PRODUCT DATA SHEET

PRODUCT DATA SHEET

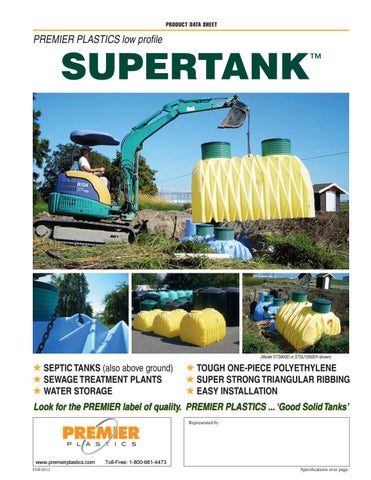

PREMIER PLASTICS low profile

SUPERTANK

™

PREMIER PLASTICS low profile

SUPERTANK

™

(Model STS900D or STSU1000EH shown)

H SEPTIC TANKS (also above ground) H SEWAGE TREATMENT PLANTS H WATER STORAGE

H TOUGH ONE-PIECE POLYETHYLENE H SUPER STRONG TRIANGULAR RIBBING H EASY INSTALLATION

Look for the PREMIER label of quality. PREMIER PLASTICS ... ‘Good Solid Tanks’

PREMIER

(Model STS900D or STSU1000EH shown)

H SEPTIC TANKS (also above ground) H SEWAGE TREATMENT PLANTS H WATER STORAGE

Look for the PREMIER label of quality. PREMIER PLASTICS ... ‘Good Solid Tanks’

Represented by:

PREMIER

P LASTICS I N C .

Represented by:

P LASTICS I N C .

8328 River Way, Delta, BC, Canada V4G 1C4 Bus: (604) 952-6686 Fax: (604) 952-6696 Toll Free: 1-800-661-4473 E-mail: office@premierplastics.com www.premierplastics.com www.premierplastics.com Toll-Free: 1-800-661-4473 FEB 2012

H TOUGH ONE-PIECE POLYETHYLENE H SUPER STRONG TRIANGULAR RIBBING H EASY INSTALLATION

8328 River Way, Delta, BC, Canada V4G 1C4 Bus: (604) 952-6686 Fax: (604) 952-6696 Toll Free: 1-800-661-4473 E-mail: premier@ultranet.ca www.premierplastics.com

Specifications over page.

SEPT. 09/REV. 1

Specifications over page.