DAVID YI 2020-2023 Collected Works

TABLE

1. Future Foundry 2. Artist Residency / Gallery 3. Resilient Residency 4. Treehouse Competition 5. Matsumoto Modern 6. Courthouse 7. Building Systems 8. Personal Work

OF CONTENTS

FUTURE FOUNDRY

ARCH 411

INSTRUCTOR: CHANDLER AHRENS

PARTNER: ANGE LONG

As AI becomes more and more developed, the world begins to move towards automation, which sees humans taking more and more of a backseat. For this project, we designed a speculative factory in the year 2054, when AI was speculated by Ray Kurzweil to overtake humanity.

We have hence designed a factory that is beyond human scale, harvesting solar energy for a steel mill that leaves out the human element, reducing the manufacturing process to spectacle for a humanity that is no longer in touch with manufacturing without the aid of computers.

This factory utilizes the power of the sun, caught with an AI powered central sun-catcher, to power a blast furnace which is used to further produce sun-catchers of many different scales, then ships them out across the country as an alternative energy source.

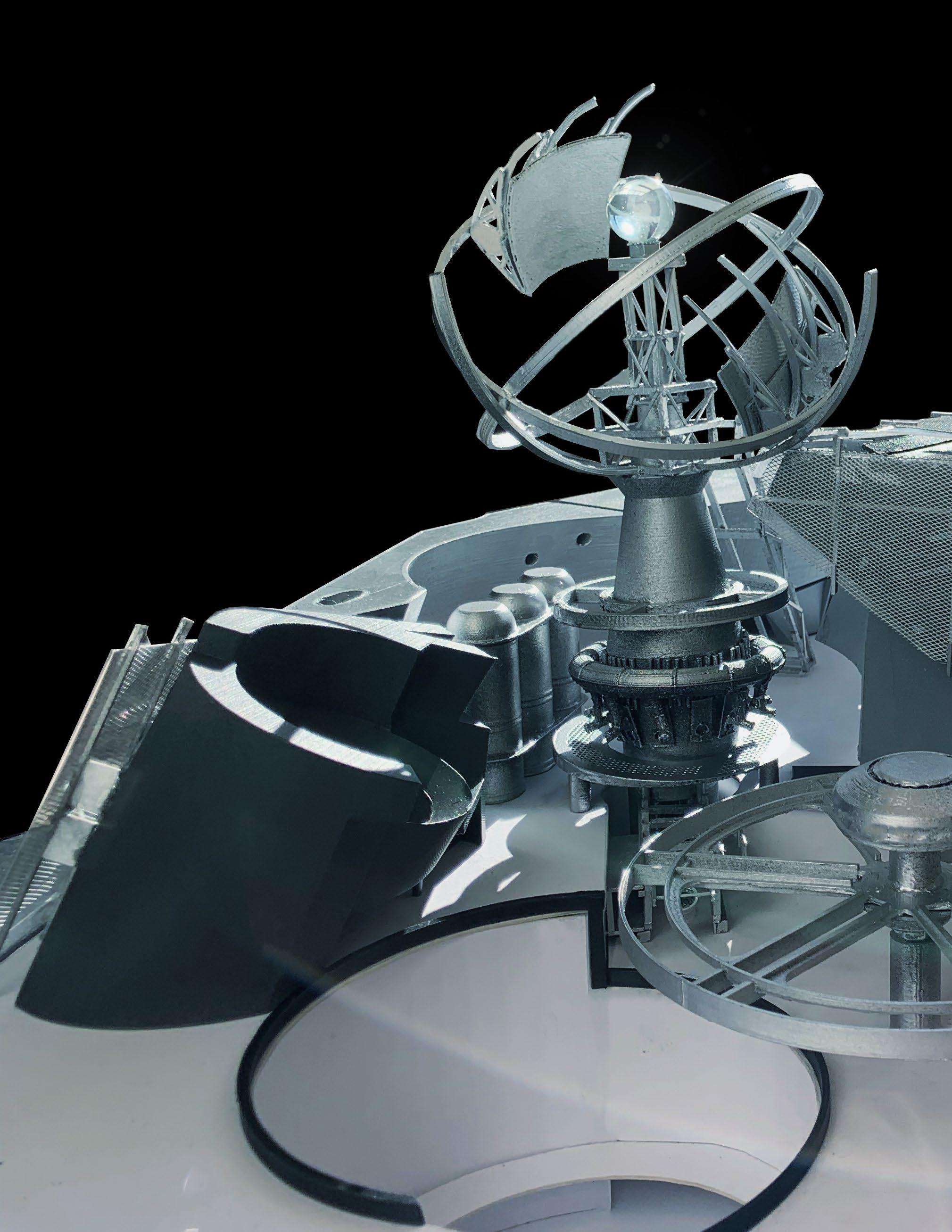

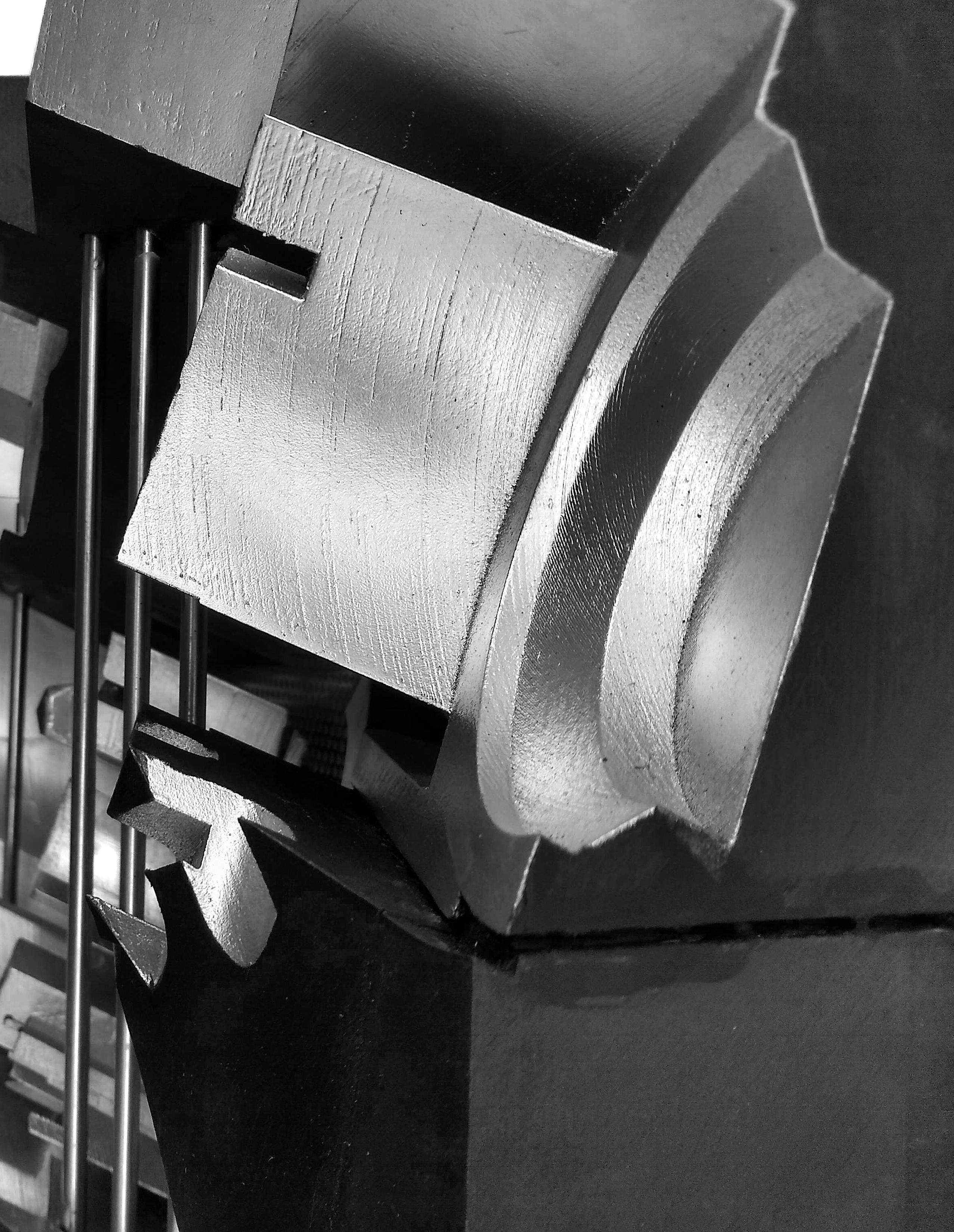

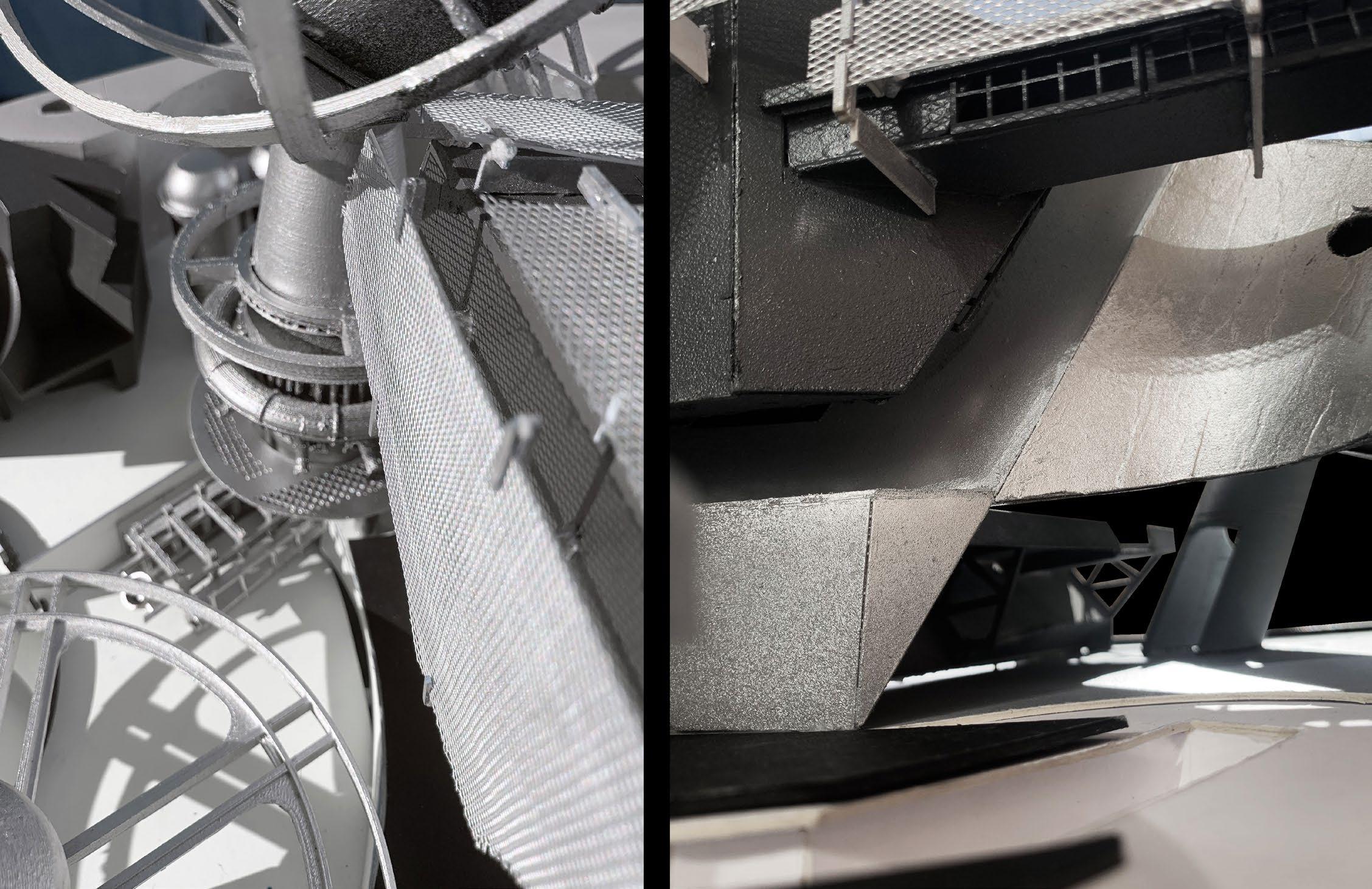

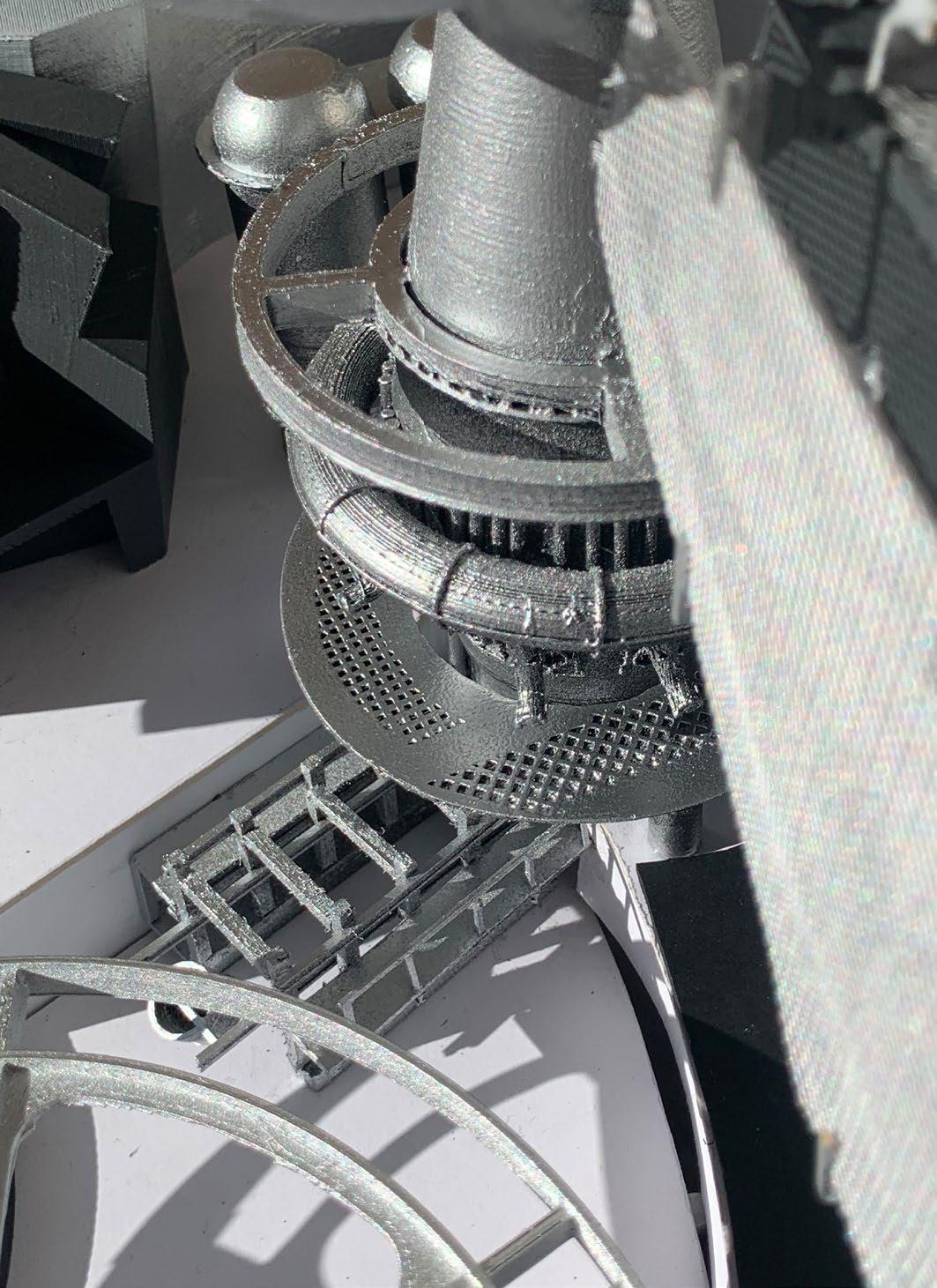

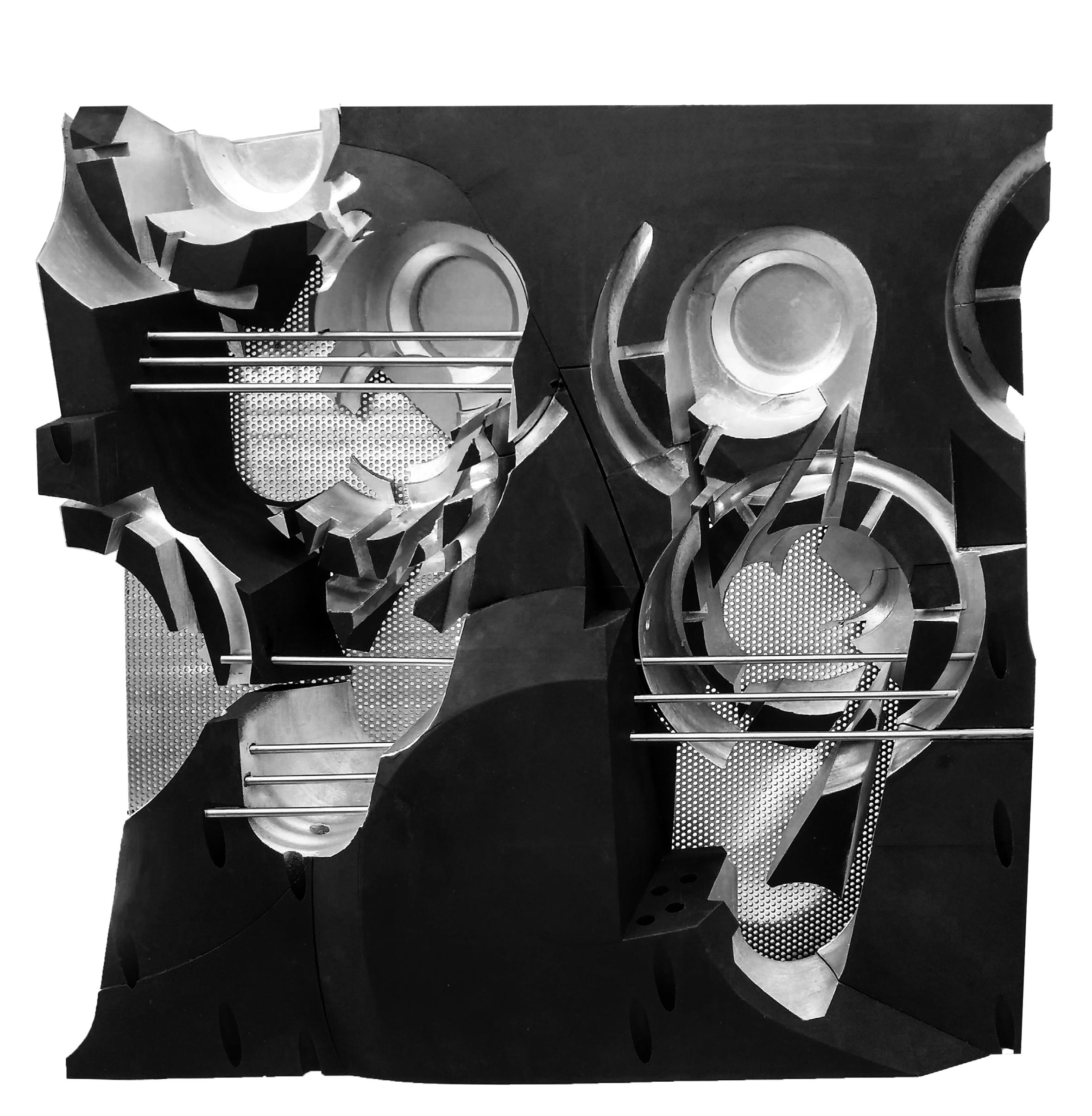

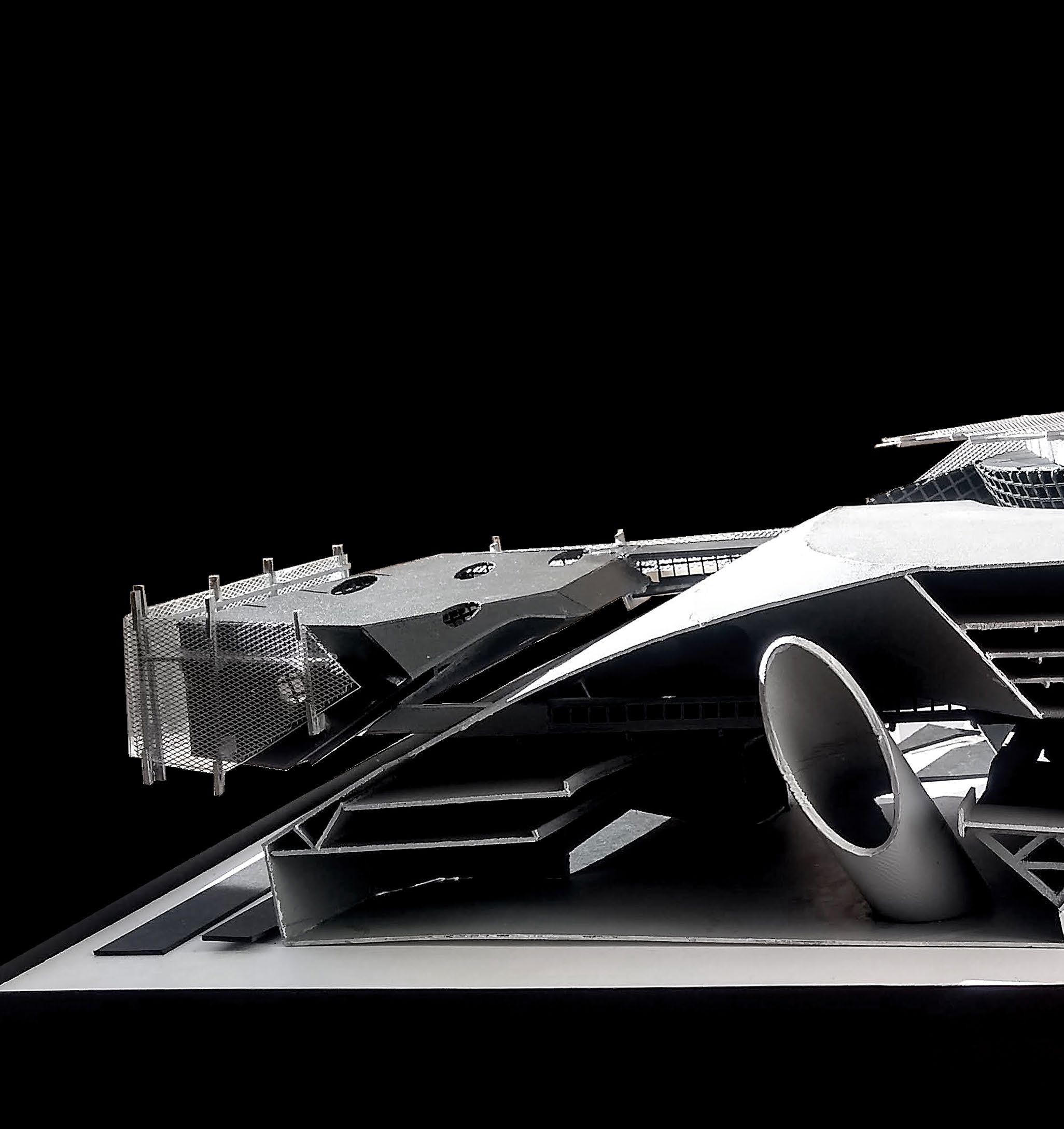

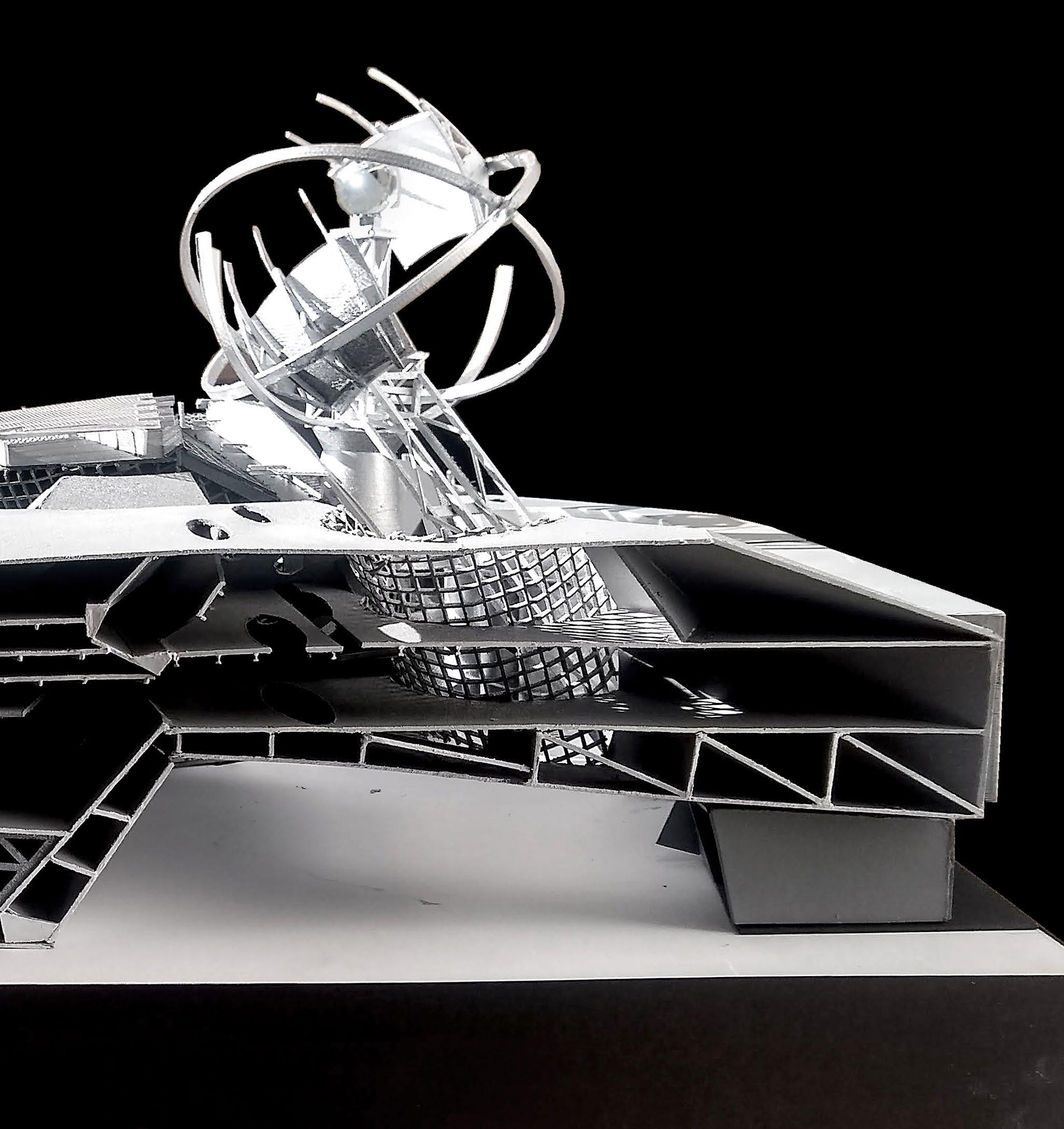

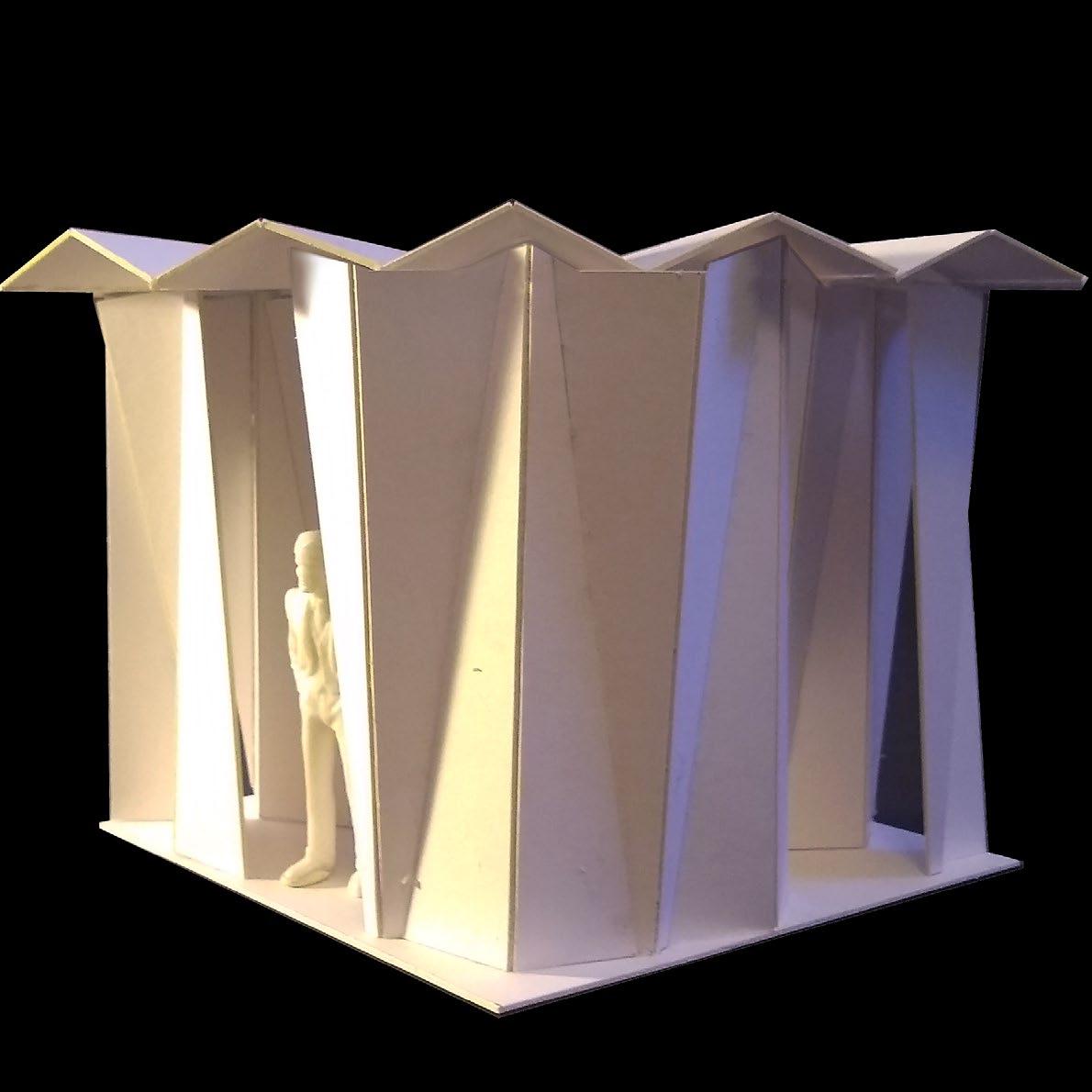

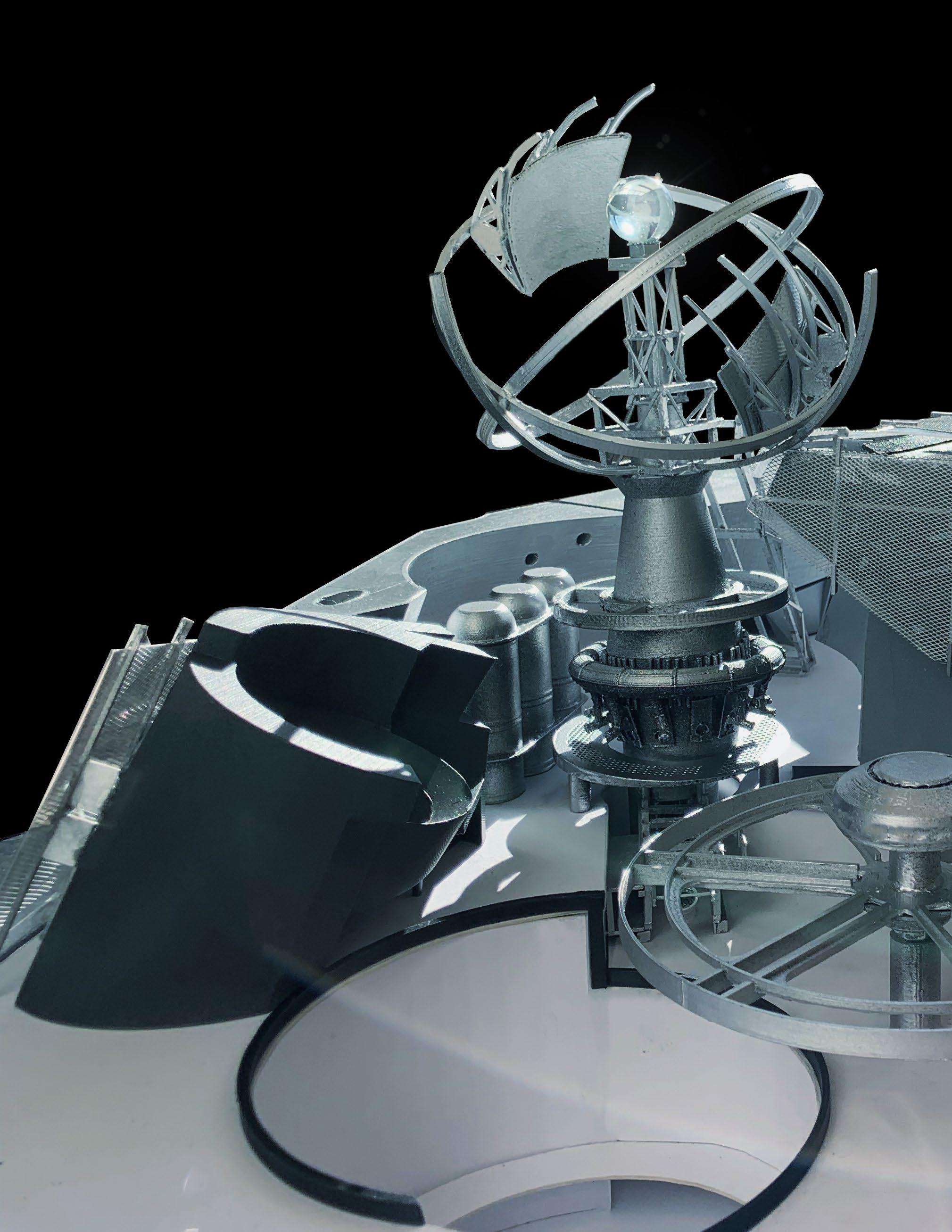

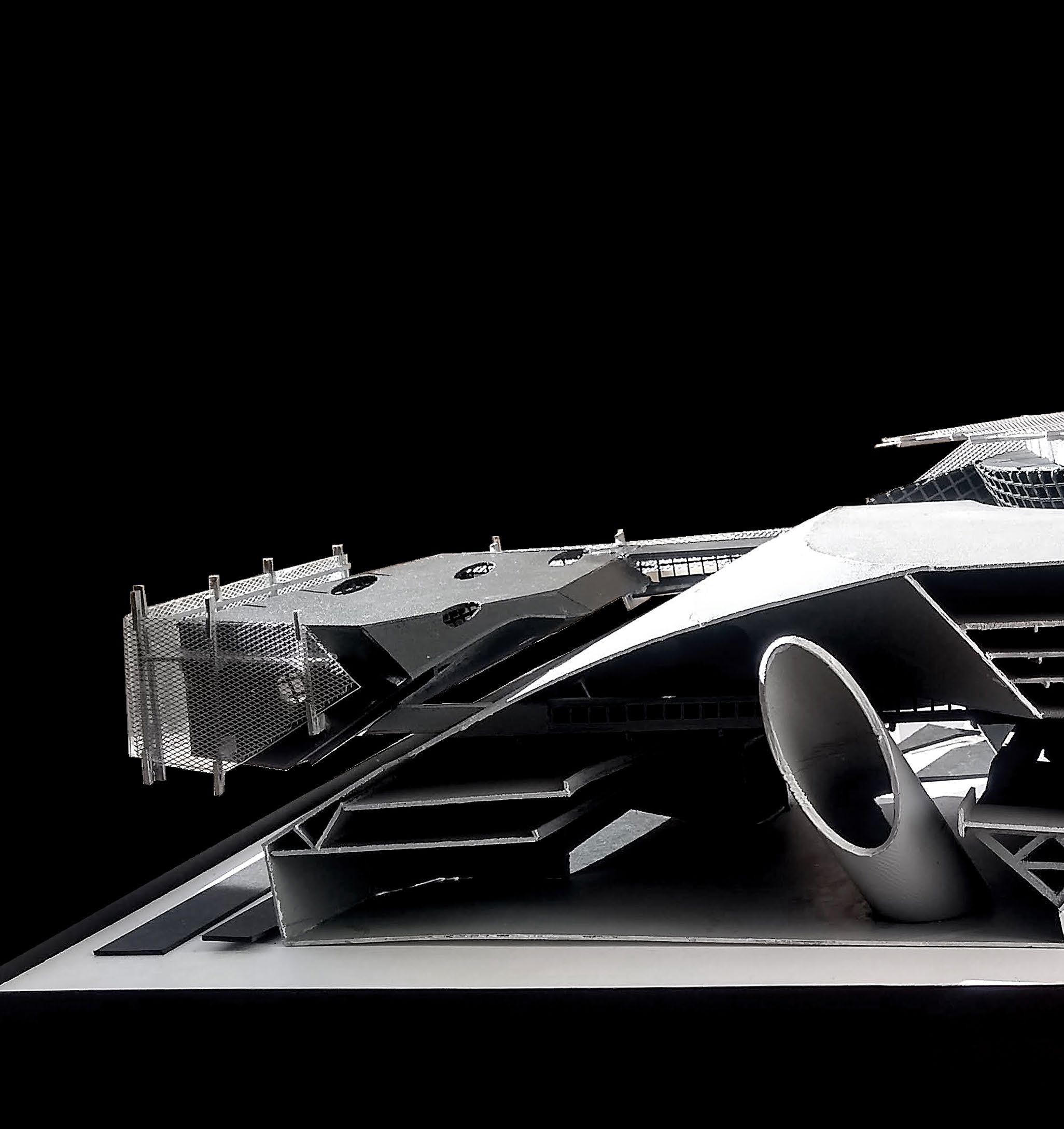

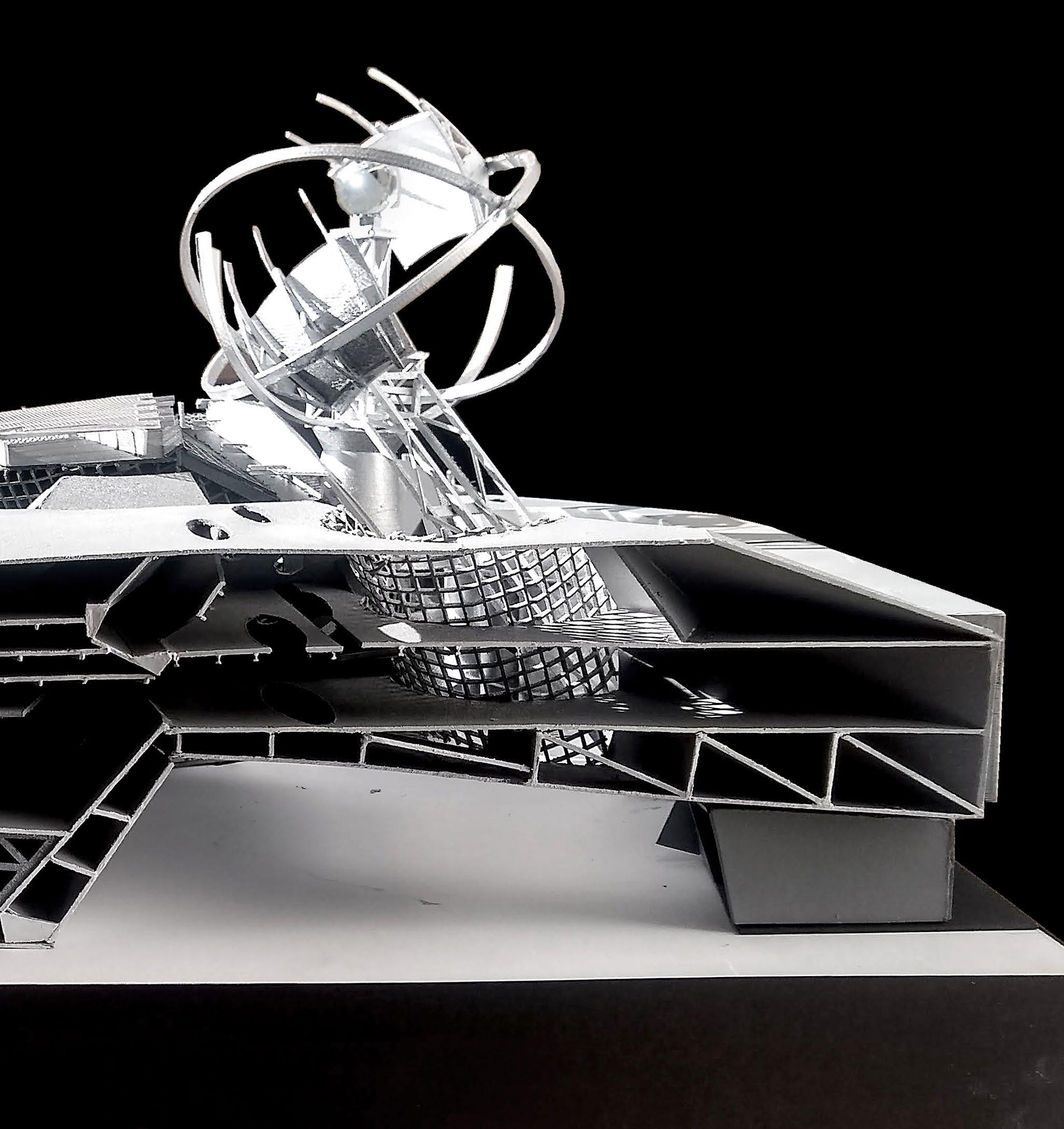

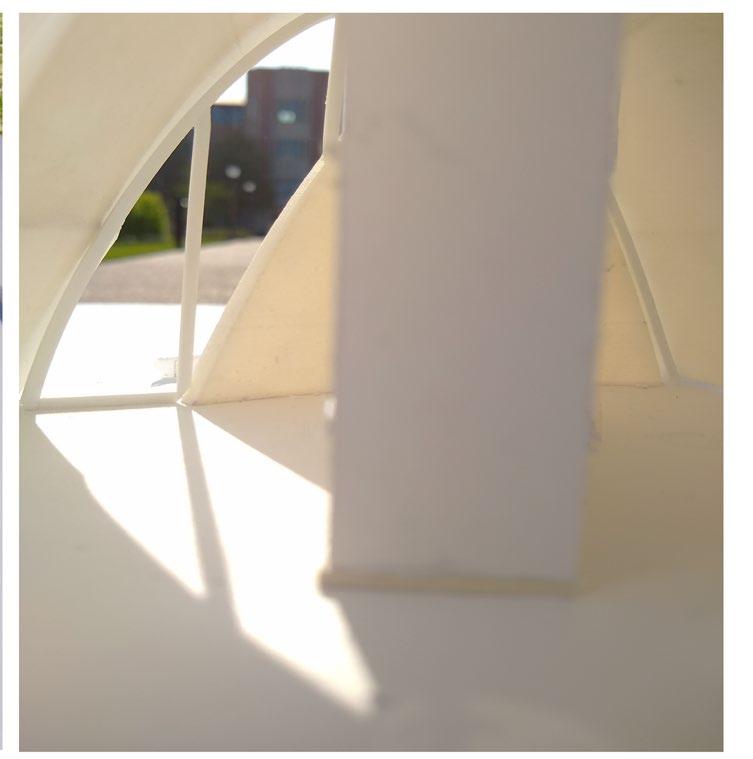

STUDY MODEL

To begin the design process, we set out to create a model in which we could study different moments and material usages. In order to do so, we first started by creating a digital rhino surface, which we then ran a grasshopper script on. This script enabled us to subtract the geometries of our solar-catcher to generate spaces that were beyond our control- which we then fabricated in a physical model (shown right) in order to isolate specific moments that we could thus utilise in our final factory plans.

The process of making this model involved a decent amount of switching between physical tests and digital design, enabling us to see the project from both fronts and aiding in a design that could both be more adventurous whilst also physically feasible.

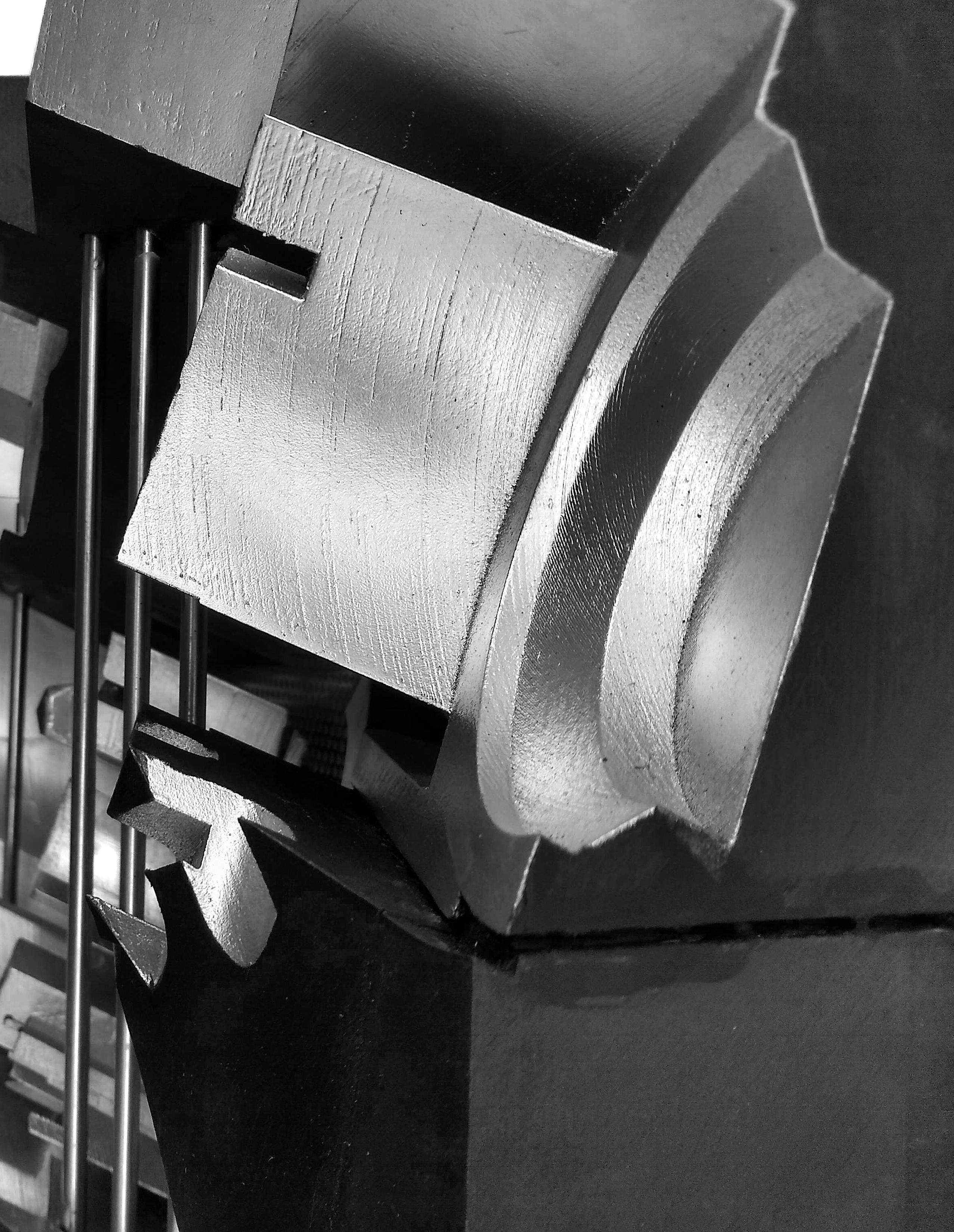

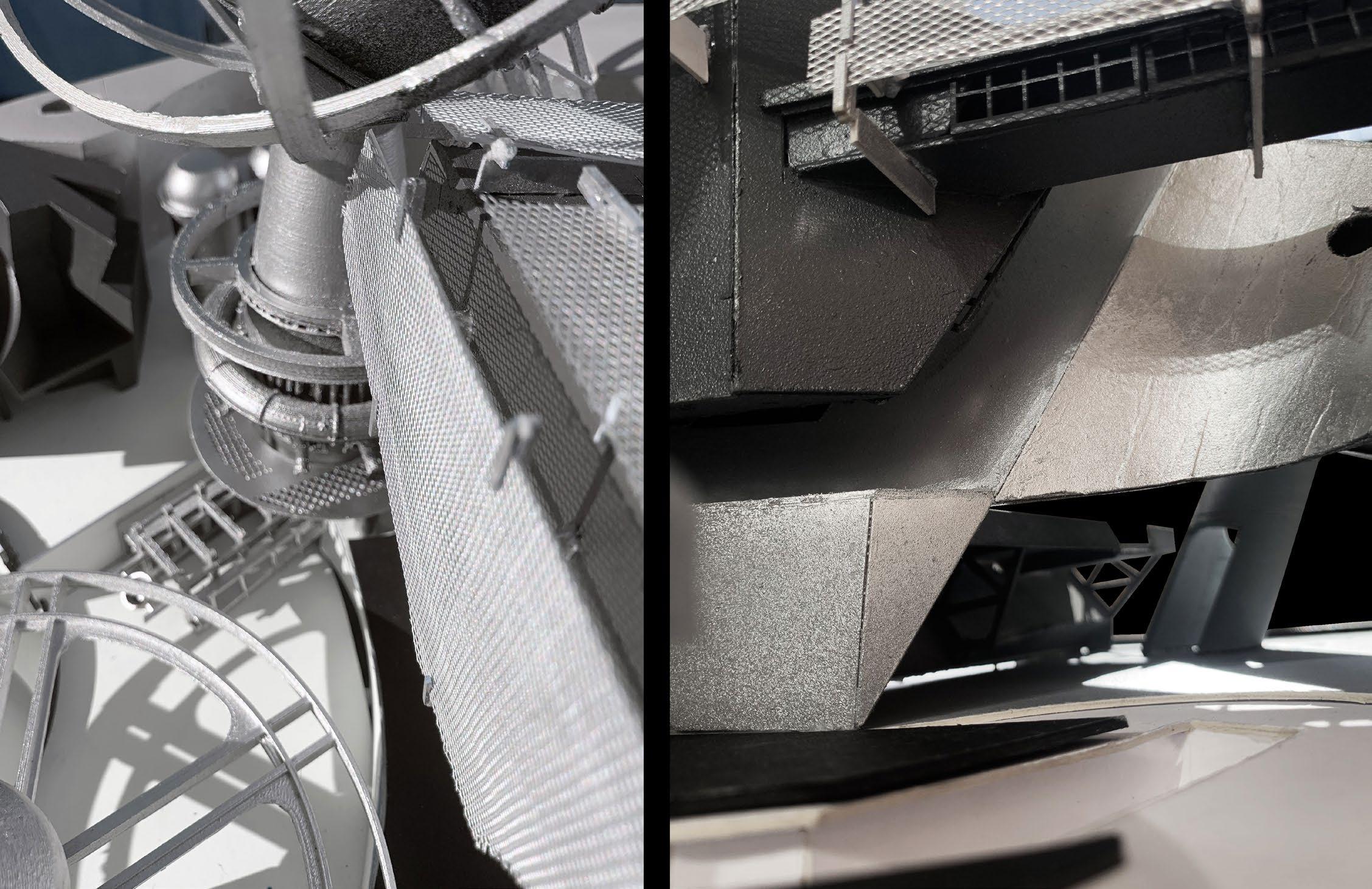

Top Left and Right: Details of the final factory, inspired by the physical model.

Bottom: Image of the physical model. Ange’s hand for scale.

Top Left and Right: Details of the final factory, inspired by the physical model.

Bottom: Image of the physical model. Ange’s hand for scale.

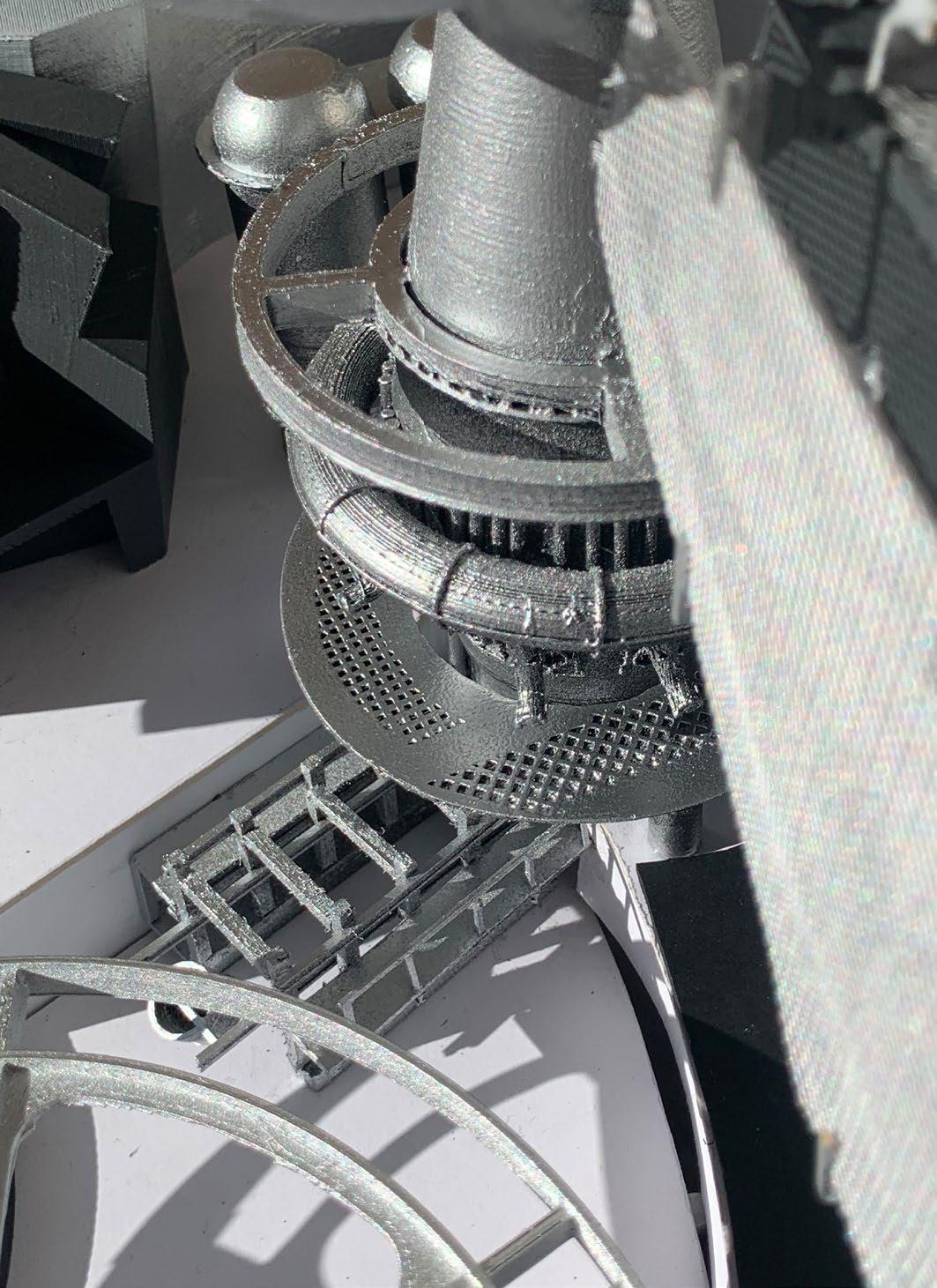

Above: The physical model, standing upright. 3d printed forms and metal structural work.

Above: The physical model, standing upright. 3d printed forms and metal structural work.

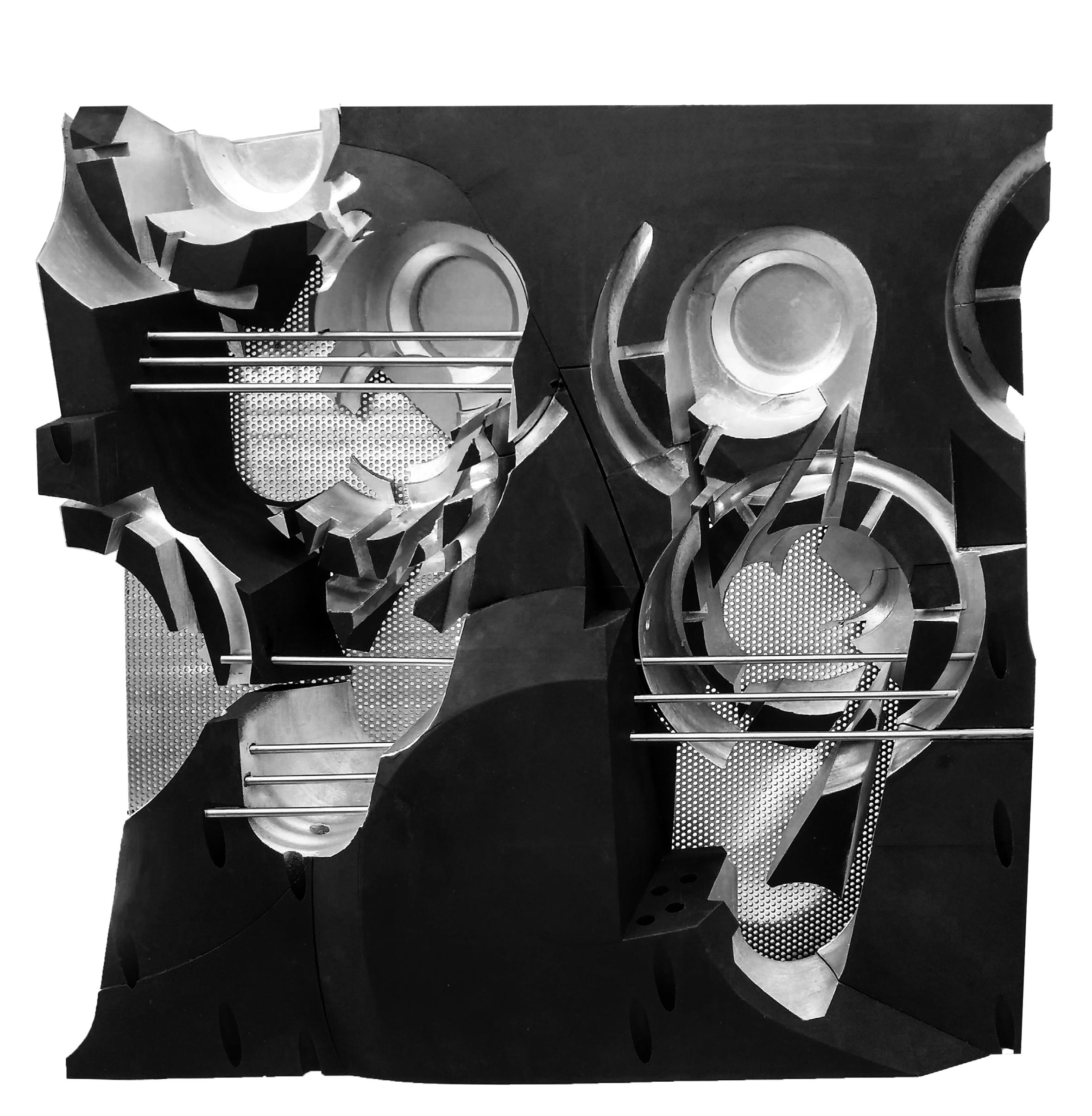

Above: The physical model of the factory, section view. Built mostly by hand using museum board, metal mesh, and plastic sheets.

Above: The physical model of the factory, section view. Built mostly by hand using museum board, metal mesh, and plastic sheets.

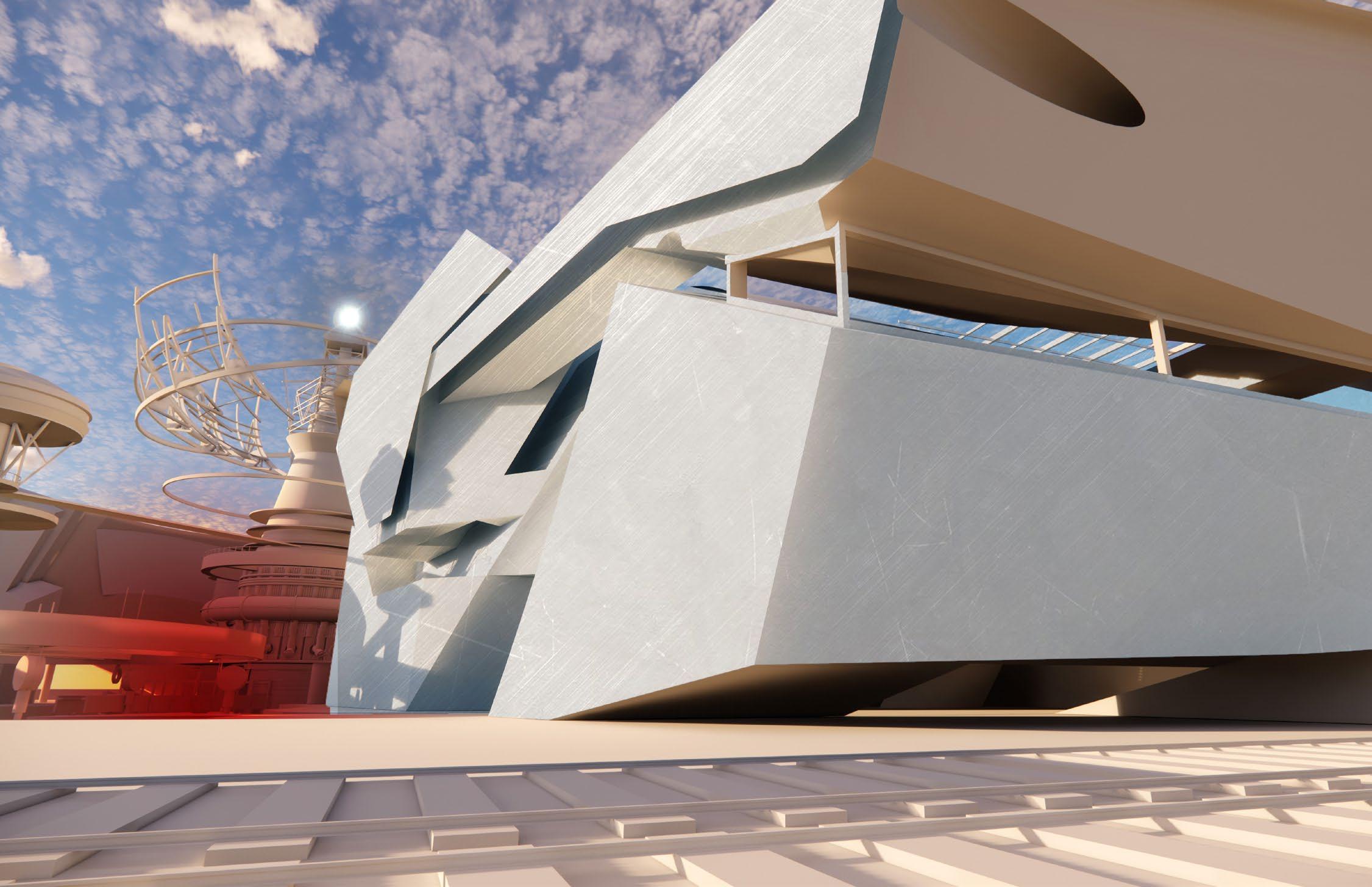

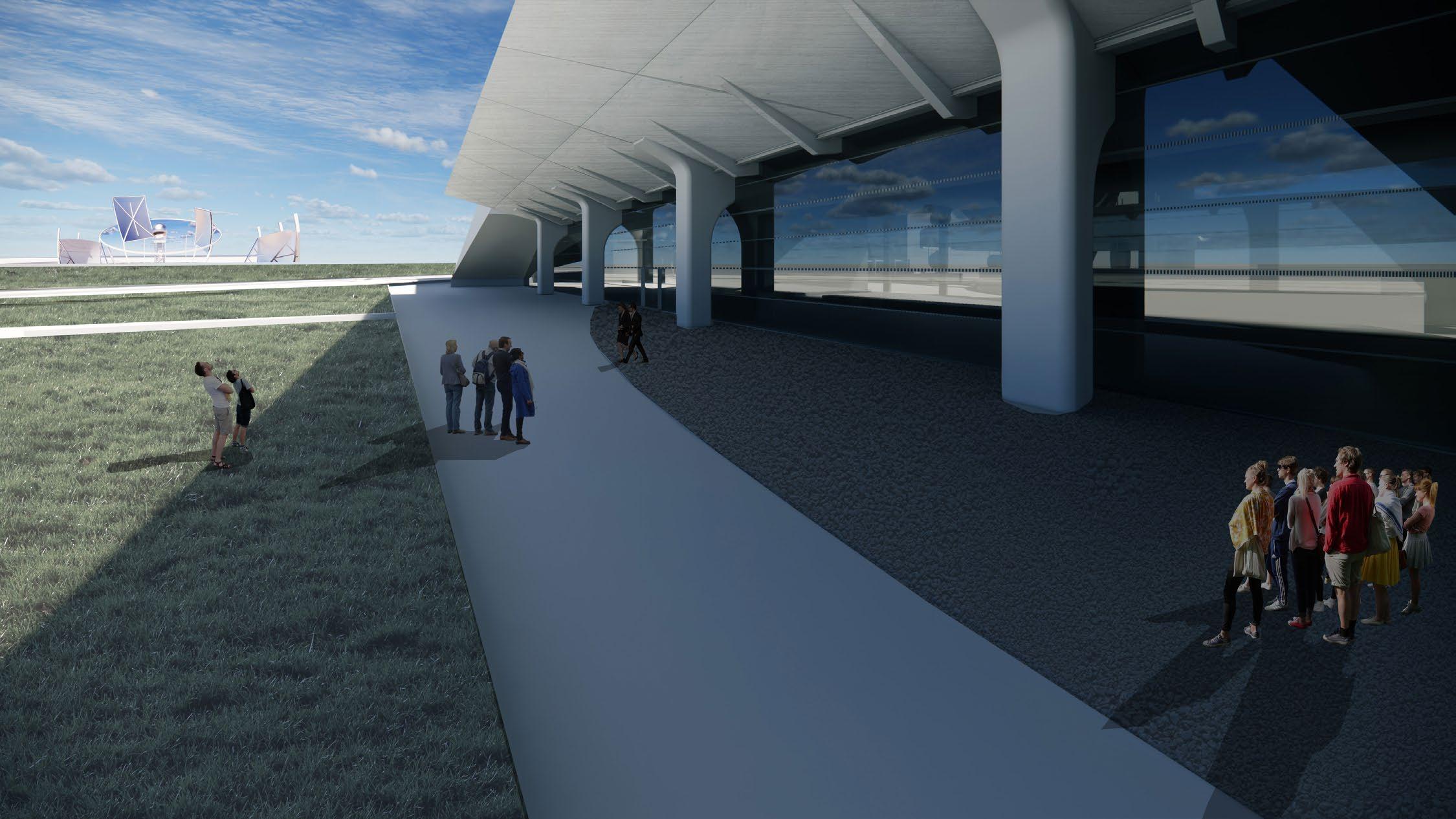

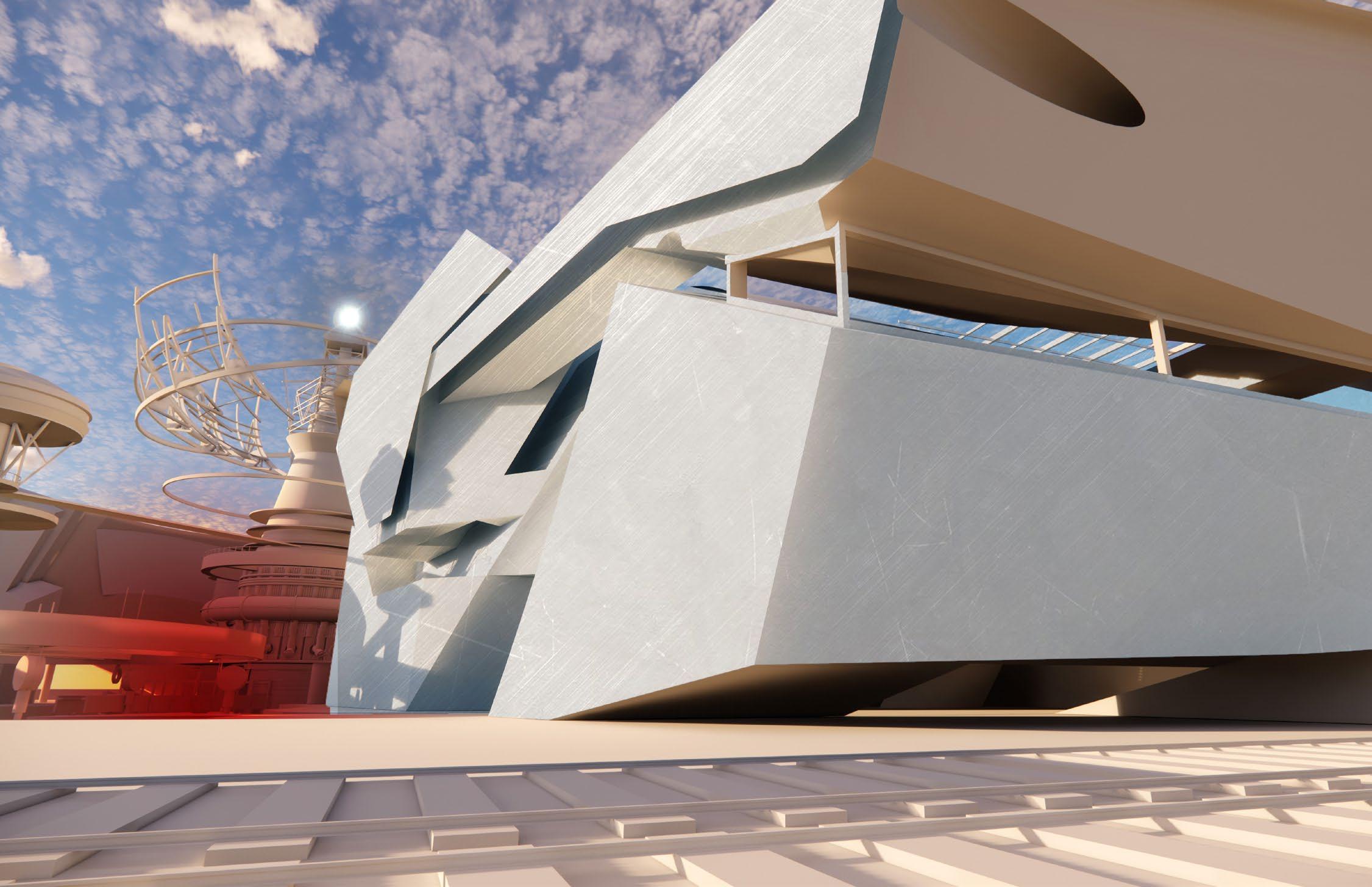

Top: Exterior render, with views of the Sun-Catcher.

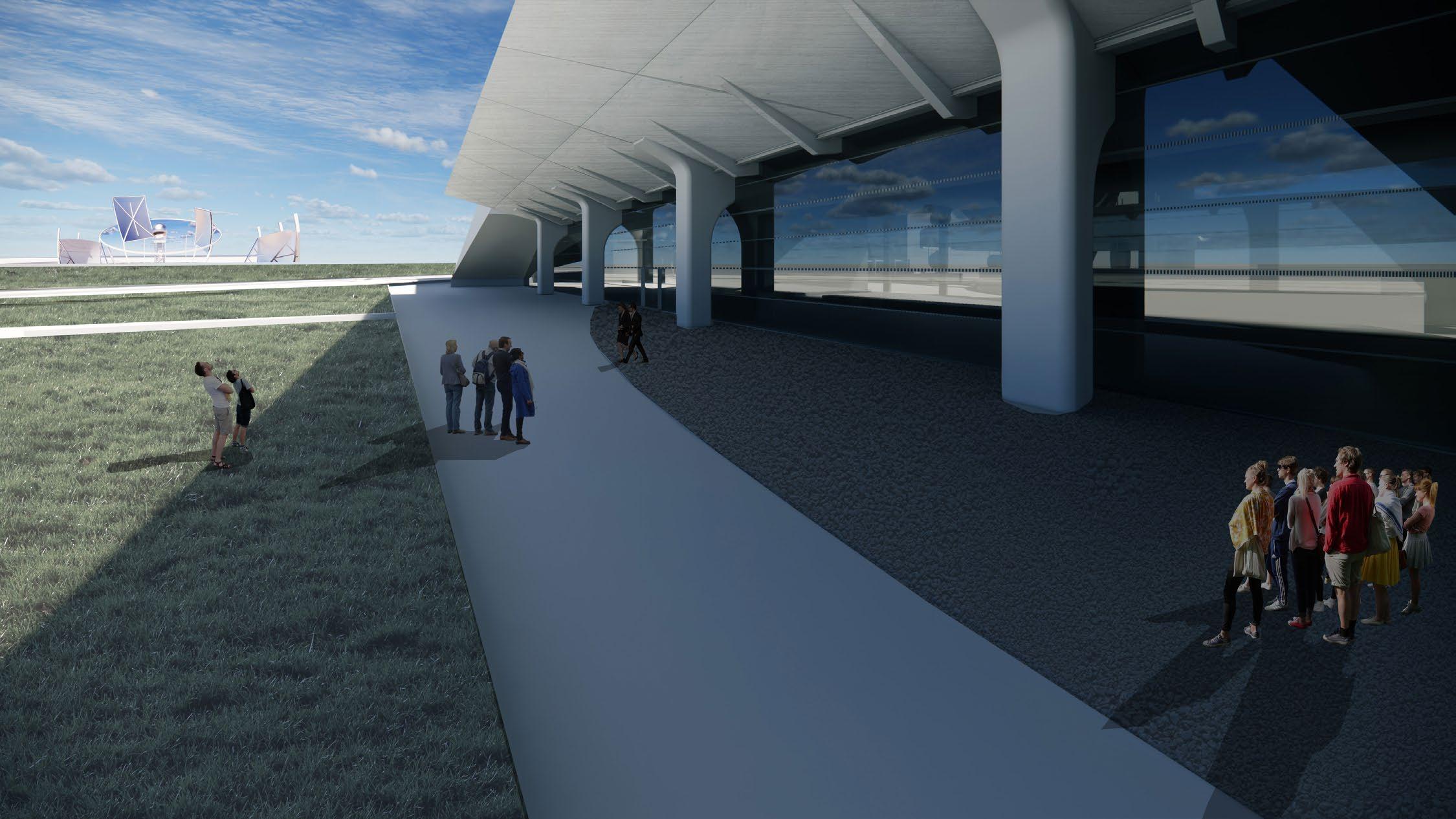

Bottom: Exterior render of the civilian entrance, with anotherSun-Catcher in the background.

Top: Exterior render, with views of the Sun-Catcher.

Bottom: Exterior render of the civilian entrance, with anotherSun-Catcher in the background.

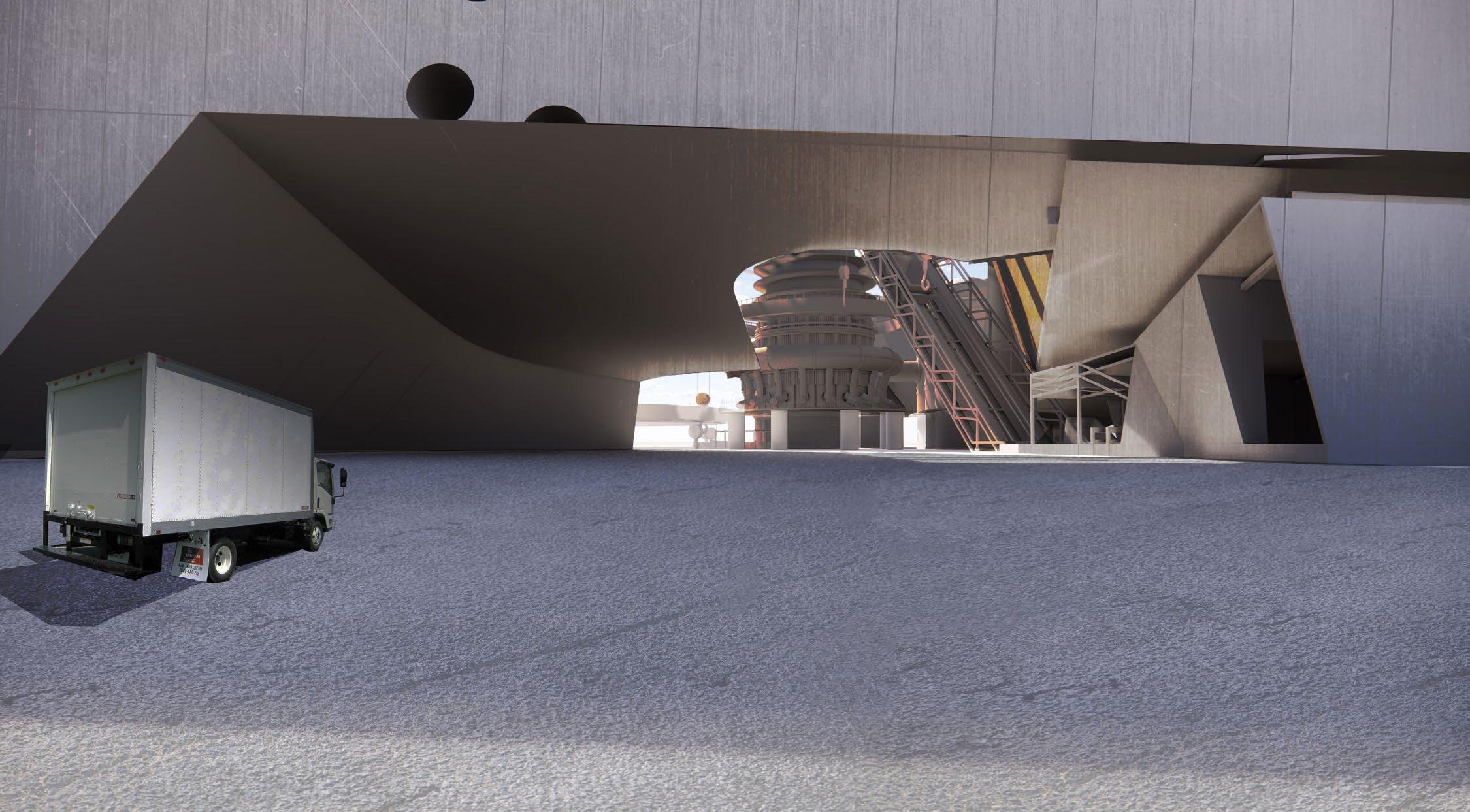

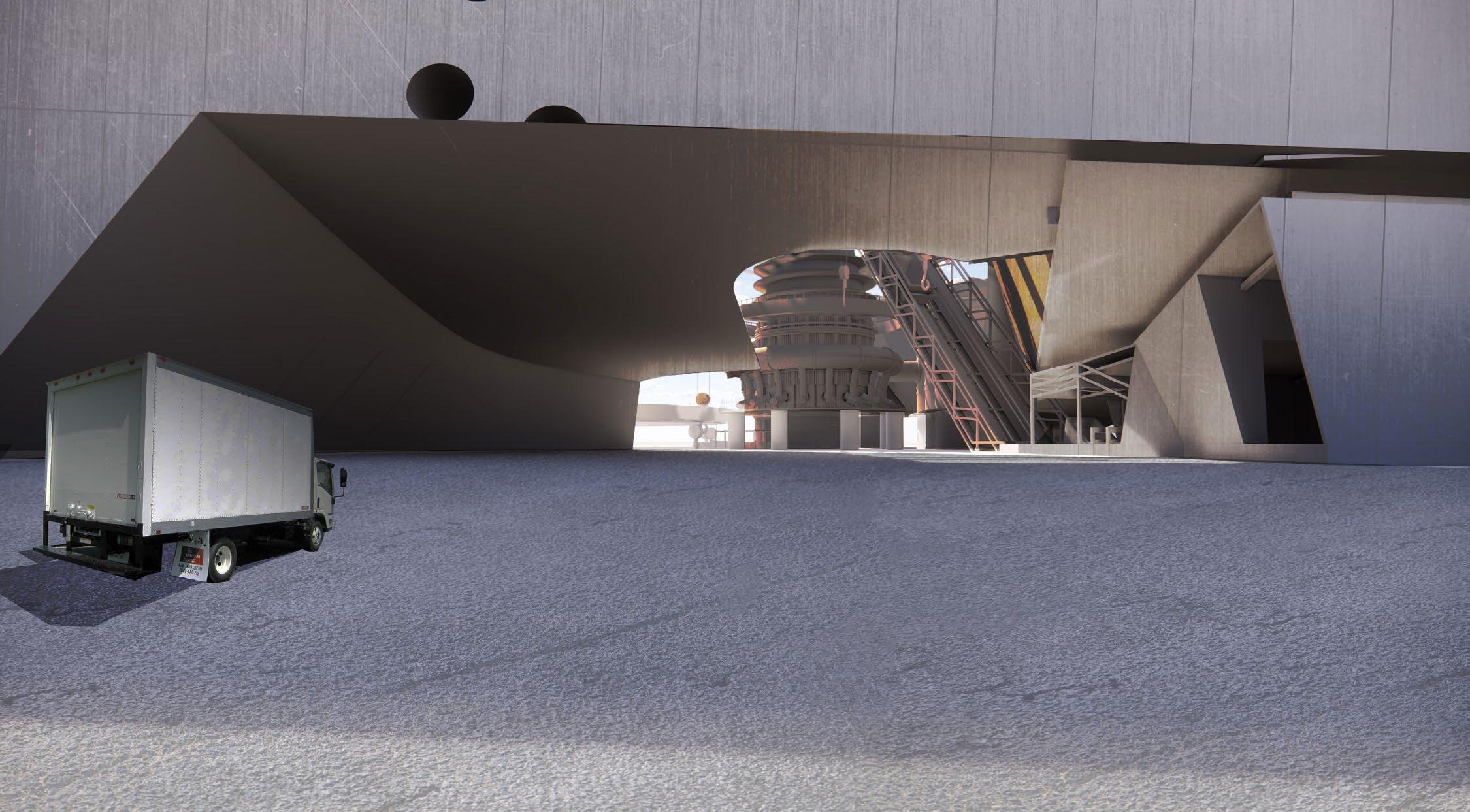

Top: The commercial entrance and loading port for the factory.

Bottom: Molten steel is poured from the blast furnace into a mold.

Top: The commercial entrance and loading port for the factory.

Bottom: Molten steel is poured from the blast furnace into a mold.

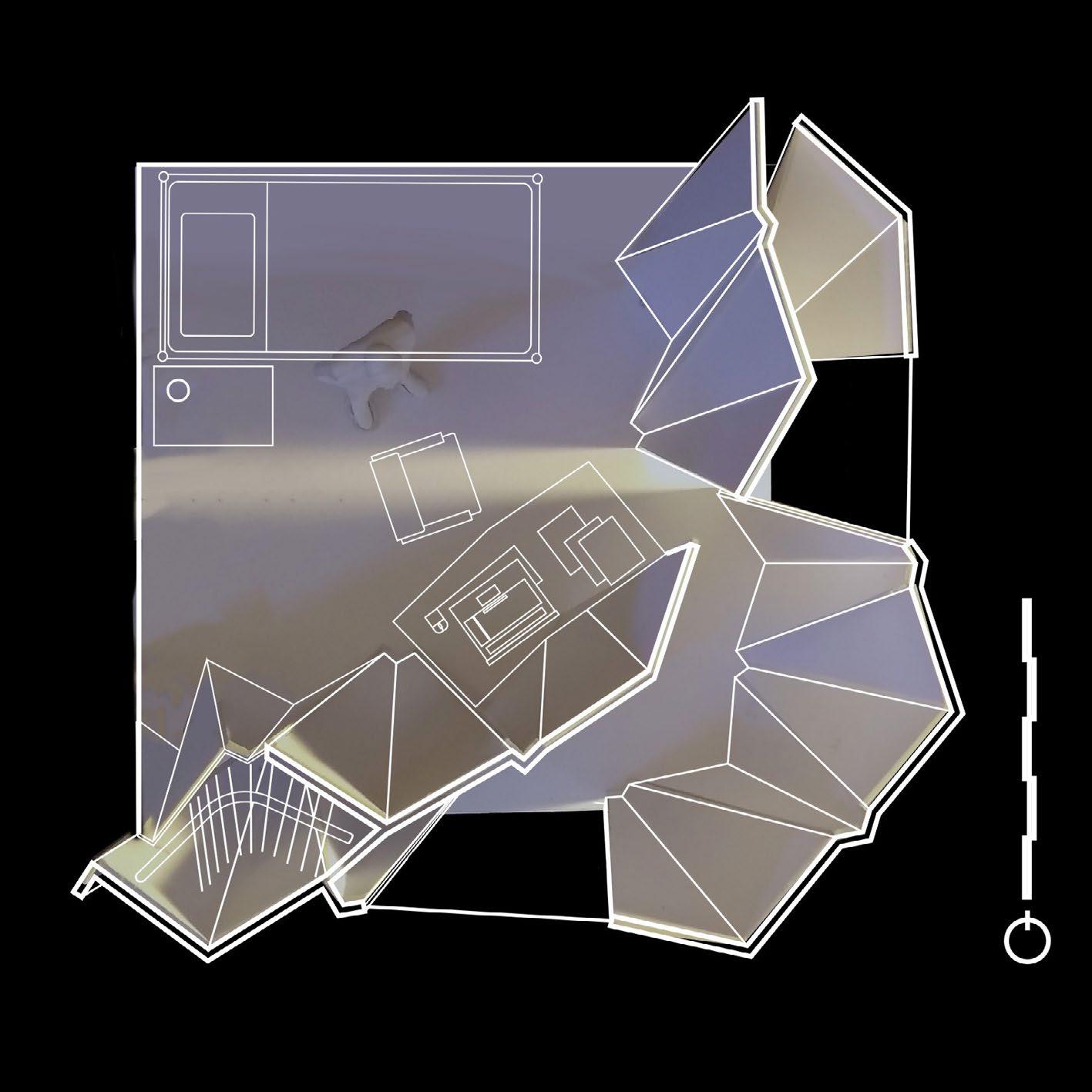

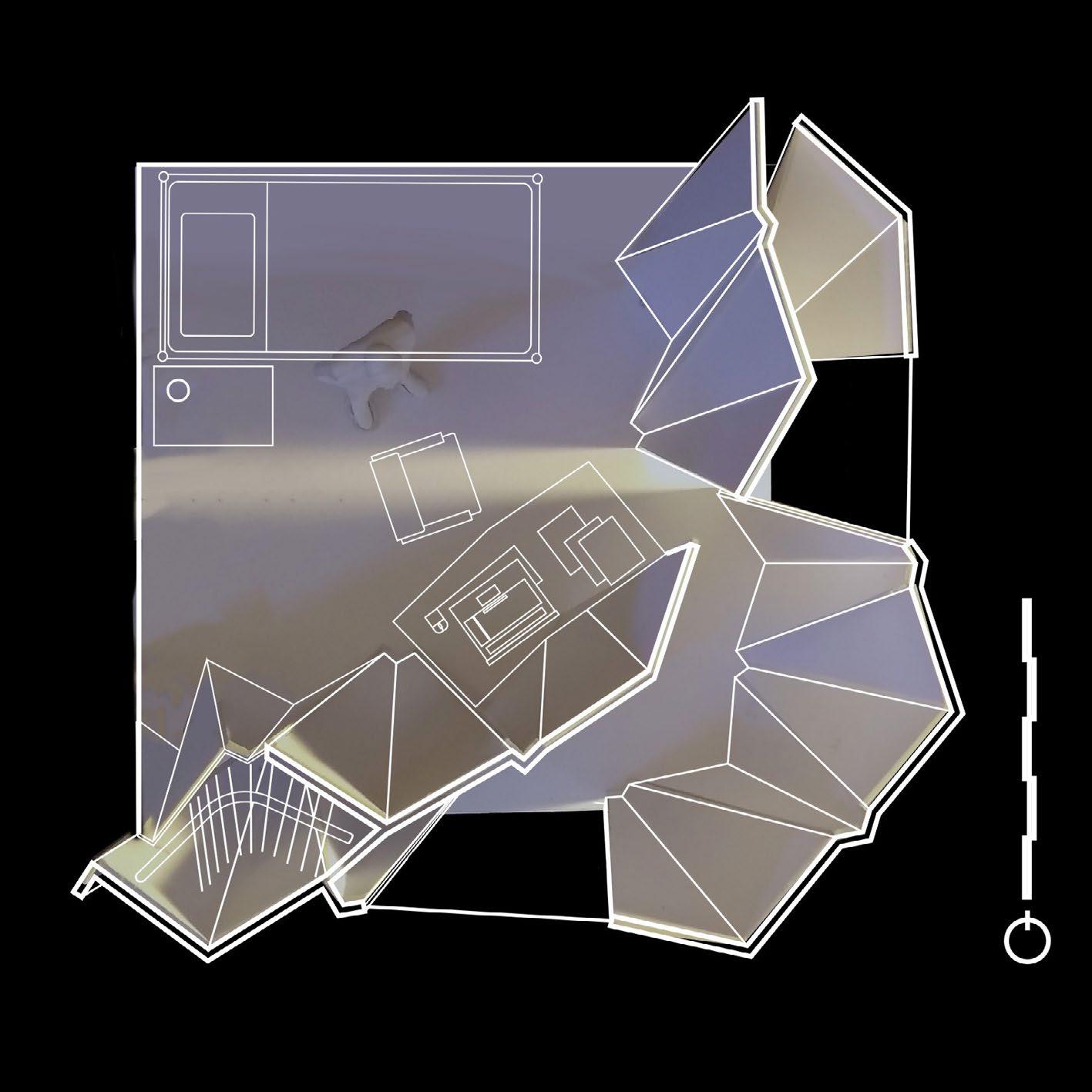

200 ft 100 ft 50 ft 30 ft 10 ft 1 2 2 3 5 4 1: parking lot 2: water filtration tanks 3: walking trails 4: visitor center 5: quenching well 6: mold wheel 7: gas management tanks 8: pyreliophorous/blast furnace 9: ingot recycling center 10: mold loading area 11: demolding area 12: coke and sinter furnace 13: loading bays 14: earth city rails

5 6 8 7 9 10 11 13 12 4 14 13

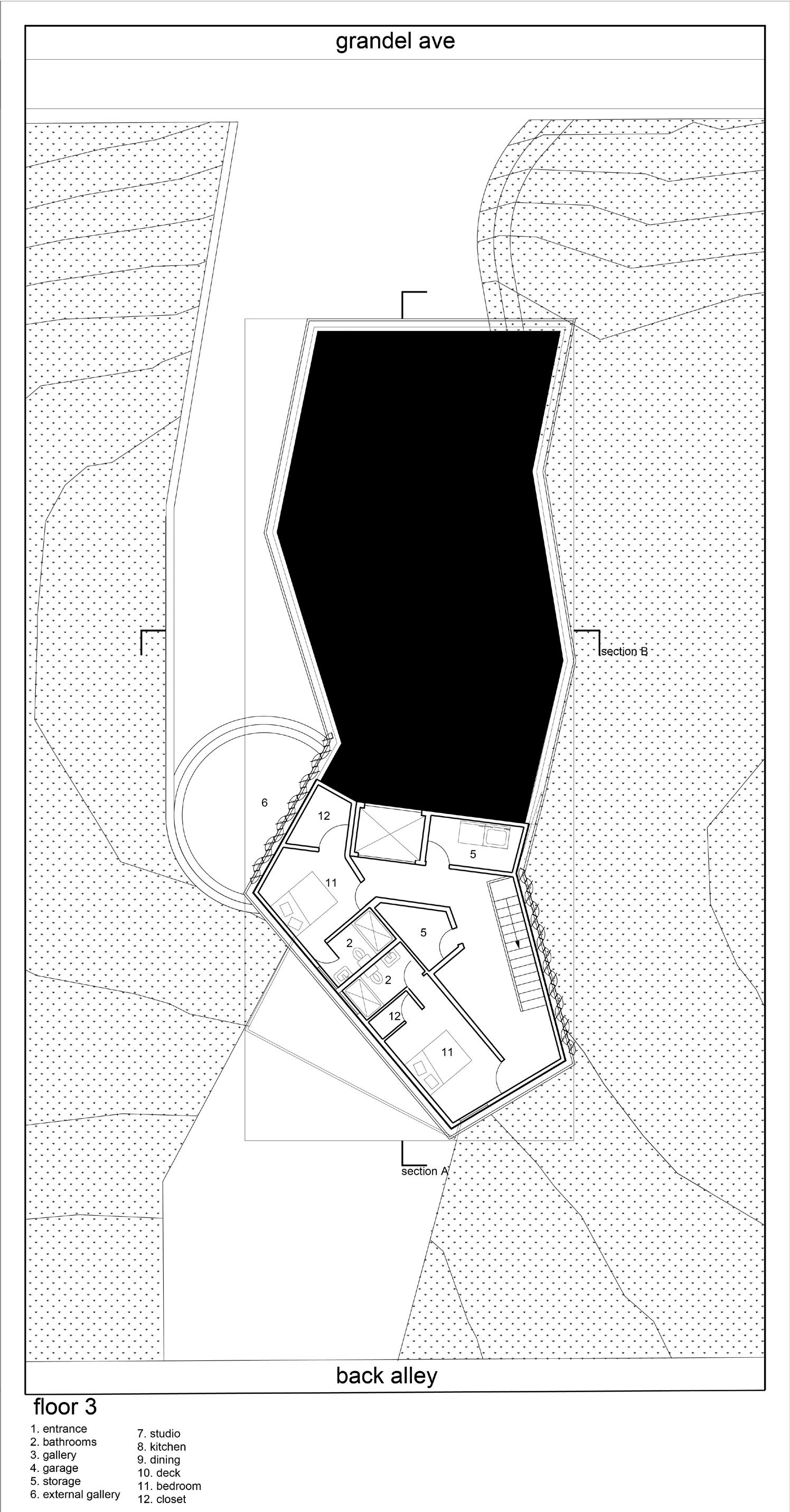

ARTIST RESIDENCY ARCH 311

INSTRUCTOR: KELLEY VAN DYCK MURPHY

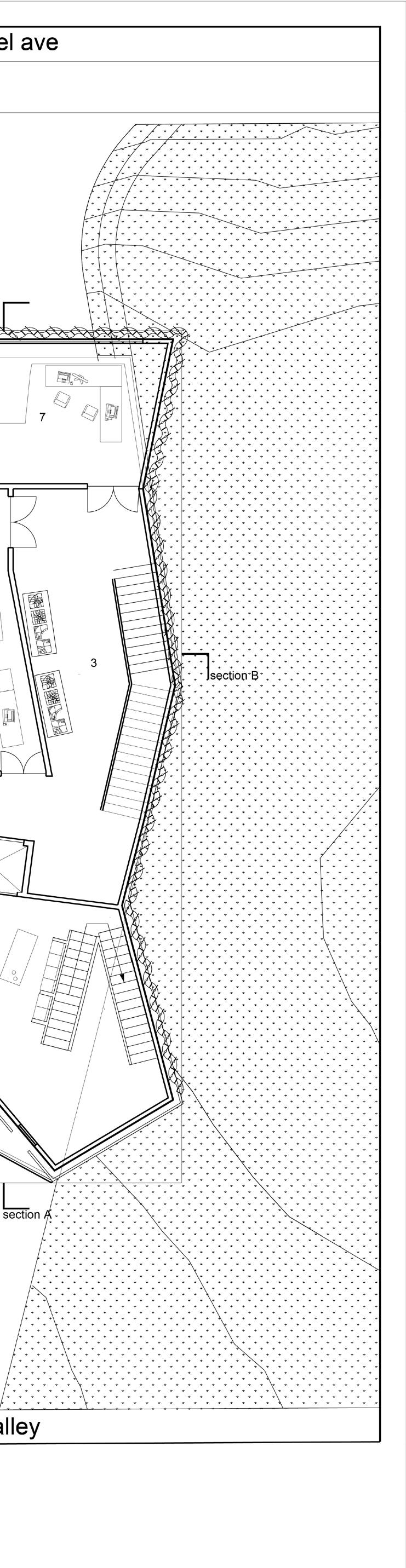

ST. Louis’ Grand Central Arts District is home to many arts venues- the Pulitzer, Fox Theater, The Symphony Orchestra, Contemporary Arts Museum, and the Kranzberg Art Center are just a few which dot the neighborhood. In the spirit of this community, this studio aimed to design an artist residency within the GCAD. project,

The project emphasized a design proportionate to the nearby surroundings, but with an envelope that both provided shading of potentially sensitive pieces, but could equally be open to allow light into studio and living spaces, and an artistic flair to denote the creative nature of the building.

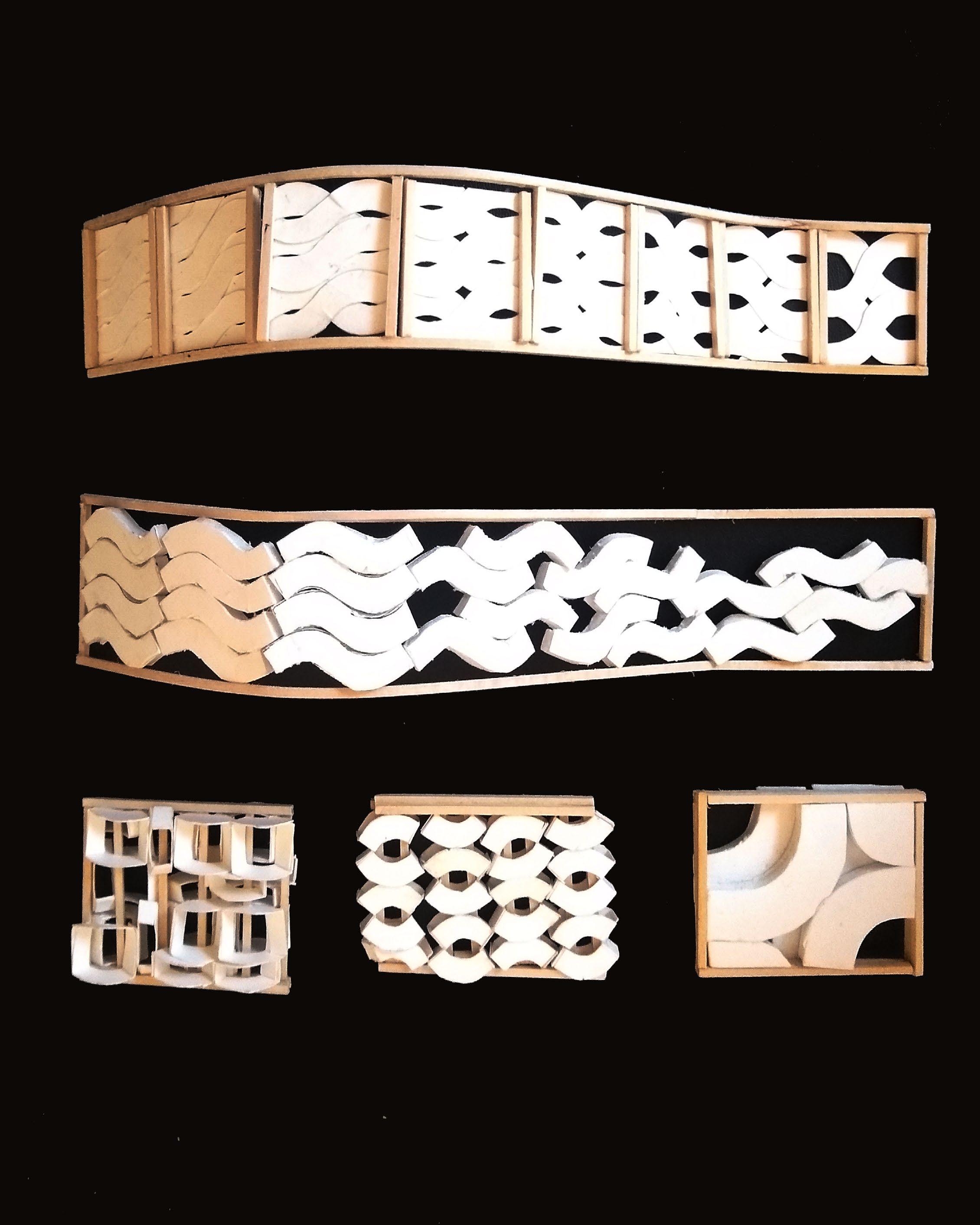

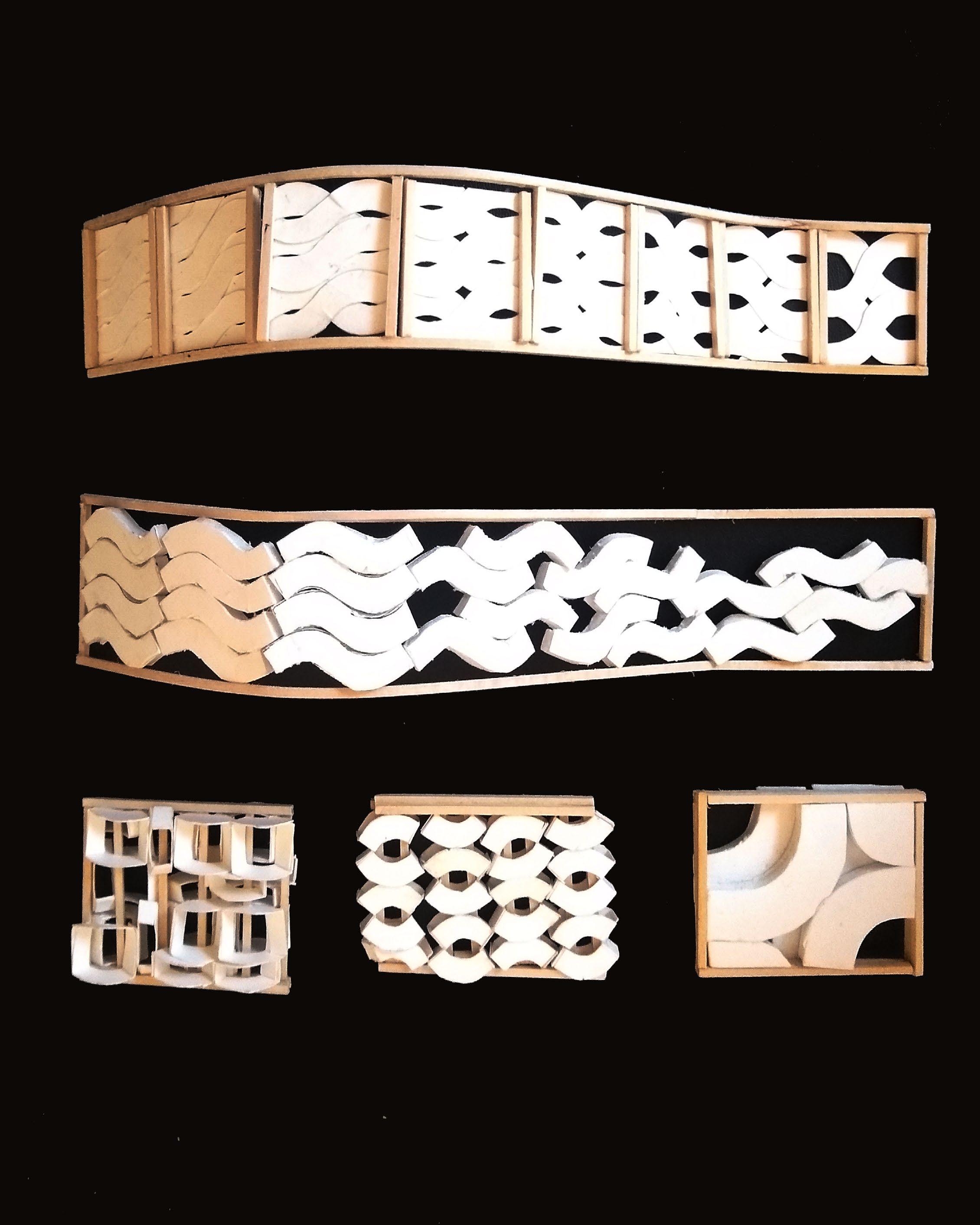

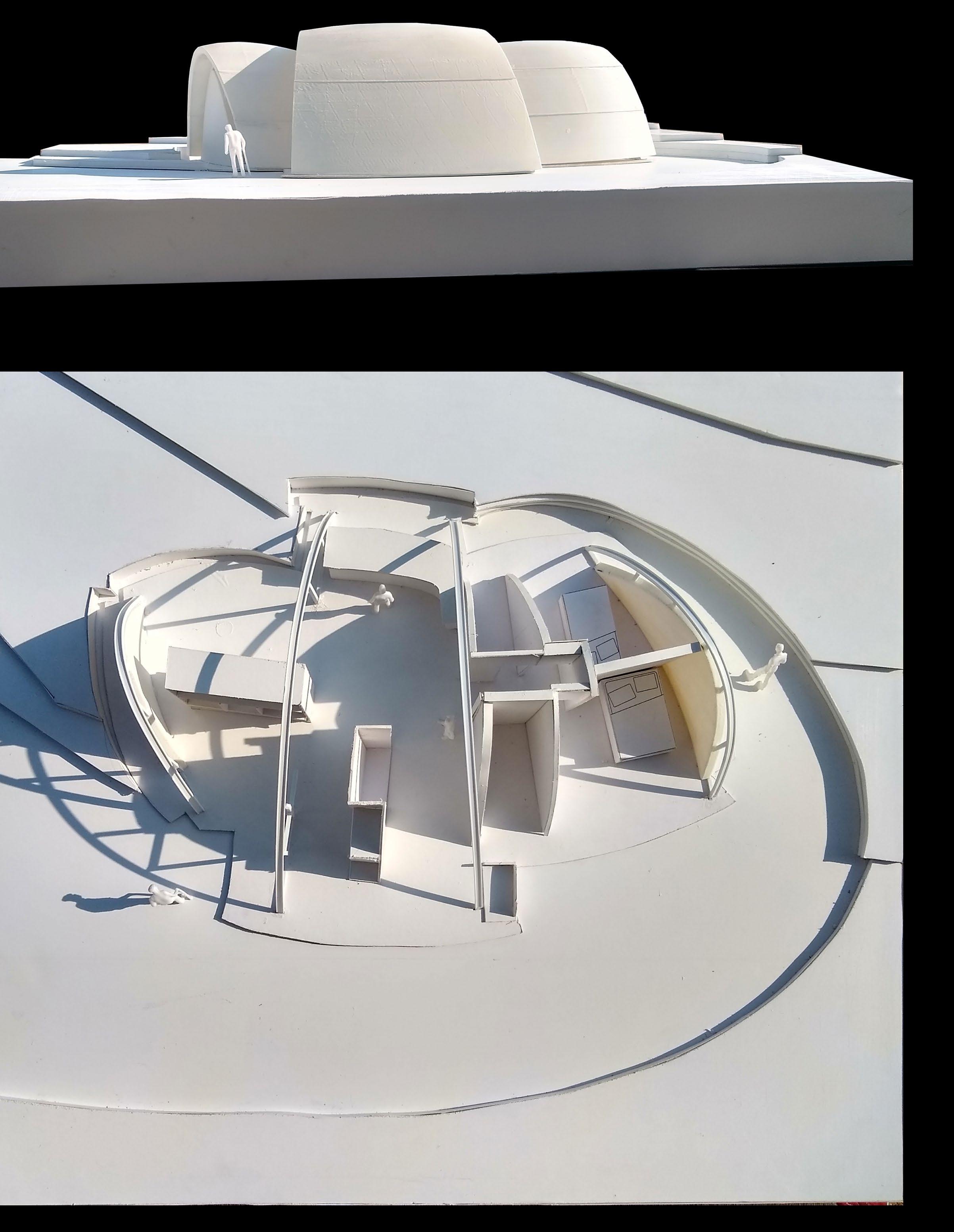

ENVELOPE STUDIES

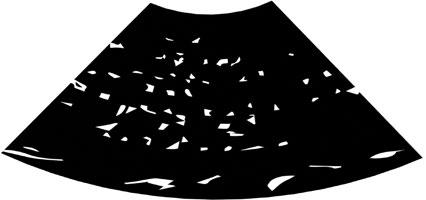

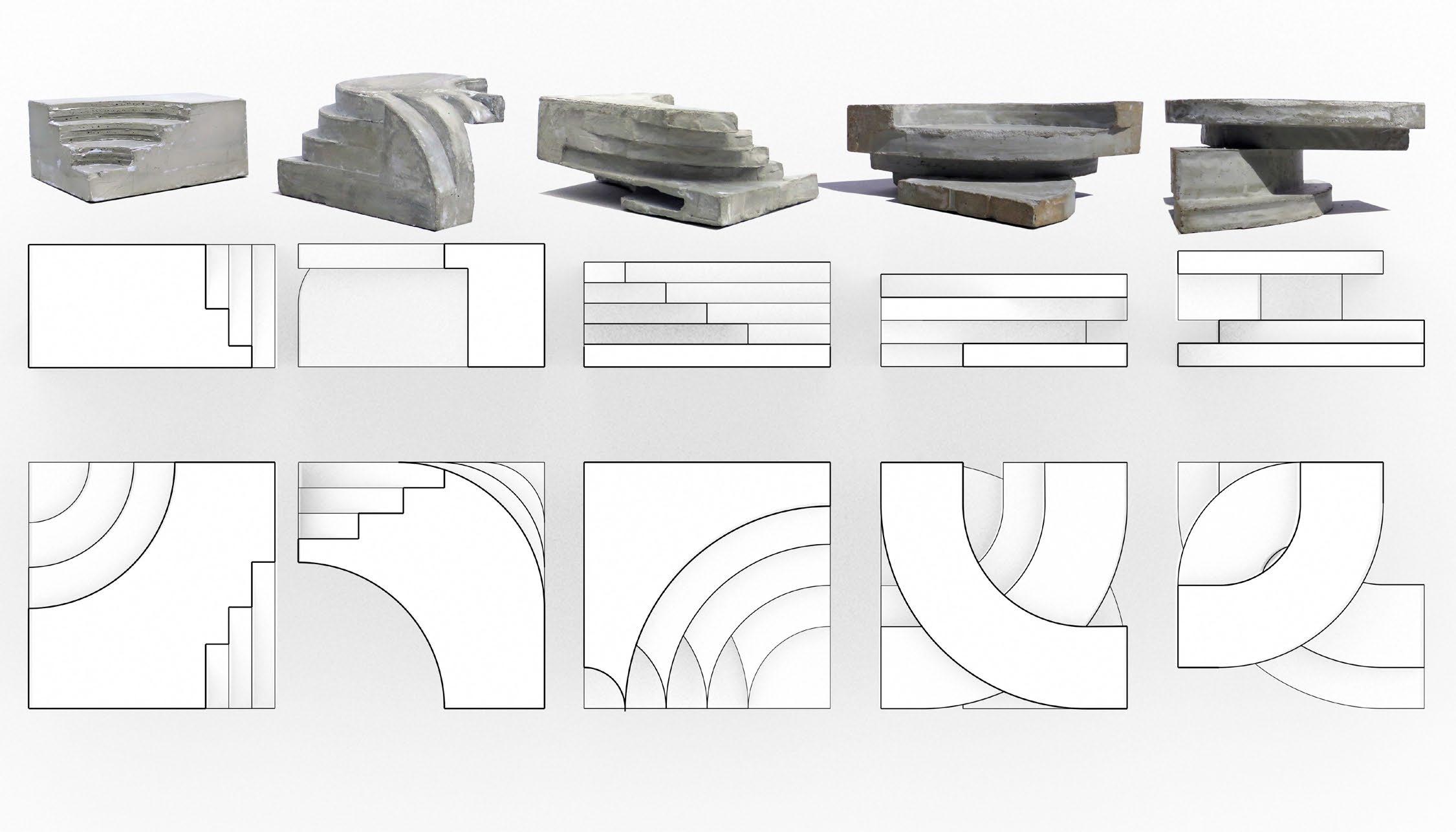

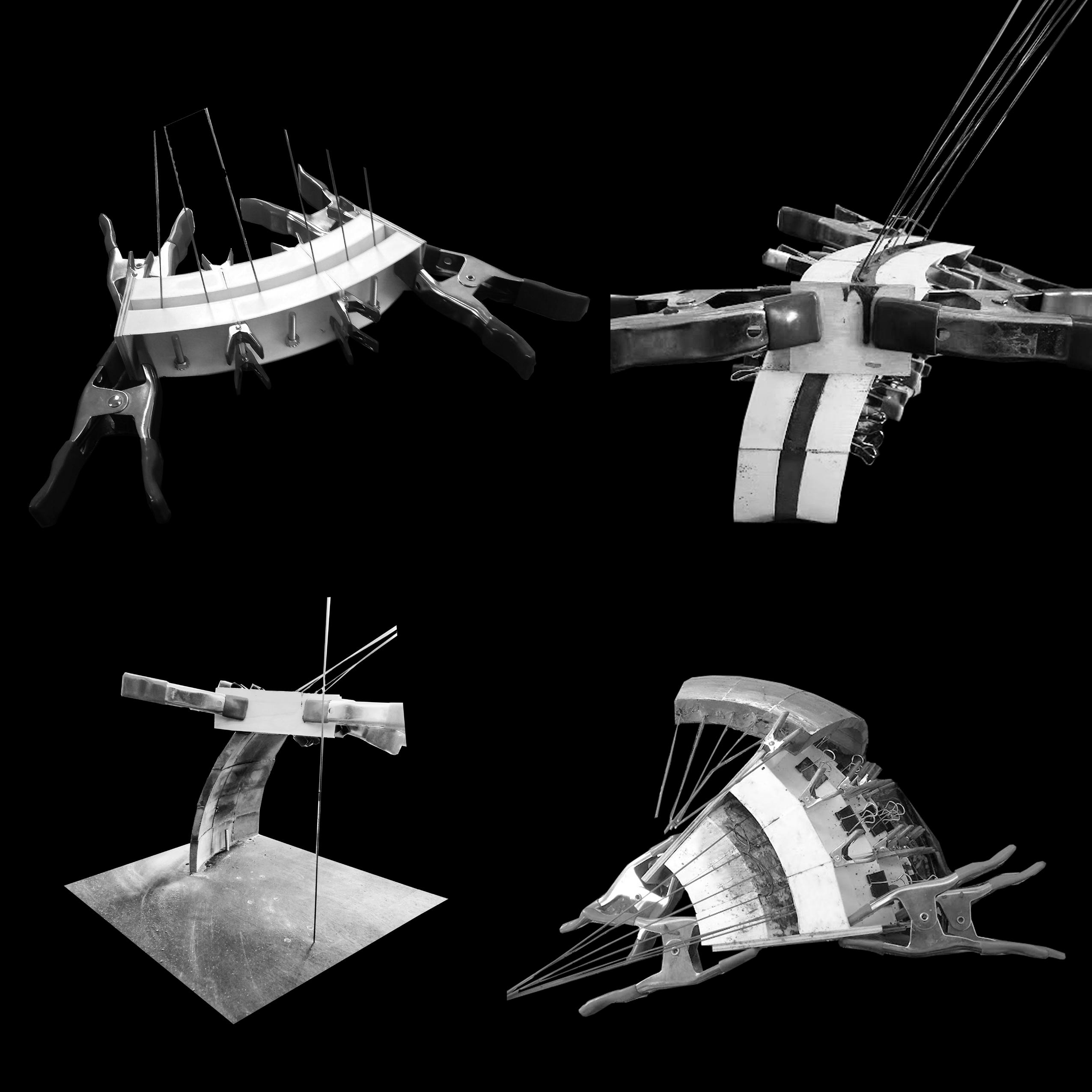

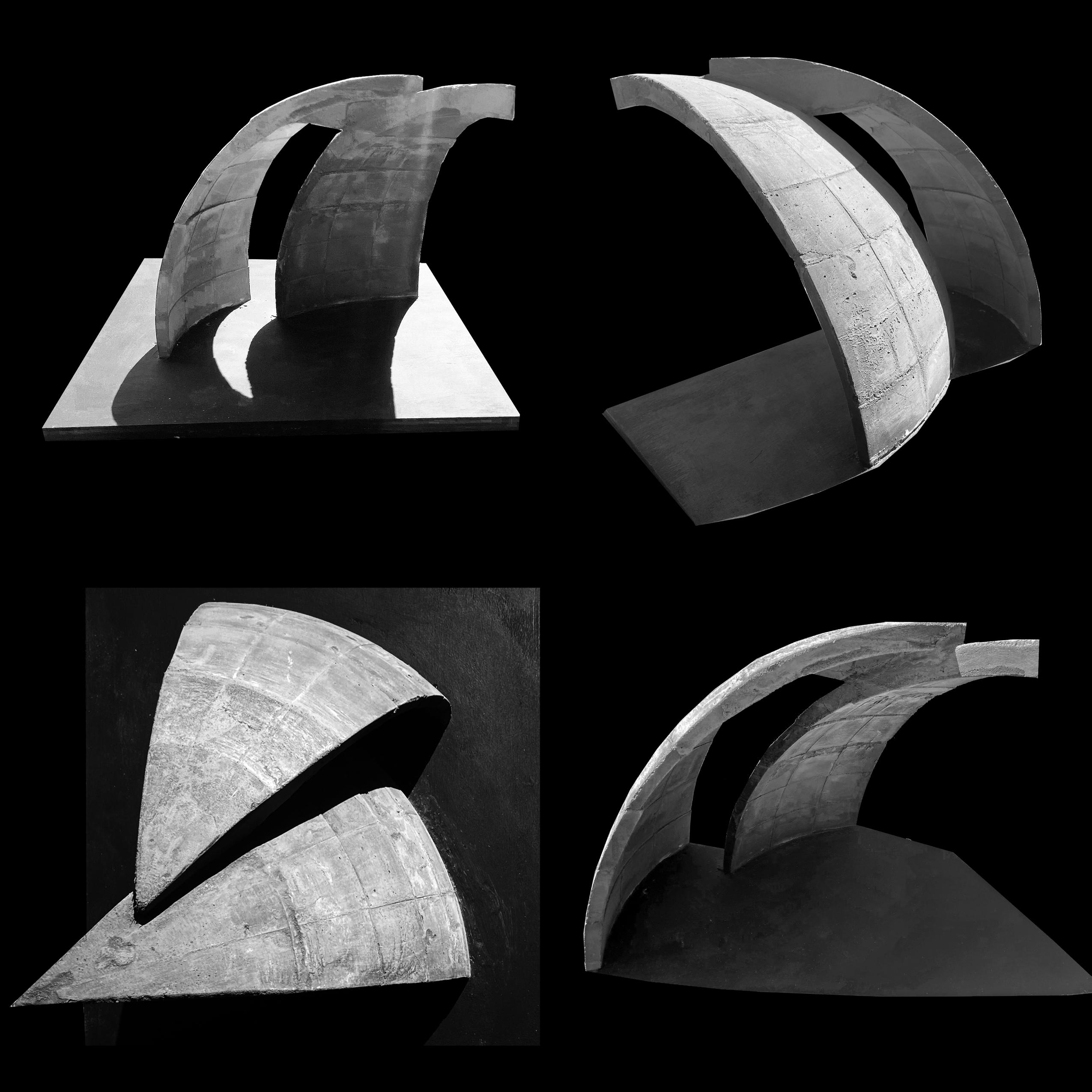

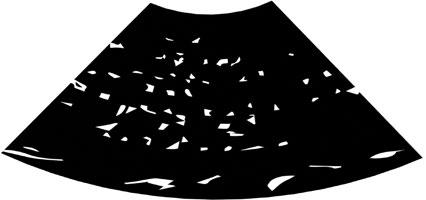

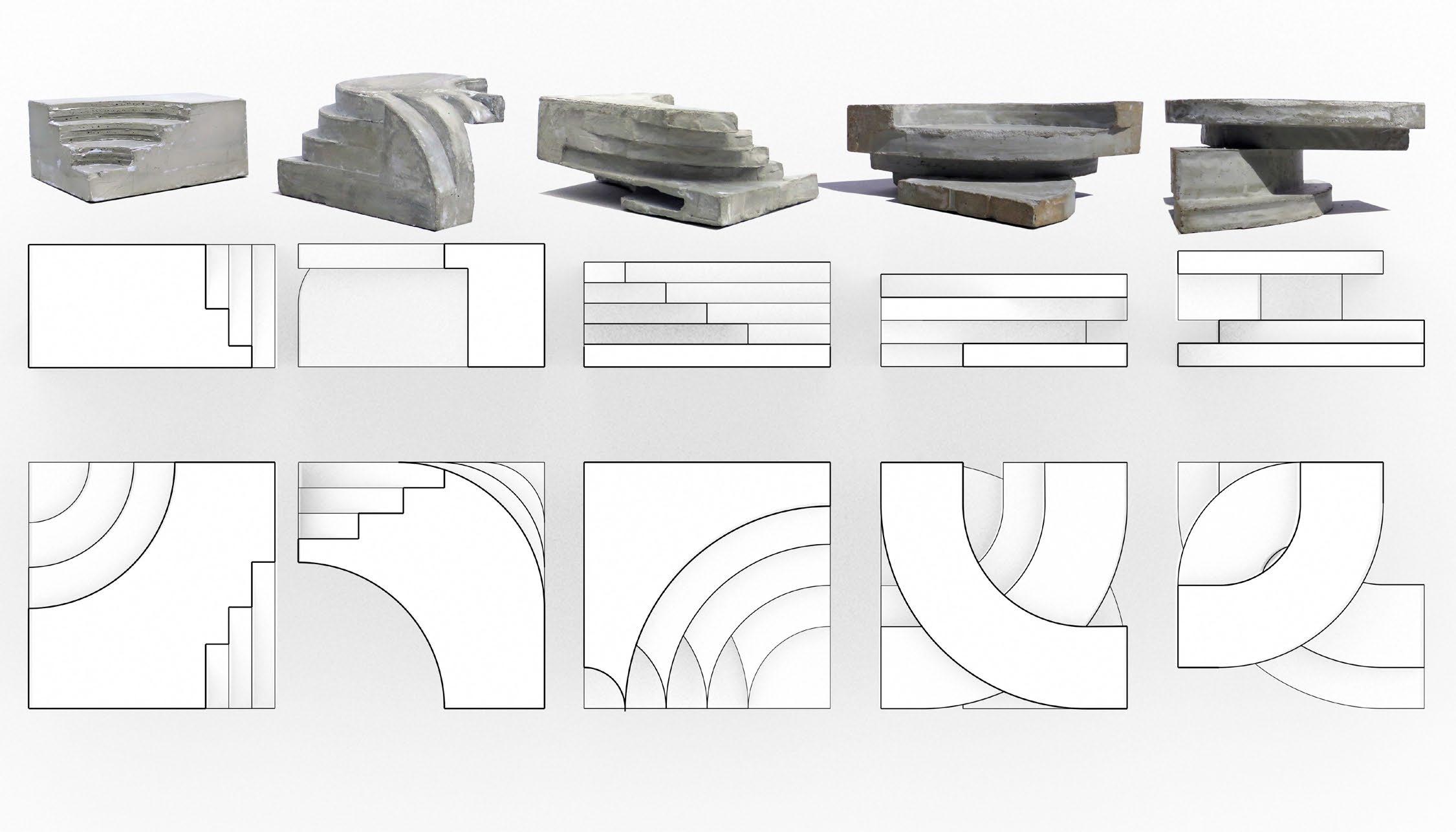

To begin the design process, a physical model was cast out of concrete, which enabled the project to begin to play with a non-normal and more gestural vernacular. In order to fully take advantage of the liquid nature of concrete, I designed a set of curved molds in which the concrete could be poured.

The envelope was developed by casting a variety of concrete blocks with different shapes, which then formed the basis for a series of wall and envelope studies which borrowed a formal language from the previously made concrete blocks.

This formal language would also begin to form the first iterations of the artist residency, and although the shape is not a one-for-one extrusion of the block models, the form of the residency borrows shapes from these blocks.

Top: The concrete blocks in a possible arrangement.

Bottom: The evolution of the concrete blocks throughout different casts. from left (earliest) to right (latest)

Top: The concrete blocks in a possible arrangement.

Bottom: The evolution of the concrete blocks throughout different casts. from left (earliest) to right (latest)

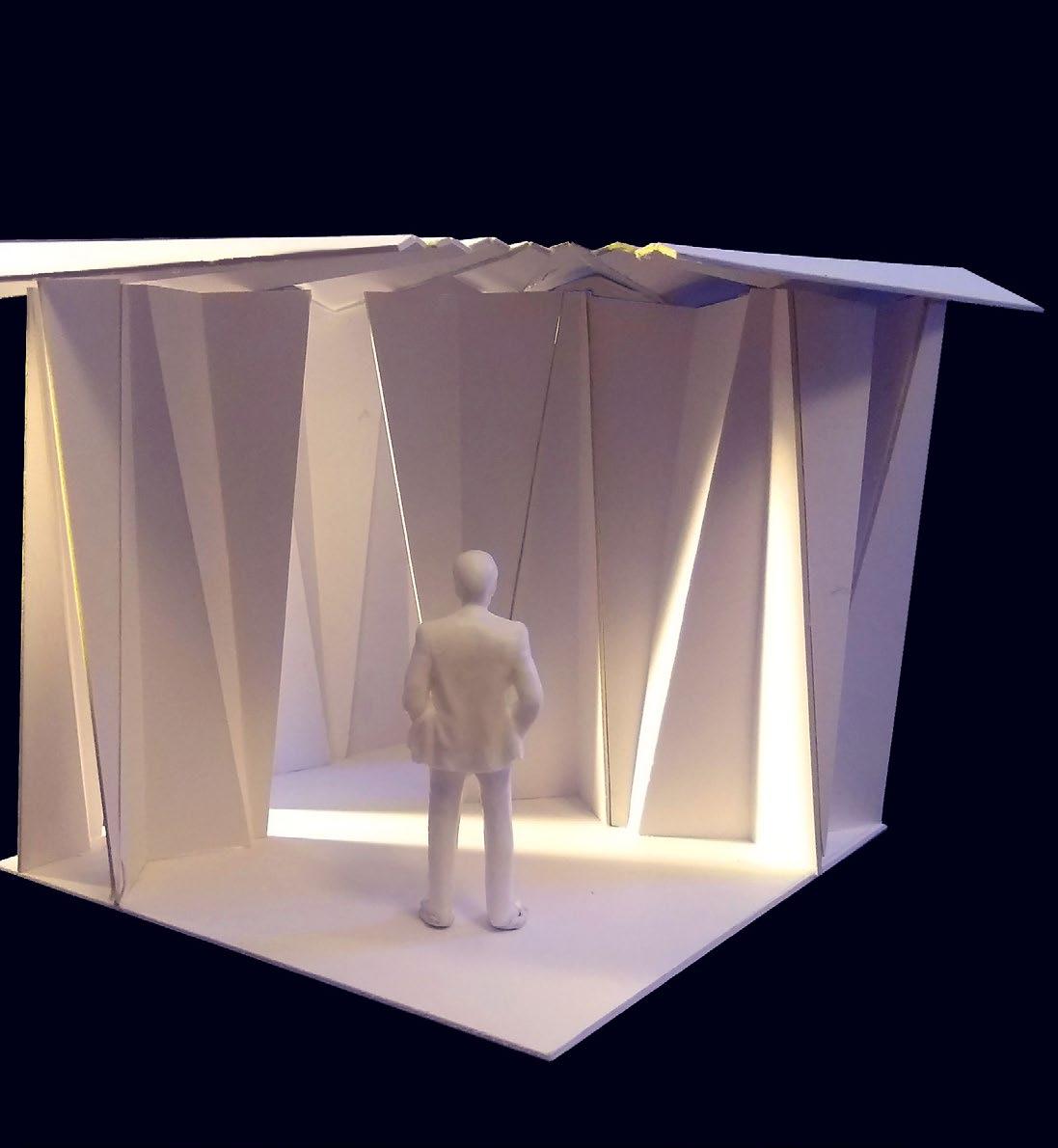

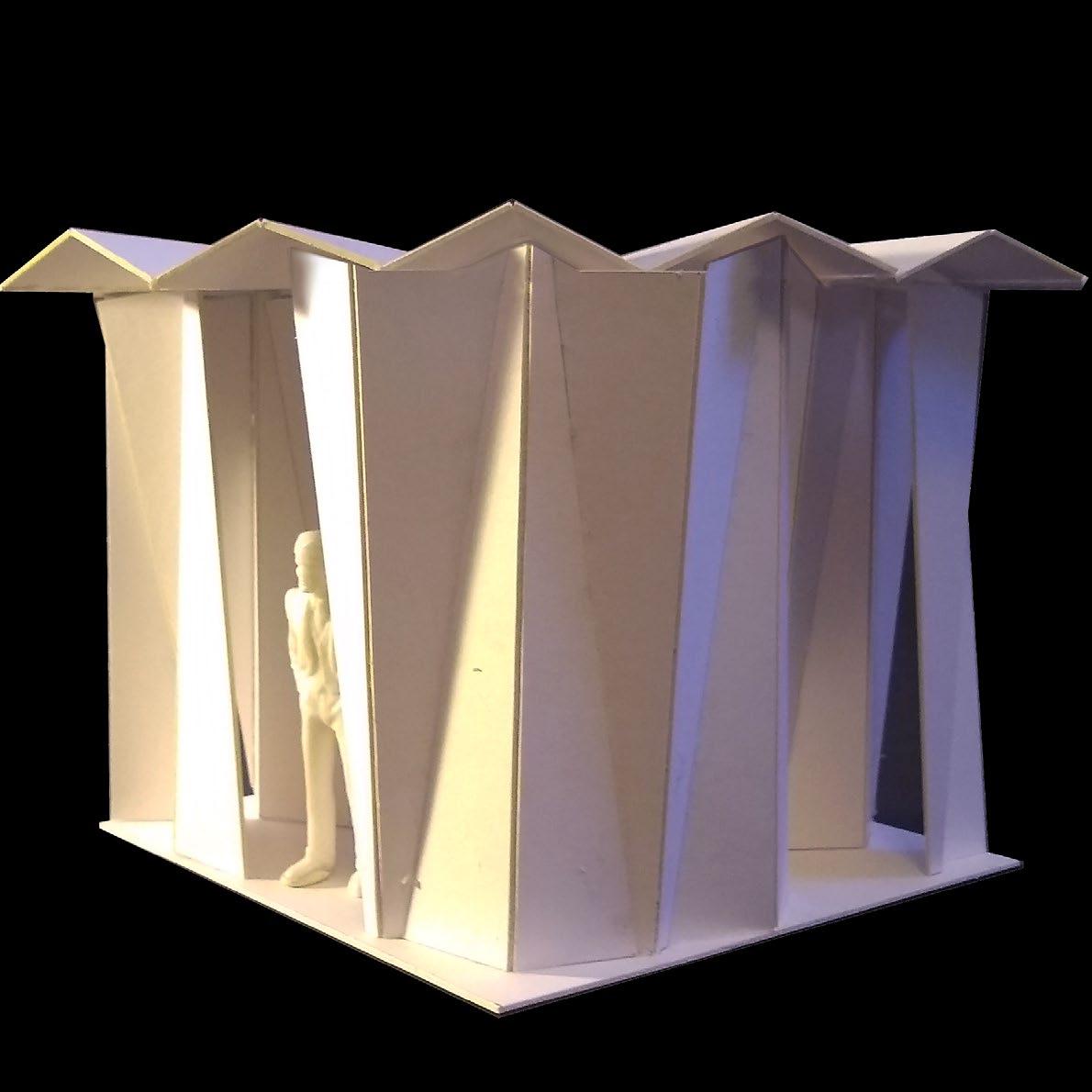

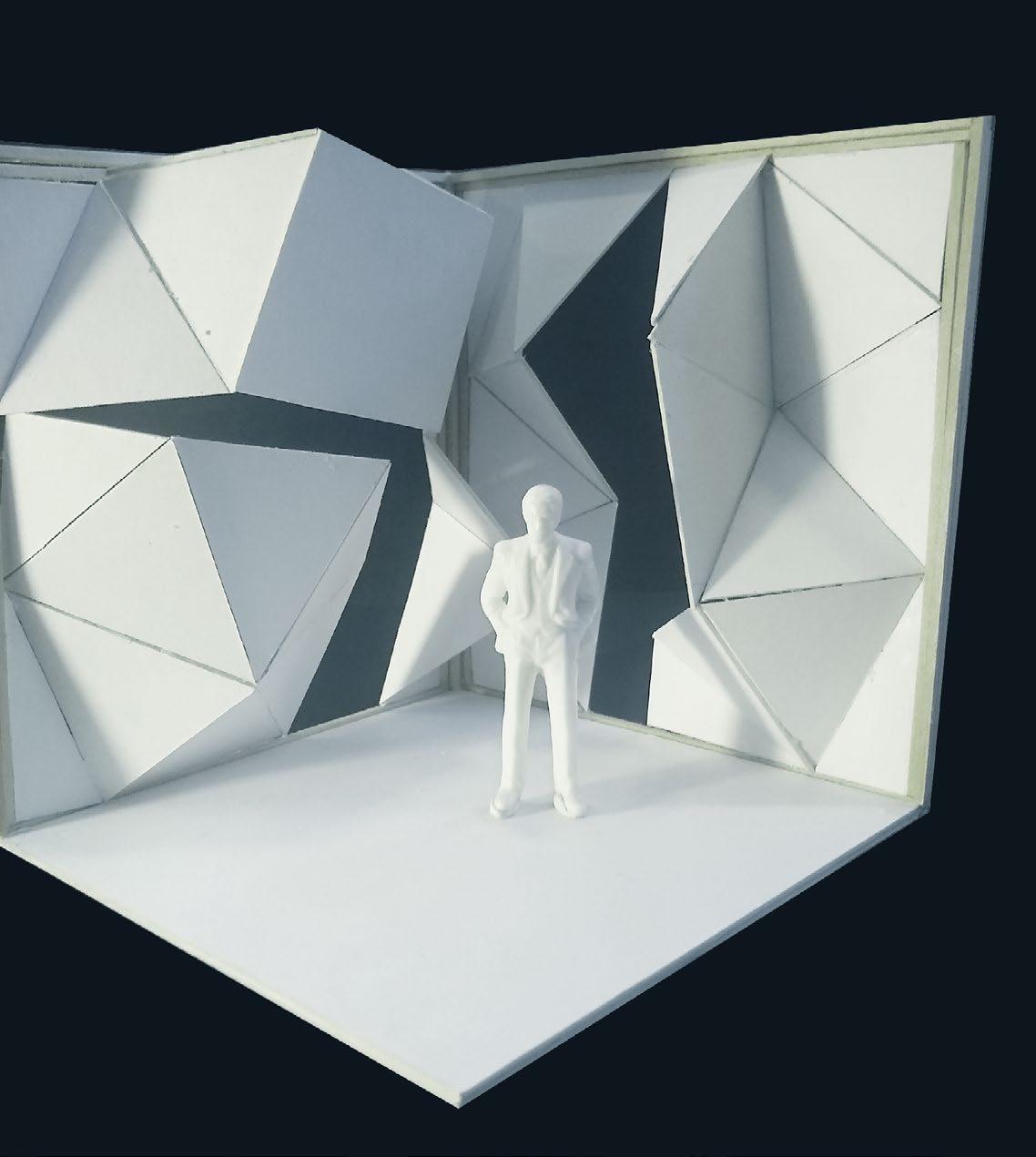

Above: Envelope studies.

Top: Render of the Interior Gallery.

Bottom: Exterior Render, with the Envelope on Display.

Top: Render of the Interior Gallery.

Bottom: Exterior Render, with the Envelope on Display.

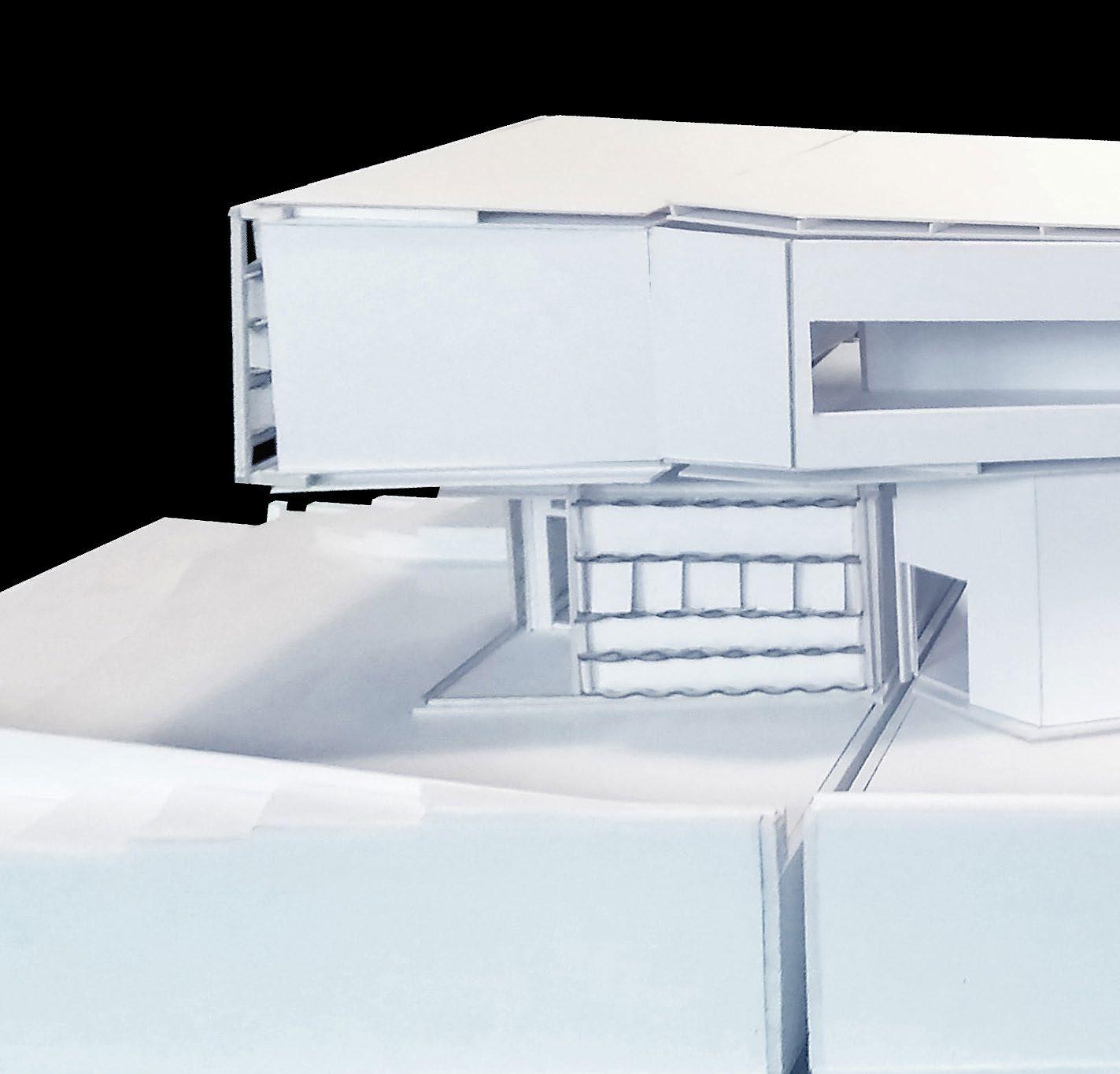

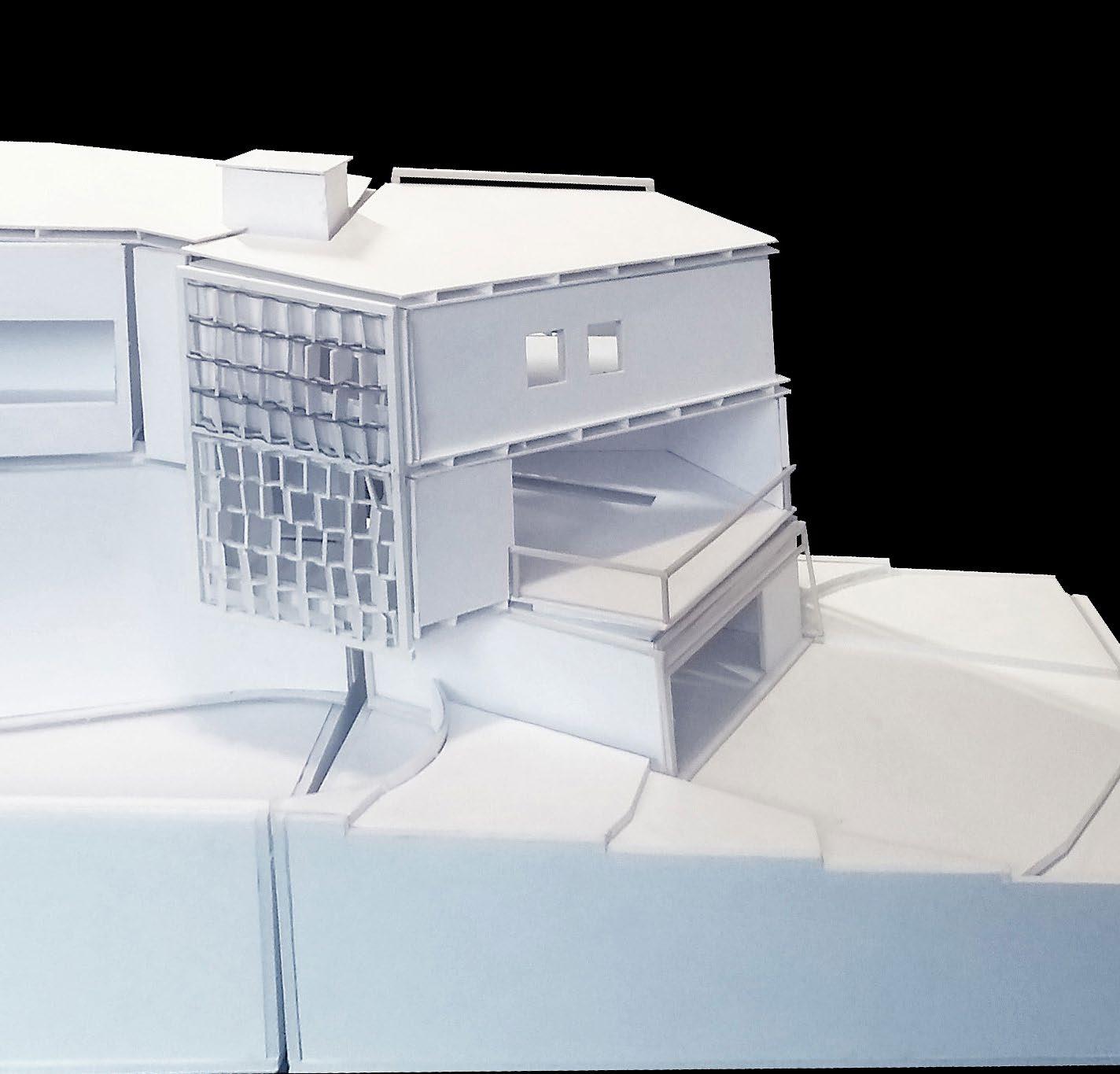

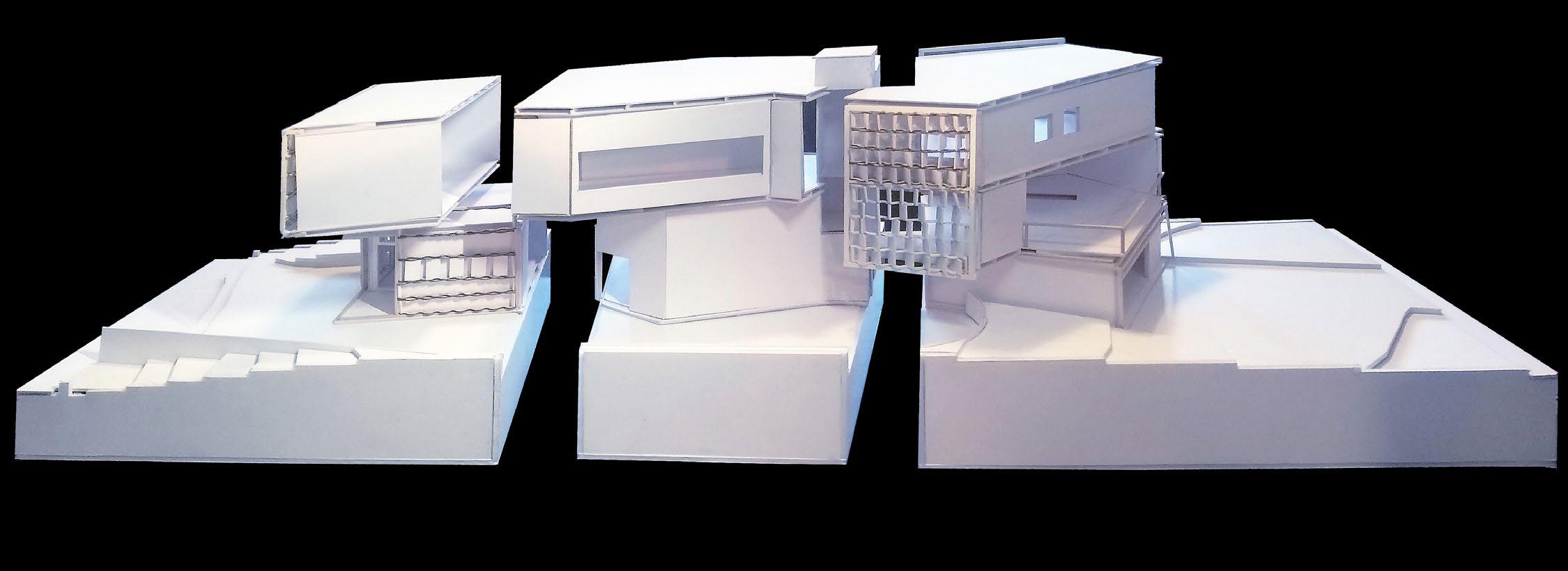

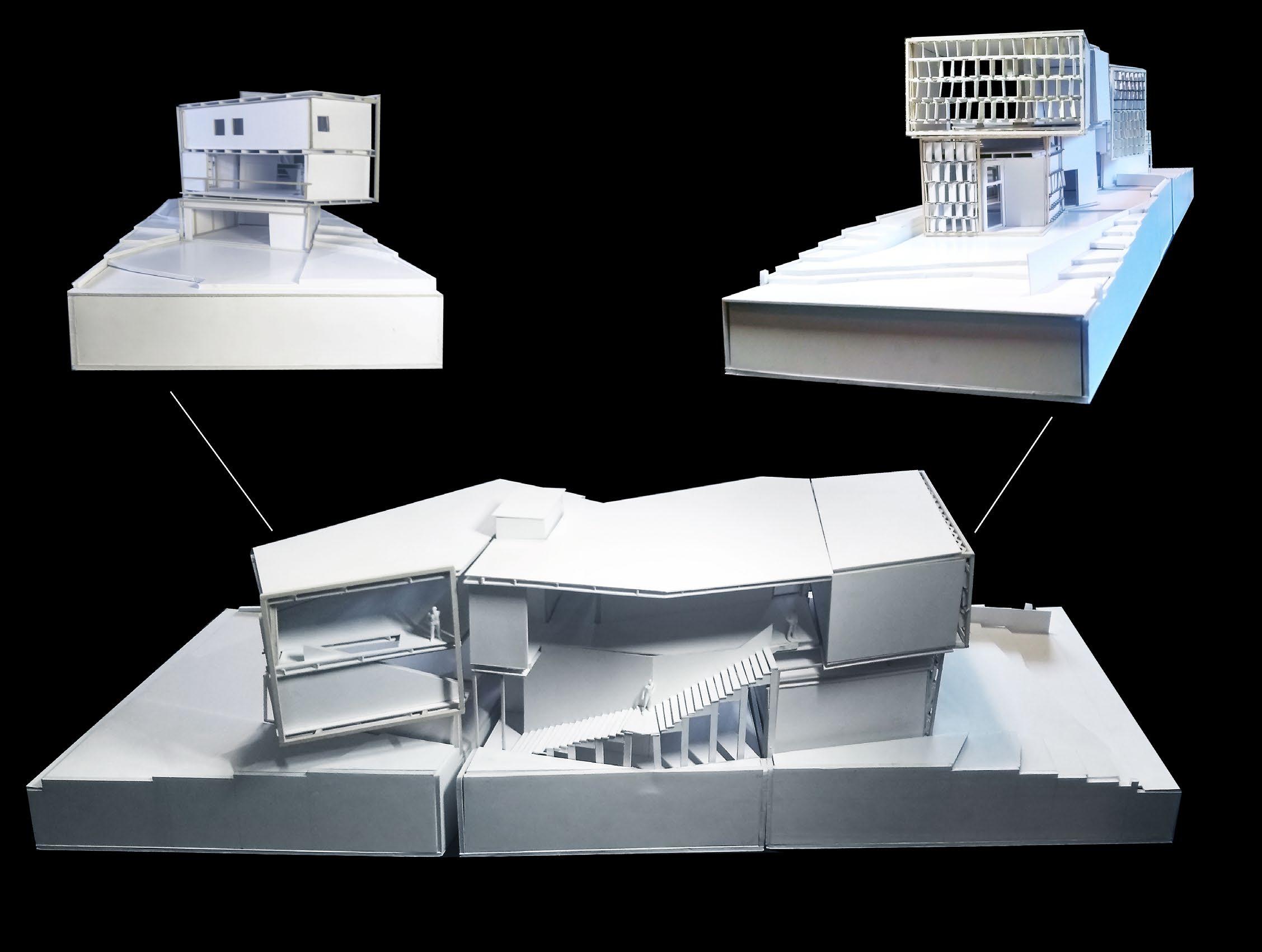

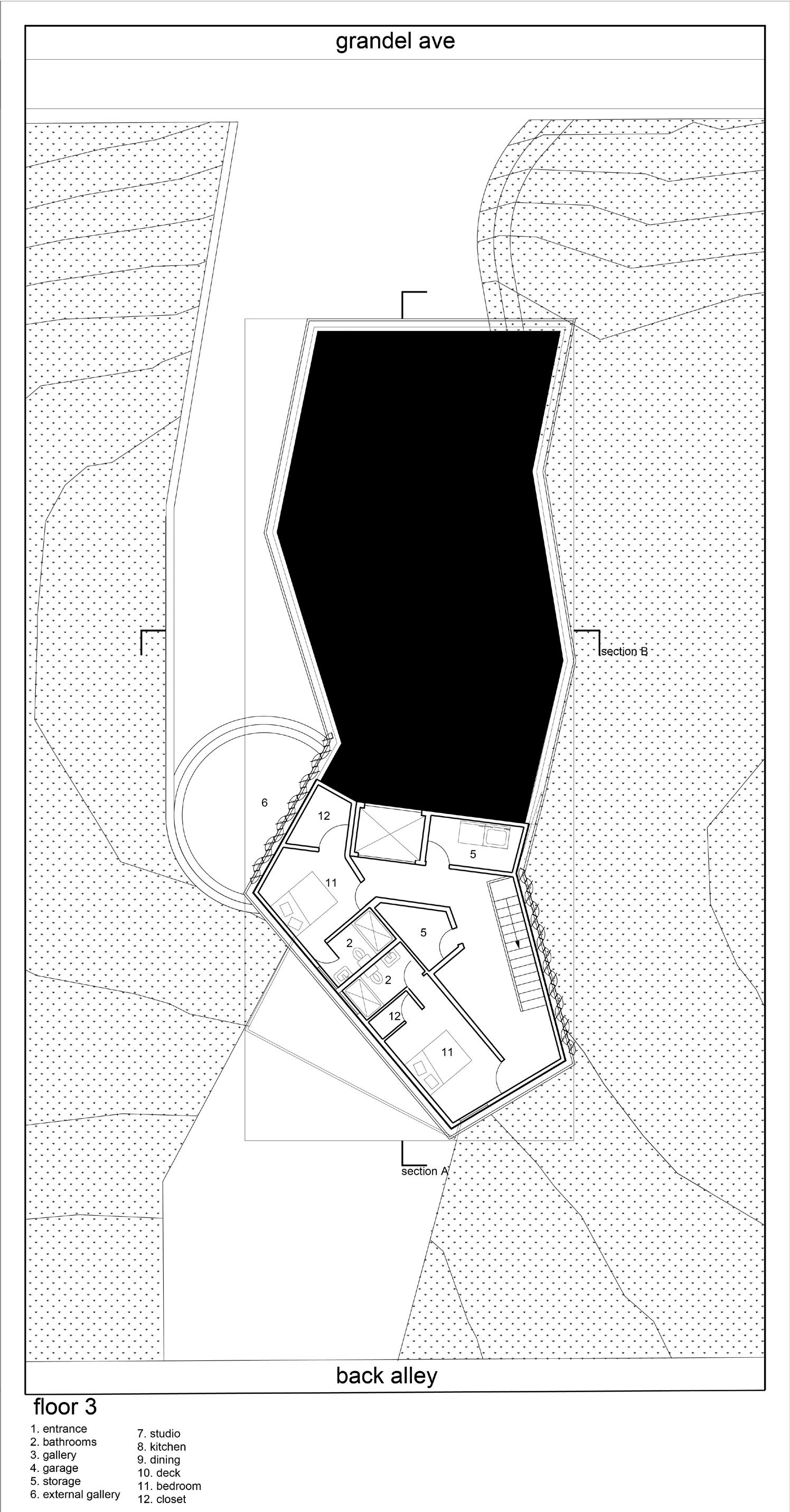

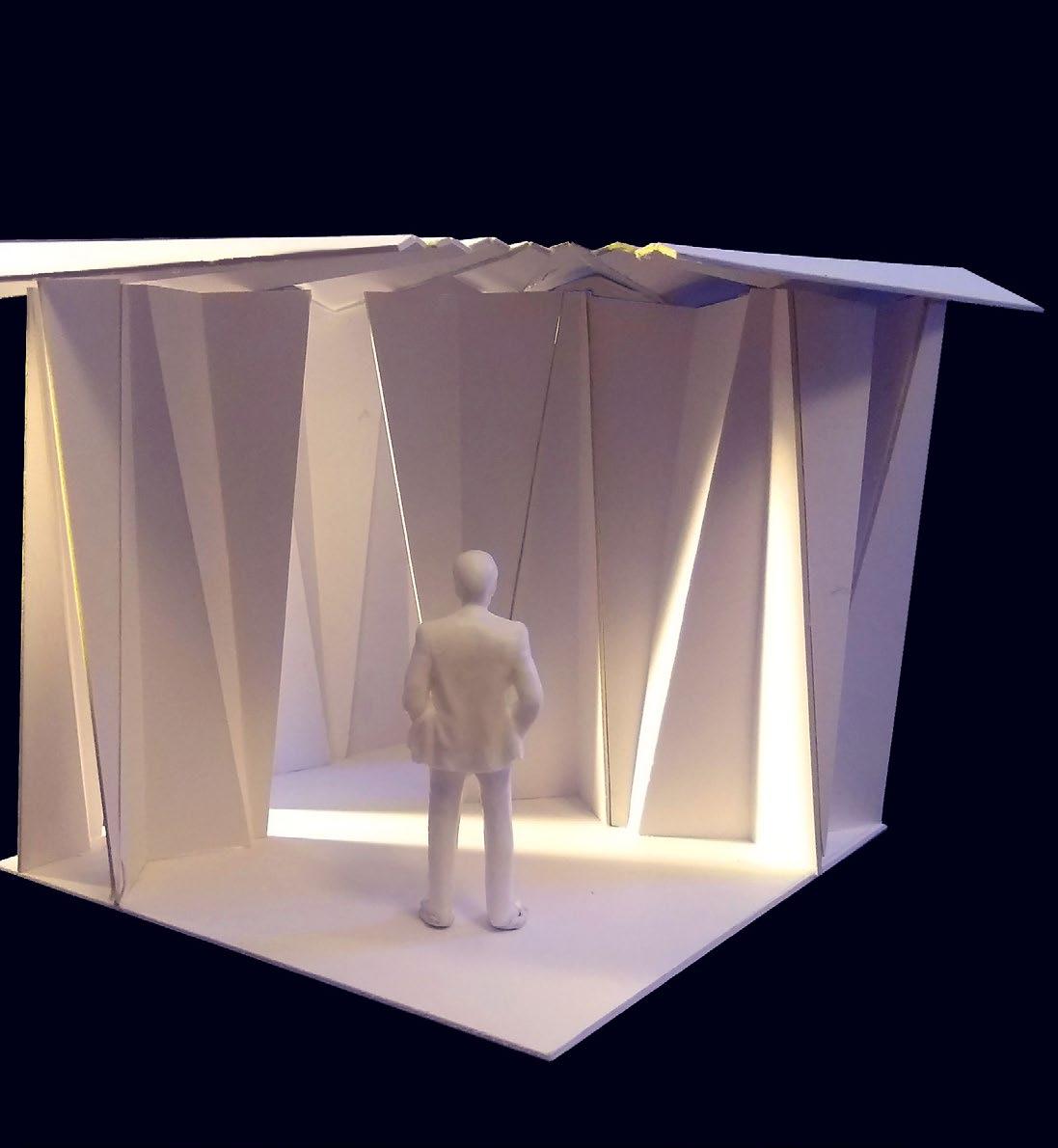

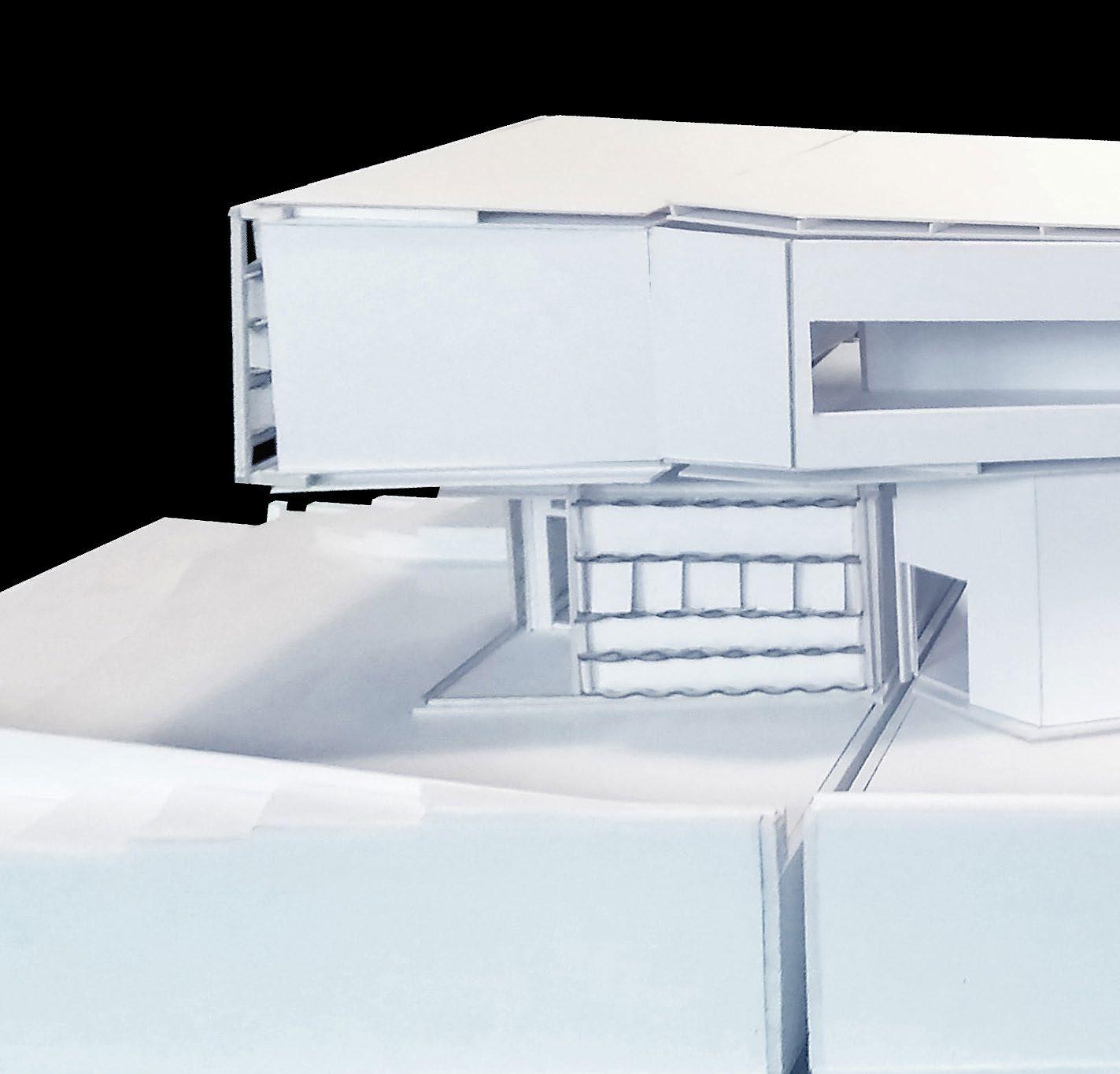

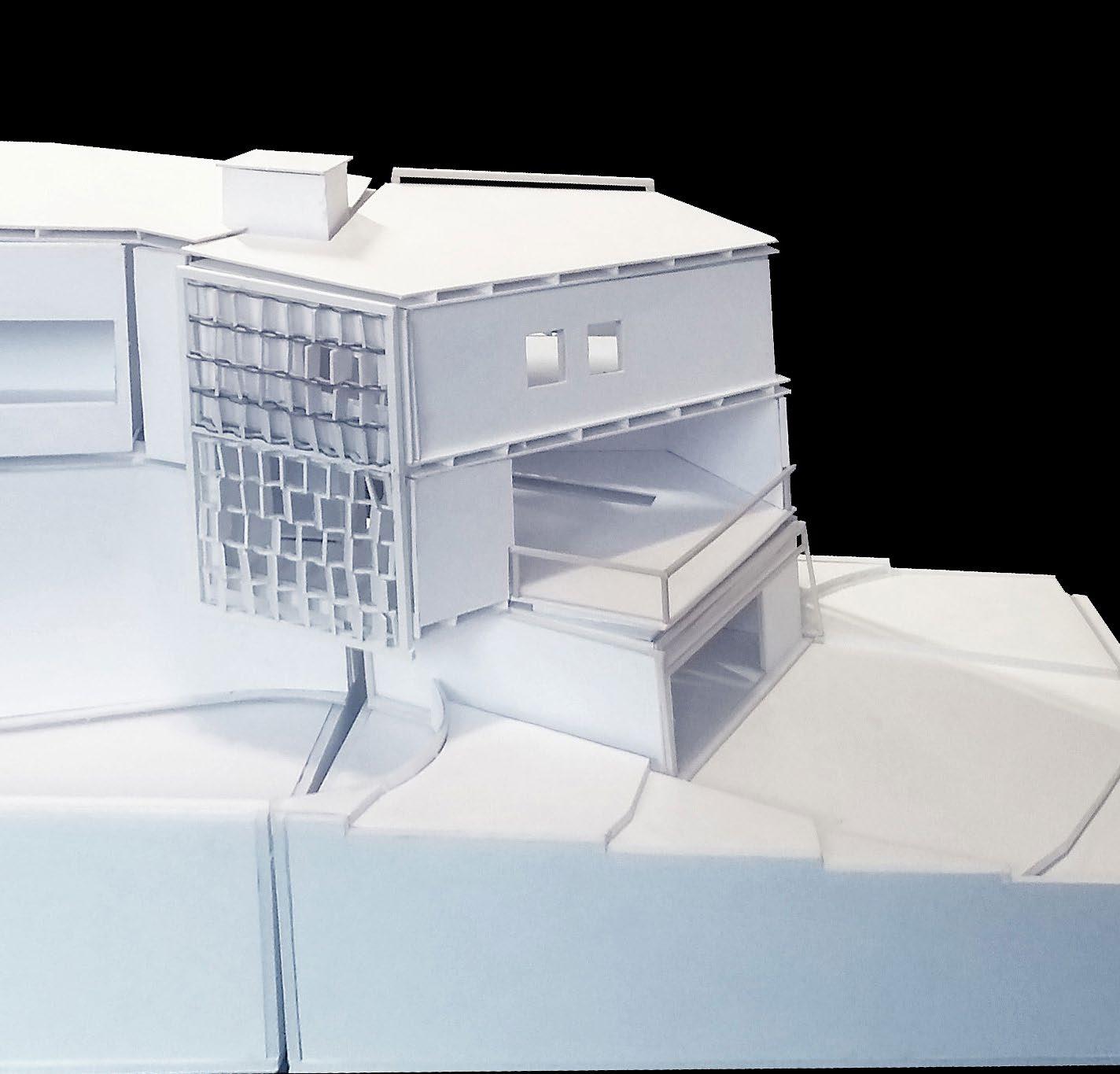

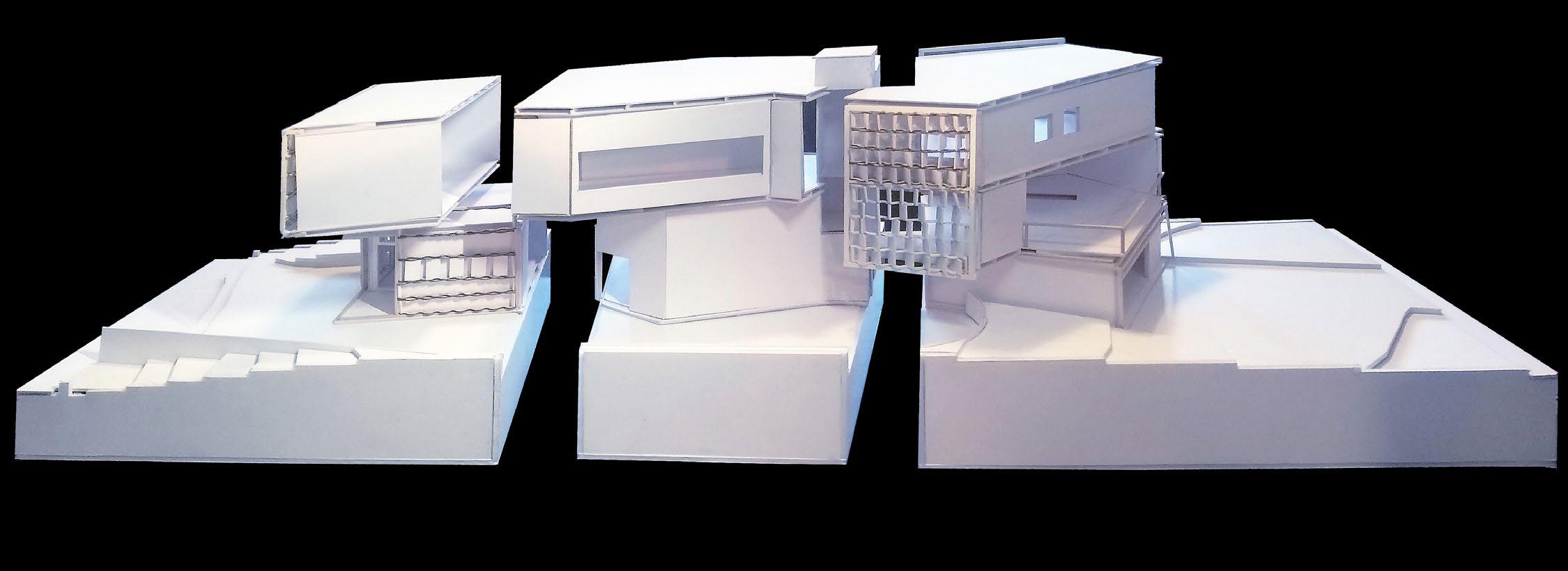

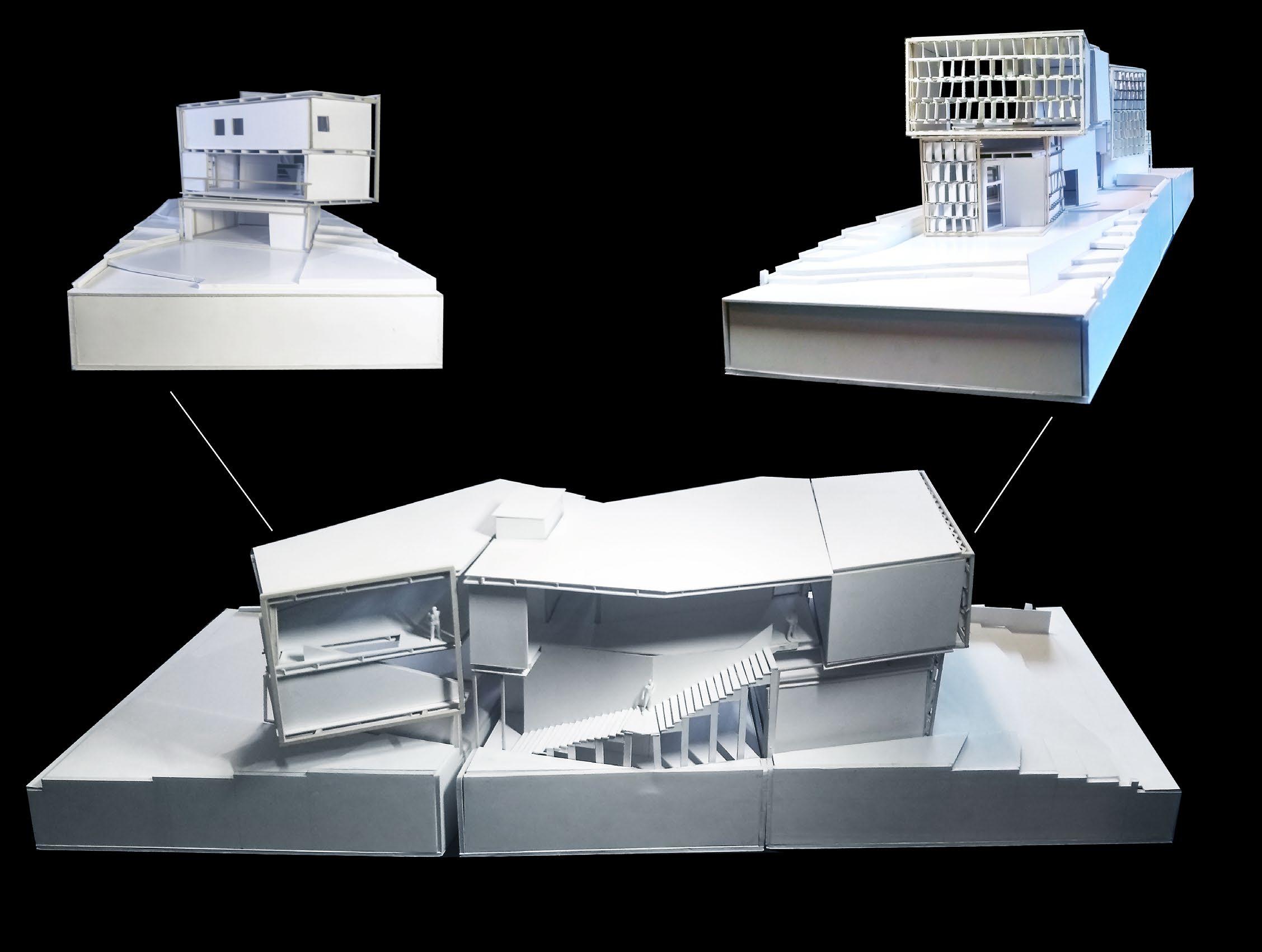

Top: Sectional and Elevational views of the Physical Model.

Bottom: Physical Model, pulled apart. Each piece has its own functionality, and the programmatic elements begin to interlock with one another. The model is designed to show this program split.

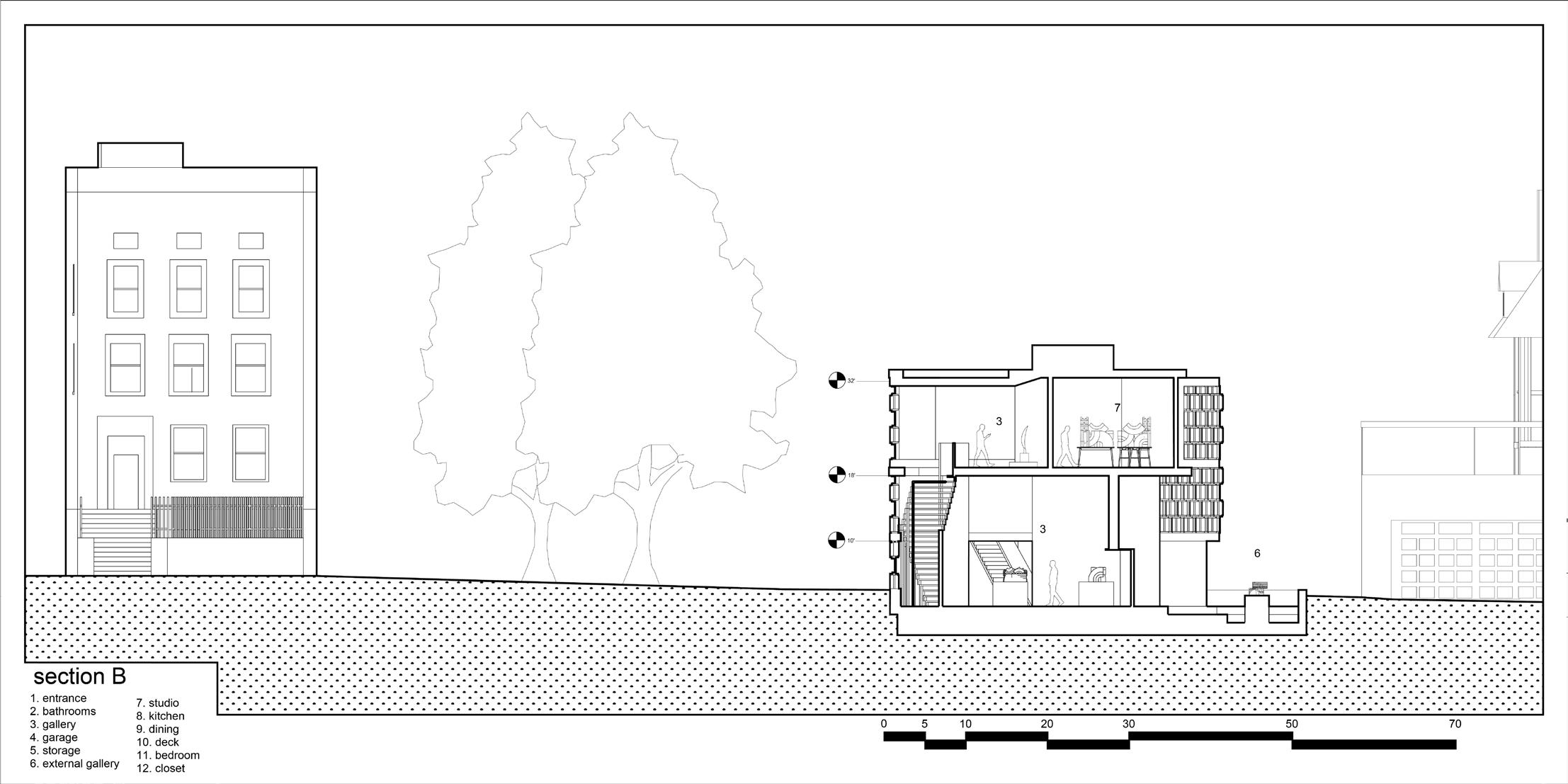

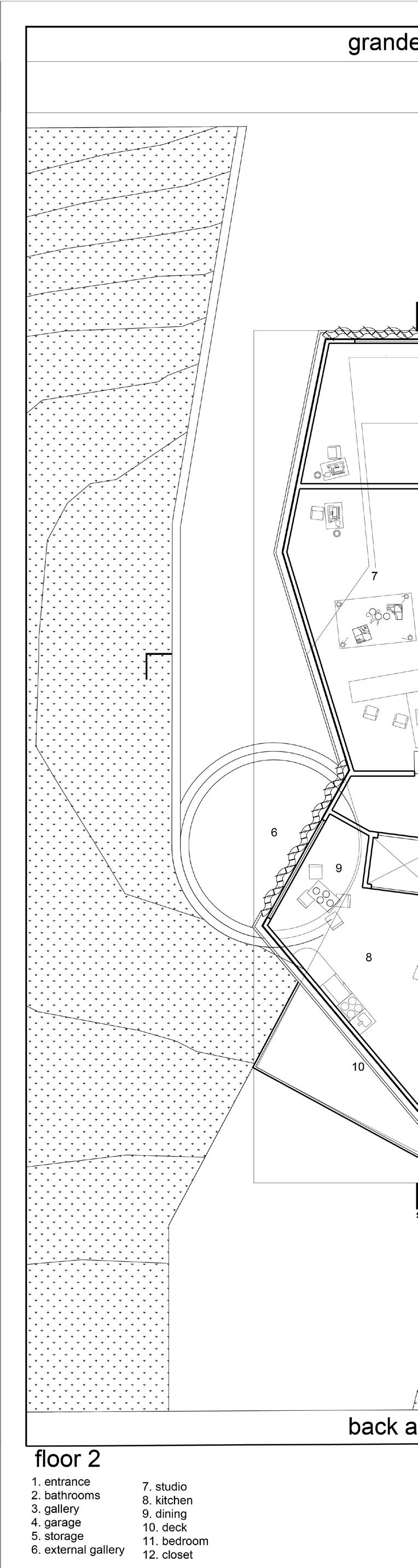

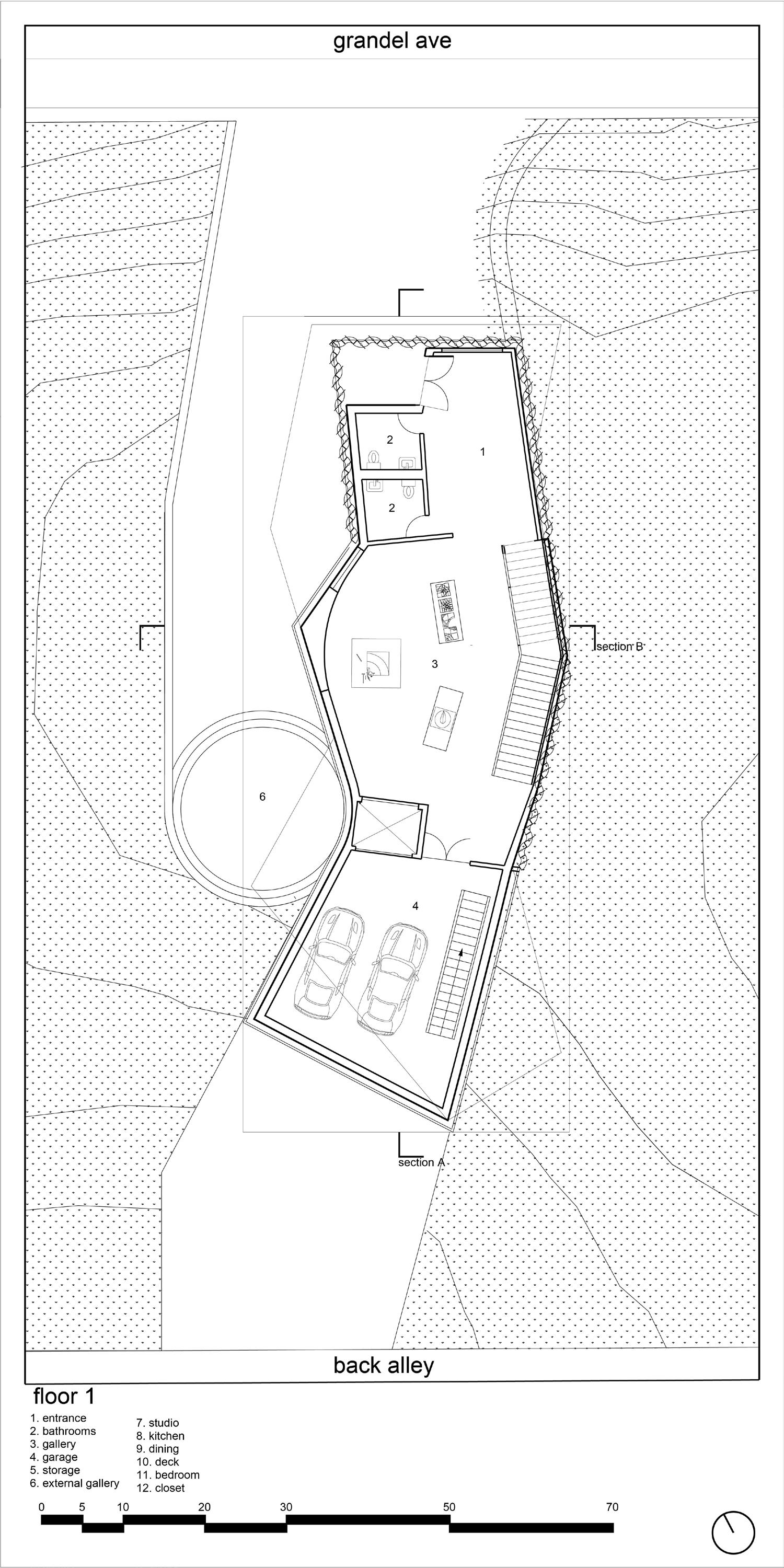

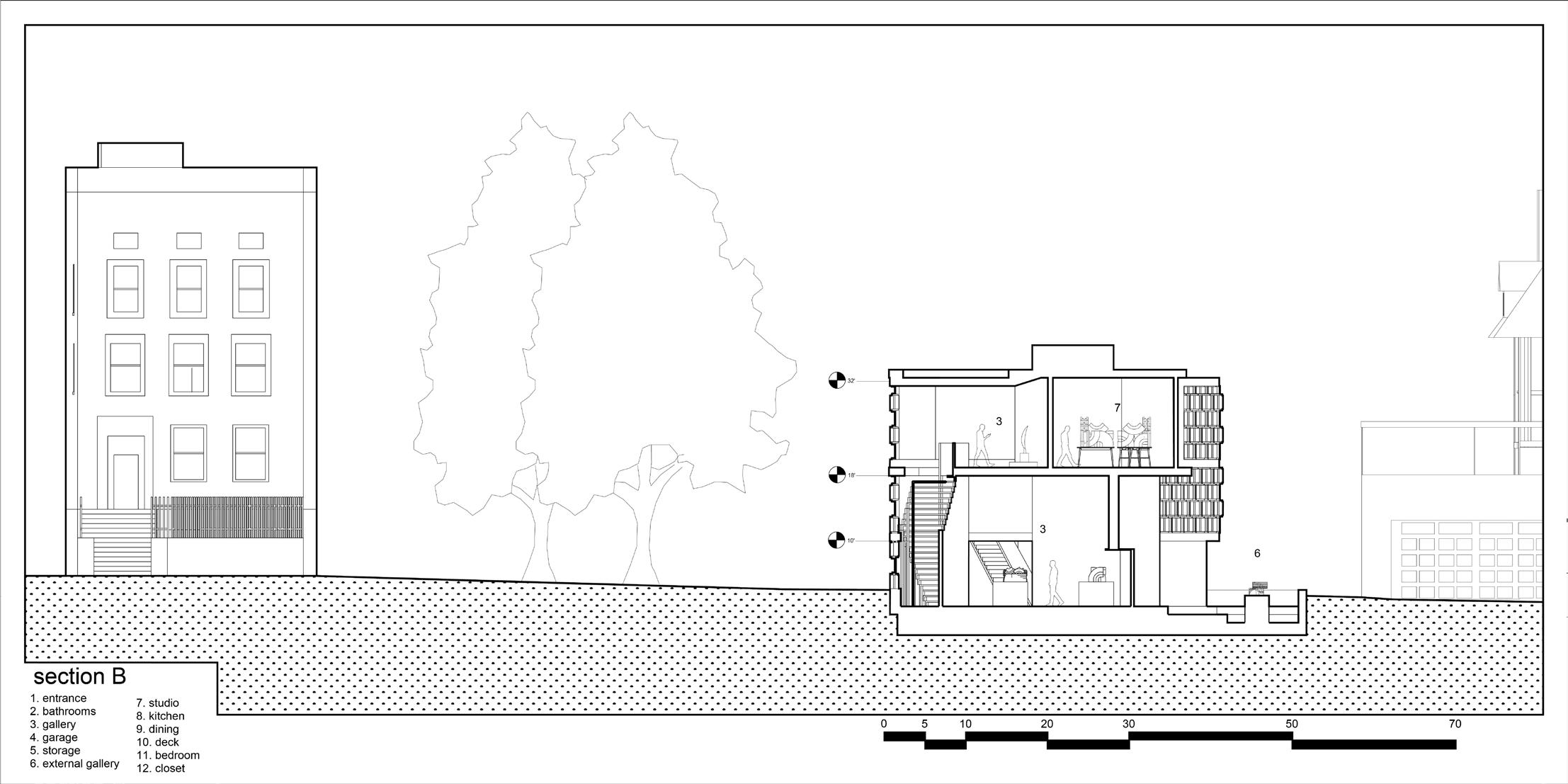

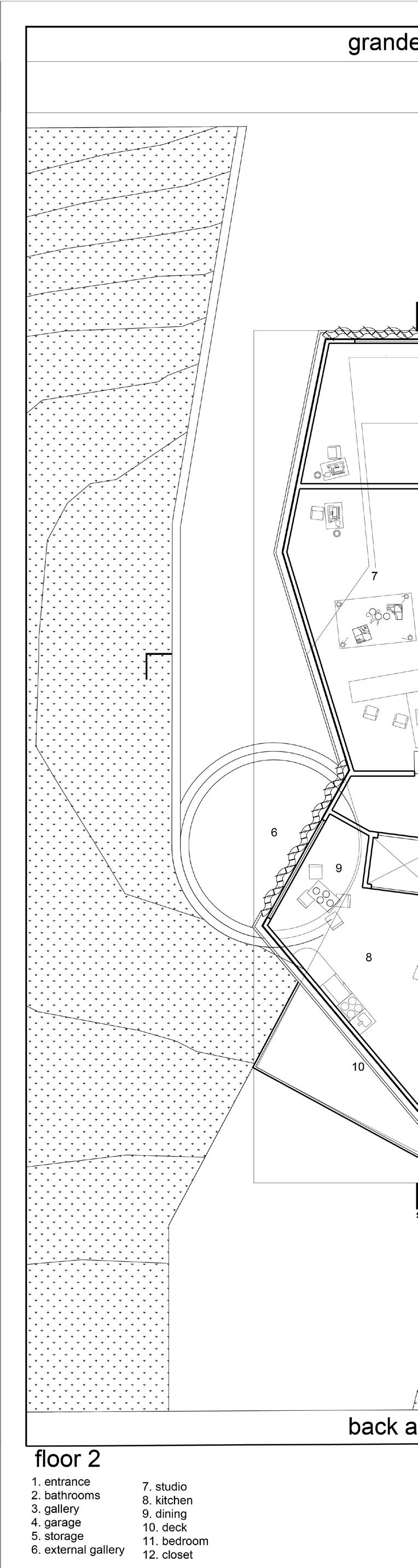

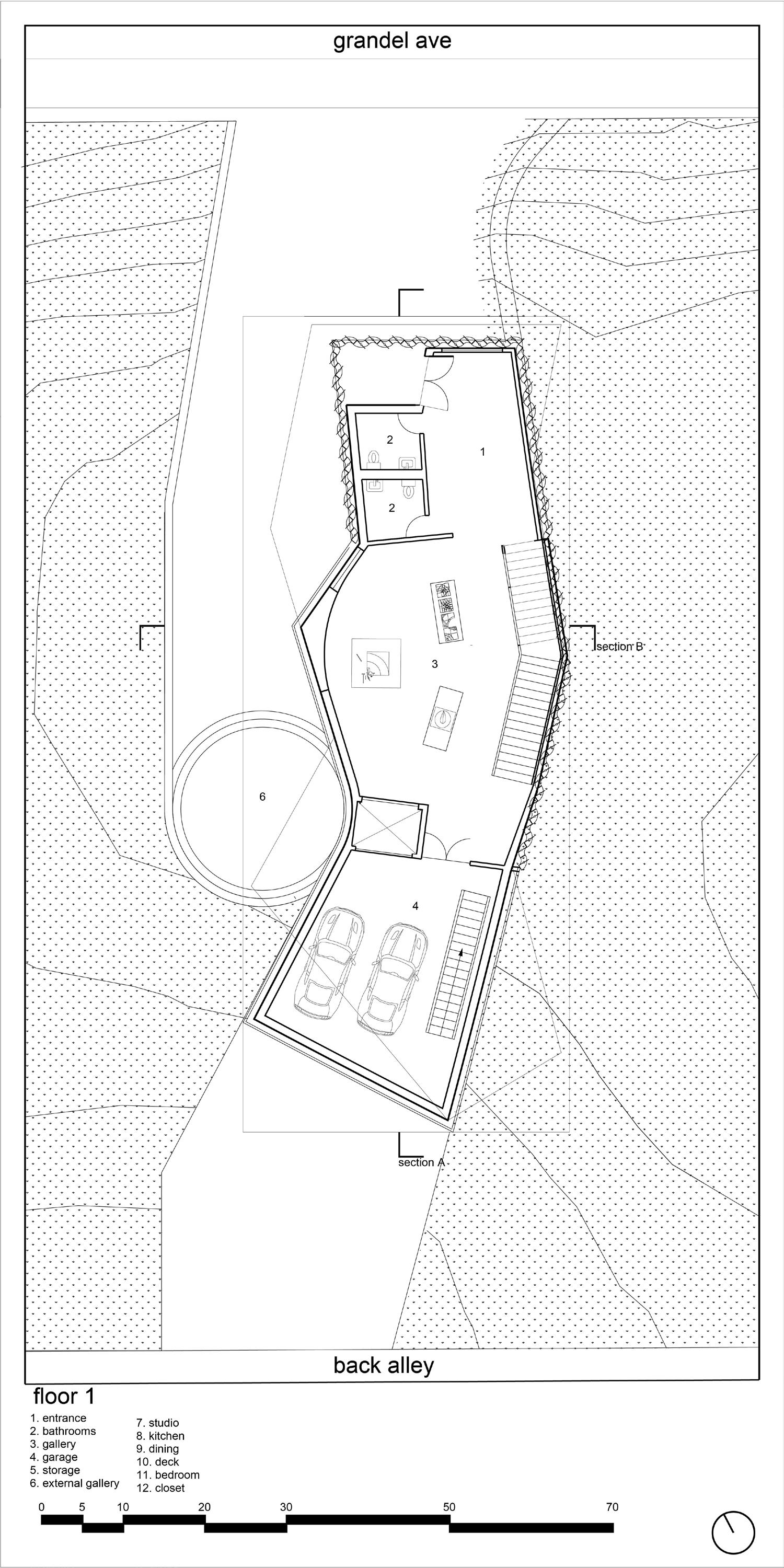

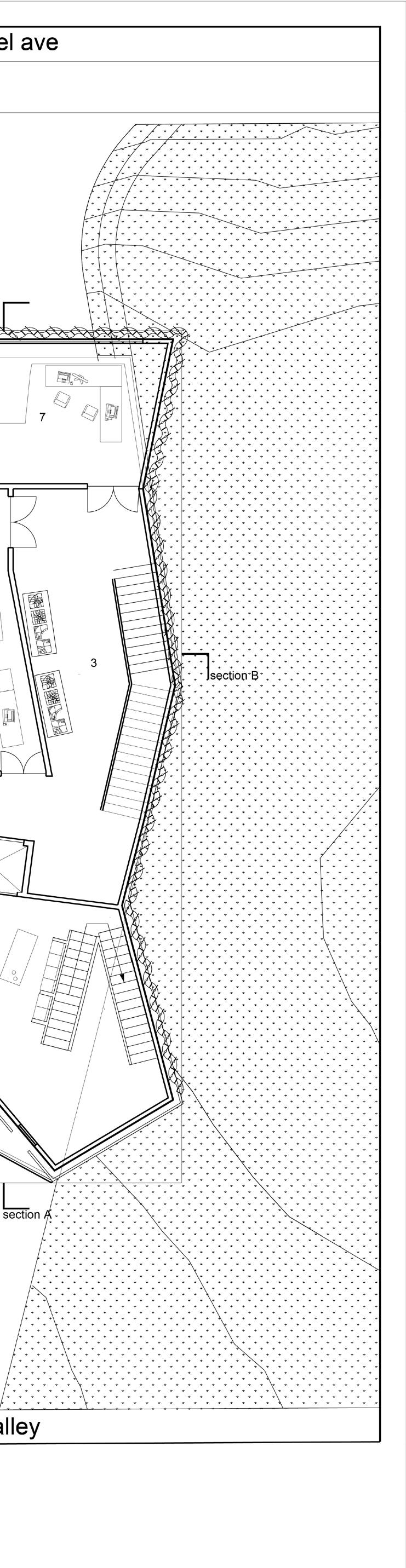

18' 14' 32' 20' section A 7. studio 8. kitchen 9. dining 10. deck 11. bedroom 12. closet 1. entrance 2. bathrooms 3. gallery 4. garage 5. storage 6. external gallery 0 5 10 20 30 50 70 1 8 4 3 7 2 2 2 7 Above: Sections

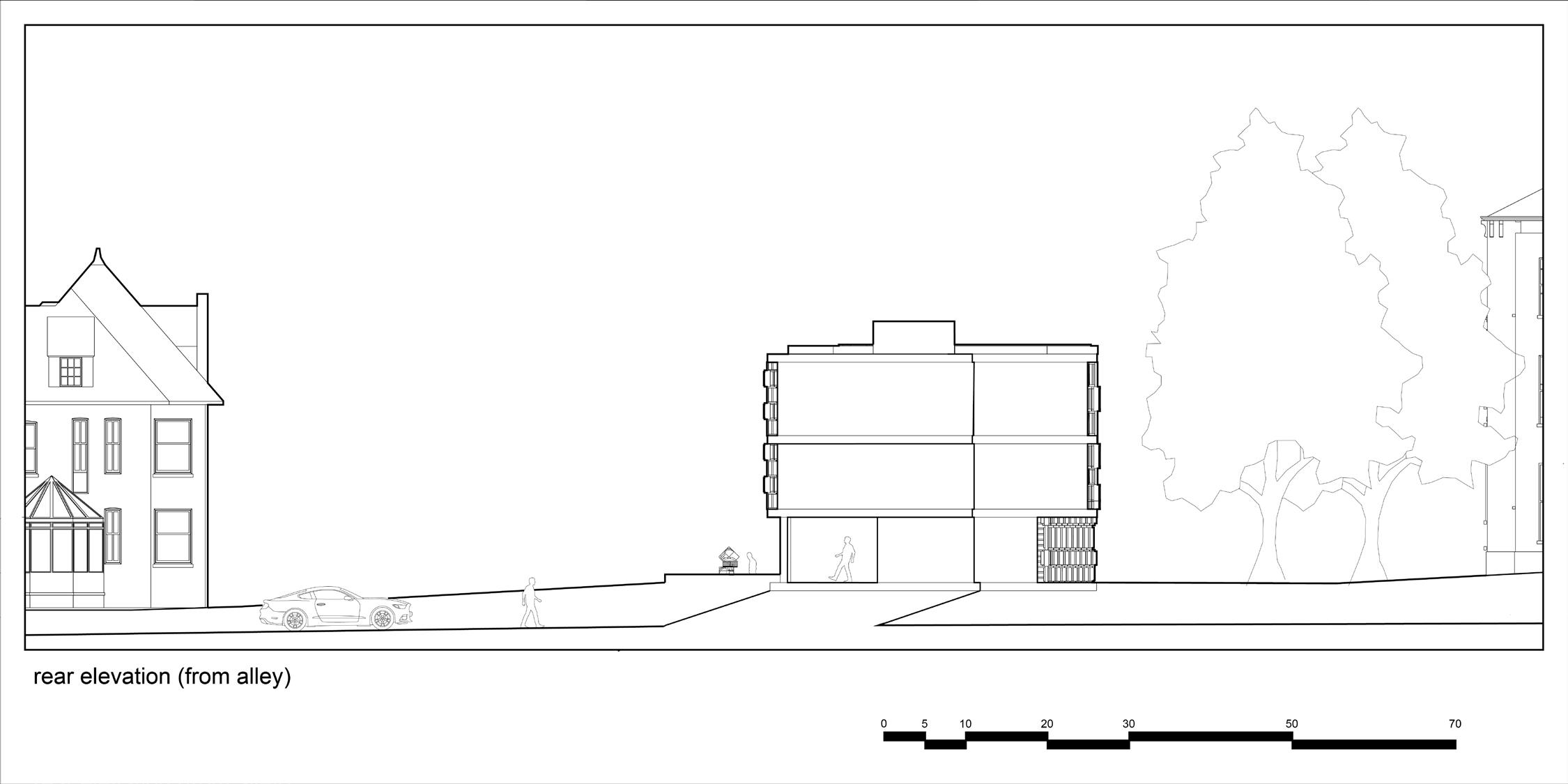

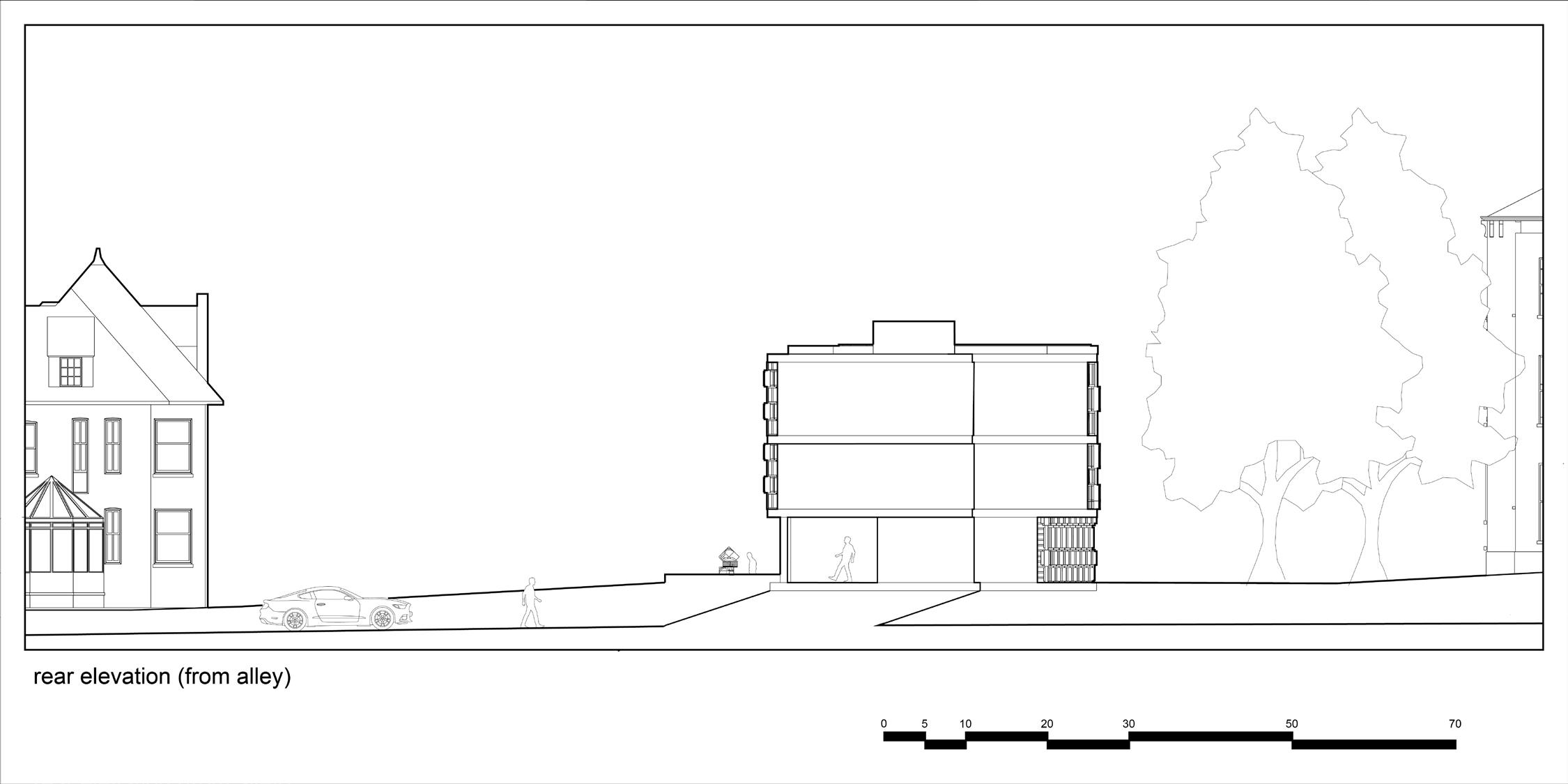

Above: Elevations

Next: Plans

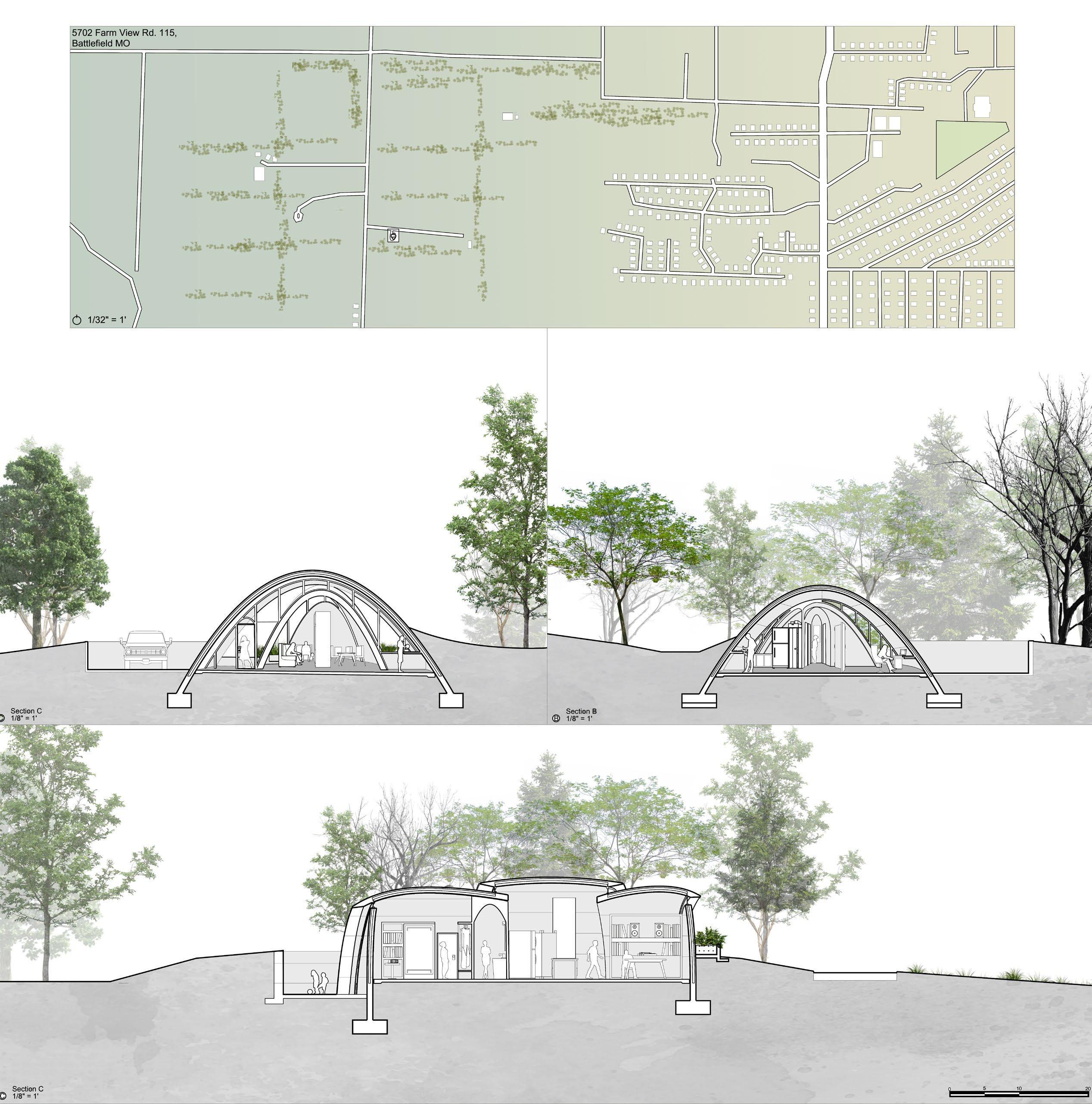

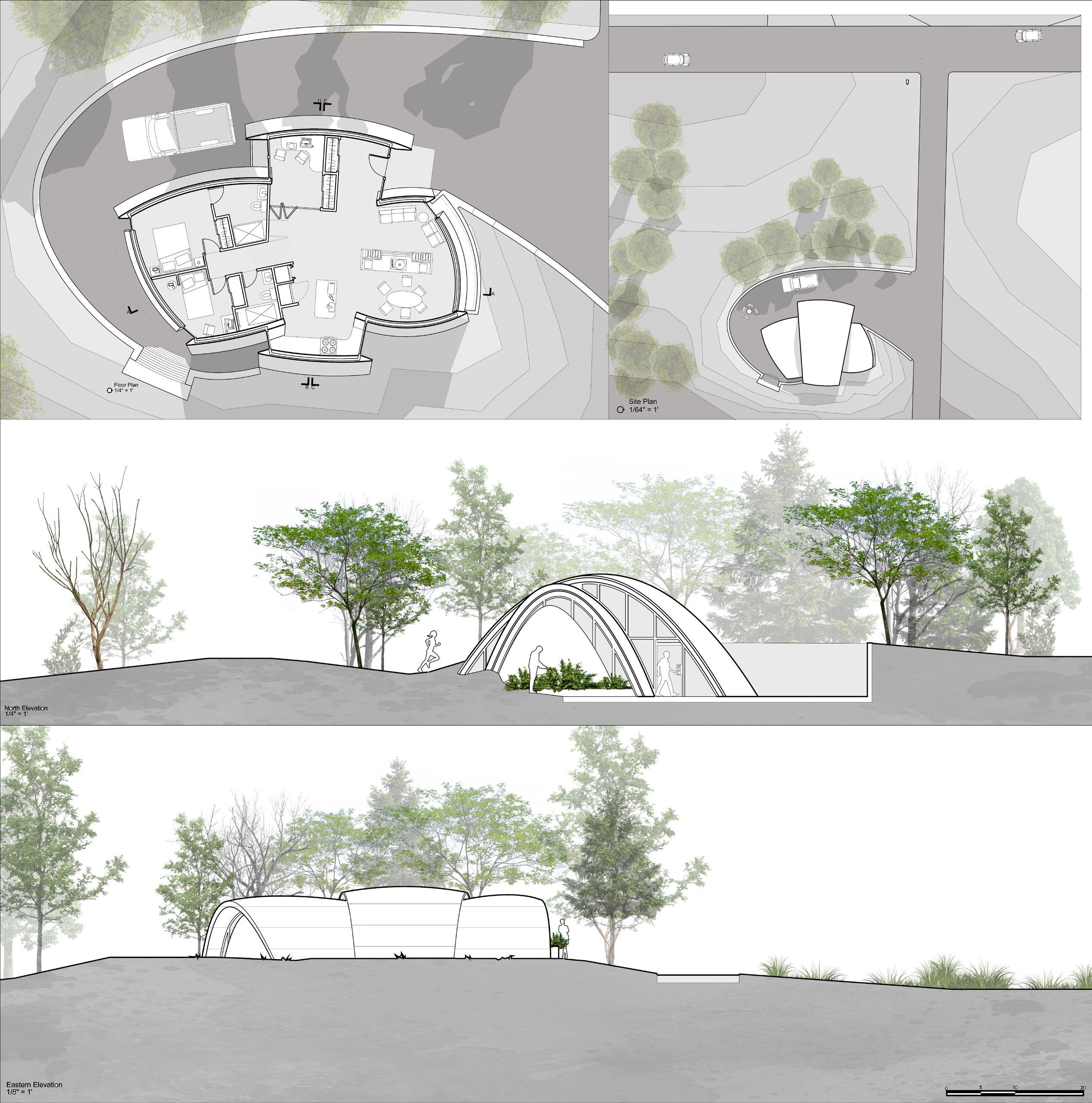

RESILIENT RESIDENCY ARCH

312

PROFESSOR: PABLO MOYANO

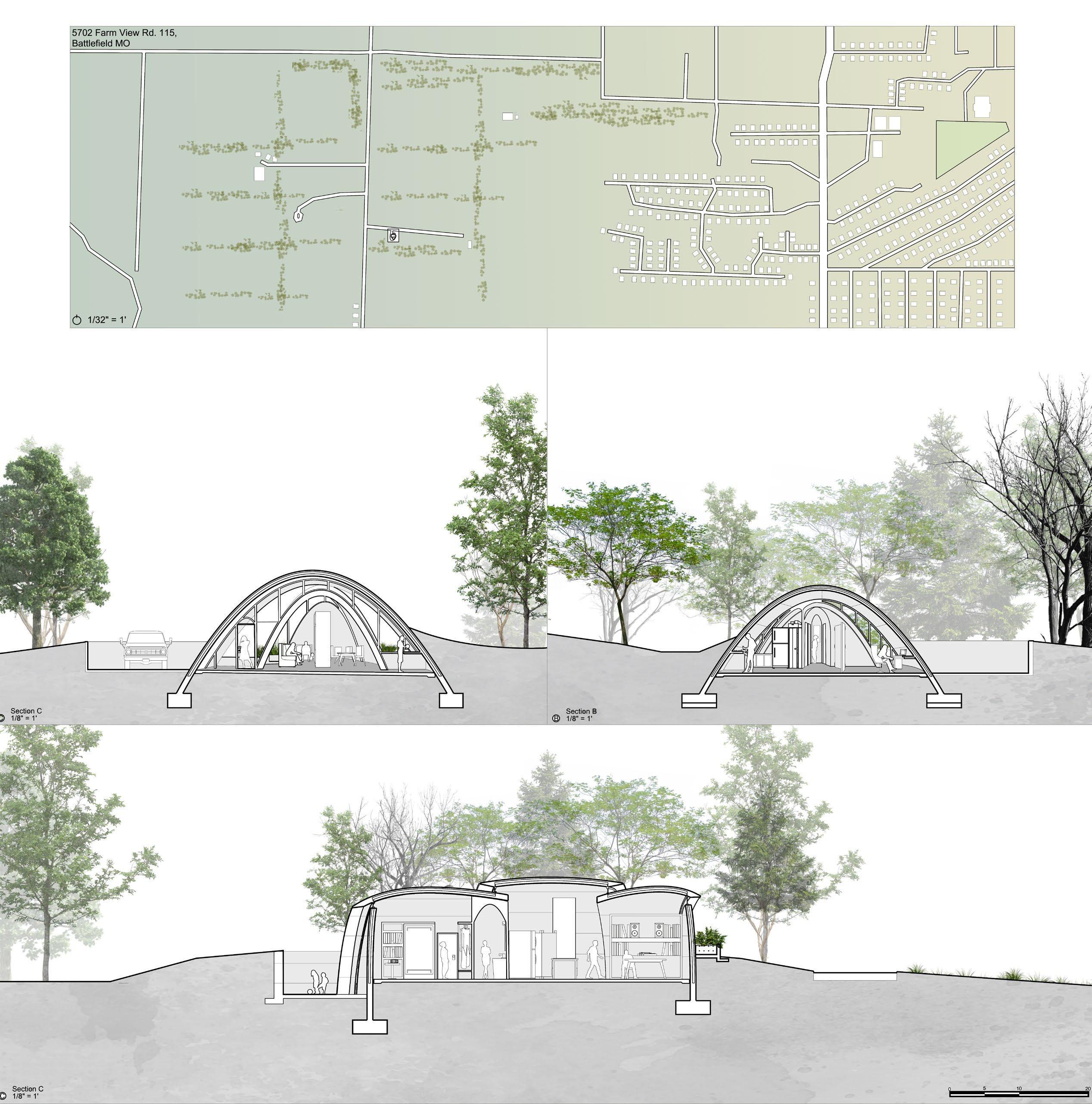

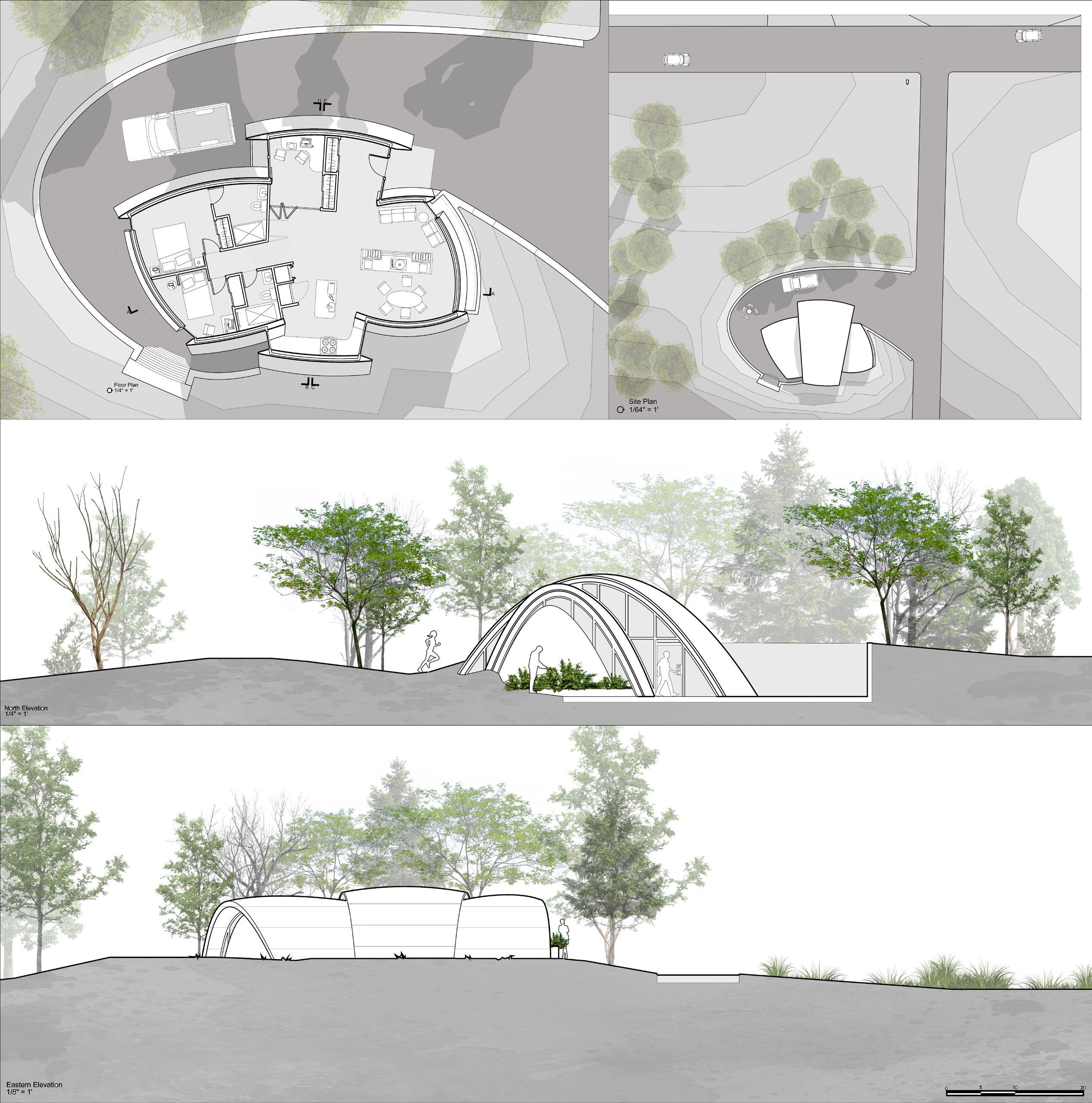

Set in an unspecified location in the lower Mississippi’s Tornado Valley, the question of this studio was to design a concrete focused dwelling which would reduce the impact of a natural disaster contacting with the house. Designing structural and protective overlaps, a lack of purely flat surfaces, and minimizing window surface area were ways to create a house that would help stave off the worst of a potential tornado.

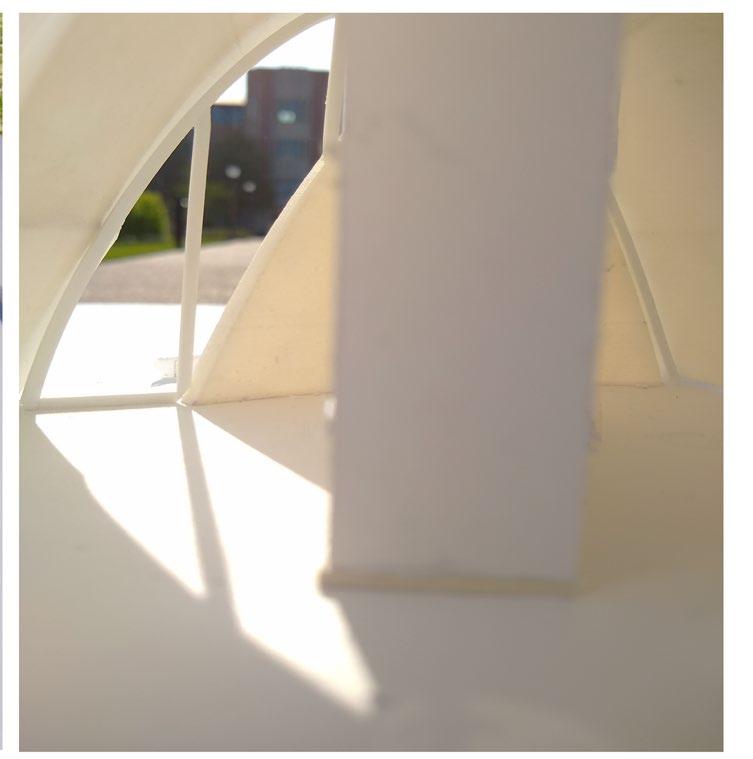

The project utilized Ultra-High Performance Concrete, a particular mixture designed for strength and durability, and the sequential casting method developed by Pablo Moyano. These techniques were first explored in a 1’:1/16” scale physical model, cast with actual concrete, and tested outside for a couple of days to form the basis for a feasible full-scale design.

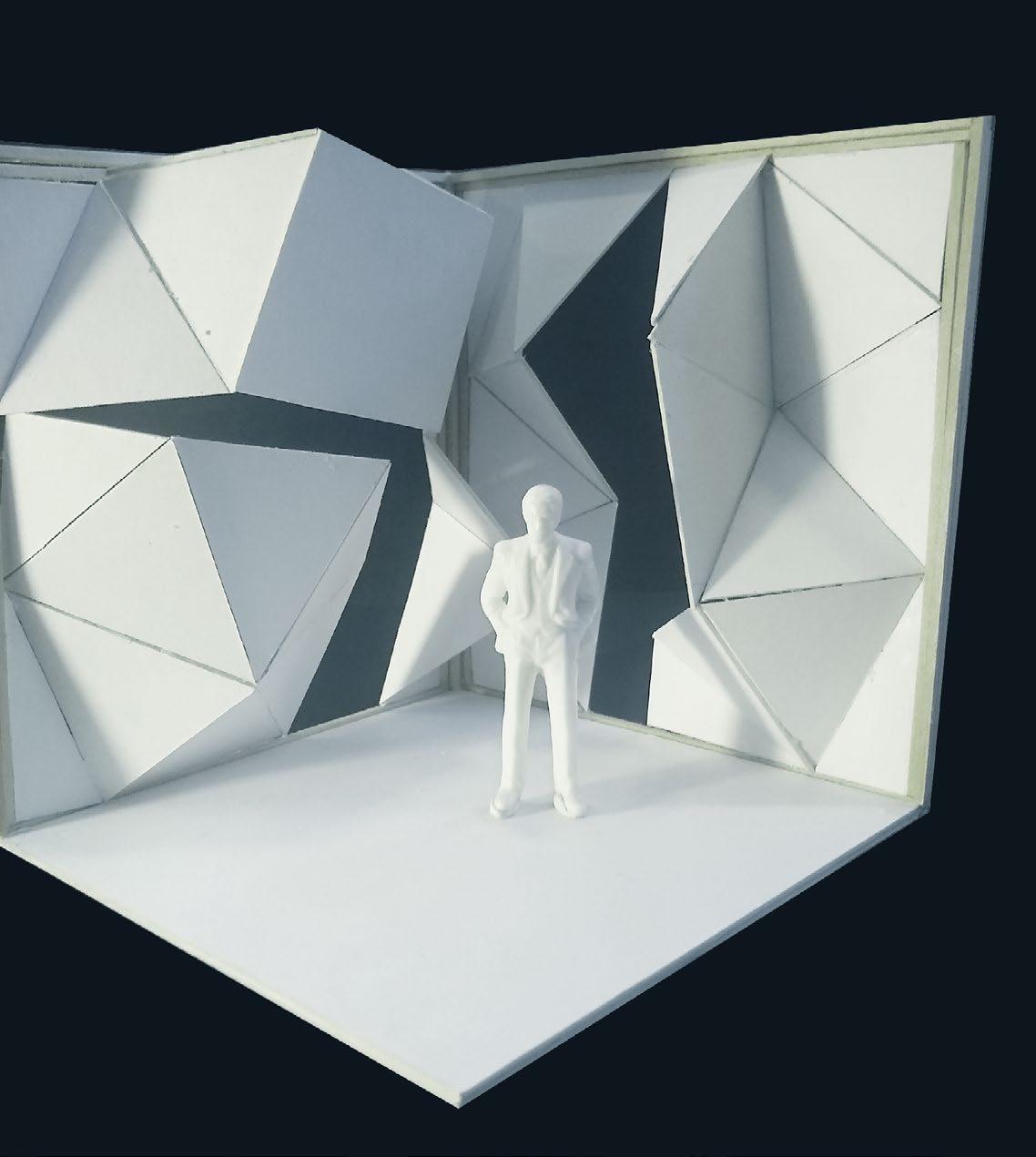

ENCLOSURE STUDIES

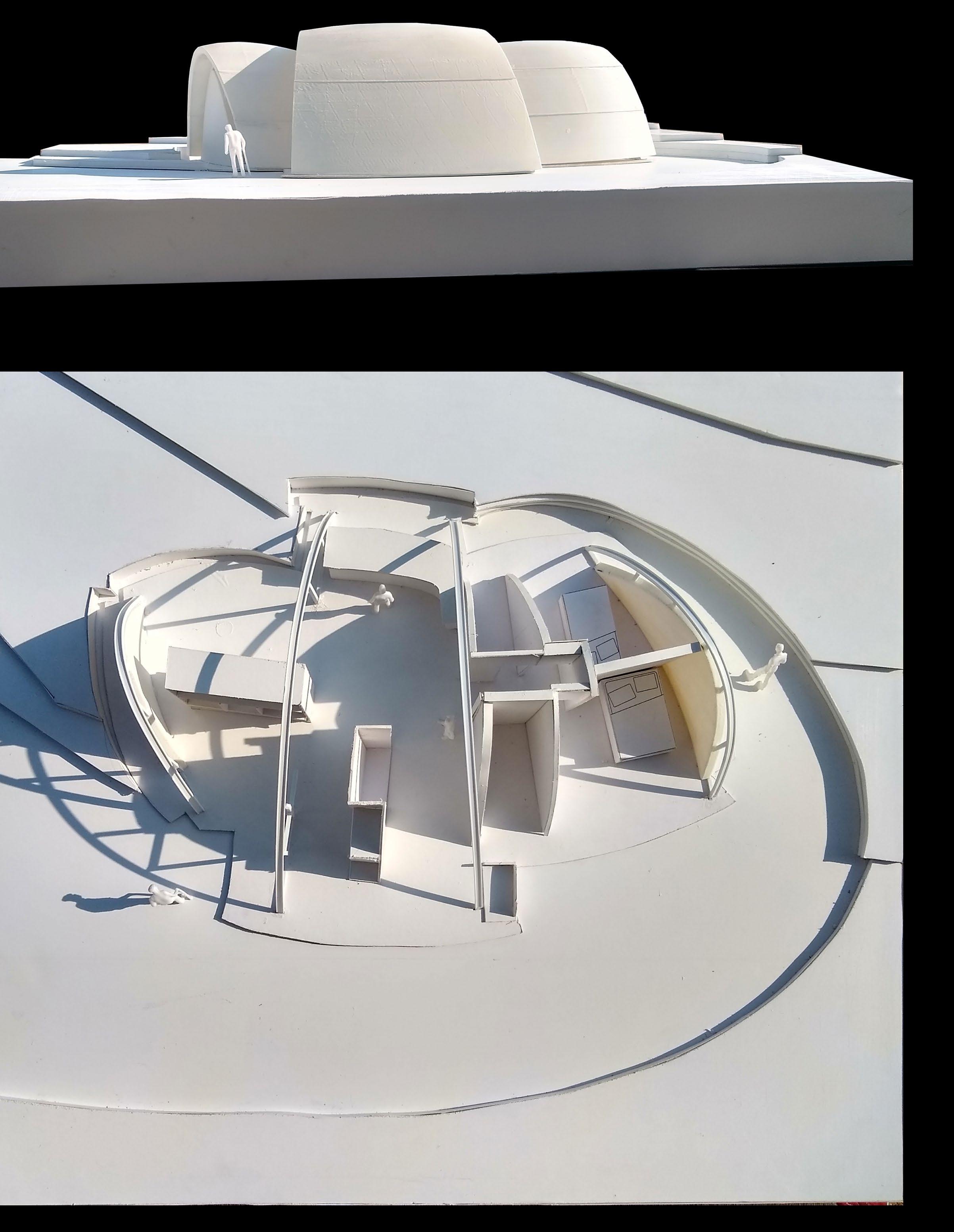

To begin the design process, a series of envelope studies were made which explored defensive walls. The reduction of purely flat surfaces was heavily emphasized in my earlier designs, exploring a sense of folded walls and corners to stabilize the wall against flying debris.

The ideas learned from this stage of study models later became the quarter domes of the concrete model (next spread) which was structurally reinforced by piano wire. This wire provided the tension that was required to offset the compression of the concrete. By using actual concrete, albeit at a smaller scale, the project could be grounded more in reality, with concrete’s limitations being tested and pushed in the study model.

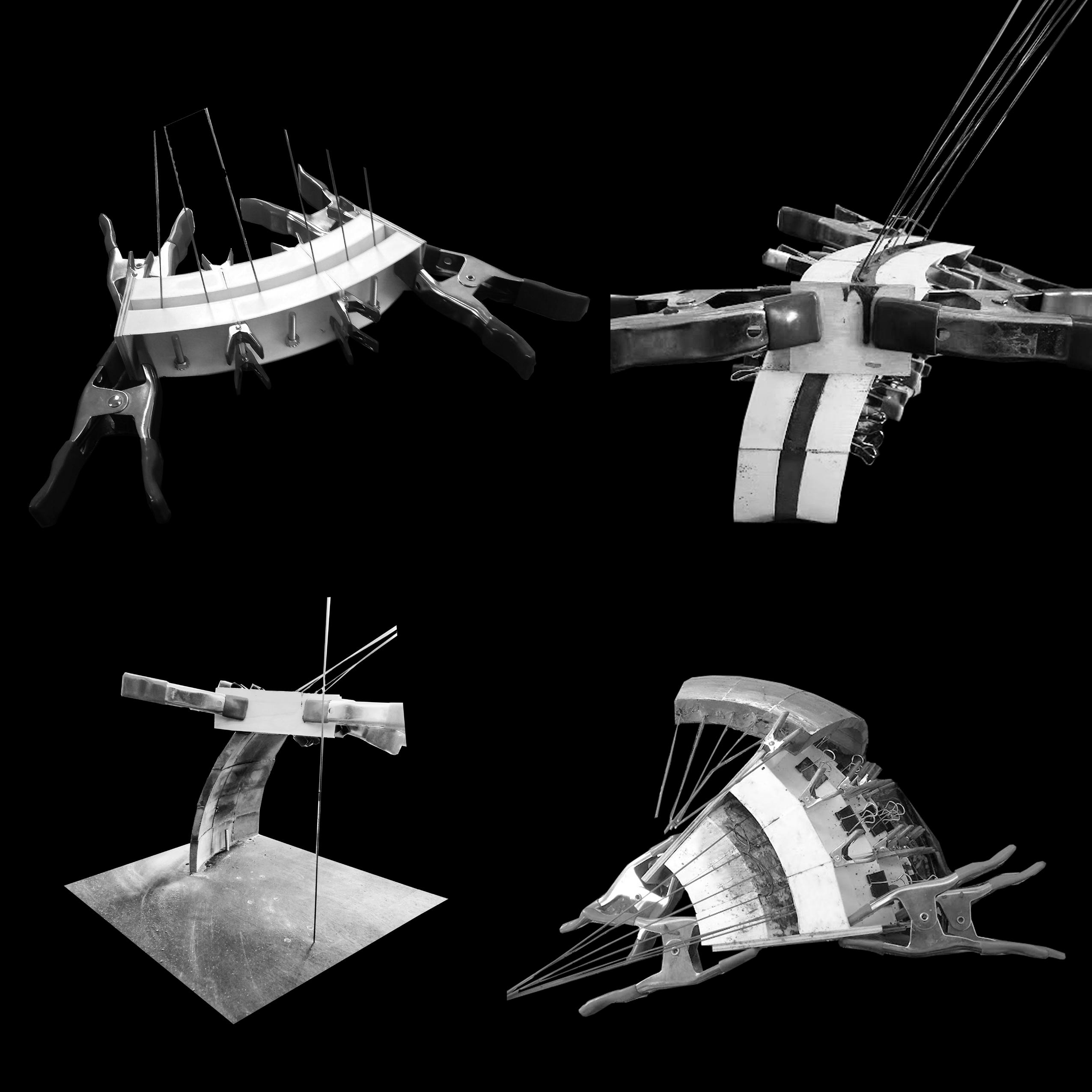

Above: The process of casting the wall. The molds were 3D printed, and held together using clamps. As each layer was cast, the molds were moved up another layer to complete the dome.

Above: The process of casting the wall. The molds were 3D printed, and held together using clamps. As each layer was cast, the molds were moved up another layer to complete the dome.

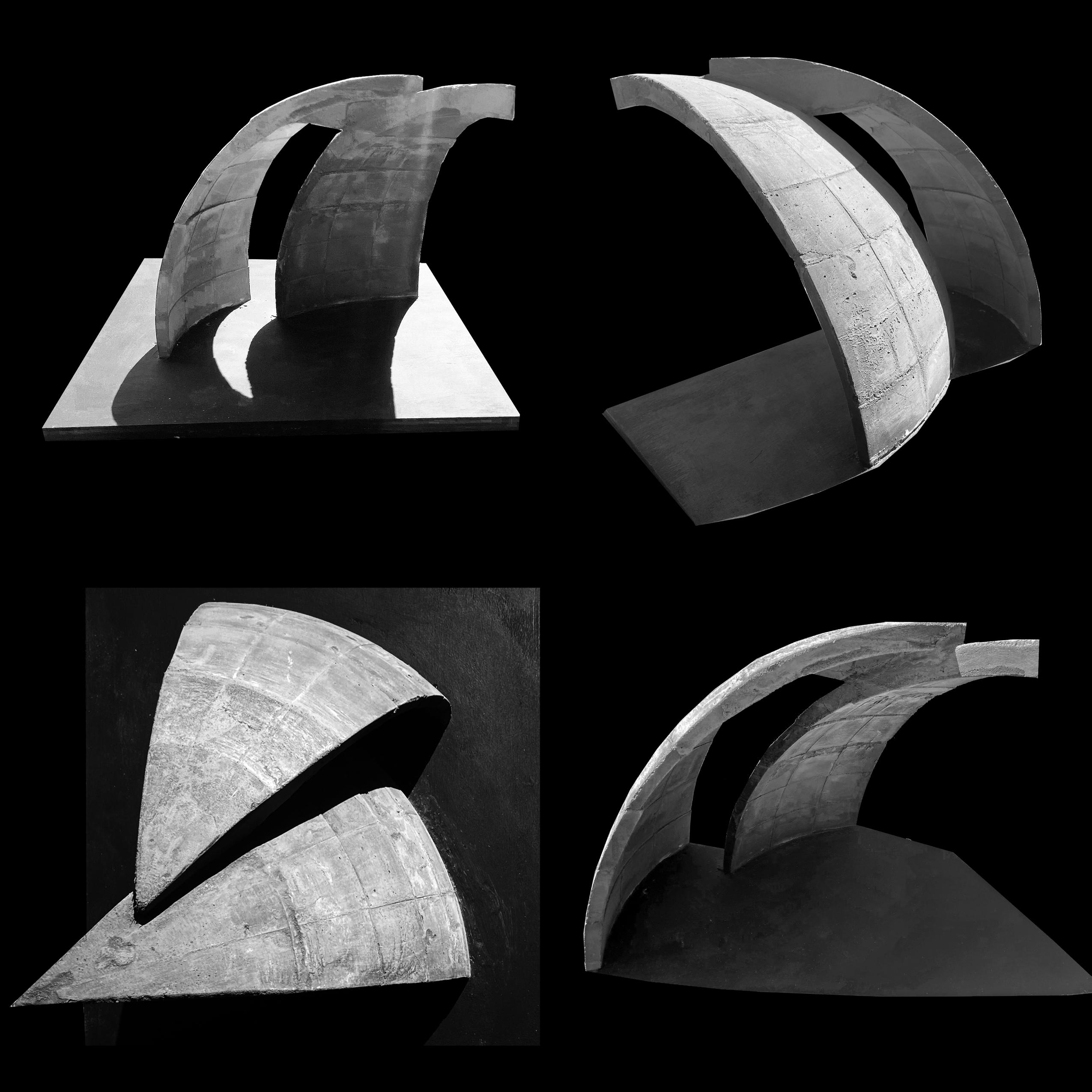

Above: The enclosure study’s final form. These were freestanding wedges of Ultra High Performance Concrete, measuring almost a foot high.

Above: The enclosure study’s final form. These were freestanding wedges of Ultra High Performance Concrete, measuring almost a foot high.

Above: The physical model of the house, opened up.

Right: A collection of renders (top) and model photos (bottom)

Above: The physical model of the house, opened up.

Right: A collection of renders (top) and model photos (bottom)

Top: Site. The location of the house was in Battlefield, MO, a rural suburb in Tornado Alley.

Bottom: Section views of the project, which is set in the ground for security.

Top: Site. The location of the house was in Battlefield, MO, a rural suburb in Tornado Alley.

Bottom: Section views of the project, which is set in the ground for security.

Top: Plan View of the Project. The concrete walls are curved and thick, for protection.

Bottom: Elevation views of the project.

Top: Plan View of the Project. The concrete walls are curved and thick, for protection.

Bottom: Elevation views of the project.

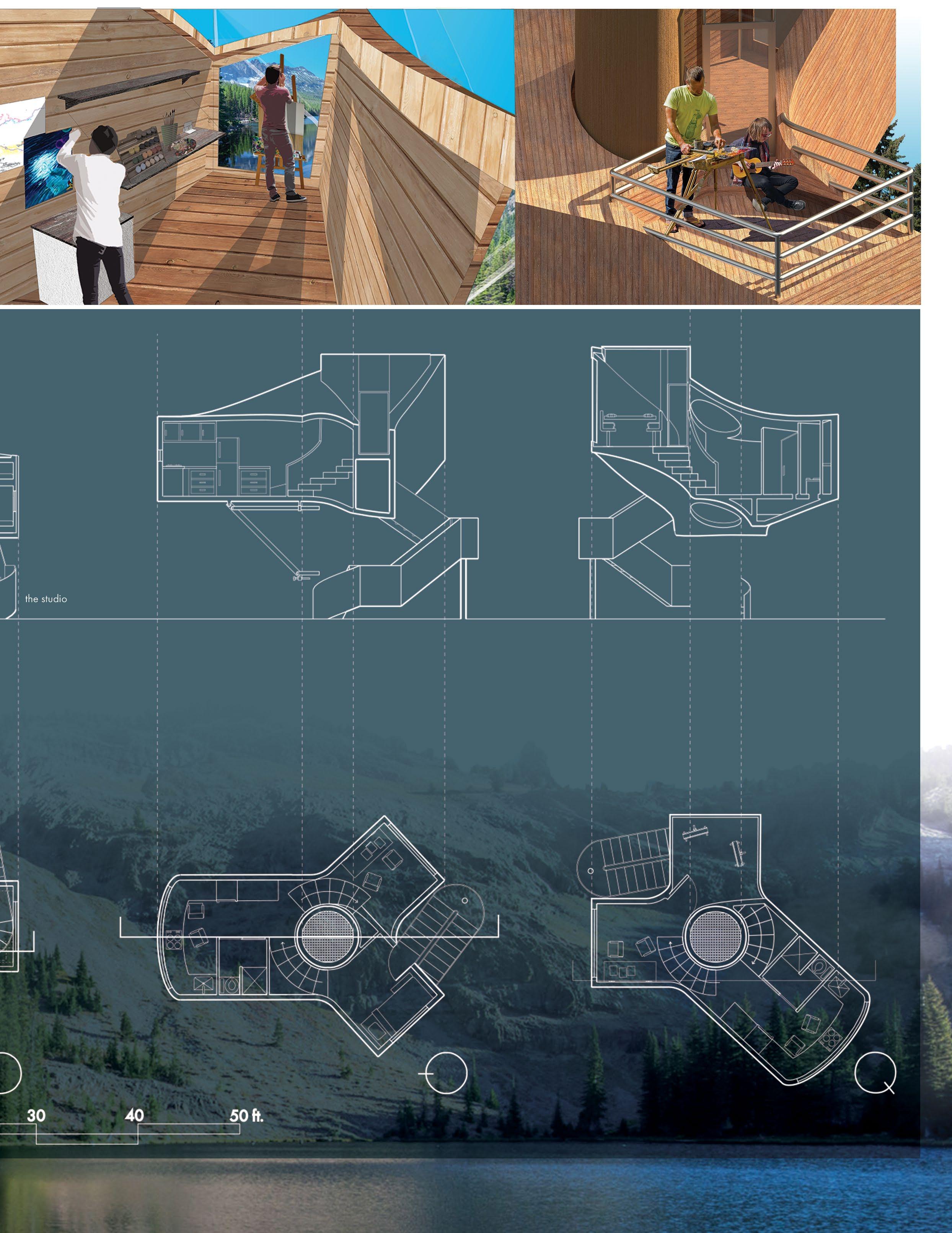

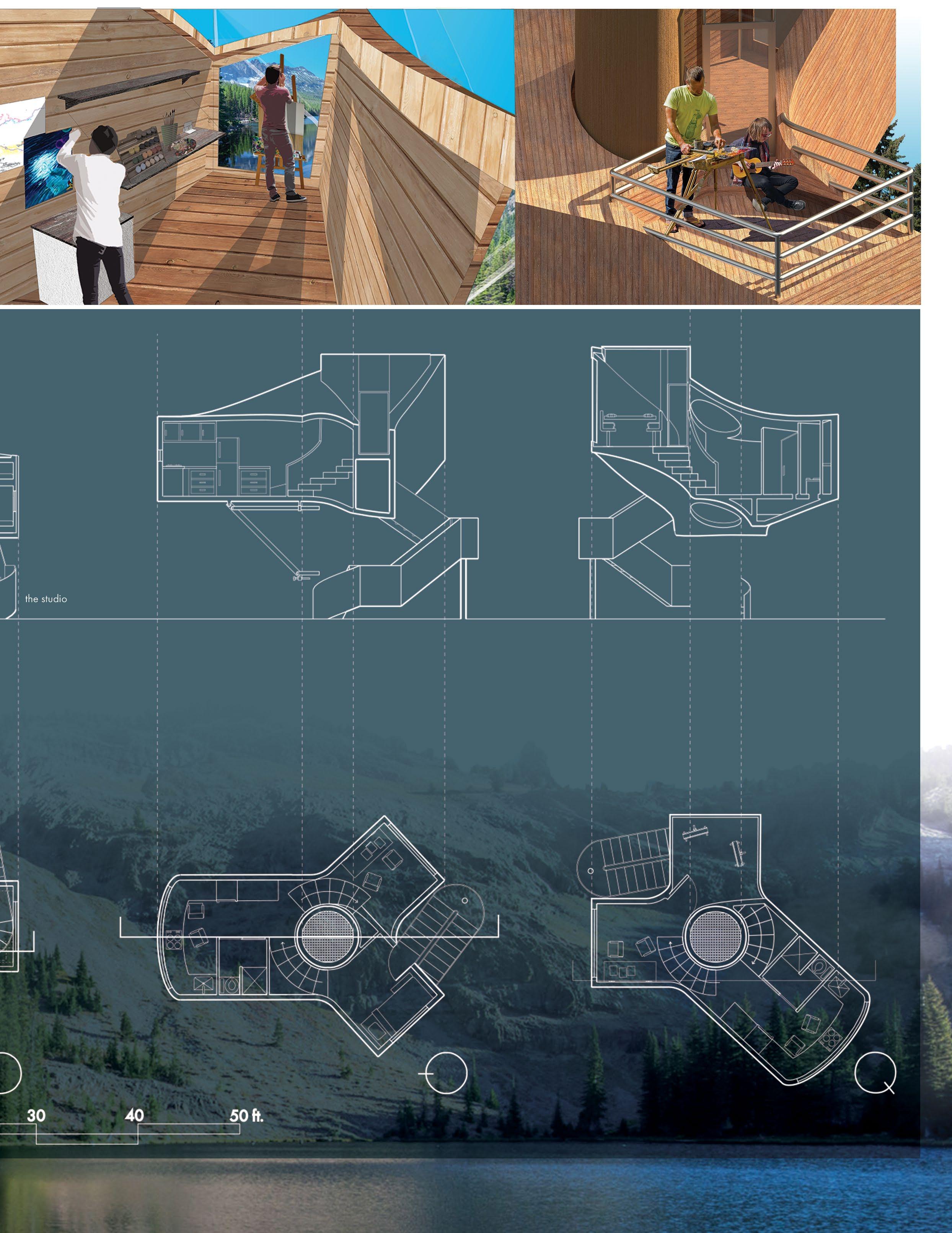

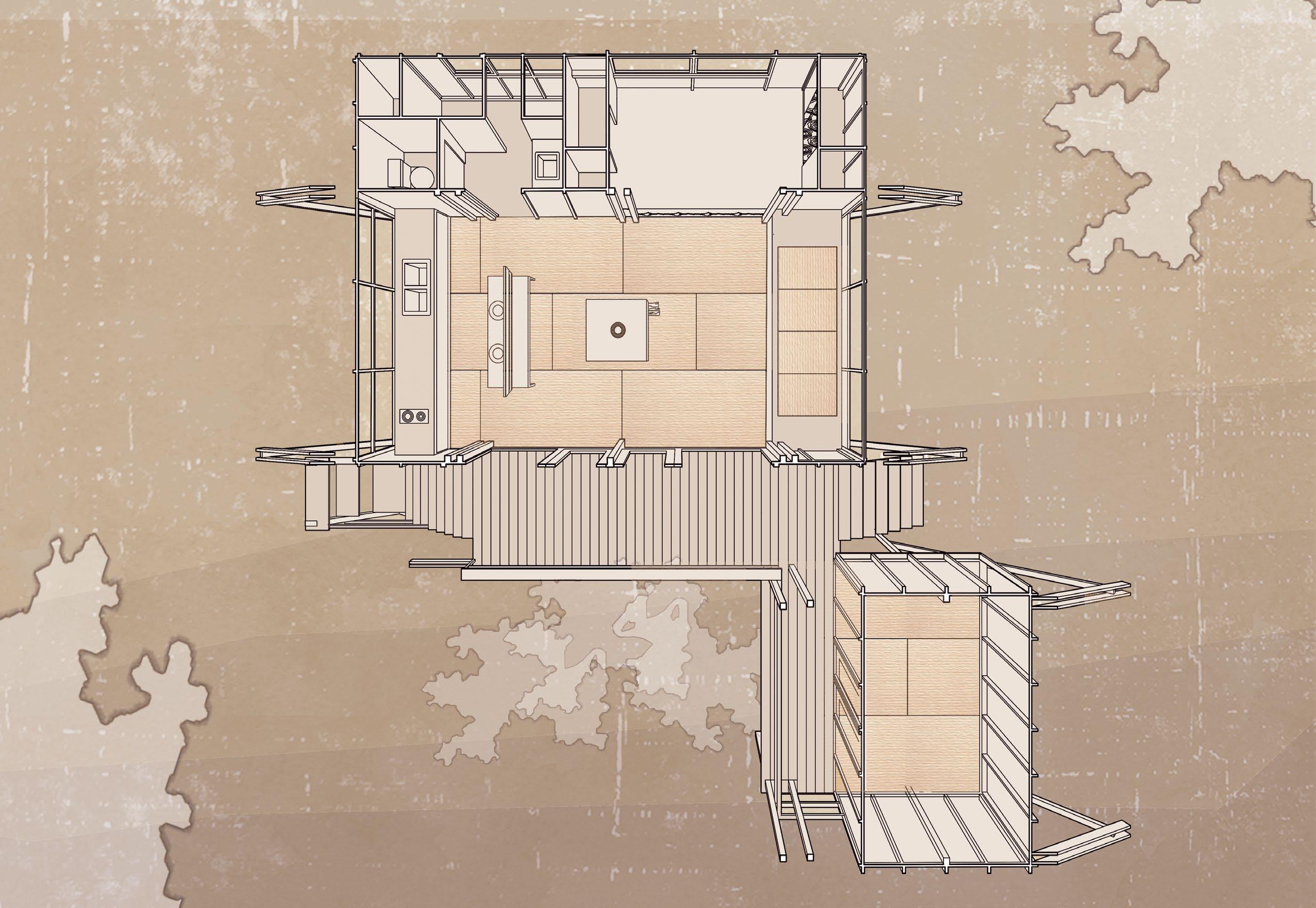

TREEHOUSE CONTEST WORK

PARTNER: AUSTIN TSAILIN

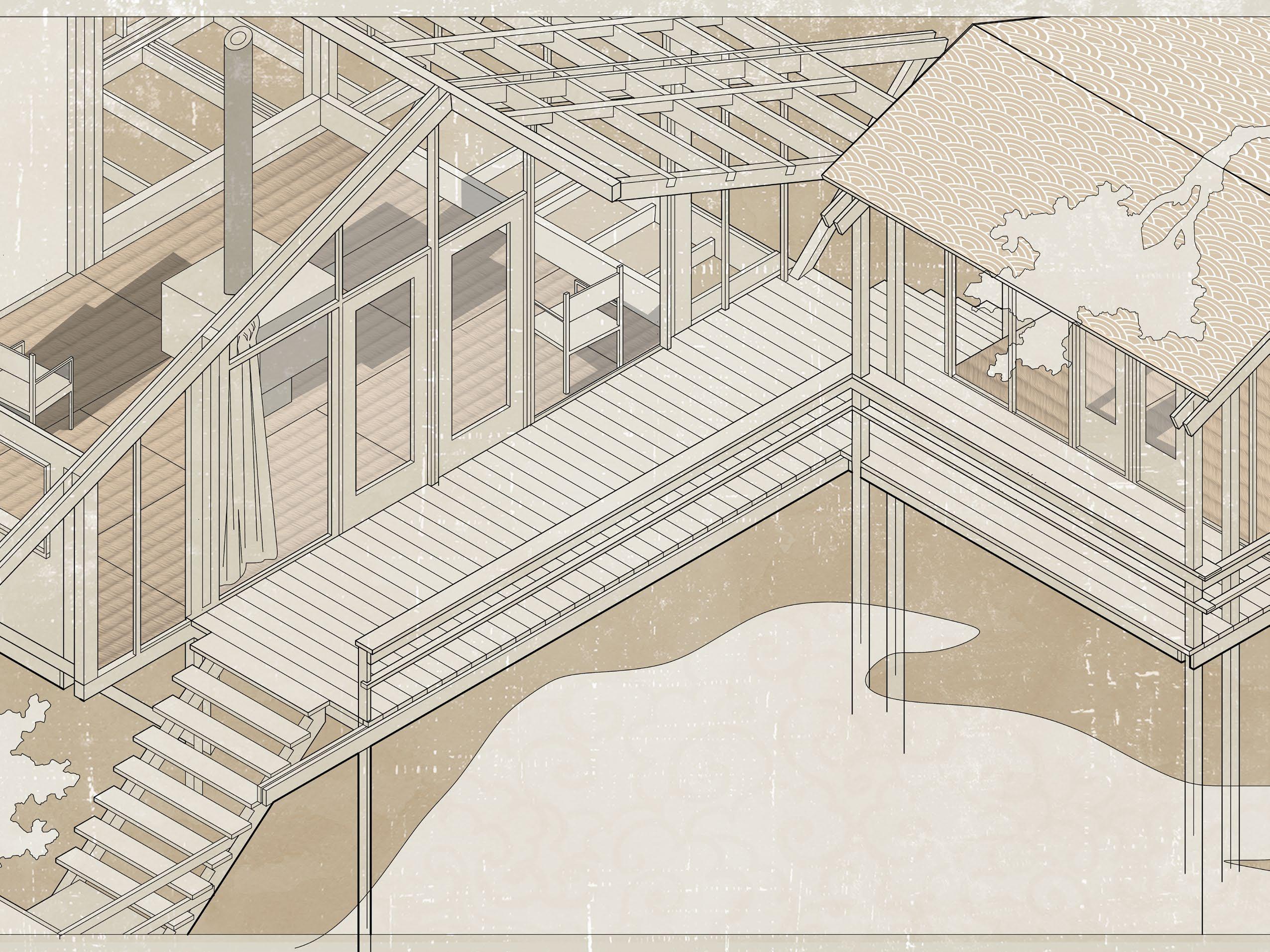

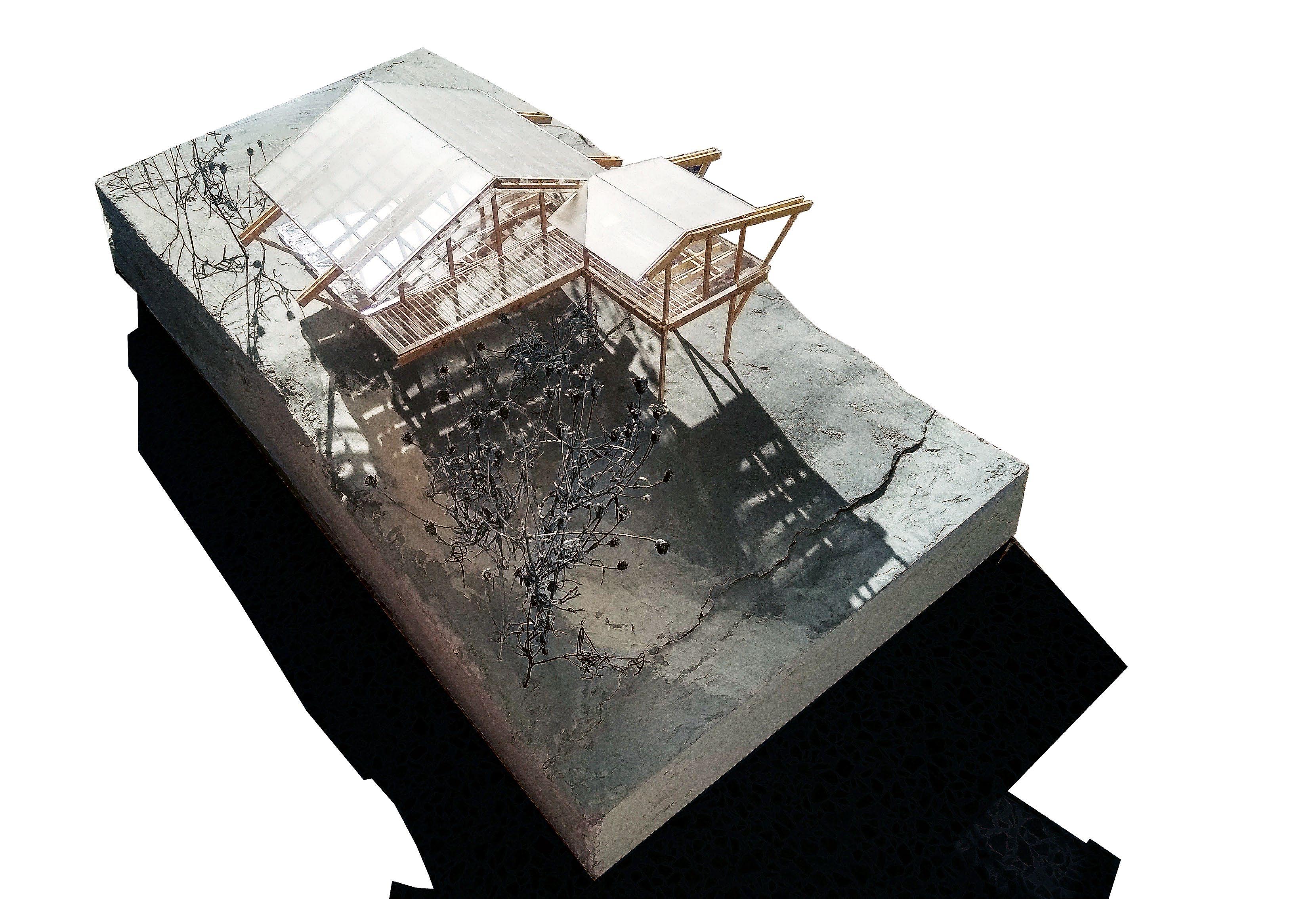

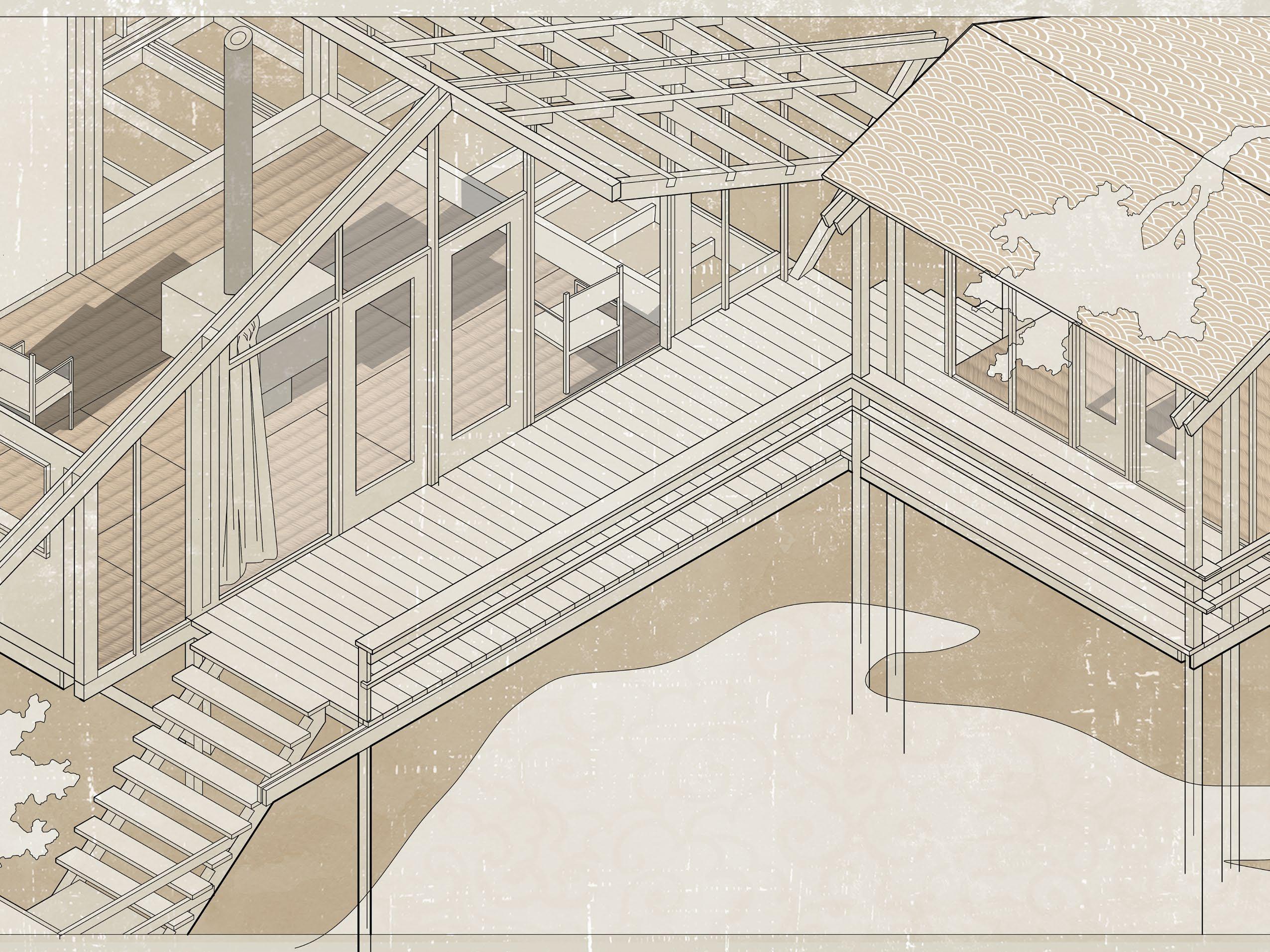

Done for a competition with volume zero, we aimed to capture the whimsy and childlike wonder of treehouses from our pasts. The residents in mind were two artists, and we wished to forge a connection with the nature around the house. Set near Strawberry Lake in Oregon, we designed the project out of local Douglas Fir and sought to forge different views of the neighboring mountains a a way to inspire the residents, and built the building on a mightly Douglas Fir sitting on the shoreline. Programmatically, the treehouse was designed to serve as a natural residency for two artists. Formally, it was built to wrap around the Fir tree, forming a wooden knot of sorts, and putting the tree front and center in the house.

MATSUMOTO MODERN EXHIBITION WORK

ARCH 333A

INSTRUCTOR: KELLEY MURPHY

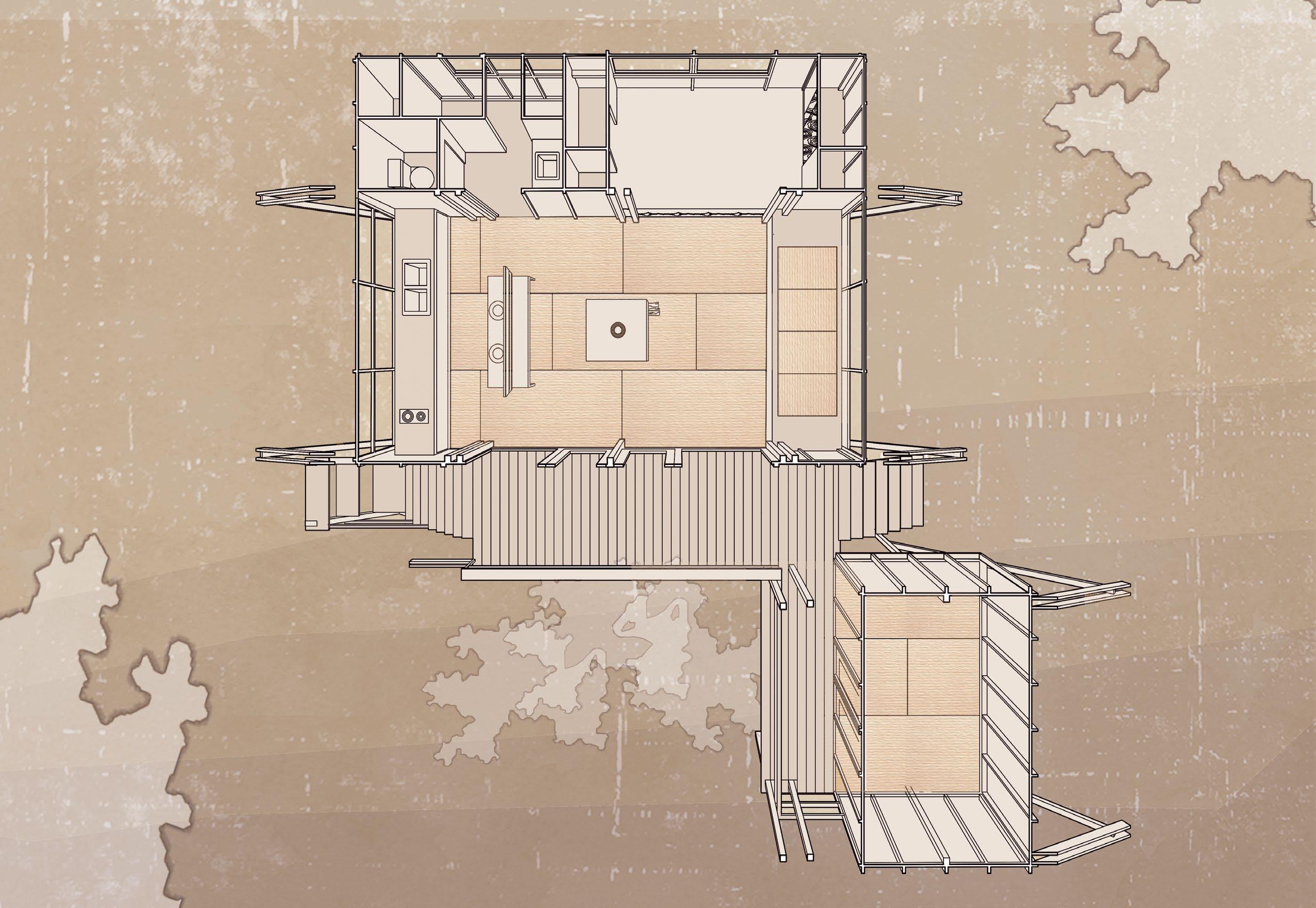

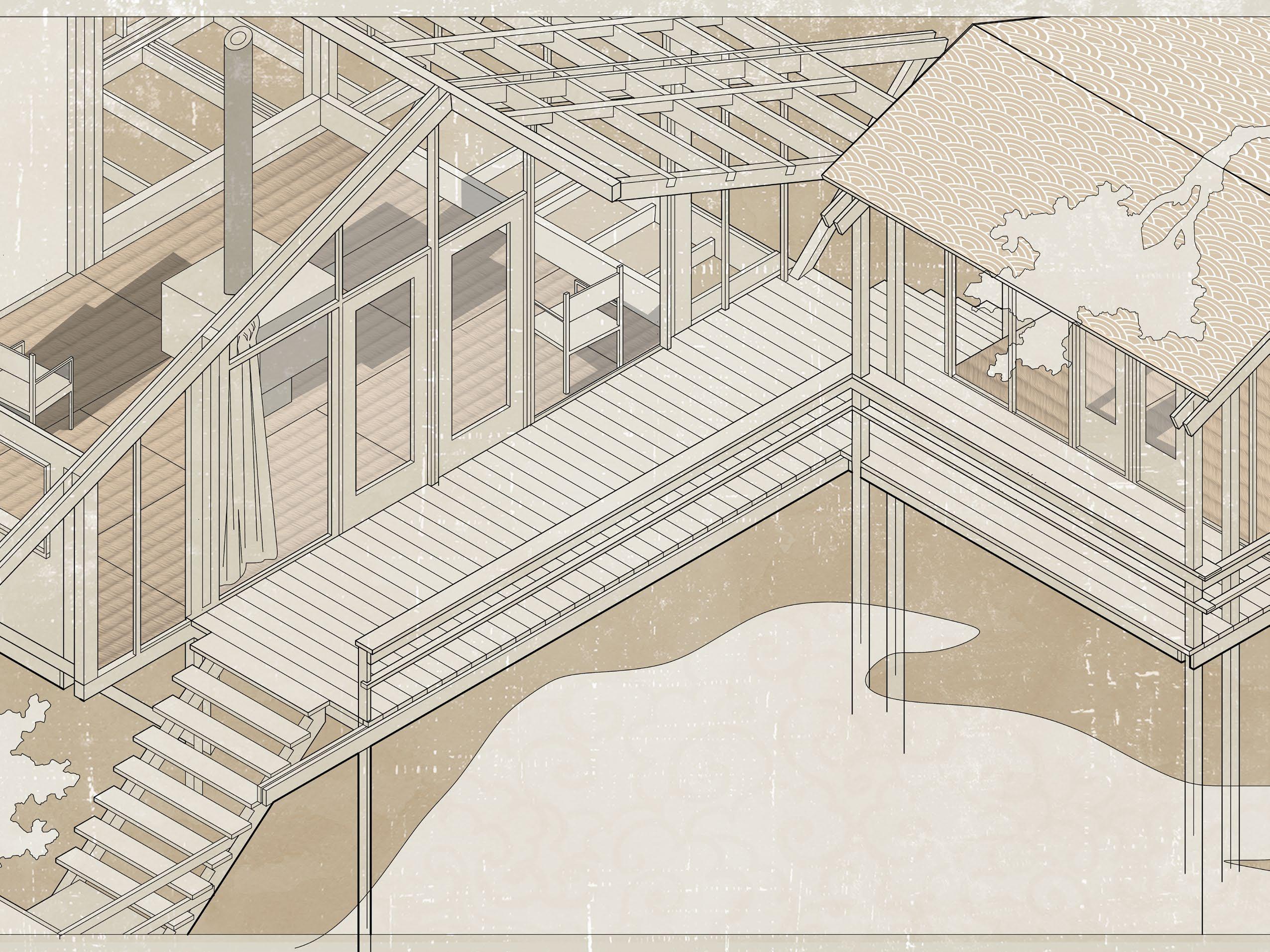

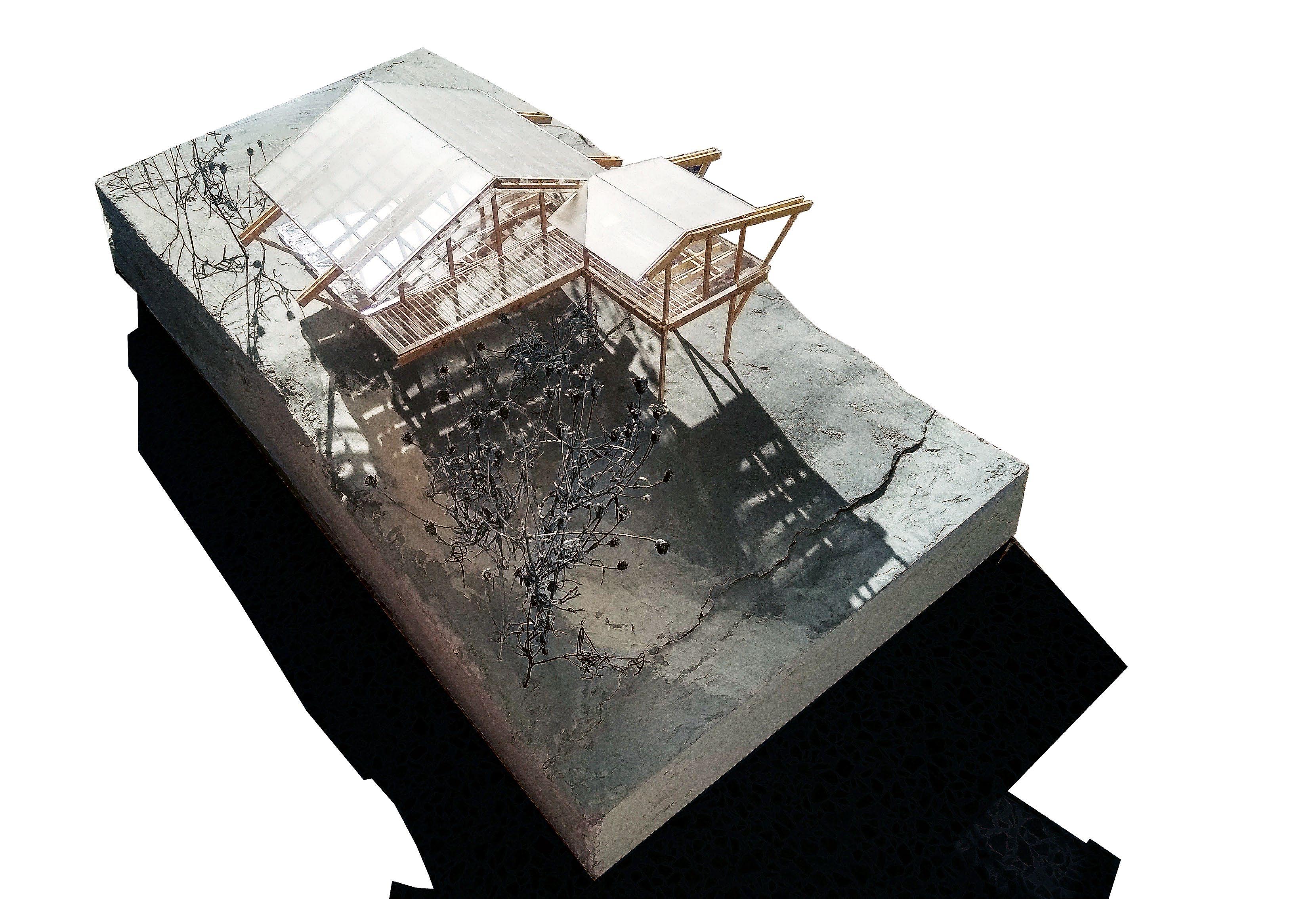

George Matsumoto was a Japanese American designer during the 40s and 50s, when Japanese Americans were being sent to internment camps. Briefly studying at Washington University in St. Louis, we were tasked with representing some of the work he did and analyzing the influences that Japanese Americans had on modernism.

This house in particular was the Women’s Day Douglas Fir Pine Association Vacation Home, which was sold to the public in magazines around the US for cheap. The house was designed as a kit of parts, being able to be assembled with minimal woodworking skill and talent. Ironically, many of these vacation homes were built in places where Japanese Americans could not move in to, and the magazine portrayed families of white Americans moving in to a house with an “oriental flair”

This presentation sought to pay respects towards the influence that Matsumoto and many other Japanese American designers had towards the Modernism Movement, with both newly made drawings and a model built according to the plans that Matsumoto had published in Women’s Day, with near proportional sticks and almost all cut and fit jointsmeaning that many of the pieces did not require gluing.

Above: A perspective plan done for the project. Note the Tatami Mat-like grid organization, a feature common in traditional Japanese housing, which Matsumoto used in his drawings frequently.

Right: Plan view of the Physical model, with the roof removed for a better look at the roof framing.

Right: Plan view of the Physical model, with the roof removed for a better look at the roof framing.

Above: Axonometric view, I attempted to present the mass produce-ability of the house and the pilotis (a staple of modernism that allowed the house to be built on any site) with a nod to the Ukiyo-E prints (floating city) of traditional japanese art, which themselves were siteless.

Above: The physical model, axonometric view. The site for this model in particular was inspired by a built example of the house in North Carolina, where a majority of Matsumoto’s projects were sited and built.

Herzog and De Meuron

BUILDING SYSTEMS

ARCH 445

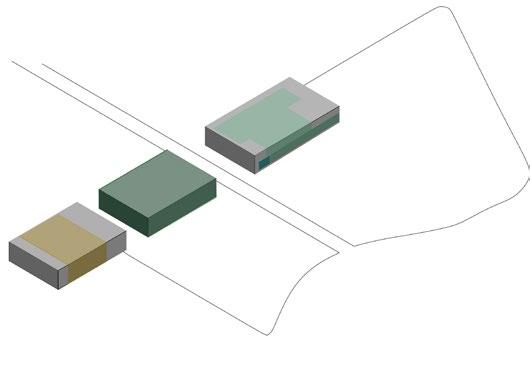

Napa Valley, CA

INSTRUCTOR: PABLO MOYANO

PARTNER: MADISON DUGAR

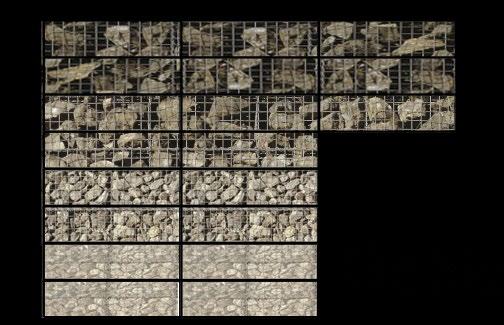

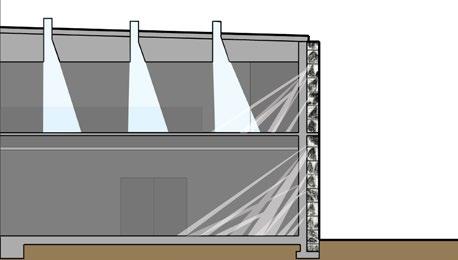

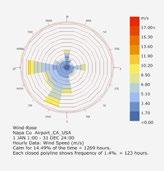

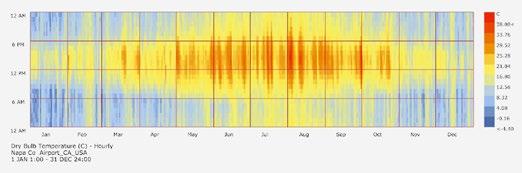

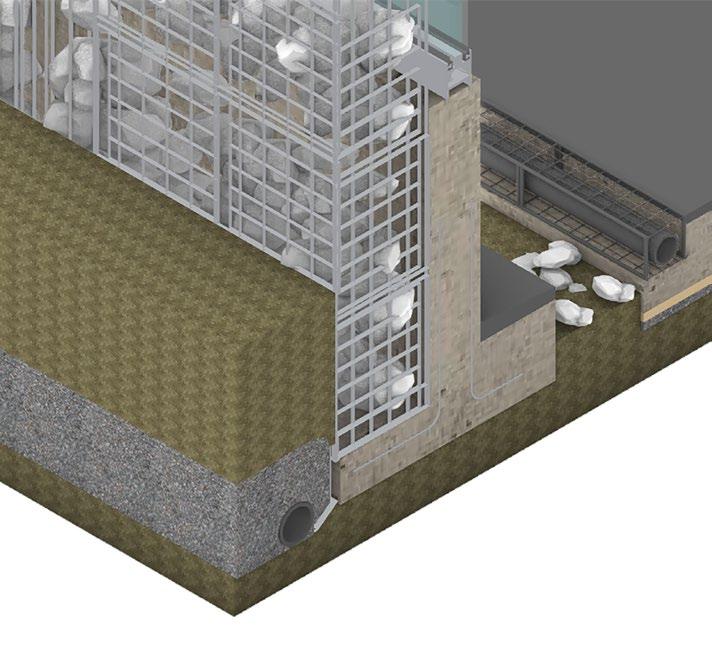

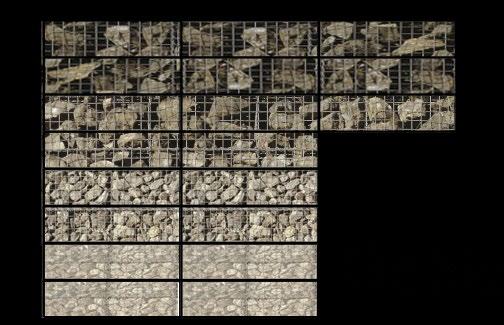

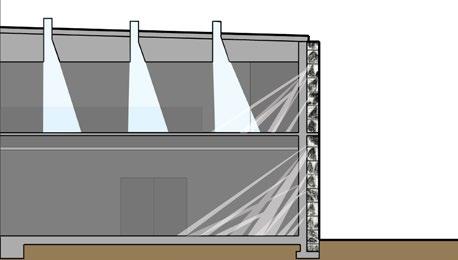

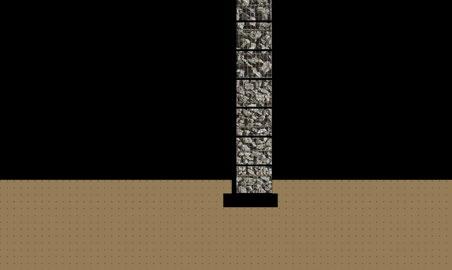

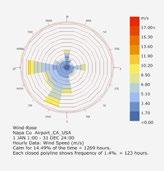

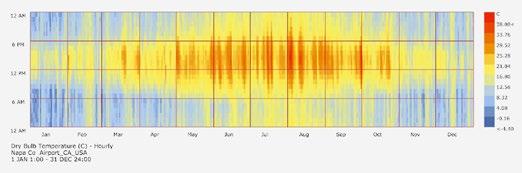

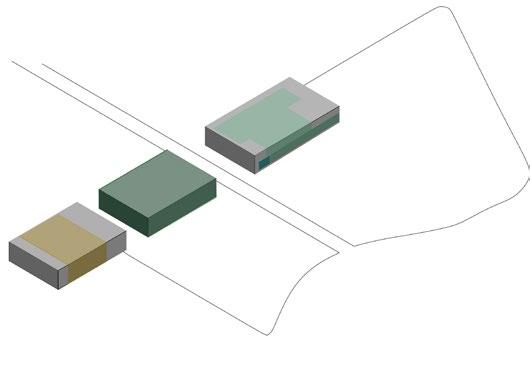

OWL BOXES AND BLUEBIRD HOUSES PROVIDE HOMES TO NATURAL PREDATORS OF VINE PESTS AND RODENTS EROSION CONTROLS PROTECT THE HOPPER CREEK WATERSHED, HOME TO NATIVE SALMON AND OTHER SPECIES PASSIVE COOLING OF THE WINERY REDUCES ENERGY CONSUMPTION COVER CROPS NATURALLY REPLENISH THE SOIL, PREVENT EROSION AND SUPPORT BENEFICIAL INSECTS FOR PEST MANAGEMENT PARKING - STOREROOM- BARRIQUE CELLAR - OFFICES- CELLAR MAN’S ROOM 0 50 ft 100 ft 150 ft 200 ft Division of Program Topo and Site Map Env. Sustainability Features Metal Basalt Concrete Glass Circulation Bioclimactic Site Data Materials DOMINUS

WINERY

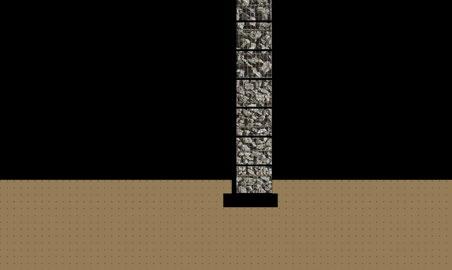

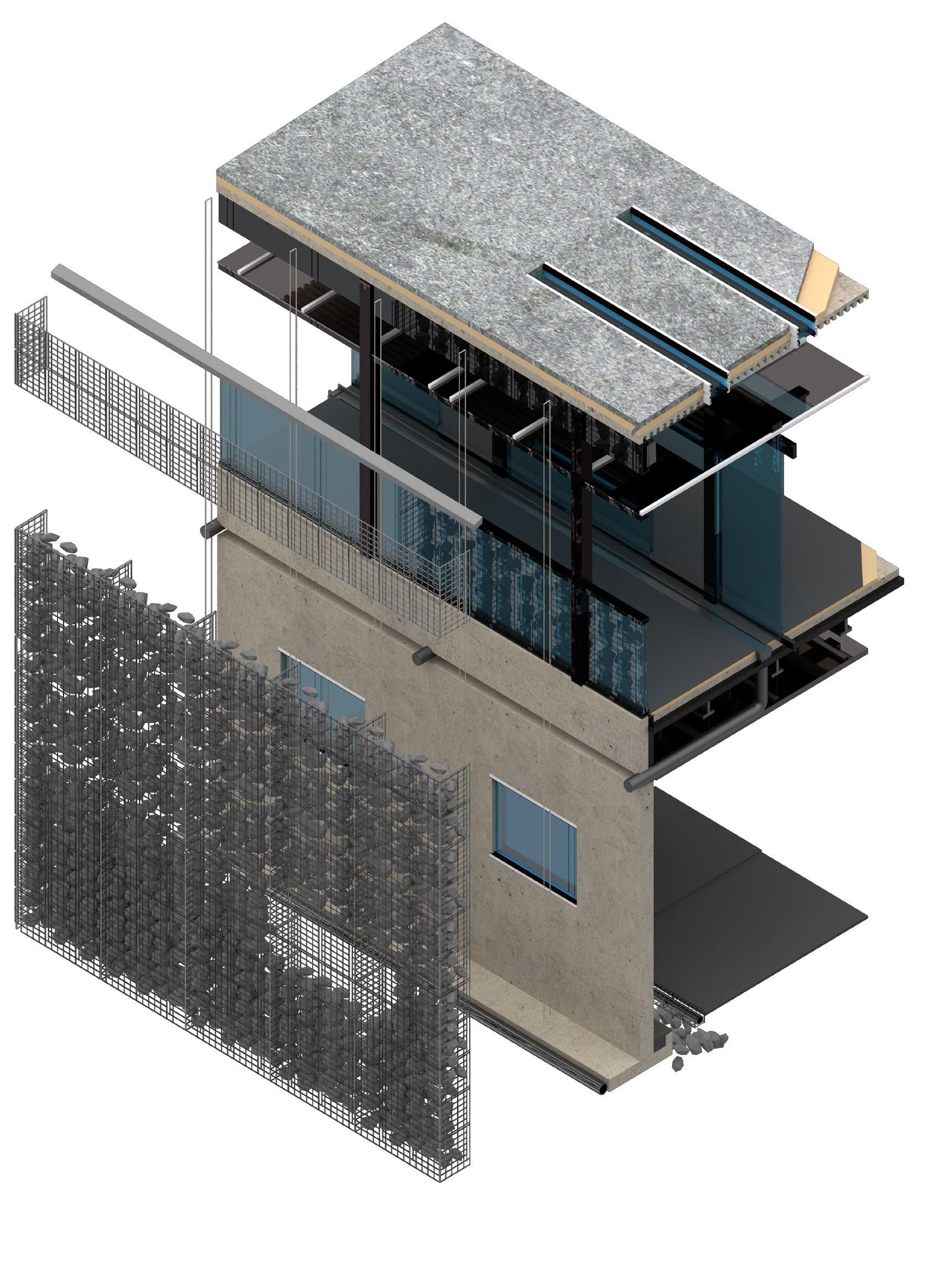

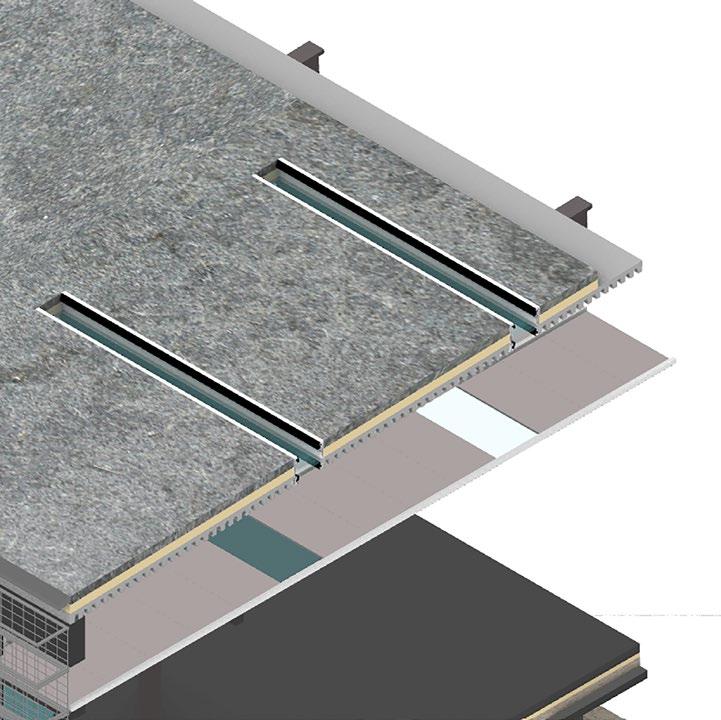

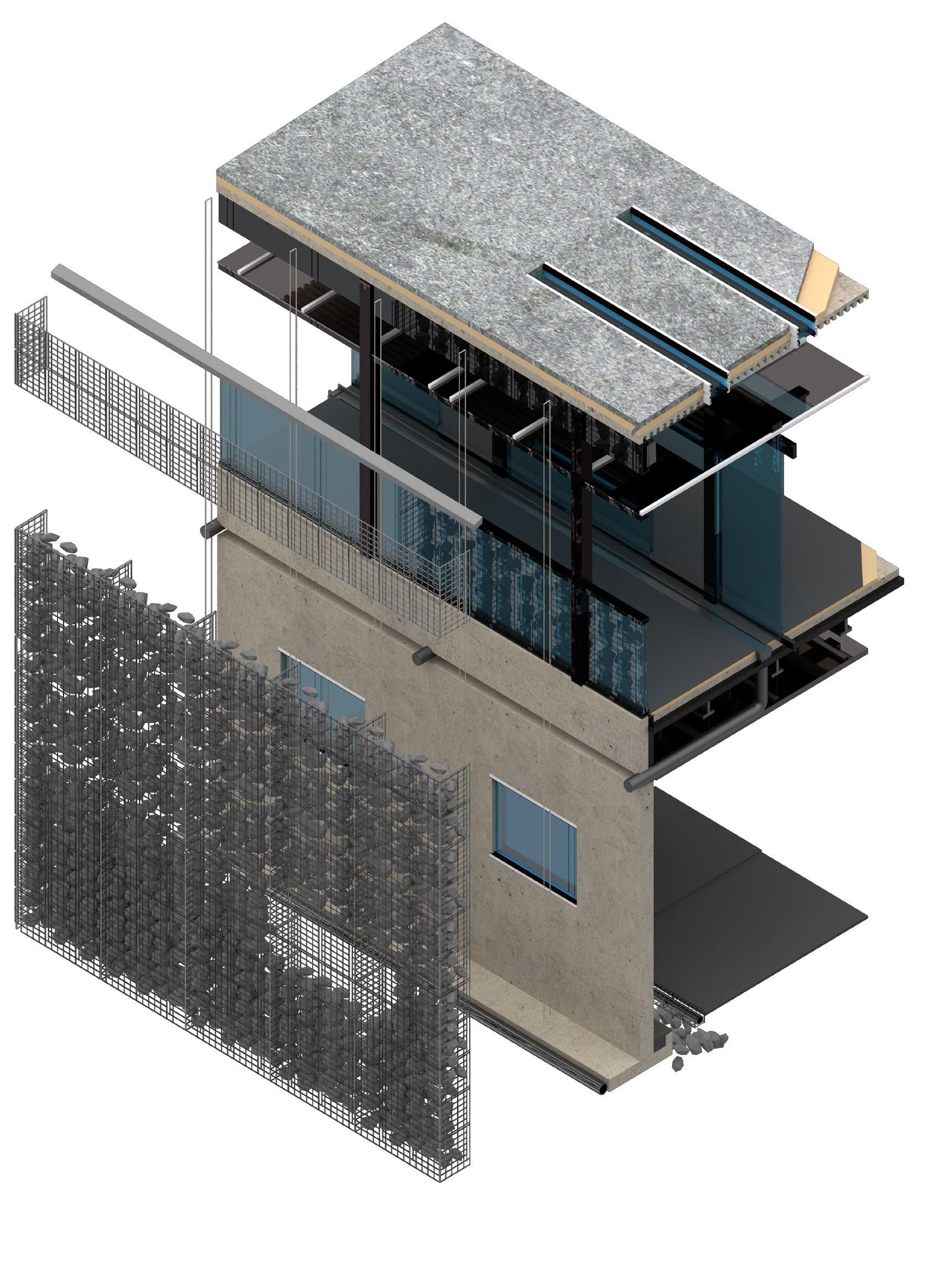

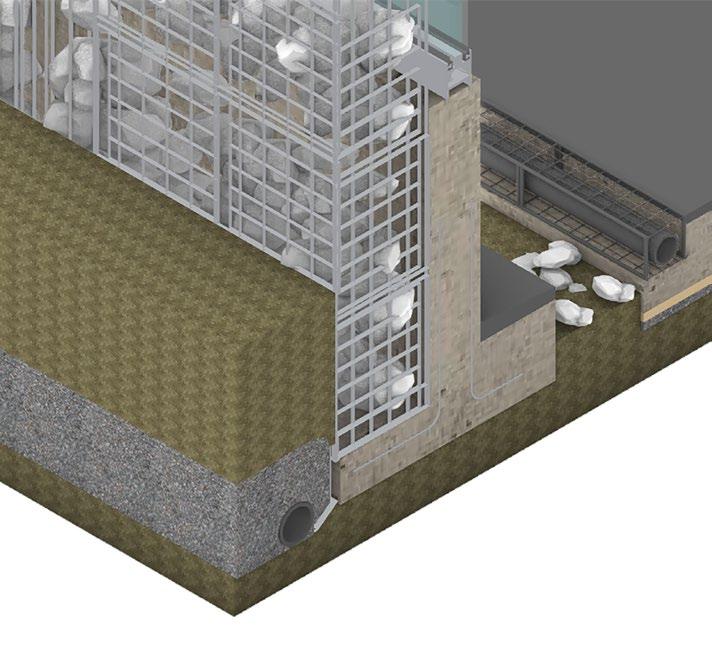

Gabion Foundations Lighting/Windows Gabion Opacity Rigid Insulation Aluminum Frame Gasket Roof Foundation Corrugated Steel Sheet Concrete Moisture Rebar Drip Sill Beam Drip Sill Flashing Gabions Steel Column Steel Tube Drainage Pipe Concrete Wall Steel Suspended Ceiling Vapor Barrier Foundational Slab Thermal Break Aluminum Framed Window 45' 22' Dominus Winery Flashing Shear Connection Drainage Pipe Steel Beam Gutter Steel Tubing Napa Valley, CA Glass Wall Steel Ceiling Panels Steel Roof Drainage Floor Drainage System Concrete

and De Meuron

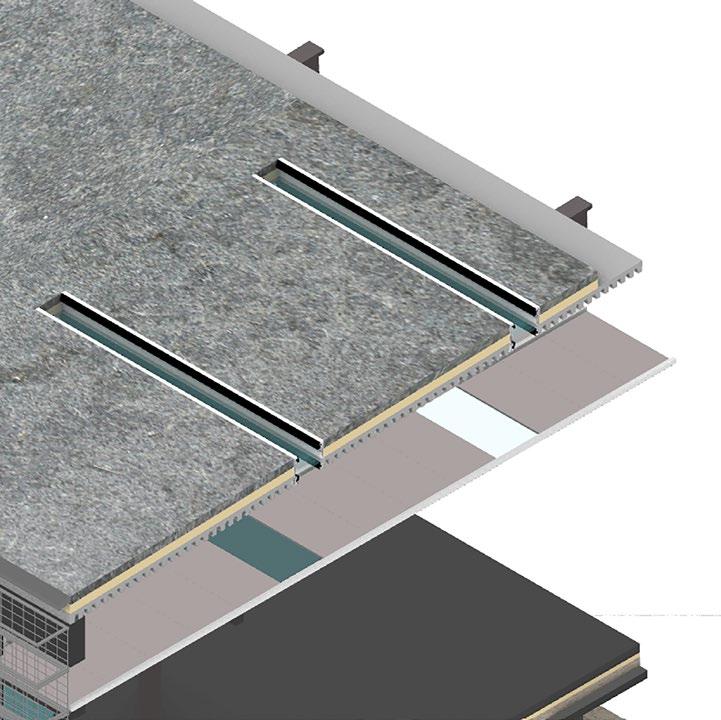

Detail Steel Column Steel Tube Steel Ceiling Panels Drainage Pipe Concrete Wall Suspended Ceiling Double Layer Thermal Glass Wall Drip Sill Aluminum Frame Corrugated Steel Sheet Concrete Basalt Ballast Layer Rigid Insulation Basalt Ballast Layer Rigid Insulation Concrete Corrugated Steel Deck Concrete Floor Slab Interior Drainage Pipe Gravel Grate Stones for Drainage Vapor Barrier Rigid Insulation Gabions Rebar Concrete Moisture Barrier Drainage Pipe Aluminum Framed Skylight Gasket Diffusion Panels Steel Ceiling Panels 1” = 1.5’ 1” = 1’ 1” = 1’ Roof Detail Roof Detail Foundation Details Corrugated Steel Sheet Concrete Basalt Ballast Layer Rigid Insulation Barrier Double Layer Thermal Glass Wall Concrete Floor Slab Interior Drainage Pipe Drip Sill Aluminum Frame Gravel Rigid Insulation Concrete Grate Vapor Barrier Gravel Pipe Vapor Barrier

Herzog

Napa Valley, CA DOMINUS WINERY Roof

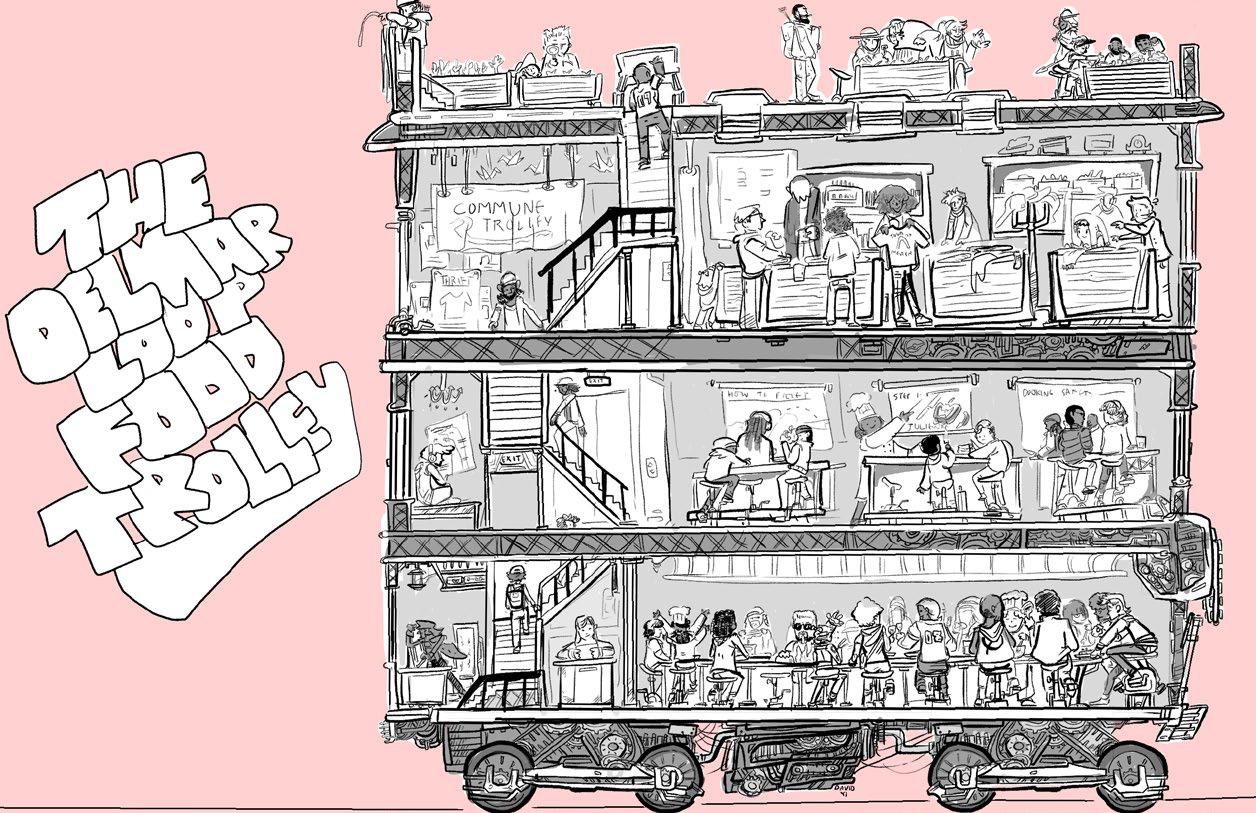

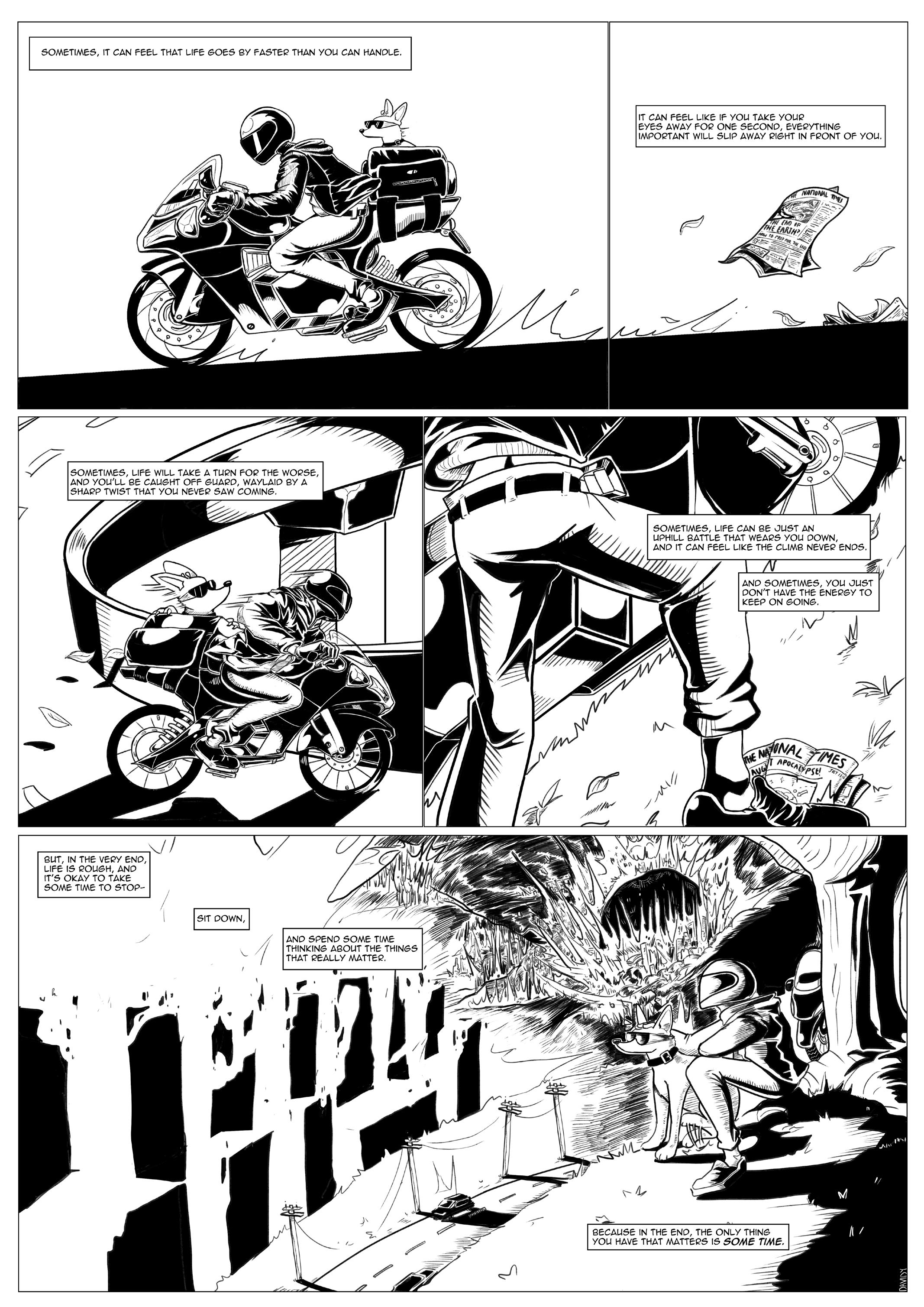

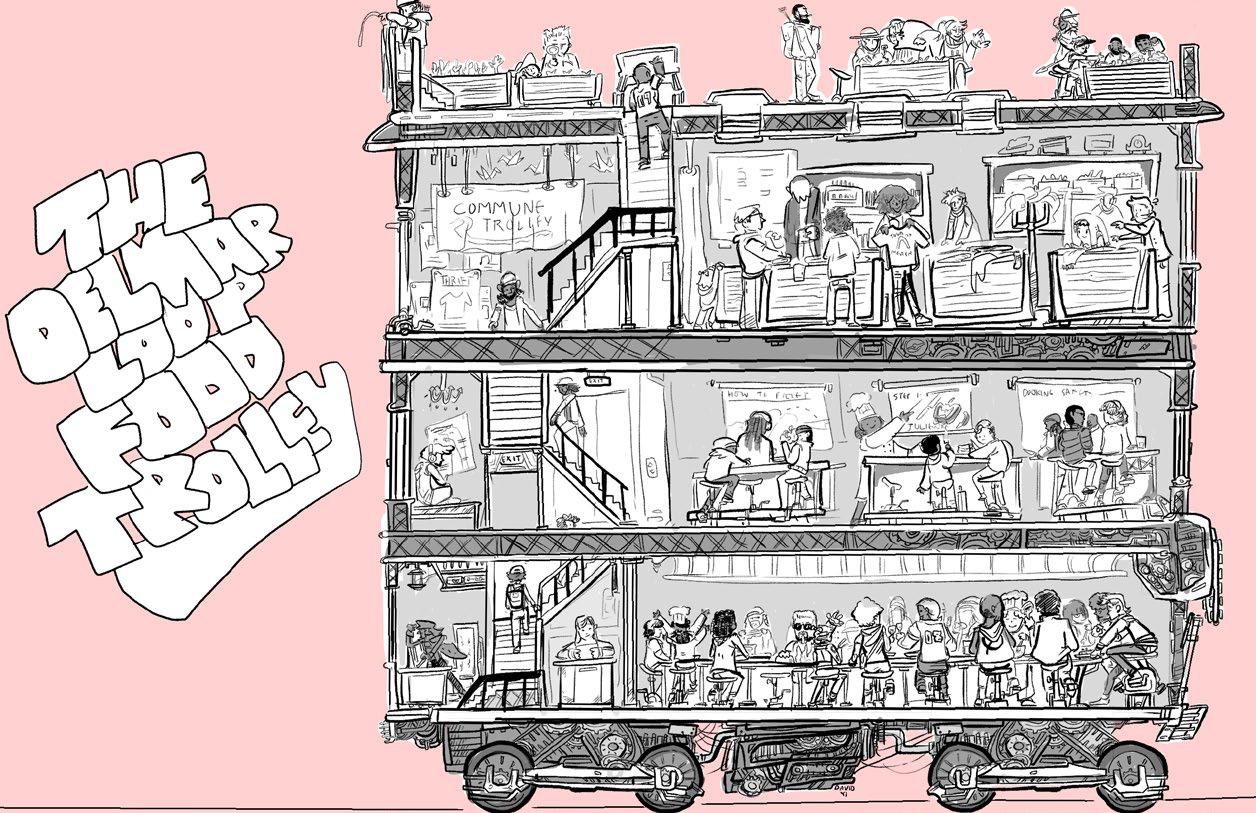

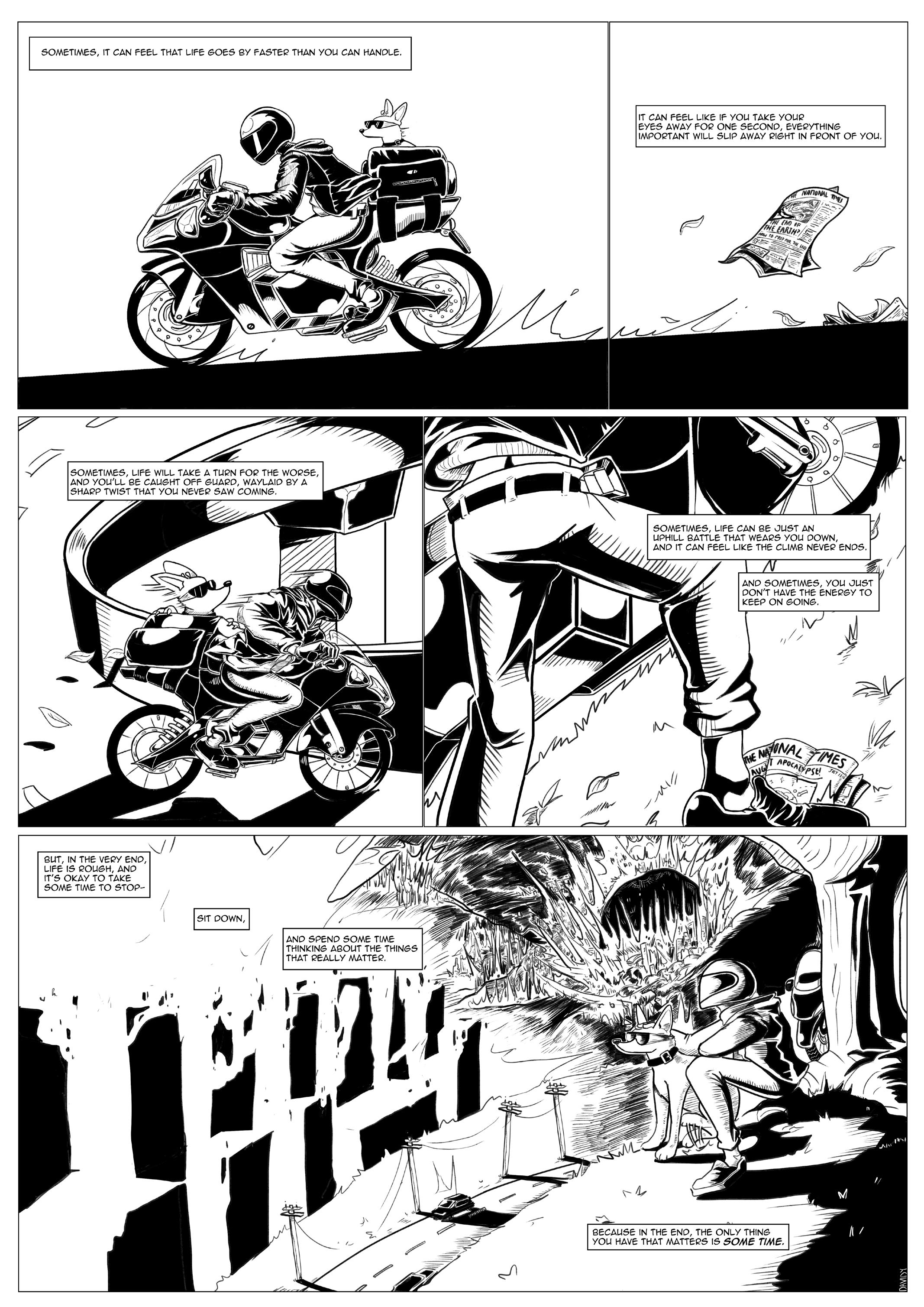

PERSONAL ILLUSTRATION WORK

DAVID YI (608)338-4257 itsdavid.yi@gmail.com

Top Left and Right: Details of the final factory, inspired by the physical model.

Bottom: Image of the physical model. Ange’s hand for scale.

Top Left and Right: Details of the final factory, inspired by the physical model.

Bottom: Image of the physical model. Ange’s hand for scale.

Above: The physical model, standing upright. 3d printed forms and metal structural work.

Above: The physical model, standing upright. 3d printed forms and metal structural work.

Above: The physical model of the factory, section view. Built mostly by hand using museum board, metal mesh, and plastic sheets.

Above: The physical model of the factory, section view. Built mostly by hand using museum board, metal mesh, and plastic sheets.

Top: Exterior render, with views of the Sun-Catcher.

Bottom: Exterior render of the civilian entrance, with anotherSun-Catcher in the background.

Top: Exterior render, with views of the Sun-Catcher.

Bottom: Exterior render of the civilian entrance, with anotherSun-Catcher in the background.

Top: The commercial entrance and loading port for the factory.

Bottom: Molten steel is poured from the blast furnace into a mold.

Top: The commercial entrance and loading port for the factory.

Bottom: Molten steel is poured from the blast furnace into a mold.

Top: The concrete blocks in a possible arrangement.

Bottom: The evolution of the concrete blocks throughout different casts. from left (earliest) to right (latest)

Top: The concrete blocks in a possible arrangement.

Bottom: The evolution of the concrete blocks throughout different casts. from left (earliest) to right (latest)

Top: Render of the Interior Gallery.

Bottom: Exterior Render, with the Envelope on Display.

Top: Render of the Interior Gallery.

Bottom: Exterior Render, with the Envelope on Display.

Above: The process of casting the wall. The molds were 3D printed, and held together using clamps. As each layer was cast, the molds were moved up another layer to complete the dome.

Above: The process of casting the wall. The molds were 3D printed, and held together using clamps. As each layer was cast, the molds were moved up another layer to complete the dome.

Above: The enclosure study’s final form. These were freestanding wedges of Ultra High Performance Concrete, measuring almost a foot high.

Above: The enclosure study’s final form. These were freestanding wedges of Ultra High Performance Concrete, measuring almost a foot high.

Above: The physical model of the house, opened up.

Right: A collection of renders (top) and model photos (bottom)

Above: The physical model of the house, opened up.

Right: A collection of renders (top) and model photos (bottom)

Top: Site. The location of the house was in Battlefield, MO, a rural suburb in Tornado Alley.

Bottom: Section views of the project, which is set in the ground for security.

Top: Site. The location of the house was in Battlefield, MO, a rural suburb in Tornado Alley.

Bottom: Section views of the project, which is set in the ground for security.

Top: Plan View of the Project. The concrete walls are curved and thick, for protection.

Bottom: Elevation views of the project.

Top: Plan View of the Project. The concrete walls are curved and thick, for protection.

Bottom: Elevation views of the project.

Right: Plan view of the Physical model, with the roof removed for a better look at the roof framing.

Right: Plan view of the Physical model, with the roof removed for a better look at the roof framing.