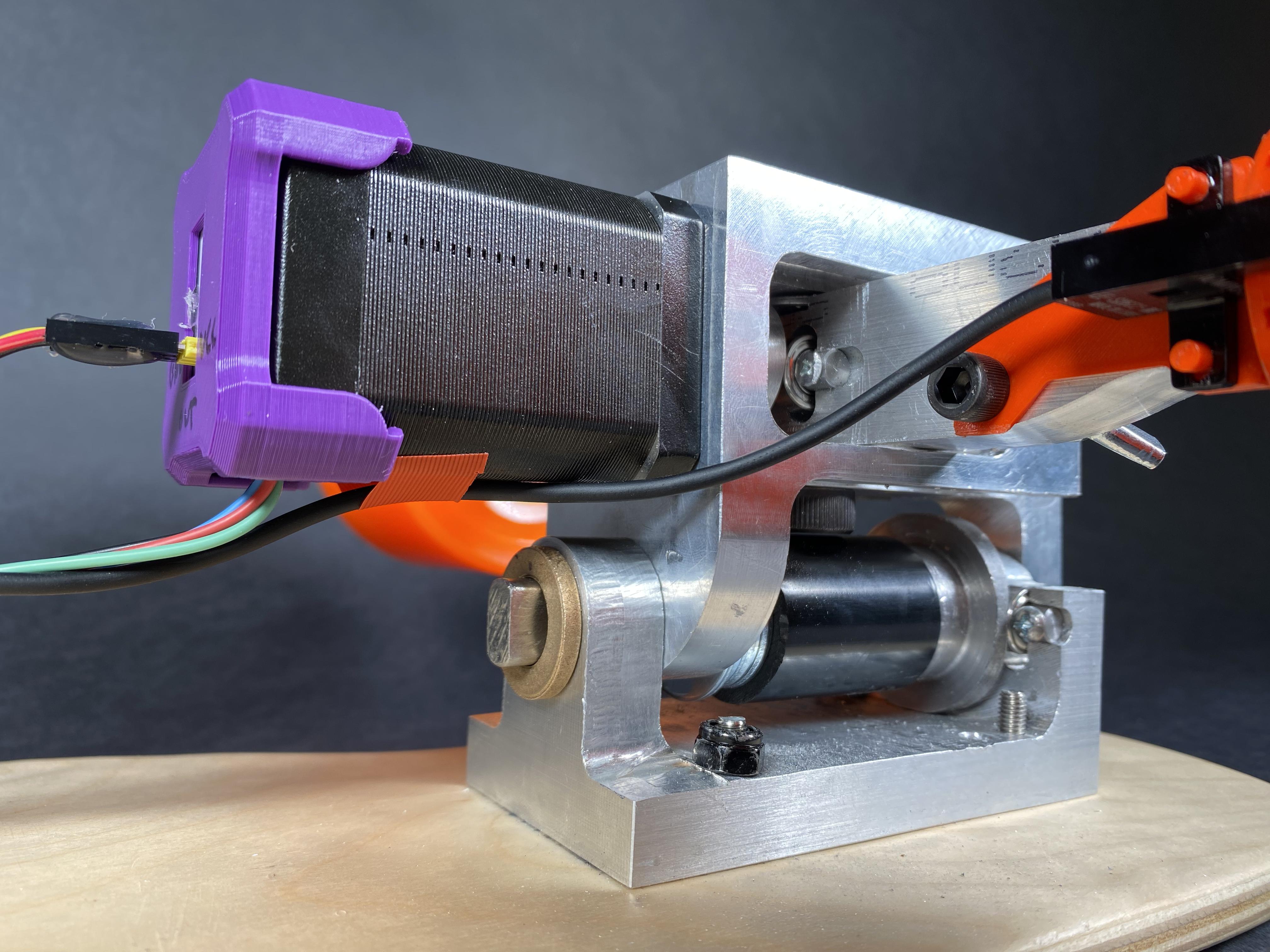

3.2.2Actuation

Aspreviouslydiscussed,theturningofthehangerisguidedbyacam(Fig. 4b).Thiscam profilewasmodifiedfromoptimizinglean-steerataparticularspeedtobeasmoothtransitionand allowsforthewholesteeringrange.Forinitialtestingwegavethecamtheabilitytoprovide ±15◦ ofrotation.Thiscamprofilewillhaverollersthatinteractwithittorotatethehanger.Theswept profileofthecamworkssuchthatthehangerhassupportfrombothsides.Asonesideofthecam pushestoturn,theothersidegivesanequalamountofspacetomaintaincontactatallangles.

Figure5:(a)Redesignedcamfor ±15◦ ofhangerrotation.(b)AprototypeoftheTulip.Thiswas aniterationthatusedapintokeeptheTulipfromrotatingandwaslaterreplacedbyatwo-sided Dshaftthroughhole.

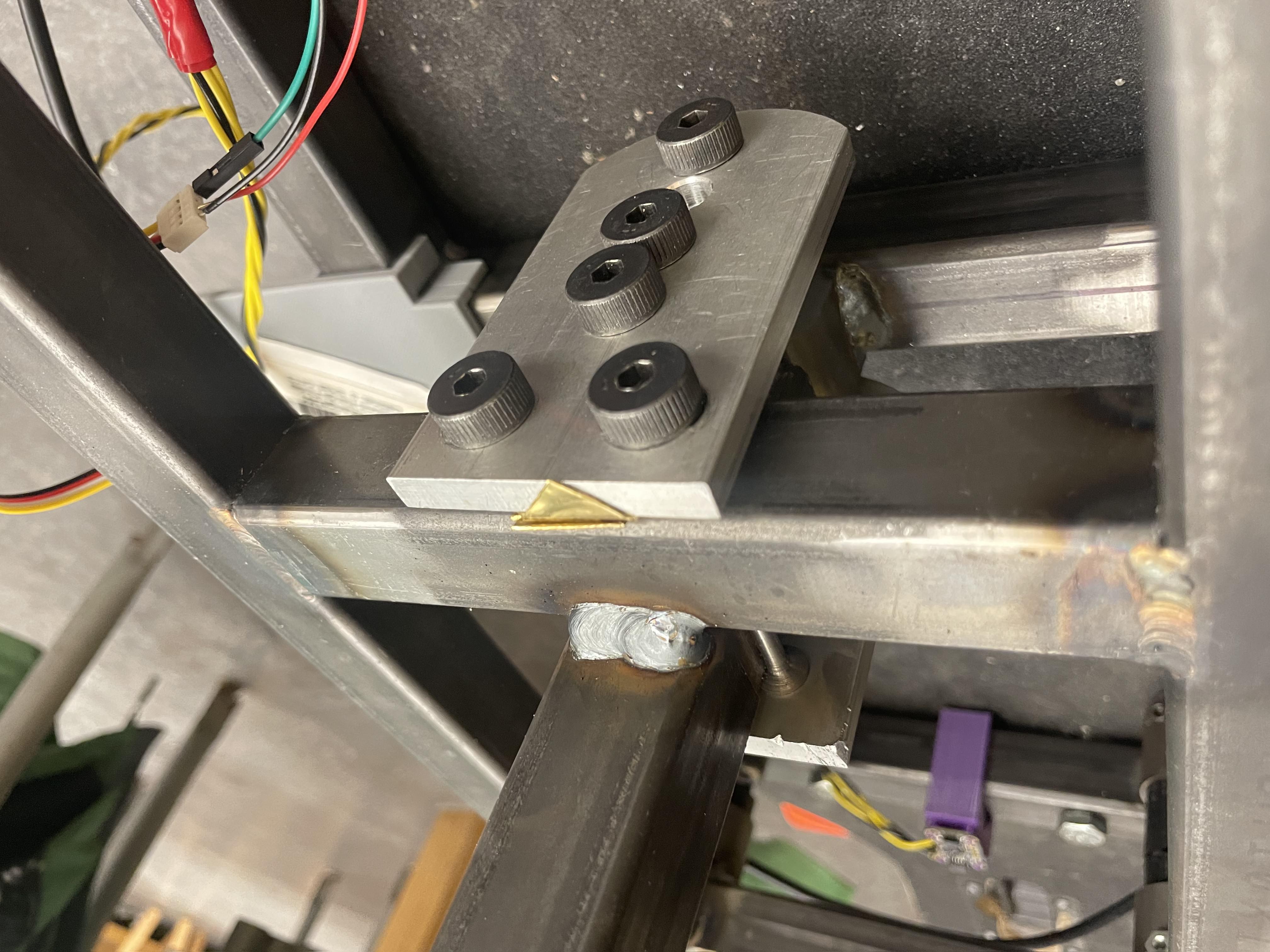

Wedecidedtomounttherollersonthetruckhanger,andthecamtothemotorbecausecan properlysecurethecamtothemotorbywayofsetscrew.

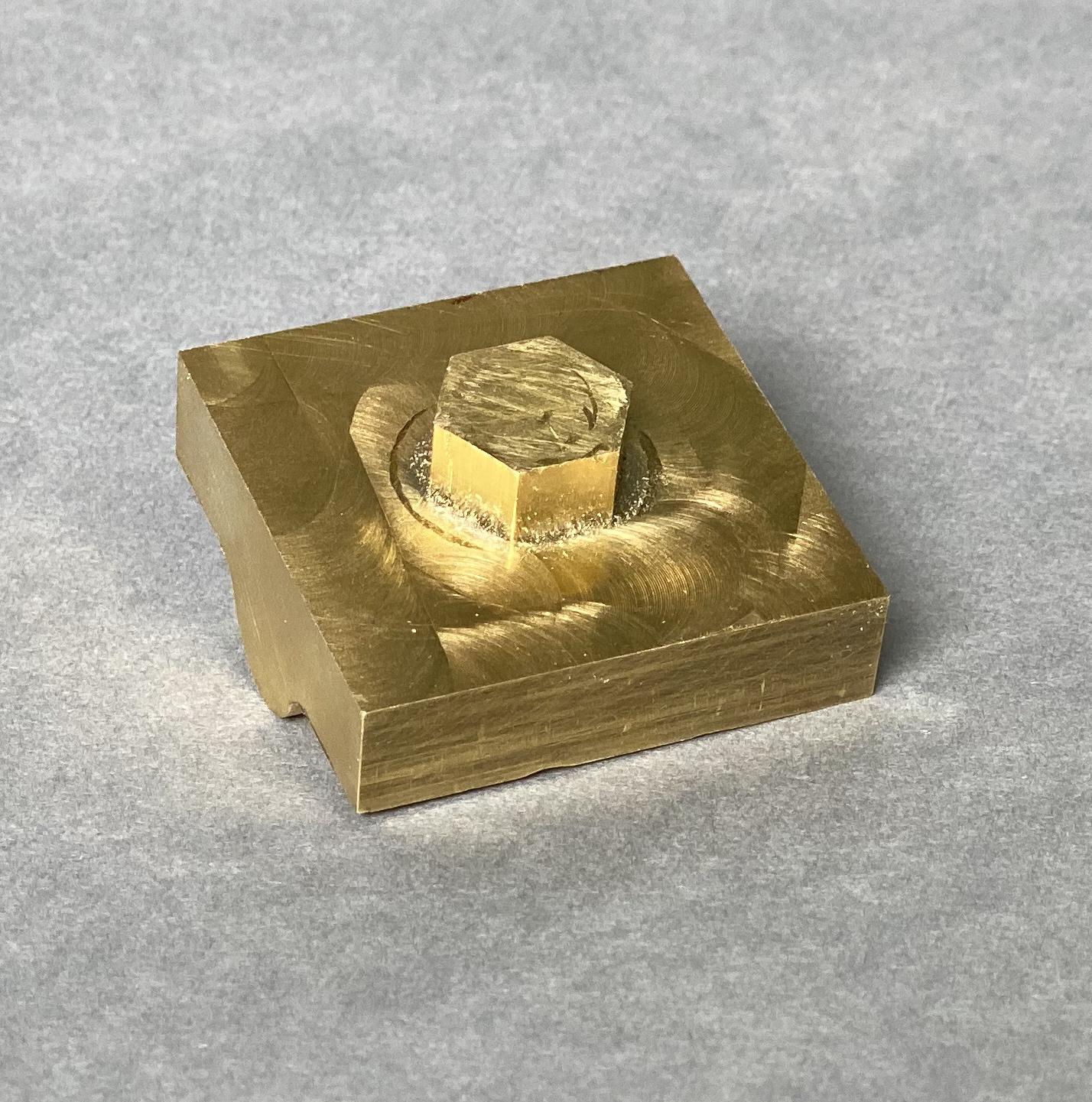

3.2.3CombinationofMechanisms

Combiningthesetwomechanismswhilemaintainingtheirindependentmovementwasacomplex task.ThenewRTCreducespartsbutincreasesthecomplexityoftheinteractionsbetweenmoving elements.TheboardneedstotiltaroundtheRTC,buttheRTCneedstoslidetocompressthe urethane.Therefore,somethingneedstokeeptheRTCfromrotatingwiththeboard.HelixDesign hadtwosmallslotsextendingthelengthoftheshafttoguidetheTulip,however,fromtesting withasteelprototypewefeltthattheywoulddeform,andbreak,underafullloadofarider.We optedforadouble-sidedDshaftthatextendsthelengthofthetruck.Despitetheincreasedarea providedbythedouble-Dshaft,theRTCstillproducesalotoftorque,especiallywhenpreloaded

(a)Hangercam

(b)TulipPrototype

forstifferleaning.Asaresult,anyplasticdesignwouldbeshort-livedbeforethedeformationlead tobreakingandexcessivebacklash.Assuch,wefabricatedanaluminumtrucktowithstandleaning andtestingunderload.However,giventimethisaluminumtruckwillalsodeform.Temperingthe aluminummaybeasolution,butpleaseseeSection. 5.2 forrecommendationsaboutmovingaway fromthecurrentdouble-Ddesignandtomorerobustsolutions.

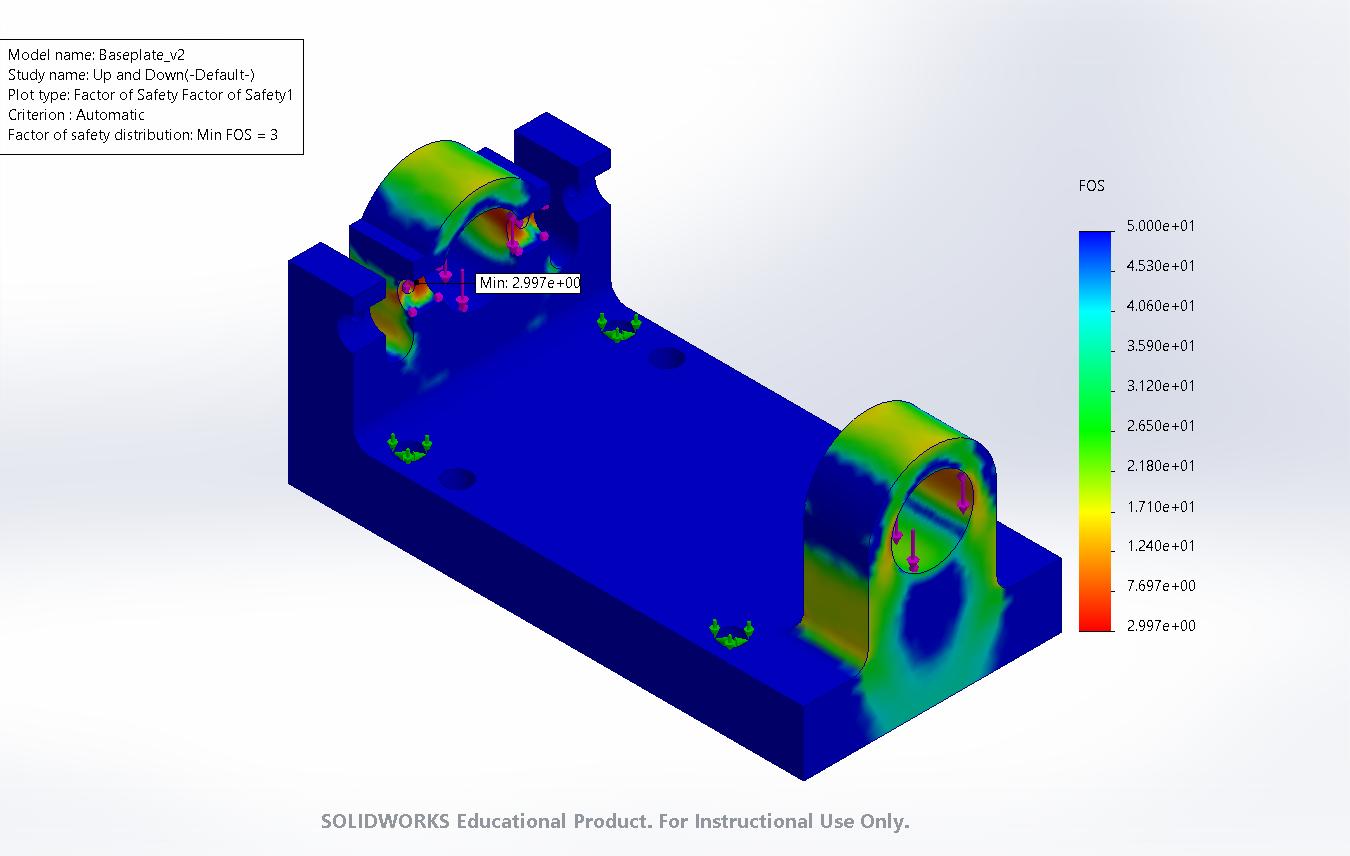

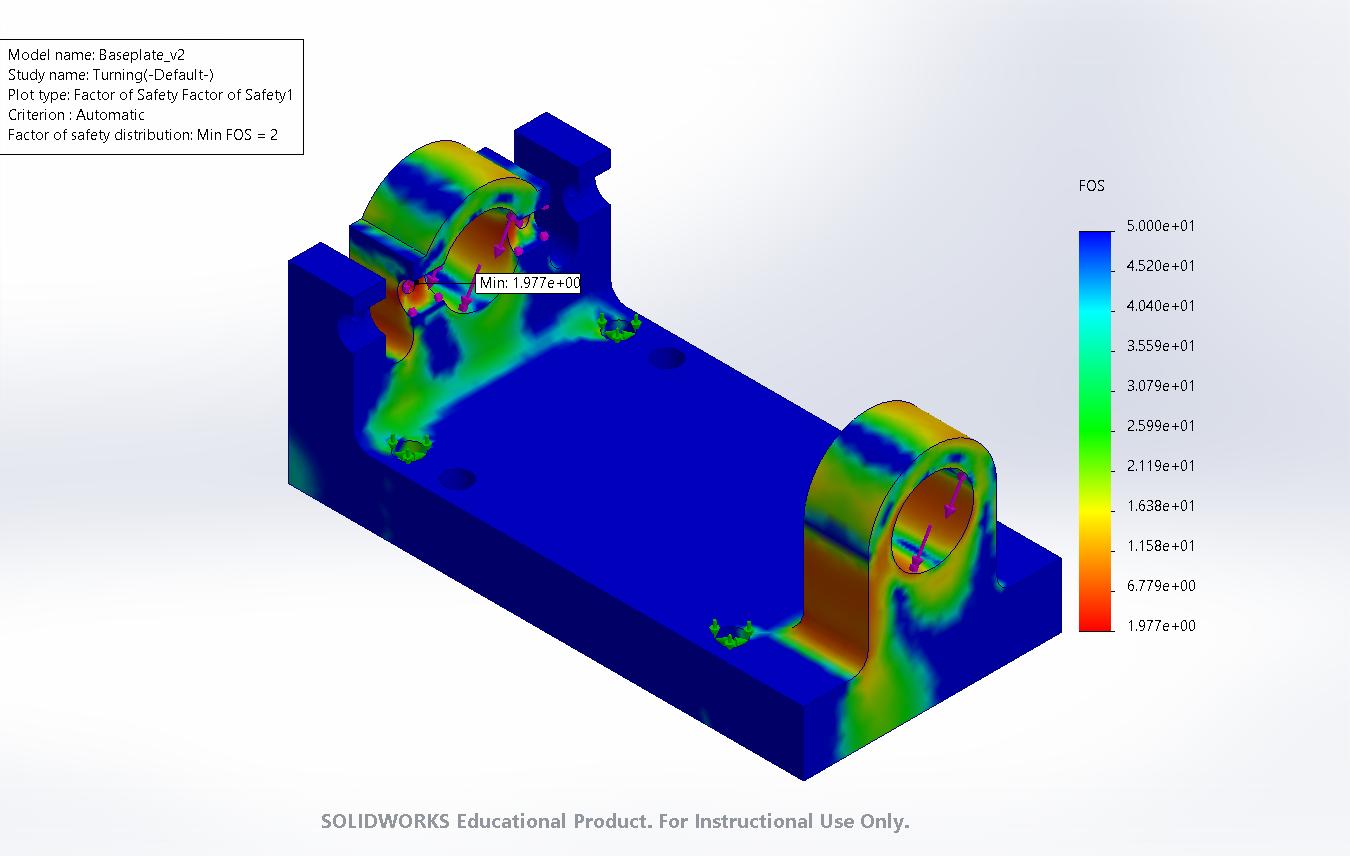

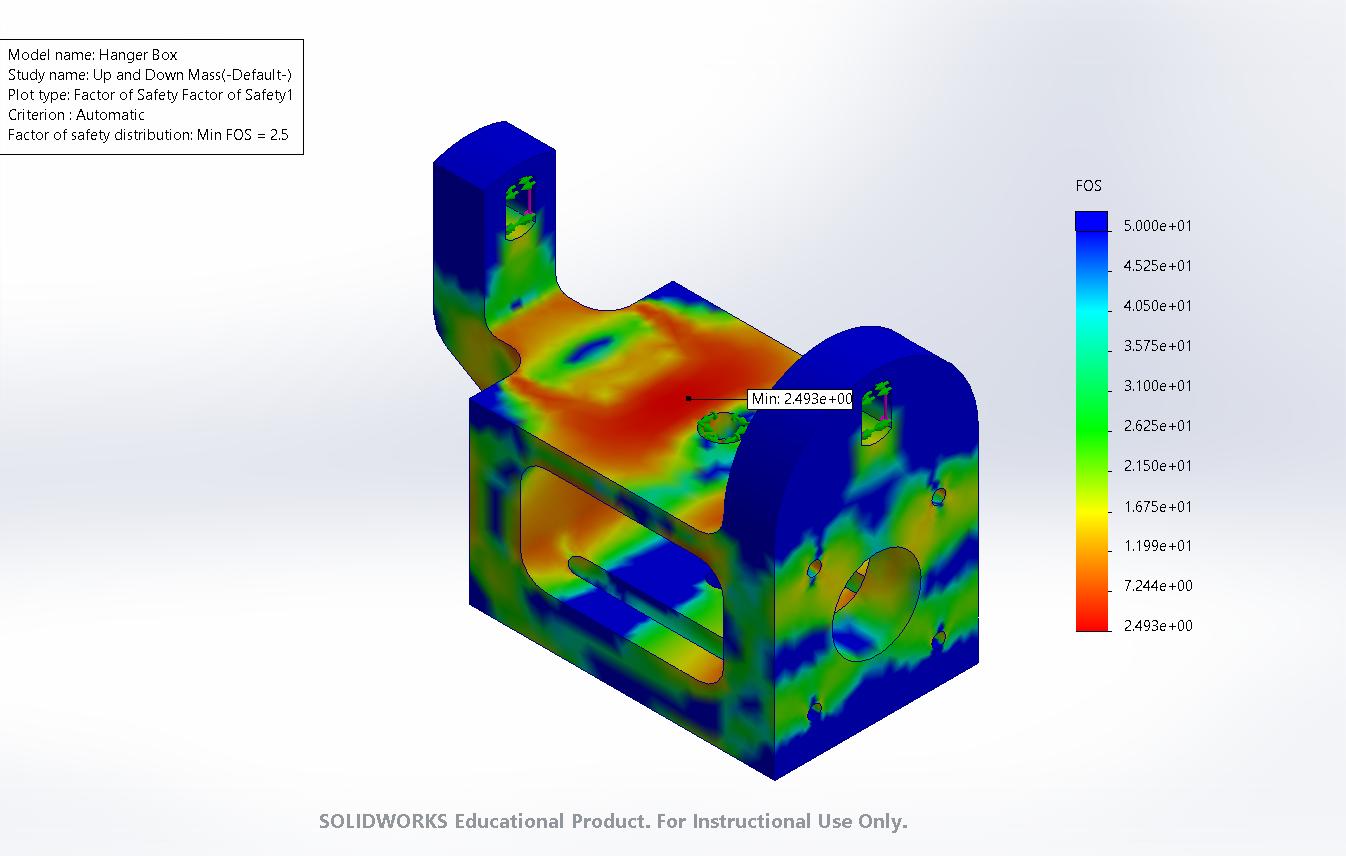

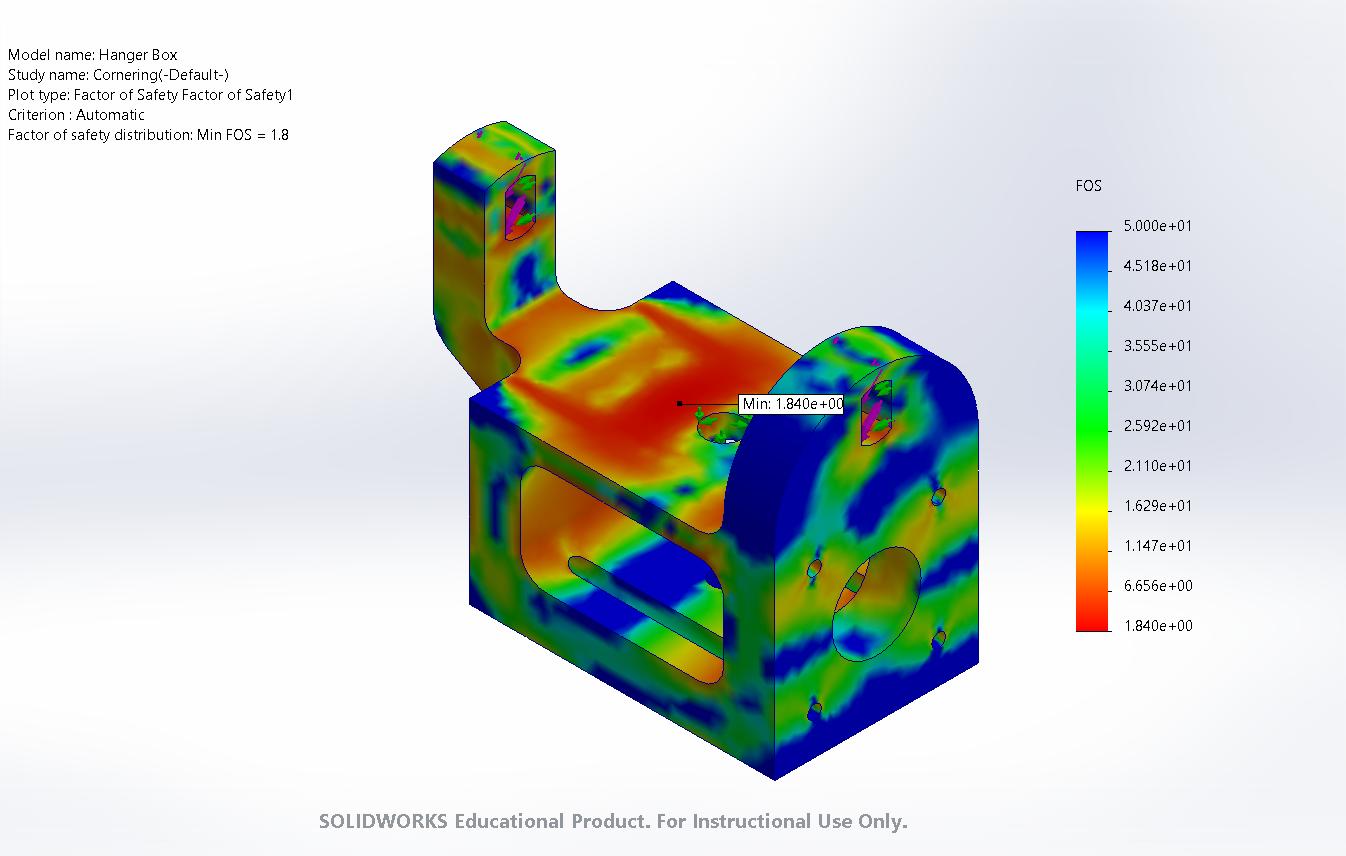

Theshaftisadeadaxle.Itonlysupportsthemechanismsrotatingaroundit.Assuchitcreates anoptimalsecuringlocationforthemountingandhousingofthemotorandhanger.Thishousing isneutral.Itdoesnotspinorrotatewitheitherhangerorboard.Withallofthisinmind,wewent throughafewdesigniterationsbeforelandingonthedesignwefabricatedandusedfortesting. Ratherthanmakingasleekdesign,weoptedforathickerandmorerobustlookfortesting.We performedFiniteElementAnalysis(FEA)onalloftheload-bearingcomponents,however,this systemisstillnotfullycharacterized,andassuch,weneededadesignthatwasover-designedto providetheleastlikelihoodofbreaking.Weperformedastaticanalysiswherea200-poundperson putalloftheirweightononeofthetrucks,aswellassimulatingtheobliqueloadsexperienced duringaturn.TheresultscanbeseeninFigures 24 and 25 ofAppendix C.3.

Figure6:(a)Prototypedesignoftheelectronictrucksandasectionviewofthecomponents(b).

3.3TruckElectronics

3.3.1Motors

ThemotorusedinoursystemisaNEMA17StepperMotoravailable fromMcMaster.We wantedtohaveahighamountofholdingtorquewhilemaintainingasmallpackagesizeandaccurate rotationcapabilities.AsseenonMcMaster,thismotoroperatesat12-24Vandhas125in-Oz.of torque.Althoughthismotorwasabletotwistthehangersusingthecamwithnoweightonthe board,itstruggledtodosowithevenaminoramountofweightbeingimpressedupontheboard. Motorselectioniscertainlyanaspectofthedesignthatcanbeimprovedandwillbeexploredin latersectionsofthisdocument.

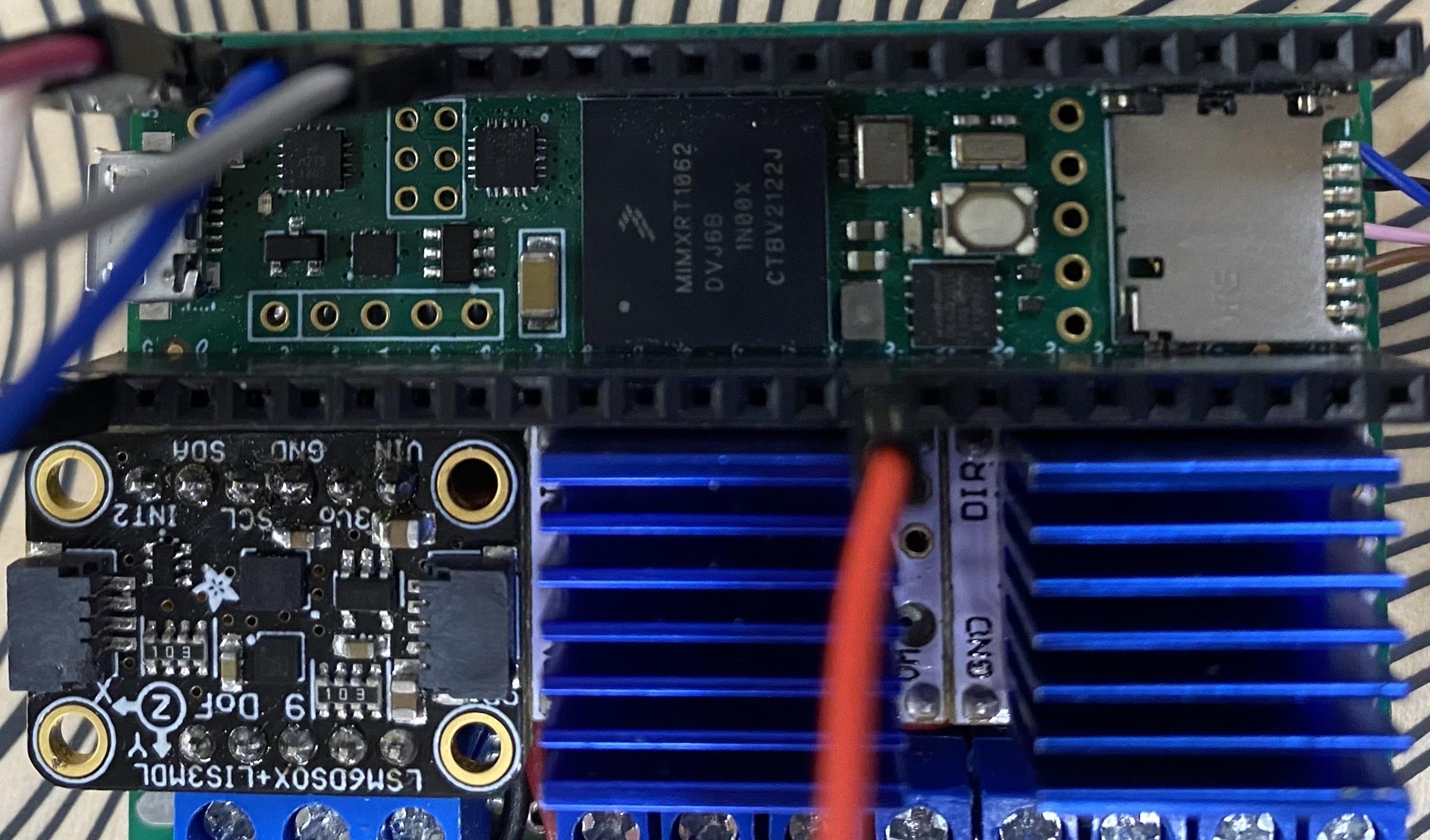

Inordertopowerthesemotors,weoptedtousethe TMC2208StepperDriver.Thesearea low-cost,easy-to-useoptionfordrivingmotorsfrom12-24V,whichiswhatwewereaimingtodo withouraforementionedNEMA17steppers.Thetwocontrollersusedbythesystemcanbeseen infigure 7 withtheblueheatsinksattheright.

3.3.2Sensors

Thereareafewdifferentsensorsusedtogatherthenecessarydatausedasinputstothecontrol loop.Thedatatobegatheredincludesgroundspeed,boardorientationwithrespecttothehorizon,

(a)

(b)

Figure7:TeensywithGyroandMotorControllers

andtheangleofthehangersrelativetotheboard.Allsensordatasheetsareprovidedwithinthe softwarehandoffzipfileunderthedocssubdirectory.

Inordertomeasureboardgroundspeed,weusedanOMRON EE-SX-672-WRPhotomicrosensor.Weacquiredoursensorfrom Adafruitatthislisting.Thesensortransistoroutputnominally uses5V,butbyenablingapull-upresistorinternallyontheTeensy,itisabletobeusedat3.3V. Thesensorisusedonadigitalinputpinasadigitalinterrupt,andeachtimeaninterruptisreceived acounterisincremented.

Figure8:EE-SX-672-WRMountedonTruckHangerswithCustomEncoderDisk

Thesensordetectswhenitsbeamisbroken,meaningthatacustomrotaryencoderwheelwith slotscouldbeusedwithourtruck’sskateboardwheelstocountpulsescorrespondingtoatwentieth ofarotation.Thesepulsesareusedeverysixtiethofasecondtogenerategroundspeed,thenthe counterisrefreshedforthenextcycle.Themountedsensorcanbeseeninfigure 8.Ofnote,the sensorislistedfora1khzminimumtopresponsefrequency.Weaimedtoavoidexceedingthis frequency,aswecouldnotguaranteeaccuratefunctionalitybeyondthisfrequency.Forthisreason, wedeterminedthattwentypulsesperrotationwouldbeasuitablechoice.Itresultsinourtarget

of1kHzat30mph,asseeninequation 1

Given:

1. Wheelradius=.0425m

2. Mphtom/sratio=.44

3. Maxgroundspeedof30mph

4. 20pulsesperrotationoncustomencoderdisk

(30 ∗ .44) (2π ∗ 0 0425) 20 ≈ 988(pulsespersecond)(1)

EE-SX-672-WR Teensy4.1

VCC(Brown)

5V(ordirectto4.5Vbattery)

LED(Pink) 5V(ordirectto4.5Vbattery)

Output(Black) 38(PullUpRequiredinCode) GND(Blue) AnyGND

Table1:EE-SX-672TerminalArrangementwithTeensy4.1Connections

AccordingtotheTerminalArrangementavailableontheOMRONlisting,thebrownandpink wiresbothreceiveVcc,whilethebluewireisgroundandtheblackwireisthesignaloutput.This isimportanttotakenoteofgiventhattheblackwireisthesignaloutput.Thiscanbeseenin Table 1

Inordertotrackboardorientation,an LSM6DSOXfromAdafruit wasused.Itprovides3-axis gyroandaccelerometerdataviaI2Coneither3.3Vor5V.Itwasanobviouschoiceduetoitssmall size,pricepoint,andeaseofuse.ItissimplymountednexttotheTeensyinitshousing,andit mustbelevelwiththesurfaceoftheboardasseeninthebottomleftofFigure 7.

LSM6DSOX Teensy4.1 Vin Any3.3V GND AnyGND SCL 19(SCLCapable) SDA 18(SDACapable)

Table2:LSM6DSOXArrangementwithTeensy4.1Connetions

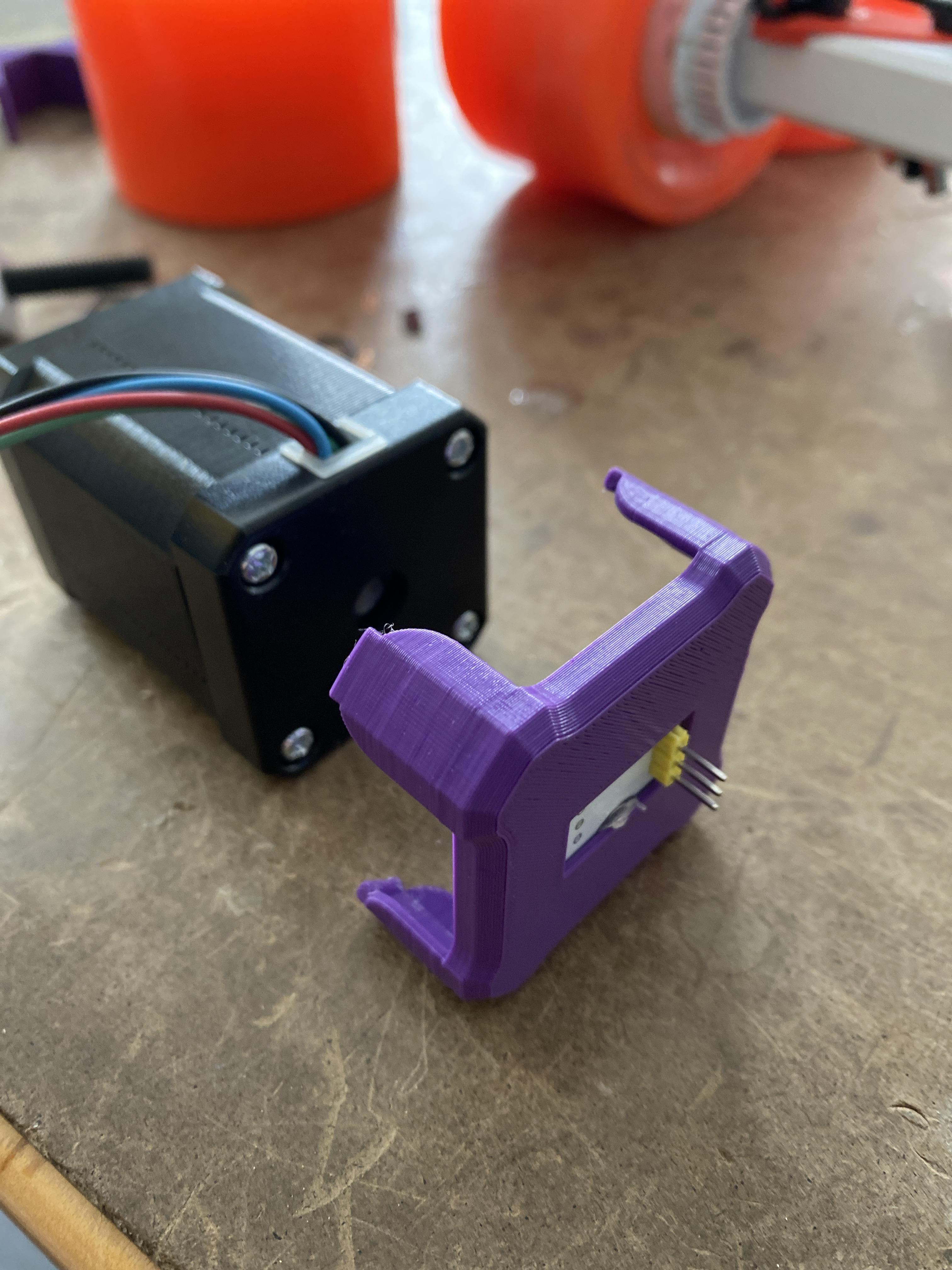

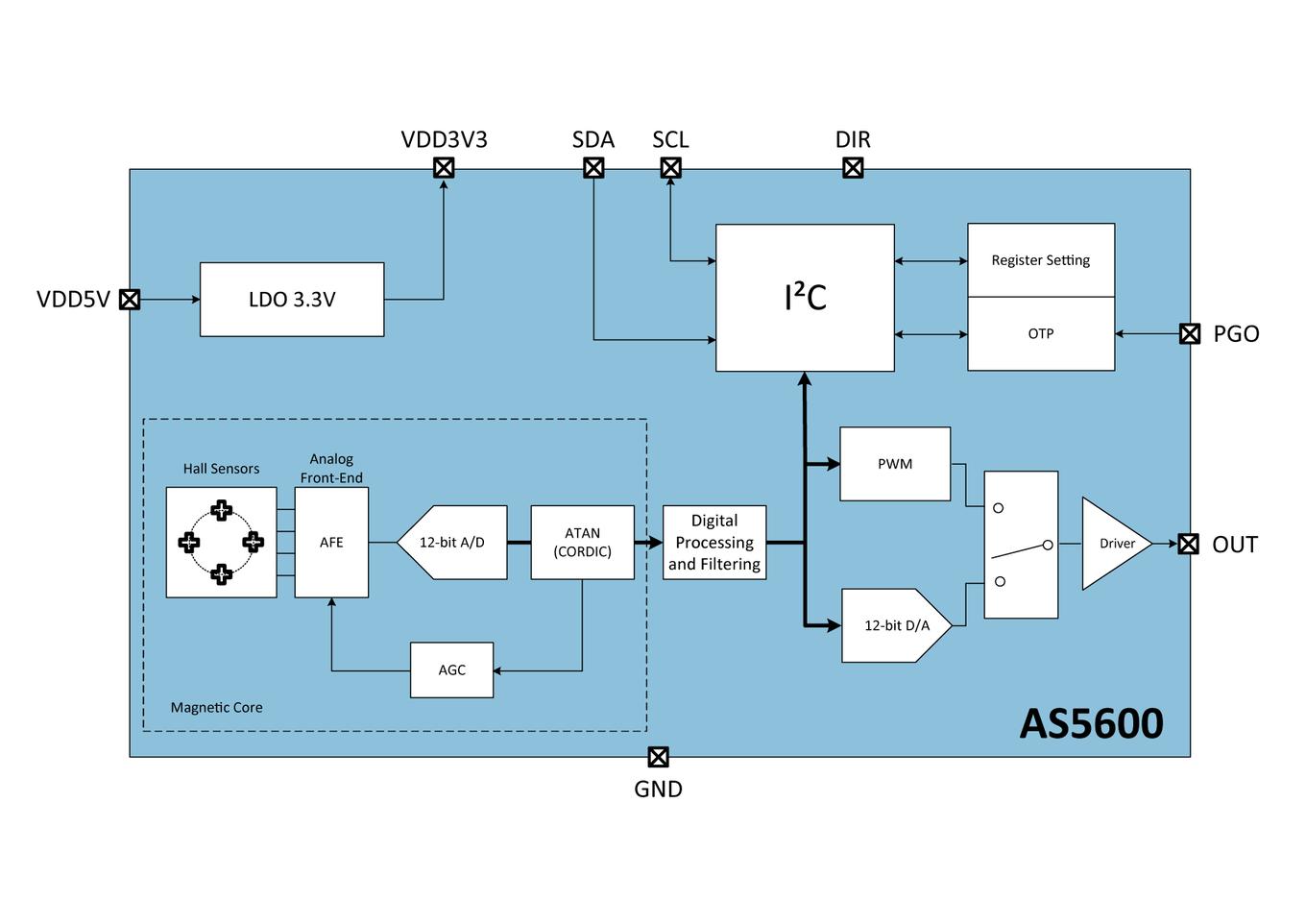

Thesensorusedtomeasurehangerangleisthe AS5600PositionSensor fromams-OSRAM.It isachipthatisabletodetectvariationsinamagneticfieldgeneratedbyasmallmagnetattached toarotaryelement.Inourcase,thiswasasmallmagnetepoxiedtothebackoftheshaftofthe motorusedtorotatethetruckhangers.Thecustommountandmagnetlocationcanbeseenin figure 9.

Thissensorcomeswiththecapabilitytorunoffofboth5Vand3.3V,whichisconvenientfor our3.3VTeensy’susage.Itcanalsooutputitsreadingseitherviai2cora12-bitDAC.Because weknewthatwewouldbeusingatleasttwoofthesesensors,wechosetousetheanalogmode duetothepotentialheadacheofchangingthei2caddressofoneormoresensorsforconcurrent usewithinoursystem.Suchcapabilitiescanbeseeninfigure 10,takenfromtheaforementioned ams-ORSRAMlisting.

OursupplierforaPCBusingthischip–accessibleat thisAmazonlink fromQCCAN–implementeda3.3Vspecificboard,andthisiswhatwechosetouseduetoitsinexpensiveprice pointandeaseofusewiththeTeensy.Delivering3.3Visaseasyaspoweringitfroma3.3VVcc railontheTeensy,anditsanalogoutputcanbereadwithanyoftheanalog-capablepins.Ofnote, theR4resistormustberemovedtoenableanalogoutputmodeforthisspecificPCB.Giventhat Amazonlistingscanandlikelywillchangeinthefuture,anyPCBimplementingtheAS5600can likelybeused.Itisimportanttomakesureasimilarresistorpull-downisnotedandaddressedif presentaswiththePCBweused.

Datasheetsforeachsensorusedinthetruckdesign(andadditionallythetestrig)arelocated inthedocssubdirectoryofthedeliveredsoftwarerepo,asseeninfigure 11

3.4TruckSoftware

Thesoftwarerepositoryusedtocontrolourdynamictruckswillbedeliveredinazipfileto LSD.Therepository’sgeneralstructurecanbeseeninfigure 11.Thecodespecifictothetrucksis

Figure9:AS5600MountingSystem

Figure10:AS5600BlockDiagram

withinthesystemsubdirectory.

Figure11:DeliveredSoftware

ThecontrolalgorithmispredominantlyimplementedinArduinocode,alanguagedesignedby Arduinosoftwarecreators.ItsimplifiesC/C++capabilities,eliminatingtheneedforsettingup Makefilesandothercomplexities.Consequently,alltruckcodeisexecutedasArduinocode.

Giventhetruck’sreal-timeresponsetoclock-basedandinterrupt-basedevents,globalvariablesandvolatileflagsareessentialfordataaccessibilityacrossmultiplefunctions.Althougha class-basedsystemcouldprovebeneficialforfuturedevelopment,timeconstraints,andmultiple contributorshindereditsimplementation.

Despitethelimitedtime,thecoderepositoryiswell-documentedandpreparedforongoingdevelopmentandversioncontrol,makingitanidealfoundationforadvancingthetechnology’ssoftware maturity.Itencapsulatesnumerouslessonslearnedinembeddeddevicesoftwaredevelopment.

Futuredevelopersshouldeasilycomprehendthecode’sgeneralstructurebyexaminingthe providedrepository,whichoffersampleopportunitiesforimprovement.

3.5FilteringandControl

Toachievepreciseturningradiiconsideringspeedandleanangle,wedesignedacontrolalgorithmtomanipulatethetrucksusingsystemdata.Thealgorithmencompassesanextended Kalmanfilter,adynamicsfunction,andafeedbackmotorcontroller.

3.5.1ExtendedKalmanFilter

Atthebeginningofeverytimestep,thesystemcollectsdatafromallitssensors.ThecompositionofthesemeasurementscanbeseeninEquation 2 where ω istherotationratevectorin thebodyframe, a isthegravitationalaccelerationvectorinthebodyframe, v isthespeedofthe board, θ1 istheangleofthefronttruck,and θ2 istheangleofthereartruck.

Intheirrawstate,thesemeasurementsonlyprovidepartialinformationneededforsystem control,andtheyareaffectedbynoiseduetouneventerrain.Thesefactorspromptedusto developafilterthatestimatestheboard’sorientationandsmoothsoutnoisefrommeasurements.

Morespecifically,wedevelopedanExtendedKalmanFilter(EKF),atypeofobserverfor systemswithnon-linearstatetransitionandmeasurementequations.Inthiscase,anEKFis requiredoverastandardKalmanfilterbecauseattitudedeterminationisanon-linearproblemwith non-linearitiesinboththestatetransitionequationandthemeasurementequation.Itachieves thisbylinearizingthesystemaboutthecurrentstateateachtimestep.Weneededtodefineour state,whichcontainsallthepropertiesrequiredtodescribeoursystem,namelytheorientationand rotationratesofthesystem,alongwithspeed,andthetruckangles.

Therearemanypossiblechoicesofparametersetstodescribeorientation,andourinitialchoice was3-2-1EulerAngles,alsoknownasyaw,pitch,androllangles.Thissetdescribesarotation ψ aboutthe z axis,arotation θ aboutthe y axis,andarotation ϕ aboutthe x axis.Thissethas thebenefitoftherollangle ϕ equalingthetiltangleweneedfortherestofourcontrolalgorithm. However,aswefoundoutinimplementation,thisparametersethasdrawbacks.Lookingatthestate transitionequationsfor3-2-1EulerAngles(Equation 3),wefindtheseequationsarehighlynonlinear,withproductsoftrigonometricterms.Additionally,therearesingularitiesaround θ = ±90◦ Althoughtheboardhopefullyshouldneverbeintheseorientationswhileriding,theycouldstill causeissuesifsomeonewerecarryingtheboardorleaningitupagainstthewall.

Becauseofthesefactors,inourfinalEKF,weendedupoptingforquaternions,a4-parameter setforrepresentingorientations(β0 ,β1 ,β2 ,β3 )whicharenon-singularandhaveamuchsimpler statetransitionequation(Equation 4).

Additionally,thetiltanglecaneasilybecalculatedusingEquation 5,whichremovesanyadvantagethata3-2-1EulerAngleEKFholdsoveraquaternion-basedfilter.

Wecancombinethequaternionorientationrepresentation(β),rotationrates(ω),speed(v), andtruckangles(θ1 ,θ2 )intothesystemstatevector(x),whichisshowninEquation 6

Havingestablishedthestatevectorcomposition,thesubsequentstepinvolvesdeterminingthe statetransitionandmeasurementequationsofthesystem.Thestatetransitionequation’sform isevidentinEquation 7.Sincetherearenoexpressionsrelatingourstatevariablestotherateof changeof v, θ1 ,and θ2 ,wehave˙v = ˙ θ1 = ˙ θ2 =0.Consequently,allchangesinthesevariablesare assumedtoresultfromexternaldisturbances.

Equation 4 provides ˙ β,whiletheequationsofmotionforarotatingrigidbodyoffer ˙ ω,as depictedinEquation 8.Byassumingthatthebodyframealignswiththesystem’sprincipalaxes, thecalculationisconsiderablysimplified,eliminatingtheneedtoinverttheinertiatensor[I].The precisevaluesinourinertiatensorcanbefoundinAppendix E.

Lastly,sincetheEKFoperatesataconstanttimestep∆t,itisnecessarytodiscretizethestate transitionequation.WiththeEKFrunningatahighfrequencyof240Hz,afirst-orderdifferenceapproximationsuffices(Equation 9),negatingtheneedformorecomputationallydemanding methodslikeRunge-Kutta.BycombiningEquations 4, 7, 8,and 9,thestatetransitionequation isobtained.

Subsequently,anexpressiondepictingoursystem’smeasurementsisrequired.Thegeneralform ofthisexpressionispresentedinEquation 2.However,arepresentationof a intermsofourstate variablesisneeded.Byconvertingthequaternionrepresentationoftheboard’sorientationtothe correspondingdirectioncosinematrix,wecanmultiplythisbythenormalforceaccelerationvector, whichis9.81 m/s2 intheinertial z direction.Thisyieldsthemeasuredbodyframeacceleration, asdemonstratedinEquation 10.

WenowhavethemeasurementequationforourEKF.Additionally,theEKFnecessitatesthe processandmeasurementcovariancematrices Q and R ofthesystem.Wederivedthevaluesfor R usingthesquareoftheRMSerrorvaluefromtheIMUdatasheet,assumingalloff-diagonal termsofthecovariancematrixwere0.Thecovariancesofspeedandanglemeasurementswere unknown,andtheirvaluesweredeterminedthroughtrialanderror.Similarly,theprocessnoise Q wasunknown,anditsvalueswereestablishedbytrialanderror.ThematricesusedintheEKF canbefoundinAppendix F

TheEKFwasinitiallyimplementedinMATLABandtestedondatacollectedusingthetest rig.Testrunswereconductedonbothsmoothandbumpysurfaces,withtheultrasonicsensoron theplatformservingasaverificationmethodtoensuretheEKFvaluescorrespondedwithreality. TheresultsofthesetestsaredisplayedinFigures 12 and 13.

Ascanbeseen,whenthegroundgetsrougher,theperformanceoftheEKFalsogoesdown. Thatsaid,thefilter’strackingerrorremainsclosetothetruevalueregardlessofthesurface.With thisresult,wemovedforwardwithimplementingtheEKFontheTeensy.Operatingatafrequency of240Hz,theboardtakesmeasurementsandrunsthemthroughtheEKFtoestimatetheboard’s

Figure12:EKFperformanceonsmoothground

Figure13:EKFperformanceonroughground

currentstate.Withthefilterimplemented,wenowhavethetiltangleandboardspeed,whichcan beusedtodeterminethedesiredturningradiususingthesystem’sdynamics.

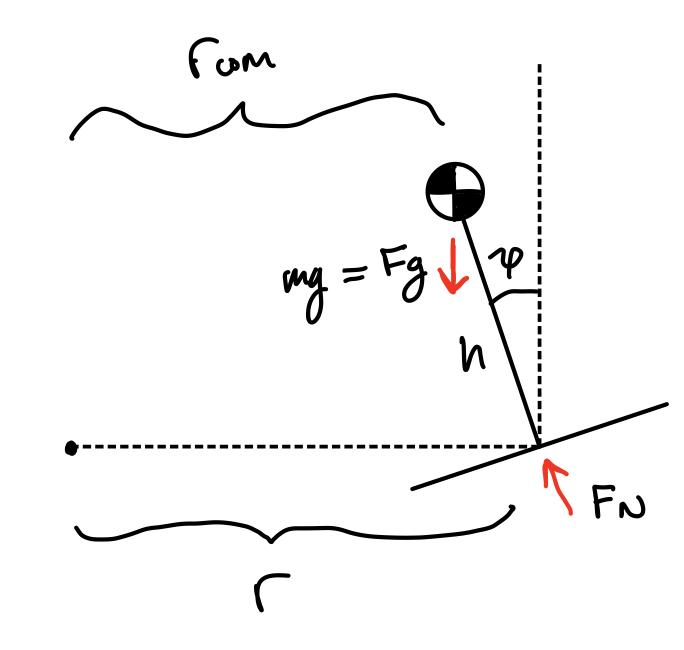

3.5.2OptimalLeanSteerPhysics

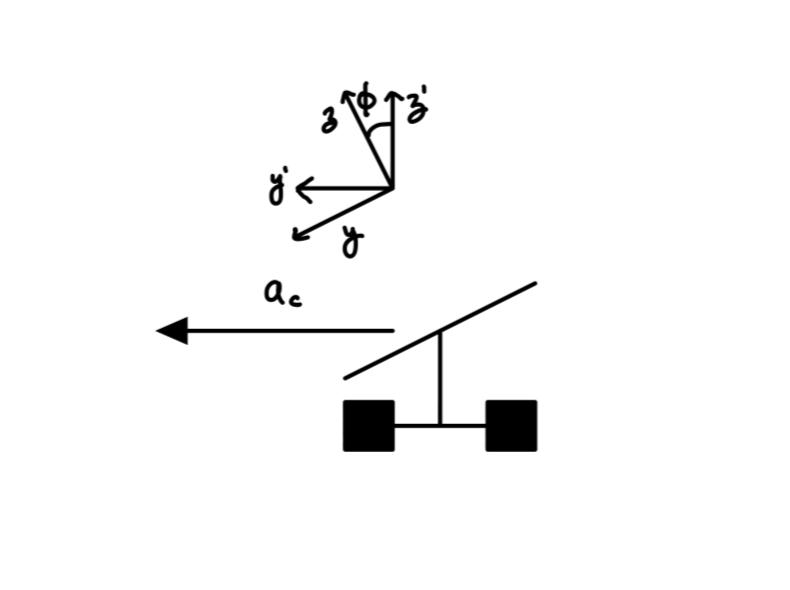

Aswewantourboardtofollowoptimalleansteerphysics,wemustdeterminethis”optimal” relationshipbetweenvelocity,tiltangle,andturningradius.Westartbymodelingthesystemas aninvertedpendulumandcreatingafree-bodydiagram,whichcanbeseeninFigure 14.Using

Figure14:Freebodydiagramoftherider-boardsysteminaturn this,wefindtheforcesactingonthesysteminthe x and y directions.

Solvingforthenormalforce FN inEquation 12,wethenplugthisintoEquation 11.

Combiningthiswiththeequationforcentripetalacceleration,weget

Theradiusofthecenterofmass rCOM isrelatedtotheturningradius r by

Finally,bycombiningEquations 14 and 15,wefindthatthefollowingrelationcandescribeoptimal leansteerphysics

Usingthetiltangleandspeedfoundabove,wecanusetheoptimalleansteertocalculatethe desiredturningradiusforthecurrentstate.Thisturningradiuscanthenbeconvertedintothe desiredtruckangletoachievethatturningradius,whichcanbeseeninEquation 17

3.5.3FeedbackMotorController

Ateverytimestep,thefilteredtruckangles y(t)arecomparedwiththereferenceinputs r(t)to calculatetheerrorsignal e(t).Thiserrorsignalisthenfedintothecontroller,whichconvertsitto adirectionandnumberofstepsforthesteppermotor.Thesestepsaresentascontrolsignals u(t) tothemotors.Thecontrolloopupdatesat60Hz,refreshingthesignalssenttothemotorswith eachtimestep.

Thecontrollerisastraightforwardproportionalcontroller,multiplyingthetrackingerrorby aproportionalgain(Kp)todeterminethenumberofstepssenttothemotor.Althoughmore advancedcontrolarchitecturescouldhavebeenemployed(PD,PID,etc.),wechoseaproportional controllerforitssimplicity.Theaddedcomplexitiesofimplementingamoreadvancedcontroller wouldyieldminimalbenefits.Forinstance,theactuationmechanismexhibitsminimalfriction, resultinginnegligiblesteady-stateerrorinthesystem,andthusanintegratortermwouldoffer littleperformanceimprovement.Furthermore,duetothesmallrangeofactuationandthehigh speedofoursteppermotor,wecouldoperateourcontrollerwitharelativelylowproportionalgain. Thiseliminatedovershootofourreferenceinput,reducingtheadvantageofaddingaderivative termtoourcontroller.

Duringtesting,wefoundourcontrollerperformedwellintwoaspects.Firstly,foragiven referenceinput,oursystemcouldtrackitwitharelativelylowtrackingerror(Figure 16).The slighttrackingerrorcanbeattributedtosystemdelaysandtheramp-likenatureofthereference input,whichintroducesasteady-statetrackingerrorevenformoreadvancedcontrollerslikePI, PID,etc.Thisexplainswhythestandarddeviationofthe5m/srunishigherthanthe10m/s run.Thesteeper”ramps”resultinincreasedsteady-stateerror.

Figure15:Closedloopmotorcontroller

Figure16:Controllerperformanceatvariousspeeds

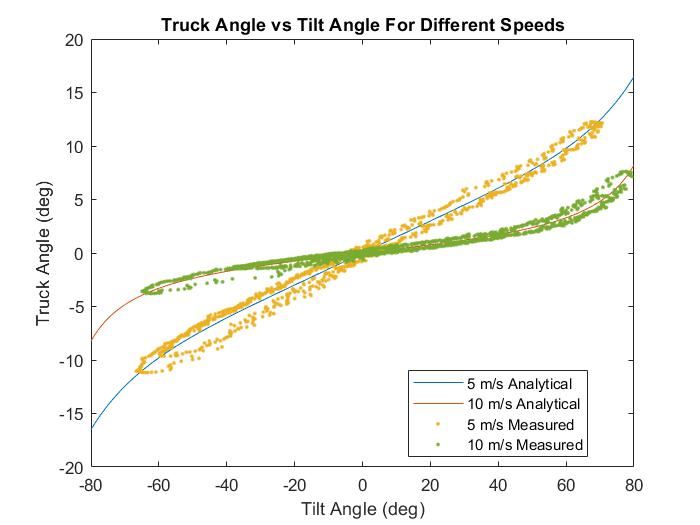

Additionally,thesystemfollowedouranalyticallyderivedmodel,asshowninFigure 17.The hysteresisseencanagainbeattributedtothedelayinthesystemaswellastheramp-likeinputs giventothesystem.

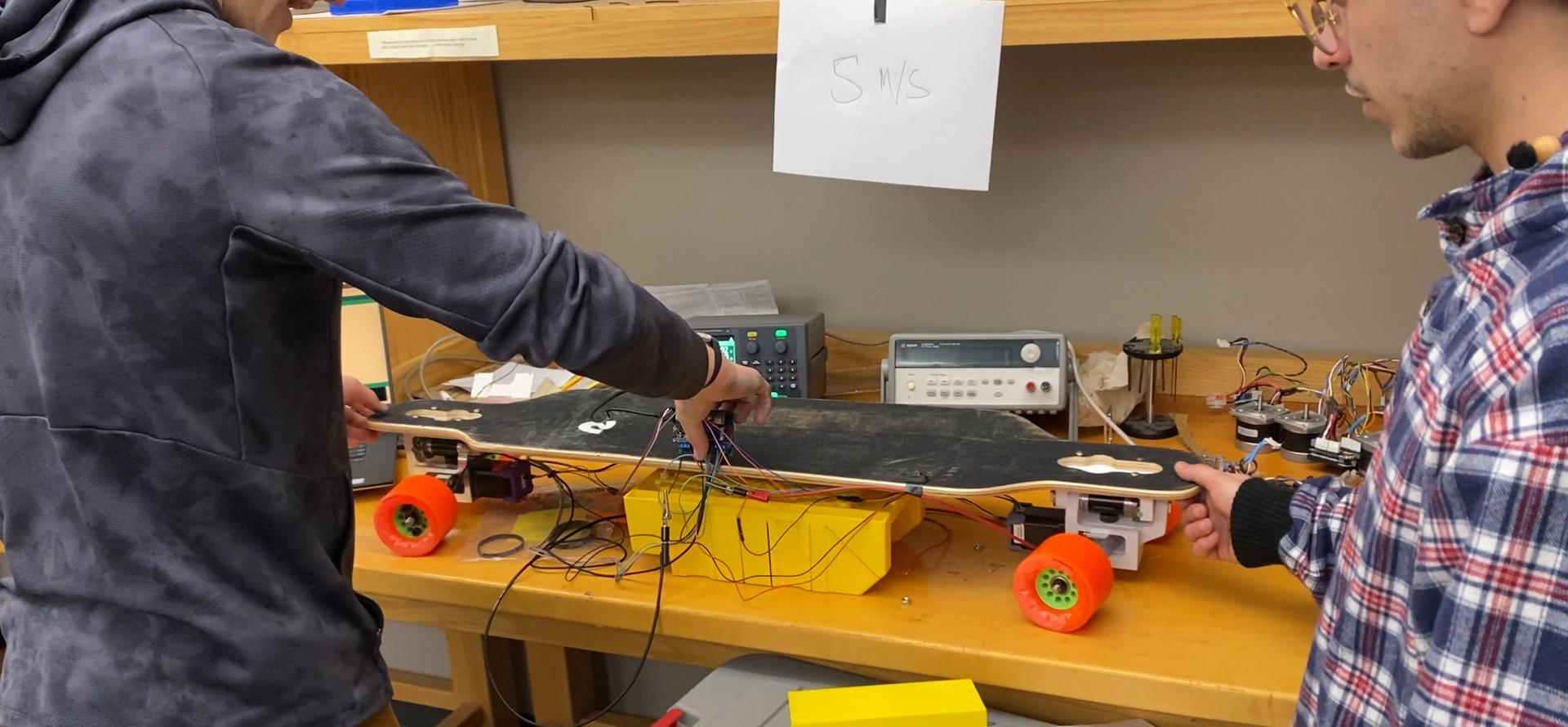

3.6BenchTopTesting

Ourprojectwrappedupwiththeinitialtestingofoursystem.Althoughwehadenvisioned performingtestingusingourtestingrig,wefirststartedbyperformingtestingonatabletop.Our setupforthistestingcanbeseeninFigure 18.Wesimulatedtheboardmovingatvariousspeeds andtestedtheactuationmechanismstoseeiftheyactedasexpected.Wefoundthatthesystem wasabletomeasuretiltangleaccurately,andwasabletodrivethemotorstothecorrectposition. ThiscanbeseeninFigure 17.Wethenproceededtoattempttoputweightontheboardand foundthatthemotorswerenotabletoproducethetorquenecessaryinordertoactuatethetrucks. Becauseofthis,itdidnotmakesensetoperformtestingusingourtestingrig.

Figure17:Truckangleandtiltanglefollowanalyticallyderivedrelationship

Figure18:Performingsystemtestingatasimulated5m/s.Ascanbeseen,thetruckscanturn themselveswhenthesensoristilting(simulatingaturn)

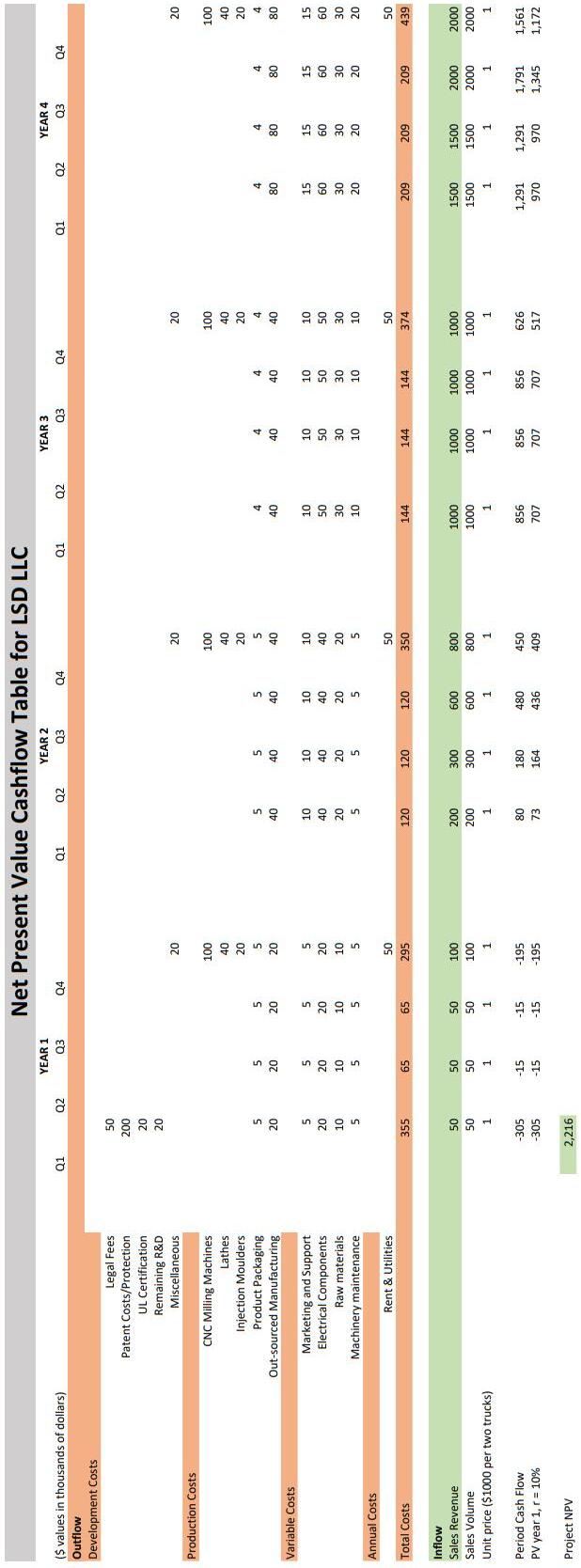

4EconomicAnalysis

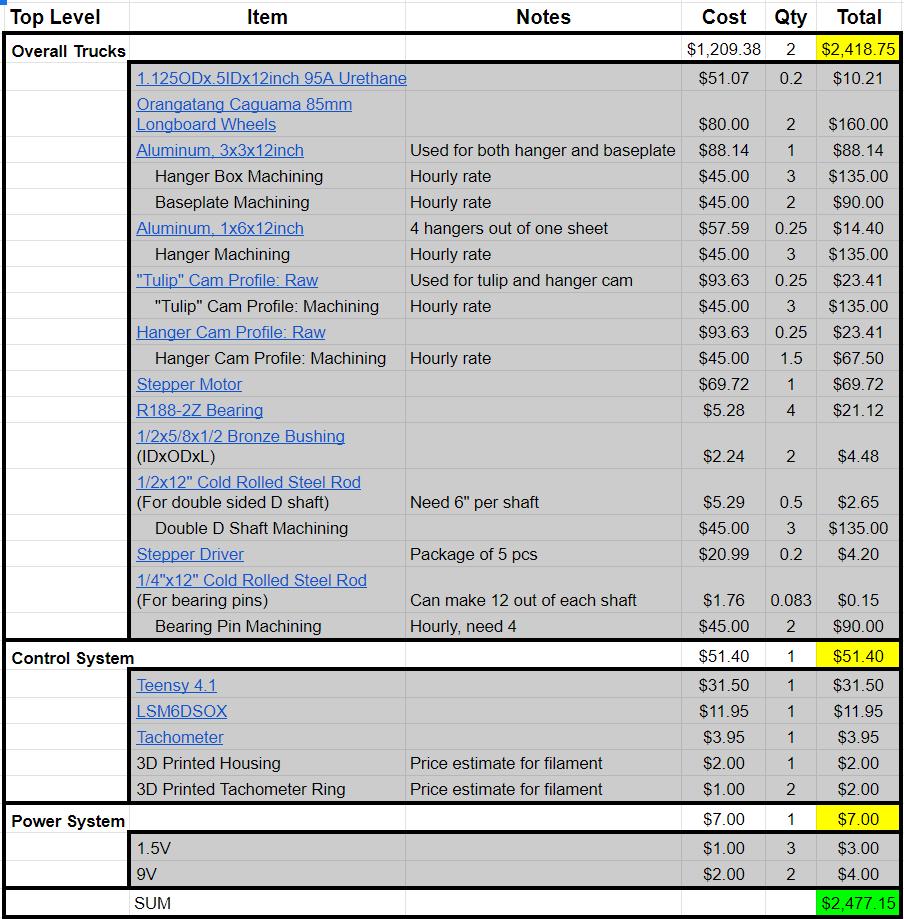

Carefulconsiderationoftheeconomicsoftheprojectisnecessarytoensureadequateplanningfor successfulproductintroductiontothemarket.FromourdiscussionswithLSDLLC,weunderstand thattheproductwillbemarketedasatruck-mountablesolutionthatcanbeattachedtoexisting boards.TheremayalsobetheoptiontocreatecompleteLSDboardswiththemountablesolution alreadyinstalled.Thepurposeofthissectionistodiscusstheeconomicsinvolvedwiththeproject andhowitalignswiththesponsor’slong-termgoals.

Tobeginwith,letusconsiderthefollowing,whichisthetotalcostofmanufacturingtheentire

truckinENGS89and90.

Figure19:ENGS89/90BOMlistincludingthecostsofthevariousmaterialsthatwentinto manufacturing

Admittedly,thetotalcostarrivedatisquitehigh.However,itisimportanttonotethatthe costfigureslistedabovearefortherawproductsthatwerecustommilledinthemachineshop.The hourswerecalculatedbasedonthetimeittookusatourexperienceleveltomaketheparts.With manufacturingprocesseslikeinjectionmolding(formorebasicparts)andmetallic3-Dprinting(for morecomplicatedpartslikethetulip),weprojectthatthelaborcosts,whichcurrentlyconstitute amajorpartofourincurredcosts,willbereducedsignificantly.We,thus,expectthemarket-ready per-truckcosttotalpricetobelowerthanthatstatedaboveifLSDstreamlinesthemanufacturing processandsupplychaintocutcosts.

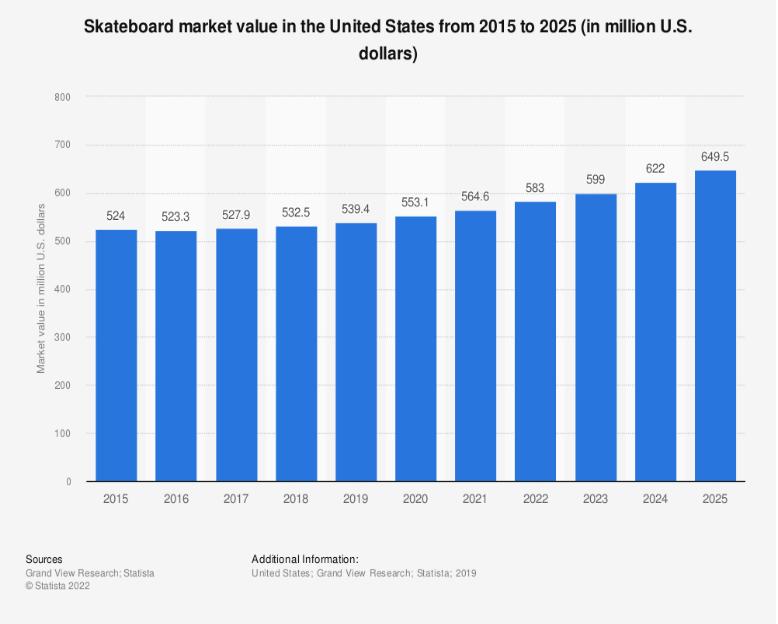

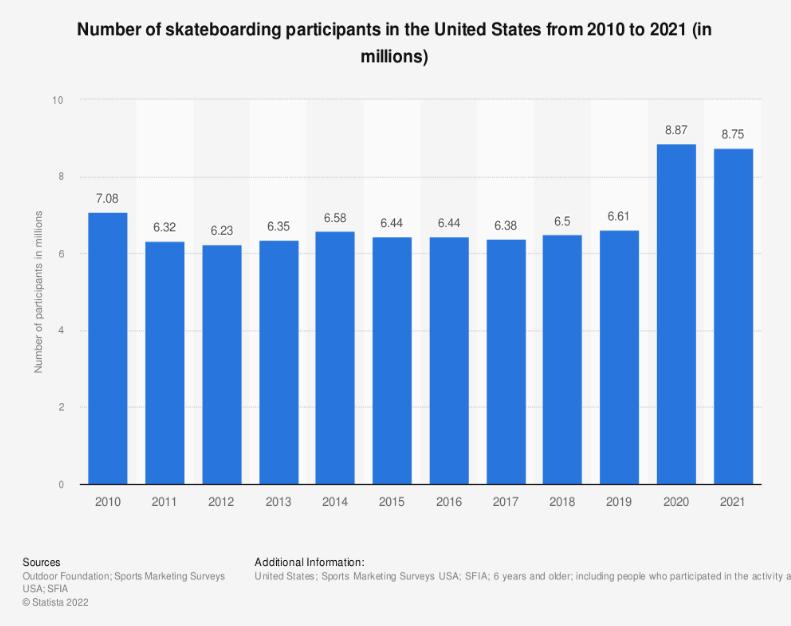

Asobservedinthetwographsabove,therehasbeenanuptrendinthevalueoftheskateboard marketintheUS.Likewise,thenumberofskateboardusersinthepastdecadehasremained relativelystable,witharecentuptickinridersinthepasttwoyears.Thisshowsthatthereisan availableandgrowingmarketthatLSDcantapinto.

Consequently,asoundproformaunderstandingofthefinancialrequirementsforlarge-scale, long-termimplementationofthedesiredproductisnecessaryforsuccessfulmarketpenetration. Ouranalysisinvolvedvariousassumptionsthattookseveralfactorslikethecostsofdevelopment,

(a)Uptrendoftheskateboardmarketvalue (b)Uptrendoftheskateboardusers

Figure20:Trendsinskateboardmarket

production,andexpansionintoaccount.Wecalculatedanetpresentvalue(NPV)ofapproximately $2millionoverafour-yearperiod,indicatingapotentiallyviablebusinessmodelforourproduct. TheNPVisafinancialmetricusedtodeterminethecurrentvalueofexpectedfuturecashflows, adjustedforthetimevalueofmoney.Thismeansthatweareabletoevaluatetheprofitabilityof ourproductbyaccountingforthefactthatmoneyreceivedinthefutureisworthlessthanmoney receivedtodayduetoinflationandtheopportunitycostofnothavingaccesstothatmoneynow.

WehaveconductedathoroughanalysisofthevaluesandfactorsthatcontributedtotheNPV calculation,whicharepresentedinAppendix G.Whileourinitialprojectoutputismodest,producingonly250samplesperyear,wehavetargetedanichehigher-endmarketsegment.Wehavekept ourprojectionsconservative,butiftheactualfinancialresultsmeetorexceedourexpectations, ourfutureyearprojectionswillbecash-flowpositiveandcontributetotheNPV.Weanticipatean initialinvestmentofabout $800thousandinstartupcapitaltofundproductdevelopment,launch, andrawmaterialprocurementtosupportproductionincaseofrevenueorderdelays.Thecostper-two-trucksisprojectedtobe $1000.Thisisareasonableestimatebasedonourprojected calculationsforastreamlinedmanufacturingprocess.Ourbreak-evenpointisprojectedtooccur withinthefirsttwotothreeyearsofoperation,afterwhichweexpecttobefullycash-flowpositive. Byyearthree,weshouldbeabletosustaingrowthandscaleupourproductionconcurrently.

Ourfinancialanalysisindicatesapromisingbusinessoutlookforourproduct.Wehavetaken acautiousapproachtoourprojections.Still,withaninitialinvestmentof $800thousandanda focusonourtargetedmarketsegment,weanticipateasuccessfullaunchandaprofitablefuture.

5RecommendationsforFutureWork

5.1TestRig

Ourbiggestsuggestionsforimprovingthefunctionalityofthetestrigareasfollows.Currently themechanismformountingthesurgicaltubingworks,butanexplorationofothertechniquesis recommended.Eitherredesigningtheattachmentpointandinteraction,orfullymovingawayfrom surgicaltubingmaybeviableoptions.Additionally,thecurrentplacementofthepullyisalittle lowerthanideal.Thisresultsinthebailroperubbingonthemaintruckforkincreasingfriction andmakingithardertoliftJerry.Changingtheheightofthepulleyorthelocationshouldbe exploredoptions.

5.2Mechanical

Generaladviceforimprovedqualityoflifeofthecurrentaluminumtruckdesignincludesreducingfrictiongenerally.Strategiesincludeaddinglithiumgreaseinareasofaluminum-aluminum rubbingandthrustbearingsoroilybronzewashersinplacesthatexplicitlyneedextendedlubrication.

5.2.1ReturntoCenterMechanism

WefeelthatdevelopingthisRTCfurtherwouldbetimewellspent.Therelativesimplicityand effectivenessofthedesignallowmuchmoreroomforexpansionoftheothermechanismstospaces closertotheboard–increasingthetiltrange.ThemainproblemswiththeRTCcanbeseparated intotwomainparts.First,thepreloading,ortighteningofthetruck,allowsforastifferRTC.This wouldbeequivalenttotighteningthebushingsonastandardtruck.Second,guidingtheTulipon theshaftandpreventingrotation.

Preloading: Preloadingisanessentialpartofcustomizingaskateboardtouserpreference.At themoment,theonlymethodofcustomizationisshimmingtheRTCbeforemountingitandthis wasusuallythemostdreadedpartofassemblingthetruck.However,stiffertrucksusuallyresulted inabetterfeel.WehavecuratedtwopotentialoptionsforcreatingandtighteningthenewRTC:

Thefirst:creatingacustomshaftcollarthatexpands.Theshaftcollarwouldworksimilarlyto a LabLift.Thecollarwouldsitontheshaftbehindtheurethaneandwouldexpandandcontract subjecttothesingleboltrunningoutofitsside.

Thesecond:Apseudo-kingpin.Thiswouldbeasleevethatfitsovertheshaftholdingthe Tulip.ThissleevewouldbebehindtheurethanewithanIDsimilartotheshaftandanODjust under3/4”.ThispinwouldhaveathreadedODthatthreadsintothebaseplateandtiltswiththe boardwhilefreelyspinningrelativetothehangerbox.Theheadofthepinwouldhaveflatsthat fitintotheslottokeepitlockedinplace.Thisisanadaptationofthe OriginalTrucks’ design thatimplementsasimilartechniquetotightenthespring.Pleasenotethatremovingtheelectrical systemwiththesuggestedimplementationwouldneedtobereworkedsuchthatthehangerrotates appropriatelytotheboard’stilt.ForpurelymechanicaltrucksthatusetherevisedRTC,reverse engineeringtheOriginalTrucksmechanismtoworkwiththecamsfromLSD’sTruckV3isneeded.

Double-DShaftAlternatives: ThedoubleDshaftholdsalotoftorqueandiscurrently madefromstainlesssteeltocombatthis.However,alternativesshouldbelookedintoasthey mayhelpreducethedeformationthatresultsfrommaxleaningandfulltorqueonthealuminum. Heavy-dutysplinedshaftsmayprovideagoodalternative.Theyareanextensionofthedesign providedbyHelixDesignwithaddedslotsandwillusuallycomewithtight-tolerancefollowers thathavemountingholesthattheTulipcanbesecuredto.Modifyingtheendsoftheshaftsto largerorsmallerdiameters,boththreadedandnotthreaded,wouldprovideversatilitytodifferent applicationsinfuturedesigns.AnotheralternativeispreventingtheTulip’srotationbysecuring ittothehangerbox.Optionsincludedirectlypinningthetulipintoaslotinthehangerbox orextendingthebottomandaddingalargeflatthatinteractswiththetopofthehangerbox andcanfreelyslideforwardandbackwardwhilepreventingrotation.Thesealternativesecuring methodseliminatetheneedforadoubleDshaftandmitigatetheconcernofdevelopingbacklash fromdeformation.However,thesuggestedpointswheretheTulipinteractswiththehangerbox arecurrentlyexposedandexcessdebriscouldresultingallingorthemechanismfailing.

5.2.2HangerActuation

Hangeractuationisoneofthemostdifficultproblemstosolveindevelopinganysortofdynamicallycontrolledtruck.Anyimplementationmustremainextremelyrobustwhilealsoresponsive. Althoughwewereabletoimplementhangerrotationwithacamprofilethatcontactstworoller bearings,itinducedseveralproblems,aslistedbelow.

1. Thecamprofilesaredifficulttodesign,machine,andmaintain.

2. Therewasasignificantamountofbacklashpresent.Itisdifficulttoperfectlyengagethecam profileupagainsttherollerbearingswithouthavinganybacklashpresent.

3. Torquetransferisnotidealduetoahighdegreeoffrictionbeingpresent.Significantgrinding waspresentonboththetulipandhangercam.

4. Thecamtakesuparelativelylargeamountofspace,whichprovedparticularlydifficultto workwithgiventhehangerbox’ssizingneedstohavesufficientgroundclearance.

Forthesereasons,werecommendpivotingawayfromacam-basedactuationsystemtoanother system.Thiscouldbelikeabevelgearsystemwithamotormountedinasimilarlocationbutwith ahigh-reductiongearbox.Overall,moretimecouldbespenttestingarobustactuationmechanism thatisalsofastandaccurate.

Italsomayprovebeneficialtomoveawayfromsteppermotorsandimplementadesignusing amorepowerfulmotor.Steppermotorsaregreatforhighpositionalaccuracy,buthightorqueis neededtomaintainhangerangle.AservomotororanormalDCmotorwithanencodermayprove moreeffectiveatchangingthehangerangleunderload.

Additionally,itmaybenecessarytointroduceagearboxtothedesigntoachievethelevelof torqueneededtoturnthehangers.Apotentiallow-profileoptionforthisisaplanetarygearbox duetoitshighreductionswithminimalreductionstages.

5.3Electrical

Withboththetestrigandsystemelectricaldesign,allthesensorsareselectedtobedurablein roughenvironments,buttheyarestillpronetofailure.Onewayelectricalfailurescanbeavoidedis toaddredundantsensors.Thiswouldallowforfaultdetectionandpreventsinglepointsoffailure.

Additionally,ourelectricalboardsaresolderedonaperforatedbreadboard.Whilethisisfine forprototyping,itcancomeundonemoreeasilythanaPCBdesignandtakesmuchlongerto manufacture.Therefore,itmaybemoreadvantageoustohaveaPCBforabetter,moresecure circuitboard.

5.3.1OneBatterywithVoltageConversion

Currently,ourpowersourcesareseparatedintoa4.5Vbattery(3SAAbatteries)andan18V battery(2S9Vbatteries).However,wecanredesignusingonlyonevoltagesourcewithappropriate voltageregulators.Forasolutionwithouttheintegratedskateboardbatteries,wecanusean18V batterywithbuckconvertersthatdropthevoltageto4.5VtosafelypowerTeensy4.1andother sensorswhileallowingthe18Vsourcetodrivethemotors.Forasolutiononanelectricskateboard, aladderconfigurationofvoltagedroppers(to18Vandto4.5V)mayberequiredastheelectric skateboardbatteriesareusuallymuchhighervoltagethan18V.

Additionally,whenselectingbuckconverters,itwouldbewisetohavethembeautomotivegradesotheycanbeshieldedfromnearbyhigh-frequencyswitchingcausedbytheTeensy4.1or anyMCU.

5.4Controls

RecommendedimprovementstothecontrolsystemincludemodifyingtheExtendedKalman Filtertoincludecentripetalaccelerationanddevelopingamoreadvancedmotorcontrollerfor improvedperformance.

5.4.1ExtendedKalmanFilterImprovements

AsdiscussedinSection 3.5.1,oursensorusesthemeasuredgravitationalaccelerationvectoras oneofthemeasurementstodeterminetheleanangleofoursystem.Inastaticenvironmentor whenmovingatlowspeeds,thisisareasonableapproximation.However,asspeedincreases,other accelerationsareexperiencedbytheboard,mostnotablycentripetalacceleration.Toaccountfor this,onewouldhavetomodifytheaccelerationequationtoincludetheseeffects.Thecentripetal accelerationvectorwouldhaveamagnitudeof v2 /r andwouldbepointingtothecenteroftheturn (Figure 21).Thespeedoftheboardismeasured,andtheturningradiuscanbederivedthrough invertingEquation 17 andusingtheanglesofthetrucks.

Figure21:Centripetalaccelerationexperiencedbythesystem.Accelerationisnotinthebody frameorinertialframe,soanewframeisneeded.Thetransformationfromprimetobodyframe isarollaboutthex-axisbythetiltangle ϕ.

Becausethisvectorisneitherintheinertialnorbodyframe,onewouldneedtoperformthe propertransformation(rotationof ϕ aboutthex-axis)todescribetheaccelerationinbodyframe coordinates.ThisupdatedformoftheaccelerationmeasurementequationscanbeseeninEquation 18,where ag isthegravitationalaccelerationdescribedinEquation 10.

WhilethisdoesincreasethecomplexityofimplementingtheEKF,itcouldleadtoincreasesin filterperformance,especiallyinhigh-speeddynamicenvironments.

5.4.2MotorControllerImprovements

Currently,thesystemusesasimpleproportionalcontrollertoconvertthetruckangleerror signaltomotorcontrolsignals.Weintentionallyimplementedasimplecontrollerasitwould requirelesstimetogetworking,andwefeltthattheperformancetradeoffswereworthitfor thisinitialprototype.Additionally,becauseweusedsteppermotors,thesignalswesenttothe motorwerethenumberofstepstotake.Wecouldnotaffectthespeedofthesteps,meaningthat addingmoreadvancedmotorcontrollerswouldnothavemadesenseforourchoiceofmotor.As wehighlightedinSection 5.2.2,steppermotorsarenotthebestchoiceforthisproject.Instead, somethinglikeaservomotororDCmotorshouldbeusedastheyoffersignificantlymoretorque. Thesemotors,however,requiremoreadvancedcontrolschemes,meaningthatfutureteamswould havetoimplementaPDorPIDmotorcontrollertogetthedesiredperformanceoutofthemotors.

5.5PotentialFuture89/90Projects

WebelievethatthereareacoupleofavenuesforfutureENGS89/90projectsthatcontinue theworkwehavedone.Theyareacompleteredesignofthetrucksandthecreationofamore sophisticatedelectronicssystem.

5.5.1Trucks

Oneofthemainfocusesofourprojectwasthecreationofskateboardtrucksthatachieve3 mainobjectives:decouplingleaningandsteering,allowingforlargertiltranges,andelectronic actuationoftheskateboardtruck.However,becauseourprojecthadsomanydifferenttasks,we couldnotdedicateenoughtimetocreateafullyfleshed-out,sleekdesign.AnENGS89/90group couldbetaskedwithoverhaulingthemechanicaldesignofthetrucks.Thiswouldentaildesignfor manufacture,aswellasthedevelopmentofanovelactuationmethodthatcanprovidethehigh torquesnecessarywhileremainingresponsiveandrobustdamagescausedbysandandwateronthe road.Thisprojectwouldbemostlymechanicalinnature,however,acursoryknowledgeofcontrol theorywouldbebeneficialasmotorcontrollersmaybeneededdependingonthegroup’smotor selection.

5.5.2Electronics

Theothermainfocusofourprojectinvolvedthecreationofanelectricalsystemthathandled sensingdatafromthesystemandprocessingthatdata.Asthiswasthemainfocusoftheproject, aspectssuchaspoweringthesystemandPCBdesignwereneglected.Agroupcouldbetasked withupdatingtheelectricalsystemtousealargebatterywithvoltageconversionformotorsand sensors,useredundantsensorswithfaultdetectionalgorithmstoincreasetherobustnessofthe system,andcreatePCBdesignstobetterhousealloftheelectricalcomponentsofthesystem. AteamforthisprojectwouldconsistofmostlyElectricalEngineersandComputerScientists/ ComputerEngineers.

AReferences References

[1] J.Fox, Dampingsystemforskateboards,en,Jun.2014.[Online].Available: https://patents. google.com/patent/US8752849B1/en?q=speed+wobble+skateboards&oq=speed+wobble+ skateboards

[2] M.Burrows,C.Burd,andB.McKenzie,“CommutingbyPublicTransportationintheUnited States:2019,”en,p.11,[Online].Available: https://www.census.gov/content/dam/ Census/library/publications/2021/acs/acs-48.pdf

[3] D.Rajewski, Turnvs.lean:Dialingintheperfectlongboardset-up,en,2017.[Online].Available: https://stokedrideshop.com/blogs/stoked-school/turn-vs-lean-dialing-in-theperfect-longboard-set-up