Plastic Free Packaging Design Guide

g.co/Hardware/PackagingGuide

Tableof contents

Foreword ➜

Thechallenge ➜

Replacingplasticcomponents ➜

Coatingsolutions

Shrinkwrapremoval

Closurelabels

Papertapes

Hangtabs

Protectiveproductwraps

Inboxtrays

Structuraldesign ➜

Thepowerofcollaboration ➜

Glossaryofterms ➜

Plasticfreemateriallibrary ➜

Acknowledgments ➜

Endnotes ➜

Foreword thinking

AtGoogle,ourmissionistoorganizetheworld's informationandmakeituniversallyaccessibleand useful.Webelieveinthepowerofknowledgeand arecommittedtosharingitinwaysthatpositively impactpeopleandtheplanet.

Manycompanieshavedesignedandengineeredsustainable solutionsfortheirproductsandserviceswithimpressive resultsandwethinkit'simperativethatallcompaniesdothis. Wealsorecognizethatthechallengesinbuildingamore sustainablefuturearenumerousanddifficult.Ifallcompanies havetosolvesimilarproblemsindependently,thenour collectiveprogresswillbeslower.

That’swhywebelieveinnovationinsustainabilityshould beacollaborativeendeavor,notacompetitiveone.Inthat spirit,we’resharingmorethansimplywhatwe’veachieved,but alsohowweachievedit.We’veparticipatedinmanyindustry collaborations,butwe’regoingfurtherandopenlypublishing whatwe’velearnedforotherstouse,startingwithourproduct packagingwork.It’sourgoaltoenableorganizationswith similarambitionsandengageotherstoimprovethesolutions we’resharing.Wealsohopeothercompanieswillbeinspiredto sharetheirinsights,amplifytheirimpactandultimatelybring aboutthechangewecollectivelywant.

0.3 Our journey

Productpackagingtraditionallyreliesheavilyonmixed materialformats,particularlythoseincorporatingplastic. Thisposesasignificantrecyclingchallengeandcreatesa significantwastestreamifitisn’tacceptedforrecycling.

Inresponse,Googlehasresearchedsolutionsthatprioritize bothsustainabilityandperformance.Thisguidedocuments ourjourneytoeliminateplasticsandtransitionourpackaging topredominantlyfiber-basedmaterialsforourconsumer electronicsproducts.Wehopethisguideservesasaresource forothersaimingtoreducetheirrelianceonmixedmaterial formatsandadoptfiberbasedsolutions.

Throughextensivematerialexploration,designoptimization, andrigoroustesting,we'veidentifiedviablealternativestoplastic thataddresskeypackagingelements.Thisguideofferspractical guidanceandmaterialinsightsforproductdesigners,packaging engineers,andsustainabilityleadersacrossindustries.By sharingourlearningsandcollaboratingwithothers,wehope toacceleratethetransitiontomoresustainablepackagingina waythatalignsinnovationwithenvironmentalresponsibility.

MeettheGoogleteam

Designguideauthorsandcontributors

Francesca DelleCese

Packaging Design Engineer Manager

YangXiang PhD

Packaging Materials Engineer

Nathan Gassmann Lead for Circular Economy

David Bourne Lead for Environmental Strategy

Rob Cook

Packaging Design Engineer Lead

Miguel Arevalo

Packaging

Sustainability Lead

Cole Hermann

Structural Packaging Design, Innovation Lead

Robert Little

Sustainability Strategy Lead Recyclability SME

Charlie Hutchinson

Structural Packaging Design, Innovation Lead

Abhinav Jha

Global Supply Chain Manager

Section 1.0

Thechallenge ofplasticin packaging

Inthissection

Confrontingtheubiquityofplastic ➜

Google’sguidingprinciples ➜

Keymaterialsinpackaging ➜

Fiber:Anemergingsolution ➜

Confronting theubiquity ofplastic

Plasticisn’taninherentlyunsustainablematerial andhasactuallyrevolutionizedthepackagingindustry. Itsbarrierpropertiesextendproductshelflife,especiallyfor perishableproductslikefood.Itslowweightreducestransportation costsandcarbonemissionscomparedtoheaviermaterialslikeglass. Plastic’sversatilityhasallowedforawidevarietyofapplicationsin packaging,leadingtoamultitudeofmixedmaterialpackaging formatsinthepackagingindustry.

The world’s plastic pollution crisis, explained National Geographic, 2024

Howeveritsubiquityinpackaging,particularlycomplexpackaging, hascreatedahighvolumeofmixedmaterialwastethatisdifficult torecycle.1Consumerconfusionaroundpackagingrecyclabilityis widespreadandoftenresultsinimproperdisposal.Largevolumes ofplasticpackagingoftenendupinlandfills,waterways,and oceansharmingecosystemsandwildlifeasitslowlydegrades intomicroplastics.It'sasignificantthreattotheenvironmentand ultimatelyourhealth.Theplasticpollutioncrisisdemandsa fundamentalshiftinhowwedesign,produce,useanddisposeof plastic.It’samajorchallenge,butonethatcanbeaddressed.

Recognizing anurgentneed

Organizationsacrossallsectorsareincreasingly seekingwaystoreducetheirpackagingwaste footprintandsoareconsumers.

“Avoidingproductswhichhavealotofpackaging”2isthenumber oneactionpeopleworldwidearetakingoutofconcernforthe environment.Wehopethisguideservesasapracticaltooltohelp organizationsmakefasterdecisionsanddesignmorerecyclable packagingsolutions.Itoffersactionabletips,designinsights andexamplesforproductdesigners,packagingengineers,and sustainabilitypractitionerscommittedtominimizingplastic wasteandmaximizingfiber-basedpackagingrecyclability.

3

Earth Day 2022

2 Per ISO 0472-2013

National Geographic, 2024

Plastic, noun. Material which contains as an essential ingredient a high polymer and which, at some stage in its processing into finished products, can be shaped by flow.

4

Note 1 to entry: Elastomeric materials, which are also shaped by flow, are not considered to be plastics.

Googlerecognizestheurgentneedforpackagingsolutions thataremoreeasilyrecycled.Forourconsumerelectronics packaging,we’vemadeastrategicshiftawayfromplasticsused inmixed-materialformats.Theseformatscomplicaterecycling effortsforconsumersandmaterialrecoveryfacilitiesalike.For theconsumer,decidingwhichpackagingpartscanberecycled andseparatingthemisconfusinganddetractsfromanotherwise delightfulproductunboxingexperience. InOctober2020wemade acommitmentthatby2025allofourconsumerelectronics packagingwillbe100%plastic-free.

Inoureffortstoremoveplastics,we’veadoptedtheISO4723 definitionofplastics:“amaterialwhichcontainsasanessential ingredientahighpolymerandwhich,atsomestageinits processingintofinishedproducts,canbeshapedbyflow.”This definitionexcludesmaterialslikeadhesivesandinks.4Evenfor thesehowever,weconductrepulpabilityandrecyclabilitytesting toensurethatGooglepackagingmaterialscanbewidelyrecycled.

Thesearefundamentaltoourapproach.

Sustainablepackagingcannotcompromisea product'sintegrity. Replacingdamagedproducts

Keymaterials intheworld ofpackaging

Plastics Plasticalternatives

PPlamination

Aplasticfilmlaminatedtopaperboard, enhancingtensilestrength,abrasion resistanceandmoistureprotection.Itis difficulttoseparateinrecyclingprocesses.

Shrinkwrap

Aversatilefilmusedtobundleandprotect packagingandcreatetamperevidence. Itslowmaterialvalueforrecyclingand tendencytocontaminaterecycling streamsoftenleadstolandfilldisposal.

Plasticwrapsforproducts

Whileofferingproductprotection, traditionalplasticfilmsoftenlack economicallyviablerecyclingoptions andendupinlandfills.

Moldedfiber

Arenewableandrecyclablealternative toplastictrays,engineeredwithcushioningpropertiesforsuperiorproduct protectionduringtransitandhandling.

Greyboard

Arobustmaterialmadefromrecycled content,offeringstructuralrigidityand impactresistancetoprotectproduct duringshippingandhandlingwhile maintainingapremiumappearance.

Corrugatedpaper

Asturdyandeconomicalmaterialmade offlutedpapersandwichedbetween twoliners.Itoffersexcellentcushioning andprotectionforproductsduring shippingandhandling.

Fiber Anemerging solution

Theshifttowardfiber-based packagingisgainingmomentum.

Materialslikepaperandcardboardoffera compellingalternativetoconventionalplastics; theyarerenewablebutcanalsobemadefrom recycledcontent.Theybreakdowneasilyand integrateintothevastmajorityofexisting consumer-facingrecyclingsystems.

Whilethistransitionpresentsopportunities, italsointroduceschallenges.Fiber-based solutionsmustmeetthefunctionalrequirementsforproductpackaging,particularly theprotectivepropertiesthatpreviously madeplasticsopopular.Thisnecessitates newdesigns,materials,productionmethods, andsupplychainadaptations.

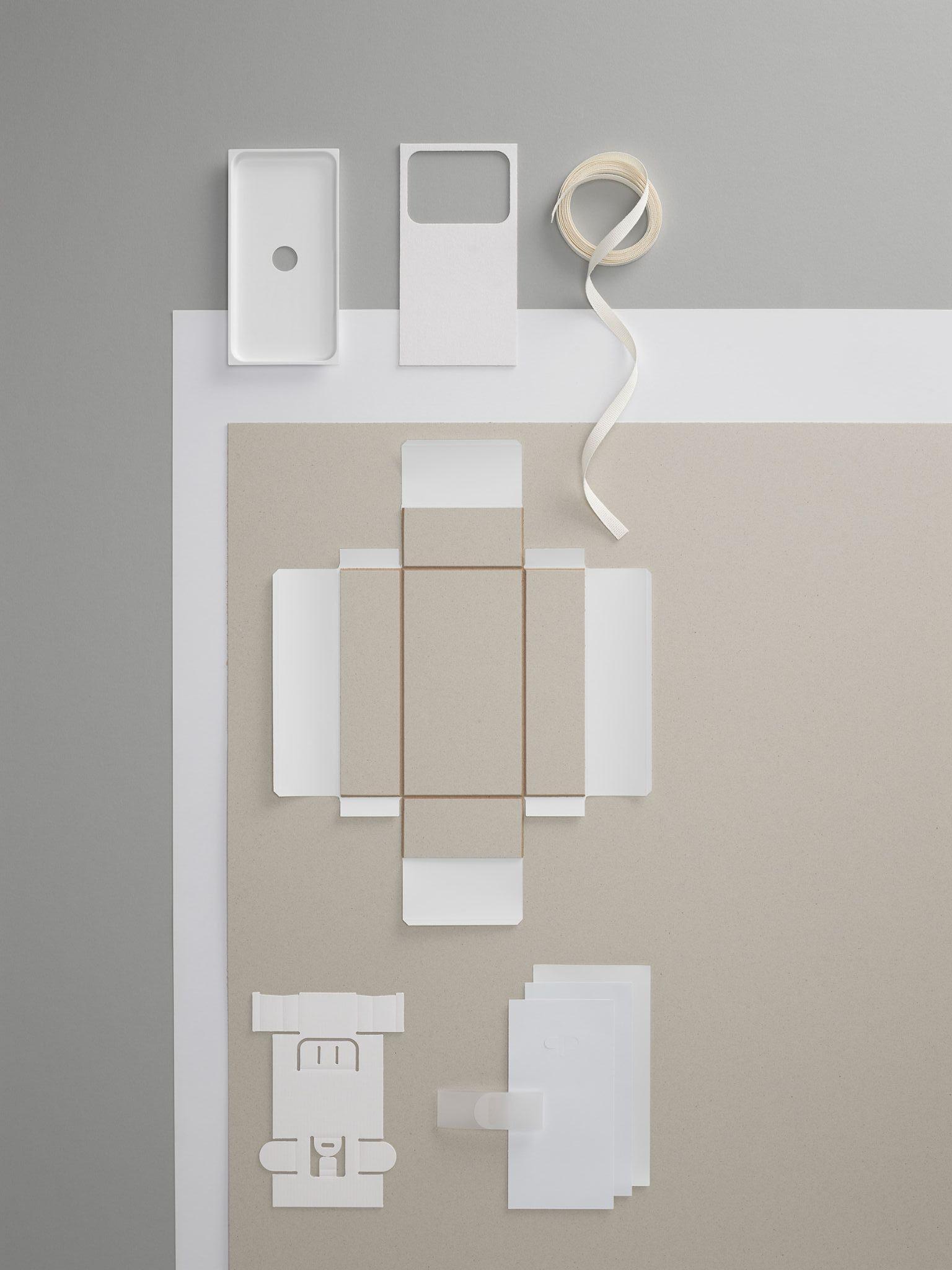

Above: A fiber-based unglued packaging set

Replacing plastic components

Inthissection

Coatingsolutions ➜

Shrinkwrapremoval ➜

Paper-basedclosurelabels ➜

Papertapes ➜

Moldedfiberhangtabs ➜

Protectiveproductwraps ➜

Moldedfibertrays ➜

Let’sget started

Wewanttoshareinsightsintothe challenges,considerations,and innovativebreakthroughsthatpave thewayforplastic-freepackaging intheconsumerelectronicssector.

Transitioningtoplastic-freepackaging,and movingawayfrommixedmaterialpackaging formatsdemandsarethinkingoftraditional components.Achievingthenecessaryproduct protection,accessibility,aestheticappeal, andresponsibledisposal–allwhilemanaging costs–requiredexpansivematerialexploration

Googleiscommittedtothistransformation, activelyseekingsustainablesolutionswithout

Whatwe’ll address

Let’sdiveintothecomplexitiesof replacingseveralcommonplastic componentswithinourpackaging.

Foreachcomponent,we'llshareanoverview ofourfiber-basedsolution,theperformance testingconducted,andtheresultsthat validatedourchoices.

Coatingsolutions ➜

Alternativestoplastic laminationsthatprovide protectionandvisualappeal.

Closurelabels

Solutionsthatensure tamper-evidentsecurityand offeraccessibilityfeatures.

Moldedfiberhangtabs

Shrinkwrapremoval ➜

Strategiestoeffectivelysafeguard retailboxgraphicsduringshipping withoutplasticshrinkwrap.

Balancingstrength withuser-friendlydesign forproductdisplay.

Moldedfibertrays ➜

Theshifttomoldedfiber traysfromthermoformed plasticandthedesign optimizationsrequired.

Papertapes ➜

Assemblysolutionsthat maintainstructuralintegrity withoutplastictapes.

Protectiveproductwraps

Materialsthatprotect sensitiveproductsurfaces andarecompatiblewith recyclingprocesses.

Coating solutions Challenge

* * * * * * * * * * * * *

Coatedanduncoatedpolypropylene(PP) filmsarecommonlyusedinpackaging. Itspopularitystemsfromitsprotectivequalities. However,whenlaminatedtopaper-basedpackaging, itcreatessignificantchallengesforrecycling.

“Thequestforarecyclable coatingwasabalancing act.Weneededtomaintain theprotectivequalitiesof PPfilmwhileensuringit wouldn’tdisruptthepaper recyclingprocess.Itwasa challenge,butonethat pushedustoinnovate.”

- Francesca

Shown:

Pixel 6 Pro packaging, Fall 2021

Coatingsolutions

Laminationisaprocessthatbonds multiplematerialstoformastronger, morefunctionalcomposite.InolderGoogle packagingdesigns,awater-basedadhesive wasusedtobindPPfilmtoprintedpaper.

PPlaminationhasseveraladvantages:

● Structuralstrengthreinforces thepaper,providingadditionaltensile strengthtopreventtearsanddamage

● Scuffing/scratchresistance

● Moistureprotection

● Visualappealwithaglossyormattefinish

Unfortunately,PPlaminatedpackaging disruptspaperrecyclingstreams.Duringthe pulpingprocess,theplasticfilmdoesnotbreak downlikepaperfibers.Instead,itmustbe screenedout,ultimatelycontributingtolandfill wasteandreducingrecyclingyields.Large piecesofPPfilmfloattothetopofeachrecycling batchwhilesmallpiecesarecontinuously strainedoutbysizewithapressuredscreen andbydensitywithcyclonecleaning.

Dependingonthesizeandthecollection system,theremainsmaynotberecycledand couldbelandfilled.Replacingplasticlaminations withcoatingsthatarecompatiblewithpaper recyclingiscrucialtothisgoal.However,we recognizethatevenwithcoatings,maximizing fiberyieldduringrecyclingisessential.

Above:

Plastic film removed / separated in mill's hydrapuller (repulping) system.

Coatingsolutions

WecollaboratedwithWesternMichigan University(WMU),leveragingtheirexpertise atthePaperPilotPlant,tocertifyrecyclabilityfor ourcoating,varnish,ink,andpapercombinations. TheFibreBoxboardAssociationtestprotocolfor waxreplacementcorrugatedcontainersguided thisprocess.

Thecertificationprotocol involvestwodistinctphases.

One:Labscaletesting

● Testingrepulpabilitytoensurematerial breaksdownforaminimum80%yield withoutoperationalissue.

● Testingdeinkability(ISO21993:2020/INGEDE Method11)totestremovingcoatingsorinks inthepaperrecyclingprocess.

● Testingforthepresenceof“stickies”which arepapercontaminantsclassifiedastacky e.g.waxes,coatings,andsoftadhesives.

Two:Pilotscaletesting

● Simulatesreal-worldconditions: Minimum200lboftestmaterialis processedalongsidecontrolpaperstock.

● Comprehensivescore: Evaluatesoperationalimpact,yield,color, strength,andstickinessofrecycledfibers.

Upper left: Waring blender

Upper right: British disintegrator (deflaking)

Bottom left: Screening (accepts)

Bottom right: Screening (rejected material)

Coatingsolutions

OurPPlamination-freesolutionswereextensively testedandsuccessfullymetouroperational andoptical/mechanicalperformancecriteria.

Thistestingincludedrunningrecycledpulpsfrom Google’snewplastic-freeprintedpackagingdesigns alongsideunprintedpaperstockandouroriginalPP laminatedsolutionforcomparisonpurposes.While bothMegamivarnishandActegacoatingpassed therecyclabilitytestandmetourperformance requirements,wehavedeprecatedtheActega coatingsolutionduetosomemanufacturingchallengesthatourteamisactivelyworkingtoresolve.

TheMegamivarnishhasbeensuccessfully implementedatscale.Detailsonthesescalable solutionscanbefoundinourMaterialLibrary.

Ascollectionandrecyclinginfrastructurefor fiber-basedpackagingchanges,designmodifications andcollaborationwithproducerresponsibility organizationswillbeimportanttoensurehigh acceptancerates.Ourintentionistounderstandthe criteriaandassessmentmethodsbeingdeveloped andoptimizeourpackagingsolutionsforseamless integrationintoevolvingrecyclingstreams.

Above: Fiber accepts after screening during repulpability test

Coatingsolutions

Ourcoating qualificationprocess

Whilequalificationneedswillvarygreatlyby companyandproductneeds,belowisGoogle’s processtoensureoursuppliersdeliver consistent,high-qualitycoatings.

Weemploya6-phasequalificationplan emphasizingcompatibility,printexcellence, real-worldperformance,andacommitment tocontinuousimprovement.

Initialvetting

● TechnicalDataSheets(TDS)andMaterial SafetyDataSheets(MSDS)reviewto verifyalignmentwithoursafetyand environmentalstandards.

● Coatingandinkvendorscompatibilitytesting, particularlyforspecializedprintneeds.

● CriticaltoQuality(CTQ):Earlyscuffing andbendresistancedataasprimary indicatorsofperformance.

● Sustainability:Repulpability,recyclability, anddeinkabilitytestsaligningwithour environmentalgoals.

Printingexcellence

● G7colormanagementfor consistentcolorreproduction.

● Quantifiablecosmeticstandard toassessdefectswithvariable tolerancesbasedonvisibility.

Phase1

Phase2

Panelslessthan200mmx200mm

Coatingsolutions

In-depthtestingforabrasion resistance,foldcracking,alcohol andwaterresistance,andadhesion.

Contractmanufacturertest

Fullassemblysimulationatourpacking linesidentifiespotentialcosmeticissues andassessescompatibilitywithlabels anddownstreamprocesses.

Monitoringforpotentialassemblyissues likedebosscrackingorcornerbunching, optimizesproductionsetup.

Reliabilitytesting

Comprehensivevibration,drop, environmental,andcosmetictesting ensuresthecoatingwithstandssupply chainanduserconditions.

Phase6

Phase3

Phase4

Coatingsolutions

Opportunities forimprovement

Improvingdeinkability:

Exploringink/coatingpairingsthat furtherminimizeinkresidualsafter recyclingcouldyieldevenhigher qualityrecycledfibers.

Shown:

Inkresidualspotsofdeinkedpulps.

S1:MegamiUVinks+PPlam

S2:MegamiUVinks+Megamivarnish

Fold/scoreprotection:

Wecontinuetoresearchcoatings withevengreaterflexibilitytoprevent artworkdamageduringfoldingwhile maintainingrecyclability,ensuringa flawlesspresentationfromproduction totheend-user.

Coatingsolutions

Keyinsights

1

Ourjourneytoreplaceplasticlamination withcoatingstaughtusvaluablelessons aboutmaterialinteractions,printquality, andsupplychainmanagement.Here'salook atsomekeyinsightswe’vegainedsofar:

Ourfinalcoatingchoiceexhibitedcomparable abrasionandfold/scorecrackingresistanceto thePPlaminate,ensuringartworkprotection. Italsopreservedcosmeticperformanceand visualappealessentialtoourbrandstandards.

● Strongadhesivesusedonclosurelabelsmeant toensuretamper-evidencecoulddamagethe boxsurfaceuponremovalandcompromise productpresentation.Wetestedmanytofind optionsthatwouldavoiddamagewithour coatingsolution.

● High-tackUVoffsetinks,whileessentialfor coatingadhesion,couldcausepaperpickingif papersurfacestrengthisinsufficient.Wetested papersourcesandestablishedsurfacestrength benchmarks(waxpickmethod)of13+forcoated gradesand18+foruncoatedgrades.

● UVoffsetinkshaveanarrowerprocess windowforfountainsolution-inkbalancewhen comparedtoconventionaloffsetinks.IfUVinks areemulsifiedexcessivelybythefountain solution,itcanleadtoirregulardotshapes. Weproactivelyoptimizedfountain-inkbalance duringprinting,minimizingfountainsolution andensuringoptimaldotquality.

Above: Dot quality comparison between print runs to evaluate dot gain/shape

Coatingsolutions

2

Keyinsights

Storageconditionsandpre-mixing proceduresforcoatingmaterials cansignificantlyimpactcoating performanceandmachineefficiency.

Real-worldshelf-lifeforacoating materialisdeterminedbytheunique coatingformulationandmaydiffer fromthetechnicaldatasheetsof individualchemicalsintheformulation. Wedevelopedspecificoperational requirementstomanagetheshelflife ofourspecificformulation.

● Whentestingvariouscoating solutionsinalarge-scalestressbuild, wediscoveredthatmachinecleaning requirementscoulddisruptproduction. Weeliminatedoptionsrequiringmore frequentcleaningtoavoidcostly productionproblems.

● Wepartneredwithourvendors toenableproductionscalability andconsistentsupplyofsustainable packagingsolutions.Thiscollaboration reducedtheinitialinvestmentneeded fordevelopmentandtesting.These solutionsarenowreadilyaccessible forusebyotherbrandswithdetails availablethroughourmaterialvendors.

Printing press: Manroland R700

Shrinkwrap removal

Plasticshrinkwrap,whileversatile, posessignificantrecyclingchallenges.

It’sdifficulttoeffectivelyseparatefromother materialsinrecyclingsystems,offerslimited valueforrecyclers,andultimatelyhasahigh chanceoflandfilldisposal.

Challenge

“Shrinkwrapwasbeenan industrystandardwayto createtamperevidenceand closure,butindesigninga morerecyclablealternative Ithinkwecreatedaneven betterunboxing experience.”

- Charlie

Shrinkwrapremoval

Ourapproach

Toreplaceshrinkwrap,wemadeseveralkey packagingdesignchangestomaintainproduct protection,tamper-evidence,andapremium aestheticwithoutcompromisingour sustainabilitygoals:

● UVprotectivecoatingssafeguard packagingartworkfromabrasion.

● Specializedadhesivesforfiber-basedclosure labelsprovideastrong,tamper-evidentseal. Closurelabelswerenotpreviouslyneeded withshrinkwrappedproducts.

● Structuraldesignrevisionsonallboxstyles compensateforthelossoftensilestrength thatshrinkwrapprovided.

Successcriteriaandtesting

● Ourpackagingundergoesextensivereliability testing,includingvibration,drop,environmental exposure,andcompressionsimulations.This ensuresthatconsumersreceiveproductsin pristinecondition,evenwithoutshrinkwrap.

● Cosmeticperformanceisevaluatedthrough rub/abrasiontestsandsupplychainsimulations. Theseguaranteethepackagemaintainsitsvisual appealthroughoutitsjourney.

● Recyclability(repulpability,deinkability,etc) testingensuresourpackaginghasimproved compatibilitywithpaperrecyclingsystems.

Shrinkwrapremoval

Keyinsights

Structuralevolution forplasticremoval

TheRollEndLockFront(RELF)boxstyleposes uniquechallengeswheneliminatingshrinkwrap differentfromthosefortelescopingboxesand tuck-endcartons.Thissectionfocuseson considerationsforRELFandcorrugatedboxes, highlightingstrategiestomaintainboth structuralintegrityandvisualappealwithout plasticwraps.

Topsheetappearance

Toachieveapremiumunboxingexperience, we’veprioritizedahigh-qualitytopsheetfor corrugatedstructures.Thisensuresasmooth, visuallyappealingsurfacewhileminimizingthe prominenceofcorrugatedribs.Additionally, usingF-flutecorrugatedmaterialreducesrib visibilityandcanbebalancedwithother structuralandcostrequirements.

Foranevenmorepolishedpresentationwhen theboxisopened,acolor-matchedinsideliner canfurthermasktheribs.Theserefinementsare especiallyimportantwhenshrinkwrapis removed,astheymaximizeabrasionresistance andmaintainahigh-qualityappearance throughoutdistributionandon-shelfdisplay.

Insideliner

Topsheet

Shrinkwrapremoval

Shrinkwrap,whilecreatingaunifiedpackage, canmaskpotentialstructuralweaknesses. Withoutit,it'svitaltoensurethatlargepanel elements,particularlythelid,maintaintheir integritytoprotecttheproductandpreservea pristineappearancethroughoutthesupply chain.Herearefourkeystrategies:

Maintainlidintegrity

1:Lidstiffeners

Droptestingmayrevealbowingorstressmarks ontheRELFboxlid.Ifthatoccurs,it'sessential toaddastiffeningelement.Greyboard,a recyclableoptionmadefromrecycledmaterial, iseffectivewhenstartingat1mmthickness.

2:Moldedfiberversatility

Ifamoldedfibertrayisalreadypartofthe designforproductsupport,itsflangecanbe extendedtoimprovelidstiffness.Insome scenariosamodestflangeextensionis sufficient,howeverextendingittotheentirelid mayfurtherincreasesupport.

Thevisualontherightdemonstrateshowa shortflangecanbeadheredinsidethelid(lower image)tohideitinthefinalassembly.

Shown: Flange extends into lid for structural support

Shrinkwrapremoval

3:Shipperadjustment

Tominimizeabrasionandmaintainthe pristinepresentationoftheretailbox,we fliptheorientationofthecorrugated shipper'sliner.Thisensuresthesmoother, thickerkraftpaperfacesinward,in contactwiththefinishedboxsurface, ratherthantheexposedcorrugatedribs.

4:Gentleprotection

Tissueorkraftpaperbuffer: Whennecessarytofurtherminimize abrasion,athinlayeroftissueorkraft papercanbeinsertedbetweenretail boxeswithinthecorrugatedshipper.This createsagentlebarrier,preservingthe pristinepackagingsurface,while remainingcompatiblewithpaper recyclingstreams.

Corrugated ribsfacingout

Topsheet facingin

Closure labels

Closurelabelsareapracticalandversatile solutionformaintainingproductintegrity.

Byprioritizingpaper-basedlabels, wegainsignificantadvantages:

● Plasticwastereduction

● Improvedeaseofopeningforeveryone

“Plasticclosurelabelsmay seemconvenient,buttheir smallplasticcomponents cancreateheadachesin recyclingoperations.”

- Yang

Closurelabels

Inclusivityattheforefront

Aswestrivetocreatepackaging that’sbetterfortheenvironment, wealsowanttocreateabetter,more inclusiveexperienceforconsumers.

Weperformedusertestingtounderstandthe unboxingexperienceofdiverseindividuals. Wepartneredwith36participantsandactively includedthosewithmobilitylimitations,vision impairments,alongsidethosewithnospecific accessibilityrequirements.

Ourstudyrevealedthatpaperclosurelabels consistentlyoutperformedplasticonesinease ofopeningacrossallparticipantgroups.The plasticlabelwasidentifiedasthemostdifficult toopenforthosewithvisualimpairments,likely duetoitssmallersizeandlackoftactile differentiationfromtheboxsurface.

Theseresultsshowthatpaperclosurelabels areanimportantconsiderationindesigning accessiblepackaging.Theireaseofgripand intuitivedesignappeartobenefituserswith varyingdexterityandvisualcapabilities.

Ourstudyrevealed:

Paperclosurelabelsareeasierto openthantheirplasticcounterparts.

Closurelabels

Parametricdesignlayout

Geometryforprotectionandefficiency

● Telescopingboxes:Adhesivecoversat least50%ofthelid'souterdimension.

● RELFboxes:Adhesiveextendsatleast 75%ofthebox'souterdimension.

● Adhesivewidth:Minimumof10mmfor optimaladhesionduringinitialcuring.

Accessibility:Pulltabdesign

● Minimumsize:8mmx8mmisrecommended tobalancevisibilityandeaseofgrip.

● Trade-offs:Largertabsmayimpact availablespaceforboxgraphics.

Parametricdesignlayout

Closurelabels

Deadening:Ensuringa smoothunboxingexperience

Amarginofdeadenedadhesive (non-sticky)withextraallowance ontheclosuresidearoundthepull stripiscrucialforaseamless openingexperience.

Withoutit,telescopingboxlidscan becomestuck,tuck-styleclosure mayhaveresidue,andpulltabscan haveadhesiveclingingtotheiredges, hinderingfunctionality.

Deadeningspecifications:

● MinimumWidth:1.0mm,eachsideof thetearstrip(tolerance+/-0.5mm).

● TypicalExtraAllowanceWidth: Approximately2.0-2.5mm.

Starterslit

Ourtestingfoundthatfiber-based labelsdonotrequireastarterslit totearcleanlyinreliabilitytesting. Addingastarterslitmayincrease theriskoftabsaccidentallyripping duringhandling.

Thisdecisionthoughshouldbe tailoredtothespecificproduction context.Ifastarterslitisused, werecommendalength≤1mm.

Closurelabels

Keyinsights

Labelface

Thelabelpapermustbalancestrength andeaseofremoval.Itsgrainshouldalign withtheteardirectiontoguideopening.

Tearstripreinforcer

Thiscomponentrequiresespeciallyhigh tearresistance.Translucentpaperscan offerthisstrengthwithminimalthickness, buttheircompositionmustbeverified. TechnicalDataSheets(TDS)andMaterial SafetyDataSheets(MSDS)shouldconfirm thatthesepapersare100%plastic-free, withnoregeneratedcellulose.

Adhesive

Apermanentadhesiveisessentialfortamper evidence.Thoroughapplicationwithsufficient timeandpressureensuresthatpartofthelabel remainsontheboxwhenopened.

Reliability

Labelsmustadheresecurelybutallowfora cleanandcontinuoustearwithouttools. Vibration,drop,andenvironmentalcondition testingwasusedtoverifylabelperformance duringshippingandhandling.Thistestingalso validatesconsistent,single-tearstripremoval.

Labelassembly

1. Labelface(artpaper) 2. Tearstripreinforcer(translucentpaper) 3.Adhesive 4. Releaseliner(glassinepaper)

plasticcornertapestoprovidetensilestrength, butthisalsohinderedrecyclability.

Papertapes

Wesuccessfullyqualified BrownKraftBillerudKorsnäs(BK) in120gsmforitssuperiortensile energyabsorptionandpassing ourdropandvibrationtestseven forheavierproducts.

Ourgoalwastofinda paper-basedalternativethat:

● Metorexceededplastictapecorner tapeperformance.

● Wascompatiblewithoursuppliers' automatedtapeapplicationprocess.

● Wasreadilyavailablewitharobustsupply chaintoavoidproductiondisruptions.

● Hadminimalthicknesstoprevent witnesslinesseenonthefinishedbox.

Arobusttapesolutionisessentialtoprevent cornertearingduringadropandensurethe verticalboxwallsstayperpendiculartothe bottompanel.Highertensileenergyabsorption providesbetterdropperformance.

Allpapersusedfortapeswerequalified usingtensileenergyabsorptioninthe CrossDirection(CD).

Highfiberyield

BKBrownKraftachieveda99%fiberyield inrepulpabilitytesting,takinguscloser toourgoaloffullyrecyclablepackaging.

Papertapes

Keyinsights

Application:

Wedebossourgreyboardby0.25mm inthecornerstohidethetape. Eliminatingtapevisibilityprovidesacleaner aestheticandimprovesourabilitytocontrol consistencyofboxopeningtime.

Desirability:

Wetargeta2-5secondopeningtime forourrigidboxesinalignmentwithISO 1156:2011accessibilitystandards.This targetiswhatwestrivefor,butsome boxdesignsmayfalloutsidethisrange.

2-5seconds

Hangtabs

Hangtabsofferbenefitsforbothretail displayandtheoverallcustomerexperience:

● Hangtabsenableorganizedandeyecatchingproductdisplayscreating visibilityforconsumerdiscoveryand providingvisualandtactileinteraction.

● Robusthangtabshelpdetertheft andmaintainproductintegrity.

Challenge

*

“Designingahangtabthat’sboth strongandrecyclablewasa challenge,butitpushedusto exploreinnovativematerialslike moldedfiber.We’reproudofthe resultsandthepositiveimpact itwillhaveontheenvironment.”

- Miguel

Hangtabs

Paperloopon rigidbox Paperloop onsbs

Moldedfiber (1mm)

SBS (600gsm)

Polycarbonate hang tab strength

Hangtabs

Keyinsights

Weevaluatedfourhangtabsolutions, includingourlegacypolycarbonate plasticsolutionasacontrol.

Double-coatedSBSpaper

Thisoptionismadefrompaperboardwith asmoothcoatingonbothsidesfor enhanceddurabilityandprintingclarity. Itcouldnothowever,withstandour maximumpullforcerequirements.

Threadedpaperloop

Createdbyinterlacingasinglestripofpaper toformasturdyhangingsolution,thisoption exhibitedanimpressive10kgfpullforcewhen assembledonrigidboxbutfailedrepulpability tests,didnotmeetautomationrequirements, andcarriedincreasedassemblycosts.

Moldedfiber

Demonstratedstrongperformance,closely matchingtheplasticcontrolatnearly8kgf pullforce,andexcelledinothercriticalareas. Wesuccessfullytestedoptionsatboth1mm thickness(heavierproducts)and0.7mm (lightweightsolutions).

Moldedfiber

Polycarbonate

Hangtabs

Keyinsights 2

Tomoveawayfromplasticwehaveadoptedmolded fiberforourhangtabmaterial.Ourteamultimately qualifiedthe2thicknessoptions(1mmand0.7mm). Thismoldedfibermaterial(composedof55%bamboo pulp,35%bagassepulp,10%woodpulp)delivered:

● Uncompromisedperformancethatmatched plasticintensilestrengthtests,providinga reliablemerchandisingsolution.

● Packagingthatcouldberecycledasasingle unitwithoutseparatingthehangtab.

● Aproduction-friendlysolutionwithnoretooling needed,enablingasmoothtransition.

Placement

Hinge

Thetabisplacedovertheproduct'scenterofgravity (notthecenterofthebox)toensureabalanceddisplay witheuro-stylecompatibilityacrossvariouspegdesigns.

Abuilt-inhingeallowsthetab tofoldflatforefficientshipping.

Protective productwraps

Firstimpressionsmatter.

Productwrapsserveastheunsungheroesthatensure devicesarriveinpristinecondition.Choosingthese materialsrequirescarefulconsiderationtoachieveboth superiorproductprotectionandimprovedrecyclability.

Protectiveproductwraps

Thefunctionsofprotective wrapsinelectronicspackaging

Scratchandabrasionprevention

Protectivewrapscreateabarrier,shielding productsurfacesfromscuffsanddamage thatcanoccurduringtransitandhandling.

Dustanddebrisshield

Thesewrapsmaintainproductcleanliness, preventingparticlesfromsettlingwithin portsoropenings.

Tamper-evidentdesign

Forconsumers,anintactprotectivewrap actsasareassuringsignofanuntouched, brand-newproduct.

Gift-likeunboxing

Therightmaterialelevatestheunboxing process.Choosingaprotectivematerialalso foritsvisualandtactilequalitiescanelevate theexcitementofunboxinganewproduct.

Enhancedaccessibility

Productwrapscanincorporatepulltabsor tactilesignifiers(liketexturesorraisedareas) tocreateamoreintuitive,accessible unboxingprocessforallusers.

Protectiveproductwraps

Testingfiber-basedsolutions

Weexploredsustainablefiber-basedsolutions forseveralcriticalpackagingapplications. Ourmulti-prongedassessmentfocusedon:

● Abrasionresistanceandsurfaceprotection: SutherlandRubtests(upto100strokesat4lbs) againstcommonproductenclosurematerialshelped measureawrapmaterial’seffectiveness.

● Dustingressprevention:Carefullyevaluated toensureatight,protectiveseal.

● Easeofmanipulation:Westudiedhowsmoothly materialswereremovedandtheirsuitabilityforwrapping variousdeviceshapes.

● Consumerexperience:Assessingvisualappeal, tactility,andcontributionto"unboxing"excitement.

● Recyclability&compatibility:Weprioritizedoptions

Above: Abrasion on a common enclosure material using a Sutherland Rub tester.

Test1 Test2

Protectiveproductwraps

Keyinsights

Ourinvestigationshaveshownthatfiber-basedwrapscanprovidethe protectivequalitiescrucialforconsumerelectronicswithoutrelyingon single-useplastics.Theycanalsocreateanenjoyableunboxingexperience. Weevaluatedmanymaterialsandidentified4optionsthatcanbeeffectively usedfordifferentsituationsrequiringaprotectivewrap.

Supercalendered paper(glassine)

Scoredwelloverall, exceptforaverage dustprevention. Suitableforgeneral product/device wrapping.

Translucent paper

Idealforbundling internalpackaging documentationand addinganextralayer ofprotection.

Performedbetterfor dust,butoverallaverage performance.Aviable optionforselectuse casesthatdonot requiretranslucency.

Coated wrappingpaper

Protectiveproductwraps

Minimaladhesion

Weprioritizeproductwrapsthatadheretothemselves or,evenbetter,requirenoadhesiveatall.Whenthatisn’t possibleforspecificproducts,applyingwrapsadjacent topackagingpartsratherthantheproductitselfcanbe aneffectiveapproach.

ForourPixelphones,we’vechosentoadhereawrap totheproduct,creatingamoreaccessibledesignand animprovedunboxingexperience.Inthesecaseswe specifymaterialsthateliminateunwantedresidue.

Shown:

Pixel 8 Pro packaging, Fall 2023

Inbox trays

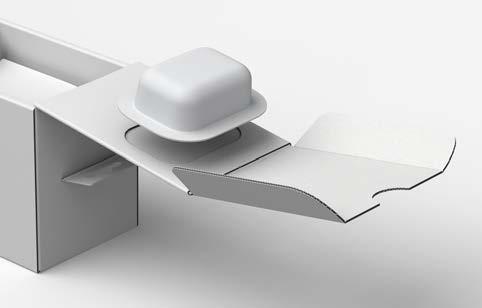

ThermoformedPETtrayshavelongbeenastaple toensurehighervalueproductsarefullyprotected, butmoldedfiberoffersexcitingpotentialtomerge recyclabilityadvantageswithpremiumfunctionality.

Moldedfiberhascushioningpropertiesthatpreventdamage duringshippingandhandling.Customizableshapesprovidea securefit,evenforirregularlyshapeditems.Additionally,the tactilequalitiesofmoldedfibermayenhancetheunboxing experienceandproductpresentation.

Challenge

“Whilethermoformedplastic trayshavetheirmerits, we’vefoundthatmolded fiberofferscomparable protectionwiththeadded benefitsofrecyclabilityand amorenaturalaesthetic.”

- Rob

Inboxtrays

Traytypes: Hingedtrays

Benefits

● Precisecutsensureavisuallyrefined presentationandseamlessintegration withthesurroundingstructure.

● Structuralstabilityminimizeswarping, ensuringreliableproductprotection.

● Highcustomizationenablesfeatures likemirroredcavitygeometrythatcan reinforcehingedpanelsforadded strengthandsupport.

● Hingestyleoptions

○ Moldedhingesareacost-effective optionintegratingdirectlyinto themoldedpulptoolduring manufacturingandofferingsuperior strengthwithslightlylessprecise dimensionalaccuracyafterfolding.

○ Postdie-cuthinges,createdby V-cuttingpre-moldedtrays,deliver higherdimensionalaccuracyfora precisefold.Theymayhaveslightly lowerstrengthcomparedtomolded hingesandpotentiallyincreasecost.

Drawbacks

● Hingesrequirecarefuldesigntoprevent tearingduringinitialand/orrepeatedfolding.

● Hingedpanelsincreaseblanksize(i.e. footprint)ofaflatpartduringmolding,which mayincreasepartcostandreducecavitation.

Inboxtrays

Traytypes:

Skirtedtrays

Benefits

● Highdimensionalprecisionacross productionruns.

● Robust,stiffstructurewithstands handlingandstacking.

● Potentiallylowercostcomparedto hingeddesigns.

● Maximizesprotectivefeatureswhile minimizingspacewithinthepackage.

Drawbacks

● Draftanglescancreateavisualgapbetween thetrayandenclosingstructure.

● Riskofsidewallmovement/flexingwithinthe packagewithoutsufficientsupport.

Inboxtrays

Traytypes: Flangedtrays

Benefits

● Sharpcutsenhancevisualappealandfit withinsurroundingstructures.

● Materialefficientdesignoption.

Drawbacks

● Large,flatsurfacesaremoresusceptible towarpingespeciallyunderloadandin hotandhumidconditions.

● Exposedtrayedgesmaybemoreprone toscratchesordents.

● Lackofverticalwallsincreasestherisk oftray(andthereforeproduct)movement duringshippingifthetrayisnotwellsecured.

Inboxtrays

Considerationsfor moldedfibertrays

Strongsupplychainpartnerships

Thisensurescost-effectivesolutionsandreliable high-volumeproduction.Weanalyzedsupplier capabilitiestoinformtraydesigns.

Structuralandvisualoptimization

● Cleanedges,securefit: Precisetraycutsenhanceeaseofremoval, ensurestackability,andcreateavisually refinedpresentation.

● Productinteraction: Subtletraycurvaturecanreflectproduct form,guidingnaturalplacementand enhancingvisualharmony.

Hingefunctionality

Weevaluatedtrade-offsbetweenmolded hingesandV-miteroptionsbasedoncost, precision,andoverallproductpresentation.

Consumerrecycling

Addingrecyclingsymbolsonthetrays promoteresponsibledisposal.

Inboxtrays

Keyinsights

1

Maintainingconsistencyacrossdevice traysensuresstabilityandvisualcohesion withinaproductpackagedesign.

Usingdifferenttraydesignscouldcontribute toreliabilityissues.Forexample,ifonetrayhas morefreedomofmovement,itcouldcause unduesurfacecontactwiththedevice.

Inboxtrays

Keyinsights

Traycavityradii

Thoughtfuldesignchoicescanbalancea cleanandvisuallyappealingappearance withoptimalfunctionality.

Becauseproductabrasionrisksare inherentlyhigherwithfiber-basedmaterials comparedtoplastic,werecommendthat radiitransitioningfromflattraysurfaces intoproductcavitiesbe5mmorless.

Radius5mm

Traymarking

Includingvisiblerecyclinglogoson moldedfibertrayscanencourage moreconsumerrecycling.

Inboxtrays

Pulpfiberrecipes

Cosmeticmoldedpulpprovidesasmooth, consistentsurfacefinishandcanbemolded intoawidevarietyofshapesandgeometry forcosmeticallysignificanttrays. Different moldedpulpmanufacturingprocesses havevaryingdegreesoffinishedpart surfacequality.

Onceamanufacturingprocessisselected, werecommendusingastandardslurry recipetostreamlineproduction,control costs,andensureaconsistent,high-quality finish.Maintainingastandardrecipeacross multipleproductsreduceschangeoverand cleaningrequirementsduringmanufacturing.

Forpurelystructuraltrays,considerusing recycledmaterialslikeoldcorrugated cardboard/container(OCC)forenhanced strength,higherrecycledcontentandlower partcostcomparedtocosmeticmoldedpulp solutions.MaterialslikeOCCtypically producepartswithlessdesirablesurface finishes,buthavelowerdensityandallowfor thickerwalls.Thistradeoffhasadvantages forshippingandassembly,butmaynotbe appropriateforproductcontactorconsumer facingsurfaces.

Inboxtrays

Keyinsights 4

Precisefit

Steepdraftanglescanhelpprovidearefined aesthetic,butcomeattheexpenseofmanufacturabilityand(inmostcases)surfacequality.Onnonproductcontactsurfaces,werecommendthat draftanglesideallynotexceed4°.Thisallowsalso forasnugfitwithinthesurroundingpackaging, minimizinggapsandenhancingstabilityand withoutsacrificingyieldorpartquality.

Tofurtherminimizegapsbetweeninboxtraysand theouterbox,considerflangedorhingedtrays.

design

Inthissection

Telescopingbox ➜

Rollendlockfrontbox ➜

Tucktopbox ➜

Isn’tit justabox?

AtGoogle,wecarefullychoose packagingstructurestomeetthe uniqueneedsofeachproduct.

Ourprimaryfocusisonfourversatile designs,theTelescopingBox(Rigid andPaperboard),the FrontBox,andtheTuckTopBox. Eachoftheseistailoredfordifferent typesofproductanddifferentend userexperiences.

Challenge

“Structuraldesignislike puzzleforme.Solving forsustainabilityjust addstothefun!”

- Cole

Telescopingbox

(Rigidandpaperboard)

● Thisboxtypefeaturesanelegantandclassic aestheticwithcleanlinesidealforshowcasing highervalueproductsuponopening.A telescopinglidoffersasimpleopeningandclosing mechanism.Custominsertsandcollarscanbe addedforatailoredunboxingexperience.

● Someaspectratiosinthisformatpresent limitations.Forexample,telescopingstructures withverylargefootprintscanbecomedifficult ifnotimpossibletoopenwithonehandand deepboxescantakealongtimetoopen especiallyiftheproductislightweight.

● Providesexcellentstructuralstabilityandasecure fit.Rigidversionsmayoccupymorerecyclingbin spaceduetoitsnon-collapsibleform.Paperboard versionsaremoreeasilybrokendowntoenable moreefficientrecycling(i.e.madetolayflat).

● Rigidboxversionsaretypicallyconstructedwith greyboard(ahigh-strengthrecycledboard).Paper tapeisappliedinthecorners,andtheboxis wrappedinapapertopsheet.Various alternativestogreyboardexist,includingtheuse ofcorrugated,laminates,andmore.Paperboardis commonlyusedforlighterproducts,offeringa smoothsurfaceforprinting.Forheavieritems, corrugatedinserts(EorFflute)canhelpprovide additionalstructuralsupportaddingrigidityand shockabsorption.

● Whilemanysupplierscanautomate constructiontoreducecostandtighten assemblytolerances,itisnotuniversal. Handmadeversionsmayinvolvemorecomplex assembly.

● Wherepossible,pre-assemblinginbox componentsintherigidboxstructurecan reducelogisticalandmanufacturingcosts.

Rollendlockfrontbox

formoreefficientrecycling.

● Intuitivetoopenandcanoftenbere-closedifneeded. Effective wheresingle-handedopeningisdesired.

● Theycomeinawiderangeofsizes,butmayhavelimitationsforvery deepproducts.Largerblanksizescaneasilybebrokenintomultiple panelstoaccommodateequipmentlimitations.Thoughtful placementofseamshelpsmaintaingoodaesthetics.Alternative designsliketheEconoRollEndLockFrontBoxareavailable.

● Constructedfrommaterialssuchaspaperboardsorvarious corrugates. Materialchoiceand/orreinforcementshouldbe informedbyintendeduse,productweightandscale.

Tucktopbox

● Simple,functionalappearancefeaturingatopflap thattucksintotheboxthatiseasytoopenandclose.

● Highlycost-effectiveandwidelyusedforsmaller accessoriesandlowerpricedproductsoffering basicprotectionandeasyassembly.

● Highlyefficienttomanufactureandshipflat.

Challenge

* * * * * * * * *

“Timeisoftheessence forourplanetanditjust makessensetoshare knowledge.Wehavea collectivegoal.”

- David

Thepowerof collaboration

Innovationcancomefromanyoneoranywhere,but industrytransformationinvolveseveryone.Webelieve thatbysharingourexperiences,findings,andchallenges, wecancatalyzeprogressinourindustryandothers. Whatwe’veachievedisn’tperfect,butwehopeit’s helpfulandwe’reeagertolearnfromsolutionsthat otherswillcreate.

We’reexcitedtofosteracommunityonourcollective journeytocreateafuturewithsustainableproductsand services.Bysharingdesignandengineeringexcellence, webelievewecanprotectthehealthofourplanetand everyoneonit.

Let'scollaboratetomakethatgoalareality. packaging_sustainability@google.com

Glossary ofterms

Accessibility

Designingforuserswith varyingabilitiesanddexterity.

Greyboard

Ahigh-densityboardwithgood stiffnessandstrength.Without flutingit’sthicknessismore dimensionallystablecomparedto

Glossary ofterms

PPlamination

Polypropylenelamination, aplasticfilmappliedto paper-basedpackaging.

Recyclability

Theabilityofamaterialtobe disposedofinamunicipal recyclingsystemandbe identified,properlysorted,and ultimatelybereprocessedand reused.

Scuffing

Surfacedamagecausedby abrasion.

Stickies

RELFbox

RollEndLockFront,atypeof foldingcartonwithtuck-intabs.

Repulpability

Theabilityofamaterialtobreak downintofibersduringthepaper recyclingprocess.

Rigidbox

Apremiumpackagingstructure, oftenusedforelectronics, typicallymadefromgreyboard.

Reliabilitytesting

Asuiteoftests(vibration,drop, environmentalconditioningand more)tosimulatesupplychain stresses.

Score/foldcracking Damageatfoldededgesof paperboard.

Small,tackycontaminantsin recycledpulpthatcandisrupt papermakingequipment.

Sustainability

Thepracticeofdesign,engineering andoperationalactivitiestocreate positiveenvironmentaloutcomes.

Tensileenergyabsorption

Theamountofenergyamaterial canabsorbbeforebreaking.

Tensilestrength

Amaterial’sresistancetobreaking undertension.

Telescopingbox

Two-piecerigidboxwherethelid slidesoverthebase.

Userexperience

Auser’sjourneyofdiscovering, opening,anddisposingofproduct packaging.

Visualappeal

Theoverallaestheticofthe packaging,includingcolor, graphics,andfinish.

Plasticfree materiallibrary

Challenge

* * * * * * * * * * * * * *

“Ourmateriallibraryreflects thedeepcollaborationand sharedspiritofinnovation thatoursuppliershave broughttooursustainable packagingsolutions” - Abhinav

Materials

Mainpart categorytype

Subpartcomponent/ categorytype

RigidBox TopSheet

Suppliername

Gradename

HuaXiaSunPaper 157gsm

RigidBox Greyboard JinTian 1200gsm

RigidBox

RigidBox

RigidBox PaperTape

SichuanHongtuScenery Environmental TechnologyCo.,LTD 1050gsm

SenHePaperCo.,Ltd. 950gsm

BillerudKorsnäs(BK) 120gsmBrown

Various UVCoatingandinks Megami LH-GESeries(inks) LH-GEMatteOP(Coating)

RELFRetailBox TopSheet

RELFRetailBox

SingleFaceCorrugate

Foldingcartonretailbox Paperboard

Foldingcartonretailbox Paperboard

Corrugatedinserts TopSheet

Mainpart categorytype

Corrugatedinserts

Subpartcomponent/ categorytype

HuaXiaSunPaper 250gsm

Various F-flute

HuaXiaSunPaper 300gsm

HuaXiaSunPaper 350gsm

HuaXiaSunPaper 250gsm

Suppliername

Gradename

Various E-flute (100gKraft/200gKraft)

Corrugatedinserts Various F-flute175g#1White (100gKraft/200gKraft)

SingleFaceCorrugate

Corrugatedinserts Various G-flute (120Kraft/180gwhitekraft)

Cablewraps, complexfoldinginserts

Cablewraps, complexfoldinginserts

Cablewraps, complexfoldinginserts

Paperboardinserts

Paperboardinserts

Paperboardinserts

HuaXiaSunPaper

StarblancC2SBristol250gsm

StarblancC2SBristol300gsm

StarblancC2SBristol350gsm

Materials (continued)

Moldedfiber Fibercomposition Thickness

Cosmeticmoldedfiber

Cosmeticmoldedfiber

65%Bamboopulp 35%Bagassepulp

0.60mm1.20mm

55%Bamboopulp 35%Bagassepulp 10%Woodpulp 1.0mm

Kraftmoldedfiber 100% OldCorrugated Containers 1.80-3.50mm

Protectivewraps

Suppliername

Documentationbandwraps Arjowiggins

Gradename

GT-63-HM

Productwrapping SIP SIP-11

Boxclosurelabels UPM

Screenprotectors Sun 128gsmArtPaper

Screenprotectors Meixin MXPR-0010AU

Packagingconverter supplierlist

Name Product(s)forGoogle Companywebsite

Cymmetrik Labels,ScreenFilms.

Intramedia Printingbundle,Moldedfiber,Boxes.

https://www.cymmetrik.com

https://www.imedia.com.tw

Lihua/Hyperpack Boxes,CorrugatedCartons,PrintedBundle AssemblyandMoldedFiber.

MYS Boxes,CorrugatedCartons,HighFrequency WeldinginBoxes.

Paishing Boxes,CorrugatedCartons,PrintedBundle Assembly,MoldedFiber.

YUTO Boxes,CorrugatedCartons,PrintingBundle Assembly.

http://www.lihua-printing.com

https://www.szmys.com

http://www.paishing.com

https://www.szyuto.com

Acknowledgements

Ourworkonplastic-freepackaginghasbeenmade possiblebythetalent,creativity,anddedicationof manyindividualsfromacrossGoogleandoursuppliers.

ContributorstothisincludeGoogle’spackagingengineering, design,operations,andsustainabilitystrategyteams.

Endnotes

1. Theworld’splasticpollutioncrisis,explained. NationalGeographic,2024

2. EarthDay2022.PublicOpiniononClimateChange.

3. PerISO0472-2013.Plastic,noun.Materialwhichcontainsasanessential ingredientahighpolymerandwhich,atsomestageinitsprocessinginto finishedproducts,canbeshapedbyflow.

4. Note1toentry:Elastomericmaterials,whicharealsoshapedbyflow, arenotconsideredtobeplastics.

PlasticFree Packaging DesignGuide

We’dlovetohearaboutwaysyou’vefoundthisguidehelpful, technicalquestionsyouhaveorsuggestionstoimproveit. Letusknowatpackaging_sustainability@google.com

Googleisdrivingsustainabilityinnovationinmany differentareasacrossourproductsandoperations.

Checkoutthelatestnewsandprogressat: sustainability.google