In today’s interconnected world, data centres are the backbone of global operations, powering everything from essential services to everyday conveniences. Ensuring they remain operational 24/7 is critical to maintaining server uptime, preventing costly disruptions, and supporting a seamless flow of information across the globe.

At Deep Sea Electronics, we specialise in delivering advanced electronic control solutions, including paralleling controllers, automatic transfer switch controllers, and industrial battery chargers. Our cutting-edge technology ensures mission-critical systems perform flawlessly, enhancing efficiency and reliability.

By providing the seamless control required to keep data centres running without interruption, we empower businesses to meet the demands of a connected world. Trust Deep Sea Electronics to power the systems that power everyday life.

At DSE, we are proud to be a global leader in electronic control solutions, supporting customers across the world in achieving their operational goals. With a comprehensive range of products and a proven track record of delivering reliable, high-performance solutions, we have earned the trust of customers in diverse industries.

Our global reach is supported by a network of offices spanning Europe, North America, the Middle East, Africa, India, and Latin America, ensuring we are always close to our customers. In addition, our extensive network of distributors, resellers, and systems integrator partners strengthens our ability to deliver world-class products and services wherever they are needed.

Customers trust DSE products to control their critical power requirements, knowing they are designed to perform under the most demanding conditions. Our solutions deliver the reliability, precision, and peace of mind required for mission-critical applications. Combined with exceptional support at every stage—from initial consultation to ongoing assistance— DSE is your dependable partner for innovative solutions and unparalleled service, anywhere in the world.

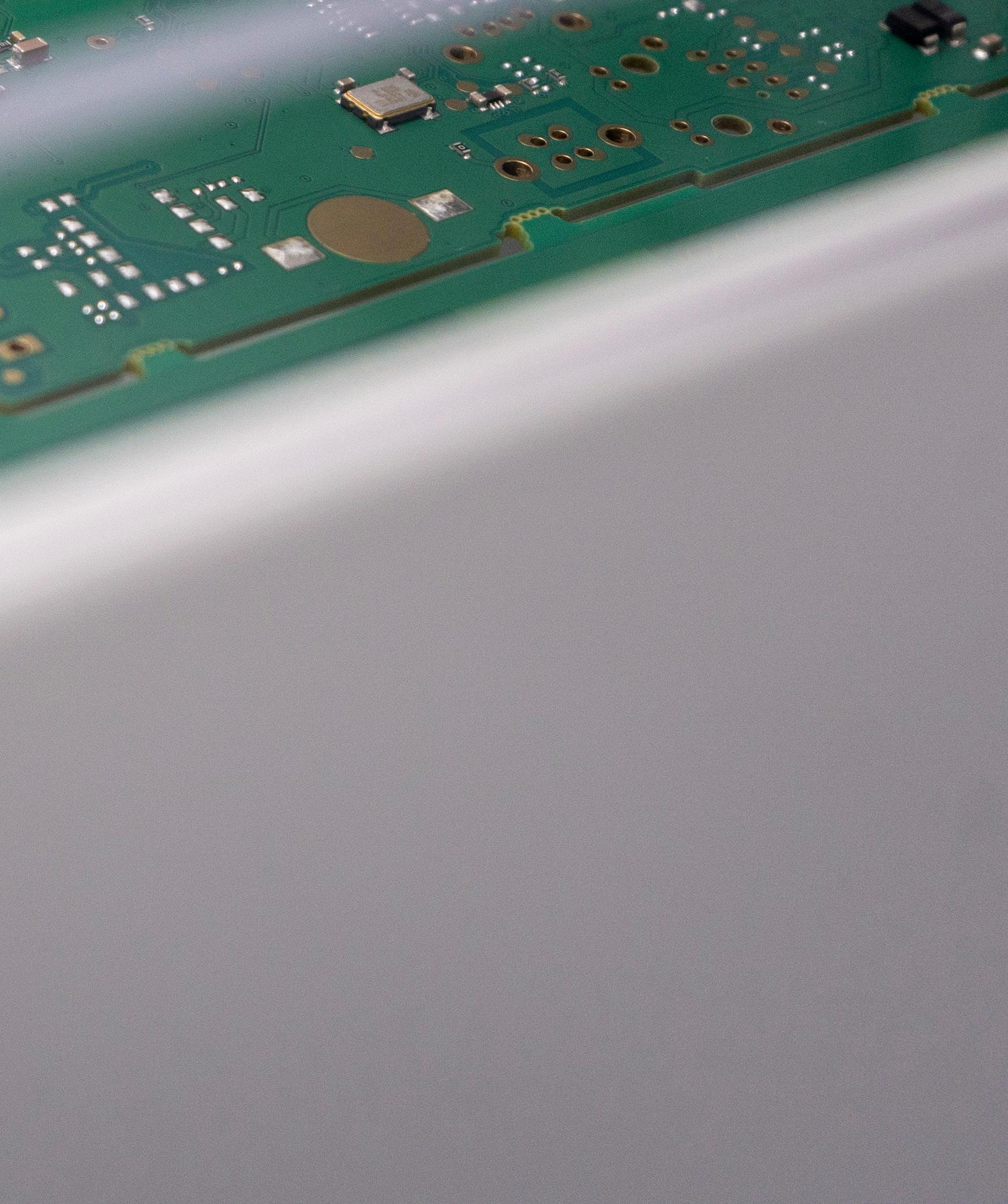

At the heart of DSE is a commitment to UK manufacturing excellence. Every electronic control solution we produce is designed and built in the UK, combining cutting-edge innovation with the highest manufacturing standards. Our advanced facilities utilise state-of-the-art automation technologies to ensure precision, consistency, and quality at every stage of production.

By integrating automation into our manufacturing processes, we can deliver reliable, high-performance solutions that meet the most demanding requirements. From concept to completion, our dedication to excellence ensures that every product we create not only meets but exceeds customer expectations, reinforcing our reputation as a trusted leader in electronic control solutions worldwide.

At DSE, we understand that the true value of our products lies in the support we provide. That’s why we’ve built an outstanding global support network that customers can rely on, no matter where they are. With offices across Europe, North America, the Middle East, Africa, India, and Latin America, as well as an extensive network of distributors, resellers, and systems integrators, we are always close to our customers, ready to offer expert assistance when it’s needed most.

Our dedicated support teams are committed to ensuring that our solutions continue to perform at their best, providing guidance, troubleshooting, and timely responses to any inquiries. Whether it’s a technical question, a need for product training, or ongoing maintenance support, DSE’s global presence ensures you have the resources and expertise to keep your systems running smoothly and efficiently.

IEC 62443 is a global standard for securing industrial control systems (ICS) and operational technology (OT). It addresses key areas like risk assessment, network security, access control, and incident response, making it essential for Industry 4.0.

Cyberattacks on industrial systems can have severe consequences. IEC 62443 offers best practices to protect industrial automation and control systems (IACS), helping organisations ensure safety, reliability, and continuity in digital operations.

Asset owners must identify risks, implement security controls, and maintain systems securely throughout their lifecycle. They play a central role in cybersecurity, working with integrators, suppliers, and regulators to protect IACS.

DSE integrates tamper-resistant identification chips in selected products, including the G86 product range to securely store cryptographic keys used for authentication and encryption. These products meet SL2 security levels, protecting against intentional cyber threats.

The DSE335 MKII automatically and independently switches the load to an alternative power source (S2) if the primary power source (S1) becomes unstable. This transition can occur due to a mains (utility) failure, a scheduled event, test on load mode, a remote start on load command, or manual intervention.

The closed transition feature enables the DSE335 MKII to switch from S1 to S2 without interrupting the load, provided that both power sources are synchronised within the close transition window.

If synchronisation is not possible—such as during a mains (utility) failure or if the supplies fail to align within the transition window—a UPS can be installed to safeguard against power drops.

The DSE7410 MKII is suitable for applications requiring Stage V compliance. Equipped with a built-in Ethernet port, it seamlessly integrates into a building management system using Modbus or SNMP protocols.

This single mains (utility) with generator backup system ensures that any faults or issues with the generators are isolated to a single load, preventing disruptions to other loads. This application is well-suited for break transfer systems as well as UPS no-break transfer solutions.

Mains (Utility)

Data Centre

Add UPS here if needed

DSE335 MKII

MKII

DSE335 MKII

Generator

DSE8610 MKII

DSE335 MKII

DSE8610 MKII

DSE335 MKII

DSE335 MKII

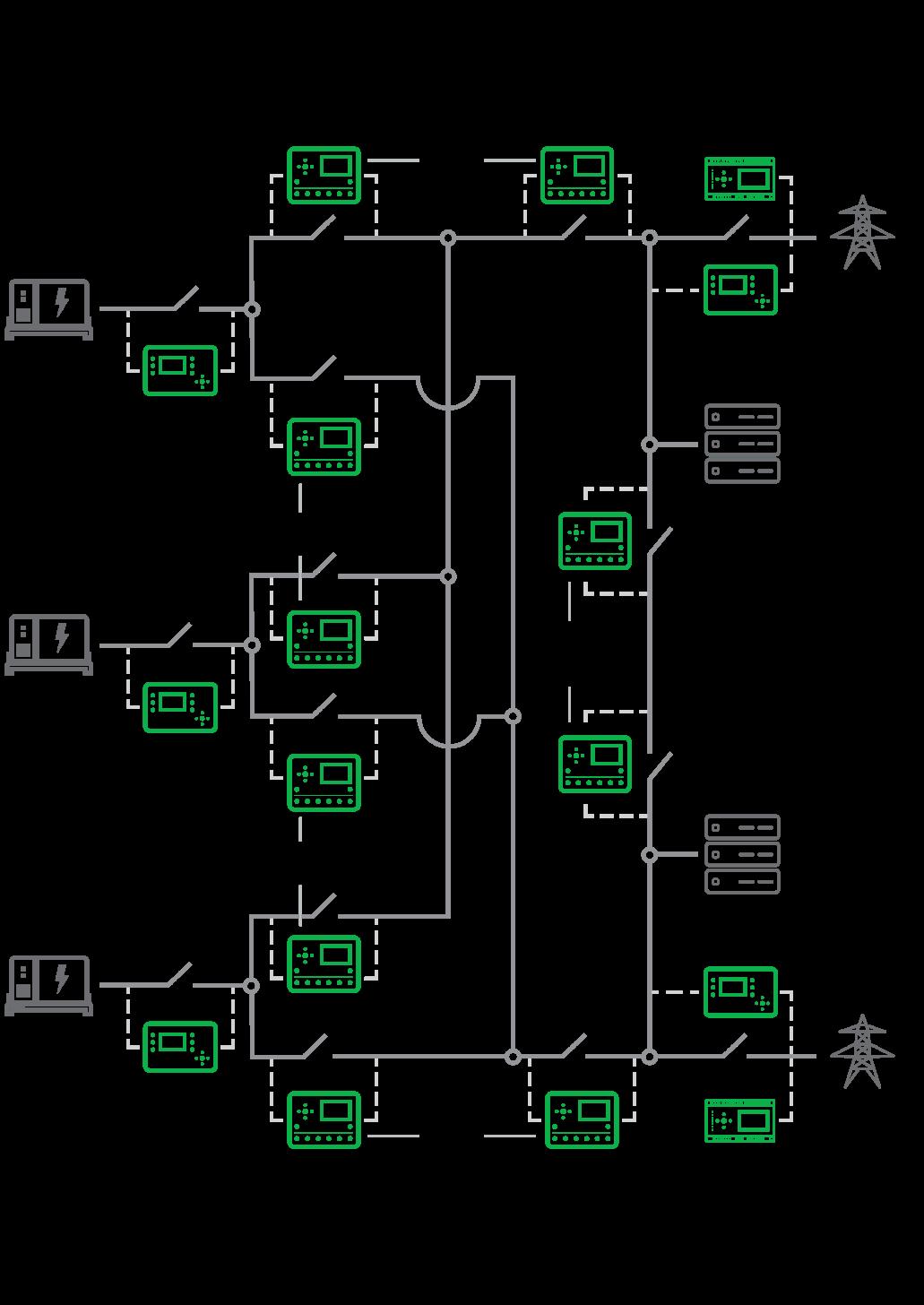

Each DSE335 MKII automatically switches from its priority power source (S1) to its secondary power source (S2) when instability is detected. In this application, there are two sets of DSE335 MKII units: one set controls the switching between two different mains (utility) sources, while the other takes the output from the first DSE335 MKII and switches between that and the backup generators.

This system of DSE335 MKII units allows each load to be powered by either of the two mains (utility) sources or a bank of generators, providing flexible switching between power sources. This capability helps to distribute load efficiently, preventing excessive demand on a single mains (utility) supply.

With multiple generators in place, if one generator fails, another can continue providing backup power to all loads, rather than each generator being restricted to a single load.

The DSE8610 MKII plays a key role in such scenarios, enabling generators to start and stop seamlessly based on load demand through the MSC link. This link also ensures that a generator can start automatically if another set experiences a warning or failure.

If maintenance is required on one mains (utility) supply or its distribution system, the setup can still function as a single mains (utility) with generator backup system, ensuring continued operation.

The closed transition feature of the DSE335 MKII enables switching from S1 to S2 without dropping the load, provided both power sources are synchronised within the close transition window.

If synchronisation is not possible—such as during a mains (utility) failure or when the supplies do not drift into sync within the transition window, a UPS can be installed to safeguard against power drops. This application is well suited for break transfer systems as well as UPS no-break transfer solutions, ensuring reliable and efficient power management.

The DSE335 MKII is designed to seamlessly manage power transitions by automatically switching from its primary source to a secondary source whenever instability is detected. This ensures a continuous and reliable power supply.

For sites requiring backup power, the system supports up to 32 generators when controlled with the DSE8610 MKII. If further scalability is needed, up to 64 generators can be integrated on a single bus using the DSEG8600, allowing the system to grow with the site.

Additionally, generators can be programmed to run during peak demand periods when the mains (utility) supply is restricted. For instance, if high loads are experienced between 10am and 3pm, the DSE335 MKII’s inbuilt scheduler can automatically transfer power to the generators, optimising efficiency and reducing dependency on the mains (utility) supply.

This modular approach enables businesses to scale their power solutions as operational demands increase. In the event of a generator failure, another unit will automatically start, maintaining uninterrupted supply. This feature can also be utilised to balance engine hours across the system, optimising maintenance schedules and prolonging equipment lifespan.

Furthermore, the DSE335 MKII facilitates generator maintenance without compromising system redundancy. Routine servicing can be carried out while maintaining power availability, including scheduled maintenance of the mains (utility) transformer while the load is seamlessly supported by the generators.

The closed transition feature of the DSE335 MKII enables switching from S1 to S2 without dropping the load, provided both power sources are synchronised within the close transition window. If synchronisation is not possible—such as during a mains (utility) failure or when the supplies do not drift into sync within the transition window, a UPS can be installed to safeguard against power drops.

This application is well suited for break transfer systems as well as UPS no-break transfer solutions, ensuring reliable and efficient power management.

Mains (Utility)

DSE335 MKII

Data Centre

DSE8610 / DSEG8XXX UPS Generator

DSE8610 / DSEG8XXX

Example, using 8610 for 1-32 Generators, or using G-Series controllers for 33 or up to maximum of 64 Generators.

The DSEG8-Series system setup provides exceptional flexibility, allowing it to be configured for mains (utility) backup or for synchronising and load-sharing with the mains (utility) to support peak shaving or base loading. To ensure compliance with G99 regulations, a DSEP100 can be integrated, enabling long-term parallel operation with the mains (utility) supply.

The system also allows sections of the bus to be separated into multiple zones, providing dynamic control over power distribution. By continuously monitoring system conditions, the DSEG8680 Bus-Tie Controller can automatically isolate or reconnect bus sections as needed, ensuring seamless operation. Additionally, the controller can be configured as a load-switching device, granting precise control over both power sources and connected loads.

When used as a mains (utility) controller, the DSEG8-Series enhances generator efficiency. In the event of a mains (utility) failure, the DSEG8600 controllers initiate the generator start-up sequence, seamlessly transferring the load. Once the mains (utility) supply stabilises within configured parameters, the generators synchronise with the grid and ramp off the bus, ensuring a smooth transition back to mains (utility) power.

Designed with scalability in mind, the DSEG8-Series system supports up to 64 controllers on the same AMSC link, allowing for future expansion as site requirements grow.

For advanced monitoring and commissioning, DSESCADA and the DSEG8015 provide real-time, multi-set visibility, enabling greater control and insight from a single interface.

DSE335 MKII Auto Transfer Switch Control Module

DSE334 Auto Transfer Switch Control Module

DSE331 Auto Transfer Switch Control Module

view

DSE890 MKII DSEWebNet® / IoT Gateway - 4G (GSM/Ethernet) and Combined 4G LTE (Main & Diversity) / GPS Antenna

DSE Self-Seeking Power Supply

DSE124 CANbus Extender

DSEG8600

Parallel Genset Controller with Integral Heater

DSEG8680

Bus-Tie Controller

DSEP100

Mains Decoupling Relay

DSE7410 MKII

Auto Start Control Module

DSE890 MKII

DSEWebNet® / IoT Gateway - 4G (GSM/Ethernet) and Combined 4G LTE (Main & Diversity) / GPS Antenna

DSE857

USB to RS485

DSE855

USB to Ethernet

Communications Device

Communications Device

DSE WebNet ® ADVANCED CLOUD-BASED REMOTE MONITORING FOR GENERATOR SYSTEMS

DSE WebNet ® is a powerful cloud-based remote monitoring solution designed to support both single and multi-set generator systems. Packed with advanced features, the software provides real-time instrumentation and control, interactive mapping with static locations, detailed event log tables, and automated system alerts.

With the ability to identify, monitor, and clear warnings and alarm conditions remotely, DSE WebNet ® helps reduce costly site visits and engineer call-outs. It also enhances the security of generator fleets, enables fuel level monitoring, and ensures optimised system performance at all times.

MAXIMISE APPLICATION FUNCTIONALITY

The Advanced PLC Editor, seamlessly embedded within DSE Configuration Suite Software, delivers unparalleled flexibility for complex data centre applications. Designed for maximum efficiency, it opens in a separate viewing window, allowing simultaneous use of both the PLC software and Configuration Suite.

The editor supports user-defined function blocks, enabling users to mix ladder logic with logic gates (AND, OR, XOR, NOT) for precise control. It also features rising and falling edge triggers, a built-in PID controller, and state machine support for advanced automation. With mathematical functions handling up to eight variables, this powerful tool provides high-level functionality to meet the most demanding site requirements.

At DSE we specialise in providing high-quality, tailor-made electronic solutions for businesses that demand data centre excellence. Based in the UK, we partner with leading data centre installers across multiple countries and market sectors to deliver industry-leading equipment that embodies precision, reliability, and cutting-edge performance.

Our commitment to quality is unwavering. From initial design to full-scale production, we rigorously test every product at all stages of the manufacturing process to ensure the highest levels of reliability. This thorough approach guarantees that each solution is robust, durable, and ready to perform at its best.

We continuously invest in our manufacturing facility and stateof-the-art equipment, ensuring our customers have access to the latest technology platforms for seamless integration into their products.

Our staff, who are highly skilled and dedicated to their craft, play a pivotal role in this process. Their meticulous attention to detail supports the automation within our factory, ensuring that every product is produced to the highest standards with unmatched precision and consistency.

Whether bespoke components or a fully integrated electronic system is required, we combine advanced technology with exceptional craftsmanship. Our innovative solutions are expertly tailored to meet specific needs.

Partner with us to bring your next project to life with confidence. Work with a company that combines premium quality, reliability, and the latest in advanced manufacturing technology.

All backed by a team of experts who care about your success.

DSE offers world-class technical support, providing expert guidance across seven continents. Whether remotely or onsite, our highly skilled team is ready to assist you with in-depth knowledge of data centre environments, generators, and building management systems. Our specialists understand the complexities of power systems and how to optimise performance for maximum reliability. From troubleshooting and system integration to fine-tuning your setup, we ensure seamless operation and efficiency.

With DSE support, you’re never alone—our commitment to excellence means expert advice is always within reach, ensuring your power solutions perform at their best, no matter where you are.

DSE products undergo rigorous testing to meet the latest industry standards, ensuring full CE compliance. Every product is subjected to comprehensive EMC testing in line with the required BS EN standards, with testing conducted at every stage of production. Real-world testing is also carried out on finished products to guarantee optimal performance. Nothing leaves the DSE facility until it is 100% ready for the operating environment in which it will be used.

Deep Sea Electronics Ltd UK

Highfield House, Hunmanby Industrial Estate, Hunmanby, North Yorkshire, YO14 0PH, UK

Telephone +44 (0)1723 890099

Email sales@deepseaelectronics.com

Deep Sea Electronics Inc USA

3230 Williams Avenue, Rockford IL 61101-2668, USA

Telephone +1 (815) 316 8706

Email usasales@deepseaelectronics.com

Deep Sea Electronics India

405, 406 Pride Gateway, Baner Pune 411045, Maharashtra, India

Telephone +91 20 68195900

Email sales@deepseaelectronics.com

Deep Sea Electronics UAE

Gold Crest Executive Tower, Office 512, Jumeirah Lake Towers, Dubai, UAE P.O. Box 72857

Telephone +971 (0) 45 910819

Email uaesales@deepseaelectronics.com

www.deepseaelectronics.com

Deep Sea Electronics Ltd maintains a policy of continuous development and reserves the right to change the details shown in this brochure without prior notice. The contents are intended for guidance only.

Registered in England & Wales No. 01319649

VAT No. 316923457