Twice the legacy, double the celebration We're all in on

Twice the legacy, double the celebration We're all in on

From pop culture to wellness trends, DFA is making sure milk's moment is here to stay.

You already know milk is the real deal — nutritious, versatile, and built on generations of hard work. Now, the rest of the world is catching up. From TikTok coffee creations to gym bag essentials, milk is quietly staging a comeback and DFA is leading the charge to make sure it sticks. Because real milk’s classic goodness doesn’t need reinvention — just a louder voice.

QASK THE EXPERT

Tim Hawk

GROUP VICE PRESIDENT

What do you think is driving the renewed hype around milk today?

When it comes down to it, people want something natural. They want something that’s local, clean, and the real deal. It doesn’t get more natural than milk.

You’re leading a task force to modernize school milk — can you share how DFA is working with school districts and policymakers to make milk cool in school again?

School districts have many regulations and menu-planning challenges. So, we work really hard to make a product that checks all of the boxes and tastes great, so kids will want to drink it. We’re also innovating ways to make milk more accessible. This school year, we rolled out shelf-stable, lactose-free milk. This helps school districts provide nutrition and natural goodness, regardless of sensitivities or intolerances.

What is the most exciting thing you’ve seen as a result of milk’s resurgence? People are asking for milk again. They’ve tried everything else and have rediscovered real, wholesome dairy. You have to have water to survive, but you have to have milk to thrive. It’s exciting that others are realizing it again.

QASK THE EXPERT

Kristen Coady

CHIEF INNOVATION AND BRAND OFFICER

What factors are contributing to milk’s renewed popularity?

There isn’t just one thing that’s driving it. People are looking closely at the makeup of their food. The simplicity and nutrient density of dairy is really attractive. That, coupled with the increased awareness of dairy as a sustainable solution, is bringing the powerhouse of milk back to the forefront.

What's the biggest trend in dairy you're seeing right now?

We continue to see consumers wanting more protein in their diet. We’re always listening to what the consumer is saying, and right now protein is the hero. Products like TruMoo® Protein bring the taste people love and the protein they want, all from the power of real milk .

What excites you most about the future of dairy?

I’m excited that it’s cool to say you like milk again. That feeling of pride is something we’re going to grab onto and bring into all of our innovations moving forward. It allows us to better deliver on our mission to bring value back to our farmer-owners.

DFA has been championing the Whole Milk for Healthy Kids Act since it was first introduced in the U.S. Congress in 2023, and we’re still going strong.

Why we're doing it: We’re on a mission to make school milk enjoyable again — it turns out that kids don’t race to the coolers when fat-free milk is the only option. Kids need the nutrients from milk to learn and grow.

What we're doing: Whether it’s digging into research, drafting letters to members of Congress, or creating new, innovative products, our teams have rallied around the goal to bring whole milk back to school lunchrooms. It’s a powerful reminder of what we can accomplish when we work as One DFA — because a brighter future starts with healthy kids.

"Over the past two years, our farmer-owners and employees have helped keep the pressure on by submitting nearly 2,000 emails in support of this legislation. We hope to finally get it passed this year."

ANNE DIVJAK | VICE PRESIDENT, GOVERNMENT AND INDUSTRY RELATIONS

"We have made progress on Capitol Hill and we are closer than ever to passing this legislation. When members of Congress hear directly from their constituents, it makes a difference."

MARY KNIGGE | VICE PRESIDENT, GOVERNMENT RELATIONS

If it tastes good, kids are going to drink it. Thanks to our research and development teams, our chocolate milk meets or exceeds all the regulatory requirements for sugar, and it tastes great! If we combine that with a higher fat milk, we’re going to see a dramatic increase in consumption.”

THIS IS MILES EZELL SR. WHEN HE BEGAN HIS DAIRY, LATER TO BECOME PURITY DAIRY ™

What started as a leap of faith and a few dozen cows has led to a century of pure, delicious dairy for Nashville, Tenn., families. This year, DFA farmer-owned brand Purity Dairy celebrates its 100th anniversary.

Purity Dairy began in 1925 when Miles Ezell Sr. purchased a delivery truck and a few dozen cows on credit. The business overcame many challenges, and even saw growth during the Great Depression, likely due in part to Miles being extremely particular about the quality of his products.

In one of many letters to his family, Miles wrote: “In order to succeed: think big, dream, work hard, and be honest.” He was a driving force behind many innovative processes and packaging breakthroughs, including vacuum pasteurization, nonwax milk cartons, and the brand’s famous yellow plastic jug, which became a symbol of freshness and quality.

Today, the brand, manufactured by 270 employees at DFA's Nashville, Tenn., plant, offers more than 100 products and sources milk from two DFA farms.

To celebrate 100 years, the team hosted the Purity Moosic City Dairy Dash earlier this year. With more than 2,100 participants, the event raised $250,000 for the Young Women's Christian Association (YWCA).

PLANT PROFILE:

Location: Nashville, Tenn.

Year opened: 1925

Employees: 270

Products made: Buttermilk, cream, eggnog, lemonade, milk, orange juice, and sour cream

Known for:

Nutty Buddy novelties and yellow jugs of milk

PLANT PROFILE:

Location: Orlando, Fla., and Orange City, Fla.

Year opened: 1925

Employees: 485

Products made:

Buttermilk, creams, milk, and teas

Known for:

Hopper Lee, a famous cow statue, on the Orlando, Fla., location's roof

Before there was Walt Disney World®, Orlando, Fla., had a different attraction: T.G. Lee® Dairy. The DFA farmer-owned brand is celebrating its 100th anniversary.

T.G. Lee Dairy hit the scene in 1925, when founder Thomas Gilbert (T.G.) Lee and his wife, Elizabeth, started the dairy with 20 acres and one cow while doing all the milking, bottling, and delivering themselves. By the mid-1930s, they had built an advanced milking parlor that attracted crowds eager to witness cows being milked by machines.

Orlando has since grown into the bustling city we know today, but T.G. Lee Dairy still stands 100 years later as Florida’s hometown dairy brand. With nearly 500 employees working for the brand across DFA's two central Florida locations, milk is sourced from 26 DFA farms. T.G. Lee Dairy produces everything from milk to eggnog. And those employees are a testament to the culture that has been created, with multiple employees being second or even third generation.

To celebrate 100 years of dairy excellence, employees received a commemorative gift box, and the team hosted The Milk Run, a community 5K and after-party attended by 800 participants. The run raised $25,000 for the Central Florida Chapter of Second Harvest Food Bank, which will provide This will provide 100,000 meals to people in need throughout the community.

ONE DFA EFFORT, ONE DELICIOUS RESULT

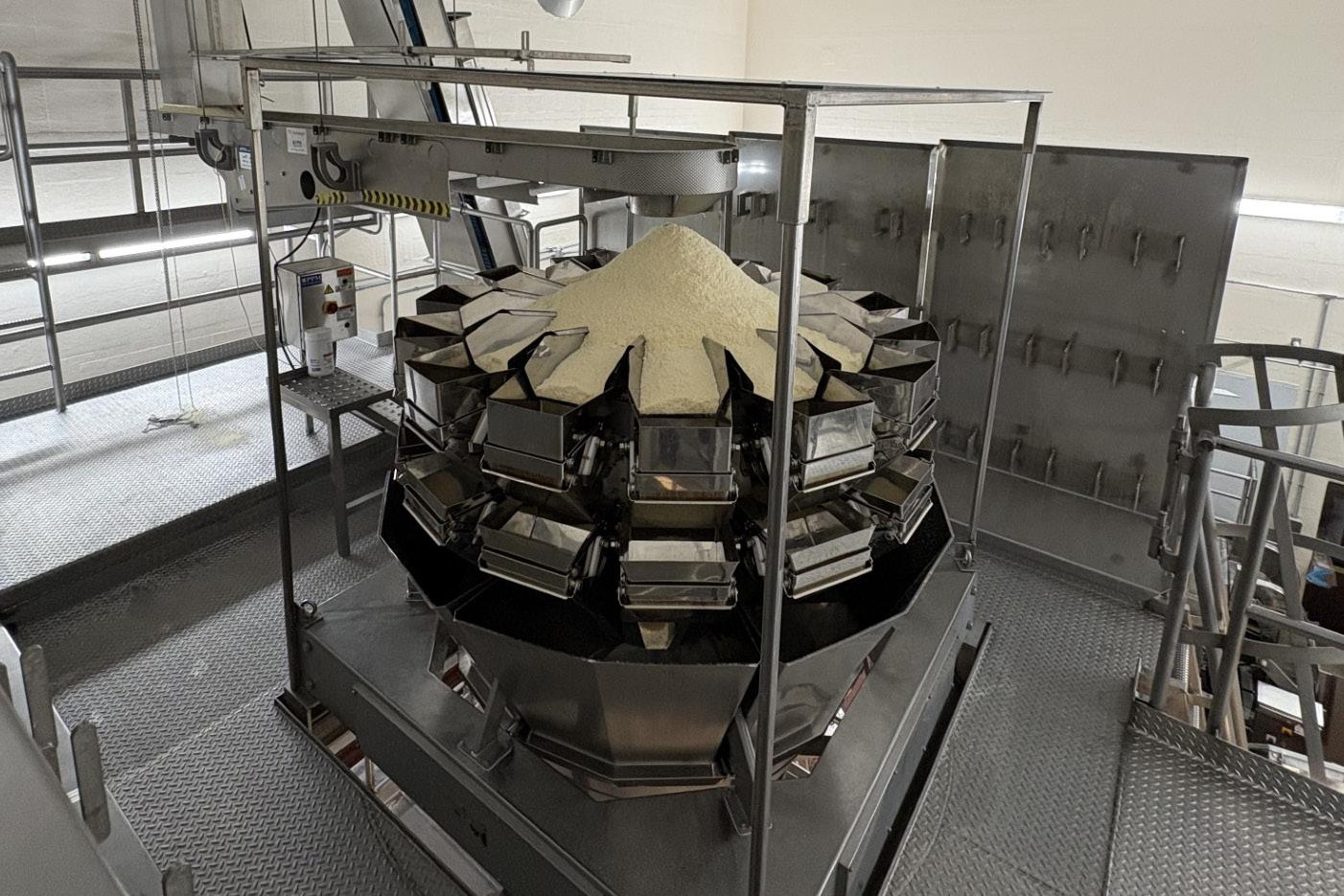

Milk50™ — a new ultrafiltered, lactose-free milk with only 50 calories and 75% less sugar than regular skim milk from DFA farmer-owned brand DairyPure® — launched earlier this year. Getting it onto grocery store shelves is a true One DFA effort. It all begins at DFA’s plant in Portales, N.M., where ultrafiltered milk is produced and shipped in tankers to DFA’s Cedar City, Utah, plant. Upon arriving, the milk is transferred to on-site tanks, blended into the correct formulation, tested for quality, and bottled into Dairy Pure-branded 1.5-quart containers in original, vanilla, and chocolate flavors. From there, DFA drivers deliver the finished product to retail locations nationwide.

Tucked away in the high desert of southwestern Utah, Cedar City is known as the “Gateway to National Parks.” The city also serves as a significant location for DFA’s manufacturing capabilities, where our plant, known as Western Quality Foods, specializes in extended shelf life processing for various customers.

The plant has a long history dating back to the 1980s, when it operated as the manufacturing facility for TCBY® frozen yogurt. Today, the plant, which is part of DFA’s Beverage Solutions Division, produces a variety of dairy and non-dairy products, including beverages, ice cream mix, and half and half.

With state-of-the-art technologies, the plant operates two unique production lines: plastics and gables. On the plastics side, the plant blows its own plastic bottles, which range in size from 14–48 ounces, bottling

products for DFA and other wellknown brands. Earlier this year, the plant launched 48-ounce bottles of TruMoo® and Milk50™ by DairyPure®.

The gable side of the plant produces bagged and Tetra Top® products in sizes ranging from pints all the way up to 64 ounces. The plant’s Tetra Top bottles boast an extended refrigerated shelf life of up to 120 days. Additionally, the plant produces 2.5- and 5-gallon bags of milk for foodservice customers.

The plant’s 115 employees have a strong reputation for their commitment to collaboration, quality, and work ethic that they credit as a key ingredient to their success. This commitment keeps the Cedar City plant at the forefront of the dairy industry, anchoring the community, and shaping the future of quality dairy foods.

At DFA, our most significant accomplishments come from effective teamwork. From projects that united unexpected partners or instances when common goals led to exceptional results, your experiences are valuable. Whether it contributed to a big initiative or a small project, we encourage you to share your One DFA story and help foster a culture of collaboration across the Cooperative.

your

Reaction Dairy is the latest innovation in DFA's ingredients portfolio. Produced at the DFA plants in Hummelstown, Pa., and Bruce, Wis., the ingredient is offered in two formats (powder and paste) and comes in three specialized lines (Reaction Milk Fat Concentrate, Reaction Enhancer, and Reaction Brown Butter). Each line is tailored for applications from bakery to confectionery. With its clean, simple ingredients, Reaction Dairy gives food manufacturers flexible solutions to boost flavor, texture, and efficiency, meeting today’s demand for multifunctional, label-friendly food ingredients.

Applications in which Reaction Dairy can be used:

Baked items and confections

Lifts caramelized and roasted flavors, extends cocoa, and supports consistent, bold taste experiences.

Beverages

Amplifies dairy and chocolate notes, mutes bitterness, and supports sugar reduction.

Ice cream and frozen desserts

Allows for lower milk fat (below 10%) without compromising the creamy mouthfeel consumers love.

Soups and sauces

Enhances flavor, stabilizes emulsions, and helps build mouthfeel — even for lower-fat or concentrated products.

A truly flexible ingredient, it works across baked items, beverages, confections, ice cream, soups, and more.

Customizable results

Depending on what a customer is looking for, it can extend cocoa intensity, enhance caramelized and roasted flavor notes, and boost the overall indulgence and mouthfeel of a product.

Some food manufacturers use high-intensity sweeteners to cut sugar. Reaction Dairy masks the bitterness of these sweeteners, enabling lower-sugar formulations without sacrificing taste.

Because Reaction Dairy amplifies flavor and texture, it helps customers replace or reduce more expensive ingredients, such as butterfat and cocoa.

Simple, recognizable ingredients help our customers win with label-conscious consumers.

INSTANT FLAVOR AND TEXTURE BOOSTER

In the quiet fields of Marcus, Iowa, the Wilcox family has spent generations growing their farm. What began in 1947 as Wilcox Bros., founded by brothers Ernie and Les Wilcox, is now Corn-Belt Dairy, a fifth-generation operation led by Joe Wilcox and his wife, Jill. The land itself has been in the family since 1876, and in 2026, they’ll mark 150 years of calling it home.

While Les Wilcox served in World War II, his brother Ernie stayed behind to keep the farm running — at the time, families with farms only had to send one son to war to ensure the land could still be worked. Ernie continued to improve the farm over the years, guiding it through changes and challenges, including rebuilding after a devastating tornado in 1952. His son Mark carried on that commitment, leading the construction of a freestall barn in 1990 and a new milking parlor in 1993, before eventually passing the reins to his second son, Joe. “You learn to adapt and look ahead,” Mark says. “That’s what keeps it alive.”

Today, Joe and Jill are raising their two children, George and Helen, on the same land where Joe grew up. They live just across the road from Mark and his wife, Sara, both still helping with morning chores and milking cows daily. “It’s a gift to raise our kids here, where they’re not only surrounded by open space, but also by family,” Jill says. “They’re growing up seeing the value of working together to feed the world.”

The Wilcoxes run the farm without full-time employees, instead welcoming local high schoolers each summer, giving the next generation hands-on experience to the ropes of running a dairy. And when Joe’s three other siblings return home from time to time, they jump back into barn boots without hesitation, helping keep the heart of this family farm beating strong, generation after generation.

It’s a gift to raise our kids here, where they’re not only surrounded by open space, but also by family. They’re growing up seeing the value of working together to feed the world.”

JILL WILCOX, DFA FARMER-OWNER

In addition to dairy farming, they also cultivate corn, soybeans, and alfalfa, ensuring their operation remains diverse and self-sustaining. As the only dairy farm in Cherokee County, the Wilcoxes are passionate about sharing their story with the local community. Every year, they host fifth-grade students from three nearby schools, giving them a firsthand look at where their milk comes from and how it's produced.

For Mary Roberts, dairy isn’t just a career — it’s a legacy. Raised in the small town of Athens, Tenn., Mary grew up surrounded by DFA farmer-owned brand Mayfield Dairy Farms® and the family who founded it.

“In a small town, families know each other well,” she says. “My parents were friends with the Mayfields. They were deeply respected in the community — and so was the brand.”

After earning her accounting degree from the University of Tennessee, Mary returned home and joined Mayfield Dairy Farm’s Accounting Department the day after Christmas in 1989.

“I spent a year with one of the Big Eight firms, but I wanted to be back in Athens,” she says. “Thirty-six years later, I’m still here.”

A fresh experience

After years in accounting, Mary was ready for a new challenge. She asked Scottie Mayfield — then President of Mayfield Dairy Farms and grandson of its founder — for a shot at sales. He hired her for a key account role and mentored her through the transition.

“He taught me what to do, and what not to do,” she says. “He gave me opportunities I wouldn’t have had under anyone else’s leadership.”

Mary rose through the ranks — Key Account Sales, Sales Manager, and Vice President of Sales. In 2001, when new ownership implemented a general manager structure, she became General Manager for Mayfield milk and ice cream, overseeing four plants, 300 routes, and full-service direct store delivery (DSD) operations. In 2022, when the Cooperative separated the fluid and frozen portions of the business, Mary chose to oversee the ice cream side. "Ice cream is so fun," she says. "It just brings joy to any occasion!"

“Becoming a General Manager was a big leap," she says. “I was managing people 20 years older than me. It took time to earn their respect, but we built a strong partnership.”

As one of the few women in leadership in a male-dominated industry, Mary has seen the landscape shift.

FUN FACT: Mary's favorite dairy treat is Mayfield Dairy Farms Brown Cow Delight™ ice cream

“For years, I was the only woman in the room,” she says. “That’s changed. Women bring a different perspective to the business. It rounds us out and makes us better.”

Leading with heart Today, as General Manager overseeing the two DFA plants that produce Mayfield Dairy Farms products, Mary remains handson — calling on customers and visiting ice cream plants daily.

“Being in the plants has changed how I connect with our teams,” she says. “Understanding what they do and what they need has been incredibly rewarding."

She also oversees the Mayfield Visitor Center, which opened in 1994 and welcomes more than 100,000 guests annually.

“It’s a pillar of our community,” she says. “We do outreach with schools, host events like milk and cookies with Santa, and celebrate Maggie’s birthday — our fiberglass cow mascot.”

Despite the changes over the years, Mary’s drive remains the same: Delivering the best-tasting milk and ice cream in the world.

“I didn’t do this alone,” she says. “I’ve had a lot of help along the way. The team has changed over the years, but the goal has always been the same — pleasing our customers. If you accomplish that, you’ve done your job,” she says. “Mayfield means quality. We’re one of the fastest-growing brands in DFA right now, and I’m proud of what we’ve built.”

“For years, I was the only woman in the room. That’s changed. Women bring a different perspective to the business. It rounds us out and makes us better.”

MARY

ROBERTS, GENERAL MANAGER, ICE CREAM, MAYFIELD DAIRY FARMS

Whether it's a recipe passed down for generations or a happy kitchen accident, our employees and farmer-owners are sharing their best not-so-secret recipes with you through our new DFA Community Cookbook. Every purchase supports our DFA Cares Foundation, helping us reach our $500,000 goal by the end of the year.

See a sneak peek of the recipes in the DFA Community Cookbook — coming soon.

Pão de Queijo

(Brazilian cheese bread)

EMPLOYEE Neri Martins-West

ROLE Sustainability Technical Services Coordinator

LOCATION Kansas City, Kan.

To Neri, this recipe is a story of tradition, creativity, and the joy of baking with her 6-year-old son, Benjamin. Her roots are in Minas Gerais, Brazil, the heartland of Brazilian dairy and the birthplace of Pão de Queijo. “It's a wonderful way to connect to my Brazilian heritage and enjoy a taste of home, even thousands of miles away,” she says.

1 cup plain Greek yogurt

1 cup grated Parmesan cheese

½ cup shredded Asiago or mozzarella cheese

(or a mix — we often use what we have on hand)

1 cup tapioca starch (plus a little extra if you need it)

1 egg

A pinch of salt

METHOD

01 Heat oven to 350 F

02 Mix all ingredients in a bowl until a dough forms. It should be slightly sticky but easy enough to handle

03 Adjust the texture if needed. If the dough is too sticky to roll comfortably, just add a bit more tapioca starch, 1 spoonful at a time, until it's just right

04 Shape the dough into small balls with lightly oiled hands. (This makes them easier to handle and prevents sticking.) Place balls on a parchment-lined baking sheet

05 Bake for about 20 minutes, or until they're beautifully puffed and golden brown

06 Serve warm and enjoy a delicious taste of Brazil — wherever you are

Holiday Cheese Ball

EMPLOYEE Victoria Walser

ROLE Senior Accounting Specialist

LOCATION East Syracuse, N.Y.

This is a fan favorite around the holidays at Victoria’s family get-togethers. For a fun holiday-themed appetizer, she recommends forming the cheese ball into a turkey, snowman, Christmas tree, or snowflake.

8 ounces cream cheese, softened

8 ounces extra sharp cheddar cheese, grated 5–6 ounces blue cheese, crumbled 1 tablespoon Worcestershire sauce (or measure with your heart)

½ large yellow onion, chopped ½ cup chopped walnuts, optional Crackers or veggies of your choice for serving

01 Add cream cheese, cheddar cheese, blue cheese, Worcestershire sauce, and chopped onions to a large bowl

02 Mix with your hands or an electric mixer until all ingredients are evenly distributed and you can form it into a ball

03 Shape into a ball and wrap with plastic wrap. Refrigerate until ready to serve

04 If using, coat the cheese ball with chopped walnuts just before serving

05 Serve with your choice of crackers or veggies for dipping

WE CAN REACH OUR GIVING GOAL

The DFA Cares Foundation is committed to creating a meaningful impact in the communities where we live and work. We’ve set a goal this year of raising $500,000 to expand our impact and help more families, farms, and future leaders in our industry.

Your donation, no matter the size, will directly support:

• Hunger relief efforts in rural and underserved communities

• Emergency aid for farmers and communities affected by natural disasters

• Scholarships for students committed to careers in dairy and food manufacturing

How well do you know their history?

DFA farmer-owned brands Purity Dairy and T.G. Lee Dairy have built legacies that have

Fill in the blanks below to complete the challenge.

1. Miles Ezell Sr. founded

2. In 1925, T.G. Lee Dairy began producing dairy products in , Fla.

3. Purity Dairy's famous plastic milk jugs are

4. One of the challenges Purity Dairy overcame through in its early days was the

5. T.G. Lee Dairy sources milk from DFA farms.

6. To celebrate 100 years, T.G. Lee Dairy hosted , a community 5K.

7. Purity Dairy began its journey in , Tenn.

8. Besides milk, another product T.G. Lee Dairy produces is

Hint: Peek at pages 4 and 5 for clues. Check your answers on the right of this page.

WIN A PRIZE

Scan to complete the challenge for your chance to win a DFA Store gift card.

Celebrating the creativity and pride of our plant teams, the Cheese, Taste, and Flavors Division recently wrapped up its photography contest. Employees captured the heart of DFA operations with great shots across three categories: Exterior, Interior, and Employee. Winning entries highlighted vibrant facilities and dedicated team members, with the DFA plant team in El Dorado Springs, Mo., earning top honors for overall participation. Enjoy a selection of these standout photos as we showcase the talent and spirit that make our plants so exceptional.

<<EMPLOYEE NAME>> <<ADDRESS>> <<CITY, STATE ZIP>> 1405 N.

Your photo won "Best in Show" in our most recent Cheese, Taste, and Flavors Division photography contest! We’re grateful for the creativity you bring to our Cooperative. Let’s hear it for Alison Henson | General Manager | Bruce, Wis.