Increasing Packaging Productivity and Reducing Labour with Protect it Right

An existing Crawford Packaging customer, a cleaning product manufacturer from Kitchener, Ontario, connected with our team to discuss their current protective packaging process. Upon further discussions and reviewing their protective packaging, it became apparent that their current process was labour-intensive, involving manually separating perforated foam sheets from a large roll. Crawford's Protect It Right audit identified areas to streamline the process, leading to significant improvements in productivity and labour optimization.

Challenge

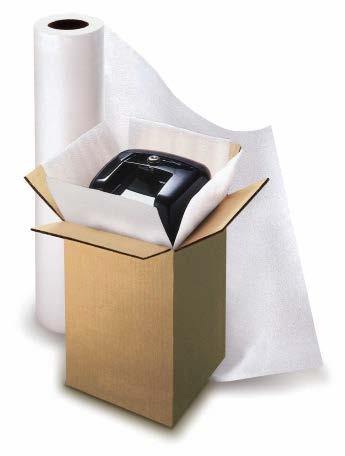

• Manual packaging process where employees had to manually tear perforated form sheets from 2000-foot rolls

• Labour intensive task involving multiple staff members to prepare void fill

• Inefficient workflow with the manual process reducing overall efficiency

Solution

• Packaging Specialist conducted a Protect It Right audit to assess their current process

• Process optimization and a customized solution to streamline packing, aligned with the customer's specific needs

Impact

• Increased Productivity: The new protective packaging process reduced the time and labour required for packaging

• Reduced Labour Costs: By minimizing manual handling, the manufacturer saw decreased labour costs

• Reduced Waste: Having pre-cut protective sheets reduced packaging waste