www.ies.org.sg

www.ies.org.sg

FEBRUARY 2025 MDDI (P) 002/03/2025

Celebrating UNESCO’s World Engineering Day for Sustainable Development 2025

The Chartered Engineering Registry aims to provide professional recognition to qualified Engineers, Technologists and Technicians across all sectors.

Being registered as a Chartered Engineering Professional will be an external validation of your experience, expertise and practising competence; and is a quality mark to differentiate your professional standing in the following sectors of engineering:

cpgconsultants.com.sg

Climate change continues to be one of the greatest challenges of this century and decarbonisation is the only effective response.

At CPG, we have developed an Integrated Decarbonisation Approach that we use to help our clients and partners accelerate their journey.

GAVIN CHAN

Head of Sustainability CPG Corporation

Build a sustainable future with us today –Connect with Gavin Chan at gavin.chan@cpgcorp.com.sg

At CPG Consultants, we leverage our multidisciplinary expertise to develop an integrated decarbonisation approach that effectively addresses both operational and embodied carbon throughout a building’s lifecycle. Coupled with our extensive project experience across different typologies, we are ready to help building owners, property developers and facility operators go greener, faster.

+Green Building Certification (Green Mark) +Green Building Gap Analysis +Energy Modelling +Environmental Simulation +Carbon Assessment (Whole Life & Embodied Carbon) +Building/Infrastructure Carbon Advisory

16 Message From The President of The Institution of Engineers, Singapore

18 Message From The President of The World Federation of Engineering Organizations

20 Engineering the way forward towards a sustainable world

22 Fostering stronger collective climate action C40 and NUS Cities forge partnership

23 AI-powered decarbonisation platform launched at COP29

24 Spreading Chinese New Year Joy

26 IES Spring Festival and Awards Appreciation Night 2025

28 Advancing Singapore’s low-carbon built environment

President Er. Chan Ewe Jin

Chief Editor T Bhaskaran t_b_n8@yahoo.com

Publications Manager Desmond Teo

desmond@iesnet.org.sg

Editorial Panel

Dr Victor Sim

Dr Chandra Segaran

Dr Ang Keng Been

Dr Aaron Sham

Mr Jaime Vega Bautista Jr

Mr Soon Ren Jun

The Hi-Flo Next Generation bag filters have been developed with performance and sustainability in mind. Performance means long service life, low energy consumption and stable filtration efficiency throughout its lifetime.

Extended operating life with the best Total Cost of Ownership (TCO)

Lowest energy consumption and initial pressure drop

Reduced energy consumption

12% vs old Hi-Flo generation 30% vs industry average

Superior indoor air quality

Particle efficiency meets requirements according to the European Standard EN779 and ISO16890 for indoor air quality (IAQ)

Reduced labour cost

25-50% Longer filter lifetime, compared to synthetic bag filters

Improved air flow

Conical and tapered pocket shape allows better airflow through the filter

Optimised design for high performance Fully incinerable with the plastic frame

Using Camfil Life Cycle Cost (LCC) Analysis software, our experts conduct a comparative analysis of different air filters to provide you with a comprehensive report on potential savings.

Camfil offers a complimentary Life Cycle Cost analysis and supports you in selecting the right air filter solution.

SCAN THE QR CODE to complete the survey. Accuracy is subject to information provided.

30 Setting sail towards net-zero

32 The cool coatings initiative to be extended to all existing HDB estates

34 Rejuvenating Singapore’s industrial landscape

36 Building a greener future

38 A call to action for engineers

40 Leading the sustainability charge

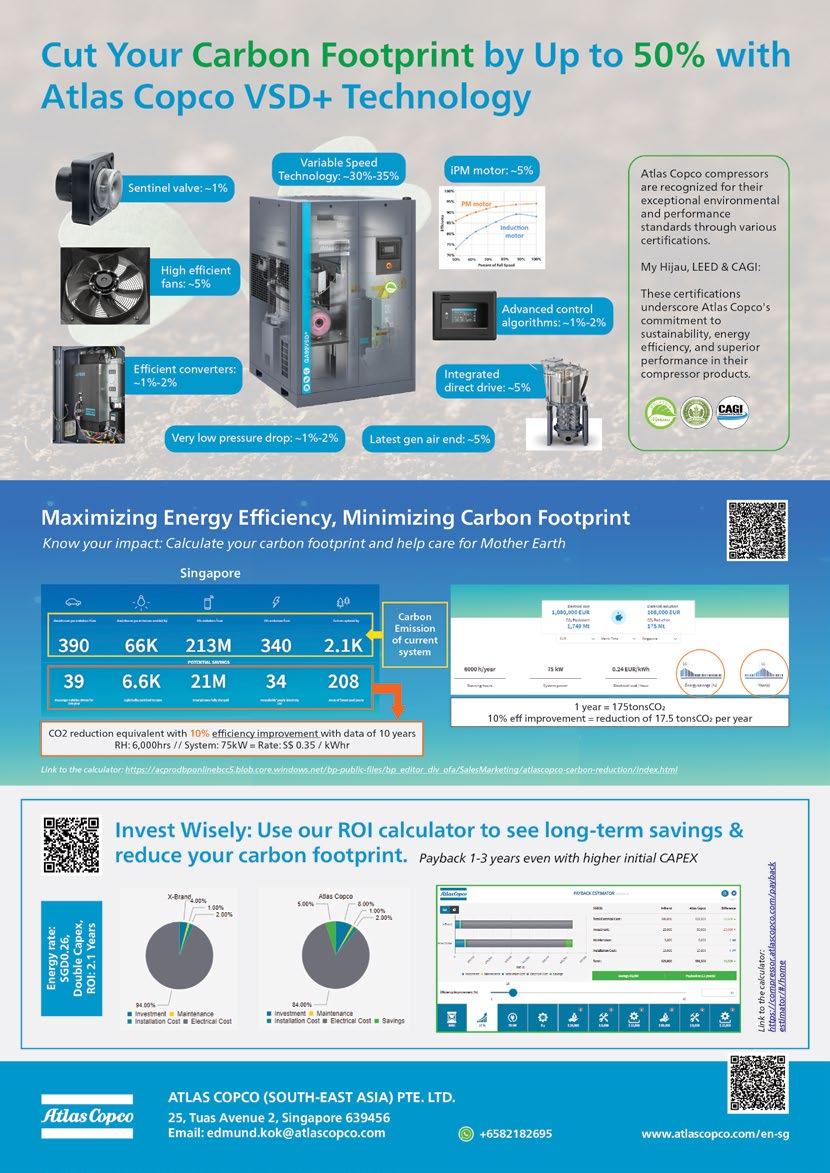

42 How energy innovation is transforming manufacturing

43 Sustainably and efficiently decarbonising manufacturing SMEs in Singapore

44 Understanding EPDs for HVAC

46 The future of EC fan technology

50 From regularisation to revelation

52 Commitment to responsible growth

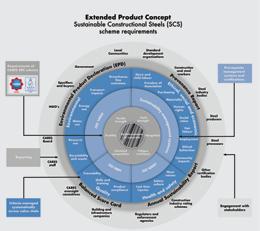

54 A case study of sustainability certification for constructional steels

56 Exploring the sustainability power of material-centric design

58 Pioneering circular aluminum hoarding system solutions for commercial spaces

60 Towards sustainable fire protection

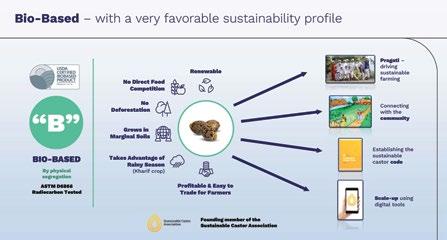

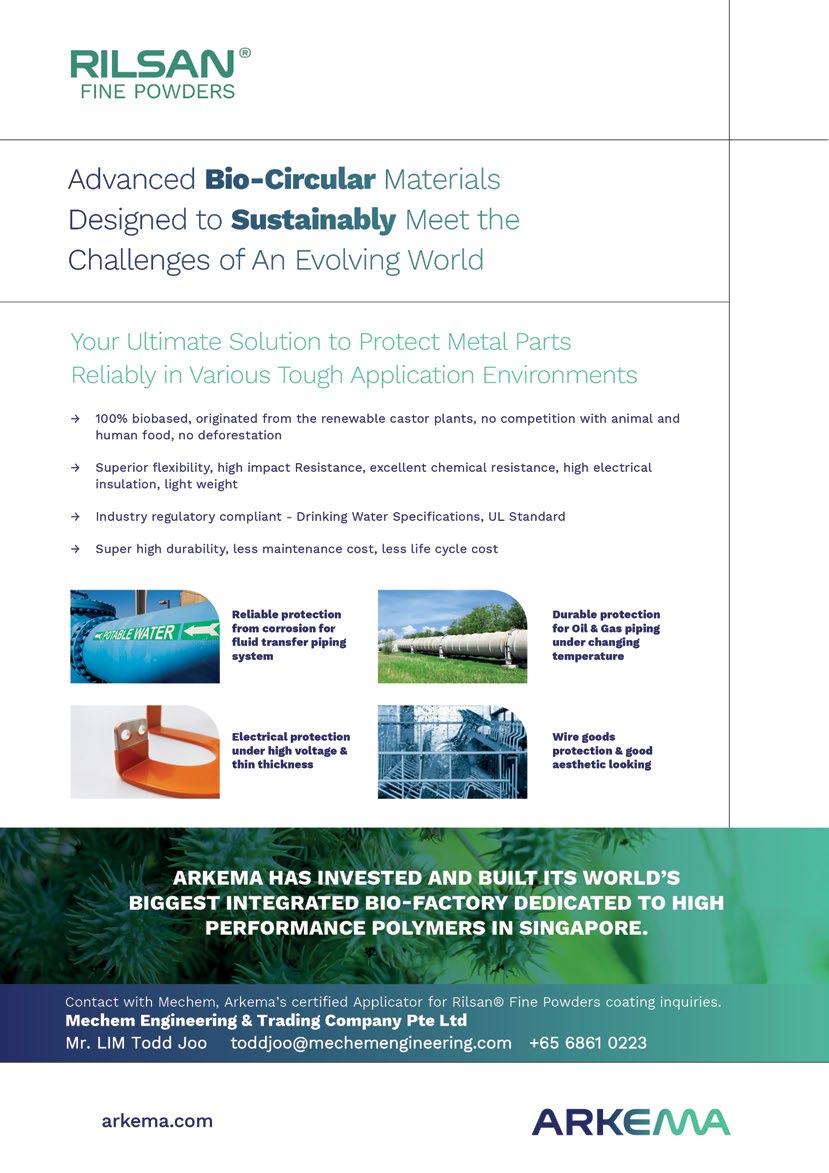

62 A sustainable modern polymer derived from plants

64 Sustainability development in the safety equipment industry

66 Leading the green future with new programme in environmental management and sustainability

68 Equipping professionals with critical sustainability expertise

70 Third edition of world university rankings on sustainability released

71 Utilising advanced technologies to serve the built environment

The Singapore Engineer is published monthly by The Institution of Engineers, Singapore (IES). The publication is distributed free-of-charge to IES members and affiliates. Views expressed in this publication do not necessarily reflect those of the Editor or IES. All rights reserved. No part of this magazine shall be reproduced, mechanically or electronically, without the prior consent of IES. Whilst every care is taken to ensure accuracy of the content at press time, IES will not be liable for any discrepancies. Unsolicited contributions are welcome but their inclusion in the magazine is at the discretion of the Editor. www.ies.org.sg

The Institution of Engineers, Singapore (IES) is proud to be a key partner of the World Engineering Day for Sustainable Development (WED). Our continued involvement in this global initiative is a testament to our unwavering commitment to advancing the engineering profession and championing sustainability.

Engineering is more than just a technical discipline – it is a powerful force for progress, bridging the gap between ambition and action to make the United Nations Sustainable Development Goals (SDGs) a reality. By harnessing engineering ingenuity, we can create innovative solutions that address critical global challenges, from climate change and resource scarcity to urbanisation and poverty.

At the heart of our WED activities is the annual Charles Rudd Distinguished Global Lectures (CRDGL). Held on 11 February in a hybrid format, this year’s CRDGL united leading experts, innovators and thought leaders from the global engineering community.

The theme ‘Towards a Sustainable World: Engineering the Way Forward’ fostered dynamic exchanges of insights, exploration of emerging technologies and collaborative solutions to tackle

complex global issues. Sustainability should not be a mere industry trend – it must be deeply embedded in the way engineers think, design and implement solutions. Recognising this imperative, IES launched the Chartered Engineer Sustainability Programme last year to empower engineers with the skills and expertise to lead sustainability efforts within their industries. By fostering a growing network of sustainability-focused professionals, IES envisions a future where engineering solutions are not only innovative but also environmentally and socially responsible.

Inspiring the next generation is equally critical on the sustainable development journey. IES continues to organise the National Engineers Day (NED) annually, a flagship event designed to inspire and encourage young minds to adopt sustainable approaches in their projects and future careers.

To be held in July 2025 featuring hands-on challenges, competitions and project showcases, NED 2025 will once again instill the values of sustainability among students, preparing them to be conscientious engineers of tomorrow.

Looking ahead, I encourage all engineers to join us at this year’s World Engineers Summit (WES), themed ‘Shaping Tomorrow: Engineering Smart Sustainable Cities’. This global gathering will offer invaluable opportunities for collaboration, learning and the exchange of best practices in sustainable urban development.

Let us continue to challenge the status quo, rethink what is possible and ensure that engineering is not just a tool for development, but a driving force for a resilient, sustainable future.

Er. Chan Ewe Jin 30th President

The Institution of Engineers, Singapore

Dear Distinguished Colleagues,

Let me begin by thanking the President, Executive Council and entire membership of the Institution of Engineers, Singapore, for inviting me again this year to give a Message at the 6th World Engineering Day celebrations which is taking place globally, while the main event is taking place at the UNESCO Headquarters in Paris.

I also want to thank you for the unflinching support you are giving me as President of WFEO, since my assumption of office in October 2023.

You are all aware of the fact that my term as President of this prestigious organisation is terminating in October this year during the 2025 General Assembly (GA) that will be taking place in Shanghai, the Peoples Republic of China. As continuation of your support for me, I expect huge attendance and effective participation from the engineering community in Singapore.

The most interesting aspect of the 2025 GA is the fact that I am handing over to ‘your own man’ and my good friend, Er. Tan Seng Chuan. It is therefore an occasion we should all look forward to, with excitement and jubilation. I also expect you to give him the

maximum support he needs to meet the expectations of the global engineering community that has confidence in him by voting for him to lead this global organisation.

Distinguished engineers, ladies and gentlemen, the theme of this year’s WED, ‘Shaping a Sustainable Future Through Engineering’, could not have come at a better time than this period when the United Nations declared the International Decade of Science for Sustainable Development (IDSSD) and instructed UNESCO to drive its implementation through an Executive Committee in which WFEO is an important member. The rationale behind the declaration of the Decade is that the world is not on track to reach

the Sustainable Development Goals (SDGs) by 2030. For example, to reach universal coverage for safe drinking water, sanitation and hygiene by 2030, current rates of progress will need to increase fourfold, according to the United Nations’ Sustainable Development Report (2022). For at least 3 billion people, the quality of the water they rely upon is unknown, for lack of monitoring.

This, among other needs, are the challenges we must address as engineers, to achieve the aims and objectives of the Decade.

I therefore call on all of you to contribute your expertise and knowledge towards the success of this global objective.

As I conclude, I want to urge IES and all of you as corporate entities and individuals, to make sure that your contributions are felt by the society we live in and that we ensure training and supporting our youth in all aspects of engineering to equip them adequately to face the daunting challenges of the future.

While looking forward to seeing you in any of the WFEO functions or in Singapore, I once again wish all of you a Happy World Engineering Day!

Mustafa B. Shehu President, WFEO

The Institution of Engineers, Singapore (IES), in collaboration with Singapore Polytechnic (SP), presented the World Engineering Day 2025: Charles Rudd Distinguished Global Lectures (WED 2025: CRDGL), on 11 February 2025 at the SP Convention Centre.

Held as a prelude to WED for Sustainable Development on 4 March 2025, this event convened leading experts, innovators and thought leaders from the global engineering community to share insights, explore emerging technologies and address engineering challenges shaping the future.

Themed ‘Towards a Sustainable World: Engineering the Way Forward’, this year’s lectures spotlighted two critical topics –Circular Economy and Resilient Future. With intensifying global challenges such as climate change, urbanisation and resource depletion, this event underscored the critical role of engineering in advancing the United Nations Sustainable Development Goals (SDGs).

The Minister of State for Home Affairs and National Development, Associate Professor Dr Muhammad Faishal Ibrahim, was the Guest-ofHonour at the event.

The event featured the presentations of two distinguished keynote speakers, Ms Tita Yowana Alwis, Minister Counsellor, Head of Economy – Indonesia Embassy and Mr Kelvin Wong, Chief Executive Officer, Building and Construction Authority (BCA). Their presentations provided valuable insights into the intersection of engineering and sustainable development, inspiring participants to envision bold new pathways to a better future.

A panel discussion, titled ‘Navigating the Future: Circular Economy and Building Resilience’ featured an influential lineup of experts, and was moderated by Professor Seeram Ramakrishna, Professor

of Mechanical Engineering at the National University of Singapore and Chair of the Sustainability Cluster at IES.

Attendees had the opportunity to participate in breakout activities, including learning journeys, technical talks and seminars, designed to foster collaboration and innovation in engineering solutions for sustainable development.

“WED 2025: CRDGL seeks to broaden public appreciation of the impact of engineering –showcasing its role in solving global challenges. By exploring the circular economy and resilient future, we aim to deepen appreciation for engineering as a driver of innovation – turning challenges into opportunities and forging solutions that balance progress with longterm sustainability,” said Er. Chan Ewe Jin, President, IES.

IES hosts the lectures annually in honour of the late Er. Charles Rudd, a distinguished IES member and engineer, who generously bequeathed over SGD 1 million to the institution.

Highlights of the lectures, held as part of the WED 2025 celebrations, have been recorded and broadcast globally to celebrate engineering achievements in support of WED 2025’s goal of ‘Shaping Sustainable Future through Engineering’. Endorsed by seven sponsors and over 45 local and international organisations, the three-hour hybrid lecture attracted more than 1,000 local and overseas participants.

“As engineers, we are called upon to address challenges that transcend borders, from subsistence farming practices to

infrastructure challenges in urban areas and overcoming poverty through digital technologies. These require a united effort from the global engineering community, alongside governments, businesses and civil society. As the incoming WFEO President, I am committed to advancing these collaborations to ensure engineering remains a catalyst for a sustainable world,” said Er. Tan Seng Chuan, PresidentElect of the World Federation of Engineering Organizations (WFEO), Chair of WED Committee and Emeritus President of IES.

This commitment to innovation and collaboration is reflected in Singapore’s strong representation at the WED 2025 Hackathon, with two shortlisted entries out of the total of 15 finalists.

A team from the National University of Singapore (NUS) has been recognised for the project ‘Empower: Digital Tools for Women’s Social Change’ which focuses on helping women in underprivileged areas access digital resources through education, mentorship and skills-building, to break the cycle of poverty.

Meanwhile, a team from PSB Academy also made it to the finals with the submission ‘Smart Irrigation Monitoring System (SIMS): Solar-Powered Irrigation & AI for Small Farmers’, which provides farmers with affordable technology to enhance climate resilience and protect their crops. These innovative solutions highlight the ingenuity and problem-solving capabilities of Singapore’s young engineers in addressing pressing global challenges.

The event also saw the launch of the Built Environment (BE) Transformation Learning Journey, which was developed by SP and supported by BCA. The launch was officiated by Mr Soh Wai Wah, Principal & CEO, SP, Er. Chan Ewe Jin, President, IES and Mr Kelvin Wong, CEO, BCA, and witnessed by Associate Professor Dr Muhammad Faishal.

Supported by BCA, the initiative offers Small and Medium Enterprises (SMEs) practical insights into this resilient and forwardlooking industry.

Focusing on the Industry Transformation Map (ITM) and its three key pillars – Integrated Planning and Design, Advanced Manufacturing and Automation, and Sustainable Urban Systems – the journey showcases transformative examples of how BE sector companies leverage innovative technologies and sustainable practices. It also equips SMEs with the tools to strategically plan their business and workforce transformation.

Participants can access followup support, including training programmes and funding opportunities, to facilitate their growth and position themselves for success in a rapidly evolving BE landscape.

Following the main programme, participants joined the breakout activities curated by co-organisers SP and the National Committee of Engineering Organisations (NCEO) members, including the Engineers Australia Singapore Chapter and INCOSE Singapore Chapter.

The Singapore Pavilion at the 29th Conference of the Parties (COP29) to the United Nations Framework Convention on Climate Change (UNFCCC) successfully concluded on 21 November 2024 in Baku, Azerbaijan.

Over the previous 10 days, the Singapore Pavilion brought together more than 100 partners to host over 40 programmes, including high-level panel discussions, fireside chats and presentations.

Themed ‘Realising Our Shared Climate Vision Together’, the Singapore Pavilion welcomed over 9,000 visitors, including foreign dignitaries, senior business leaders, academia and youths to advance discussion and foster collaboration on topics including climate finance, carbon markets, regional grid infrastructure, and more.

The Singapore Pavilion featured interactive exhibits to showcase Singapore’s climate initiatives. Visitors had the opportunity to sample NEWBrew, a specially brewed craft beer made using NEWater, and learn about Singapore’s experience in strengthening climate resilience through innovative water solutions.

The pavilion saw several noteworthy announcements, launches and Memorandum of Understanding (MoU) signings.

Building on the launch of the Financing Asia’s Transition Partnership (FAST-P) at COP28 in 2023, the Singapore Government announced that it will pledge up to USD 500 million as concessional capital, to match dollar-for-dollar, other concessional capital from partners, to support Asia’s green transition.

The Monetary Authority of Singapore (MAS) also launched an interim report on Transition Credits Coalition (TRACTION), which outlines developments on the use of transition credits to accelerate the early retirement of coal-fired power plants.

Ms Grace Fu, Minister for Sustainability and the Environment and Minister-in-charge of Trade Relations, Singapore, delivering a speech at the closing ceremony of the COP29 Singapore Pavilion.

Other key announcements included the launch of a USD 5 million ‘Climate x Health: Lighthouse for Asia’ by AVPN, with support from the Bayer Foundation, and the launch of the world’s first Master of Science in Sustainable Healthcare programme and an accompanying Executive Fellowship by the Centre for Sustainable Medicine (CoSM) at the Yong Loo Lin School of Medicine, National University of Singapore.

In addition, Singapore and Zambia signed a MoU to collaborate on carbon credits aligned with Article 6 of the Paris Agreement, while Singapore and Peru have substantively concluded negotiations on an Implementation Agreement on carbon credits cooperation, aligned with Article 6 of the Paris Agreement.

In line with the theme ‘Realising Our Shared Climate Vision Together’, the Singapore Pavilion advanced multilateral action on climate change through inter-pavilion collaboration, including a panel discussion with the Intergovernmental Panel on Climate Change (IPCC), a side event with the UNFCCC on the Article 6 Crediting Protocol, and other joint events with Azerbaijan, Brazil, UK and Australia.

Ambassador Andre Correa do Lago, Secretary for Climate, Energy and Environment, Ministry of

Foreign Affairs, Brazil was also in attendance for the ‘From Singapore to the Amazon: Breakthroughs in Rainforest Conservation through XPrize’ programme at the Singapore Pavilion.

Strengthening youth involvement in climate action

Twenty Singaporean youth delegates from the Climate Youth Development Programme (CYDP) attended COP29. The youth delegates planned and executed programmes at the Singapore Pavilion to explore climate action in biodiversity, education and youth resilience.

Youth speakers from 14 different countries engaged with Singapore’s youth delegates, enabling the delegates to expand their knowledge and build their international networks to further contribute to climate action.

The C40 Cities Climate Leadership Group (C40) and NUS Cities, an interdisciplinary centre based at the National University of Singapore’s (NUS) College of Design and Engineering, signed a MoU during COP29's Urbanisation Day.

The initiative seeks to build urban climate resilience, advance urban planning research, co-organise conferences and seminars, and develop executive education programmes for city officials and industry practitioners.

The collaboration leverages both parties’ expertise to deliver research-based insights and courses, equipping city leaders to implement equitable climate actions.

The Sustainable Energy Association of Singapore (SEAS) announced the launch of DigiLeap, a pioneering artificial intelligence (AI)-powered platform which is expected to revolutionise the decarbonisation landscape.

Developed with KPMG in Singapore as SEAS’ knowledge and technical partner, DigiLeap is said to be the first-of-its-kind sustainability services and solutions marketplace. At the Singapore Pavilion during COP29, SEAS also announced the platform’s regional access, significantly

enhancing its reach and impact.

This innovative tool leverages advanced AI matchmaking to bridge the investment gap, effectively connecting solution seekers with providers, for sustainability and decarbonisation initiatives. By aligning with COP29 priorities, DigiLeap enhances precision, efficiency and scalability in matching projects with the right partners.

The DigiLeap initiative has received support from Enterprise Singapore (ESG) and Asian Development Bank (ADB). SEAS has separately

onboarded SGTech, Global Compact Network Singapore (GCNS), Singapore International Chamber of Commerce (SICC), National Trade Union Congress (NTUC) and the Singapore Business Federation (SBF), along with various key financial and academic institutions as partner organisations.

Focusing on sustainable and decarbonisation projects valued at below USD 10 million, DigiLeap targets key areas such as renewable energy and smart grid technology, industrial decarbonisation, and green construction and real estate.

On 5 February 2025, IES President, Er. Chan Ewe Jin, together with Er. Simon Lee (Honorary Secretary), Er. Ng Say Cheong (Assistant Honorary Secretary), members of the Corporate Social Responsibility (CSR) Committee, Community Services Committee and Young Engineers Committee (YEC), along with students from the Singapore Institute of Technology Student Chapter, visited the Moral Home for the Aged Sick, to spread Chinese New Year cheer to the residents.

Also joining the event were Mr Syafiq Shahul, IES Executive Director and Ms Emily Tan, IES Head of Secretariat.

The team joyfully distributed red packets and mandarin oranges to about 180 grateful residents and helped to serve them lunch,

bringing festive warmth and companionship to those in need.

This initiative exemplifies IES’s strong commitment to corporate

social responsibility and its ongoing dedication to giving back to the community.

Keep up the great work, IES!

On the evening of 11 February 2025, the Institution of Engineers, Singapore (IES) hosted a joyous Chinese New Year celebration, while also recognising the invaluable contributions of its dedicated volunteers throughout 2024. Nearly 200 IES members gathered to rekindle friendships, foster camaraderie and celebrate the spirit of volunteerism. The event was graced by Guest-ofHonour, Mr Khaw Boon Wan, Chairman of SPH Media Holdings and SPH Media Trust, along with Mrs Khaw.

The evening’s festivities included an exciting lion dance performance, the traditional ‘lohei’ (tossing of raw fish) for prosperity in the Year of the Snake and a lavish eightcourse dinner. This memorable night also provided an opportunity to honour the hard work and dedication of volunteers from various IES committees.

The following awards were presented in recognition of outstanding contributions:

• Friend of IES Award: Mr Chan Yew Kiang, Ms Chua Soo Rui, ITE College Central, and SIA Engineering Company.

• Outstanding Volunteer Award: Mr Chua Yi Bin (IES Interest

Group), Er. A/Prof Gopinath Menon (Assessment Panel, Chartered Engineering Board), Er. Victor Tan

(Young Engineers Committee), and Dr Zhou Yi (Skills Development Partner).

• Best Student Chapter: Nanyang Technological University Student Chapter and Singapore Polytechnic Student Chapter.

• Outstanding Committee Award: Civil and Structural Engineering Technical Committee, Mechanical and Electrical Engineering Technical Committee, Maritime Engineering Technical Committee, and Railway and Transportation Engineering Technical Committee.

• Special Recognition Award: IES History Book Editorial Committee. In addition, over 30 IES members were presented with the inaugural IES Active Volunteers Award, recognising their consistent commitment and contributions.

Congratulations to all the volunteers whose selfless efforts continue to uplift the engineering

community. Your dedication is the cornerstone of IES’ success and growth!

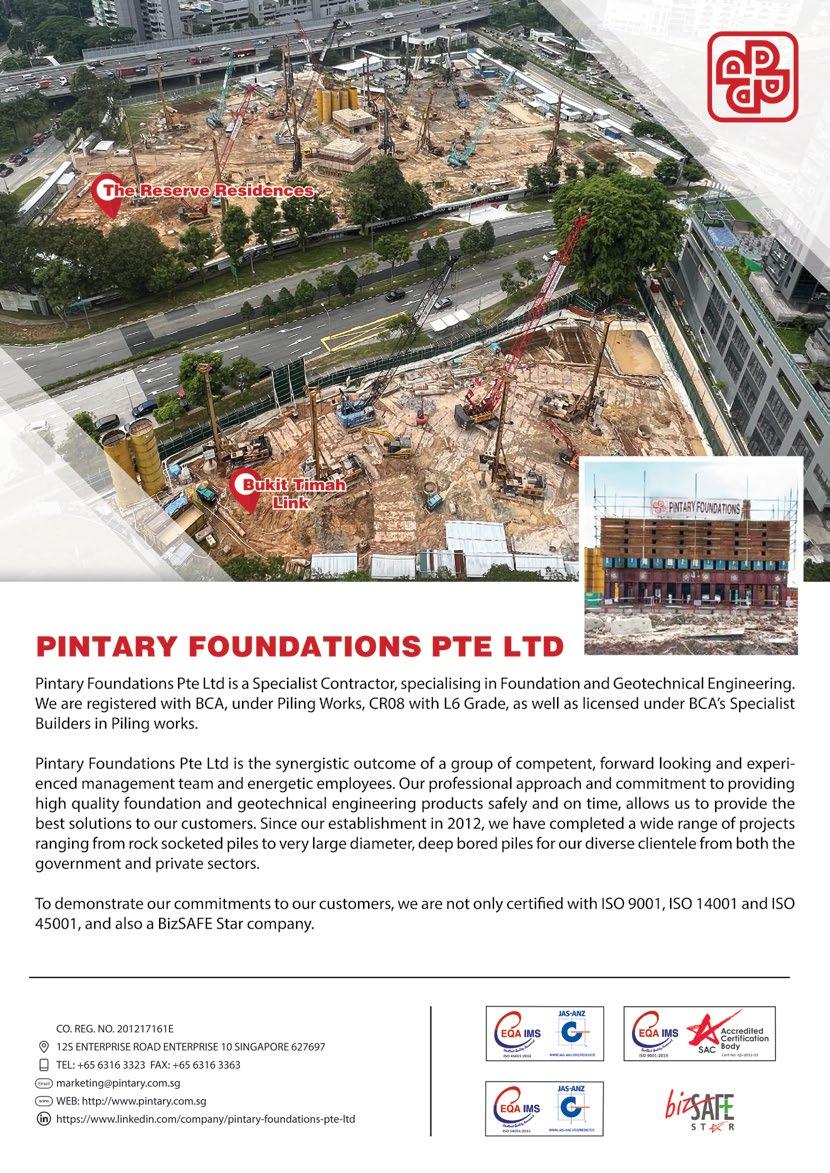

The Building and Construction Authority (BCA) highlights two case studies that demonstrate green engineering.

Singapore’s urban landscape is undergoing a quiet yet transformative revolution, where engineers are at the forefront of sustainable development. As global concerns over climate change intensify, Singapore has taken decisive steps towards reducing its carbon footprint, with a bold target to achieve net zero emissions by 2050. Given that buildings contribute approximately 20% of the nation’s carbon emissions, the built environment plays a pivotal role in this transition to a lowcarbon, climate-resilient future.

To support this transition, the Building and Construction Authority (BCA) launched the Singapore Green Building Masterplan in 2021, as part of the broader Singapore Green Plan 2030. The masterplan, developed in collaboration with the Singapore Green Building Council (SGBC), sets ambitious sustainability standards in the built environment, encapsulated in its ‘80-80-80 in 2030’ targets:

• 80% of buildings (by Gross Floor Area or GFA) to be green by 2030

• 80% of new developments (by GFA) to be Super Low Energy buildings from 2030

• 80% improvement in energy efficiency for best-in-class green buildings (compared to 2005 levels) by 2030

These targets set out the direction for the built environment sector to work towards achieving the country’s ambitions of achieving net zero emissions by 2050.

Significant strides have been made towards reaching these 80-80-80 goals. As of December

2024, about 61% of the building stock (by GFA) has been greened. Achieving the second 80% target requires the mainstream adoption of Super Low Energy, Zero Energy and Positive Energy buildings. Research and innovation remain critical drivers under the masterplan, to push the boundaries of energy efficiency to achieve the third 80% target.

Technology development is key to realising these sustainability goals. This includes driving more passive design strategies, through naturally ventilated design and alternative cooling strategies, such as hybrid cooling. Such initiatives not only foster innovation in sustainable design and construction but also challenge engineers to develop and implement creative, cutting-edge, energy-efficient solutions, as well as adopt green building products and materials, and low-carbon building practices.

However, achieving deep decarbonisation requires a collaborative approach, by breaking down silos across the built environment value chain and fostering multidisciplinary cooperation.

A 2024 report by Cushman & Wakefield, ‘Banking on Green Office Buildings in Singapore’ underscores the tangible benefits of green buildings. The study reveals that Green Mark-certified buildings command higher rental yields and occupancy rates compared to buildings that are not Green Mark-certified. This reflects an increasing demand for sustainable, energy-efficient and

wellness-centric workplaces. There are also long-term cost savings through improved energy efficiency and reduced operational expenses, for the building owner.

Beyond financial benefits, green buildings enhance occupant well-being and productivity. Employees in these working environments report higher satisfaction levels, leading to improved productivity and reduced absenteeism. As sustainability and employee wellness become key considerations, green buildings are emerging as strategic assets in the commercial real estate market.

Case Study 1

The Singapore Land Tower, a 44-year-old commercial building, exemplifies the potential of sustainable retrofitting. This project, recognised as one of the winners of the SGBC-BCA Leadership in Sustainability Awards in the Building Project Leadership in Sustainability (Carbon Performance) category, showcases the potential for older buildings to embrace sustainability and remain relevant in today’s market.

Rather than demolishing and rebuilding, Singapore Land Group (SingLand) undertook an extensive asset enhancement initiative (AEI) that earned a Green Mark Platinum certification. By prioritising retrofit, more than 50% of embodied carbon emissions were avoided. Key enhancements included a double-glazed curtain wall, energyefficient lighting, and enhancing the air conditioning and mechanical ventilation systems.

The project team, comprising Arup Singapore Pte Ltd as the ESD

Consultant and G-Energy Global Pte Ltd as the Green Mark Consultant, demonstrated how existing buildings can be revitalised to meet contemporary sustainability standards.

CapitaSpring, a 51-storey, 280 m tall, biophilic skyscraper, showcases the seamless integration of nature into urban spaces. This Green Mark Platinum certified development, owned by CapitaLand Development, was engineered by Arup Singapore Pte Ltd as the ESD Consultant, C&S Consultant and Facade specialist, alongside Beca Carter Hollings & Ferner and Squire Mech as the M&E Consultant.

The project features the iconic Green Oasis, a 35 m high and 42,900 ft2 open-air garden that mimics a tropical rainforest, suspended 100 m above ground. This naturally-ventilated semioutdoor space exemplifies the building’s biophilic design principles. The Sky Garden on level 51 hosts Singapore’s highest urban farm, supplying fresh and sustainable ingredients for the building’s F&B tenants.

CapitaSpring prioritises occupant health and well-being, through green mobility, active lifestyles, mental wellness and healthy diets. State-of-the-art research, design and technology have been employed to ensure optimal occupant health, comfort and energy efficiency. Its holistic approach earned CapitaSpring recognition in the SGBC-BCA Leadership in Sustainability Awards, under the Building Project Leadership in Sustainability (Health & Wellbeing) category.

As Singapore advances towards a low-carbon built environment, engineers remain instrumental in driving sustainability innovations. The Singapore Building Carbon Calculator, which won the IES Sustainability Award and the ASEAN Outstanding Engineering Achievement Award in 2024, exemplifies this spirit of progress.

The Singapore Building Carbon Calculator was developed through collaborative efforts by JTC Corporation, BCA, SGBC and the NUS Energy Studies Institute, to help the built environment sector make more informed decisions

about sustainable materials and construction methods.

Through engineering innovation, Singapore is not only constructing greener buildings but also shaping a sustainable future for generations to come.

The Maritime and Port Authority of Singapore (MPA) is raising ambition to accelerate decarbonisation on all fronts.

Climate change has significant implications for the shipping industry. As a low-lying island nation, Singapore is particularly susceptible to rising sea levels which pose a threat to coastal areas and infrastructure. Urgent action is crucial to safeguard the environment as well as protect the well-being and livelihoods of current and future generations.

As the steward of Singapore’s global hub port and international maritime centre, the Maritime and Port Authority of Singapore (MPA) plays a pivotal role in maritime decarbonisation, at three levels.

International collaborations Internationally, MPA collaborates with Member States of the International Maritime Organization (IMO) and other multilateral fora, to shape global measures to achieve net-zero emissions by or around 2050.

MPA is also working with governments and port authorities to align efforts across stakeholders in the value chain, such as establishing Green and Digital Shipping Corridors with international partners, to facilitate the transition to low- and zero-emission fuels.

Maritime Singapore

To support the decarbonisation of Maritime Singapore, MPA is accelerating efforts with industry and research partners to trial and pilot low- and zero-emission fuels. This includes developing fuel and bunkering standards as well as building the supply chain and infrastructure for bunkering such fuels.

MPA is also leading the electrification of the domestic harbour craft sector which includes coalescing research and technical know-how for a new,

greener generation of harbour craft, and establishing the charging infrastructure masterplan for electric harbour craft. Moreover, MPA is spearheading initiatives with industry and unions to equip the Maritime Singapore workforce with the necessary skills for the green transition.

sustainability

As an organisation, MPA is committed to achieving the public sector’s target to peak emissions around 2025 and achieve netzero emissions by 2045, under the GreenGov.SG initiative. MPA is optimising the deployment of operational assets and exploring the use of biofuel and renewables to reduce emissions.

Smart Facilities Management (FM) is being implemented across MPA facilities to optimise and reduce usage of brown electricity, and an integrated smart FM platform is planned to be operational by 2027 to monitor smart FM dashboards.

MPA is intensifying solarisation efforts at offshore sites and waterfront facilities. Plans are underway to explore the installation of a solar photovoltaic and energy storage system for decarbonisation

of Pulau Satumu’s Raffles Lighthouse.

MPA is also planning to progressively expand the solar panel coverage at Marina South Pier, which will transform it into the first public maritime terminal to achieve net-zero emissions. Upon implementation, this will support the charging of electric harbour craft (eHC), as part of the national eHC charging infrastructure.

Additionally, MPA is developing three net-zero energy buildings to strengthen Singapore’s position as a premier global hub port and leading international maritime centre.

MPA is also actively fostering a sustainability culture within the organisation, through various forms of communication, events and training, to instill eco mindsets and habits in its staff.

Addressing the impact of climate change on the maritime sector requires collective commitment and innovation. It is imperative for all stakeholders to collaborate and take decisive steps towards a greener, more resilient future.

Together, a meaningful difference can be made in safeguarding Singapore’s environment, for generations to come.

More initiatives, such as the installation of smart electric sub-meters, will be added to the Green Towns Programme.

HDB will intensify its sustainability efforts to create more energyefficient and climate-resilient public housing estates, with the 10-year Green Towns Programme (GTP) reaching its mid-point in 2025. This intensification of efforts includes the expansion of the cool coatings initiative to all existing HDB estates islandwide, as well as the inclusion of new initiatives, such as the installation of smart electric submeters, under the GTP.

The GTP is a plan to bring sustainable living to all existing HDB towns, with large-scale implementation of green features to improve the residents’ quality of life. It is a key initiative under the Singapore Green Plan which aims to build a more sustainable future for Singapore, in the face of climate change.

In 2021, HDB and Tampines Town Council launched a joint pilot project to apply cool coatings – a type of specialised paint, containing additives that reflect the sun’s heat, reducing surface heat absorption and emission – to approximately 130 HDB blocks in Tampines. With the use of such paint, HDB aims to reduce the ambient temperature of the site, enhancing comfort for residents and reducing energy consumption.

To monitor the ambient temperature and collect data for analysis, sensors were installed on the blocks’ external facades and at the ground level. Findings from the two-year pilot showed that the cool coatings reduced ambient temperatures by up to 2 °C, thereby meeting HDB’s target. Besides enjoying a cooler

environment, residents living in blocks painted with cool coatings also benefitted from a reduction in electricity consumption, as less energy is needed for air conditioning systems to cool their flats.

Following the successful pilot, HDB will work closely with the Town Councils to extend the cool coatings initiative to all existing HDB estates, by 2030. The paints used will be water-based paints containing low volatile organic compounds, similar to conventional paints, and comply with Singapore’s safety and environmental standards.

As the largest housing developer in Singapore, HDB plays a pivotal role in supporting the nation’s commitment to sustainable development. Besides cool coatings, other initiatives under the GTP have seen considerable progress. Building on these successes and to further advance its sustainability targets, HDB, in collaboration with relevant agencies, will introduce additional initiatives in the GTP, including the following:

Installation of smart electric sub-meters

From 2Q2025, smart electrical sub-meters will be installed in the consumer switch rooms of HDB blocks. These sub-meters will enable HDB and Town Councils to monitor and analyse energy consumption patterns and the performance of common services i.e. lighting, water pumps and lifts, at each block.

With this data, Town Councils can compare energy usage across HDB blocks and track the demand and supply of energy usage for individual blocks in the estate. The data collected will also help the Town Councils to optimise their maintenance cycles for common services, as well as detect anomalies such as equipment faults, to minimise downtime.

To reduce the carbon footprint of buildings, HDB will be upgrading and designing 38 HDB-managed complexes, by 2030. The complexes will have the following:

• Solar panels installed on the rooftop and more energy-efficient

equipment/fittings to reduce energy usage by 10%.

• Water-efficient fittings to reduce water usage by 10%.

• Machines to turn food waste into compost, reducing waste by 30%.

With these efforts, HDB aims to obtain the BCA Green Mark Super Low Energy (SLE) Certification for four HDB complexes in 2025. Thereafter, it has a target to progressively roll out green initiatives at an average of eight complexes a year.

Beverage container return points In support of the National Environment Agency’s (NEA) Beverage Container Return Scheme, a network of more than 1,000 return points (such as Reverse Vending Machines) will be deployed islandwide, including at HDB-owned and Town Council spaces.

The scheme, which aims to manage packaging waste and increase the recycling rate of beverage containers, will commence on 1 April 2026.

With these inclusions, the original focus areas of recycling rainwater and reducing waste will be subsumed under a broader category on optimising resources.

DRIVING SUSTAINABILITY IN HDB ESTATES

HDB remains committed to driving sustainability and green initiatives across Singapore’s public housing landscape. Moving forward, it will continue to review the progress and explore innovative solutions to enhance the performance of the initiatives, so as to build a sustainable and liveable environment for current and future generations.

STATUS OF INITIATIVES BEING IMPLEMENTED UNDER THE HDB GREEN TOWNS PROGRAMME

Cooling HDB towns

Greenery intensification: HDB has been introducing more greenery in the form of urban farms, extensive greenery or community / allotment gardens to the top decks of selected Multi-Storey Car Parks

(MSCPs) in HDB estates.

This is done through the implementation of the Prefabricated Extensive Green (PEG) Roof Tray System – a lightweight and modular system developed by HDB.

As at end-January 2025, the top decks of 24 MSCPs have been installed with PEG trays and converted for greenery. Of these, five have been planted with extensive greenery, while 19 have been transformed into community / allotment gardens, where residents can plant herbs, vegetables or ornamental plants.

Reducing conventional energy consumption

Solar panels: Under the SolarNova programme, HDB has been installing solar panels on HDB blocks to power common services, such as lifts, lights and water pumps, with green energy.

As at end-January 2025, more than 4,300 blocks have been installed with solar panels. Solar panels for the remaining committed HDB blocks will progressively be installed in batches, over the next two years, where feasible.

Elevator energy regeneration: With the Elevator Energy Regeneration System (EERS), energy generated during lift motions and braking operations, is recovered to power other services within the lift, such as lighting, ventilation and the lift display panel. With the EERS, lift energy consumption can be reduced by an average of 20%.

As at end-January 2025, more than 500 lifts have been retrofitted with the EERS. HDB is in the process of awarding two more tenders which will bring the total number of lifts retroffited with the EERS to 7,400.

Smart LED lighting: To reduce energy consumption in the common areas of HDB estates, HDB is working with Town Councils to implement smart LED lighting.

The smart lighting is equipped with analytics capabilities, as well as smart sensors that can automatically adjust the luminosity of LED lights when

motion is detected. Compared to conventional LED lighting, smart LED lighting can further reduce energy used for lighting, by up to 60%.

Since late 2024, Town Councils have begun replacing approximately 300,000 existing LED lights, that have reached the end of their lifespan, with smart LED lighting.

Promoting green commute

Dual bicycle racks: As at endJanuary 2025, more than 26,500 dual bicycle racks have been installed across 23 HDB towns. By the end of 2025, about 30,000 such racks will be installed islandwide.

Electrical vehicle (EV) chargers: As at end-January 2025, more than 3,600 electric vehicle (EV) chargers have been installed at 850 HDB carparks. HDB is on track to bring the number of carparks with EV chargers to approximately 2,000, by end 2025.

Optimising resources

UrbanWater harvesting system:

The UrbanWater Harvesting System (UWHS) is designed to maximise the volume of rainwater collected, by harvesting stormwater surface runoff from the ground into an underground detention tank.

In 2024, HDB commenced installation of the UrbanWater Harvesting System in Jurong and Yishun, as part of a pilot announced in 2022. Approximately 12 UWHS will be installed in those two towns. As at end-January 2025, in Jurong, one system has been installed, while the remaining three systems will be installed by 4Q2025. In Yishun, works to install the first system will commence in 3Q2025.

E-waste recycling bins: In 2023, HDB worked with the National Environment Agency (NEA) to deploy e-waste recycling bins at Hong Kah North, Punggol Clover and Fengshan Mulberry. Proper disposal of e-waste helps to prevent toxic hazards from polluting the environment and protect human health.

JTC’s lifecycle approach to sustainability.

JTC, the master planner and developer of Singapore’s industrial infrastructure, has positioned itself at the forefront of sustainable development in the nation’s industrial sector. As a statutory board under the Ministry of Trade and Industry, JTC plays a pivotal role in shaping Singapore's industrial landscape whilst addressing environmental concerns.

The organisation has aligned its strategies with Singapore’s sustainability targets, including achieving net-zero emissions around 2045, reducing energy and water consumption by 10%, by 2030, and slashing waste disposal by 30% within the same timeframe.

To guide its sustainability journey, JTC has established a comprehensive sustainability framework that spans the entire business value chain. The framework covers five key areas –planning and design, construction, lessee/tenant management, operations and maintenance, and rejuvenation.

For starters, JTC integrates sustainability principles from the earliest stage of development. The Punggol Digital District (PDD) exemplifies this approach. As Singapore’s first smart business district and largest Green Mark Platinum mixed-use development, PDD seamlessly incorporates smart technologies, green buildings and community spaces, demonstrating JTC’s approach to sustainable urban planning.

To minimise environmental impact during the construction phase, JTC has implemented guidelines for sustainable material usage. These include requirements for recycled concrete aggregates and materials certified by the Singapore

Green Building Council (SGBC). In collaboration with the Building and Construction Authority (BCA) and SGBC, JTC developed the Singapore Building Carbon Calculator to quantify and manage embodied carbon in construction projects.

JTC also actively engages its lessees and tenants to promote green practices within its industrial spaces. It has introduced green lease policies that set out sustainability requirements for energy and water efficiency. Through initiatives like the Aerospace Open Innovation Challenge, JTC fosters collaboration between industry players and other stakeholders to address sectorspecific sustainability challenges.

In its operations and maintenance, JTC employs a mix of active and passive strategies to reduce energy and water consumption. This includes smart building management systems and innovative solutions, such as web-based design tools for chilled water plant selection, to optimise energy efficiency.

As part of its rejuvenation strategy, JTC has developed a framework for repurposing industrial buildings. At Kolam Ayer Industrial Estate, an existing terrace factory is adapted for continued industrial use. This approach

not only preserves Singapore’s industrial architectural legacy but also significantly reduces carbon emissions associated with demolition and new construction.

Sustainability has become an imperative in the global agenda. Beyond its role as an industrial developer, JTC supports various industry clusters in their economic transformation efforts. With the emerging green economy, the support includes helping companies to decarbonise and leverage sustainability as a competitive advantage. This requires a delicate balance between technological developments, business readiness and the careful pacing of new initiatives to achieve national sustainability targets.

This challenging yet exciting journey requires strong collaboration among industries, government bodies and solution providers, collectively exploring innovative ideas and forging new frontiers in sustainability. Starting small, demonstrating solutions in real-world applications, and building credibility are important steps in navigating this path.

CPG Corporation’s commitment to decarbonisation.

CPG’s projects, such as

Climate change is one of the greatest challenges of our time, threatening lives, livelihoods, and global weather systems. Since Singapore joined 195 other nations in signing the Paris Agreement in 2015, there has been intensification of decarbonisation efforts by the nation. In November 2024, the Republic submitted a report to the United Nations outlining mitigation measures such as electrifying vehicle fleets and greening buildings to help Singapore cut emissions by nearly 12 megatonnes by 2030. With buildings responsible for an estimated 20% of Singapore’s total emissions, the built environment industry is in a pivotal position to contribute more to decarbonisation efforts.

CPG Corporation (CPG), a built environment firm with multidisciplinary expertise spanning architecture, engineering consultancy, and project, construction and facilities management, has long championed sustainable green design.

Since 2003, CPG has explored innovative ways to integrate nature

into its developments. Many of its iconic projects such as Khoo Teck Puat Hospital, State Courts, Eunoia Junior College, Gardens by the Bay and Jurong Lake Gardens, demonstrate how biophilic design enhances greenery in the built environment or seamlessly integrates buildings with natural surroundings.

nature-based solutions with grey infrastructure to

Complementing this, CPG’s expertise in engineering solutions that enhance energy efficiency has enabled it to deliver 95 Green Mark-certified projects to date, including 44 Green Mark Platinum projects, three Zero Energy Building (ZEB) Green Mark Platinum projects, and two Super Low Energy (SLE) buildings.

As CPG continues leading the green built environment sector, it also aims to accelerate the sector’s transition to a greener future through collaboration. Today, CPG provides strategic guidance to industry partners looking to reduce their carbon footprint.

“Our rich experience and multidisciplinary capabilities enable

us to engage in all building lifecycle phases, providing a holistic view of carbon across the entire value chain. By focusing on whole life carbon, we believe effective decarbonisation should reduce emissions at every stage, from pre-design to end of life. Our expertise ensures that businesses can navigate the complexities of carbon management effectively and sustainably,” says Mr Tan Shao Yen, CPG’s President and Group Chief Executive Officer.

Last year, CPG published ‘Embodying Sustainability – A Decarbonisation Playbook for the Built Environment’, a framework supporting holistic decarbonisation strategies that help clients understand regulatory requirements, set ambitious yet achievable carbon reduction targets and develop comprehensive decarbonisation roadmaps.

Looking ahead, CPG remains committed to driving meaningful change by sharing its expertise, fostering industry collaboration and advocating for a more sustainable, decarbonised future.

Embracing sustainability is a necessity.

Climate change is no longer a distant threat. It is a present reality. Across the globe, its impact can be felt, daily, from scorching heatwaves and devastating storms to increasingly erratic weather patterns.

Singapore, too, has experienced its share of anomalies, with record-breaking temperatures and unpredictable bouts of intense rainfall and flooding. The writing is on the wall. Embracing sustainability in all aspects of life is not just an option, it is a necessity. And engineers, the builders of our world, must be at the forefront of this transformation.

For too long, sustainability considerations have not been prioritised within the engineering profession. Engineers, by nature, are often inclined towards overdesign, prioritising safety factors above all else. The traditional approach often favours building, tearing down and rebuilding – a cycle that consumes vast resources.

Redundancy is often a key design principle and design methods frequently rely on rules of thumb rather than modern, computationally driven solutions. While these practices have served engineers in the past, they are fundamentally incompatible with a sustainable future.

With climate change now posing an existential threat to humanity, engineers must fundamentally shift their thinking. They must move beyond a purely functional approach and embrace sustainability in every facet of the projects. This requires a paradigm shift – a move away from the ‘build first, consider later’ mentality to one where sustainability is embedded from the initial concept stage.

This means questioning

It is the responsibility of engineers to build a sustainable future.

traditional design principles:

• Can we achieve the necessary safety margins with less material?

• Can we design for adaptability and reuse, rather than demolition and reconstruction?

• Can we leverage advanced computational tools to optimise designs for both performance and resource efficiency?

These are the questions that must be asked.

The Singapore Exchange (SGX) has played a pivotal role in shaping the sustainability reporting landscape. Since the introduction of the ‘comply or explain’ mandate in 2016, listed companies have been required to disclose their sustainability practices, adhering to internationally recognised frameworks like the Global Reporting Initiative (GRI) and the Sustainability Accounting Standards Board (SASB).

This push for standardisation has enabled stakeholders to make informed decisions, based on comparable and consistent data. However, reporting is just the first step. True sustainability must be ingrained in the engineering DNA.

The challenges are significant. Many businesses, particularly small

and medium-sized enterprises (SMEs), struggle with data collection and verification, due to limited resources and expertise.

The complexity and costs associated with implementing comprehensive reporting frameworks can be daunting. Furthermore, the risk of greenwashing necessitates stronger enforcement mechanisms to ensure genuine commitment. Finally, balancing comprehensive disclosures with business confidentiality remains a delicate act.

The road ahead requires a multipronged approach. Strengthening regulations, capacity building, leveraging technology, encouraging integrated reporting and fostering public-private partnerships are all crucial. But most importantly, there must be a change in mindset, within the engineering profession itself.

Engineering companies must recognise that embedding sustainability into the business model is not just an option – it is a strategic imperative. They should be committed to change, embracing the challenge head-on.

Engineering companies can turn sustainability requirements into opportunities for growth.

This is not just about meeting regulatory requirements.

• It is about recognising the responsibility, as engineers, to build a sustainable future.

• It is about moving beyond traditional practices and embracing innovation.

•It is about working towards a new era of climate action, where engineering expertise is harnessed to create a world that is both functional and sustainable.

The time for incremental change is over. The time for bold action is now!

In an age where sustainability is no longer optional but has become essential, APM Property Management stands at the forefront of the industry, partnering asset owners to push the frontiers of sustainability excellence.

Staying ahead of the competition is one of the key values that APM brings to its clients. Through APM’s suite of specialised services, clients are able to achieve recognised certifications and accolades that demonstrate their organisation’s commitment to sustainability.

APM’s unique approach to energy management prioritises helping asset owners to reduce their energy consumption through practical operational means, instead of through huge capital investments and expenses on equipment replacement.

APM’s comprehensive energy management approach stems from its property management domain expertise and the contribution of a specialised team that drives energy efficiency through continuous improvements in maintenance and operations, and an optimisation regime for air conditioning equipment which is the main energy guzzler in a building.

Asset owners can benefit from the following range of energy services that APM offers:

Energy management and audit

This process analyses a property’s energy usage patterns, to identify inefficiencies and recommend tailored solutions that enhance its energy performance which translates to savings on energy bills.

Proprietary dashboard solution

Asset owners are provided with visibility of the building’s current and forecasted energy

performance, which are benchmarked against the industry performance. The dashboard also provides actionable insights, based on the asset’s air conditioning data, to enable asset owners drive further reductions in energy consumption.

Equipment life cycle planning and project management

An equipment’s operational efficiency and lifespan are closely monitored, so as to effectively implement cost optimisation strategies and reduce unnecessary Capex investments, thereby bringing more value for asset owners.

APM’s sustainability team works with asset owners to enhance their properties’ ESG performance and address the complexities of attaining the various green credentials. Achievement of such credentials gives recognition to the sustainability efforts and increases the marketability of the assets.

certifications (eg. Green Mark, LEED)

The team provides end-to-end support, from conducting gap studies, implementing strategic improvement works and working

with asset owners through the certification process.

GRESB and sustainability reporting Investors and stakeholders increasingly prioritise sustainability performance as a key decisionmaking factor. APM works with clients to improve their GRESB scores and prepare their sustainability reports to build and enhance investor confidence.

Leveraging on APM’s unique energy management approach and proprietary energy dashboard, the Management Corporation Strata Title (MCST) of Suntec City reduced the annual energy consumption of the development by 26% in 2023, against the consumption in 2019.

In 2024, APM’s project management team kickstarted an equipment lifecycle replacement plan, starting with the replacement of the fans for the Air Handling Units (AHUs) of Suntec City’s five office towers with the more energyefficient EC fans, to drive further reduction in energy consumption. This enabled the office towers to obtain the Green Mark Platinum certification.

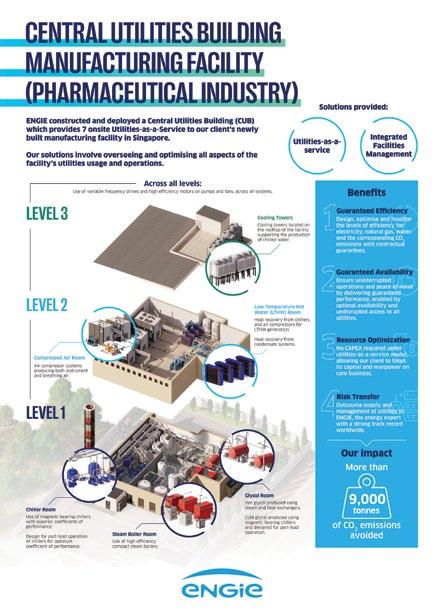

A facility in Singapore significantly slashed its carbon emissions, without compromising productivity.

Meeting complex energy demands in pharmaceuticals

When a leading, global pharmaceutical company set out to build a stateof-the-art manufacturing facility in Singapore, it encountered dual challenges – how to power specialised equipment while meeting ambitious environmental targets.

To address this, the company turned to ENGIE, a leader in lowcarbon energy solutions. Leveraging its expertise in sustainable manufacturing practices, ENGIE implemented a Central Utilities Building (CUB) to manage seven essential utilities, including steam, chilled water and compressed air. Operated through a Utilities-asa-Service (UaaS) model, the CUB seamlessly integrates sustainability into every stage, from design to implementation, showcasing the impact of tailored energy solutions.

This greenfield project exemplifies a growing trend in manufacturing – integrating sustainability into facilities from the start, to meet rising investor and consumer expectations for environmental responsibility. Using advanced technologies like magnetic bearing chillers and heat recovery systems, the facility avoids over 9,000 tonnes of CO₂ emissions. These efficiencies demonstrate how new facilities can achieve significant environmental impact from day one.

Accelerating sustainability through regulatory drivers

Southeast Asia’s regulatory frameworks are accelerating the shift towards sustainable practices. In Singapore, its progressively rising Carbon Tax – from SGD 5 to SGD 25 per tonne by 2024 and 2025 – and mandatory climate-related financial disclosures are reshaping

investment decisions.

For energy managers ready to lead the charge, the message is clear. Innovation and sustainability are not just compatible, they are the foundation for a resilient future.

To learn about ENGIE’s tailored

solutions, visit www.engie-sea.com or scan the QR Code below:

by Prof Lock Kai Sang and Dr Deepak L Waikar, Energy Efficiency Technology Centre, Singapore Institute of Technology

Energy assessments lead to lower energy bills, improved business competitiveness and a reduced environmental footprint.

Energy efficiency plays a pivotal role in sustainability, particularly for Manufacturing Small and Medium Enterprises (MSMEs) in Singapore. For MSMEs, systematic energy efficiency measures translate to lower energy bills, improved competitiveness and a reduced environmental footprint. According to the International Energy Agency (IEA) [1], energy efficiency improvements could contribute to more than 40% of the emissions reductions needed to meet global climate goals by 2040.

Singapore has implemented various initiatives to enhance energy efficiency in the manufacturing sector. The Energy Efficiency Grant (EEG), previously Energy Efficiency Fund (E2F), administered by the National Environment Agency (NEA), supports MSMEs in adopting innovative energy-efficient technologies, processes and solutions.

The Energy Efficiency Technology Centre (EETC) of the Singapore Institute of Technology (SIT), in collaboration with the NEA, has systematically performed energy assessment for 225 significant energy-using industrial systems, such as compressed air systems, boilers, pumps, motors, lighting and HVAC, used by MSMEs in Singapore, since February 2021. Such ISO 50002 Energy Management Standard level assessments led to an estimated annual energy savings of 17.6 million kWh, an annual carbon abatement of 7.4 million kgCo2e, and SGD 3.0 million savings in annual energy bills.

For example, optimisation in one of the Food MSMEs, having 14 dryers, resulted in an annual energy savings of 290,000 kWh and an annual carbon abatement of 120,000 kgCo2e. Similarly, the implementation of energyefficient lighting and HVAC systems achieved a 20% reduction in energy consumption [2], for one of the precision engineering MSMEs, and the adoption of an energy management system [2] achieved a 30% reduction in energy usage for another MSME.

Such examples testify to how systematic energy assessment can contribute to energy savings and decarbonisation for MSMEs.

To sustain the momentum, one of the crucial aspects of the service to MSMEs is the upskilling of engineers, technologists and managers in the energy efficiency domain. Over 400 such professionals were trained from June 2020 to December 2024, as a result of collaborative efforts between NEA, EETC-SIT and SSG.

In addition, 85 undergraduate students benefitted from the Integrated Work Study Programme (IWSP), through hands-on involvement in the energy assessment of MSMEs under the supervision of energy specialists from EETC-SIT.

SIT offers a sustainability learning roadmap for undergraduates and working professionals. In it, EETC plays a key role especially in the energy aspect of sustainability.

Sustainability education in SIT covers Pre-employment Training (PET), with strategies that build

a strong foundation to prepare learners for advanced, crossdisciplinary sustainability topics and projects; and deepen sustainability knowledge through integrated core and discipline-specific modules on key topics such as life cycle assessment and green financing.

Working professionals can supercharge sustainability knowledge through Continuing Education and Training (CET) and workshops that stack to a Specialist/Graduate Certificate.

The ASEAN Plan [3] of Action for Energy Cooperation (APAEC) 20162025 outlines a comprehensive strategy to enhance energy efficiency and conservation across the region. This includes setting energy intensity reduction targets and promoting energy-efficient technologies and practices. NEA, EETC-SIT, and other industry stakeholders can collaborate to take advantage of the opportunities within the ASEAN region.

It can be concluded that managing energy consumption through systematic energy assessment and efficiency measures can lead to the sustainability and decarbonisation of MSMEs in Singapore.

References

[1] https://www.iea.org/commentaries/ how-energy-efficiency-will-power-netzero-climate-goals

[2] https://www.nea.gov.sg/ourservices/climate-change-energyefficiency/energy-efficiency/energyefficient-singapore

[3] (2021-2025) ASEAN Plan of Action for Energy Cooperation (APAEC) 2016-2025

Phase II - ASEAN Centre for Energy

by Yeo Wei Liam, Managing Director, Systemair and Hannah Jouy, Marketing Consultant, Systemair

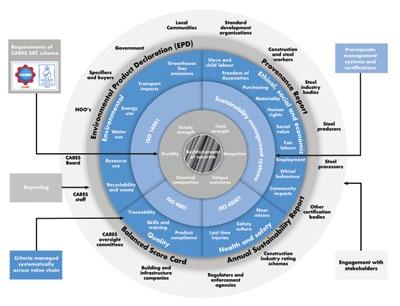

They are important in advancing sustainable construction practices.

Today’s sustainability in the built environment has evolved beyond energy efficiency to encompass over 20 environmental factors, including material efficiency, CO₂ emissions and the Global Warming Potential (GWP). These complexities are evaluated through lifecycle assessments (LCAs) and verified via Environmental Product Declarations (EPDs). As sustainability reporting laws worldwide grow stricter, the demand for EPDs is surging, raising the question, “What are EPDs, and how should they be interpreted?” At its core, LCAs comprehensively assess a product’s environmental impacts throughout its lifecycle. At the same time, EPDs certify these evaluations, offering vital environmental information about materials and components used in construction. While EPDs for traditional materials have been available for years, their scope has expanded to encompass technical equipment and HVAC products. This shift is crucial, as ventilation systems influence indoor air quality (IAQ) and energy consumption.

EPDs are gaining global traction, as national building codes increasingly mandate LCAs for new buildings. Organisations like the Singapore Green Building Council are highlighting their importance and EPDs also contribute valuable credits to green building certifications such as BREEAM and LEED.

All LCAs in the construction sector adhere to the same structure, whether for individual products or entire buildings, as defined by the most globally recognised standard, EN 15804 (Sustainability of construction works – Environmental Product Declarations). EPDs communicate ‘verifiable, accurate,

non-misleading environmental information’, through the following lifecycle stages:

• Production: Raw materials, transport, and manufacturing.

• Construction: Transport and installation processes.

• Use: Maintenance, repair, replacement, refurbishment, and resource consumption.

• End-of-Life: Deconstruction, demolition, waste processing, and disposal.

• After-Life Benefits: Potential for reuse, recovery or recycling. These stages are categorised into three types of EPDs:

• Cradle-to-Gate: Covers production and end-of-life stages.

• Cradle-to-Gate Plus Options: Includes additional construction and use stages.

• Cradle-to-Grave: Encompasses all five stages.

Systemair adheres to globally recognised standards to ensure accurate and transparent EPDs. The company’s EPDs typically follow a Cradle-to-Gate model, reflecting what is generally applicable across all projects. As operational energy use varies significantly, depending on project-specific factors such as airflow, pressure, climatic conditions and local energy sources, these variations make it impractical to generalise energy use within EPDs.

Product selection tools and lifecycle cost calculators address this variability, enabling project-specific energy performance assessments. This helps stakeholders make informed decisions that align with their sustainability goals.

As LCAs become mandatory in building projects, EPDs play a pivotal role in ensuring accurate environmental assessments and are critical in choosing the right solution for a project. For example, Systemair EPDs, compliant with EN 15804, ISO 14025 and ISO 14040/14044 standards, are published on the company’s website and verified by the Norwegian EPD Foundation, which is a member of the ECO Platform, making our EPDs globally recognisable.

In total, these EPDs cover tens of thousands of item numbers. Examples include the MUB EC fans and air curtain series like Pamir and Arden. These certifications support sustainable construction globally, reinforcing the importance of integrating EPDs into every building lifecycle phase.

As the demand for sustainable practices continues to rise, EPDs play a pivotal role in driving compliance, fostering innovation and ensuring quality ventilation. Together, these efforts pave the way for a more sustainable future in the built environment.

Your perfect climate solutions, tailored by Systemair and Frico

Pamir Series

Super Energy-Efficient: Designed for ultimate comfort and energy savings.

Stylish Design: Perfectly complements modern interiors.

Flexible Installation: Adaptable to various settings with ease.

Vertical & Horizontal Type available.

Scan the code to learn more about our EPDs!

Arden Series

Almost Invisible: Recessed air curtains seamlessly blend into any aesthetic.

High Efficiency: Save up to 50% energy with advanced EC motors.

Intelligent Control: Configure settings for maximum indoor comfort.

Customised Air Curtains

Tailored Designs: Meet your unique design and functional needs.

Premium Performance: Engineered for efficiency and reliability.

Versatile Applications: Ideal for commercial and bespoke spaces.

At Systemair, we adhere to globally recognised standards to ensure accurate and transparent Environmental Product Declarations (EPDs). Systemair EPDs, compliant with EN 15804, ISO 14025, and ISO 14040/14044 standards, are published via the ECO Platform and the Norwegian EPD Foundation.

Contact Us Today

Revolutionising energy efficiency.

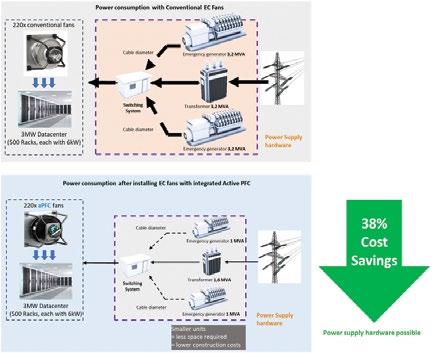

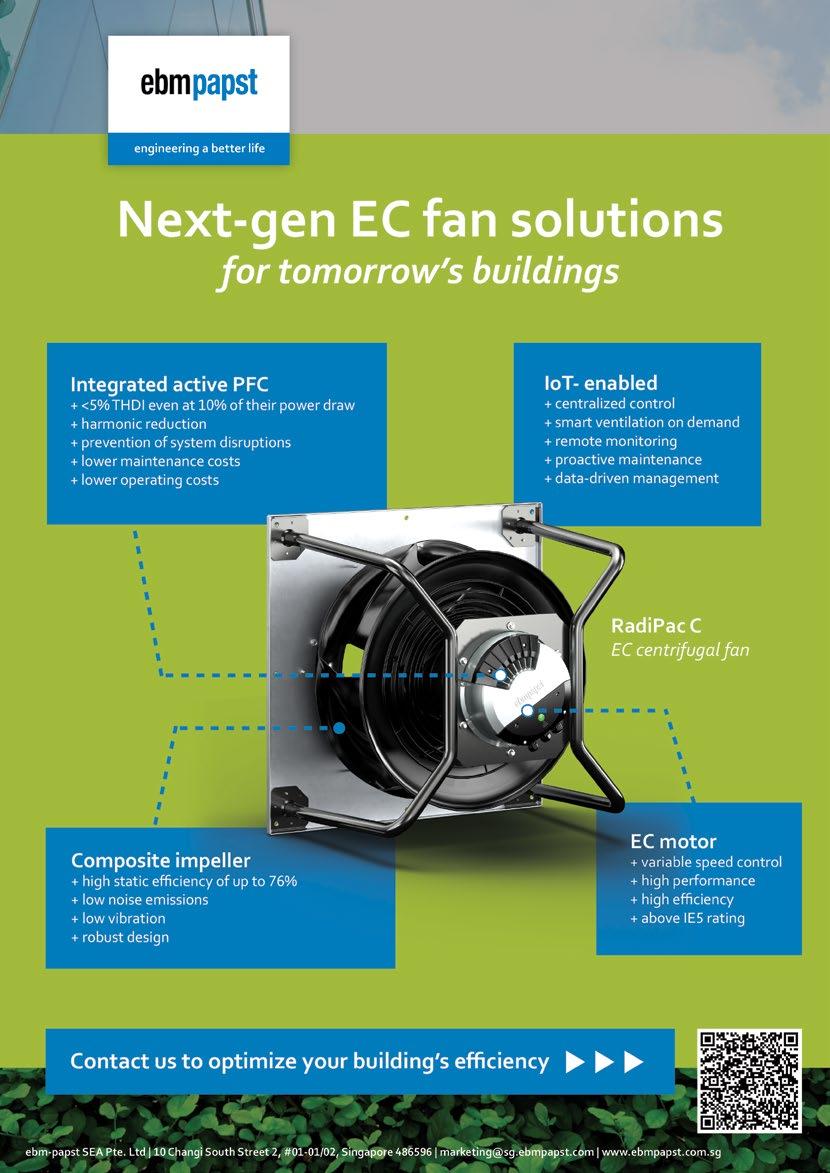

In Singapore’s older buildings, many fans use AC motors, resulting in high energy consumption. Retrofitting with EC fans offers a quick solution. While most energyefficient buildings have already switched to EC fans for their HVAC systems, energy consumption can be further optimised by upgrading to the latest EC fans with integrated Active PFC (Power Factor Correction) and IoT-enabled smart ventilation.

The next generation of advanced EC technology products includes super-efficient motors with higher power density, enhanced control algorithms, integrated Active PFC and sensors.

The latest EC fan models will increasingly be connected to IoT platforms, incorporating machine learning for predictive analytics and adaptive control, enabling real-time adjustments to optimise performance. These EC fan models will utilise eco-friendly materials and are designed to minimise both energy consumption and waste.

Key benefits of Active PFC in energy efficiency

Active PFC plays a crucial role in enhancing the energy efficiency of EC fans. By correcting the phase difference between current and voltage, Active PFC improves the power factor, bringing it closer to 1.0. This ensures that the fan consumes power more efficiently, reducing wasted energy.

Another key benefit is harmonic reduction. Active PFC minimises current and voltage distortion in switching power supplies, which can disrupt the power supply. In some of the more advanced EC fan models with integrated Active PFC, <5% Total Harmonic Distortion (THDI), down to 10% of their power draw, can be achieved, even in disturbed power supplies, without

requiring adjustments onsite during installation.

By smoothing out distortions, integrated Active PFC ensures a stable, high-quality power supply which prevents overheating, energy disruptions and electrical noise, thus improving overall system efficiency. In the long run, Active PFC extends the lifespan of electrical equipment by reducing wear and tear, leading to lower maintenance costs and reduced utility and operating expenses.

Unlocking digital sustainability with IoT

Smart Ventilation Systems, powered by IoT, are at the forefront of the transformation of building management. These systems use IoT technology to monitor and regulate indoor air quality in real time. They adjust ventilation rates based on occupancy levels, outdoor air conditions and other

environmental factors, ensuring optimal indoor air quality while minimising energy consumption. The integration of these IoTenabled systems with Building Management Systems (BMS) represents a significant step forward. Enhanced connectivity allows for centralised control of HVAC systems, facilitating proactive maintenance and optimising operational efficiency. This integration improves overall building management, ensuring that energy usage is always balanced with occupant needs.

Smart ventilation systems are shaping the future of sustainable indoor spaces by enhancing air quality, energy efficiency and comfort, while integrating with modern building management.

The combination of Active PFC, IoT connectivity and next-gen EC technology drives eco-friendly, energy-efficient solutions for a greener future.

According to the World Green Building Council, we spend 90 percent of our time indoors. Given that statistic, it’s clear the quality of the air we breathe in buildings can dramatically impact our health and well-being. At Reliable Controls we believe sustainable buildings are a key component to reducing the health and environmental impacts of indoor and outdoor air pollution.

1

Improve comfort and productivity.

Research from the US Environmental Protection Agency (EPA), informs us that indoor air contains two to five times more volatile organic compounds than outdoor air due to chemicals found in buildings. This impacts human health, from eye and throat irritation to respiratory diseases and cancer.

And while you can’t yet monitor the presence of a virus like COVID-19 in the air, you can measure a number of factors that affect the risk of viral transmission: temperature, humidity, and CO2. These air-quality measures are also linked to workplace well-being and productivity, so the better the air in your building, the better your occupants are likely to feel—and perform.

2

Save energy.

Excessive ventilation wastes energy. Ideally, a building’s ventilation system provides just the right amount of air. Many ventilation systems, especially older ones, are based on constant air volume, which means they always operate at full capacity. By converting to a variable air volume system, you can optimize your energy efficiency with demand-controlled ventilation. The EPA found that a ventilation upgrade from constant air volume to variable air volume can achieve annual energy savings of 10 to 21 percent. Beyond that, with air-quality sensors, you have access to real-time data that informs when and where to efficiently deploy air filtration and temperature control.

Identify trends.

4

3 Spot problems.

Integrating IAQ sensing technology into your building automation system means you can collect building data that helps you perform preventative maintenance and avoid system failures. By tracking pollutant levels continuously over time, for example, you can easily identify where and when to address changes in air-quality parameters. Long-term trends are almost impossible to detect with periodic spot sampling, which provides only a snapshot of data points at a particular time.

5

Most people know IAQ sensors can warn building managers about safety issues like smoke or carbon monoxide. Did you know they can also tell you how much particulate matter is in the air? Or how many harmful volatile organic compounds are circulating in your space? IAQ data can help you determine where to focus cleaning, when to service equipment, when to change filters, and when to increase or decrease ventilation.

IAQ monitoring is a crucial component in healthy building certifications like NABERS. To earn an Indoor Environment (IE) star rating under NABERS v2, for example, a facility must meet a minimum IAQ requirement intended to benefit occupants, maintain ventilation system equipment, and follow guidelines for mechanically and naturally ventilated spaces, in addition to other measures of indoor comfort.

HUMIDITY

According to the World Green Building Council, we spend 90 percent of our time indoors. Given that statistic, it’s clear the quality of the air we breathe in buildings can dramatically impact our health and well-being. At Reliable Controls we believe sustainable buildings are a key component to reducing the health and environmental impacts of indoor and outdoor air pollution. Learn more reliablecontrols.com/IAQ

by Stephen Huong and Er. Cavan Chai, CVC Engineers Pte Ltd

The unexpected journey into sustainability.