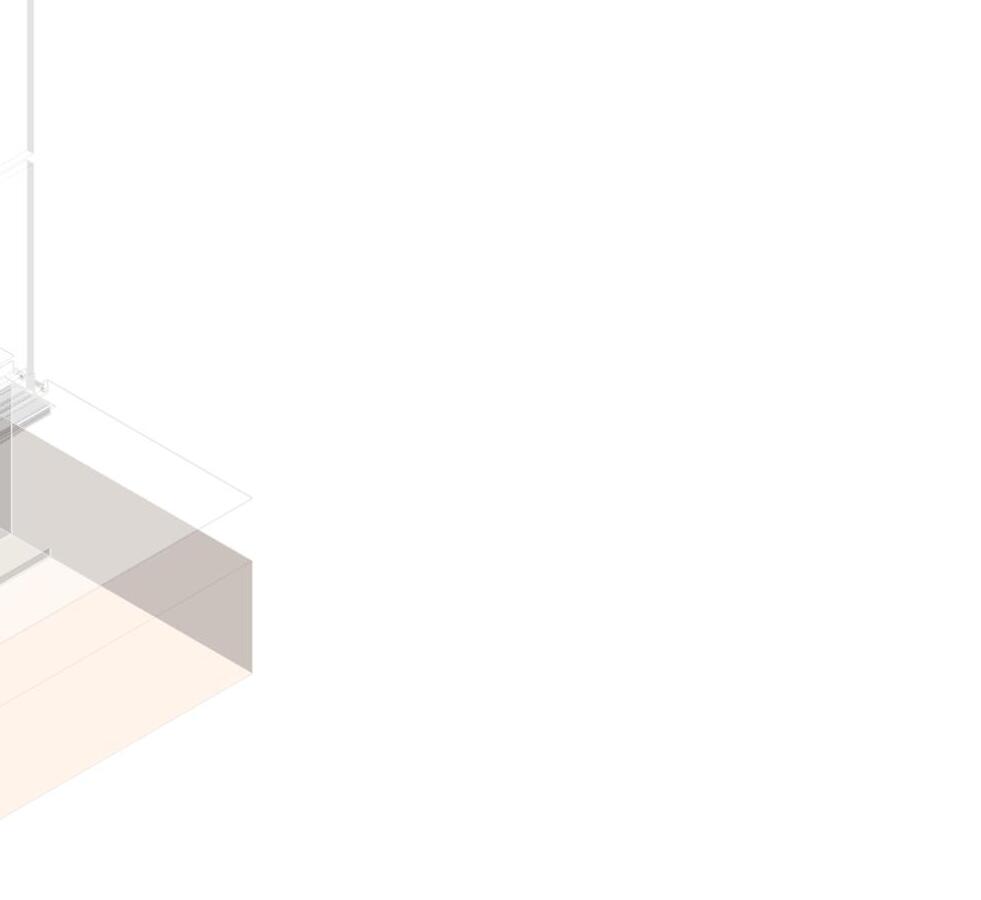

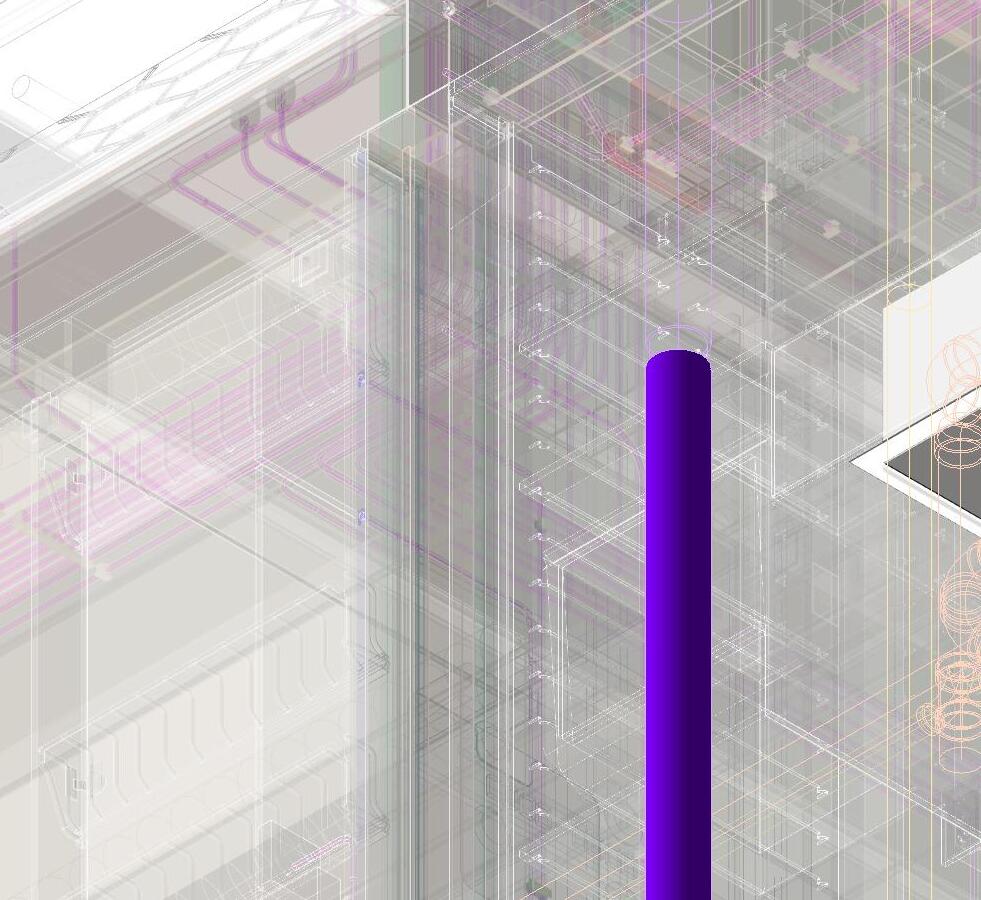

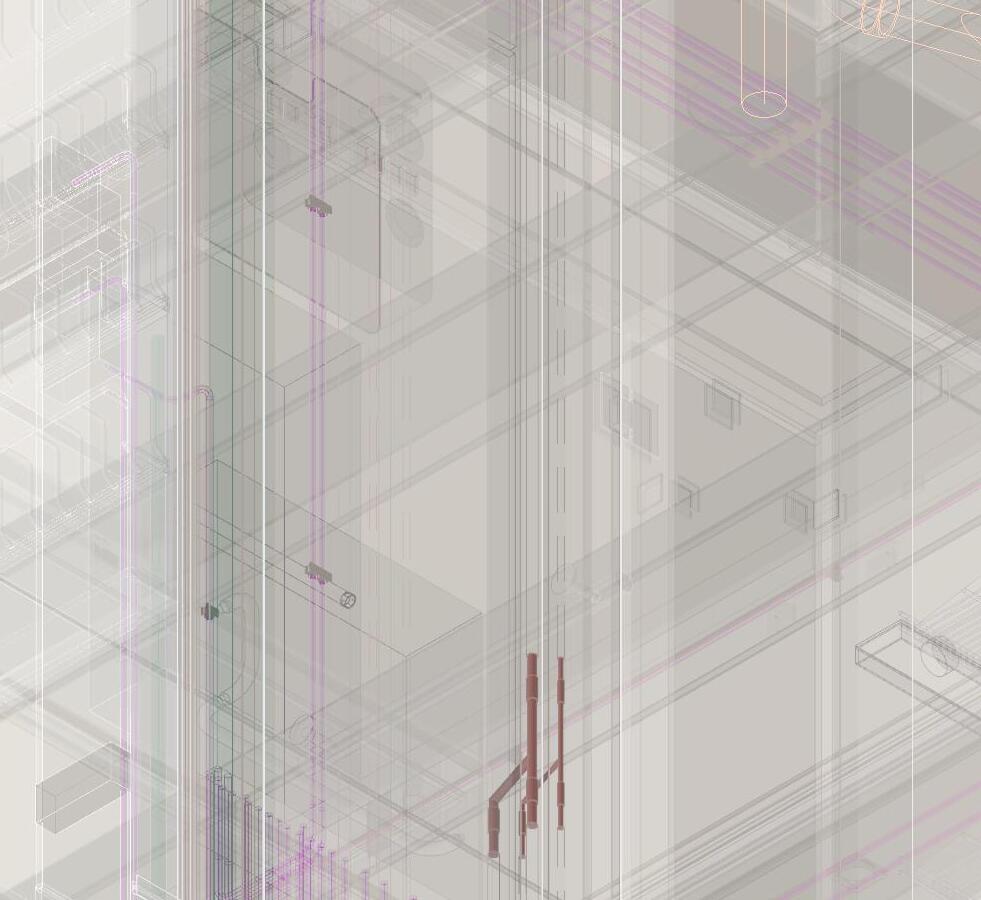

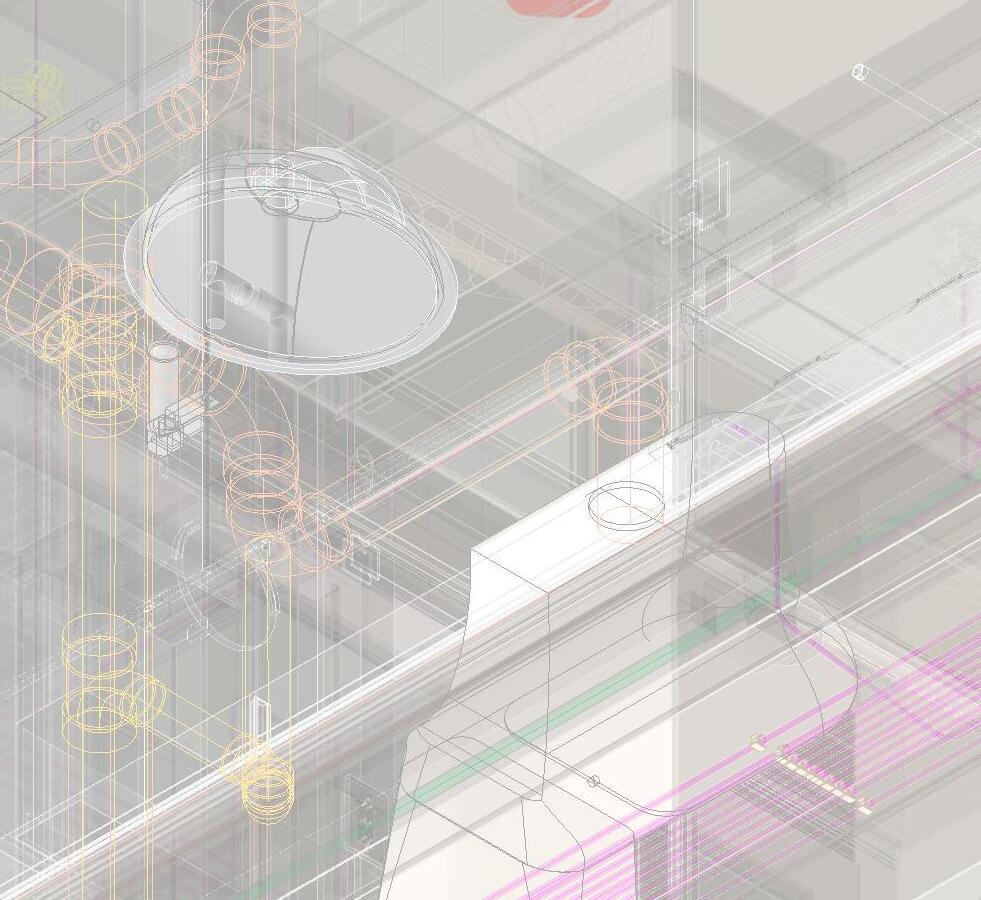

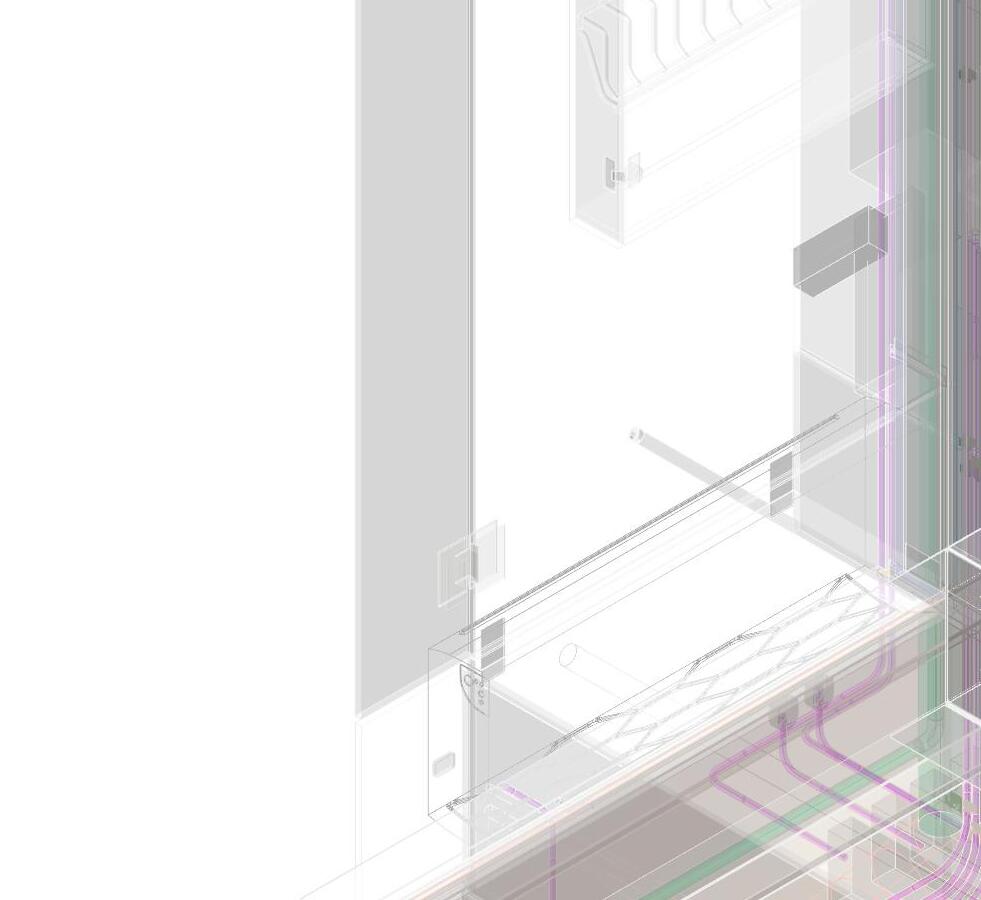

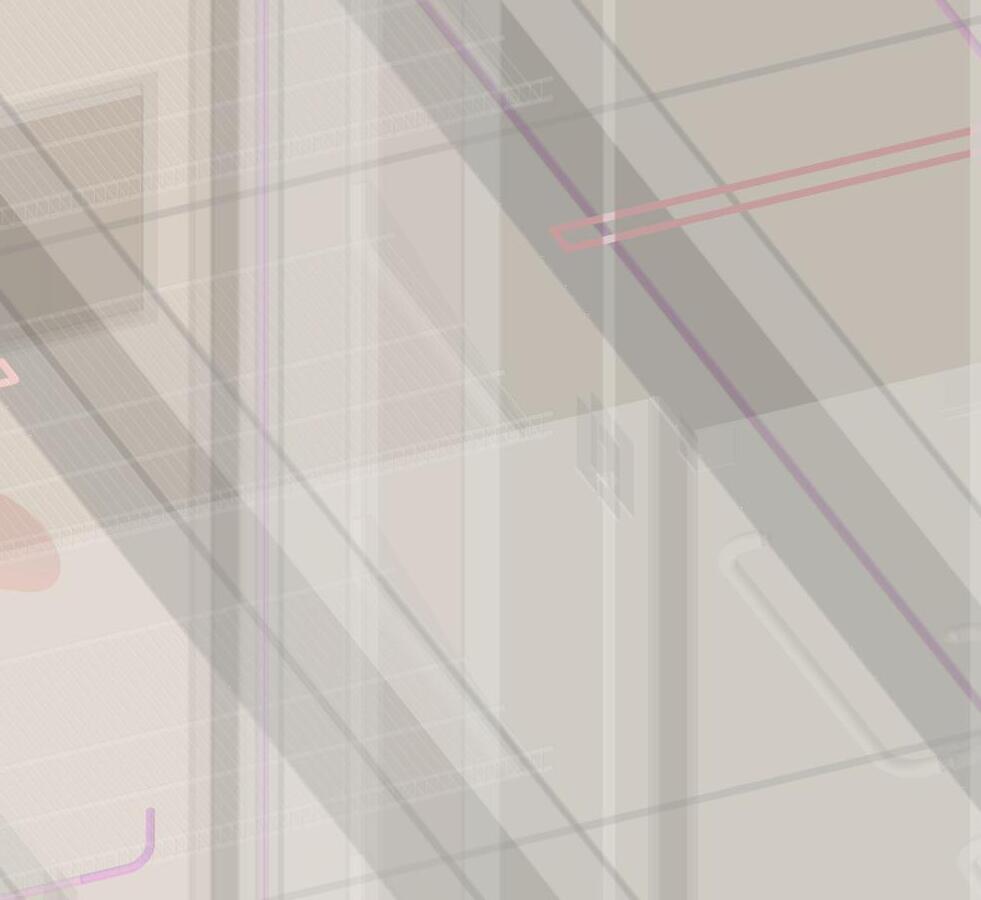

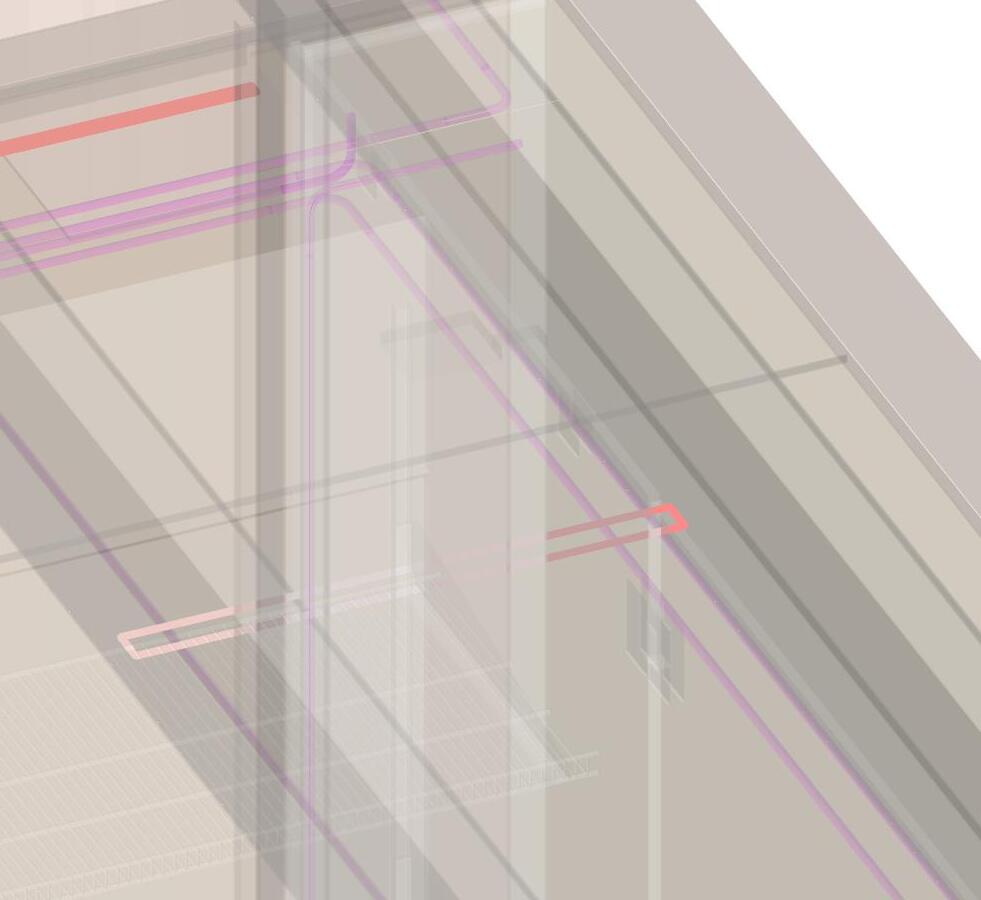

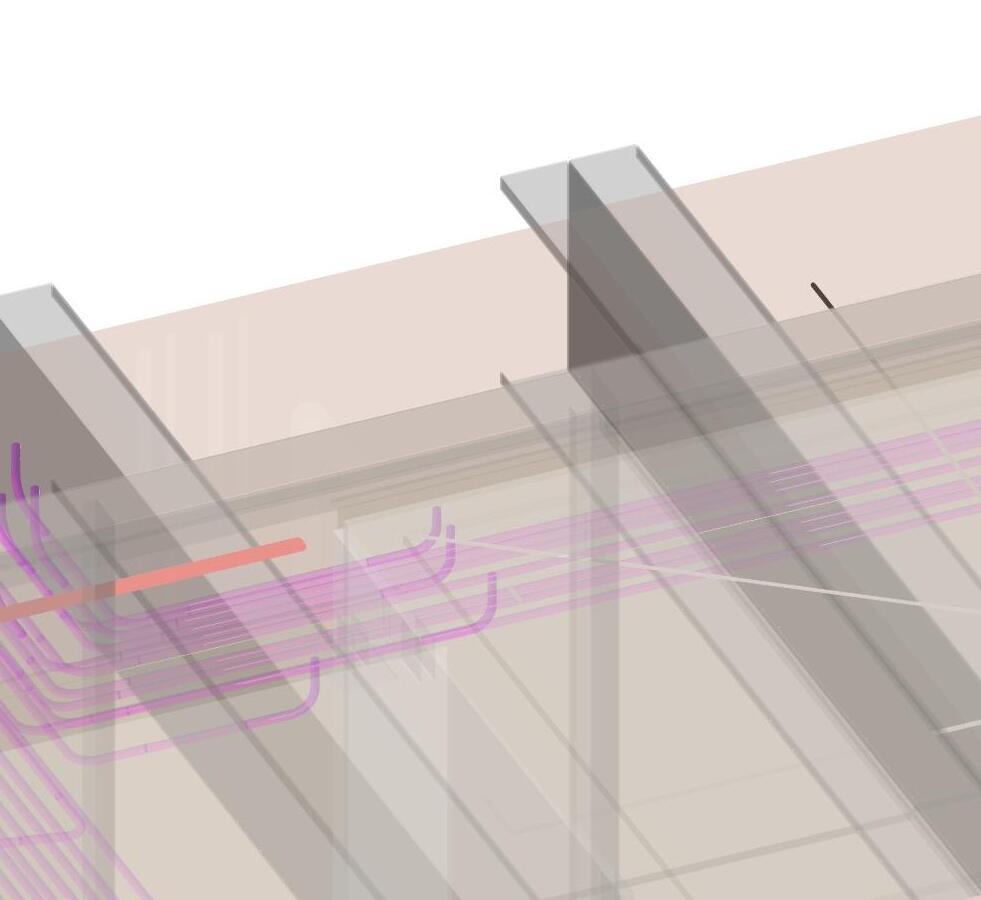

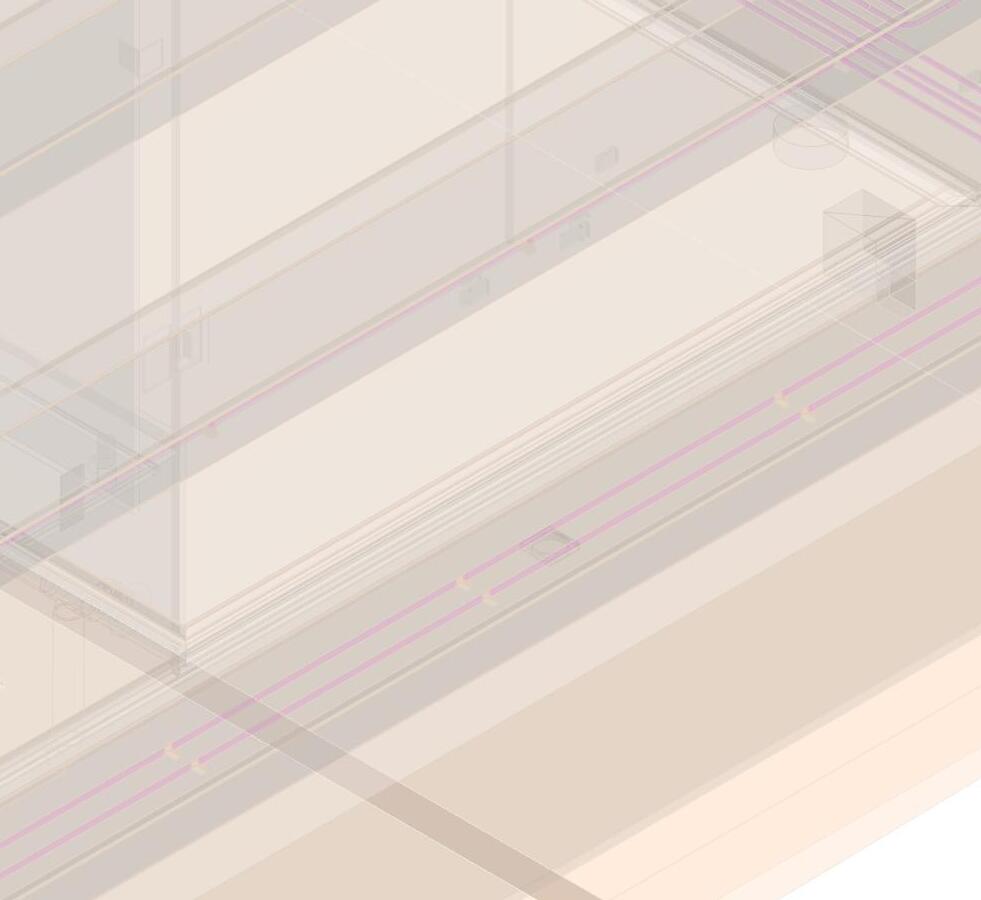

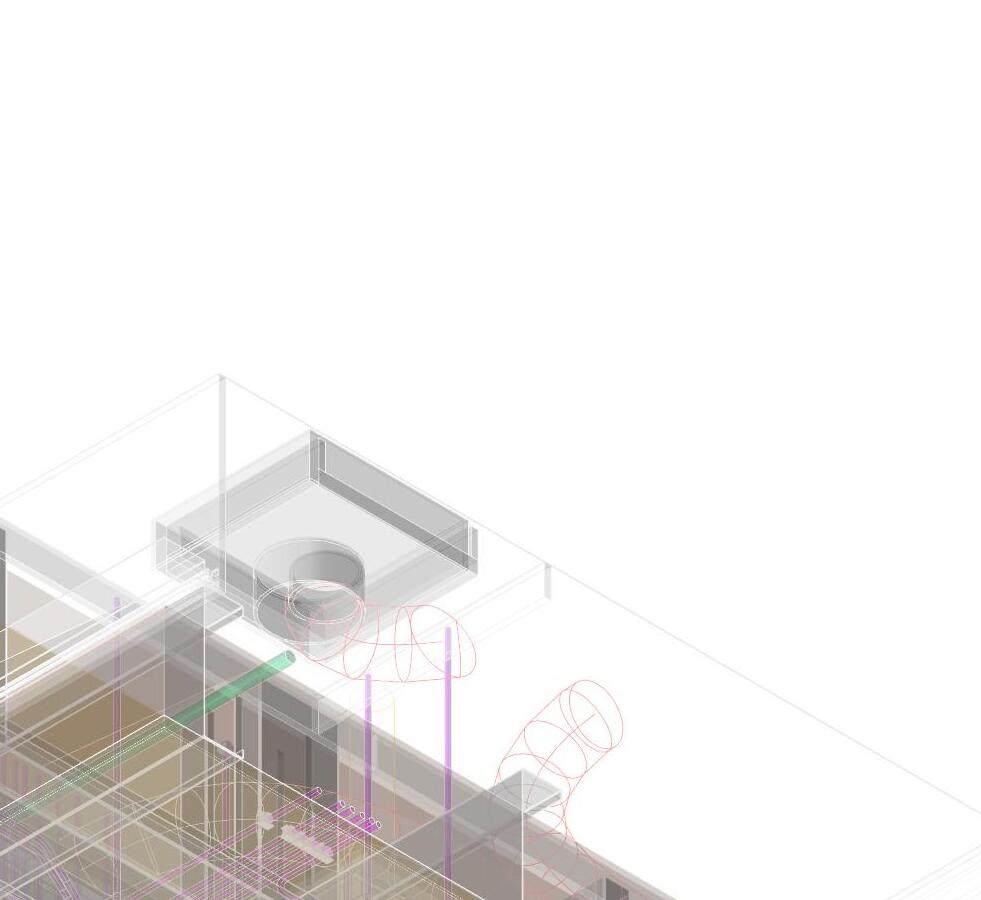

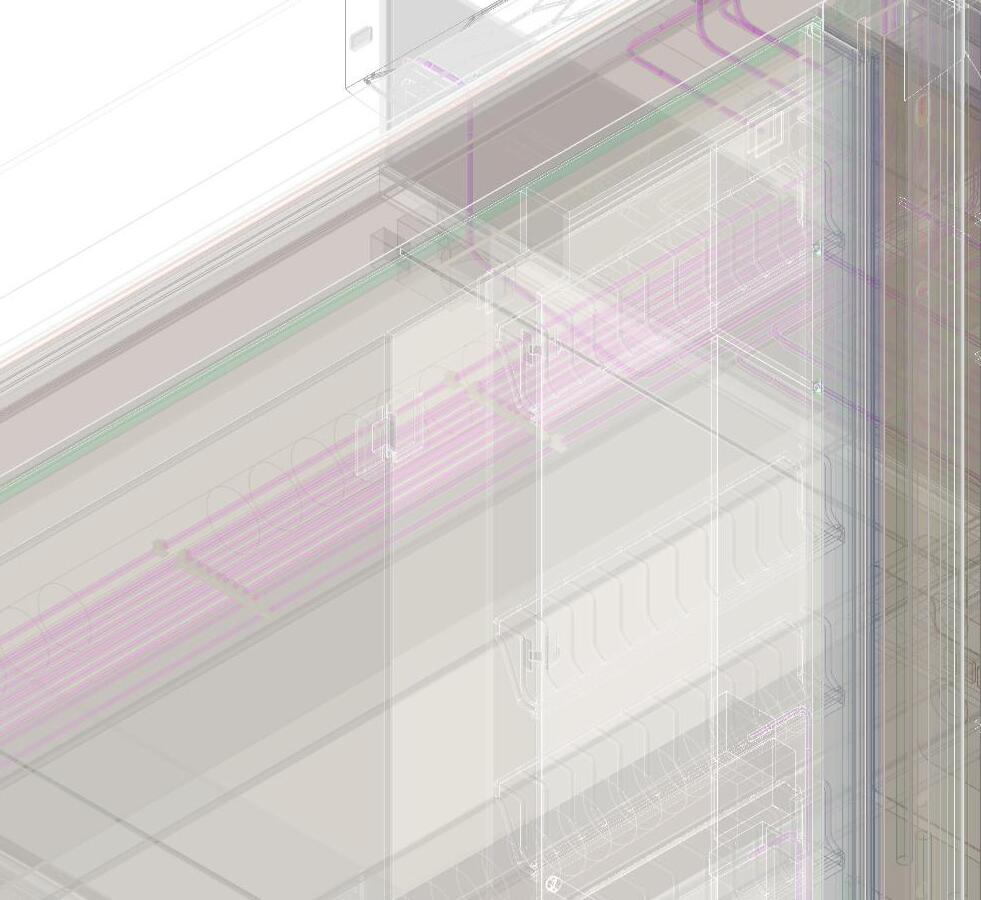

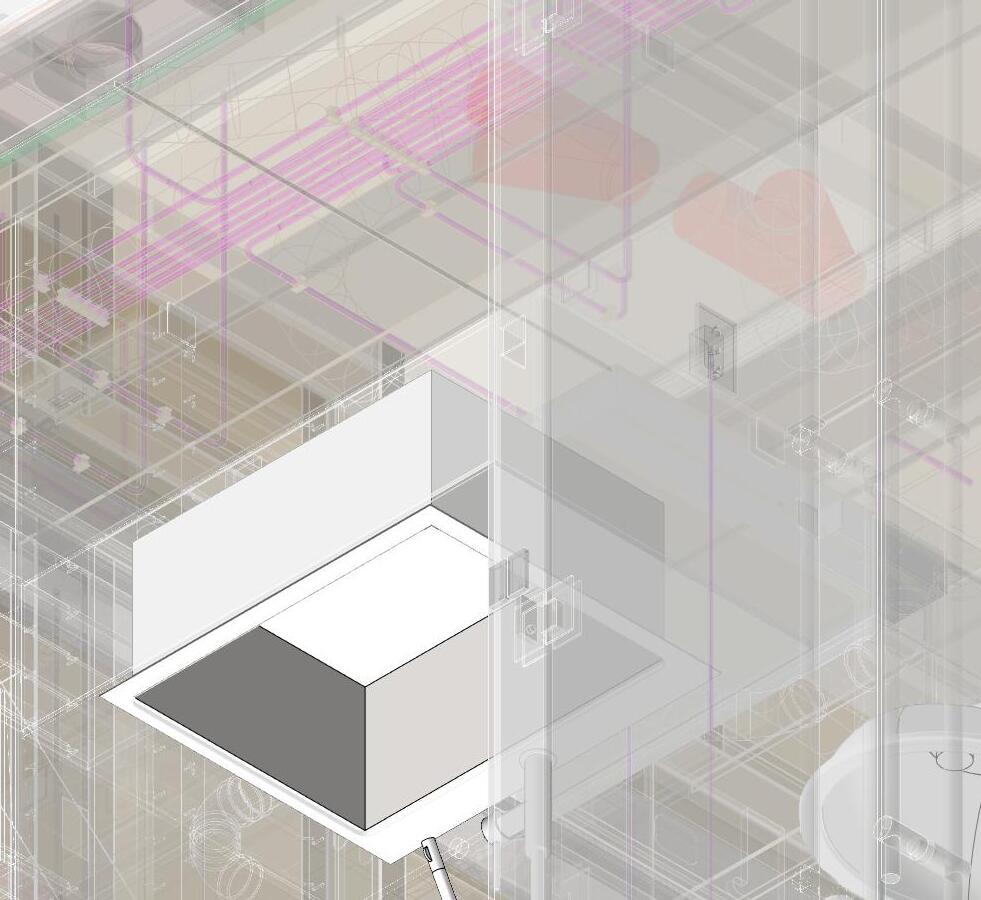

VESSEL INSTALLTION MANUAL ONE BEDROOM UNIT PLUMBING

32"122 3/8"

15/16"

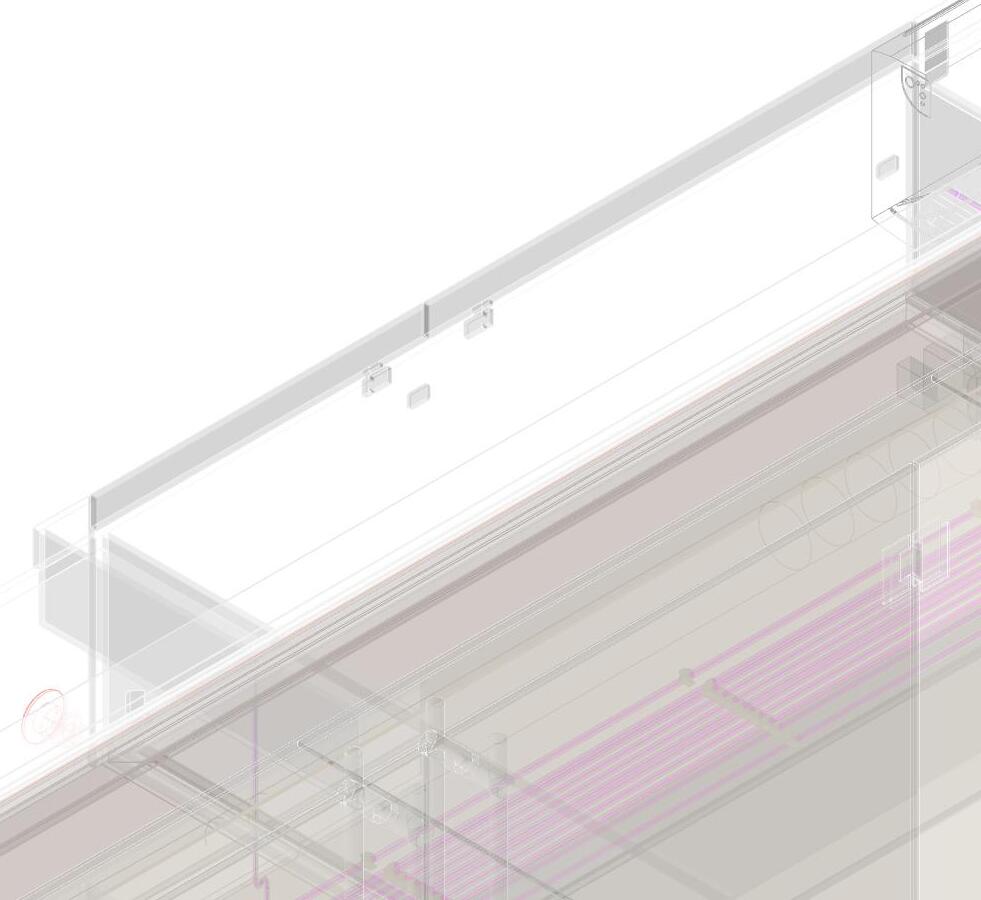

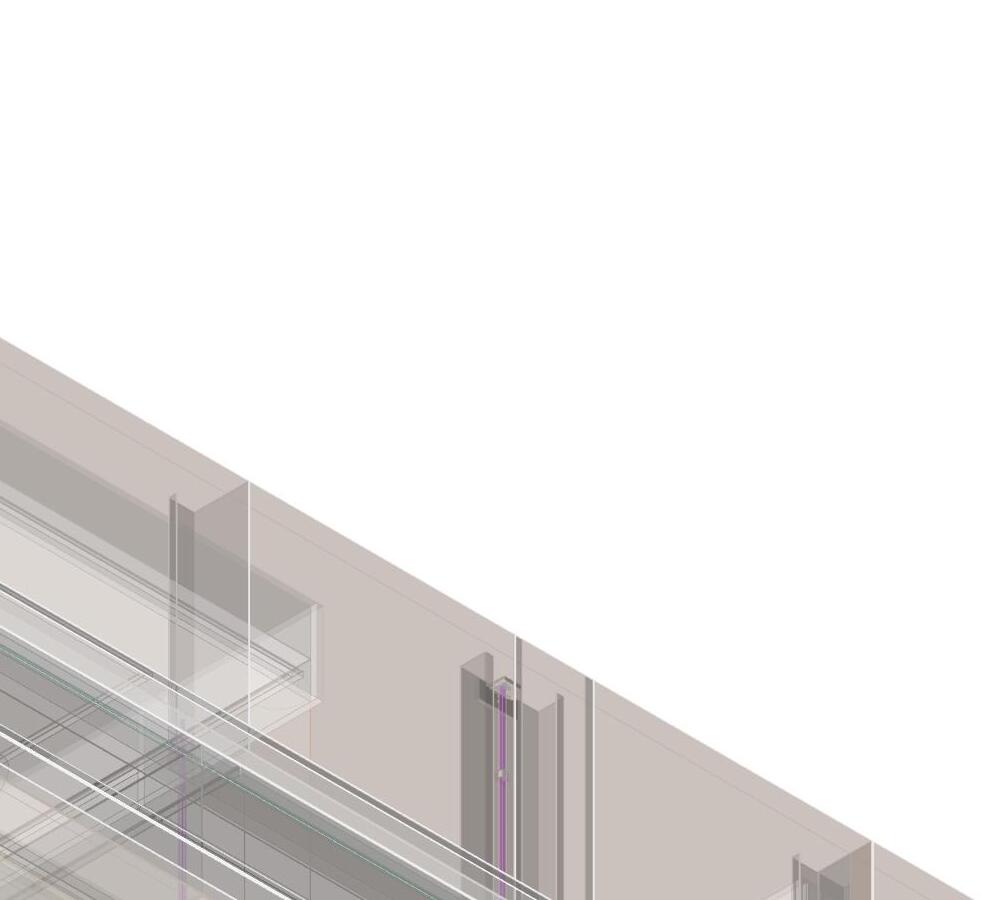

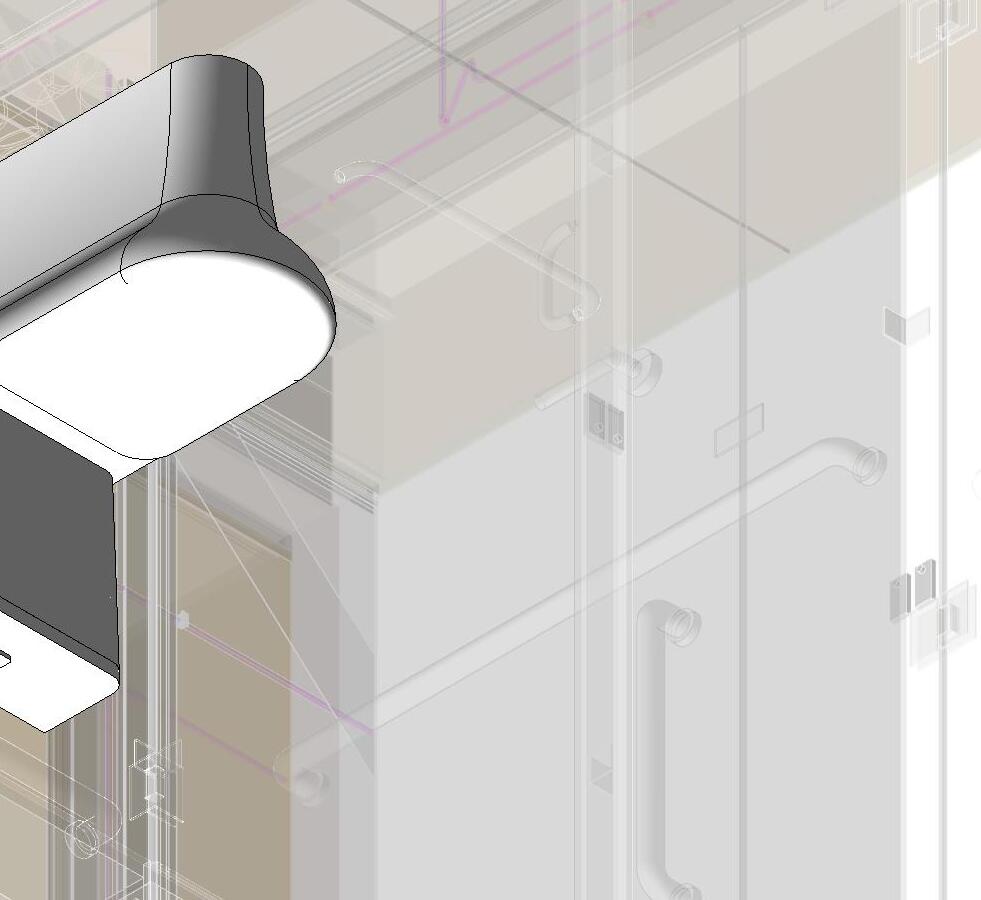

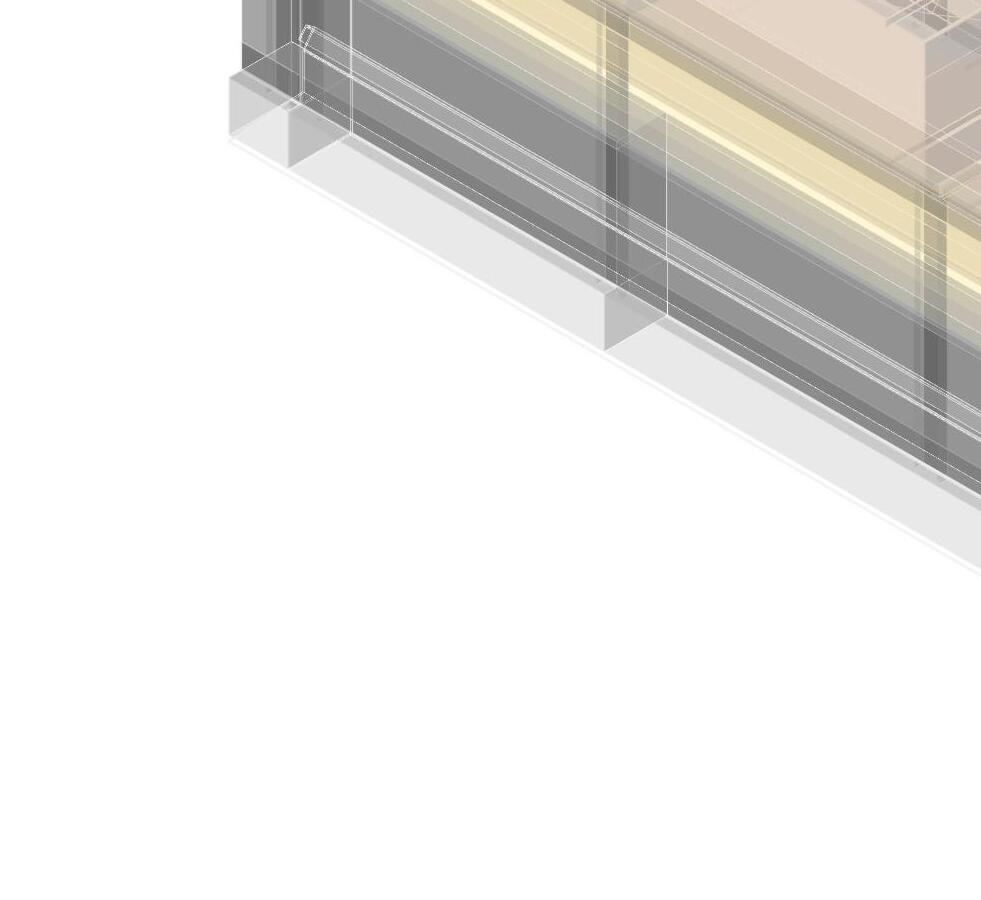

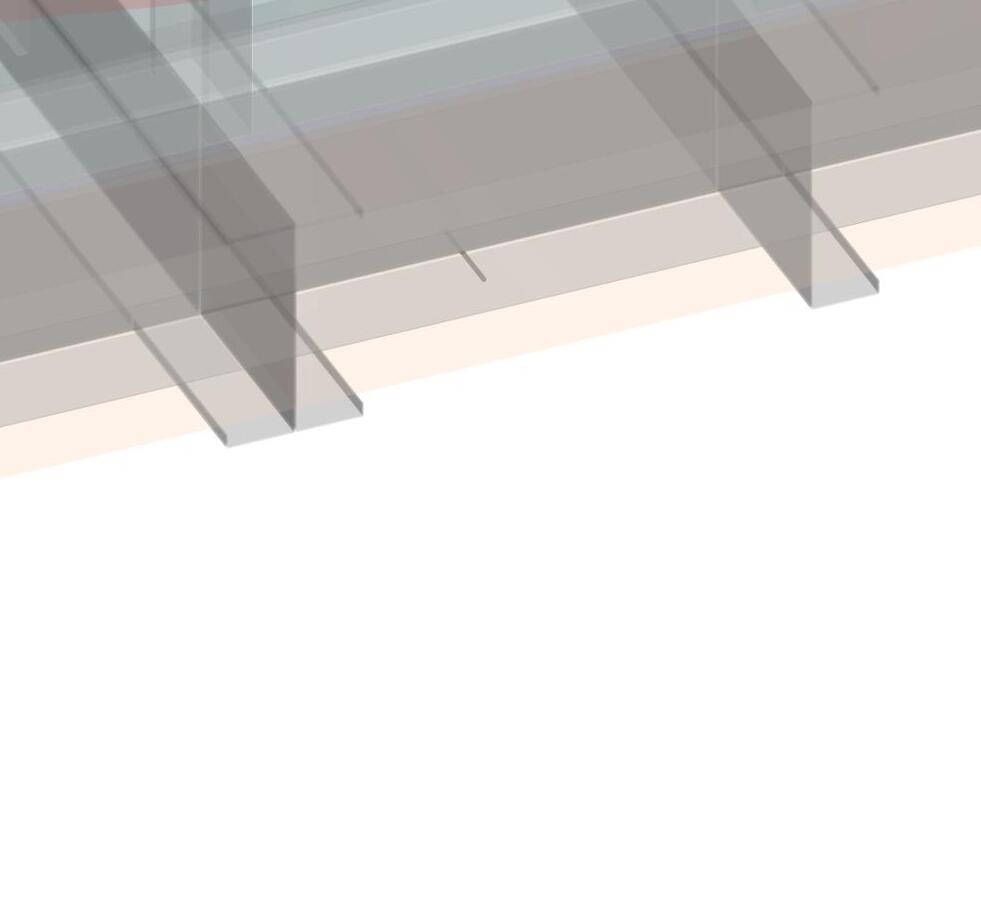

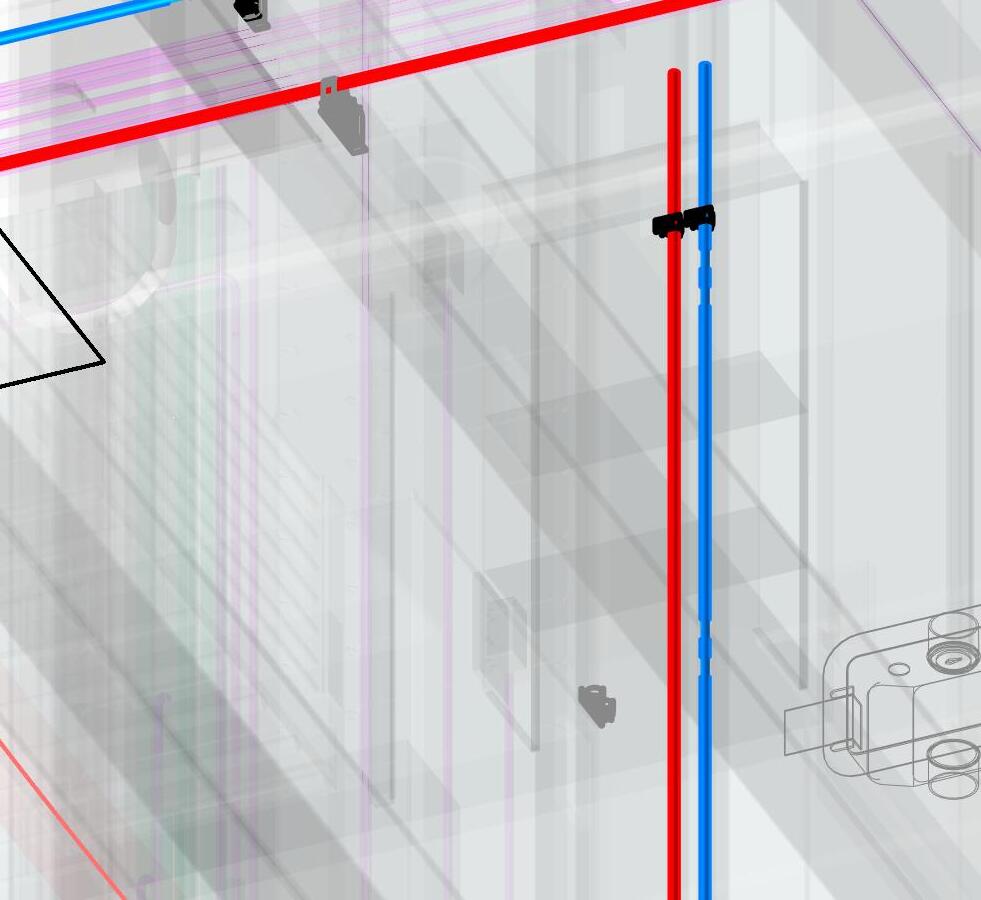

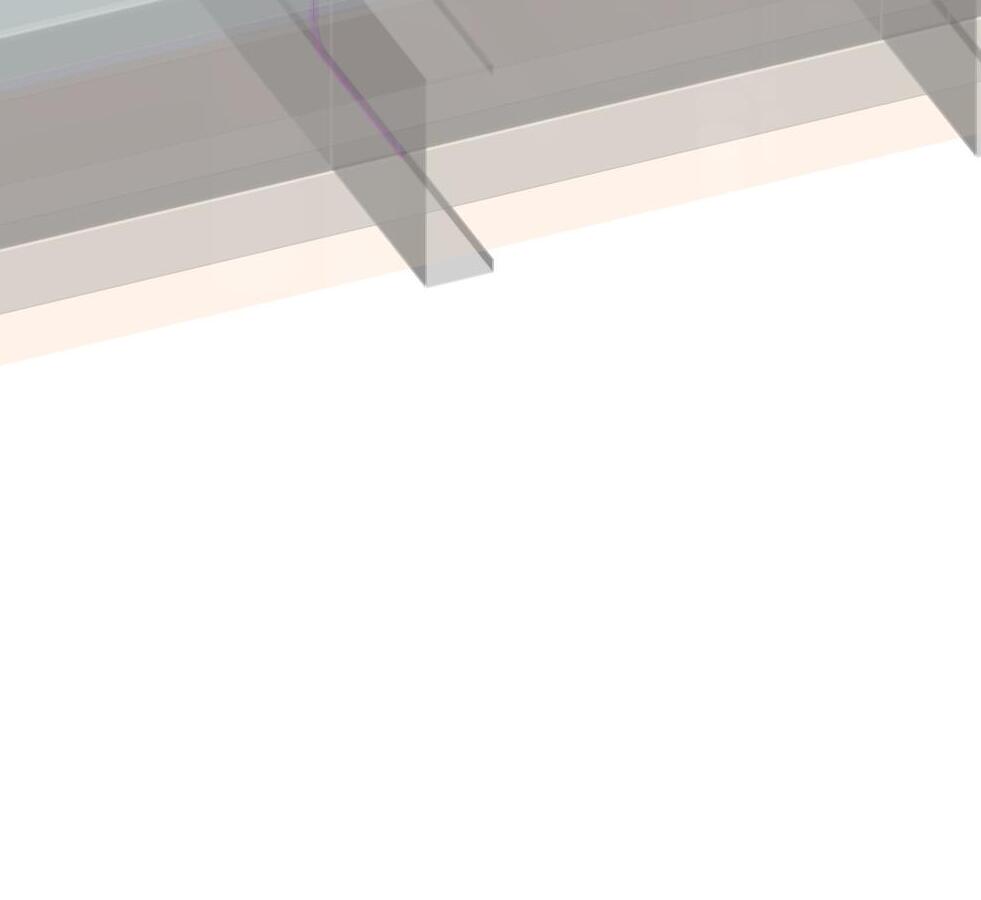

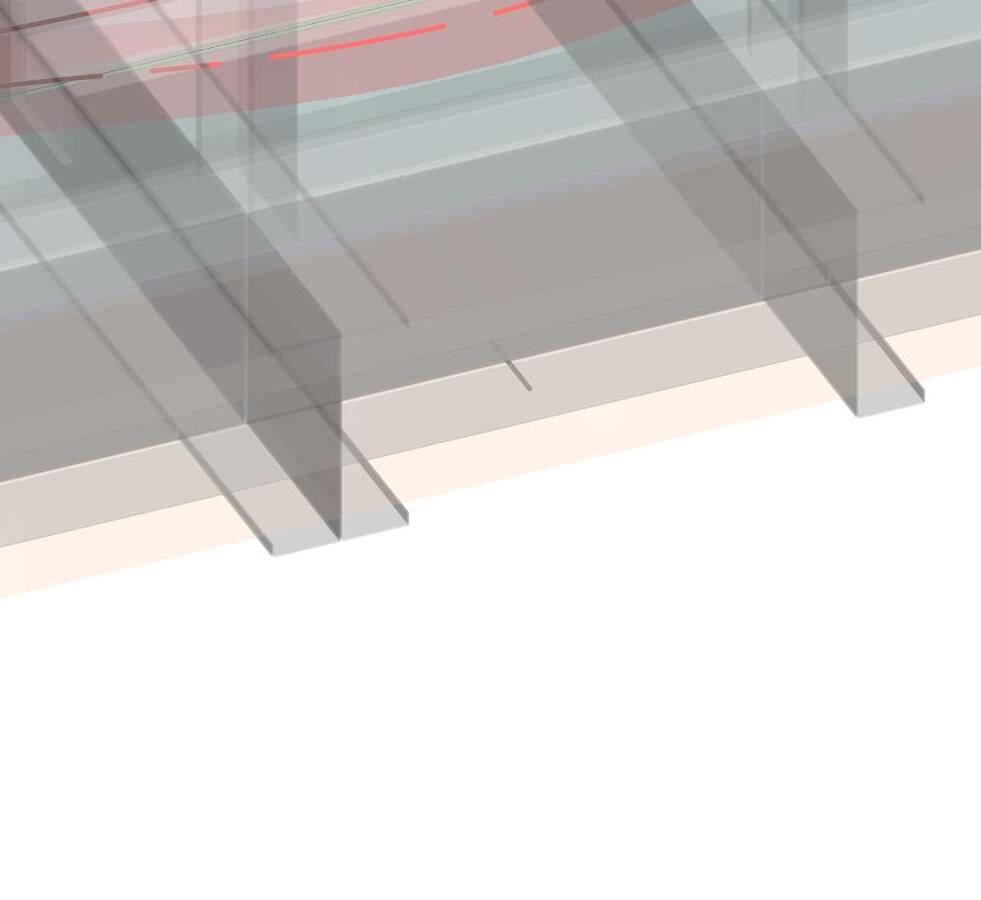

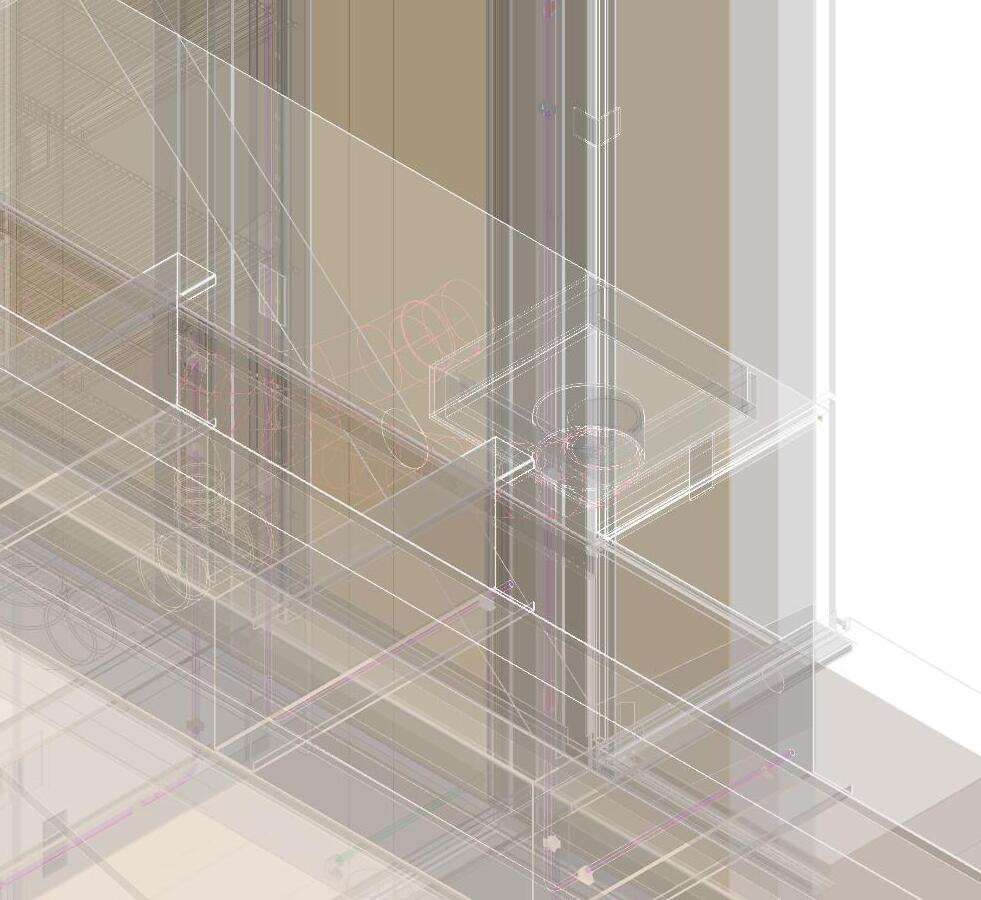

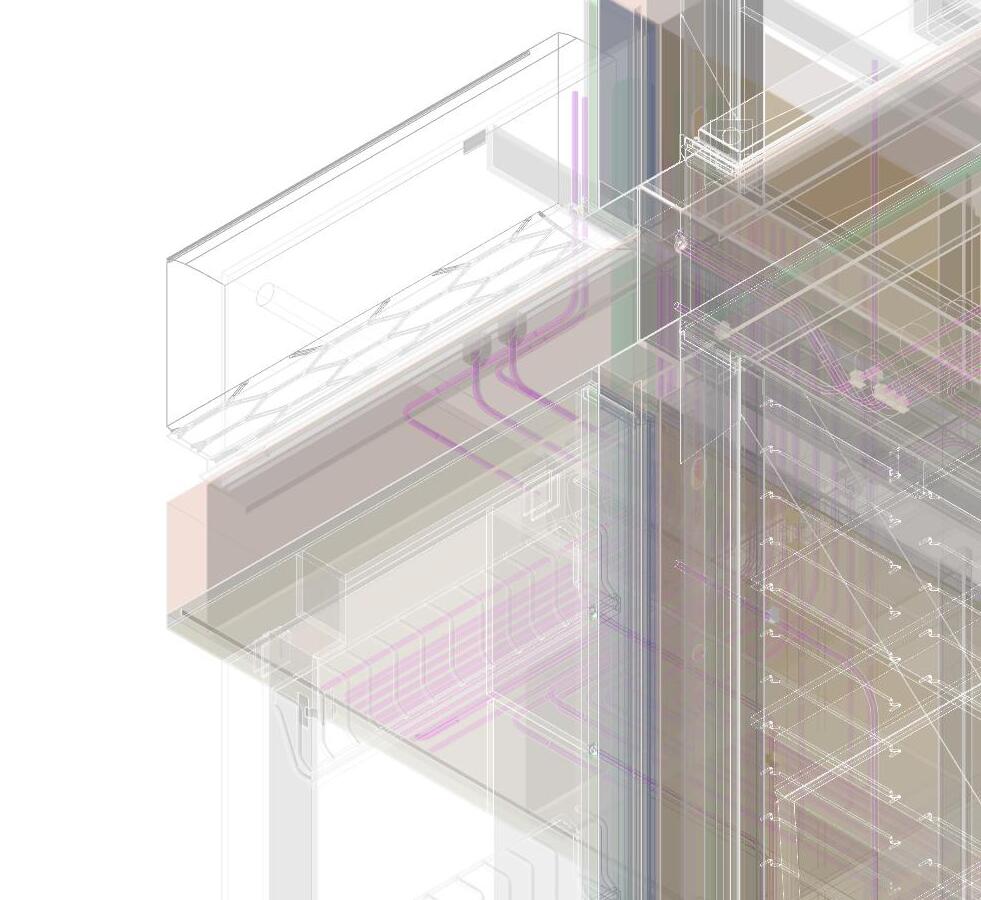

WALL MOUNTED UNISTRUCT

PRE CUT AND KITTED PARTS FOR UNISTRUT HANGER INSTALLATION

(6) 32" 1/2"X1-1/2" UNISTRUT

(12) #8x1-1/4" HEX DRIVE DRYWALL SCREW, 3/8" WASHER

(4) #8x1" HEX DRIVE SELF TAPPING SCREW, 3/8" WASHER

(1) DEAD MAN MEASURING GUIDE

(1) 1/4" HEX DRIVE BIT

1 LABORER

30 MIN PER APARTMENT

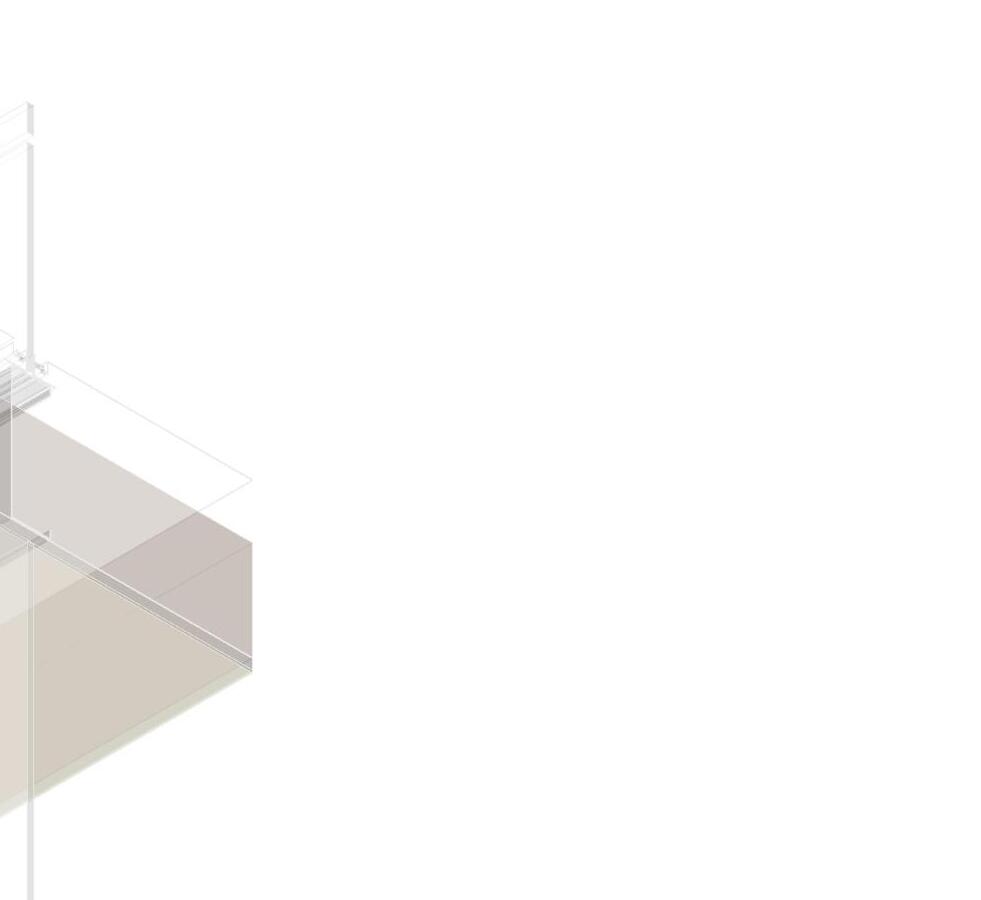

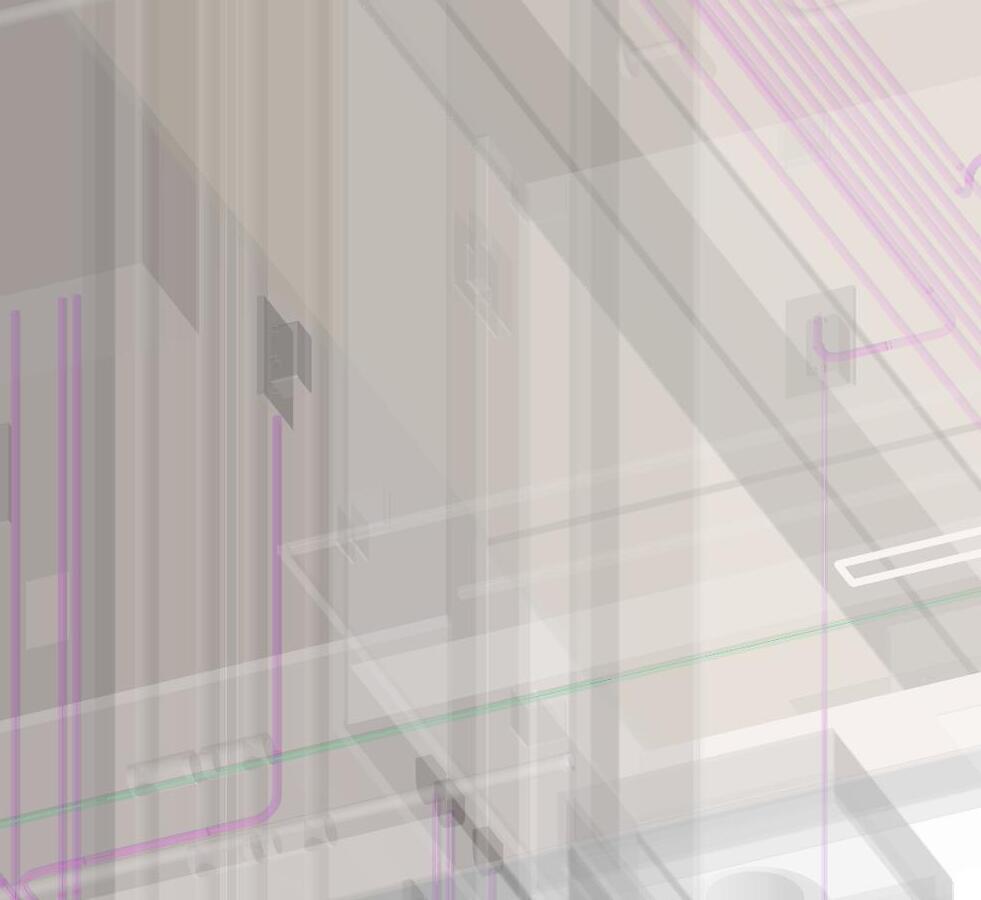

STEP 1: USING THE LASER MEASURING TOOL FROM THE PROVIDED ASSEMBLY KIT, MEASURE 182-3/8" FROM THE FACE OF STUD ON THE WINDOW WALL, NON WINDOW SIDE. MARK LINE ON FLOOR.

STEP 2: TAKE THE DEAD MAN (Z) AND PLACE VERTICALLY AGAINST THE WALL AT THE 182-3/8" MARK FROM STEP 1. MARK THE WALL AT THE TOP OF THE DEAD MAN.

STEP 3: ALIGN THE 32" LENGTH OF UNISTRUT (A) HORIZONTALLY AGAINST THE WALL WITH THE MARKS FROM STEP 1 & 2.

STEP 4: FASTEN IN PLACE WITH (2) #8 SELF TAPPING SCREWS AND WASHERS - ONE AT EACH PLACE THE STRUT INTERSECTS A STUD

STEP 5: TAKE THE DEAD MAN (Z) AND PLACE VERTICALLY AGAINST THE WALL AT THE END OF UNISTRUT 1 (A) FROM STEP 3. MARK THE WALL AT THE TOP OF THE DEAD MAN.

STEP 6: ALIGN THE 32" LENGTH OF UNISTRUT 2 (A) HORIZONTALLY AGAINST THE WALL WITH THE MARKS FROM STEP 1 & 2

STEP 7:FASTEN IN PLACE WITH (2) #8 SELF TAPPING HEX DRIVER SCREWS AND WASHERS - ONE AT EACH PLACE THE STRUT INTERSECTS A STUD

STEP 8: USING THE LASER MEASURING TOOL FROM THE PROVIDED ASSEMBLY KIT, MEASURE 122-3/8" FROM THE FACE OF STUD ON THE WINDOW WALL, WINDOW SIDE. MARK LINE ON FLOOR.

STEP 9:TAKE THE DEAD MAN (Z) AND PLACE VERTICALLY AGAINST THE WALL AT THE 122-3/8" MARK FROM STEP 8. MARK THE WALL AT THE TOP OF THE DEAD MAN.

STEP 10: ALIGN THE 32" LENGTH OF UNISTRUT (A) HORIZONTALLY AGAINST THE WALL WITH THE MARKS FROM STEP 8 & 9.

STEP 11: FASTEN IN PLACE WITH (3) #8 DRYWALL HEX DRIVE SCREWS AND WASHERS - ONE AT EACH END AND ONCE IN THE CENTER OF THE UNISTRUT LENGTH

STEP 12: TAKE THE DEAD MAN (Z) AND PLACE VERTICALLY AGAINST THE WALL AT THE END OF UNISTRUT 3 (A) FROM STEP 9. MARK THE WALL AT THE TOP OF THE DEAD MAN.

STEP 13: ALIGN THE 32" LENGTH OF UNISTRUT 4 (A) HORIZONTALLY AGAINST THE WALL WITH THE MARKS FROM STEP 10 & 11

STEP 14: FASTEN IN PLACE WITH (3) #8 DRYWALL HEX DRIVE SCREWS AND WASHERS - ONE AT EACH END AND ONCE IN THE CENTER OF THE UNISTRUT LENGTH

STEP 15: USING THE LASER MEASURING TOOL FROM THE PROVIDED ASSEMBLY KIT, MEASURE 205-15/16" FROM THE FACE OF STUD ON THE WINDOW WALL, WINDOW SIDE. MARK LINE ON FLOOR.

STEP 16: TAKE THE DEAD MAN (Z) AND PLACE VERTICALLY AGAINST THE WALL AT THE 205-15/16" MARK FROM STEP 15. MARK THE WALL AT THE TOP OF THE DEAD MAN.

STEP 17: ALIGN THE 32" LENGTH OF UNISTRUT 5 (A) HORIZONTALLY AGAINST THE WALL WITH THE MARKS FROM STEP15 & 16.

STEP 18: FASTEN IN PLACE WITH (3) #8 DRYWALL HEX DRIVE SCREWS AND WASHERS - ONE AT EACH END AND ONCE IN THE CENTER OF THE UNISTRUT LENGTH

STEP 19: TAKE THE DEAD MAN (Z) AND PLACE VERTICALLY AGAINST THE WALL AT THE END OF UNISTRUT 5 (A) FROM STEP 17. MARK THE WALL AT THE TOP OF THE DEAD MAN.

STEP 20: ALIGN THE 32" LENGTH OF UNISTRUT 6 (A) HORIZONTALLY AGAINST THE WALL WITH THE MARKS FROM STEP 15 & 17

STEP 21: FASTEN IN PLACE WITH (3) #8 DRYWALL HEX DRIVE SCREWS AND WASHERS - ONE AT EACH END AND ONCE IN THE CENTER OF THE UNISTRUT LENGTH

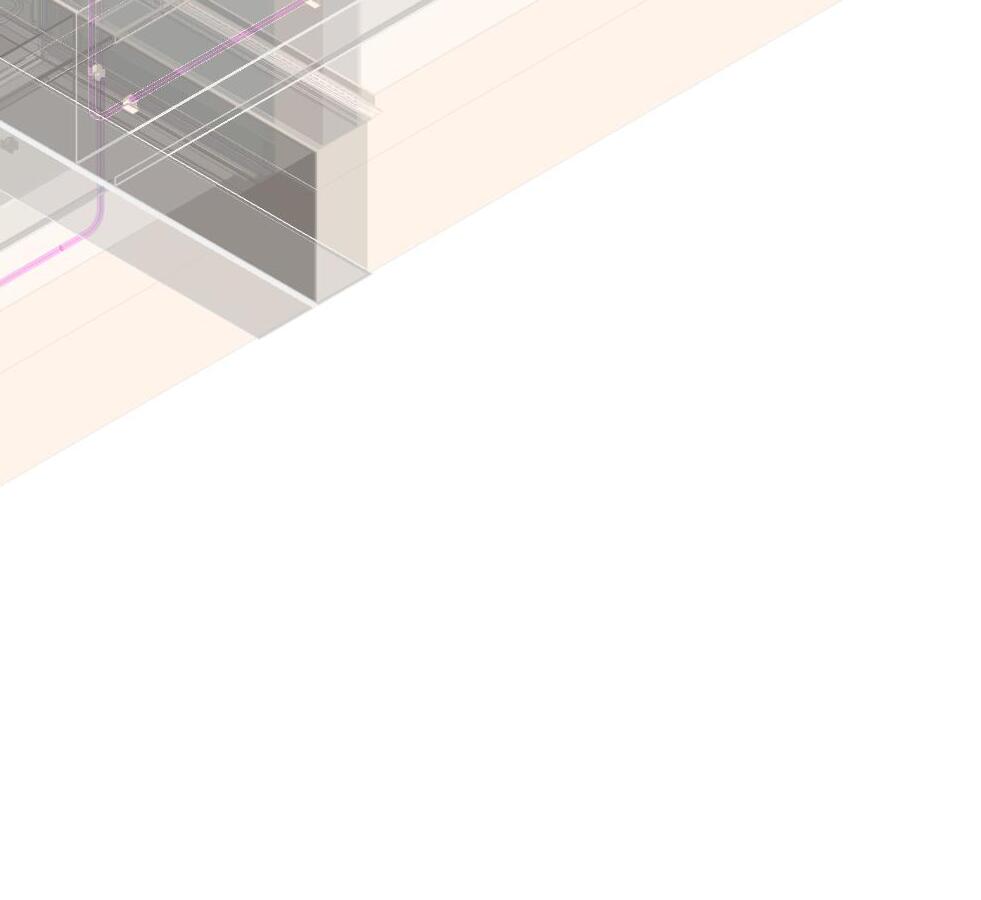

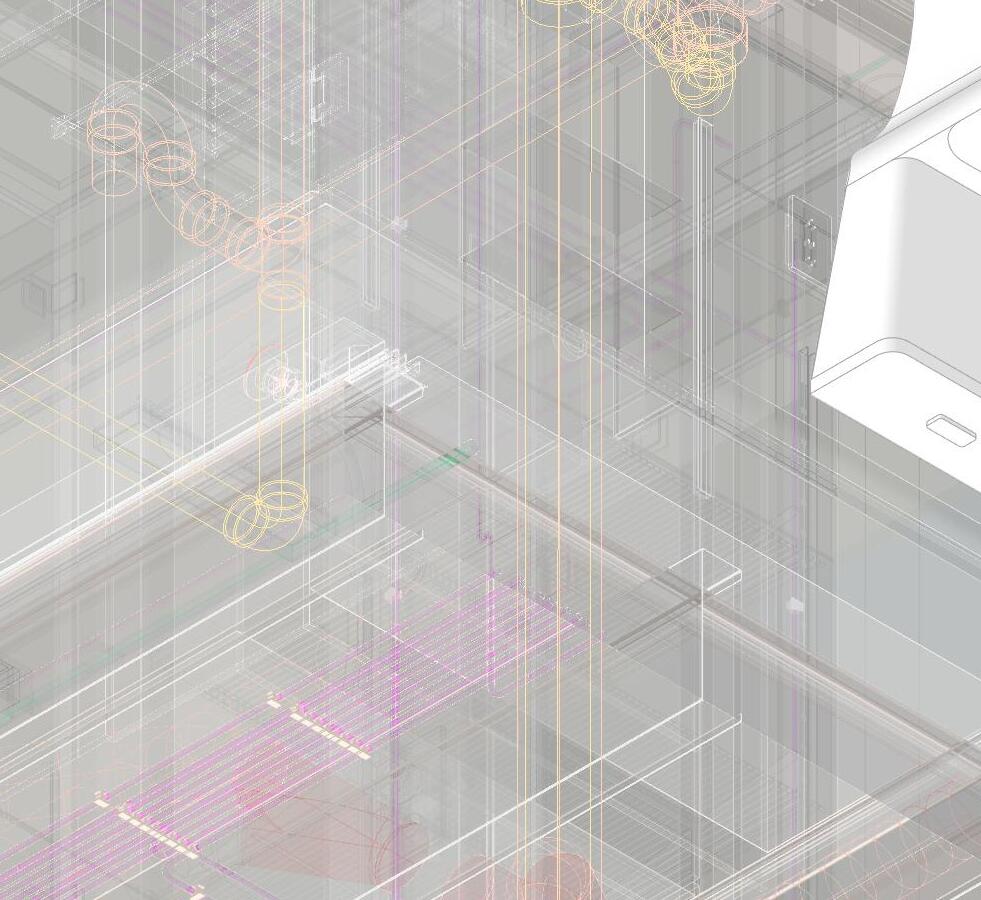

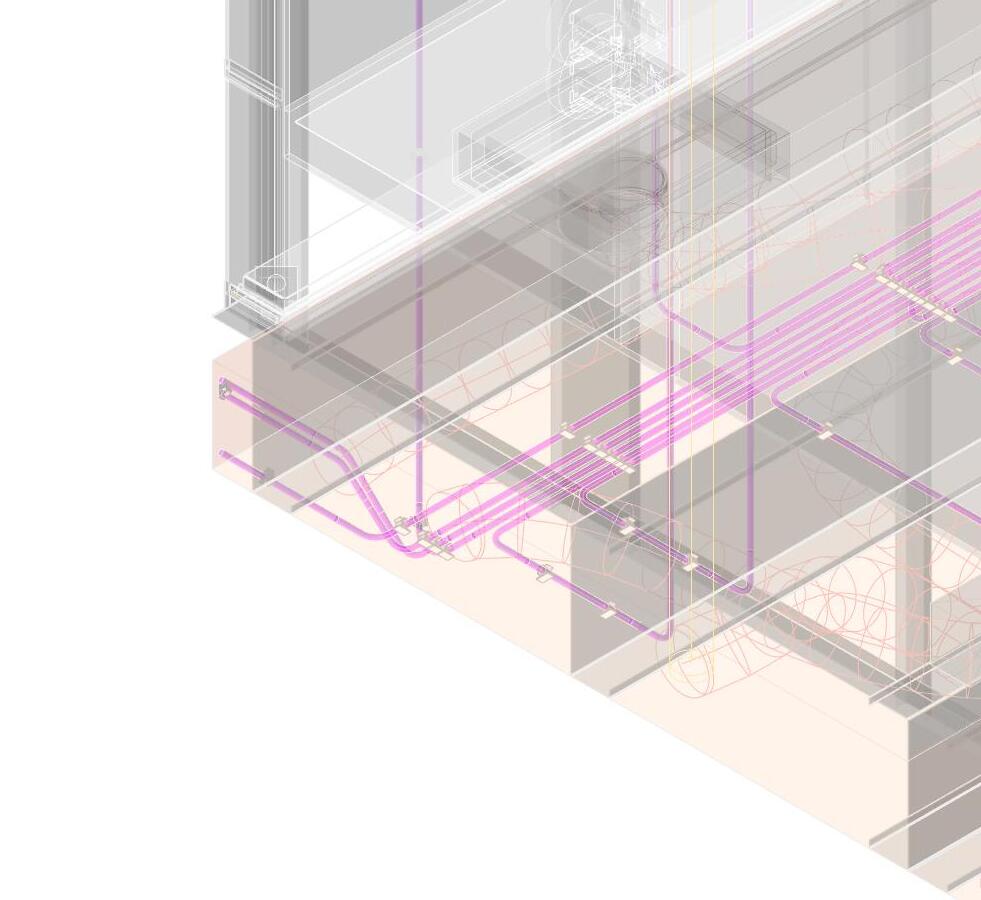

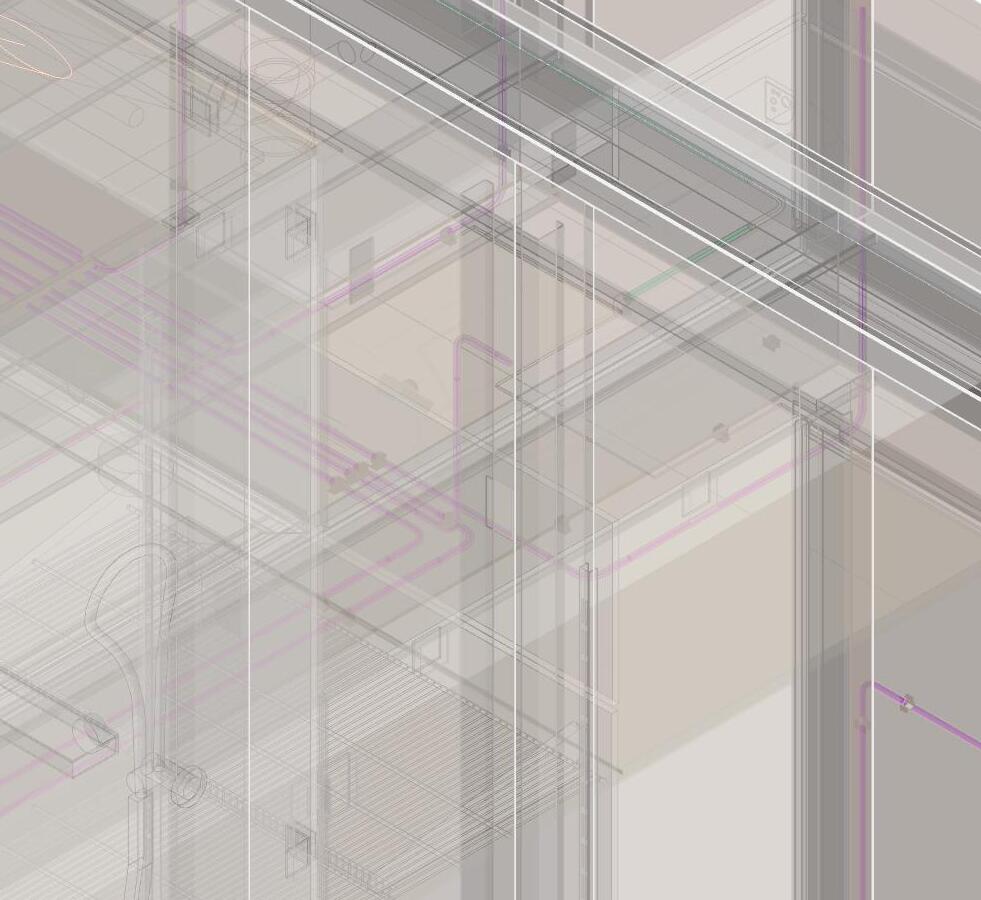

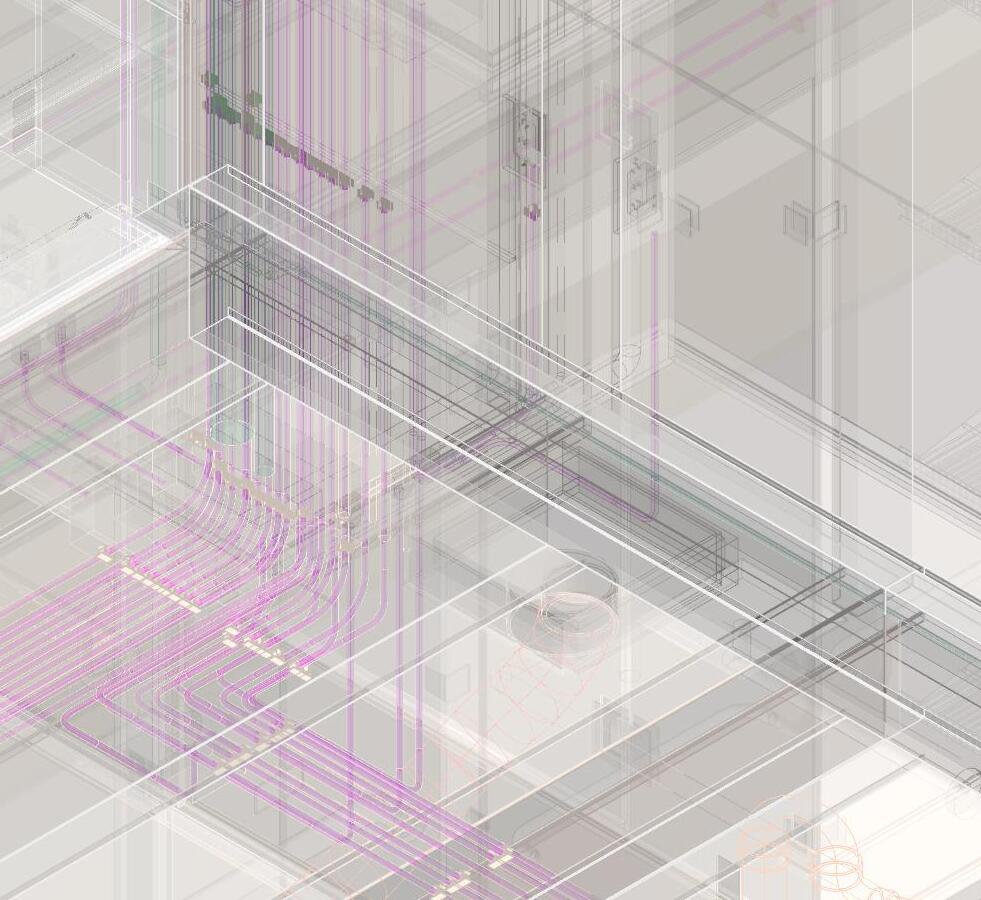

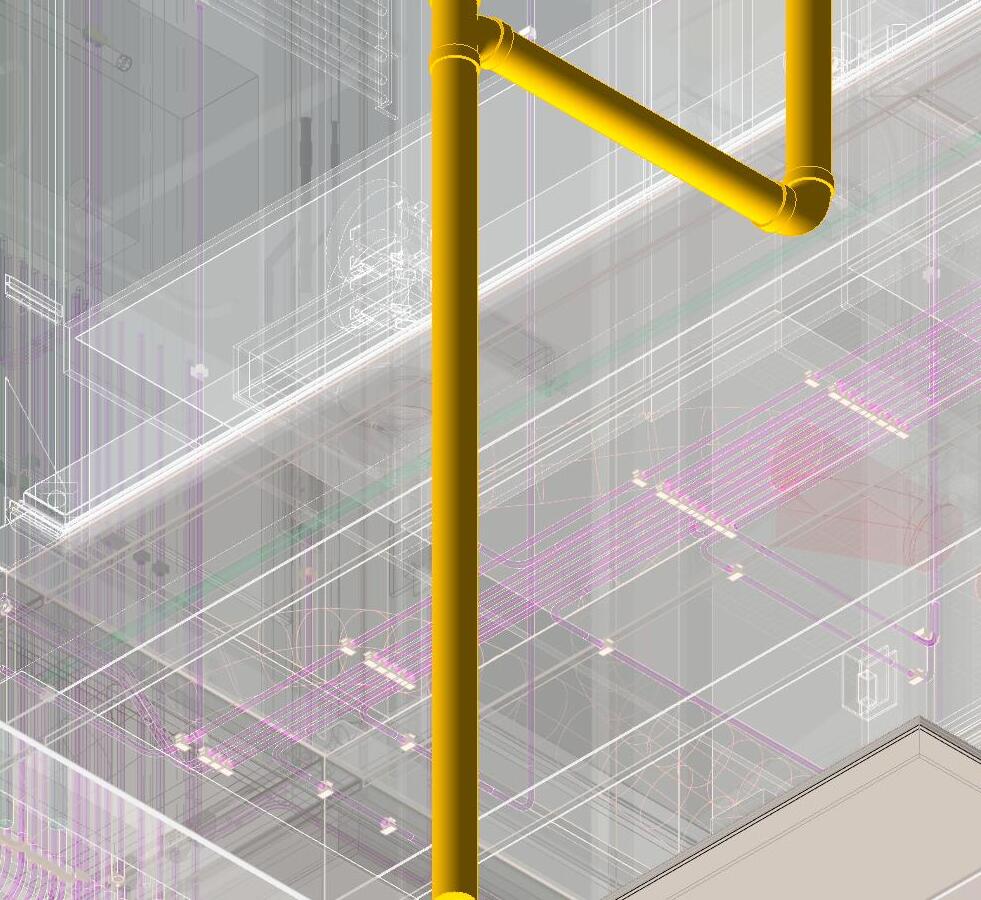

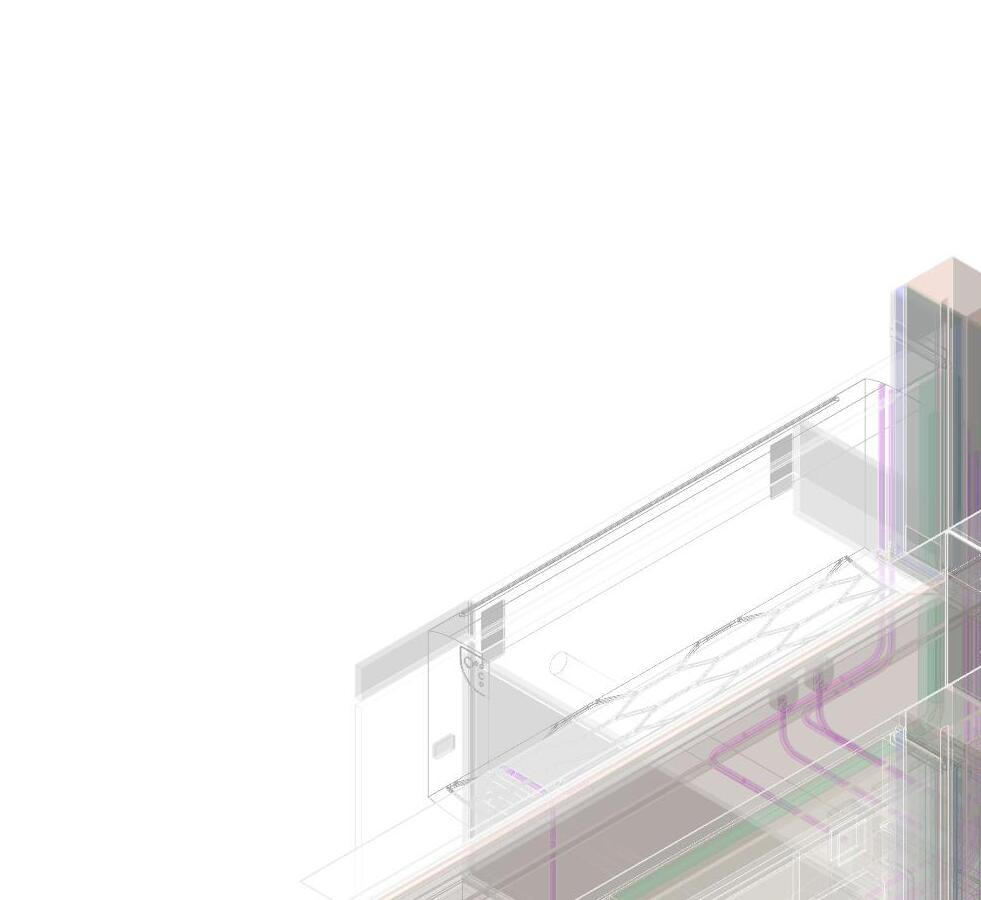

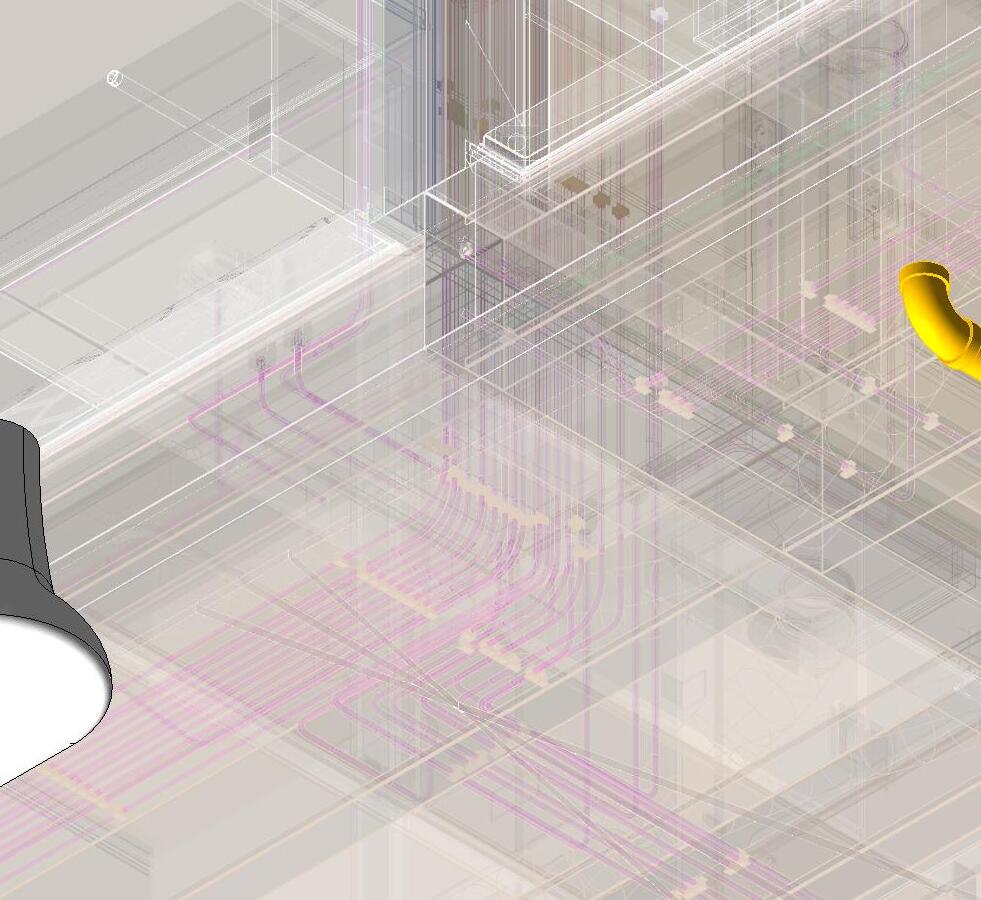

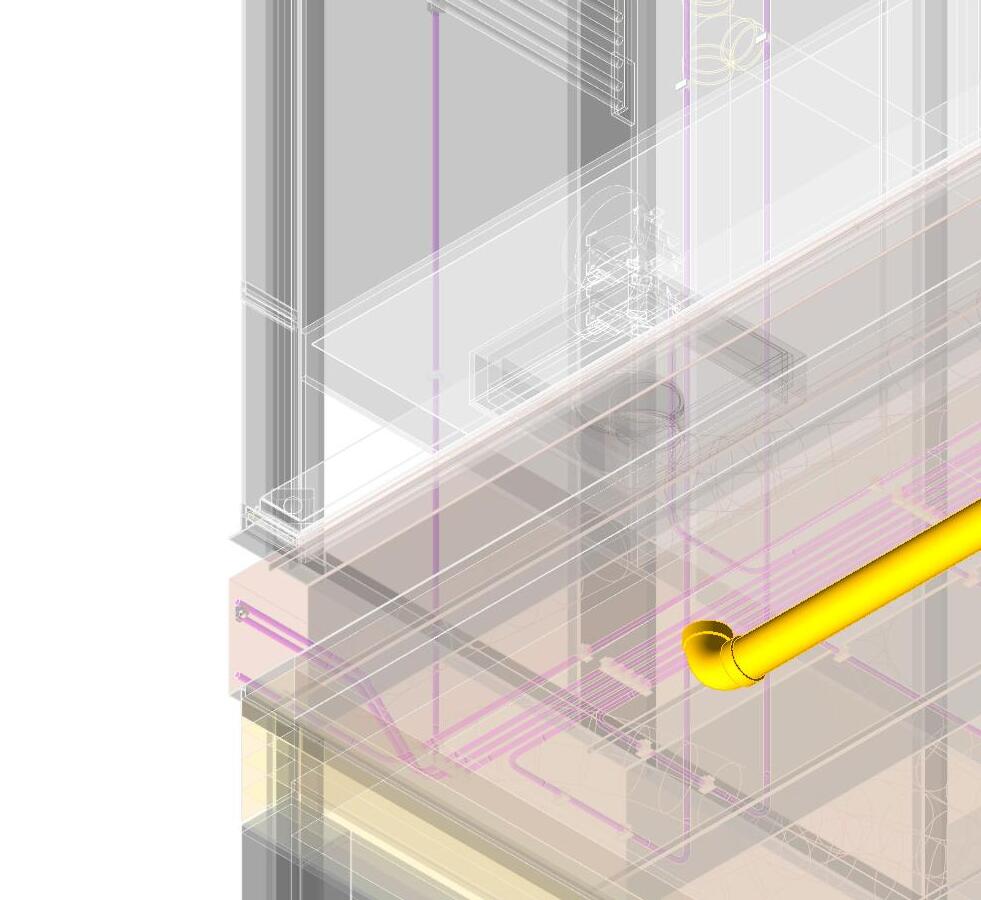

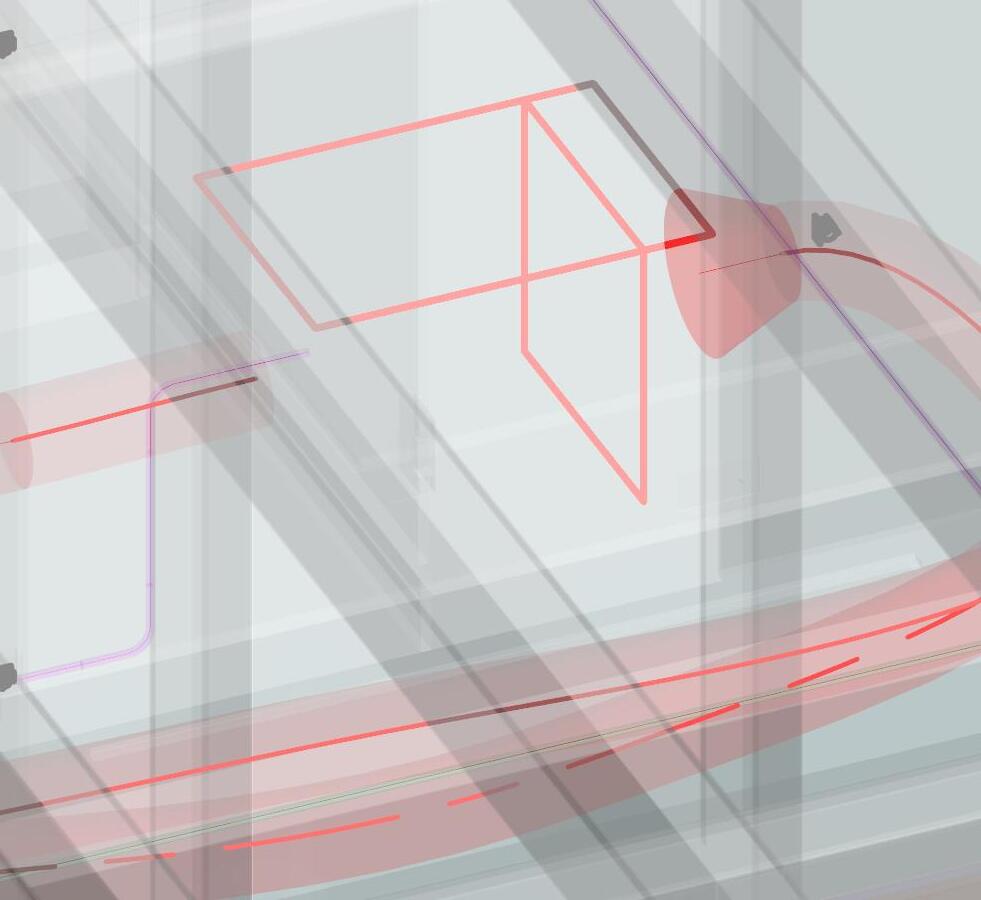

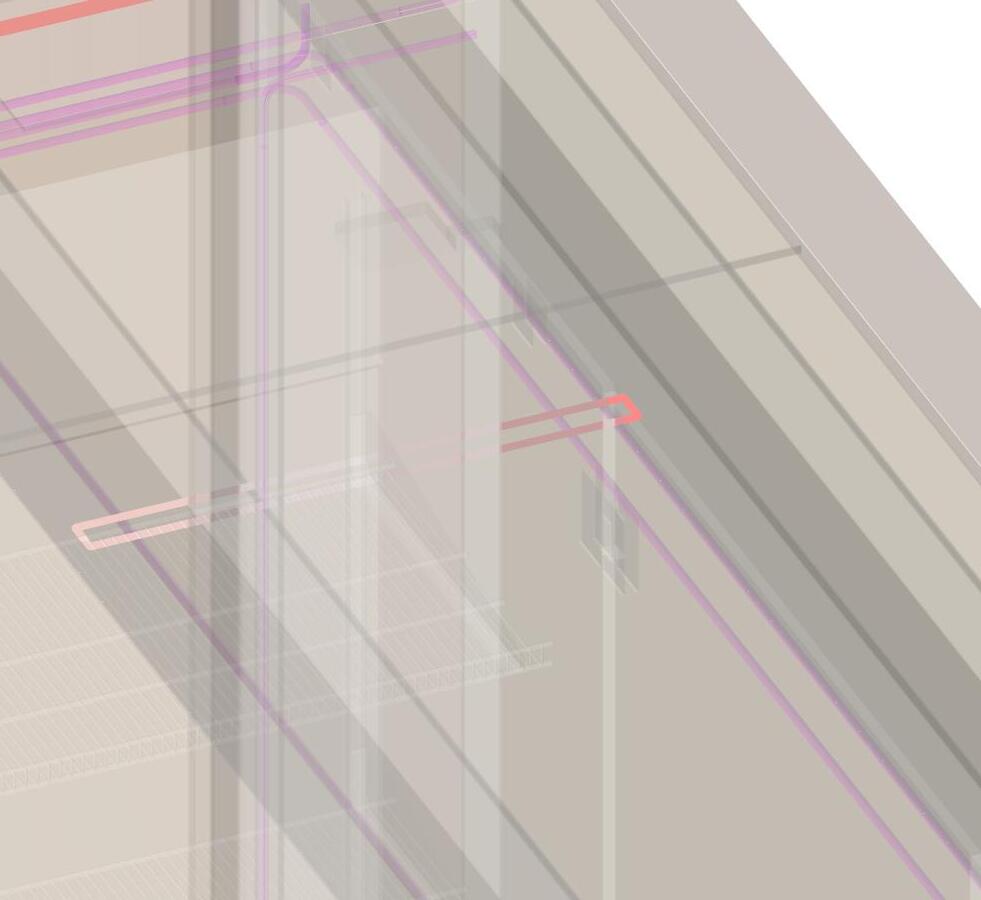

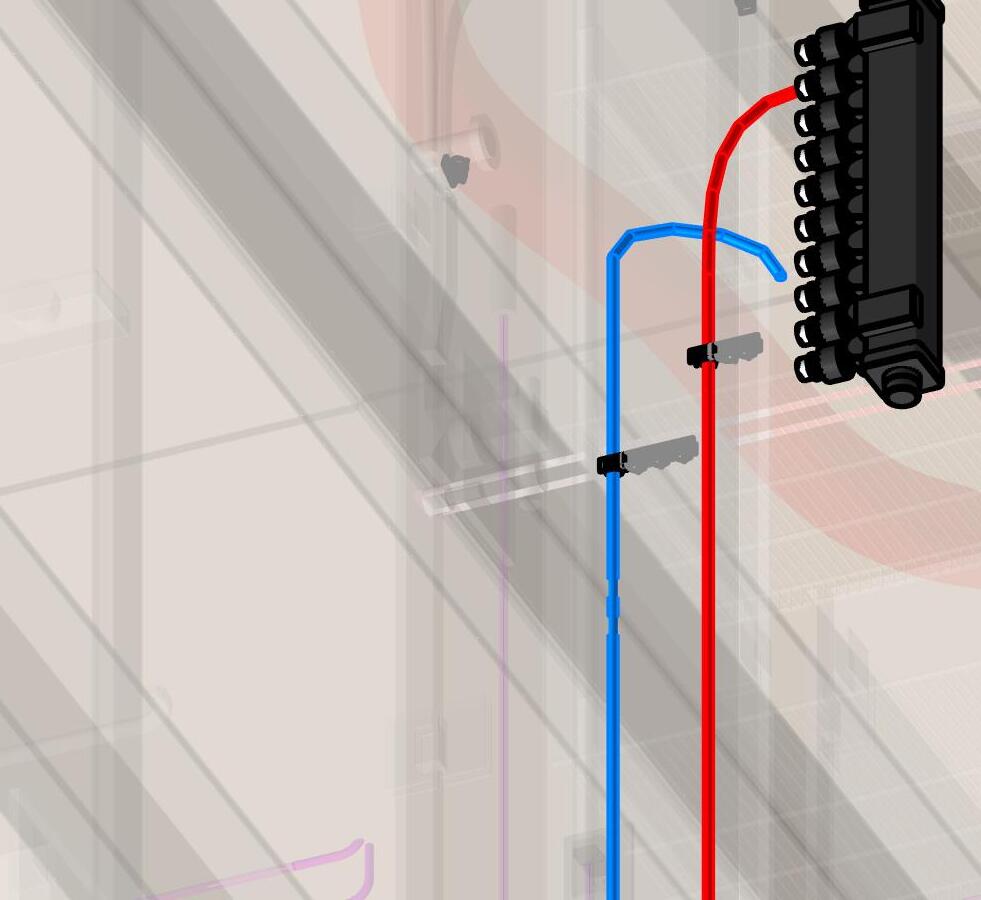

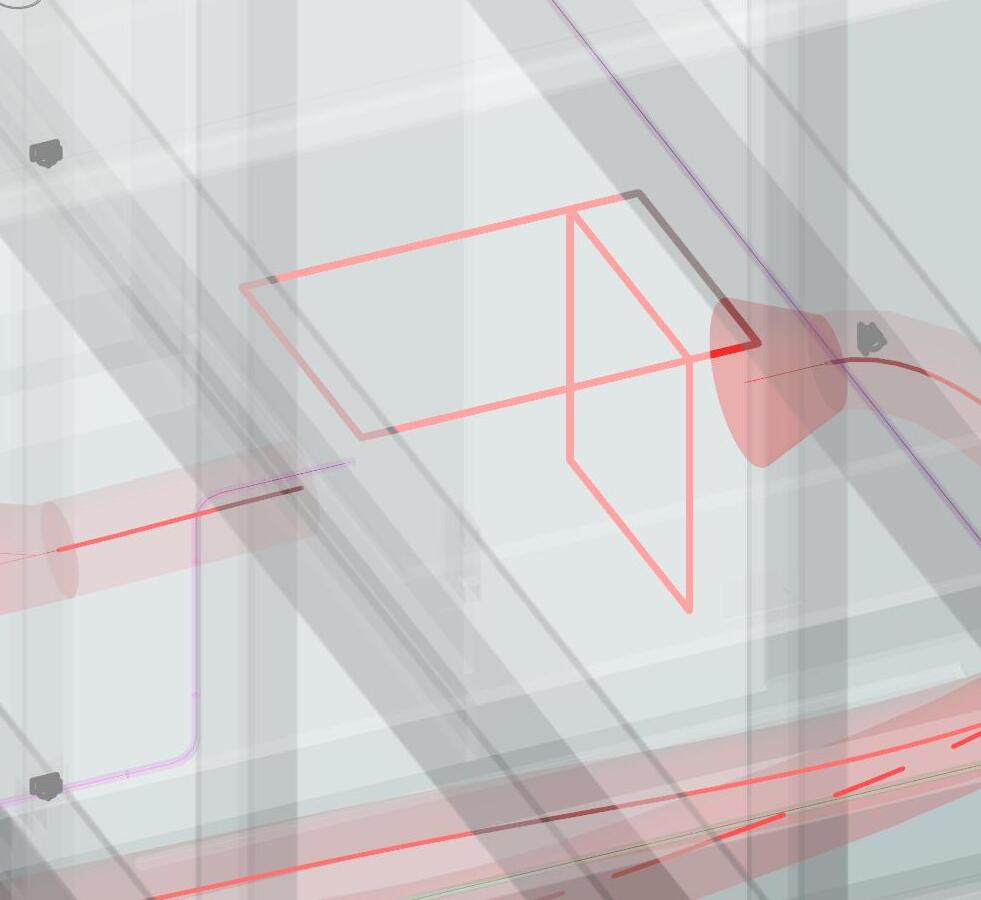

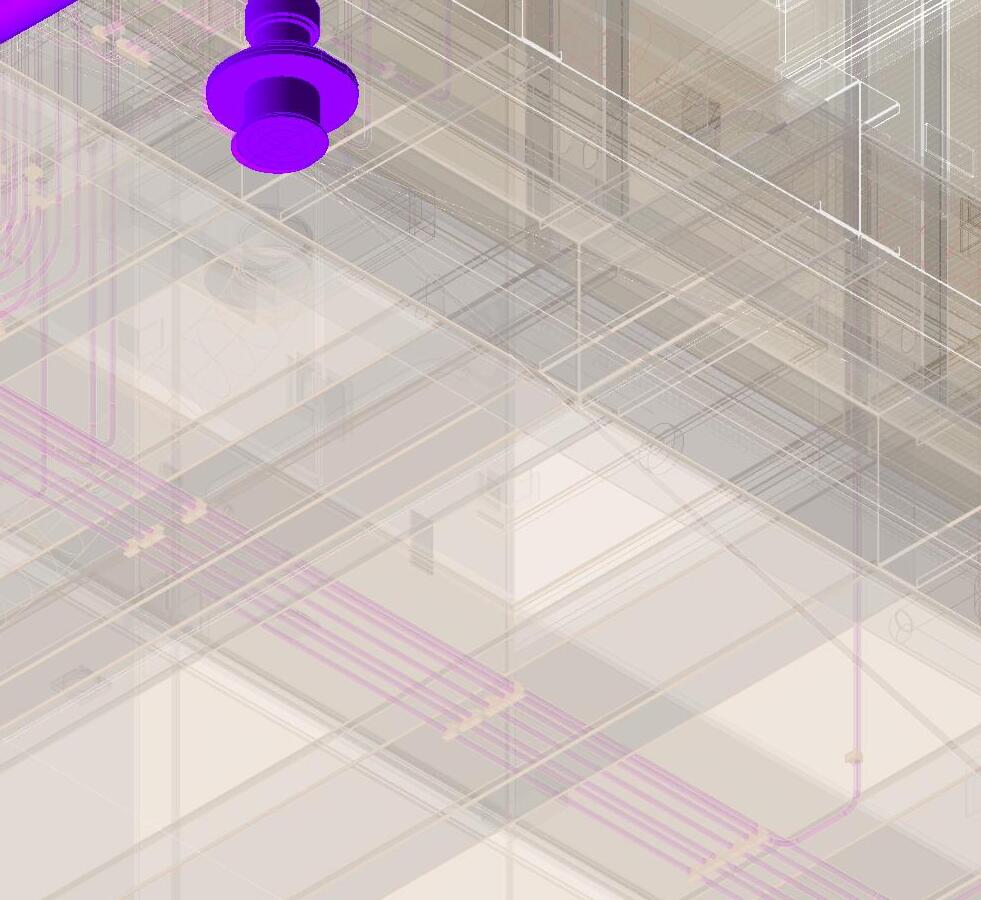

ONE BEDROOM UNIT PLUMBING

WILL ALSO NEED TO INCLUDE:

(2) HOT WATER 3/8" MANIFOLD REDUCER VALVE FITTINGS

(2) HOT WATER 1/2" MANIFOLD REDUCER VALVE FITTINGS

(3) COLD WATER 3/8" MANIFOLD REDUCER VALVE FITTINGS

(2) COLD WATER 1/2" MANIFOLD REDUCER VALVE FITTINGS

(2) 1" TO 3/4" NPT TO CPVC REDUCER FITTING

MARK DESCRIPTION SIZE QTY

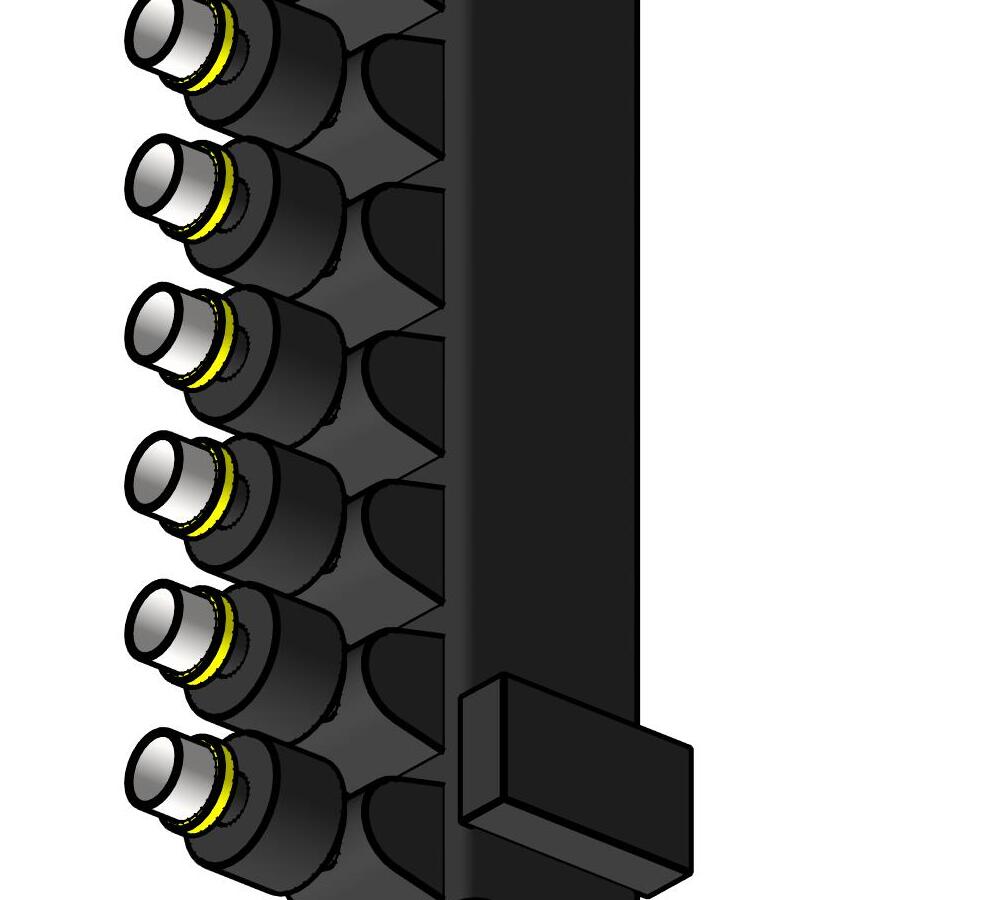

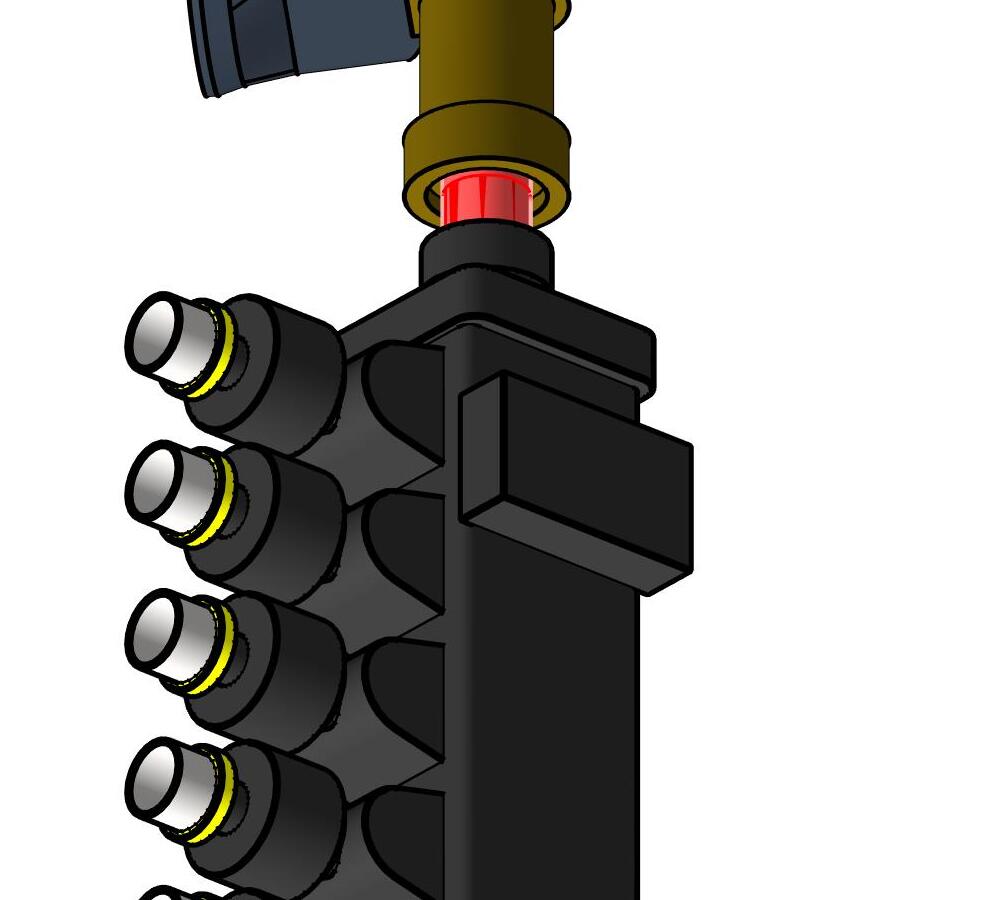

A1 6 WAY MANIFOLD 1 6 WAY

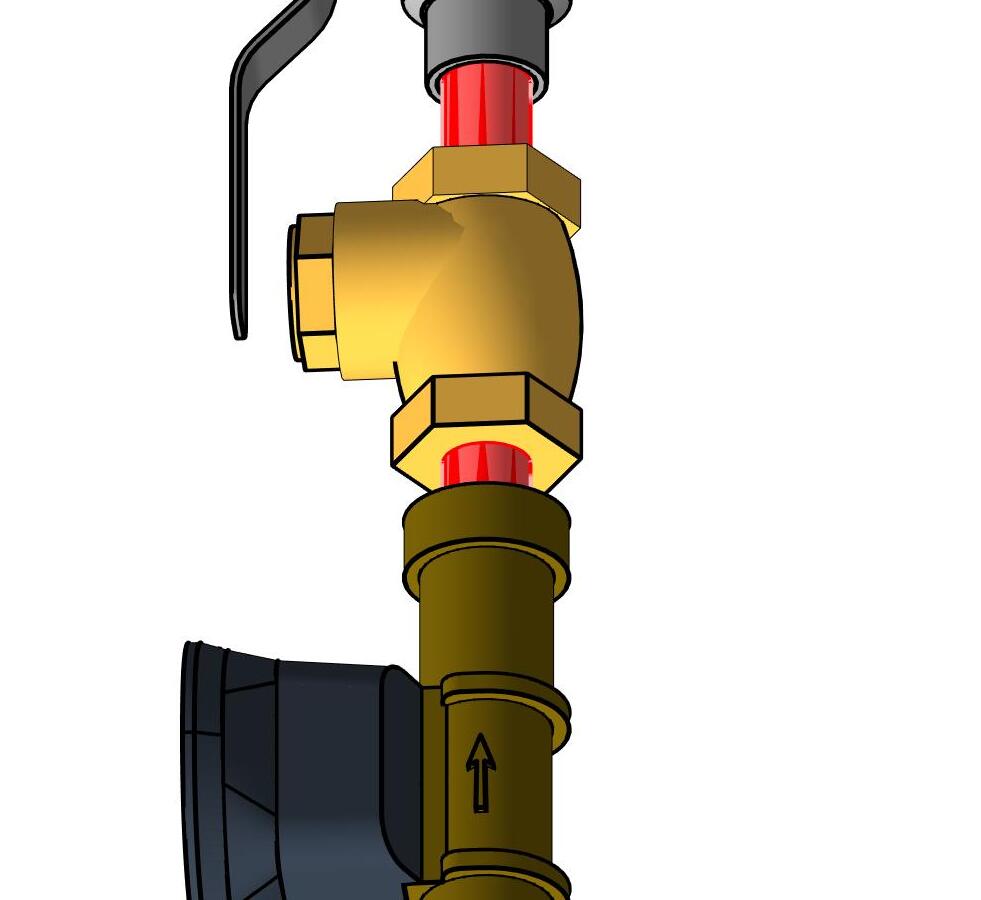

B1BALL VALVE1 3/4"

C1SHUT-OFF13/4"

D1WATER METER13/4" B2 1"1

BILL OF MATERIAL BOM FROM MODEL HERE

DOMESTIC HOT WATER-PEX

H2DOMESTIC HOT WATER-PEX

H3DOMESTIC HOT WATER-PEX

H4DOMESTIC HOT WATER-PEX

H1 3/4"

(1) COLD WATER METER (SEE VOS SPEC)

(1) HOT WATER METER (SEE VOS SPEC)

C2 1"1

D21"1 WATER METER BALL VALVE SHUT-OFF MARK DESCRIPTIONSIZE

H6

H5DOMESTIC HOT WATER-PEX DOMESTIC HOT WATER-PEX H8

H7DOMESTIC HOT WATER-PEX DOMESTIC HOT WATER-PEX

DOMESTIC COLD WATER-PEX 1"DOMESTIC COLD WATER-PEX

DOMESTIC COLD WATER-PEX

COLD WATER-PEX

COLD WATER-PEX DOMESTIC COLD WATER-PEX

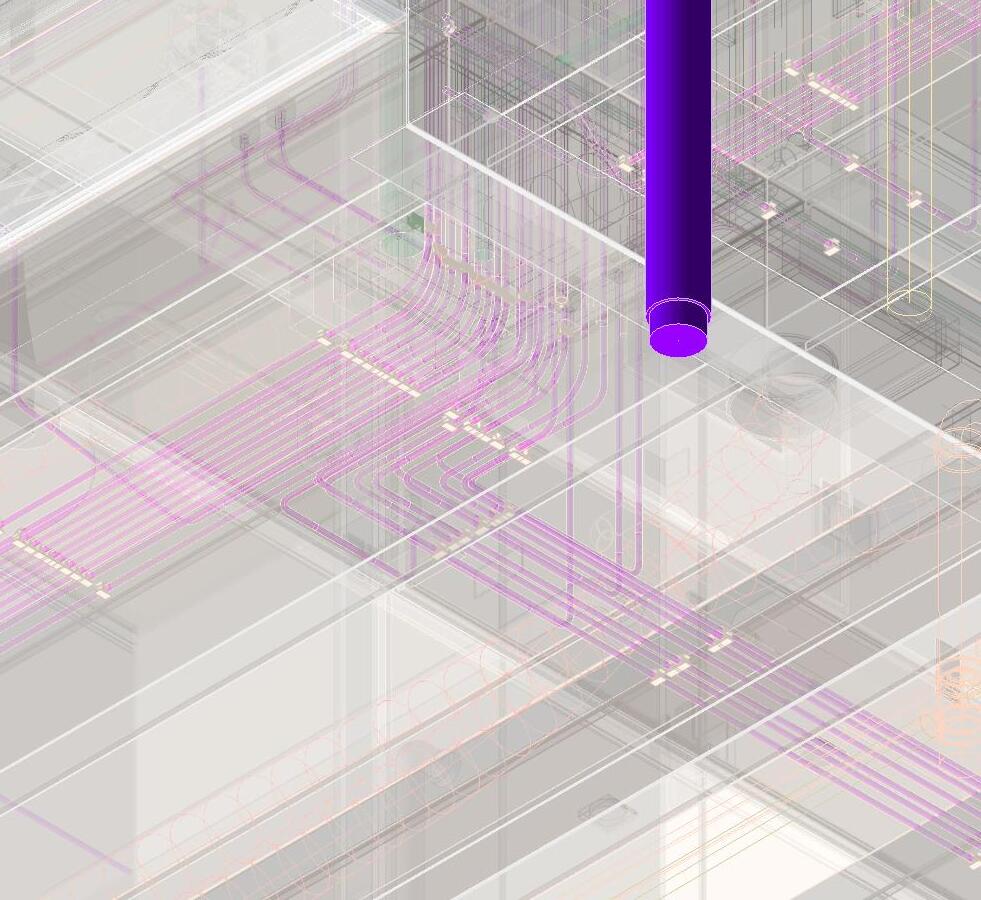

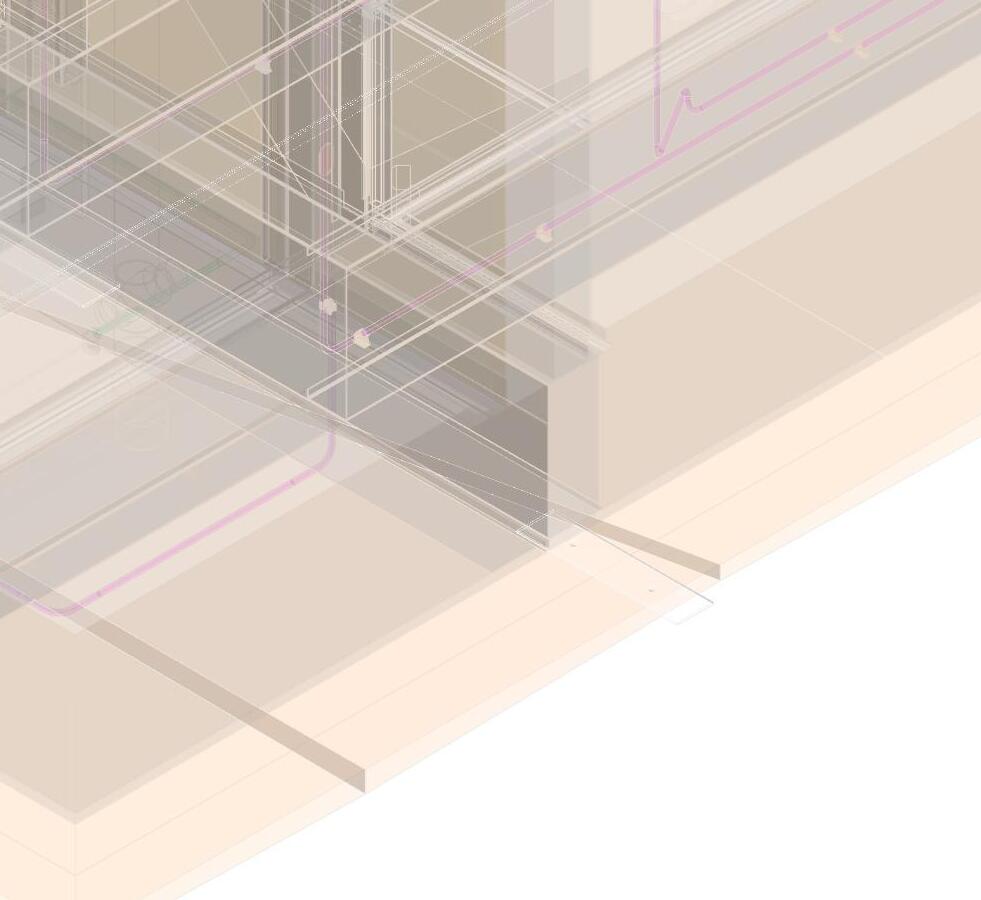

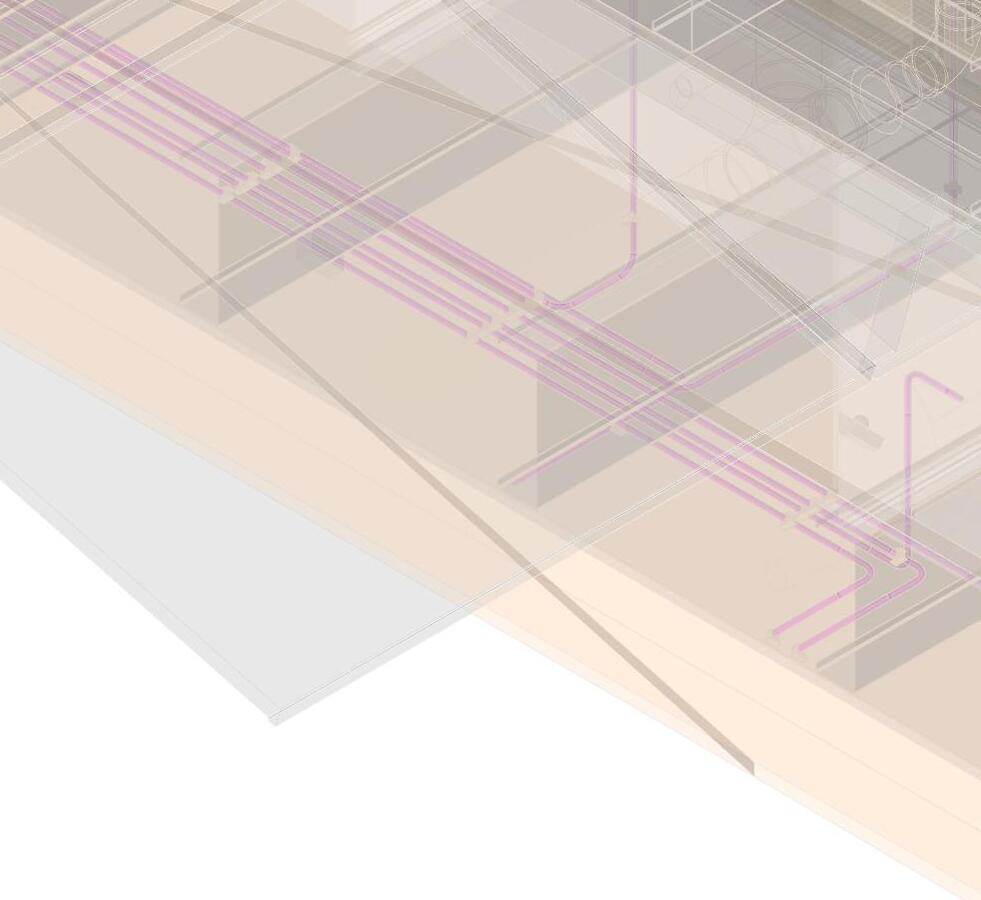

THIS IS TO BE PRE-ASSEMBLED EITHER IN A SHOP, OR DESIGNATED PRE-ASSEMBLY AREA ON SITE FLAT ON AN ASSEMBLY TABLE.

THE COMPLETED ASSEMBLY IS TO BE DELIVERED TO THE INSTALL LOCATION AS ONE UNIT THESE DIRECTIONS INCLUDE CUTTING LENGTHS OF PIPE TO LENGTH. WHERE LENGTHS ARE PRE-CUT BY THE MATERIAL SUPPLIER, EXCLUDE THESE STEPS AND PROCEED DIRECTLY TO ASSEMBLY.

M8 (1) @ xxx"

M9 (1) @ yyy"

M10 (1) @ zzz"

M11 (1) @ zzz"

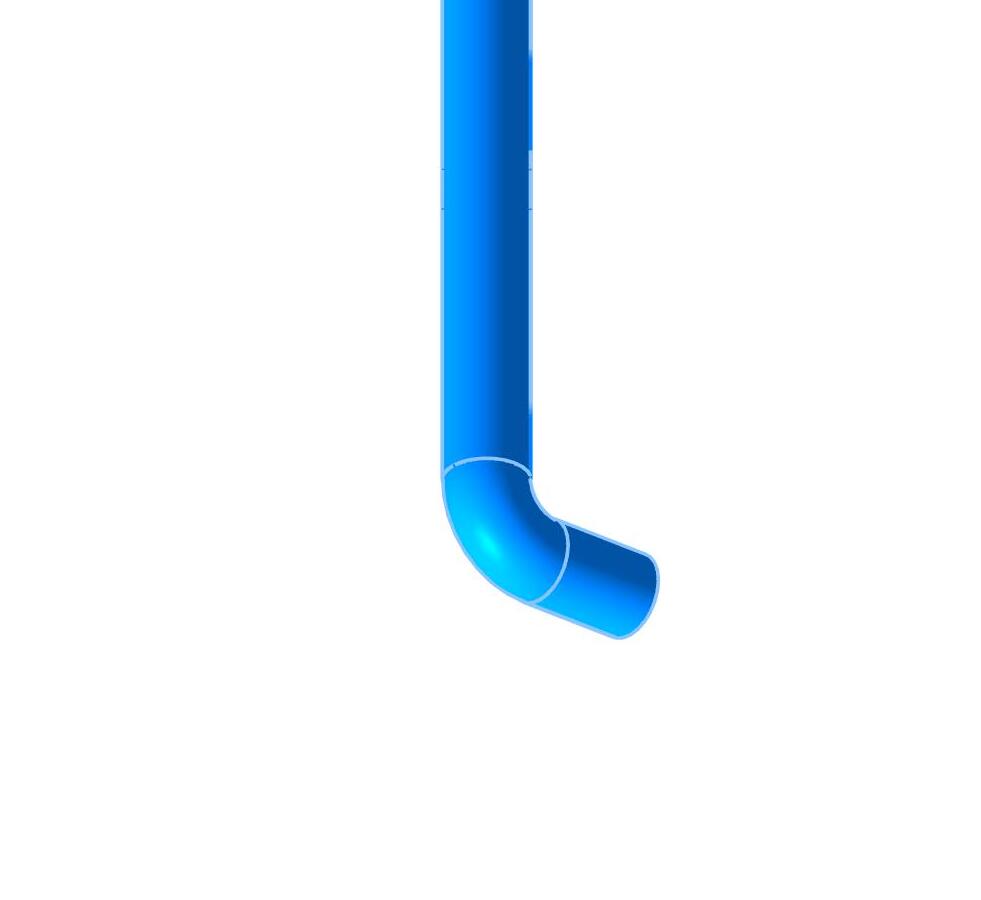

STEP 1: CUT STOCK LENGTH OF 3/4" DIAMETER CPVC PIPE INTO THE PARTS AND LENGTHS BELOW:

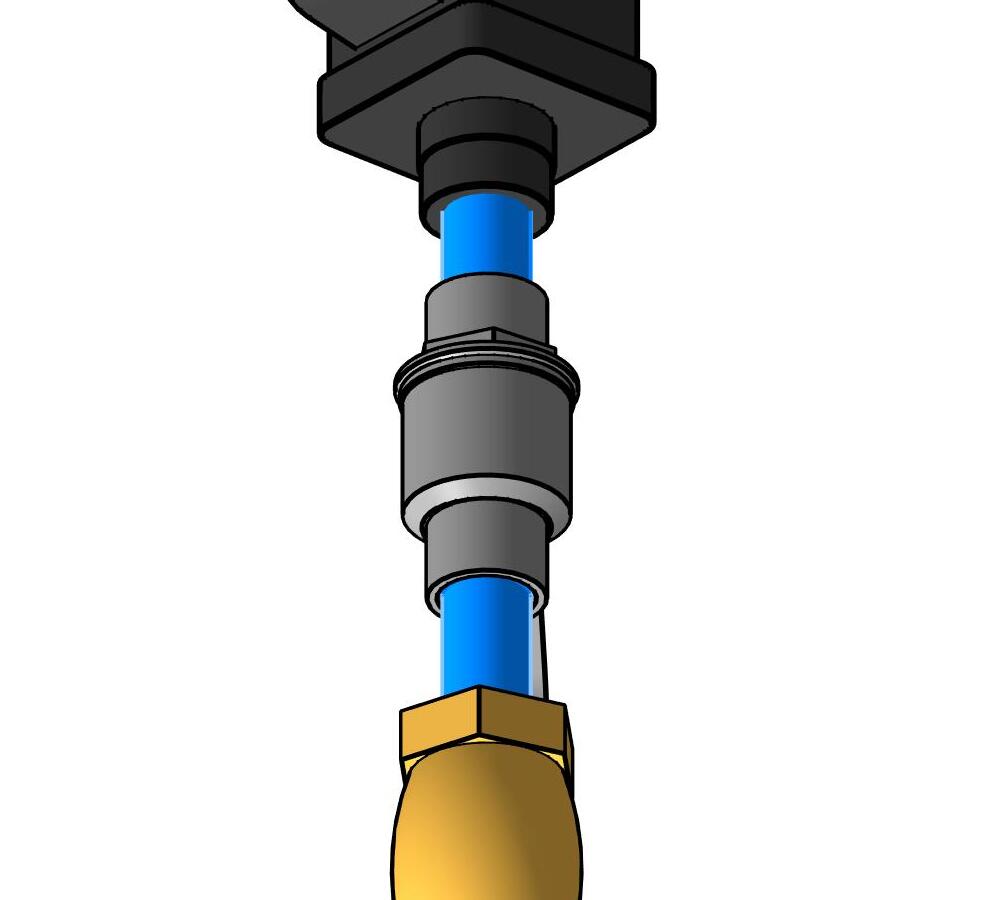

STEP 2: CONNECT REDUCER FITTING M2 TO EACH END OF THE MANIFOLD INLET, USING TEFLON TAPE TO SEAL THREADS OF MANIFOLD TO ADAPTER CONNECTION

STEP 3: USING PLUMBER'S CEMENT, GLUE PIPES M11 TO M2

STEP 4: USING PLUMBER'S CEMENT, GLUE M3 TO M11 ON THE HOT SIDE OF THE MANIFOLD

STEP 5: USING PLUMBER'S CEMENT, GLUE M6 TO M11 ON THE COLD SIDE OF THE MANIFOLD

STEP 6: USING PLUMBER'S CEMENT, GLUE PIPES M10 TO EACH M3 & M6

STEP 7: USING PLUMBER'S CEMENT, GLUE SHUT OFF VALVE M4 TO M10 ON THE HOT SIDE OF THE MANIFOLD

STEP 8: USING PLUMBER'S CEMENT, GLUE SHUT OFF VALVE M7 TO M10 ON THE COLD SIDE OF THE MANIFOLD

STEP 9: USING PLUMBER'S CEMENT, GLUE PIPES M9 TO EACH M4 & M7

STEP 10: USING PLUMBER'S CEMENT, GLUE ELBOWS M12 TO EACH M9

STEP 11: USING PLUMBERS CEMENT, GLUE PIPES M8 TO ELBOWS M12

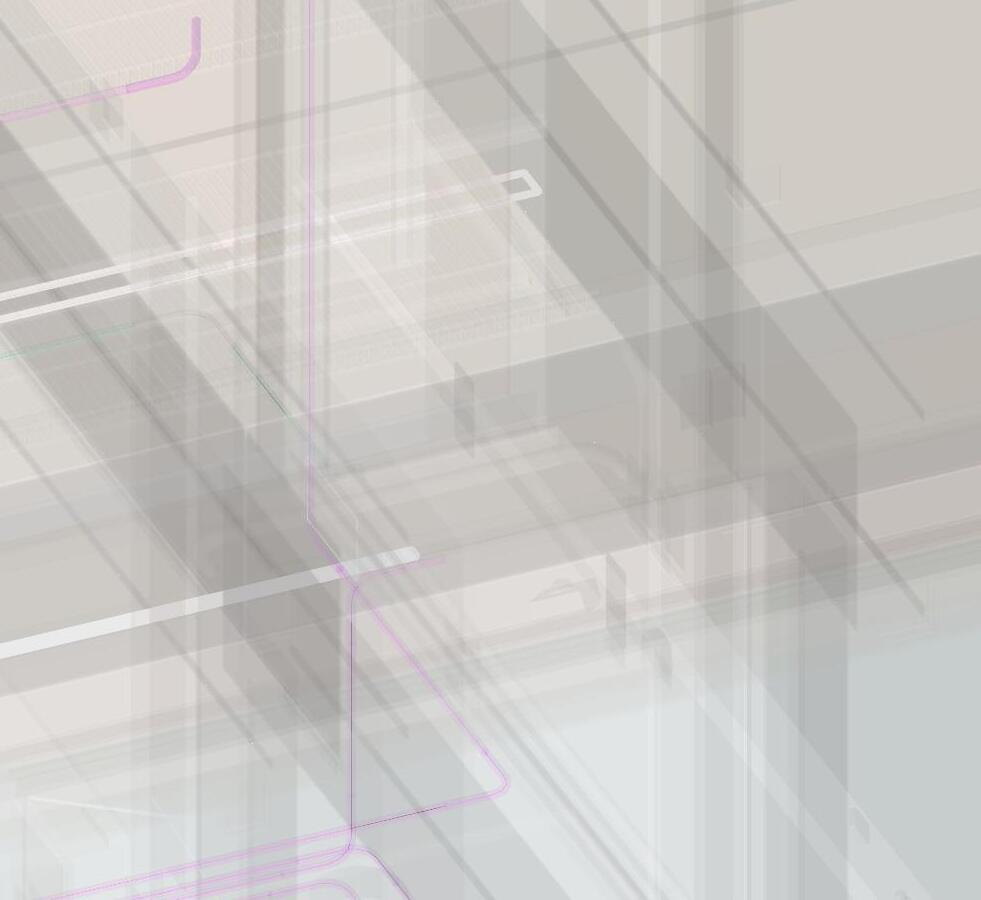

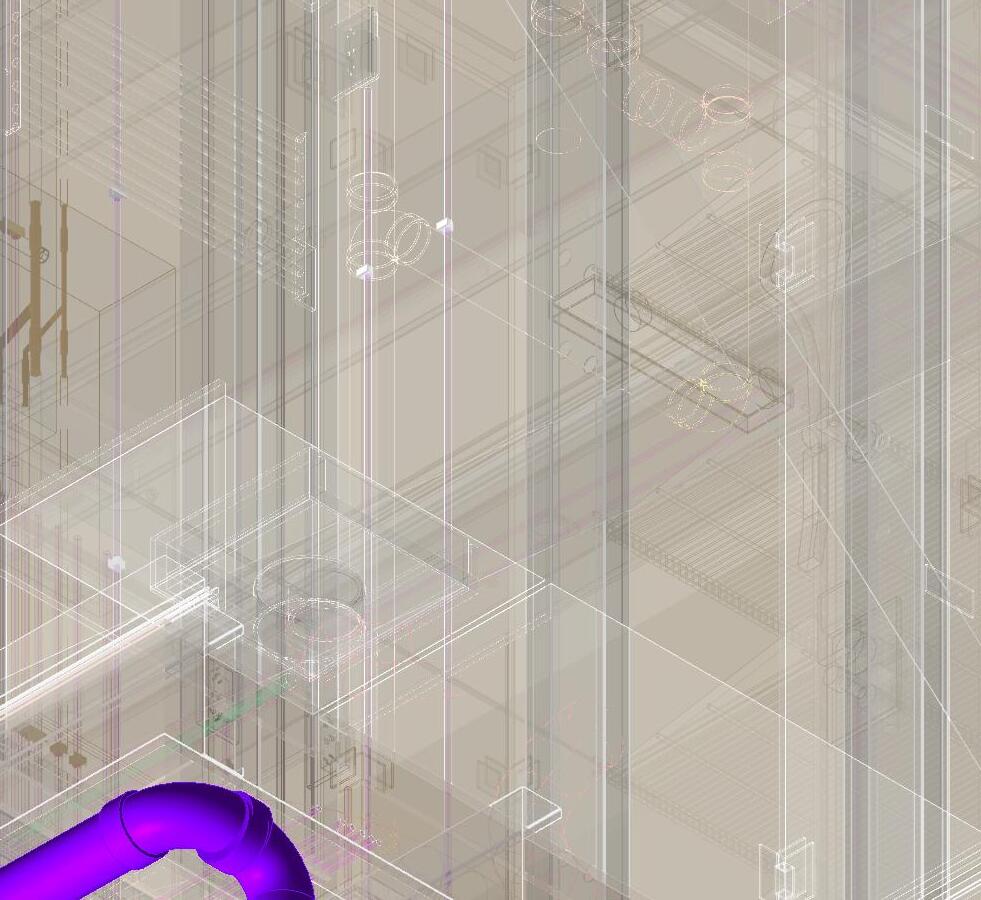

BILL OF MATERIAL MarkItem DescriptionSizeLength

MarkItem DescriptionSizeCount

THIS IS TO BE PRE-ASSEMBLED EITHER IN A SHOP, OR DESIGNATED PREASSEMBLY AREA ON SITE FLAT ON AN ASSEMBLY TABLE.

THE COMPLETED ASSEMBLY IS TO BE DELIVERED TO THE INSTALL LOCATION AS ONE UNIT

THESE DIRECTIONS INCLUDE CUTTING LENGTHS OF PIPE TO LENGTH. WHERE LENGTHS ARE PRE-CUT BY THE MATERIAL SUPPLIER, EXCLUDE THESE STEPS AND PROCEED DIRECTLY TO ASSEMBLY.

S2 (1) @ vv"

S4 (1) @ ww"

S6 (1) @ xx"

S7 (1) @ yy"

S9 (1) @ zz"

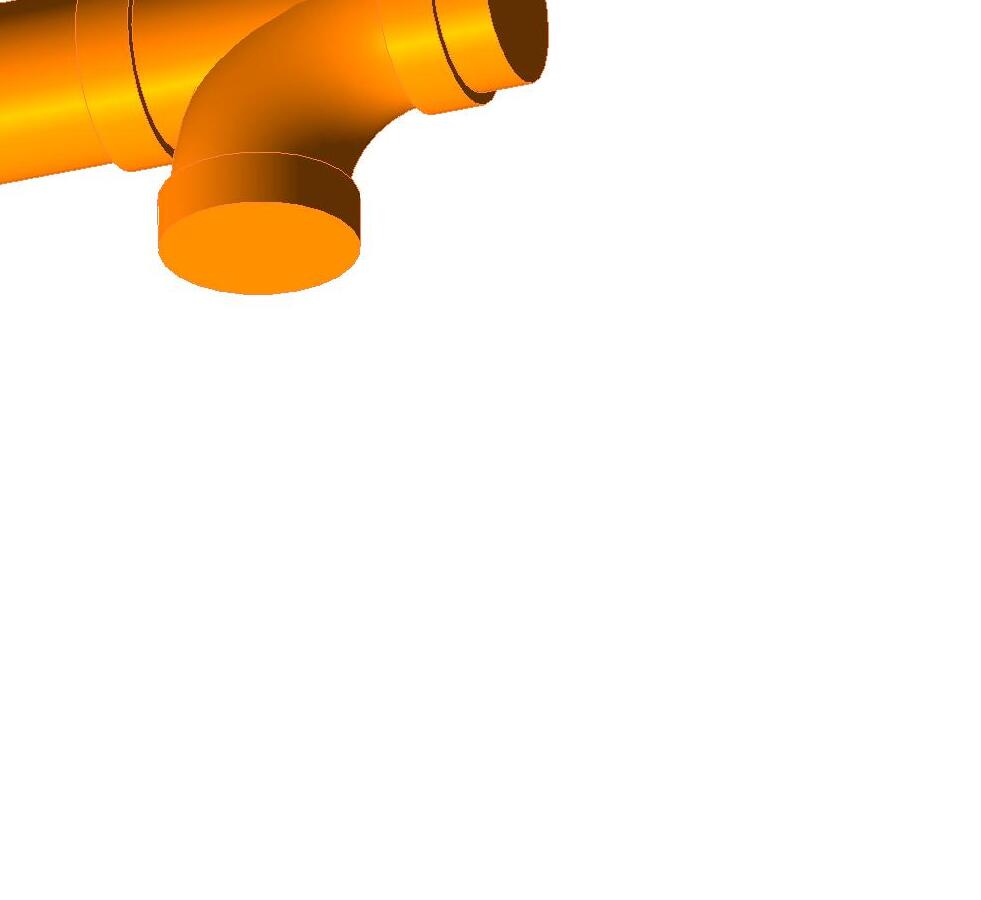

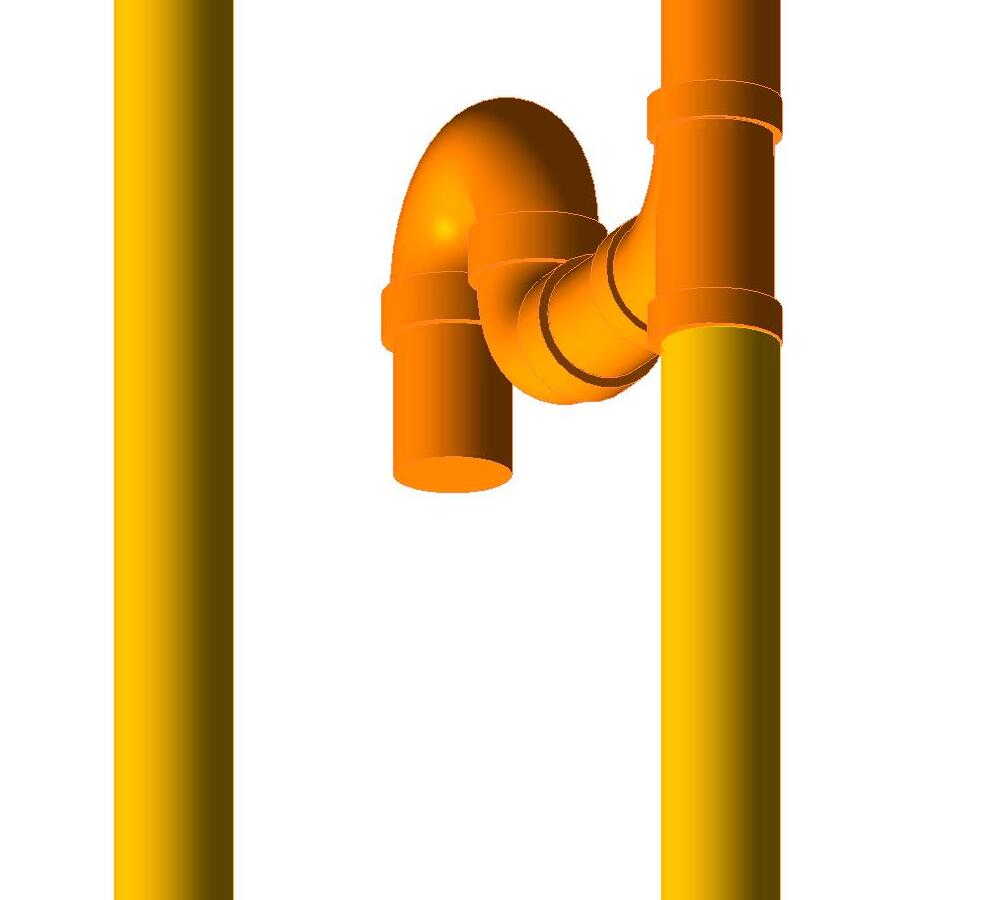

STEP 1: CUT STOCK LENGTH OF 2" DIAMETER PVC PIPE INTO THE PARTS AND LENGTHS BELOW:

STEP 2: USING PLUMBER'S CEMENT, GLUE S2 INTO THE STRAIGHT LEG OF THE KKRUX SIDE OF "Y" FITTING S1.

STEP 3: USING PLUMBER'S CEMENT, GLUE S3 TO S2. ENSURE THE REDUCER FITTING OF S3 POINTS UP WHEN THE WHY IS SET ON THE TABLE AND THE ANGLED BRANCH IS ON THE LEFT.

STEP 4: USING PLUMBER'S CEMENT, GLUE S4 TO S3

STEP 5: USING PLUMBER'S CEMENT, GLUE S5 TO S4. ENSURE S5 IS POINTING UP, IN LINE WITH THE "T" FROM S3 WHEN THE ASSEMBLY IS SET ON THE TABLE.

STEP 6: USING PLUMBER'S CEMENT, GLUE PIPE S6 INTO THE UPWARD FACING CONNECTION OF S5

STEP 8: USING PLUMBER'S CEMENT, S9 TO S8

STEP 7: USING PLUMBER'S CEMENT, GLUE S7 TO THE "Y" BRANCH ARM OF S1, ON AN ACUTE ANGLE TO PIPE S3.

STEP 9: USING PLUMBER'S CEMENT, THE S8/9 ASSEMBLY TO S7 SO THAT S9 IS PARELLEL TO S4, AND THE ENTIRE ASSEMBLY SITES FLAT ON THE TABLE.

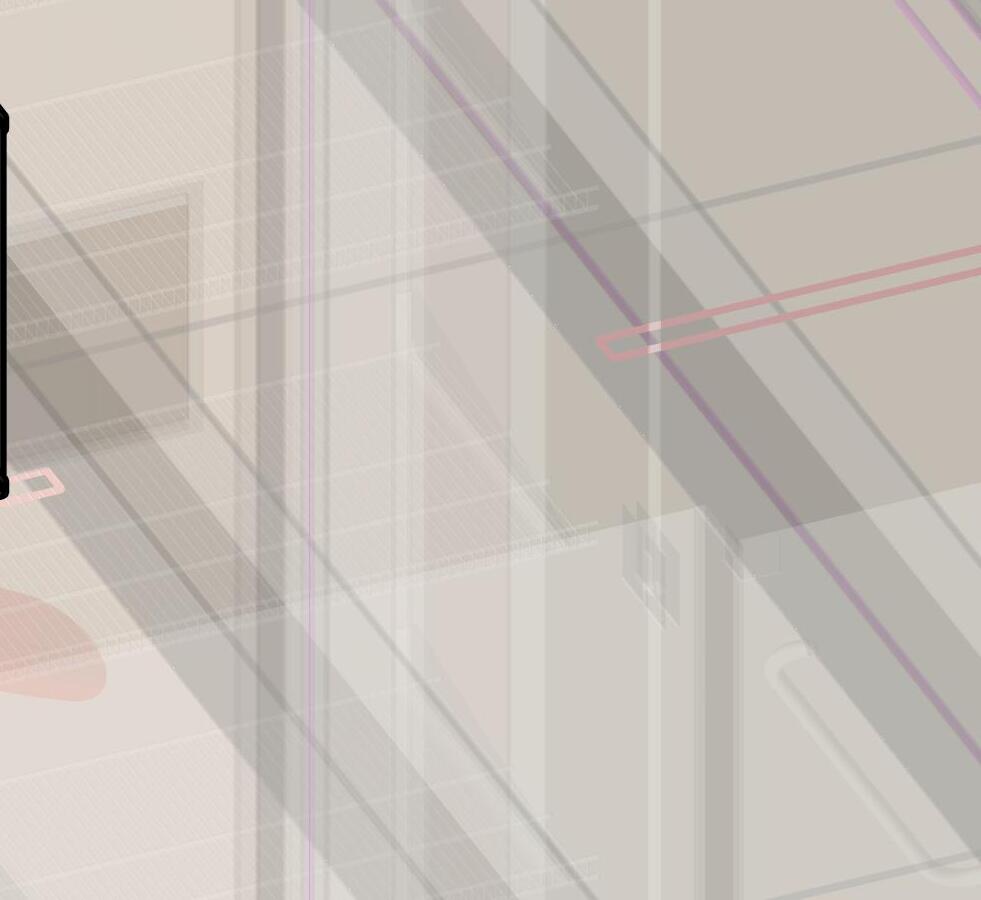

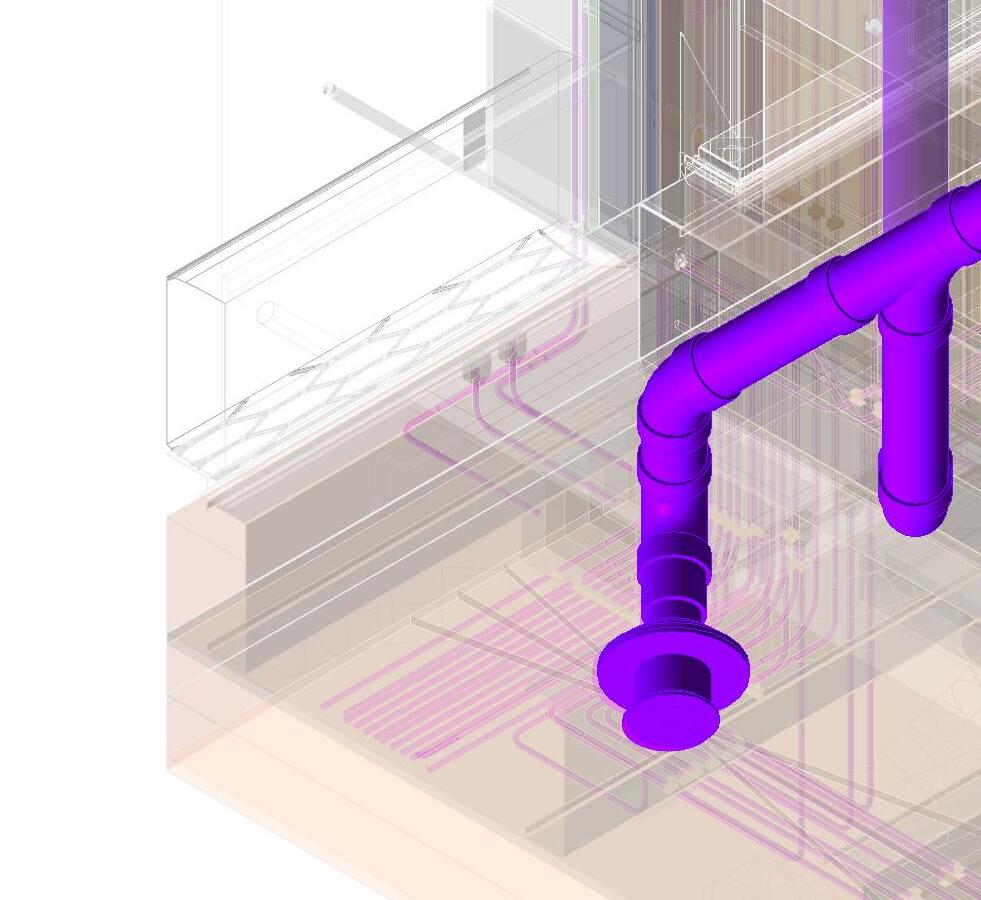

ONE BEDROOM UNIT PLUMBING

MarkItem

BILL OF MATERIAL

THIS IS TO BE PRE-ASSEMBLED EITHER IN A SHOP, OR DESIGNATED PRE-ASSEMBLY AREA ON SITE FLAT ON AN ASSEMBLY TABLE.

THE COMPLETED ASSEMBLY IS TO BE DELIVERED TO THE INSTALL LOCATION AS ONE UNIT

THESE DIRECTIONS INCLUDE CUTTING LENGTHS OF PIPE TO LENGTH. WHERE LENGTHS ARE PRE-CUT BY THE MATERIAL SUPPLIER, EXCLUDE THESE STEPS AND PROCEED DIRECTLY TO ASSEMBLY.

L1 (1) @ vv"

L3 (1) @ ww"

L5 (1) @ xx"

L6 (1) @ yy"

L7 (1) @ zz"

L9 (1) @ aa"

L11 (1) @bb"

L12 (1) @cc"

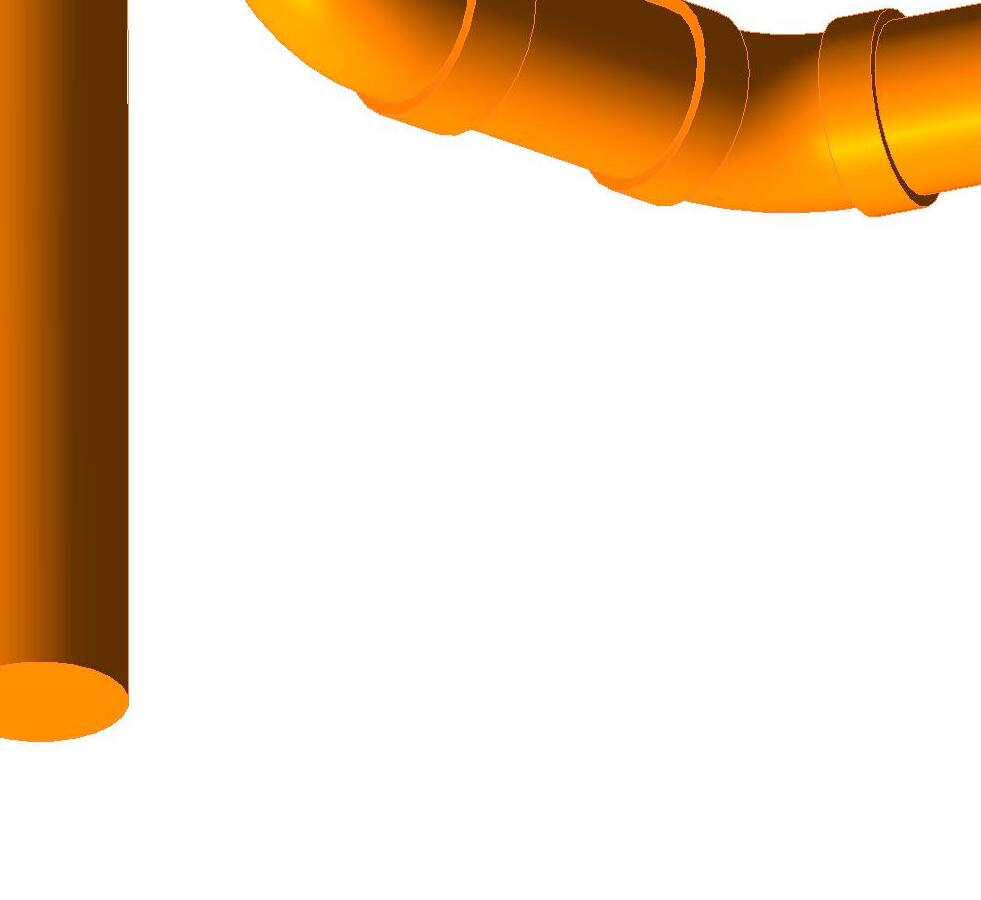

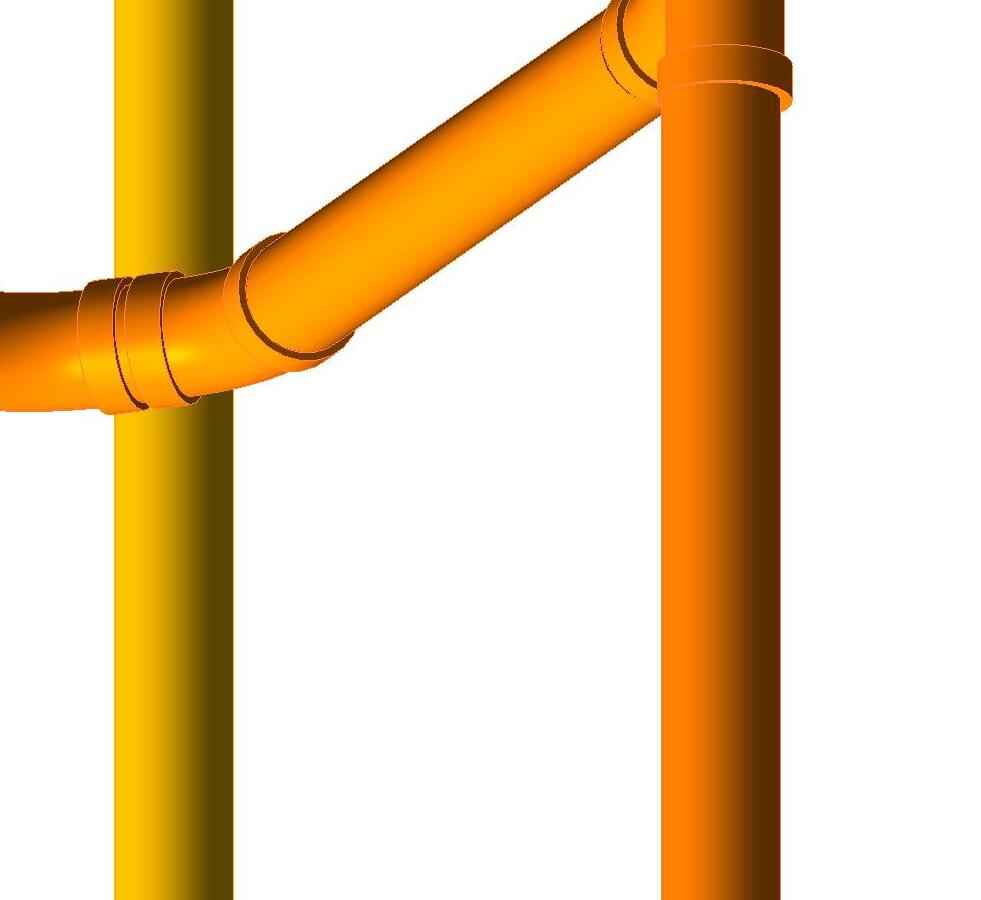

STEP 1: CUT STOCK LENGTH OF 2" DIAMETER PVC PIPE INTO THE PARTS AND LENGTHS BELOW:

L14 (1) @dd"

STEP 3: USING PLUMBER'S CEMENT, GLUE L3 TO S2

STEP 4: USING PLUMBER'S CEMENT, GLUE L4 TO L5

STEP 2: USING PLUMBER'S CEMENT, GLUE L2 TO L1, WITH THE FLOW DIRECTION POINTING TOWARDS L1

STEP 5: USING PLUMBER'S CEMENT, GLUE L4 TO L3. ENSURE L5 IS RUNNING PARELLEL AND IN THE SAME DIRECTION AS L1

STEP 6: USING PLUMBER'S CEMENT, GLUE L2 TO L5 WITH THE "T" POINTING DIRECTLY AT L1

STEP 7: USING PLUMBER'S CEMENT, GLUE L11 TO THE BOTTOM OF L2, IN LINE WITH L5.

STEP 8: USING PLUMBER'S CEMENT, GLUE L2 TO THE BOTTOM OF L11, ORIENTED THE SAME AS L2 IN STEP 6

STEP 9: USING PLUMBER'S CEMENT, GLUE L12 TO THE "T" OF L2 FROM STEP 8. L12 IS TO RUN TOWARDS L1.

STEP 10: USING PLUMBER'S CEMENT, GLUE TOGETHER THE TWO L13S TO FORM A SWEEPING 90 DEGREE BEND.

STEP 11: USING PLUMBER'S CEMENT, GLUE THE L13 ASSEMBLY TO L12. THE SWWEPING 90 DEGTREE BEND IS TO POINT UP FROM THE ASSEMBLY TABLE.

STEP 12: USING PLUMBER'S CEMENT, GLUE L14 TO THE UPWARD POINTING L13.

STEP 13: AT THE L2 FROM STEP 6, USING PLUMBER'S CEMENT, GLUE L6 TO L2

STEP 15: USING PLUMBER'S CEMENT, GLUE L7 TO L4

STEP 16: USING PLUMBER'S CEMENT, GLUE L8 TO L7

STEP 14: USING PLUMBER'S CEMENT, GLUE L4 TO L6. THE OPEN END OF L4 IS TO POINT DIRECTLY TOWARDS L12

STEP 17: USING PLUMBER'S CEMENT, GLUE L9 TO L8

STEP 18: USING PLUMBER'S CEMENT, GLUE L10 TO L9

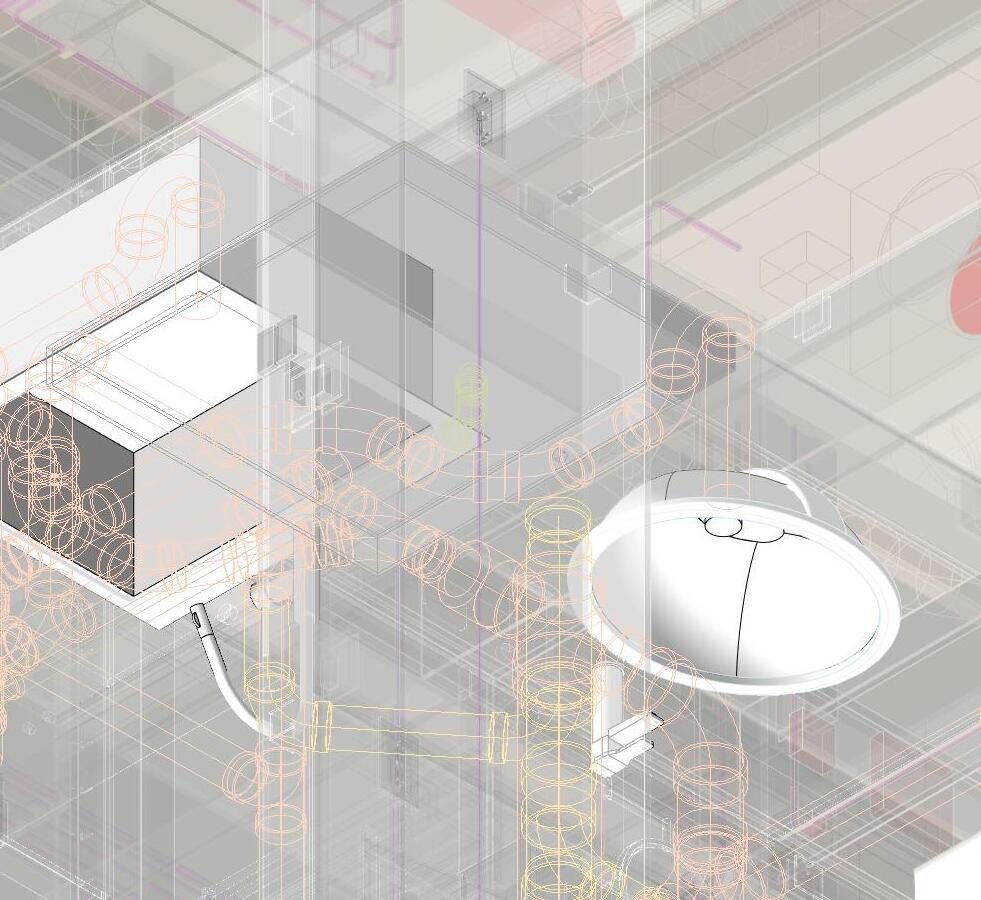

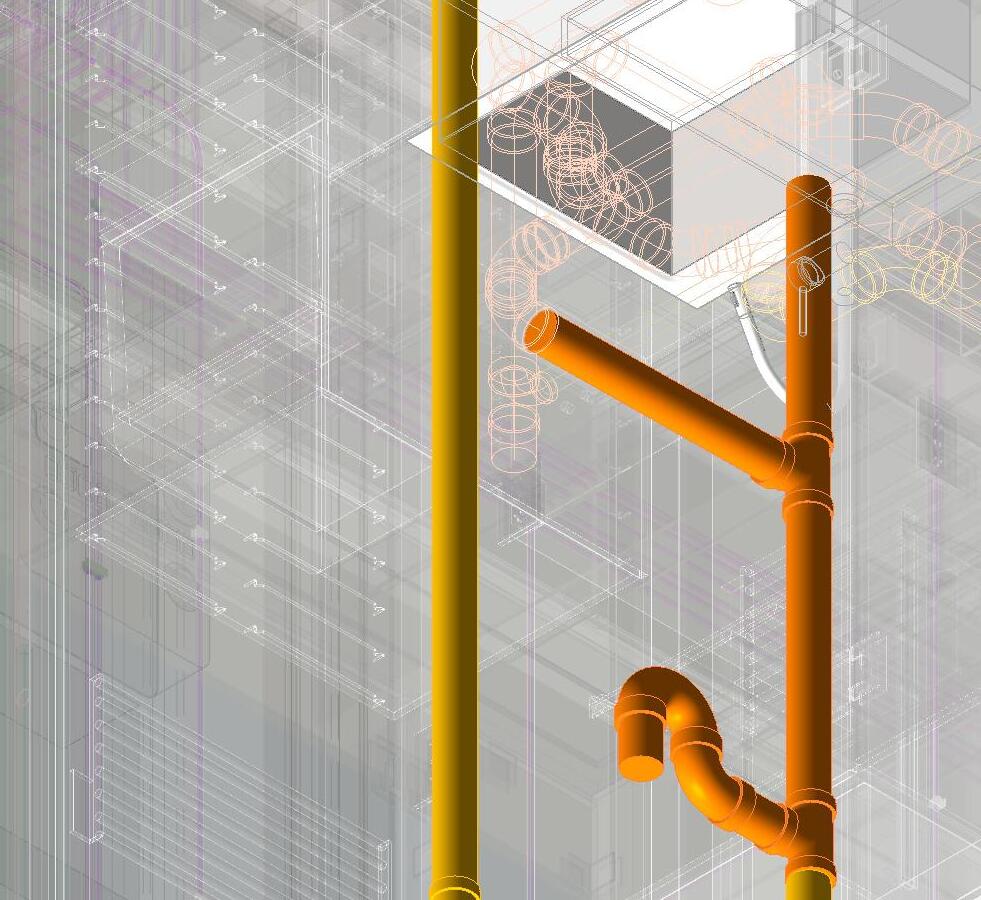

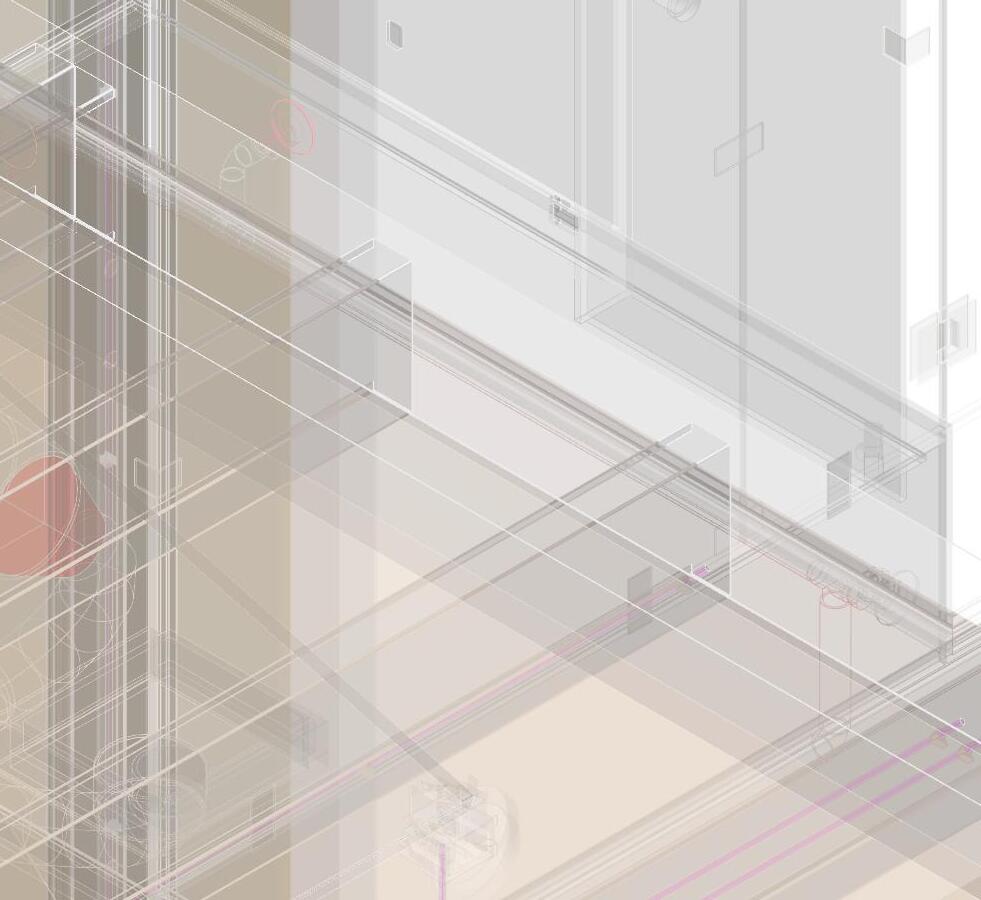

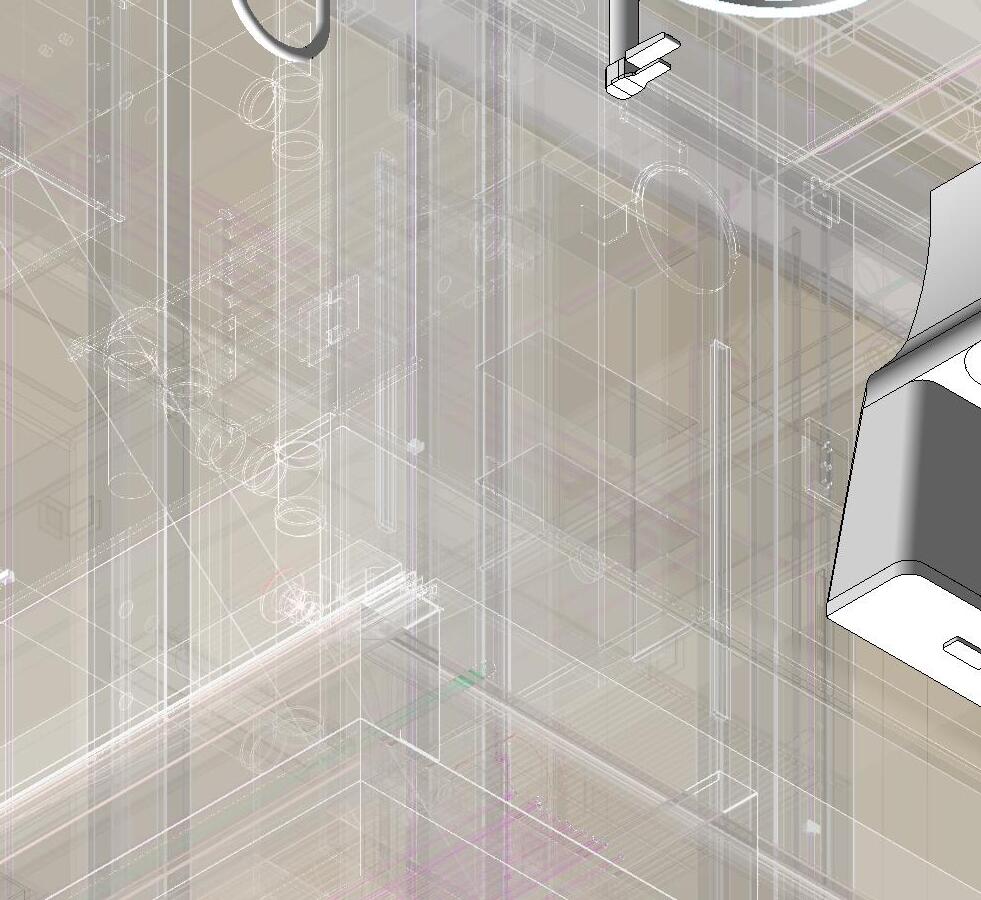

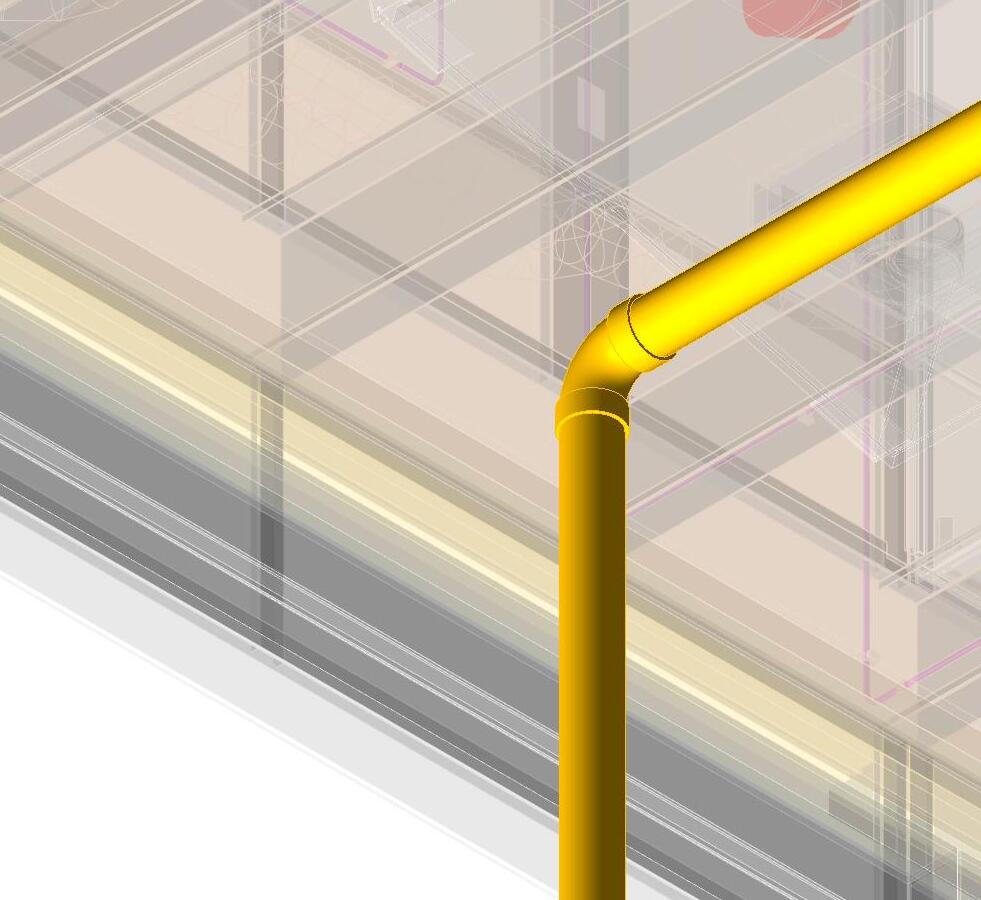

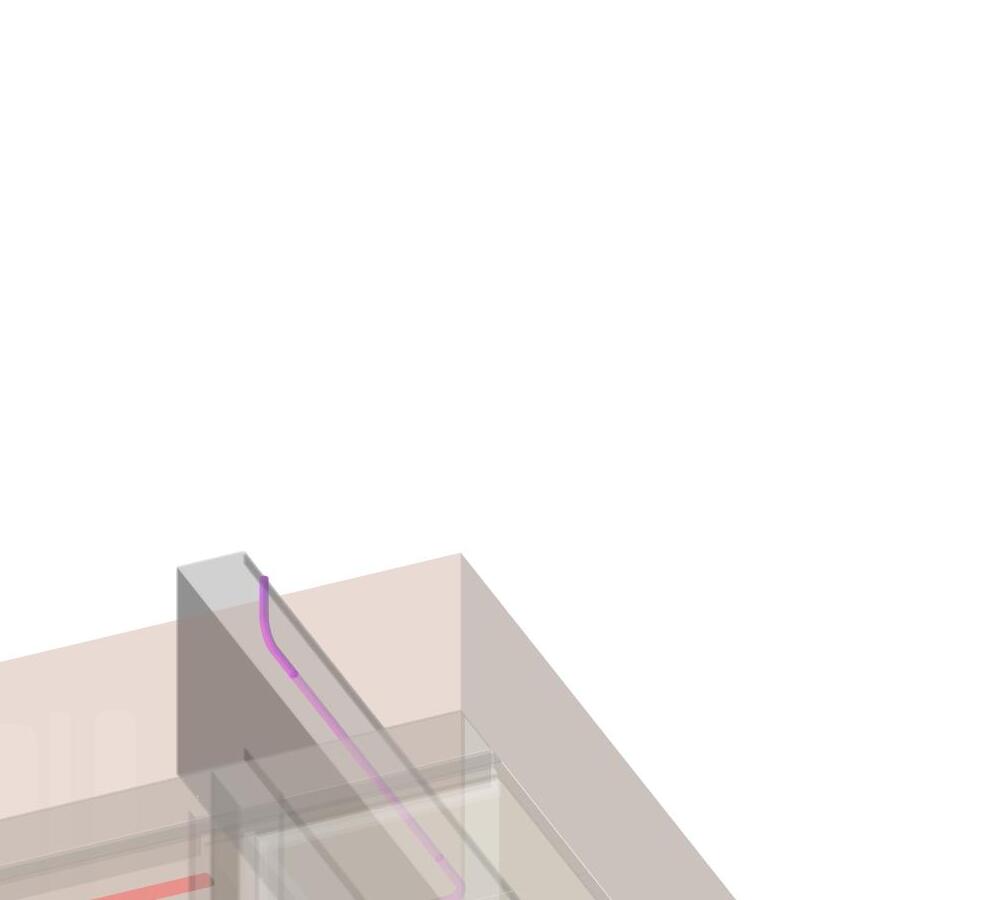

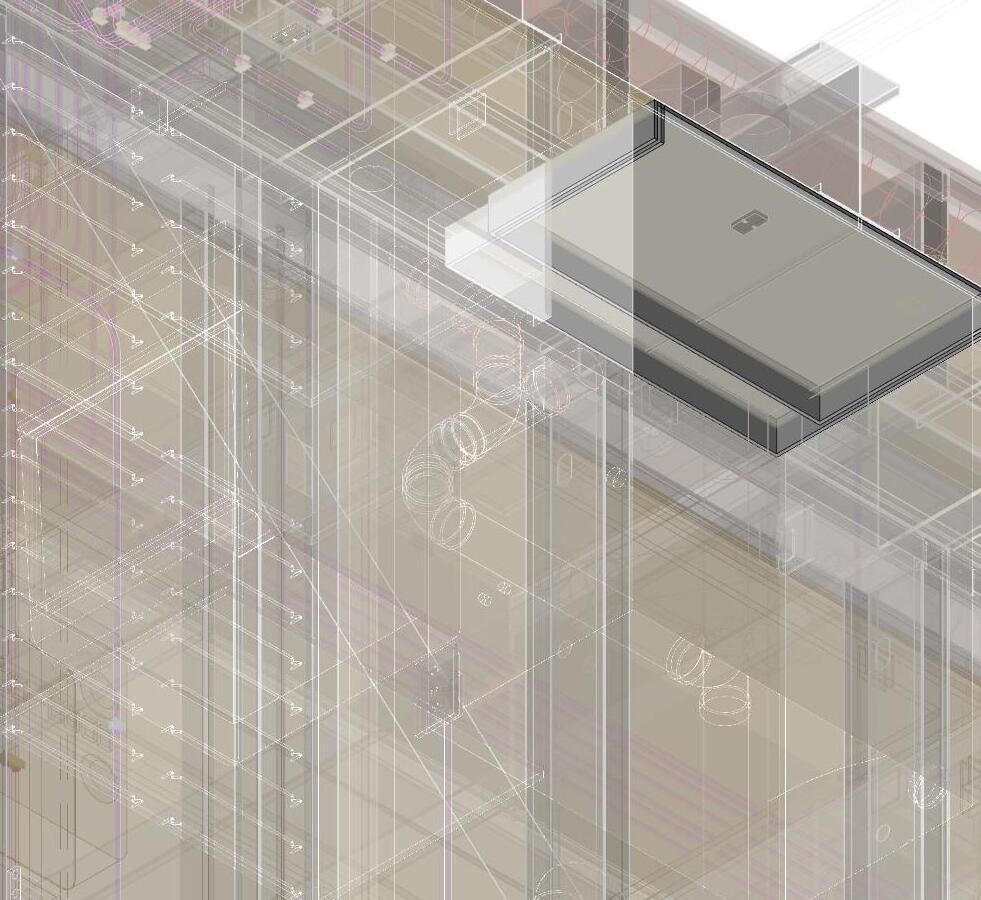

VESSEL INSTALLTION MANUAL

ONE BEDROOM UNIT PLUMBING

-One laborer -15 min

BILL OF MATERIAL

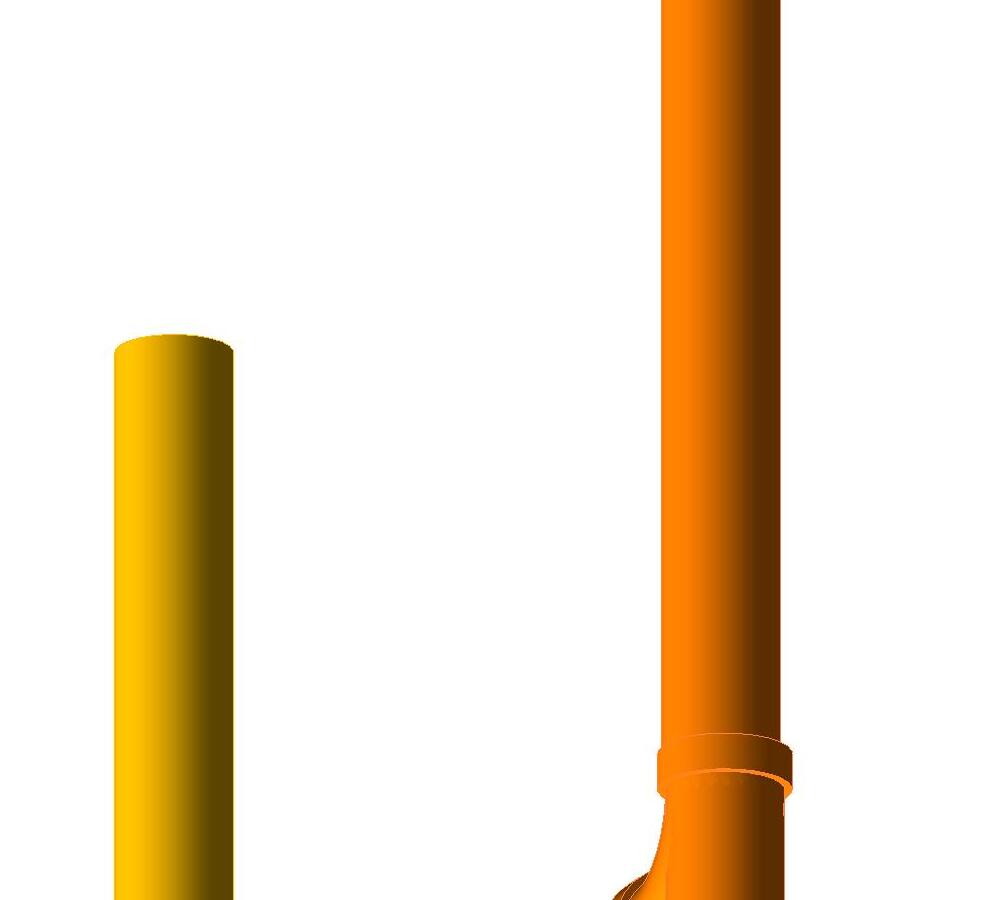

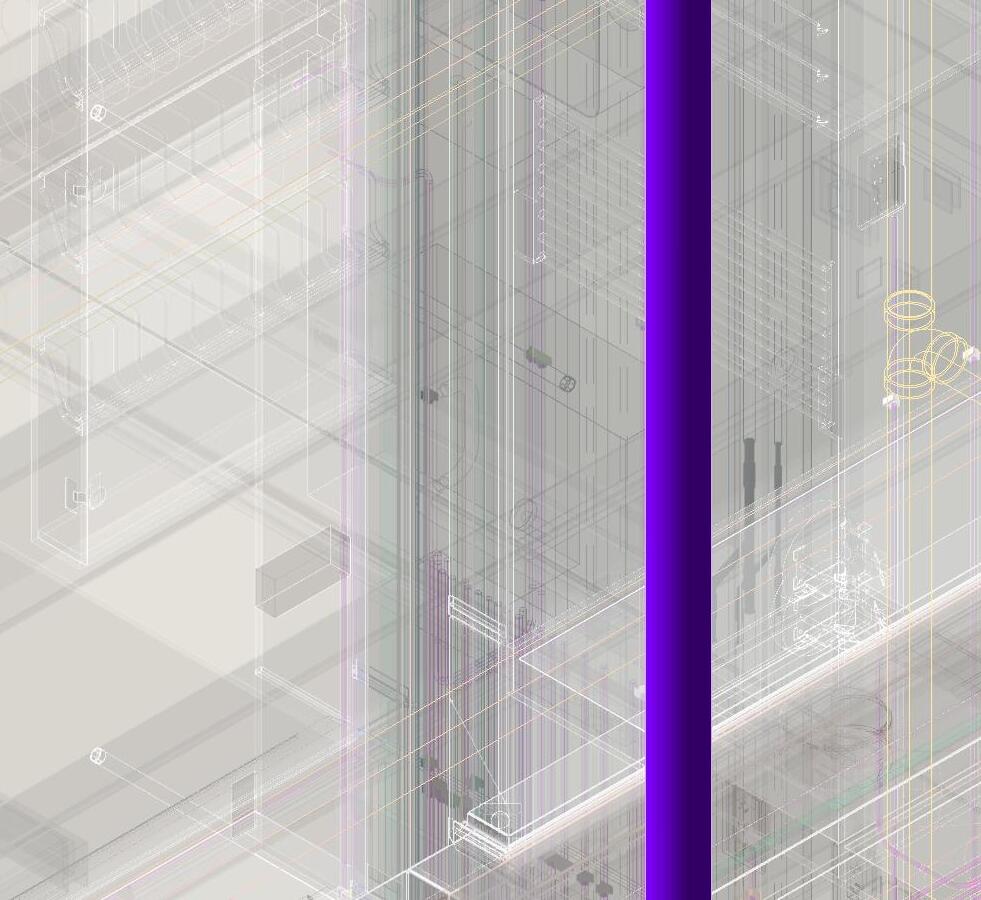

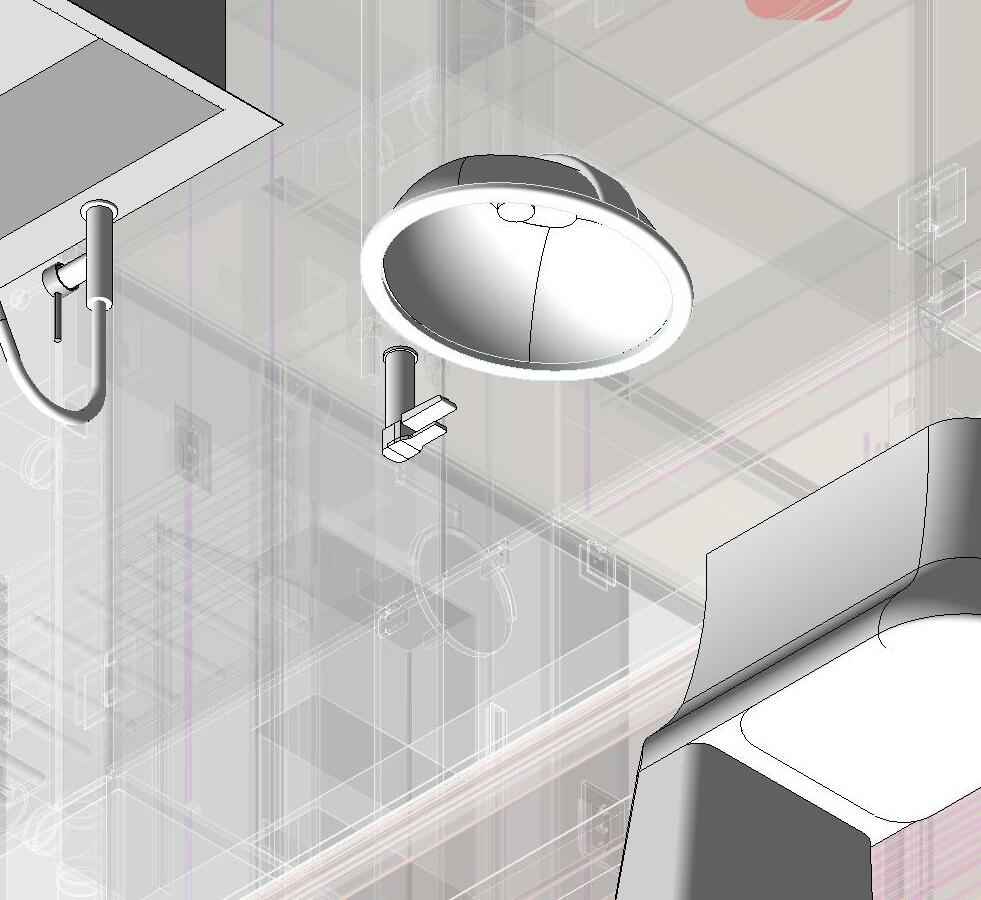

-Locate the riser penetration for the roof leader riser. (at the northern most unit only)

NOTE:

-Install the roof leader riser (Q) and the coupling to the pipe above (R) to the pre-existing unistrut installed on the riser wall (2) 6” 1/2” unistrut and 3” pipe clamp w/ 3/8-16x1” bold and nut @3' AFF and 6' AFF

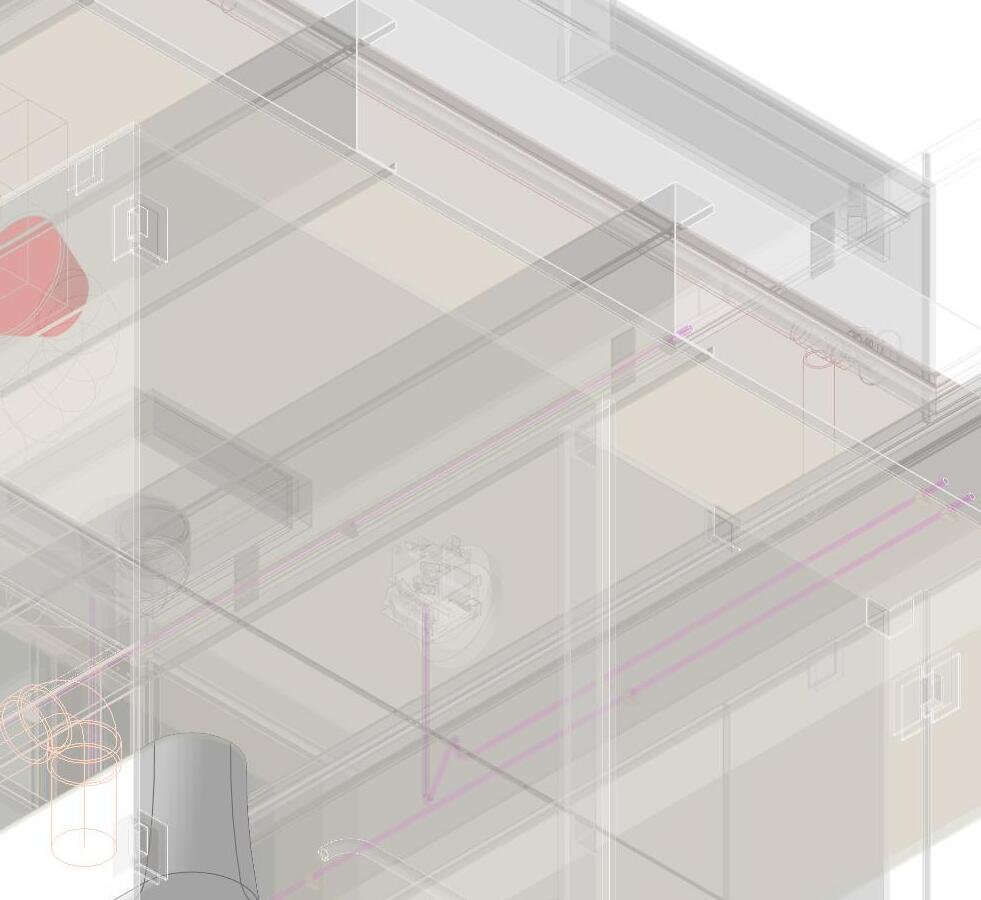

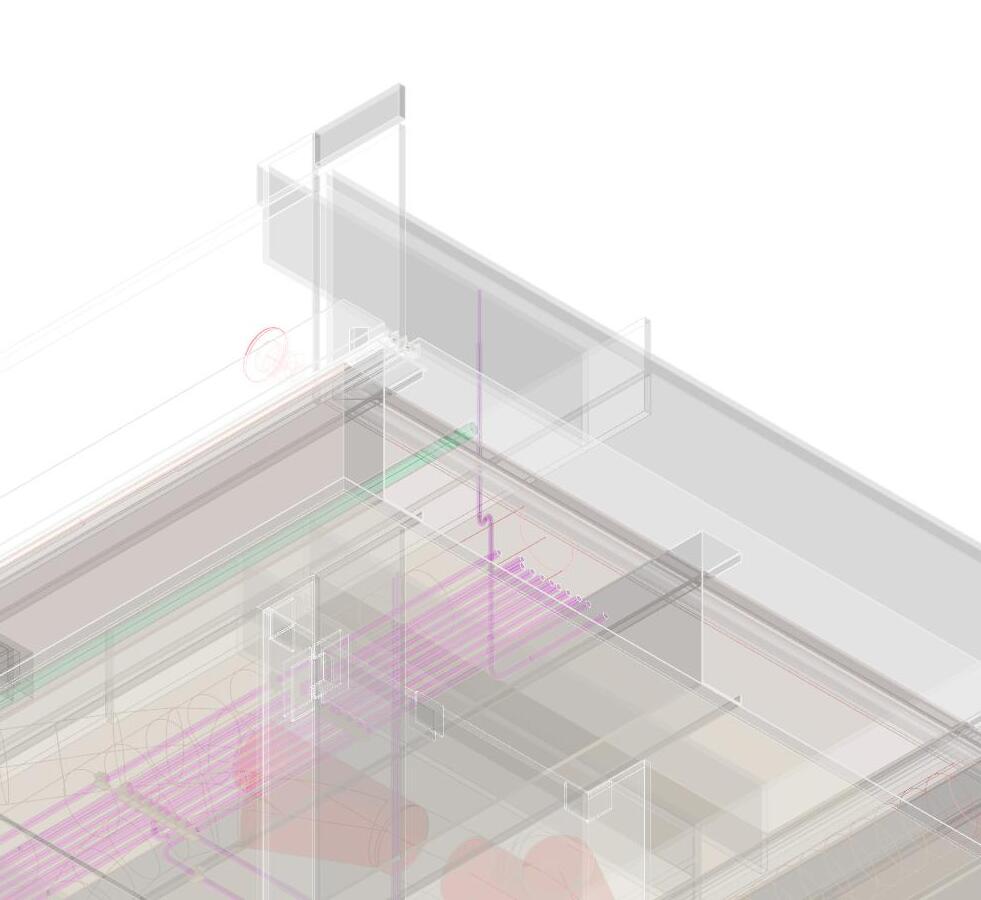

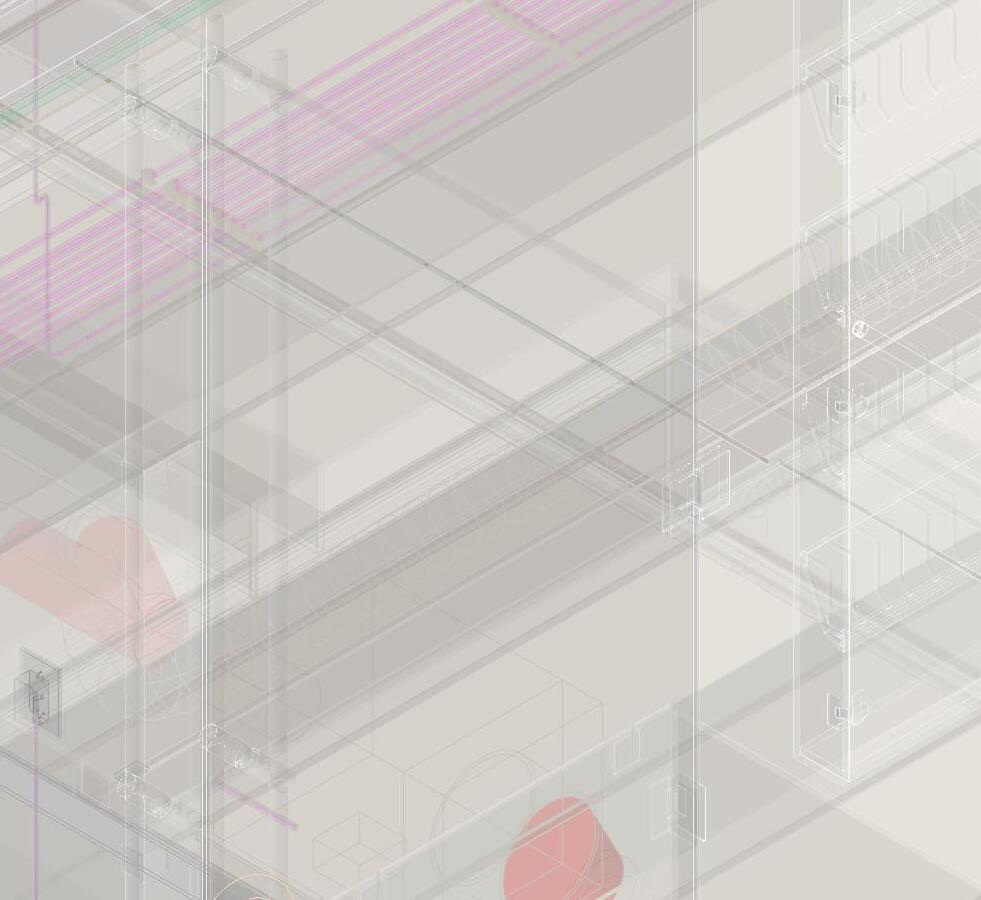

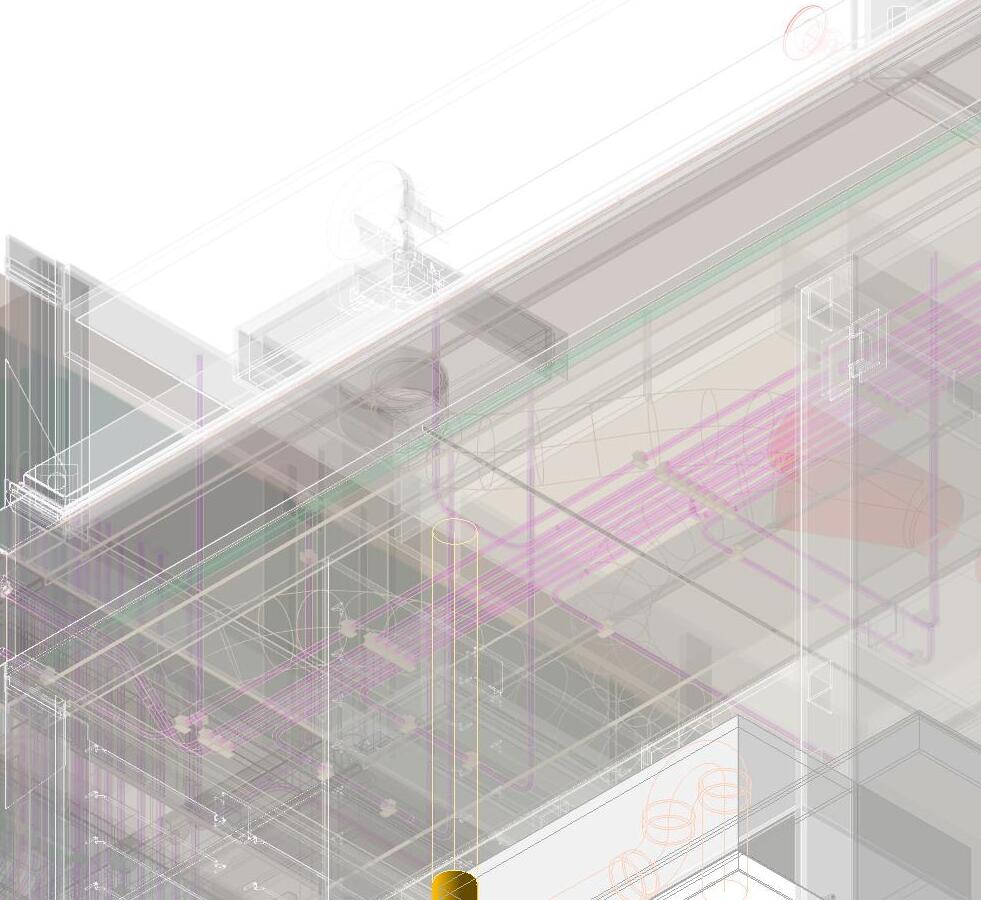

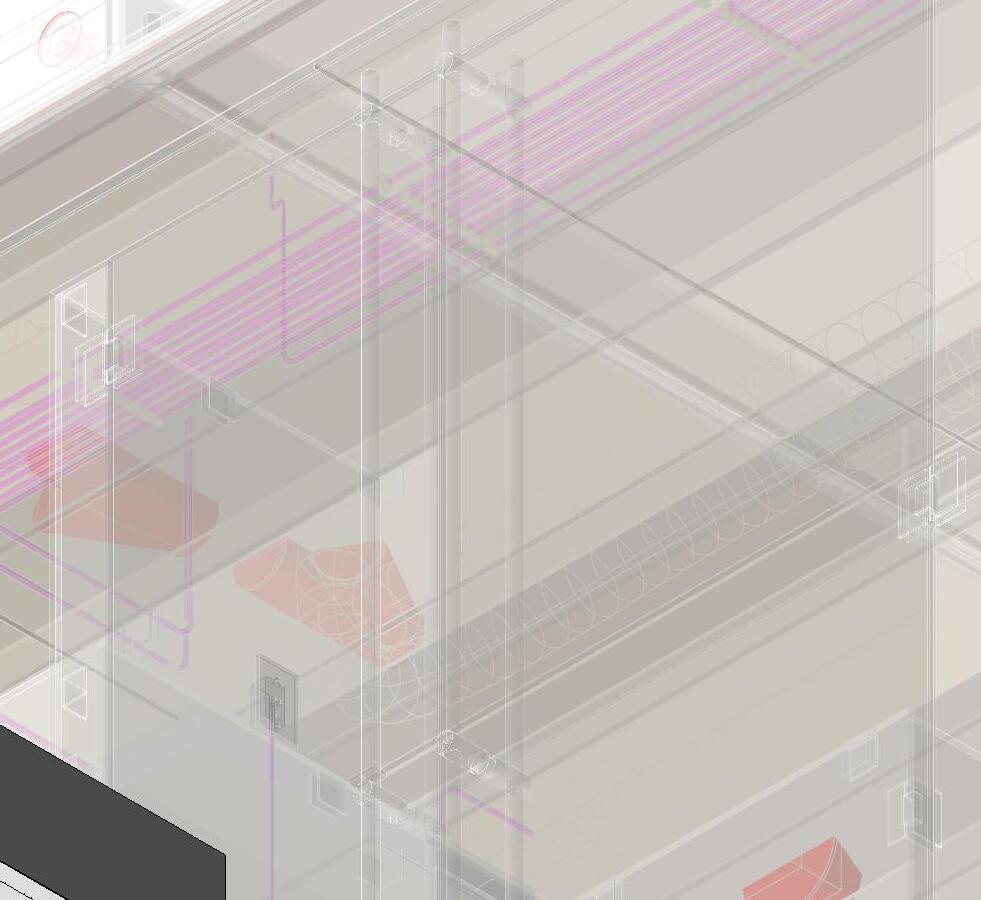

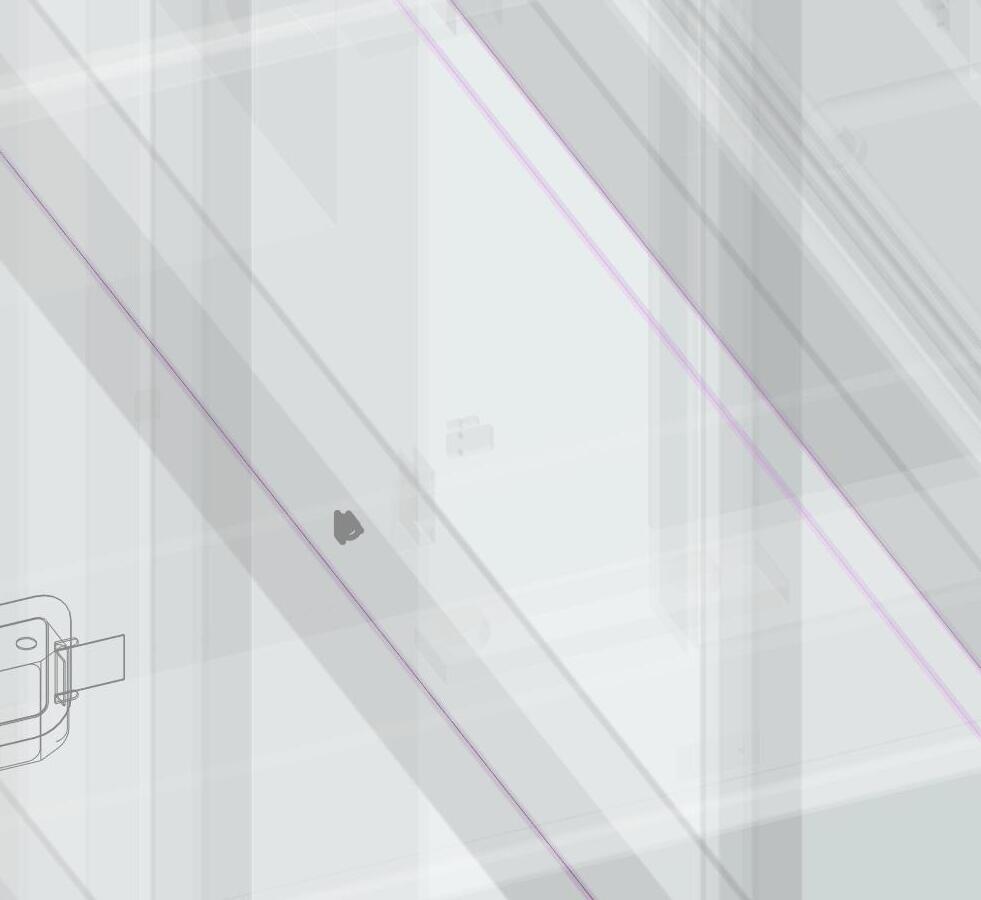

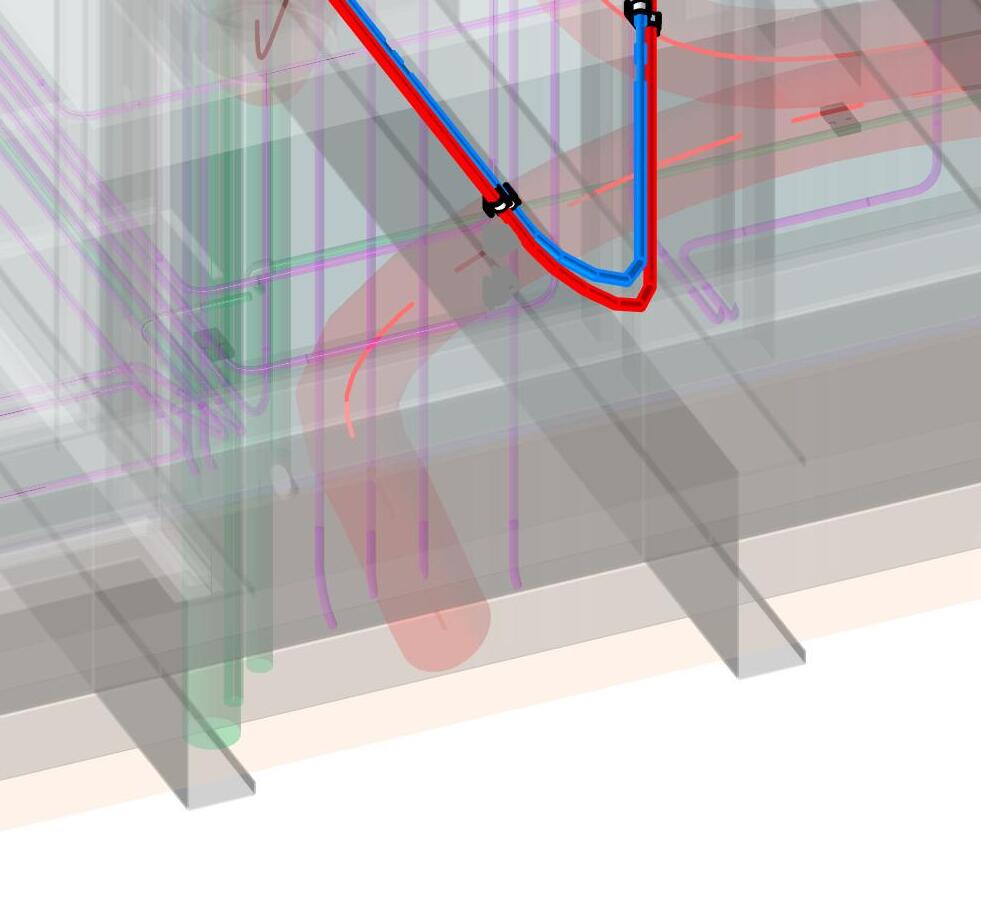

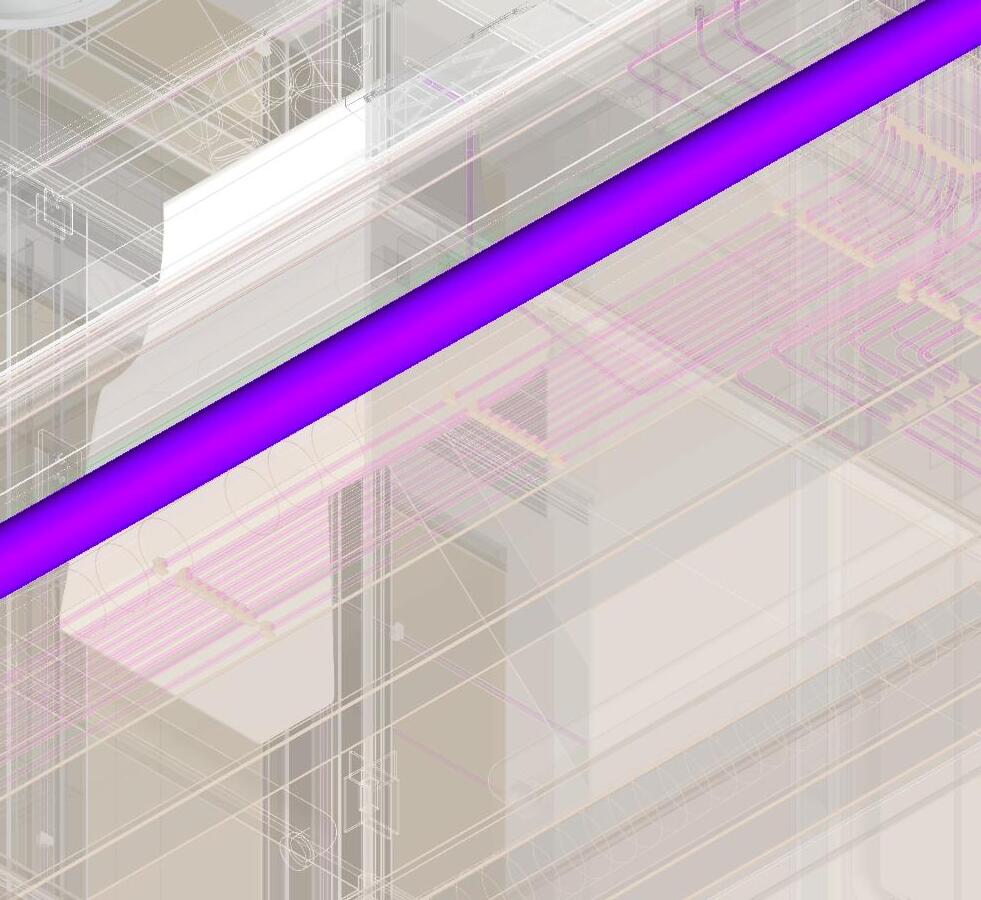

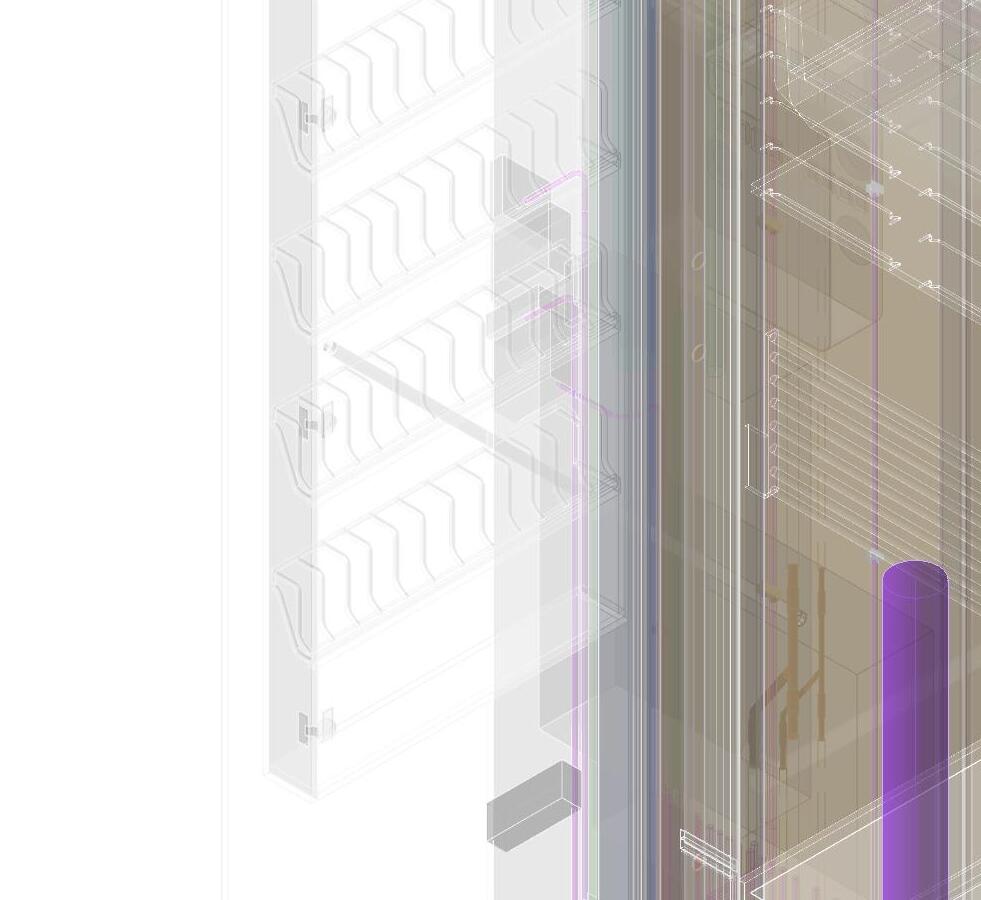

ONE BEDROOM UNIT PLUMBING

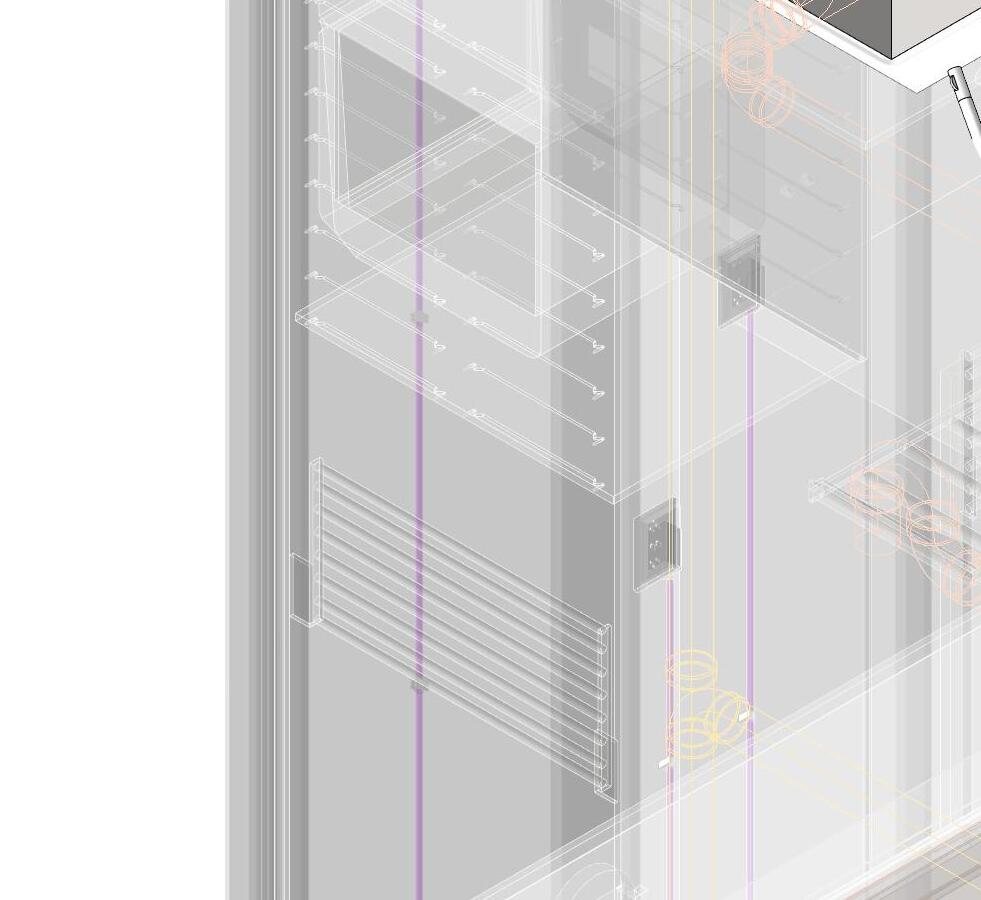

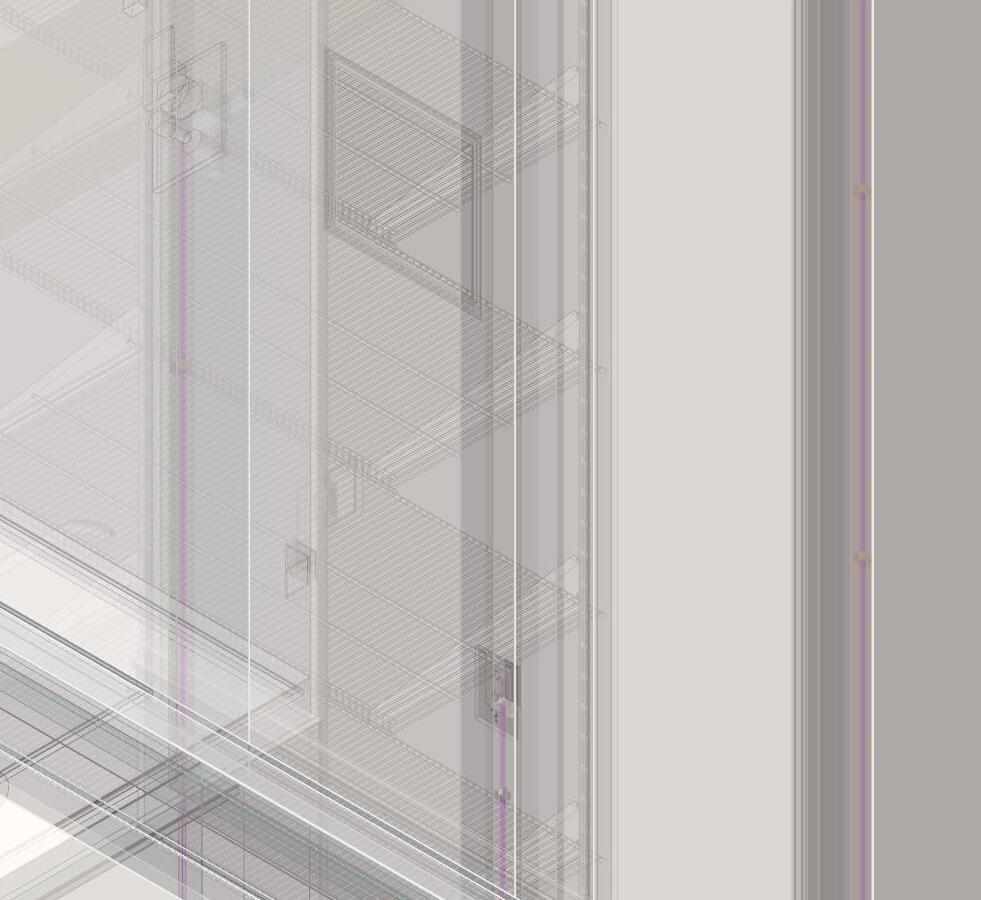

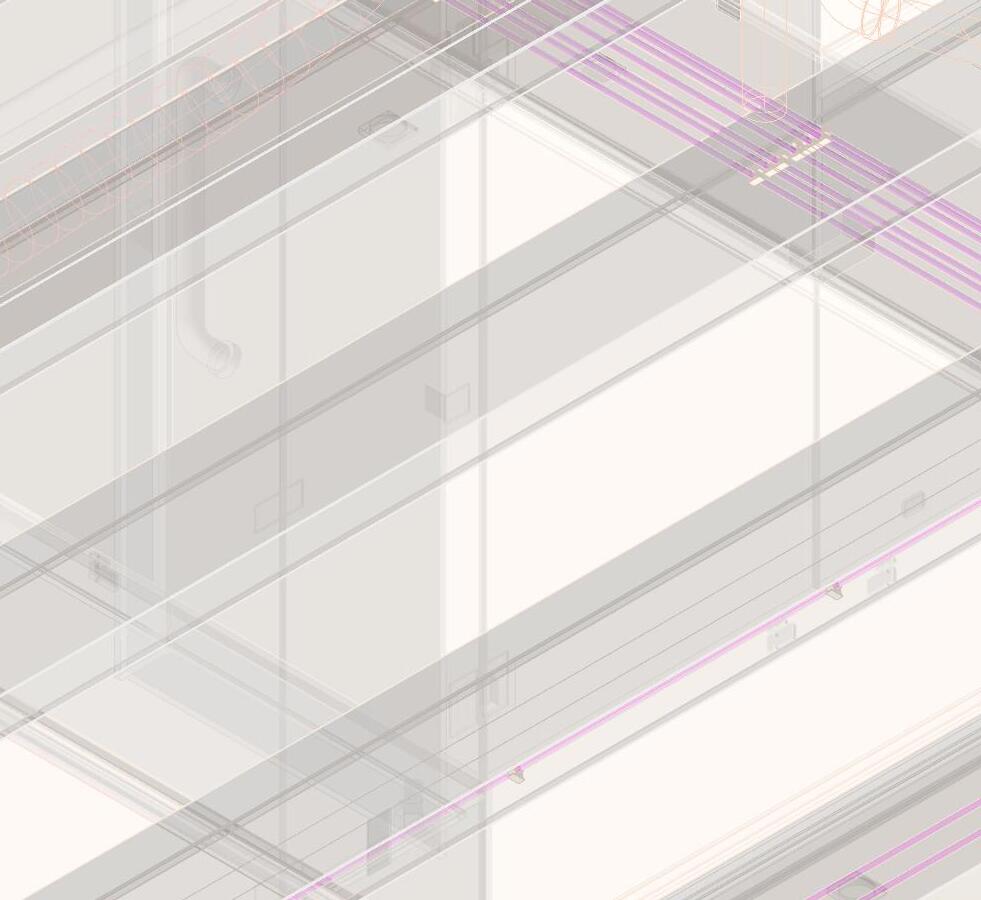

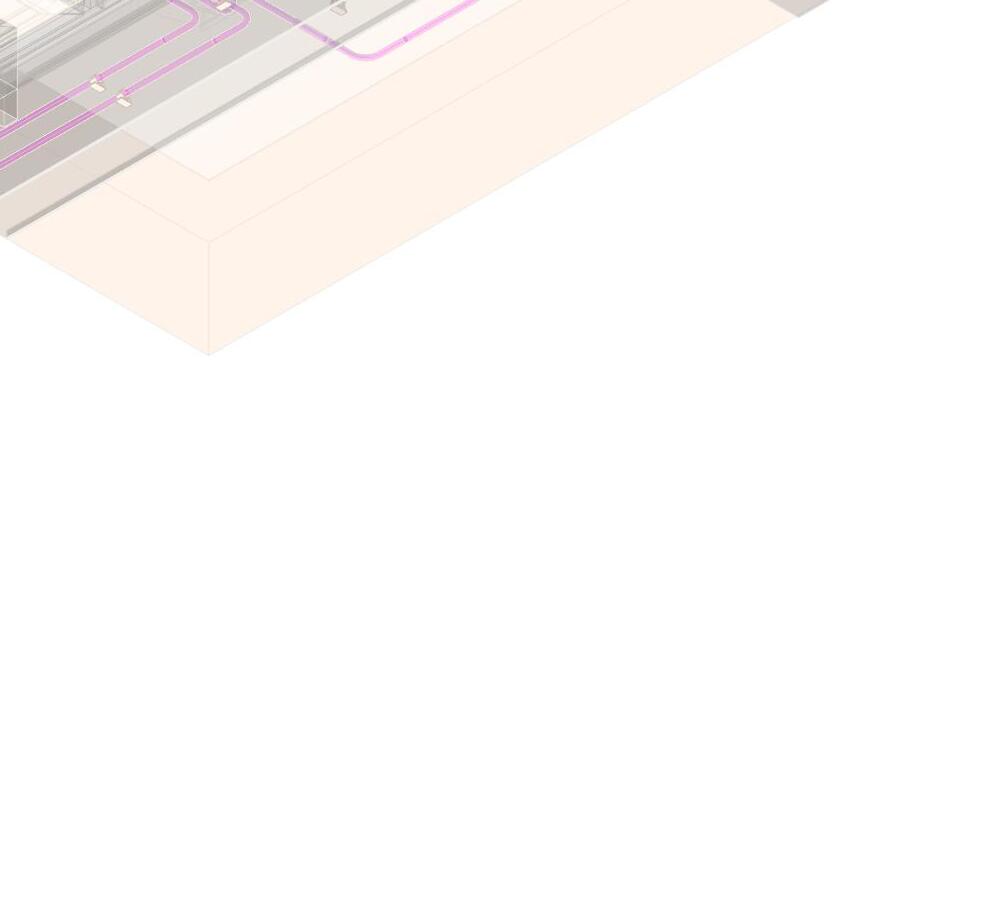

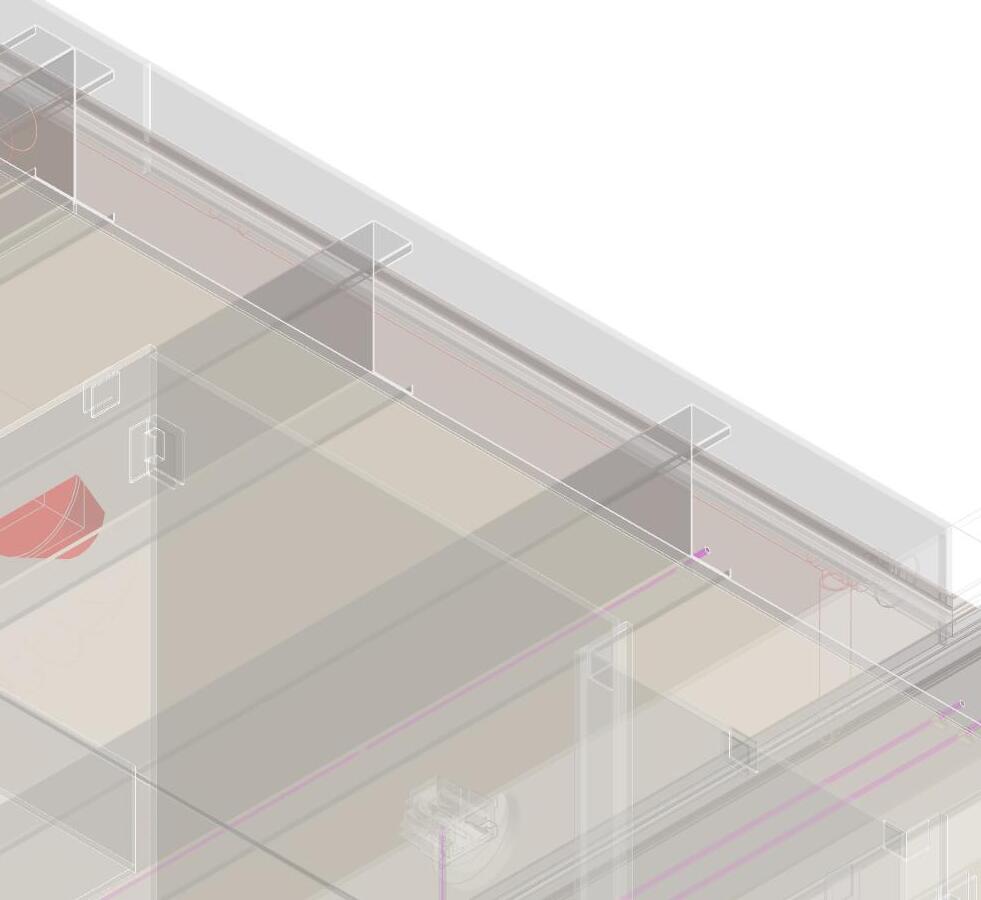

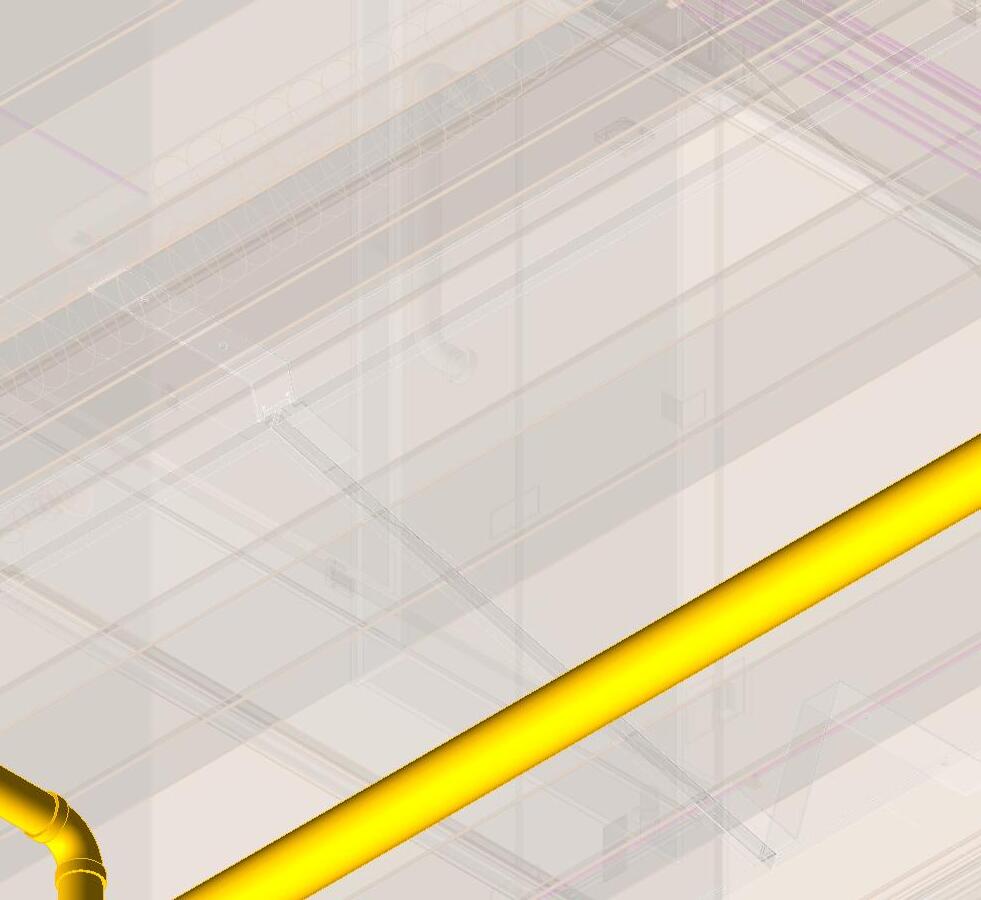

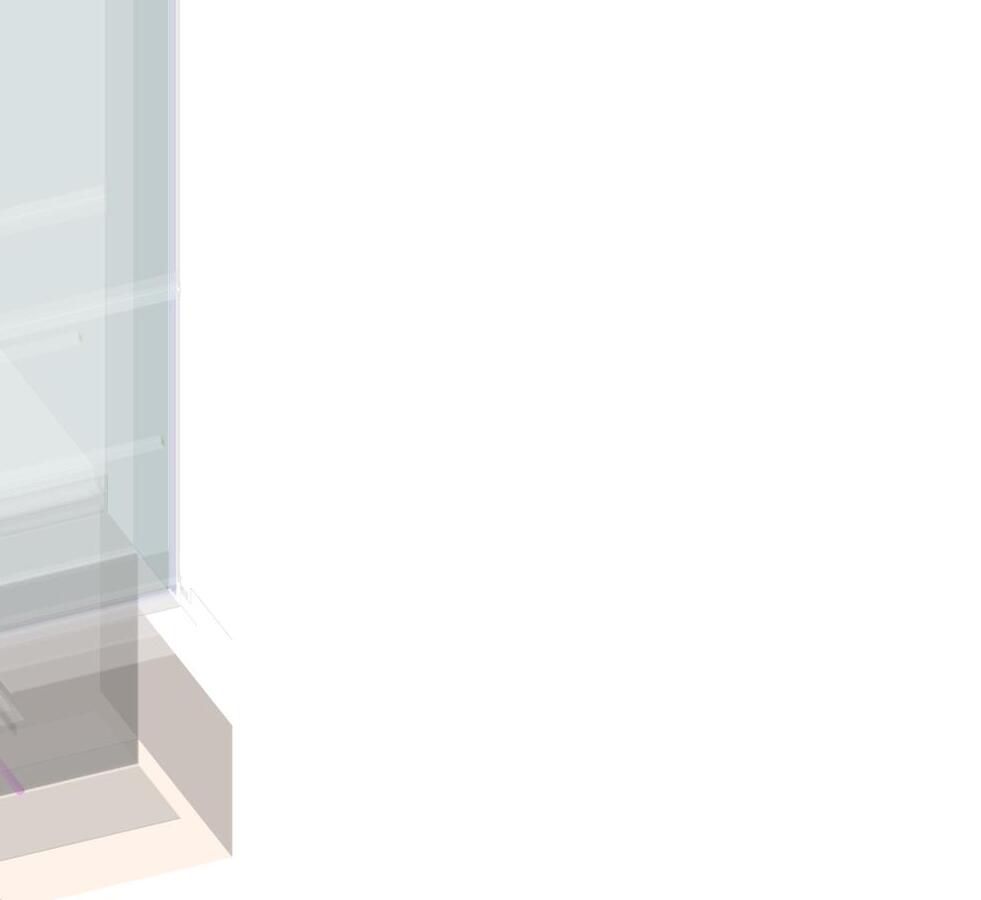

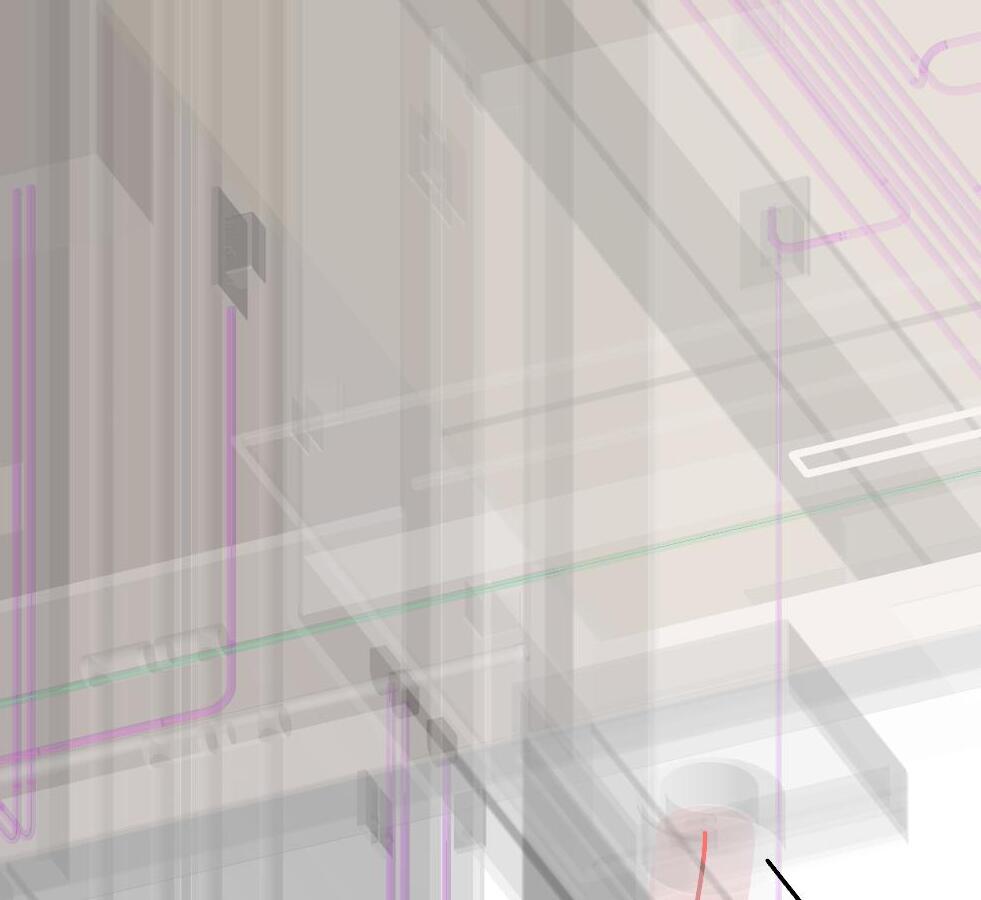

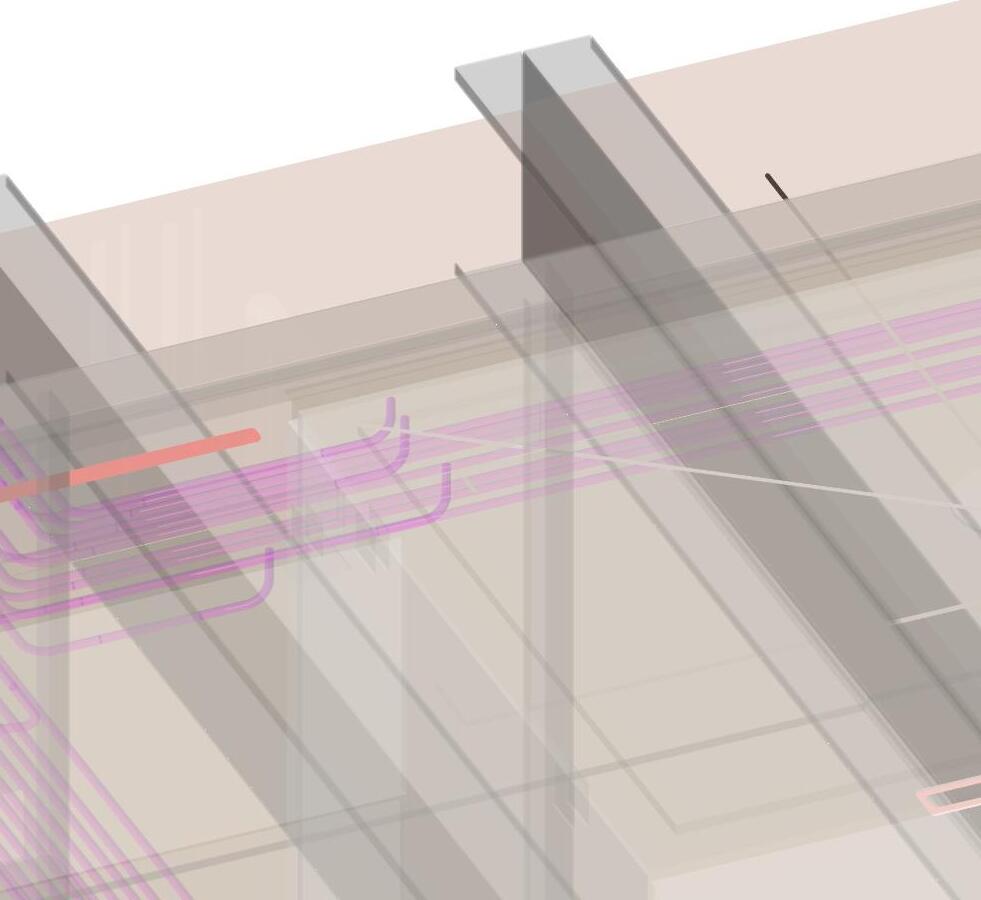

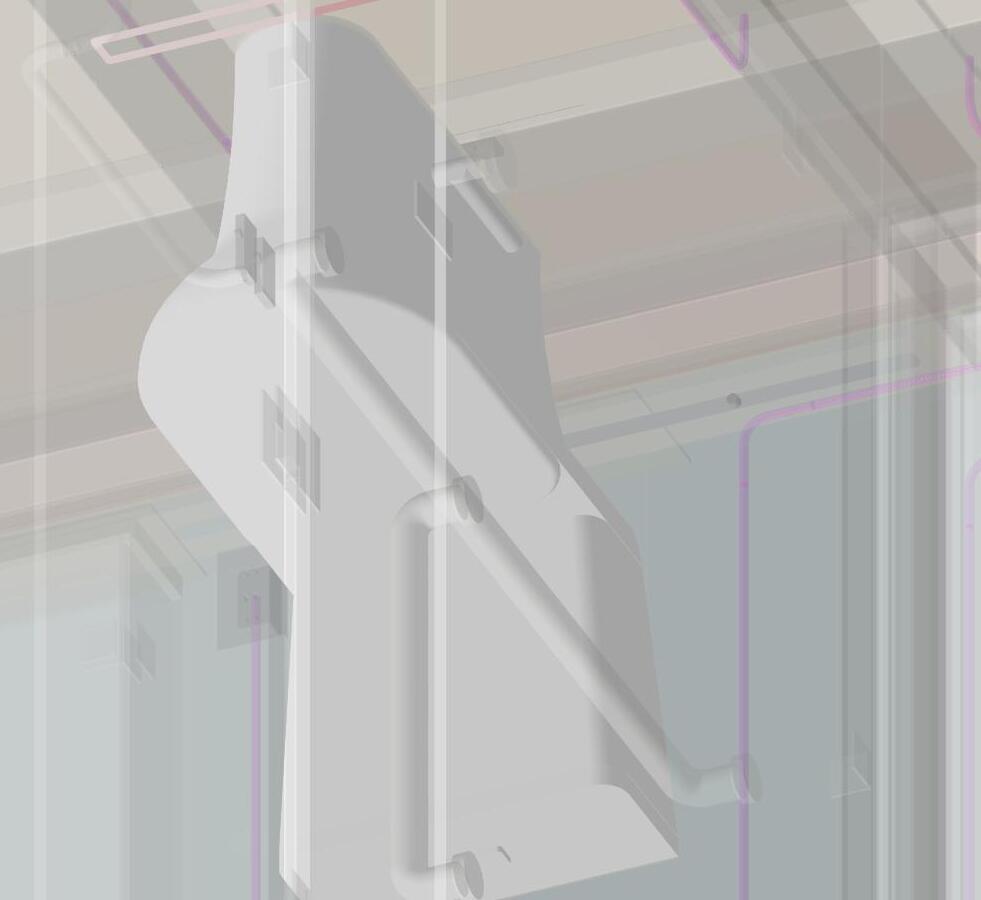

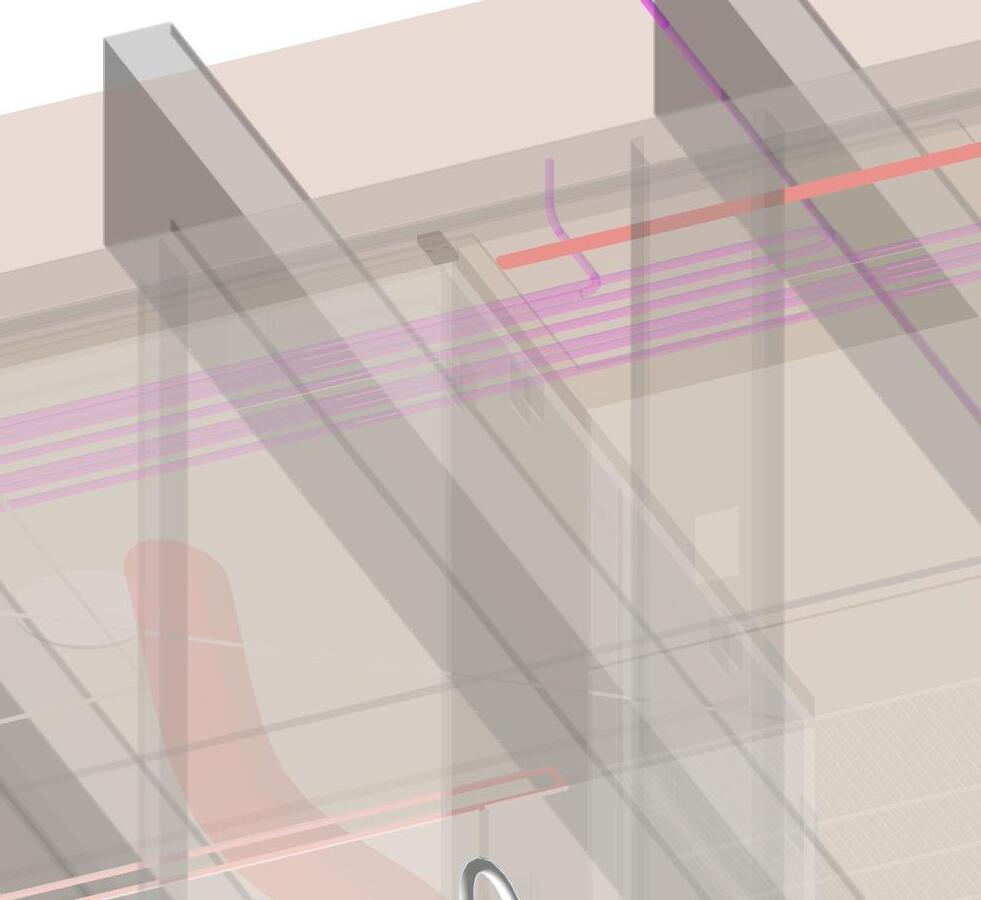

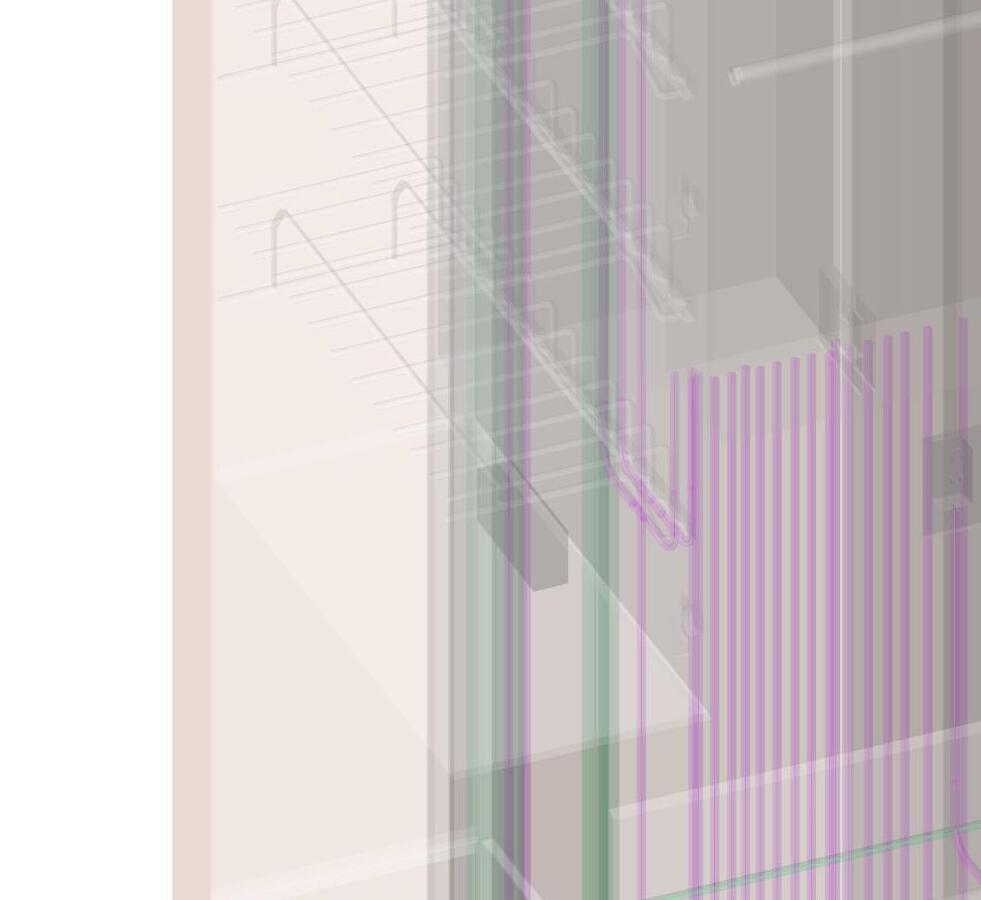

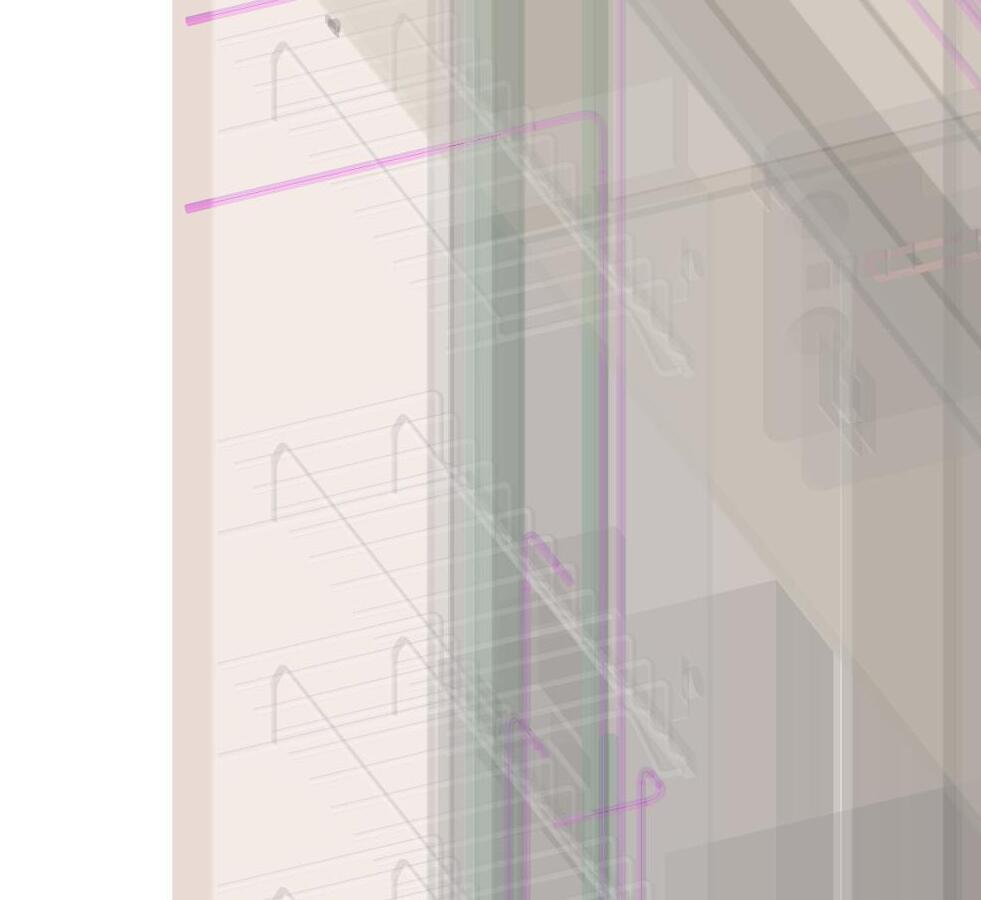

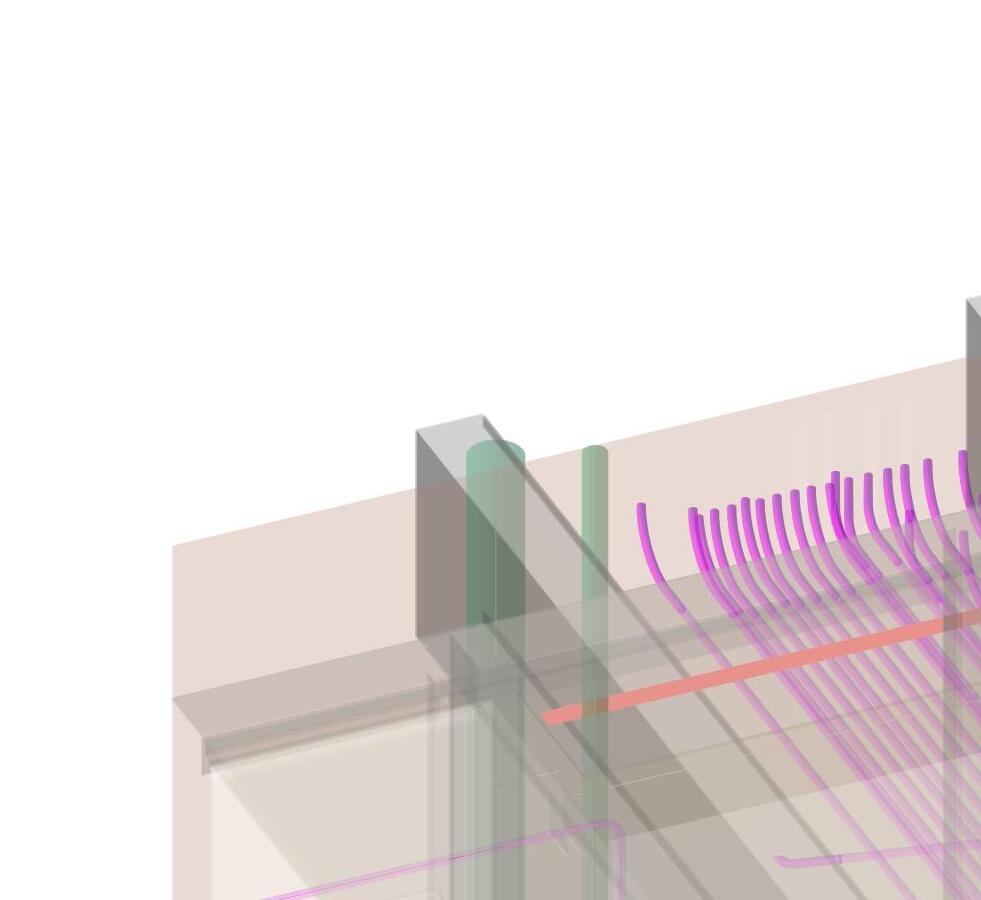

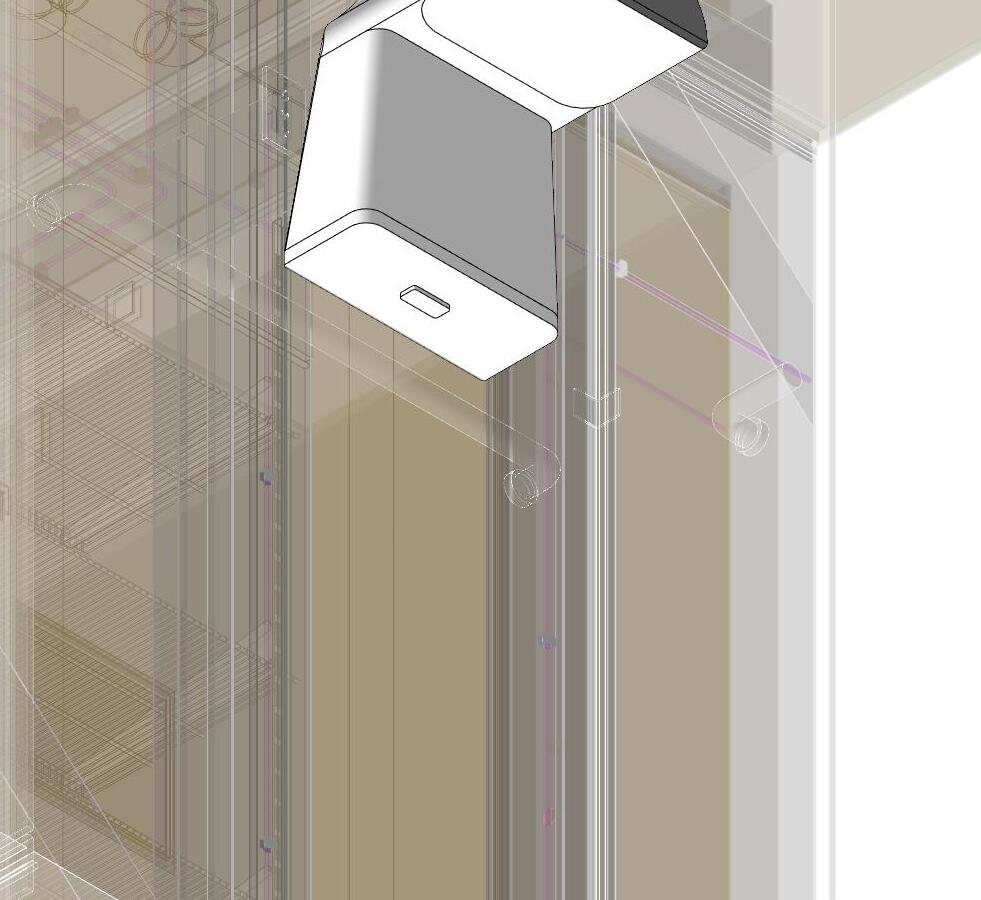

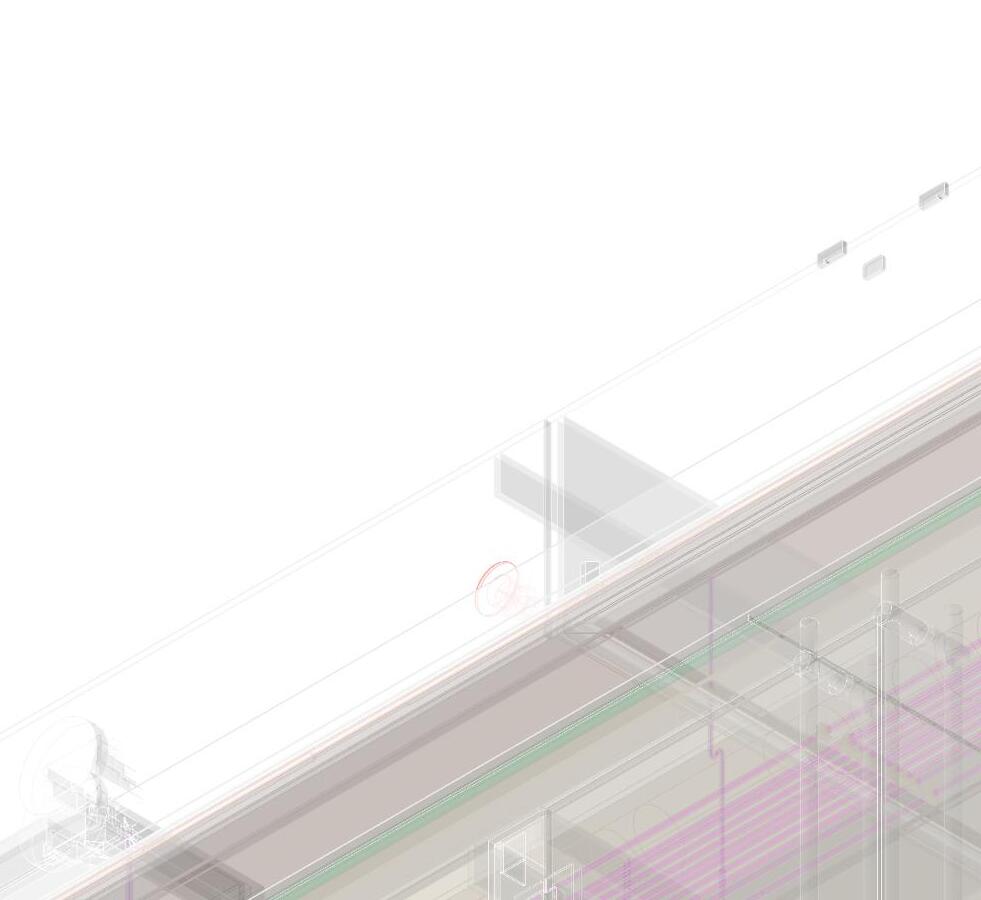

UNISTRUT BETWEEN JOISTS

PRE CUT AND KITTED PARTS FOR HANGER INSTALLATION

(4) 24" WOOD 2X4 EXPANDABLE METAL HANGER (16) #8X1-1/2" HEX DRIVE SELF TRAPPING SCREW (1) 1/4" HEX DRIVE BIT

1 LABORER 30 MIN PER APARTMENT

STEP 1: USING A 6' STEP LADDER TO ACCESS THE 5TH JOIST CAVITY FROM THE WINDOW WALL, MEASURE TWO BLOCKING LENGTHS FROM THE TOILET WASTE ROUGH. MARK LOCATION.

STEP 2: ALIGN CENTER OF BLOCKING ON MARK FROM STEP 1, SPANNING BETWEEN JOISTS.

STEP 4: SECURE THE BLOCKING IN PLACE WITH TWO WOOD SCREWS INSTALLED THROUGH THE PILOT HOLES BLOCKING, ATTACHING SECURELY TO JOIST

STEP 5: MEASURE TWO BLOCKING LENGTHS (48"). MARK LOCATION.

STEP 6: REPEAT STEPS 2-4

STEP 10: REPEAT STEPS 1-6 IN 7TH JOIST BAY FROM THE WINDOW WALL.

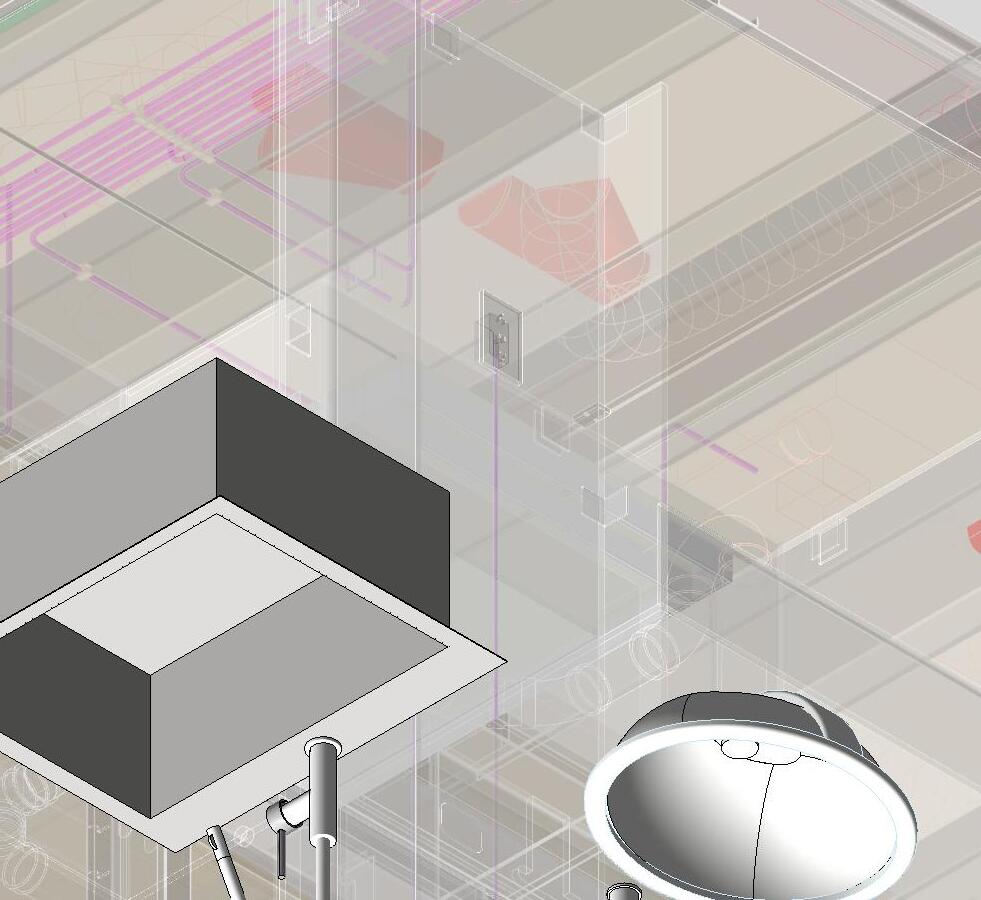

VESSEL INSTALLTION MANUAL

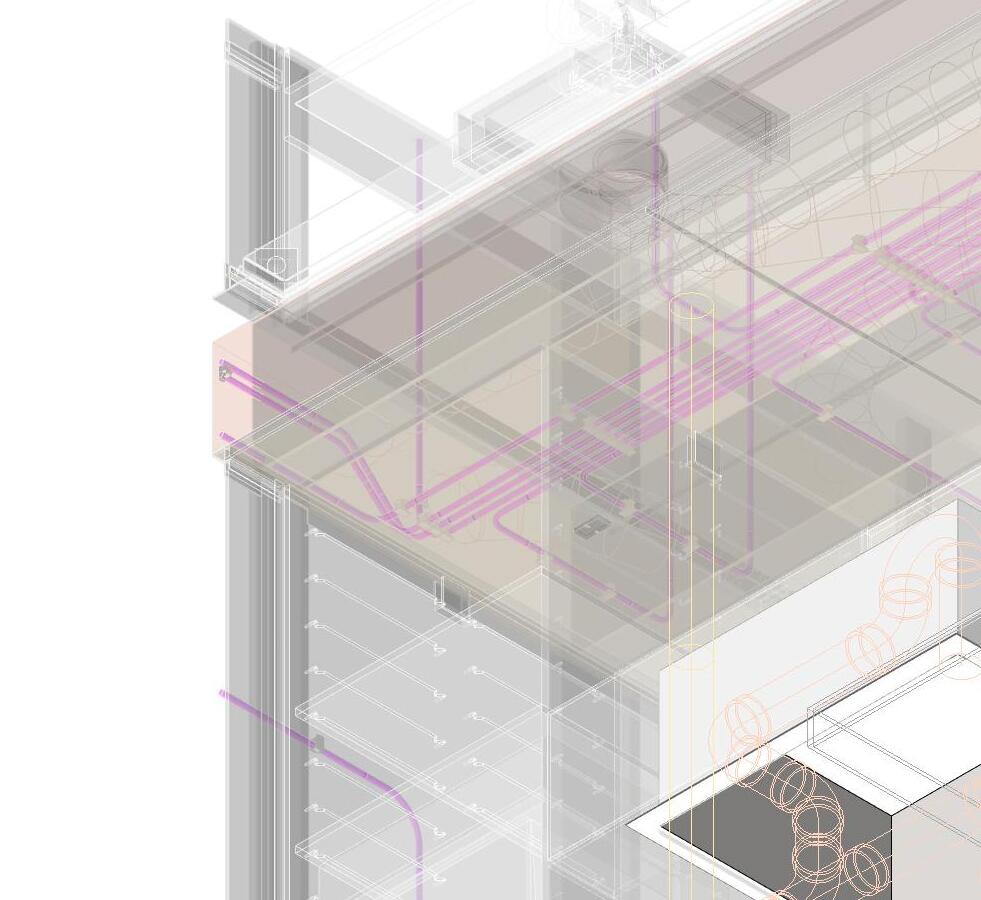

ONE BEDROOM UNIT PLUMBING

1 laborer 20 min

BILL OF MATERIAL

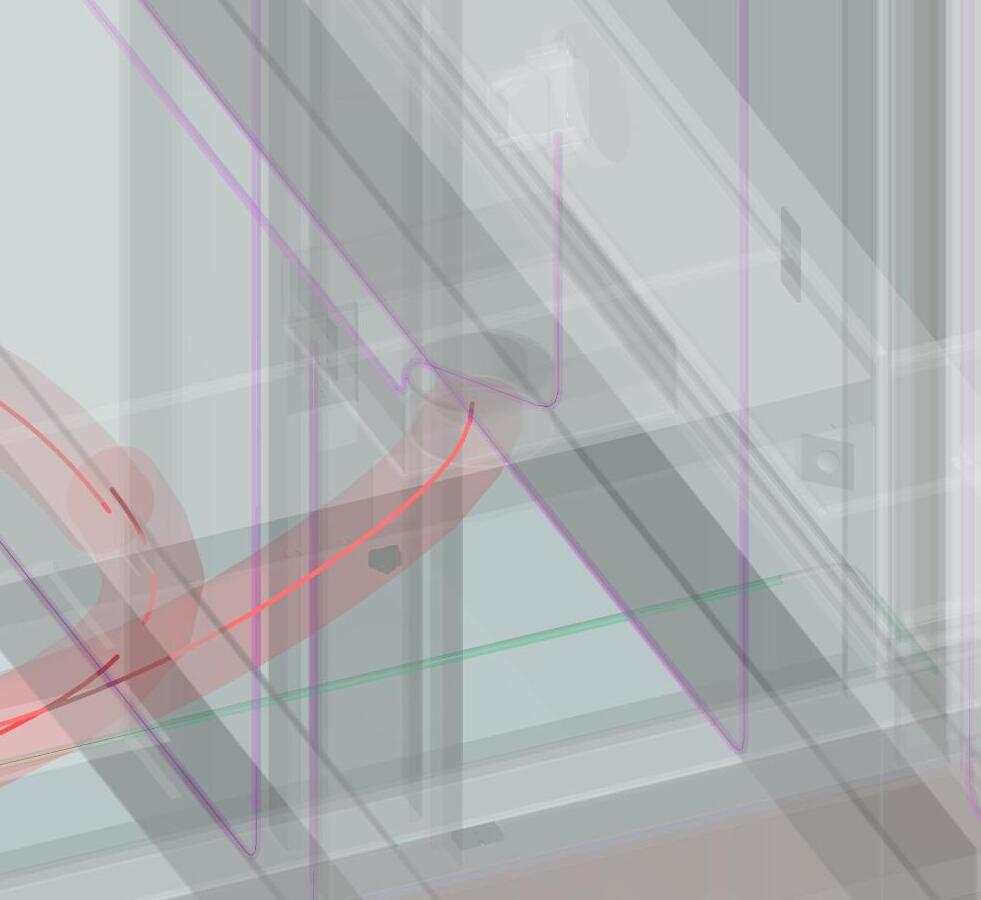

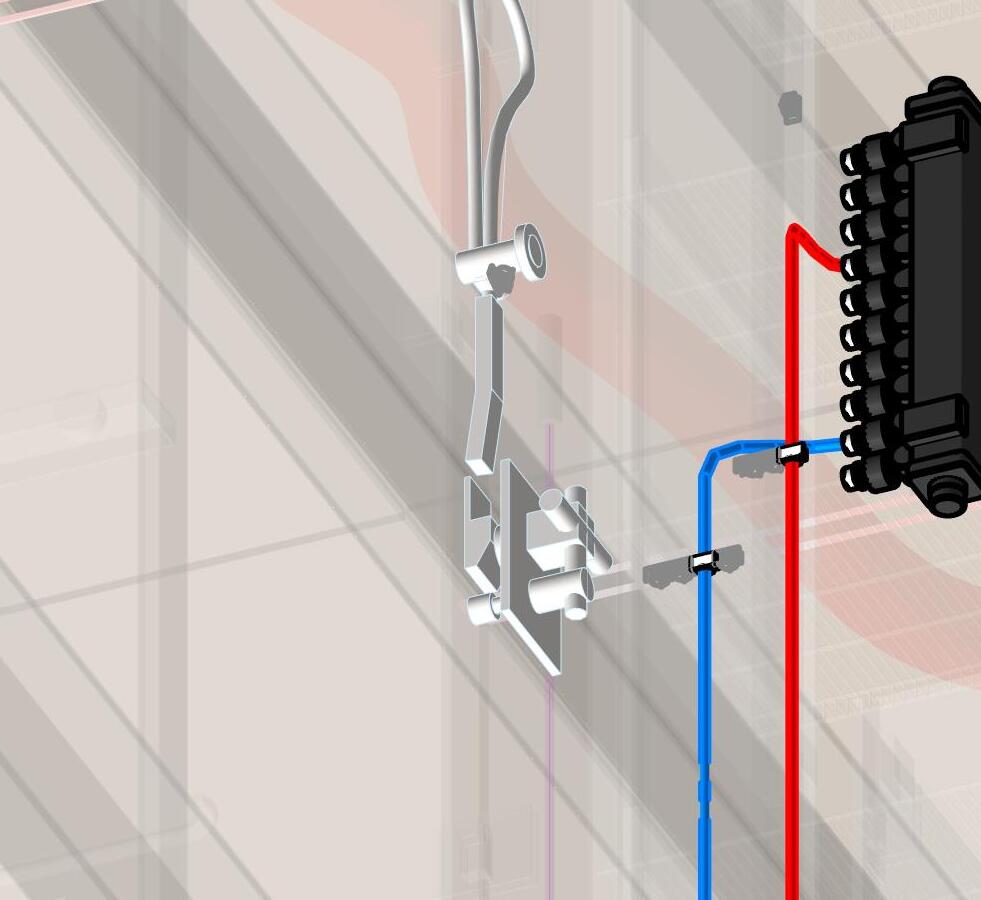

-Locate the "Laundry Tree" assembly against the pre-installed unistrut on the open stud side of the room, with the drain closest to the toilet side, and vent closest to the kitchen side.

-Align to riser holes, and fittings from floor below.

NOTE:

-Attach riser to pre-hung unistrut @ 36" where each pipe crosses the unistrut with 2" pipe clamps. @ 72" AFFF attach the waste and vent lines to the pre-installed unistrut with 2” pipe clamps, 3/8-16x1” bolt and nuts

-Secure laundry box connections to studs on each side using (2) #8 self tapping screws each side

51Vent

52Vent

BILL OF MATERIAL

59Vent

BBendPVCSch

BBendPVCSch

MarkItem DescriptionSizeCount

ø1

BBendPVCSch 40 - DWV 2"ø-2"ø PVC Sch 402"ø-2"ø1

BBendPVCSch 40 - DWV 2"ø-2"ø PVC Sch 402"ø-2"ø1

BBendPVCSch 40 - DWV 2"ø-2"ø PVC Sch 402"ø-2"ø1

BBendPVCSch 40 - DWV 2"ø-2"ø PVC Sch 402"ø-2"ø1

ETee Reducing Sanitary - PVC - Sch 40DWV 3"ø-3"ø-2"ø PVC Sch 403"ø-3"ø-3"ø1

ETee Reducing Sanitary - PVC - Sch 40DWV 3"ø-3"ø-2"ø PVC Sch 403"ø-3"ø-2"ø1

FCoupling Reducing - PVC - Sch 40 3"ø-2"ø PVC Sch 403"ø-2"ø1

YVent Cowl3"ø1

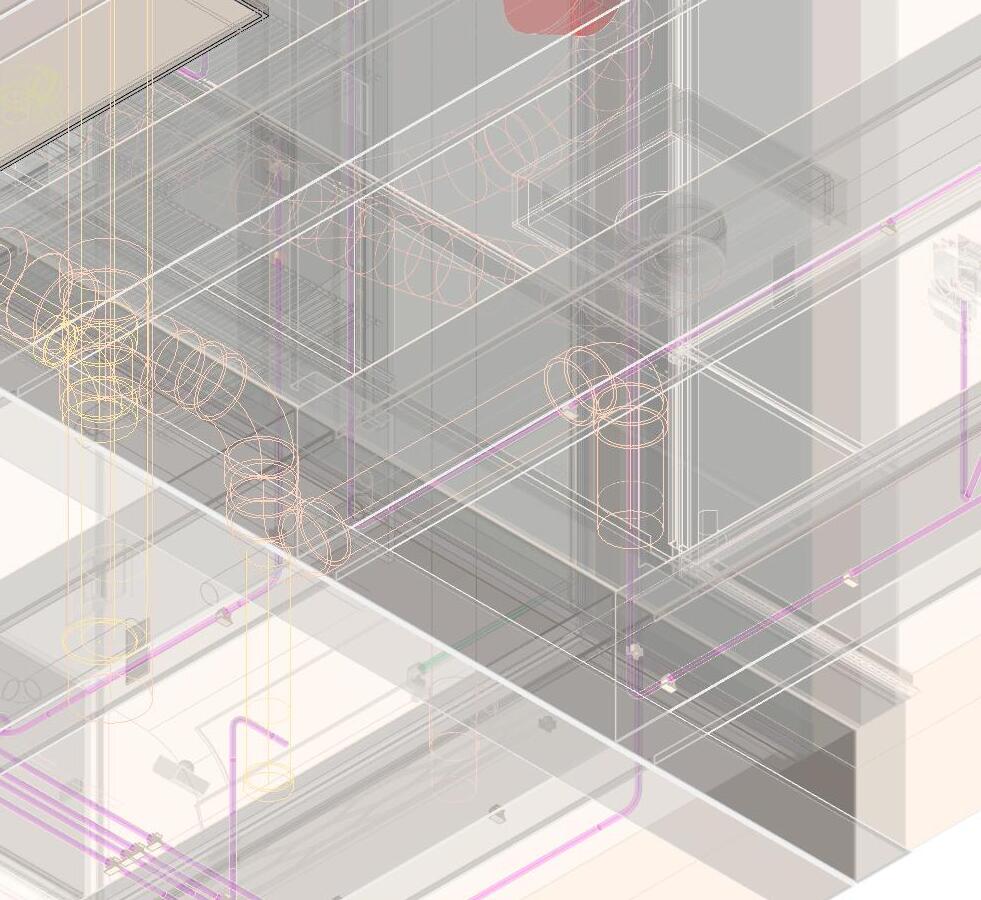

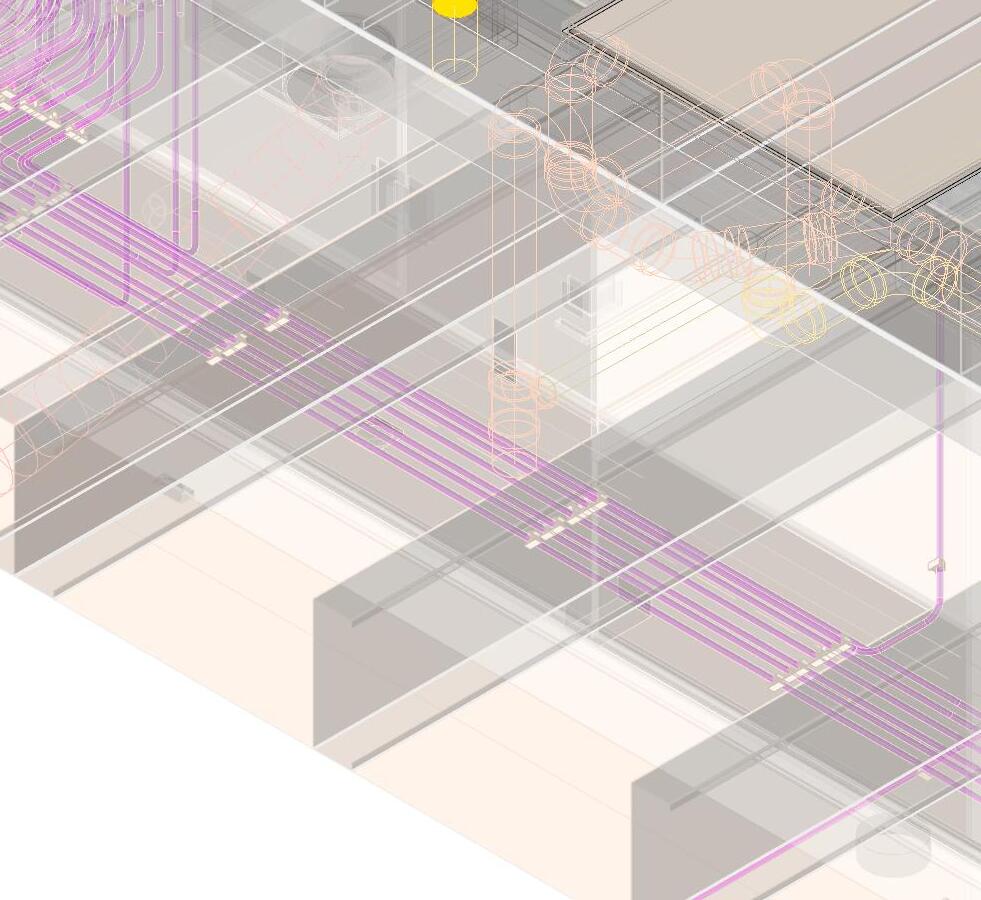

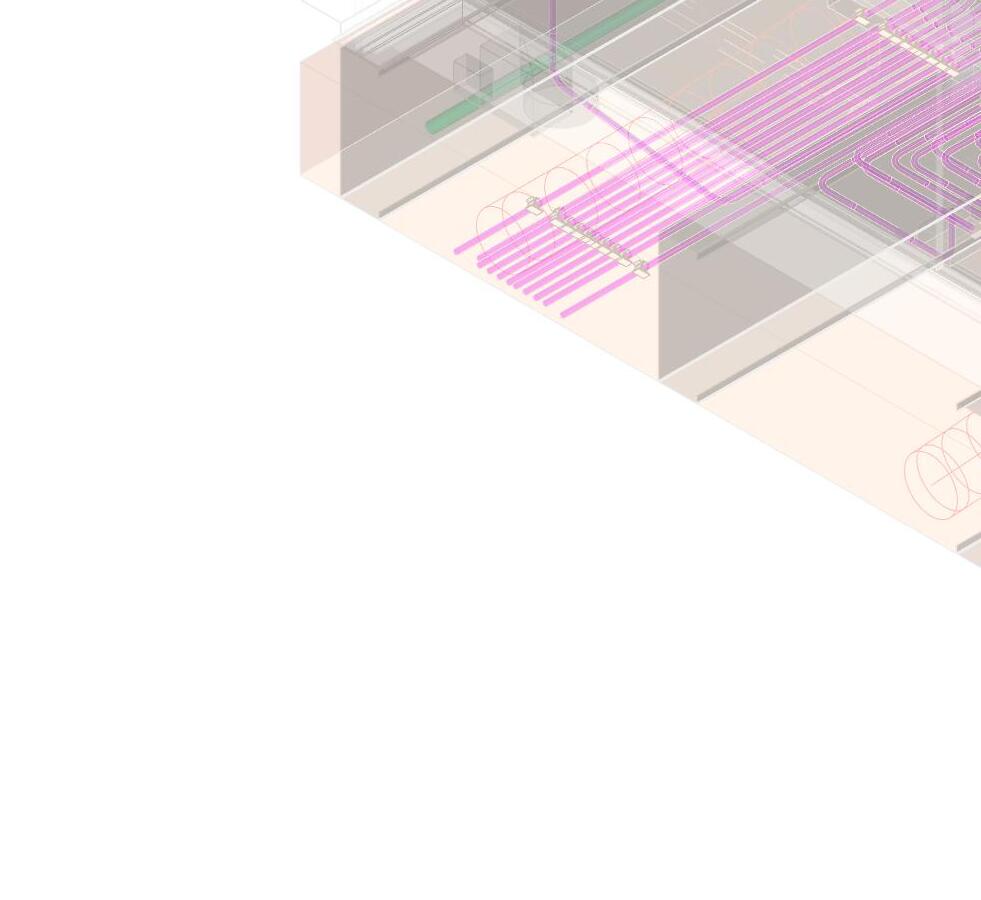

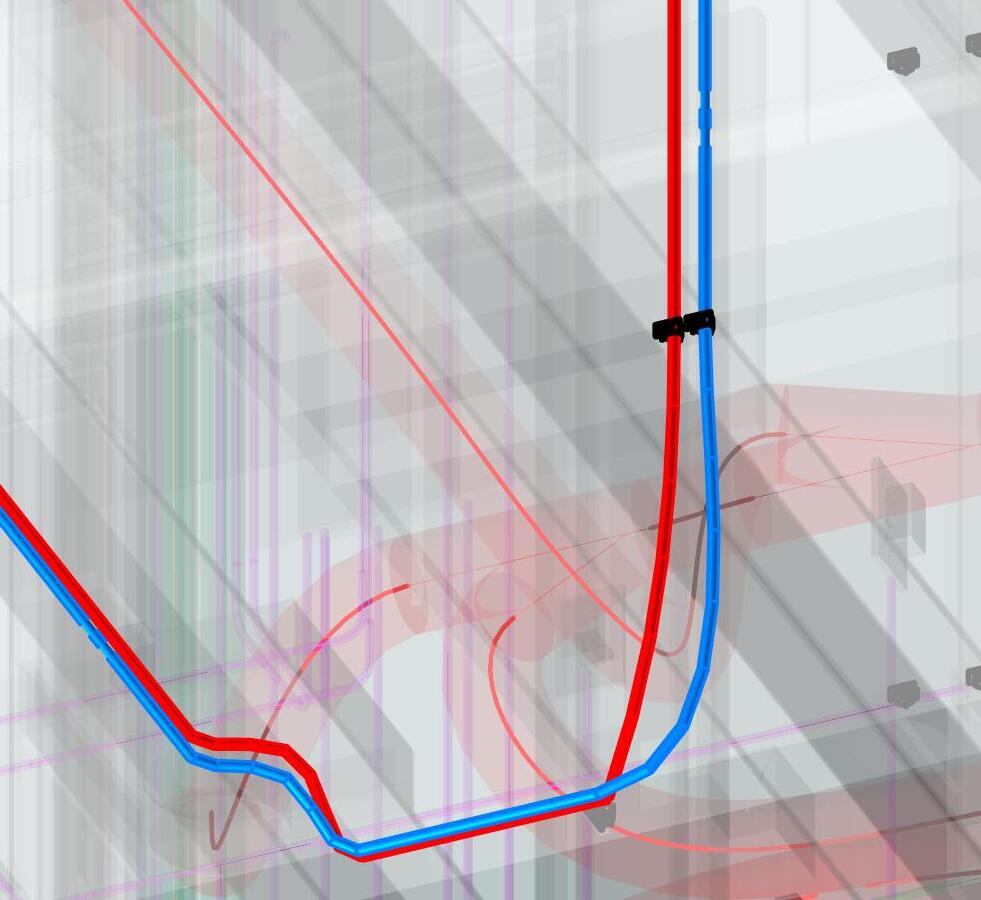

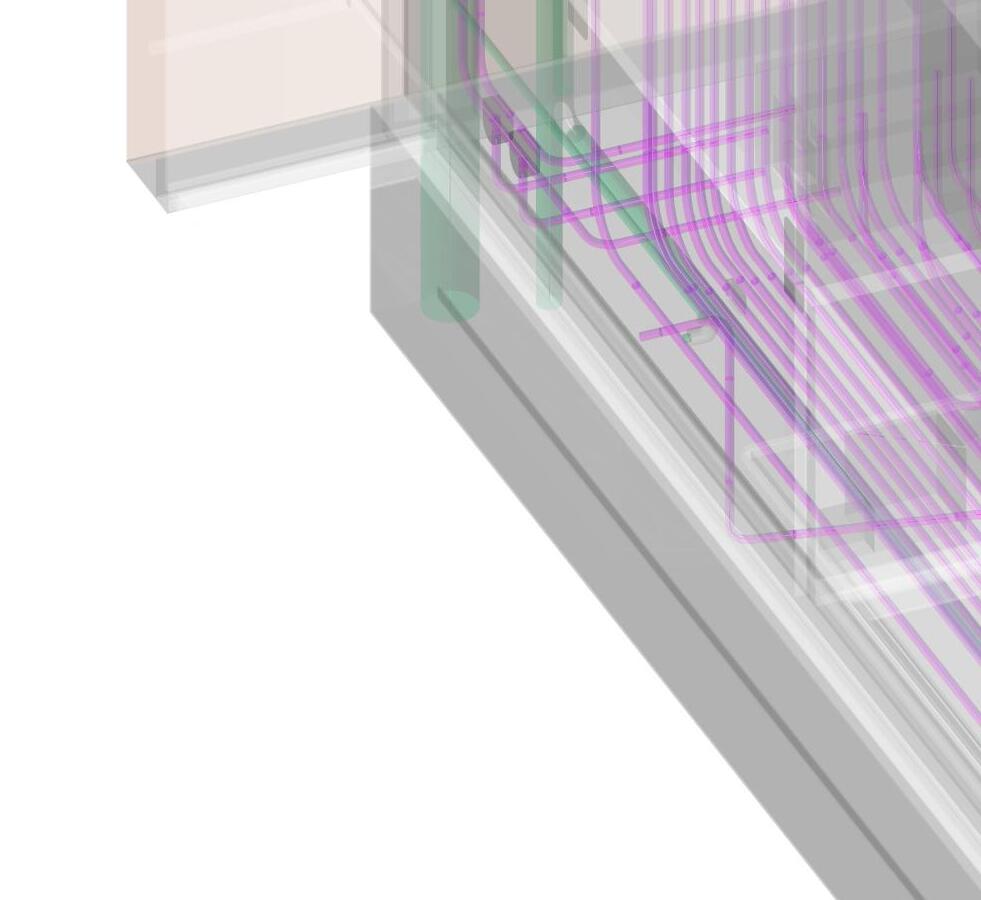

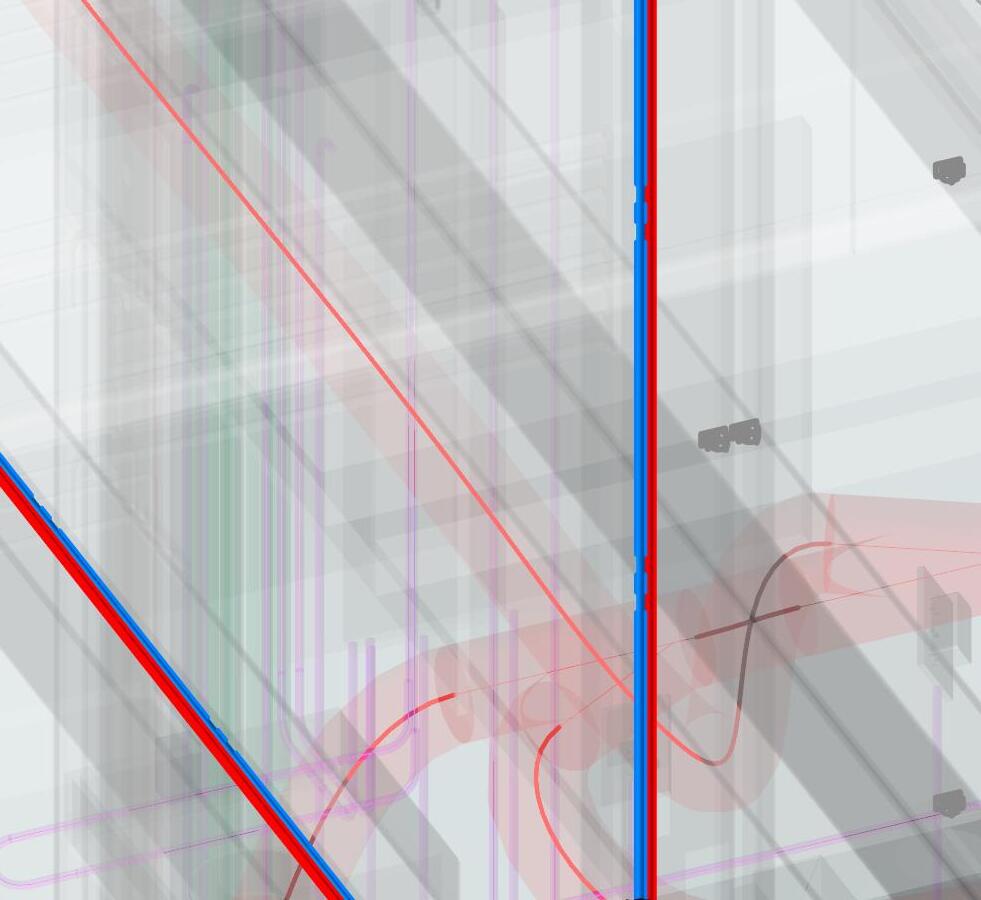

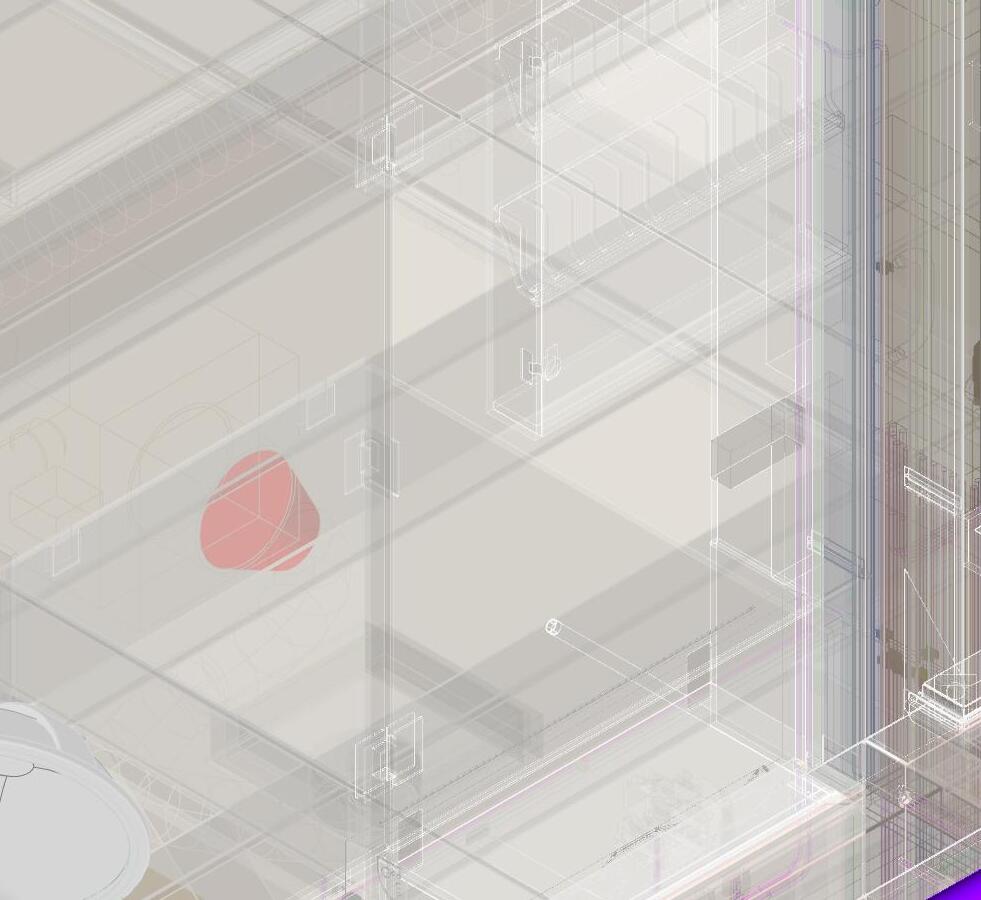

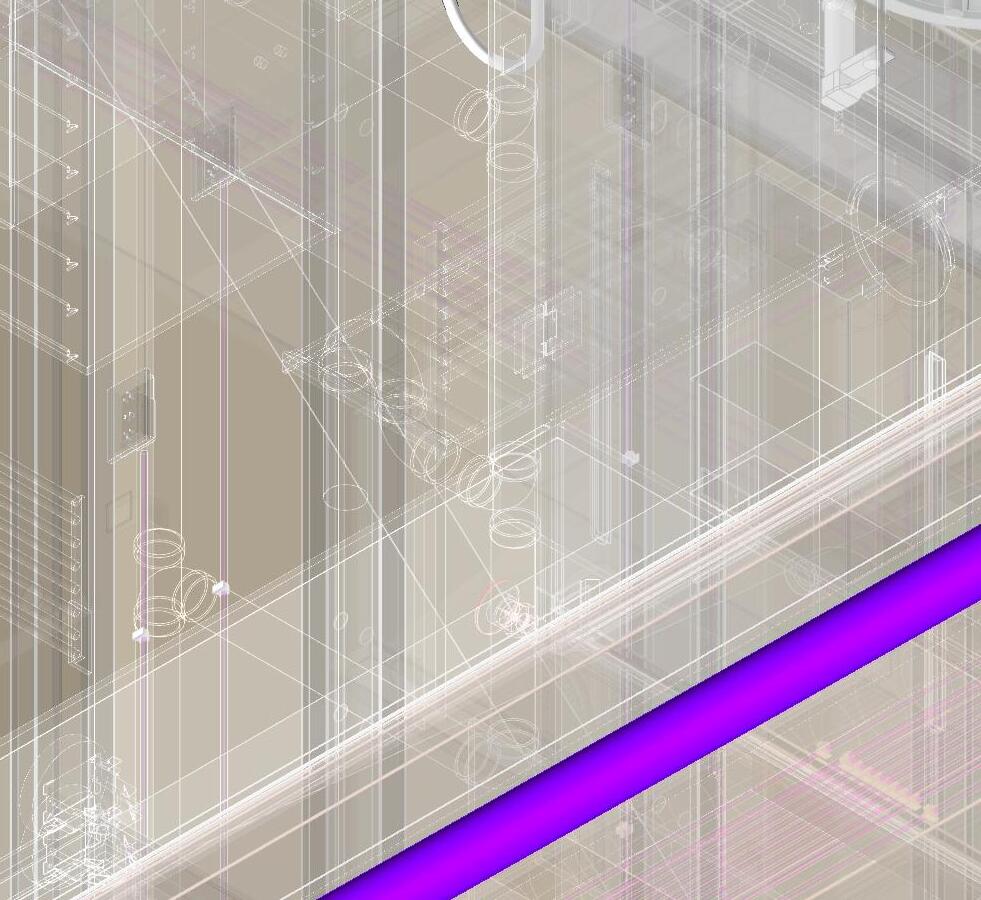

ONE BEDROOM UNIT PLUMBING

1 laborer 15 min

BILL OF MATERIAL

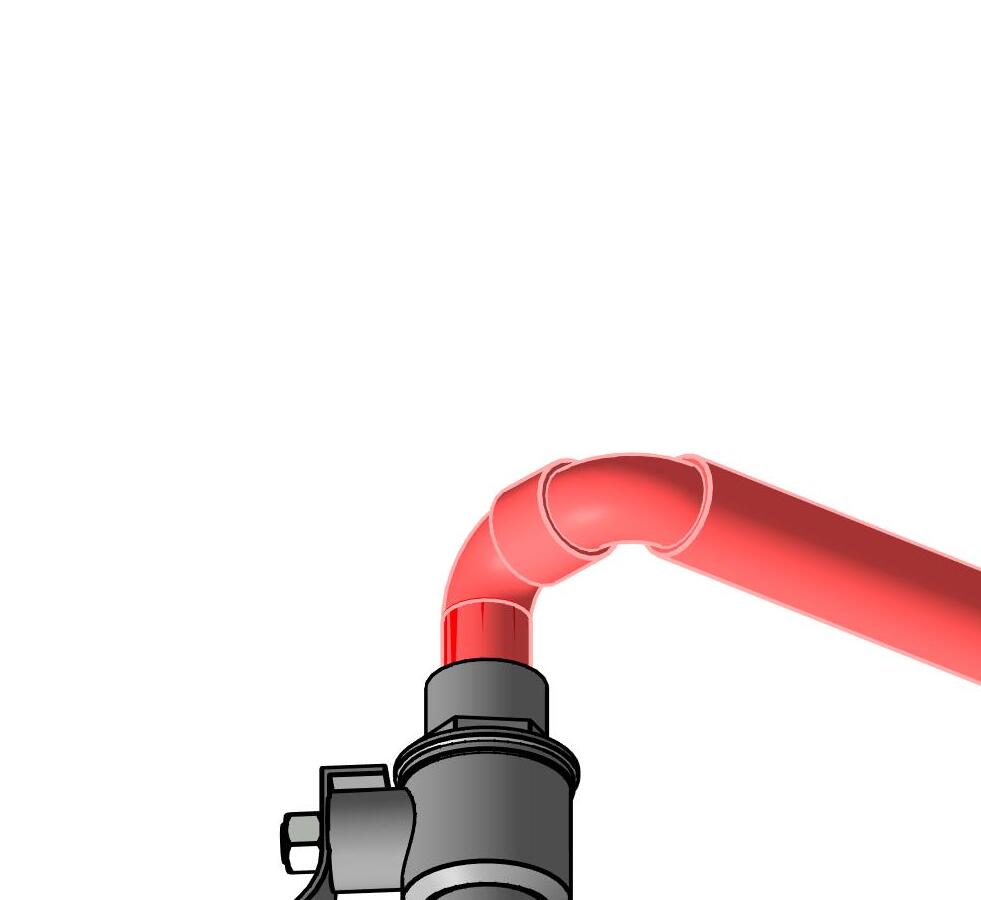

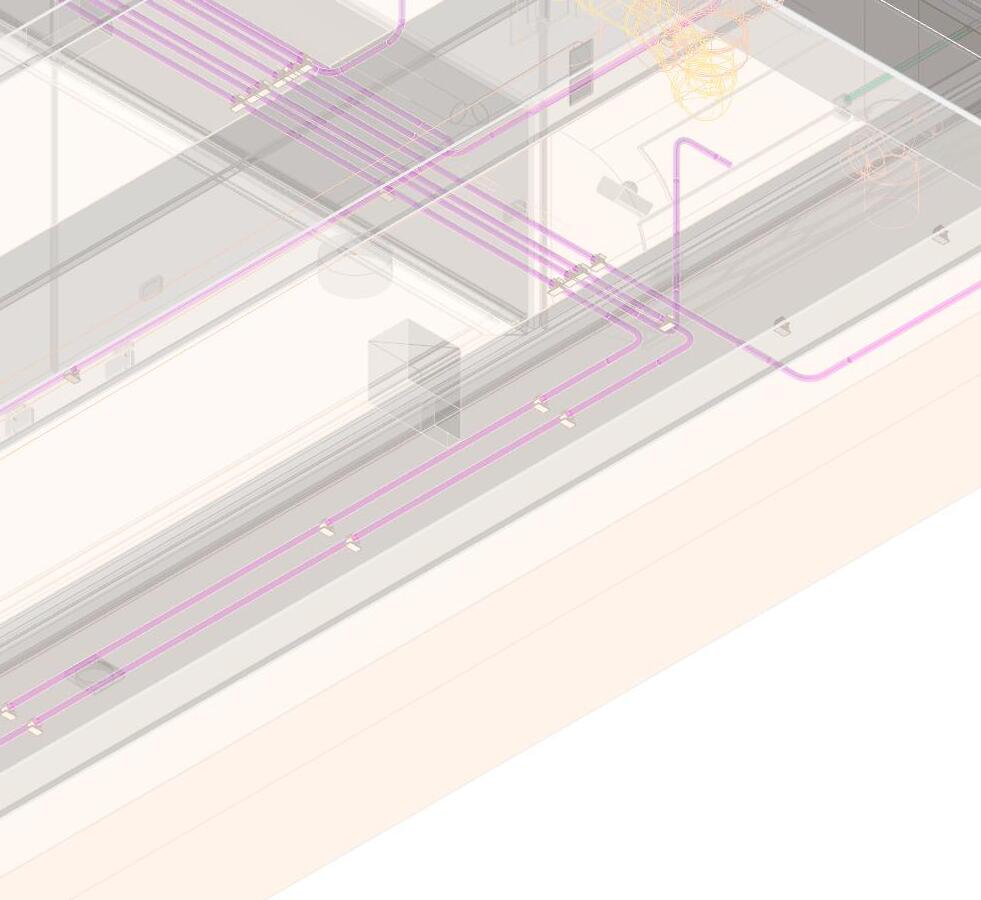

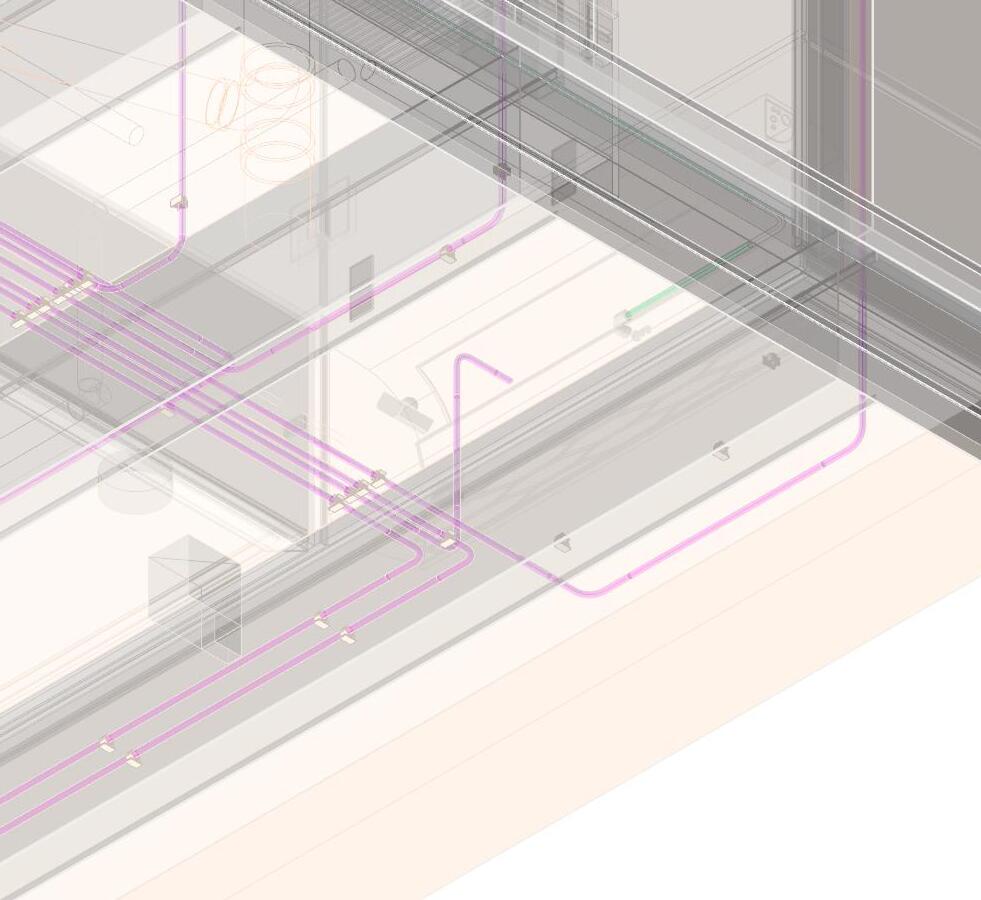

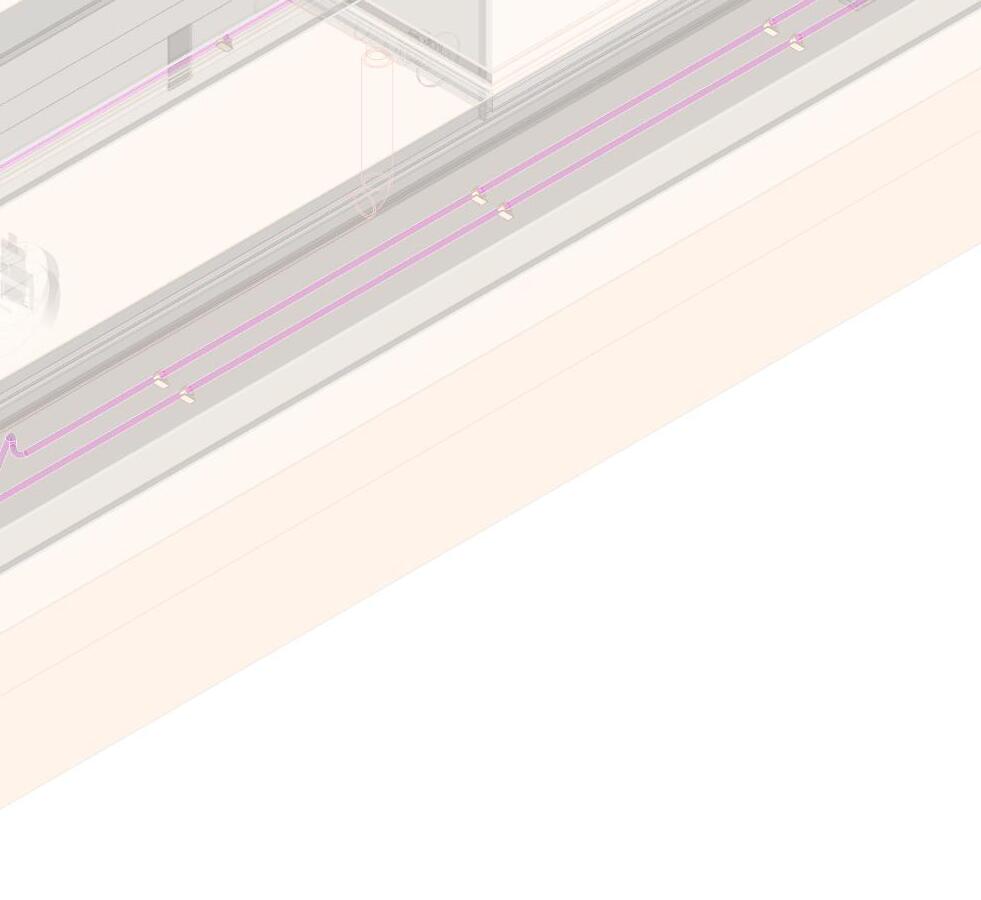

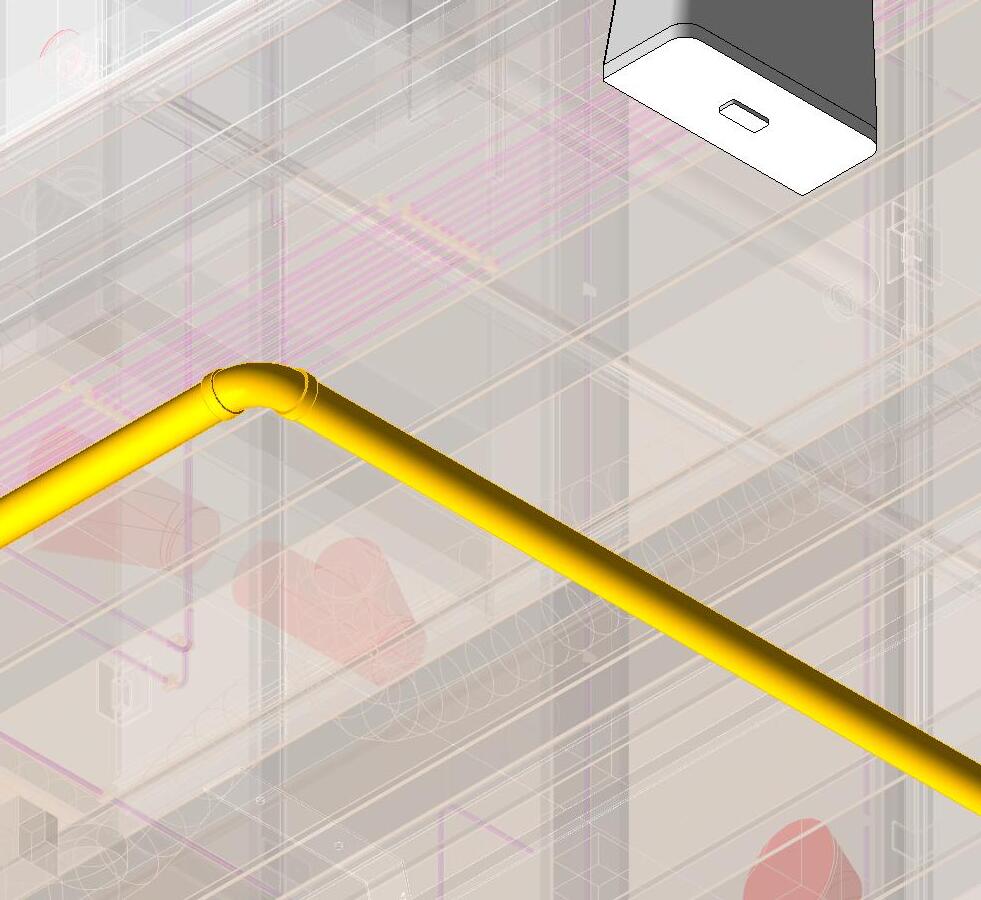

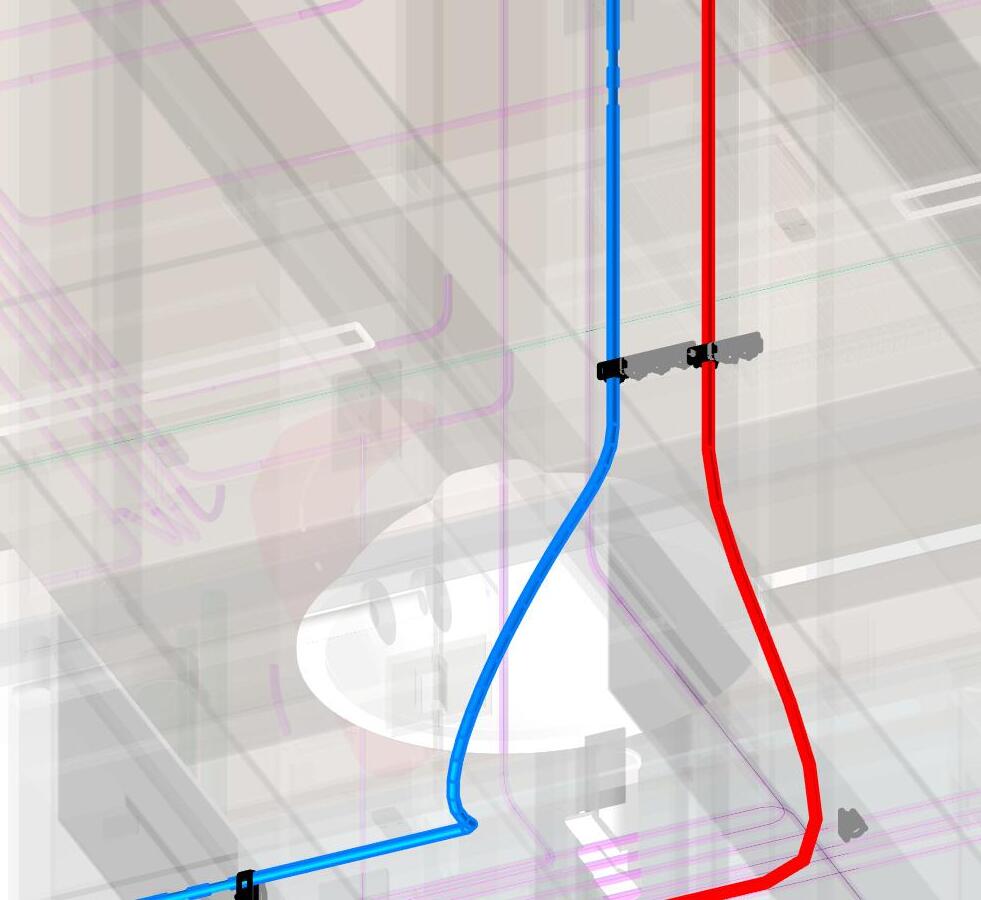

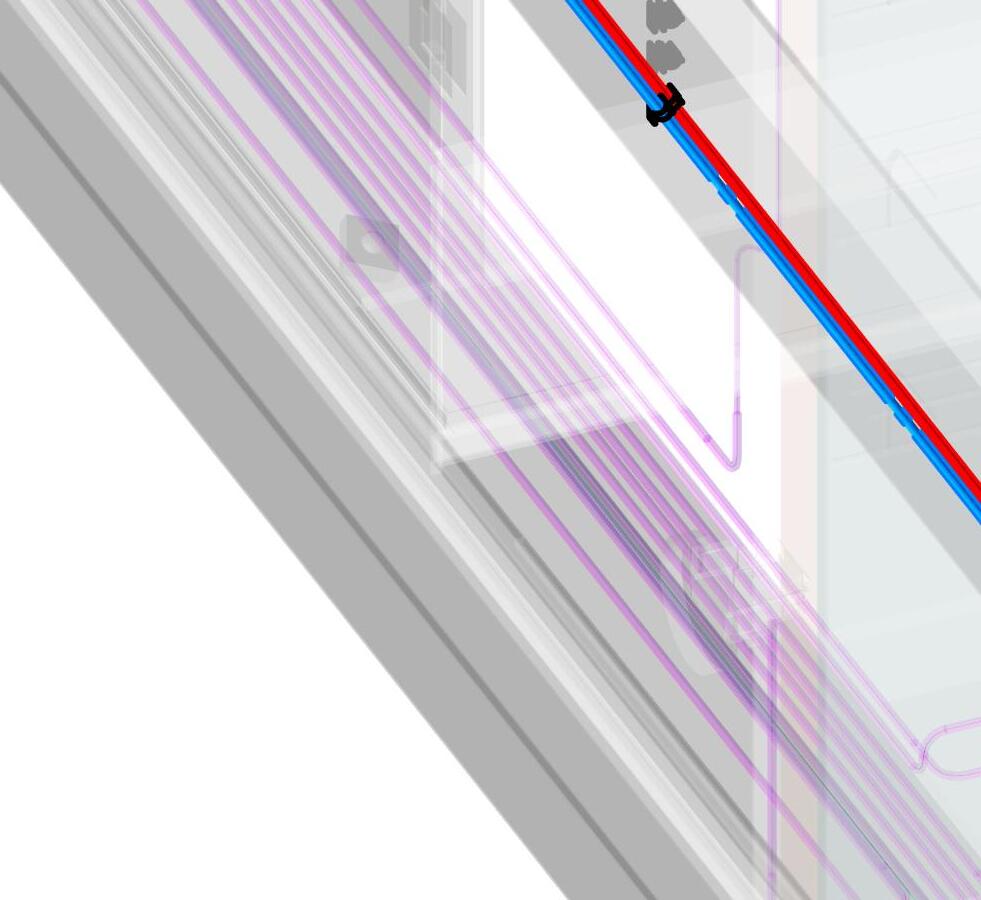

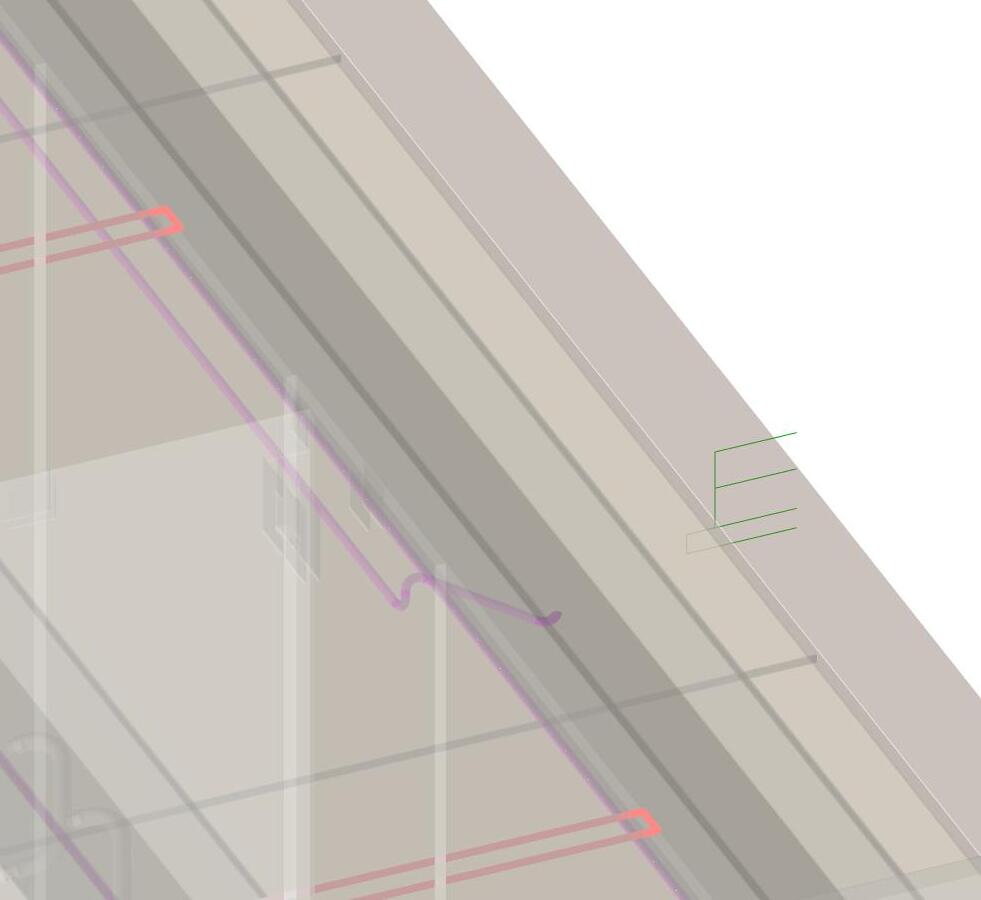

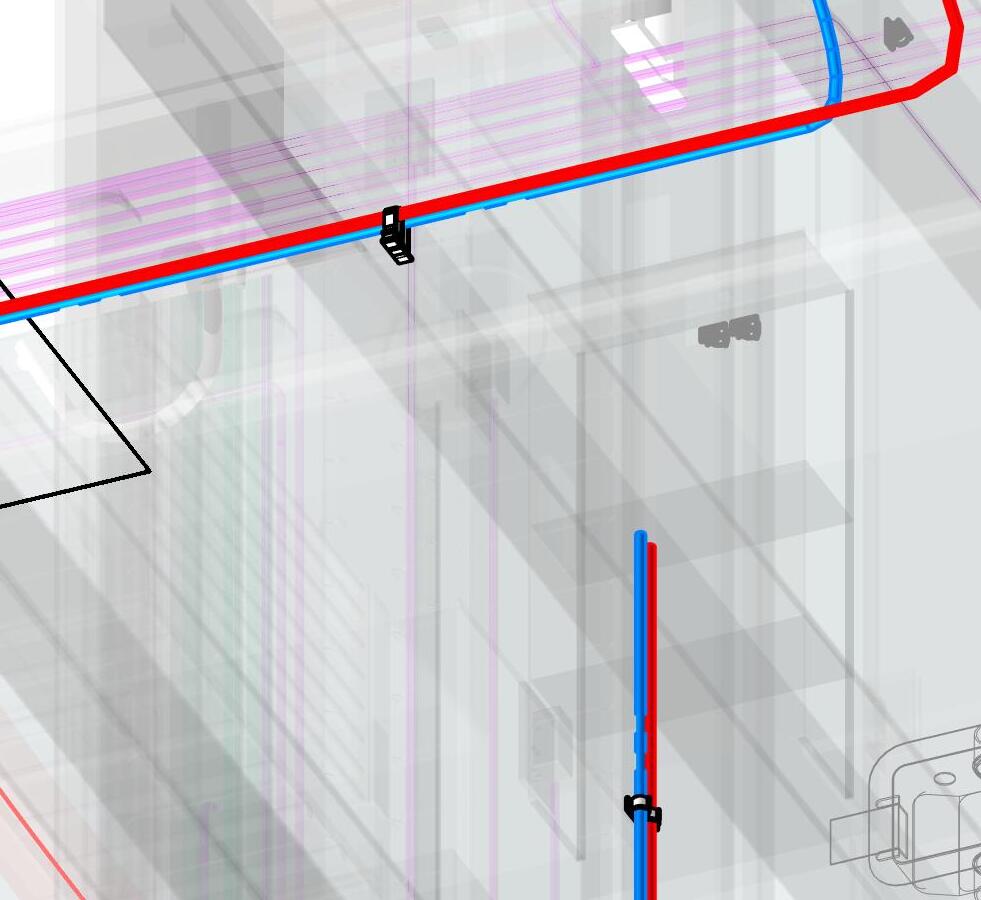

-Starting on the floor infront of the manifold, connect one end of each pre-cut supply pex (SSS, TTT) to the manifold with a 3/8" crimp (LLL).

-Secure the supply lines (SSS, TTT) to the densglass at the end of the radius turning up from the manifold connection with a pex clip (MMM) and drywall screw (NNN)

-Using a ladder to access the ceiling, pull the supply pex (SSS, TTT) up to the joist above. at end of radius from wall to ceiling bend, secure to joist with a pex clip (MMM) and self tapping screw (OOO) into the joist

-Attach the pex lines (SSS, TTT) to the side of the joist at two 32" intervals across the unit with (MMM and OOO).

-Coil and hang (SSS, TTT) in joist depth for later connection to vanity sink supply

ONE BEDROOM UNIT PLUMBING

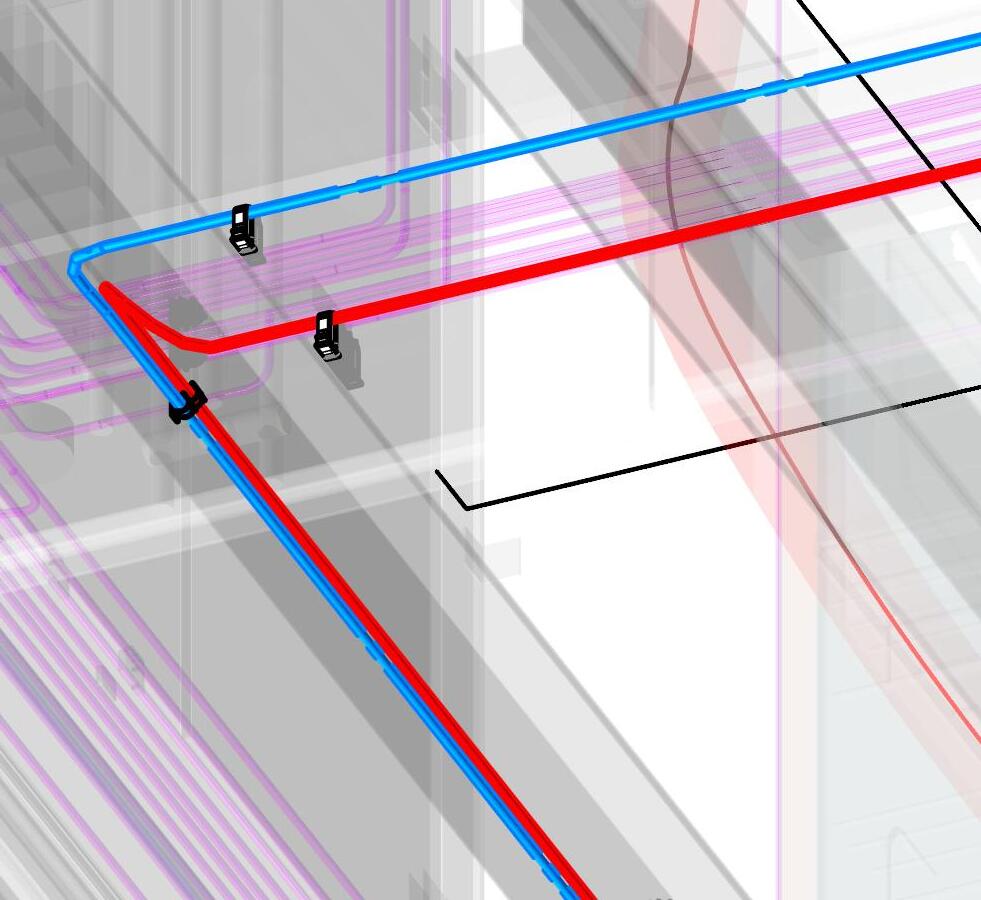

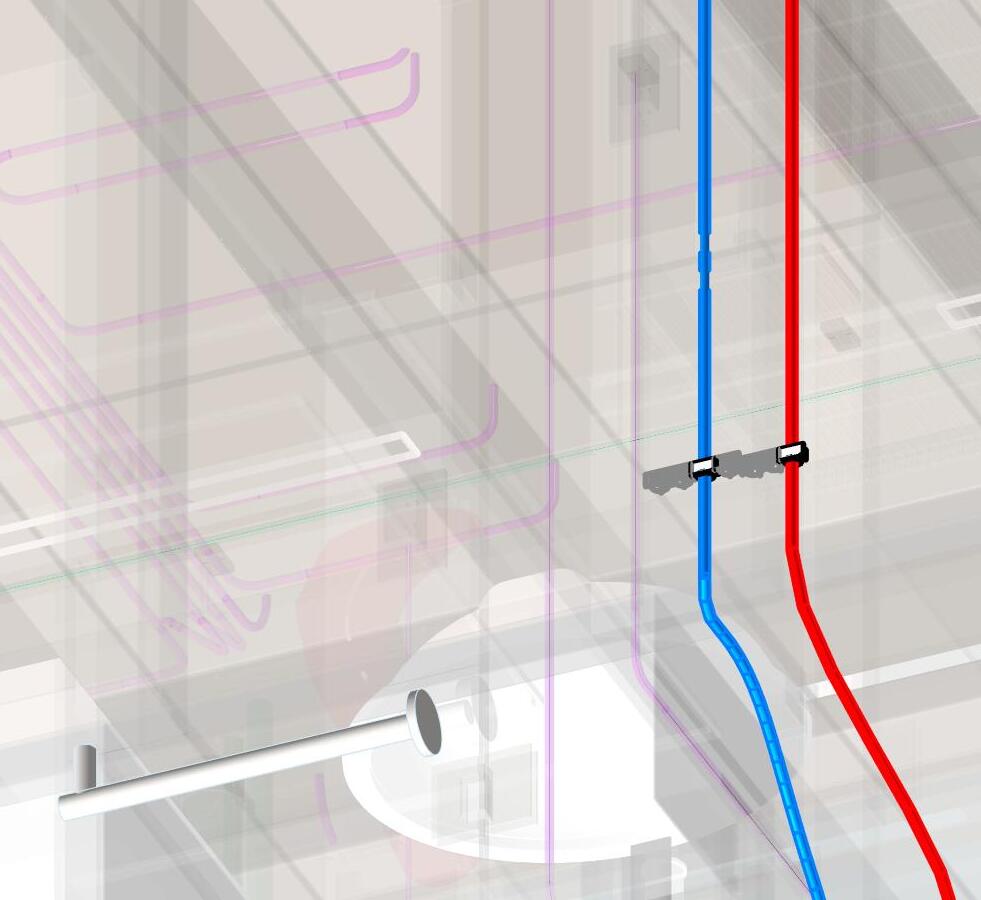

-Starting on the floor infront of the manifold, connect one end of each pre-cut supply pex (UUU, VVV) to the manifold with a 3/8" crimp (LLL).

-Secure the supply lines (UUU, VVV) to the densglass at the end of the radius turning up from the manifold connection with a pex clip (MMM) and drywall screw (NNN)

-Using a ladder to access the ceiling, pull the supply pex (UUU, VVV) up to the joist above. at end of radius from wall to ceiling bend, secure to joist with a pex clip (MMM) and self tapping screw (OOO) into the joist

-Attach the pex lines (UUU, VVV) to the side of the joist at two 32" intervals across the unit with (MMM and OOO).

-Coil and hang (UUU, VVV) in joist depth for later connection to kitchen sink supply

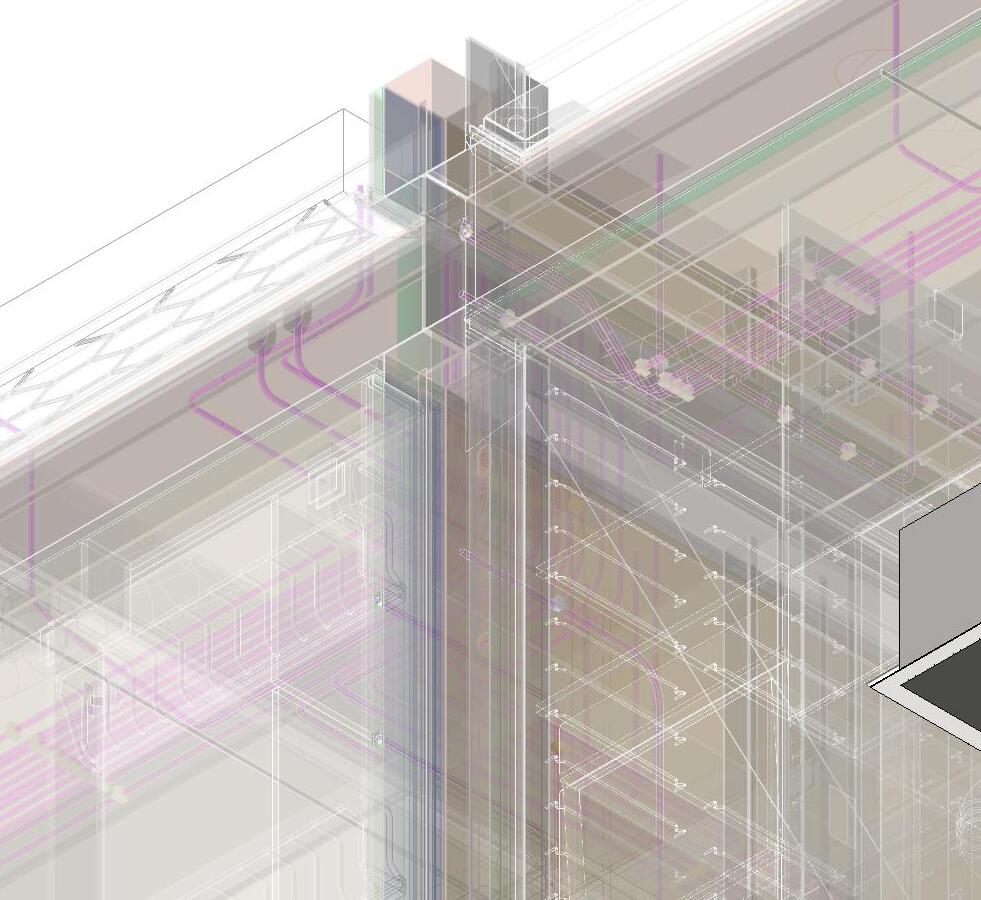

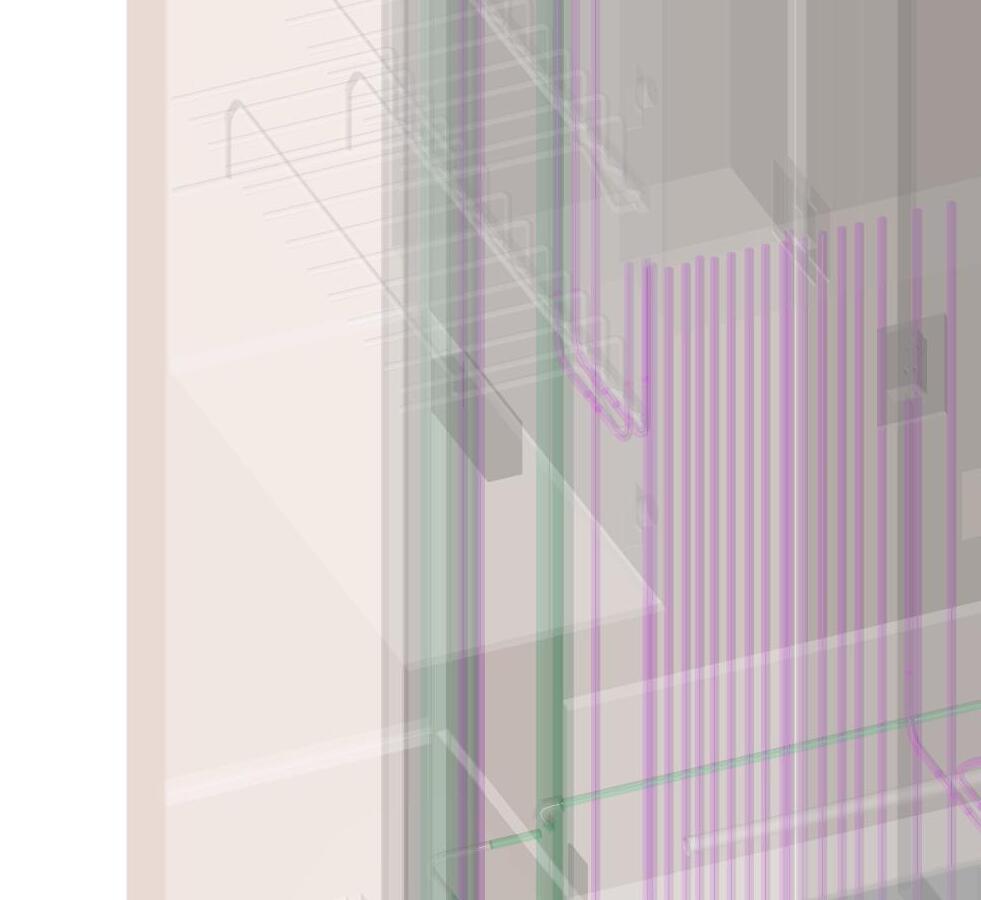

ONE BEDROOM UNIT PLUMBING

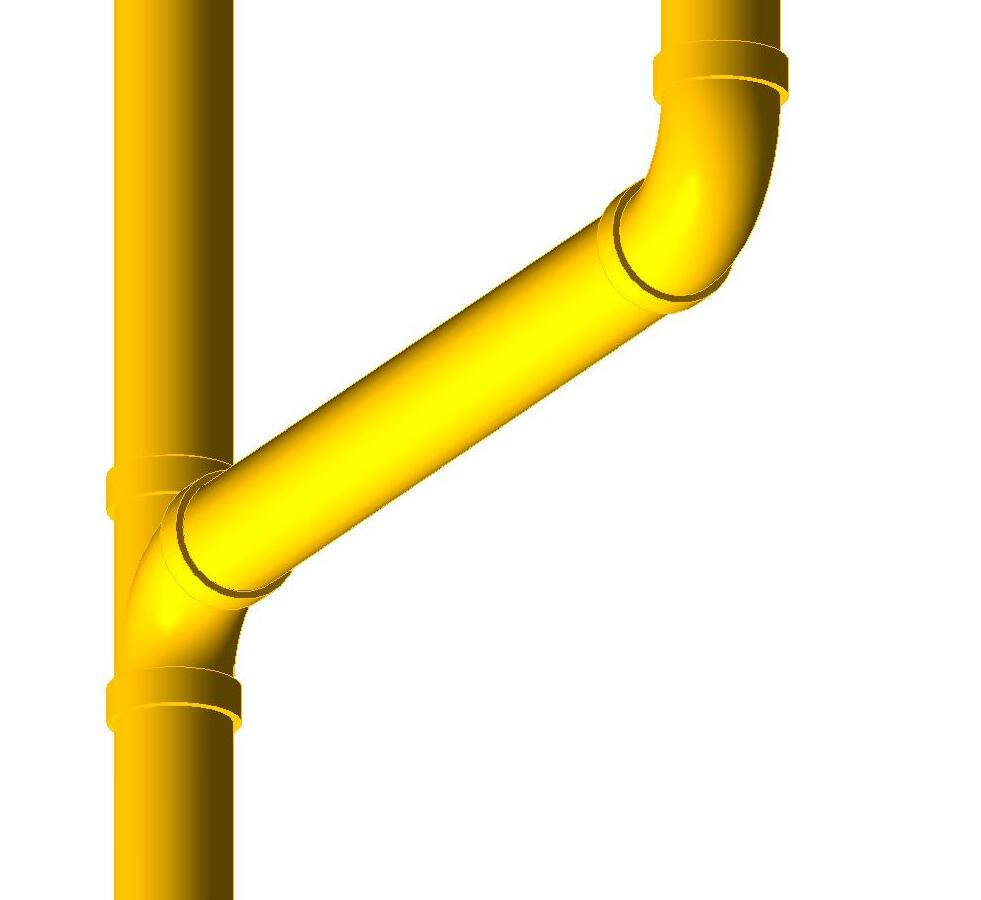

HBendPVCSch

HBendPVCSch

MarkItem DescriptionSizeCount

ø1

HBendPVCSch 40 - DWV 3"ø-3"ø PVC Sch 403"ø-3"ø1

HBendPVCSch 40 - DWV 3"ø-3"ø PVC Sch 403"ø-3"ø1

HBendPVCSch 40 - DWV 3"ø-3"ø PVC Sch 403"ø-3"ø1

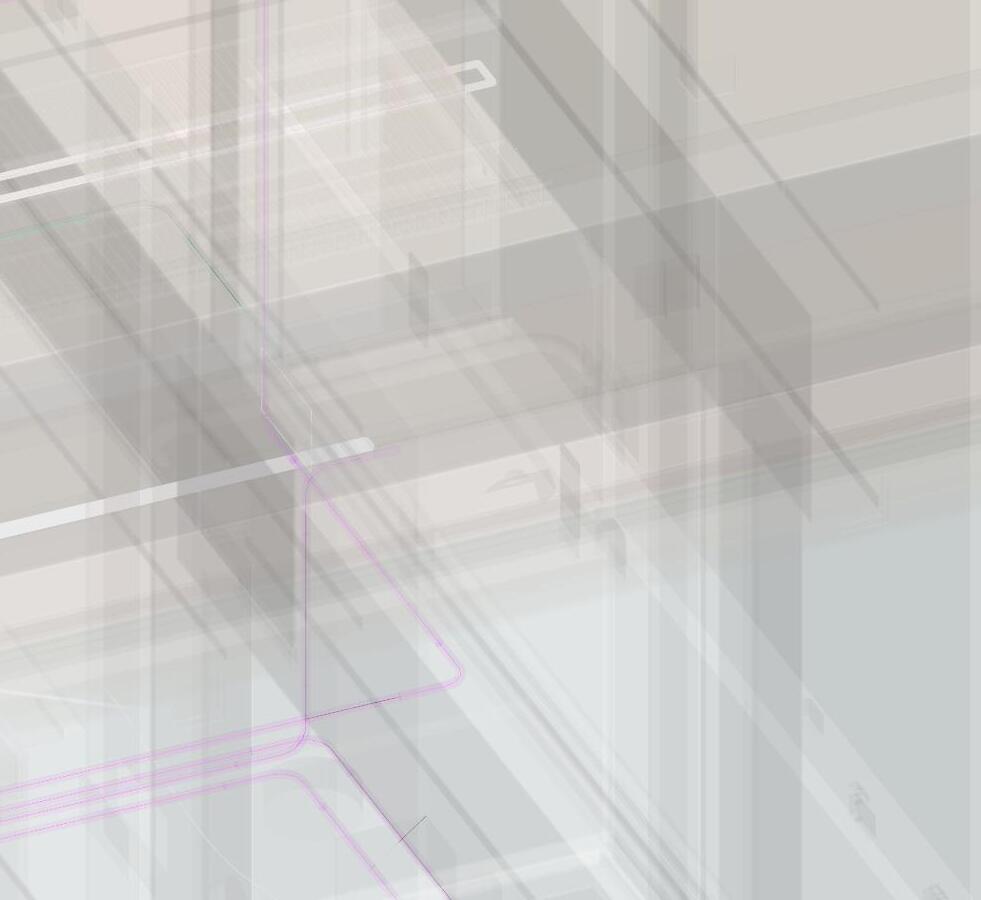

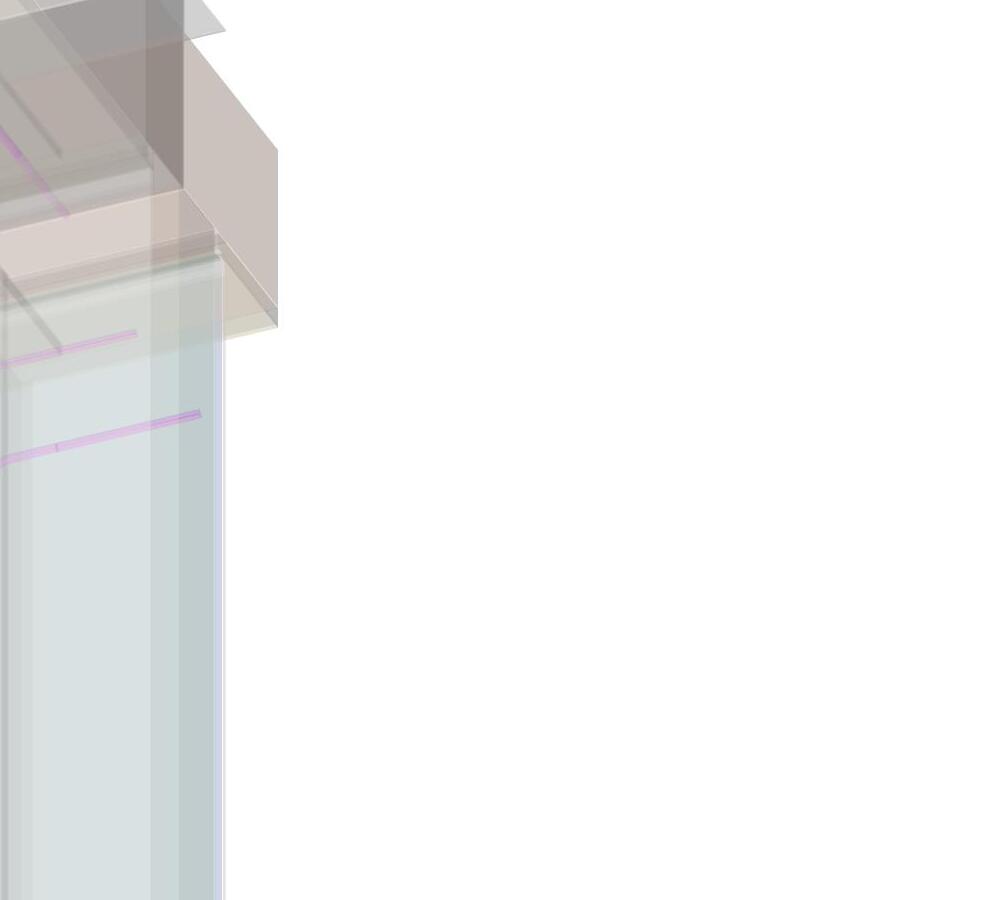

VESSEL INSTALLTION

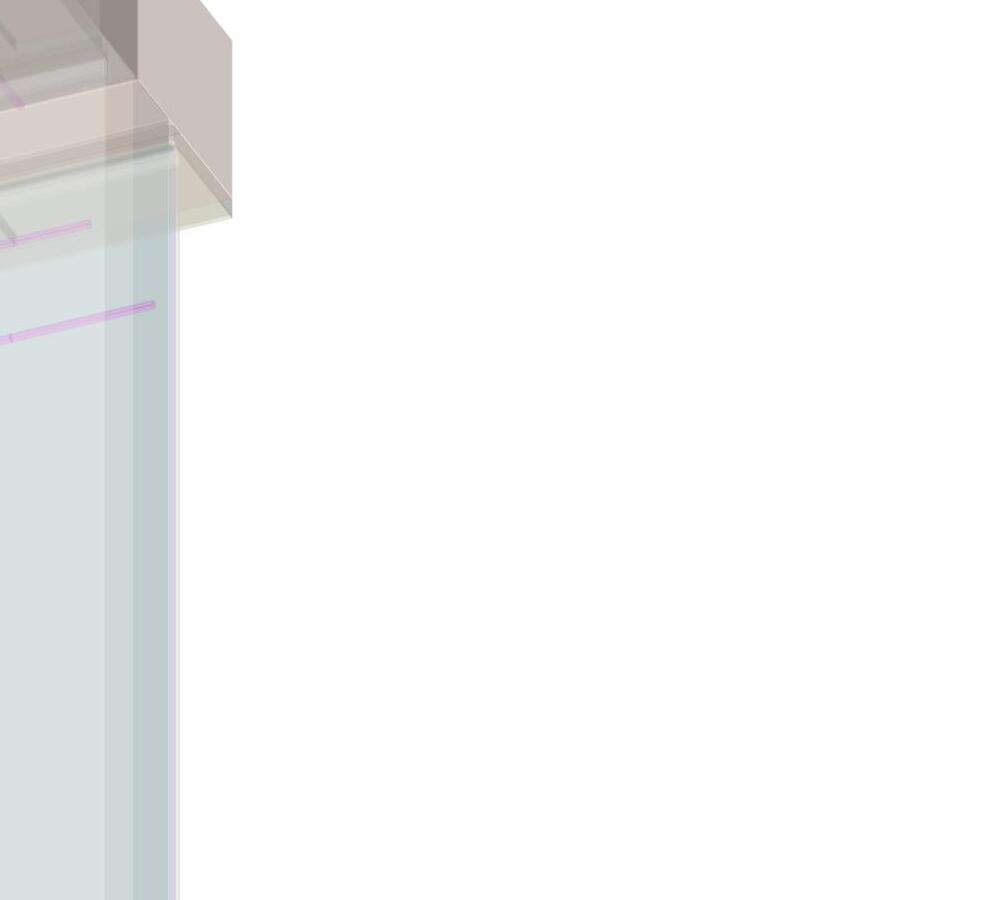

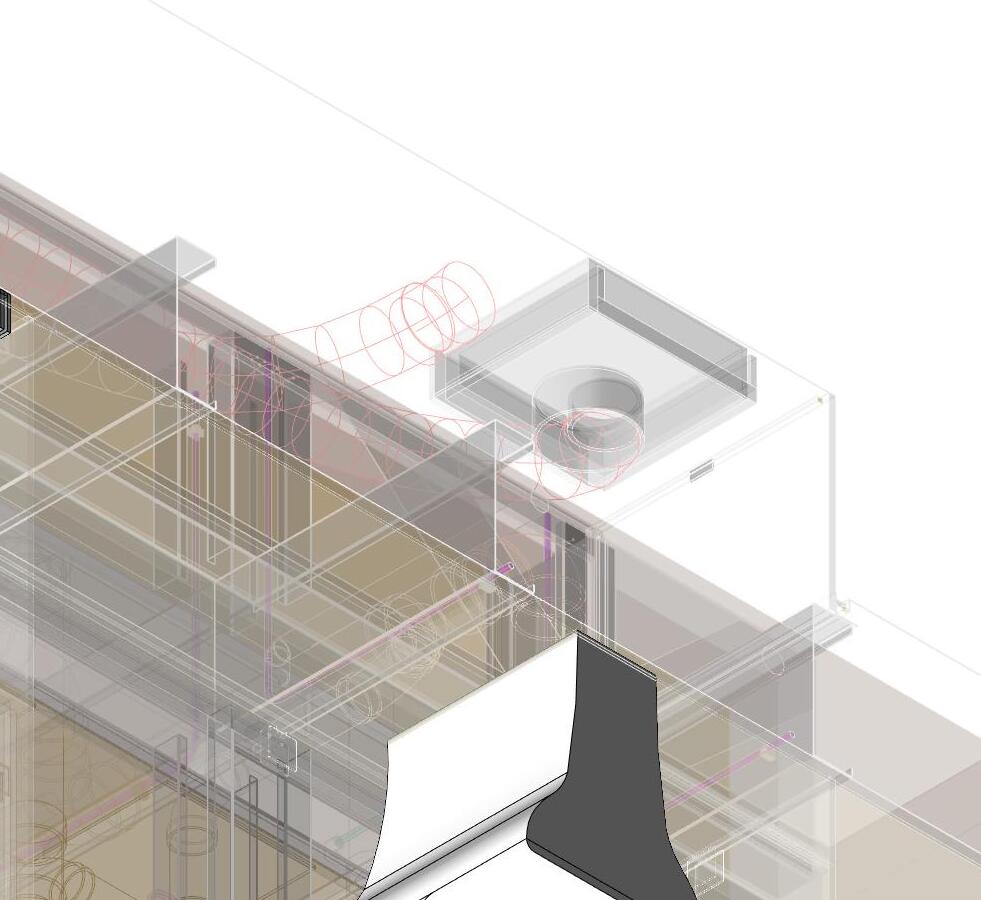

ONE BEDROOM UNIT PLUMBING

UNISTRUT BETWEEN JOISTS ADDITIONAL AT TOP FLOOR ONLY Mark Description Size Count 1

PRE CUT AND KITTED PARTS FOR HANGER INSTALLATION

(4) 24" WOOD 2X4 EXPANDABLE METAL HANGER (16) #8X1-1/2" HEX DRIVE SELF TRAPPING SCREW (1) 1/4" HEX DRIVE BIT

1 LABORER

30 MIN PER APARTMENT

STEP 1: USING A 6' STEP LADDER TO ACCESS THE 10TH JOIST CAVITY FROM THE WINDOW WALL, MEASURE TWO BLOCKING LENGTHS FROM THE TOILET WASTE ROUGH. MARK LOCATION.

STEP 2: ALIGN CENTER OF BLOCKING ON MARK FROM STEP 1, SPANNING BETWEEN JOISTS.

STEP 4: SECURE THE BLOCKING IN PLACE WITH TWO WOOD SCREWS INSTALLED THROUGH THE PILOT HOLES BLOCKING, ATTACHING SECURELY TO JOIST

STEP 5: MEASURE TWO BLOCKING LENGTHS (48"). MARK LOCATION.

STEP 6: REPEAT STEPS 2-4

NOTE: