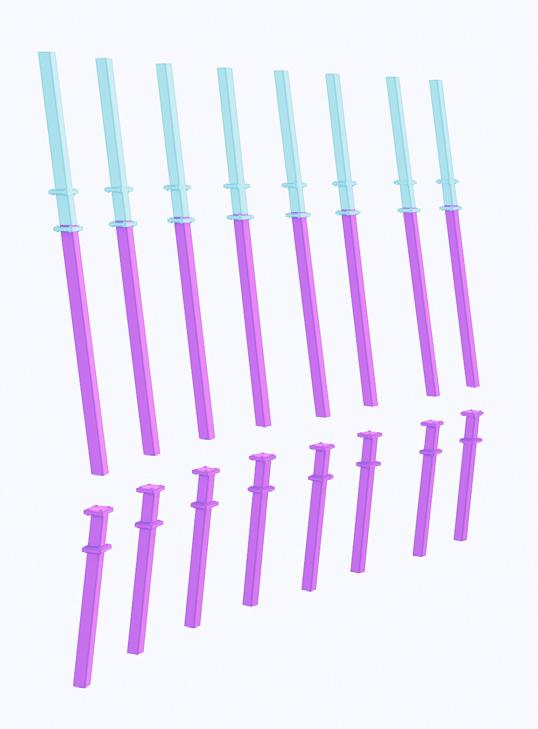

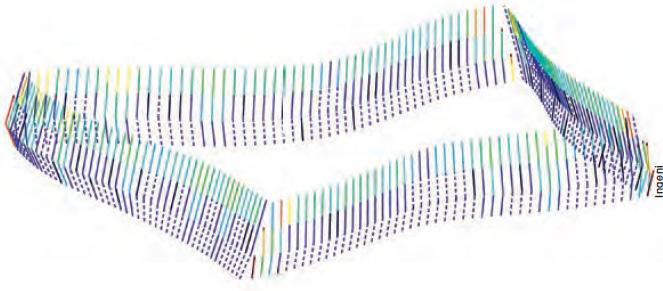

To accurately fit the facade onto the building, the outer perimeters of the entire structural shell were mapped using a 3D laser scanner, allowing the contractor to manage the coordination of complex geometry. This however would have involved higher costs, reliance on computational workflows. Therefore maximising the use of prefabricated elements was necessary.

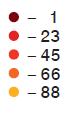

The perimeter columns’ axial forces distribute the vertical loads the vertical loads from the slabs above These columns were essential to the the design rationale, enabling the building to support both static and active forces, thereby ensuring structural soundness and aesthetic design intent.

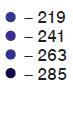

of Perimeter Columns (kN)

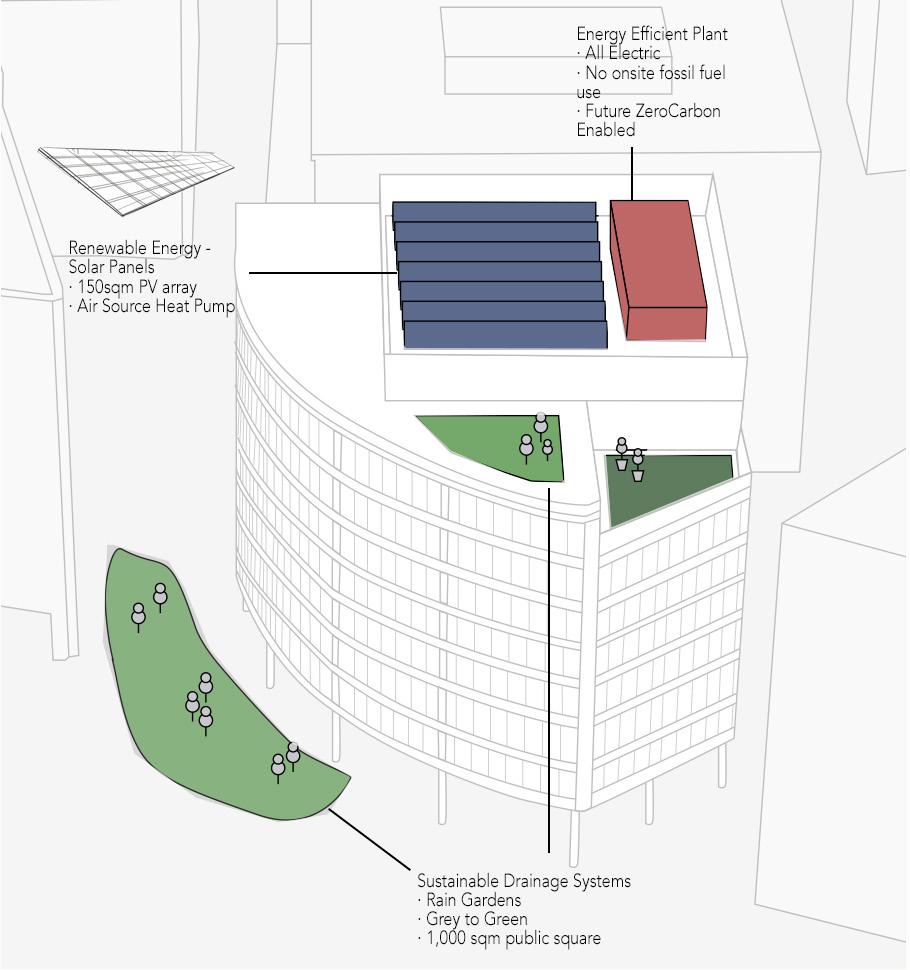

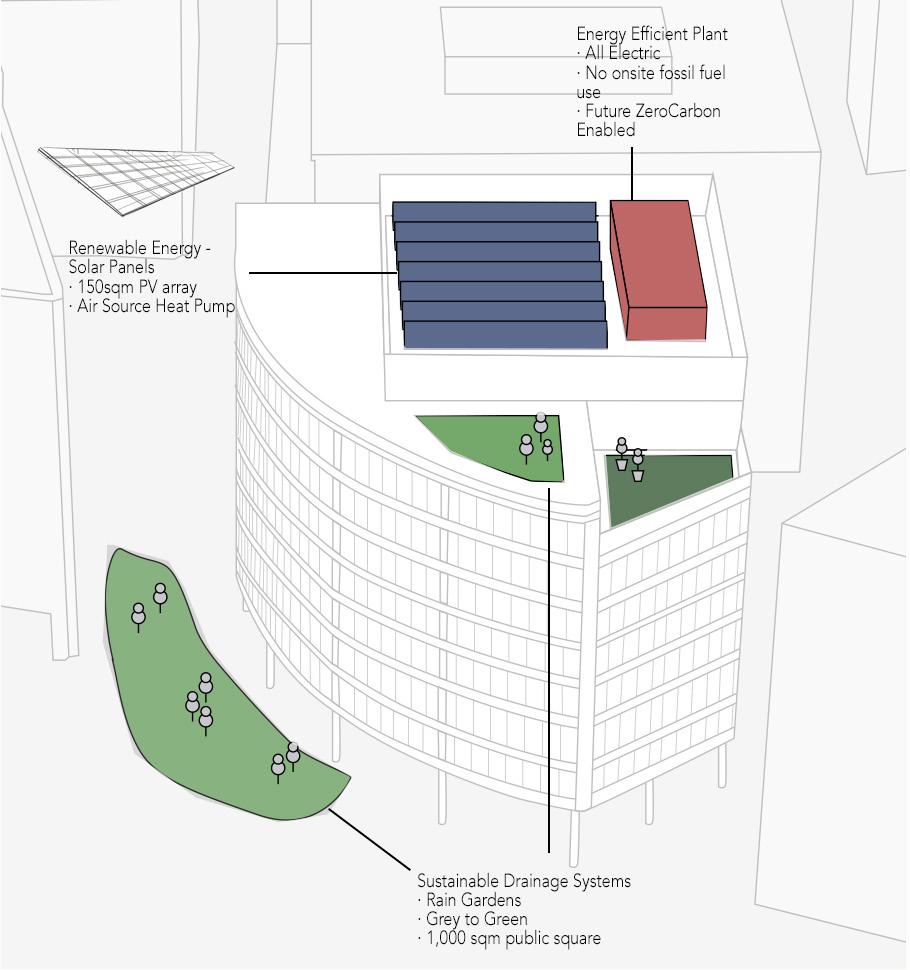

Environmental

Material

building has received the highest - Platinum LEED Certification, SNBS Platinum and Minergie P Certification for its outstanding sustainability performance. However, due to the facade’s complex geometry, a high number of individual pieces of formwork was required, which requires a higher level of embodied

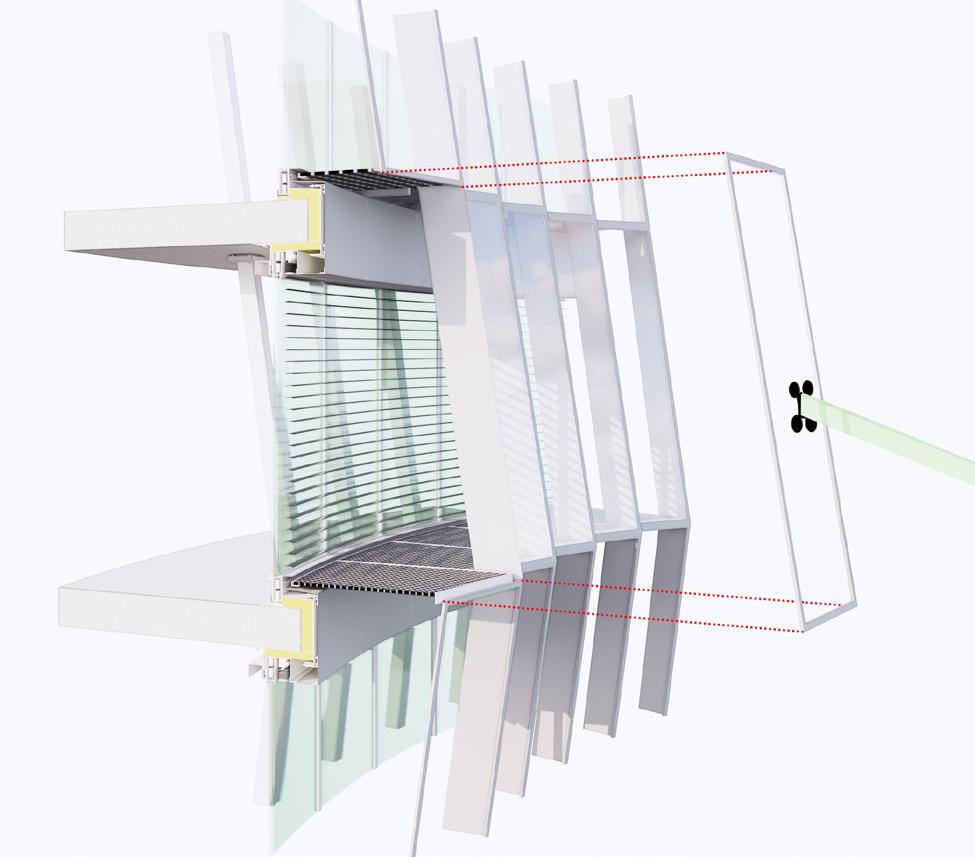

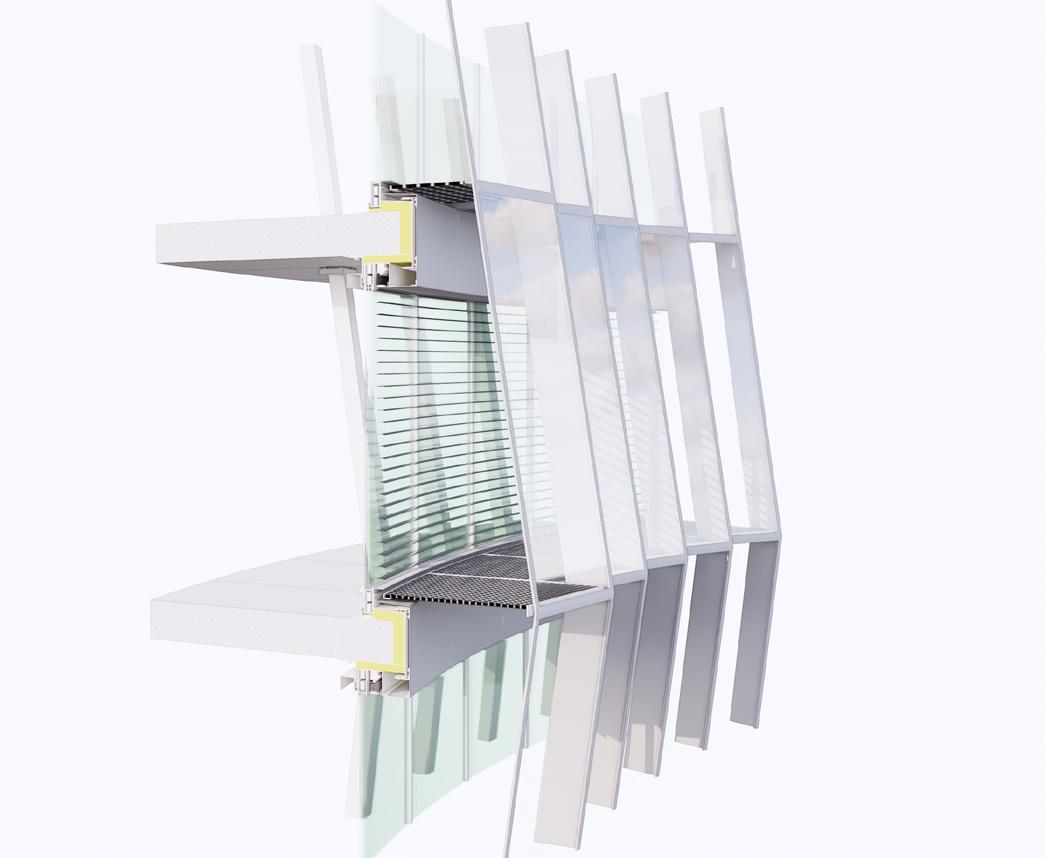

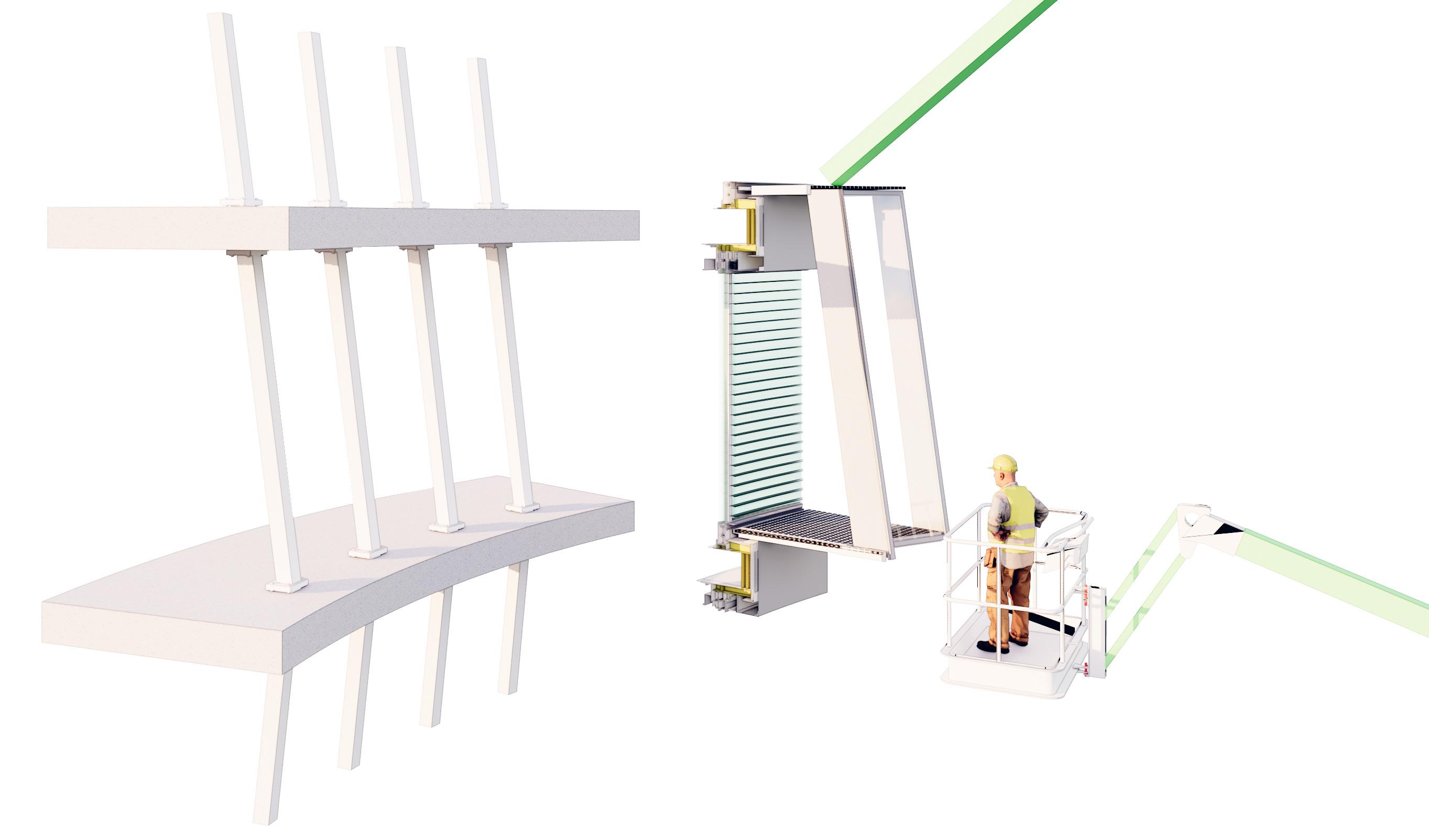

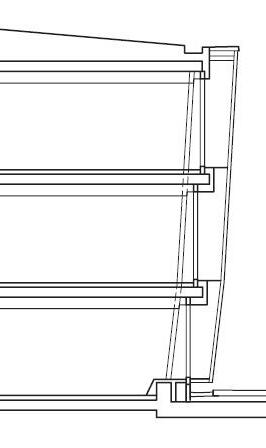

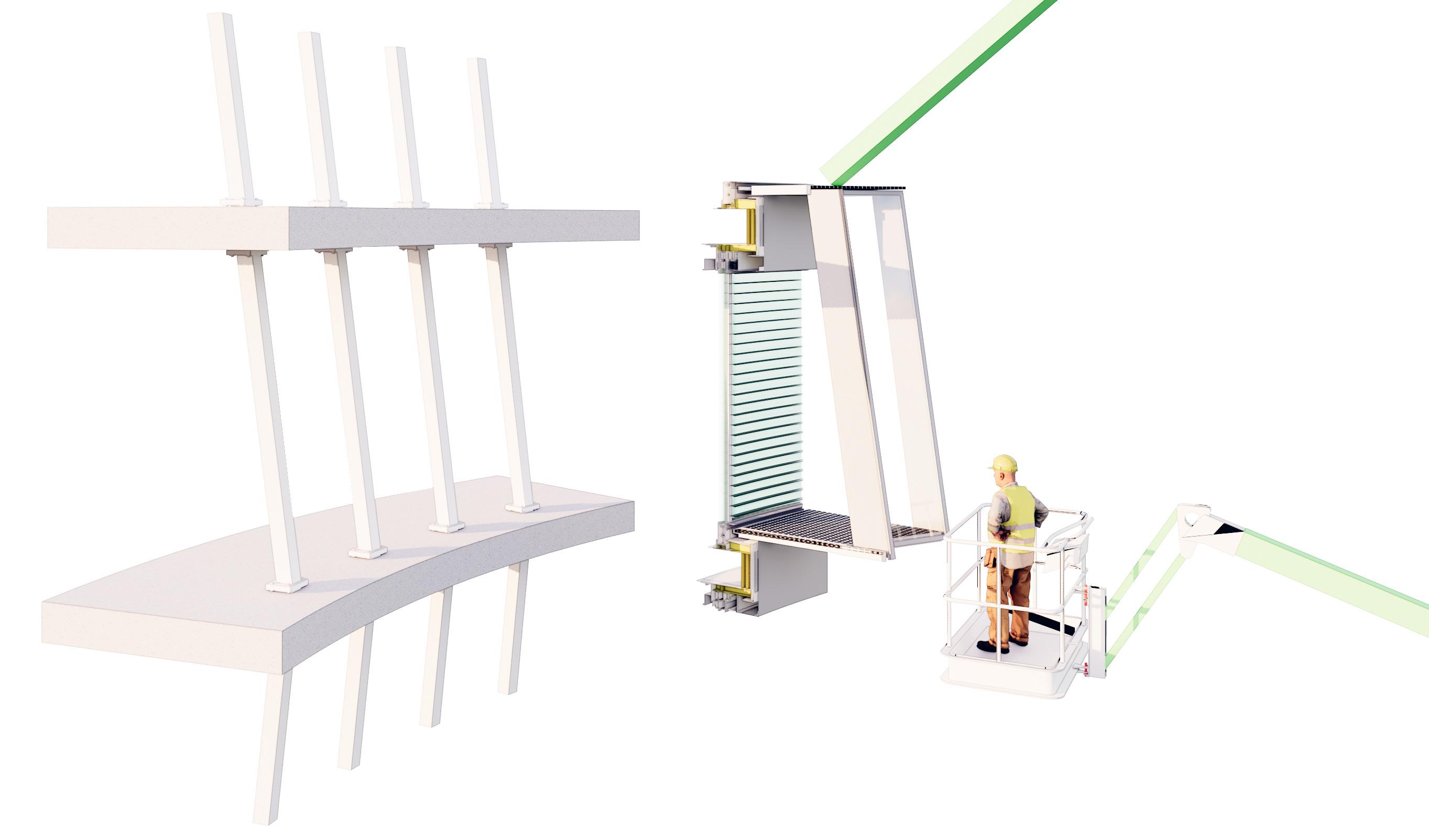

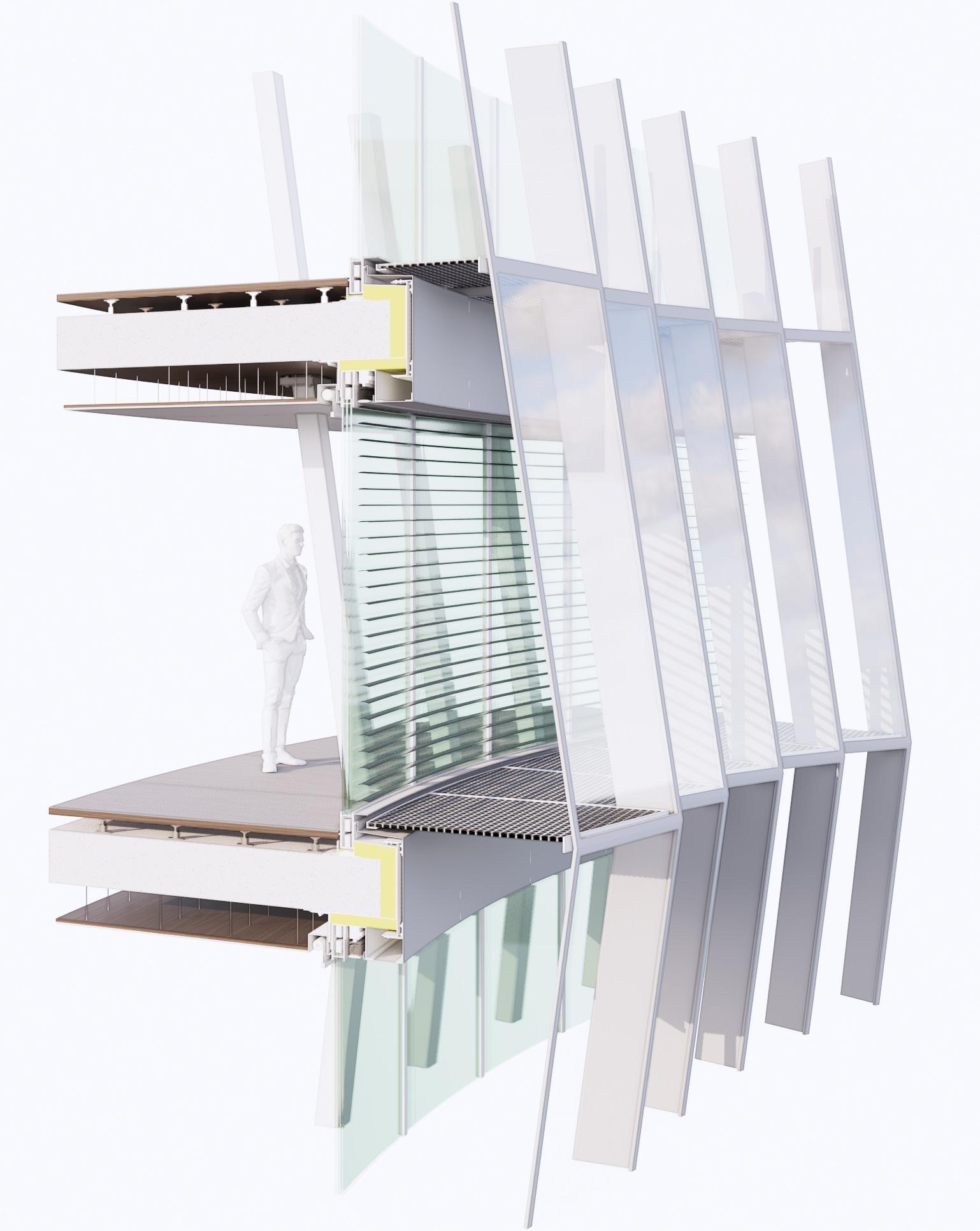

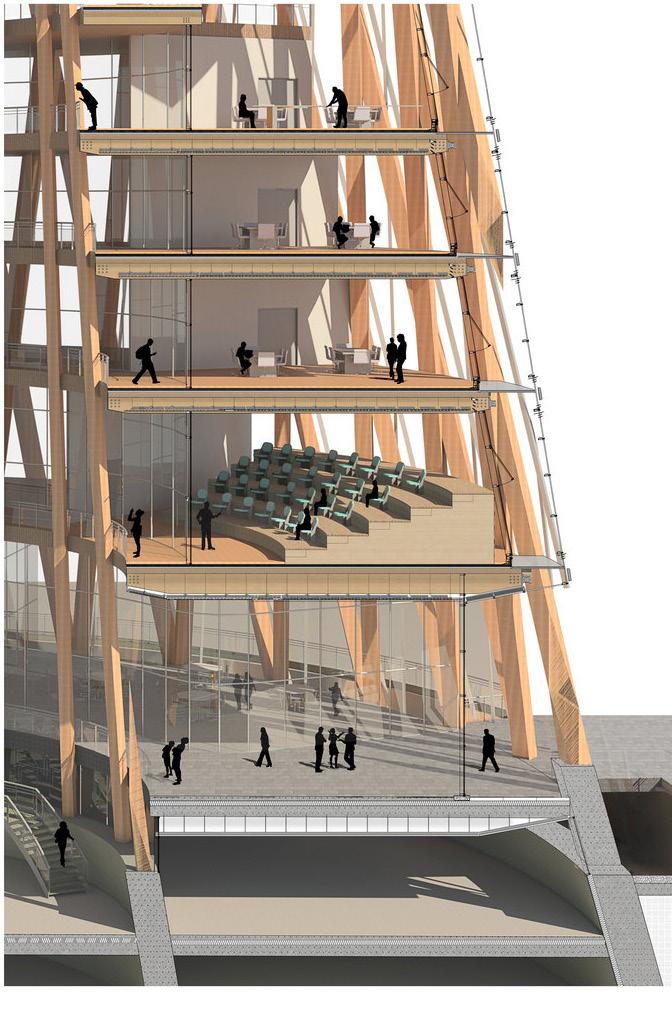

Upper floors, including the first, use columns to transfer vertical loads, with inclination on higher levels preventing eccentric load transmission. The aluminium frames with safety glass panels are mounted onto the interconnected vertical fins using a glass vacuum lifter. Then the additional secondary steel frame for the outer layer of the double skin facade is installed on site.

CPU Atelier - Olympic House IOC Headquarters by 3XN, Lausanne, Switzerland Denizhan Peker (21437597) Construction Process

BA3 Technologies Part A: Fragment Case Study -

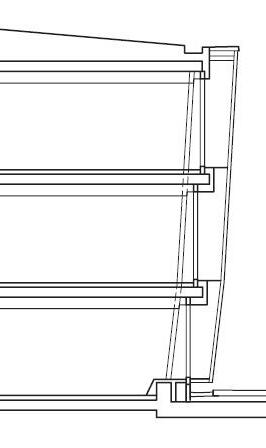

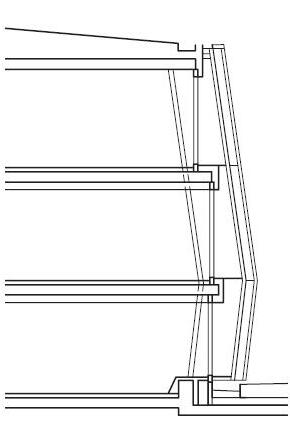

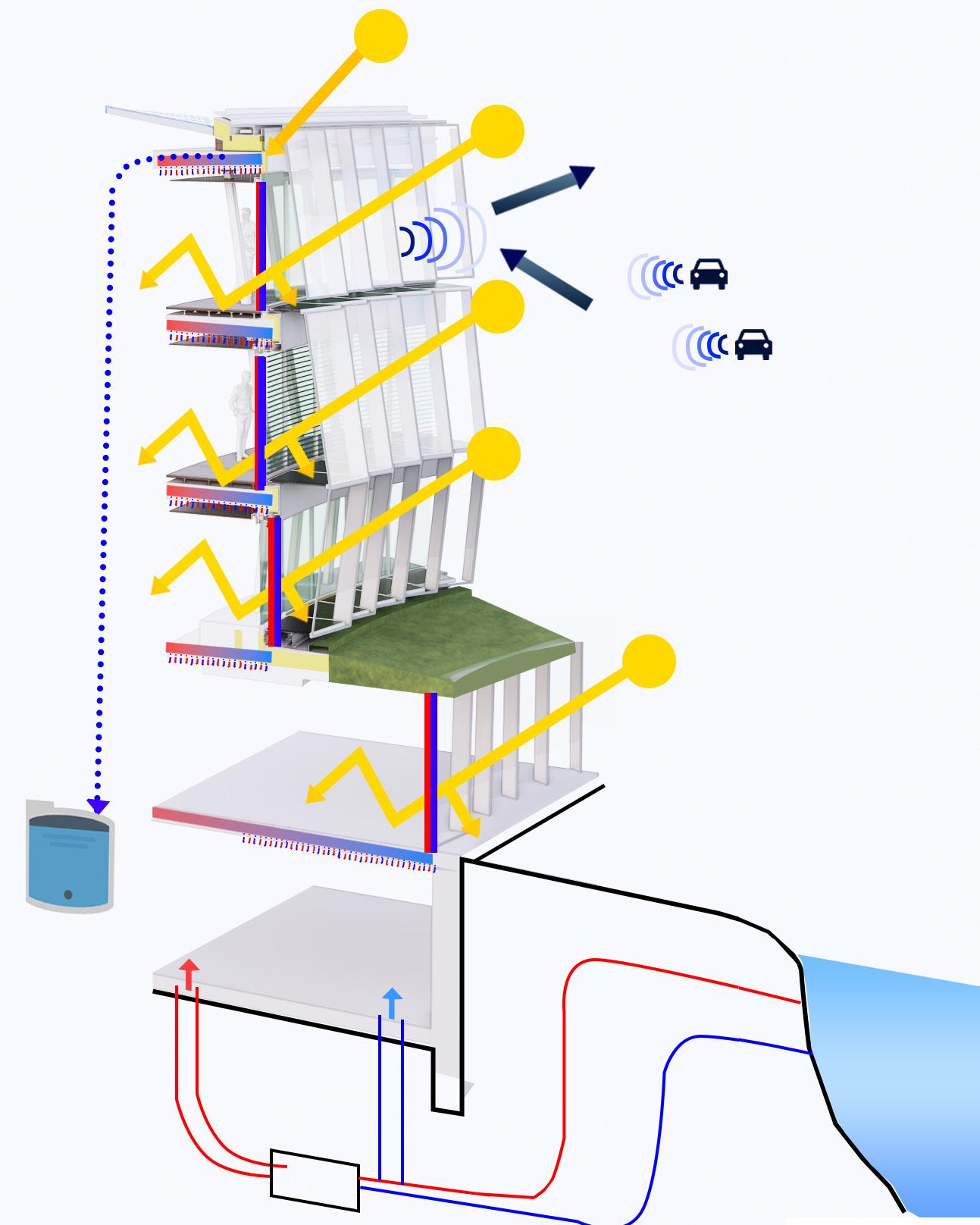

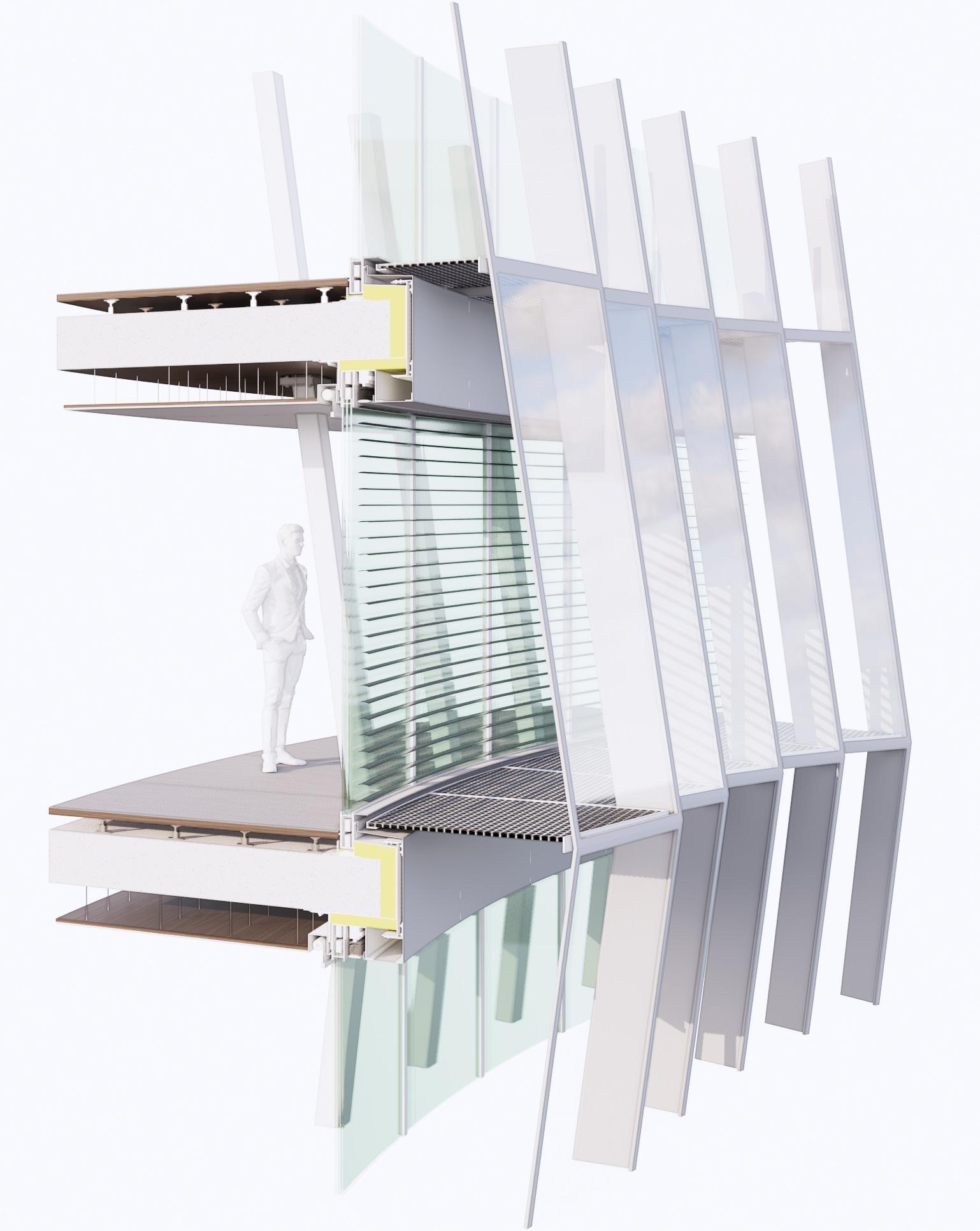

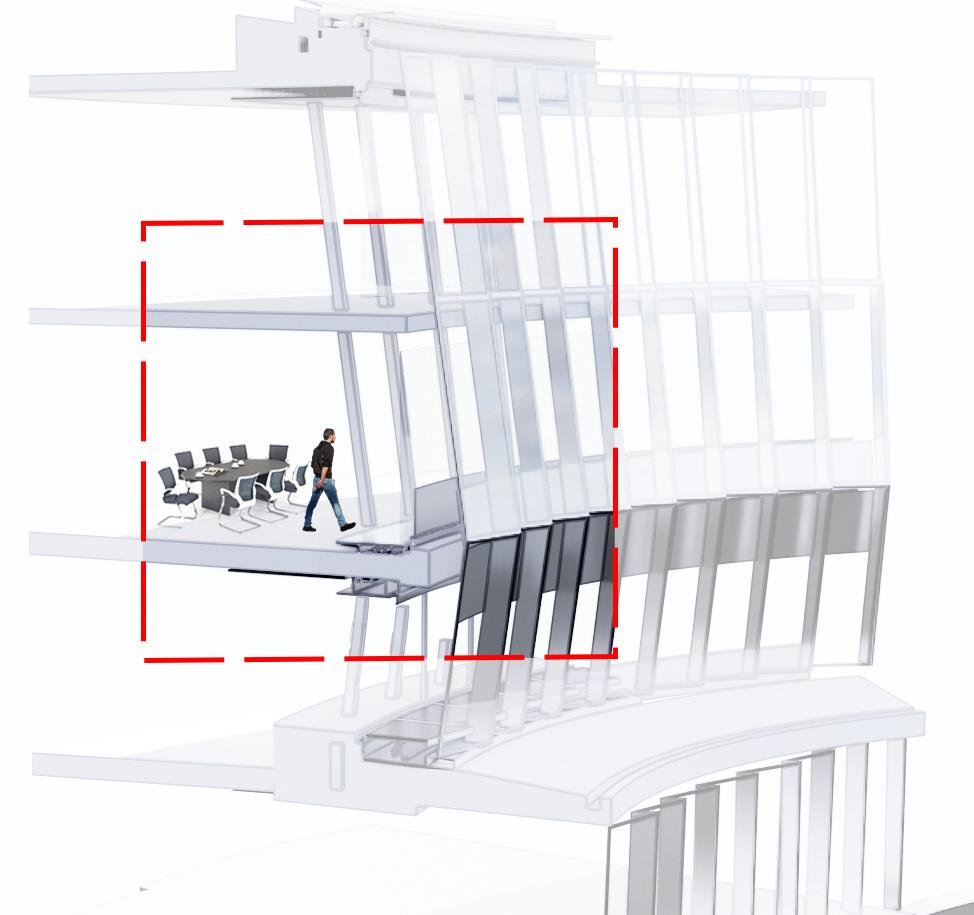

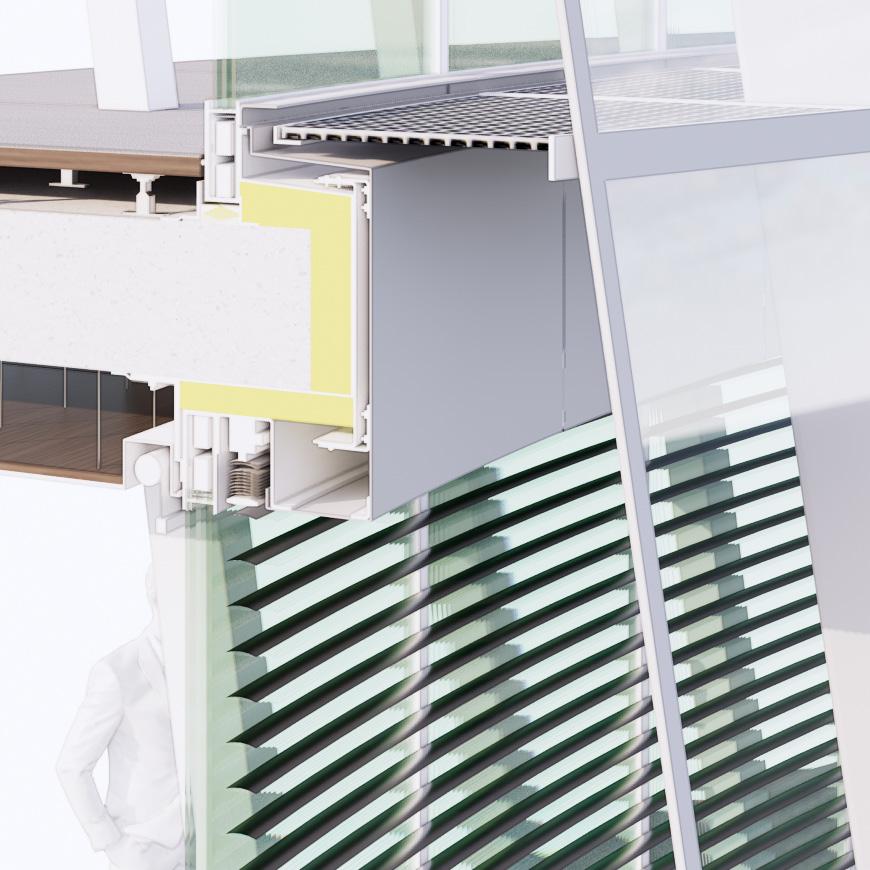

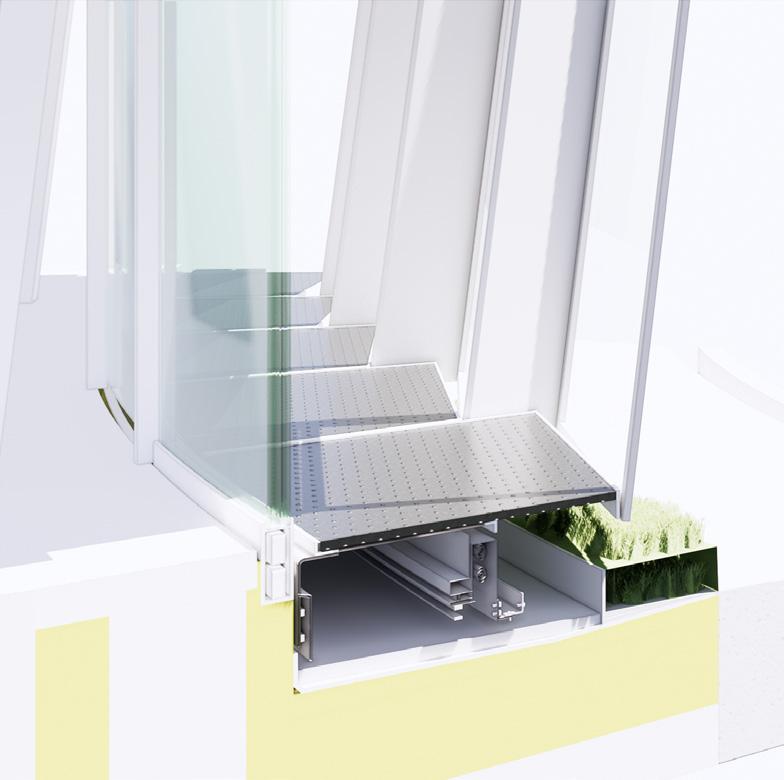

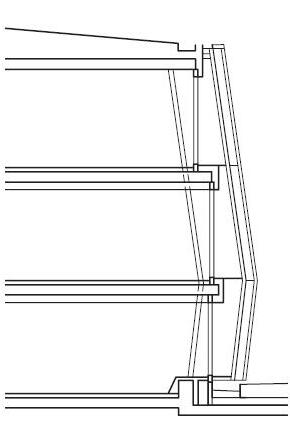

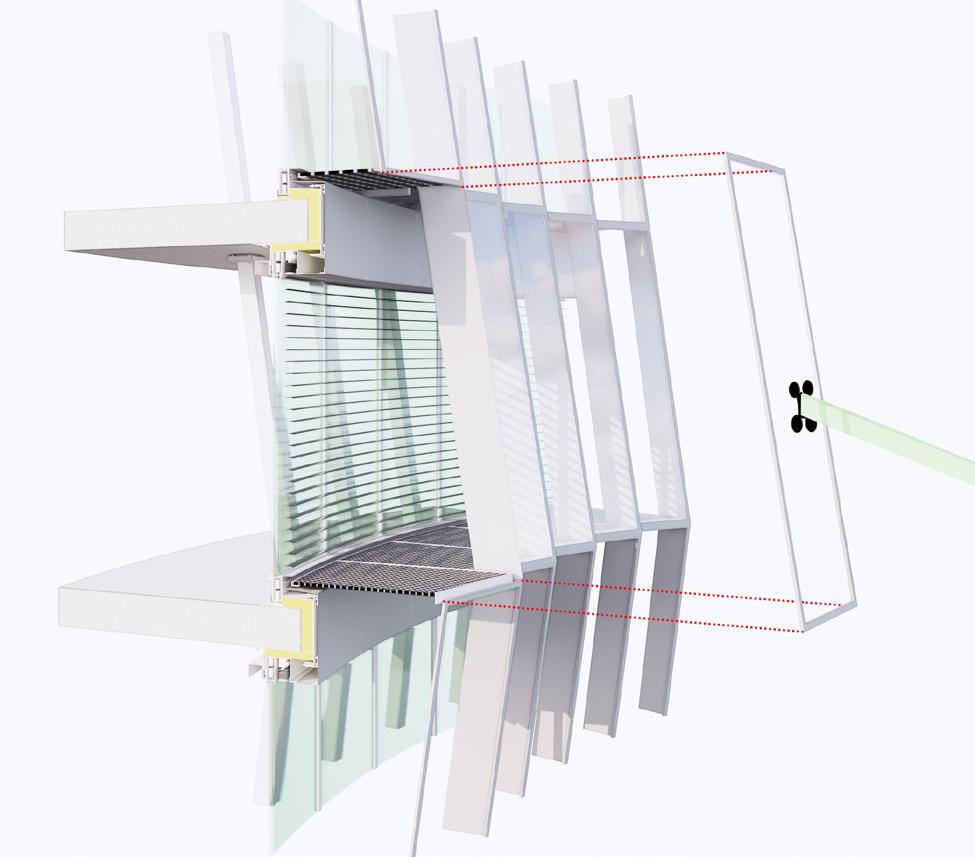

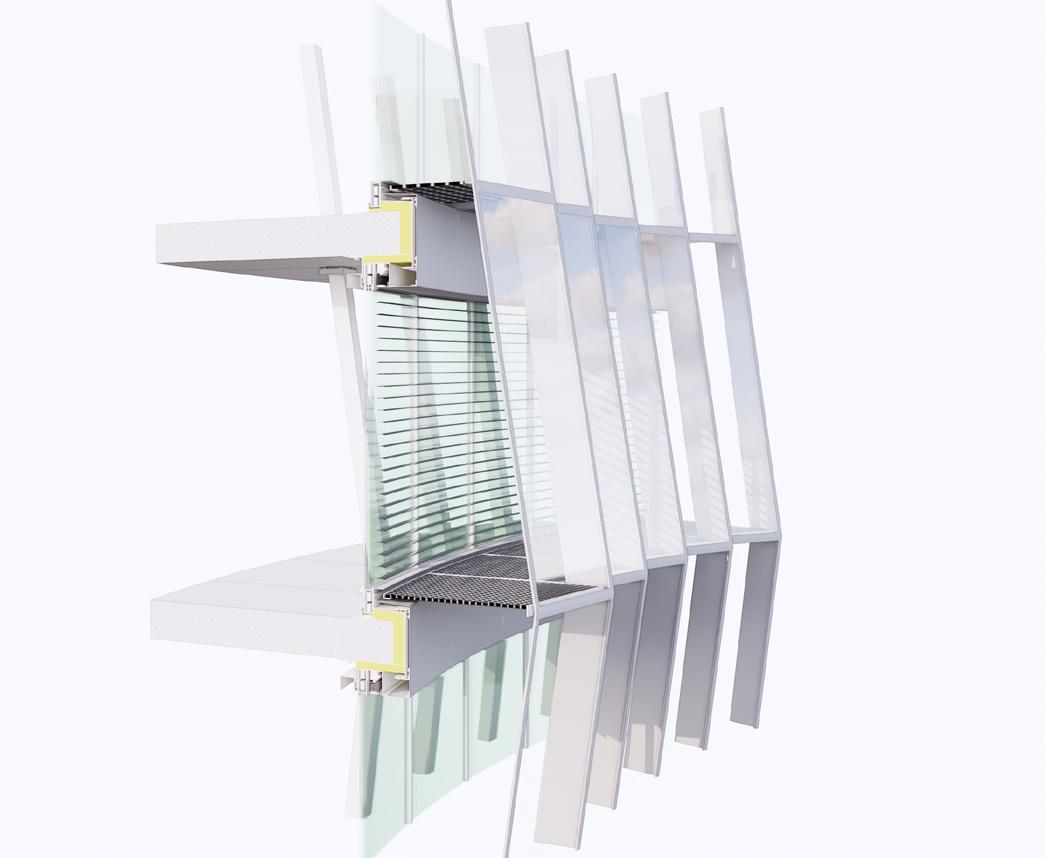

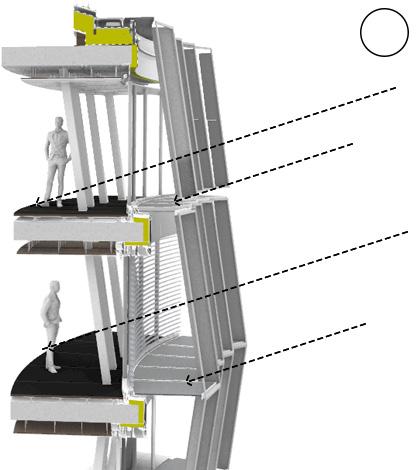

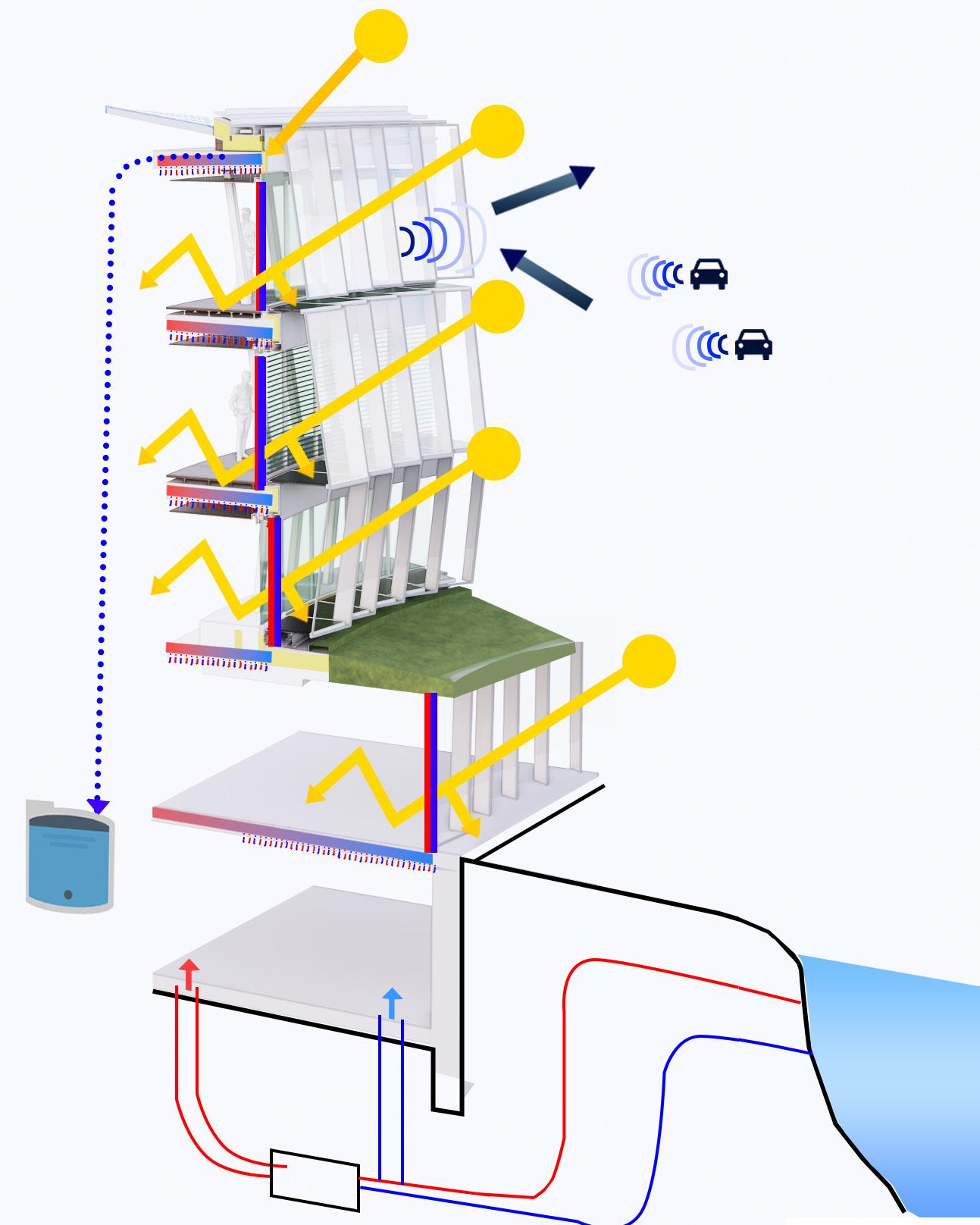

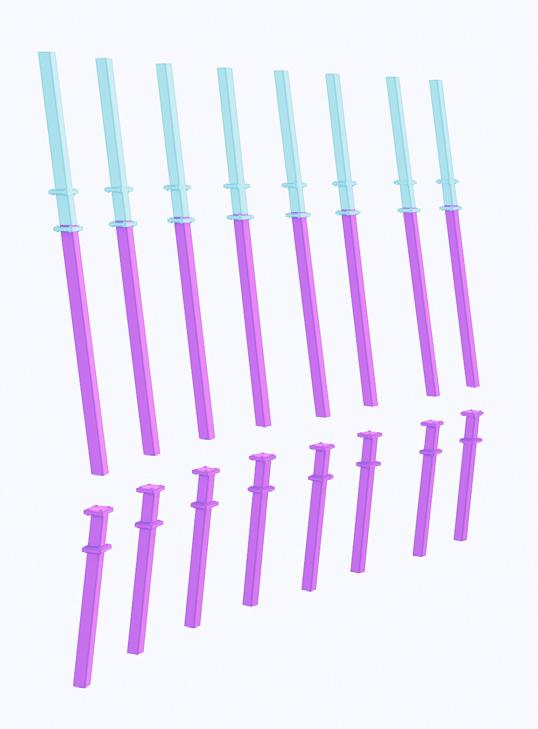

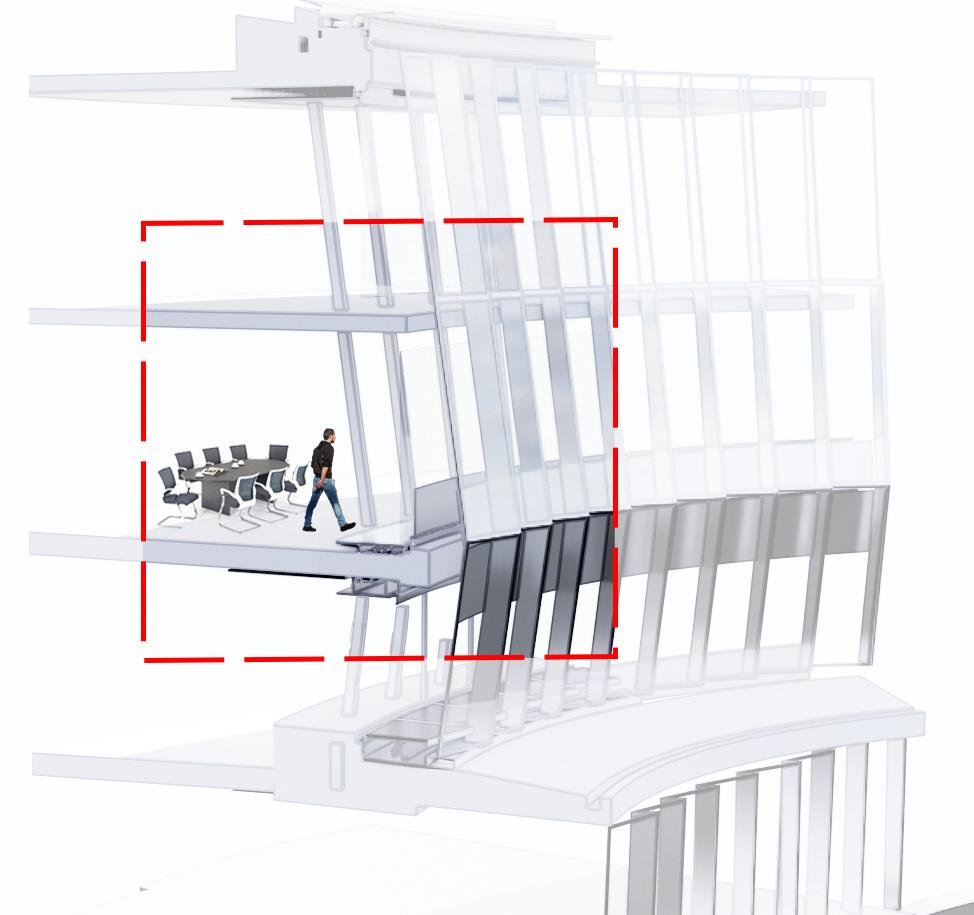

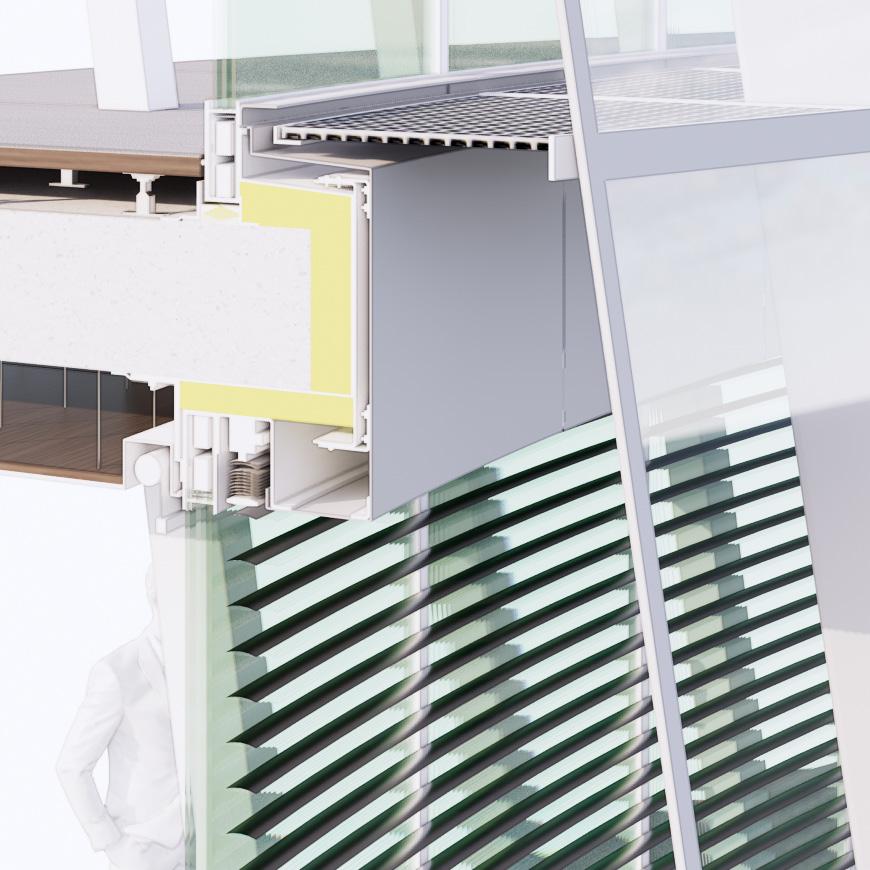

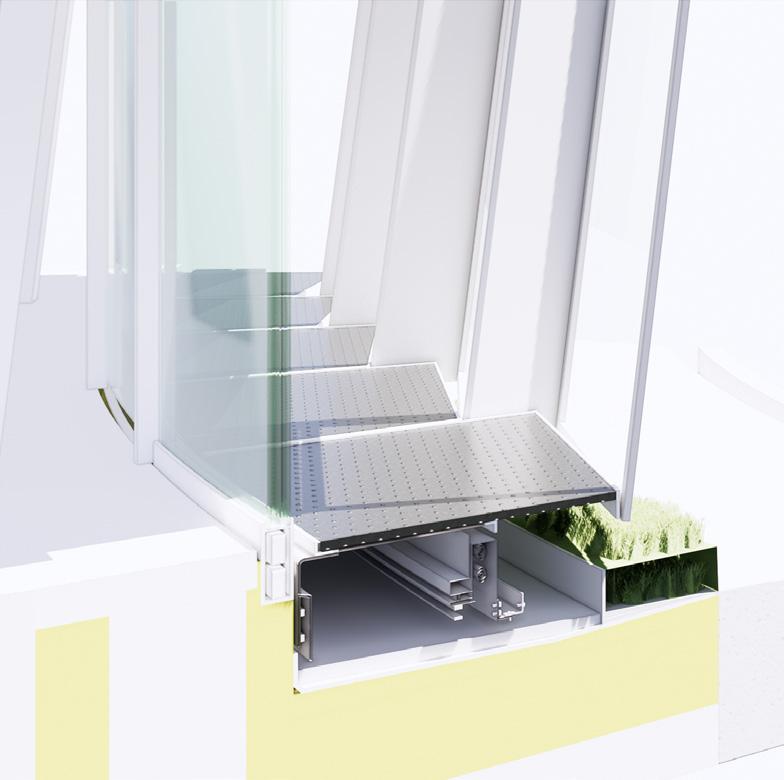

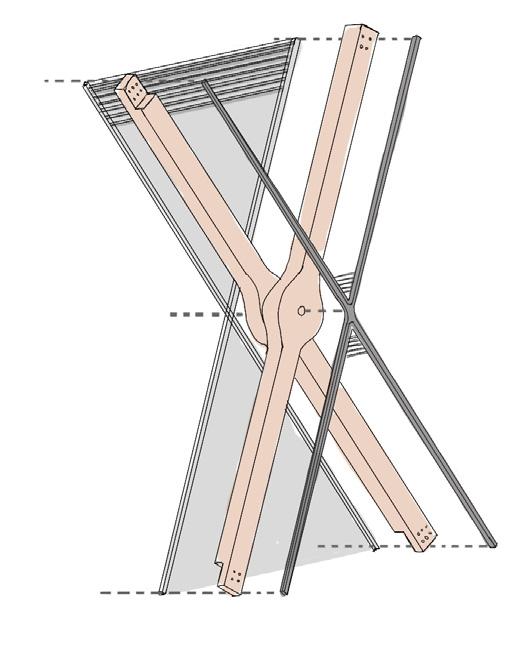

Design Methodologies Reflections Environment & Energy The steel columns at the facade line are cast into the concrete slabs which are cast in-situ on site. The pre-fab unitised system is mounted onto the slab using a crane and secured with steel brackets. The inner face of the double skin facade is installed first. First the concrete is poured onto the steel rebar. Lastly the finishes will be installed to the building such as the suspended ceiling and raised floor, which conceals the building services. Reflection on building regulations: Wheelchair accessibility is ensured on every floor, with bathrooms tailored for accessibility present on each level, provision for adapted showers, and multiple parking spots designated for individuals with disabilities. In areas where the building experiences higher axial forces, owing to the specific column geometry and the consequent increased risk of buckling, columns have been either filled with concrete or constructed from solid steel to adhere to regulatory standards. They could have further streamlined manufacturing and construction by having both the inner and outer skin of the facade as a single prefabricated element, which would have sped up the construction programme. However, it could be argued that the reason they split the assembly of the two layers is to allow a greater ease of maintenance where they can easily take apart the outer skin without effecting the integrity of the inner skin. In addition, to test the fire safety of the system, smoke extract and integrity simulations would firstly have been undertaken by a qualified fire engineer. The team would then have tested the integrity of the bespoke system using a physcial mock up and running fire simulation tests. 1 200/120/16 mm steel RHScolumn with concrete fill primary structure element - loadbearing column. 2 80mm and 60mm Fibe glass insulation fill - provision of thermal tightness 3 Steel raised floor support pedestal 4 Damp Proof Membrane vapour and damp protection, providing water tightness 5. Suspended ceiling system: soundproofing, ventilation, loudspeakers, fire alarm, embedded lighting within aluminium cassette - maintenance and building services spaces. 6 17,5 mm laminated safety glass adhesively bonded to 32/70 mm alumunium h-profile thermal, accoustic comfort, provision of natural light, moisture resistance. 7 Aluminium secondary support. 8 25mm ceramic floor finish visual and maintenance comfort and efficiency 9 30 mm metal grating on 60/30/8 mm steel h-profile frame - ventilation space and shading (sun-glare control) 10 350 mm pre-stressed reinforced concrete ceiling slab - Primary loadbearing structure 11Suspended ceiling tension rods/ support frame 12 80 mm motorized sun protection slats Automated sun and heat control 13 Suspended ceiling panels 14 Anti-glare roller blind 15 Triple thermal glazing 8 mm + 14 mm cavity + 6 mm + 14 mm cavity + 25,3 mm lam. safety glass with vertical silicone joint. 12 14 13 15 5 3 4 1 2 8 10 11 7 6 9 Structure Steel Rebar Automatised, external blinds optimise sun gains and enable efficient shading system. Cold air enters the double skin facade at the lower levels. This air then flows upwards between the two layers, the pressure differential and cooler air “pulls” the warmer stagnant air out from the office floor plates into the vaccuum of the facade. This warm air then rises and vetilates at the top of the double skin facade through a ventilation grill. This creates a passive reduction in the need for mecahnical cooling, which lowers the building’s operational carbon demand, whilst in addition reducing solar heat gainduring the warm summer months. i. Primary structure is a hybrid reinforced concrete frame with embedii. First layer triple glazed panels iii. RHS steel bars protruding elements shape triangular, supporting frame for vertical fins and metal grating. iv. Aluminium fins - interconnected vertical plates follow the inclination of internal columns. They bond the steel frame at the top and bottom of each facade panel. v. Metal grating allows for ventilation of double skin facade system. vi Second layer triple glazed panels - aluminium frames simplify the assembly process, additional Envelope & Slab Connection Double skin facade with triple glazing provides acoustic comfort and allows daylight into interior, reducing demand for artificial lighting. Automatised, external blinds optimise sun gains and enable efficient shading system. Envelope & Roof Connection Overhangs of the envelope reduce excessive solar and heat gains, providing comfortable working space. Hot air leaves the cavity space between the two layers of the facade Envelope & Ground Floor Connection Concrete slabs result in high thermal mass, helping with efficient heating and cooling of structure. Also choosing concrete enabled reuse of concrete aggregate of pre-existing office structure. Unitised facade system Isometric bay cut-out location within plan context Light colours create sense of calmness & clarity. Materials chosen with lower pollution emission after installation. The fragment was taken from the first floor ground to ceiling level. Moreover the function of the interior was open plan office space. The envelope was highly transparent allowing lots of sunlight during the day. Interior Office Space. The fragment allows sunlight into interior, reducing need for AC & artifical lighting. Net Zero Operational Carbon If this project was in the UK it would have met the following RIBA sustainable goals Building Standards & Certificates Achieved Net Zero Embodied Carbon Minergie P Outstanding Sustainable Water Cycle SNBS Platinum Good Health & Well Being LEED Platinum Winter: Maximum Altitude: -20. During Switzerland’s winter, the translucent facade optimizes the scarce sunlight throughout the day. Sun blinds and overhangs are employed to block direct sunlight and reduce glare. The building’s envelope has good thermal insulation achieved through airtightness, insulated slab edge and triple glazing. The vacuum of the double skin and integrated sunscreen system on the outer layer, shields the building and minimizing noise and acoustic disruption from the nearby highway Summer: Maximum Altitude: -62. The building’s suspended exterior creates overhangs that shield against summer glare and heat in Switzerland. Sun shades offer manual adjustment for both shading and soft, diffused lighting. Axial Force

3D Detailed Representation of Architectural Fragment

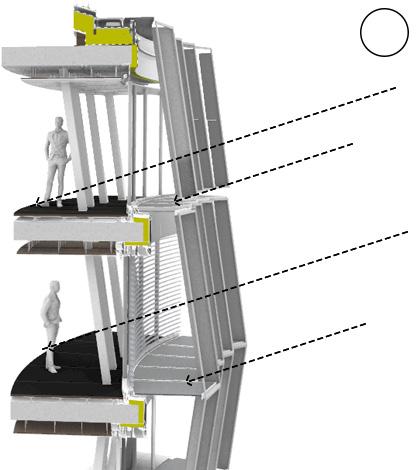

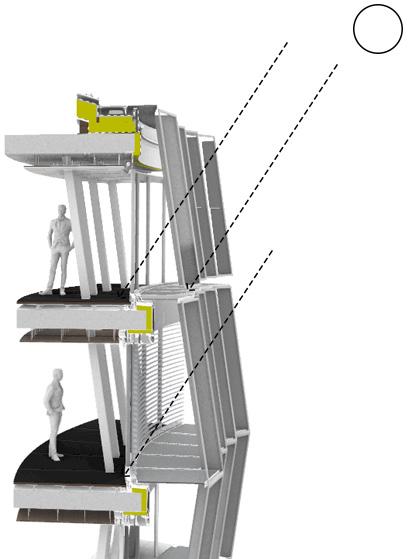

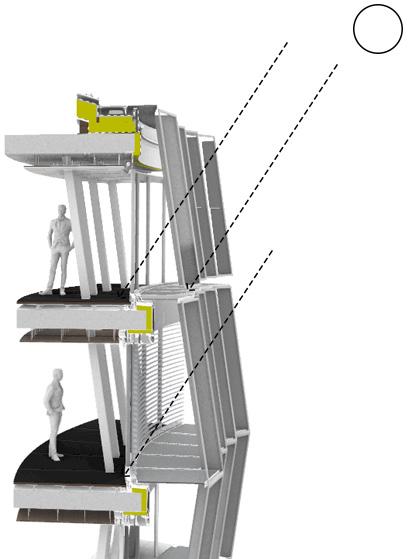

Section 1 The exterior pane is tilted and turned. Section 3 The column inclination corresponds to the exteriSection 2 The interior thermal glazing is vertical. From cut-away fragment 3D Geometry Used from 3XN website

carbon compared to a completely standardised system. Thus,

LEED certification could

a form of greenwashing as the metrics focus more on the operational carbon, rather than an overall representation which includes the high level of embodied carbon during fabrication. Daylight Control: The double-skin facade creates a protective overhang that scatters direct sunlight, ensuring a workspace that has a high quality of internal light. Photovoltaic Panels: 1000m2 of solar panels provide elecitricty which is directly consumed for lighting, hvac systems, heat recovery pumps and building operations. Thermal Mass: Throughout the day, the slabs and walls absorb and then gradually release heat or cold, diminishing the reliance on external energy sources for heating and cooling Water Collection: The building employs a rainwater harvesting system to gather and channel water for use in flushing toilets and watering plants. Additionally, the installation of low-flow fixtures, including faucets and toilets, serves to minimize water consumption. Lake Water Heating & Cooling: The building employs a lake source cooling system by taking water that has been cooled by the nearby lake through the floor slabs. This cold water absorbs heat from within the office. This warm water is then pumped out through pipes in the lake, which absorbs the heat and then the cycle begins

The

the

be

Performance of the Facade: The key to the facade’s design is the double-skin facade, enhancing thermal, air and acoustic quality. Integrating an additional layer of triple glazing within a secondary structure has significantly boosted sound insulation and reduced unwanted passive solar heat gain, whilst passively cooling the internal spaces.

Recycling: The debris from the demolished predecessor was entirely repurposed, with about 2338 tons of concrete being upcycled for the use as aggregate in the foundation and external walls of the basement. This recycling effort reduced the deman for virgin material, enhanced sustainability, and energy and carbon efficiency, and conserved natural resources, as well as reducing the need for landfill.

and Sustainability: Initially, the building’s environmental impact is high due to energy-intensive materials resulting in a high embodied carbon demand. However, the durability of selected materials is projected to extend the building’s lifespan to between 50 and 100 years. Aluminum components are expected to last 70 years before being recyclable, while the triple-glazed windows, susceptible to climatic and wear conditions, are estimated to last about 20 years. The building’s construction system allows for easy replacement of these windows, albeit at a high cost, without necessitating comprehensive structural alterations. Double Facade: The outer glazing shields the inside spaces from the disturbances of traffic noise and shields sunblinds against the effects of wind. Double skin facade provides an overhang and diffuses direct light, providing comfortable working space. Embodied Carbon: 75% of former building material was recycled. Hence, non-structural elements were made from recycled aggregate and up to 30% of structural elements including reycled concrete. All of the demolition waste from existing structure was recycled and used for waterproof walls and basement walls resulting in reduced embodied carbon. Operational Carbon: Solar panels produce approximately 200 MWh per year, equivalent to the consumption of 60 Swiss households. Energy models project that the Olympic House will use 35 per cent less energy than a conventional new construction. Sustainable Water Cycle: 60 percent reduction in municipal water consumption. Good Health & Well Being: The layout of the workstations ensures that 90% of the spaces regularly occupied (more than one hour per day) offer quality views to the outside. Lighter colors were chosen for interior coverings and the lake. Ventilation Cavity Load Diagram Dead Load Live Load Winter Sun Summer Sun The building has utisilises a double skin facade with a high degree of geometrical complexity, containing many variations in angles to form the overall geometry. The design coordination and fabrication of such geometry was made possible by the utlisation of a coordinated BIM environment. In addition, the use of scripting through grasshopper and dynamo helped create an efficient workflow of data and geometry as the building progresses in resolution through design stages. Materials and estimated amount of energy as a percentage they contribute to the fragment Fibre glass Insulation Total Embodied Carbon estimated: 4% Laminated safety glass Total Embodied Carbon of all glasses: 20% Reinforced concrete ceiling slab. Total Embodied Carbon estimated of recyled concrete: 40% Aluminium ceiling system Total Embodied Carbon: 5% Timber Support Total Embodied Carbon: 3% Ceramic floor finish Total Embodied Carbon:5% Steel RHS Column & steel metal grating Total Embodied Carbon of steel: 20% Speculative services distrubiton to the ceiling: Openable Ceiling Panel being fitted during construction Suspended ceiling panels allows for ease of access to the building services that are concealed between the finish layer of the ceiling and the strucutural concrete slab. So people can reach when needed to repair. Varied Geometry of Double Skin Facade People can reach the panel when its open so its easy to repair services. Airduct vents Openings for light fixtures Lighting cablework

Durability

BA3 Technologies Part B: Technological Discourse - Lecture Commentary Denizhan

Lecture 1: Developing a technological environmental envelope design with glass

Date: 29/01/2024

Speaker: Rhodri Evans

Position: Façade Consultant

Organisation: BDA (Billings Design Associates)

The lecture discusses the technological advancements and the environmental impacts of using glass in building envelopes. The lecture’s focus on low iron glass, with its higher transparency and reduced colour distortion, is pivotal for creating visually clear and luminous spaces. This glass type enhances spatial quality by maximizing natural light, thereby contributing to energy efficiency through reduced artificial lighting needs. In my studio project, intend to utilize low iron glass in the facade facing the green corridor to the train station, offering clear views and integrating seamlessly with the environment, thereby enriching the visitors’ experience in Stockport.

Additionally, in the lecture, learnt that the application of solar control coatings is crucial in managing solar heat gain while maintaining natural light. These coatings applied through advanced processes like magnetron sputtering, play a vital role in moderating internal temperatures and reducing the need for artificial cooling. Their effectiveness is exemplified in projects like Snowhill 3 (that BDA was involved in), where they significantly lower the g-value, balancing light transmission and heat control. In my studio project, incorporating these coatings will be especially crucial for facades with extensive glass, ensuring that the internal environment remains comfortable without sacrificing the aesthetic appeal of transparent surfaces. While these technologies hold immense potential for enhancing building performance and aesthetics, I will critically assess their cost and environmental implications. This includes considering the lifecycle of materials, from production to disposal, ensuring that my design choices are not only innovative but also environmentally responsible.

Evans’ extensive expertise in façade procurement and strategic development is pivotal in navigating the intricacies of high-value façade systems across various sectors, including commercial, residential, and educational. His adeptness in guiding clients through bid negotiation, performance evaluation, and compliance with tender returns underpins a commitment to achieving design excellence that meets aesthetic and budgetary objectives. Evans’ role encompasses a holistic approach to façade design, from supply chain management and concept development to meticulous specifications and rigorous site and factory inspections. This comprehensive methodology ensures that architectural solutions are not only visually appealing but also adhere to the highest standards of quality and functionality from conception to post-installation. Moreover, mockup modules are built by architects so they can be functionally and asthetically tested. The manafacturer would be held accountable for weathering effects and damages which is why BDA has a 12 year warranty granted.

Evans delves into the critical aspects of compliance and regulatory considerations within façade design, underscoring the need for safe material specification. He advises against the use of monolithic toughened glass in areas above head height, advocating for laminated glass to reduce risks. Further, he addresses the constraints imposed on materials for High-Risk Buildings, citing fire safety regulations that limit the use of laminated glass spandrels as mandated by Part B. Evans also highlights how Building Regulations, particularly those focusing on fire safety (Part B) and energy efficiency (Part L), significantly shape material selection and design approaches to achieve regulatory compliance. Additionally safety considerations (Part K) is crucial to dictate the safety glass in specific areas where Evans recommended in the lecture for both outer and inner layers for optimal safety. Additionally, developing budget control is key considering coating, colours, etc impacting the overall cladding system budget. From my learning am planning to use double or triple glazing favade system to meet building codes. Additionally in my design especialy the ground floor where thres lots of glazing am considering polycarbonate sheets of different opacity which could reduce installation and material costs. Additionally Part O is to due to with glazing and ventilation that one must follow to construct a building.

Lecture 5: Design for High Environmental Performance Standards

Date: 19/02/2024

Speaker: Laura Stafford

Position: Architect

Organisation: 5 Plus Architects

Laura Stafford’s lecture on advanced facade systems underlines the pivotal role of architectural design in mitigating climate change, emphasizing a ‘Fabric First’ approach to significantly reduce the UK’s building emissions. Stafford proposes innovative strategies, such as the integration of natural ventilation systems and the utilization of materials like the ones in No.1 West Bar Square, Sheffield, to decrease embodied carbon and operational energy. The No.1 West Bar Square is fully sealed and entirely mechanically ventilated because it is next to the main road which is why this was designed like this to combat air and noise pollution. This is one methodology might acquire as my site is by the A6 road in Stockport with lots of traffic and air pollution affecting the site. According to Stafford the glazing is efficient fabric with good air tightness and is reorientated to reduce solar gain. However, is this the right approach going forward as cars become electric there would be less air pollution. Additionally, they incorporated clear floor plates for flexibility in the future. This is because reuse will be crucial in the future as embodied energy becomes more of a problem. Overall, in theory the fully electrical is the most energy inefficient but is the only one that can reach net zero because its entirely electrically heated whereas the others actually use gas. The building achieves heating demand requirements for heating as it ensures consistent, controllable heating, vital for meeting the LETI heating targets but not energy demand due to tenant power density using the LETI energy targets. This emphasizes the importance of comprehensive energy strategies, including tenant power usage, to meet broader environmental targets.

Architects hold the crucial responsibility of implementing sustainable practices from the design phase to occupancy, advocating for a shift towards Net Zero Carbon by 2050. This includes adopting techniques that ensure buildings not only meet environmental performance targets but also enhance occupant well-being through biophilic design principles. One thing that the 5 Plus Architects suggested for enhancements to reduce operational carbon energy and to reach net zero in the future is to change to mixed-mode ventilation whilst still maintaining electrical energy which means being able to open at 15 degrees helps reduce the fan power required to deliver air to open spaces. However, it’s crucial to understand that for there to be a big change occupier behaviour must change with a reduction in demand in equipment which is the biggest challenge that will make the biggest change.

Stafford outlines the necessity of aligning with frameworks like the RIBA 2030 Climate Challenge and LETI/UKGBC guidance, focusing on energy use intensity as a new measurement metric. Compliance involves a detailed consideration of embodied carbon and operational energy, with strategies aimed at reducing, reusing, and recycling materials to meet stringent UK regulations and standards

Lecture 4: Brick: Past & Future of Masonry Building

Date: 12/02/2024

Speaker: Andrea Cooley

Position: Technical and Design Support Manager Organisation: Wienerberger UK

Lecture 2: Future Vision for a Healthier Greener City

Date: 31/01/2024

Speaker: Kevin P.Flanagan

Position: Architect

Organisation: PLP Architecture (Until 2020); Kevin P Flanagan Architects (now)

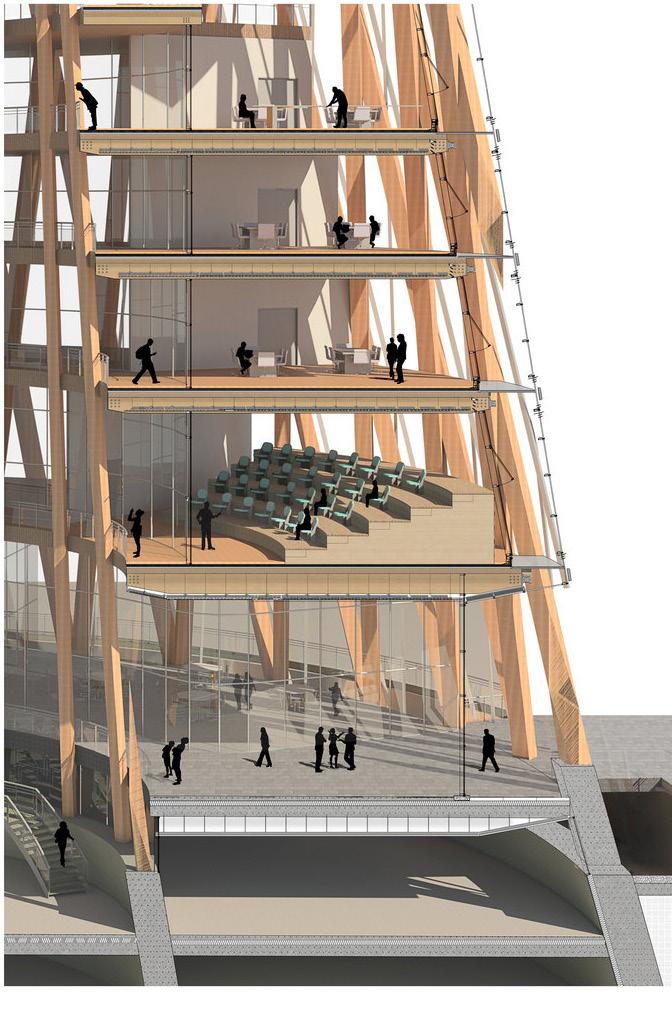

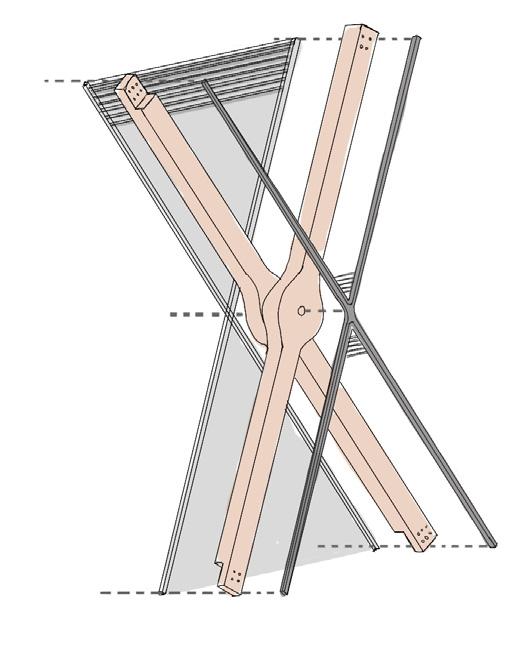

The Oakwood Timber Tower project embraces the principles of biophilic design, reflecting a commitment to ‘Healthier Cities’ by harmonizing built environments with nature. This aligns with Flanagan’s insights into bio-architecture, where buildings are designed to ‘grow’ from the natural fabric of the city By prioritizing engineered mass timber, particularly CLT, the design methodology not only promises substantial carbon sequestration—potentially halving the volume in weight of CO2—but also underscores the mental and physical well-being benefits associated with natural materials. The methodology is reinforced by the statistic that the use of engineered mass timber could lead to a 75% reduction in the carbon footprint and a 40% reduction in waste, further underlined by the potential for 4000 times more CO2 savings when compared with traditional construction methods. The lecture’s focus on the CO2 savings potential of mass timber, particularly CLT, is integral to my design approach. As timber sequesters and absorbs c02 getting us closer to paris agreement. Also helps with the 21st century response to ai methods of construction uses robotics but allows us to move forward to cheaper better buildings when using timber. It aligns well with my atelier’s commitment to environmentally responsive urban design, pushing for buildings that are not just energy-efficient but carbon-negative and renewable. So it manages to tackle many RIBA sustainable goals from energy to good health & well being to sustainable communities all from the use of advanced CLT.

The responsibility of the architect extends to the implementation of sustainable practices that contribute to both environmental health and human well-being. Flanagan’s lecture underscores the imperative of incorporating biophilic design, echoing research that suggests spending time in natural or nature-mimicking environments can lead to enhanced health and longevity. Thus, the architect’s duty transcends mere compliance with safety regulations; it encompasses a broader commitment to fostering well-being through design, particularly in the choice of materials like mass timber that resonate with our innate affinity for nature. Additionally, with mass timber’s properties favoring both carbon sequestration and reduced construction waste, the responsibility extends to advocating for and implementing these sustainable technologies. This responsibility also encapsulates the duty to comply with the UK’s stringent safety regulations, such as those covered in Part B for fire safety, necessitating innovative approaches to ensure the viability of timber in highrise construction.

Navigating regulatory requirements within innovative construction like the Oakwood Timber Tower, which won a RIBA Award, showcases how sustainability can drive design within strict building codes. Regulatory compliance serves as an opportunity for innovation, particularly with UK Building Regulations Part B, enhancing fire safety without sacrificing the benefits of mass timber. However today the main challenge is ensuring that fire codes and building regulations are up to date with advancements in wood products. Many existing codes may not fully recognize the fire-safe properties of CLT, leading to bureaucratic hurdles for architects and builders. Given Kevin P. Flanagan’s lecture, which touched on the potential 4000-fold CO2 savings with mass timber compared to traditional materials, and the market’s leaning towards more ethical and sustainable living solutions, it’s plausible that the project also considered guidance from bodies like the Structural Timber Association. These guidelines, alongside an anticipation of evolving UK regulations, ensure the project not only meets current standards but is future-proofed for sustainability. However, we can’t overlook the benefits of cocncrete in building performance, its thermal mass and durability. Overall, by infusing Flanagan’s principles of bio-architecture into my projects, a forward-thinking vision for urban development is encapsulated—one that cherishes the symbiotic relationship between humans and their natural environment, manifesting in architectural designs that are sustainable, health-promoting, and compliant with the highest standards of building regulations.

Lecture 3: Designing Structural Frames: Steel v Concrete v Timber

Date: 05/02/2024

Speaker: Les Postawa

Position:

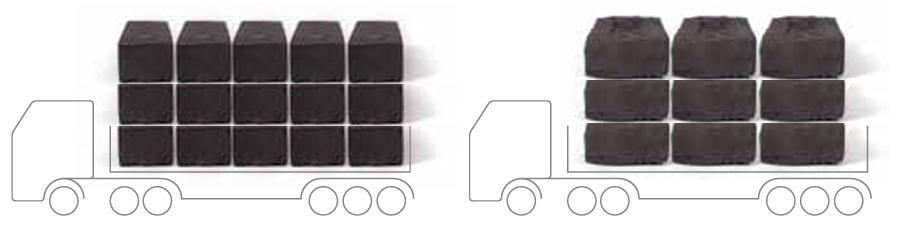

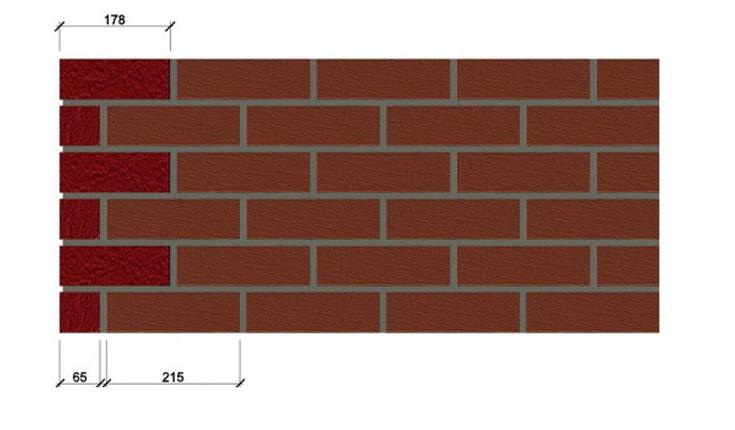

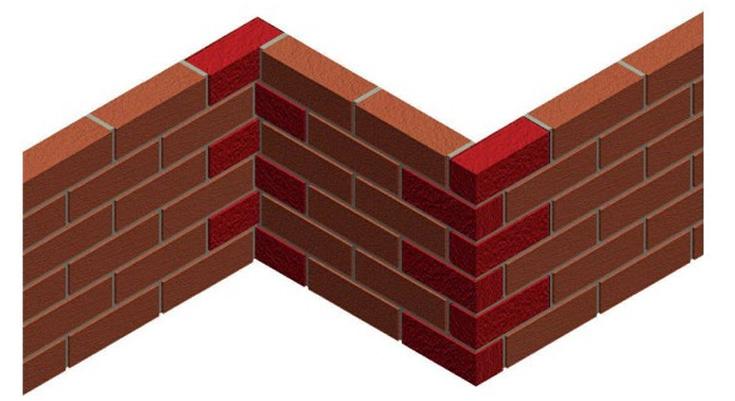

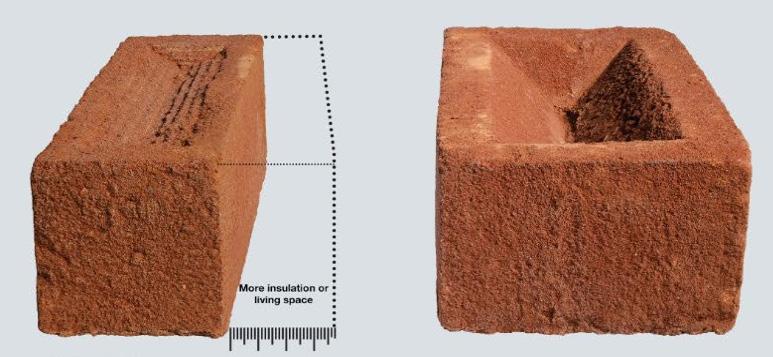

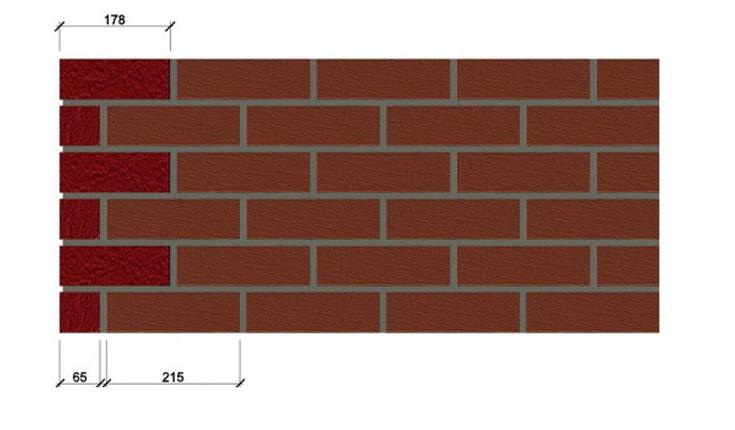

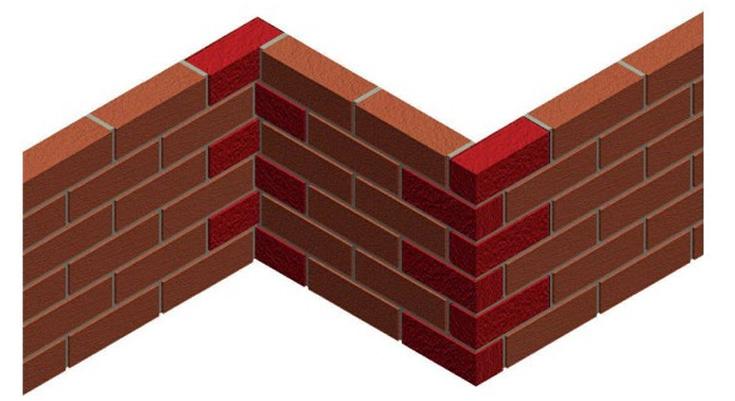

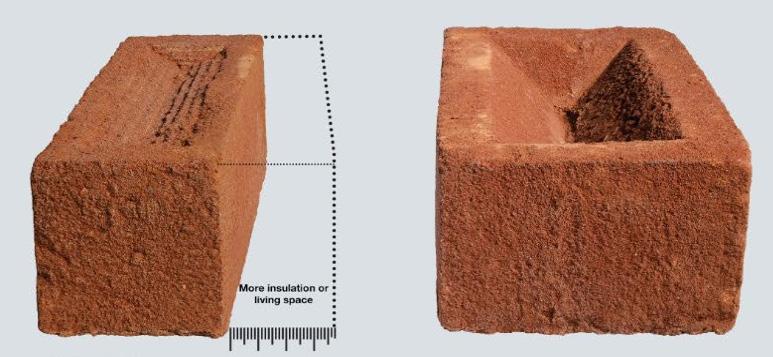

Andrea Cooley is in charge of the wall and facade in the technical and design services team of Wienerberger a brick architecture company. The lecture discusses the past and the future of masonry buildings and things like durability and details, from the earlist fired bricks from Mesopotamia to advanced bricks in the contemporary period such as Ecobrick The reduction in material usage through advanced bricks like Ecobricks, aligns with sustainable practices, addressing both historical continuity and modern efficiency Eco-brick reduces the size of a standard brick to 65mmx65mm, and this reduction in material usage means reduction in embodied carbon and overall building will be lighter in weights.Another method that would want to explore in the future is precast bricks as it not only improves the speed of construction and consistency but also precast bricks are highly accurate and helps when fine details are needed but reduces the cost of doing it on site. Such materials not only advance construction speed but also uphold aesthetic integrity, essential for creating spaces that are both high-quality and experiential. My design approach, therefore, integrates these methods as they contribute to building performance and create spatial effects that are at once functional and evocative.

The architect’s role extends beyond design; it involves understanding the historical context and the evolving material technology, ensuring that design choices honor both past wisdom and future potential. Legal and professional responsibilities include ensuring that designs respect the cultural significance of traditional materials like brick while innovating responsibly. This is evident in the design decisions shaped by considerations of durability and detail, as highlighted in the lecture. In my own projects, this translates to a design philosophy that embraces traditional materials with a forward-thinking approach, ensuring they meet contemporary demands.

Key regulatory considerations such as height restrictions for new materials like Ecobricks, as mentioned in the lecture, have a significant impact on design development as buidlings are limited to 4 floors. Another building regulations Wienerberger look at when designing is the specification for masonry units bsi and the reccomendations for the design of masonry structures when looking at durability overall. One can argue some factors that make this is design of the structure, specification of brick and mortar as mentionned and likely exposure zones more frequent in the West side of the UK.

Compliance with these regulations, along with adherence to building codes, ensures the project’s feasibility. The organizational and regulatory framework involved in the approval process—reflecting land law, development control, and health and safety legislation—determines the successful application of these innovative materials.

In reflection, the themes covered by Cooley resonate with the contemporary challenges of sustainable design in architecture. The push for reduced material use, increased durability, and innovative design all contribute to building performance and the creation of high-quality, experiential spaces. This lecture underscores the importance of integrating traditional materials like brick with modern technology and sustainable practices to create buildings that are both functional and have a reduced environmental impact.

struction - predoimanlty concrete up to upper concourse level with main concrete columns spaced at 18m centres with spine beamstanding between these columns. The main roof trees with its distinctive wave-like roof, showcases the strength and flexibility of steel as a construction material. Steel allowed for the creation of the airport’s sweeping, cantilevered roof forms, which would have been difficult to achieve with concrete or timber. There is a rich transition between concrete and steel frame a hybrid use of materials. The prefabricated roof structures, juxtaposed with bamboo ceilings for aesthetic enhancement, showcase an intricate balance between functionality, sustainability, and aesthetic appeal, serving as a prime example of thoughtful material integration and lifecycle planning.

Reflecting on the lecture, my design incoproates a curved concrete shell supported by timber which significantly enhances both the building’s performance and the quality of spatial experiences. This combination leverages concrete’s robustness and wood’s natural insulation properties, optimizing energy efficiency and indoor comfort. Architecturally, it creates a visually stunning and inviting environment, blending strength with warmth.

The selection of materials for T4 Barajas Madrid Airport necessitated an in-depth analysis of carbon impact across all lifecycle stages, aligning with standards such as the RIBA 2030 Climate Challenge and the Paris Agreement goals. This project showcases how regulatory compliance can drive innovation, particularly in addressing thermal stress and modular design to minimize the carbon footprint. The project’s approach exemplifies adherence to stringent building codes and environmental regulations, ensuring that the material selection not only meets structural and aesthetic criteria but also advances sustainability goals. Incorporating advanced environmental modeling and assessment tools, such as Life Cycle Assessment (LCA) and Building Information Modeling (BIM), played a pivotal role in achieving this compliance, illustrating a shift towards more sustainable construction practices mandated by contemporary building standards. Architects bear the responsibility to make informed choices that balance structural efficiency with environmental stewardship. This involves a critical engagement with the embodied carbon of materials and u values.

UK eco-brick: 65mm, (37.5mm reduction so more insulation or living sos=ace can be found here.)

Peker (21437597)

Architectural Director Organisation: Thornton Tomasetti (13 years Until 2019) and is now Director at Les Postawa Associates (now)

for sustainable construction. Overall in my project want to incorporate mixed-mode ventilation whilst incorporating renewable energy through things like solar panels to help generate the energy as it benefits operational energy consumption achieving the UK Green Building Council’s target for 2025. The

view

all phas-

life,

whole lifecycle approach

modular con-

lecture by Les Postawa presents a nuanced

of material selection in structural framing, emphasizing that no single material can be universally declared ‘lowest carbon.’ Instead, the choice between steel, concrete, and timber should be based on project specifics like structural requirements and environmental impact. A responsible design methodology integrates these materials in a way that accounts for

es of a building’s

from production to end-of-life, emphasizing a

(‘Cradle to Grave’) to minimize embodied carbon. The T4 Barajas Madird Airport: Designed as a

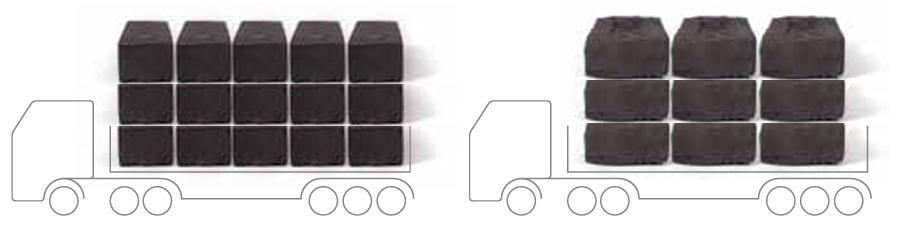

By understanding the intricacies of carbon factors and sequestration, architects can advocate for designs that contribute positively to the environment and meet rigorous sustainability goals However, from the lecture learnt that even though concrete structures have the highest initial emissions, the use and end of life changes are smallest followed by steel. And actually wasteful use of timber could rather have a greater impact. Thats why the use of less material and efficiency is crucial. Innovative Advanced Materiality 1 2 3 5 4 Engineered Mass Timber CLT User Centric Design Fire Safety Operational Energy Recycling Materials in Construction Glass Green Certificates End of life changes are smallest as it has a higher life span can take any shape and form Glass Reinforced Concrete (GRC) Biophylic design Brick Concrete Timber Steel Material Choice Hybrid Structures: Combining materials for optimal performance Modular Design: Prefabrication, on-site assembly, flexibility Long-Span Techniques: Bridge design, large public spaces Eco bricks prefab bricks Corium bricks Thermal Testing Daylight Testing Structurual Accessibility Nature & Living Aesthetics Structural Innovation Regulatory Constructability Double Skin Glazing Curtain Wall Surface Treatments: Textures, colors, facade treatments Natural Light Utilization: Glazing techniques, daylighting Interior-Exterior Transitions: Open spaces, material continuity Structurally its a more cellular material. No concrete core used. New calculation for foundations, they can take double the loading. Timber is so light you can build so much more on top than compared to steel and concrete hybrid structures. Another case study Rhodri discusses is the One Nine Elms. The building is finished with a range of bespoke cladding systems that provide the required aesthetic for this 5 star development. The shopping area and hotel entrance will use steel stick curtain walling systems, finished with a solid bronze plate cladding system all to the requested level of blast resistance. The upper levels of the podium, are composed of a combination bespoke double height steel stick systems with SSG double glazed units, anodised aluminium and stone rain screen systems. Shading device speculation? still reliant on concrete in the basement structure. Timber lightweight tower exposed fairface concrete upper concourse level circular roof lights, kipper truses post tension cable trusses supported main glazed facade. Offside BIM Models In Situ Part B Part O LEED BREAM Achieving up to a 31% decrease in initial carbon emissions, the construction method also enables a 36% leaner profile, enhancing insulation possibilities. Transportation needs are cut by up to 37%, which can result in saving up to five tonnes of CO2. Additionally, the approach demands up to 36% less mortar and water usage on-site, while also reducing the weight of materials by 36%. Double skin Facade Exploded Axo

Images

from Wienerberger

Glass Natural Light Low-E Coating UV Coating Timber Double Skin Facade Vent Exterior Rain Screen Interior thermal line steel stick curtain walling systems, finished with a solid bronze plate cladding system Timber cladding specilation double height steel stick systems with SSG double glazed units, anodised aluminium and stone Solar Gains Renewable

Images from Wienerberger: Up to 37% reduction in transportation journeys