PASSENGER CAR TYRE RANGE

PASSENGER CAR TYRE RANGE

EXPERT ENGINEERING AT THE HEART OF

EVERY TYRE

Developed and manufactured using advanced technologies, Davanti’s passenger car tyre range has been designed to cater for smaller vehicles, ultra-high performance vehicles and SUVs, so whatever the drive, there is a Davanti tyre for every journey.

Each pattern features core design elements that work together to provide safe, quiet and efficient tyres, leaving drivers feeling confident and in control.

5 independent testing organisations 15 rigorous testing disciplines

THE SCIENCE OF INNOVATION

The enhanced silica compound and innovative tread patterns ensure a perfect balance of responsiveness and fuel efficiency.

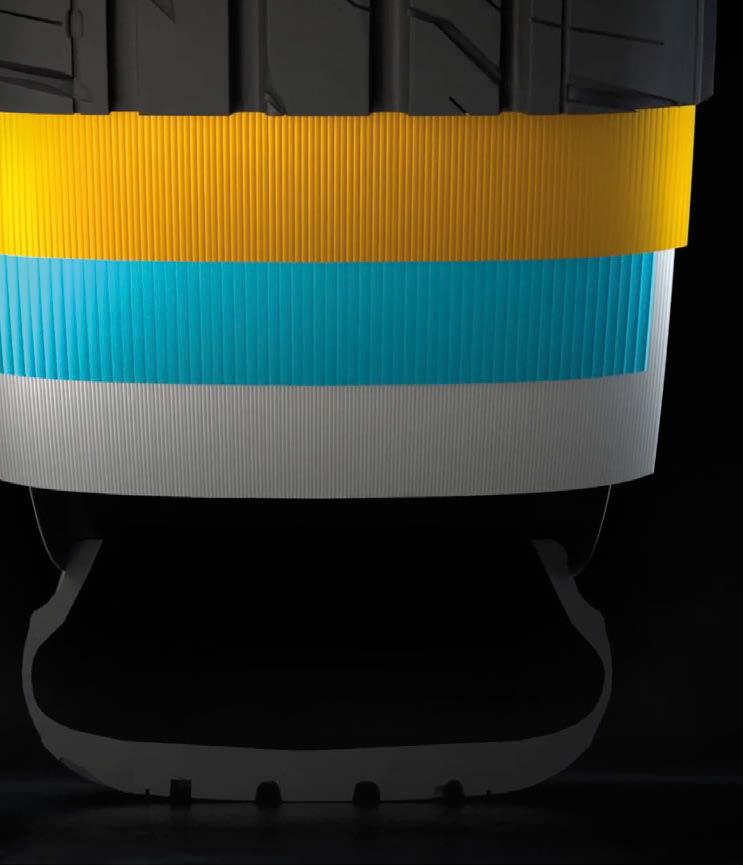

The extended rigid crown ply works together with flexible sidewalls to provide a consistent wear profile and maximise the contact area between tyre and road.

The solid central block design with inner block sections works dynamically, adapting the tyre performance throughout the tread wear and the life of the tyre.

INTEGRATED RIM PROTECTION

EXTENDED RIGID CROWN PLY

CONNECTED SHOULDER BLOCKS

Integrated rim protection ensures that the alloys don’t get damaged from everyday use.

Four wide circumferential grooves work to channel water away from the contact patch for optimal traction, reducing the risk of aquaplaning, while deep outer sipes maximise water dissipation and increase traction in wet conditions.

An enclosed outer groove delivers a more comfortable and quieter drive by reducing sound leakage from the side of the tyre, and the varying tread block size is randomly arranged to prevent unwanted repetitive frequencies.

Finally, large interconnected shoulder blocks allow the tyre to have consistent contact with the road.

RESPONSIVE SIDEWALLS

EFFICIENT EVACUATION

SOLID CENTRAL RIB DESIGN

ENCLOSED OUTER GROOVE

Ecoura HP1 is an efficiency-led, high performance asymmetric tyre for passenger cars.

Circumferential grooves facilitate efficient water evacuation, for high levels of wet grip and aquaplaning resistance.

Varying tread block pitch works to reduce noise by removing resonant frequencies, for a quieter, more comfortable drive.

Deep outer grooves work to maximise water dissipation and maximise traction in wet conditions.

Enclosed outer groove helps to contain noise and provide a more comfortable drive.

PATTERN TYPE: ASYMMETRIC

LOW NOISE PASSENGER CAR TYRE FOR SMALL VEHICLES

Designed for smaller passenger car applications, the DX240 provides exceptional wet and dry grip with high levels of straight line and cornering traction.

TYRE FEATURES

Three longitudinal grooves channel water away from the contact area and provide drainage channels for safe wet weather driving.

Inner shoulder area contains open sipes to disperse water in wet conditions, whilst the angular bend in the outer shoulder helps to contain noise and reduce resonance for a quiet drive.

The outer shoulder consists of a contained horizontal groove to actively contain sound and provide a progressive drive with high levels of grip when cornering.

PATTERN TYPE: ASYMMETRIC

The DX390 is a high performance asymmetric tyre for compact vehicles and smaller passenger cars. The dynamic design offers a responsive drive in all conditions.

TYRE FEATURES

Three main blocks feature a 3D design that dynamically changes performance as the tread depth decreases.

Varying tread block pitch and compartmentalising grooves work together to minimise and contain noise.

Flared block sections combine with a continual longitudinal band to provide excellent traction.

Integrated rim protection to prevent wheel damage.

Four wide and deep groove channels designed for optimal drainage and excellent handling in wet weather.

PATTERN TYPE: ASYMMETRIC

DYNAMICALLY DESIGNED CAR AND SUV TYRE FOR MAXIMUM GRIP AND ULTRA HIGH PERFORMANCE

Cutting edge tread design coupled with an advanced silica compound for optimum performance and a responsive drive.

Asymmetrically designed with a continuous outer band for advanced cornering grip and an inner tapered block design for wet weather traction.

Flared shoulder block layout with compartmentalised grooves actively contains noise and delivers a quiet drive.

Innovative block shapes vary with tread wear providing progressive performance throughout the tyre’s life.

Integrated rim protection to prevent wheel damage.

Four longitudinal grooves provide optimal water dissipation, enabling superior levels of wet grip.

PATTERN TYPE: ASYMMETRIC

OPTIMISED ASYMMETRIC

The DX740 offers the optimum balance of wet and dry grip for SUV applications.

Four longitudinal deep grooves run the circumference of the tyre to provide drainage from the road contact areas of the tread pattern.

The inner block section works in conjunction with the outer-inside block section to dissipate water out of the central grooves and away from the contact zone.

The outer block section contains U-shaped grooves which work to both contain noise dissipation and provide grip in muddy conditions.

PATTERN TYPE: ASYMMETRIC

TESTING DISCIPLINES

The range has been rigorously tested to ensure optimum safety, performance and guaranteed excellence.

A global leader in testing, certification and verification services across a wide range of manufacturing and engineering disciplines, including automotive.

EXCEPTIONAL MILEAGE

Committed to delivering exceptional mileage capability and outstanding performance at a low cost per mile, Davanti works with two of the industry’s leading testing organisations.

Davanti’s passenger car range has been evaluated by both DEKRA and IFV, giving drivers performance peace of mind.

A world-renowned automotive safety and evaluation organisation which operates in more than 60 countries worldwide. Its services include vehicle-manufacturer homologation testing, safety consultancy and product certification. It carries out open-road wear testing on a mix of motorway and standard roads to evaluate tread wear using laser mapping.

Home to the Davanti European Development Centre, Applus IDIADA boasts some of the best summer testing facilities in the world.

TREAD subjects tyres to the most extreme challenges, pushing them beyond their limits to establish quality of performance and resilience.

An independent testing organisation based in Lower Saxony, Germany, providing tyre wear evaluation for the world’s leading tyre manufacturers.

TESTING AND DEVELOPMENT HIGHLIGHTS

DRY BRAKING

This test involves driving a vehicle at 110km/h, then applying the brakes. The distance covered by the car between 100km/h and a complete stop is measured by ultraprecise GPS equipment.

DRY HANDLING

This is where the reaction to steering input, cornering and rear axle stability are evaluated. The test also assesses how tyres react to changes in direction and pace, the amount of steering lock required and for any loss of grip to be progressive.

WET HANDLING

This consists of objective and subjective tests. The objective test is a lap time of a wethandling circuit which takes into account the tyre’s ability to transfer the car’s power to the road, and the amount of control the driver has. The subjective test gives more insight into the tyre’s performance specifically focusing on the driving experience and assessing its safe, predictable handling and effortless road performance.

WET BRAKING

A vehicle is driven at 110km/h onto a heavily-watered section of track, then the brakes are applied. The distance covered by the car between 110km/h and a complete stop is measured by ultra-precise GPS equipment.

LONGITUDINAL AQUAPLANING

Using GPS and precision-recording equipment, aquaplaning resistance is measured when the driven front wheel speed is 15% faster than the speed the vehicle is actually travelling at. The higher the speed, the better the tyre is at preventing aquaplaning.