ChatGPT agrees...

The Foundation of our Safety Program is Solid!

by Scott Allen, Corporate Safety Director

At Crowder (regardless of your career path), there are individuals meeting on a regular basis to evaluate schedules, costs, lead-times, and other potential issues at the project, division, and corporate levels. These review sessions consist of thorough evaluations and, at times, brainstorming sessions on how we can better leverage technology to streamline and simplify various aspects of how we deliver projects. For example, many of you utilize COINS for reviewing/approving invoices, processing subcontracts, performing HR related functions, etc. Some of you work diligently within our mobile job tracking software known as mJobTime to input or approve weekly time so that our employees are paid correctly. Most of our project teams are utilizing Procore, which is a construction management platform designed to improve efficiency and communication during the construction and commissioning phases of a project. As for safety at Crowder, our chosen safety management platform is MeritEHS (aka Safety Operating System.) All our Behavior Based Observations, project inspections, corrective actions, incident investigations, and much more information is readily available for review.

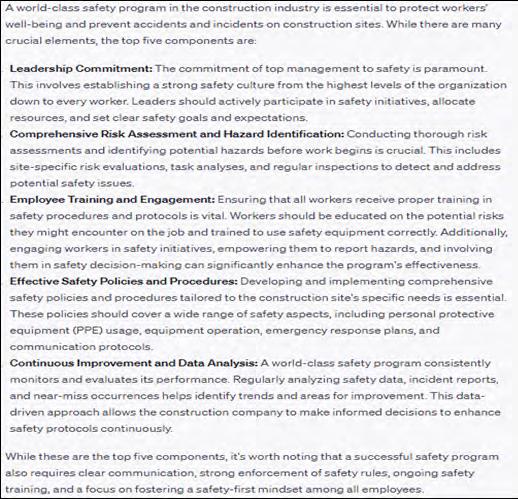

These are four examples of how we utilize technology to improve and streamline our processes. During my daily conversations with individuals at all levels of our Company, I do feel as if we have some of the most talented individuals in the industry. Recently, I’ve had multiple unsolicited discussions surrounding the realization that we are witnessing the emergence of a technological rival to the human mind. Although it is unclear how Artificial Intelligence (AI) will ultimately impact our daily lives in the future, we do know that it is currently a technological resource available for use by those curious enough to explore. I thought it would be interesting to see the response of a commonly used AI platform to the following question:

What are the top five components of a world-class safety program in the construction industry?

From the information that was generated through ChatGPT, it is obvious that Crowder has the foundational pieces in place of a world-class safety program. However, what makes our safety program successful is our employees and we appreciate your efforts; keep looking out for each other and continue to embrace technology!

CROWDER CORPORATE SAFETY

[3]

Information obtained from ChatGPT

North Durham Water Reclamation Facility - Phase 2 Improvements

Progress on the North Durham Phase 2 Project is going well and is about 75% complete. Crews are focused every week on working safely and efficiently. This project includes the construction of two new odor control facilities, a new lift station and various other mechanical and electrical repairs and improvements. Our goal here is to obtain substantial completion by the end of the year.

As work has neared completion and equipment has been installed, we have started up several new systems, which include the Camden Ave Pump Station and hypochlorite storage facility. Some remaining startups to be completed in the coming months include digesters, odor control facilities, primary sludge pumps and digesters.

Winding Pine Pump Station

June and July were very productive for us at the Winding Pine Pump Station. We poured the top slab of the pump station, closing out the concrete work in our main structure. We also closed out concrete work in the chemical building by pouring the walls and slab-on-grade (SOG). The mechanical work began inside the pump station while also pouring the slab and walls of the meter vault. We look forward to busy months ahead as we transition into more architectural work when our mason is mobilized on site. Soon we will also begin concrete work at the odor control facility and electrical building. This project is around 60% complete.

THIRD EDITION 2023 PROJECT UPDATES

[4]

Odor Control A Progress and Road Completion

Odor Control A

Air

N Durham Team Safety/ Appreciation Lunch

Foul

Tie-In

Finished Concrete Work in the Chemical Building

Meter Vaults 15’ Walls Being Formed

Graham Wastewater Treatment Plant Expansion

The expansion of the Graham WWTP is in full swing. We are around 22% complete at this site. The crew has placed all the SOGs for biological nutrient removals (BNRs) 1-2, 85% of the sloped walls over the existing concrete tank and have placed 7 of the vertical walls. We have placed all the concrete for the chlorine contact tank, and we are getting ready for a leak test. The SOG for digester 3-4 has been set and is ready for forms. Our mason has mobilized and constructed the chemical feed facility. The SOG for the new pre-engineered metal is progressing with our electrical crews busy installing the in-slab conduit in anticipation of the building being delivered in November. The electrical crews have also been busy with installing electrical manholes and duct banks.

Mayfield and Chickahominy Sewage Pump Station Upgrades

At the Henrico County Mayfield & Chickahominy Pump Station project, last-minute structural repairs on the pump station’s existing wet well pushed completion later than anticipated. Crews have worked diligently to complete this work as quickly as possible to allow for the final 24-hour test period to be completed. The team has now moved to final cleanup, completion of a short punch list, and demobilizing from the site.

Crowder officially mobilized to the jobsite in mid-June. We set up the trailers for the Crowder team as well as Hazen and Sawyer (Engineer) and received the notice to proceed for July 5, 2023. Crews have started running conduit in the residuals area. We will be continuing with installing the conduit in the residuals area and filter press building.

CROWDER CROWDER CIVIL & ENVIRONMENTAL [5]

James E Quarles WTP 2 SCADA Renovation

Excavating for Installation of Exterior Wet Well Wall Bracing

Jobsite Trailers

Beginning Final Site Cleanup

Chlorine Contact Tank and Stone for Digester 3-4

BNR 1-2 Aerial

Byrd Park Reservoir Rehabilitation

The team has finalized mobilization to the site and is attempting to drain the west reservoir. The dewatering area was setup, and demolition began on the center berm between the east and west tanks. The team attempted to dewater the west tank to begin full demolition operations, but due to excessive water infiltration, an underwater diving team has been constructing and sealing bulkheads to isolate the west tank. Once the west reservoir is isolated, dewatering operations will continue, and demolition of the west roof will begin. Overflow structures and overflow piping and manholes will begin to be installed across the site. Once demolition operations have cleared a path into the tank, concrete operations will begin.

Yadkin River Water Treatment Plant

The Yadkin Regional WTP is closing in on final completion for Union County. Crowder filed for Substantial Completion under our subcontract with CDM Constructors on June 30, 2023, as the main process trains and the entire site electrical is complete and has been started up. The overall project team is still active on the site as the commissioning team continues to home in on the appropriate chemical dosing to produce clean drinking water and receive North Carolina Department of Environmental Quality’s (NCDEQ’s) approval to distribute to the public. Once complete, Union County will have its first locally produced water, providing them with independence from other municipal sources and the ability to support the growth happening within their county. The remaining tasks include completing startup with CDM, completing punch list work, and filing for final completion.

THIRD EDITION 2023 PROJECT UPDATES [6]

Constructing the Temporary Bulkheads

Dewatering Area Earthwork

Generator Tank Crane Set

Chemical Building Corridor

Dive Team Setup

Mallard Phase 1A Water Reclamation Facility Expansion

The Mallard 1A team completed startup, testing, and commissioning of all systems and instrumentation at the blower building. The project is substantially complete, and we are addressing the final punch list items and will file for final completion.

Mallard Creek WWTP RUVI Project - Phase I Construction

Work on the Mallard Creek project recently reached final completion. Through close coordination with the Engineer (B&V) and multiple bid package subcontractors, Crowder was able to close out another successful project for Charlotte Water. The scope consisted of modifying the existing filters, replacing clarifier mechanisms, return-activated sludge (RAS) waste-activated sludge (WAS) pump upgrades, new UV equipment, and constructing a new cascade aeration structure. Many individuals worked diligently to manage this construction manager at-risk (CMAR) contract for Crowder. While keeping safety, quality, and schedule as their top priority, the team has built lasting relationships with the client and engineer that will help solidify Crowder as the preferred water and wastewater contractor in the region.

CROWDER CROWDER CIVIL & ENVIRONMENTAL [7]

Aeration Piping

RAS Pump Station

Completed Blower Building and Aeration Piping Installation

Completed Blower Installation, Startup, and Commissioning

Filter and UV Structure

Rocky River WWTP Phase 3 Upgrades

Crowder has maintained momentum through the Spring and Summer at Rocky River on the Phase 3 Upgrades project. We are firmly in the midst of the mechanical and equipment installation phase of construction activities. We are currently running yard pipe of varying diameters (6” to 42”), and installing exposed mechanical piping, supports, handrails, and miscellaneous metals at the new aeration basin 6. Our new equalization (EQ) tank 1 is coming along nicely, with the subcontractor roughly 75% of the way complete with structural construction. Both of our pre-engineered metal buildings are getting close to completion as well. Our electrical team continues to simultaneously work on underground duct bank and exposed rough-in at all areas onsite.

Crowder’s team has continued to grow and build a positive and productive relationship with both our design partner (Brown and Caldwell) and our client (Water & Sewer Authority of Cabarrus County or WSACC) as we work towards our goal of completion in the Summer of 2024. Some of the next steps include completing aeration basin 6, mechanical and metals installations including mixers and diffusers, installing pipe, supports, and blowers at the blower building to tie-in to aeration basin 6. We also want to make significant progress on yard piping, complete and backfill EQ Tank 1, and prepare to put the plant on bypass for the new flume 103 tie-in work in the Fall.

Calls Creek Phase 1 (Construction)

Construction at the influent pump station and aeration basin #2 is ongoing and is expected to be completed next month. Work at RAS pump station, blower building, and effluent building is complete and was ready for startup this month (August). The dewatering screw press is expected to be delivered in late September/early October, which will be the final activity for Phase 1. We are around 75% complete at this project.

THIRD EDITION 2023 PROJECT UPDATES [8]

New

New

Completion New EQ Tank No. 1

Aeration Basin No. 6

Maintenance Canopy Near

New Blowers and Process Air Piping in Blower Building

Fine Bubble Diffusers Installed in Aeration Basin 2

Stowe Regional Water Reclamation Facility

The Stowe Joint Venture team has gotten off to a quick start to our structural concrete this Summer. To-date, we have placed over 4,800cy for stages #1A & #1B and are already shoring and pouring launder decks (slightly sloped channels) inside two clarifiers. Mass earthwork has continued for Stage #2 with over 80,000cy of suitable soils, PWR & pre-blasted rock moved in the past three months for structure excavations. The yard pipe crews have ramped up having installed PCI/PCE, FCI/FCE and RAS Piping and have begun installation of the process drain systems. Electrical crews have established a consistent presence while installing the medium voltage temp power distribution system and planning the permanent duct bank work. We look forward to receipt of the building permits for stage #2 and a break in temperatures this fall.

The Wilmington Interim Rehab Project is on its way to a very quick and successful completion. The team has made it look easy to bring this one in under budget and well ahead of schedule. The precast maintenance staff office building is up, and the finishing touches are well underway. Cape Fear’s maintenance staff is ready to abandon their 1980’s site trailer and move into the luxury state of the art office.

The chlorine building conversion to a maintenance shop is complete and the staff is moved in and ready to work. We pulled out some old school tactics on the placement of the slab using the existing overhead crane to place the interior slab with a bucket saving pump truck costs. Very cool! Installation of the new polymer thick film (PTF) mechanical screens and screw conveyors went exceptionally well with minimal shutdowns and a very successful commissioning.

To say Cape Fear Public Utilities is happy is an understatement and during our time onsite for this project we were awarded the big upgrade design-build project as well. Hats off to this team for paving the way for this huge deal of a project for Crowder.

CROWDER CROWDER CIVIL & ENVIRONMENTAL [9]

Southside WWTP Interim Rehabilitation – Phase II

New Maintenance Building

Placing a Wall at Final Clarifier #1

Primary Clarifier in Background with Soil Stockpile & Pipe Laydown in Foreground

Overhead Crane Used for Concrete Slab Placement

Crew Picture at New Maintenance Office: (L-R) Gene White, Steve Claburn, Jesse Duty, Jermaine Brown

Fall in Love with Safety Training

by Denis Logie, Crowder Construction Company Safety Director

The construction industry is inherently dangerous and presents opportunities for employees to be injured or suffer illness. One of the most prevalent dangers plaguing our current workforce is the constant threat of falling while working at height. Falls continue to be one of the leading causes of injury and fatality within construction year after year.

In 1994, the Occupational Safety and Health Administration (OSHA) established their “Focus Four” initiative which is a targeted and focused effort to increase awareness on four common hazards within construction. These hazards include falls, struck-by’s, caught-betweens, and electrocutions. As it pertains to falls, current safety practice provides multiple options for controlling exposure to work-at-height. Of these control options, one is of utmost importance which provides for the necessary knowledge, skills, and abilities to effectively recognize fall hazards and manage exposures on the jobsite. This option is TRAINING!!!!

Providing competent and experienced employees/supervisors is key to ensuring the safety of our workforce both during work-at-height activities and during general construction tasks. Supervision is and will remain the backbone of Crowder’s culture and safety management. Empowering our supervision by providing them with critical training leading to competence and confidence in their abilities to effectively manage safety is key to ensuring employees are adequately equipped to perform their jobs safely.

THIRD EDITION 2023 SAFETY UPDATES [10]

Employees Pictured: (Top): Denis Logie (Far left): Marc Powers (2nd from left): Matt Lamb (3rd from left): Dustin Moffit (Far right): Jerry Ruiz

Conducting Fall Protection Competent Person Training (24 hours)

SCDOT Blythe/Zachry JV I85 Widening Railroad Bridge

At the Blythe/Zachry JV project, the wall 5 footing has been poured and cured. This was a mass pour, so a chiller system and cooling tubes were used. The crews finished pouring out the walls to complete wall 5 at the end of July. The crews here had one wall pour per week for three weeks to finish out the concrete for wall 5. At the end of July, the waterproofing sub was scheduled to be on site to waterproof/dampproof the structure. BZJV is set to backfill when complete and soon the handrail sub will begin installing handrail on the project. We are around 90% complete.

Crabtree Creek West Greenway

The L1 portion of the Crabtree Creek West Greenway has been opened to the public. The remaining L2 portion of the project is currently under construction and on-track to complete by the end of 2023.

Gwinnett County Rowen Pump Station DB: Pedestrian Trail

This project is in pre-construction with anticipated mobilization date sometime in August of 2023. Once the land development permit and the proposed change notice are approved for Work Area #6, JDS will begin clearing and grading trail sections north of Work Area #6.

CROWDER CROWDER HEAVY CIVIL [11]

Wall 5 Pour and Cure Footing

Wall 5 Pour and Cure Footing

L1 Open to the Public Creek West Greenway

Forming For Wall Pour

L2 Suspension Bridge Side

Charlotte Douglas Airport Taxiway Bridge

Currently, we have completed 8 of 14 deck pours on the Taxiway and vehicle service road (VSR) bridge. We are looking to complete them all by the end of August. We have finished the grading, asphalt, curb and sidewalk and switched traffic at the end of July onto the new roadway alignment. We are also working on the under-bridge lighting and anti-graffiti painting on the mechanically stabilized earth (MSE) walls. We are continuing with pouring the bridge decks for the taxiway and VSR bridge.

City of Hendersonville French Broad River Intake and Pump Station

Another major milestone has been completed as the 54” raw water influent pipe has been installed. Leak testing is also taking place at the pump station. Walls and columns are complete up to ground level at the pump station. We are in the process of forming, tying, and placing the first half of the intake walls. When walls reach 28-day strength (break was 6/30) we will fill the PS and begin crack injection and leak testing. We will also button up and place intake walls, complete backfill of 54’’ raw water (RW), pull and return trench boxes, and excavate, form, tie, and place arch culvert footing. We will continue to tie and place elevated slab at pump station and backfill pump station after completion of leak testing. We are roughly halfway through this project.

THIRD EDITION 2023 PROJECT UPDATES [12]

Formed and Tied Walls for Pour 1

Yorkmont Site

Bridges Completed, Preparing for Approach Slabs 1

Completed Bridges

Aerial View

Intake Structure

Briar Creek - Green Oaks Storm Drainage Improvement Project

Paving has started along Eastbound I-40 this past month. We are continuing on the concrete slab replacement operation and the fibercrete joint sealing work along Westbound I-40. We are about 50% complete at this site.

SCDOT Orangeburg US21 US178 Improvements

We have reached the start of major milestone work on this project. In the next month, the stair tower will be complete and multiple subs are on site from building contractors for the guard house to electrical. We are working to complete stairs on stair tower, complete majority of wall 7, and start the flatwork southside of Chestnut.

CROWDER CROWDER HEAVY CIVIL [13]

Block Wall View 1

Block Wall View 2

Clearing and Creek Crossing

I-40 Wade Ave to US-1

Poured and Stair-Tower Landing

Westbound to I-40 Concrete Slab Replacement

Westbound to I-40 Concrete Slab Replacement

Applied Poly-Fibercrete Work EB I-40 95% Complete

Briar Creek - Green Oaks Storm Drainage Improvement Project

The Briar Creek Stormwater project is moving along with the large precast culvert completed in early July. All underground storm and sewer work has been completed in the roadway and the curb and gutter along with asphalt has been replaced. Chase Reline, a subcontractor, is working hard to install the 60’’ High Density Polyethylene (HDPE) slip line inside the existing corrugated steel pipe that is failing. Once the HDPE is in place, the annular space will be grouted with high strength non shrink grout. This project should be completed well ahead of schedule in early September.

CDIA Old Dowd Road Relocation

At the Old Dowd Road Relocation project, we are working on erosion control, cut to fill 25k CY cap bent 1, and we have poured columns at bent 4. The bent 2 platform pile has been installed and the welding completed. In July, we completed work on bent 2 platform drill shafts, bent 2 caps, bent 3, 4 and end bent 1 grading. On the North side of the project, we completed the reinforced fill at end bent 2 and the waterline thru roadway on Wilkinson Blvd. Railroad boring started in mid-July.

THIRD EDITION 2023

PROJECT UPDATES [14]

Cut Fill Operation

Regional Detention Basin Reinforced Fill End bent 2 End

1 Work

Cut Fill Operation Site Overview

Bent

Setting the Final Culvert Sections

SCDOT US 301 Over Four Hole Swamp

The work trestle installation has been completed and the index piles for all interior and end bents are completed. Production piles have continued through July and the unit 3 bent cap formwork and reinforcement has begun. We are currently working on the production piles and are around 41% complete with this project.

SCDOT Spartanburg County Emergency Rehab Repairs I-26 and SC 9

The emergency bridge rehabs over Lake Bowen project has begun with the repair of two bridges. The SC 9 bridge scope involves strengthening the current structure in the event it needs to be utilized as a detour during the construction of the I-26 bridge. Strengthening involves adding saddle beams to three interior bents, applying carbon fiber reinforced polymer (CFRP) to the existing beams, concrete spall (areas where the concrete has cracked and broken away) repairs, and epoxy resin injection. Once this is completed Crowder will mobilize to the I-26 Bridge. Scope on this project involves substructure spall repairs, extensive cap repairs on two interior caps including post-tensioning, jacking bridge, and replacing bearings, partial and full depth deck repairs. Work on I-26 began at the beginning of June 2023.

VDOT Bridge Repairs Over Nottoway River

The VA Department of Transportation requested that we remove rumble strips for shifting traffic onto the inside shoulder. This was not in the original scope and will be change order work. The work for the inside lane has been completed, and the continuous right lane closure was installed in early July. Milling and the deck survey in the right lane has also been completed and API has mobilized and begun the substructure repairs.

CROWDER CROWDER HEAVY CIVIL [15]

Bridge over Nottoway River

Reconfigured Barges for I-26 setup

Index

2-5

Aerial View of Project

Piles

Concrete Repairs and Saddle Beam Installation

Beam Jacking, Beam End, and Beam Seat Repairs

Allison Creek Access

We have finished all striping and paving at the Allison Creek Access project. All landscape has been completed and the ranger station and gatehouse received final completion. A final walk through/punch list has been generated and we will continue to work to complete the water tie-in after chlorination.

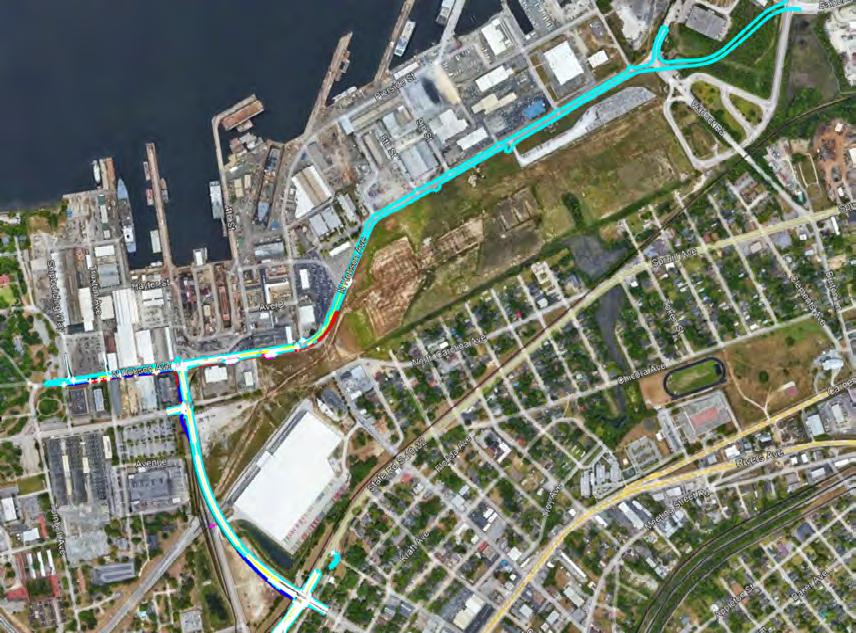

Cosgrove Avenue Extension Bridge

The Cosgrove Avenue Extension Bridge project in North Charleston, SC is a project with the South Carolina Port Authority awarded to Crowder in April 2023. The project consists of a 1,032 LF over the Palmetto Railways. This bridge has earthquake drains, 36 EA 78” drilled shafts, 54” modified bulb tees, 4000 CY of concrete, and 1.7M lbs. of reinforcing steel. The project also involves the improvement and widening of North Hobson Avenue which is parallel to the Cooper River and on the old navy base. Crowder began this project in mid-July 2023 with a 720-day project duration. Cape Romain will look to mobilize their crane to Bent 5 and 6 in an effort to complete this bent prior to Rail Works coming through with their rail across McMillan. McMillan was shut down at the end of July and the critical path work is well under way.

THIRD EDITION 2023 [16]

PROJECT & SAFETY UPDATES

Day Use Area, Ranger Station, and Playground Completed

Installation of Silt Fence on the North Side of McMillan

Tent Camping, Parking, Bathroom, and Trail Entry

Overflow Parking and 34 site RV Campground

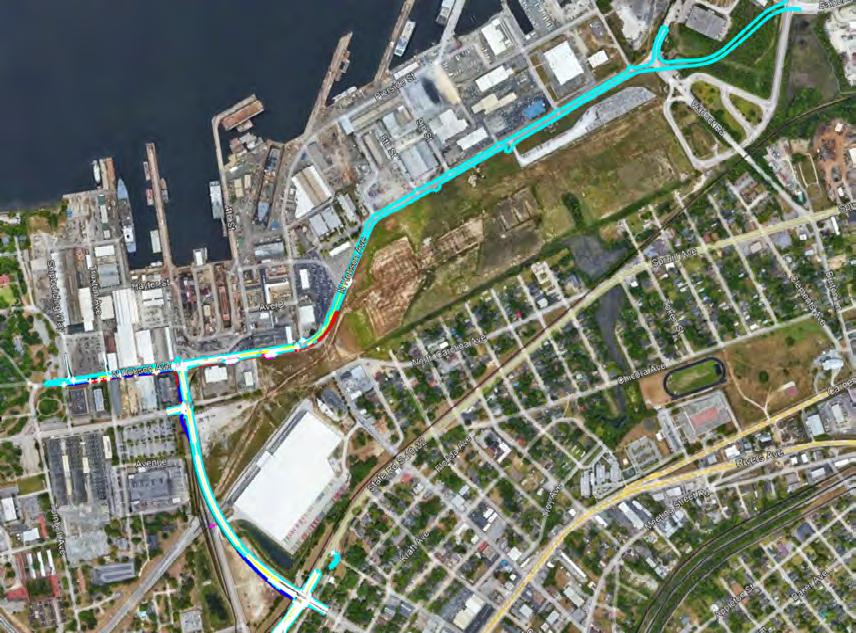

Project Map

Windsor Woods Tide Gate Project

CROWDER CROWDER HEAVY CIVIL [17]

The Windsor Woods Tide Gate project is located in Virginia Beach, VA. Over June and July, we completed installing the sheet pile, the undercut, and the backfill up to the waler and tie-rods for the tide-gate bulkhead wall.

Sheet Pile Installation

Bulkhead Wall

Site Aerial

Perimeter Block Installaion

Perimeter Block

Perimeter Block Installaion

Total Fiber Recovery

At our Total Fiber Recovery project in Chesapeake, VA, we have completed pile installation, formwork, and rebar for the outside tanks. We have also started to install steel inside and around the pulper for the pulping equipment. Work continues on the tank foundation piles, tank foundation formwork and rebar, and the steel erection inside the building.

Lake Michie and Little River Raw Water Pump Station Improvements

We have begun mobilization activities including office trailers delivery/set-up, the installation of crane mats/stone for protection of existing underground raw water lines, and implementation of a full-time security guard at Lake Michie site completed. Installing erosion and sedimentation control (E&SC) measures (silt fence, tree protection fence, etc.) by subcontractor in progress. The lead abatement work began at the beginning in May and continued for the next 3 months. CIC continues submittal processes with the engineer and procurement activities for major equipment/ materials and subcontracts. Clear & grub work began after the completion of E&SC, and we will create the remote laydown & parking area after clear & grub work concludes.

Richmond WTP Substation 1 Replacement

A site visit with Crowder and Eaton for DATA collection was completed in early April and a submittal for transformer has been approved. The transformer was released to manufacturer at the beginning of April with a lead time of 95 weeks . We are currently waiting for the submittal drawing approvals for 5KV and 35KV submittals.

Crowder is an equal opportunity and affirmative action employer. It is the policy of Crowder to provide equal employment opportunity without regard to race, color, religion, sex, marital status, age, genetic information, national origin, veteran status, mental or physical disability, sexual orientation, or gender identity. Visit our website to view current open positions and to see other news!

THIRD EDITION 2023

[18]

PROJECT UPDATES

Steel Erection Inside Building for Equipment Platform Dump Chest RW Line Protection

Tank Foundation Piles

Wayne Township (PA) Landfill RNG Facility

We have completed the acceptance test and are working on demobilization at this site.

SPSA Landfill RNG Facility (VA)

At the SPSA Landfill RNG project in Virginia, the dry commissioning of metering site is complete and wet commissioning took place at the end of June. The fire water supply line installation is 100% complete, including back flow preventer (BFP) at public roadway. The mechanical piping systems are 100% installed, tested, and reinstated. Electrical scope is complete with functional checkout and last few instruments remaining. The 480V transformer has been set and both 4160V and 480V transformers have been energized as of the beginning of July. The site has begun mobilizing and supporting vendor and factory reps to begin checkout and recommissioning activities on all process equipment.

Bear Creek TIV

The Bear Creek TIV project is complete! Thank you for a job well-done!

CROWDER CROWDER INDUSTRIAL CONSTRUCTION [19]

Commissioning of the Valve

Completed Gas Metering Site Final Connections Final Connections Final Grade Being Set and Stone Placement

Lube Oil Cooler System Process Skids

Kings Bay Dry Dock Repair

All Phase C Work is complete along with commissioning by the CxA. Only remaining work is the installation of the 4 new concrete caisson pumps. The discharge tubes and frames have been installed and the pump installation and field testing occurred during the first 3 weeks of July.

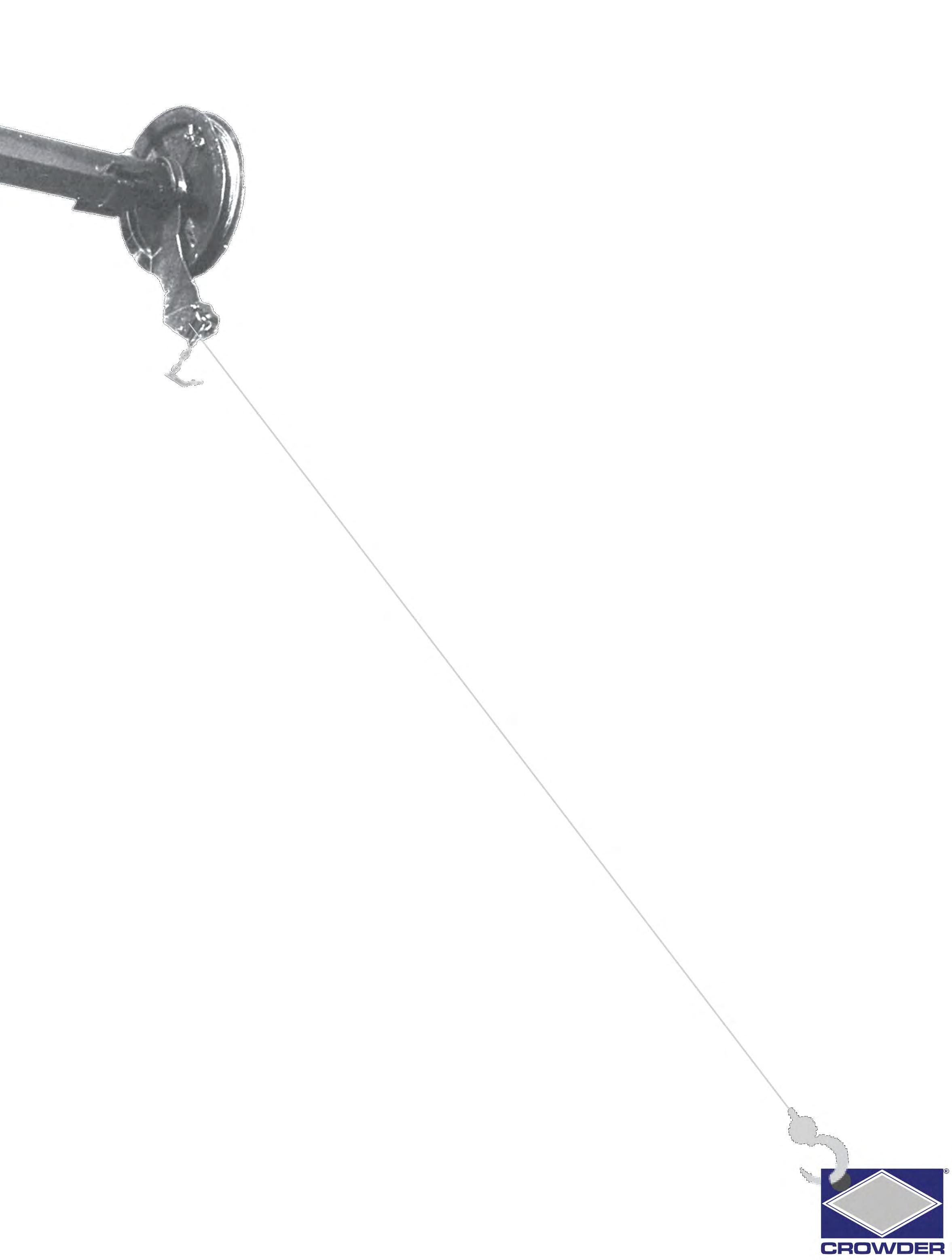

Tallulah Falls Material Cart Installation

We are making our way to the final stages for this project located in Tallulah Falls, Georgia. The original material cart at this site is over 100 years old, so it will be placed on display in the Tallulah Falls area for historical preservation.

Plant Scherer Ash Pond Dewatering Project

Crowder’s work at our Plant Scherer site has been completed! Construction at the site finished at the end of June and a small crew stayed on site for dry commissioning through mid-July.

Safety From Start to Finish

by Steve Fortson, CIC Division Safety Director

CIC took on four sister projects for Terreva Renewables (Formally MAS Energy). These design build projects purify landfill gas to produce pipeline quality natural gas. CIC not only handled the construction of these projects, but we were also responsible for developing and implementing the commissioning plan. The commissioning plan for any project begins with safety in mind. The process has inherent hazards, especially during commissioning, including hydrogen sulfide, high gas pressures (700+ PSI), explosive gases (CH4), and high voltage equipment (4160V). To make sure these projects were safe and successful, CIC not only relied on all our standard safety procedures during the construction phase but also completed plans not as common on many of our projects.

Due to these added concerns, the team spent many grueling hours researching and planning for the safe execution of the task. Quality Assurance/Quality Control (QA/QC) documentation for these projects was critical for the safety aspect of making sure that all equipment would be safe to operate once landfill gas was introduced. Wiring and termination checkouts and powering up equipment prior to gas being introduced, high pressure nitrogen leak tests were performed based on piping specifications to ensure no leakage at any connections on the piping, complex piping and equipment systems were purged of oxygen to ensure systems remained safe. The entire team had to be precisely aligned to make sure everyone went home safely at the end of each day and ensure that the equipment was protected and remained in safe working order.

After construction activities were completed, the commissioning of the plants could begin. With safety at the forefront, we dedicated Superintendents to work as commissioning leads for mechanical and electrical. These field leaders worked hand and hand with the project management team, equipment vendors and owner to ensure a safe start-up. Start-up was divided into multiple phases to isolate the plant to the handful of items being worked on at one time. This allowed for focused attention on the one or two systems starting up to make sure everything was functioning safely and correctly prior to moving to the next step in the process.

These phases of start-up included many checklists, documented lock-out tag-out (LOTO) requirements for many non-critical systems, restricted workspace areas (exclusion zones), along with step-by-step guides for the sequence of start-up that would take place during that particular phase. The team formulated plans but also maintained excellent communication between all the parties involved and adjusted the plan as required as issues arose during the start-up. Getting systems to a safe place and having the entire team regroup and discuss any change to the plan to make sure everyone was a key function of the entire team. Having qualified people that understand the safety expectations, the process, and a true understanding of the need for clear and concise communication allowed for the safe execution of the plant start-ups.

THIRD EDITION 2023 PROJECT & SAFETY UPDATES [20]

Hoist System

Installing New Hoist System

CROWDER [21] Welcome Fall 2023 Co-Ops

Dylan Brown University of Cincinnati Working at: Chesapeake Bay Project

Ellis Rogers Purdue University Working at: Byrd Park project

Will Nusbaum University of Cincinnati Working at: Stowe Project

Josh Kinyo University of Akron Working at: Graham Project

Remember to follow Crowder on Social Media Today! Facebook and LinkedIn: @Crowder Instagram and Twitter @Crowder_USA CO-OPS

Tommy Hogan University of Cincinnati Working at: Graham Project

French Broad River Intake and Pump Station Project

French Broad River Intake and Pump Station Project