Please call your Con-Tech sales representative or explore on-line extensive inventory of chassis that we have readily available either in stock or in upcoming build slots with the chassis manufacturers. Whether your preference is Freightliner, International, Kenworth, Mack, Peterbilt, or Western Star, allow Con-Tech to fast-track new equipment directly into your production stream and ultimately, your bottom line!

OPEN NOW FOR EXCLUSIVE MIXER PROMOTIONS & SAVINGS! QUALITY BACKED BY EXPERIENCE www.ctmmixers.com 507-374-2239 EXPRESS BUILD TIMES

WHAT’S INSIDE MEET THE FLEET................................................4 MIXER CONFIGURATIONS..................................5 TOP REASONS...................................................6 SPECIAL PROMOTION........................................7 PETERBILT CHASSIS OPTIONS............................8 KENWORTH CHASSIS OPTIONS..........................9 WESTERN STAR CHASSIS OPTIONS..................10 FREIGHTLINER CHASSIS OPTIONS....................11 MACK CHASSIS OPTIONS.................................12 INTERNATIONAL CHASSIS OPTIONS.................13 AFTER-MARKET PARTS SALES FLYER...............14 CALENDAR SUBMISSIONS...............................15 FLEET INSPECTIONS........................................16 HIGH PREFORMANCE DRUM......................17-19 SERVICE & MAINTENANCE.........................20-21 MEET THE TEAM..............................................22 YOUR EMAIL HERE SUBMIT WWW.CTMMIXERS.COM/ SUBSCRIBE KEEP UP WITH CON-TECH SUBSCRIBE TO OUR EMAILS! CTM sends out monthly sales promotions, chassis availability/build slot notifications, event information, and the occasional industry update. SCAN TO SUBSCRIBE Manufacturing, parts sales, warehousing, shipping, engineering, manufacturing offices CON-TECH MANUFACTURING, INC. LARGE SELECTION OF STOCK CHASSIS ARRIVING DAILY!

3

Scan this QR code to request a factory tour! Or visit www.ctmmixers.com/visit-us CHRIS M c LAMB, ON-ROAD SHOP SUPERVISOR THE SUNROCK GROUP

pieces

a better product—

ATTENTION NEW CUSTOMERS Experience excellence firsthand at our state-of-the-art factory and witness the Con-Tech difference. We invite you to visit us, where all expenses for up to two people will be graciously covered by Con-Tech. Come explore innovation and quality with us!

The thing that really struck me there at the factory was the fit and finish of the drum. They are not beating and banging and prying them to get the

into place. They are manufactured in such a way that the parts fit together the first time, which ends up being

which speaks to why they last the way they do.

MEET THE FLEET

The BridgeKing®, Extreme Duty™ and Extended Tag models represent years of commitment, loyalty, and innovation in the ready mix industry. At Con-Tech, our mixers have been revised, updated, and redesigned, but our dedication to provide you with the best product for the job has remained the same.

The Extreme Duty™ standard mixer has the ability and the flexibility to maximize your profits because reliability, serviceability, and profitability are built-in to the design.

• Equipped with proven components such as Danfoss hydraulics, 2F or PMP gearbox, and Aeroquip hoses and fittings

addition offers more flexibility in maximizing your payload

• Easy and balanced operation while loaded, at the job site, or empty

• Up to 10+ yards legal payload on federal bridge formula, with some state roads 12+ yards legal payload

• Scan code for video testimonial on the XT axle configuration, as well as the HP™ Drum:

• Scan code for testimonial on a customer's switch to XD™ after decades running front discharge:

The Con-Tech® BridgeKing® allows for the most efficient load delivery while maintaining federal bridge compliancy. Our bridge trailer maximizes your payload while en route to the job site, and minimizes your footprint while heading back to the plant. Our flexible design allows us to engineer equipment built specifically for your region and your operation. From extreme paving down to filling a wheel barrow, the BridgeKing® is the answer.

• Scan code for a video walkthrough and in-service lesson from our service department on the BridgeKing® mixer:

We put our first Con-Tech mixers into use in June of 2019. We made that purchase to have something to compare side-by-side with what we thought at that point was the industry standard. Since 2019, our working relationship with Con-Tech has really evolved. The product, the personnel, the level of expertise and support that we receive at Con-Tech has created a new benchmark for our industry standard—that is now what we rely on in terms of product quality and reliability day in and day out.

STEVE LODE, PRESIDENT NATIONAL READY MIXED CONCRETE CO.

SCAN HERE

®

SCAN HERE

TM

SCAN HERE

XT EXTENDED TAG 6 AXLES

SIDE

CROSS MOUNT WATER TANK SET BACK CHASSIS XD

XD EXTREME DUTY TWIN STEER SPREAD TANDUM 4 AXLES

SIDE MOUNT WATER TANK SET BACK CHASSIS

BRIDGEKING 4 AXLES

SIDE MOUNT WATER TANK SET FORWARD CHASSIS

BRIDGEKING 7 AXLES

CROSS MOUNT WATER TANK SET BACK CHASSIS

XD EXTREME DUTY TWIN STEER 4 AXLES

SIDE MOUNT WATER TANK SET BACK CHASSIS

BRIDGEKING 5 AXLES

CROSS MOUNT WATER TANK SET FORWARD CHASSIS

XD EXTREME DUTY 4 AXLES

OVERHEAD WATER TANK SET BACK CHASSIS

XD EXTREME DUTY TRI-DRIVE 4 AXLES

CROSS MOUNT WATER TANK SET BACK CHASSIS

BRIDGEKING 6 AXLES

CROSS MOUNT WATER TANK SET FORWARD CHASSIS

5

EXTREME DUTY 3 AXLES

MOUNT WATER TANK SET BACK CHASSIS

CALL YOUR SALESMAN TODAY! YOUR SPECIFIC NEEDS,OUR COMPLETE COVERAGE

TOP REASONS TO OWN CON-TECH MIXERS

THE CUSTOMER IS THE BOSS

At Con-Tech, the customer is the boss. This commitment ensures that your needs are prioritized and met with excellence.

MADE IN THE USA

Con-Tech proudly manufactures its products in the USA, supporting local industries and ensuring adherence to rigorous quality standards.

FAMILY-OWNED

Being a privately owned, family-run company enables Con-Tech to act swiftly and effectively, catering to your individual needs with personalized attention.

CUSTOMIZATION

ATTENTION TO DETAIL

Con-Tech pays meticulous attention to details that contribute to time and cost savings for their customers, enhancing overall efficiency.

Utilizing specialized forming methods, Con-Tech ensures the precision-built drums, guaranteeing optimal performance and reliability.

Con-Tech mixers boast the highest established resale value in the industry, providing return on your investment over time.

COST OF OWNERSHIP

Each product is tailored to the specifications of the producer, ensuring that it perfectly fits your operational needs.

CONTINUOUS IMPROVEMENT

Con-Tech values customer feedback and utilizes it to drive continuous product enhancements, ensuring that you benefit from the latest innovations.

DIRECT ACCESS TO OWNERS

The accessibility of Con-Tech’s owners underscores their dedication to customer satisfaction, providing reassurance that your concerns will be addressed promptly and personally.

With meticulous steel preparation and paint application, Con-Tech ensures maximum protection for your investment, enhancing durability and longevity.

COMMITMENT TO QUALITY

Every truck produced by Con-Tech is treated as a showpiece, reflecting their unwavering commitment to delivering top-notch quality.

With a focus on durability, efficiency, and quality, Con-Tech mixers offer the lowest cost of ownership, minimizing long-term expenses.

AFTER-SALES SERVICE

Con-Tech’s commitment to service extends beyond the sale, ensuring that you receive unparalleled support and assistance whenever needed.

TRADE-IN OPTIONS

Con-Tech welcomes trade-in equipment, simplifying the process of upgrading or replacing your existing mixers.

Benefit from the expertise of Con-Tech’s seasoned employees, with an average of 20-30 years of experience in the industry, ensuring superior craftsmanship.

Benefit from the expertise of our chassis engineer, available on-site to address any technical queries or concerns, ensuring optimal performance and reliability.

6

PRECISION ENGINEERING

HIGH RESALE VALUE

LOWEST

EXCEPTIONAL

SUPERIOR

COATINGS

EXPERIENCED

ON-SITE EXPERTISE

WORKFORCE

SPECIAL PROMOTION

7

ON CHASSIS & MIXER PACKAGES UNBEATABLE PRICING & VALUE CALL YOUR SALESMAN TODAY TO LEARN MORE ABOUT THIS PROMOTION! NEWS EXCITING WATCH FOR OUR ANNOUNCEMENT OF ADDITIONAL PARTS & SERVICE LOCATIONS IN 2024!

STANDARD

ENGINE

CONFIGURATION Inline 6 Cylinder

HORSEPOWER 355-445 HP

TORQUE 1,250-1,700 LB-FT

DISPLACEMENT 10.8 Liters

COMPRESSION RATIO 18.5:1

WEIGHT 2,200 LBS

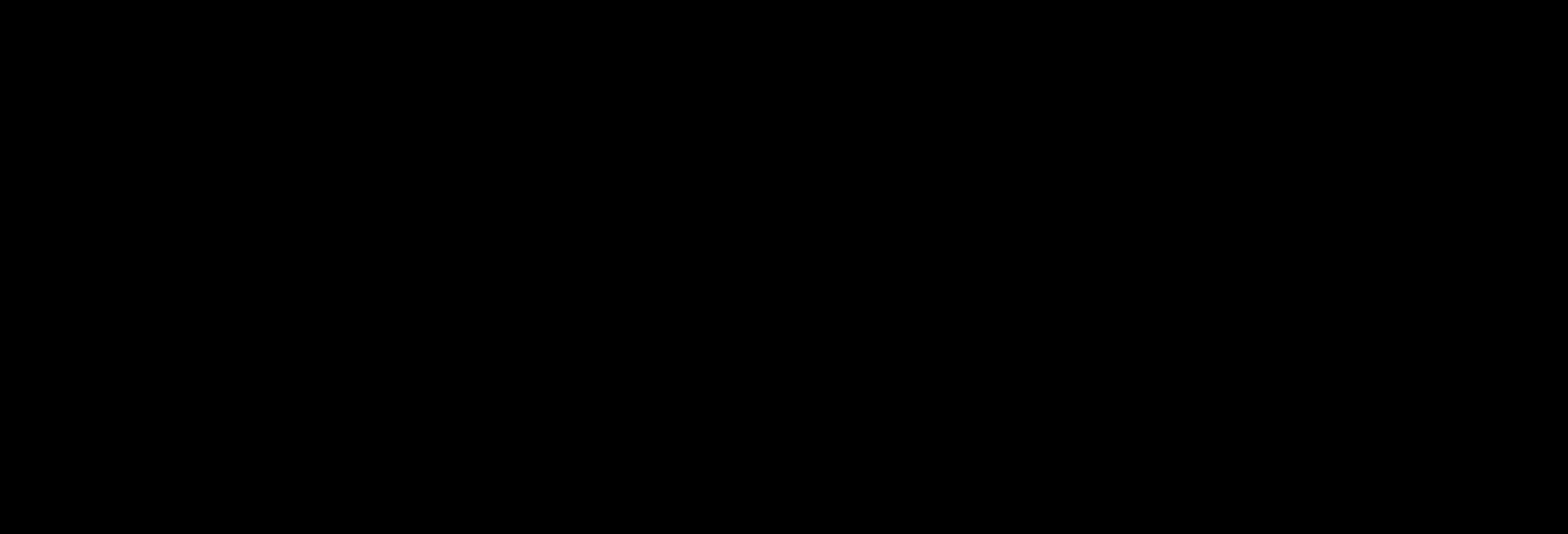

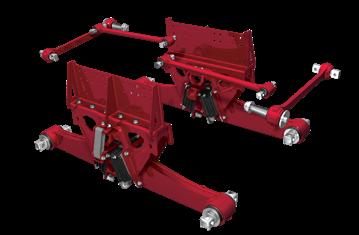

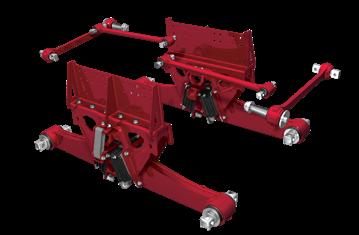

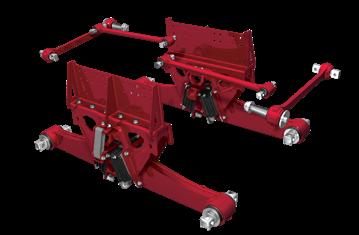

• Lightweight vocational rear suspension is hundreds of pounds lighter over competitive suspensions without sacrificing durability

• Optimized bolster springs carries the majority of the payload without sacrificing ride quality

• Progressive load spring increases stiffness as the load increases for improved stability

• Up to 17” of diagonal articulation improves off-highway mobility

• Integrated jounce stop protects rubber components from over compression

OPTIONAL

• Equalizing beam distributes load equally between both axles for improved maneuverability, stability and handling

• Optional shock absorbers provide additional driver comfort

• Bar pin end bushing provide a rugged axle connection extending bushing life and allow for easy axle alignment and serviceability

ENGINE TRANSMISSION TRANSMISSION

PX-9

CONFIGURATION Inline 6 Cylinder

HORSEPOWER 260-450 HP

TORQUE 860-1,250 LB-FT

DISPLACEMENT 8.9 Liters

COMPRESSION RATIO -

WEIGHT 1,695 LBS

SUSPENSION SUSPENSION

• Hendrickson TRAAX ROD® torque rod come standard at TVTR at most OEM’s to enhance handling during cornering by controlling lateral forces and maintaining axle position.

CONFIGURATION Inline 6 Cylinder

HORSEPOWER 405-510 HP

TORQUE 1,550-1,850 LB-FT

DISPLACEMENT 12.9 Liters

COMPRESSION RATIO -

WEIGHT 2,500 LBS

*Set-forward and set-back front axle position configurations available

• Optional vertical or beam-type shock kits

• HS-Model for high stability on high center of gravity applications

• SR-Model for softer ride

• Shock kits recommended for all tractor applications

8

MX-13 MX-11

16909ALL

Allison 4500RDS Allison 4700RDS

Hendrickson HAULMAAX® EX

STANDARD

ENGINE

CONFIGURATION Inline 6 Cylinder

HORSEPOWER 355-445 HP

TORQUE 1,250-1,700 LB-FT

DISPLACEMENT 10.8 Liters

COMPRESSION RATIO 18.5:1

WEIGHT 2,200 LBS

OPTIONAL

SUSPENSION

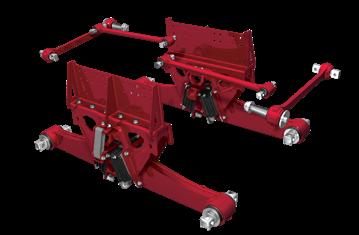

• Lightweight vocational rear suspension is hundreds of pounds lighter over competitive suspensions without sacrificing durability

• Optimized bolster springs carries the majority of the payload without sacrificing ride quality

• Progressive load spring increases stiffness as the load increases for improved stability

• Up to 17” of diagonal articulation improves off-highway mobility

• Integrated jounce stop protects rubber components from over compression

• Equalizing beam distributes load equally between both axles for improved maneuverability, stability and handling

• Optional shock absorbers provide additional driver comfort

• Bar pin end bushing provide a rugged axle connection extending bushing life and allow for easy axle alignment and serviceability

ENGINE TRANSMISSION TRANSMISSION

• Hendrickson TRAAX ROD® torque rod come standard at TVTR at most OEM’s to enhance handling during cornering by controlling lateral forces and maintaining axle position.

PX-9

CONFIGURATION Inline 6 Cylinder

HORSEPOWER 260-450 HP

TORQUE 860-1,250 LB-FT

DISPLACEMENT 8.9 Liters

COMPRESSION RATIO -

WEIGHT 1,695 LBS

CONFIGURATION Inline 6 Cylinder

HORSEPOWER 405-510 HP

TORQUE 1,550-1,850 LB-FT

DISPLACEMENT 12.9 Liters

COMPRESSION RATIO -

WEIGHT 2,500 LBS

SUSPENSION

• Optional vertical or beam-type shock kits

• HS-Model for high stability on high center of gravity applications

• SR-Model for softer ride

• Shock kits recommended for all tractor applications *Set-forward and set-back front axle position configurations available

9

MX-13 MX-11

16909ALL

Allison 4500RDS Allison 4700RDS

Hendrickson HAULMAAX® EX

STANDARD

OPTIONAL ENGINE

CONFIGURATION Inline 6 Cylinder

HORSEPOWER 355-445 HP

TORQUE 1,250-1,700 LB-FT

DISPLACEMENT 10.8 Liters

COMPRESSION RATIO 18.5:1

WEIGHT 2,200 LBS

SUSPENSION

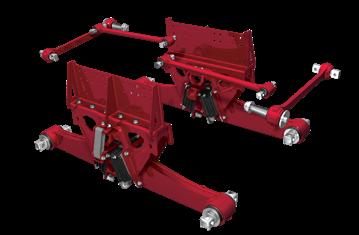

• Lightweight vocational rear suspension is hundreds of pounds lighter over competitive suspensions without sacrificing durability

• Optimized bolster springs carries the majority of the payload without sacrificing ride quality

• Progressive load spring increases stiffness as the load increases for improved stability

X12

CONFIGURATION Inline 6 Cylinder

HORSEPOWER 335-513 HP

TORQUE 1250-1696 lb-ft

DISPLACEMENT 11.9 Liters

COMPRESSION RATIO -

WEIGHT 2,050 LBS

ENGINE TRANSMISSION TRANSMISSION

• Up to 17” of diagonal articulation improves off-highway mobility

• Integrated jounce stop protects rubber components from over compression

• Equalizing beam distributes load equally between both axles for improved maneuverability, stability and handling

• Optional shock absorbers provide additional driver comfort

• Bar pin end bushing provide a rugged axle connection extending bushing life and allow for easy axle alignment and serviceability

• Hendrickson TRAAX ROD® torque rod come standard at TVTR at most OEM’s to enhance handling during cornering by controlling lateral forces and maintaining axle position.

SUSPENSION

• Optional vertical or beam-type shock kits

• HS-Model for high stability on high center of gravity applications

• SR-Model for softer ride

• Shock kits recommended for all tractor applications

10

*Set-forward and set-back front axle position configurations available DD13 Allison 4500RDS Allison 4700RDS 16909ALL

EX

Hendrickson HAULMAAX®

STANDARD

OPTIONAL ENGINE

CONFIGURATION Inline 6 Cylinder

HORSEPOWER 370-525

TORQUE 1250-1850 LB-FT

DISPLACEMENT 781 cu in (12.8 L)

COMPRESSION RATIO 20.3:1

WEIGHT 2200 lb

SUSPENSION

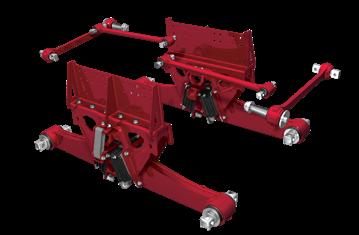

• Lightweight vocational rear suspension is hundreds of pounds lighter over competitive suspensions without sacrificing durability

• Optimized bolster springs carries the majority of the payload without sacrificing ride quality

• Progressive load spring increases stiffness as the load increases for improved stability

• Equalizing beam distributes load equally between both axles for improved maneuverability, stability and handling

• Optional shock absorbers provide additional driver comfort

X12

CONFIGURATION Inline 6 Cylinder

HORSEPOWER 335-513 HP

TORQUE 1250-1696 lb-ft

DISPLACEMENT 11.9 Liters

COMPRESSION RATIO -

WEIGHT 2,050 LBS

ENGINE TRANSMISSION TRANSMISSION

• Up to 17” of diagonal articulation improves off-highway mobility

• Integrated jounce stop protects rubber components from over compression

• Bar pin end bushing provide a rugged axle connection extending bushing life and allow for easy axle alignment and serviceability

• Hendrickson TRAAX ROD® torque rod come standard at TVTR at most OEM’s to enhance handling during cornering by controlling lateral forces and maintaining axle position.

SUSPENSION

• Optional vertical or beam-type shock kits

• HS-Model for high stability on high center of gravity applications

• SR-Model for softer ride

• Shock kits recommended for all tractor applications

11

*Set-forward and set-back front axle position configurations available DD13 Allison 4500RDS Allison 4700RDS 16909ALL

Hendrickson HAULMAAX® EX

STANDARD

OPTIONAL ENGINE

CONFIGURATION Inline 6 Cylinder

HORSEPOWER 325-425 HP

TORQUE 1260-1560 LB.-FT

DISPLACEMENT 11 Liters

COMPRESSION RATIO 16:1

WEIGHT 2,207 LBS

SUSPENSION

• Lightweight vocational rear suspension is hundreds of pounds lighter over competitive suspensions without sacrificing durability

• Optimized bolster springs carries the majority of the payload without sacrificing ride quality

• Progressive load spring increases stiffness as the load increases for improved stability

• Equalizing beam distributes load equally between both axles for improved maneuverability, stability and handling

• Optional shock absorbers provide additional driver comfort

MP8

CONFIGURATION Inline 6 Cylinder

HORSEPOWER 415-505 HP

ENGINE TRANSMISSION TRANSMISSION

TORQUE 1460-1860 LB.-FT

DISPLACEMENT 13 Liters

COMPRESSION RATIO 16:1

WEIGHT 2,560 LBS

• Up to 17” of diagonal articulation improves off-highway mobility

• Integrated jounce stop protects rubber components from over compression

• Bar pin end bushing provide a rugged axle connection extending bushing life and allow for easy axle alignment and serviceability

• Hendrickson TRAAX ROD® torque rod come standard at TVTR at most OEM’s to enhance handling during cornering by controlling lateral forces and maintaining axle position.

SUSPENSION

• Optional vertical or beam-type shock kits

• HS-Model for high stability on high center of gravity applications

• SR-Model for softer ride

• Shock kits recommended for all tractor applications

12

*Set-forward and set-back front axle position configurations available

4500RDS Allison 4700RDS 16909ALL

MP7 Allison

Hendrickson HAULMAAX® EX

CONFIGURATION Inline 6-Cylinder

HORSEPOWER 370-475

TORQUE 1350-1750 LB-FT

OPTIONAL ENGINE TRANSMISSION TRANSMISSION STANDARD

DISPLACEMENT 12.4 L (758 cu. in.)

COMPRESSION RATIO 18.5:1

WEIGHT 2,314 LBS

SUSPENSION

• Lightweight vocational rear suspension is hundreds of pounds lighter over competitive suspensions without sacrificing durability

• Optimized bolster springs carries the majority of the payload without sacrificing ride quality

• Progressive load spring increases stiffness as the load increases for improved stability

• Up to 17” of diagonal articulation improves off-highway mobility

• Integrated jounce stop protects rubber components from over compression

• Equalizing beam distributes load equally between both axles for improved maneuverability, stability and handling

• Optional shock absorbers provide additional driver comfort

• Bar pin end bushing provide a rugged axle connection extending bushing life and allow for easy axle alignment and serviceability

• Hendrickson TRAAX ROD® torque rod come standard at TVTR at most OEM’s to enhance handling during cornering by controlling lateral forces and maintaining axle position.

SUSPENSION

• Optional vertical or beam-type shock kits

• HS-Model for high stability on high center of gravity applications

• SR-Model for softer ride

• Shock kits recommended for all tractor applications

13

*Set-forward and set-back front axle position configurations available A26 Allison 4500RDS Allison 4700RDS 16909ALL

Hendrickson HAULMAAX® EX

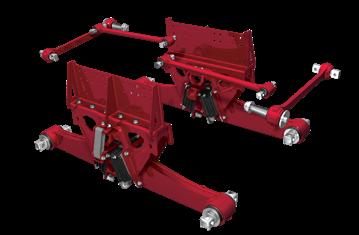

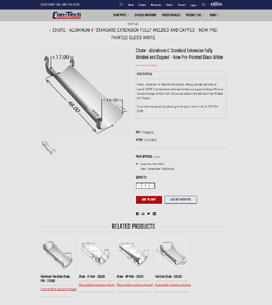

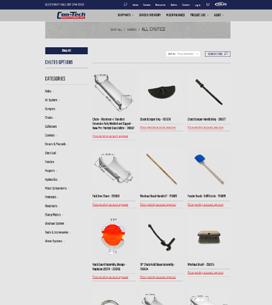

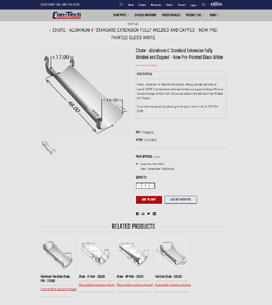

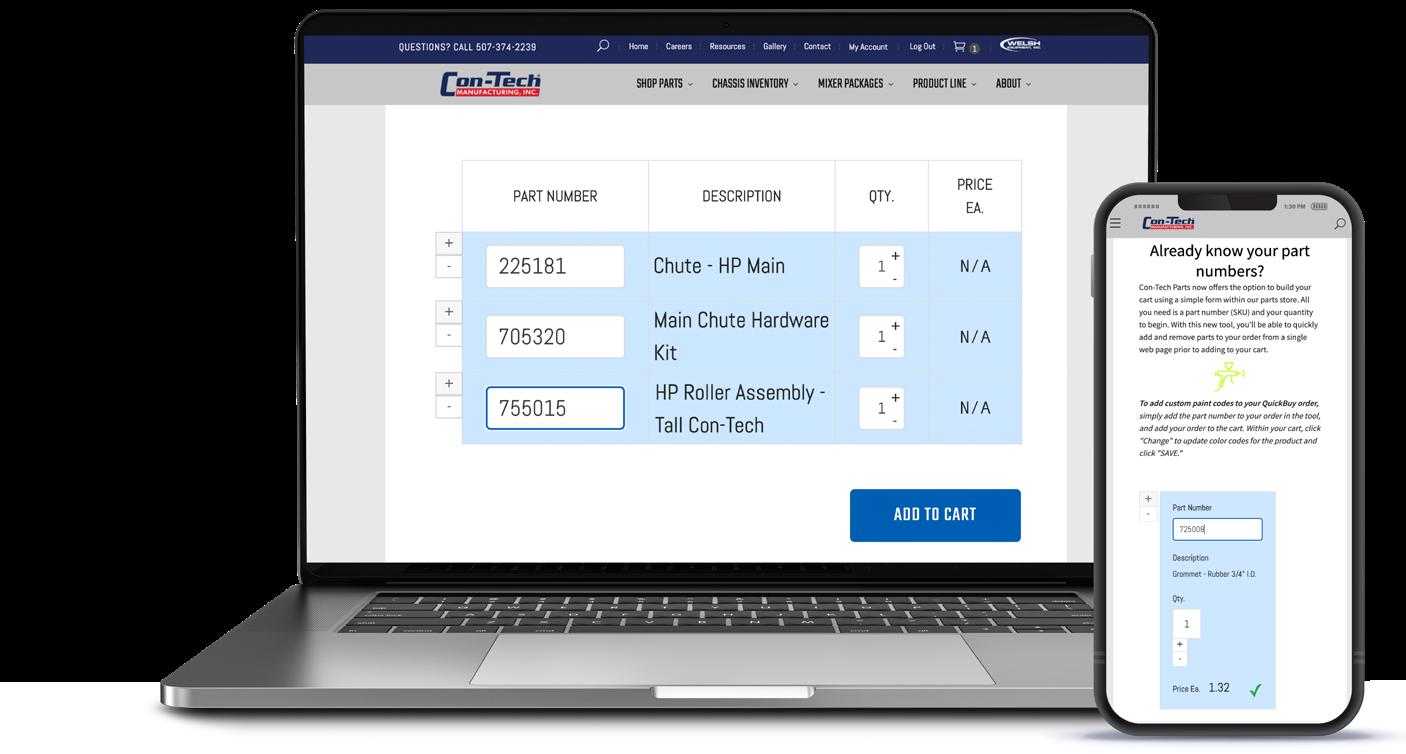

14 1 2 GET YOUR FREE CON-TECH SAFETY T-SHIRT WITH YOUR NEXT ONLINE AFTER-MARKET PARTS ORDER: ENTER PROMO CODE SUMMERTEE @ CHECKOUT Promo code SUMMERTEE is applicable only for online after-market parts orders totaling $250.00 or more on www.ctmmixers.com. Orders must be placed before July12th, 2024, to qualify for the promotion. Upon order placement, you will be contacted to confirm your preferred shirt size. T-shirt will be shipped along with your order, except in cases where inventory depletion requires additional t-shirts to be ordered. Exclusions may apply. This promo code is limited to one per customer. www. CTMMIXERS.com 1. Save items to your favorites list 2. Access order history 3. Track new parts orders 4. Save multiple shipping addresses 5. Add parts and check out faster using our new CTM Parts QuickBuy cart builder tool Visit us online at WWW.CTMMIXERS.COM to learn more. << SCAN THE CODE TO CREATE A NEW ACCOUNT WITH CTM PARTS WHAT YOU CAN DO WITH AN ONLINE PARTS ACCOUNT $250 MINIMUM PURCHASE REQUIRED FOR QUALIFICATION.

CONTEST OBJECTIVES

Con-Tech is gearing up for our 2025 calendar photo selection! We are looking for amazing photos of your Con-Tech Mixer truck to be submitted for a chance to be featured in our 2025 Con-Tech Calendar. If selected, not only will your photo be featured in the 2025 calendar, the 14 finalists will also receive a gift voucher to the CTM Merchandise store.

All photos MUST BE submitted before June 5th, 2024 to be entered to win a spot in the calendar. Your company can submit as many photos as you would like, but all photo submission requirements must be met in order to be eligible.

IMAGE FORMAT AND SIZE

HIGH-RESOLUTION IMAGES ONLY.

Photographs must be in digital format. All digital files must be 3 megabytes (MB) or larger, in jpeg, png, or tif format, and 300 dpi or higher.

CONTENT

The photo must be of your Con-Tech mixer/s with no other mixer brands in the picture. Preferably with an interesting/scenic background.

For examples of angles we like or to view pictures that have been chosen in the past, please check out our photo gallery of past calendar submissions here.

SUBMITTING PHOTOS/ INFORMATION NEEDED

Complete this release form giving Con-Tech permission to use your company’s photo for Marketing use. If you have any questions, please reach out to our marketing team at marketing@ctmmixers.com

ANY PHOTOS SUBMITTED MAY BE USED FOR AN OF THE FOLLOWING:

-2025 Calendar

-Monthly Parts Flyers

-Social Media Posts

-Printed Marketing Materials

-Digital Marketing Materials

SUBMISSION METHODS

Use one of the methods below to submit your photos UPLOAD FILES HERE: https://secureshare. ctmmixers.com/filedrop/photos

Mail a flash drive to:

Con-Tech Manufacturing Attn: Marketing 65740 State Hwy 56 Dodge Center, MN 55927

FROM CON-TECH PARTS

WE’RE ON THE ROAD FOR FLEET INSPECTIONS

Fleet inspections from Con-Tech Parts are at no cost to you. We can assist in planning for capital expenses down the road and we’ll even do the measuring for you. Let us help you track efficiency, minimize your downtime, anticipate your expenses, and maximize your efficiencies. Give us a call at 507-374-2239 to set up your inspection appointment.

FLEET INSPECTION INCLUDES:

• Drum thickness measurements

• Sheet metal evaluations

• Hydraulics overview

Free expert inspection and complete drum evaluation includes a detailed report for your entire fleet. Whether you have five trucks or five hundred, we’ve got you covered.

Flexible inspection appointments to work around your schedule (after hours upon request.) Please call your regional parts office for details.

16

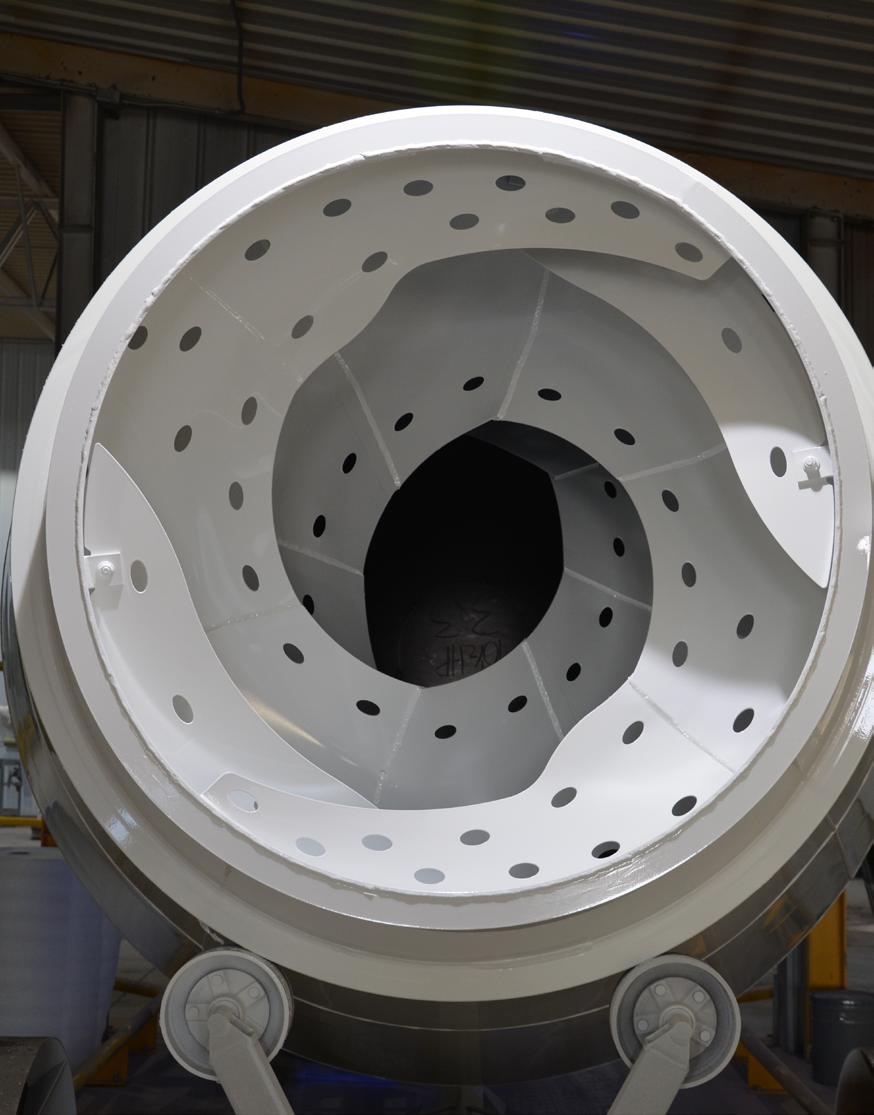

IT’S WHAT’S ON THE INSIDE THAT COUNTS.

BRANCH INFO

HIGH PERFORMANCE ™ DRUM

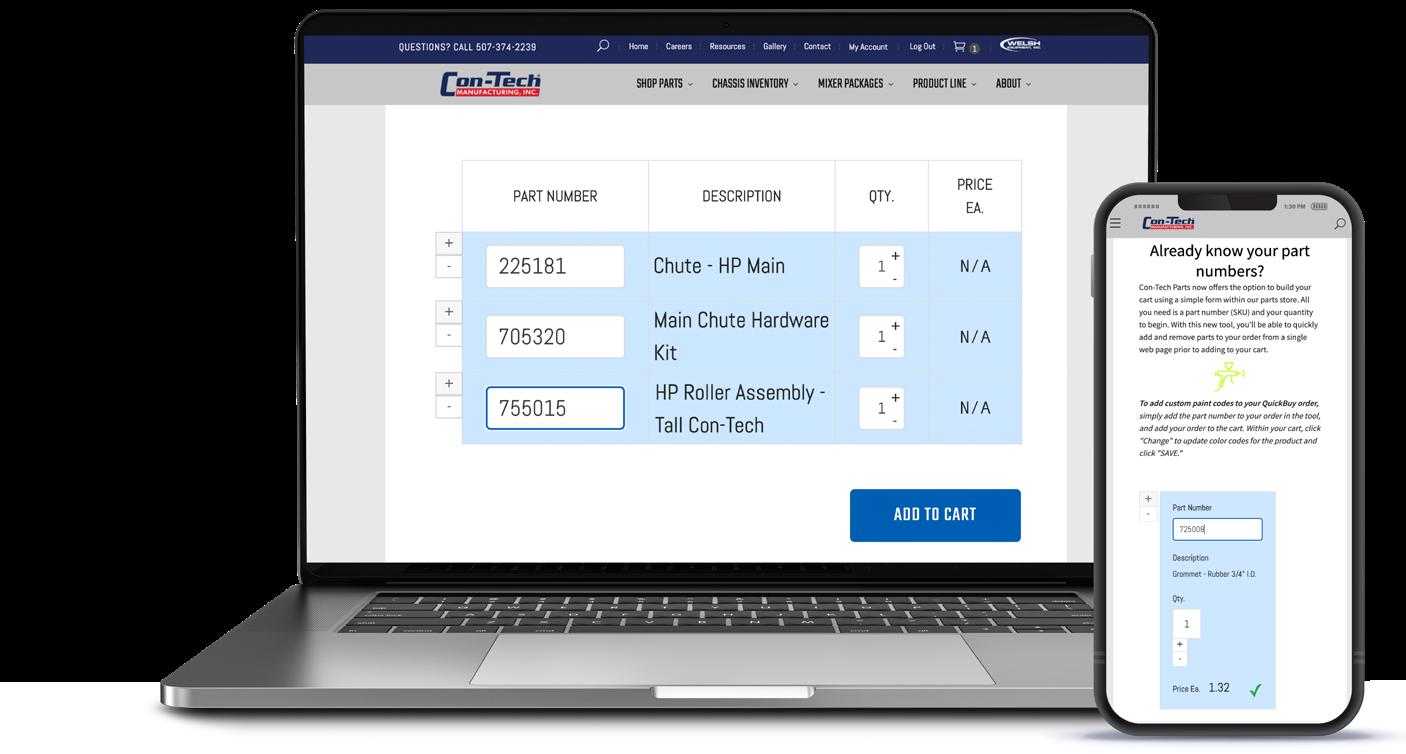

The Con-Tech® High Performance™ Drum is designed from head to tail cone with the producer in mind. With the manufacturing process, and materials used, we worked with the industry to develop this drum which sets the standard.

BENEFITS OF THE CON-TECH

Tail Cone Fin Hole Configuration with Elevated Surge Fins: Limits buildup, improves mixing, and reduces wear on your equipment

Manufactured in the USA: All HP drums are built with pride in Dodge Center, Minnesota

Patented A.R. Steel Lip Doubler: Doubles fin thickness for ultimate wear protection and fin life

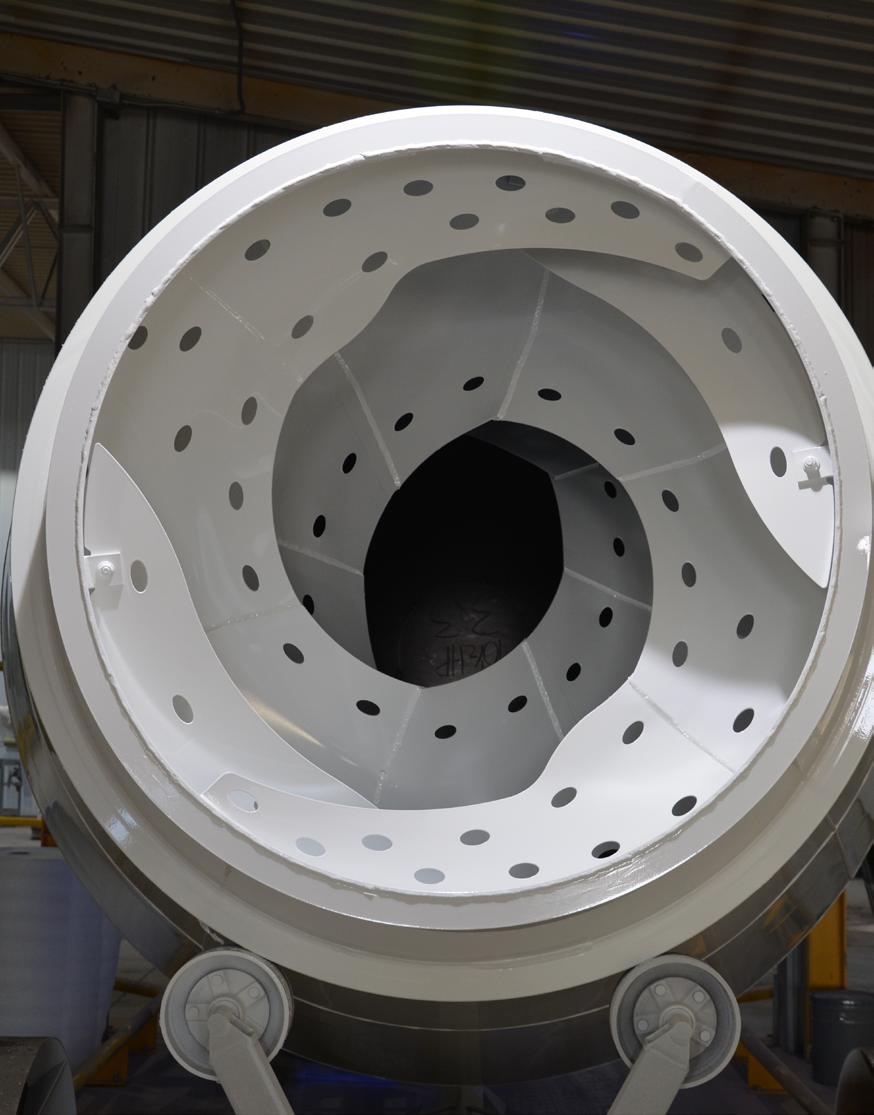

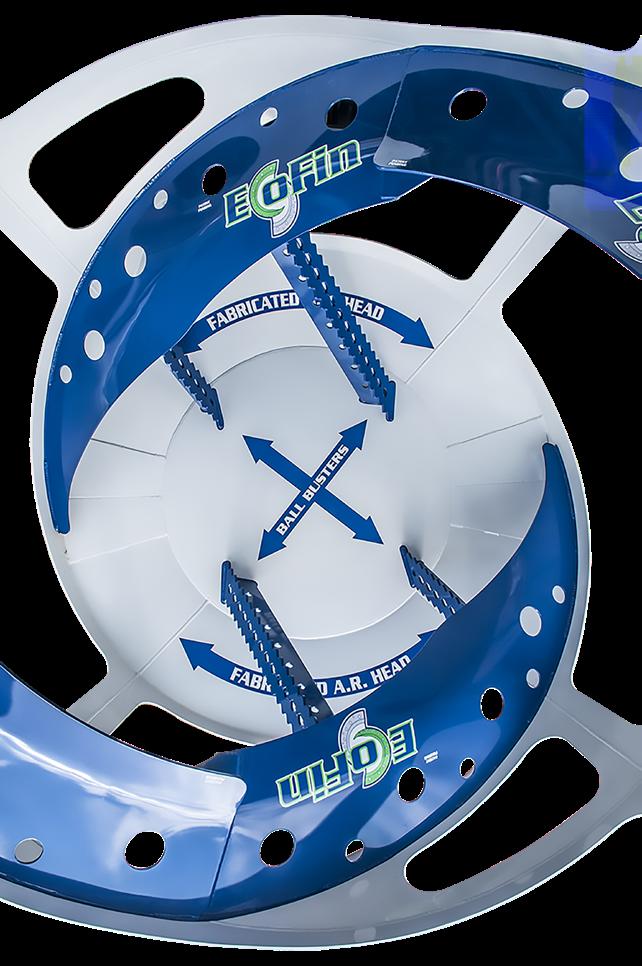

EcoFin® Technology: Reduces wear, buildup, and improves mix consistency (See next page)

Precision Fit Panels: Eliminates flats spots that cause accelerated wear areas — Ensures optimal fin position for even, smooth pours

® HIGH PERFORMANCE ™ DRUM:

High Performance Tail Cone: Special fin spiral with an additional 1/4 turn allows for unmatched charging speed and discharge performance

Fabricated A.R. Steel Head: 1/4” true nominal thickness reduces wear areas throughout

Straight Taper Cone: Straight angle from the belly to the drip ring eliminates surging caused by non-straight cones in a high-production pour

One-Piece Solid Roller Track: Premachined and crowned — eliminates weld cracking and increases structural integrity over hollow designs

High Capacity Mixing Bowl: 25% increase in mixing area with a lower center of gravity for improved stability

Ball Buster Paddle System: Drastically reduces or eliminates cement balls

5/16 Hatch Frame with Tapped Holes: Increases frame thickness by 85% and eliminates square-welded nuts

Removable Lifting Lug: For easy and safe drum removal and replacement — a removable lifting lug is included with each HP drum

SUPERIOR DESIGN

Con-Tech’s patented design allows smooth concrete to flow through each hole and immediately fold into the mixture coming over the top of the fin.

EFFICIENT MIXING

EcoFin® provides a more homogenized mix faster and more efficient than ever before. Each fin contains multiple mixing holes to incorporate each material with ease.

REDUCED WEAR & TEAR

The EcoFin® allows the material to flow over and through the fin rather than against it. This reduces stress and fatigue on the mixing fins and drum shell connection point.

TM The New Standard.

NEW FIN SPIRAL

The new self cleaning fin design allows for small amounts of material to pass through the fins which drastically reduces build up. Elevated surge fins allow water to flush underneath to reach the main fin row during clean up.

SOLID ROLLER TRACK

is lighter and stronger than hollow designs, providing 350% more contact surface area and eliminates flexing and cracking.

ECOFIN TECHNOLOGY

UPGRADE TO HIGH

STRAIGHT CONE TAPER

allows for a smooth discharge with virtually no surging, while allowing maximum discharge performance.

It’s What’s on the

Con-Tech’s patent pending EcoFin technology allows concrete to flow through the mixing fins then folded into the mix coming over the top of the fin. This provides a much more homogenized mix in a much more efficient manner than conventional designs.

Mixing holes allow concrete to pass through the fin along the drum skin providing a barrier from the mixing chamber. Reducing the wear on your mixing fins and drum skin.

18

VS.

HIGH PERFORMANCE!

HIGH CAPACITY

head and belly sections allow for 25% more material in the mixing bowl.

FABRICATED A.R. STEEL HEAD

MORE WEAR RESISTANT

Up to 300% more wear resistant than typical Gr. 50 spun heads.

MORE USABLE STEEL

1/4” and 5/16” heads are true nominal thickness unlike spun heads that get thin on the forward radius.

LIGHTER

1/4” heads are 172 lbs. lighter than 1/4” spun heads.

BALL BUSTER

paddle system is strategically located for breaking apart floating dry balls.

Con-Tech’s patent pending A.R. steel ‘lip doubler’ provides ultimate wear protection.

19

OTHER BRANDS

TM The New Standard.

Inside that Counts! OTHER BRANDS

MAXIMIZING SAFETY AND EFFICIENCY IN THE READY MIX INDUSTRY:

THE IMPORTANCE OF PREVENTATIVE MAINTENANCE AND TRAINING

In the fast-paced world of ready mix concrete, where efficiency and safety are paramount, it’s easy to overlook the underlying reasons for truck downtime. While safety remains a critical concern, the strategic importance of preventative maintenance often gets buried in the day-today operations. However, Con-Tech Manufacturing, is not only dedicated to providing top-notch equipment but also prioritizes product training in order to minimizing downtime.

Every fall, Con-Tech Manufacturing hosts a two-day Maintenance and Training Seminar at its factory in Dodge Center, MN. This year, the seminar attracted nearly 300 technicians from across the United States and even as far as Alaska, Canada, Puerto Rico, and Hawaii. The swift registration, filling up within just nine days, underscores the commitment of ready mix producers to prioritize the training and expertise of their technicians.

Jim Cunningham, Con-Tech’s seasoned Service Manager with over 32 years of experience, emphasizes the importance of knowledge dissemination and proactive maintenance. “My goal is to share as much information as possible with technicians,” says Cunningham. “Empowering them to expedite repairs and get trucks back online swiftly is the ultimate reward for me.”

One key aspect of effective maintenance

is adhering to routine service intervals and conducting thorough pre-trip mixer inspections. By following manufacturerrecommended service schedules and conducting simple inspections before each trip, operators can significantly enhance equipment performance, prolong critical component life, and minimize emergency service calls.

In terms of hydraulic systems, Cunningham highlights the criticality of the initial 100-hour service, emphasizing the removal of manufacturing and assembly contaminants to prevent

premature wear. Subsequent fluid and filter changes are recommended every 1000 hours to maintain optimal system health. According to Cunningham, strict adherence to maintenance plans and using appropriate hydraulic fluids drastically reduces hydraulic system failures.

Attention to detail is another cornerstone of successful maintenance. While truck chassis inspections are common, many overlook the mixer body. Implementing detailed pre-trip or daily inspections of mixer components can identify

MAINTENANCE MAINTENANCE SERVICE SERVICE SERVICE & 2024 SAVE THE November 6th-7th, 2024 REGISTRATION OPENS AUGUST 6TH SIGN UP FOR OUR EBLASTS TO BE THE FIRST TO RECEIVE THE REGISTRATION LINK

2023 SERVICE & MAINTENANCE TRAINING SEMINAR

SERVICE & MAINTENANCE

potential issues before they escalate into emergencies. From hydraulic hose dampness to loose bolts and uneven tire wear, these signs indicate underlying problems that require attention.

Moreover, understanding the impact of cleaning chemicals is crucial. Despite claims of being acid-free, some products still possess pH levels that can cause severe damage to equipment components. Awareness of the potential risks associated with cleaning products is essential for preserving electrical harnesses, paint, frames, hoses, cylinders, and hardware integrity.

In conclusion, informed personnel and well-maintained equipment are indispensable in the ready mix industry. Scheduled maintenance proves to be far more cost-effective than reactive repairs prompted by equipment failures. Access to recommended service information and training resources, equips technicians with the knowledge and skills needed to ensure operational efficiency and safety.

Collaboration within the industry also plays a vital role in advancing best practices and standards. Sharing insights, experiences, and innovations among producers, and technicians fosters a culture of continuous improvement and excellence. By prioritizing preventative maintenance and ongoing training, the ready mix industry can enhance operational efficiency, prolong equipment lifespan, and prioritize safety in an ever-evolving business landscape.

For additional resources and inquiries, technicians can access recommended service information and mixer pre-trip procedures on Con-Tech Manufacturing’s website. Furthermore, mixer in-service and safety training videos are available on YouTube. For any questions or further assistance, technicians can reach out to Jim Cunningham directly via email. With a collaborative approach and a commitment to excellence, the ready mix industry can navigate the challenges of today’s business climate while ensuring the highest standards of efficiency, safety, and reliability.

You can access recommended service information along with mixer pre-trip procedures at www.ctmmixers.com/resources/ .

Also, there are mixer in-service and safety training videos located on youtube at www.youtube.com/watch?v=_Lbt-mYUs6k&t=18s www.youtube.com/watch?v=_clg-fvJKMc

Furthermore, if you have any questions, please don’t hesitate to contact Jim Cunningham at jimc@ctmmixers.com

“To each there comes in their lifetime a special moment when they are figuratively tapped on the shoulder and offered the chance to do a very special thing, unique to them and fitted to their talents. What a tragedy if that moment finds them unprepared or unqualified for that which could have been their finest hour.”

Sir Winston Churchill

-SAFETY

-MAIN PUMP - HYDRAULICS THEORY AND APPLICATION

-BRIDGE KING HYDRAULIC SYSTEM

-CYLINDERS (TRAILER & CHUTE)

-GEARBOX

-ELECTRICAL

-AIR SYSTEM

-PARTS INFORMATION

HANDS-ON TRAINING STATIONS

-BK CYL MAINTENANCE

-ELITE

-PUMPS & CONTROLS

-MAC VALUES

-STANDARD CONTROLS & ELECTRIAL HARNESS

-WEBSITE TUTORIAL

-DRUM MEASURING & ROLLER ADJUSTMENT

-BK HYDRAULICS

-BRIDGEKING AXLE AND PUSHER AXLES

2023 SERVICE & MAINTENANCE TRAINING

21

MAINTENANCE MAINTENANCE SERVICE SERVICE SERVICE & 2024

CLASSROOM KEY POINTS

SEMINAR

DODGE CENTER

MINNESOTA (MIDWEST/CANADA) 65740 State Hwy. 56 Dodge Center, MN 55927 dcsales@ctmmixers.com 507-374-2239

CLEVELAND

OHIO (NORTHEAST) 38134 Western Pkwy., Unit 2 Willoughby, OH 44094 northeast@ctmmixers.com 440-946-3322

ATLANTA

GEORGIA (SOUTHEAST)

108 Hudson Industrial Dr. Griffin, GA 30224 southeast@ctmmixers.com 770-229-1773

SAN BERNARDINO

CALIFORNIA (WESTERN)

378 E. Commercial Rd. San Bernardino, CA 92408 west@ctmmixers.com 909-478-0017

HOUSTON

TEXAS (SOUTH CENTRAL) 11175 Windfern Rd. Houston, TX 77064 houston@ctmmixers.com 832-688-8449

DALLAS

TEXAS (SOUTH CENTRAL) 205 Wilcox St., Ste. 100 McKinney, TX 75069 dallas@ctmmixers.com 972-941-8592

LUKE SCHROM

MIDWEST REGION MIXER SALES

507-951-3417

lukes@ctmmixers.com

DEAN BUNGUM

SOUTHEAST REGION MIXER SALES

507-206-8998 deanb@ctmmixers.com

MIKE TAYLOR

SOUTHEAST REGION MIXER SALES

507-251-3110 miket@ctmmixers.com

JAMISON SOULE

WESTERN REGION MIXER SALES

507-208-3452 jamisons@ctmmixers.com

GERARD HOPPA

WESTERN REGION MIXER SALES

507-279-9223 gerardh@ctmmixers.com

NATIONAL MIXER SALES

507-923.5590

stevec@ctmmixers.com

JED DART SOUTH CENTRAL REGION MIXER SALES 507-251-3544 jedd@ctmmixers.com WES AUSTIN SOUTH CENTRAL REGION MIXER SALES 507-251-2784 wesa@ctmmixers.com RAY SAMSON NORTHEAST REGION MIXER SALES

rays@ctmmixers.com

507-226-4503

EXPORT EXPERT STEVE CHICOS

MEET THE TEAM TRADE-INS AVAILABLE WITH WELSH EQUIPMENT INC.

Take advantage of trade-in opportunities with Welsh Equipment Inc. to make upgrading your fleet even more cost-effective. Our partnership ensures a seamless process for trading in your existing vehicles.

FINANCING OPTIONS

Inquire about our flexible financing options tailored to meet your specific needs. Our team is ready to assist you in finding the best financial solution for your business.

EXCLUSIVE WARRANTIES

Explore the peace of mind that comes with our exclusive warranties. We prioritize the longevity and performance of our trucks, and our warranties are a testament to the confidence we have in the quality of our products.

CHECK OUT OUR RESOURCES PAGE New Mixer New Mixer IN-SERVICE VIDEO IN-SERVICE VIDEO DO YOU HAVE A NEW MECHANIC? NEED TROUBLESHOOTING HELP? WATCH VIDEO

65740 State HWY 56 Dodge Center, MN 55927 Information contained in this literature was accurate at the time of publication. Product changes may have been made after the copyright date that are not reflected. © 2006-2024 Con-Tech Manufacturing, Inc. All Rights Reserved. Printed in the USA 3000-11 REV SUM 05-24 BUY 10 STOCK CHASSIS PACKAGES & GET 1 FREE REPLACEMENT DRUM! DODGE CENTER MINNESOTA (MIDWEST/CANADA) 65740 State Hwy. 56 Dodge Center, MN 55927 dcsales@ctmmixers.com 507-374-2239 DALLAS TEXAS (SOUTH CENTRAL) 205 Wilcox St., Ste. 100 McKinney, TX 75069 dallas@ctmmixers.com 972-941-8592 ATLANTA GEORGIA (SOUTHEAST) 108 Hudson Industrial Dr. Griffin, GA 30224 southeast@ctmmixers.com 770-229-1773 HOUSTON TEXAS (SOUTH CENTRAL) 11175 Windfern Rd. Houston, TX 77064 houston@ctmmixers.com 832-688-8449 CLEVELAND OHIO (NORTHEAST) 38134 Western Pkwy., Unit 2 Willoughby, OH 44094 northeast@ctmmixers.com 440-946-3322 SAN BERNARDINO CALIFORNIA (WESTERN) 378 E. Commercial Rd. San Bernardino, CA 92408 west@ctmmixers.com 909-478-0017 FAMIL Y - O WNED M ADE I N T HE US A WWW.CTMMIXERS.COM 507-374-2239 SCAN TO STAY UP TO DATE WITH CON-TECH ® PROMOTIONS & INNOVATIONS. FOLLOW US ON: