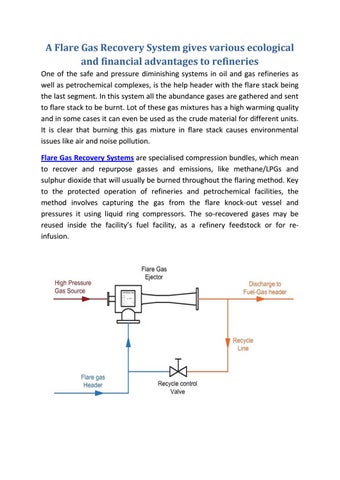

A Flare Gas Recovery System gives various ecological and financial advantages to refineries One of the safe and pressure diminishing systems in oil and gas refineries as well as petrochemical complexes, is the help header with the flare stack being the last segment. In this system all the abundance gases are gathered and sent to flare stack to be burnt. Lot of these gas mixtures has a high warming quality and in some cases it can even be used as the crude material for different units. It is clear that burning this gas mixture in flare stack causes environmental issues like air and noise pollution. Flare Gas Recovery Systems are specialised compression bundles, which mean to recover and repurpose gasses and emissions, like methane/LPGs and sulphur dioxide that will usually be burned throughout the flaring method. Key to the protected operation of refineries and petrochemical facilities, the method involves capturing the gas from the flare knock-out vessel and pressures it using liquid ring compressors. The so-recovered gases may be reused inside the facility’s fuel facility, as a refinery feedstock or for reinfusion.

A Flare Gas Recovery System gives various ecological and financial advantages to refineries

Issuu converts static files into: digital portfolios, online yearbooks, online catalogs, digital photo albums and more. Sign up and create your flipbook.