Dean Forest Railway

The Journal of the Dean Forest Railway

Dean Forest Railway

The Journal of the Dean Forest Railway

The Journal of the Dean Forest Railway is a quarterly publication.

© Dean Forest Railway Society CIO, 2023

All rights reserved. No part of this publication may be reproduced, copied or transmitted in any form or means, or stored in any information storage or retrieval system without the written permission of the Dean Forest Railway Society.

Views expressed within this publication belong to their individual authors and are not necessarily those of the editor, the Dean Forest Railway family of organisations, the Society or its Trustees.

The Dean Forest Railway Society accepts no liability or responsibility for any loss resulting from information provided in this publication.

How to submit an article

We prefer articles in electronic format (preferably Word), to be emailed to the editor at: magazine@ deanforestrailway.co.uk Or by post to: The Editor

This issue has been edited and produced by Alastair Clarke on behalf of the Trustees of the Society. Layout in Adobe

Please send your reports, letters, comments, photographs and any other content for Issue 65 by, at the absolute latest 20th May 2023

All DFR Society post (donations, membership renewals and general correspondence) should be sent to: DFRS Honorary Secretary (Mrs. S. Williams)

www.dfrsociety.org.uk

As I write this, the operating season has started with good passenger numbers. Just prior to opening to the public, we had a ‘Members Day’, held jointly by the DFLG and the Society. This allowed members to ‘preview’ the return to traffic of Pannier No. 9681. The day was a success, and it was lovely to see so many members present to enjoy the long-awaited return of this locomotive. However, we could not have held the Members Day, or started the operating season, without a lot of hard work during the ‘closed season’ in January, February and early March by many departments. This magazine features reports on much of this work which often goes un-noticed by our visitors, such as permanent way repairs, rolling stock restoration , S&T works and lineside clearance, but is vital to our ability to offer a steam-era railway experience for our visitors. My sincere thanks to everybody who has worked so hard during the winter period to achieve so much, often in less than ideal weather conditions. This operating season will feature two Steam Galas, a Diesel Gala, plus many normal operating days together with some new events such as a family-focussed ‘Forest Railway Stories’ event, and a 1960s Weekend. Visit the DFR website for more details and please consider supporting your railway by visiting during 2023. If you haven’t visited for a while, I am sure you will see some pleasant changes and improvements to the railway. If all else fails, a ride

behind 9681 as it barks its way uphill towards Parkend is bound to put a smile on your face!

Finally, I’d like to address a matter which has started to concern me recently as we have moved out of the COVID era and back to a more normal way of life at the DFR. I expect many of you have seen the World War Two-era poster with the slogan ‘Careless Talk Costs Lives’. I do wonder if we need an updated version to make people think about the effects of comments on Social Media or via email which may be well-intended, but are worded in such a way that they cause unnecessary hurt or upset to the recipients. I often think that we shouldn’t be prepared to say things from behind our keyboards that we would perhaps think twice about saying in person. All of the Trustees and Board Members would, I am sure, welcome criticism put over in a constructive way, but in our hobby there should be no place for hurtful or disrespectful communications.

Anyhow, I will get off my soapbox now and get on with something for the railway!

With best wishes

Forest of Dean Railway Limited Chairman, Adam Dickinson, writes on the theme of “Us and Them”.

Frequent topics of conversation around the mess room table will start with ‘why haven’t...’ or ‘why don’t...’, with topics ranging from extensions, sheds, to restoration of a particular piece of rolling stock. Conversation often evolves into re-examining decisions made 20, 30, 40 years ago, assessing them with the benefit of the equivalent hindsight. All too quick to blame ‘the management’ or ‘the board’ from the time, this attitude can roll on to discussion of how the railway is operated today, our current plans, with the perceived lack of progress in some areas being seen as a failing by ‘them’. But, who are ‘them’?

We recently had a session to continue to reorganise Lydney Junction and dispose of unwanted or life expired equipment, which allows more space for future sessions. These sessions are vital to improve our public image, bring in revenue, as well as ensure we know what materials we have on the ground in store, and longer term help to prepare for the developments at Lydney Junction. From the relatively small team, the following areas were represented – FODR Chair, DFRCL Co-Chairs, DFRS Society Chairman and Trustees, operational staff from steam, diesel, DMU, guard, signalling and crossing keepers departments.

This is the reality of the railway – lots of areas working independently, often unseen, but often coming together towards a common goal.

There is a perception in some areas that the management of the railway can be remote, unaware of what’s happening on the ground, making decisions without the knowledge of what came beforehand, or how it will affect the railway and its volunteers. It’s time to correct that perception, and it’s time to break down those barriers.

There is no ‘them’, there is just ‘us’. We’re all volunteers, supported by a small team of paid members of staff. We’re all doing our upmost to support and develop the railway. In the near future we’ll be confirming our overall development plan – it won’t all happen at once, and will generally be a phased approach at each site rather than straight to the final design. Our aims and objectives –which have been guiding the development and investment on the railway – are as follows:

• Operate the railway safely

• Ensure our financial systems are robust

• Increase passenger revenue

• Increase non-passenger revenue

• Retain and build our workforce, both volunteer and paid

• Develop the heritage and educational aspects of the railway

• Enhance our locomotives and rolling stock

• Build upon relationships with internal and external partners

• Enhance our operational infrastructure

• Maintain, renew and improve the infrastructure and property

The railway press are currently full of articles of railways around the country struggling in the post-covid world, with the cost of living crisis and other international issues impacting the heritage sector in general. While we continue to keep a close eye on our ever increasing costs and are taking actions accordingly, any additional support you can provide will be gratefully received and put to good use. We’re continuing to expand our commercial offering, both with family and enthusiast events.

Finally, I’m pleased to welcome the National Wagon Preservation Group into the DFR family, who have brought their unique rake of TTA tankers to our railway. Further details are available elsewhere in the magazine, and I’m sure many of us are looking forward to seeing them in use up and down our line, representing the end of liquid fuel by rail in four wheel tankers, and will complement our Berry Wiggins tankers in due course.

It’s that time of year again! Following last year’s successful trial, we have decided to stick to the format of two, shorter, draws for 2023. With this mailing you will find some tickets enclosed. As usual, please help your Society by either purchasing them yourselves, or selling to family and friends. Stubs and monies can be returned in the envelope enclosed. Cheques should be made payable to ‘Dean Forest Railway Society’. The proceeds from the draw will be invested into projects and improvements around the railway - please help support the draw to raise vital funds for your railway. If you do not wish to take part, please return the unsold tickets as we can reuse them for on-train sales, which are already underway organised by our Raffle Co-Ordinator Stan Rudge.

At the recent DFRS AGM (minutes will be enclosed in the next mailing), a new trustee, Stan Rudge, was elected. Stan will be well known to many at the railway, as he is a regular volunteer in the Shop, Booking Office and selling Raffle Tickets. Stan is already making a very positive contribution to the Society, and we welcome him on board! He is a very experienced fund-raiser who is heavily involved with the Poppy Appeal.

At the same time, Jan van der Elsen has decided to step down as a Trustee - we thank Jan for his contribution during his period of office.

Work is progressing steadily on the complete restoration of the Society’s LMS Brake Van, by a contractor based in Staffordshire. This work has been extensive and has involved stripping the van back to a bare metal framework, replacement of corroded metalwork, replacement of the vast majority of the woodwork, as well as the repainting which can be see in this photograph.

The van will be primarily used for works trains, in order to reduce the wear and tear on the Society’s Shark Ballast Plough van, and the DFR Heritage Wagon Group’s Queen Mary brake van. In addition, a dedicated van can be more easily kitted out with appropriate facilities and equipment for works trains (like a big kettle for a start!). We look forward to the return of this van to DFR metals in the next few months.

The Trustees were pleased to hear that the Society has been awarded a grant from Lydney Town Council to install solar-powered lighting at Middle Forge foot crossing. Whilst not required by legislation, illuminations will make the foot crossing easier for pedestrians to use during winter months when mornings and evenings are very dark! Installation of the lighting will take place in good time for it to make a difference this winter!

As DFRS Members, you are entitled to a 50% discount on travel on normal operating days at the railway, on production of a valid membership card. As we are now encouraging pre-booking via the DFR website, please use discount code DFRSMDX4892 when checking out to get your 50% discount, and remember to bring your membership card with you when you visit.

John Metherall recalls the overhaul of 9681, which formally returned to DFR service on 11th March 2023 at the joint DFRS / DFLG Members’ Day.

Bryn Thomas’s photo shows the locmotive undergoing steam trials on 16th February 2023, looking splendid!

Bryn Thomas’s photo shows the locmotive undergoing steam trials on 16th February 2023, looking splendid!

As 9681 reappears on DFR rails the time has come to look back over the years to 1975 when the loco arrived on a back of a low loader at the nascent Norchard site.

There is not room in this article to repeat all that happened between then and 1984 when it first ran on the DFR, as that history can be found in the ‘Forest Pannier 9681’ booklet still on sale in the DFR shop at a very modest £5. Its visits to other railways are also covered together with its major overhaul at Norchard and the Flour Mill which was completed in 2005.

In 2005 with a new ten-year agreement in place, 9681 could be seen for the next two years in regular service on the DFR. However, the lack of rail greasers resulted in the tyres needing re-profiling in 2007 and renewal the following year. The wheels were removed at the Flour Mill and dispatched to the South Devon Railway (SDR) for new tyres to be fitted. On return to the Mill they were reprofiled before the loco returned to Norchard for reassembly and painting, returning to service in August 2009. This work resulted in a £31,000 expenditure.

In early 2009 an ultrasonic (NDT) test was carried out on the boiler to determine any cracks or wastage. Our insurers were insisting on conducting the next hydraulic test after seven years’ service instead of ten but fortunately they rescinded this decision. 9681 was ready for the 2010 season and remained in regular use until the end of 2013 when with leaking tubes the trustees decided to withdraw the loco from service and start dismantling it for the next major overhaul. In anticipation of needing storage space for the removed parts the Group had acquired the Fruit D van from the company and restored it at a cost of £13,000

2013 also saw the start of changes in the orgainsation, Harry Rawlins stood down as our CME and handed over the reins to Neil Cooper and Tom Halford who were given the task of drawing up a detailed plan for overhauling 9681.

ing a Down train near Whitecroft on the Members’ Day on 11th March 2023. Below: Looking resplendent, with a highly-polished finish, 9681 stands at the coaling stage at Norchard on 11th March 2023. (A. Buckley)

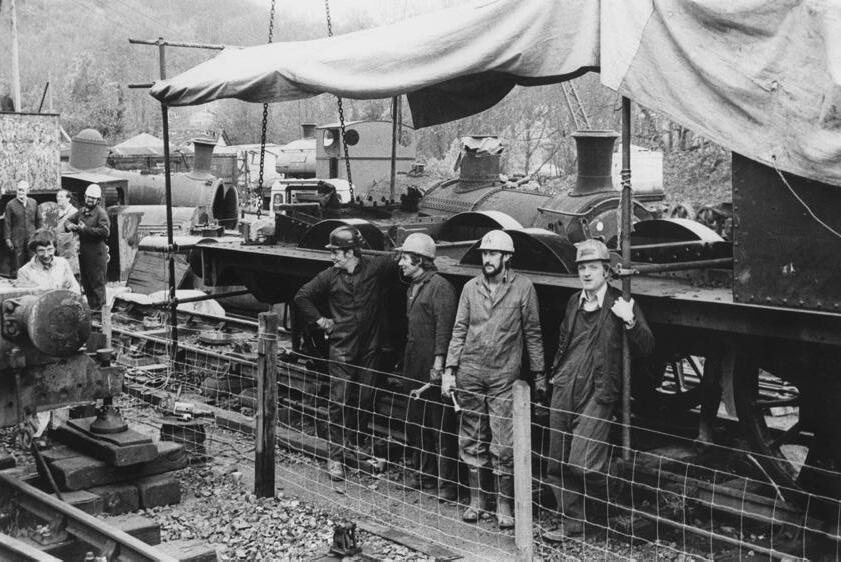

Opposite page top: Back in 1975, 9681 arrives at Norchard on a King’s Haulage low loader. (J. Hatton)

Opposite page middle: Work has commenced on the original restoration, amongst the chaos of a slowly-developing Norchard Steam Centre. (J. Hatton)

Opposite page bottom: The original restoration team - from left, Andy Baptist, Mike Pearce, John Smerkinich and John Metherall, showing the primitive conditions! (DFR Museum Trust)

In May 2015, the DFLG and the Forest Prairie Fund, owners of 5541, amalgamated under the DFLG banner and in December that year the group became a Charitable Incorporated Organization (CIO). Up to this point in time £130,000 had been spent on 9681 including the purchase price of £3918.50

While the removal of smaller items commenced during 2014 it wasn’t until July 19th, 2016, that the tanks, cab, bunker and boiler were removed, the chassis put over the pit, to allow removal of the eccentrics and connecting rods and then finally the frame jacked up in the shed for the wheel sets to be rolled out – all in one day!

Tubes, flues and steam pipes followed and with sludge cleaned out it was ready for assessment by the boiler inspector. Following a deal of needle gunning, work commenced on painting the boiler and frames and importantly gaining access to the cylinder block to see what repairs were needed. This involved careful removal of the concrete which sits above the block and acts as a floor in the smokebox. By the spring of 2017 new running plates were constructed and the wheel sets which had been sent to the SDR in December 2016 returned together with a new smokebox and door which had also been fabricated. By now the boiler inspectors report was available and work commenced drilling out

the stays that needed renewing. A major job completed in early 2018 was the boring out of the cylinder block and fitting new liners. The block was then split into two castings and together with the pistons were sent off site for repairs and machining. By the autumn of 2018 new running plates had been fitted and work had started on a new cab floor, cabsides and a buffer beam while the eccentrics had been repaired and fitted. Work had also started on the axle boxes and horn guides. The repaired cylinder block returned and was fitted back in the frames which together with the brake rigging allowed 9681 to be re-wheeled by the autumn of 2019. Over the winter work progressed on the bunker and cab roof and attention turned to the vacuum and steam pipes which was completed by the early spring of 2020. However, the 19th of March 2020 saw the first lockdown due to Covid 19 and volunteer work at Norchard ceased. Fortunately contract work was able to continue at Norchard while at Tyseley progress, although necessarily slowed, was being made manufacturing the new pistons. During the lockdown essential maintenance work carried on to the group’s other loco, 5541. Undaunted Tom worked at home doing what he could including repairing the firehole door and mechanism. However, towards the end of May the railway had Covid compliant schedules in place which allowed work to continue, albeit under difficult conditions. Work on the cab and bunker continued with WSE installing a new cab floor. Although another lockdown started at the end of 2020 by the time it ended in May 2021 the new pistons had been fitted and the boiler stay work completed.

From the outset the trustees intended that the locomotive would be turned out in as near ex-factory condition as is possible. To that end every mechanical part, pin and bush has been renewed while every part of the motion and valve gear has been inspected. The cylinders have been relined and new pipe work fitted.

Interestingly and rarely seen these days hot riveting has been employed.

We anticipate that the latest overhaul will have cost £295,000 which includes parts and contract labour while the volunteer time spent on the locomotive amount to somewhere near 30000 manhours.

This short resume of the history of 9681 cannot do justice to the time and unstinting efforts of a few dedicated members led by Tom Halford and our contractor Western Steam Engineering led by Ed Freeman.

This loco was rescued from Barry in 1982 by the GWR Preservation Group and moved to their site at Southall. It was returned to service in 2000 and could be seen on various preserved railways in the following years. It was withdrawn for overhaul in 2009 and partially dismantled and the fittings placed in store from where they were stolen in 2018.

In 2018 the GWRPR decide to sell 9682 and the DFLG were successful in obtaining the loco. Since then, fundraising for the missing parts, estimated at the time at £35K, has progressed and although some parts have already been secured there are many more required

Tom Halford’s program of restoration work has shown up what is needed to put 9682, double headed with 9681, on a train to Parkend, or further if the DFR‘s plans to expand come to fruition in time. So, if you would like to see this happen, please consider a donation, Gift Aided, if possible, towards any of the missing parts.

http://www.deanforestlocogroup.org/

Top: The DFR’s chaplain, the Rt. Rev’d Christopher Hill, redediactes 9681 during a ceremony at Norchard on 11th March 2023. (A. Buckley)

Above: During the same ceremony, DFLG Chairman Matt Sexton presented Tom Halford with a model of 9681 to recognise Tom’s major role in the locomotive’s recent restoration. (A. Buckley)

Below left: The next project, sister loco 9682, waits in the restoration shed at Norchard. (A. Copley)

Below: Some of the DFLG restoration team pose with the fruits of their labours. The loco is a credit to all involved. (A. Buckley)

Visitors to the Museum over the autumn may not have noticed the occasional wooden locomotive hiding in some of the cabinets. Children are more observant (see photograph for an example). These Thomas and Friends are not escapees from their siblings in the Shop but rather part of a children’s quiz devised by our own Jenny Barnett. From half-term to the end of Santas about 200 entries were filled in to work out the secret name (note the letter by the locomotive). The result is ‘Norchard’. Thanks not only to Jenny but to all in the Shop who issue a prize-sticker to all with (or even without!) the answer. Very clearly the children have been enjoying the quiz.

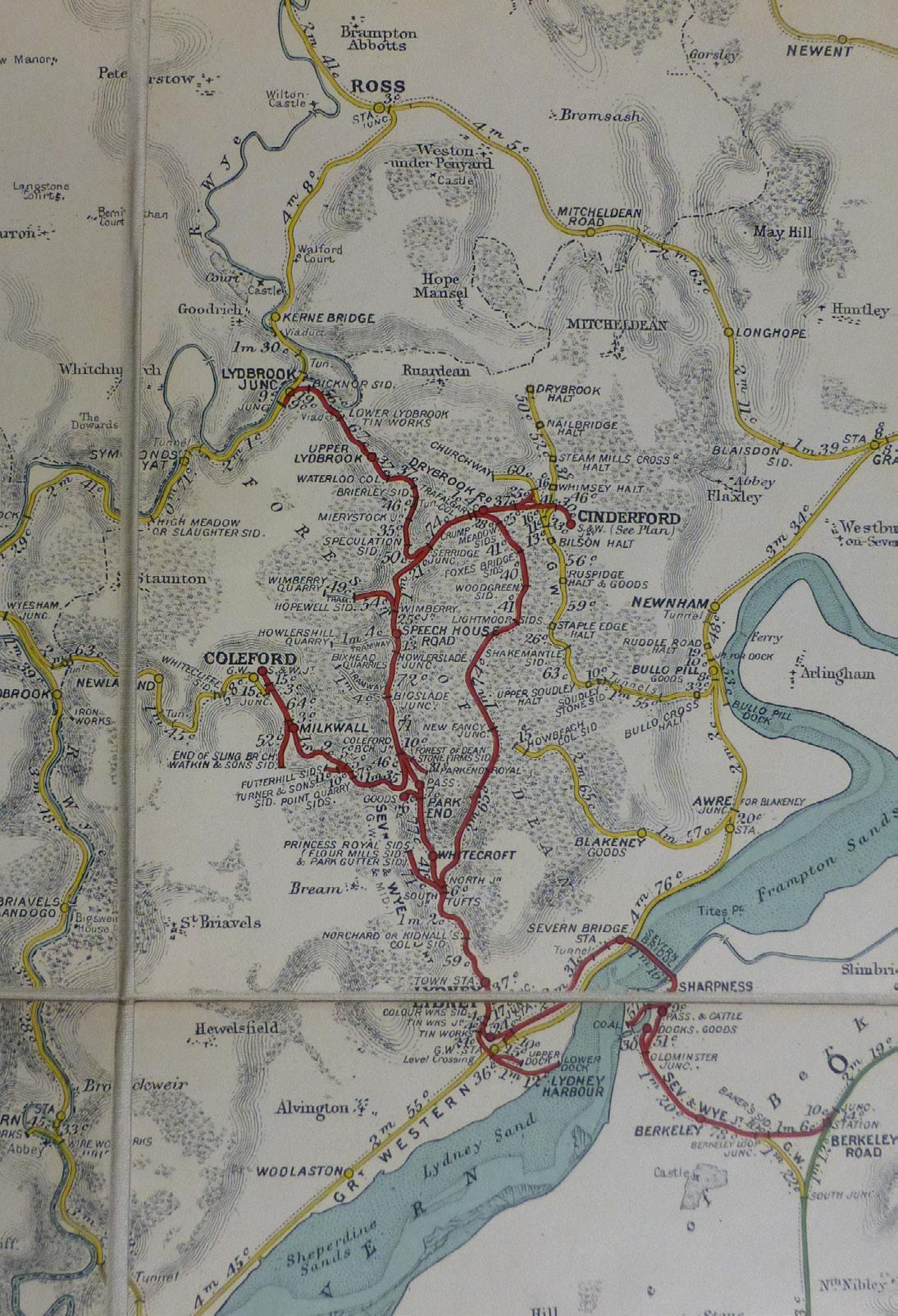

Maps are fascinating things; from the A-Z of Gloucestershire to the Mappa Mundi (Hereford Cathedral). The Museum has a good collection of Railway Clearing House (RCH) maps produced by John Airey. They are functional, accurate and printed in various colours to indicate the many different railways of pregrouping Britain. Of varying scales by 1883 the regional series numbered 15. The RCH began life in 1842, though not all companies joined immediately, typically the GWR but there were also others who only joined in the 1860s. The RCH booked through passengers over different companies’ lines, though goods on a mileage basis and arranged the settlement of inter-company debts. Accurate mileage maps were essential for these functions. The RCH later attempted some standardization of the production of good wagons and other vehicles. For example where the vacuum pipe was placed had a bearing on whether vacuum connections could be made between different companies’ vehicles. And even the placement of buffers! The RCH maps have sometimes been criticised for being inaccurate (as in the wonderfully illustrated ‘Mapping the Railways’, Times Books, 2011) but the example cited, a projected but not yet built line from Bridgnorth on the Severn Valley Railway to Wolverhampton GWR, is actually correct. The line was projected and surveyed (as shown on the map as a projected line) but the GWR eventually decided it was cheaper to run a GWR bus service instead. Here (see photograph) is the RCH Airey map covering the DFR territory. (For the history of the RCH see ‘The Oxford Companion to British Railway History’, Oxford, 1997).

A recent acquisition of another map duplicates one already in the Museum’s possession. It was produced by G W Keeling in 1894 to show all the railways in the

Forest at the time of the GWR/Midland take-over. But the interesting thing about this is that it is leather-bound and on the inside cover is inscribed ‘Mr Grierson’s Copy’. This looks like the Swindon record office copy or even a personal copy of the GWR Superintendent. At first sight could this be the GWR General Manager appointed in 1863. But no, because he died in 1887, seven years before Keeling produced his map. But there was a later W W Grierson ( a relative?) who became GWR Engineer in 1903. He would probably have been in service with the GWR well before this. Do DFR members have any wisdom on this particular Grierson? No doubt another copy was sent to Derby. The other version of this map is already on display in the Museum, just opposite the ‘Ticket Office’.

Above: One of the wooden locomotives hiding amongst the museum exhibits for the children’s quiz.

Right: An extract from the RCH Airey map covering the Forest of Dean.

Below: The title block of the RCH map.

The alarm goes off at ‘stupid o’clock’, otherwise known as 04.30 on 11th December. The worst part of the day is over by the time you have summoned up the courage to pull off the covers and step onto the cold bedroom floor. The heating isn’t even thinking of coming on for another 3 hours and my phone tells me that the temperature will drop to –2 celsius by 06.00. An incoherent grunt from the other side of the bed warns me to keep quiet. The dog lies luxuriously in her basket and looks at me like I am some kind of alien lunatic but the kettle is soon on and after tea, toast and muesli, I feel almost human.

Outside the snow is starting to come down as I step out to the car. Clevedon is soon left behind and I’m on the M5, going up the hill towards the M5 bridge over the Avon. It’s higher ground here and the snow is certainly getting its act together now but soon we are up to the M4, then crossing the old Severn Bridge and down into Chepstow.

The A48 up to Lydney starts to feel like a bit of a challenge as the snow is definitely settling now but a nutcase in a BMW seems to think I should be going much faster even though the front wheels are starting to develop a mind of their own. He roars past and I smile, making a mental note to keep an eye out for the ditch where he will very likely end up.

Norchard is a lovely spot at all times of year but today, as the light comes into the sky, it is a beautiful blanket of pure, pristine whiteness, tinged in blue. It seems a shame to spoil it with footprints but Mark pulls up at the same

time and we trudge to the shed. Driver Scott is already there (what a star!), oiling up and we get stuck into the jobs needed to get pressure up by about 09.00. Luckily 5541 has been out the previous day so it’s been nicely prewarmed and the pressure soon starts to rise.

We start thinking ahead and the question arises as to whether we will be able to get water at the column at Parkend or whether it will be frozen solid. I am delegated to go and see, so it’s off in the car again, sliding all over the road until I drive past the first vehicle casualty, neatly parked in a ditch just before Whitecroft. Tyre marks all over the road illustrate other dicing with disaster moments. Why don’t more drivers know how to drive in these conditions?

Parkend looks even lovelier than Norchard and a kind soul in the station team has already lit the brazier under the arm of the column in anticipation of a possible freeze so I just empty another bag of coal into the fire devil and head back.

On the engine, pressure climbs up in the glass, the fire roars comfortingly, lamps are lit and we are soon ready to see what fun awaits us. We leave Adam and Sam on platform de-icing duty and a proving mission down as far as Lydney Town gates and then up to Parkend begins, to ensure that the service trains don’t come to a premature icy halt. It soon becomes clear that several sets of points, starting at Middle Forge, are well frozen. Advanced technology comes to the rescue in the shape of a screwdriver to

scrape away at the ends of the point blades and we get quite proficient at this as we proceed.

Back at Norchard and happy to report that the 4 trains today will operate as they should, we attach to the first Santa train about an hour late, feeling smug that we have been up so much earlier than everyone else and that we are also so much warmer – at least until the steam heat finds its way through the train.

From then on, all goes very well, the 4 trains are all full and there are lots of happy and contented faces leaving the trains laden with presents and crazy Xmas jumpers. It feels good to have given everyone a nice day out send them home ready for Xmas with these memories.

We say goodbye to our happy customers and head for coaling and disposal. I’ve done quite a lot of ‘ashing-out’ this year so I am very grateful indeed when Scott volunteers for that duty underneath the engine that covers you in filth, cold water and hot ashes, no matter how clean well you’ve kept yourself throughout the day. Cleaning the smokebox feels like a let-off in comparison. 5541 has been a star, as usual. She worked hard all day and there is quite a lot of ash to clear but we are done by just after 6pm: a long day that sends me home tired but happy.

To my mind, there really is nothing quite as wonderful as being on the footplate of a steam engine with a supportive and agreeable crew.

Aren’t we lucky to be able to do this?

Alan Pace tells of the disposal of vehicles which the group had previously purchased for component recovery, plus servicing work on the running fleet. He also looks ahead to the 2023 season, which will feature plenty of DMU running!

As we prepare for another DMU running season it is interesting to note that some of our DMU vehicles have been in preservation for about as many years as they were in BR service. M56492 was in service with BR from 1960 to 1991, during that time it was looked after by various depots in the Liverpool and Manchester area, before moving to Chester, Tyseley and then Bristol Bath Road. It visited BR works at Derby, Swindon and Doncaster during that period. Since entering preservation in 1992 it has been well looked after by our DMU group with restoration and maintenance work carried out at Norchard depot apart from one visit to Bristol St Philip’s Marsh depot for tyre turning. Notable work done by our group includes fitting a new cab front, refurbished bogies which were previously fitted to M56495 and a buffet. M56492 has been well used in preservation, having run more miles on the DFR than any of our other vehicles and it has a very popular set of first class style seats. We hope to see it out and about in 2023.

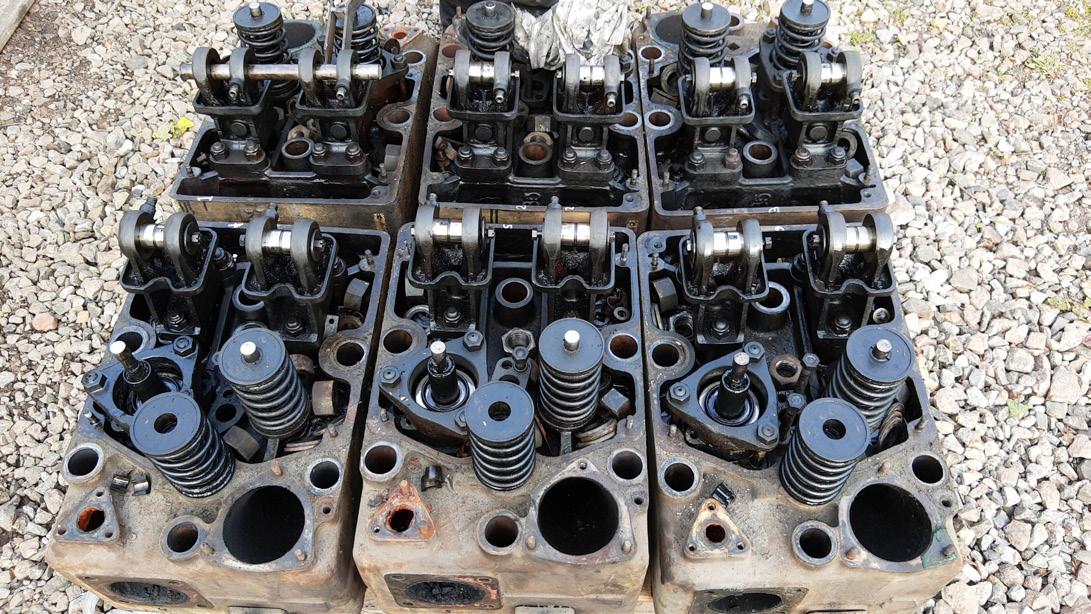

In early November 2022 vehicles 50632 and 52044 which

were purchased for spares in 2020 were broken up at Lydney Junction. When purchased these were in a very poor state. A lot of work went in to recovering spares for ourselves and many other groups around the country. Smiths of Gloucester brought in some heavy machinery and most of the breaking up work was completed in one day, the job was finished the next day and the scrap taken away for sorting and weighing of the various materials. Thanks to the DFR for allowing the work to take place and to those who helped to clear the site at Lydney Junction prior to the work.

The DMU team has been busy with restoration and servicing work to keep the fleet in working order for the 2023 season. This has included repairs to a brake cylinder on M51566 which refused to create high side vacuum in the normal manner. Following various tests a problem with the ball valve was suspected. While class 108 trailer cars have brake cylinders mounted separately from the bogies in a similar arrangement to mark 1 coaches the power cars have them hidden away within the bogies, presumably

due to engines, gearboxes and other items taking up the space underneath the vehicle. This makes working on a power car brake cylinder difficult.

One option is to lift the vehicle, roll out the bogie and lift out the brake cylinder, but this is a major job needing access to suitable space and lifting equipment and disconnection of lots of items. Instead the work was done from underneath in the DMU depot area, requiring various heavy items of brakegear to be removed to get access to the cylinder then lowering the heavy parts requiring attention, not easy for those working underneath in a confined space. Following dismantling and cleaning the parts were tested. Thanks go to John Clarke of the carriage and wagon team for helping to provide test equipment in the blueline building to ensure that the items were working before fitting them back on to the vehicle. Various jacks, pallets, packing and a lot of teamwork followed, resulting in the cylinder being reassembled and successfully tested on M51566.

Plans for the 2023 DMU running are similar to 2022 but without the gala. Due to the popularity of the Forest Flyer services these are returning on most Tuesdays during the school summer holiday period and a DMU will provide a second train on the Wednesdays during that period. These two train days are a good time to visit the DFR with a busy timetable and the opportunity for travel on both steam and diesel services.

If anyone is looking for some uniform items for the new running season the DMU group have a selection of items. If you want to know more then email dmugroup@ deanforestrailway.co.uk.

No sooner does the new magazine land on the door mat than the editor reminds us that the deadline for the next issue is looming. Flicking through the pages of the magazine is a trip back in time. Did I really write all that waffle all those months ago? Apparently so. Has enough happened for me to write more waffle now? You be the judge.

My last article bemoaned the summer heat and how it impeded our work but, as always, it’s a case of ‘be careful what you wish for’ and the turning of the year saw us ramping up activities again. Initially with more work on the point timbers at the junction and then with our second large track relaying project of the year – Kings Meadow Court.

For those less familiar with the line than myself (and that probably means most of you) Kings Meadow Court is the retirement complex on the east side of the line just south of Lydney Town station. A few years ago, we noticed a problem with chair bolts on the E type concrete sleepers in this section failing and a plan was devised to lift the track and replace it with flat bottom rail on G44 sleepers similar to the ones used on the relaying work between the bypass and Harbour Road four years ago.While we waited for a window of opportunity to do this tie bars were installed to prevent the gauge from spreading where bolts had failed and a 10mph speed restriction was imposed on the section.

The pandemic and other priorities delayed the work but, progressively, materials were moved to the site and plans drawn up ready for an opportunity to do the work. That opportunity finally arrived in November during the break in services between the end of the running season and the start of the Santa specials.

Much of the work was carried out by volunteers but we brought in Quattro for a week to assist with the core work of lifting out the old track and putting the new track in using both the Society’s RRV and one of Quattro’s.

As there was nothing wrong with the bull head rail we were taking out, we decided on a radical approach to recycling materials. First the existing 95lb bull head rail was swapped out for worn out 85lb rail. The 85lb rail was then cut into 15ft lengths, which enabled the RRVs to lift out the rail with the sleepers attached and stack it opposite Lydney Town station.

These short track panels will be moved to Lydney Junction where they will use to lay out the sleepers for a new siding south of the bypass. Once the sleepers are laid out the rail will be removed and replaced with better quality rail. The 15ft lengths of old rail will then be sent for scrap. It is also planned that two or three of these short panels will be moved to Norchard high level where they will form a ‘trolley park’ to store hand trolleys alongside the main running line.

Back at Kings Meadow Court the RRVs (the DFR one and one hired in, both driven by Quattro operators) set about grading the track bed, laying out the G44 sleepers and putting the flat bottom rail in place. The rail used for this job was also recycled, having been removed from the national network and donated to us by Network Rail.

With the heavy lifting completed, Quattro departed and the volunteers set about the task of ‘fettling’ the line, including dropping ballast on the section. Originally a Network Rail tamper and ballast regulator had been due to visit to tamp and align the section as part of a shake down test but problems with the ballast regulator meant

that this visit was cancelled. This, unfortunately, meant that rather than lifting the speed restriction we were forced to impose an even slower speed for the duration of the Santa and Mince Pie specials and, as anyone who travelled on those services can probably attest, the ride over the section is not all it could be.

Throughout the work the RRV Land Rover performed sterling service supporting the work by ferrying tools to and from the tool van, which was in the St. Mary’s siding and, latterly, between Norchard and the work site. It was during an early morning run from Norchard that we had a rather rude awakening when we found a large boulder had fallen onto the line side from the bank just north of Lydney Town crossing. The boulder was quickly removed by the RRV but it was fortunate that we discovered it before any train did.

Although there is still no sign of a tamper visit, we are drawing up plans to ensure that the section is correctly tamped and aligned and appropriate lift plates have been fitted so that the speed restriction can be lifted in time for the start of the 2023 season.

The inevitable mix of rain, wind and cold in December presented its usual round of issues with drainage ditches needing clearing and patrols to check for fallen trees before running days. On some of these patrols I was accompanied by the four-legged member of our team, now sporting her new hi-vis jacket, Daisy the spaniel. She may not be too handy with a key hammer but she has a thorough knowledge of the line and the various features along the way.

As I write this article, we are in the process of preparing the Parkend yard siding to take rail traffic for the first time in many years. By the time you read this a number of restored wagons should be on display at Parkend.

A project that has occupied a fair amount of my time over the Christmas and New Year period has been an attempt to catalogue all the various jobs on the permanent way team’s to do list. This has turned into a fairly extensive document with around 50 individual tasks already listed. Some of these are simple jobs which can be addressed in a couple of weeks with the right equipment, others are major undertakings and still others are on-going projects that will take years to complete.

One problem which has dogged us for a few years now is a lack of undercover storage for tools, consumables and more delicate track components. Our current base, in the Undercroft area below the pagoda on the Norchard high level platform is extremely damp and increasingly cramped. The situation became a bit worse at the start of 2023 with the decision to restore a box van that had been used for storing materials in Whitecroft siding. We have had to empty the van so that work can begin on its restoration and while some of the contents can be scrapped other pieces need to be stored. The good news is that the board has approved the purchase of a new 20ft container for us to use. This will initially be located at Whitecroft where an

existing, rotten container will be scrapped. It is hoped that a second container will join it next year.

Volunteers on the HOPS system may have noticed that there has been very little mention of the Lydney Town crossing renewal work in recent months. That is because we have decided to delay the project for another year. The increasing complexity and cost of the work meant that we needed more time to plan it and get everyone on board.

“How difficult can it be?” I hear you cry. Well, the short answer is “very”. It is only one track and it is only about 60 feet but it is 60 feet across one of the busiest roads in the forest. Anyone who has ever glanced out of a carriage window as the train crosses the town crossing will have seen the queues of traffic that build up in just a few minutes. Imagine closing that road for a week or more.

Those of you who live in the local area will recall the outcry last summer when Gigaclear dug up most of the roads in Lydney to install fibre optic broadband cables – and all they did was implement one-way systems and traffic control.

Then there is the proposed track slew.The solution we are putting in place will last for 50 years or more.The crossing gates, sadly, probably won’t. Operating the town crossing is labour intensive and again as anyone on the HOPS system knows, the most common appeal for volunteers is for crossing keepers at the town. Replacing the gates with automatic barriers is both desirable and inevitable but it’s also impossible unless the track is realigned to allow enough space the barriers and their motor units. So, as I mentioned in the last article, we are not simply planning to replace the track through the town crossing, we are also planning to move it a couple of feet to the south west (or up the hill if you prefer) to make room for the barrier motors.

In summary this job is proving to be a lot more complicated and expensive than we originally thought so more time is required both to plan it and to fund it. At the moment we are looking at three options for the crossing renewal itself, each of which has pros and cons. More details will follow as the year progresses. We’re always on the lookout for new volunteers, and you don’t have to be out in all weathers or in the middle of the week to work with our gang.

We are looking for mechanically minded people to help our ‘back office’ team repairing and refurbishing tools and materials. We urgently need to refurbish a number of point hand lever mechanisms so that we can replace failing ones in the yard an Norchard and elsewhere.We also have a large number of petrol engine tools, ranging from simple generators and impact wrenches up to the Geismar motorized trolley, that would benefit from servicing by a capable engine mechanic.

We are also looking for people who can help sort and catalogue the various permanent way ‘assets’ that the railway has. In the early days of the DFR we, like most infant heritage railways, acquired any materials that we

Opposite Top: The track bed prepared ready for new track to be laid. (A. Davies)

Opposite Middle: The RRV lifts the sleepers into place using a plate grab - a very useful attachment indeed! (R. Alpin)

Opposite Bottom: Daisy the spaniel inspects the track (A. Davies)

Above Left: the new track in place. Modern flat bottom rail and concrete sleepers massively reduced the maintenance burden. (A. Davies)

Above Right: The DFR’s RRV and a hire-in Quattro machine work together. (A. Davies).

Left: Not what you want to meet on your way! (C. Kyte)

could from the various railways and engineering firms that were closing down at the time. Many of these materials were simply stored at points along the line side in case they were ever needed. Now, as a more mature railway, we have a much clearer idea of what we will and will not need going forward. The special projects team are progressively ‘tidying up’ the railway by recovering materials from various locations and moving them to Lydney Junction. Once there they need to be sorted into items we want to keep, items that may be of use to other railways and museums and items that should be weighed in for scrap. This is the sort of activity that could be done on sunny weekend days during the summer.

If you think you could help with either of these tasks please email volunteering@deanforestrailway.co.uk – we’d love to hear from you.

Stuart Bearne tells of progress made by the Friends of Parkend Station Group on all fronts over the last quarter.

The continuing helpful Tuesday weather has allowed work to continue at Parkend on all fronts with just a short break over the Christmas and New Year period.

The steps up into the Goods Shed have been the major issue to contend with. As reported in the last edition, completely new steps and railings had to be ordered, funded by the Society. This was done in the Autumn with the various sections being delivered to the shed where priming/undercoating was undertaken prior to assembly by the contractor. Once the steps had been installed, gloss paint was applied over a few weeks and the finished job looks impressive.

The future dedication of the Parkend Goods Shed to a Museum extension has resulted in a review of where the various equipment/paint/tools are to be kept once FOPS are displaced from the Shed and it is likely that we will be able to come to a resolution on this subject in the next few months.

FOPS are currently carrying out the annual inspection/ renovation of all signage at the station plus white lining and track weeding. The completion of the bridge repaint late last year does give a clean and pleasing aspect to the south end of the station.

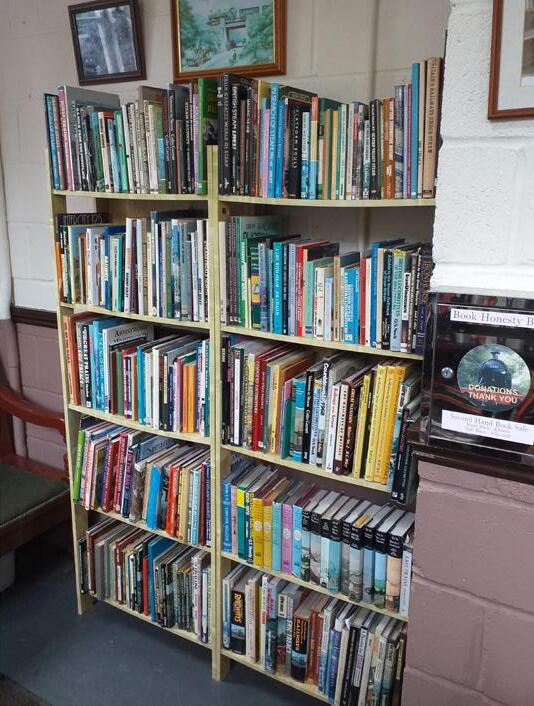

The sale of railway and other books from Parkend Waiting room went well in 2022 and it is hoped that this continues in 2023. Restocking of the shelves ready for the 2023 season has gone well over the winter but further additions to the stocks are always welcome and many thanks to those who have donated books in recent months. All proceeds are used to purchase essential supplies/equipment. Many thanks also to Rosie who keeps an eye on the books for us and ensures that the shelves are always well stocked. Rosie also makes sure that the site is as neat and tidy as possible.

We have lost the services of our good friend Doug Heeps who has moved from the area to be nearer family and the contribution he made to Parkend and the FOPS over the years are so much appreciated. FOPS have been fortunate in acquiring the services of two new volunteers, Trevor and Robin to complement our team and we hope that the good atmosphere and presentation of the station continues into 2023 and beyond.

Rick Gillingham updates us on a project to move communications systems on the DFR firmly into the 21st Century!

A couple of years ago I was asked to look into the possibility of installing optical fibre along the length of the Dean Forest Railway. I assume this was partly due to the fact that some of the existing copper cable had been accidentally damaged and required replacement but at the same time copper had become very expensive.

Eventually I persuaded a company that installed optical fibre cables to supply a rough estimate (without visiting the site) of the cost to supply and install fibre along the length of the DFR. In November 2021 the estimate was for £36500 plus VAT - this assumed that there was suitable troughing and/or conduit the length of the line and easy access to all buildings and suitable space for fitting data cabinets.

About this time I was made aware that there was a possibility that another railway company were maybe giving away some drums of fibre cable. Some time passed without the appearance of the fibre cables but then quite fortuitously 2 new volunteers joined the telecoms group – one had data experience and the other had fibre cable installation experience.

After some discussion we decided to purchase a 100 metres of fibre and install it between the cafe and the station master’s office at Norchard as an experiment to give us much needed experience of working with fibre. This was completed in October last year and it is still working satisfactorily.

This area was chosen as we already had previously installed data cabinets in both the cafe and the SMO for the cctv cameras and could also be used for the card machine. Following this success it was decided to press on and plan a fibre network around Norchard site and we have been installing ducts and footway boxes around the site in readiness.

In the middle of October last year the promised fibre cable arrived at Norchard - 9 drums with various lengths of cable on them but all the drums were damaged which has made it difficult to work with. However we have managed to unreel sufficient cable to start laying in the fibre cable at various places ready for connecting.

The main problem at Norchard is there is no suitable ductwork across the tracks from the cafe side to the shop side. This was a problem when the cctv cameras were installed and was overcome by using a wi-fi link as

at the DFR! (A. Williams)

a temporary measure. A solution has been agreed and a new duct should be laid across the tracks next to the level crossing and then into the shop building fairly soon. Once this has been done it will allow easier digital expansion around Norchard site - this may take a while but the basics will be in place.

Of course at this time we need to consider the appropriate placement of the main digital cabinet at Norchard. Once again this has been discussed and agreed in principle but like everywhere on the DFR space is at a premium and we are awaiting final agreement. Ideally it needs to be in a place that is secure and not easily accessible to everyone but allows access for upgrades and maintenance.

The Telecoms department are working toward supplying the DFR with a reliable up to date comms system using fibre and digital technology but it is a very slow process due mainly to economics and also the fact that digital technology is always moving on.

John Metherall, Honorary Archivist of the DFR Museum, writes about an abortive railway project grandly titled the Worcester, Dean Forest and Monmouth Railway.

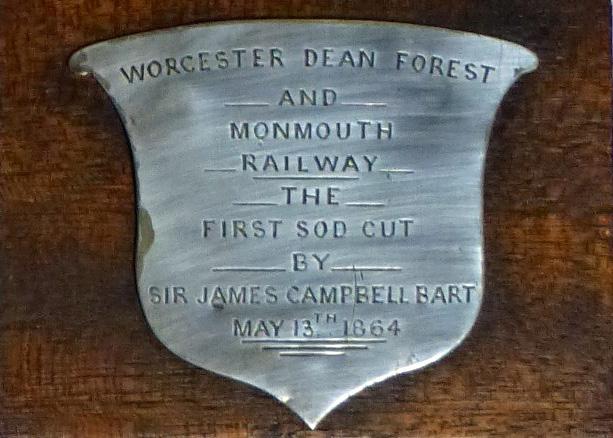

The arrival in the museum of a notice headed the Worcester, Dean Forest & Monmouth Railway (WDF&M) reminded me of the brass plaque we have in the collection inscribed ‘Worcester Dean Forest and Monmouth Railway. The First Sod Cut by Sir James Campbell Bart, May 13th 1864’, which it is documented has having come from a wheelbarrow used in the digging.

In 1862 plans were submitted to parliament for the construction of a railway from Great Malvern to Monmouth. The route from Malvern took it via Welland, Castle Morton, Pauntley, Newent and Longhope, where it crossed the Hereford and Gloucester railway before proceeding to Abinghall (now Abenhall) some 20 route miles from the start. Here it was to cross a turnpike road with a 195 yard long, 59ft high,14 arch viaduct before in a mile or so diving into a 1215-yard tunnel near Folly Farm. A further mile on the plans show it crossing the FOD branch close to Winning Pits south of Whimsey taking the line towards Speech House and onto to its junction with the Coleford ,Monmouth, Usk and Pontypool Railway at Dixton Newton (Mon)

Harry Paar mentions in his book ‘The Great Western in Dean’ that on the 13th May 1864 Sir James Campbell dug the first sod of the railway somewhere near Speech House. Intrigued as to the route of the railway in this area I looked up plans in the Gloucestershire Archive. Unfortunately, this section doesn’t produce much evidence apart from stating that it crossed Severn & Wye tramroads twice between four and five miles on from the FOD Rly crossing and twice more crossing the S&W Birch Hill tramway between Parkend and Coleford.

However, investigation in a newspaper of the time gave more details. The Gloucestershire Chronicle of May 14th, 1864, reported that this new enterprise would provide a direct route between Monmouth (already connected to the ‘narrow gauge’ system) and the West Midland system near Malvern and so avoid the double handling caused by using the GWR broad gauge via Gloucester. In addition, a new plan was already before parliament to provide a ‘narrow gauge’ line from Newent to Gloucester so that

Gloucester could obtain Aberdare steam coal.

Turning to the eventful day the article reported that the turning of the first sod of the main line took place at Speech House Hill. A special train had brought the directors of the line from Worcester via Hereford to Monmouth. However, the ceremony which had been fixed for one o’clock was delayed by two hours awaiting the arrival of the FOD Rifle Corps and Band at the Speech House Inn. Here a procession was formed, led by Sir James Campbell (Deputy Surveyor of the Forest of Dean) and others who walked to the scene of the ceremony at the bottom of the hill.

The report noted that on either side was forest with a corkscrew road winding up a steep assent and near at hand was a coal pit and that the first sod was turned in a hollow scooped out of the pit’s embankment. The hollow and the surrounding trees were full of local people waiting for the event to start and enjoying a general holiday.

By a quarter to three volunteers had cleared a space in the hollow where Sir James presented Lady Campbell with a silver bladed spade engraved with the same words as the plaque in our collection. She lifted the first sod into a polished oaken wheelbarrow (complete with our plaque presumably) and then wheeled it along a plank to a tipping point, accompanied by the cheers of the crowd. Three further sods were cut by some ladies present before a larger wheelbarrow and spade was provided for Sir James and Abraham Darby, the Chairman of Directors and well known for his involvement in the Ebbw and Coalbrokedale

iron works. So, if the report is accurate the inscription on the plaque is incorrect.

Sir James gave a speech in which he hoped that now the first sod had been turned it wouldn’t be long before the last one occurred. He was right there, as apart from some minor works little else occurred along the proposed route of the railway. The deed done the party returned to a large marquee erected near Speech House where luncheon was served for the many dignitaries including the Mayor of Worcester and Mr. Wilson, the engineer of the line. For the locals who attended the event the day ended by further festivities in Coleford and its neighborhood. In his speech after the luncheon Sir James said that tramways had served a former generation and that Foresters had been represented in the tramway world but not in the railway world. The engineer said ‘the line had been started that day in a manner he had never seen equaled and that progress would be with lightning speed’ All these plans and fine words came to nought as apart from the first sods dug at what appears to be the site of Cannop Bridge Pit, an embankment built at Pauntley by an affected landowner and some work at Newland nothing else was achieved in the five year allowed to starts the works..

There are plans in existence for deviation to the line in

the Newland and an 1871 plan show a much-reduced affair with the line from Monmouth terminating in the Bilson area, the route now being via what was to become the Mineral loop of the S&W to Tufts and then via the Oakwood branch passing the Flour Mill Colliery on its way to Coleford and Monmouth.

As was mentioned earlier the same company laid plans before parliament in 1864 to provide an extension from Newent to Gloucester, following in the main what would eventually be the route of the Ledbury to Gloucester railway.

The banking crisis in 1866, brought about in the main by the speculative investment in building railways, didn’t help the project and in December 1868 the Board of Trade using the 1850 Abandonment of Railways Act declared the railway between Great Malvern and Newland abandoned followed in 1880 by the remaining section. Interestingly in order to reduce the size of the Statute book the Law Commission repealed the Acts of 1863-65 which provided, amended and extended the WDF&M railway (and over 200 other abortive railway projects) by the Statute Laws (Repeals) Act 2013.

We guess the wheelbarrow has rotted away but we would of course be interested in knowing the whereabouts of that silver-bladed spade.

We were extremely saddened to learn of Tony’s unexpected death after a short illness. Tony had been an active volunteer at the railway for many years, initially joining Telecoms in 2007 to work on electrics, and later moving into operational roles as a Guard, Porter and TTI. It is in this role that many of us remember Tony most fondly.

He took great pride in telling visitors about the railway, and also in making sure everyone had paid their fare! Whenever I encountered Tony, he was always friendly and would always go out of his way to be helpful.

Even if he had identified a problem,Tony would always raise it in a constructive way, often having also identified a possible solution. When I circulated the sad news of Tony’s death to working members, I received many replies from volunteers sharing their own memories and tributes. Two phrases came up time and time again: “Such a lovely man” and “Tony was always such a gent!”. I don’t think we can pay a better tribute than that!

Away from the railway, Tony was a strong church-goer, and had been heavily involved in the Boys Brigade for many years too. We extend our warmest sympathies to his family, and it was good to see a strong DFR turnout at his funeral, including a lovely tribute given on our behalf by Tony Green.

Alastair

Alastair

Clarke

The last report took us through the tail end of the summer and into the Autumn, the dry period ended and then came the rain, problem is that excess rain adds to the growth, weakens the embankments and makes it difficult to work. But we pushed on where we could with various tasks.

We had a good day’s work at Norchard, we were clearing in three different areas. We started in the carpark, the sides and hedges were cut back and tidied. We completely cut back the Island area which had become very over grown, this revealed some posts for a notice board and a lot more of the signals there. Arrangements are in had to clean and paint the signals as well as install a new notice board. We also cleared the riverbank area and the embankment next to the toilets.

Andy was back with us for a day of chainsaw work and he and Chris set to clearing more of the embankment opposite the builders yard north of Town crossing, they cut down a lot of ash and we spent some time trying to clean it and remove it. There is a lot of it on the embankment which we need to get back to with a winch tractor and clear it all sometime soon.

While they were clearing this area a group of us operated a works train, we cleared some hedging at Lydney Town

for our neighbours and Trunkarb (tree surgeons), taking two full loaded loriots to bonfire curve. It was then back to where Andy and Chris were working and cleared four more loaded lorriots to bonfire curve before running out of time.

The following week during another wet day the team worked at Lydney junction building a new planter for the platform, it is awaiting filling with compost and some suitable plants. Then they dealt with the hedge next to the DFDA and signal box, it

down in size.

By now the cuttings/arisings at bonfire curve had reached very large proportions, I had estimated that we had dropped in excess of 20 loriets there over the summer. With the dry weather and fire risks we had not been able to deal with it for most of the year. So it was time to take a team there and get it cleared. It was a much bigger job than I had estimated and during most of the day we did not believe we would get it done.

However with three fires running all day we left the site burning out and had cleared the massive pile, it was a fantastic team effort. While we were doing that John cleared the nearby wall with his trusty hedge cutter.

There had been a report of a small rock fall opposite the builders yard as well as drainage issues at Middle forge so one Tuesday we headed out to both sites. At Middle forge we cut back and strimmed a large area so the 360 digger could be brought in to clear the temporary drainage ditch. We then headed to the embankment opposite the builders yard where we cleared as much of the embankment as we could. We were able to examine the area where a rock had fallen from and check for further possible issues. Also clearing this area will make it easier to get back and finish some of the ash removal.

In the last report I had mentioned some preparation work we had been doing to allow contractors to access some very large ash trees just north of Middle forge. The area had been cleared using the RRV and a flail head but a lot more work was needed to get this area ready.

A road is needed from Middle forge and fencing needed clearing, to allow the contractors to bring in equipment. There was also some growth/trees that needed clearing. So the team spent several weeks working in this area with a mix of good and bad weather clearing the fence line and area for the road. While this was going on Adam worked with the 360 to prepare the roadway that was needed. Working at the Middle forge end of the roadway the drainage became a problem so the work also included some temporary digging to divert the water flow. The

drainage is beyond our expertise and is something that is going to be ongoing for a while.

Fortunately the temporary road was completed over several wet weeks, and a lot of fencing has had to be removed which we hope to return once the job is complete.

So hopefully by the time you are reading this report we hope that the contractors (Trunarb) will have been able to get in and remove the affected ash trees.

Adrian Copley reports on a busy winter period for the Operations Department. Even though we may not have run passenger services for much of the period, that doesn’t mean nothing is happening...

Hello readers and a belated Happy New Year to you all!

What weather we had during the Santa season prior to Christmas! Unfortunately not a white Christmas but a white November! It was a Saturday morning when I arrived at Norchard with the duty Driver (for a lift it is easier if you’re related!) at 06:00 and the thermometer in the car read minus 6 degrees. Gathering our ‘traps’ including cans of de-icer, we signed on duty and went about our duties. The loco was 5541 and the injectors were frozen, the water supply was……yes you got it, frozen, at least the water in the kettle wasn’t (it is has not been unknown in the past). So kettle on, and as I was Duty Officer for the day, plans duly made, salt spread etc. Luckily water was available for the loco at Parkend. The first train departed only 10 minutes late which was good going considering the circumstances. I managed to capture the train in the atmospheric conditions on my camera, which is the nearest I have got to snow in years. Guess what! That night it snowed and the railway had a white covering the next day (missed it again!) causing a different set of problems. The following weekend we had to cancel a couple of trains on the Saturday because of the ice that had lingered all week. The following day we cancelled all trains timetabled that day because of falling rain which was immediately freezing upon reaching the ground making it extremely dangerous under foot. The first time in years we have cancelled services but it was the correct decision for the safety of everyone. This weather always reminds me of the winter of 1963 when snow started falling on Boxing Day and lasted 10 weeks. My Grandfather was a passenger Guard and was on duty that day, so my father drove him from our family Christmas celebrations back to Yeovil which was a journey of about 30 miles. We did wonder if Dad would make it back. The family home is in Frome which is on the edge of the Mendip Hills and father had to dig his way out each morning (snow was as high as the door frame) to get to work, I think he was commuting to Chippenham to work at Westinghouse at this time . I was approaching my 8th birthday and in those days you wore shorts until you went to ‘big school’ at 11 years old. I was reminded recently when looking at a photograph of me during that winter and in my shorts, looking very cold! Back to the DFR and the weather changed soon after to a

higher temperature and down came the rain, but all trains ran as scheduled to the end of the year. We finished the running season on 1st January, so then started the winter maintenance period for the railway. Large projects were planned for the Lineside team working with contractors to remove diseased trees (that could open up some photographic oportunities perhaps), S&T to renew worn equipment at Lydney Junction and some serious fettling on a couple of sites by the Permanent Way Department. The coaching stock needed a good inspection/maintenance before the start of the new running season and the many projects around Norchard continued to make progress. The end of February will see the running-in turns for 9681 ready for the new season although 5541 has a ticket until 2024, so the train engine will vary throughout the year.

About a year ago, I was approached by another preservation society for some help. They were to obtain a class 315 electric unit from Greater Anglia Ilford Depot and needed to transport it to Llanelli, firstly by rail to Lydney, then use our loading area for road transport onwards. Many dates came and went while they tried for the stars to align! Eventually after a couple of false starts, the unit was to arrive on 23rd December which was a Santa running day. I happened to be the duty signalman at Lydney Junction that day. The DFR team assembled before the arrival time as I watched the train’s progress on the internet and thinking is it going to dovetail with our Santa Specials, what last minute plan do I have? As it turned out all was well, the train hauled by one of ROG’s class 37 locos (37884) duly arrived, shunted the unit to the East Loop and loco returned to the Network Rail gate about 20 minutes early,

well in time before the next Santa Special arrived.The next stage was the road transport. This was to happen over 3 days, so the dates of 9/10/11 January was organised, DFR staff duly arrived on the first day, lots of shunting and the first of 4 cars of the unit was away. On the second day I was rostered as signalman again and the plan was 2 cars to go that day, but due to weather conditions (a bit wet!) and other factors the first car wasn’t delivered until 11:00 on the second day. Because of that and the fact that the special translator coupling (borrowed from Wolverton Works) had to be returned on the Wednesday morning, the job was postponed. There then came 3 hours of shunting and a trip to Norchard to return the coach we were using as a barrier vehicle. As I write this in late January, we are awaiting for the dates somewhere around the end of February for the next time the stars align to finish the move! I would like to thank all our volunteers who have helped so far on this project. Our visitors from Greater Anglia and the 315 Preservation Group also thank us and remarked how professionally we handled everything, well done team DFR.

In early January I was saddened to hear of the passing of Tony Macey. He was, of late, a Travelling Ticket Inspector (TTI) although had been a Passenger Guard and started off in the electrical department (before he was persuaded to come to Ops.). The last time I was on Guard duty he came to me at the end of the day as we berthed the stock with “I’ve cleaned through and locked the doors except yours, I’m off now, see you”. He was a great member of the team, always willing to help and will be greatly missed. The middle of March will see the start of this year’s running season. All the running days and train types have been agreed I have formulated this into a document called the ‘Traffic Circular’ as usual. I now await the train formation

details and loco rosters which are normally a rolling story due to regular maintenance routines and seasonal demand, also the annual game of print the timetable only once gets ever closer! A glitch has already happened with our timetable guru off sick (get well soon Derek!) so his ‘partner in crime’ will have to step up to the plate to get things finished by early March I hope. We have two steam galas this year, the first in May will be with the home fleet but the one in October will have a visitor or may be two!

A diesel gala in September will provide more visitor(s) and no doubt photo charters around these events means my camera will be looking for action this year! Meanwhile the plethora of Works Train requests continues to flow in as our work teams go about their usual or one off tasks. Keeping the paperwork up to date has to go on as usual even when trains are not running.

Please would everyone note that my email address for all railway matters is ‘operationsmanager@deanforestrailway. co.uk’. The ‘AOL’ personal address has been used recently but that was switched off over a year ago, please do not use it! I do have a new personal address which was on HOPS for a while, this can also be used. Many thanks for your co-operation. Until next time take care and please plan a journey on our great little line!

Opposite page: In the fading sun on 23rd December, 37884 stands in the West Loop at Lydney Junction, having arrived with the Class 315 unit from Ilford Depot. (A. Clarke)

Above: Some of the unit’s cars being shunter by Class 08 Gladys in preparation for loading onto road transport. (A. Copley)

David Collins reports on renewals work undertaken by the S&T Department at Harbour Road Level Crossing recently, demonstrating the vital and often unseen work undertaken by the S&T volunteers.

Between Monday 20th and Friday 24th February, S&T volunteers, supported by those from other departments replaced the signalling equipment (point rodding and signal wires) that run under Harbour Road crossing.As will be described, the work was carried out “to timescale and budget” and is an excellent example of the work that volunteers can undertake. The willing coopertion received from Gloucestershire County Council (GCC) is acknowledged.

The level crossing on Harbour Road at Lydney Junction was installed in 1996 when the Lydney bypass and associated roads were built. Since that time, the signalling equipment which runs under the road in a duct has not been examined.

The equipment is subject to all the dirt, including road salt which comes off the road and was clearly deteriorating as we suffered a broken signal wire within the duct last year. Fortunately we were able to use a wire from one of the lesser used signals to keep the other signal operational. In addition, the points leading from platform 2 line to the West Loop were unduly difficult to operate suggesting that all was not well with the rodding in the duct.

GCC is responsible for funding all maintenance and renewals at this (and the Bypass) crossing as the railway was in place before the road. Early in 2022 we estimated the cost of the work and started a discussion with GCC which resulted in the necessary finance being made available. We then had to order new equipment (rodding components and signal wire) or use material we had “in stock” if this was not available from Unipart Rail. In addition, a Method Statement and Risk Assessment had to be prepared. As it is not possible to close the crossing as this is the only access to the main line station, Lydney Trading Estate and some residential properties, traffic management (temporary traffic lights) had to be arranged through GCC in order that the work could be done with half road closures.

A small amount of preparatory work could be done beforehand, but the main work commenced on the Monday with the south (station) side of the road closed.

The work involved disconnecting all affected equipment and lifting the concrete Bowmac panels over the duct with the help of the Railway’s Road-Rail Vehicle (they weigh the proverbial “ton”!),.Then the rods and wires could be removed from this half of the duct, the duct cleared of dirt, new fixings for wires and rodding rollers installed together with the new signal wires and rodding. On Wednesday, the traffic management was changed so that a similar process could be carried out on the north (Norchard) side of the crossing. This was complete by Thursday, leaving the Friday to reconnect the rodding and wires and test all equipment. A spare signal wire was installed as insurance against the hopefully remote chance of a wire breaking again.

There has been increased deterioration of the road deck over the crossing recently and further issues were found during the work. We are currently in discussion with GCC regarding a survey as there appear to be issues with the sub-structure of the crossing. Once this is resolved, the crossing will have a more frequent condition examination than in the past which will hopefully detect issues before major work is required.

The duct, showing the condition of the signalling equipment before work commenced!

No wonder it wasn’t performing properly! Corrosion and salt-damage evident in this photograph.

The south-side rodding has now been completely renewed, waiting for the Bowmacs to be lifted back into position

After renewal - hopefully good for the next couple of decades!

Dave Chappell brings us up to date with the ongoing restoration of Mark 1 TSO No. 4862, and also reports on other matters including keeping the carriages fit for Santa!

Progress on TSO 4862 in the restoration shed has been fairly slow, because of the refurbishment of the transverse floor support girders. On closer inspection, where the corrosion was too severe, replacement lengths of top-hat profile were required to replace the weakened girders. Purchasing these involved liaison with another heritage railway who, I believe, manufacture them on demand. Once available, installation involved the support of Ed from Western Steam Engineering to cut them to length and weld them into position.

Meanwhile the main team, Peter, Ollie, Eric & Barry, in between supporting the Santa Specials running set, have been working on the doors of 4862, overhauling the door mechanisms, window support springs, door locks, hinge alignment, and glazing channels, as well as the relevant mountings in the door frame and surround. The cold and damp weather has often often made progress more difficult even indoors.

First mentioned just over a year ago, the low voltage LED lights for the Small Works Group Workshop in the car park (affectionately known as the ski hut) have finally become a reality. Used by Bob Bramwell, Martin Hillier and their teams, the initial installation concentrated on Bob’s section, but there are now requests to extend the lighting provision to the other half of the Ski Hut. The solar panel which keeps the 12v battery charged was fitted in the window. A south facing aspect ensures that there is sufficient power to keep the battery well charged - confirmed when one day the lights were accidentally left on overnight. Even so the winter sunshine was sufficient to recharge the battery.

4980 was being checked and overhauled during the Autumn, in readiness for inclusion in the Christmas running set, but while it had been out of service, the batteries had deteriorated and reached the end of their useful life. Shield Batteries, who manufacture batteries to rail specifications, were able to supply a replacement set in a matter of a week or two. These were installed with assistance from the ‘Wagoneers’ who happened to be available when

the task was undertaken and provided some very welcome ‘muscle’, lifting the old battery cells out of the wooden crates or boxes, loading the new cells into the vacant boxes and then transferring these boxes back into the battery bays slung underneath the carriage. With these new batteries, 4980 had sufficient battery reserve to provide carriage lighting whenever required.

The running set has required some urgent repairs over the Christmas running season. In one of the Mk2 carriages the table mountings were weak enough that when some passengers needed some support when taking their seat or standing up to leave the carriage, pressure on the table was sufficient to break or dislodge the mountings. A concerted effort by Peter, Ollie and Eric and others, on non-running days, made it possible to refit the broken tables and overhaul and strengthen most, if not all, of the remaining table mountings.

During the Santa specials, thoughts have turned again to providing local power underneath the platform edge. This could provide 240v for intelligent chargers, one on each carriage, so allowing battery charging without the danger of long-term overcharging and damage to the batteries.

Last year, to keep a little warmth in the carriages when it was frosty overnight, cables were deployed across the platform to each carriage after the last passengers had alighted, but only limited power was available on the existing platform circuit, and the heaters were barely effective. With some of the cables having been borrowed or ‘gone AWOL’, providing overnight power was more difficult this year and no heaters were deployed.

The spare capacity on the existing feed cable and circuit breakers to the platform would be capable of supporting individual carriage battery chargers, but it is not known whether the additional load of higher power heaters could be accommodated as well if the proposed new cabling under the platform edge becomes a reality. The investigation is on-going!

George Smith brings us up to date on a busy winter period for the team at Parkend, with much progress being made on rebuilding of the Permanent Way hut and other projects.

I write this in late January having just started to read the last issue. The autumn and winter have been wet and cold at times but this has not stopped us. With long holidays for some, the Xmas and New Year breaks, our numbers have ben low at times but we have only missed two Mondays apart from Xmas in five months.

In November and December John Philips was unable to attend and Chris was on a long antipodean holiday. Now Ed Gordon has returned after deciding not to continue with studies, but John Goldrick has gone on extended holiday to Sri Lanka.

After we had renewed the five rotten sleepers, the PW team have reorganised and relaid the rails in the siding after cutting to length and redrilling for the fishplates. The siding has been returned to traffic and rumour has it that a rail vehicle has since run along it. The grass has been cleared of fittings and stone, the ballast has been put back around the sleepers which had been replaced.

John Goldrick has done an excellent job on the chimney. The stonework has risen bit by bit each week as the flue had to be built first before the outer skin could be laid. The inner skin is brick but the outside is stone: a much slower job as each piece has to be selected to fit. A scaffold tower was used to reach the roof level and beyond. A vintage chimney pot was fitted and lead flashing has been added to interface with the roof felt. Inside John has done a fine job of the chimney breast. In October a quote was obtained from Lydney saw mill to supply muntins for the hut and for fence posts and rails. This was duly submitted, accepted and the wood was ordered. Upon delivery the wood was treated ready for fitting. Outside, all of the rotten wood has been replaced and muntins added (muntin: upright covering the gap between timbers). Timbers were cut to fit above the door and door stops were fitted. The paving slabs under the door were replaced and the bottom of the door was shaved to allow it to close without scraping. The outside of the hut has been re-coated with black preservative (Creocote).

Work has continued on the walking path and the wall supporting it has been extended using old sections of concrete sleepers. This work is on going.

Work has stated on renewing the fencing alongside the adjacent property behind the loading gauge. The wall here is in poor condition and was covered with a rusty wire mesh. This has been removed (with the occupiers consent) with the aim of rebuilding the top to a constant level. A new fence will be installed here to form a photographic enclosure more in line with the loco when it is on the south end of the train.

Right: Attaching the chimney pot. Also, the new muntins can be seen on the front of the hut. These pieces of timber had to be specially cut to size by the sawmill as there was no suitable modern ‘standard’ size timber available.

Below Right: George hard at work refitting timbers into the base of the PW hut, to replace rotten wood.

All photographs: G. Smith.

Above: The PW Hut, complete with rebuilt chimney, can be seen on this misty morning! (G. Smith)

Below: The same hut has stood at Parkend since the 1920s and can be seen in this picture from the very early days of the DFR, when stock was moved from Parkend to Norchard down the then BR-owned branch on 16th January 1978. Even in this view, the hut was missing its chimney! (DFR Museum Trust)

Jon Barry of the Wagoneers Group adds a fascinating postscript to his previous article on wagons at the DFR which originally came from ROF Glascoed.