AMS Galaxy system allows more freedom for Junk family

By Abby Wiedmeyer abby.w@dairystar.comEPWORTH, Iowa — Jeremy and Melanie Junk have a lot going on.

Between milking cows, running an IBA dairy supplies

route, oating cows for other dairy farmers, being a dealer for AMS Galaxy robotic milking systems and raising children, any time they can save is a bonus.

Now that they are milking with a robot of their own, their saved time has increased.

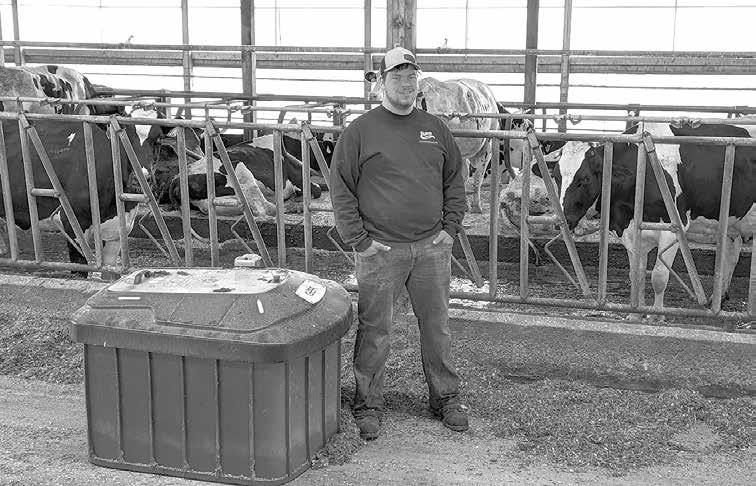

The Junks milk 70 cows near Epworth with the help of their children, Keaton, Lexi and Ivan, and part-time employee, Amelia Frisch.

The IBA route takes Jeremy on the road ve days a week, serving 150 customers.

Melanie manages routes part time and helps Jeremy with big jobs. Although they have been Galaxy dealers for two years,

they did not start construction to install their own system until fall 2023. Startup was in January, and Jeremy said it has been a smooth transition.

“I’m not sure why it’s gone so well, but we’re happy,” Jeremy said. “It just keeps getting better; we’re really fortunate.”

The Junks were milking twice a day in a double-6 parlor. When transitioning to the robot, they had two technicians help for ve days. Then, they hired a person to help during the day for another week.

Throughout the process, Melanie or Jeremy were on-site as well. They were warned that herds take weeks to adjust, but the Junks accelerated that process and stopped pushing cows aggressively after the rst two weeks.

“Our lives had to move on,” Jeremy said. “We put this in to milk the cows, and we walked away. I actually think that was the right thing to do.”

During the initial two-week transition period, the cows increased milkings to 2.7 times per day, and production went up to 89 pounds of milk per cow. Those milkings and pounds achieved did decrease when the cows stopped being pushed as hard, but the couple said they are ahead of where they were before they upgraded to robotics with an increase of 10 pounds per cow.

Jeremy said he has debated whether he should

“I’m not sure why it’s gone so well, but we’re happy. It just keeps getting better; we’re really fortunate.”

JEREMY JUNK, DAIRY FARMER

hire someone to push cows an extra time while they are away from the farm. But, he said the added labor cost would likely offset the benets.

“That’s the million-dollar question,” Jeremy said. “We’re content where we’re at and happy the cows are doing well.”

Melanie said aggressive cows tend to get more robot visits than timid cows. Part of the learning curve was getting a boss cow out of the way. Melanie said once the cows all go through a dry period and calve in again, the pecking order may establish itself better.

– Jose A.

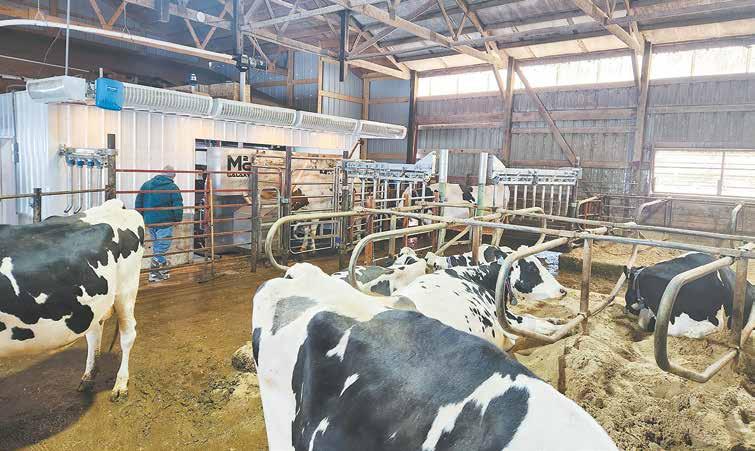

The robot was installed in a space that was not being used before, in an area between the parlor and freestall barns. Cows are sorted with commitment pens that are equipped with nger gates. The gates can be locked to act as one-way gates, or they can be opened up. Melanie said the gates have been useful in processing fresh cows.

“We can scan them and make sure everything is in the computer while they’re waiting,” Melanie said. “Then, we make sure they get attached properly.”

Cows are monitored with activity collars, which is a new system for the family.

Turn to JUNK | Page 5

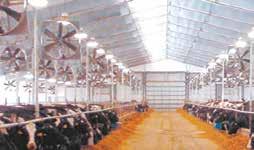

The robot room is in a pit. When a person is standing by the robot, the udder is torso-level, similar to a parlor. This makes treating and drying cows more user-friendly. With the startup being in winter, the Junks took precautions to prevent the robot from freezing. There is a heater in the robot room and an air curtain above the robot on the freestall side.

The air curtain blows air straight down. In winter, it keeps the warm air in and the cold air out. Melanie said she hopes it will keep the ies out of the robot room in the summer.

The robot is mostly run on electronics. The entry gates to the robot are powered by air, and the scrub brush has an air-blow option to dry teats after post dip is applied.

Cows are fed a total mixed ration once a day in winter and usually twice a day in summer. Barns are scraped with a skid loader twice a day. Chores consist of feeding, scraping, fresh cow management and fetching cows.

The Junks said all their cows have adjusted; the only fetch cows so far are fresh cows and rst-calf heifers. At one point only six weeks after startup, there were only two fetch cows.

“The cows adjusted better than we did,” Melanie said. “They have been super calm.”

“We

had another vertical mixer before but our Cloverdale is

- Peter Kimball Hidden Pond Farm, Baldwin,WI

RT Equipment Baltic, SD •605-359-0228

Farwest Equipment Dunn Center, ND 701-260-4959 Hefty Equipment Ashley, ND • 701-321-0203

CHETEK, Wis. — Organic dairy farming is more than a chosen career pathway for Cheyenne Christianson. It is a lifestyle and mindset that has been fostered since childhood.

“We’ve always been part of what I call the quality food movement,” Christianson said. “Everything we do, everything we eat, everything we use is organic.”

With his wife, Katy, and their children, Christianson milks 80 cows on the family’s 325-acre Barron County dairy farm near Chetek.

Christianson has been shipping his milk to Organic Valley since 1999 and was an early leader in bringing a dedicated grass-fed route to the cooperative in 2014.

“We started on this farm in 1993, doing everything as organic,” Christianson said. “I was raised in that mindset. I detest chemicals on a level most people can’t comprehend. In 1995, we bought the land across the road from the farm and automatically began transitioning that to organic as well. … We’ve never looked back.”

The herd of cows that roam the Christiansons’ pastures is slightly different than one might expect. Christianson began his organic grazing herd by purchasing two small herds of Holsteins and has continued with the breed for more than 30 years.

“If we had known in the beginning that I would pursue grass-fed production, I might have started with a more typical grazing breed,” Christianson said. “They were big cows, and maybe that shouldn’t have worked so well. But, it didn’t seem like it mattered. They did what I wanted them to do.”

Christianson attributes his herd’s alignment to his goals with the approach he has taken to breeding

his cows. The herd has always been bull bred, using bulls Christianson retains from the cows that best meet his criteria.

“I like shorter, stockier cows and cows with lots of width,” Christianson said. “When we’re doing forage only, we want a really big barrel to pack the forage in.”

Christianson said he regrets not being more selective of the animals he kept in the herd. He said he wishes he would have culled more aggressively for traits that did not meet his standards, helping him reach his ideal cow faster.

Throughout his career, Christianson has found pleasure in continuing to push the edges of organic dairy farming with new concepts and practices.

Calves are raised on dedicated nurse cows and are not weaned until 5 or 6 months of age. Christianson said a nurse cow can typically raise two or three calves.

“Feeding calves is a big job,” he said. “Since we’ve started raising calves on nurse cows, we have had no issues with our calves. If the calf is born alive, we’re pretty much home free.”

During the winter, calves are kept in a section of the loang barn, and the nurse cows are turned in twice daily to feed calves. During the grazing months, Christianson manages his nurse cows and calves as a separate group, rotating on pasture.

One of the bigger changes Christianson has made was the transition to grass-fed production, one he called seamless.

“We haven’t fed grain since 1998,” he said. “We were grass-fed for a lot of years without the marketing. I didn’t think it was going to take that many years to get there. I knew that it was what I wanted to do, and we headed that way immediately. I believed the market would become a thing.”

Christianson said the health benets of grassfed milk production, both for cows and consumers, drew him to the idea.

“We have virtually no metabolic issues with our cows,” Christianson said. “When you take away the grain, you remove the heat source that causes acid.”

Christianson said his cows reap the benets of a lifetime of grazing and consuming forages with overall increased longevity as a trade-off for lower milk production. Christianson said he has had three cows pass 20 years of age.

“I’m a micromanager, and pasture is my thing,” he said. “That is what I do, and I do it really well. I spend a lot of time with the cows, watching and making sure they are getting enough grass and seeing what types of grasses they are liking.”

falfa scattered throughout. Christianson seeds ryegrass into the pastures as well.

“There isn’t much alfalfa out there right now,” Christianson said. “Most of it was killed off in 2019, and I have been hesitant to put more in. I could really see its absence last year during the drought.”

Despite the challenges presented by the weather, Christianson said the soil and grasses remain his true passion.

“It’s hard to imagine when we started in 1993, there were over 29,000 dairy farms in Wisconsin, and now, there are 5,500.”

CHEYENNE CHRISTIANSON, DAIRY FARMER

Grazing on the lighter, sandy loam soil that makes up his farm is not for the faint of heart, Christianson said.

“There has been a string of drought years: 2005 to 2009 was a rough stretch and then 2012 and 2013,” he said. “Now, we’ve had four years of drought again. Then, there was the ice and freeze kill in 2019.”

The pastures are a mix of many grasses: Timothy, orchard, quack and June grasses with red clover and al-

“The cows are part of the system,” Christianson said. “I just try to make sure they get what they need to do a good job. They are hard-core grazers. That is what paid for this farm.”

Christianson sees organic dairy farming as a way to preserve the small, family farm.

“It’s hard to imagine when we started in 1993, there were over 29,000 dairy farms in Wisconsin, and now, there are 5,500,” he said. “It’s an absolute disgrace. Fewer farms, a few big farms is not a solution for the future. Our economy was so much better when there were tens of thousands of dairy farms in our state.”

TheAirFLEXSDXfeaturessensorsandairsuspensionthatallowthe exheader toshavetheground,pickingupmoreofthecrop.It’slightweightyetdurable, sophisticatedyeteasytouse,allwhileintegratingcutting-edgeinnovation.Crafted onthefarm,you’llappreciatethecombinationofthoughtfuldesign,highperformance andsimplicity–andtheextramoneyitwillgenerate.

Fort Atkinson Hay Ft. Atkinson, Iowa • 563-534-7513

May 15, 19 loads

Rock Valley, Iowa • 712-476-5541

May 16, 70 loads

Large Squares

$115-147.50/ton 2nd crop

$67.50/ton Straw

$67.50-77.50/ton

Large Rounds

$110-157.50/ton

2nd crop

3rd crop

Grass

Mixed

$107.50-165/ton

$125-165/ton

$172.50/ton

$120-200/ton

$112.50/ton

$25-47.50/ton

Mid-May CME dairy prices were mostly higher, though the cheddar blocks back tracked from the previous week’s $1.98 per pound, ending seven weeks of gain and falling to $1.90 Thursday. They closed Friday at $1.9425, down 3.75 cents on the week but still 40.75 cents above a year ago.

The barrels saw almost daily gains and marched to $2.1250 Friday, up 21.25 cents on the week, highest since Oct. 20, 2022, 65.50 cents above a year ago and 18.25 cents above the blocks. Thirty-four cars of block were traded and 10 barrels.

Dairy Market News reported that there were multiple Midwest processing plants on either scheduled or unexpected downtime this week. The top of the spot milk price range was holding mid-week at 50 cents over Class III, while the bottom got as low as $4 under Class.

Cheese plants able to run full schedules were busy, and some added a weekend day to the schedule. Demand tones have shifted since mid-April. Cheddar and Italian style cheesemakers say they are turning down new orders. Barrel cheesemakers say that when a load is available on the spot market, customers are there.

“Cheese market tones are clearly nding some bullish tailwinds,” said DMN, though the price split between blocks and barrels “tends to create a lessthan-assured overtone.”

Cheese manufacturing is steady in the West, though some plants are bringing in additional milk to boost production. A few are running lighter schedules due to “less than stellar domestic demand,” DMN said. Class III spot milk loads are tightening slightly in parts of the region. Domestic cheese demand over recent weeks has been stronger and exports steady; however, with domestic prices shifting above international prices, that may change. Market tones have been bullish, DMN said, but “sentiments of industry participants are mostly neutral to somewhat bearish this week.”

Spot butter jumped 3.75 cents Monday, gave most of it back Tuesday, rallied Wednesday and closed Friday at $3.07 per pound, up 8 cents from the previous Friday and 61 cents above a year ago. There were 20 CME sales for the week.

Central butter makers report a similar market environment to previous weeks.

“Customers’ interests have picked up due to both seasonal trends and as a push to get ahead of continued bullish market prices,” DMN said.

Food service demand is not noted as robust but meeting expectations, while retail orders are ahead of previous years’ numbers, according to some contacts. Cream remains widely available, particularly in the southern area of the region; however, cream handlers relay that Class III interests have begun to pull from the cream supply. Butter makers do not expect near-term cream tightness. Bulk butter is available but not abundant. DMN said the current sentiment is, “How bullish and for how long?”

Western butter manufacturers are running strong schedules, with a few saying they will continue to do so ahead of the upcoming downtime in June for churn maintenance. Milk volumes are slightly tighter in some parts of the region, but milkfat components are up. Cream availability remains comfortable. Domestic butter demand is strong, with export interest moderate.

Grade A nonfat dry milk climbed to $1.1675 per pound Monday, highest CME price since March 12, 2023. It closed Friday at $1.1650, 1.25 cents higher on the week and 1.25 cents above a year ago. There were 30 sales on the week, 26 on Tuesday alone, the most in a single day since Feb. 3, 2021, when 33 sold.

“With June Class III now more than $5 per cwt above April, there may be growing incentive for U.S. buyers of fresh milk who can also use non-fat dried milk in the production of their products to buy NFDM more aggressively,” StoneX said.

Dry whey saw its Friday nish at 41.50 cents per pound, up 3 cents on the week and 15 cents above a year ago, with 12 sales for the week at the CME.

While dairy prices look hopeful, Rabobank’s quarterly report warns, “The initial surge in dairy prices seen in late 2023 and early 2024 was largely due to a period of restocking at lower prices rather than a robust uptick in consumer demand.”

The report suggests that “the global dairy market may experience a slower recovery than previously anticipated, particularly as China’s dairy imports remain lackluster.”

Rabobank analyst Lucas Fuess said in the May 20 Dairy Radio Now broadcast that low cheddar production and strong cheese exports tightened the U.S. market, but globally, we saw “relative weakness in

second quarter with a slight recovery into the second half of the year.” Some of that is due to “easy prior year comparable data,” he said. “It will be easier for countries like the U.S. and Europe to make gains,” Fuess said.

He said it follows a period of lower supply and weakened demand.

“Things are looking a little bit better into the second half of the year,” Fuess said.

But, he does not see a huge resurgence in buying from China, although Southeast Asian nations and Mexico are stepping up purchases.

When asked about the impact of avian inuenza, Fuess said Rabobank has not seen any huge impact. The cheese market gains were due more to other factors, though there may be a slight impact on milk supply, particularly in Texas.

There isn’t a lot of data on the demand side of things yet, he said.

“Anecdotally, there has been limited impact from consumers because of the inuenza, though it remains a cautionary watch factor,” Fuess said.

The U.S. Department of Agriculture raised its 2023 milk production forecast in its latest World Agricultureal Supply and Demand Estimates report and gave us a preview of what it expects in 2025. It also raised its estimate of the 2023 Class III milk price average and lowered the Class IV projection.

This month’s corn outlook is for larger supplies, greater domestic use and exports, and higher ending stocks. The corn crop was projected at 14.9 billion bushels, down 3% from last year’s record as a decline in area is partially offset by an increase in yield. The yield projection is 181 bushels per acre. Total corn supplies are forecast at 16.9 billion bushels, the highest since 2017-18. Total corn use was forecast to rise just under 1%. Food, seed and industrial use is forecast at 6.9 billion bushels. Corn used for ethanol was unchanged.

The outlook for soybeans is for higher supplies, crush, exports and ending stocks. The soybean crop is projected at 4.45 billion bushels, up 6.8%, or 285 million bushels, on higher area and trend yield. Soybean supplies are forecast at 4.8 billion bushels, up 8%. The soybean crush was projected at 2.43 billion bushels, up 125 million.

The latest crop progress report shows 49% of corn was in the ground as of the week ending May 12, up from 36% the previous week but 11% behind a year ago and 5% behind the ve-year average. 23% was emerged, 2% behind a year ago. 35% of the soybeans were in the ground, 10% behind a year ago but 1% ahead of the ve-year average. 16% were emerged, 1% behind a year ago.

Turn to MIELKE | Page 11

Dairy cow slaughter for the week ending May 4 totaled 49,000 head, down 4,300 from the previous week and 8,100, or 14.2%, below a year ago. Yearto-date, 1,171,000 have been culled, down 153,400, or 13.1%, from 2023.

The May 16 Daily Dairy Report said, “With dairy heifer inventories at multi-decade lows, producers have fewer opportunities to cull low-producing milk cows and replace them with heifers that are ready to enter the milk parlor. Producers who don’t want to pay sky-high prices for replacements can keep more low-producing cows in the herd, effectively lowering cull rates, or milk fewer cows.”

This week’s livestock, dairy and poultry outlook mirrored the milk price and production projections in the May 10 WASDE. The outlook shows the 2024 dairy herd forecast was raised 10,000 head to 9.345 million.

In response to better-than-expected average milk yields in the rst quarter and overall lower expected feed costs, the 2024 milk-per-cow forecast was raised to 24,330 pounds, 85 pounds above the previous forecast, thus the increased projection in milk output.

The 2025 dairy herd was projected to increase by 20,000 head from 2024 and to average 9.365 million. The forecast for average milk per cow is 24,485

pounds, up 0.6%.

“The projected growth reects expectations of improved farm margins through 2024 that will affect 2025 production levels,” the report said.

As of May 14, highly pathogenic avian inuenza had been conrmed in nine states and 46 dairy herds, according to the outlook.

“Mandatory testing for lactating dairy cattle is required prior to interstate movement. Additional guidelines were issued by USDA’s Animal and Plant Health Inspection Service May 8. USDA has found that the virus can spread in several ways: within the same dairy herd, when dairy cattle change location and from dairy to poultry. In some cases, dairy cows tested positive without showing any symptoms. The affected cows recovered within several weeks.

“Pasteurization has continually proven to inactivate bacteria and viruses and hence reduce the risks to human health. Moreover, the U.S. Food and Drug Administration continues to advise against the consumption of raw milk.”

For further updates, visit the APHIS or FDA websites.

Cooperatives Working Together members accepted 16 offers of export assistance this week that helped them capture contracts for 2.9 million pounds

The Lehner Dairy has been in operation for about 1 1/2 years. They currently milk 120 head. Mike researched the GEA Feed Pusher online, then contacted Jon at Centre Dairy about incorporating equipment in his operation. “Jon and Centre Dairy were easy to work with and had the equipment fine-tuned in about a week after installation. The Pusher is easy to operate and runs 19 times

of American-type cheese and 3.1 million pounds of whole milk powder. The product is going to customers in Asia, Central America, the Caribbean, Middle East-North Africa and South America through September.

This week’s Global Dairy Trade Pulse auction saw 3.75 million pounds of product sold, down from 3.79 million April 30. 97.2% of the total offered was sold. There were 498,240 pounds more instant whole milk powder and 597,447 pounds less regular whole milk powder sold versus the last pulse and 59,524 pounds more skim milk powder on offer was sold.

HighGround Dairy said this was the largest volume of instant whole milk powder ever sold on the GDT Pulse platform.

The International Dairy Foods Association announced that the Capitol Hill Ice Cream Party will celebrate its 40th year June 12. As Washington’s most popular warm weather celebration, the party, on the National Mall just outside the U.S. Capitol Building, is one of Washington’s most anticipated for professionals working in food and agriculture, bringing together thousands of guests, including members of Congress and ofcials from the executive branch, in a fun event showcasing America’s favorite frozen treats.

210

3 point, front fenders, 3 point, 3 remotes, 19 speed powershift, New LED lights, Fresh service including all new transmission and engine oil, new filters and coolant, New Trelleborg tires, Very nice!! Sells w/ride and drive; John Deere 4455 tractor, 4WD, CAH, 15k hours, Solid tractor; John Deere 4230 tractor, 2WD, 6728 original hours, Quad range transmission, 4 post canopy, Good working condition!; White 2-70 tractor w/loader, 2WD, open station, runs and drives nice; Skidsteers

John Deere CT332 track loader. 5200 hours, open station, hydraulic quik-tach, new tracks, new drive motor. Nice machine!; Gehl V330 skid steer, 2015 model, 2960 hours, CAH, pilot controls, 2 speed, hydra-glide, aux hydraulics, power quik-tach, new 8ft bucket, 1417.5HD BKT tires, Nice!; Mustang 2200R skid steer, 2017 model, CAH, 2 speed, 14k hours, new 72” bucket, Runs and drives as it should; New Holland 170 skid steer, 4800 hours, open ROPS, Good solid unit!; Forage Handling

John Deere 702 rake, 10 wheel, Good working condition, Has seen some acres; New Holland 255

Summer Hammann

Parents: Scot and Becky Hammann Barron, Wisconsin

Tell us about your family’s farm. I was raised on my family farm where we milk 40 registered Holstein and Jersey cows. We milk in a tiestall barn. My parents, three siblings and grandpa are involved in the farm. Along with the dairy herd, we raise beef, sheep and turkeys, and we farm 500 acres.

What are your responsibilities on the farm? My responsibilities on the farm include feeding heifers and calves and helping my mom milk. I also work with the show animals to get them ready for shows through the spring, summer and fall. My favorite chore is working with the show cattle and seeing them improve throughout the season as they get on a program.

What is your favorite memory of living on a dairy farm? Working with my family to build our genetics and watching cattle develop to their full potential.

What lessons have you learned from living on a dairy farm? I have learned many life lessons living and working on my family’s farm like developing my work ethic and determination and learning how to deal with adversity. I’ve learned that no two days are similar and to persevere when something does not go the way you plan.

What are your plans going forward? I plan to continue working alongside my parents and siblings, developing the cattle within our herd. I will attend college next fall at the University of Wisconsin-Madison for dairy science and agricultural business management. I plan to work in the dairy industry after college and nish out my junior years in the show ring.

Brock Sluga

Parents: Matt and Crystal Sluga Whitehall, Wisconsin

Tell us about the farm you work for. Giese’s Family Farm is managed by brothers Ken and Gary Giese. Ken milks about 105 cows in his at-barn parlor. I have been working part time at the farm since 2020. However, my time became more consistent when the barn blew down in a storm in December 2021. I was going to help milk and feed whenever I had time around my busy school and sports schedules. During the summer of 2022, I became a full-time farm hand. During the 2022-23 school year, I was part time whenever I could help. At the end of my junior year, I signed up for a youth apprenticeship. This allowed me to go to work and get paid during school hours during my senior year.

What are your responsibilities on the farm? Some of my responsibilities at work include feeding, milking, scraping manure and any kind of eldwork or operating that needs to be done. My favorite job is probably raking hay in the John Deere 4640 with the Vermeer hydraulic rake.

What is your favorite memory of working on a dairy farm? My favorite memory was getting to watch the sunrise every morning during chores.

What lessons have you learned from working on a dairy farm? While working on the farm, I have learned how to be a hard worker. I have also learned that paying attention to small details may save you time in the long run.

What are your plans going forward? After high school, I will be starting a job at J&R Underground LLC as well as coming back to help on the farm when I have time. I enjoy being on the farm and doing things with the cows and tractors. I never see myself fully getting away from the farm and agriculture in general.

Jill Evers

Parents: Philip and Kay Evers Kellogg, Minnesota

Tell us about your family’s farm. Evers Family Farms is milking around 3,000 cows in a double-48 parallel parlor. The herd is mostly Holsteins, but there’s a few Jerseys and other breeds mingled in. All the calves are under one roof in the calf barn. We haul our milk to Associated Milk Producers Inc., mostly to Blair, Wisconsin. We raise our heifers on many farms around the main farm. Many of my cousins and some of my siblings work on the farm, but there are still quite a few hired hands who aren’t family. My dad and his three brothers work together and are the main four in charge.

What are your responsibilities on the farm? To take care of heifers, which consists of feeding, scraping, bedding barns, running foot baths, vaccinating and sorting for pregnancy checks. I mix feed for 1,000 head a day with my brother. On a normal day, I’ll go to two farms and take care of cattle. My favorite thing on the farm is simply working with the cattle alongside my family. Sometimes Dad will have me help for eldwork. I’m more of a cattle person, but I don’t mind getting in the eld to change things up.

What is your favorite memory of living on a dairy farm? When I was younger, I would check cows in the pasture with my dad and brother on the four-wheeler. Going out to give Dad supper and riding along in whichever equipment he was in will always be a core memory too.

What lessons have you learned from living on a dairy farm? To name a few, you learn what responsibility means at a young age. Showing up every day to get your chores done is one way. Not everything goes the way you would like it to go, but you have to accept that and change accordingly. You work for what you get. Nothing is given; it’s earned. Getting along can sometimes be challenging, but you have to work it out in order for things to progress. I wouldn’t have wanted to grow up any other way.

What are your plans going forward? I plan to stay on the farm. I plan to start taking over little by little and keep the farm going with my family.

Turn to SENIORS

UW-Platteville’s School of Agriculture offers...

• Courses that focus on Farm to Fork concepts for a better producer, consultant, and consumer

• Opportunities for competition with other dairy schools through Pioneer Dairy Challenge Team & Pioneer Dairy Judging Team

• A wide variety of industry support and resources available to Dairy Science majors through internships and other networking opportunities

• Agriculture-focused Faculty-Led Education Abroad with Service Learning Components Dairy Science major 50+ students & growing!

• Agribusiness

• Ag Engineering Technology

• Spanish

• Soil and Crop Science

Tell us about your family’s farm. I live on my family’s dairy farm where we milk 2,250 Holsteins. The farm is owned by my dad and his two brothers. They are the third generation of owners of the farm. Since we expanded in 2015, we have been milking three times a day in a 60-stall rotary parlor. We have around 35 employees, 12 of which are family members.

What are your responsibilities on the farm? I primarily help to feed the newborn Holstein and beef calves. Our newborn calves are kept in a transitional pen for one to four days after they are born, before they are either taken to our heifer barn if they are Holsteins or sold if they are beef. During this time, I also help to monitor for and treat diseases, ensure the pen is clean and transport heifers to the heifer barn. I also help with eldwork during harvest season. In the eld, I merge hay, drive silage truck, and spread fertilizer and manure. My favorite is merging hay while we are harvesting alfalfa.

What is your favorite memory of living on a dairy farm? My favorite memory on the farm was swimming in our new manure pit before we started using it. When we expanded in 2015, we poured an in-ground manure pit that

we would not start using until the barn was nished and there were cows in it. So, for about three months, the pit was clean and collecting water every time it rained. Logically, my family and I would go up to the pit occasionally and swim in the rainwater that had accumulated. Before we started using the pit, it had accumulated somewhere around 2.5 feet of water to swim in, which was all we needed to be able to have a good time together.

What lessons have you learned from living on a dairy farm? Growing up on a farm has taught me a large variety of lessons and skills. Being that I get to work so closely with my family in the calf barn every week, I have grown to appreciate all that we do for each other and have been able to develop a close relationship with them. I have also developed a strong work ethic and good sense of responsibility since there are many things that need to be done around the farm every day in order for everything to run as smoothly as possible.

What are your plans going forward?

Next year, I will attend the University of Wisconsin-Madison to pursue a degree in either history or political science, with hopes to become either a high school social studies teacher or lawyer. After college (and maybe law school), I hope to return to the Menomonie area to pursue one of these two careers.

Turn to SENIORS

Savana Mata Spring graduate in dairy science, agricultural business Northcentral Technical College

How did you choose Northcentral Technical College to further your education? I am from southern California. The closest I had ever been to agriculture was the dairy section of the grocery store. I attended Loyola Marymount University, majoring in biology and philosophy, with plans to go into neuroscience. I met someone from a dairy farm. After learning from them, I decided that after I graduated I was going into dairy. A staff member gave me a tour at NTC. I realized almost all of the people teaching had farmed themselves. I chose NTC because I would be learning directly from the source. That tour was the rst time I had seen a cow milked by a robot. I had no idea cows were being milked by robots.

How has NTC facilitated your learning? Before I started classes, the school helped me get a job at Miltrim Farms Inc. I had never touched a cow or even been close to one, and then, I was in this place with 3,000 cows. I will be forever grateful for them allowing me to come in with zero experience and helping me follow my dreams by teaching me about the dairy industry. I was learning about milking cows with robots and in a parlor, but I wanted to learn about milking in a tiestall barn. I made a connection that helped me get hired by the Blaubach family. They milk 160 cows in a tiestall barn.

How have extracurricular activities added to your learning experience? I have been involved in the National Professional Agricultural Student Organization and have taken part in the dairy specialist competition. Everyone was so supportive, especially the instructors. They kept telling me it was just a learning experience, to study and practice and see what I could do. I was so excited to see my progression — how much I had learned in the rst semester at NTC to do so well in the rst competition.

How has NTC prepared you for your career? I will continue to work at Miltrim Farms and at the Blaubach family’s farm. I also work at Merrill Equipment Company. Since I am new to the dairy industry, there is so much to learn, and I want to learn every aspect. I have loved everything, which is a problem because I cannot pinpoint what exactly I want to do in the industry. By working at all three businesses, I can learn so much. I have also been working with Marathon County Partnership for Progressive Agriculture, setting up the June dairy breakfast, so I have been learning about connecting with consumers. My schedule is hectic, but I’m grateful to continue working with all these places. I learn so much from each, and I would not want to give that up.

What would you tell a perspective student? NTC is a great college for people who want to learn quickly and be handson. It is great if you are worried about a busy schedule and being able to work alongside going to college. You have to take an internship; a lot of the classes you take are in the barn or the eld, seeing and doing things.

Tell us about your family’s farm. We have a 60-cow dairy, consisting of mostly grade Holsteins with a handful of registered colored breeds. We milk in a tiestall barn with automatic takeoff units.

What are your responsibilities on the farm? My responsibilities on the farm are milking, feeding the calves and goats, and occasionally feeding the cows. My favorite job is feeding and taking care of the newborn calves.

Jaden DreierParents: Randy and Becky

DreierNorwalk, Wisconsin

Tell us about your family’s farm. We milk 75 registered Holsteins twice a day in a tiestall barn. We also have 60 youngstock split on two farms. My dad, mom, sister, Ashley, and I run the farms.

What is your favorite memory of living on a dairy farm? My favorite memory is picking out my rst show heifer when I was old enough to show at our county fair.

What lessons have you learned from living on a dairy farm? Working on a dairy farm has taught me patience and how to properly care for animals.

What are your plans going forward? I plan to take over my parents’ dairy farm and have a herd of registered dairy cattle and a small herd of Nigerian Dwarf goats.

What are your responsibilities on the farm? My responsibilities are feeding youngstock and dry cows before school. After school, I also milk and bed cows. My favorite job is eldwork.

What is your favorite memory of living on a dairy farm? My favorite memory is learning how to drive tractors and being able to do eldwork myself.

What lessons have you learned from living on a dairy farm? I have learned that I don’t like xing equipment, but sometimes, it is necessary.

What are your plans going forward? After graduation, I plan on returning to the family farm, but I also want to leave my options open to other ag-related things.

Breanne Zawislan Parents: Shawn and Bridget Zawislan Unity, Wisconsin

Tell us about your family’s farm. My dad is the owner of our family farm, Zawislan Dairy, and we are a 130cow lactating dairy herd. The cows are milked in a tiestall barn, and my family members are our only workers. Most of our heifers are raised at home, and we have many facilities for each age of our heifers.

What are your responsibilities on the farm? I have become an industrious, fast-learning, experienced farm worker. My duties include the maintenance of buildings, herd health, feeding and providing comfortable housing conditions for all cows while also milking cows daily and helping with unpredictable necessary tasks each day. My favorite chore is everything that goes along with caring for my fair heifers.

What is your favorite memory of living on a dairy farm? My favorite memory is sharing memories with my siblings while milking cows and laughing.

What lessons have you learned from living on a dairy farm? Working on my family’s dairy farm both morning

and night, before and after school, has become a routine in my life that has had its peaks and valleys. I have acquired time management, adaptability and problem-solving skills that will help me uctuate in my life. I was granted experiences and leadership opportunities that many kids may never get to experience. My life growing up on a farm and participating in agriculture-related activities through school has shown me a lot about agriculture. It has shown me what makes up the industry as well as what is needed to keep it thriving. Agriculture has greatly impacted my life and has taught me to become a humble person. Without it, I would not be where I am today to have the foundation that is setting me up for success.

What are your plans going forward? I am enrolled and will be taking classes at Northcentral Technical College, working toward an associate degree in dental hygiene. I will hopefully be able to work at a dental ofce soon after graduating college. Although I am not continuing my education in agriculture, it will always be a part of my life.

Jewett represents fourth generation of cheesemakersBy Amy Kyllo amy.k@star-pub.com

NORWOOD YOUNG AMERICA, Minn. — Cheese runs in Jacob Jewett’s veins. A self-proclaimed “fourth-generation cheese head,” he is continuing his family’s legacy of cheese making.

“I’ve always been a fan of cheese,” Jewett said.

Jewett is a production supervisor at Bongards, overseeing about 35 employees on the process cheese lines.

Jewett is one of three members of his family working at Bongards. His father, Brent, works as a plant manager in Norwood Young America, and his brother, Mitchell, works in purchasing and scheduling.

Jewett was inspired to be a cheesemaker from connecting with his family.

“We’ve been a very family-oriented family our whole life,” Jewett said. “I just saw what success my dad had in the industry.”

In his role, Jewett assists production staff in keeping on schedule and changing over the machines for products. He focuses on keeping employees safe, making sure the food is manufactured safely and maintaining their production rate.

“If there’s an issue or something, I nd myself getting pulled to that,” Jewett said. “You gravitate toward the issues to try to keep everything running smoothly. ... Getting that (conict) res-

olution and things get back on pace, or people are back happy again, those are the satisfying things in my job.”

Jewett’s production lines make process cheese slices and loaves. One of the main varieties they produce is American.

“It’s cool to see how you can make a natural cheese into the processed cheese and basically give it similar characteristics of what a natural cheese would be,” Jewett said.

The rst cheesemaker in Jewett’s family was his great-grandfather, Floyd. Floyd owned and operated cheese factories near Richland Center, Wisconsin. Later in his career, he worked as a eld representative for cheese factories.

Two members of the next generation of Jewetts also became cheesemakers. Jewett’s great-uncle, Lee, worked in a cheese factory for 50 years. His grandpa, Marvin, was more adventurous than his brother, Jewett said. Marvin worked at many cheese factories across the nation in Wisconsin, Iowa and California before landing at Bongards, in Minnesota, in 1986. Jewett’s dad joined Bongards at the same time.

Growing up, when the Jewetts needed to do a science project for school, their dad helped them make cheddar cheese on the stove. Jewett said the rst time he was part of it, he was 8. Recently, Jewett said his dad and brother made stovetop cheese with Jewett’s 3-year-old nephew.

“We’re getting some practice in, so we can later show our kids someday when they’re older and keep that making of the cheese on the stovetop tradition going,” Jewett said.

On childhood trips to visit family, Jewett said cheese was part of the trip.

“Going across the countryside of

Jacob Jewe holds cheese May 15 near a process cheese line at the Bongards plant in Norwood Young America, Minnesota. Jewe is a fourth-genera on cheesemaker and one of three members of his family working for Bongards.

Wisconsin nding new cheese plants, ... (that) was one of my fondest memories,” Jewett said.

Jewett’s rst job with Bongards was a part-time position in high school.

“The (cheese making) process to me ... was very cool,” Jewett said. “I was pretty amazed at what the manufacturing and production of food was. It’s a big spectrum, and I just thought it was interesting.”

Jewett attended South Dakota State University for dairy manufacturing.

“I thought, ‘Well, I already know quite a bit about (cheese making),” Jewett said. “(I thought) I would have success doing it. ... I really liked the industry, and it’s been treating me well.”

During college, Jewett completed two internships with Bongards. In the future, Jewett said he hopes to advance within Bongards. “I don’t plan on leaving anytime soon,” Jewett said. “Bongards has been good to me, and I like what I do. I like the atmosphere I work (in).”

Harlee Harbaugh Parents: John and Jeri Harbaugh

Coon Valley, Wisconsin

Tell us about your family’s farm. In 2017, my family sold our milking cows, and we decided to keep some of the herd and use them for showing. We raise our show heifers on a small pasture that we rent outside of town, and our milking cows are held on a large dairy in Camp Douglas, Wisconsin.

Isaac Jakobi Parents: Denny and Tracy Jakobi Granton, Wisconsin

Tell us about your family’s farm. We farm about 600 acres and milk 75 cows in an 8-stall stepup parlor with a sand-bedded freestall barn. I also own 20 beef cattle that I keep at my grandparents’ farm.

Logan Brand Parents: Steve and Mary Brand Ellsworth, Wisconsin

What are your responsibilities on the farm? My jobs include breaking heifers to lead, washing, tting, feeding, watering and showing cattle. My favorite job is leading and showing cattle.

What is your favorite memory of living on a dairy farm? My favorite memory is working with my Jersey cow and prepping for shows.

What lessons have you learned from living on a dairy farm? It takes dedication to get up every day and take care of the animals and do the job you love.

What are your plans going forward?

I will attend Southwest Wisconsin Technical College, seeking a degree in dairy and livestock management, with plans to become an articial insemination technician and nutritionist.

What are your responsibilities on the farm? I milk cows, help with eldwork and manage my custom baleage business. My favorite job is doing eldwork.

What is your favorite memory of living on a dairy farm? My rst calf from my beef herd.

What lessons have you learned from living on a dairy farm? The value of hard work.

What are your plans going forward? In addition to high school, I am also graduating from Mid-State Technical College in the farm operations program. I will continue to run my baling business, help on my family’s farm, raise my beef cattle and hope to own a farm someday.

Tell us about your family’s farm. I grew up on my parents’ dairy farm which evolved to milking 1,200 cows in a double-16 parallel parlor. I am the youngest of four kids, and we all worked on the farm while we grew up. I also milked cows and did various farm chores on two neighboring farms while in high school. One had a parlor and milked 150 cows, and the other milked 60 cows in a tiestall barn.

What are your responsibilities on the farm? I milked cows, helped feed and care for calves, and did various herd health tasks. My favorite job is milking cows. I love milking cows because it is relaxing to me.

What is your favorite memory of living on a dairy farm? Getting to milk cows with my brother and making memories with him in the parlor.

What lessons have you learned from living on a dairy farm? Things go wrong that you can’t always plan for, so you need to go with the ow. This experience has helped me to be more exible in general.

What are your plans going forward? I will attend Iowa State University for agricultural business.

Carmen Haag Parents: Rob and Becky Haag Watkins, Minnesota

Tell us about your family’s farm. I work for Kuechle Dairy. My mom, two of my aunts and an uncle all own the farm together. There’s also four people who are hired help along with some of my cousins and my grandma and grandpa. We milk around 240 cows and raise our calves, crops and steers. We milk in a double-12 herringbone parlor. We recently got a manure robot that is working very nicely.

What are your responsibilities on the farm? My main responsibilities on the farm are milking and random jobs like feeding calves or eldwork.

What is your favorite memory of working on a dairy farm? Having water ghts with my brother using the hoses in the parlor.

What lessons have you learned from working on a dairy farm? Quality over quantity.

What are your plans going forward? I plan to study aviation at South Dakota State University.

Midwest Machinery Co. wants to help young mechanics enter the industry. They offer paid internships to two separate age groups of young adults.

“We know that by getting kids interested younger and getting them into a company, hopefully we can have them enjoy working with us and get to know our culture,” said Heather VanZee, human resources director with Midwest Machinery. “It gives them a head start on their career.”

VanZee has been working for Midwest Machinery for a decade.

Midwest Machinery has an internship for students 18 years and older. Through this internship, a student receives a sponsorship for the John Deere Tech Program. They also have an internship for students ages 16-18 that is designed to expose young adults to the industry.

“They can come in and get experience and see what it would be like,” VanZee said. “Would they want to do this for a job and what every day would look like for them.”

Students may hear about the internships from schools while others stop in at a dealership and speak to a manager. They are also able to apply on the company’s website and a corporate service manager will reach out.

The corporate service managers will give them the details and make sure it is a mutual t.

“If they are interested, then we get the paperwork signed,” VanZee said.

During the beginning of an internship, interns observe until they are comfortable with being hands-on.

“You’re going to get your hands dirty as soon as you can possibly get your hands dirty,” VanZee said. “We encourage throwing on that uniform and getting dirty.”

VanZee said there are several colleges John Deere partners with to offer advanced technician training. In order to get into the program, a student has to be sponsored by one of Midwest Machinery’s 30 dealership locations.

As students go through college, they learn handson skills at Midwest Machinery on their days off from school.

“We try to give them as many different types of machinery as much as possible, so if we can show them everything from a small utility tractor to a combine and bigger,” VanZee said.

Throughout the internships, students are exposed to different aspects of diesel engines, hydraulics and more. They also have interns who focus on small engines in school and at a dealership.

Midwest Machinery does not have a set limit of interns for each dealership.

“We don’t think we can have too many interns,” VanZee said.

They gauge the number of interns by the location and what they can handle depending on available managers.

They also have a dedicated aftermarket support specialist who answers questions.

“We make sure they are getting the attention that they deserve,” VanZee said.

The aftermarket support specialist also serves as a connection between the school and the business.

After the students complete college, they may have the opportunity to become a Midwest Machinery employee. If they are hired full time, they are eligible for tuition reimbursement, including books and oncampus housing.

“We hire on at least 98% of them to become full-

time employees,” VanZee said. “The longevity of those employees really pays off in the end for both us and the student.”

Parents: Mike Wielenberg and Sarah Maland

Long Prairie, Minnesota

Tell us about your family’s farm. My uncle, James, owns a dairy farm near Clotho, Minnesota. We milked around 100 cows in a double herringbone parlor until this past July when we sold our cows. We are raising the youngstock and selling them as springer replacement heifers. This farm used to be my grandparents’. When I was young, we basically lived on the farm. My grandma helps as much as she can, but my grandpa has passed. My dad, my uncle, Neil, my brother and I often help on the farm whether it’s eldwork, moving heifers or xing equipment. I also own a few heifers. When I was around 10, my dad bought me my rst Jersey calf. My dad and I starting growing a Jersey herd, which we housed at my uncle’s farm. We had around 55 head before selling the cows. I use my cattle to show in 4-H along with a few of my uncle’s.

What are your responsibilities on the farm? Helping wherever help is needed. I usually help with things like feeding calves, moving heifers, servicing heifers or sorting heifers for pregnancy checks, and I help make and deliver lunches or dinners for the boys while they do eldwork. My favorite chore is anything I can do with my 4-year-old sister, because she really loves the cows.

What is your favorite memory of living on a dairy farm? One Saturday night, I was milking cows with my dad, brother and boyfriend. A cow had an abscess on her side, and it was oozing and looked like it needed attention. I grabbed a needle, syringe and hydrogen peroxide and went to work. I poked at the hole it was oozing from and got it opened so the pus could drain. I helped push the uid out to relieve the pressure. My brother and boyfriend were watching and gagging because it smelled so bad. I stood there with a smile on face, not bothered at all by the smell. After I nished ushing the pocket with hydrogen peroxide, I had the abscess uid on my clothes, my boots, the oor in the parlor and my milking gloves, and the boys where petried by how the smell didn’t bother me. I laughed so hard I cried, because they were gagging at a smell that didn’t bother me. My dad also made fun of them the rest of the night.

What lessons have you learned from living on a dairy farm? I have learned a lot of lessons about responsibility, respect and work ethic. I have also learned that you have to work hard for what you want to achieve your goals. I also learned what I want to do with my life while working on the farm.

What are your plans going forward? I will attend the University of MinnesotaCrookston to major in animal science and complete my pre-veterinary medicine courses. I am hoping to transfer to the University of Minnesota-St. Paul veterinary school and get my Doctorate of Veterinary Medicine. I want to move somewhere rural and work as a large farm animal veterinarian.

Tell us about your family’s farm. I have grown up on my parents’ farm, Wilbar Dairy. We milk 300 registered Holsteins and Brown Swiss with the prex Wilbar. Cows are housed in sand-bedded free stalls. We milk in a double-8 step-up parlor. It takes about three hours to milk twice a day. We raise our youngstock and average 300 head of youngstock at all times. My parents and older brother, Brice, and younger sisters, Brenna and Blair, and I are the work force along with two fulltime milkers. I have enjoyed showing our Brown Swiss cattle in 4-H at the county fair and Wisconsin State Fair.

What are your responsibilities on the farm? I relief milk, scrape barns, pull calves when needed, help my mom move calves and heifers, relief feed calves for my mom or help her get done early so she can get to my sisters’ sporting events. Occasionally, I feed a newborn calf when needed. I relief feed for my dad and haul manure. Along with Brice, I do tillage and planting. Brice and I then move on to cutting, baling and wrapping hay as we mostly feed

baleage. In fall, I help haul corn silage, occasionally run the pack tractor and always help cover the bunker silo. In the past few years, we have acquired newer tractors, and I really enjoy playing with GPS. If I am available on herd check days, my mom will put me to work sorting cows for the veterinarian and giving shots.

What is your favorite memory of living on a dairy farm? The days when all six of us are working together, whether it be milking or in the elds. Recently, dancing in our new shop to “Pocketful of Sunshine” comes to mind. I also love the ice cream runs after milking Sunday nights.

What lessons have you learned from living on a dairy farm? Growing up on a farm has taught me the basics of life. I have learned the cycle of life, how to care for animals and the land. I have learned responsibility, exibility and team work.

What are your plans going forward? After graduating, I am attending Fox Valley Technical College and pursing a degree in precision technology and agronomy. Farming is becoming dependent on precision technology in order to stay sustainable, and I hope to bring what I learn back to the family farm and to help other producers become more sustainable.

Emi McCarville

Parents: Eric and Jackie McCarville Mineral Point, Wisconsin

Tell us about your family’s farm. I help milk on my family’s dairy farm. We milk about 60 cows in a stanchion barn. I milk with my parents and my grandpa.

The agriculture field is full of new opportunities and innovations. Evolving technology impacts the industry and the family farm, from robots in the barn to GPS and the science behind balanced nutrition. Hands-on learning with NICC at the world-renowned Iowa Dairy Center positions you to impact the future.

Explore training and careers in:

•Agronomy and Crop Science

•Agriculture Finance

Take the Next Step.

•Conservation Agronomy

•Precision Ag and more!

Schedule Your Visit and Apply Today!

What are your responsibilities on the farm? I am responsible for feeding calves morning and night along with helping milk cows and feed heifers.

Gabbie Neumann

Parents: Bjorn and Jamie Neumann Osceola, Wisconsin

What is your favorite memory of living on a dairy farm? My favorite memory is being able to buy my own heifers, watching them have their own calves and having my herd expand.

What lessons have you learned from living on a dairy farm? I have learned that hard work goes a long way. Many kids don’t understand hard work and all the work that goes into farming.

What are your plans going forward? I plan to attend the University of Wisconsin-Platteville for agriculture education and a minor in agribusiness.

being able to show my cows at county and state fairs. It is so fun to be able to compete with friends and family.

Tell us about your family’s farm. I live on a family farm that milks around 200 dairy cows. We have Holsteins and Red and Whites along with Brown Swiss and a few Jerseys. We milk our cows with four DeLeval robotic milking units.

What are your responsibilities on the farm? My jobs on the farm depend on who is there that day. Some days I help with general chores of cleaning robots and fetching cows, and some days, I may do eldwork all day. My favorite job has to be fetching cows, because the cows have such a different temperament with the installment of robots that you get to see their personalities more.

What is your favorite memory of living on a dairy farm? One of my favorite memories of living on a dairy farm is

What lessons have you learned from living on a dairy farm? As the daughter of a farming family and community, my ideals and values have been taught through experience and tough love. My situation has also provided me with endless opportunities to learn the hardships and beautiful parts of life. The most valuable lesson I have learned is to never back down and never quit. My parents taught me this from a young age. I learned quickly that the farming industry is harsh. There are times when I don’t want to do certain tasks, like pulling calves, but the job is always more signicant than what I want to do; it is something that I needed to do.

What are your plans going forward? I plan to attend Iowa State University with a major in animal science on the pre-veterinary track.

• Dairy & Livestock Judging Teams

• Many clubs (including the Dairy Science Club with about 100 members)

• Internships

• Study Abroad

• 100% Dairy Science placement rate

Abel Kooima Parents: Bob and Helen Kooima Waupun, Wisconsin

Tell us about the farm you work for. At L&N Dairy, we have a double-8 step-up pit parlor where we milk 300 cows. The cows stay in our freestall barn, overlooking our parlor. My bosses, Larry and Nate, are easygoing and keep mornings moving while also nding time to enjoy the workers’ company. This year, I worked with my triplet brother, Owen. It’s been a great time training and working with him while also expressing my love for agriculture. At L&N, we also have a bull nicknamed “King Abel.” We raise our calves for around two months before we send them to heifer raisers.

What are your responsibilities on the farm? I help with milking, including preparing cows. I keep a lookout for cows in heat, those needing oxytocin or any level of care. After milking, we shovel down the parlor and then spray it with water. After parlor chores are complete, we tend to the calves. We feed them grain, ll their water and get them ready for shots, if needed. If I had to pick a favorite chore, I would pick anything while I work with my bosses’ kids or with my brother. The kids are young but know so much about the farm, responsibilities and the day-today operation that I feel like I am learn-

ing so much from them. Owen is a hard worker but also a great friend to talk to. We don’t get much time to sit down and chat with our busy schedules, so having the time to catch up during work is something I try not to take for granted.

What is your favorite memory of working on a dairy farm? The sunsets after working night shifts. Alto has some of the most magnicent sunsets you will ever see. It was always a reection of a hard day’s work coming to a close.

What lessons have you learned from working on a dairy farm? The importance of hard work and making sacrices to be successful while nding time for family and faith. My bosses are perfect examples as they are absolute work horses, but they work hard to provide for their loved ones, which is extremely important. They help me navigate through life and nd time to work, learn and play. I am forever grateful for Nate and Larry.

What are your plans going forward? I will run for state FFA ofce to give back to the organization that gave me everything I needed to get to where I am at. I plan on going to Moraine Park Technical College to pursue a re protection technician degree. I want to help people on their worst days and be a community hero and role model, kind of like Batman.

Turn to SENIORS | Page 23

Collin Witte Assistant operations manager Burchinal, Iowa

Collin Witte Assistant operations manager Burchinal, Iowa

most fullling part of my job is seeing my team members and our members be successful knowing that I had a part in it.

Tell us about yourself and your agricultural background. This year will mark the 151st anniversary of my family stewarding our home farm where we raise corn, soybeans, cattle, sheep and goats. I enjoy being outside, gardening and reading.

Why did you choose to work for Five Star Cooperative? I started working for Five Star in March 2022 through an internship for my degree program at North Iowa Area Community College. I stayed on and became a seasonal employee before becoming a full-time operations specialist working in grain and agronomy. In February, I became the assistant operations manager at our Burchinal location.

Tell us about your role at Five Star Cooperative. In Burchinal, we have 1.75 million bushels of corn and soybean storage and are in the process of completing the largest single infrastructure project Five Star has ever constructed. The facility includes bulk seed, climate-controlled seed warehouse and treater, 75,000 gallons of indoor bulk chemical capacity, a 500,000-gallon 32% UAN tank, two drive-thru loadout bays, including one which is capable of 24-hour shipping and receiving, and a 4,000-ton dry fertilizer building. I play a major role in directing the work of our location’s operations team whether that be in the seed, chemical, fertilizer or grain aspects. I also am responsible for assisting the operations manager in maintaining the accuracy and quality of our assets and inventory. The

Tell us a favorite memory from working for Five Star Cooperative. The rst Thanksgiving that I worked here, the Dougherty location had a potluck dinner to celebrate the end of harvest and a successful growing season. The food was excellent, but the comradery and fellowship I shared with my fellow team members was and still is one of the big reasons I enjoy working here.

How do you expect to see the agriculture industry grow and develop? Agriculture will continue to evolve. Technology will continue to play a bigger role, and the way we do things will change. We will have to adapt to changing conditions in the marketplace and increased regulations as well as shifting priorities from the public.

What career advice would you give to your younger self? To not worry and just go for it. Don’t be ashamed or embarrassed about not knowing things.

How does your role at Five Star Cooperative positively inuence your community? Five Star can trace cooperative roots to 1889 when the original Cooperative Farmers’ Society of Rockwell was founded with the purpose of serving the members’ needs. For the last 135 years, our purpose has stayed the same. I now play a key role in continuing our tradition of service. My role also helps me promote the success of my team members. Everyone in our cooperative, from entry-level employees all the way up to our member-owners, is part of our local communities. When our people do better, our community does better.

Ashlan Bruins

Parents: Joel and Tonya Bruins Alto, Wisconsin

Tell us about your family’s farm. Homeland Dairy milks 700 cows three times a day and owns/rents 1,500 acres on which we grow corn, alfalfa, soybeans and wheat. Homeland Dairy also has a beef division where we raise 300 steers per year. We also own and operate a trucking company, Bruins Brothers, where we haul milk and commodities for Homeland Dairy and other farmers. Our farm is multi-generational, and several family members are involved, including my dad, uncle, cousins and grandpa.

What are your responsibilities on the farm? I help with feeding calves and mowing the lawn.

Abigail Becker

Parents: Steve and Shelly Becker

Auburndale, Wisconsin

Tell us about your family’s farm. My parents have owned the farm for 20 years. We are milking about 70 cows. Our barn is a head-to-head tiestall and holds 82 cows. My siblings and I are helping our parents on the farm.

What is your favorite memory of living on a dairy farm? I love spending my summers on the farm preparing my dairy animals for the fair. I love cows and all of the things I have learned through my time growing up on the farm.

What lessons have you learned from living on a dairy farm? I have learned to be patient. Most of my time on the farm is spent preparing fair animals, and this isn’t an easy task. It takes time, hard work and a whole lot of patience before animals are ready to be shown.

What are your plans going forward? I will attend the University of WisconsinWhitewater to study elementary education, and I hope that I am able to share my experiences about growing up on the farm with others.

What are your responsibilities on the farm? Feeding the calves and helping my mom milk. I used to do a lot of the smaller chores before my oldest sister went to college. I usually do the dehorn-

ing and give shots to the cows. My favorite chore is feeding calves.

What is your favorite memory of living on a dairy farm? My favorite memory is helping our veterinarian with emergency cesarean sections and displaced abomasum surgeries on the farm.

What lessons have you learned from living on a dairy farm? I have learned to never give up, and if you are determined and have God by your side, you can get through anything.

What are your plans going forward? I will attend Fox Valley Technical College for their agribusiness science and technology-animal science program.

Janelle Wolfe Parents: Justin and Jennifer Wolfe Waumandee, WisconsinTell us about your family’s farm. We milk 65 certied organic Holsteins. We milk in a 60-stall barn twice a day. My parents, my three younger siblings and I share responsibility for all day-to-day operations. We do all of our own eldwork.

What are your responsibilities on the farm? I am responsible for helping with daily chores, daily feedings and eldwork. My favorite job is helping

HannaWard Parents: Randy and Minnie Ward St. Charles, Minnesota

Tell us about your family’s farm. We have a custom calf raising facility. We house 100-120 calves on milk along with 120 calves to 5 months of age.

with hay harvest every summer.

What is your favorite memory of living on a dairy farm? My favorite memory is getting to work with my siblings to complete chores on a daily basis.

What lessons have you learned from living on a dairy farm? Working on my family’s dairy farm has taught me the importance of teamwork and communication.

What are your plans going forward? This upcoming fall, I plan to attend the University of Wisconsin-River Falls to major in agricultural business.

What are your responsibilities on the farm? My responsibilities include taking care of the young calves on the automatic feeder. I help with vaccinations and cleaning of the pens. I also have taken care of my show animals. My favorite job is the calves. Coaching them on the feeder and then having them learn on their own is fullling.

What is your favorite memory of living on a dairy farm? The calves are fun to interact with. With our auto-feeder, they are in a group setting, so interacting with them is fun.

What lessons have you learned from living on a dairy farm? Responsibility of taking care of something beyond yourself. The dedication you need to have as you are on their schedule and they joy it provides on a daily basis even when there are tough days.

What are your plans going forward? I will attend Winona State University, majoring in elementary education.

Poppler graduates, adds on program to further education

By Sherry Newell Contributing writerWILLMAR, Minn. —

Known for years as a top provider of two-year agriculture degree programs, Ridgewater College in Willmar recently took an extra step toward preparing its students for careers.

The school has added certicate options that zero in on specic skills for use in current or future jobs in agriculture.

Certicates in agricultural marketing and communications, precision agriculture, meat cutting and poultry management are among the offerings. A oneyear hands-on agronomy applicator technician is also offered.

At the same time, Ridgewater College continues to provide two-year programs in agribusiness, dairy management, agronomy, farm operation and management, precision agriculture and agriculture equipment mechanics.

Tammy Howe, agricul-

ture department coordinator at Ridgewater College, said the certicate programs are designed to make an impact in a short time.

“Today’s students seem to want to get started on their career path as soon as they can,” Howe said.

One of the newest certicates is agricultural marketing and communications.

“This is a great option for someone interested in marketing and maybe works for a smaller company in our agriculture communities,” Howe said.

Halli Poppler, who comes from a 650-cow dairy near Waverly, is one of the students pursuing the agricultural marketing and communications certicate. She graduated with a degree in agricultural business this spring but is adding the certicate through additional classes in fall.

“I didn’t really know what I wanted to do (with ag business),” Poppler said. “I talked with the staff and saw this new certicate, which put together all the things I was wanting to do. I enjoy marketing and communications as there are a lot of opportunities and different parts of it. Every day is different, and there is never a dull moment.”

Poppler is completing a marketing internship at Centra Sota Cooperative in Buffalo and will have a similar one at First District Association over the summer.

Ridgewater College helped Poppler combine classes with a work-study opportunity. She created a program outline for the ag department and made daily posts on its social media pages for her electronic publishing class. She also worked on the school’s student recruitment plan as part of her strategic marketing class.

The classes for her certicate also include e-commerce, social media, website creation, editing, design, video and photography.

“It all relates to what I’ve been doing in my internship,” Poppler said. “I’ve already utilized it in real life.”

Other certicates are meant to be useful to high school graduates as well as adults seeking additional training.

The poultry management certicate is offered online, while meat cutting gives students hands-on training in butchery in a set of two stackable certicates on a exible schedule.

Precision agriculture is a hy-

brid offering, both online and in person. It emphasizes technology such as GPS along with aerial and satellite imagery. The agronomy applicator

technician program helps students build condence in operating forklifts, self-propelled sprayers, fertilizer applicators, skid loaders and semis.

• Long-standing Dairy Management training excellence

• 12 ag-specific programs — close to home!

• Student-focused, hands-on, affordable education

• 98% average graduate job placement rate (2022)

• Passionate industry partners committed to student success

• Paid internships designed to build skills and experience

Students benet from small classes, close

RIVER FALLS, Wis. — Making decisions about what their next steps in life should be is not always an easy decision for high school students nearing graduation.

Dr. Steven Kelm, chair of the University of Wisconsin-River Falls Animal and Food Science Department, said the programs and opportunities available on the UWRF campus offer a range of agricultural degree options through four-year programs and the more focused, hands-on option of the Farm and Industry Short Course.

“UWRF offers a complete college experience for all our students whether it is in our four-year programs or in our short-course program,” Kelm said. “In addition to taking courses that focus on the cow, students are taking courses that focus on business management, forages, soil sciences.”

One of the greatest tools a student can take from their secondary education is a strong network of industry-related contacts, Kelm said.

“We encourage our students to take advantage of learning opportunities throughout the industry,” Kelm said. “Several of our students have participated in the Pro-

fessional Dairy Producers mentorship program and attend the PDP Business Conference each spring as part of that program.”

The campus has a small-town feel with class sizes to match, which Kelm said draws many students.

Rachel Rynda, of Montgomery, Minnesota, said UWRF was the only college application she submitted as a high school student.

Rynda graduated with a degree in agricultural business this spring. The small class sizes made her experience a great one, Rynda said.

“You really get to know your professors,” Rynda said. “They become your friends, your biggest cheerleaders, and you push yourself more because of that. Where else can you get that kind of experience?”

The university’s Mann Valley Farm provides a benet to all students in terms of exposure to techniques for management practices, Kelm said.

“We do a signicant amount of hands-on learning and have access to the farm which really functions as our laboratory,” Kelm said. “It’s a teaching space where we have access to the animals all the time. We put students in scenarios that are very much real-life and then give them the cows to work with to bring that home even more.”

Jack Saemrow, of Waterville, Minnesota, who graduated this spring with a degree in dairy science, said the network he created

as a student paired with the knowledge he gained as a result of the hands-on learning experiences secured him an internship at a 4,500cow dairy in Fabius, New York. Saemrow visited the farm on a trip with the UWRF Dairy Club.

“The hands-on learning at the lab farm is very benecial,” Saemrow said. “The labs I had at UWRF prepared me for the hands-on aspect of an internship and a career as a herdsman.”

That hands-on learning coupled with the abbreviated school calendar drew Connor Weltzien, of Arcadia, to the Farm and Industry Short Course.

“The program caught my eye because I wanted to be home for harvest and planting seasons,” Weltzien said. “It was more geared toward dairy and all my interests in farming. I loved that way of learning: a short lecture on a specic topic and then going out to put it to practice at the farm.”

The program gave Weltzien more than the dairy-centric approach he desired.

“We learned everything from nancials and succession planning and other things we need for the day-to-day operating side of things that will help down the road,” he said. “Every Friday, we toured farms and businesses, which gave us many different perspectives.”

Weltzien said he enjoyed being on campus so much that he enrolled as a four-year student to pursue a degree in agricultural business. He transferred in with 16

credits he earned as a short-course student.

Dr. Steve Kelm demonstrates how to administer an IV to Farm and Industry Short Course students at the University of Wisconsin-River Falls. The 2023-24 academic year marked the rst year the program was hosted at the River Falls campus. velopment than you would think,” Schuh said. “I learned a lot about managing people, delegating and really about running a business model. It was denitely a leadership opportunity at a whole new level.”

Not all learning at UWRF happens in the classroom, a fact Joe Schuh, of Freedom, can attest to. Schuh, who will graduate in December with a degree in dairy science, served as a co-chair for the Dairy Club’s Falcon Premier Sale in March.

“I am passionate about genetics,” Schuh said. “Visiting farms to select consignments was a great opportunity.”

While he enjoyed laying the groundwork for a successful sale, Schuh said sale week provided him with a bevy of educational opportunities.

“It was a lot more personal de-

Kelm said personal growth is the foundation of the college experience. The goal at UWRF is to offer as many opportunities as possible.

“I don’t think there is a time of greater personal growth than that 18- to 22-year-old phase,” Kelm said. … “College is a perfect place to become exposed to other areas of the industry and students who have similar, yet different, experiences.”

At Farmers Win Cooperative, Crop Scout Interns are given an opportunity to connect classroom agronomic knowledge to the field first-hand. Throughout the season, you will learn to identify weeds, diseases, and insects affecting crop growth and development. You will gain experience testing soil and plant nutrients, and analyze reports used to make crop input recommendations with an experienced Agronomist.

The crop scout interns will be based out of Fredericksburg, IA, Waucoma, IA, Cresco, IA, Jackson Junction, IA, Burr Oak IA, Ridgeway, IA, Mabel, MN, and Spring Grove, MN.

Sophomores and up can receive on average $3,800 in department scholarships per year

Careers include: plant management, product development specialist, flavor chemist, microbiologist or marketing specialist

Position Duties:

• Inspect assigned grower fields to identify weeds, insects, diseases, pest and crop population counts, crop and weed staging and other crop diagnostic issues.

Internship opportunities available for 2025!

• Utilize crop scouting software/weekly reports to document and share observations with partnered field Agronomist.

• Keep current on agronomic products, trends, and precision ag technologies.