PORTFOLIO ARCHITECTURE

PHILIP LADD

UNDERGRADUATE

SELECT WORKS

2019-2023

PHILIP LADD

UNDERGRADUATE

SELECT WORKS

2019-2023

Dedicated Architecture student specializing in efficient and logical design. Advanced knowledge of sustainable design elements and LEED green building standards. Projects focused on commercial and residential designs ranging from a 250 sq. ft. tiny house to a 115,000 sq. ft. apartment complex.

CCD Architecture - Architectural Intern

09/2023 - Current

• Worked to help build new graphical templates for firm bid documents.

• Aided in schematic design, as well as design development on several projects ranging in size and cost.

• Generated presentation quality renderings of different schemes

Mississippi State Event Services - Audio Visual Technician Starkville, MS

08/2019 - 05/2023

• Monitored and repaired audio, video, control systems and video conferencing equipment.

• Provided troubleshooting techniques in integrating professional audio/video systems.

• Oversaw multiple large scale events and aided in the running of many high profile meetings.

Self-employed - Swim Lesson Instructor

Columbus, MS

05/2019 - 08/2022

• Taught students pool and water safety guidelines.

• Taught daily swim instruction to students varying in ages and skill levels.

YMCA - Lifeguard

Columbus, MS

05/2017 - 05/2019

• Monitored safety of guests in and around swimming pool.

• Learned and maintained proficiency in first responder skills such as First Aid and CPR to offer individuals in distress optimal support.

pal4msu@outlook.com

(662)251-4833

Starkville, MS 39759

Mississippi State University

Starkville, MS

Bachelor of Arts: Architecture

Anticipated in May of 2024

• 3.73 GPA (Deans List all Semesters)

• Stephanie M. and Don F. Pizzetta

Annual Scholarship Recipient

• Featured in BARNworks 20/21

• Relevant Coursework: Historic

Preservation, Site Planning, & Passives

New Hope High School

Columbus, MS 05/2019

High School Diploma

• 4.0 GPA

• Awarded Star Student for highest ACT in the class

• AutoDesk Revit - Advanced

• AutoDesk AutoCAD - Intermediate

• Adobe InDesign - Intermediate

• Adobe Photoshop - Advanced

• Enscape - Advanced

• SketchUp - Advanced

• Cura - Advanced

• Rhino - Beginner

• Physical Modeling - Intermediate

Digital Portfolio

Chicago, IL

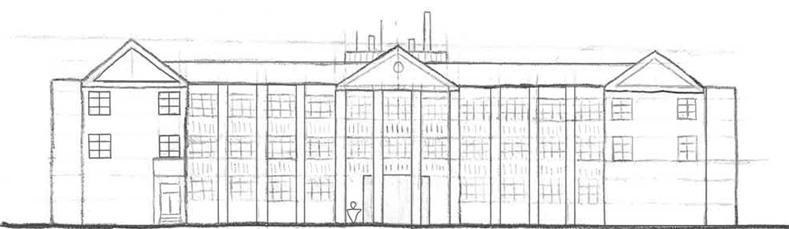

The objective of this project was to study what makes a home and implement our findings into a multi-use apartment complex. In my research, I discovered the home is a place of psychological comfort. It is a space that you can control; a space that is entirely your own. In search of these tenets I found myself designing The Cross, a building made to feel like home.

The apartment units stack atop a podium housing a private gym and storefronts. A delineation between the two-story podium and the apartments creates visual cohesion with the shorter surrounding Chicago cityscape. The additional floor in the plinth also allows for a wrap-around balcony, giving guests downtown views while they enjoy their pizza. The apartments themselves slide into place in a doublecross grid system producing interlocked, identical living quarters while efficiently utilizing square footage. Means of egress are centrally located providing efficient and equal access to each unit.

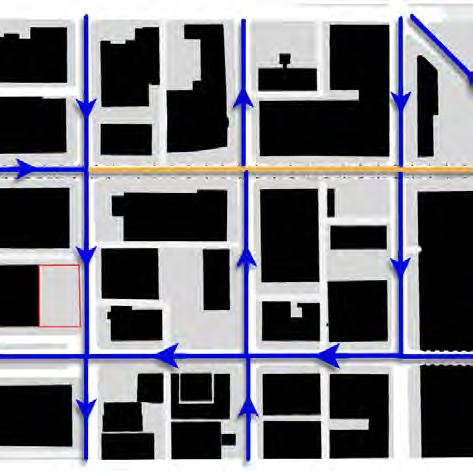

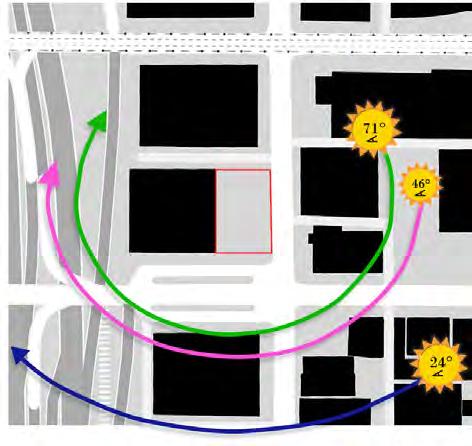

Circulation around the site

The standard unit layout was designed in tandem with the overall form of the building from the very start. Every single unit is identical down to the brick, and each has its place in the structural grid that makes up The Cross. Units contain two different areas, the public and the private. For a person to feel truly at home they must have a space that is theirs, we can see this in teenagers when they fight to have their own space. With the limited amount of space we had to work with the best move was to make the bedroom feel completely cut off from the living space. This decision led to the addition of a second balcony off of the bedroom, allowing the residents to have a space off of their room that was their own. Generating this boundary between private and public spaces is a perfect sample of The Cross as a whole.

Inside The Cross there are 6 residential floors and each one of those is equipped with an ADA unit directly next to the public laundry room. The ADA units have only a few minor changes to acheive compliance, being the bathroom and the kitchen.

A rigorous study into how other designers address the issues presented by this code allowed me to create the unit seen on the left. A feeling of home is reliant on a feeling of comfort, and part of said comfort is knowing that others around you are not that different. The Cross accomplishes that by implementing many ADA compliant design philosophies into the base unit, only adding the luxary of extra counter space in the main units.

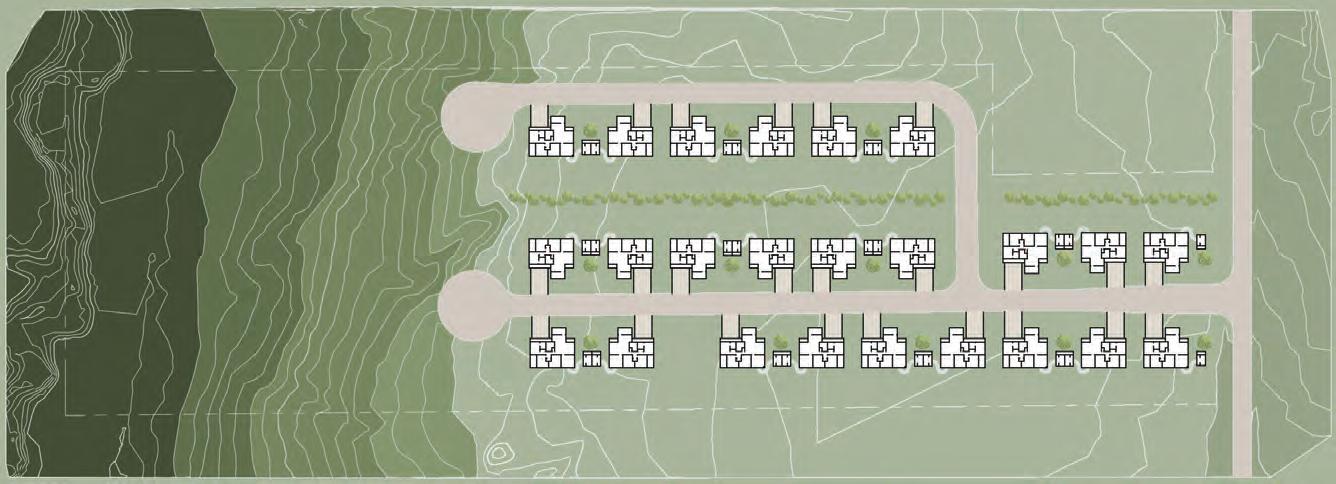

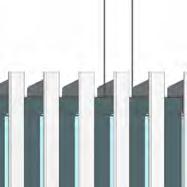

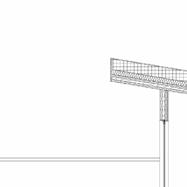

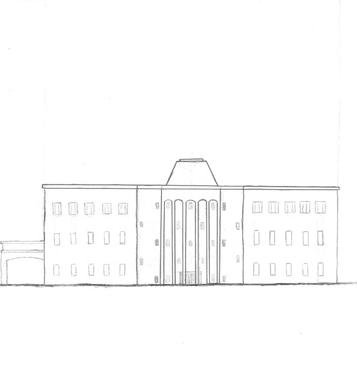

IMPLEMENTING CONCRETE FOR AFFORDABLE HOUSING

STARKVILLE, MS

When designing residential architecture, the preconceived notion of what it can and should be, for the past few centuries, has changed drastically from what residential architecture has been. This is in part to several factors, most foremost of which is the rise of suburbia. A set type of building construction with a small material palette has left the vast amount of mid-range to low-range architecture devoid of any personality or substance. These quasi-laws set into place designating how residential architecture should be designed make it difficult to break from the suburban archetype without making a too-strong statement. Due to these factors, the task of designing a Habitat house in Starkville, MS using precast concrete seemed momentous at first, a challenge which had no real solution. Pre-cast housing, traditionally, does not feel very homelike. Due to the nature of the construction, pre-cast housing often feels foreign, cold, and unwelcoming. Beyond that, precast housing by necessity of efficiency is mass produced, often leading to cookycutter neighborhoods with no real variance.

Because of these challenges, the goal of the project was suprisingly clear from the start. The goal was to design an efficient pre-cast concrete form which would feel more like a welcoming home than a safety shelter. More than this, the goal was to design a precast typology which could bring personality and variance to a neighborhood.

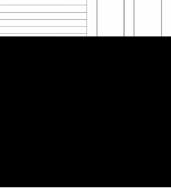

GYP.

OSB SPACER

GYP.

OSB SPACER

JAMB EXTENSION

JAMB EXTENSION

WEATHER STRIPPING

WEATHER STRIPPING

STOOL

STOOL

APRON SPACER

APRON SPACER

GYP.

GYP. BATT INSULATION

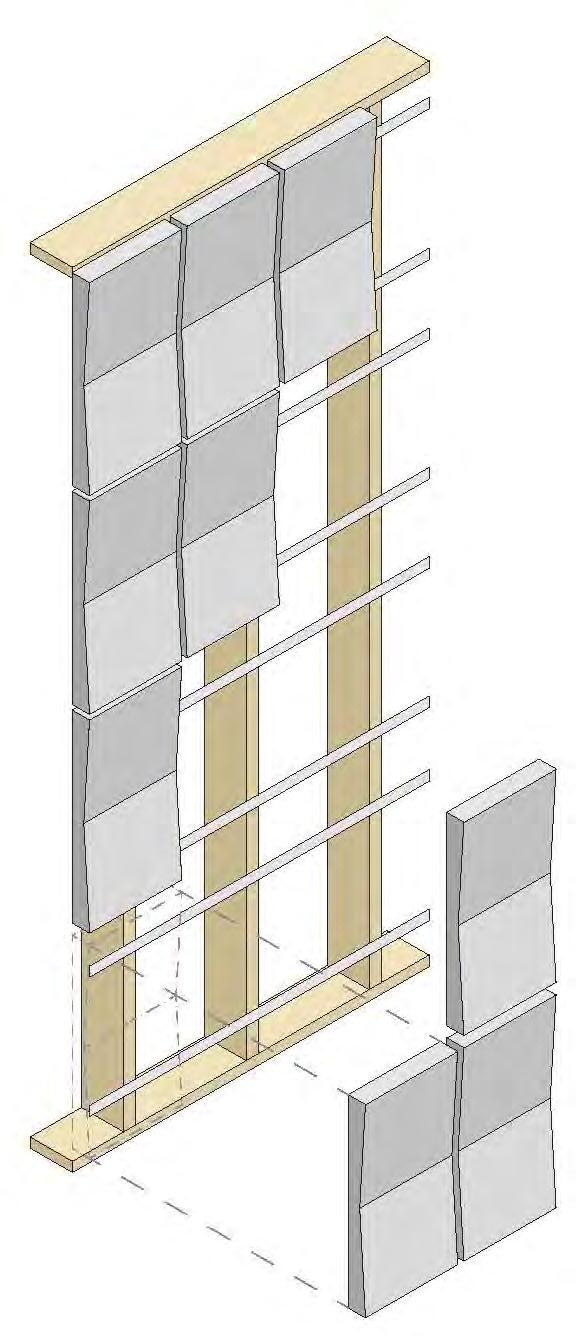

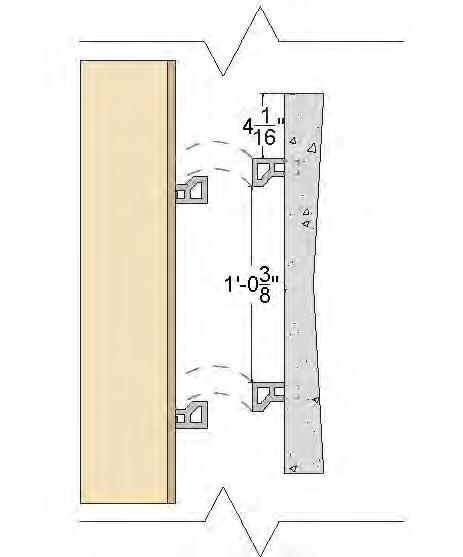

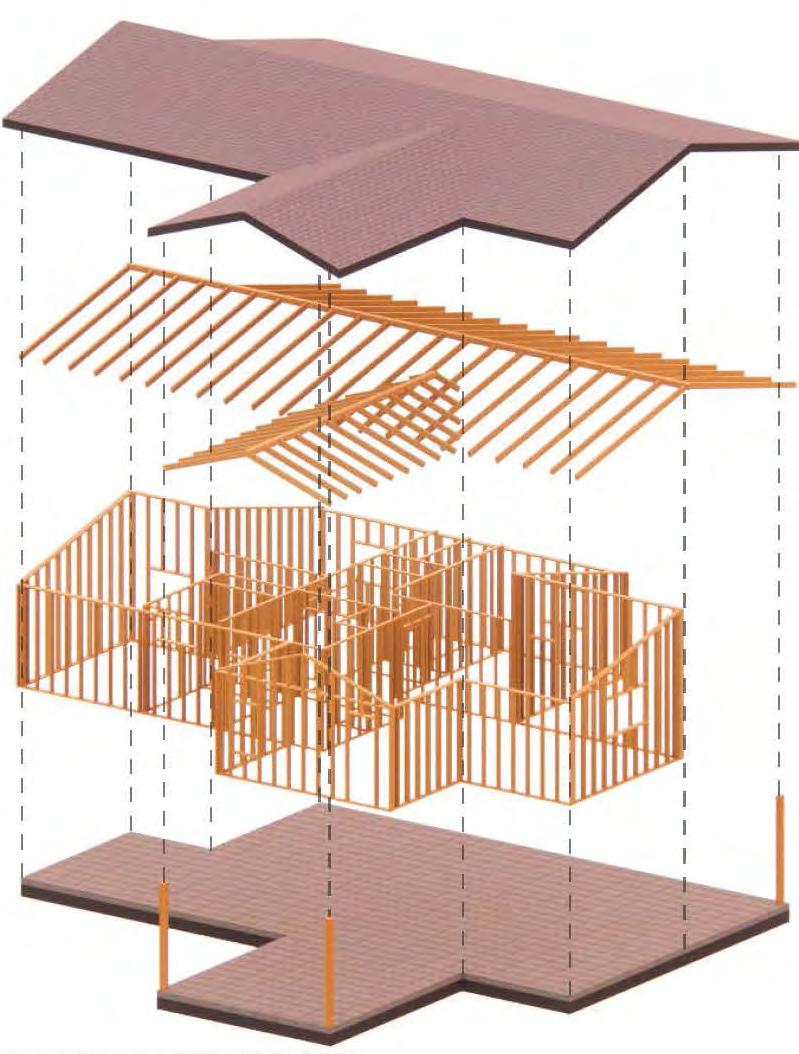

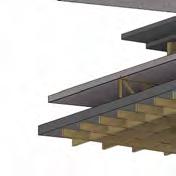

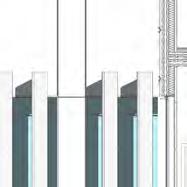

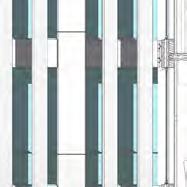

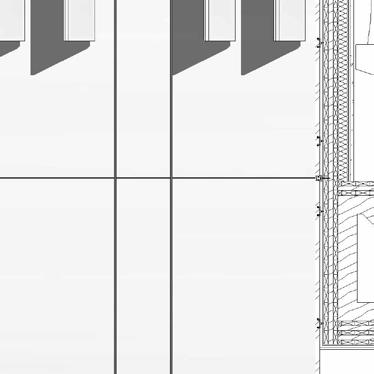

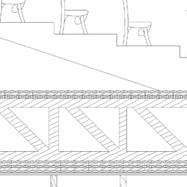

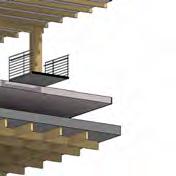

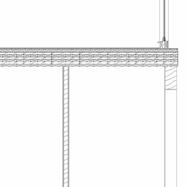

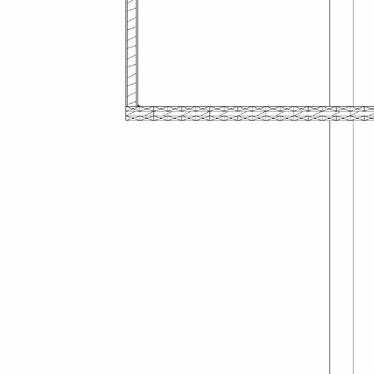

A.S.H. (Affordable Sustainable Housing) was the brainchild of a group with the stipulation that we must have the facade consist entirely of concrete. To meet this guideline, we had to dive deep into research and discover any possible way that we could coat a building in concrete and still have it feel like ahome while maintaining a low cost. Concrete is not made for small-scale projects, especially not the precast system used in this project. The ability to mass-manufacture the concrete panels and apply them universally was essential to the projects success.

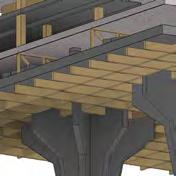

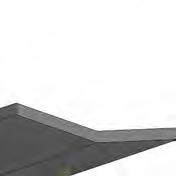

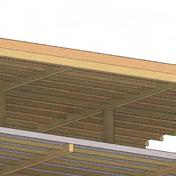

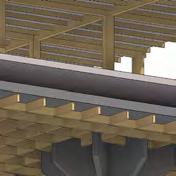

Throughout the project, I was tasked with designing and implementing the structural system that would compose each home. The goal of my design was to create a series of panels that were aesthetically pleasing and could be put together by volunteers. This idea was accomplished with custom-designed Z-clips that allowed the panels to be placed onto a series of 2” x 6” boards and were held on by their own weight. Each panel weighs around 125 pounds but that can easily be lifted by 2 volunteers working together. These factors together, along with uniform panel sizes and adjustment of the overall design, resulted in a beautiful and delicate exterior that does not feel oppressive to the occupant.

OSB

OSB

BATT INSULATION

BATT INSULATION

2" X 6" STUD

2" X 6" STUD

PRECAST PANEL

SHINGLES

SHINGLES

PLYWOOD AND FELT

PLYWOOD AND FELT

BATT INSULATION

BATT INSULATION

WOOD SIDING

WOOD SIDING

On top of the panel systems design, I was also placed in charge of the overall structure of the project as seen to the right.

CASEMENT FLASHING

PRECAST PANEL CASEMENT FLASHING

PRECAST PANEL

PRECAST PANEL

Z-RUNNER CONNECTION

Z-RUNNER CONNECTION

SUBSILL

SUBSILL

FLASHING

FLASHING

2" X 6" STUD

2" X 6" STUD

GYP.

GYP.

BATT INSULATION

BATT INSULATION

Z-RUNNER CONNECTION

Z-RUNNER CONNECTION

ANCHOR BOLT

ANCHOR BOLT

PRECAST PANEL

PRECAST PANEL

2" X 6" STUD

2" X 6" STUD

FLASHING

FLASHING

REINFORCEMENT REBAR

REINFORCEMENT REBAR

5" SLAB

5" SLAB

COMPACTED GRAVEL

COMPACTED GRAVEL

EARTH

EARTH

DOOR FRAME

DOOR FRAME

RUBBER SEAL HINGE DOOR

RUBBER SEAL HINGE DOOR

2" X 6" STUD

2" X 6" STUD

BATT INSULATION

BATT INSULATION

PRECAST PANEL

PRECAST PANEL

Z-RUNNER CONNECTION

Z-RUNNER CONNECTION

BATT INSULATION

BATT INSULATION

2" X 6" STUD

2" X 6" STUD

GYP. SIDING

GYP. SIDING

TRIM

TRIM

VAPOR RETARDER

OSB

VAPOR RETARDER

OSB

CLIP FOR PRECAST

CLIP FOR PRECAST

CONNECTION

CONNECTION

PRECAST PANELS

PRECAST PANELS

2" X 6" STUD

2" X 6" STUD

BATT INSULATION

GYP.

BATT INSULATION

GYP.

TRIM

TRIM

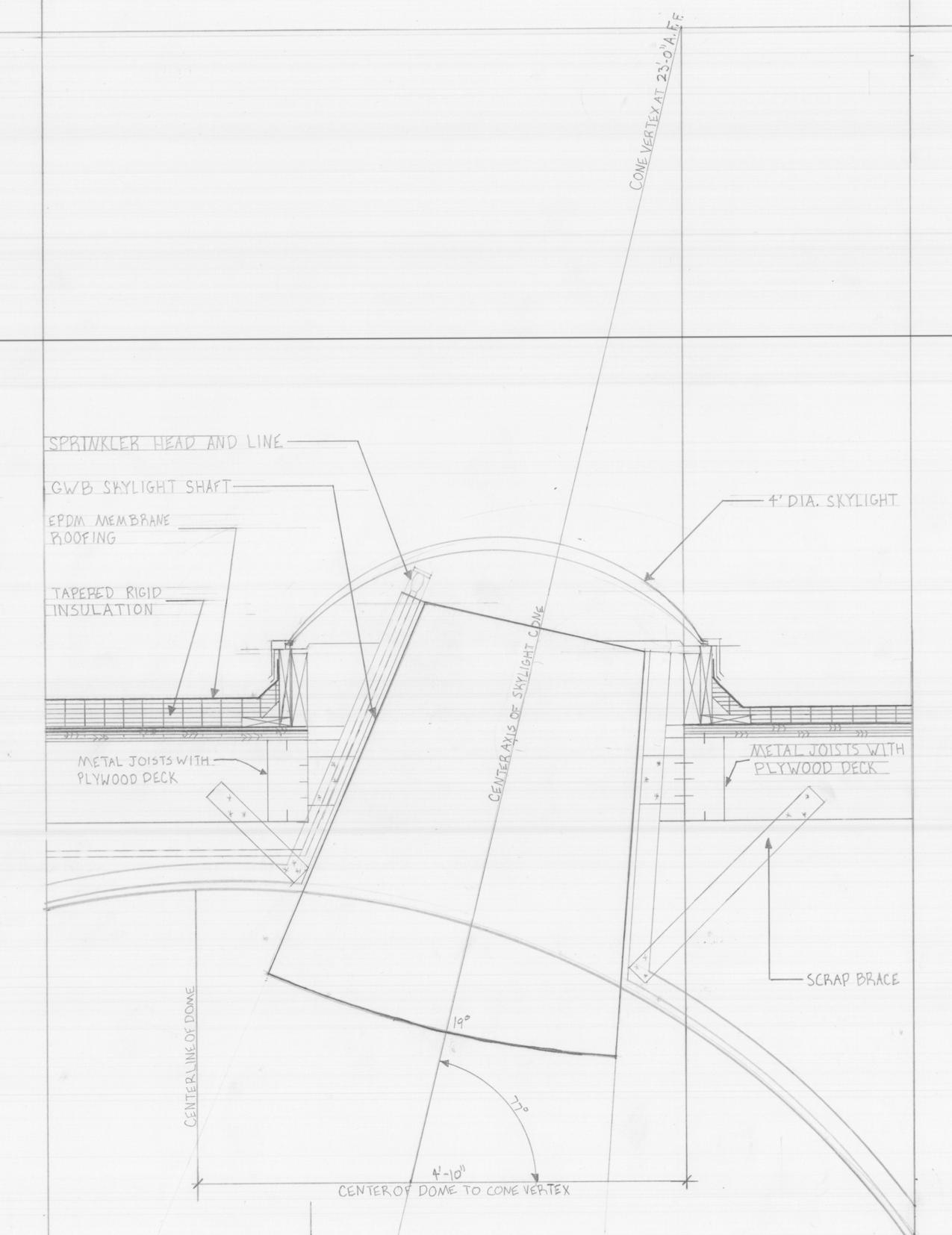

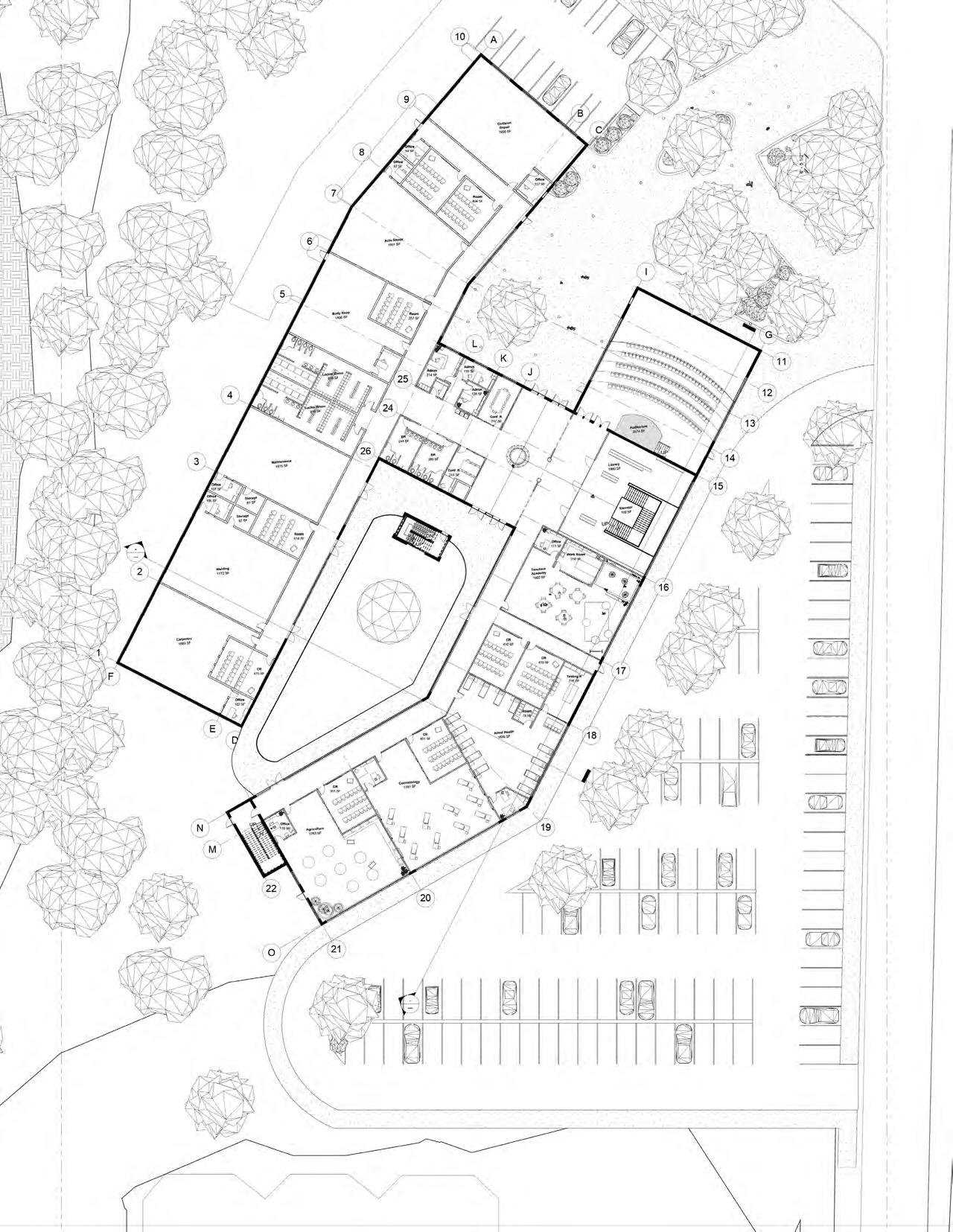

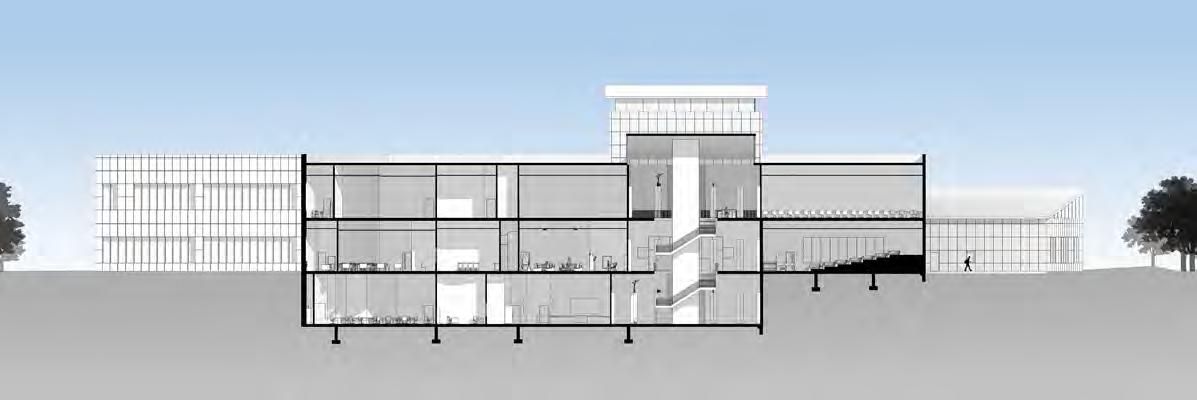

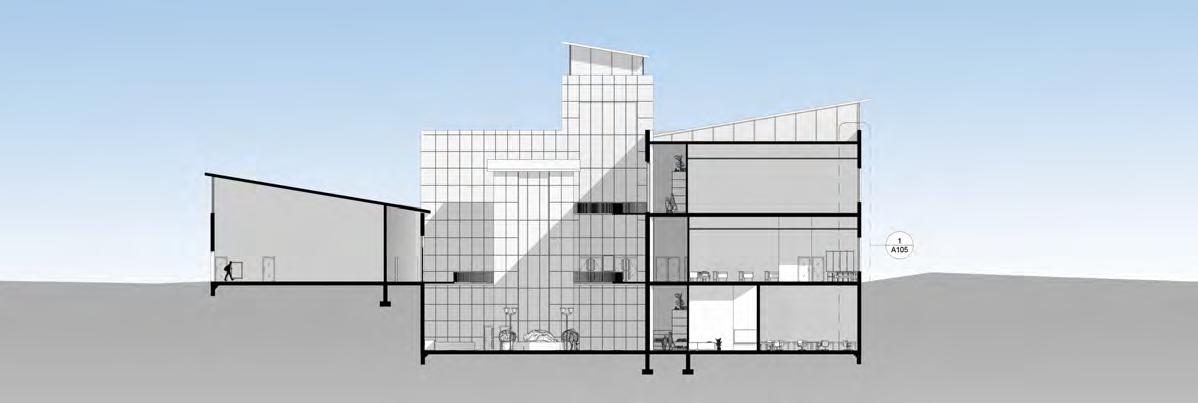

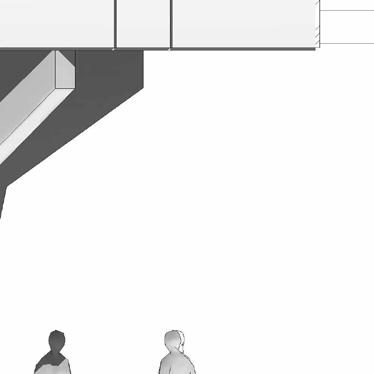

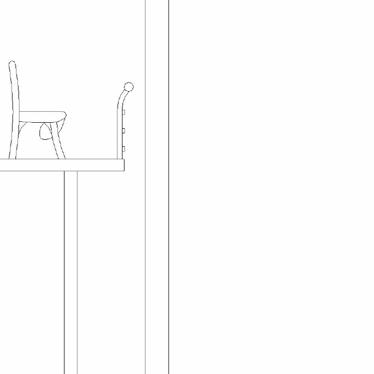

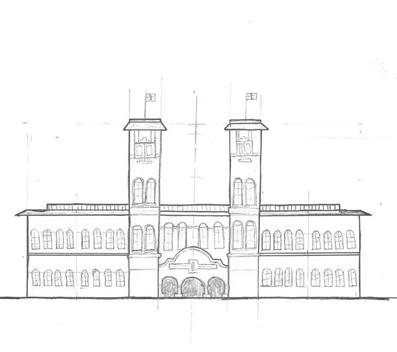

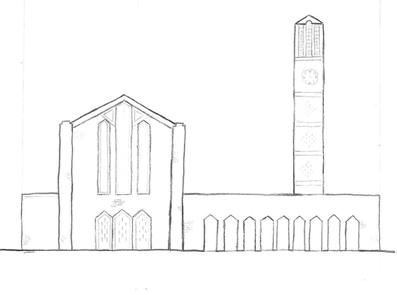

The Ross Collins Vocational School project was a wonderful opportunity to study how architecture can affect the mental state of the people who interact with the space. This factor is of the utmost importance when it comes to educational facilities, especially public schools. Attempting to design a building that generates a feeling of safety and openness is no small task, but The Hub accomplishes that splendidly. Using a layout that is easily comprehended and focusing the students through 2 major hubs allows the environment to be one of community and comfort. On top of that, large skylights create light and airy spaces throughout.

Students today spend 40 hours a week and up to 12960 hours over their 12 years of primary school inside a building. Why, of all buildings, do we not put full effort into these? This building shapes young children more than their own home does in most cases. A school should be a place of learning and a place of beauty, not a prison. Cinderblock construction is cheap and effective, but it is outdated and creates an environment that is not conducive to learning. The fact that our schools have similar layouts and materiality to modern prisons is awful. We as designers should look further into the psychological effects of our architecture on the people who occupy it, and where better to start than with our children.

We as designers must consider every little facet of a design, even the ones that the occupants of a space may never consciously notice. These details range from the height of a specific window to the materiality of the walls and floors, as each of these has a profound effect on the people who interact with our creations. So, what makes a school what it is and how can we design a building that challenges those standards while maintaining a sense of familiarity? That is the question that The Hub aims to answer.

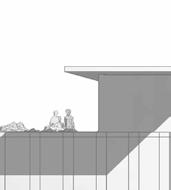

The focus throughout this design was sat squarely on the library and outdoor courtyard space (pictured on the left). These were the two areas that every other part of this facility funneled into, therefore they would see the most amount of people. The approach taken here was to create spaces where students would like to spend their time and would excite them about coming to the building.

The core factors that contribute to that are quite simply access to natural light and openess. Heavy concrete walls that we typically see at schools accomplish neither of these, while the storefront walls and metal paneling attribute a certain lightness to the building’s facade. These design choices aim to bring a feeling of brevity to the students that use these spaces, encouraging comfort and enjoyment.

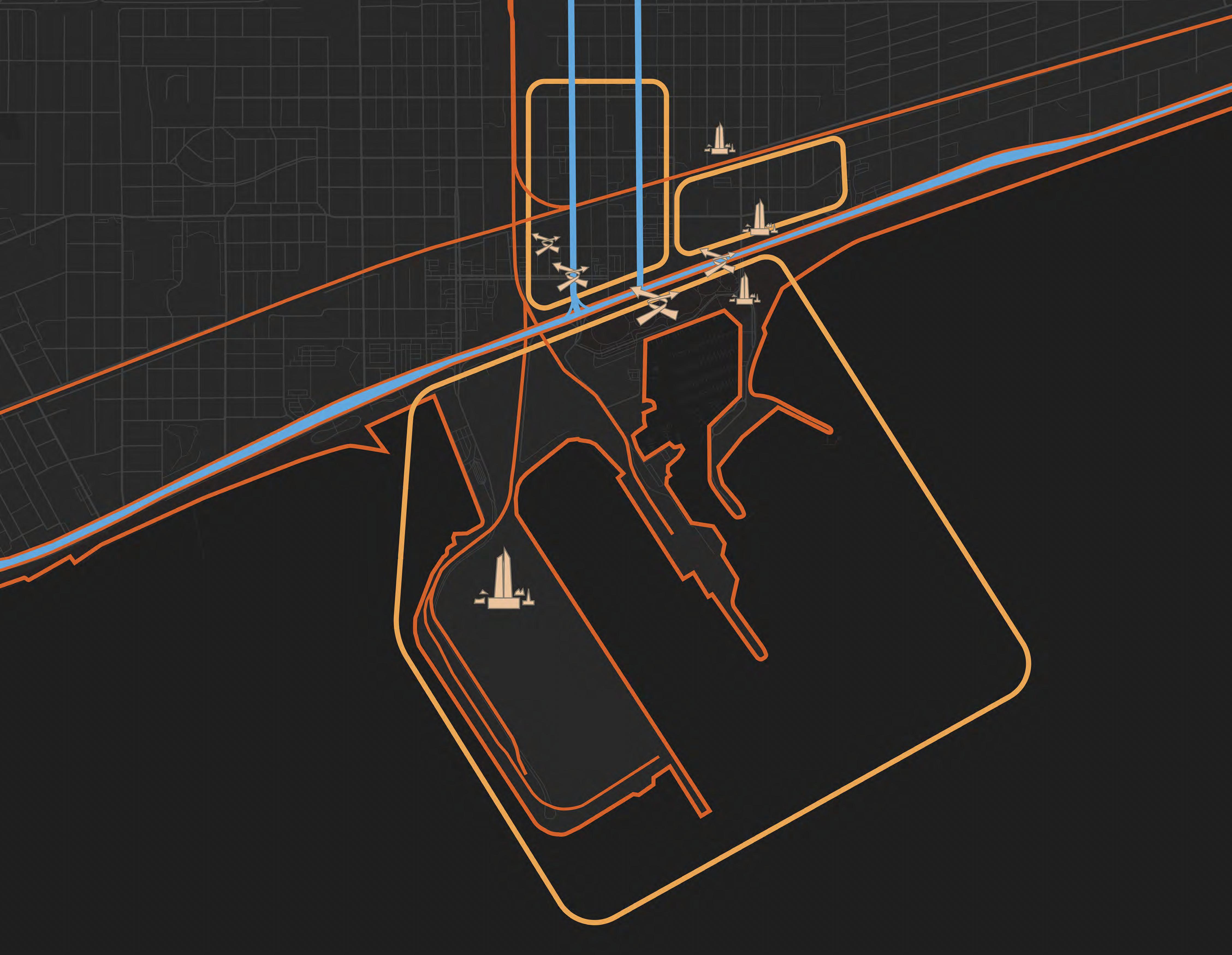

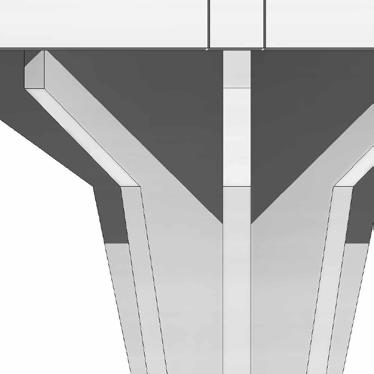

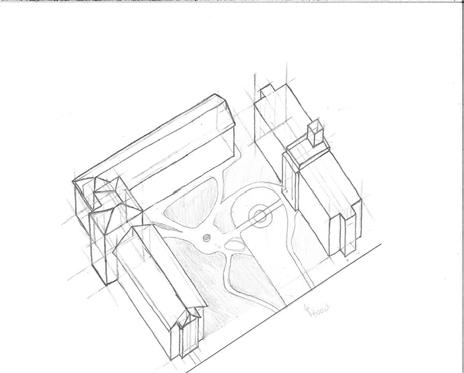

BRINGING THE COAST TO LIFE GULFPORT, MS

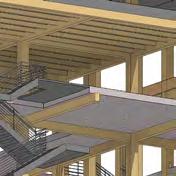

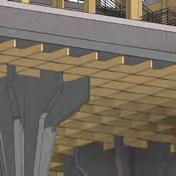

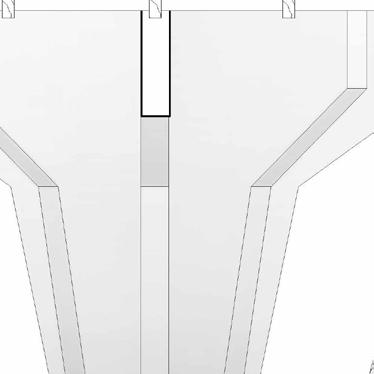

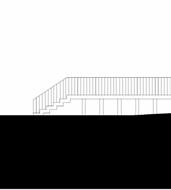

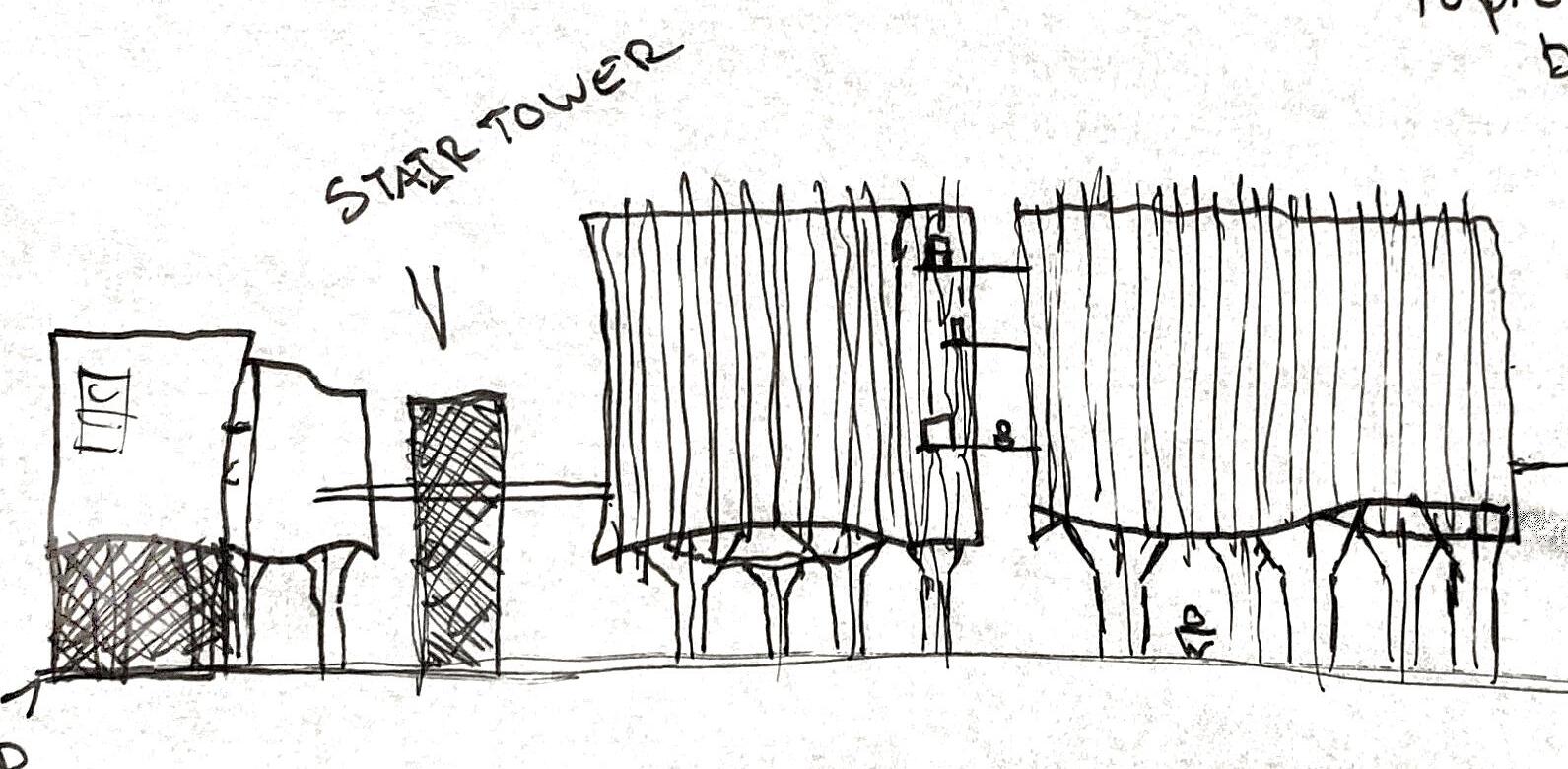

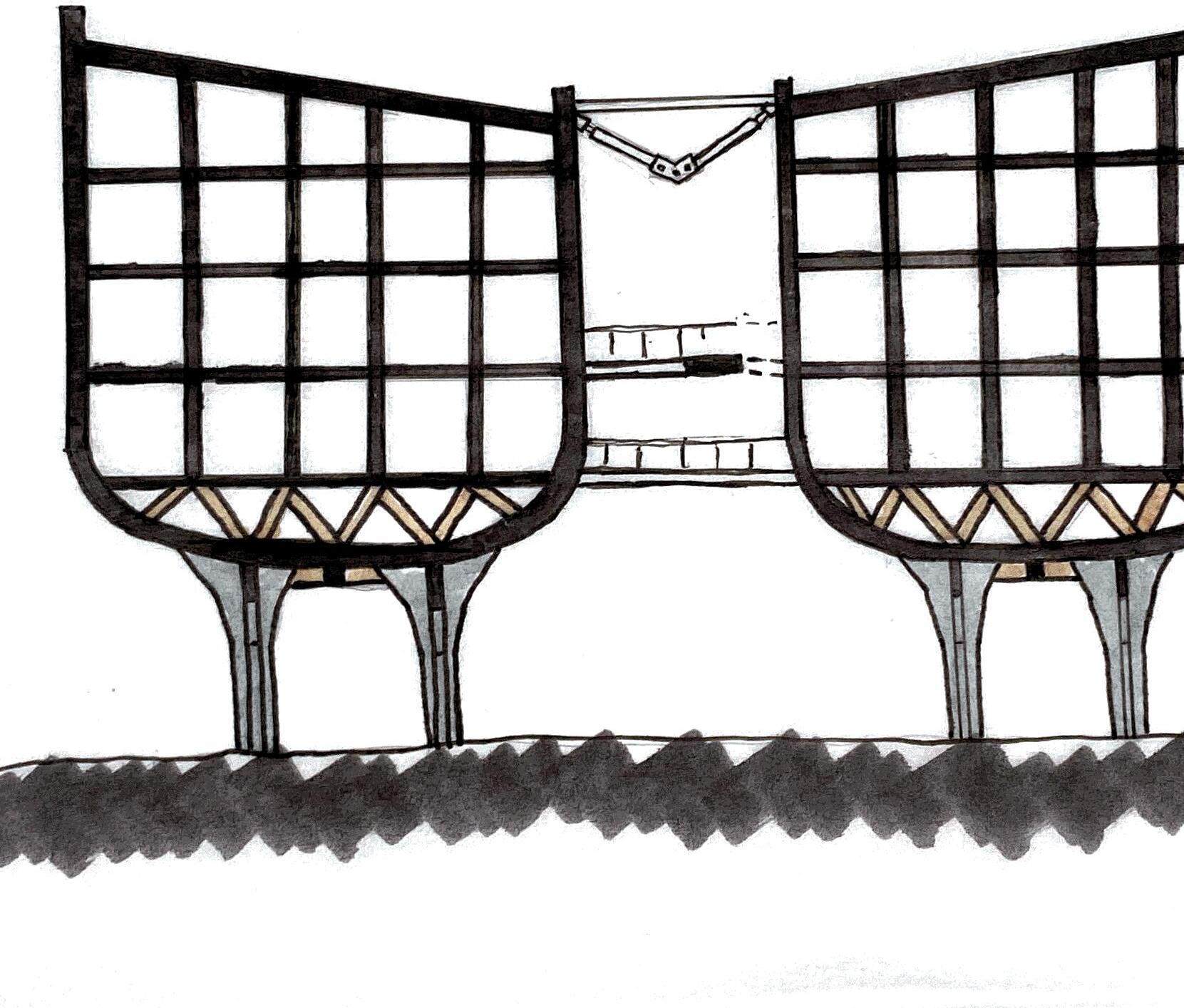

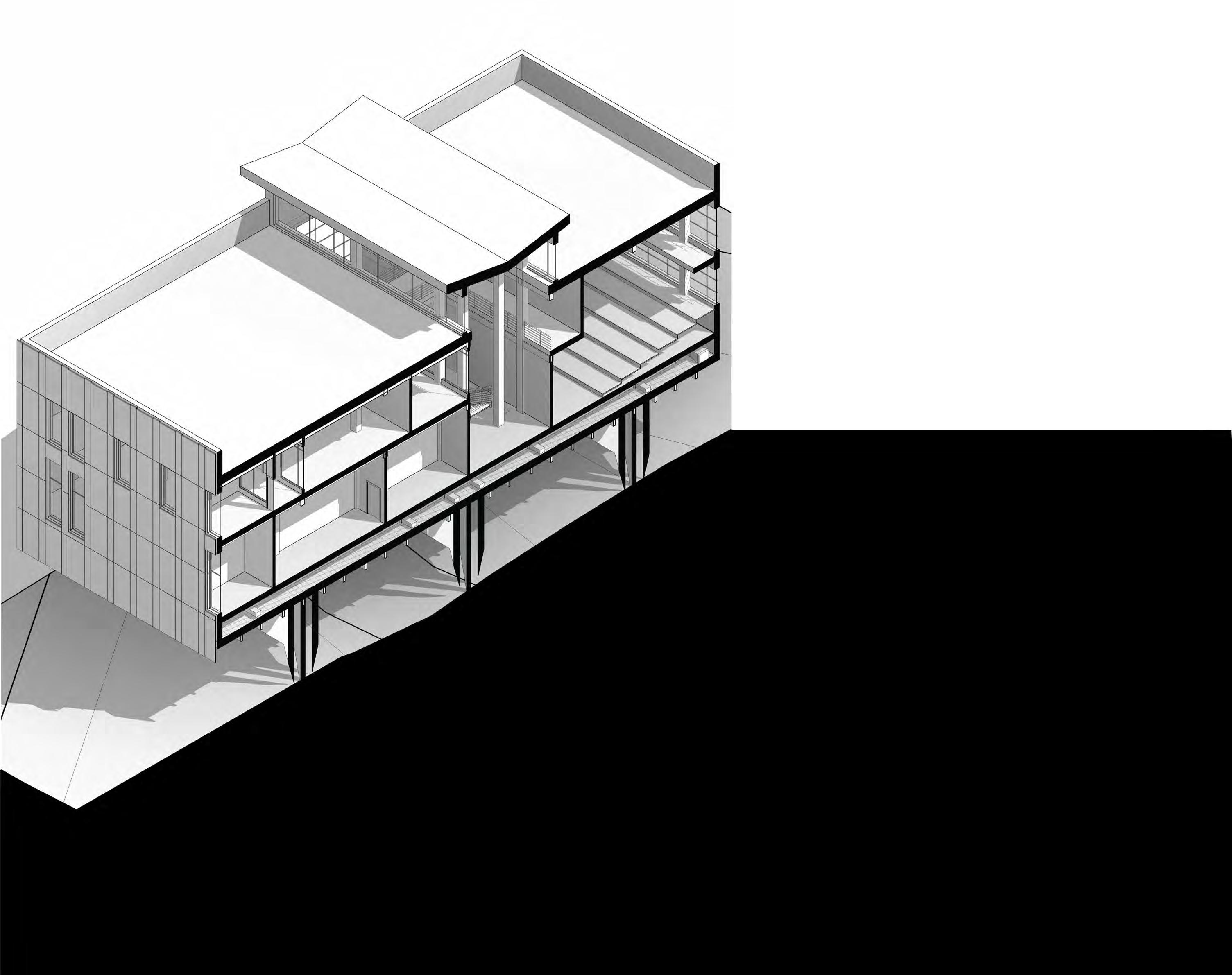

There are many construction challenges when approaching construction on the coast, the main one being the requirement to be 25 feet above ground level in case of flooding. The Doldrum solves this problem with a series of flower-inspired columns holding up individual buildings that make up the complex. These columns are composed of concrete with a hollow center to allow for rainwater collection. The rest of the complex’s structure is composed entirely of mass timber with a metal panel facade system. The column system underneath is calculated to hold double the weight of the building, and is even rated to be able to support lateral force equal to hurricane force winds up to category 3 comfortably.

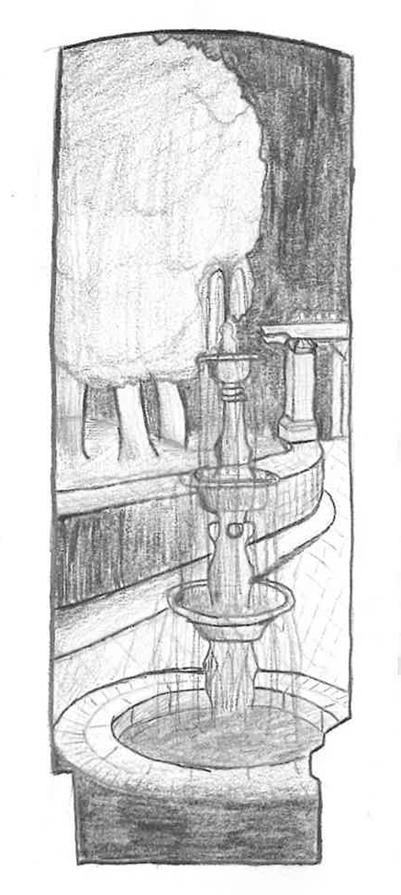

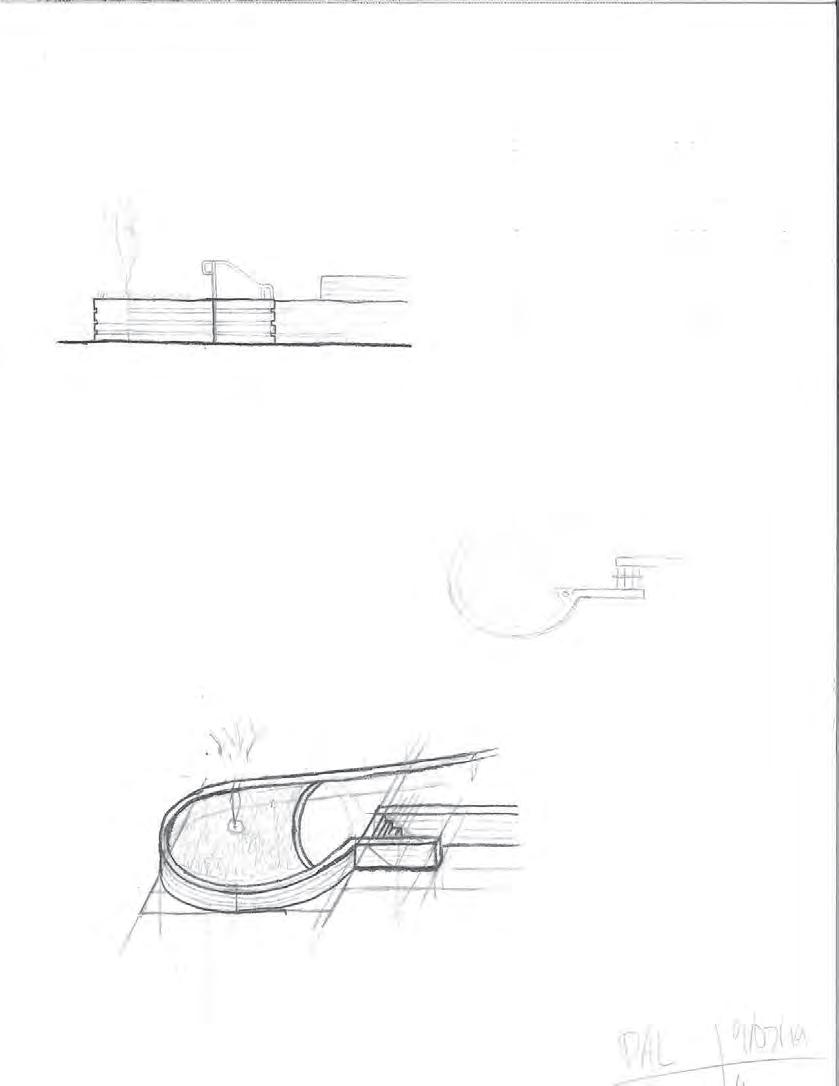

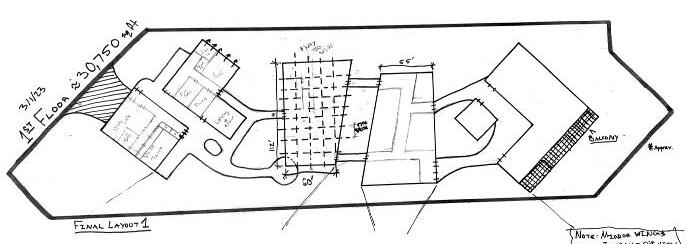

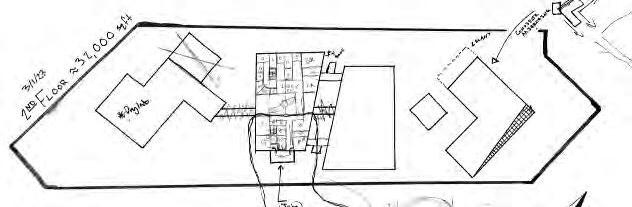

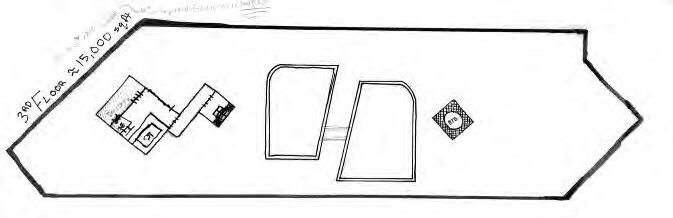

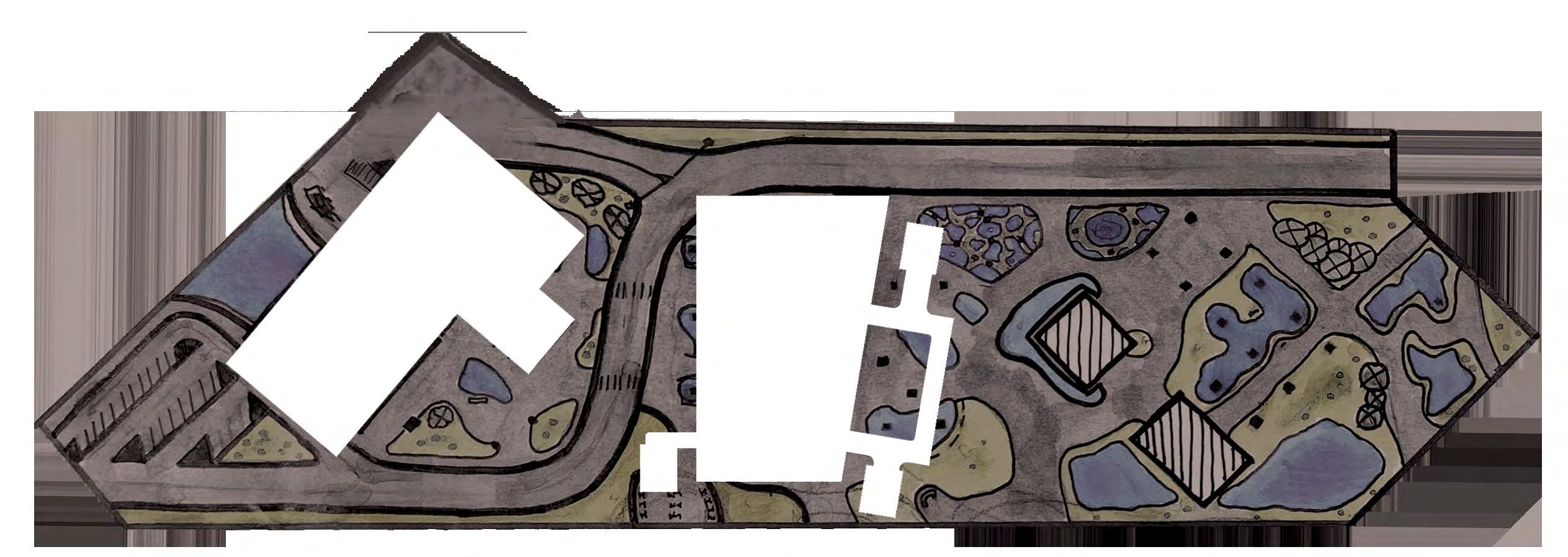

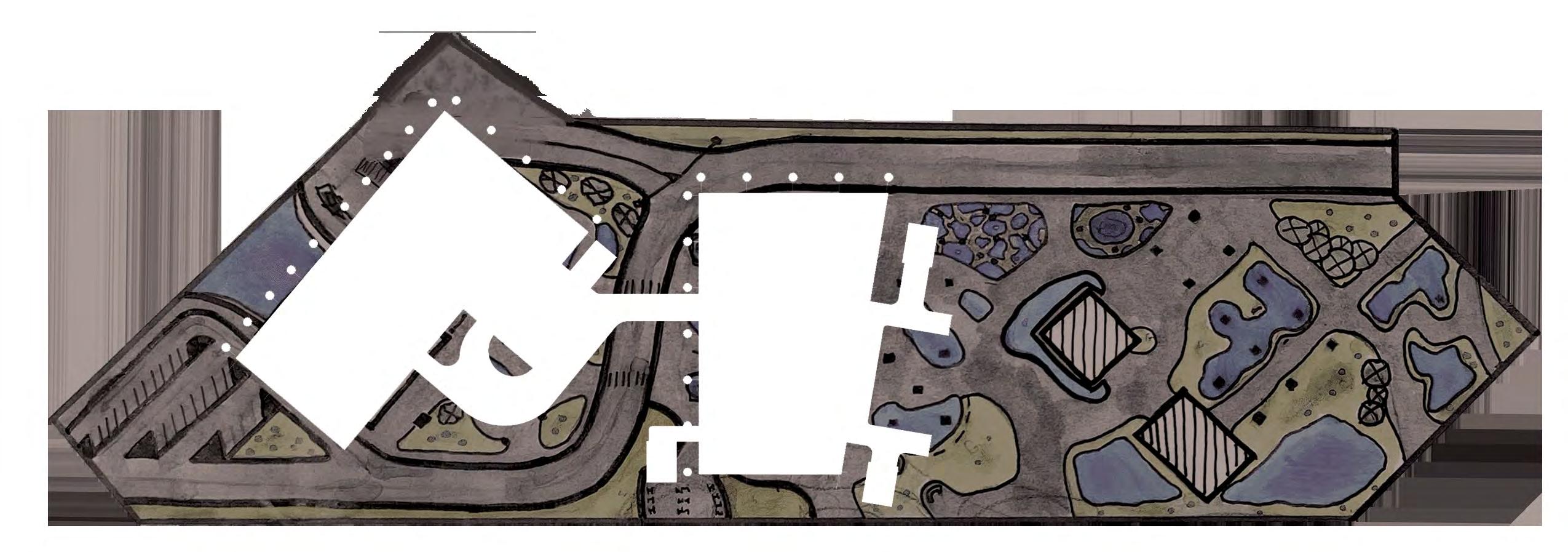

These drawings are a result of an attempt to fully comprehend the site and all of the factors and problems that come with it. The site at hand presents many unique problems to solve, namely transportation to the site and pedestrian flow around the buildings that are created. The focus of my design effort up to this point has been on the human interaction at the ground plane, which consists of an aquarium extension center and park area for the public. The areas above aim to bring nature into the site in a way that feels organic, resulting in a connection to the environment around the pedestrian.

The core concept of the design is humanity and its place in the order and chaos of the natural world, or in this case more so, the architects will and how much it can affect. How do we as designers control the site and the people who interact with our projects? We have limited control over the chaos, therefor we implement what little we have over very specific parts of the design. We can control the aesthetic and we can control the core circulation of a project. Both of these factors do slip from our grasp a bit as the budget and environment can affect the freedom of these. An area with a vast amount of freedom comes in the form of program implementation. The program may be provided, but we may put the key parts of that program wherever we so desire as designers. This factor, as well as the freedom provided to the first floors programming, is where I chose to focus my concept. The parts of the design storm I attempted to take and make completely mine are the first-floor program and the overall circulatory feel of the space.

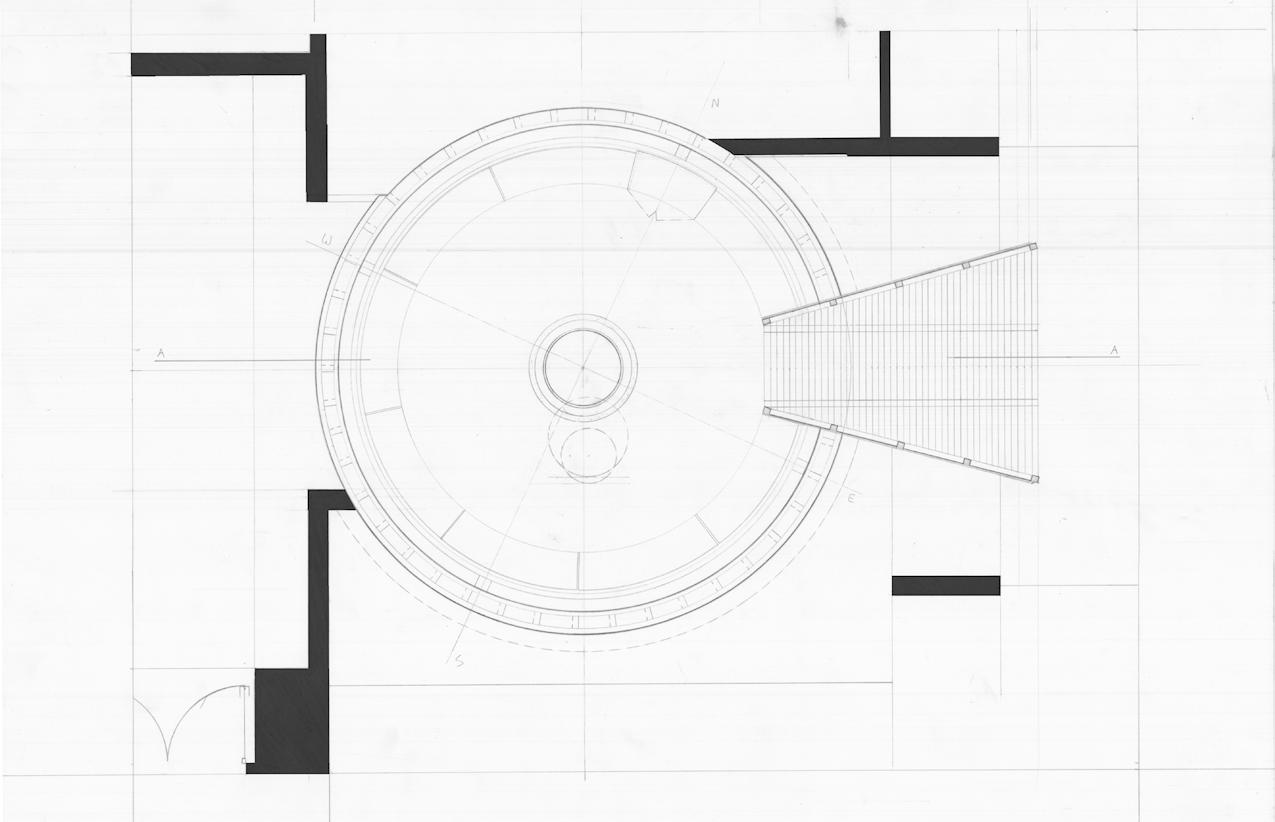

I chose to design the Research Park half of the overall program and I chose to place it on the western half of the site bordering the harbor. This decision was made to create easy access to the water to allow for the launching of nautical research vessels, as well as docking underneath the lab building near the dive tank for essential vehicles. This half of the site is also intended to be private, at least compared to the interpretive center, so the placement makes it much more difficult for pedestrians to find their way in unintentionally. Of course, it will not be completely disconnected, but it does create the closing gate for the site.

Moving into schematic design the priority shifted to circulation throughout the site and the space itself. As I was designing the professional half of the site, I decided to focus on ease of movement into and out of the labs while leaving plenty of circulation space moving forward to bend into more beautiful areas during design development. Each design move was made to further the design into the stages to come with full confidence in its ability to adapt to the needed conditions.

Bringing the program into the third dimension displays the way the structure underneath brings together the entire design. The large columns create an atomsphere that encourages exploration, but allows the designer to properly limit pathways throughout the space. The circulation underneath the spaces on the ground level is controlled by these columns, but complemented by the building layout. The overall design encourages the oberserver to walk through the columns to discover the next bend or gap in the structure. Each nook and cranny compliments the next with this form. The above drawings only show the programmed half with context, while the 3D shows the entire massing.

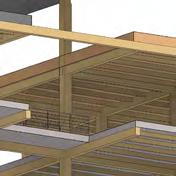

3D Graphic DisplayIn addressing the materiality of The Doldrum I came to the conclusion that I wanted to clad the entire building in an alluminum rain-screen and have the interior be composed entirely of wood. The shear walls are made of CLT and the beams are Glulam, and all of this was done with the intention of showing off the connection between the modern day method of construction and the future that we’re constantly staring down. Mass timber on the coast is a difficult task to accomplish, and this method is one that accomplishes all of the necessary goals. The rain-screen protects the mass timber structure from the elements while also allowing for a change in aesthetic that would otherwise be impossible. This combination of elements comes together to create the meshing of systems that is the Doldrum.

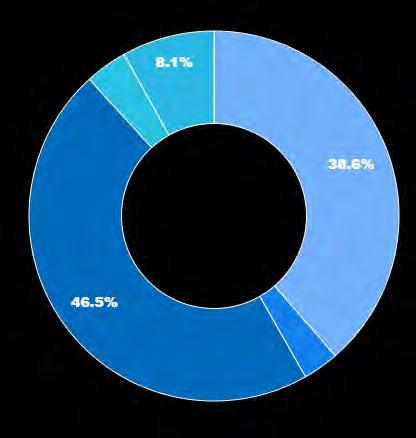

Total Operating Hours= 12,624,602.12hrs

Unit Weight= 150 lbs

Amount of Material= 2400 sq. ft. EE for Material= .75 MJ/Kg

Total Operating Hours= 850,819.58 hrs

Unit Weight= 8.1 lbs

Amount of Material= 2,706 sq. ft. EE for Material= 19 MJ/Kg

Total Operating Hours= 1,323,433.62 hrs

U.S.

737

Carbon

Total

Avoided

Unit Weight= 6 lbs

Amount of Material= 3,214 sq. ft. EE for Material= 15.50 MJ/Kg Total Oper-

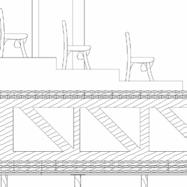

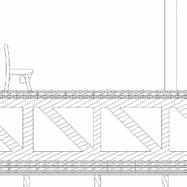

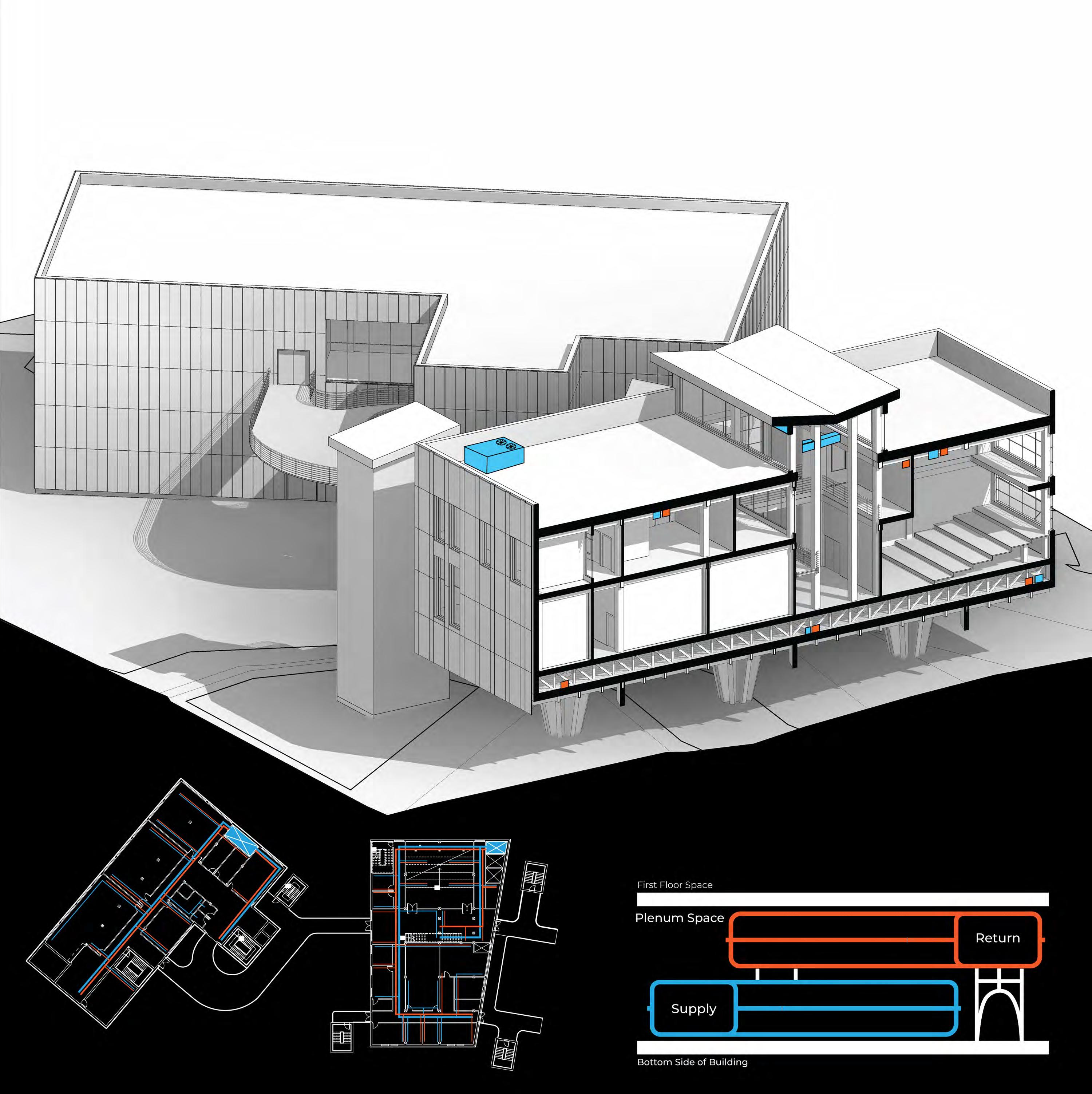

The approach to passive and active cooling in the Doldrum is a simple, yet effecient one. The goal of these systems is to create a system that is undetectable to the pedestrian while providing substantial air flow and quality. The main concepts of the design are complimented by the implementation of a plenum space to hide the majority of the duct work, as well as many of the main mechanical components. This space also allows for a sort of cooled flooring that falls under the passives category of air control.

Each of the main buildings will be equipped with a rooftop consdenser hidden behind the parapet. These systems can easily supply enough cooling to this building throughout the summer in tandem with passive cooling techniques.

Taking advantage of the clearstory space, the Doldrum passively forces the hot air from the atrium up and out of the vented sides using natural air pressure. This effecitvely cools the space below as it pulls out the warm air as it is replaced by the cold air provided through the system. The atrium is the only space that will have visible ventilation as the ducts cross across the space on top of the roof. This decision was made intentionally to create a unique experience as you walk through the space. The concept of connection that the sky bridges provides is accentuated by this briding of ducts.

The Doldrum will be taking advantage of a forced air system as it is the most logistically plausible option

The below diagram demonstrates what the inside of the plenum space is going to look like in a very simple visual style. The return ducts will have pleny of space to stack on top of the supply ducts as the space is 6 feet in height. This provides the opportunity to put much more then just these two main components, but for the sake of the diagram that is what is shown.

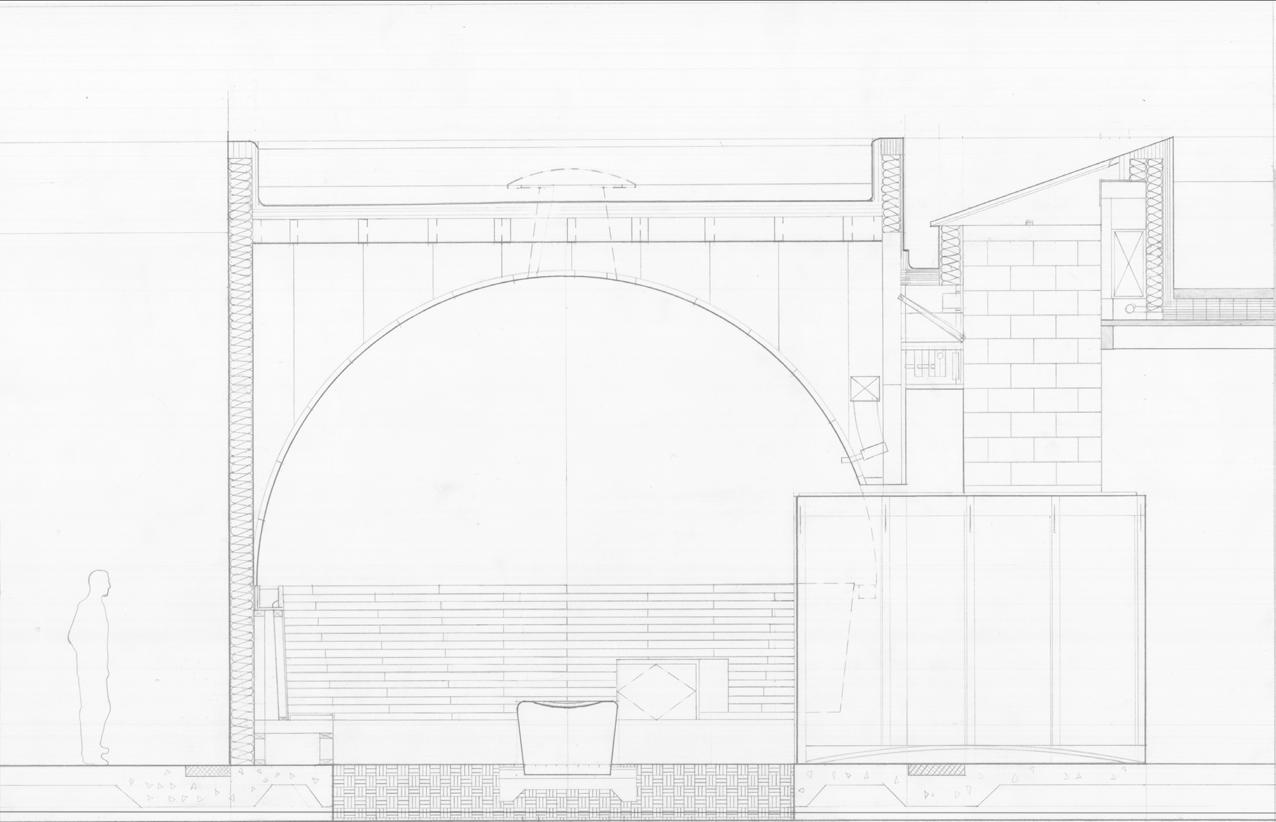

SCALE: 3/32” = 1’