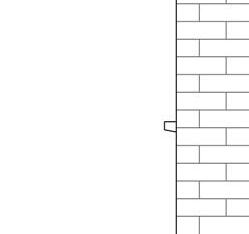

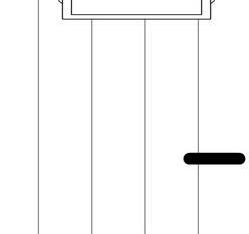

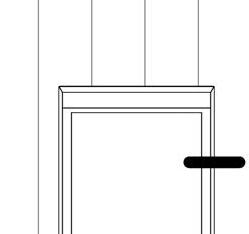

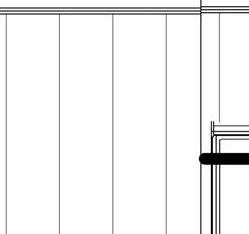

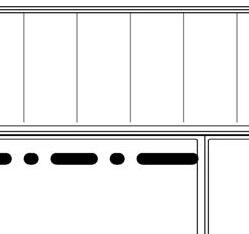

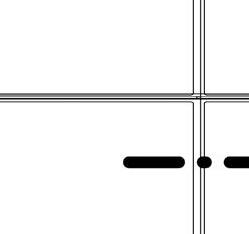

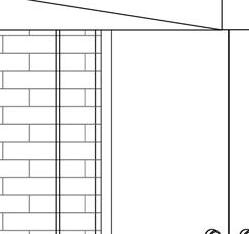

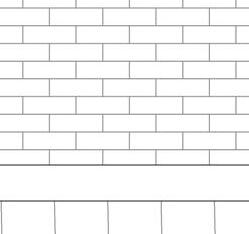

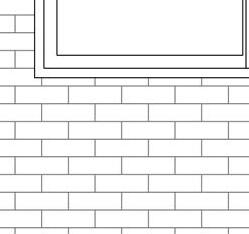

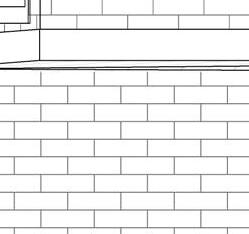

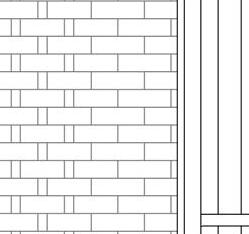

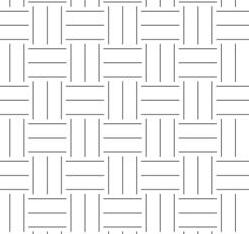

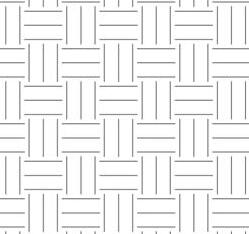

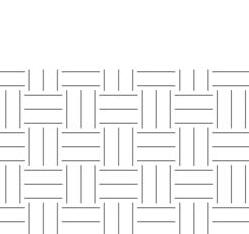

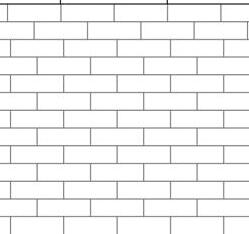

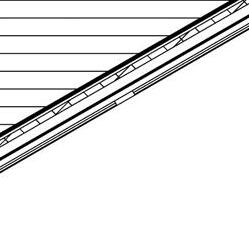

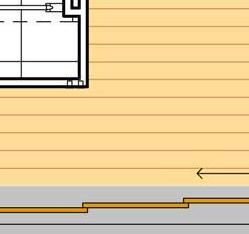

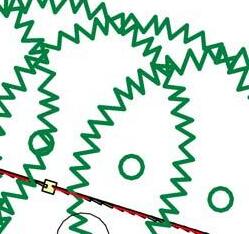

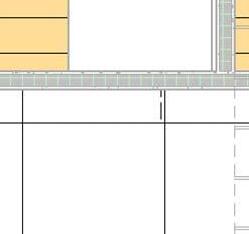

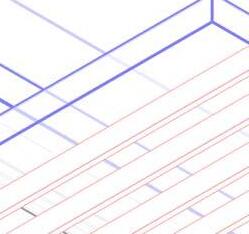

1 : 25 First Floor Setting-out Plan 2 0 SCALE 1:

1000 800 600 400 200 200

1

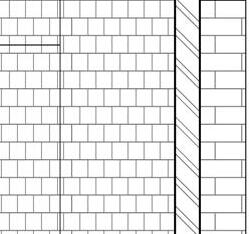

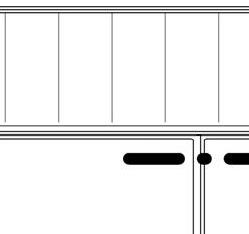

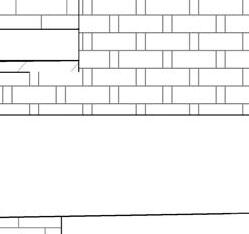

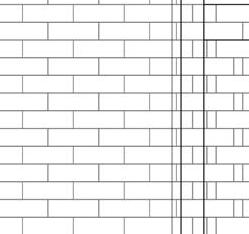

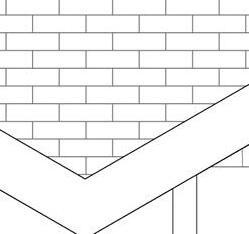

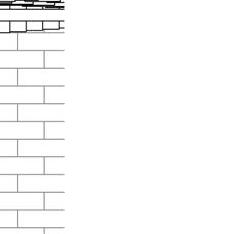

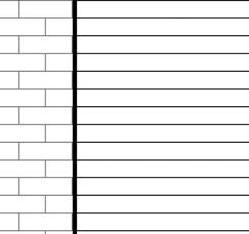

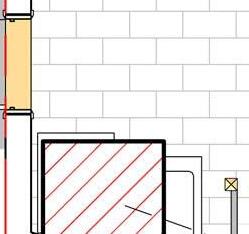

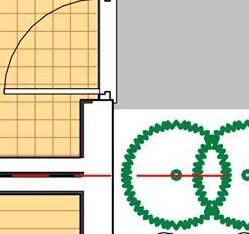

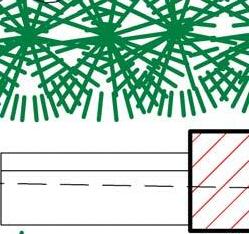

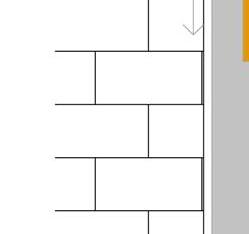

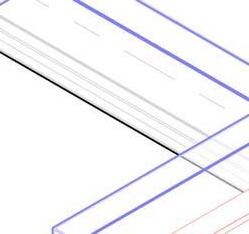

1 : 50 FIrst Floor New Wall and Demolition Plan

2.5 2 1.5 1 0.5 0.5

mm 25 0 SCALE 1:

m 50

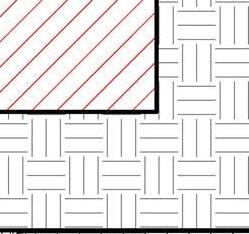

CRS RLS

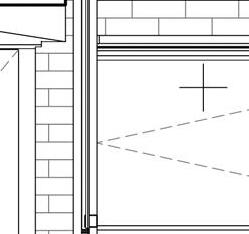

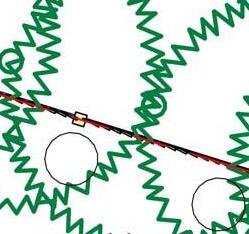

Denotes galvanised mild steel lateral restraint strap position at 2000mm max centres at ceiling chord level spanning 3no. Min trusses with 50 x 50mm softwood noggins under including packing noggin between wall and truss

Denotes galvanised mild steel lateral restraint strap position at 2000mm max centres at rafter chord level spanning 3no. Min trusses with 50 x 50mm softwood noggins under including packing noggin between wall and truss

C24 Bolted together @600 centers

Roof Slope Direction in Decimal Degree

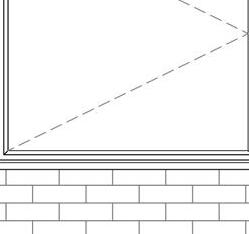

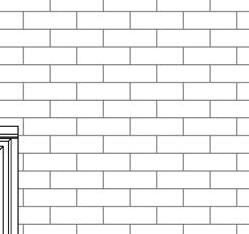

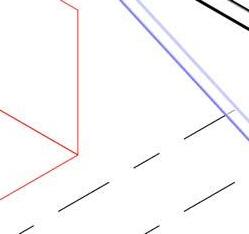

Dashed line indicates Walls and Windows to be demolished

Notes:

1. ALL DIMENSIONS IN MILLIMETERS UNLESS OTHERWISE SPECIFIED.

2. THE CONTRACTOR TO CHECK ALL DIMENSIONS, ANGLES, DRAIN RUNS AND CONDITIONS ON SITE BEFORE WORKS COMMENCEMENT. ANY DISCREPANCIES REPORT IMMEDIATELY TO THE ENGINEER.

3. CONDITION OF ALL EXISTING STRUCTURAL ELEMENTS, WITH PARTICULAR ATTENTION TO EXISTING BEARING WALLS TO BE USED FOR THE PROPOSED DEVELOPMENT, TO BE CHECKED BY THE CONTRACTOR BEFORE WORKS COMMENCEMENT.

4. DRAWINGS TO BE READ IN CONJUNCTION WITH RELATIVE STRUCTURAL CALCULATIONS, DETAILS AND SPECIFICATION.

5. DO NOT SCALE FROM DRAWINGS. DIMENSIONS ARE INDICATIVE ONLY.

6. CONTRACTOR AND CLIENT TO BE AWARE OF CONSTRUCTION & DESIGN MANAGEMENT (CDM) DUTIES.

50 Woodrush Way, Dagenham, Romford RM6 5BL

First Floor Demo & New walls plan + Setting out Plan

ROOF Client Project Drawing Scale Date : Rev Dwg No

Lulezim Gashi NC-22 12/10/21 Planning

As indicated

D E S I G N L A B S L O N D O N

LEGEND Status ARCHITECTURE / INTERIOR / MANAGEMENT / PLANNING T: 07870661614 07888831314 E: info@designlabslondon.com W: www.designlabslondon.com

Denotes galvanised mild steel lateral restraint strap position at 2000mm max centres at ceiling chord level spanning 3no. Min trusses with 50 x 50mm softwood noggins under including packing noggin between wall and truss

Denotes galvanised mild steel lateral restraint strap position at 2000mm max centres at rafter chord level spanning 3no. Min trusses with 50 x 50mm softwood noggins under including packing noggin between wall and truss

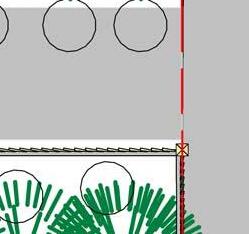

Denotes galvanised mild steel Wall Plate strap position at 2000mm max centres. X

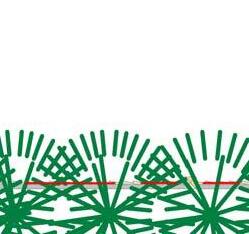

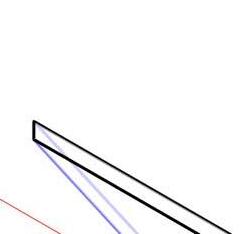

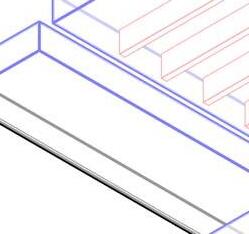

Joist/Rafter Direction - Joist sizes 200x50mm C24 @400 centers - Rafter Size 150x50mm C16 @400 Centers

Double/Triple Trimmers - Floor and Flat Roof Trimmers 2x200x50mm C24 Bolted together @600 centers - Sloping Roof Trimmers 2x150x50mm C24 Bolted together @600 centers Roof Slope Direction in Decimal Degree Dashed line indicates Walls and Windows to be demolished

Notes:

1. ALL DIMENSIONS IN MILLIMETERS UNLESS OTHERWISE SPECIFIED.

2. THE CONTRACTOR TO CHECK ALL DIMENSIONS, ANGLES, DRAIN RUNS AND CONDITIONS ON SITE BEFORE WORKS COMMENCEMENT. ANY DISCREPANCIES REPORT IMMEDIATELY TO THE ENGINEER.

3. CONDITION OF ALL EXISTING STRUCTURAL ELEMENTS, WITH PARTICULAR ATTENTION TO EXISTING BEARING WALLS TO BE USED FOR THE PROPOSED DEVELOPMENT, TO BE CHECKED BY THE CONTRACTOR BEFORE WORKS COMMENCEMENT.

4. DRAWINGS TO BE READ IN CONJUNCTION WITH RELATIVE STRUCTURAL CALCULATIONS, DETAILS AND SPECIFICATION.

5. DO NOT SCALE FROM DRAWINGS. DIMENSIONS ARE INDICATIVE ONLY.

6. CONTRACTOR AND CLIENT TO BE AWARE OF CONSTRUCTION & DESIGN MANAGEMENT (CDM) DUTIES.

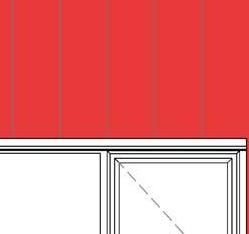

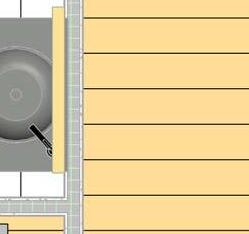

Soler Panals to be Installed by Specialist Contractor

Denotes galvanised mild steel lateral restraint strap position at 2000mm max centres at rafter chord level spanning 3no.

trusses with 50 x 50mm softwood noggins under including packing noggin between wall and truss

Denotes position of galvanised mild steel restraint straps at max 2000mm c/c: Straps located at Wall Plate straps; gable masonry

or party wall to roof truss and ceiling joists. Refer to specialist manufacturers layout and specification to suit joist/beam

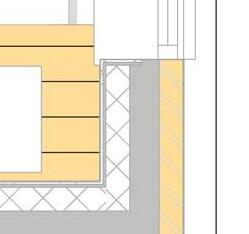

REFER TO DRAWINGS -NC-34 TO NC-35 FOR 1:10 ENHANCED DETAILS

REFER TO STRUCTURAL ENGINEERS DETAILS FOR FOUNDATIONS SPECIFICATIONS

REFER TO DRAWING NC-36 FOR WALL LEGEND

Denotes galvanised mild steel lateral restraint strap position at 2000mm max centres at rafter chord level spanning 3no. Min trusses with 50 x 50mm softwood noggins under including packing noggin between wall and truss

Denotes position of galvanised mild steel restraint straps at max 2000mm c/c: Straps located at Wall Plate straps; gable masonry wall or party wall to roof truss and ceiling joists. Refer to specialist manufacturers layout and specification to suit joist/beam spans

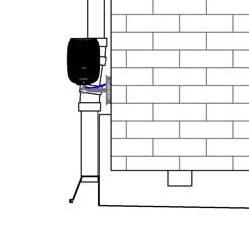

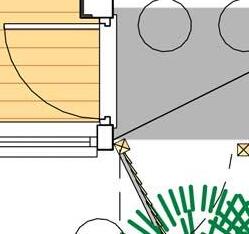

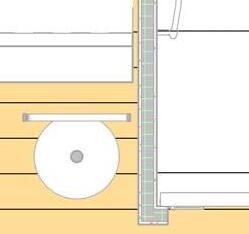

Ecology: Schwegler SP1 Terrace Permanently built-in nesting terrace feature for sparrows for biodiversity

Ecology: Schwegler SP1 Terrace Permanently built-in nesting terrace feature for sparrows for biodiversity

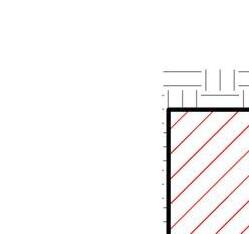

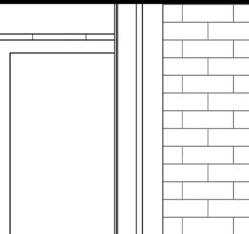

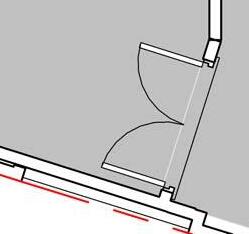

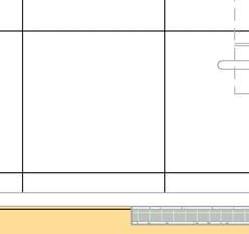

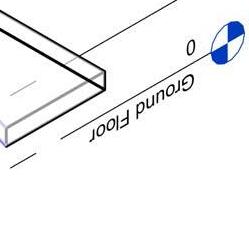

Proposed Section CC 1

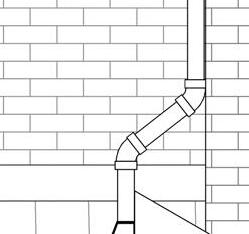

Rainwater pipe to drain into 2 cubic meter soakaway in rear garden

Garden benches Bins

Sliding door to access garden from living space bin are stored hidden from street view

Bicycle Store

2169 2 4 4 4

Store /Utility 789

Secure Cycle Store with lockable metal doors Gate Gate

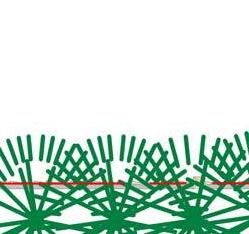

A B D D D D D D DD D D B B B C EEEEEEE A A A A A Existing Tree -Conifer Douglas_Fir-6.1_Meters 7 Nos Existing Shrub Forsythia-2.44_Meters 4 Nos Existing Shrub Fraser_Photina-2.14_Meters 1 Nos Proposed Shrub Boxwood -0.8 Meters 13 Nos Proposed Tree -Conifer Chinese_Juniper-2.14_Meters 7 Nos A B C D E © THIS DRAWING IS THE COPYRIGHT OF DESIGNLABS LONDON LTD. It shall not be in any way used or reproduced or construct without their prior written consent. All dimensions are to be checked on site by client or contractor prior to commencing any work. Work only to figured dimensions. Any discrepancies are to be reported to the DLL in writing and DLL shall not take responsiblity for site failing to inform discrepancies. Client Project Drawing Scale Date : Rev Dwg No Status ARCHITECTURE / INTERIOR / MANAGEMENT / PLANNING T: 07870661614 07888831314 E: info@designlabslondon.com W: www.designlabslondon.com D E S I G N L A B S L O N D O N 1 50 LandScape Plan 50 Woodrush Way, Dagenham, Romford RM6 5BL Lulezim Gashi NC-30 12/14/21 Planning 1 : 50 Proposed Landscape Plan 1 0 SCALE 1: 2.5 2 1.5 1 0.5 0.5 m 50

NOTES

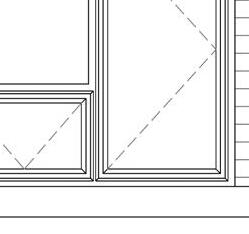

REFER TO DRAWINGS NC-33 FOR INTERNAL DOORS TYPES AND SCHEDULES.

REFER TO DRAWINGS NC-32 FOR WINDOW TYPES AND SCHEDULES.

REFER TO DRAWINGS NC-34 and NC-35 FOR LARGE SCALE DETAILS.

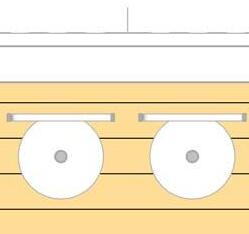

Sanitaryware Specification:

WC : ROCA Valor c/c Pan White, Z34230C00P -tbc

Cistern : ROCA Valor C/C Cistern White, Z34130C00P -tbc

WC Seat : ROCA Valor Seat White, Z80139C00P -tbc

WHB : Roca valor basin 1TH, Z814721124 -tbc

WHB Taps : CHROME VADO MATRIX, MAT-100/CC-CP

WHB Waste : 1 1/4" Brass Basin Waste Slot Brass Plug Chain & STY CP -tbc

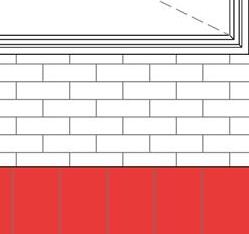

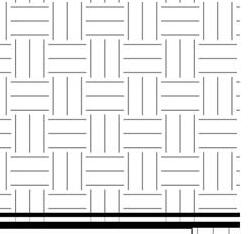

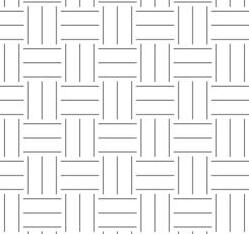

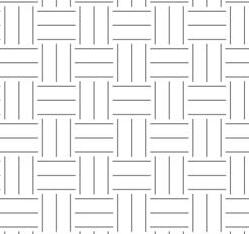

Walls Specification: Bathrooms : Tiles (specs tbc) 600mm x 600mm

Mirrors : By Dekko - size as shown

Flooring Specification: Bathroom : Poltysafe Standard PUR Nordic Grey 4090 w/r 8680

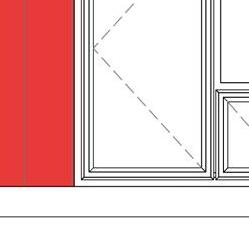

SinglePanel

WG04TypeWG17748850885Ground

WF01TypeWD177811958752070First FloorUserDefined WF02TypeWE117411748001974First FloorSinglePanel

WF03TypeWD177811958702065First FloorUserDefined WG07TypeWF6001200First Floor Ceiling Sky Light

WG08TypeWF6001200First Floor Ceiling Sky Light

REFER TO DRAWINGS NC - 34 and NC 35- FOR 1:10 ENHANCED DETAILS

REFER TO STRUCTURAL ENGINEERS DETAILS FOR BLOCK STRENGHTS & LINTOL SPECIFICATIONS

REFER TO DRAWING NC-36 FOR WALL LEGEND FOR TYPICAL SECTIONS THROUGH REFER TO DRAWINGS

REFER TO DRAWINGS NC - 34 and NC 35- FOR 1:10 ENHANCED DETAILS REFER TO STRUCTURAL ENGINEERS DETAILS FOR BLOCK STRENGHTS & LINTOL SPECIFICATIONS

REFER TO DRAWING NC-36 FOR WALL LEGEND FOR TYPICAL SECTIONS THROUGH REFER TO DRAWINGS

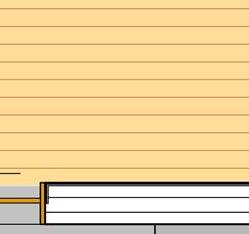

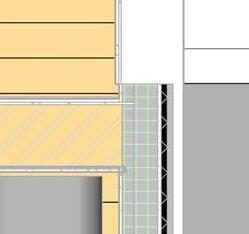

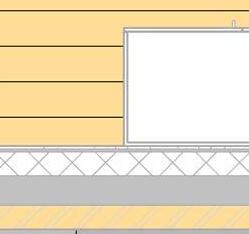

with/without heating pipes over,

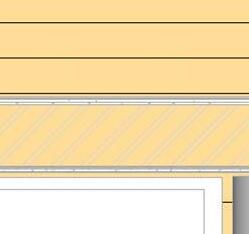

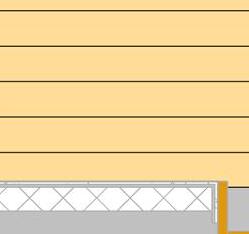

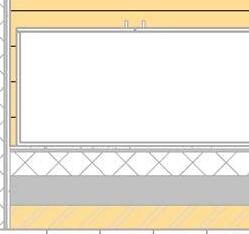

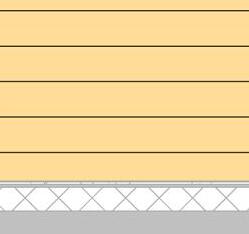

100mm Kingspan Insulation over,

1200mm guage polyethene DPM membrane over,

150mm Concrete Slab with/without reinforcement mesh over,

50mm Cement Blinding Layer over,

300mm Type A Site Hardcore

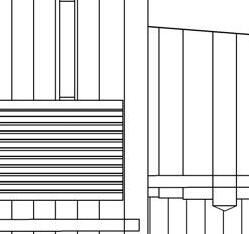

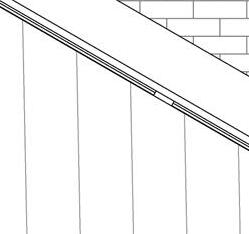

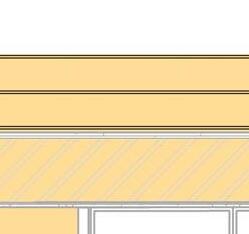

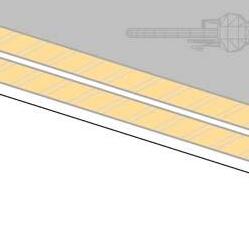

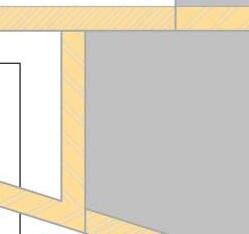

Vertical S/W Battens (Fixed to Rafter)

Over 150 x 50mm Tanalised S/W C16 Rafters Filled With 100mm Rigid Insulation,

GENERAL CONSTRUCTION NOTE TO COMPLY THE CONSTRUCTION WITH BUILDING REGULATION

GENERAL

THE FOLLOWING SPECIFICATION MUST BE READ IN CONJUNCTION WITH ALL ARCHITECTURAL GENERAL ARRANGEMENT DRAWINGS, SCHEDULES ETC. AND IS APPLICABLE WHETHER SPECIFICALLY REFERRED TO OR NOT. IT IS THE RESPONSIBILITY OF THE CONTRACTOR/SUB-CONTRACTOR TO ENSURE THAT ALL THEIR WORK IS IN COMPLIANCE WITH THE APPROPRIATE REQUIREMENTS OF THE RELEVANT BUILDING REGULATIONS, NHBC STANDARDS AND OTHER ALLIED LEGISLATION.

ALL MATERIALS ARE TO BE USED AND INSTALLED IN ACCORDANCE WITH THE RELEVANT MANUFACTURER'S INSTRUCTIONS AND RECOMMENDATIONS. ALL NEW SERVICES ARE TO BE PROVIDED IN ACCORDANCE WITH THE STATUTORY UNDERTAKER'S REQUIREMENTS. THE QUALITY OF ANY MATERIAL SHALL NOT BE LOWER THAN THAT DEFINED IN THE RELEVANT BRITISH STANDARD, OR THAT THE MATERIAL HAS BEEN SATISFACTORILY ASSESSED BY AN APPROPRIATE INDEPENDENT AUTHORITY I.E. BBA, BRE. THE CONTRACTOR/SUB-CONTRACTOR MUST ENSURE THAT MATERIALS ARE 'FULLY SUITABLE' FOR THEIR LOCATION AND THAT ALLIED MATERIALS/BACKGROUNDS ARE APPROPRIATE. WHERE THERE IS NO LEGISLATED STANDARD, THE QUALITY AND USE OF THE PRODUCT SHALL BE IN ACCORDANCE WITH ESTABLISHED SATISFACTORY CUSTOMS AND PRACTICES. ALL WORK SHALL BE CARRIED OUT IN A SOUND, NEAT, DURABLE AND WORKMANLIKE MANNER. REASONABLE PRECAUTIONS SHALL BE TAKEN TO PROTECT FIXED AND UNFIXED MATERIALS AGAINST ANY DAMAGE LIKELY TO AFFECT THE FINISHED QUALITY OF THE BUILDING.

ALL CONTRACTORS/SUB-CONTRACTORS MUST ENSURE TO THEIR OWN SATISFACTION THAT THEY ARE IN POSSESSION OF THE CURRENTLY ISSUED DRAWINGS AND DETAILS, BEFORE COMMENCING THE RELEVANT 'WORK-STAGE' ON SITE.

NOTE: UNLESS STATED ALL CONSTRUCTION DETAILS ARE TO BE IN ACCORDANCE WITH THE ROBUST DETAILS DOCUMENT -LIMITING THERMAL BRIDGING AND AIR LEAKAGE PUBLISHED BY DTLR.

THE PRINCIPLE CONTRACTOR IS TO ENSURE THAT THE PROVISIONS OF THE CONSTRUCTION DESIGN MANAGEMENT (CDM) REGULATIONS ARE CARRIED OUT FULLY, INCLUDING ALL NOTIFICATIONS OF WORK REQUIRED UNDER LEGISLATION, PRIOR TO START OF WORKS.

FOUNDATIONS

THE EXISTING GROUND WITHIN THE EXTENT OF THE PROPOSED BUILDING CONSTRUCTION SITE SHALL BE CLEARED OF ALL TURF AND VEGETABLE MATTER PRIOR TO ANY FURTHER EXCAVATION BEING MADE. METHOD OF DISPOSAL OF ANY CONTAMINATED SOIL TO BE AGREED WITH THE LOCAL ENVIRONMENTAL OFFICER. FOUNDATION TRENCHES SHALL BE CLEAN AND TRUE AND CHECKED FOR SOFT AREAS, WATER ETC. AND LEFT WITH COMPACTED BOTTOMS.

FOUNDATIONS SHALL BE LOCATED CENTRALLY UNDER EXTERNAL AND LOAD BEARING INTERNAL WALLS UNLESS IS IT INDICATED IN ARCHITECTURAL DRAWINGS. ALL FOUNDATIONS SHALL BE DESIGNED WITH DUE REGARD TO SUBSOIL CONDITIONS, WATER TABLE, PRESENCE OF SULPHATES AND PREVIOUS GROUND USES ETC. DEPTH OF THE FOUNDATIONS TO SUIT SOIL CONDITIONS, ORIGINAL AND PROPOSED GROUND LEVELS, DRAINAGE TRENCHES AND PROXIMITY OF TREES/HEDGES, ALL TO THE SATISFACTION OF THE RELEVANT BUILDING CONTROL AUTHORITY/NHBC INSPECTOR. READY MIXED CONCRETE WILL ONLY BE ACCEPTABLE FROM SUPPLIERS USING A FULL QUALITY CONTROL SYSTEM.

ENTIRE FOUNDATION DESIGN TO BE IN-ACCORDANCE WITH STRUCTURAL ENGINEERS DESIGN DRAWINGS AND CALCULATIONS.

CONTRACTOR / SUB-CONTRACTOR TO MAKE SURE THERE IS NO ENCROACHMENTS ON SITE.

BELOW GROUND DRAINAGE

ALL DRAINAGE WORKS SHALL BE IN FULL ACCORDANCE WITH APPROVED DOCUMENT H OF THE BUILDING REGULATIONS, BS 8301 AND TO THE COMPLETE SATISFACTION OF THE RELEVANT BUILDING CONTROL BODY. WHERE DRAINS PASS THROUGH EXTERNAL WALLS THEY ARE TO BE PROTECTED WITH A PRE-STRESSED CONCRETE LINTEL OVER (AS DESIGNED BY ENGINEER) WITH MIN. 150MM END BEARINGS, WITH 150MM CLEARANCE ALL ROUND PIPE AND THE OPENING IS TO BE MASKED WITH RIGID SHEET MATERIAL TO PREVENT THE INGRESS OF VERMIN OR FILL.

IF APPLICABLE, REFER TO DRAINAGE ENGINEER'S DETAILED DRAWINGS FOR DRAINAGE LAYOUT AND SPECIFICATION DETAILS.

GROUND FLOOR CONSTRUCTION

GROUND FLOOR CONSTRUCTION AS INDICATED IN ARCHITECTURAL GENERAL ARRANGEMENT DRAWINGS AND TO BE CONFIRMED BY ENGINEER.

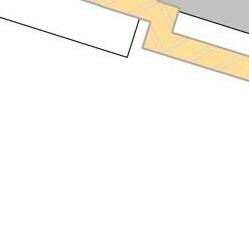

GROUND BEARING FLOOR: 75MM REINFORCED SAND/CEMENT SCREED (UNDER FLOOR HEATING TO SPECIALIST'S DESIGN -TO BE CONFIRMED BY THE END USE) ON 1200G POLYTHENE PROTECTION LAYER ON 100MM GA4000 CELOTEX INSULATION (FF4000 FOR UNDER FLOOR HEATING) OR SIMILAR APPROVED ON 1200G DPM ON 150MM CONCRETE GROUND BEARING FLOOR SLAB WITH A393 MESH REINFORCEMENT WITH MIN. 50MM COVER, (ENGINEER TO CONFIRM), ON BRICK BALLAST/CRUSHED STONE BASE ON WELL COMPACTED SOIL 25MM CELOTEX INSULATION STRIP TO BE PROVIDED TO ALL PERIMETER WALLS. CONSTRUCTION TO ACHIEVE U-VALUE OF 0.16

PLEASE NOTE FOR EXTENSIONS ANY EXISTING FLOOR VENTS TO BE CONNECTED WITH 4" PIPE AND VENTED TO EXTERNAL LEAF.

DAMP PROOF COURSE

HORIZONTAL DAMP PROOF COURSE TO BE MINIMUM 150MM ABOVE ADJACENT GROUND LEVEL. A SECONDARY DPC WILL BE PROVIDED 150MM ABOVE FLOOR LEVEL FOR MINIMUM DISTANCE OF 1.5M FROM ALL EXTERNAL DOORS WITH A LEVEL THRESHOLD. DPC/ CAVITY TRAY TO BE MARLEY AQUAGARD OR SIMILAR APPROVED AND IS TO BE INSTALLED STRICTLY IN ACCORDANCE WITH THE MANUFACTURERS INSTRUCTIONS AND RECOMMENDATIONS.

IF THE EXTERNAL GROUND LEVEL IS EQUAL OR ABOVE THE INTERNAL FINISH FLOOR LEVEL, THEN DOUBLE DPC TO BE PROVIDED, ONE AT FINISHED FLOOR LEVEL AND THE SECONDARY 150MM ABOVE EXTERNAL GROUND LEVEL. BOTH HORIZONTAL DPC'S TO BE CONNECTED WITH AND VERTICAL LAYER OF DPC ALL IN ACCORDANCE WITH ARCHITECTURAL DESIGN AND DETAILS.

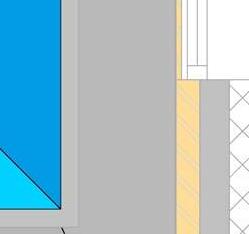

CAVITY CLOSURE TO ALL WINDOWS AND DOORS TO REPLACE ALL VERTICAL DPC'S AND IN ORDER TO AVOID COLD BRIDGING.

THE HORIZONTAL DAMP PROOF COURSE SHALL CONSIST OF A LAYER OF 2000 GAUGE POLYTHENE DAMP COURSE TO BS 743/6515 ADEQUATELY LAPPED AT CORNERS AND JOINTS AND LAID ON A MORTAR BED.

WHERE EXTERNAL WALL CAVITY IS BRIDGED I.E. AIR BRICK/VENTILATOR OPENINGS AND METER CUPBOARD ETC. PROVIDE POLYTHENE CAVITY TRAYS COMPLETE WITH STOP ENDS OVER IN THE EXTERNAL WALL WITH OPEN PROPRIETARY PERPENDS. CAVITY TRAYS ARE TO PROJECT 150MM BEYOND EITHER SIDE OF LINTEL/OPENING.

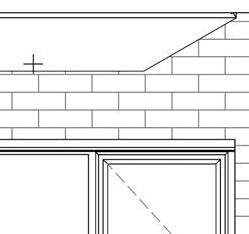

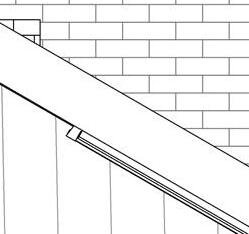

AT ALL ROOF ABUTMENTS I.E PORCHES, GARDEN ROOMS ENSURE STEPPED D.P.C'S CAVITY TRAY WITH STOP ENDS ARE PROVIDED AND LINKED TO CODE 4 LEAD FLASHINGS AND SOAKERS. CODE 4 LEAD DRESSED BENEATH CAVITY TRAYS AND OVER ROOF SLOPES WITH ALTERNATE PERPENDS LEFT OPEN FOR WEEPHOLES ALL AS NECESSARY TO FORM WEATHER PROOF JUNCTION. ALL LEADWORK TO SOAKERS, FLASHINGS, VALLEYS ETC. ARE TO BE IN COMPLIANCE WITH THE RECOMMENDATIONS OF THE LATEST EDITION OF THE LEAD SHEET ASSOCIATION'S 'GUIDE TO GOOD PRACTICE'.

MOVEMENT JOINTS

REFER TO FLOOR PLANS AND STRUCTURAL ENGINEERS DETAILS FOR RECOMMENDED LOCATION OF MOVEMENT JOINTS TO OUTER LEAF BRICKWORK/BLOCKWORK, GENERALLY TO BE PROVIDED AT NOT GREATER THAN 6 METRE CENTRES FOR BLOCKWORK AND 12-15 METRE CENTRES FOR BRICKWORK. MOVEMENT JOINTS TO BE 10MM MINIMUM WIDE, LOCATED BEHIND RAIN WATER DOWN PIPES WHERE POSSIBLE AND FORMED WITH PROPRIETARY POLYURETHANE SEALING STRIP, WITH FLAT TIES BETWEEN PANELS AT 450MM VERTICAL CENTRES WITH ONE END DE-BONDED WITH POLY-SULPHIDE SEALANT TO EXTERNAL FACE OF BRICKWORK -COLOUR TO MATCH. NOTE PROVIDE CAVITY WALL TIES WITHIN 150MM HORIZONTALLY, AT 225MM MAXIMUM VERTICAL CENTRES, EITHER SIDE OF MOVEMENT JOINTS.

EXTERNAL CAVITY WALL ('U' VALUE = 0.16 W/m²K)

CAVITY WALLS TO COMPLY WITH BS 5628.

300MM EXTERNAL WALL CONSTRUCTION ABOVE DPC COMPRISING 100MM AIRCRETE BLOCKWORK (TC=0.11) INNER SKIN, STRENGTH TO BE 7.3 N/MM.SQ, 12.5MM PLASTERBOARD ON DABS, STRICTLY IN ACCORDANCE WITH THE MANUFACTURER'S RECOMMENDATIONS. ALL WALLS ARE TO RECEIVE A PLASTER SKIM FINISH READY TO RECEIVE DECORATION. 100mm CAVITY TO BE FILLED WITH 90 mm KINGSPAN KOOLTHERM K106 CAVITY BOARD OR SIMILAR APPROVED WITH 10mm RESIDUAL CAVITY IN ACCORDANCE WITH MANUFACTURERS DETAILS. OUTER LEAF GENERALLY TO BE 102.5MM (FL DURABILITY) FACING MATCHING BRICKWORK TO LOCAL AUTHORITY APPROVAL. TOTAL EXTERNAL CAVITY WALL TO ACHIEVE MINIMUM 'U' VALUE 0.16 W/m²K

THE CAVITY IS TO BE FILLED WITH A LEAN MIX CONCRETE UP TO A LEVEL OF 225MM MINIMUM BELOW DPC & IS TO BE LAID WITH SULPHATE RESISTANT MORTAR. PROVIDE PERPEND WEEPHOLES EVERY FOURTH VERTICAL JOINT IN THE OUTER LEAF AT THE BASE OF THE CAVITY AT 150MM BELOW D.P.C.

PROVIDE PROPRIETARY INSULATED CAVITY CLOSERS AT ALL WINDOW/DOOR OPENINGS AND CLOSE CAVITY AT TOP WITH INSULATED LINTEL.

INTERNAL WALLS

INTERNAL PARTITIONS TO BE BRITISH GYPSUM 'GYPWALL' METAL STUD-PARTITIONING SYSTEM OR APPROVED TIMBER STUDS, TOTAL OVERALL THICKNESS 95MM. USING 70MM METAL /TIMBER STUDS AT 600MM CTRS. WITH 12.5MM BRITISH GYPSUM 'SOUNDBLOC' BOTH SIDES (MOISTURE RESISTANT TO BATHROOM & ENSUITES). PARTITION TO ACHIEVE 40DB SOUND REDUCTION.

ADDITIONAL 12.5MM STRUCTURAL PLY BOARD TO BE ADDED BETWEEN/ABOVE BATTENS TO SUPPORT THE KITCHETN/BATHROOM FITTINGS AND APPLIANCES.

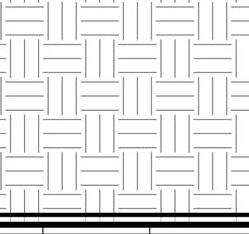

UPPER FLOORS

UPPER FLOOR IN ACCORDANCE WITH SPECIALISTS'S DESIGN AND DETAILS 18-22MM THICK MOISTURE-RESISTANT FLOORING TYPE C4 CHIPBOARD TO B.S 5669, ENSURE THROUGHOUT EDGES OF BOARDS SUPPORTED ON JOISTS OR NOGGINS, WITH 10MM EXPANSION GAP AT ROOM PERIMETERS BETWEEN CHIPBOARD AND WALLS. BOARDS TO BE SECURELY FIXED THROUGH TO 50X200MM (TBC BY ENGINEER) DEEP C24 TIMBER JOIST SYSTEM OR ATTIC TRUSSES AT CENTRES AS SPECIFIED BY SPECIALIST MANUFACTURER/ STRUCTURAL ENGINEER. THE ENTIRE FLOOR IS TO BE INSTALLED IN STRICT ACCORDANCE WITH THE MANUFACTURER'S INSTRUCTIONS -STANDARD DETAILS AND SETTING OUT JOISTS TO BE SUPPORTED ON HANGERS AT PARTY WALL AND EXTERNAL WALL. AT PARTY WALLS THE JOISTS ARE TO BE SEALED FOR FIRE AND ACOUSTIC REQUIREMENTS IN STRICT ACCORDANCE WITH THE MANUFACTURERS INSTRUCTIONS.

UNDERSIDE OF JOISTS TO RECEIVE 12.5MM SOUNDBLOCK PLASTERBOARD CEILING, TAPED, SKIMMED AND SET FINISHED. FLOOR VOID TO HAVE 100MM THICK MINERAL FIBRE INSULATION FOR SOUND REDUCTION.

OVERALL CONSTRUCTION TO ACHIEVE MINIMUM AIRBORNE SOUND REDUCTION OF 40DB

ROOF CONSTRUCTION

ROOFING TILES AS APPROVED TO MATCH NEIGHBOURING PROPERTY (TO BS 5534 PT.1 AMENDED 1981) LAID WITH PITCH AND LAP IN ACCORDANCE W ITH MANUFACTURER'S INSTRUCTIONS ON 50X38MM SW BATTENS (SIZE TO BE IN ACCORDANCE WITH BS 5534) ON 'TYVEK SUPRO' OR SIMILAR APPROVED VAPOUR PERMEABLE BREATHER MEMBRANE. MEMBRANE DRESSED INTO GUTTERS ON 'TYVEK' EAVES CARRIER. ON SW PRE FABRICATED TRUSSED RAFTERS AND BRACINGS TO BS 5268 PART 3 1985, AT MAX 600 CTS. 30X5G.S RESTRAINT STRAPS AT VERGE AND CEILING LEVEL. PROVIDE AND BED ON 1:1:6 MORTAR 100X50MM SW TREATED WALL PLATE WITH RESTRAINT STRAPS TO WALL PLATE AT MAX 2 M CTS. TO BS 5628 PART 1. ALL EXTERNAL TIMBERS TO BE PRESERVATIVE TREATED.

SLOPING CEILING -MINIMUM 175MM DEEP LOOSE RAFTERS / TRUSS RAFTERS AT 400C/C TO ROOF MANUFACTURER'S OR ENGINEER'S DESIGN AND DETAILS. AT SLOPING CEILING, BREATHABLE ROOFING MEMBRANE WITH 125MM KOOLTHERM K107 PITCHED ROOF BOARDINSULATION BETWEEN RAFTERS WITH MIN 50MM VOID OVER INSULATION AND KINGSPAN KOOLTHERM INSULATED PLASTERBOARDUNDER RAFTERS WITH VAPOUR CHECK LAYER, ROOF CONSTRUCTION TO ACHIEVE MIN. U-VALUE OF 0.11

FLAT ROOF AT RAFTER LEVEL (WARM FLAT ROOF) FIBER GLASS WATER PROOFING LAYER OR SIMILAR APPROVED TO MANUFACTURER'S INSTRUCTIONS AND DETAILS. ON 18MM OSB 3 BOARD, ON 210MM (110MM + 100MM) KINGSPAN THERMAROOF TR27 WITH VAPOUR CONTROL LAYER ON BOTH SIDES, ON 2MM OSB2 BOARD, ON SW FURRINGS TO GIVE MINIMUM 1:60 FALL, ON 50X175MM JOISTS (TBC BY ENGINEER), 15MM CEILING BOARD WITH VAPOUR ONTROL LAYER, CONSTRUCTION TO ACHIEVE U-VALUE OF 0.11 ALLOW FOR CUTTING THE OVERHANGING RAFTER FEET SQUARELY TO ACHIEVE ERFECT VERTICAL ALIGNMENT TO THE NEW FASCIA BOARDS, AS WELL AS A ONSTANT SOFFIT WIDTH.

TRUSSES TO BE SECURED TO WALL PLATES USING PROPRIETARY TRUSS CLIPS WITH NAILS FIXED THROUGH EACH AVAILABLE HOLE.

FORM HIPS AND RIDGE USING PROPRIETARY RIDGE AND BONNET HIP TILES, & CODE 5 LEAD ON VALLEY BOARDS IN ACCORDANCE WITH LEAD ASSOCIATION DETAILS,(ALTERNATIVELY A GRP VALLEY CAN BE USED AND INSTALLED STRICTLY IN ACCORDNACE WITH MANUFACTURES / SUPPLIERS GUJIDLINES AND RECOMMENDATIONS.

PROVIDE CAVITY TRAYS & CODE 4 STEPPED AND APRON LEAD FLASHINGS AT ABUTMENTS OF ALL ROOFS WITH WALLS, LEAD CHASED INTO WALLS AND WEDGED AT MAXIMUM 450MM CENTRES AND POINTED IN 1:3 CEMENT/ SAND MORTAR. PROVIDE SOAKERS TO HIPS, VALLEYS AND ROOF/ WALL ABUTMENTS.

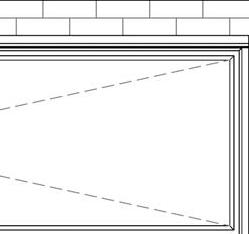

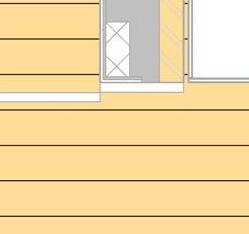

WINDOWS AND DOORS

WINDOWS: UPVC WINDOWS STYLE TO MATCH AS INDICATED ON ARCHITECTURAL DRAWINGS. ALL FIRST FLOOR WINDOWS AND ABOVE TO BE DESIGNED WITH EASY CLEAN HINGES TO ALLOW FOR CLEANING EXTERNAL GLAZING FROM WITHIN ROOM. NO WINDOW OPENINGS FIRST FLOOR AND ABOVE TO BE LESS THAN 800MM ABOVE FINISH FLOOR LEVEL UNLESS SAFETY GLAZING & GUARDING, (REFER TO AD N1 AND GLAZING SPECIFICATION BELOW), PROVIDED TO AT LEAST THE HEIGHT OF 800MM FROM FFL. CHILD RETRACTORS TO BE FITTED.

WINDOWS/EXTERNAL DOORS TO ALL HABITABLE ROOM UPTO 4.5M FROM GROUND LEVEL TO BE EMERGENCY EGRESS WINDOWS WITH UNOBSTRUCTED OPENABLE AREA 0.33M² WITH MIN 450X450MM OPENING AND BOTTOM OF OPENING NOT MORE THAN 1100MM FROM FFL, ALL INACCORDANCE WITH AD PART B.

PROVIDE TRICKLE VENTILATOR UNITS TO HEAD OF WINDOWS PROVIDING 2500MM2 EQUIVALENT TO HABITABLE ROOMS AND STRICTLY ACCORDANCE WITH AD PART F.

WINDOWS TO BE FITTED TO PROVIDE A 30MM EXTERNAL REVEAL FROM THE FACE OF BRICKWORK AND TO OVERHANG CAVITY CLOSURES BY A MINIMUM OF 30MM.

DOORS: PROPRIETARY MADE. PROVIDE LEVEL THRESHOLD IN COMPLIANCE WITH BUILDING REGULATION REQUIREMENTS PART M, ACCESS FOR THE DISABLED

FRONT ENTRANCE DOORS TO BE PROVIDED WITH A LEVEL THRESHOLD AND RAMPED ACCESS IN ACCORDANCE WITH AD PART M.

DRAUGHT STRIPPING TO ALL EXTERNAL DOORS AND WINDOWS. MASTIC TO BE APPLIED BETWEEN FRAMES AND BRICKWORK INTERNALLY AND EXTERNALLY.

WINDOWS AND DOORS TO ACHIEVE A U-VALUE OF 1.6 W/M2K.

EXTENDED CILLS OF APPROPRIATE LENGTH ARE TO BE ALLOWED FOR AREAS OVER RENDER TILE HANGINGS/ STUB CILLS TO BE PROVIDED FOR WINDOWS ABOVE STONE CILL

GLAZING

ALL GLAZING TO WINDOWS BELOW 800MM AND GLAZING TO DOORS BELOW 1500MM INCLUDING SIDELIGHTS WITHIN 300MM HORIZONTALLY TO BE FITTED WITH LAMINATED SAFETY GLAZING TO BS 6206 1981. ALL HEIGHTS TO BE MEASURED FROM FINISHED FLOOR LEVEL.

GLAZING TO BE INSTALLED IN FULL ACCORDANCE WITH AD PART L OF THE BUILDING REGULATIONS. 24MM DOUBLE SEALED GLAZED UNITS WITH LOW E GLASS TO BE USED. OBSCURE GLASS TO WC AND BATHROOM WINDOWS.

SMOKE ALARMS

AUTOMATIC MAINS OPERATED SELF-CONTAINED SMOKE DETECTORS WITHIN EACH UNIT CONFORMING TO BS 5446 TO BE PROVIDED TO CEILINGS AT LOCATIONS INDICATED ON THE PLANS. ALARMS TO HAVE PERMANENTLY WIRED CONNECTION WITH BATTERY BACK UP, INTERLINKED ONE AT EACH FLOORAND PROVIDED WITH SEPARATE FUSED CIRCUIT AT DISTRIBUTION BOARD IN ACCORDANCE WITH CURRENT IEE REGULATION. ALARMS TO BE LOCATED MINIMUM 300MM CLEAR FROM ANY WALL OR FITTINGS, AND NOT LOCATED DIRECTLY ABOVE ANY RADIATORS.

HEAT ALARMS TO BE PROVIDED IN OPEN PLAN KITCHEN.

VENTILATION

THE VENTILATION REQUIREMENTS ARE TO BE IN ACCORDANCE WITH THE BUILDING REGULATIONS 2006, WITH PARTICULAR REFERENCE TO THE FOLLOWING ITEMS:-

HABITABLE ROOMS -AN OPENING WINDOW OF 1/20TH (MINIMUM) OF FLOOR AREA, TOGETHER WITH A TRICKLE VENTILATION OPENING NOT LESS THAN 8000MM2 IN AREA TO HABITABLE ROOMS AND 4000MM2 ELSEWHERE DUCTING FROM EXTRACT FANS TO EXTERNAL AIR IS TO INCORPORATE CONDENSATION TRAPS. DUCTWORK SHALL FOLLOW THE SHORTEST PRACTICAL ROUTE TO THE EXTERNAL GRILLE WITHIN THE CONFINES OF STRUCTURAL VOIDS. ANY DEVIATIONS FROM THESE ZONES IMPACTING ON FINISHED ARCHITECTURAL SURFACE LEVELS MUST HAVE PRIOR APPROVAL KITCHEN -A COOKER HOOD WITH AN EXTRACT OF 30 LITRES PER SECOND, DUCTED TO EXTERNAL AIR WITH 15 MINUTE OVERRUN. EXTRACT FANS IN KITCHENS WITH WINDOWS NEED NOT HAVE 15 MINUTE OVERRUN BUT THE WINDOWS MUST BE OPENABLE AND HAVE TRICKLE VENTILATION OF 4000MM2.

BATHROOM -A MECHANICAL FAN WITH AN EXTRACT RATE OF 15 LITRES PER SECOND DUCTED TO EXTERNAL AIR WITH 15 MINUTE OVERRUN. WINDOWS IN BATHROOMS TO BE OPENABLE TOGETHER WITH TRICKLE VENTILATION OF 4000MM2.

UTILITY ROOM -WILL HAVE AN INTERMITTENT EXTRACT VENTILATION RATE OF AT LEAST 30L/S IN ACCORDANCE WITH APPROVED DOCUMENT F, TABLE 5.1A.

INTERNAL DWELLINGS WITH NO THROUGH VENTILATION ARE TO HAVE WHOLE HOUSE VENTILATION SYSTEMS IN ACCORDANCE WITH SPECIALIST MANUFACTURERS DESIGN, SPECIFICATION AND FULLY IN ACCORDANCE WITH THE BUILDING REGULATIONS

ELECTRICAL INSTALLATION

ELECTRICAL INSTALLATION TO BE IN ACCORDANCE WITH APPROVED DOCUMENT PART P WITH LOCATIONS OF SWITCHES, SPURS ETC IN ACCORDANCE WITH APPROVED DOCUMENT PART M. REFER TO ELECTRICAL SERVICES INSTALLATION AND DRAWINGS, WHERE APPLICABLE. .

ALL ELECTRICAL WORK REQUIRED TO MEET THE REQUIREMENTS OF PART P, MUST BE DESIGNED, INSTALLED, INSPECTED AND TESTED BY A PERSON COMPETENT TO DO SO. PRIOR TO COMPLETION THE COUNCIL SHOULD BE SATISFIED THAT PART P HAS BEEN COMPLIED WITH. THIS MAY REQUIRE AN APPROPRIATE BS 7671 ELECTRICAL INSTALLATION CERTIFICATE TO BE ISSUED FOR THE WORK BY A PERSON COMETENT TO DO SO.

RAINWATER GOODS

115MM WIDE PVC-U OR TO MATCH WITH THE EXISTING HALF ROUND DEEP FLOW GUTTERS LAID TO FALLS TO DISCHARGE INTO 63MM DIA. UPVC RAINWATER DOWNPIPES. RAINWATER DRAINAGE DESIGN TO BE IN ACCORDANCE WITH APPROVED DOCUMENT H AND VERIFIED BY THE SUPPLIER.

ALL GUTTERS ADJACENT TO TREES TO BE PROVIDED WITH LEAVES GUARD.

LINTELS

LINTELS SIMILAR AS INDICATED IN ARCHITECTURAL DRAWINGS TO BE CONFIRMED AND DESIGNED BY STRUCTURAL ENGINEERS. GENERALLY IG GALVANIZED PRESSED METAL LINTELS OR SIMILAR WITH INTEGRAL INSULATION AND CAVITY TRAYS OVER, SIZE, TYPE, END BEARING & INSULATION TO MANUFACTURERS RECOMMENDATIONS TO SUPPORT ALL OPENINGS IN ALL INTERNAL & EXTERNAL LOAD BEARING WALLS. PROVIDE CONTINUOUS DPC CAVITY TRAYS BUILT OVER ALL LINTELS IN EXTERNAL CAVITY WALL. CAVITY TRAYS JOINED AND LAPPED MINIMUM 100MM AND SEALED BY APPROPRIATE CONTACT ADHESIVE. ALL LINTELS TO HAVE A MIN END BEARING OF 150MM EACH SIDE. PROVIDE MIN. 2 NO WEEP HOLES PER LINTEL AND AT 450MM CENTRES ABOVE LINTELS.

STRUCTURAL STEELWORK

STRUCTURAL STEEL WORK TO BS 5950.

ALL STEELWORK TO BE PAINTED WITH RED OXIDE PRIMER OR EQUIVALENT STEELS WITHIN FLOOR CONSTRUCTION AND SUPPORTING ANY STRUCTURE TO ACHIEVE A MIN. 30 MIN. FIRE RESISTANCE BY USING INTESUMENT PAINT OR 2 LAYERS OF FIRE RESISTANT BOARDS.

ALL EXTERNAL STEEL AND METAL WORK TO BE PAINTED GLASS BLACK.

TIMBER TREATMENT

ALL SOFTWOOD TIMBERS TO BE ADEQUATELY TREATED TO PREVENT INFESTATION BY THE HOUSE LONGHORN BEETLE IN ACCORDANCE WITH CURRENT BUILDING REGULATIONS. ALL STRUCTURAL TIMBERS, EXTERNAL FRAMES, WINDOW & SOFTWOOD CLADDING SHALL BE TREATED AGAINST FUNGAL ATTACK. ALL STRUCTURAL TIMBER TO BE MARKED DRY OR KD AND TO HAVE STRESS GRADE MARK.

PLUMBING INSTALLATION

ALL SANITARY PIPEWORK TO BE IN ACCORDANCE WITH BS 5572 : 1994 AND THE BUILDING REGULATIONS.

SOIL AND WASTE TO BE A SINGLE STACK DRAINAGE SYSTEM TO BS 5572:1978, CONNECTING VIA A SUITABLE ADAPTER TO THE UNDERGROUND DRAINAGE SYSTEM.

DEPTH TO INVERT TO BE MINIMUM 450MM AT CONNECTIONS TO SVP.

INTERNAL VENT PIPES -REDUCE TO 75MM DIAMETER ABOVE TOPMOST CONNECTION AND TERMINATE WITH AN AIR ADMITTANCE VALVE IN ROOF SPACE WHERE POSSIBLE, OTHERWISE FIT AN AIR VENT IN THE BOX-OUT. DRAINAGE SCHEMES TO BE DESIGNED TO MEET THE REQUIREMENTS OF BUILDING REGULATIONS APPROVED DOCUMENT H, IN ACCORDANCE WITH THE INSTITUTE OF PLUMBING ENGINEERS ENGINEERING SERVICES DESIGN GUIDE AND IN ACCORDANCE WITH MANUFACTURERS INSTRUCTIONS AND BBA CERTIFICATION.

ALL WASTES TO HAVE 75MM DEEP SEAL TRAPS. ALL APPLIANCE TRAPS TO BE EITHER REMOVABLE OR FITTED WITH CLEANING EYE FACILITY. SVP -100MM DIA PVCU TERMINATED AT PROPRIETARY ROOF VENT TILE 900MM ABOVE ANY WINDOW OPENING, OR DURGO AIR ADMITTANCE VALVE, WHERE INDICATED.

BRANCH WASTES TO BE SVP CONNECTED EITHER ABOVE CENTRE LINE OR 200MM BELOW CENTRE LINE OF WC SOIL CONNECTION. ROCKER PIPES USED WHERE DRAINS PASS THROUGH EXTERNAL WALLS. UNLESS OTHERWISE INDICATED -BATH, SINK AND SHOWER -40MM DIA. UP TO 3M MAX. LENGTH 50MM DIA. FROM 3M -4M MAX. LENGTH. WASH BASIN, BIDET -32MM DIA. UP TO 1.7M MAX. LENGTH 40MM DIA. FROM 1.7M -3M LENGTH .

100 NOMINAL DIAMETER, SALT GLAZED WARE, SUPERSLEVE OR SIMILAR OR EQUAL APPROVED. TOP RUNS MINIMUM GRADIENT OF 1:40 WITH INSPECTION CHAMBERS AT MAXIMUM 12M INTERVALS. PIPEWORK BELOW BUILDINGS TO BE ENCASED IN 100 THICK GRANULAR OR OTHER FLEXIBLE FILLING IN ACCORDANCE WITH THE MANUFACTURER'S RECOMMENDATIONS. SEE SITE DRAINAGE PLAN FOR DRAINAGE RUNS, GRADIENTS AND MANHOLE INVERTS. DRAINS PASSING THROUGH WALLS TO HAVE 50MM CLEARANCE ALL ROUND WITH LINTEL OVER.

SERVICES

SEAL AT FLOOR AND CEILING LEVELS THE BOXING-IN OF CONCEALED SERVICES. SEAL AROUND ALL PIPED SERVICES WHERE THEY PENETRATE OR PROJECT INTO HOLLOW CONSTRUCTIONS OR VOIDS.

GENERAL

THESE NOTES DO NOT COMPRISE A FULL SPECIFICATION. THEY ARE FOR GENERAL GUIDANCE ONLY AND THEIR PRIMARY FUNCTION IS TO ASSIST LOCAL AUTHORITY OFFICERS IN DETERMINING BUILDING REGULATION APPLICATIONS.

WHERE CLARIFICATION IS CONSIDERED NECESSARY, REFERENCE SHOULD BE MADE TO THE ARCHITECTURAL SERVICES CONSULTANT.

THE BUILDER WILL BE RESPONSIBLE FOR ENSURING THAT ALL BUILDING WORK CARRIED OUT BY THEM OR UNDER THEIR INSTRUCTIONS COMPLIES WITH THE RELEVANT CURRENT REGULATIONS, BRITISH STANDARDS AND CODES OF PRACTICE, BYE-LAWS AND MANUFACTURERS' INSTRUCTIONS.

THE U-VALUES QUOTED ABOVE ASSUME THAT A CALCULATION UNDER THE GOVERNMENT'S STANDARD ASSESSMENT PROCEDURE. BETTER VALUES MAY BE REQUIRED BY THE BUILDING REGULATION AUTHORITY TO IMPROVE THE ENERGY PERFORMANCE.

THE BUILDER WILL BE RESPONSIBLE FOR ENSURING THAT ALL BUILDING WORK CARRIED OUT BY THEM OR UNDER THEIR INSTRUCTIONS COMPLIES WITH THE RELEVANT CURRENT REGULATIONS, BRITISH STANDARDS AND CODES OF PRACTICE, BYE-LAWS AND MANUFACTURERS' INSTRUCTIONS.

THE U-VALUES QUOTED ABOVE ASSUME THAT A CALCULATION UNDER THE GOVERNMENT'S STANDARD ASSESSMENT PROCEDURE. BETTER VALUES MAY BE REQUIRED BY THE BUILDING REGULATION AUTHORITY TO IMPROVE THE ENERGY PERFORMANCE.

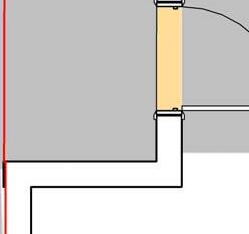

PLUMBING NOTES 1 : 25 Foundation Plan -Drainage 1

EXISTING MAN HOLE

PIPE LEGEND

DRAINAGE PIPE

DRAINAGE UNDER FLOOR PIPE

RAIN WATER PIPE

Lulezim

PIPE SHOULD BE AWAY 100MM FROM THE FOUNDATION

FOR RAIN WATER PIPE DISCHARGE SEE

1

1 : 25 Ground Floor PlanDrainage

FOR RAIN WATER PIPE DISCHARGE

50 Woodrush Way, Dagenham, Romford RM6 5BL

Ground Floor Plan - Drainage

As indicated

Lulezim Gashi NC-62 12/19/21 Planning

PLUMBING NOTES DRAINAGE PIPE Client Project Drawing Scale Date : Rev Dwg No

D E S I G N L A B S L O N D O N

DRAINAGE UNDER FLOOR PIPE PIPE LEGEND Status ARCHITECTURE / INTERIOR / MANAGEMENT / PLANNING T: 07870661614 07888831314 E: info@designlabslondon.com W: www.designlabslondon.com

VENT PIPE TO ROOF SOIL PIPE DROPPING DOWN

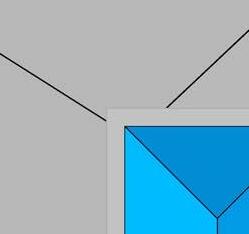

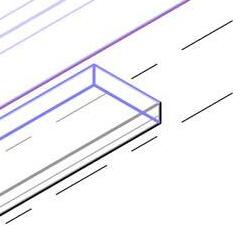

1 : 25 First Floor Plan -Drainage 1 3D Drainage View 2

50 Woodrush Way, Dagenham, Romford RM6 5BL

DRAINAGE PIPE

DRAINAGE UNDER FLOOR PIPE

PIPE LEGEND RAIN WATER PIPE

Lulezim Gashi NC-63 12/19/21 Planning

First Floor Plan - Drainage

As indicated

PLUMBING NOTES Client Project Drawing Scale Date : Rev Dwg No

Status ARCHITECTURE / INTERIOR / MANAGEMENT / PLANNING T: 07870661614 07888831314 E: info@designlabslondon.com W: www.designlabslondon.com

D E S I G N L A B S L O N D O N

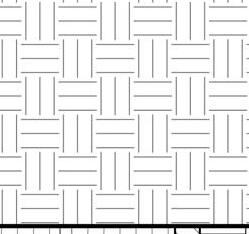

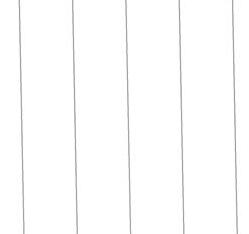

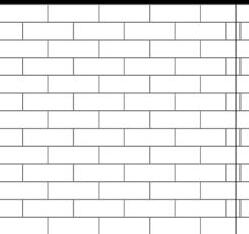

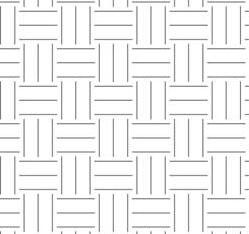

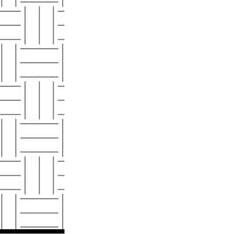

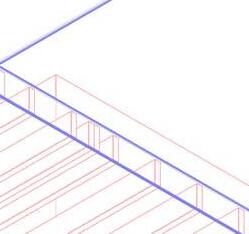

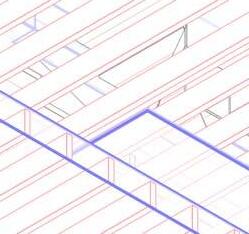

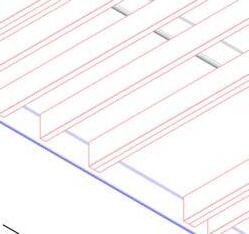

Denotes galvanised mild steel lateral restraint strap position at 2000mm max centres at ceiling chord level spanning 3no. Min trusses with 50 x 50mm softwood noggins under including packing noggin between wall and truss

Denotes galvanised mild steel lateral restraint strap position at 2000mm max centres at rafter chord level spanning 3no. Min trusses with 50 x 50mm softwood noggins under including packing noggin between wall and truss

Denotes galvanised mild steel Wall Plate strap position at 2000mm max centres. X

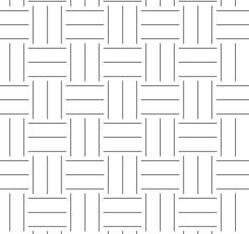

Joist/Rafter Direction - Joist sizes 200x50mm C24 @400 centers - Rafter Size 150x50mm C16 @400 Centers

Double/Triple Trimmers - Floor and Flat Roof Trimmers 2x200x50mm C24 Bolted together @600 centers - Sloping Roof Trimmers 2x150x50mm C24 Bolted together @600 centers Roof Slope Direction in Decimal Degree

Dashed line indicates Walls and Windows to be demolished

Notes:

1. ALL DIMENSIONS IN MILLIMETERS UNLESS OTHERWISE SPECIFIED.

2. THE CONTRACTOR TO CHECK ALL DIMENSIONS, ANGLES, DRAIN RUNS AND CONDITIONS ON SITE BEFORE WORKS COMMENCEMENT. ANY DISCREPANCIES REPORT IMMEDIATELY TO THE ENGINEER.

3. CONDITION OF ALL EXISTING STRUCTURAL ELEMENTS, WITH PARTICULAR ATTENTION TO EXISTING BEARING WALLS TO BE USED FOR THE PROPOSED DEVELOPMENT, TO BE CHECKED BY THE CONTRACTOR BEFORE WORKS COMMENCEMENT.

2

4. DRAWINGS TO BE READ IN CONJUNCTION WITH RELATIVE STRUCTURAL CALCULATIONS, DETAILS AND SPECIFICATION.

5. DO NOT SCALE FROM DRAWINGS. DIMENSIONS ARE INDICATIVE ONLY.

6. CONTRACTOR AND CLIENT TO BE AWARE OF CONSTRUCTION & DESIGN MANAGEMENT (CDM) DUTIES.

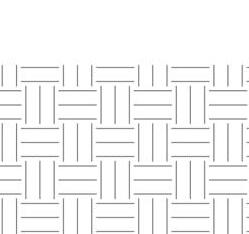

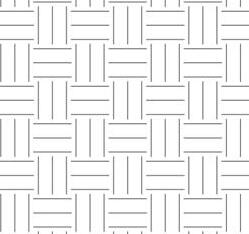

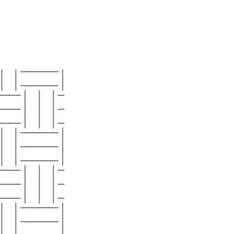

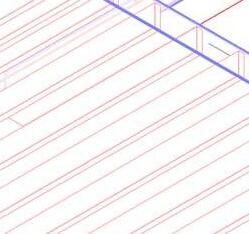

Denotes galvanised mild steel lateral restraint strap position at 2000mm max centres at ceiling chord level spanning 3no. Min trusses with 50 x 50mm softwood noggins under including packing noggin between wall and truss

Denotes galvanised mild steel lateral restraint strap position at 2000mm max centres at rafter chord level spanning 3no. Min trusses with 50 x 50mm softwood noggins under including packing noggin between wall and truss

Denotes galvanised mild steel Wall Plate strap position at 2000mm max centres. X

Joist/Rafter Direction - Joist sizes 200x50mm C24 @400 centers - Rafter Size 150x50mm C16 @400 Centers

Double/Triple Trimmers - Floor and Flat Roof Trimmers 2x200x50mm C24 Bolted together @600 centers - Sloping Roof Trimmers 2x150x50mm C24 Bolted together @600 centers

Roof Slope Direction in Decimal Degree Dashed line indicates Walls and Windows to be demolished

Notes:

1. ALL DIMENSIONS IN MILLIMETERS UNLESS OTHERWISE SPECIFIED.

2. THE CONTRACTOR TO CHECK ALL DIMENSIONS, ANGLES, DRAIN RUNS AND CONDITIONS ON SITE BEFORE WORKS COMMENCEMENT. ANY DISCREPANCIES REPORT IMMEDIATELY TO THE ENGINEER.

3. CONDITION OF ALL EXISTING STRUCTURAL ELEMENTS, WITH PARTICULAR ATTENTION TO EXISTING BEARING WALLS TO BE USED FOR THE PROPOSED DEVELOPMENT, TO BE CHECKED BY THE CONTRACTOR BEFORE WORKS COMMENCEMENT.

4. DRAWINGS TO BE READ IN CONJUNCTION WITH RELATIVE STRUCTURAL CALCULATIONS, DETAILS AND SPECIFICATION.

5. DO NOT SCALE FROM DRAWINGS. DIMENSIONS ARE INDICATIVE ONLY.

6. CONTRACTOR AND CLIENT TO BE AWARE OF CONSTRUCTION & DESIGN MANAGEMENT (CDM) DUTIES.

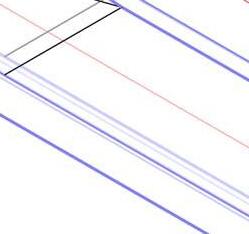

2 PL-DR-PR-XX-62 1 NC-27 2 NC-27 1 NC-28 B1.01 UKC203x203x46 2x Trimmers 2x Trimmers 2x Trimmers 1 ST-DR-P1-00-04 2 ST-DR-P1-00-042x Trimmers

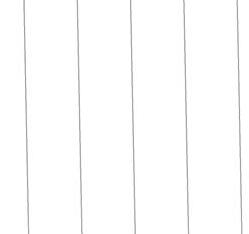

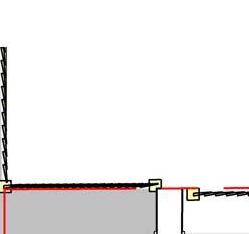

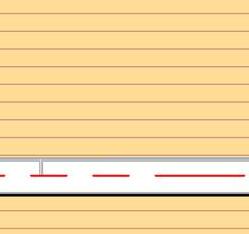

SCALE 1:

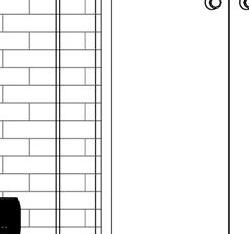

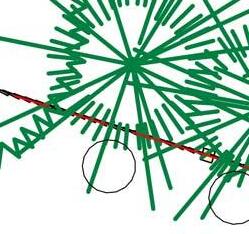

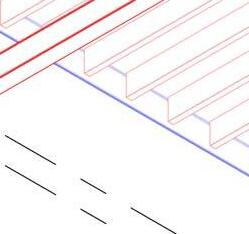

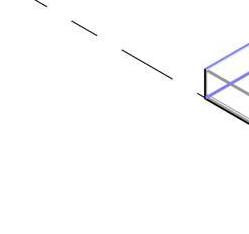

CRS

Denotes galvanised mild steel lateral restraint strap position at 2000mm max centres at ceiling chord level spanning 3no. Min trusses with 50 x 50mm softwood noggins under including packing noggin between wall and truss

RLS

Denotes galvanised mild steel lateral restraint strap position at 2000mm max centres at rafter chord level spanning 3no. Min trusses with 50 x 50mm softwood noggins under including packing noggin between wall and truss

Joist/Rafter Direction - Joist sizes 200x50mm C24 @400 centers - Rafter Size 150x50mm C16 @400 Centers

Double/Triple Trimmers - Floor and Flat Roof Trimmers 2x200x50mm C24 Bolted together @600 centers - Sloping Roof Trimmers 2x150x50mm C24 Bolted together @600 centers

Roof Slope Direction in Decimal Degree

Dashed line indicates Walls and Windows to be demolished

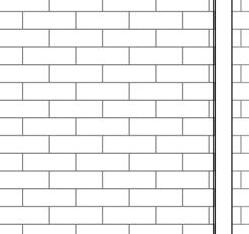

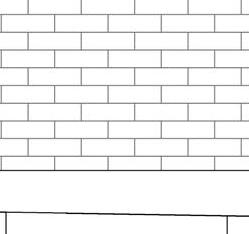

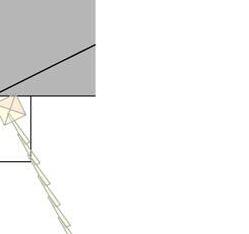

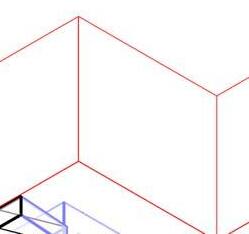

1000 800 600 400 200 200 mm 25 Proposed Steel Beam Schedule Reference Level MarkTypeCut LengthVolume Start Level Offset End Level Offset Comments First FloorB1.01UKC203x2 03x46 41450.02 m³-37-37 First Floor Ceiling R1.01UKB203x1 33x30 42360.02 m³26902690 Ground Floor Plate15X30041340.02 m³25062506

Notes:

1. ALL DIMENSIONS IN MILLIMETERS UNLESS OTHERWISE SPECIFIED.

2. THE CONTRACTOR TO CHECK ALL DIMENSIONS, ANGLES, DRAIN RUNS AND CONDITIONS ON SITE BEFORE WORKS COMMENCEMENT. ANY DISCREPANCIES REPORT IMMEDIATELY TO THE ENGINEER.

3. CONDITION OF ALL EXISTING STRUCTURAL ELEMENTS, WITH PARTICULAR ATTENTION TO EXISTING BEARING WALLS TO BE USED FOR THE PROPOSED DEVELOPMENT, TO BE CHECKED BY THE CONTRACTOR BEFORE WORKS COMMENCEMENT.

4. DRAWINGS TO BE READ IN CONJUNCTION WITH RELATIVE STRUCTURAL CALCULATIONS, DETAILS AND SPECIFICATION.

5. DO NOT SCALE FROM DRAWINGS. DIMENSIONS ARE INDICATIVE ONLY.

6. CONTRACTOR AND CLIENT TO BE AWARE OF CONSTRUCTION & DESIGN MANAGEMENT (CDM) DUTIES.

50 Woodrush Way, Dagenham, Romford RM6 5BL

Proposed Roof Plan Structure

ROOF Client Project Drawing Scale Date : Rev Dwg No

Lulezim Gashi ST-DR-P1-00-03 12/15/21 Planning

1 25

Status ARCHITECTURE / INTERIOR / MANAGEMENT / PLANNING T: 07870661614 07888831314 E: info@designlabslondon.com W: www.designlabslondon.com

D E S I G N L A B S L O N D O N

2 PL-DR-PR-XX-62

1 NC-27

2 NC-27

1 NC-28

R1.01 UKB203x133x30

1 ST-DR-P1-00-04

2 ST-DR-P1-00-04

2x Trimmers

2 PL-DR-PR-XX-62

1 NC-27

2 NC-27

1 NC-28

R1.01 UKB203x133x30

1 ST-DR-P1-00-04

2 ST-DR-P1-00-04

2x Trimmers

1.0 GENERAL

1.1 DO NOT SCALE DRAWINGS. THE CONTRACTOR IS TO CHECK ALL DIMENSIONS ON SITE BEFORE CARRYING OUT ANY WORKS.

1.2 THIS SPECIFICATION TOGETHER WITH THE STRUCTURAL ENGINEER'S DRAWINGS AND CALCULATIONS ARE TO BE READ IN CONJUNCTION WITH ARCHITECT'S AND ALL OTHER CONSULTANT'S DRAWINGS AND SPECIFICATIONS, WHICH SHOULD BE USED TO VERIFY LAYOUT, SETTING OUT, FINISHES ETC.,. ANY DISCREPANCIES ARE TO BE REPORTED TO THE ARCHITECT BEFORE PROCEEDING WITH THE WORKS.

1.3 THE CONTRACTOR MUST ENSURE THAT THE CLIENT HAS AGREED ALL NECESSARY PARTY WALL NOTICES PRIOR TO CARRYING OUT WORKS UNDER, ON OR ADJACENT TO PARTY WALL.

1.4 SETTING OUT DETAILS ARE SHOWN ON THE ARCHITECT'S DRAWINGS UNLESS NOTED OTHERWISE ON THE DRAWINGS.

1.5 THE CONTRACTOR IS TO INFORM THE ARCHITECT AND STRUCTURAL ENGINEER IF THE EXISTING FABRIC, INCLUDING FOUNDATIONS, IS OPENED UP AND FOUND TO BE INADEQUATE, UNSUITABLE TO SUPPORT THE PROPOSED WORKS, OR AT VARIANCE FROM THE DETAILS SHOWN ON THE DRAWINGS.

1.6 ITEMS NOTED ON THE DRAWINGS "TO BE VERIFIED ON SITE" ARE TO BE EXPOSED BY THE CONTRACTOR FOR INSPECTION BY THE STRUCTURAL ENGINEER AT THE EARLIEST OPPORTUNITY.

1.7 HOLES OR CHASES MUST NOT BE CUT THROUGH ANY STRUCTURAL MEMBERS WITHOUT THE WRITTEN CONSENT OF THE STRUCTURAL ENGINEER.

1.8 NOTHING INCLUDED OR OMITTED FROM THIS OUTLINE SPECIFICATION WILL RELIEVE THE CONTRACTOR OF HIS DUTY TO CARRY OUT THE WORKS IN ACCORDANCE WITH CURRENT STANDARDS OF SAFETY AND GOOD BUILDING PRACTICE.

2.0 TOLERANCES

2.1 ALL TOLERANCES ARE TO BE AGREED WITH THE ARCHITECT, AND THE CONTRACTOR WILL BE RESPONSIBLE FOR ENSURING THAT SUFFICIENT TOLERANCES ARE PROVIDED AND INTEGRATED THROUGHOUT ALL ELEMENTS OF THE WORKS.

2.2 THE CONTRACTOR IS TO TAKE ACCOUNT OF TOLERANCES DETAILED ELSEWHERE IN THE DRAWINGS, APPENDED SPECIFICATIONS, AND BRITISH STANDARDS WHEN COMPLYING WITH THE ABOVE CLAUSE

3.0 MATERIALS AND WORKMANSHIP

3.1 ALL ARTICLES, MATERIALS AND GOODS SHALL BE NEW AND OF GOOD QUALITY, SUITABLE FOR THE REQUIRED PURPOSE AND SHALL CONFORM TO THE APPROPRIATE BRITISH STANDARD WHERE SUCH EXISTS. WHERE REFERENCES TO THE ABOVE ARE MADE IT SHALL BE INFERRED THAT THE LATEST EDITION APPLIES, TOGETHER WITH SUBSEQUENT AMENDMENTS, UNLESS OTHERWISE SPECIFIED.

4.0 TEMPORARY WORKS AND STABILITY

4.1 THE CONTRACTOR IS ENTIRELY RESPONSIBLE FOR MAINTAINING THE STABILITY OF ALL EXISTING BUILDINGS AND STRUCTURES, WITHIN AND ADJACENT TO THE WORKS, AND OF ALL THE WORKS FROM THE DATE OF POSSESSION OF THE SITE UNTIL PRACTICAL COMPLETION OF THE WORKS.

4.2 THE CONTRACTOR SHALL DESIGN, INSTALL AND MAINTAIN ALL NECESSARY TEMPORARY WORKS AND SHALL ADVISE BOTH THE ARCHITECT AND STRUCTURAL ENGINEER AT LEAST TEN WORKING DAYS FROM COMMENCEMENT OF THE WORKS, OF HIS PROPOSALS FOR TEMPORARY SUPPORTS AND SEQUENCE OF CONSTRUCTION FOR THE WORKS. THESE PROPOSALS SHALL BE SUPPORTED BY DESIGN CALCULATIONS IFREQUESTED.

4.3 THE DESIGN OF TEMPORARY WORKS SHALL INCLUDE AN ASSESSMENT OF THE LOADS TO BE RESISTED AND IS TO BE UNDERTAKEN BY A COMPETENT PERSON. DUE REGARD SHALL BE GIVEN TO LATERAL STABILITY AS WELL AS TO THE SUPPORT OF VERTICAL LOADS. TEMPORARY SHORING TO VERTICAL ELEMENTS (EG. PARTY WALLS) TO BE DESIGNED TO RESIST A MINIMUM OF 5% OF DEAD LOAD, SUPPORTED BY THE PARTICULAR ELEMENT, ABOVE ANY LEVEL OF THE POINT OF CONTACT OF THE SHORING.

4.4 THE CONTRACTOR IS TO FAMILIARISE HIMSELF WITH THE BUILDING AND ITS STRUCTURE SO THAT HE IS AWARE OF THE NATURE AND MAGNITUDE OF THE LOADS TO BE SUPPORTED.

4.5 PARTICULAR CARE IS TO BE TAKEN TO ENSURE THAT TEMPORARY PROPS REMAIN ADEQUATELY SEATED AND TIGHTENED SO THAT SUPPORT TO THE STRUCTURE ABOVE IS NOT ALLOWED TO YIELD DURING BUILDING OPERATIONS.

4.6 THE CONTRACTOR IS TO ENSURE THAT TEMPORARILY PROPPED STRUCTURE IS ADEQUATELY WEDGED, PINNED OR PACKED OFF THE PERMANENT WORKS PRIOR TO REMOVAL OF ANY TEMPORARY SUPPORTS.

4.7 THE CONTRACTOR SHALL ENSURE THAT ANY COMPLETED OR PARTIALLY COMPLETED STRUCTURAL ELEMENT IS NOT OVERLOADED. DETAILS OF DESIGN LOADS MAY BE OBTAINED FROM THE STRUCTURAL ENGINEER.

4.8 ALL TEMPORARY WORKS TO SUPPORT THE SIDES OF EXCAVATIONS FOR NEW FOUNDATIONS SHALL BE DESIGNED IN ACCORDANCE WITH BS 8000 PART 1: 1989 AND ANY OTHER APPROVED DOCUMENTS.

4.9 EXCAVATIONS SHALL IN NO CIRCUMSTANCES ENCROACH WITHIN 45° OF THE BOTTOM NEAR SIDE OF ANY EXISTING FOOTING.

5.0 DEMOLITION

5.1 DEMOLITION IS TO BE CARRIED OUT TO AND IN ACCORDANCE WITH BS 6187: 1982, HEALTH AND SAFETY EXECUTIVE GUIDANCE NOTE GS 29/1 PARAGRAPH 32, AND ANY OTHER RELEVANT STATUTORY UNDERTAKINGS OR REGULATIONS.

5.2 DEMOLITION IS TO BE UNDERTAKEN IN THE REVERSE ORDER OF CONSTRUCTION. NO PART OF THE STRUCTURE IS TO BE LEFT IN AN UNSUPPORTED CONDITION OVERNIGHT OR FOR LONG PERIODS.

5.3 DEMOLITION IS TO BE UNDERTAKEN IN A MANNER WHICH AVOIDS EXCESSIVE NOISE AND NUISANCE. ALL WORK IS TO BE WELL-WATERED TO MINIMISE DUST. ALL MATERIAL IS TO BE CARTED AWAY FROM SITE AS SOON AS PRACTICABLE.

6.0 EXCAVATING AND FILLING

6.1 TRIAL PITS TO BE CARRIED OUT TO INDICATE UNDERLYING SOIL.

6.2 GROUND WATER LEVEL ON THE SITE IS NOT KNOWN.

6.3 INSPECT ALL AVAILABLE DRAWINGS AND MAKE ENQUIRIES ABOUT EXISTING SERVICES ON SITE. VERIFY POSITIONS AND DEPTH OF ALL SERVICES BEFORE COMMENCEMENT OF WORK ON SITE. SERVICES WHICH ARE BEING RETAINED DURING ANY PHASE OF THE WORKS ARE TO BE PROTECTED.

6.4 BEFORE STARTING WORK VERIFY WITH THE ARCHITECT WHICH EXISTING FENCES, GATES, WALLS, PAVED AREAS, TREES, SHRUBS, HEDGES, BUSHES AND ANY OTHER SITE FEATURES ARE TO BE REMOVED. MATERIALS ARISING ARE TO BE REMOVED FROM SITE.

6.5 WORKMANSHIP FOR EXCAVATING TO COMPLY WITH BS 8000: PART 1, SECTIONS 3.1, 3.2 AND 3.3.

6.6 WHERE AN EXCAVATION ENCROACHES BELOW A LINE DRAWN AT AN ANGLE OF 45° FROM THE HORIZONTAL FROM THE NEAREST FORMATION LEVEL OF ANOTHER HIGHER EXCAVATION, THE LOWER EXCAVATION, ALL WORK WITHIN IT AND BACKFILLING THERETO MUST BE COMPLETED BEFORE THE HIGHER EXCAVATION IS MADE.

6.7 MAKE ADVANCE ARRANGEMENTS WITH THE BUILDING CONTROL OFFICER AND/OR ARCHITECT FOR INSPECTION OF FOUNDATIONS AND TRENCHES REQUESTED AT THE BEGINNING OF THE WORKS.REMOVE THE LAST 150mm OF EXCAVATIONS JUST BEFORE INSPECTION. TRIM EXCAVATIONS TO REQUIRED PROFILES AND LEVELS, AND REMOVE ALL LOOSE MATERIALS. UNLESS OTHERWISE INSTRUCTED SEAL FORMATIONS WITHIN 4 HOURS OF INSPECTION WITH CONCRETE OR OTHER SPECIFIED FILL.

6.8 BACKFILL ANY EXCAVATIONS FOR FOUNDATIONS TAKEN DEEPER THAN REQUIRED WITH LEAN MIX CONCRETE. EXCAVATIONS OTHER THAN FOUNDATIONS TAKEN DEEPER THAN REQUIRED MAY BE BACKFILLED WITH WELL GRADED GRANULAR MATERIAL.

6.9 HARDCORE TO BE GRANULAR MATERIAL, FREE FROM HARMFUL MATTER, WELL GRADED, PASSING A 75mm BS SIEVE AND ONE OF THE FOLLOWING: -CRUSHED CONCRETE, BRICK OR TILE, FREE FROM OLD PLASTER. -GRAVEL. SPREAD AND LEVEL BOTH BACKFILLING AND GENERAL FILLING IN LAYERS NOT EXCEEDING 150mm. THOROUGHLY COMPACT EACH LAYER WITH A VIBRATORY ROLLER, VIBRATING PLATE COMPACTOR, VIBRO-TAMPER, POWER RAMMER OR OTHER SUITABLE MEANS APPROPRIATE TO THE AREA BEING WORKED.

6.10 HARDCORE UNDER GROUND BEARING CONCRETE SLABS TO BE AS ABOVE AND NOT LESS THAN 150mm THICK, UNLESS NOTED OTHERW ISE ON THE DRAWINGS. EXCAVATE EXTRA MATERIAL AS NECESSARY. INCREASE THICKNESS OF HARDCORE AS NECESSARY TO MAKE UP LEVELS FROM STRIPPED SITE LEVELS TO UNDERSIDE OF SLABS.

6.11 SURFACES OVER HARDCORE TO RECEIVE SHEET OVERLAYS OR CONCRETE TO BE BLINDED WITH SUFFICIENT SAND OR FINE GRAVEL TO FILL INTERSTICES AND PROVIDE A CLOSE SMOOTH SURFACE (50mm MIN THICKNESS), UNLESS NOTED OTHERWISE ON THE DRAWINGS. PERMISSIBLE DEVIATIONS ON SURFACE LEVEL TO BE + 0-15mm.

6.12 MINIMUM VOID UNDER SUSPENDED GROUND FLOORS TO BE 225mm FOR PRECAST CONCRETE AND 300mm FOR TIMBER FLOORS. SUSPENDED IN-SITU CONCRETE FLOORS SHALL BE CAST OVER A SUITABLE VOID FORMER TO PROVIDE A VOID OF 150MM UNDER THE SLAB, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

7.0 FOUNDATIONS

7.1 FOUNDATIONS ARE TO BE CAST TO THE PROFILES INDICATED ON THE DRAWINGS. THEY ARE TO BE CAST SYMMETRICALLY ABOUT PIERS, STANCHIONS OR WALLS, UNLESS NOTED OTHERWISE ON THE DRAWINGS. ALL FORMATION LEVELS FOR FOUNDATIONS TO BE AGREED WITH BUILDING INSPECTOR ON SITE.

7.2 NEW FOUNDATIONS HAVE BEEN DESIGNED TO IMPOSE A SAFE BEARING PRESSURE OF 100kN/m2 ON CLAY 1100mm BELOW FINAL EXTERNAL GROUND LEVEL. THE CONTRACTOR IS TO ENSURE THAT ALL NEW FOUNDATIONS BEAR A MINIMUM OF 150mm ONTO FIRM CLAY. WHERE POOR GROUND CONDITIONS ARE ENCOUNTERED OR THE BUILDING CONTROL OFFICER REQUESTS AMENDMENTS THE STRUCTURAL ENGINEER IS TO BE NOTIFIED IMMEDIATELY.

7.3 WHERE TREE ROOTS ARE ENCOUNTERED, FOUNDATIONS ARE TO EXTEND 600MM BELOW THE LAST TRACE OF ANY ROOT ACTIVITY.

7.4 FOUNDATIONS SITED WITHIN A ZONE 1.25 X MATURE TREE HEIGHT FOR HIGH WATER DEMAND TREES, 0.75 X MATURE TREE HEIGHT FOR MODERATE WATER DEMAND TREES AND 0.50 X MATURE TREE HEIGHT FOR LOW WATER DEMAND TREES WHICH ARE TO REMAIN OR TO BE REMOVED, OR OVER TREES AFTER REMOVAL, ARE TO BE PROTECTED AGAINST CLAY HEAVE AS FOLLOWS:

(i) TRENCH FILL FOUNDATIONS PROVIDE COMPRESSIBLE MATERIAL AGAINST INSIDE FACE OF ALL EXTERNAL WALL FOUNDATIONS GREATER THAN 1.5M DEEP TO GIVE A 35mm VOID. THE COMPRESSIBLE MATERIAL IS TO BE POSITIONED 500mm ABOVE THE BOTTOM OF THE FOUNDATION.

(ii) PIER AND GROUND BEAM FOUNDATIONS PROVIDE COMPRESSIBLE MATERIAL AGAINST FACES OF ALL PIER FOUNDATIONS GREATER THAN 1.5m DEEP TO GIVE A 35mm VOID. THE COMPRESSIBLE MATERIAL IS TO BE POSITIONED 500mm ABOVE THE BOTTOM OF THE FOUNDATIONS. ALSO, PROVIDE COMPRESSIBLE MATERIAL OR VOID FORMER BELOW ALL GROUND BEAMS AND AGAINST THE INSIDE FACE OF EXTERNAL GROUND BEAMS TO GIVE A 150mm AND 35mm VOID RESPECTIVELY.

(iii) PILE AND GROUND BEAM FOUNDATIONS PROVIDE COMPRESSIBLE MATERIAL OR VOID FORMER BELOW ALL GROUND BEAMS AND AGAINST THE INSIDE FACE OF THE EXTERNAL GROUND BEAMS TO GIVE A 150mm AND 35mm VOID RESPECTIVELY. PILES ARE TO BE DESIGNED IN ACCORDANCE WITH THE PERFORMANCE PILING SPECIFICATION.

7.5 WHERE CONSTRUCTION JOINTS IN TRENCH FILL FOUNDATIONS ARE UNAVOIDABLE THEY SHOULD NOT BE POSITIONED NEAR A RETURN IN THE FOUNDATION. CONSTRUCTION JOINTS SHOULD BE FORMED USING 4 NO. 20mm DIAMETER AND 1200 LONG HIGH TENSILE DOW EL BARS CAST 600mm INTO ADJACENT SECTIONS.

7.6 THE CONTRACTOR IS TO ENSURE THAT THE BUILDING CONTROL OFFICER IS NOTIFIED FOR HIS INSPECTION OF THE BOTTOM OF ALL FOUNDATIONS PRIOR TO CONCRETING

8.0 INSITU CONCRETE

8.1 MATERIALS AND WORKMANSHIP ARE TO COMPLY WITH BS 8110.

8.2 CONCRETE FOR NEW FOUNDATIONS IS TO BE DESIGNATED MIX FND 2 TO BS 5328. "SUITABLE FOR CLASS 2 SULPHATE CONDITIONS"

8.3 CONCRETE FOR REINFORCED CONCRETE STRUCTURES, INCLUDING GROUND BEARING SLABS, IS TO BE DESIGNATED MIX RC35 TO BS 5328.

8.4 CONCRETE FOR THE ENCASEMENT OF STEEL BEAMS AND FOR PADSTONES IS TO BE GEN3 TO BS 5328 WITH 10mm MAXIMUM AGGREGATE AND 260 kg/m3 OF CEMENT

8.5 READY MIX CONCRETE IS TO BE USED UNLESS OTHERWISE ALLOWED BY THE STRUCTURAL ENGINEER. THIS MUST BE OBTAINED FROM A PLANT WHICH HOLDS A CURRENT CERTIFICATE OF ACCREDITATION UNDER THE QUALITY SCHEME FOR READY MIX CONCRETE. DETAILS OF CEMENT TYPE, AGGREGATE GRADING AND SOURCES, WITH CHLORIDE AND SULPHATE CONTENT OF MIXES TO BE SUBMITTED TO THE STRUCTURAL ENGINEER FOR HIS APPROVAL PRIOR TO ORDERING ANY CONCRETE.

8.6 THE USE OF SITE MIXED CONCRETE FOR STRUCTURAL ELEMENTS MAY ONLY BE USED FOLLOWING THE WRITTEN APPROVAL OF THE STRUCTURAL ENGINEER. BATCHING AND MIXING EQUIPMENT WILL NEED TO COMPLY WITH BS 1305 AND BS 4251.

8.7 THE CONTRACTOR IS RESPONSIBLE FOR THE DESIGN AND INSTALLATION OF ALL FORMWORK. DESIGN AND STRIKING OF THE FORMWORK IS TO BE IN ACCORDANCE WITH BS 8110.

8.8 DO NOT PLACE CONCRETE WHEN THE AMBIENT AIR TEMPERATURE IS LESS THAN 5°C.

8.9 ALL HOLES SHALL BE FORMED AND ALL INSERTS CAST IN AT THE TIME OF POURING CONCRETE. NO PART OF THE CONCRETE WORKS SHALL BE DRILLED OR CUT AWAY WITHOUT THE APPROVAL OF THE STRUCTURAL ENGINEER.

8.10 REINFORCEMENT SHALL BE:

(i) PLAIN BARS TO BS 4449, GRADE 250 (MILD STEEL), PREFIX R ON DRAWINGS AND SCHEDULE. OR

(ii) DEFORMED BARS TO BS 4449, OR BS 4461, GRADE 460 (HIGH YIELD) TYPE 2, PREFIX T ON DRAWINGS AND SCHEDULES. MESH TO BS 4483.

8.11 REINFORCEMENT SHALL BE FIXED ADEQUATELY USING TYING WIRE OR STEEL CLIPS. CONCRETE COVER IS TO BE AS SPECIFIED ON THE DRAWINGS. CHAIRS AND SPACERS ARE TO BE PROVIDED BY THE CONTRACTOR AS NECESSARY TO MAINTAIN THE SPECIFIED COVER.

8.12 UNLESS NOTED OTHERWISE ON DRAWINGS, ALL REINFORCEMENT IS TO BE LAPPED 50D (WHERE D IS DIAMETER OF THE SMALLER BAR).

8.13 THE RATE OF SAMPLING FOR COMPRESSIVE TESTING OF CONCRETE S TO BE AGREED WITH THE STRUCTURAL ENGINEER PRIOR TO COMMENCEMENT OF ANY CONCRETE WORKS

8.14 USE MECHANICAL VIBRATION TO FULLY COMPACT CONCRETE FOR STRUCTURAL ELEMENTS. COMPACT CONCRETE TO FULL DEPTH (UNTIL AIR BUBBLES CEASE TO APPEAR ON THE TOP SURFACE), ESPECIALLY AROUND REINFORCEMENT, CAST-IN ACCESSORIES, INTO CORNERS OF FORMWORK AND AT JOINTS.

8.15 BEFORE PLACING STRUCTURAL CONCRETE (NOT BLINDING) ON HARDCORE OR OTHER ABSORBENT SUBSTRATES LAY BUILDING PAPER TO BS 1521 CLASS 3 OR POLYTHENE SHEET 250 MICRONS THICK. LAP EDGES 150MM. THIS IS NOT A DPM -SEE ARCHITECT'S DETAILS FOR THIS.

8.16 STRIKE FORMWORK WITHOUT DISTURBING, DAMAGING OR OVERLOADING STRUCTURE, AND WITHOUT DISTURBING PROPS. NOTWITHSTANDING OTHER CLAUSES IN THIS SPECIFICATION AND ANY CHECKING OR APPROVALS BY THE CA, THE RESPONSIBILITY FOR SAFE REMOVAL OF ANY PART OF THE FORMWORK AND ANY SUPPORTS WITHOUT DAMAGING THE STRUCTURE RESTS WITH THE CONTRACTOR.

8.17 MINIMUM PERIODS:

THE FOLLOWING PERIODS (IN DAYS) FOR RETAINING FORMWORK IN POSITION BEFORE STRIKING APPLY TO CLASS 42.5 OR SULFATE-RESISTING PORTLAND CEMENT CONCRETE WITH NO CEMENT REPLACEMENT MATERIALS OR ADMIXTURES:

SUBMIT DETAILS OF PROPOSED PERIODS FOR MIXES USING ADMIXTURES OR OTHER TYPES OF CEMENT.

MINIMUM PERIODS: ALTERNATIVE METHODS OF DETERMINING MINIMUM PERIODS FOR RETAINING FORMWORK IN POSITION MAY BE SUBMITTED FOR APPROVAL. ACCEPT RESPONSIBILITY FOR COST OF CHECKING OF PROPOSALS BY CA AND FOR ANY TESTING.

8.18 FORMED FINISHES

BASIC FINISH: NO PARTICULAR REQUIREMENTS, EXCEPT THOSE FOR TOLERANCES AND FULL COMPACTION. FINISH TO RECEIVE ASPHALT TANKING: PRODUCE AN EVEN FINISH WITH A SHEET MATERIAL (E.G. PLYWOOD), SUITABLE TO RECEIVE ASPHALT, AND ACCEPTABLE TO ASPHALT CONTRACTOR. AVOID EXCESSIVE USE OF RELEASE AGENTS. ABRUPT IRREGULARITIES TO BE NOT GREATER THAN 3mm. GRADUAL IRREGULARITIES, EXPRESSED AS A MAXIMUM PERMISSIBLE DEVIATION FROM A 1mm STRAIGHT EDGE, TO BE NOT GREATER THAN 3mm. BLOWHOLES LESS THAN 10mm IN DIAMETER WILL BE PERMITTED BUT OTHERWISE SURFACE TO BE FREE FROM VOIDS, HONEYCOMBING, SEGREGATION AND OTHER LARGE DEFECTS.

8.19 TOLERANCES

UNLESS SHOWN OTHERWISE ON THE DRAWINGS, THE MAXIMUM PERMITTED DEVIATIONS OF DIMENSIONS AND LEVELS IN THE COMPLETED STRUCTURE FROM THOSE SHOWN ON, OR CALCULABLE FROM, THE DRAWINGS ARE SET OUT BELOW.

THE FIGURES GIVEN INCLUDE, BUT ARE NOT LIMITED TO, SUCH VARIABLES AS:

a) POSITION ON PLAN OF ANY POINT OF THE STRUCTURE FROM NEAREST GRID LINE.

b) VERTICALLY.

c) CROSS SECTION AND OTHER LINEAR DIMENSION OF MEMBER.

d) CLEAR HORIZONTAL AND VERTICAL DIMENSIONS BETWEEN MEMBERS.

e) BOW AND CAMBER OTHER THAN SPECIFIED CAMBER

f) TWIST (THE DISTANCE OF ANY CORNER FROM A PLANE CONTAINING THE OTHER THREE CORNERS).

g) SQUARENESS OF CORNERS (THE LONGER OF TWO ADJACENT SIDES SHALL BE TAKEN AS THE BASE LINE). DEVIATION IS

h) RELATED TO THE LENGTH OF THE SHORTER SIDE.

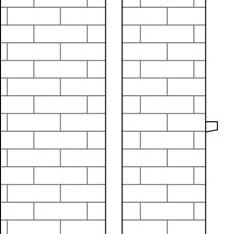

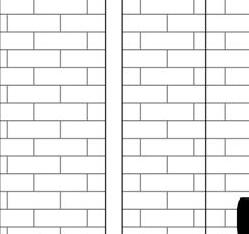

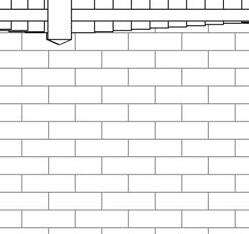

9.0 MASONRY

9.1 WORKMANSHIP IS TO COMPLY GENERALLY WITH BS 5628 PARTS 1 & 3 BRICKWORK TO BE BS 3921. BLOCKWORK TO BE TO BS 6073.

9.2 NEW BRICKWORK ABOVE DPC IS TO BE A MINIMUM OF CLASS 3 CLAY BRICKS (20 N/mm2) SET IN 1:1:6 MORTAR UNLESS NOTED OTHERWISE ON THE DRAWINGS.

9.3 NEW BLOCKWORK ABOVE DPC IS TO BE OF MINIMUM STRENGTH OF 10.4N/mm2 SET IN 1:1:6 MORTAR, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

9.4 BRICKWORK AND BLOCKWORK ARE TO BE LAID PROPERLY BONDED AS AGREED WITH THE ARCHITECT AND FULLY BONDED INTO EXISTING WORK OR AS SPECIFIED OTHERWISE ON THE DRAWINGS. ALL PERPENDS MUST BE FULLY FILLED WITH MORTAR.

9.5 NEW FACING BRICKWORK BELOW DPC IS TO BE MINIMUM FL DURABILITY BRICKS SET IN 1:3 MORTAR WITH SRPC, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

9.6 ALL OTHER MASONRY BELOW DPC IS TO BE CLASS B ENGINEERING BRICKS, SET IN 1:3 MORTAR WITH SRPC OR AS NOTED OTHERWISE ON THE DRAWINGS.

9.7 DO NOT LAY MASONRY WHEN THE AMBIENT AIR TEMPERATURE IS LESS THAN 5°C.

9.8 CAVITY WALL TIES SHALL BE STAINLESS STEEL DOUBLE TRIANGLE TYPE TIES TO BS 1243, FOR CAVITIES OF 75mm OR LESS, SPACED AT 450mm c/c VERTICALLY, 900CRS HORIZONTALLY STAGGERED, AND AT 225mm c/c VERTICALLY 150mm FROM ALL OPENINGS, CORNERS, MOVEMENT JOINTS AND REVEALS. MINIMUM EMBEDMENT TO BE 50mm INTO EACH MASONRY LEAF. CAVITIES OF GREATER THAN 75MM WIDTH TO HAVE STAINLESS STEEL VERTICAL TWIST TIES AT SIMILAR CENTRES.

9.9 MOVEMENT JOINTS IN FACING BRICKWORK ARE TO BE FORMED BY BUILDING IN 'AEROFIL' JOINT FILLER BY SERVICISED LTD, AS THE WORKS PROCEED ENSURING NO PROJECTIONS INTO CAVITIES. IN JOINTS TO BE POINTED WITH SEALANT, POSITION FILLER ACCURATELY AT THE RECOMMENDED DISTANCE FROM THE FACE OF WALL. LEAVE JOINTS OPEN FOR AS LONG AS POSSIBLE BEFORE SEALING WITH APPROPRIATE SEALANT TO ARCHITECTS' SPECIFICATION.

9.10 WHERE PINNING UP TO SOFFITS IS REQUIRED, COMPLETELY FILL THE JOINT AT THE TOP OF LOADBEARING WALLS WITH 1:3 CEMENT/SHARP SAND DRY PACK MORTAR, W ELL RAMMED INTO POSITION USING TEMPORARY SHUTTERING.

9.11 CARRY UP WORK WITH NO PORTION OR SECTION OF WALL MORE THAN 1.2m ABOVE ANOTHER AT ANY TIME, RAKING BACK BETWEEN LEVELS. DO NOT CARRY UP WORK HIGHER THAN 1.5m IN ONE DAY.

9.12 SPACING OF MOVEMENT JOINTS IN BRICKWORK AND BLOCKWORK ARE NOT TO EXCEED 12.0m AND

6.0M, RESPECTIVELY.

9.13 PROVIDE STAINLESS STEEL BED JOINT REINFORCEMENT, "BRICKTOR" BY BRC, AT 225mm AND 450mm VERTICAL CENTRES ABOVE EXTERNAL DOORS & ALSO ABOVE AND BELOW WINDOWS. BED JOINT REINFORCEMENT TO EXTENT 500mm MINIMUM PAST DOOR WINDOW LINE.

10.0 STRUCTURAL TIMBER

10.1 NEW TIMBER IN THE WORKS IS TO BE SELECTED STRUCTURAL TIMBER NOT INFERIOR TO EUROPEAN REDWOOD/WHITEWOOD GRADE SC3 TO BS 5268: PART 2, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

10.2 NEW TIMBER IN THE WORKS IS TO BE VACUUM IMPREGNATED WITH PRESERVATIVE TO BS 5268: PART 5 AND THE MANUFACTURER'S RECOMMENDATIONS. CUT ENDS ARE TO BE THOROUGHLY TREATED WITH BRUSH APPLIED COATS OF APPROPRIATE PRESERVATIVE BEFORE FIXING. ALL PRESERVATIVES ARE TO BE TO THE ARCHITECT'S APPROVAL.

10.3 STRUCTURAL TIMBERS MAY ONLY BE DRILLED OR CUT FOR SERVICES AS NOTED BELOW. NOTCHES IN THE JOISTS ARE TO BE AT THE TOP AND LOCATED BETWEEN 0.1 AND 0.25 OF THE SPAN FROM THE SUPPORT. NOTCH CANNOT BE DEEPER THAN 0.125 OF THE JOIST DEPTH. HOLES IN THE JOISTS ARE TO BE ALONG THE CENTRE WITH MAXIMUM DIAMETER OF 0.125 OF THE JOIST DEPTH.

10.4 SIZES OF NEW STRUCTURAL TIMBERS NOTED ON THE DRAWINGS ARE SAWN BASIC SIZES.

10.5 ALL SCREWS, NAILS, TIMBER CONNECTORS, JOIST HANGERS, STEEL STRAPS ETC., ARE TO BE GALVANISED. JOIST HANGERS, STRAPS, CONNECTORS ETC., SHALL BE PURPOSE MADE AND OF MANUFACTURE OR PERFORMANCE STATED ON THE DRAWINGS. ALL SUCH ITEMS ARE TO BE FIXED IN ACCORDANCE WITH THE MANUFACTURER'S RECOMMENDATIONS, UNLESS SHOW N OTHERWISE ON THE DRAWINGS.

10.6 ALL EXISTING TIMBERS ARE TO BE INSPECTED AT THE BEGINNING OF THE WORKS BY A SPECIALIST SUB-CONTRACTOR FOR ROT AND INFESTATION. DETAILS OF REPLACING OR STRENGTHENING ANY DEFECTIVE TIMBERS RECOMMENDED BY THE SPECIALIST ARE TO BE AGREED ON SITE.

10.7 TRIMMERS TO OPENINGS IN FLOORS AND CEILING CONSTRUCTION SHALL BE JOINTED TO THE TRIMMING JOISTS WITH JOIST HANGERS UNLESS NOTED OTHERWISE ON THE DRAWINGS.

10.8 DOUBLE UP JOISTS UNDER NEW PARTITIONS RUNNING PARALLEL TO THE JOIST SPAN. DOUBLED JOISTS ARE TO BE BOLTED TOGETHER AT 600mm c/c USING M12 BOLTS AND OVERSIZE WASHERS, UNLESS NOTED OTHERWISE ON THE DRAWINGS. PROVIDE SOLID NOGGINS UNDER NEW PARTITIONS RUNNING PERPENDICULAR TO THE JOIST SPAN.

10.9 IN ALL NEW TIMBER FLOORS FULL DEPTH NOGGINS 50mm WIDE ARE TO BE PROVIDED ALONG LINES OF SUPPORT AND AT MID SPAN FOR SPANS EXCEEDING OVER 2500mm AND AT 1/3 AND 2/3 SPAN POSITIONS FOR SPANS EXCEEDING 4500mm, UNLESS NOTED OTHERWISE ON THE DRAWINGS. IN EXISTING FLOORS NEW NOGGINS ARE TO BE PROVIDED AS SHOWN ON THE DRAWINGS.

11.0 STEELWORK

11.1 ALL WORKMANSHIP IS TO COMPLY WITH BS 5950: PART 2 AND THE STRUCTURAL STEELWORK SPECIFICATION BY BRITISH STEEL.

11.2 ALL STRUCTURAL STEEL SECTIONS ARE TO BE GRADE S275 JR TO BS 5950, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

11.3 ERECTING STEELWORK: SET OUT AND ERECT TO BS 5950 : PART 2. PROVIDE ALL TEMPORARY ERECTION BRACING NECESSARY TO ENSURE STABILITY OF THE BUILDING DURING ERECTION. REMOVE WHEN IT IS SAFE TO DO SO, TIMING TO BE AGREED WITH THE MAIN CONTRACTOR. DO NOT DISTORT STEELWORK AND DO NOT EXCEED STRESS LIMITS DURING ERECTION UNLESS OTHERWISE APPROVED.

11.4 ALL BOLTS ARE TO BE GRADE 8.8 PRECISION BOLTS TO BS 3692. BOLTS TO HAVE A CLASS 1 SHERARDISED FINISH TO BS 4921.

11.5 ALL WELDING IS TO COMPLY WITH BS 5135. SITE WELDING SHALL NOT BE PERMITTED EXCEPT WITH THE WRITTEN APPROVAL OF THE STRUCTURAL ENGINEER.

11.6 ALL WELDS ARE TO BE 6MM FILLET WELDS OR FULL STRENGTH BUTT WELDS, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

11.7 THE STEEL FABRICATOR IS TO OBTAIN DIMENSIONS FROM SITE. SETTING OUT DIMENSIONS ARE TO BE OBTAINED FROM THE ARCHITECT'S DRAWINGS.

11.8 ALL STEELWORK IS TO BE THOROUGHLY POWER BRUSHED CLEAN DOWN TO BRIGHT STEEL IN ORDER TO REMOVE ALL MILL SCALE, RUST, OIL, GREASE ETC., AND PAINTED WITH TWO COATS ALKYD BASED HIGH BUILD ZINC PHOSPHATE BEFORE ERECTION, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

ENDS OF BEAMS WHICH ARE BUILT INTO THE INNER LEAF OF A CAVITY W ALL OR INTO SOLID BRICK WALLS ARE TO BE PAINTED WITH AN ADDITIONAL COAT ON SITE OF HB BITUMEN PAINT TO DRY FILM THICKNESS OF 175 MICRONS .

CONTRACTOR TO ENSURE THAT ALL COATING MATERIALS TO BE USED ARE RECOMMENDED BY THEIR MANUFACTURERS FOR THE PARTICULAR SURFACE AND CONDITIONS OF EXPOSURE, AND THAT THEY ARE COMPATIBLE WITH EACH OTHER.

11.9 FIRE PROTECTION TO ALL STEELWORK IS TO BE TO THE ARCHITECT'S DETAILS.

11.10 STEELWORK THAT IS TO BE CONCRETE ENCASED IS TO BE CLEANED AS NOTED ABOVE AND LEFT UNPAINTED. WRAP STEELWORK WITH D98 MESH PRIOR TO CONCRETING. PROVIDE A MINIMUM 50MM OF CONCRETE TO THE STEEL BEAM, WITH THE MESH PLACED CENTRALLY W ITHIN THE CONCRETE. SEE CONCRETE SPECIFICATION FOR MIX REQUIREMENTS.

11.11 ALL STEELWORK THAT IS BURIED IN THE GROUND TO HAVE A MINIMUM OF 100 MM CONCRETE ENCASEMENT AND MESH AS NOTED ABOVE. REFER TO CONCRETE SPECIFICATION FOR FOUNDATION CONCRETE MIX REQUIREMENTS.

11.12 ENSURE THAT INSIDES OF HOLLOW SECTIONS ARE DRY AND CLEAR OF DEBRIS, BEFORE SEALING ENDS AND OPENINGS.

11.13 THE FINISH OF ANY STEELWORK THAT IS TO REMAIN VISIBLE OR IS OF AN ARCHITECTURAL NATURE MUST BE AGREED WITH THE ARCHITECT PRIOR TO MANUFACTURE. ALL WELDS IN AREAS NOTED ABOVE ARE TO BE GROUND SMOOTH.

11.14 ALL FABRICATION DRAWINGS TO BE SUBMITTED TO ENGINEER, ALLOWING 10 WORKING DAYS FOR CONSIDERATION.

11.15 EXTERNAL STEELWORK IS TO GALVANIZED IN ACCORDANCE WITH ITEM 11.18 BELOW.

11.16 ALL STEELWORK IN CAVITIES TO BE BLASTED CLEAN TO SA2.5 OF BS7079:PART A1:1989 AND FINISHED WITH 125 MICRONS OF 'LEIGH'S PAINTS' 'EPIGRIP M555 SHEEN PROTECTIVE FINISH' EPOXY ZINC PHOSPHATE.

11.17 TOLERANCES:

THE TOLERANCES FOR THE ERECTED STEELWORK AT ANY LEVEL ARE RELATED TO THE MAJOR GRID LINES AND DATUM PROVIDED BY THE CONSTRUCTION MANAGER AT THAT LEVEL. THE TOLERANCES FOR THE ERECTED STEELWORK SHALL BE AS FOLLOWS:

POSITION OF CENTRE LINE OF COLUMN AND COLUMN BASE ± 3mm

LINEAR DIMENSIONS UP TO 9m± 6mm

LINEAR DIMENSIONS UP TO 18m ± 10mm

PLUM OF COLUMN CENTRE LINE WHICH IS WITHIN THE POSITIONAL TOLERANCE: -IN ANY STOREY HEIGHT -IN ANY TWO STOREY HEIGHT -OVERALL HEIGHT

± 6mm ± 8mm ± 10mm

LEVEL OF BASE OF FIRST ERECTED COLUMN± 5mm

LEVEL OF BEAM AT JUNCTION WITH COLUMN MEASURED FROM THE TRANSFERRED BENCH MARK

LEVELS OF UPPER OR LOWER SURFACES OF TWO OR MORE BEAMS MEETING AT A COLUMN

DIFFERENCE IN LEVEL OF ENDS OF A BEAM OR TRUSS TOLERANCES ARE:

12. LINTELS

12.1 PRECAST CONCRETE LINTELS ARE TO BE BS 5977: PART 2 BY TARMAC 'TOPFLOOR', TELEPHONE 01335 360601. SIZES AND TYPES ARE AS INDICATED ON THE DRAWINGS. END BEARING LENGTHS ARE TO BE AT LEAST 150MM ON NEW MASONRY AND 225MM ON EXISTING MASONRY, UNLESS NOTED OTHERWISE ON THE DRAWINGS.

12.2 GALVANISED STEEL LINTELS ARE TO BE BS 5977: PART 2 BY CATNIC COMPONENTS LTD, PONTYWINDY ESTATE, CAERPHILLY, MID GLAMORGAN, CF8 2WJ, TELEPHONE 0222-885-955. SIZES AND TYPES ARE AS INDICATED ON DRAWINGS. END BEARING LENGTHS ARE TO BE AT LEAST 150MM ON NEW MASONRY AND 225MM ON EXISTING MASONRY, UNLESS NOTED OTHERWISE ON THE DRAWINGS. 12.3 THE CONTRACTOR SHALL OBTAIN THE STRUCTURAL ENGINEER'S OR ARCHITECT'S WRITTEN CONSENT, PRIOR TO COMMENCEMENT OF THE WORK, TO THE USE OF LINTELS BY ALTERNATIVE MANUFACTURERS TO THOSE LISTED ABOVE.

± 8mm

± 3mm

-UP TO 9m -UP TO 18m ± 5mm ± 10mm

THE CONTRACTOR SHALL NOTE THE TOLERANCES OF THE SETTING-OUT GRID AND DATUMS IN ARRIVING AT ANY ABSOLUTE VALUES OF HEIGHT OR DISTANCE BETWEEN STEELWORK COMPONENTS.

11.18 GALVANIZING PLUS DECORATIVE COATING ALL EXPOSED STEELWORK IS TO BE GALVANISED. UNLESS NOTED OTHERWISE ON DRAWINGS. EXPECTED PERIOD TO FIRST MAINTENANCE: GREATER THAN 18 YEARS IN POLLUTED INLAND ENVIRONMENT.

PREPARATION: BLAST CLEANING TO BS 7079:PART A1, PREPARATION GRADE SA2 (FOR ROUGHNESS) USING CHILLED IRON GRIT GRADE G24, FOLLOWED BY ACID PICKLING.

GALVANISING: TO BS729, MINIMUM AVERAGE COATING THICKNESS 85 MICRONS.

PREPARATION FOR PAINTING: THOROUGHLY DEGREASE (USING AN EMULSIFYING AGENT), LIGHTLY ABRADE (BY HAND USING WIRE-WOOL OR BY LIGHTLY BLASTING WITH A FINE GRADE NON-METALLIC ABRASIVE) FOLLOWED BY RINSING WITH FRESH CLEAN WATER.

RESIDUE OF GREASE AND/OR INSUFFICIENT ABRASION: REPEAT PREPARATION LOCALLY AND RE-APPLY MORDANT WASH.

SHOP PRIMER: APPLY ONE COAT EPOXY MI0 (E.G. W & J LEIGHS EPIGRIP K267). DRY FILM THICKNESS: 50 MICRONS.

DECORATIVE TOP COATS: APPLY TWO COATS ACRYLIC URETHANE SHEEN (E.G. W & J LEIGH'S RESISTEX M237). DRY FILM THICKNESS: 40 MICRONS EACH COAT.

COLOUR: AS SPECIFIED BY ARCHITECT.

FINISH: IF GLOSS FINISH IS REQUIRED THEN THE SECOND TOP COAT SHOULD BE REPLACED WITH AN ACRYLIC URETHANE ENAMEL. (E.G W E J LEIGH'S RESISTEX M437)