MX-11 standard

PX-9 optional

MX-13 optional

Hendrickson HAULMAAX® EX

Allison 4500RDS standard

Allison 4700RDS optional 16909ALL optional

MX-11 standard

PX-9 optional

Hendrickson HAULMAAX® EX

Allison 4500RDS standard

MX-13 optional

DD13 standard

X12 optional

Allison 4700RDS optional 16909ALL optional

Hendrickson HAULMAAX® EX

Allison 4500RDS standard

Allison 4700RDS optional

16909ALL optional

DD13 standard

X12 optional

MP7 standard

MP8 optional

Allison 4500RDS standard

Allison 4700RDS optional

16909ALL optional

Allison 4500RDS standard

Allison 4700RDS optional

16909ALL optional

DD13 standard

X12 optional

Allison 4500RDS standard

Allison 4700RDS optional

16909ALL optional

*Set-forward and set-back front axle position configurations available

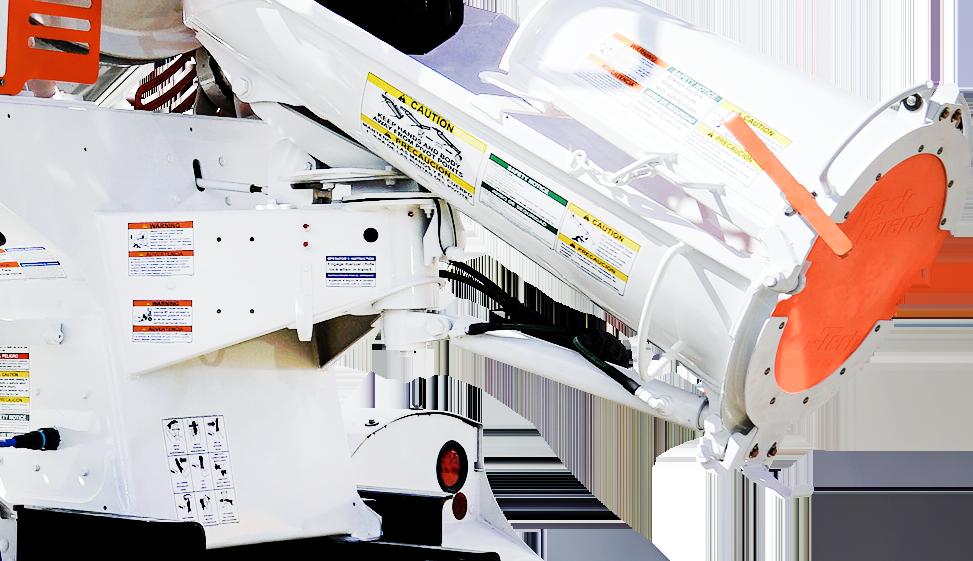

The Con-Tech® Extreme Duty Mixer delivers proven durability and superior performance across a variety of demanding job sites. With enhanced load capacity and rugged design, it ensures reliability and stability, even in the harshest conditions. Optimized for efficiency, the Extreme Duty Mixer maximizes productivity while minimizing operational costs, making it ideal for heavy-duty applications and high-volume operations.

Simplicity in design ensures ease of operation and maintenance, reducing downtime and extending the lifespan of your equipment. Advanced engineering features, including customizable controls and heavy-duty components, provide the flexibility to meet specific operational needs. The Extreme Duty Mixer is built to last, withstanding daily wear and tear while delivering consistent, high-quality results, ensuring long-term profitability and peace of mind for your business.

Con-Tech offers multiple options for your mixer’s pump controls. Both cab and rear controls can be customized to your preference. We offer both cable controls and RE (12-volt electric) pump controls. Rear controls can be toggle pendant, manual, or a wireless rear control box. Drum saver (constant speed) options are available.

Con-Tech offers the reliable PMP Straight Drive or the fully proven ZF P-7300. Both options deliver excellent performance, with a focus on durability, reduced maintenance, and longterm reliability, ensuring your mixer operates efficiently under the toughest conditions.

In partnership with Con-Tech’s HP™ Drum, the Extreme Duty® addition offers more flexibility in maximizing your payload.

Con-Tech trucks come standard with heavy-duty EATON pumps and motors. Included is a 5-year limited warranty. Our hydraulic system comes standard with Chevron Rando HD oil (with advanced additive and base oil technology).

Con-Tech wiring harnesses are built with simplicity and durability in mind. All wiring harnesses have each wire labeled for ease of troubleshooting and are built with Deutsch connectors for unsurpassed reliability.

Con-Tech’s High Performance rear pedestal is built with six fully welded pieces for maximum corrosion resistance and strength. The lower roller deck plate and wash bands direct materials away, making cleaning easier and extending the pedestal’s lifespan by reducing buildup and corrosion.

Our newly designed High Performance main chutes are wider, providing higher capacity. They are designed to reduce clearance issues and minimize material overflow while the chutes are in a horizontal position. All Con-Tech chutes are capped and 100% welded for strength and resistance to the elements.

Our newly designed High Performance ladder and platform feature a nonslip, level, open-tread design with extra-wide upper and lower grab bars for a safe and easy transition.

Con-Tech’s rollers were designed alongside the High Performance pedestal. The combination of the taller roller and the lower deck creates easier access to the roller bracket for cleaning and maintenance.

UNMATCHED DURABILITY

• Built with heavy-duty components that are engineered to withstand the most challenging environments, ensuring longlasting performance and minimal downtime.

SUPERIOR LOAD CAPACITY

• The Extreme Duty mixer is designed to handle larger payloads, optimizing efficiency and productivity on every job site.

OPTIMIZED FOR EFFICIENCY

• With components like the HP Drum and PMP Straight Drive gearbox, the mixer maximizes fuel efficiency and reduces operational costs, making it a cost-effective solution for highdemand operations.

CUSTOMIZABLE CONFIGURATIONS

• The Extreme Duty mixer offers a range of customizable options, allowing you to tailor the mixer to your specific operational needs, whether it’s through different axle configurations, control systems, or hydraulic setups.

• Incorporates cutting-edge technology, including customizable controls and high-performance hydraulic systems, to enhance ease of operation and overall efficiency.

• Features like the HP Ladder and Main Chute provide safer and easier access, while the Rear Pedestal design ensures stability and reduces wear, offering peace of mind in demanding conditions.

• Backed by years of field-tested performance, the Extreme Duty mixer has a reputation for reliability, ensuring consistent results and reduced maintenance needs across various job sites.

-OPTIMIZED

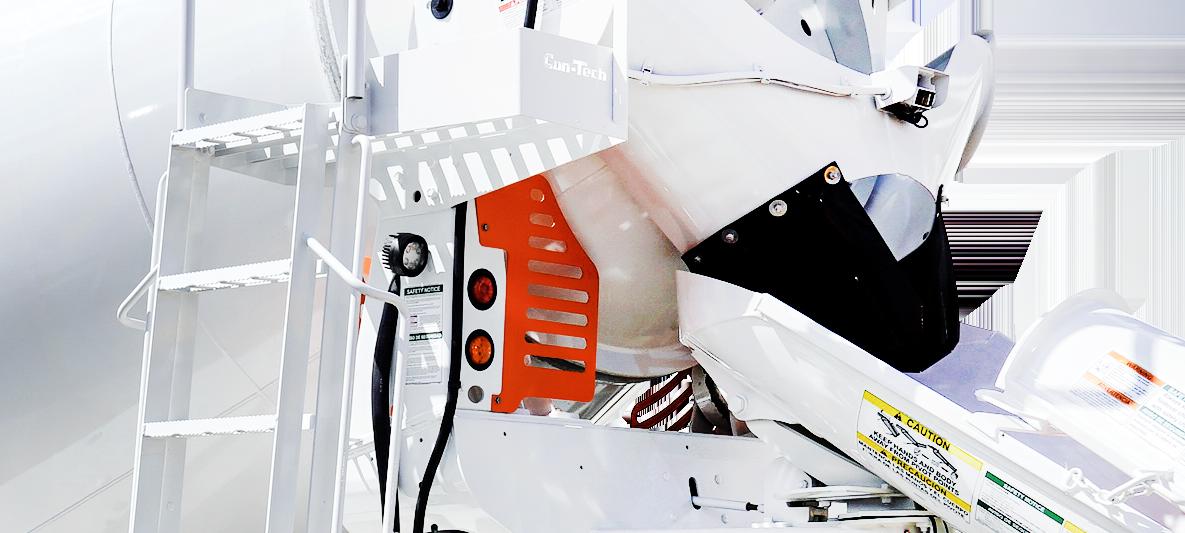

The Con-Tech® BridgeKing® mixer offers proven strength and superior performance in compliance with strict federal and state bridge laws. With its optimized payload capacity and durable design, the BridgeKing® ensures exceptional reliability and stability, even under the most demanding job site conditions. Engineered for efficiency, this mixer maximizes productivity while reducing operational costs, making it an ideal solution for high-volume and specialized concrete projects.

Simplicity in design promotes ease of operation and maintenance, reducing downtime and extending the service life of your equipment. The BridgeKing® mixer is built with advanced engineering features, including customizable axle configurations and rugged components, providing the flexibility to meet diverse operational requirements. Designed to last, it withstands daily wear and tear, delivering consistent, high-quality performance and ensuring long-term profitability and peace of mind for your business.

Con-Tech offers numerous options for your mixer’s pump controls. The cab and rear control stations can be customized to fit your needs. We offer Cable, RE (Remote Electronic) as well as the latest in mixer control technology from Con-Tech, the Elite® Control System. Reliability is a priority regardless of the system you choose.

Con-Tech offers the reliable PMP Straight Drive or the fully proven ZF P-7300. Both options deliver excellent performance, with a focus on durability, reduced maintenance, and long-term reliability, ensuring your mixer operates efficiently under the toughest conditions.

In partnership with Con-Tech’s HP™ Drum, the Extreme Duty® addition offers more flexibility in maximizing your payload.

Con-Tech trucks come standard with heavy-duty EATON pumps and motors. Included is a 5-year limited warranty. Our hydraulic system comes standard with Chevron Rando HD oil (with advanced additive and base oil technology).

Con-Tech wiring harnesses are built with simplicity and durability in mind. All wiring harnesses have each wire labeled for ease of troubleshooting and are built with Deutsch connectors for unsurpassed reliability.

Con-Tech’s High Performance rear pedestal is built with six fully welded pieces for maximum corrosion resistance and strength. The lower roller deck plate and wash bands direct materials away, making cleaning easier and extending the pedestal’s lifespan by reducing buildup and corrosion.

Con-Tech utilizes the same polyurethane Atro bushings for the trailer pivot and the booster cylinder. Optimum performance, with minimum maintenance. Our pivots come with a 5 Year Warranty.

Our newly designed High Performance main chutes are wider, providing higher capacity. They are designed to reduce clearance issues and minimize material overflow while the chutes are in a horizontal position. All Con-Tech chutes are capped and 100% welded for strength and resistance to the elements.

Con-Tech’s rollers were designed alongside the High Performance pedestal. The combination of the taller roller and the lower deck creates easier access to the roller bracket for cleaning and maintenance.

• Designed to optimize payloads up to 10+ yards on federal bridge formulas, ensuring compliance with strict road laws while maximizing profitability.

• Built with heavy-duty, high-performance components that can withstand extreme conditions and rigorous job site environments, ensuring long-lasting performance

• Equipped with industry-leading EATON pumps and motors, backed by a 5-year warranty, delivering reliable hydraulic power and efficiency.

• Featuring robust components like pivot bushings, HP drums, and corrosion-resistant materials, minimizing downtime and reducing the need for frequent repairs.

• Available in multiple configurations to meet specific operational needs, including various state and federal bridge laws, offering flexibility for different regions.

• Engineered for balanced load distribution, providing superior stability on and off the road, even in challenging terrains.

• Designed with fuel efficiency and operational productivity in mind, ensuring high performance while keeping operational costs low.

- 6 AXLE AND 7 AXLE CONFIGURATIONS

- ALL AXLES CONTROLLED BY ONE SIMPLE SWITCH (NO ADJUSTING PRESSURES TO YARDAGE)

- LIGHTWEIGHT HARDOX ® 500 TUF DRUM OPTIONS AVAILABLE FOR MAXIMUM PAYLOAD

The Extended Tag® offers proven performance with enhanced stability and safety both on and off the road. It ensures a consistent front axle load whether the auxiliary axles are up or down. Efficiency and profitability are increased through optimized legal payload capacities, making it ideal for federal, state, low-tonnage, and seasonal frost law roads.

Design simplicity is key, with easy operation and maintenance that reduces downtime, alongside customer-tuned product optimization to meet specific operational needs. Advanced engineering features include a dual or triple steerable pusher and extended tag axle, creating a longer wheelbase for increased efficiencies and durable, reliable components designed to withstand daily use. The Special High Lift Tag provides more clearance for better maneuverability and reduces wear on the tag axle, extending the equipment’s lifespan.

Con-Tech offers multiple options for your mixer’s pump controls. Both cab and rear controls can be customized to your preference. We offer both cable controls and RE (12-volt electric) pump controls. Rear controls can be toggle pendant, manual, or a wireless rear control box. Drum saver (constant speed) options are available.

Con-Tech offers the reliable PMP Straight Drive or the fully proven ZF P-7300. Both options deliver excellent performance, with a focus on durability, reduced maintenance, and longterm reliability, ensuring your mixer operates efficiently under the toughest conditions.

In partnership with Con-Tech’s HP™ Drum, the Extreme Duty® addition offers more flexibility in maximizing your payload.

Our newly designed High Performance main chutes are wider, providing higher capacity. They are designed to reduce clearance issues and minimize material overflow while the chutes are in a horizontal position. All ConTech chutes are capped and 100% welded for strength and resistance to the elements.

Our newly designed High Performance ladder and platform feature a non-slip, level, open-tread design with extra-wide upper and lower grab bars for a safe and easy transition.

Con-Tech trucks come standard with heavy-duty EATON pumps and motors. Included is a 5-year limited warranty. Our hydraulic system comes standard with Chevron Rando HD oil (with advanced additive and base oil technology).

Con-Tech wiring harnesses are built with simplicity and durability in mind. All wiring harnesses have each wire labeled for ease of troubleshooting and are built with Deutsch connectors for unsurpassed reliability.

Con-Tech’s High Performance rear pedestal is built with six fully welded pieces for maximum corrosion resistance and strength. The lower roller deck plate and wash bands direct materials away, making cleaning easier and extending the pedestal’s lifespan by reducing buildup and corrosion.

Con-Tech’s rollers were designed alongside the High Performance pedestal. The combination of the taller roller and the lower deck creates easier access to the roller bracket for cleaning and maintenance.

• Provides superior stability on and off the road.

• Consistent front axle load with auxiliary axles up or down, maintaining a balanced mixer regardless of load conditions.

DURABLE AND RELIABLE COMPONENTS

• High-quality materials and construction ensure longevity and minimal maintenance.

• Designed to handle the toughest job site conditions with ease.

• Dual or triple steerable pusher and extended tag axle provides a longer wheelbase for increased efficiencies and payload.

• Durable and reliable components designed to withstand the rigors of daily use.

• Provides better maneuverability in tight spaces and on uneven terrain.

• Reduces wear on the tag axle, extending the lifespan of your equipment.

• Ideal for rough terrain and challenging job site conditions.

• Ensures that the mixer can navigate difficult environments without compromising load stability.

EFFICIENCY AND PROFITABILITY

• Increased legal payload capacities optimize load efficiency.

• Optimized for various road conditions including federal, state, low-tonnage, and seasonal frost law roads.

• Easy operation and maintenance reduce downtime.

• Customer-tuned product optimization ensures that the mixer meets the specific needs of the operation.

• Simplified controls make the mixer easy to operate, reducing training time.

• Designed with the operator in mind for maximum comfort and efficiency.

• Feedback from operators and customers is incorporated into the design.

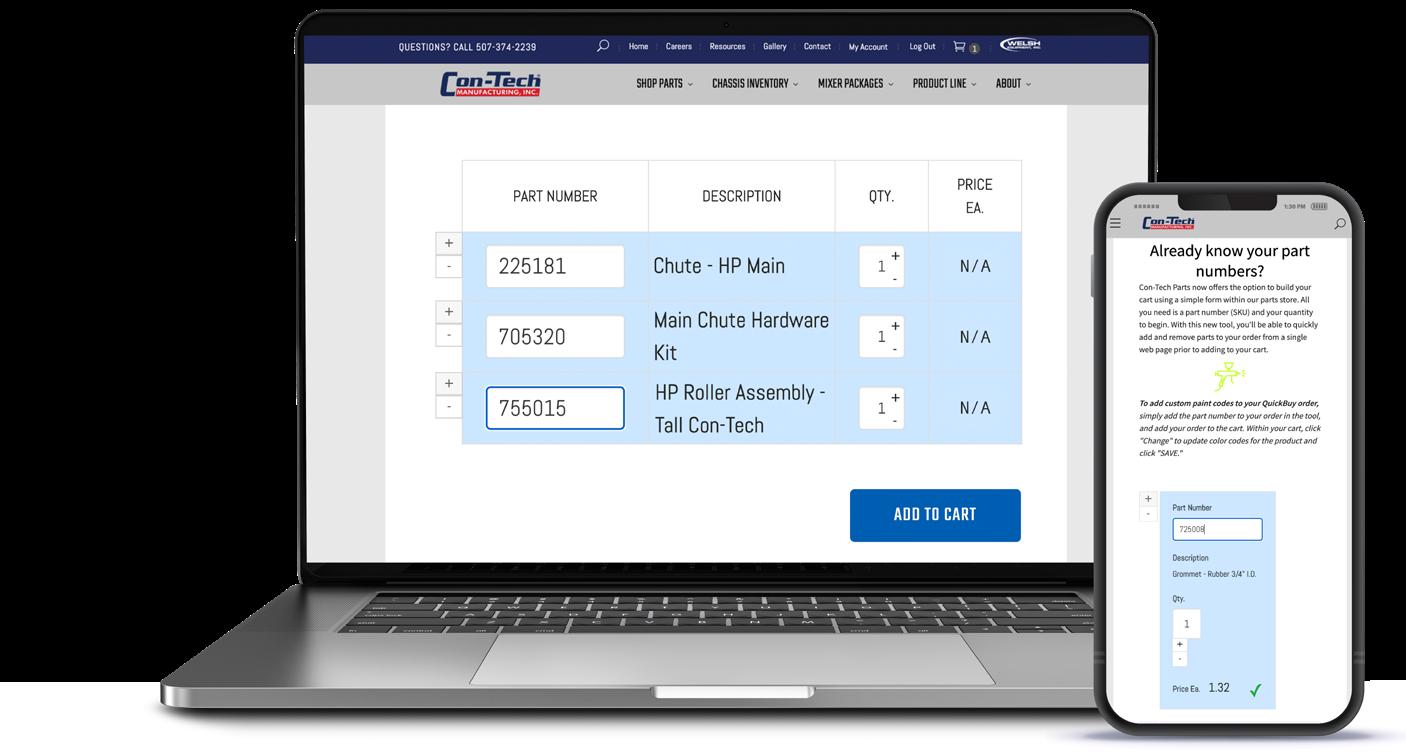

At Con-Tech®, we know the sale is just the beginning. We employ an experienced team dedicated to supporting your equipment throughout its life cycle. From troubleshooting service issues to replacement drums and parts, we have you covered.

IN AN EVER CHANGING INDUSTRY, WE ARE HERE TO MEET AND EXCEED YOUR PARTS NEEDS THE CON-TECH ® ADVANTAGE

We are grateful to be a part of this industry. We have always placed our customers first in everything we design and build. We are expanding our parts department and we continue to invest in new, automated manufacturing technology that delivers the highest quality parts you can buy.

We recently completed an additional 200,000 square foot expansion that allows us to continue to meet the growth in demand for our high quality mixers and parts. Not only do we have a complete line up of products to fill your service and maintenance needs, but we also provide you with world-class support after the sale through our network of service branches across the United States as well as our OEM parts store.

We are grateful to have experienced strong, sustainable growth every year since our founding in 2006. Our roots in this business are incredibly deep. We are committed to our industry and we are committed to listening to you, our customer. We believe that we provide the best concrete mixers and the highest quality parts/service in our industry.

THANK YOU FOR YOUR BUSINESS AND FOR TRUSTING CON-TECH WITH ALL YOUR PARTS NEEDS

Online resources, parts store, and promotions

In-person fleet inspections, visits, and annual Service & Maintenance training Call-in service and maintenance troubleshooting and parts sales

MIDWEST / HQ

65740 State Hwy. 56 Dodge Center, MN 55927 dcsales@ctmmixers.com 507-374-2239

SOUTH CENTRAL

11175 Windfern Rd. Houston, TX 77064 houston@ctmmixers.com 832-688-8449

NORTHEAST

38134 Western Pkwy., Unit 2 Willoughby, OH 44094 northeast@ctmmixers.com 440-946-3322

SOUTH CENTRAL 205 Wilcox St., Ste. 100 McKinney, TX 75069 dallas@ctmmixers.com 972-941-8592

NORTHEAST

74 Grace Boulevard Morgantown, PA 19543 484-722-2948

WEST

378 E. Commercial Rd. San Bernardino, CA 92408 west@ctmmixers.com 909-478-0017

SOUTHEAST

108 Hudson Industrial Dr. Griffin, GA 30224 southeast@ctmmixers.com 770-229-1773

SCAN TO LEARN MORE ABOUT CON-TECH PARTS

Including physical and online parts catalogs, online parts store, monthly sales promotions, email communications, and in-person fleet inspections across the USA

We’re thrilled to announce that the 2024 Service & Maintenance Training Seminar was a tremendous success! Registration filled in just one week, bringing together industry professionals from over 30 states and Canada. This year’s seminar offered participants the opportunity to deepen their expertise in maintaining Con-Tech mixers through expert-led presentations, hands-on training, and a behindthe-scenes look at our production process.

The seminar began with an impactful classroom session led by Jim Cunningham, ConTech’s Service Manager with over 30 years of experience. Jim covered essential topics such as advanced troubleshooting, preventative maintenance, and inspection strategies. His engaging teaching style ensured that complex technical concepts were accessible and immediately applicable. Attendees left Day 1 equipped with actionable insights to enhance mixer performance, reduce downtime, and extend equipment lifespan.

Day 2 focused on practical, hands-

on training. Participants rotated through various stations, tackling real-world service scenarios under the guidance of skilled Con-Tech instructors. These sessions allowed attendees to put their newfound knowledge to work and build confidence in performing essential maintenance tasks.

The day also featured an exclusive facility tour, giving participants an in-depth look at Con-Tech’s state-of-the-art manufacturing process. From design to assembly, attendees witnessed the innovation, precision, and craftsmanship that go into every mixer. The tour reinforced Con-Tech’s dedication to quality and excellence in

every step of production. It also gave participants a better understanding of the thought and detail behind every component, leaving them with a deeper appreciation for the equipment they work with daily.

Beyond the technical training, the seminar provided a collaborative environment where attendees could connect, share experiences, and exchange best practices. Professionals from across North America built valuable relationships that will continue to support their careers. Many attendees noted how discussions with peers brought fresh perspectives and innovative ideas

to overcome shared challenges. The camaraderie and collective learning created a lasting impact, underscoring the power of community in driving success.

Save the Date for 2025! As we celebrate the success of the 2024 seminar, we’re excited to announce that next year’s event will be held on November 5–6, 2025, in Minnesota. Packed with expert training, hands-on opportunities, and valuable networking, the 2025 seminar

promises to be another can’t-miss event.

Be the first to know when registration opens by subscribing at www.ctmmixers.com/ SUBSCRIBE.

We extend our heartfelt thanks to all who participated, especially Jim Cunningham for his exceptional leadership during Day 1. Your passion and dedication drive the success of these events. Together, we’re setting new

standards in mixer performance and maintenance. Whether you’re a returning attendee or a firsttimer, we can’t wait to welcome you to Minnesota in 2025 for another impactful event!

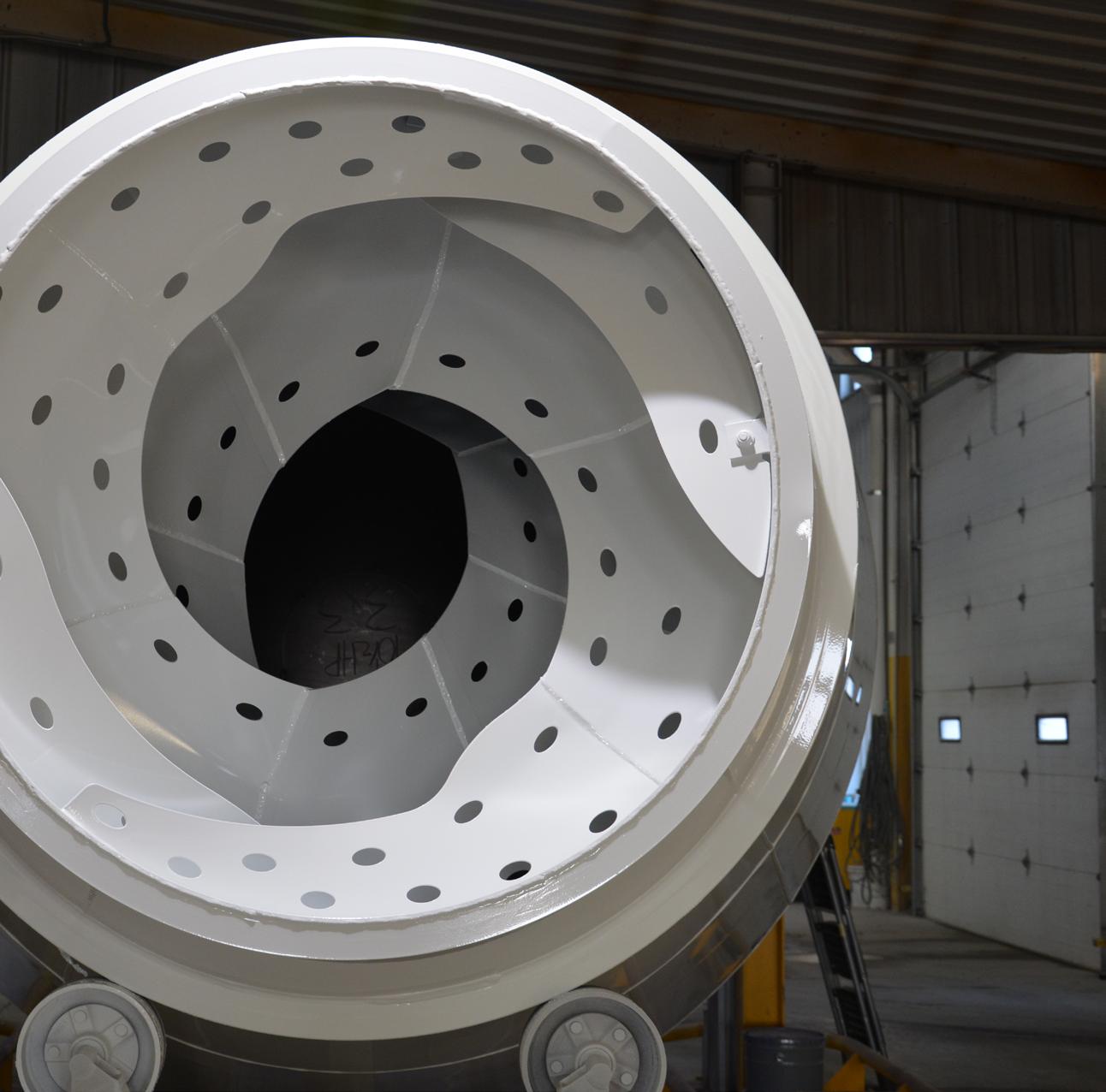

The Con-Tech® High Performance™ Drum is designed from head to toe with the producer in mind. From the material we use, to the manufacturing process, to the jobsite, we have developed the drum that sets the industry standard. Expect smooth, consistent pours from extreme paving to filling wheel barrows.

NEW! Tail Cone Fin Hole Configuration with Elevated Surge Fins: Limits buildup, improves mixing, and reduces wear on your equipment

Manufactured in the USA: All HP drums are built with pride in Dodge Center, MN

Patented A.R. Steel Lip Doubler: Doubles fin thickness for ultimate wear protection and fin life

EcoFin® Technology: Reduces wear, buildup, and improves mix consistenc

Precision Fit Panels: Eliminates flats spots that cause accelerated wear areas — Ensures optimal fin position for even, smooth pours

High Performance Tail Cone: Special fin spiral with an additional 1/4 turn allows for unmatched charging speed and discharge performance

Fabricated A.R. Steel Head: 1/4” true nominal thickness reduces wear areas throughout

Straight Taper Cone: Straight angle from the belly to the drip ring eliminates surging caused by non-straight cones in a high-production pour

One-Piece Solid Roller Track: Premachined and crowned — eliminates weld cracking and increases structural integrity over hollow designs

High Capacity Mixing Bowl:

25% increase in mixing area with a lower center of gravity for improved stability

Ball Buster Paddle System: Drastically reduces or eliminates cement balls 5/16 Hatch Frame with Tapped Holes: Increases frame thickness by 85% and eliminates square-welded nuts

Removable Lifting Lug: For easy and safe drum removal and replacement—a removable lifting lug is included with each HP drum

UPGRADE TO HIGH PERFORMANCE

SUPERIOR DESIGN

Con-Tech’s patented design allows concrete to flow through each hole and immediately fold into the mixture coming over the top of the fin.

EFFICIENT MIXING

EcoFin® provides a more homogenized mix faster and more efficient than ever before. Each fin contains multiple mixing holes to incorporate each component with ease.

MAXIMIZED CAPACITY

Mixing holes allow for concrete to pass through the fins along the drum skin. This process creates a larger mixing area, increasing the capacity of the mixing chamber.

REDUCED

The EcoFin® allows the material to flow through the fin rather than against it. This reduces stress and fatigue on the mixing fins and drum shell connection point.

Modern Concrete Materials, led by President Trent Almond, has achieved remarkable growth since its founding in 2019. Based in Beaumont, Texas, the company operates six ready-mix facilities in a region known for its challenging conditions, including extreme heat, soft ground, and tight construction timelines. Trent attributes their success to a skilled team and a strong partnership with Con-Tech Manufacturing, which provides the advanced concrete mixers essential to meeting their demanding schedule.

Con-Tech’s mixers have transformed operations at Modern Concrete. With features like rapid loading and discharge, they allow drivers to maximize efficiency and meet critical deadlines. Their durable design stands up to tough conditions, while safety features such as chute locks and ergonomic ladders reduce workplace risks. Trent notes, “At the end of the day, nothing we do is worth someone getting hurt,” emphasizing the importance of Con-Tech’s safetyfocused innovations.

Operators appreciate the thoughtful engineering of Con-Tech’s mixers, including user-friendly controls that simplify daily tasks and improve productivity. The large drum design easily handles a range of materials, making it versatile

enough for Modern Concrete’s diverse operations. These features save time, enhance performance, and allow the company to deliver superior service to their customers.

Equally critical to Modern Concrete’s success is Con-Tech’s outstanding customer support. With a warehouse in nearby Houston, Con-Tech provides fast access to parts and service, even during emergencies. “Their dedication aligns perfectly with ours,” Trent explains, praising ConTech’s commitment to solving problems and strengthening trust between the companies.

This partnership reflects shared values of quality, innovation, and community focus. “Partnering with Con-Tech was the right decision,” Trent says. “They’ve helped us grow while staying true to our mission of delivering

excellence to our customers and community.” Together, Modern Concrete and Con-Tech continue to set a standard of reliability and innovation in the ready-mix industry.

To view the full testimonial from Modern Concrete Materials, visit Con-Tech Manufacturing’s YouTube channel or scan the QR code below for direct access. Hear firsthand how Con-Tech mixers and exceptional customer support are driving success in challenging conditions.

When we talk to customers across the country, driver safety ranks above all other concerns. We design our mixers to respond to the needs of the ready mix industry, including the needs of your drivers.

Con-Tech offers various in-person and online video training opportunities. Scan the code to learn more about our safety goals.

Take advantage of trade-in opportunities with Welsh Equipment Inc. to make upgrading your fleet even more cost-effective. Our partnership ensures a seamless process for trading in your existing vehicles.

Inquire about our flexible financing options tailored to meet your specific needs. Our team is ready to assist you in finding the best financial solution for your business.

Explore the peace of mind that comes with our exclusive warranties. We prioritize the longevity and performance of our trucks, and our warranties are a testament to the confidence we have in the quality of our products.

By 2027, CARB (California Air Resources Board) will enforce stricter compliance regulations that will impact diesel vehicles operating in California and CARB opt-in states. This guide provides a detailed overview of the upcoming changes and what you need to know to keep your fleet compliant.

Beginning in 2027, the CARB ACT mandate requires a significant increase in Zero-Emission Vehicle (ZEV) sales ratios. Specifically, 7% of new Class 8 tractor sales and 11% of Class 6-8 rigid sales must be ZEVs. These percentages will continue to rise annually through 2035.

The availability of Internal Combustion Engines (ICE) will be restricted as OEMs must now balance ICE sales with ZEV credits. For every ICE-powered vehicle, specific BEV (Battery Electric Vehicle) sales must offset it. This will result in limited availability.

OEMs will be restricted in their ability to sell non-compliant diesel vehicles, impacting availability.

Due to supply chain constraints, ZEV lead times are expected to be longer. Early planning for your chassis purchases is crucial.

We can help evaluate your current fleet and provide guidance on compliance strategies.

Our team is available to help you understand these new CARB requirements and how they will affect your purchasing decisions. We can assist you in navigating the complex environment and selecting the best options for your fleet.

We will continue to provide updates and guidance as more details become available, ensuring you are well-prepared for the upcoming changes.

Take advantage of flexible financing plans tailored to help manage the costs of compliance.