2

Over half a century of design.

7 Welcome 8 Our Expertise 10 Our Awards 12 Our People 14 Medical device development process 16 Medical and Scientific services 20 Our connected disciplines 22 Research and Strategy 25 Mechanical Engineering 27 Industrial Design 29 Human Factors and Usability 31 Interaction Design 33 Electronic Engineering 34 Software Engineering 37 Prototyping and Evaluation 44 The art of persuasion: Designing devices for patients who don’t want to adhere 60 Sustainability and drug delivery devices Drug delivery 9, 38-43, 50-59, 66-69, 74-77, 84-96, 104 Connected 74-77, 96, 103, 106-107, 160-161 Sustainability 58-59, 60-65 Other Medical 112, 116-119, 126-129, 134-135, 140-143 Scientific Instruments 18, 116-119, 120-125 Consumer Healthcare 130-133, 154-161, 168-189, 191-192 Commercial and Industrial 144-149, 194-195 Contents 70 Designing for uncertainty 78 Cybersecurity and connected drug delivery, an integrated risk-based approach 97 Don't develop a connected drug delivery device without reading this 108 How smart do smart medical devices need to be? 114 Why the IVDR is changing the way we develop diagnostic devices 136 The future of radiotherapy treatment 150 Beyond compliance. What is the role of human factors in medical device development? 162 Designing products that stand the test of time 196 Our location 201 Contact Medical and Scientific Overview 7

8

Welcome

Since the early sixties we have helped a wide variety of companies design and develop market leading products that users still value every day, ranging from the Stanley knife to the Eurotunnel Shuttle.

Today we focus on building long term relationships with large corporations in four market sectors: ‘Medical and Scientific’, ‘Consumer’, ‘Commercial and Industrial’, and ‘Transport’.

Founded in 1960, we are one of the world’s leading product design and development consultancies, operating globally from our campus in Warwick, UK.

9

Our Expertise

We do this through an intelligent approach to design, based on the transparent management of risk, informed decision making, true integration of disciplines and rigorous development processes.

We believe that the outstanding commercial success of the products we help create is dependent ultimately on delivering exceptional value to our clients customers.

We provide the right blend of strategic thinking and pragmatism to deliver our clients’ projects successfully.

We balance the creativity and the technical discipline needed to achieve commercially successful product innovation.

Every client is unique. To support our clients, we like to understand them, their place in the market and their ambitions thoroughly.

We add value by improving the success of product innovation.

10

Sanofi

SoloStar®

Disposable insulin pen injector

Design planning

Usability and HF

Mechanical engineering

Industrial design

Colour, material and finish

Instructional design

Graphic design

Prototyping

Testing and evaluation

Production support

11

Our Awards

A multi award winning design and development service .

12

gold winner 2015

Multi award winner

Multi award winner

Stanley Caplan

User-Centered Product Design Award

Multi award winner

13

Multi award winner

14

Our People

They combine to create a vibrant fusion of disciplines including mechanical engineers, electronics and software engineers, industrial designers, usability and interaction experts, researchers, strategists, prototyping technicians and specialist project managers. Each person is an expert in their own field, but has the curiosity, understanding and flexibility to reach

across traditional inter-disciplinary boundaries. Our organisational structures and team culture encourage this synergistic blending and integration of specialist skills. Our clients benefit not only from each individual’s depth of knowledge and experience but also from a team whose combined strength exceeds the sum of its individual members’ expertise.

DCA is a collection of over 130 extraordinary individuals. Intelligent, creative and thorough, our people make the difference to our clients’ projects.

15

How do you meet the challenge of delivering your new product to market quickly with the right performance and a strong intellectual property position, whilst industrialising robustly and cost effectively?

Medical

process 1 Foundation Pre-prototype Iteration Prototype Iteration Industrialisation Support 3 Design Output 2 Design Input 16

device development

It’s a complex problem, but one in which we have a great track record, with many commercially successful products delivered for clients in the pharmaceutical, medical device, consumer healthcare, hospital equiptment and scientific instrument markets.

An effective development process underpinned by informed decisionmaking is fundamental to our work. If a project is planned and structured correctly from the outset, then key risks can be identified early and managed towards a positive outcome.

Successful medical and scientific device development requires keen attention to detail, with commercial realities meaning that development effort must always be appropriately directed. You can have confidence that our creativity, technical rigour and sensitive design skills will be intelligently focussed to deliver exciting and effective solutions to the challenges you bring.

5

4

17

7 Production Support 6 Design Transfer

Design Verification Design Validation

Production Validation

Medical and Scientific services

We offer a comprehensive design service to the medical and scientific industries, with development processes aligned to standards and regulations in the EU and US.

18

19

Microbial Systems

CellFacts II

Modular real-time cell analysis instrument

Design planning

Mechanical engineering

Industrial design

Prototyping

Production support

20

With extensive experience of strategically important and technically demanding projects, our large multidisciplinary development team comprises mechanical engineers, electronics and software engineers, industrial designers, usability and interaction experts, researchers, prototyping technicians and specialist project managers. We provide fully integrated product development services from initial project direction through to detailed support for industrialisation. Our skills include product development strategy, design research, project planning and management,

intellectual property strategy, concept creation, prototyping, feasibility studies, design auditing, risk management, detailed design, IEC62304 compliant medical device software development, engineering analysis, evaluation testing, usability engineering, design verification, supplier selection and technical support for industrialisation. We can provide a complete turn-key development service, or staged input to a project.

Our design and development service is certified to ISO 9001 and ISO 13485.

Fully integrated product development services from initial project direction through to detailed support for industrialisation.

21

Our connected disciplines

DCA’s specialists offer robust tools and techniques in every field of product design and development, but it’s the connection between these different disciplines that we believe make us unique.

Our studios, laboratories and workshops have different disciplines working side by side. Our ability to connect and integrate the right disciplines, at the right time, in the right way is the cornerstone of our approach.

Since our foundation a multidisciplinary philosophy has been the cornerstone of our approach to product design and development.

22

Software Engineering

Interaction Design

Mechanical Engineering

Electronic Engineering

Industrial Design

Design Research & Planning

Prototyping

Human Factors & Usability

23

Research and Strategy

Research and Strategy at DCA exists to inspire and inform these decisions, providing the cultural and user insight on which to build great product strategy and designs.

Practised by a team with diverse experience we use a range of tools to build robust data and rich stories. No two projects are the same. We go wide and we go deep, gaining intimate knowledge of the relationship between people, brands, products and their environments.

Deciding which direction to take a design, or even what to design next, often proves one of the greatest hurdles in product development.

24

25

26

For us, this means employing the best engineers with a wealth of individual and collective experience. It means planning projects rigorously and applying individually tailored development processes during their implementation. It means using cutting-edge tools and techniques to develop and test our ideas. And it means integrating our engineering thinking, closely with

our other in-house product development skill bases to deliver unified project results.

World class engineering is at the heart of most projects we undertake and provides our clients with the highest probability of success, even with the most technically challenging developments.

To consistently deliver market leading products you need a world class approach to engineering.

27

Mechanical Engineering

28

Industrial Design

The space between medical devices and consumer products has become blurred and market tolerance for poorly executed visual design is low. Yet there are still some important differences between medical and consumer products. Safety must always be paramount, usability cannot be compromised and longer market lifecycles mean that visual design must transcend short-term fashions and trends.

In this context we believe industrial design should be informed and relevant. It should be highly creative and push what is technically possible.

We achieve this by integrating the industrial design team with research, usability and engineering disciplines and by employing designers who understand strategic context and are passionate about detail.

In an increasingly sophisticated world, external form and visual detailing have become an important expression of the quality and performance of a medical device, or scientific instrument.

29

30

Human Factors and Usability

We integrate human factors and usability throughout the design process, adopting domain-specific regulations and guidance from ISO 62366.

Emphasis is placed on moving beyond compliance to leverage the commercial benefits of more inclusive products and services that optimise system performance.

We inform ideas and their implementation through a deep understanding of the relationship between people, products, and their environment.

31

32

Interaction Design

In an increasingly connected world, new challenges have emerged in delivering compelling user experiences. Our multidisciplinary approach delivers product interactions across integrated physical and digital platforms that are simple, intuitive and a delight to use.

Our team combines interaction, graphic and industrial designers, researchers, electronics hardware and software engineers to develop

co-ordinated product experiences. Whether extending products with digital touchpoints or developing interactions for embedded hardware, we use an integrated approach to create future facing concepts and develop these through to production.

Our multidisciplinary approach delivers product interactions across integrated physical and digital platforms.

33

34

Electronic Engineering

Success in these areas depends on robust requirements definition and careful partitioning of functionality between electronic, mechanical and software sub-systems. The effective management of interfaces and interactions between sub-systems is key, and is greatly enhanced by an integrated team structure. For this reason our electronics engineers, designers, mechanical engineers and researchers work very closely together from the start of projects to capture, define and translate requirements into effective design solutions.

Whether electronic functions are an inherent part of your new product architecture, or an existing mechanical system needs to be enhanced with new electronic features, we have the skills and knowledge to meet your development challenge.

Our electronics team have developed medical devices and scientific instruments with functions ranging from simple automated monitoring to sophisticated electromechanical control, diagnostics and connectivity.

35

Software Engineering

Software must be carefully planned and diligently executed, but this does not mean that it has to be slow. DCA’s agile software development process is fully compliant with IEC 62304, but also draws on years of experience developing code efficiently for the consumer goods and automotive sectors.

With a powerful blend of experience, talent and rigour, our software engineers integrate seamlessly

with our electronics, mechanical engineering and interaction design teams to deliver products ranging from complex electro-mechanical systems through to more simple, but equally compelling devices.

A rigorous approach to software engineering is fundamental to safe, effective and successful medical device development.

36

37

38

Prototyping and Evaluation

Prototyping is at the heart of our business.

Since our foundation we have always had extensive workshop and prototyping facilities in the centre of our studios.

This enables us to explore, test and iterate concepts at increasing levels of resolution throughout a project and is a fundamental part of our product development and risk management processes.

39

DCA partnered Sanofi throughout the development of SoloStar®, applying our rigorous evidencebased approach to all aspects of the design. The result is a device that delivers leading performance in almost every respect. With superior levels of safety and comfort, the pen is sophisticated, yet simple to use.

Since its launch in 2007, SoloStar® has been adapted for use across a range of therapies and can now be found in almost every market around the world.

The multi-billion selling SoloStar ® pen injector is one of the world’s best known drug delivery devices.

40

Sanofi

SoloStar®

Disposable insulin pen injector

Design planning

Usability and HF

Mechanical engineering

Industrial design

Colour, material and finish

Instructional design

Graphic design

Prototyping

Testing and evaluation

Production support

41

Sanofi

Toujeo® SoloStar®

Disposable pen injector for concentrated insulin

Design planning

Mechanical engineering

Industrial design

Colour, material and finish

Instructional design

Packaging design

Graphic design

Prototyping

Testing and evaluation

Production support

42

Toujeo ® SoloStar ®

Building on the multi-award winning SoloStar® platform, DCA partnered Sanofi to develop a new range of pen-injectors for Toujeo®, a triple concentrated basal insulin.

Toujeo® SoloStar® contains 450 insulin units, deliverable in single unit increments. Due to the triple-concentrated formulation,

dose accuracy tolerance limits are three times tighter than for a standard pen, meaning that doses need to be delivered within a ±0.0033mL window.

Toujeo® SoloStar® was painstakingly engineered to achieve this exacting requirement and also to provide an ultra-low injection force.

43

Sanofi

Toujeo® Max SoloStar®

Disposable pen injector for concentrated insulin

Design planning

Mechanical engineering

Industrial design

Colour, material and finish

Instructional design

Packaging design

Graphic design

Prototyping

Testing and evaluation

Production support

44

Toujeo ® Max SoloStar ®

Toujeo® Max SoloStar® has a capacity of 900 insulin units, the largest of any long-acting insulin pen on market, and an increased maximum dose of 160 units, selectable in 2 unit increments.

This means fewer pen changes and fewer injections, making life easier for the increasing number of patients on higher insulin doses.

45

By some estimates, half of patients with chronic medical conditions fail to take their drugs as prescribed. For many, this is a conscious decision. Intelligent design of drug delivery devices can help to change this.

Within the context of drug delivery devices, the conventional approach to improving therapeutic compliance is often to think in terms of reminders or dose counters. While these devices have a clear role to play, they only tackle one part of the problem – unintentional nonadherence. They do little to explicitly challenge patients who elect not to take their drugs as prescribed. The scale of the problem is hard to quantify, but there is evidence that a significant proportion of patients with chronic medical conditions actively decide not to comply with their prescribed treatment; some estimates attribute intentional nonadherence as high as 70% of the issue ²

There is a consensus that the reasons for intentional nonadherence are complex and often idiosyncratic, meaning that it is unlikely that any single intervention will ensure that all patients take their medication as directed. Systemic solutions are needed that help patients to better understand and engage with their therapy, along with drug delivery solutions that cater for the patient’s emotional, as well as physical needs.

This article will explore what device developers can do to confront these issues within realistic commercial constraints that tend to favor ‘standardized’ device solutions.

The Non-Adherence Problem

Medication non-adherence is one of the biggest challenges facing health care providers. It is incredibly difficult to determine exactly how many people are affected, or why patients are not taking their drugs as prescribed, however, current estimates from the World Health Organisation 1 are that 50% of patients around the globe, with long-term illnesses, do not take their medications as prescribed. In the USA alone, it is estimated to cost $290 Billion a year 3, cause 125,000 deaths annually, and account for 10% to 25% of hospital and nursing home admissions 4

Intentional or Non-Intentional?

Unintentional non-adherence is usually related to some form of forgetfulness or confusion. The result is that patients may forget to take a dose, take the wrong amount, repeat a dose, or take the incorrect drug.

Intentional non-adherence, on the other hand, relates to situations where patients are aware of what drugs they should be taking and when. However, they decide that they do not wish to take their drugs as prescribed. This may mean that users fail to take any of the prescribed drugs, end a course

By some estimates, half of patients with chronic medical conditions fail to take their drugs as prescribed.

Published on 17th December 2015 46

The art of persuasion: Designing devices for patients who don’t want to adhere

prematurely, or take a different dose to that prescribed.

Behaviour Change

Ostensibly, the intentional nonadherence challenge is one of behavioral change. One commonly adopted approach is to address this challenge by viewing patients as the problem. Designs then focus on making patients more motivated, preventing them from doing something, or to persuade them to do something else. Fear tactics are one example of this; however, their efficacy is questionable, moreover, they can lead to patient anxiety, often in individuals who have no issues with adherence.

An alternative approach is to view the patient as a rational decision maker that has absorbed the information provided to them, considered it in the context of their

particular situation and decided to depart from the prescribed drug regimen. Like the reasons for non-adherence, the way in which individuals make decisions are largely idiosyncratic. However, there have been many attempts in the past to describe decision making activities. One model commonly used is the OODA loop. This describes a feedback loop where decision makers observe the information available to them, they then Orientate this information to their own lives and the specific context, Decide which of the available actions they should adopt, and then act.

Learning from decision making theory, it is evident that the presentation of information alone does not change user behavior, rather it is the process

of interpretation, or orientation, that is key. In order to both gain and maintain user engagement, users need to be able to relate the information provided to their own lives and the specific context of use.

47

Many people in the drug development and distribution chain also have their role to play in increasing adherence.

Accordingly a key opportunity in helping users to adhere to their drug regimen lies in the orientate phase of this decision making cycle.

What is clear is that much of the patient information currently provided is often not being read or not being understood. A Danish study 5; found that 40% of elderly patients did not understand the purpose of the drugs they were taking, while only 21% understood the implications of the omission of a drug or dose. This is perhaps unsurprising when viewed in the context of how many drugs some people are taking – with 60% of over 65s in the US taking five or more medications 6 .

A recent study assessing the impact of text messaging on adherence 7; also provides some interesting insights. The study involved 303 participants; half of which received SMS alerts prompting them to take their drugs, while the other half, the control group, received no intervention. The first insight is that the reminders were helpful; in fact 60% reported that they were reminded at least once to take a dose that they may have forgotten. This is perhaps unsurprising, but validates the assertion that reminders have a role to play in the adherence challenge.

What gets a bit more interesting is what else the study found. When

In many cases, there are opportunities to simplify drug regimens by viewing them holistically and reducing the number of drugs required.

48

comparing drop out rates (i.e. those either stopping completely or taking less than 80% of their medication), it is apparent that the drop out rate was considerably lower for those in the test group (25% in the control group compared to 9% of those receiving text messages). Further examination reveals that those in the test group were asked to text back with any concerns that they might have. 15% of the test group reported concerns on at least one occasion, because of uncertainty over the need for treatment, concern over side-effects, or another medical illness. Each case was followed up with a telephone call to address these concerns. This intervention, simply by calling them up and explaining these concerns, resulted in 87% (13% of the test group) resuming treatment.

These findings of this study suggest that actively addressing patient concerns and uncertainty can have a marked impact on adherence rates.

For device manufactures the next logical question should therefore be how can medical devices, and the ecosystems that surround them, be designed to support this.

What Can Device Developers Do?

As a systems issue, health care providers are well placed to make changes to adherence levels. In many cases, there are opportunities to simplify drug regimens by viewing them holistically and reducing the number of drugs required. Likewise, the way patients receive their drugs can be simplified, a number of pharmacists are now offering clearly labelled sachets containing all of the drugs a patient should take at a given time.

Many people in the drug development and distribution chain also have their role to play in increasing adherence. Within the marketing team, the way drugs are presented and even named have the potential to impact adoption,

packaging design will undoubtedly have an impact on the way drugs are perceived, likewise the way drug devices look, feel, sound, taste, and function will all shape perceptions. Focusing on medical device development, and more specifically products that patients are using to self-manage their regimens, there remains much that can be done. As highlighted in the text message study, engagement has a key role to play in tackling the adherence challenges. This challenge can be split between gaining and maintaining engagement.

Maintaining Engagement

The concept of seeking to maintain engagement is often more familiar to device developers, involving topics that are well understood by those familiar with good usability engineering practice. This involves minimizing the impact on patients’ lifestyles.

49

Article by Dr D. Jenkins Research Lead Human Factors and Usability

Rob Veasey Senior Sector Manager Medical and Scientific

Matthew Jones Senior Sector Manager Medical and Scientific

Common tactics include focusing on:

• Convenience and flexibility of use (products should generally be unobtrusive on users’ lifestyles. Extending the time between doses and flexibility in the timing of doses. They should be transportable, allowing users to use them, and safely dispose of them in a wide range of scenarios. Patients should be supported in managing their drug regimen).

• Time taken (devices should minimize the time required to set up, use, and safely dispose).

• Complexity of use (devices need to be intuitive to use – matching the cognitive abilities and expectations of the target users).

• Physical effort and comfort (the forces and postures required to deliver a drug need to be carefully considered and controlled).

• Capturing and sharing information on adherence (can the device system communicate progress to the patient, providing feedback and reward? Where appropriate, can the system capture the level of adherence for health care providers or carers).

Gaining Engagement

Understanding the patient’s initial decision making process is central to gaining engagement. This is a topic that tends to receive less attention in standards (e.g. IEC 62366) and guidance documents (e.g. HE75).

Playing the decision cycle described in the OODA loop backwards can reveal some interesting insights. Explicitly considering the decisions that users are making, and how their specific view of their condition and context shapes this, is critical.

Ultimately, the way we design and present information to users should be driven by a clear understanding of the way they orientate themselves with this information.

In this context, the ‘information’ goes well beyond written instructions. It includes all sensorial aspects of the device that patients are interacting with. The form, the colour, the material, the way it feels, and the way it responds are all information prompts that shape the way users decide whether to engage.

A second opportunity lies in the decision making section of the model. Carefully controlling the options available to the patient can also assist in the process. Pre-metered doses or treatments in a single pill may help to reduce patients under dosing or overdosing. There are a number of activities that can help device developers to understand the orientate phase:

• Understanding the context (understanding the condition and the system of therapy, considering how and when patients are engaging with this product and other products used in conjunction).

• Developing an emotional connection (Getting products out of the medicine cabinet. Designers and developers should ask what makes users love and engage with a product and not want to hide it away. There are many lessons here that can be learnt from how traditionally ‘taboo’ consumer products are now packaged).

Ultimately, the way we design and present information to users should be driven by a clear understanding of the way they orientate themselves with this information.

This article was originally published on the MDT - Medical Design Technology website 50

References

• Information that the users can relate to (Devices should be designed to support simple instruction. Instructions should be limited to major points presented using clear, everyday language and photographs or pictograms, covering why they should follow each instruction, along with how).

What does it mean for Standardized devices?

Based on the guidance captured thus far, it is apparent that devices that resonate with individual needs, or certainly the needs of sub-groups of the population are important. This may be in the form of fun ‘funky’ products for children, or ruggedized products for those who are keen to take part in outdoor pursuits. However, this requirement for multiple variants of the same device presents significant challenges for medical device manufacturers. Even subtle differences in colour can mean separate regulatory submissions – resulting in additional cost and potential delays in getting drugs to market.

The result is that, in most cases, a single product must be found that balances the needs of its diverse user base. This requires detailed

1 World Health Organisation report (2003). Adherence to long-term therapies: evidence for action. ISBN 92 4 154599 2.

2 Reid. K (2012). The Heart Of The NonAdherence Epidemic. Available at http://www. atlantishealthcare.com/news-media/details/ the-heart-of-the-non-adherence-epidemic accessed 06/07/14.

3 CVS Caremark (2012). State of the States: Adherence report.

4 Smith DL. Compliance packaging: a patient education tool. Am Pharm. 1989;NS29(2): 42–45. 49–53.

consideration to ensure that product can be both standard while still meeting the needs of as wide a patient group as possible.

Arguably, the challenge of maintaining engagement is far better understood and well captured in guidance (e.g. HE75). The FDA focus on safety and efficacy seeks to ensure that the physical forces required and the complexity of use is appropriate for the user population. However, the process prescribed in IEC 62366 does far less to encourage explicit consideration of how devices can be optimized to gain engagement. For that, a different focus is required. There is a wide range of tools from the fields of human factors and design research that can help to structure this focus. Techniques such as ethnography and semistructured interviews allow device developers to gain a richer insight into the lives of device users. Furthermore, they can help inform how an emotional connection can be established. In addition, a detailed understanding of decision-making psychology can help structure what information is required, along with where, when and to whom it should be displayed.

5 Barat I, Andreasen F, Damsgaard EM (2001). “Drug therapy in the elderly: what doctors believe and patients actually do”. British Journal of Clinical Pharmacology 51 (6): 615–622.

6 Belcher VN, et al., (2006). View of older adults on patient participation in medication-related decision making. Journal of general Internal Medicine. 21 (4): 298-303.

7 Wald DS, Bestwick JP, Raiman L, Brendell R, Wald NJ (2014) Randomised Trial of Text Messaging on Adherence to Cardiovascular Preventive Treatment (INTERACT Trial). PLoS ONE 9(12).

Even subtle differences in colour can mean separate regulatory submissions – resulting in additional cost and potential delays in getting drugs to market.

51

Sanofi

Lyxumia®

Disposable pen injector for GLP-1

Design planning

Usability and HF

Mechanical engineering

Industrial design

Colour, material and finish

Instructional design

Packaging

Graphic design

Prototyping

Testing and evaluation

Production support

52

It is the product of an intensive, evidence-based development programme focused on improving the injection experience of patients, for whom Lyxumia® may be their first experience of self-injection.

Providing a device that is not only intuitive to use, but is also comfortable and reassuring was a primary consideration in the design.

The Lyxumia® pen is an easy to use disposable injector, intended to help people with type 2 diabetes.

53

Sanofi

Variable dose auto injector

Colour, material and finish

Industrial design

Insight and strategy

Mechanical engineering

Packaging design

Industrialisation support

Prototyping

Testing and evaluation

Pen

'3D'

54

‘3D Pen’ is a disposable pen injector with an unparalleled feature set for precise delivery of variable doses of medicine. It enables a class-leading maximum dose of 120U to be selected and delivered in single unit increments.

Unlike traditional pen injectors, the innovative spring-powered mechanism avoids the need for the button to wind out of the housing when selecting a dose. This means that very large doses can be comfortably delivered automatically, at the touch of a button.

The ‘3D’ variable dose pen injector with zero dial extension, automatic injection and innovative user feedback features, provides class-leading usability and flexibility.

55

AllStar ® is the first reusable insulin pen produced by a global pharmaceutical company in India.

The pen injector is the result of three years exemplary team work between DCA and Sanofi, with the sole purpose of offering a product that matches the needs of people living with diabetes in India and other developing markets.

AllStar® is a state-of-the-art device that is easy for patients to use and also supports physicians in early initiation of insulin therapy, for better glycaemic control and enhanced therapeutic outcomes.

56

57

Sanofi

AllStar®

Reusable insulin pen injector

Design planning

Usability and HF

Mechanical engineering

Industrial design

Colour, material and finish

Instructional design

Prototyping

Testing and evaluation

Production support

58

59

Sanofi

TouStar®

Reusable pen injector for concentrated insulin

Colour, material and finish

Industrial design

Insight and strategy

Mechanical engineering

Packaging design

Production support

Prototyping

Testing and evaluation

60

With a dedicated replaceable cartridge system, TouStar® can only be used with Toujeo® insulin cartridges. These contain a concentrated ‘U300’ formula with 50% more insulin than a regular cartridge, making them more convenient and longer lasting.

To prevent users from accidentally attaching incompatible insulin cartridges to TouStar®, the new dedicated cartridge system simplifies the cartridge exchange process and helps to prevent insulin mix-ups from occurring.

TouStar ® is the first reusable insulin pen for a concentrated insulin.

61

Sustainability and drug delivery devices

We are witnessing a global boom in the use of drug delivery systems. Valued at approximately $500 billion in 2016, this market is forecast to reach nearly $900 billion by 20251 . Increase in demand for self-administration and home healthcare devices has helped fuel this expansion, meaning that today drug delivery devices are not only much more widespread, they have become easier to use, safer and more effective. They form an essential part of our healthcare infrastructure, enabling delivery of countless therapies that save lives and improve patient outcomes on a vast scale.

As they have been targeted at wider audiences, drug delivery systems have become more disposable. This market trend has been driven primarily by the desire to improve safety and usability. Disposable devices typically require fewer operating steps than reusable ones and because they have a finite life, they are less susceptible to wear and contamination. A good example is the evolution of Dry-Powder Inhalers (DPIs). These began in the 1970s as relatively simple re-

usable devices, such as Spinhaler and Diskhaler in which users fitted replaceable capsules or blister packs containing the drug product. They are now predominantly disposable products, in which the primary pack is sealed for life.

Drug delivery devices have also evolved to become more mechanically sophisticated. For DPIs, the requirement to automatically manage drug primary packaging and the addition of safety features such as dose counters has driven this trend. A similar story is found with injection devices, where one of the latest generation spring-powered disposable insulin pen injectors has seventeen components. In contrast, when first developed in the late 80s and early 90s, disposable pen injectors typically had fewer than ten parts. As device complexity has increased, designers are also able to select from an ever-growing pallet of polymers. This has enabled improvements in performance and reliability, but the mix of materials now found in many devices adds to already significant challenges for recyclability.

In this article, Rob Veasey, Senior Sector Manager, Medical and Scientific, at DCA Design International, explores the environmental challenges facing the drug delivery device industry, and the opportunities they bring.

Published on 30th September 2020 62

The need for change

As scientific evidence of the environmental challenges we face becomes clearer, the necessity to improve the impact of products we use every day has become more pressing. We all share this responsibility, but governmental bodies have taken measures to drive adoption of more sustainable practices. Under the 2015 Paris Agreement, the UN is aiming to keep global temperature rise to below 2°C above pre-industrial levels. Nationally determined contributions will lay out how each country aims to reduce emissions and adapt to the impacts of climate change. The UK’s current target is a reduction in greenhouse gas emissions of at least 80% by 2050, relative to 1990 levels2. As countries develop and publish their individual strategies, the impact of commitments will become evident. It can be expected that changes will be needed to the way that most products are manufactured,

distributed, used and recycled.

The contribution of our industry to environmental damage is also beginning to receive greater attention. Within the last couple of years, reports have emerged describing the global warming effects of pressurised metered dose inhalers (pMDIs). For example, it has been estimated that the propellants used within these devices contribute a staggering 4% of the total carbon footprint of the National Health Service (NHS) in the UK3. ‘Greener’ alternatives are being developed, with at least two major players, AstraZeneca and Chiesi, recently announcing a commitment to develop pMDIs with near zero Global Warming Potential. This is one example of the steps our industry is taking, but further substantial actions will be needed and we must all start to plan for and develop more sustainable drug delivery systems.

A further concern that has recently received publicity is the dramatic increase in plastic waste entering and damaging marine environments. In response, the EU has taken action to ban an array of singleuse items, put in place new targets to encourage recycling of plastic products and mandated the use of more recycled polymers4. Due to the vital role that single-use plastics perform in healthcare and the difficulties in re-using many types of medical devices, this EU legislation does not apply to the medical industry. The performance and inherent safety of polymers, coupled with their cost-effectiveness, makes them ideal for medical applications. This is unlikely to change in the short term, but in the context of increased legislation and efforts within other sectors, it seems almost certain that our reliance on single-use plastics in healthcare will start to come under greater scrutiny.

Figure 1 - Single-use plastics play a vital role in healthcare.

Figure 1 - Single-use plastics play a vital role in healthcare.

63

The contribution of our industry to environmental damage is also beginning to receive greater attention. Within the last couple of years, reports have emerged describing the global warming effects of pressurised metered dose inhalers (pMDIs).

The Circular Economy

The environmental challenges we face are complex and multi-faceted, meaning there is unlikely to be a simple ‘one size fits all’ solution. So what factors should we be thinking about and what opportunities might these bring?

At the heart of sustainable thinking is the concept of the circular economy. This idea involves the gradual decoupling of economic activity from consumption of finite resources and seeks to remove waste from systems. The aim is to build longterm resilience, generate new economic opportunities and provide environmental and societal benefits.

One important aspect of this model is the distinction drawn between biological and technical cycles. The ultimate aim is that consumption happens only within biological cycles, where biologically derived materials can be returned to the system through processes like composting. In contrast, technical cycles should aim to recover and restore products, components, materials and chemicals through strategies like reuse, repair or recycling.

Whilst a fully circular economy will be hard to achieve, by searching out opportunities to minimise waste throughout the lifecycle of products, we can take steps towards this goal.

The environmental challenges we face are complex and multi-faceted, meaning there is unlikely to be a simple ‘one size fits all’ solution.

64

Figure 2 - At the heart of sustainable thinking is the concept of the circular economy.

Measuring sustainability

When you set out to improve a system, it is essential to define the metrics by which the improvement will be assessed. Without this, it is impossible to know if or when progress has been made. The first step in defining sustainability targets is therefore to decide what to measure and how to compare performance. In the context of the circular model, three key parameters are important:

• The energy consumed in manufacture, distribution and use of a product.

• The amount of material that is derived from renewable or recycled content.

• The amount of material that can be recovered for re-use at end of life.

In some instances, factors influencing the choices made in relation to these parameters may be conflicting, or they may conflict with other design requirements. It is therefore essential that we develop objective ways in which conflicts can be understood and resolved to achieve the best environmental profile for a product. This understanding is typically gained through life cycle analysis (LCA), following methods defined within the ISO14000 standards. Owing to the huge array of factors involved in manufacture and distribution of products, LCAs are complex and time consuming to compile. This makes them an impractical tool to inform design decisions in real-time and as a result, they are often used to analyse designs and production systems retrospectively.

To achieve most value from LCA, detailed analysis of existing product

solutions is best used to inform the development of new ones. This identifies where the biggest opportunities for improvement exist, enabling effort to be directed where it will be most effective. This can sometimes be in unexpected places; for example in the case of a device that requires cold-chain distribution, significantly more energy may be consumed in transporting and storing the product than manufacturing it. In this instance, improving secondary packaging to increase packing density may be the most effective way to improve the environmental profile.

Whilst LCA remains the ‘gold standard’ means for assessing the environmental impact of a product, the design industry needs other tools to help assess and inform design decisions rapidly during development. Such tools do not need to be fully comprehensive, but they should allow engineers to make informed decisions about options that might impact on the environment. Some promising early options, such as Eco-Indicator 995 have been developed, but to remain relevant and useful it is essential that these continue to be maintained and improved. Given the increasing focus on sustainable development, it seems inevitable that new tools will become available in coming years.

Developing more sustainable devices

If we restrict our analysis to mechanical drug delivery devices, two issues that are commonly encountered in relation to sustainable development are materials selection and product lifetime. Neither of these issues are straightforward, since environmental design decisions are never taken in a vacuum. Instead, these factors

must be weighed alongside many other requirements that safety critical products such as drug delivery devices must achieve.

Sustainable materials

Most drug delivery devices are made predominantly from plastics, so careful selection of these materials is important when targeting more sustainable solutions. Following the principles of the circular economy, we can break this down into three aspects for consideration.

• Renewable and recycled polymers

Devices are typically manufactured from ‘medical grade’ polymers. These can be traced back to their raw material batches and come with guarantees that the formulation will not change. Recycled polymers are not currently available with medical grade certification and so the most sustainable alternatives in the medium term are likely to be biopolymers. Derived from biological rather than petrochemical sources, a small range of biopolymers are starting to emerge. Unfortunately, in the short-term, device developers are likely to be faced with a lack of choice for biopolymer grade variants. They also carry a price premium compared with conventional polymers and some grades need to be separated from standard recycling streams. Because of the relatively small size of the medical sector in comparison with the wider polymer market, it is unlikely that our industry will drive the development of new sustainable materials. Instead, we should seek to be fast followers of other industries such as food packaging, that use greater quantities of polymer and for whom regulations and customers are demanding rapid adoption of greener solutions.

65

Most drug delivery devices are made predominantly from plastics, so careful selection of these materials is important when targeting more sustainable solutions.

Article by Rob Veasey Senior Sector Manager Medical and Scientific

• End-of-life solutions that enable better recovery and recycling

Recycling of polymer materials contained in drug delivery devices is challenging, leading to problems in establishing the infrastructure to do this safely and effectively. Firstly, they usually contain some residual drug product and may also be contaminated with biological materials. Secondly, because each component is optimised for its particular function, they typically contain a mix of polymer types as well as materials such as glass, aluminium and rubber. Thirdly, they are often designed to be inherently difficult to disassemble to deter tampering or counterfeiting. As a result, it is difficult and expensive to reprocess devices by any means other than incineration for energy recovery. Chemical recycling, in which polymers are broken down into more basic chemicals that can be reprocessed to create new highperformance polymers may be one option, but this technology is not yet widely established. To improve the recyclability of drug delivery devices, many of these issues will need to be addressed at a design level, so must become a requirement at the outset of new development programmes.

• Lower embodied-energy

Not all polymers are created equal and they have subtly different environmental profiles. Generally, more complex polymers require higher energy usage during their manufacture. For this reason, simple polyolefins such as HDPE and PP are usually considered more sustainable than alternatives such as ABS, PC or POM. Clever design and materials selection can optimise part count and the use of polymers, ensuring that more complex and highly refined materials are only used where they are absolutely necessary.

Extending device life

Given challenges in sourcing more sustainable materials, extending product life may be the most effective path to improving the environmental profile of drug delivery devices in the near-term. The longer a device can be used, the lower the environmental impact is likely to be in terms of material usage, waste and energy expenditure when assessed over a fixed period of therapy.

In this context, it is evident that re-usable drug delivery devices are likely to have better environmental profiles than disposable ones. At the beginning of this article, I outlined that recent trends have been in the other direction, so what can be done to reverse this?

• Reusable devices that are easier, safer and more convenient to use

A primary concern with reusable drug delivery devices has often been usability. Patient groups regularly contain large numbers of individuals with reduced manual dexterity or vision impairments. These patients can struggle to correctly replace a primary pack, or reset the operating mechanism. To address this, we should continue to make reusable devices easier to use, for example ensuring that the mechanism resets automatically when the old primary pack is removed, or when a new one is fitted.

• Reusable devices that are more appealing

In the past, there have often been no real advantages to selecting a reusable device over a disposable one. Indeed, as described above there have been some legitimate concerns in relation to usability; yet this should not be the case. With reusable devices, cost is typically offset against a usable life of years

In this context, it is evident that re-usable drug delivery devices are likely to have better environmental profiles than disposable ones.

This article was originally published in the September/October 2020 issue of ONdrugDELIVERY magazine. 66

References

rather than days or weeks, so there is an opportunity to specify better materials to achieve improved performance and to include more automated features. One interesting development that may help to tip the balance in favour of reusable devices is the advent of connected drug delivery systems. For many applications, the cost of electronic monitoring and control functionality is currently seen as a barrier to embedding this technology within disposable devices, making reusable solutions much more attractive. Connected systems may also help to balance some usability downsides of reusable devices, for example by providing warnings against potential use errors. For some applications it may remain impractical to offer fully reusable drug delivery devices. In these circumstances an alternative solution may be to develop disposable products that have greater dose capacity, so that their use-life is prolonged. This approach may of course bring challenges with drug stability and device affordability, but it is a trend that is already well established in some consumer markets and we are likely to see further developments of this sort within drug delivery in the future.

Closing thoughts

The environmental challenges we face are complex, but they also bring opportunities. By good design, there is no reason why more sustainable drug delivery devices cannot also be more cost effective and better for patients. But given the relatively long development cycles required for drug delivery devices, new environmental legislation may emerge that imposes targets that some businesses find hard to achieve. We are currently witnessing this in the automotive industry, where companies that have proactively developed sustainable product ranges are now in a much stronger position than those that left it late.

In many ways our industry is well equipped to deal with environmental challenges. We are systematic in our approach, data driven and highly analytical in our methods. Drug delivery devices are not subject to the whims of fashion; their performance and effectiveness must be comprehensively demonstrated before they enter the market, meaning that we tend not to embrace short-term thinking. To effect change, we will all need to adopt a more sustainable mind-set, in which we question the environmental impact of our decisions in the same way that we currently think about patient safety and therapeutic efficacy.

1 Size of the global drug delivery systems market in 2016 and a forecast for 2025, Statista Research, October 2018.

2 UK action following the Paris Agreement - UK Government, October 2016.

3 Progress on reducing F-gas Emissions - House of Commons Environmental Audit Committee, April 2018.

4 Press Release from the European Parliament, March 2019.

5 Eco-indicator Manual for Designers – a damage oriented method for life cycle impact assessment, October 2000.

By good design, there is no reason why more sustainable drug delivery devices cannot also be more cost effective and better for patients.

67

AllStar ® Pro premium reusable pen injector.

Sanofi have recently launched the AllStar® Pro pen injector in Europe and Canada. AllStar® Pro is a reusable pen injector, intended to help people living with diabetes. The pen uses replaceable cartridges, providing a convenient option for patients who inject regular doses of insulin. DCA partnered Sanofi throughout the development of

AllStar® Pro, targeting a product that delivers high quality with efficient use of materials. This important new device is the result of a rigorous development programme, which builds on the award winning AllStar® device platform.

68

69

Sanofi

AllStar® Pro

Reusable insulin pen injector

Design planning

Usability and HF

Mechanical engineering

Industrial design

Colour, material and finish

Instructional design

Prototyping

Testing and evaluation

Production support

70

71

Designing for uncertainty

Making decisions about the future direction of a product or service is not easy. Not only does it require commercial acumen and technical ingenuity, but it also requires an element of prediction – determining how the product or service will fit the future user and market needs.

Project teams can fall foul of one of two clear traps when deciding on the future direction for a product or service. Some teams limit the information collected, in favour of relying on intuition – progressing the design without a clear understanding of risk, while others collect too much, delaying decision making in a quest for clearer, more unequivocal, information. In the latter, there is a risk that analysis paralysis can set in – where decisions can be repeatedly deferred as additional questions are raised resulting in further research.

The pragmatic middle ground is to base decisions on a grounding of appropriate information, recognising when the information available is enough to progress for a given risk level. Perhaps more critically, the challenge is to ensure that the right information is sought.

While we cannot be certain of the future, we can make educated assumptions. Some assumptions will have high levels of certainty, others less so. Likewise, some assumptions will be critical to the design, others less so. Products stand the greatest chance of success if they are designed based on an explicit understanding of the assumptions that underpin key design decisions along with a description of their robustness and their criticality to the design. Furthermore, actively monitoring,

72

Article by Dr D. Jenkins Research Lead Human Factors and Usability

Rob Woolston Managing Director Malcolm Boyd Senior Sector Manager Medical and Scientific

and protecting, those assumptions plays an important role in increasing the likelihood of success.

Assumption-based design

The approach we have been refining over the past few years and describe as Assumption-based design creates an explicit, and auditable, link between the information available, the assumptions that are made based on this information, and design recommendations.

Understanding the links between information, assumptions, and design recommendations is critical. By linking assumptions to design recommendations, it is possible to understand which assumptions are more critical to the project, and which are less (or even irrelevant). Likewise, the information that is being used to direct future product recommendations can be explicitly highlighted.

When a rating of confidence is applied to the assumptions, the approach serves as a structured process for prioritising future research, focusing first on the

assumptions that have significant sway on design direction and those with lower levels of certainty.

The process can be summarised as follows:

1. Record information and insights collected

2. Record assumptions made

3. Link assumptions to information and capture a rating of assumption confidence

4. Record recommendations made

5. Link recommendations to assumptions and capture a rating of recommendation confidence

6. Identify critical assumptions

7. Determine the required processes to confirm and monitor information and assumptions

Information

The type of information collected will be dependent on the type of product being designed. However, it is likely to include a mixture of factors that can direct innovation:

Products stand the greatest chance of success if they are designed based on an explicit understanding of the assumptions that underpin key design decisions.

1 3 5 7 6 2 4 73

Needs

• Explicit stakeholder (end users, manufacturers, installers, maintainers, etc.) wants and needs

• Latent stakeholder needs

• Market demands (e.g. regulatory requirements, cost models)

Technology

• Latest component availability

• Current R&D pipeline

• Predicted technological innovations and costings (extrapolation of trends)

Category trends

• Descriptions of current competitor products

• Intelligence around competitor pipelines (what they are talking about coming next)

• Patent searches and landscaping

Macro trends

• Trends from parallel worlds (what is happening in other markets that tend to cascade down)

• Broader trends (e.g. attitudes towards disposable plastics, views on cashless transactions)

Assumptions

Assumptions are made based on the interpretation of one or more pieces of information.

As an example, for a given product, a number of information sources (such as ‘voice of the customer’ data and competitor portfolio mapping) may indicate the importance of a connected version of a product, leading to an assumption that a connected variant would be critical to the design.

We can be very confident about some of the assumptions that we make about a product or a service. Others can feel like little more than a guess. As such, it is important to have some way of capturing a description of their certainty, along with a link to the information source(s) used. This creates an auditable trail and allows assumptions to be revisited should the validity of an information source be subsequently questioned.

Recommendations

Recommendations can be treated in much the same way as assumptions.

74

When a rating of confidence is applied to the assumptions, the approach serves as a structured process for prioritising future research.

It is important to record what they are based upon, and the level of confidence in them. The adoption of a recommendation is likely to determine the importance of each of the linked assumptions and, in turn, the associated information elements. This may lead to further research to confirm the information.

Continuing with the example of a need for a connected device, this is likely to lead to a recommendation to develop a connected variant of a product. However, it may be critical to re-test this assumption throughout the development process to ensure that the product being developed is indeed meeting the needs of the consumer.

Improving the model

Once all of the assumptions are listed out, and linked to recommendations and information, it is then important to understand which are the most critical to the success of the product or service. This allows critical assumptions to be monitored and a focus to be placed on the assumptions that are critical to product success. Critical

assumptions can then be tracked, protected and hedged.

For example, if product success is linked to two core assumptions: that the product will have the lowest cost of goods (COGs) and that the cost will be a key driver in purchase decisions, then it may be critical to monitor competitor portfolios and innovation pipelines (e.g. patent searches) to understand if they are developing technologies or processes that may give them a cost advantage.

Cost advantages can be protected by further reducing COGs through cost reduction exercises (making it harder for the assumption to fail).

It can also be hedged by ensuring that the product has added value to consumers that would allow it to be a viable proposition even if the assumption were to fail (no longer the lowest cost on the market).

Conclusions

Our experience is that assumptionbased design provides a highly structured approach to product and portfolio planning. The explicit

nature of the approach provides a clear audit trail for decisionmaking providing a more efficient, transparent, evidence-based process.

This not only helps to guide product development, but it also helps to reduce instances of ill-informed decision-making and analysis paralysis.

This is particularly relevant when initiating a product in the face of uncertainty. Rather than delaying project kick-off in pursuit of further information, this approach can be employed to start the project based on a clear understanding of the assumptions made, resulting in a specification that is refined over time and allowing timelines to be met, while still managing risk and uncertainty.

75

We can be very confident about some of the assumptions that we make about a product or a service, others can feel like little more than a guess.

Sanofi

AllStar® Connect

Reusable connected pen injector

Colour, material and finish

Industrial design

Insight and strategy

Mechanical engineering

Electronic engineering

Software engineering (IEC 62304)

Packaging design

Production support

Prototyping

Testing and evaluation

76

Developed to help the treatment of diabetes by automatically recording the details of every insulin dose delivered. Dose records can be automatically and seamlessly transferred wirelessly to a smartphone.

AllStar® Connect is operated just like the rest of the AllStar® device family on which it is based, with no added user steps for data sync. It maintains the same ergonomic features, such as large maximum dose, low dispense force, short thumb reach and simple cartridge exchange.

Integrated connectivity without compromise to usability.

77

78

79

Cybersecurity and connected drug delivery, an integrated risk-based approach

John Whitehouse, Rob Veasey and Shane Day, discuss the value of integrating cybersecurity into a holistic, multidisciplinary approach to risk management for connected medical devices.

We are all becoming increasingly aware of concerns about the security of digital information impacting our lives. Most people routinely communicate online and, in the wake of covid-19, many of us now also extensively work, shop, bank and socialise in the digital space. This inexorable trend is revolutionising the way we live and is impacting the medical industry as both healthcare providers and device companies embrace digital technology as a means to improve patient outcomes and streamline service efficiency.

Of course, electronically programmable medical devices have been around for decades; what is different now is the widespread integration of these devices with a patient’s own electronic products and systems, such as mobile phones and home networks. This integration significantly increases the vulnerability of personal medical data to cyber-snooping and raises the very serious prospect that malicious attacks could be made that disrupt safe and effective operation of devices that are critical to the health and well-being of patients.

In 2017, the WannaCry ransomware attack affected hundreds of thousands of computers around the world. Whilst this attack was not specifically targeted at medical systems, it exposed the vulnerability of large, interconnected healthcare providers, such as the UK’s NHS. The attack resulted in

the cancellation of thousands of appointments and operations within the NHS. It was also reported that some staff had to revert to pen and paper and the use of private mobile phones, as centralised IT systems had become completely disrupted. Perhaps even more alarmingly, reports by cybersecurity researchers have demonstrated the potential vulnerability of safety-critical devices, such as wireless-connected insulin pumps and pacemakers, to hacking¹, raising the genuinely sinister prospect of targeted, remote, life-endangering attacks on individuals.

Whether inadvertently or deliberately, it is clear that cyber-attacks have the potential to inflict serious harm on patients. In response, regulators expect that cybersecurity vulnerabilities are adequately identified and addressed by developers and manufacturers of all electronically programmable medical devices.

What Needs To Be Protected?

When determining how to protect the cybersecurity of a medical device, the first step is to understand the data assets that the device manages. Data records, especially sensitive patient data, need protection from snooping and manipulation for both privacy and safety reasons. Additionally, the software running on the device may be a key intellectual property asset that needs to be protected from theft or tampering.

Published on 29th September 2021 80

As a second step, one needs to consider the environment in which the device will be used. For example:

• Will the device be connected to the internet?

• Does sensitive data need to be transferred to, as well as from, the device?

• Does the device need to be operating at all times?

• Will the device be used in public or private spaces?

The answers to these questions will help to inform decisions on the most appropriate type of communications technology for the device, such as Bluetooth, near-field communication (NFC) or cellular, which in turn enables the developer to explore potential system risks and vulnerabilities.

Consider a hypothetical scenario, wherein a new drug delivery device is being designed with connectivity features to support a patient in

tracking their medication and to enable live monitoring by clinicians (Figure 1). In this scenario, a patient interacts with their device using an app on their smartphone via a short-range, personal area network (e.g. Bluetooth Low Energy), which allows the patient to read a log of their dose history. Additionally, the device has an internet connection that allows data to be uploaded to a cloud-hosted database server. The patient’s clinician can access the data from the database for remote patient monitoring. The device also includes a wired access port for device maintenance and diagnostics by the manufacturer.

An initial cybersecurity assessment identifies that there are a number of possible points of interest for a potential attacker. Data records, including the details of a patient’s medication history and any sensitive personal data, could be of interest to an attacker looking to profile or track an individual. Access to the software and configuration settings

that control the device’s behaviour, either via the wired access port or wirelessly, could provide an avenue for malicious attacks, as well as theft of intellectual property. The presence of an internet connection could also make the device vulnerable to a variety of attacks, such as “denialof-service”, where the device is flooded with superfluous requests in an attempt to make it unavailable to its intended users.

Whether inadvertently or deliberately, it is clear that cyberattacks have the potential to inflict serious harm on patients.

Figure 1: An example system containing a connected drug delivery device.

81

Identifying Vulnerabilities

Once the device and its system architecture are defined, threat modelling should be applied methodically to identify potential vulnerabilities that need to be addressed. By examining the potential for cyber-attacks, such as spoofing (disguising a communication from an unknown source as being from a known and trusted source), tampering, data repudiation (hidden manipulation or invalidation of data), information leaks, unauthorised use or denialof-service, the potential impacts on device behaviour can be explored. The device developer should aim to generate a comprehensive list of cybersecurity risks that require consideration and mitigation during the development of the detailed design for the device.

When evaluating the potential severity of cybersecurity risks and assessing possible risk controls, a common approach is to consider confidentiality, integrity and availability (CIA) for each scenario. The US National Institute of Standards and Technology (NIST)

defines these terms as follows²:

• Confidentiality: Preserving authorised restrictions on information access and disclosure, including means for protecting personal privacy and proprietary information.

• Integrity: Guarding against improper information modification or destruction, including ensuring information non-repudiation and authenticity.

• Availability: Ensuring timely and reliable access to and use of information.

The relative importance of each criterion will depend on the intended use of a medical device. For a connected drug delivery device, integrity of data, such as records of drug delivery activity, may often be considered more important than confidentiality or availability. However, availability of data might be more important in scenarios where the drug delivery device needs to provide real-time updates, such as alerting a clinician to an occurring problem.

82

Figure 2: The relationship between cybersecurity and safety risks.

83

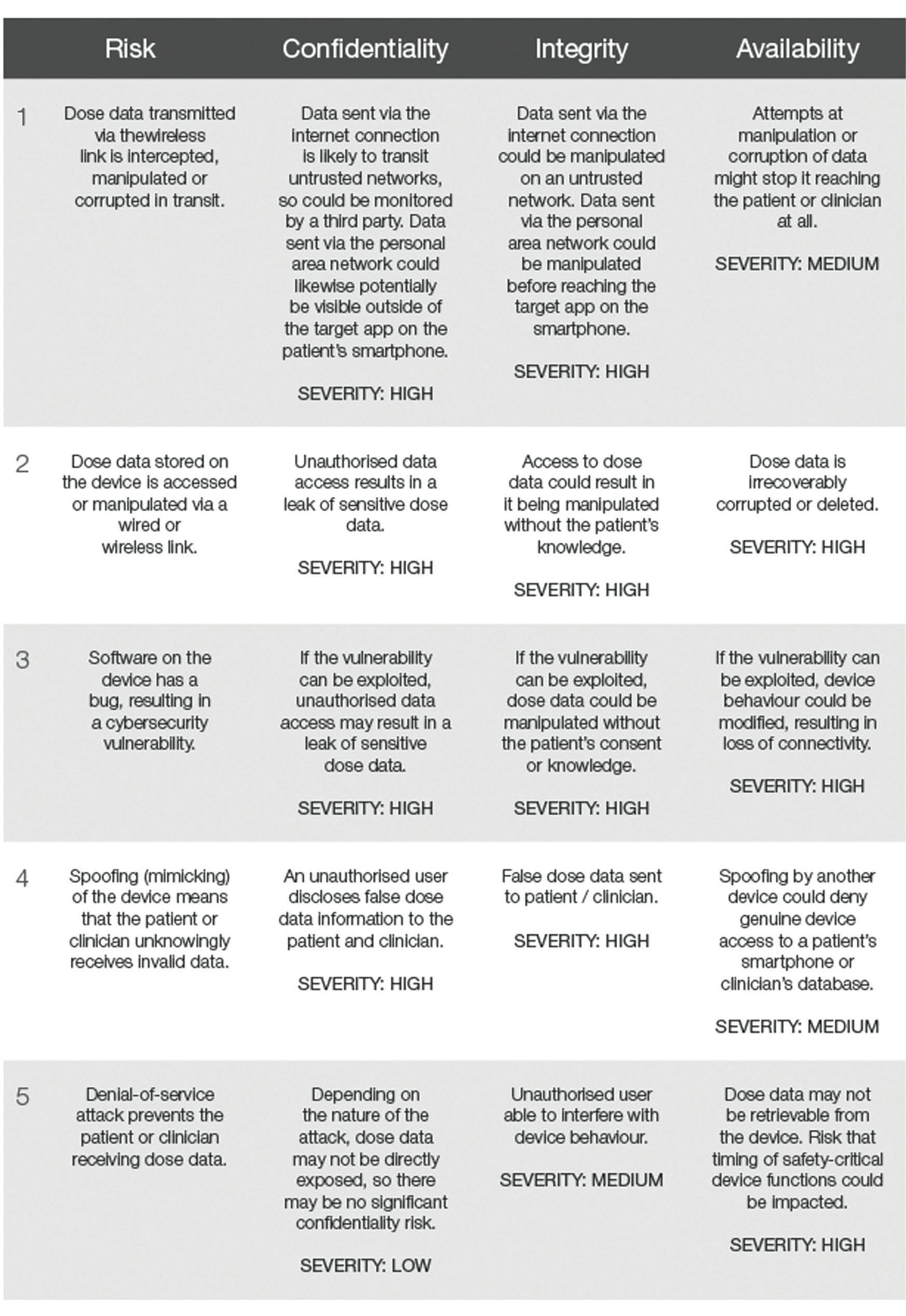

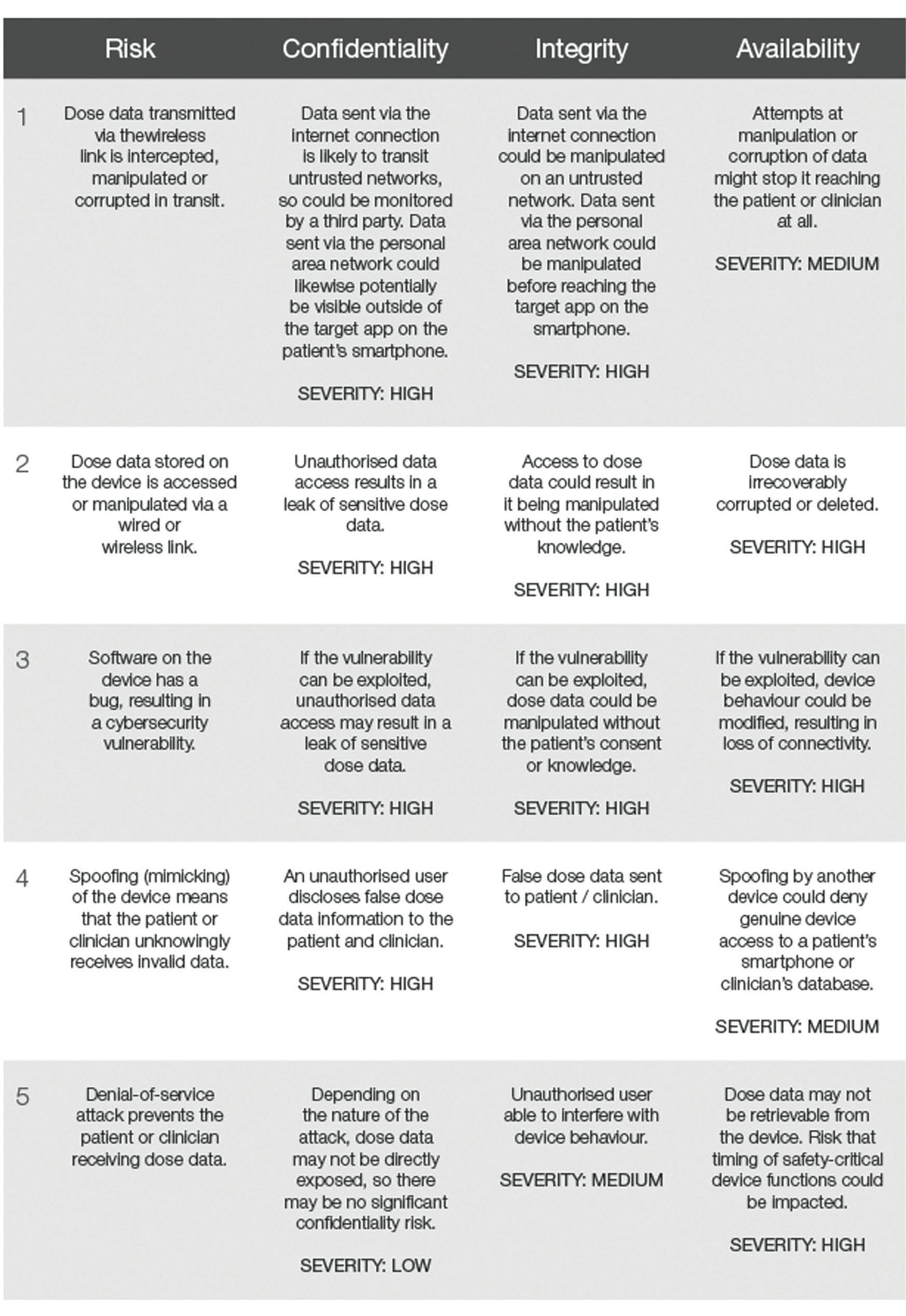

Table 1: Example cybersecurity risks identified using the CIA framework.

Article by John Whitehouse Senior Software Engineer

Rob Veasey Senior Sector Manager Medical and Scientific

Shane Day Senior Skill Leader Electronics and Software

Rob Veasey Senior Sector Manager Medical and Scientific

Shane Day Senior Skill Leader Electronics and Software

Taking our hypothetical drug delivery device example, we have identified a few example cybersecurity risks and evaluated their potential impact using the CIA framework in Table1. Having identified cybersecurity risks in this way, they can then be resolved within the overarching connected device risk analysis.

When developing electronically programmable medical devices at DCA, the company also performs detailed research into known issues and published vulnerabilities for the hardware and software used in a medical device to support further risk identification. This includes examining supporting software documentation and assessing published information in open-source databases, such as the Common Vulnerabilities and Exposures (CVE) database. DCA also consults any appropriate guidance on the secure use of data communication protocols, such as Bluetooth Low Energy, that has been published by authorities like NIST.³

Cybersecurity As A Part Of Multidisciplinary Risk Assessment

After identifying potential cybersecurity risks, DCA’s approach is to manage and review the identified vulnerabilities as part of the overall risk management process for the device. This approach helps to ensure that all aspects of performance are considered and appropriately balanced. It is important to remember that a secure device is not necessarily a safe one, as shown in Figure 2, adapted from the Association for the Advancement of Medical Instrumentation’s (AAMI’s) technical report on the principles of medical device cybersecurity.4 The application of a cybersecurityfocused risk control measure in isolation from safety-related risk management could compromise essential performance of the device, for example by negatively impacting usability. One possible situation

where this might arise is if extra authentication steps are added to improve the security of the data shared from the device.

Returning to our hypothetical example device, let us consider some potential mitigations to the cybersecurity risks highlighted in Table 1 and the wider design impacts that their adoption could involve.

Risk 1 – Dose Data Transmitted Via The Wireless Link Is Intercepted, Manipulated Or Corrupted In Transit

In the case of dose data interception, manipulation or corruption in transit, one mitigation could be to specify and implement end-to-end encryption when dose data is transferred from the device to a smartphone or database. This could be supported by some form of pre-shared encryption key, though a better approach would probably be to use a secure key agreement protocol, such as Diffie-Hellman, for generating a shared encryption key across an insecure communications channel.

In reviewing this proposed mitigation, a relevant safety consideration would be whether the use of a computationally intensive encryption algorithm could impact on the timing of safety-critical functions, such as generating new dose activity records. This may require new design constraints to be specified to ensure that other device functions which impact patient safety are not compromised, such as the segregation of data transfer functionality from dose delivery or monitoring activities.

Risk 2 – Dose Data Stored On The Device Is Accessed Or Manipulated Via A Wired Or Wireless Link

When considering this risk, minimising the opportunities for data to be changed from outside of the device after manufacture would provide a useful mitigation. This could include restricting access

After identifying potential cybersecurity risks, DCA’s approach is to manage and review the identified vulnerabilities as part of the overall risk management process for the device.

article was originally published on the

This

MDT - Medical Design Technology website.

84

to dose data via the wireless and wired links, such as making it readonly. Adding integrity checks, such as error detection codes, could provide an additional detection mechanism in case of inadvertent data manipulation due to a device fault. In these cases, cybersecurity and safety mitigations are likely to be complementary, though the impact on essential performance should always be considered.

Implementing a user authentication scheme could provide a further mitigation for this risk, as well as for risks involving spoofing of a device. Authentication could, for example, involve the patient using their smartphone to scan a unique identifier printed on the device. Data from this identifier would subsequently be used to cryptographically confirm that the data is coming from the expected device. When reviewing this potential mitigation, however, there is a usability trade-off that needs careful consideration. The developer must assess whether the addition of this type of authentication means that the device remains usable and accessible for all target patients. Requiring additional authentication steps via a smartphone app may well be beyond the capabilities of some elderly or cognitively impaired users.

Risk 3 – Software On The Device Has A Bug, Resulting In A Cybersecurity Vulnerability

Where a software bug is published that may result in cybersecurity vulnerability, a couple of mitigation strategies can be employed. To improve monitoring and detection of such risks, a cybersecurity bill of materials(CBoM) can be prepared, which holds a list of software and hardware components that are, or could become, susceptible to cybersecurity vulnerabilities. The CBoM can be used to support risk

management through the device’s lifecycle. This includes assessment of purchasing controls and supply chains during manufacture and monitoring exposure to new vulnerabilities when the device is on the market.

Additionally, a device could be designed such that it supports remote software updates to patch software bugs associated with cybersecurity vulnerabilities. However, design of such a capability needs to be carefully considered to prevent the introduction of new cybersecurity risks. Such an update feature may provide a “back door” into the device for data manipulation, allowing pathways for unauthorised software changes or reloading of an old version of the software that has exploitable vulnerabilities. The remote software update protocol also needs to be sufficiently secure to avoid inadvertent loss of intellectual property. Microprocessor manufacturers are improving their capabilities for supporting secure remote software updates, but these should be carefully reviewed and evaluated as part of device risk management, as well as in design verification and validation planning.

Risk 4 – Spoofing Of The Device Means That The Patient Or Clinician Unknowingly Receive Invalid Data