Print - Packaging INNOVATION Asia

The SPECIAL drupa issue. Starting with this issue and next month, we will feature all the new products from the world’s leading manufacturers. Get your drupa hit list before you travel.

News from and more

Serving Printing, Packaging and Publishing Industries across Asia Pacific since 1985 Issue 4 2024

Get to know us and you’ll discover our passion for building successful, long-lasting partnerships driven by core values of trust, innovation and sustainability. Discover

What makes Fujifilm unique is the way we combine both analogue and digital expertise with one goal in mind – to help you grow your business.

Discover the difference at drupa 2024

the difference

Hall 8B, Stand A02 Discover More

24th Published by Asian Print Awards Management Pte Ltd 65 Chulia Street #46-23 OCBC Centre 049513 Singapore Print Innovation Asia Labels and Packaging Innovation Asia Asian Print Awards Packageing Excellence Awards Label and Packaging Conferences Publisher Paul Callaghan paul@printinnovationasia.com Editorial Elizabeth Liew elizabeth@printinnovationasia.com Packaging Sales Elizabeth Liew elizabeth@printinnovationasia.com Issue 4 - 2024 In this issue Print - Packaging INNOVATION Asia Magazine ASIAN PACKAGING EXCELLENCE AWARDS: 2024 4 drupa in Düsseldorf: The prime-time event for the global printing industry in 2024 8 Fujifilm Group announces its presence at drupa 24, as it invites visitors to “Discover the difference” 10 BOBST unveils innovations on the road to drupa 24 14 See the Potential in the Future of Print 16 Innovative thinking and modern aesthetics - IST METZ at drupa 24 – more than UV 20 Cost pressures, the skills shortage, and sustainability 24 XSYS to launch new plate manufacturing and focus on sustainability 32 Miraclon - drupa line-up that guarantees packaging printers a path to modern flexo 36 Workflow Automation Drives the Future of Print 42 Canon demonstrates ‘The Power to Move’ at drupa 24 46 Positive future prospects for the printing and paper industry: Packaging as a driver of the sector 48 drupa Print Horizons Report: Print Industry in transition to a digital world 50 How product packaging affects buying decisions 52 Books printing – all changed – a closer look to the new operating model 56 Unveiling the Future of Packaging: Trends in Sustainable and Smart Substrates 58 New and information from around the region and the world

drupa in Düsseldorf: The prime-time printing industry from 28 May to

Over a period of eleven days, 1,537 exhibitors from 49 countries will present innovative technologies, solutions and topics that affect the industry now and in future. A wide range of special events will provide valuable know-how. Focus on digitalisation and sustainability.

There’s a great deal of excitement in the international printing industry right now, as everyone will finally be able to meet up in person and exchange information at drupa, the world’s most important event for the sector, from 28 May to 07 June in Düsseldorf. In these very volatile times characterised by large social and also rapid technological changes and global megatrends, companies have to react: Those who do not anticipate important developments and adjust accordingly will endanger their competitive edge and waste opportunities for the future.

drupa is being held at just the right moment for this. In an international comparison, the leading global trade fair for print technologies both demonstrates the state of the industry’s art and a wide spectrum of innovations which will shape the future and offers a multitude of opportunities for high-calibre knowledge exchange, discussions and networking with word-renowned sector experts. On a net area of approx. 140,000 m² with 18 show halls, 1,537 exhibitors from 49

countries will present the entire spectrum of current trends and visionary ideas within print technology. Production of packaging and printed packaging are two areas which have also significantly gained in importance. From renowned global players to aspiring newcomers and startups – the list of registered exhibitors is almost a who-is-who of the printing and packaging industry.

Here is a small sample: Bobst, Canon, Comexi, Duplo, EFI, Epson, ESKO, Fujifilm, Heidelberg, Horizon, HP, Kodak, Koenig & Bauer, Kolbus, Komori, Konica Minolta, KURZ, Landa, Müller Martini, Ricoh, Screen, Windmöller & Hölscher, Xeikon. You can view the complete list of exhibitors online at www. drupa.com .

drupa 2024 focus topics

Limited fossil resources and carbon emissions have caused sustainability to become an essential part of long-term company strategies. Depending on the use of resources, the print and packaging

prepress/print

premedia/multichannel

postpress/converting/ packaging

future technologies

materials

equipment/services/ infrastructure

Gewichtung der Produktkategorien in den Hallen:

Emphasis on the product categories in the halls:

hoch/high mittel/average wenig/low

Print Innovation Asia Issue 4 2024 4

Eingang/Entrance CCD PRINT& DIGITAL

Stand: Oktober 2023 / As of: October 2023

prime-time event for the global to 07 June 2024

industries are already using manufacturing procedures that save energy and resources today. drupa explains the important facts for sustainable production of print and packaging solutions and which trends are evolving within the sector in order to achieve the goal of a circular economy.

Digitalisation is changing analogue processes, while artificial intelligence is taking on more and more tasks in Industry 4.0. drupa presents top technologies across the industry’s entire added value chain with a special focus on future and cross-sectional technologies. With this scenario in mind, topics like

Eingang Nord Entrance North

Eingang/Entrance

CCD Stadthalle

circular economy, automation, printing/ finishing 4.0, artificial intelligence, platform economy and connectivity will be taking centre stage in the conference programme and expert forums.

Special forums

In times of constant change, disruptive processes and the resulting new business models, the drupa special forums are important aids for decision-making. They provide impetus and show best practices which the industry cannot do without. Together with its partners, drupa relies on its impressive range of competence across the industry and the topics which concern the future of its target groups. drupa cube

Eingang/ Entrance CCD Süd

Why is printing more important than ever in the digital age? Why do customers not always perceive printed products as

Eingang Süd Entrance South Messe Center Nord/ North

CCD OST

Eingang Ost Entrance East

Eingang Süd Entrance South

Print Innovation Asia Issue 4 2024 5

U-Bahnhof Tram station Merkur Spiel-Arena/ Messe Nord

7a 70–2 6 61 5 8a 8b 9 10 11 12 13 14 15 16 17 4 3 1 AL CONVENTION

sustainable? And how do you calculate your carbon footprint? These are just some of the issues that will be discussed in the drupa cube in 2024. In more than 50 sessions, the conference offers inspiration and expertise.

The programme features five great keynotes from renowned international industry specialists and presentations about topics like increasing your business success, circular economy and sustainability, the future of print and packaging as well as sessions and best practice examples regarding new business models and trends. Hall 6/Booth F03

drupa touchpoint sustainability touchpoint sustainability deals with the role of the printing and paper industries in sustainable transformation and offers an overview of current, mid- and long-

term developments. Technologies from mechanical and systems engineering are especially important in this context, above all with regard to quality, process safety during production and sustainability.

Digitalisation and AI play key parts in order to accelerate the transformation process in the print and paper industries and to realise scaling effects. Manufacturers, industry players, brands and users together show how change can become reality in their many exhibits at touchpoint sustainability. Visitors to touchpoint sustainability can also enjoy a broad accompanying programme. Hall 14/Booth D60

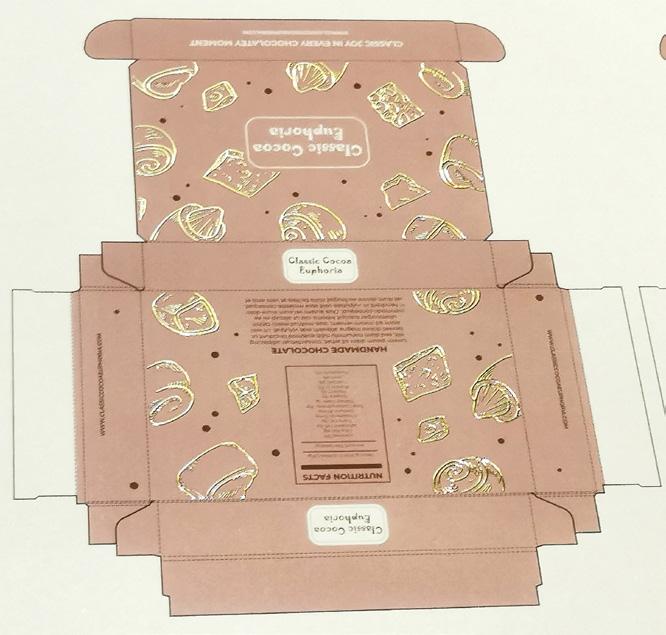

drupa touchpoint packaging touchpoint packaging concentrates on visionary, intelligent packaging solutions

and brings brand owners together with designers, print service providers and converters. The involvement of students and young talents in partner projects with exhibitors promises unique packaging solutions for folding boxes, labels, flexible packaging and corrugated cardboard.

Beyond this, there will be discussion of important questions regarding global megatrends and their impact on packaging production, for example sustainability or e-commerce. The five key topics of touchpoint packaging are neo-ecology, connectivity, glocalisation, consumer mind and future regulations. Hall 3/Booth/B31drupa dna

Big ideas, tiny budget – for many young companies, it’s not easy to make the right contacts and establish their fascinating and innovative solutions on the market. For this target group, drupa has created a special platform: drupa next age (dna). Newcomers, young talents, start-ups and established companies can network on a level playing field, find matching partners for cooperation and exchange innovative business ideas. For some participants, this is the first chance ever to present their businesses to an international audience of experts. Hall 7/Booth 09

drupa touchpoint textile

The drupa touchpoint textile presents the world’s first digital textile microfactory. This is a fully connected, integrated process chain – from digital simulation to design, animation and virtual rendering to production. One thing is sure: The industry is constantly gaining new fields of application, and inkjet technology not only opens doors to sectors like clothing and fashion, but also to the interior design, architecture, automotive and many other vertical markets. Hall 4/Booth B30

For details regarding the programme, partners and speakers of each special forum, see: https://www.drupa.com/en/ Program

drupa 2024 is open for visiting professionals from Tuesday, 28 May to Friday, 07 June 2024, Mon–Thurs from 10:00 a.m. to 6:00 p.m., Sat + Sun from 10:00 a.m. to 5:00 p.m. A 1-day ticket costs 60 euros, a 3-day ticket 165 euros, and a 5-day ticket 255 euros. Information about parking tickets and tickets for public transport is also available at the ticket shop.

Print Innovation Asia Issue 4 2024 6

we create the future

think digital — be sustainable

How will megatrends such as sustainability and digitization impact on processes, products, business models, and the future of the industry? In Düsseldorf, you will find out how the printing and packaging community is shaping the future.

May 28 – June 7, 2024 Düsseldorf/ Germany

Messe Düsseldorf Asia Pte Ltd 3 HarbourFront Place #09-02 HarbourFront Tower Two Singapore 099254 Tel. +65 6332 9643 / 6332 9620 Fax +65 6337 4633 / 6332 9655 mdrep@mda.com.sg

http://mda.messe-dusseldorf.com/ #drupa2024 www.drupa.com blog.drupa.com

Fujifilm Group announces its as it invites visitors to “Discover

Fujifilm Group print technologies – from analogue to digital; toner to inkjet, through to printheads, inks and software will be showcased this year on Fujifilm’s biggest ever drupa stand. Fujifilm Group today announces its presence at drupa 2024, 28th May to 7th June, Dusseldorf, Germany (Hall 8b / A02).

At the first iteration of the show in eight years, Fujifilm Group will showcase its credentials as a trusted and sustainable partner, adding value to businesses across the printing industry as they “Discover the difference” with Fujifilm.

Summary of Exhibition Areas

1. Commercial Area

Explore the latest insights into the Jet Press 750S, highly respected for more than a decade with its incomparable print quality, achieved through unique inkjet technology. The Revoria Press GC12500, will also feature in this area. Its use of dry toner allows for impressive paper versatility and high usability. In addition

to the two B2 digital presses, the Jet Press 1160CFG, full colour high-speed continuous feed inkjet printing system for the commercial print market, will be exhibited for the first time.

In addition, two new mid-range production printer will also be unveiled for the first time. This new press is modelled on the hugely successful Revoria Press PC1120, with its specialty colours and massive application range, which also features in the Commercial Area. New processless plates for offset printing and DX solutions for automation and streamlining with workflow software, will also feature, in addition to demonstrations of Fujifilm photographic products. The inclusion of third party

finishing equipment will showcase the huge variety of applications possible with Fujifilm technology.

As the print industry continues its trend from analogue to digital, Fujifilm Group will lead customers as a sustainable partner on that journey.

2. Industrial Area

Discover the recently released Jet Press FP790, water-based inkjet digital press which brings innovation to the flexible packaging printing process, and the new automation options for our hybrid wideformat machine, enabling even higher production capacity. Alongside this, Fujifilm’s award-winning Acuity range of wide format inkjet printers will be

Print Innovation Asia Issue 4 2024 8

Jet Press 750S

Revoria Press GC12500

its presence at drupa 2024, “Discover the difference”

showcased, as well as a broad range of applications delivered by Fujifilm Group’s latest technology, including signage and packaging.

For customers whose demands cannot be met by standard printers, we offer customised printing equipment and inks through FUJIFILM Integrated Inkjet Solutions. We will present case studies across a wide range of applications, including direct mail, transactional printing, labels, and embellishments, demonstrating our proven track record.

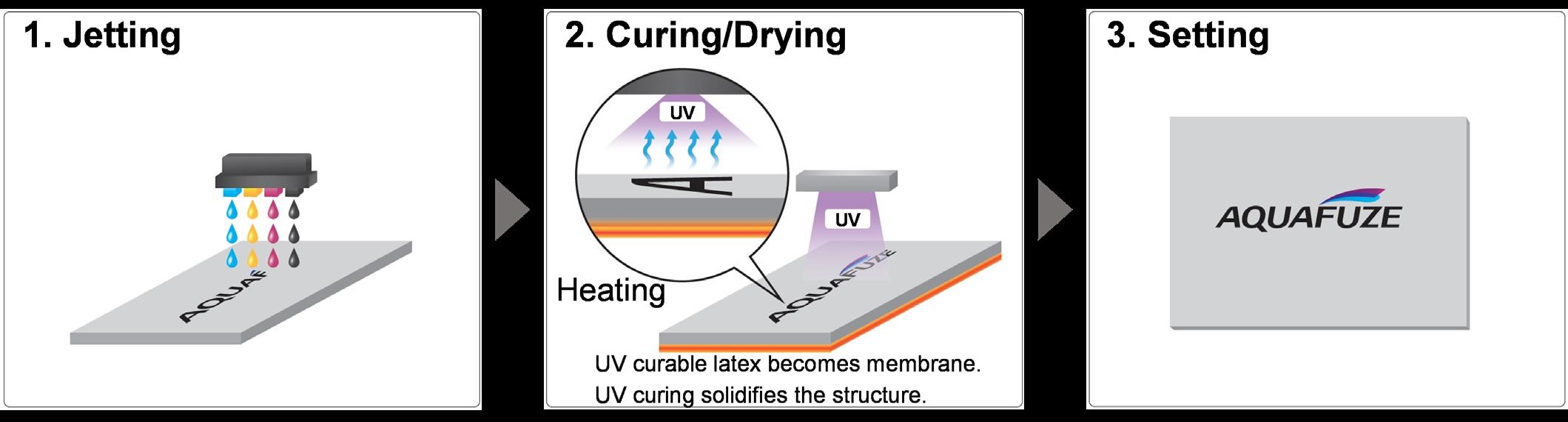

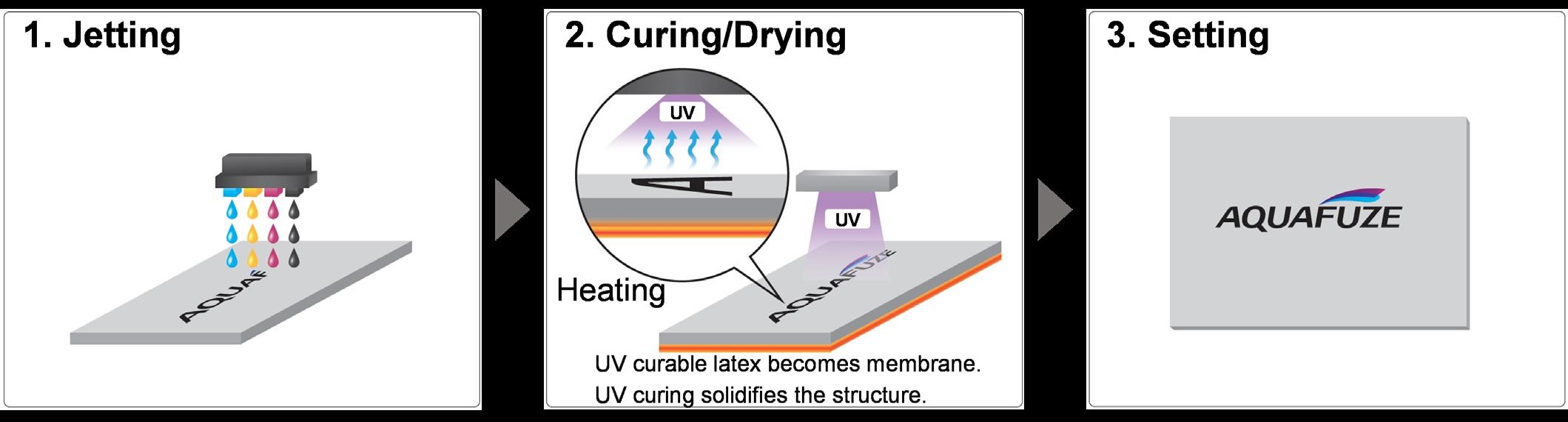

Introducing "Aquafuze" technology, a new water-based ink that prioritises safety and environmental considerations, as a key inkjet technology element. This innovative ink technology encompasses the functionalities of UV and solvent inks while still being water-based, contributing to our customers' job expansion and work environment improvement.

We will also exhibit the "RxD Series," a pigment dispersion with high stability in the face of diversifying ink formulations spurred by digitalisation. This supports ink formulation designs that meet the

increasing need for faster inkjet systems and broader substrate compatibility.

Moreover, we will announce new products for print heads that enable versatility across a wide range of applications.

New Fujifilm Group environmental strategies will also be introduced. These include short run with the use of digital on demand printing, processless offset printing plates, carbon neutral production facilities, and recycling initiatives.

Fujifilm Group has also unveiled its new Global Purpose: “Giving our world more smiles,” in celebration of its 90th anniversary this year. At drupa 2024, Fujifilm Group wishes to show its capability of providing the “difference” in value, eventually giving our world more smiles. We look forward to your visit.

Print Innovation Asia Issue 4 2024 9

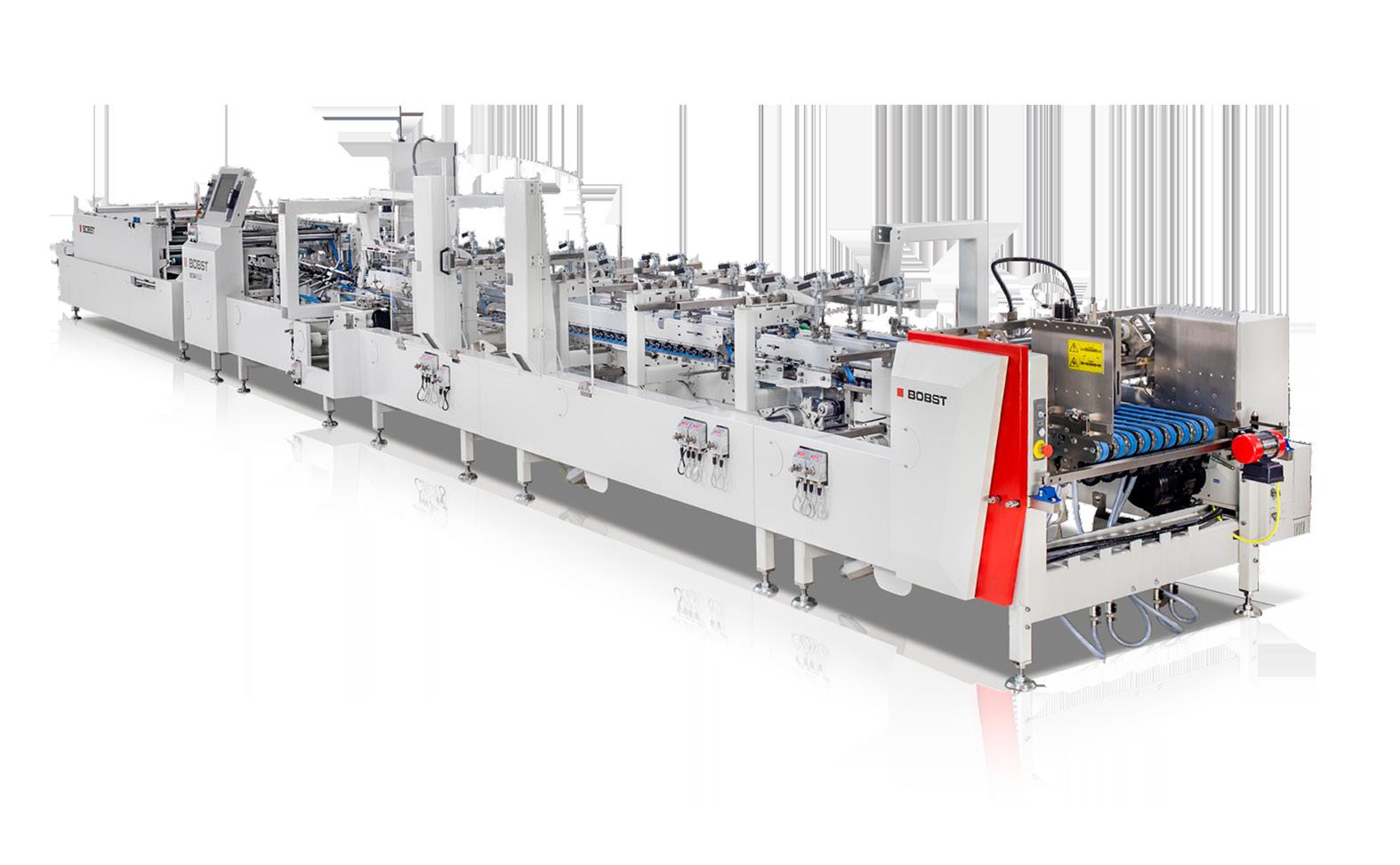

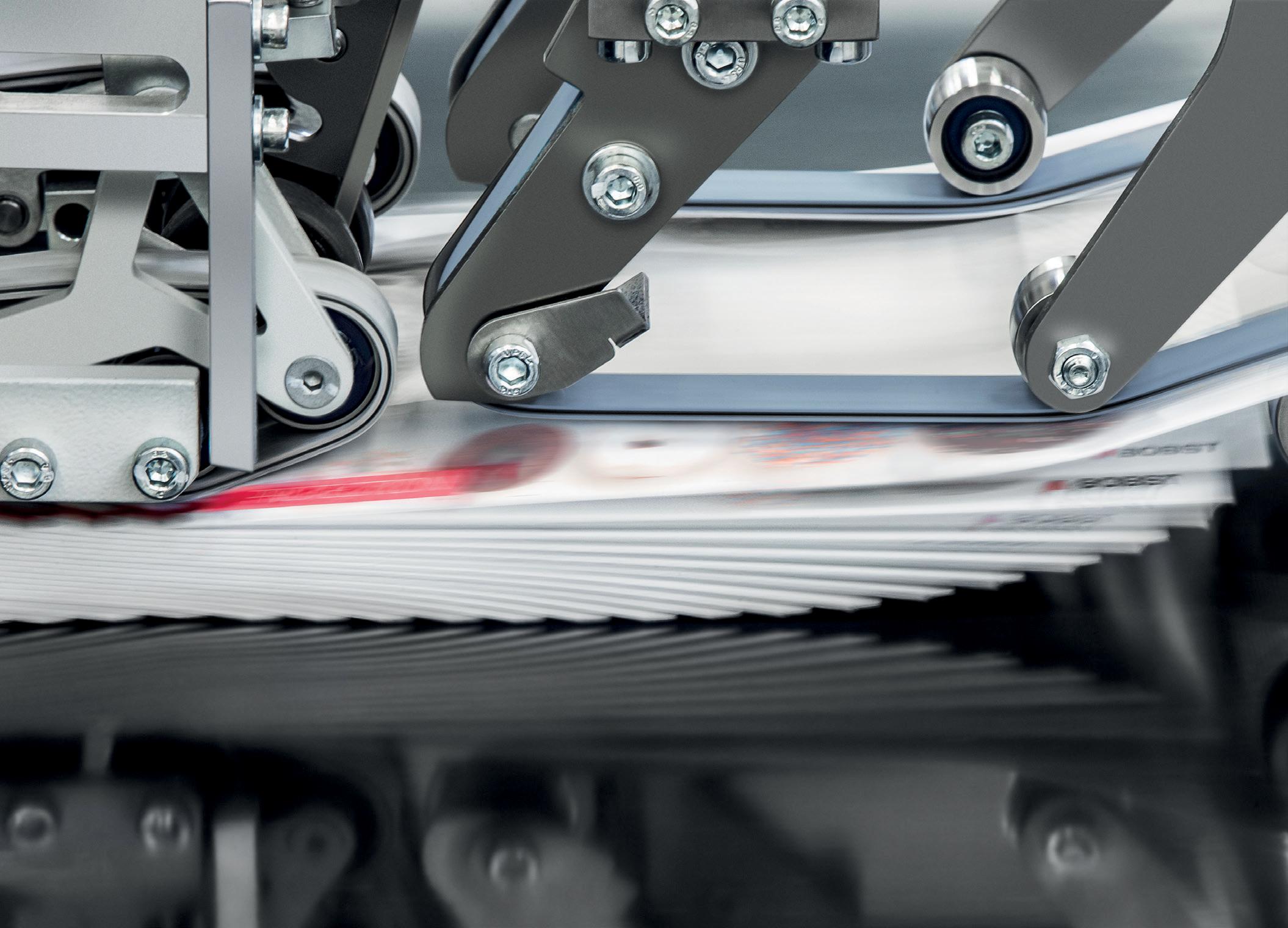

BOBST unveils innovations on the road to drupa 2024

BOBST has announced its latest advancements across all industry segments – flexible packaging, labels, folding carton, corrugated board, and services – to help its customers to thrive in the current and future packaging environment.

At drupa 2024, visitors to the stage area will have the opportunity to find out how BOBST is bringing its vision to reality through a live-show experience on a “concept machine”.

“We have made great progress with our vision to shape the future of the packaging world based on the pillars of connectivity, digitalization, automation, and sustainability,” said Jean-Pascal Bobst, CEO, Bobst Group. “Now, with an extensive portfolio of solutions that answer our clients’ needs, we can tailor our offering to them based on their evolving requirements over the years to come. Our latest solutions announced today, embed machines and software with the aim to increase performance, complementing our global offering beyond machine operation, helping us all to build towards a more connected and sustainable future.”

Below are the newly announced highlights from each industry sector. Several of these will be officially launched at drupa 2024.

Flexible Packaging

• New machine with new elements of digitalization and automation smartGRAVURE revolutionizes the gravure printing process with elements of automation and digitalization. This innovation will help to overcome the important set-up time and tuning required with gravure printing, which require high level operator skills. With automated color management, digitalized set up and controls, and connectivity with BOBST Connect, smartGRAVURE will increase productivity and output consistency, reduce downtime and complexity, and

making it highly flexible both as both a laminator and a coater.

Labels

• Closed loop workflow from PDF to TWIN PDF: BOBST is taking connectivity and digitalization to the next level by providing new solutions supporting closed-loop workflow ecosystem from pdf to twin pdf to boost productivity, ease of use and sustainability. The features will allow label converters to accelerate job preparation, with faster job completion less dependent on operator skills, and with a more

offer considerable sustainability benefits.

• New BOBST intelligent Metallizing Assistant

The BOBST AI driven intelligent Metallizing Assistant represents a breakthrough in machine integrated process expertise for vacuum metallizing. BOBST intelligent Metallizing Assistant supports the machine operator by automating the deposition process, resulting in more output and consistency of the end product.

• New machine with new elements of digitalization EXPERTLAM 900 is a multi-technology coater and laminator, which is configurable in different forms, EXPERTLAM 900

Print Innovation Asia Issue 4 2024 10

connected production floor, thanks to a range of new BOBST Connect and prepress features.

• OneECG – advanced color consistency between flexo and digital: BOBST has optimized its workflow leveraging oneECG, enabling digitalization of color information to reach the highest color consistency between digital and flexo. Customers can easily allocate orders to the most suitable technology, optimizing machine utilization and profitability while reducing waste and increasing overall output.

• oneBarrier / FibreCycle on UV in-line flexo presses: Following the success of the oneBARRIER sustainable solutions developed by BOBST together with industry leading partners and first introduced on BOBST wide-web machines, converters with UV-based inline flexo machines can now experience all the benefits of oneBarrier substrates – dedicated to the production of highbarrier and recyclable applications – on narrow-mid-web solutions.

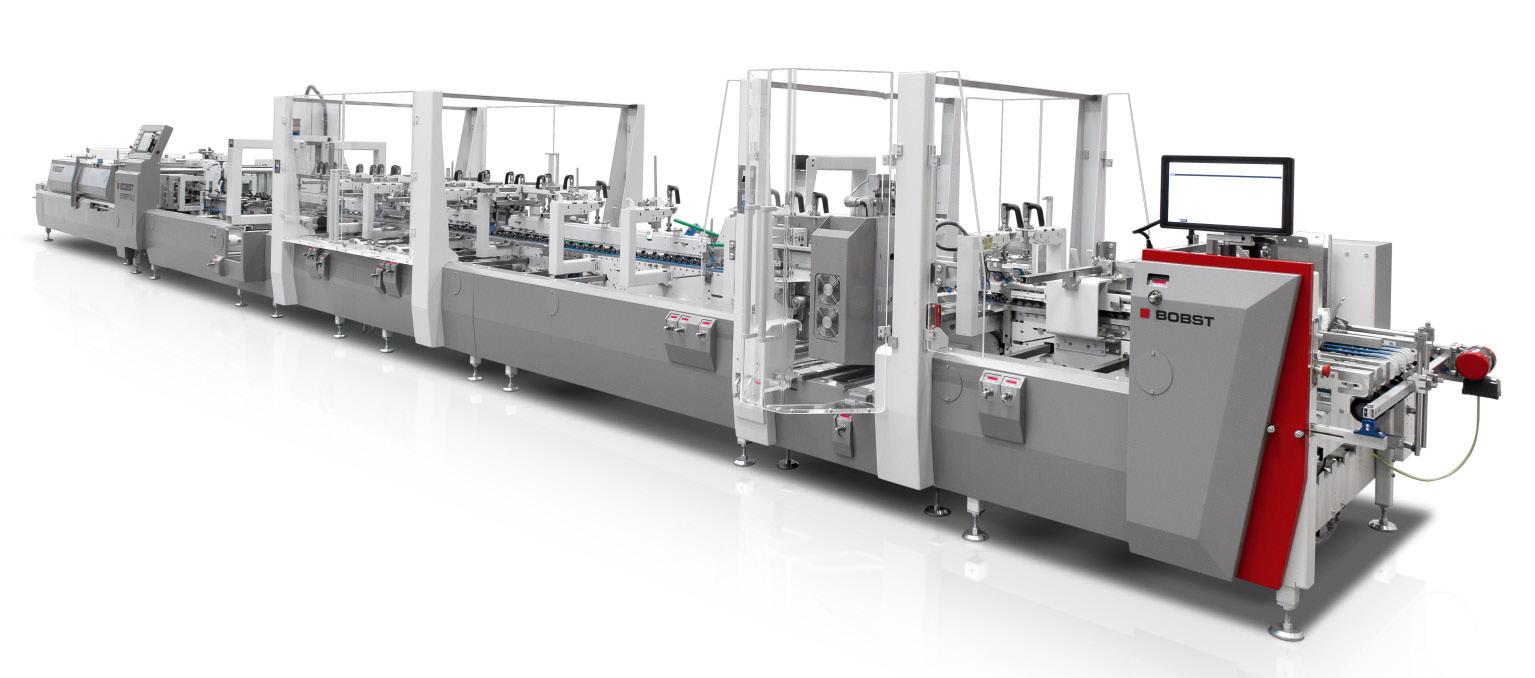

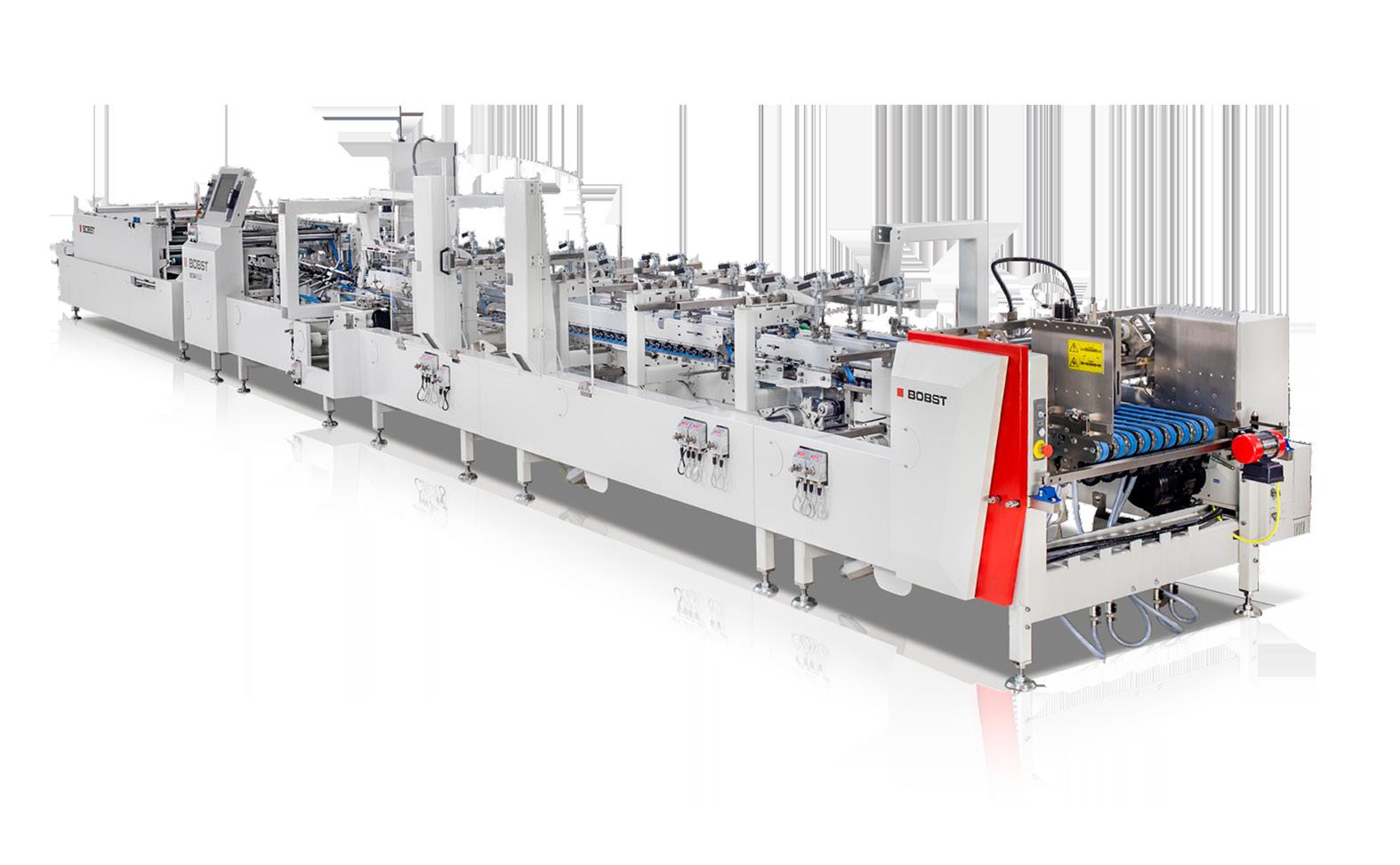

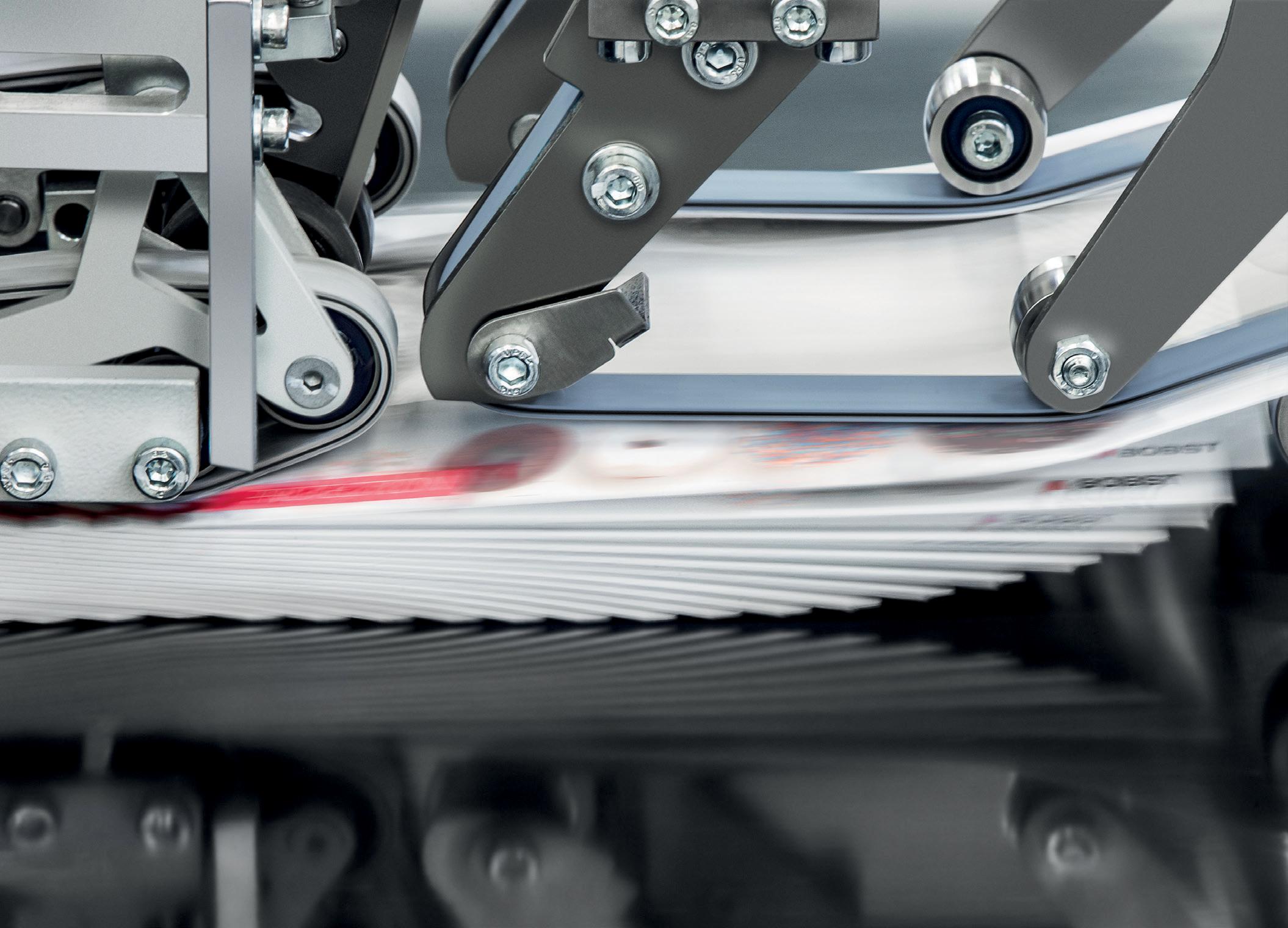

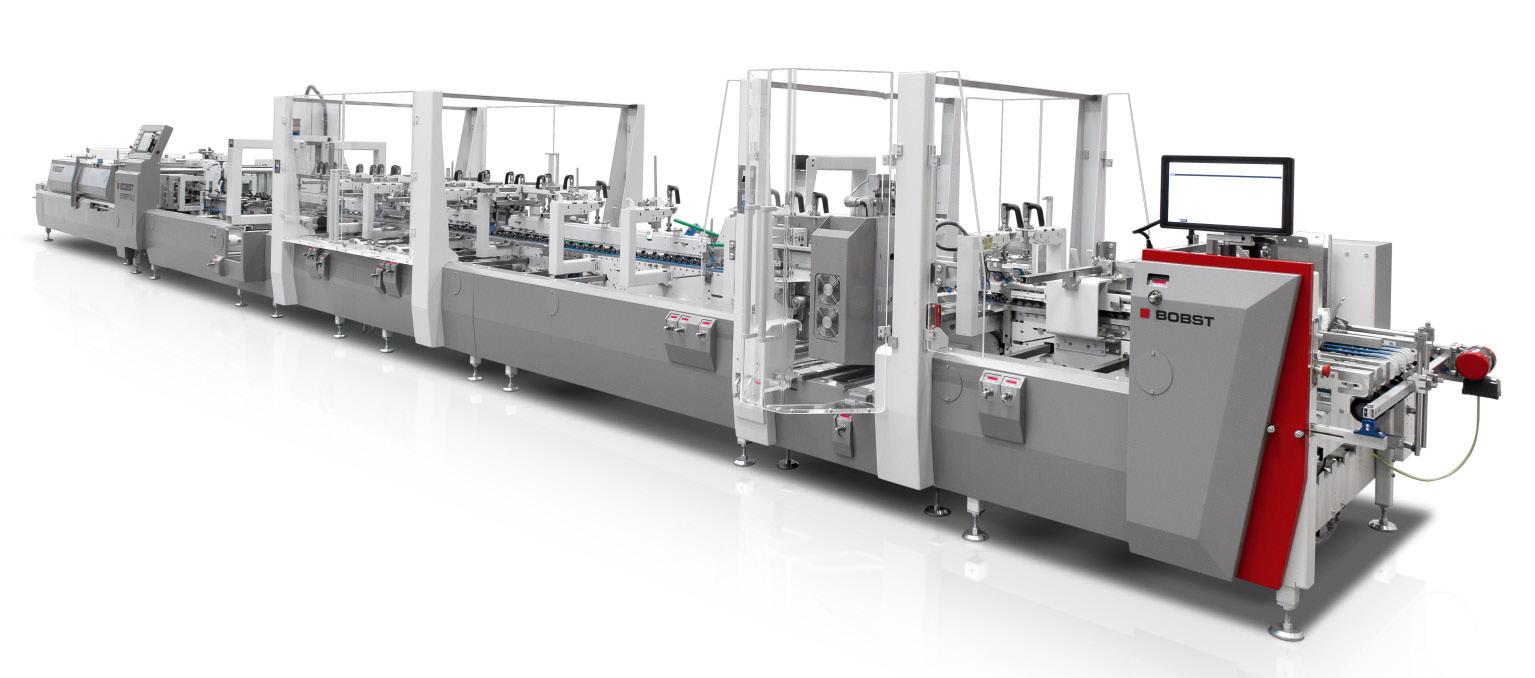

Folding carton

• New machine with new elements of digitalization

EXPERTCUT 106 PER: New generation die-cutter, which increases performance up to 20% with increased throughput and positive sustainability impact. The EXPERTCUT 106 comes equipped with breakthrough new functions such as the ACCUPLATEN - a new system that will drastically reduce the patching effort during setting and increased running speed.

• TooLink on folder-gluers: TooLink brings converting into the digital world. It is a platform that connects machines and tooling and brings together the entire converting process to transform production flexibility, job turnaround times, and overall productivity. Soon available on folder-gluers, TooLink will

simplify and shorten the changeover by automating recipe management.

Corrugated board

• Robotic solutions: An important milestone in bringing our vision to reality, BOBST now offers a wide range of robotic solutions for both loading and palletizing, which will allow configuration of complete and seamless production lines for our customers.

• New machine

FFG (flexo folder gluer) portfolio EXTENSION – machines with what matters for RSC (regular slotted carton) converting: Printing (1/2 colors) and die-cutting with flexibility in production, robust design and short setup time with top printer. New JUMBO, from simple “printer-slotter” up to full line including stitching, taping and inline folder-gluer.

• New machine with new elements of digitalization and automation

MASTERFLEX HD+:

New generation of the reference flexo printer, for unmatched productivity and

highest quality. By incorporating a new feeder, upstream pre-feeder and stacker outlet, the MASTERFLEX HD+ achieves a staggering throughput of 15,000 sheets per hour, covering an impressive area of 53 million square meters per year. This enhancement results in a remarkable 8% boost in productivity.

Services and Performance

• The new, updated BOBST Connect: Providing digital solutions to prepare, produce, react to, maintain, and optimize the production workflow of a job. BOBST Connect is a one-stop shop for increasing productivity capability at every stage.

• Extended capacity of the EMEA Logistics Hub: Our Genk facility gives us the ability to serve our customers with speed and efficiency. We are extending its capacity by more than 60% this year to increase customer reach, increase service quality, while ensuring that our site meets the highest sustainability certifications.

• Remote Assistance with TeamViewer: Our Remote Assistance service, which includes video with augmented reality support using TeamViewer, allows fast, high-priority remote resolution of electrical and mechanical problems, and reduced downtime. The feature now includes live caption and chat translation.

• Operational Excellence Program: Through our Operational Excellence program, customers get support to drive continuous improvements with our combined data analysis, process expertise and proven consultancy.

Print Innovation Asia Issue 4 2024 12

EXPERTFOLD

MASTER DM5oneECG_

Discover our solutions!

CGS ORIS offers a wide range of software solutions to tackle the specific needs of the packaging, proofing and decor markets. Find your perfect match! Visit

Print Innovation Asia Issue 4 2024

A T D R U P A 2 0 2 4 !

M E E T U S

us! Join us in hall 8A, booth A06 from May 28June 7 in Düsseldorf!

See the Potential in the Future of Print

Konica Minolta has unveiled more details of its drupa presence where it plans to showcase 20 premieres, pioneering digital transformation and live running of the biggest machines it has ever shown at the exhibition in Duesseldorf, Germany, where it will have one of the largest stands (Hall 8b).

Under the main message of “See the Potential in the Future of Print”, Konica Minolta will set up a 2,400 square metre exhibition booth to demonstrate how it is strengthening and expanding the business of commercial and industrial printing customers, and ways of sustainable production in line with the philosophy of Industry 5.0. This will be achieved by assistance technology, labour-saving, and skill-less operations. It will include not only printing processes, but also postpress processes and improving the total throughput of the entire processes.

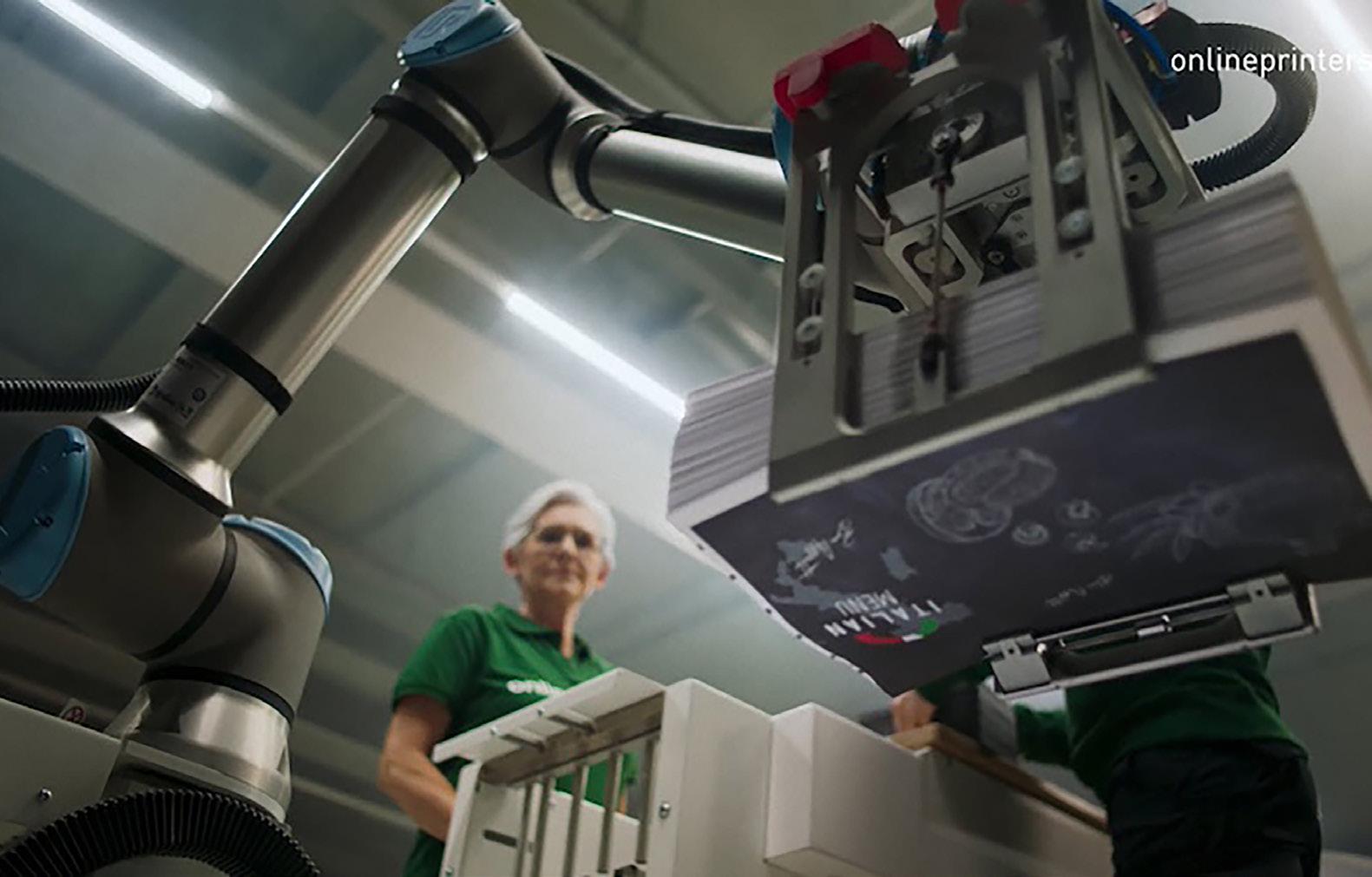

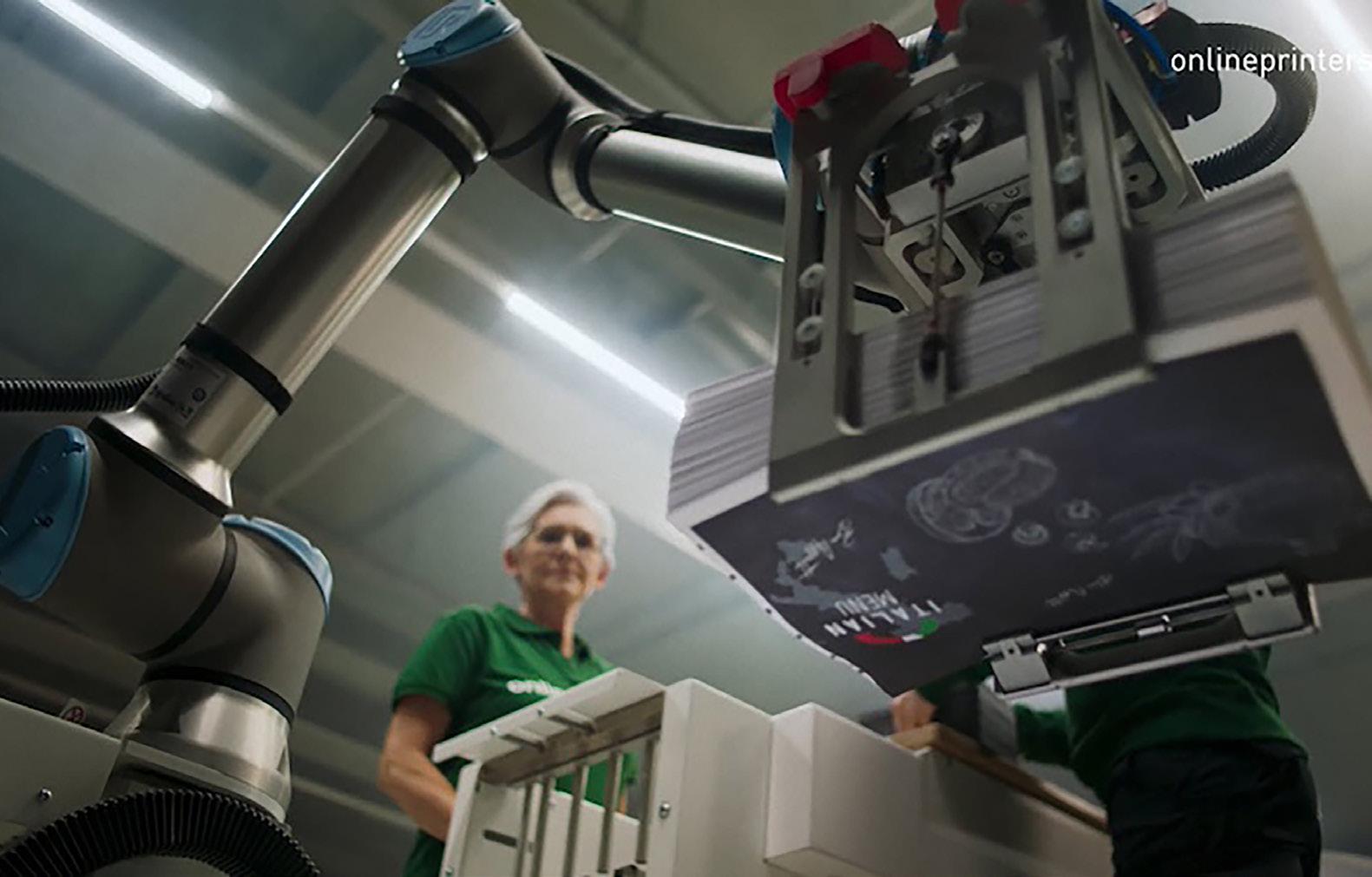

Unique robotic solutions and completely automated product lines

Among the highlights from Konica Minolta at drupa will be showing completely automated production lines driven by Artificial Intelligence, a state-ofthe-art webshop and never-before-seen use of robotics and software solutions – including major advances in remote service engineering.

Konica Minolta will be underpinning the unstoppable shift from analogue printing to the use of digital printing1 that is expanding into most print-for-profit applications - particularly in labels and packaging - in a world where high-value printed materials are produced efficiently

with minimal environmental impact. A wide range of business scopes will be demonstrated from commercial printing to label printing, packaging and industrial printing, and as products and solutions.

Announcing the future model within the KM-1 family: The next generation High-Speed UV Inkjet Press AccurioJet 60000

Konica Minolta has also announced further details of its next generation HSUV Inkjet Press, AccurioJet 60000, the high-end model that follows the quality and technology of the AccurioJet KM-1/ KM-1e series and has been further developed for maximizing customer value and improving usability.

Engineered for industry-leading productivity, this printer is designed to minimize downtime, ensuring easy operation and continuous monitoring of device conditions for optimal throughput. In addition to its exceptional operational efficiency, the AccurioJet 60000 guarantees outstanding image quality and

reproduction stability. Leveraging the AccurioJet KM-1 stable image quality, the printer employs Konica Minolta inline sensors and a spectrophotometer to automatically monitor printing conditions. This meticulous attention results in a wonderful image quality and reproduction stability across various printing media.

Konica Minolta takes pride in offering customer service of global standards, establishing trust with its clientele. Alongside considerate service, the company provides reliable customer support through an exclusive remote monitoring system unique to Konica Minolta.

The AccurioJet 60000 features an HSUV Inkjet Press with a remarkable capacity of 6,000 sheets per hour (sph) and offers both-side printing capabilities, ensuring versatility and efficiency in printing operations. In the near future, KonicaMinolta will have two effective product lines, the AccurioJet KM-1e, which emphasizes small turnaround for digital printing, and the next-generation high-end model, which emphasizes productivity.

Print Innovation Asia Issue 4 2024 14

AccurioJet 60000

Applications will appeal to brand owners and advertising agencies

In other demonstrations, Konica Minolta will show unprecedented set-up configurations and new applications for its technology that will have far-reaching implications for not only commercial printers and converters, but also brand owners and design and advertising agencies in the way they do business.

As one example, Konica Minolta and partner MGI (MGI Digital Printing Systems) will show how separate processes such as foiling, varnishing, printing, folding, and drying and can be combined into just one full integrated production run where MGI’s AlphaJet will be centre stage and showing the benefits of a complete single-pass factory.

For customers, this will mean major savings in space requirements, power consumption and staff costs. Manual setups from different production engines will be combined into one completely automated system, including the use of software up to B1+ format size.

Exhibition highlights include 20 premieres

colours consistently. It is the world’s only platform using the new toner free of the restrictions imposed by the colour gamut of ordinary toners.

Other premieres will involve a Cobotrobotics arm, new options for the MGI JetVarnish 3DWeb 400 such as a JetSeal and inline die cutter and the launch of a more advanced version of the AccurioPro Colour Manager suite of software solutions. From Konica Minolta’s Sensing Business Unit, there will be the unveiling of MYIRO colour management tools for graphics arts applications. These will include spectrophotometers for advanced colour management and for high-speed auto scanning.

Creativity and sustainability

Human centricity and sustainability will be important talking points for Konica Minolta. Novel ways of showing the benefits of digital printing and exciting people to ensure they concentrate on the creative tasks,with assistance technology taking away many of the mundane tasks. Konica Minolta will show how digital printing empowers printing on demand instead of “printing for the shelf”. An example of Konica Minolta’s “sustainability by default” will involve using recycled paper for all the print-ondemand brochures and other marketing

materials produced on-demand at drupa.

Konica Minolta will not be taking printed materials to drupa. Instead, any of the Konica Minolta product sheets or other marketing materials can be ordered on a big display (think how it’s done at McDonalds!) and will be printed within seconds of any request on the automated lines running live.

The road to sustainable scalability: Industry5.0 Automation

Aiming to ignite printing possibilities, Konica Minolta will be showcasing its vision of digital transformation in the print room of the future. A significant aspect of its demonstration revolves around the efficient use of digital equipment, specifically highlighting print automation.

Under the ‘mixed reality service’, Konica Minolta’s remote servicing operations will be spotlighted where operators using headsets or smartphones with cameras can connect through the cloud to the Konica Minolta service desk to help with real-time remote visual support in the rare event of a problem.

Among the products being shown in public for the first time will be the Konica Minolta AccurioPress C84hc, which uses high chroma toner that prints bright vivid AccurioPress C84HC

Print Innovation Asia Issue 4 2024 16

MGI Alphajet

Unbox faster turnarounds

Make the move to digital – and unbox your business with the flexibility to accommodate fast turns, versioning requests, last minute edits, and changing buying decisions.

With the new EFITM Nozomi 14000 LED digital press for corrugated packaging and POS, you can reduce process steps from weeks and days to hours and minutes. And personalize runs from one to infinity at higher margins and with lower costs – all in a single pass.

Let’s build your brilliant future. Together.

Scan to learn how corrugated converters and packaging printers are opening up new ways to say, “Yes!”

Innovative thinking and modern aesthetics - IST METZ at drupa 2024 – more than UV

After a long break, the time has come again: drupa will take place in Düsseldorf from May 28 to June 7. UV system manufacturer IST METZ from Nürtingen, will celebrate a special milestone in the company's more than 45-year history this year.

While the first UV installation rolled off the production line in Nürtingen in 1977, this year marks a very special highlight for IST METZ and IST INTECH: Having grown to become one of the world market leaders in UV curing, we will be able to hand over the 100,000th curing device (UV, UV LED and Excimer) to a customer in the next few weeks. As luck would have it, this special date coincides with the drupa trade fair. We are not yet revealing what is planned for this occasion, but we will of course not let this success pass without a little happening.

What else do we have? On our 400 m², everything revolves around UV products that are essential and trendsetting for the print industry. In addition to UV lamps and UV LED systems, thermal drying solutions and excimer systems can be impressively experienced in action and a look at the future of printing can be taken.

Our team has come up with a special highlight: The Heidelberg Speedmaster CX104-6+LX3 will demonstrate to viewers three times a day, live and accompanied by media, how the use of UV lamp systems in packaging printing and UV LED systems in commercial printing are shaping today's print industry. The results will be vividly illustrated, as

the specially developed print product can already be looked forward to.

The "HotSwap" product concept will also be a focal point of the IST trade fair stand. More flexibility for changeovers in sheetfed, web and narrow-web printing thanks to suitably equipped units make it possible to switch between UV lamps, UV LEDs or hybrids - depending on the job and the desired end product.

The product presentation is rounded off by the UV Analyzer measuring device. The combination of UV app (compatible for Android and iOS), measuring strips and Analyzer Stick offers a handy tool for quality assurance and documentation of common UV and LED systems.

And because our experience and expertise are already focused on the next generation of UV curing, we have also given our company image a bit of a makeover. Visitors can therefore look forward to the IST trade fair presentation under the heading “more than UV”.

Print Innovation Asia Issue 4 2024 18

Glunz& Jensen A/S (Headquarters) Selandia Park 1 4100 Ringsted Denmark +45 5768 8181 gj@glunz-jensen.com Glunz& Jensen s.r.o Kosicka, 50 08001 Prešov, Slovakia +421 51 7563811 gj@glunz-jensen.com Glunz& Jensen Inc 2185 Hwy 292 Inman SC 23349 USA +1 864 568 4638 gj-americas@glunz-jensen.com ww w .g l u n z - je n se n . co m

greatest innovation

With a footprint of just 17 sqm (183 sqfeet) FlexiLine 520 Compact makes flexographic platemaking automation a service within everyone's reach. Forget the crazy prices of the competition and Flex Line 520 Compact The

since the invention of the flowlines... ask G&J for an offer.

Cost pressures, the skills shortage,

HEIDELBERG is addressing these megatrends with innovations at drupa 2024

• Competitiveness: Up to 20 percent higher productivity significantly cuts costs for print shops

• Skills shortage: Autonomous printing and cluster production reduce staffing requirements in print production

• Sustainability: New technologies save energy and lower consumption of raw materials

• HEIDELBERG exhibiting at drupa 2024 in Düsseldorf and at Wiesloch-Walldorf site

The printing sector is facing a combination of three challenges – ever-increasing cost pressures, a shortage of skilled workers, and growing sustainability requirements. In response to these megatrends, Heidelberger Druckmaschinen AG (HEIDELBERG) will be presenting numerous innovations under the motto “Unfold Your Potential” at this year’s drupa trade show.

The focus will be on customers and the need for their print shops to optimize the development and leveraging of business potential using state-of-the-art technologies and services. Thanks to the innovations being unveiled at drupa, such as the new-generation Speedmaster XL 106, HEIDELBERG can support its customers with a holistic concept that delivers up to 20 percent higher productivity than the previous solutions.

“HEIDELBERG has been an industry pioneer in the digitalization of printing for 20 years. Our main goal is to optimize our customers’ entire value chain,” says HEIDELBERG CEO Dr. Ludwin Monz. “To this end, we have almost fully digitalized and integrated print shop processes, and our solutions at drupa offer our commercial and packaging printing customers maximum efficiency in industrial print production,” he adds.

• How can printing businesses make their production more efficient?

Increasing cost pressures are forcing print shops to make ongoing investments in maintaining their competitiveness – i.e. in higher productivity, enhanced efficiency, and new areas of business. HEIDELBERG understands the value drivers of customers in the commercial and packaging printing industry. Innovations such as the new Peak Performance generation of the Speedmaster XL 106, with its higher print speed of up to 21,000 sheets per hour, AI-supported assistance systems, and enhanced Push to Stop functions, are making industrial offset printing even more competitive.

HEIDELBERG will be exhibiting another innovation, too – the efficiency of the Boardmaster is setting new productivity standards in the packaging printing industry. The new Boardmaster is a flexographic web printing system that boasts machine availability of up to 90 percent and a maximum printing speed of 600 meters per minute. Compared with the previous generation, its machine concept dramatically reduces the total cost of ownership in industrial packaging production.

• How can print shops respond to the shortage of skilled workers?

The shortage of labor and skilled workers is becoming more and more acute in the printing industry, too. With this in mind, HEIDELBERG is offering customers solutions for automating products and processes, including training for print shop staff. Fully automated Plate to Unit plate logistics on the Speedmaster XL 106 and the new P-Stacker robotics solutions for postpress operations are two examples of this in commercial printing. The new-generation Speedmaster XL 106 also supports cluster production, whereby a single operator controls an entire machine park.

In the future, HEIDELBERG will make autonomous printing possible for standardized applications in packaging printing. The company will also help operators with more complex print jobs by providing navigated user guidance.

• How can the printing sector produce sustainably and yet economically?

Sustainability in print production is one of the biggest trends worldwide and, at the same time, a major challenge for the sector. Modern print shops are aiming to become even more sustainable by

Print Innovation Asia Issue 4 2024 20

shortage, and sustainability

reducing their consumption of energy and resources. Print products are also changing, though, moving away from plastic and toward more paper.

HEIDELBERG offers sustainable print solutions, helping its customers to make savings on energy and raw materials. If you compare a Speedmaster from 1990 with the current version, the energy consumption per 1,000 sheets has been reduced by up to 40 percent. At this year’s drupa, HEIDELBERG will be presenting its latest generation of presses, which have a maximum speed of up to 21,000 sheets per hour. This increased production speed will help customers further lower their energy consumption

per sheet. What’s more, the use of artificial intelligence and new assistance systems will also result in paper being saved by reducing the amount of paper waste.

• How is the printing industry benefiting from digitalization? Digitalization in the printing industry enables end-to-end integration of the production process – from receiving the digital customer order, preparing the print data, planning and carrying out the print job, and passing on the print product to postpress, all the way through to delivery and billing. In this context, HEIDELBERG will be exhibiting end-to-end autonomous printing for commercial and packaging customers at drupa. With its new customer portal, the company is taking digitalization to the next level and further expanding press management, including aspects such as capacity utilization, maintenance, and upkeep.

• drupa 2024 – “Unfold Your Potential” in Düsseldorf and Wiesloch-Walldorf

HEIDELBERG will be demonstrating in two different locations how printing businesses can boost their capacity. In

Hall 1 in Düsseldorf, the company will be exhibiting a highly automated end-toend packaging workflow for the diverse requirements associated with industrial packaging production. Its focus will be on how to become more competitive when faced with cost pressures and changing conditions.

Also in Hall 1, commercial and publishing printers will find a workflow that benefits from end-to-end connectivity thanks to Prinect. In the Experience Center, HEIDELBERG will be showcasing the wide range of services that extend beyond press technology as such, with AIbased analysis tools, intelligent assistance systems, online services, and sustainable production solutions all on show.

At the HEIDELBERG site in WieslochWalldorf, the focus will be on business potential right across the HEIDELBERG portfolio. Here, the company will be exhibiting its entire product range, including presses and software solutions for all market segments – from commercial and packaging to label printing, from sheetfed offset and digital to flexo printing, and from products for small companies to fully automated production lines.

Print Innovation Asia Issue 4 2024 21

2024

World premiere at drupa – the new Peak Performance generation of the Speedmaster XL 106

“The new Peak Performance Speedmaster XL 106 cuts print production costs significantly, which makes our customers in the commercial, packaging, and label printing sectors more competitive,” says Dr. Ludwin Monz, CEO of HEIDELBERG. “Compared to the previous generation, we expect users who produce packaging in the 70 x 100 cm format to achieve an increase in overall productivity of up to 20 percent.”

Costs down – competitiveness up: HEIDELBERG has the solution to this in the form of more speed and automation. The new Peak Performance generation of the Speedmaster XL 106 can print up to 21,000 sheets per hour. With this new generation, autonomous printing is now also possible in packaging production, thanks to the enhanced Push to Stop concept.

This means complex production parameters can now be configured completely automatically in packaging and label printing, too. “We anticipate that a high-volume packaging producer or wet-glue label manufacturer will very soon achieve a benchmark of 100 million sheets per year. This figure represents a 20 percent increase on the 85 million sheets currently being produced by today’s industry leaders,” says Markus Leichtle, Senior Manager Industrial Packaging at HEIDELBERG

Mike Günther, Managing Director of colordruck Baiersbronn GmbH and a pilot customer trialing the new Peak Performance generation, agrees: “We are expecting a significant reduction in makeready times, set-up times, and general downtime to improve the efficiency of our printing with low costs per box.”

Alleviating the skills shortage with the “I like working here” concept: Print shops compete to attract the best skilled staff, so it is important to make the workplace more appealing by offering cutting-edge, intuitive user interfaces and a low-emissions working environment. With further improvements to the HEIDELBERG User Experience (UX) and a new ergonomic design, the new Peak Performance Speedmaster XL 106 is setting high standards. The new PowderStar XL (Duo) reduces powder consumption by up to 15 percent and powder emissions by up to 45 percent.

What’s more, strain on personnel capacity is eased, because use of production clusters means that fewer staff can operate the same number of presses efficiently. When fully automatic Plate to Unit printing plate logistics is incorporated, it is possible to save on one assistant entirely, while also handling up to 150 printing plates per hour automatically.

Sustainability – new DryStar Combination Eco energy-saving dryer:

Featuring insulation in the delivery, a cross-flow heat exchanger, and an improved dryer-cassette design, the new DryStar Combination Eco dryer uses up to 30 percent less energy for drying.

What’s more, the complete press uses less energy per 1,000 sheets when the production speed is faster – for example,

when the printing speed is increased from 18,000 to 21,000 sheets per hour, energy consumption drops by around 4.5 percent. “It is precisely because of rising energy prices that we expect this new dryer technology to really help ease the pressure we’re under in terms of energy consumption,” says Stefan Leonhardt, Managing Director of WEIG Packaging in Emskirchen, who is also a pilot customer trialing the new generation. “The new press also automates key processes in folding carton production. For us, this means greater efficiency, shorter makeready times, and increased uptime.”

Digitalization – fully automatic job processing and avoiding waste:

With its Prinect workflow system, HEIDELBERG takes automation up to a whole new level in terms of productivity by offering a solution for increased digitalization. For example, Prinect supplies additional data to many assistance systems, which increasingly work with artificial intelligence. Many new and enhanced digitalization functions, such as Intellistart 3 – which alone results in some 70 percent fewer operations at the Press Center – or the improved Color Assistant Pro assistance system for fully automatic ink presetting without operating errors, dramatically reduce the number of manual interventions required.

These functions save up to four minutes of makeready time and between 100 and 150 sheets of paper waste per job. When combined with the Prinect Inpress Control inline color measurement system and the automated delivery logistics, the inline ejection of waste sheets means that a waste-free stack is delivered for postpress operations, thus increasing the efficiency of the entire process.

Print Innovation Asia Issue 4 2024 22

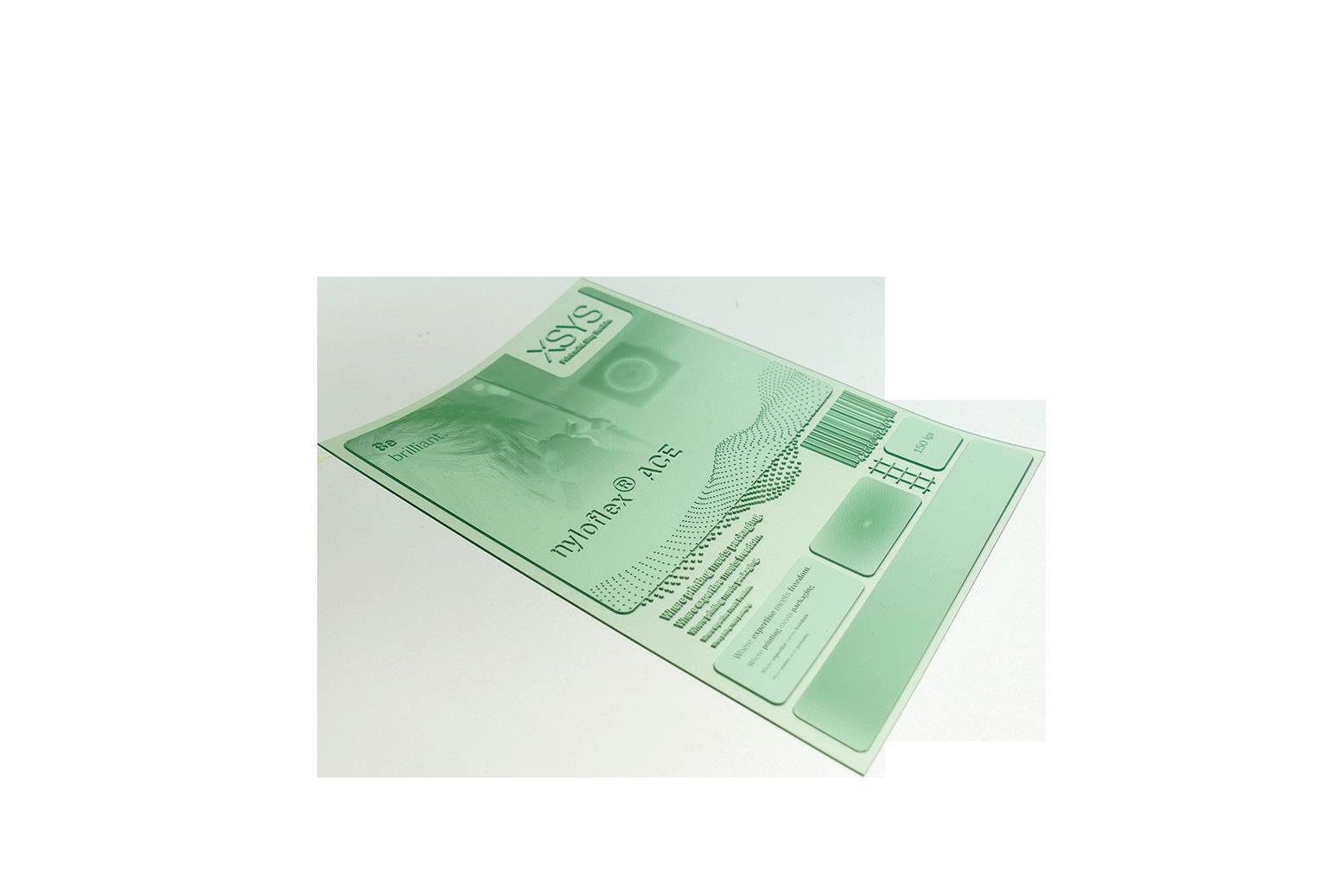

XSYS to launch new plate manufacturing and focus on sustainability

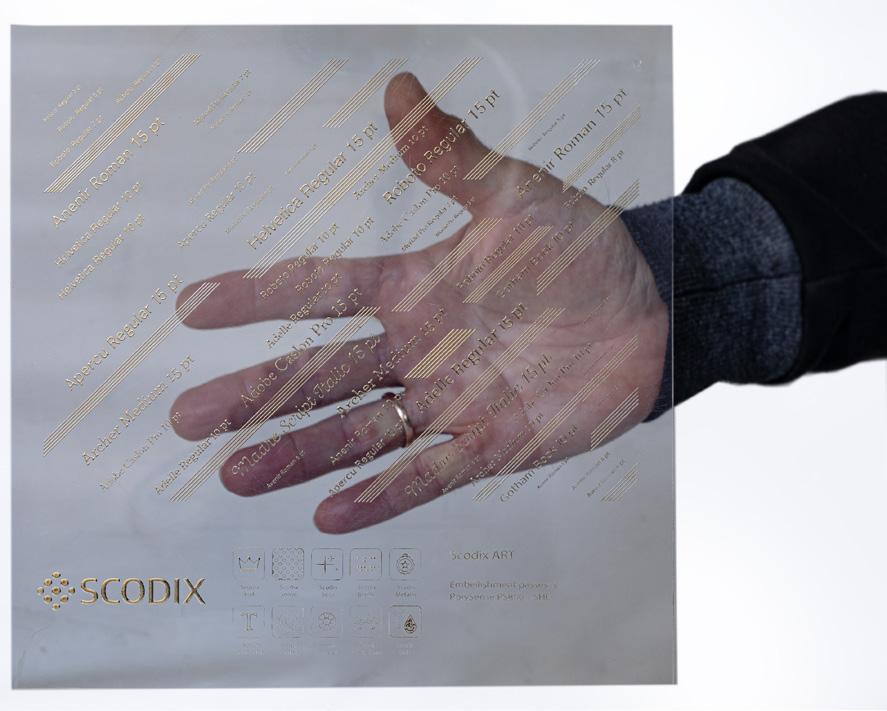

XSYS is showcasing what it says are new eco-friendly innovations from its portfolio of plates, platemaking equipment, PrePress software, and sleeves & adapters at Drupa 2024.

The print specialist will show a full range of solutions for repro houses, printers, retailers and brand owners, and will feature the exclusive launch of the Nyloflex eco series, Catena ProServX, and new PrePress software solutions.

The Nyloflex eco series is a ‘groundbreaking’ milestone in flexo plate manufacturing, showcasing high print quality and consistency but and setting a new standard in reducing environmental impact.

Other Drupa booth highlights designed by XSYS will include live demos of the highly-rated ThermoFlexX Catena+ fully automated plate processing line, the Woodpecker surface patterns for improved quality and reduced ink usage, as well as the expansive portfolio of Rotec precision-engineered sleeves and adapters for process optimization.

Thomas Strohe, director commercial

excellence, said: “At Drupa, XSYS will demonstrate how to embrace a productive and profitable future with the latest innovations for sustainable printing. The world of packaging production is changing rapidly. The pressure on printers and converters is accelerating and XSYS is here to help to alleviate those

challenges with innovative products and solutions solving their pain points, most importantly, the demand from brand owners, retailers and end consumers for more sustainable packaging.”

Creating a brilliant future for flexo “We Create The Future – the tagline of drupa 2024 – resonates deeply with the mission of XSYS, which is to introduce products and services that enable our customers to ‘Print Solid and Stay Flexible’. The only way to achieve this goal is through continued, sustainable development, bringing to market innovative solutions that minimize the impact on the environment, while maximizing printing quality and efficiency,” concludes Thomas Strohe.

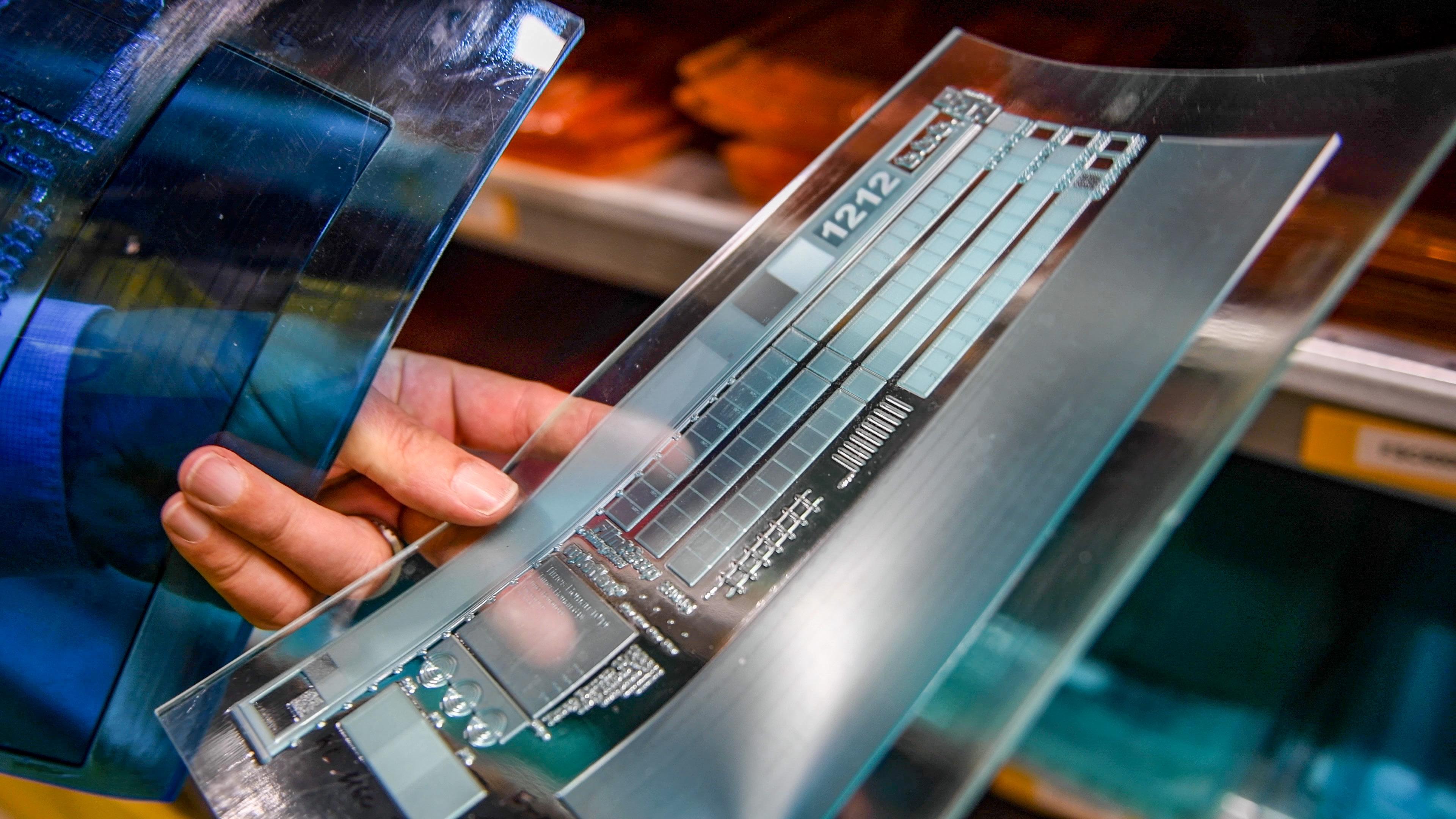

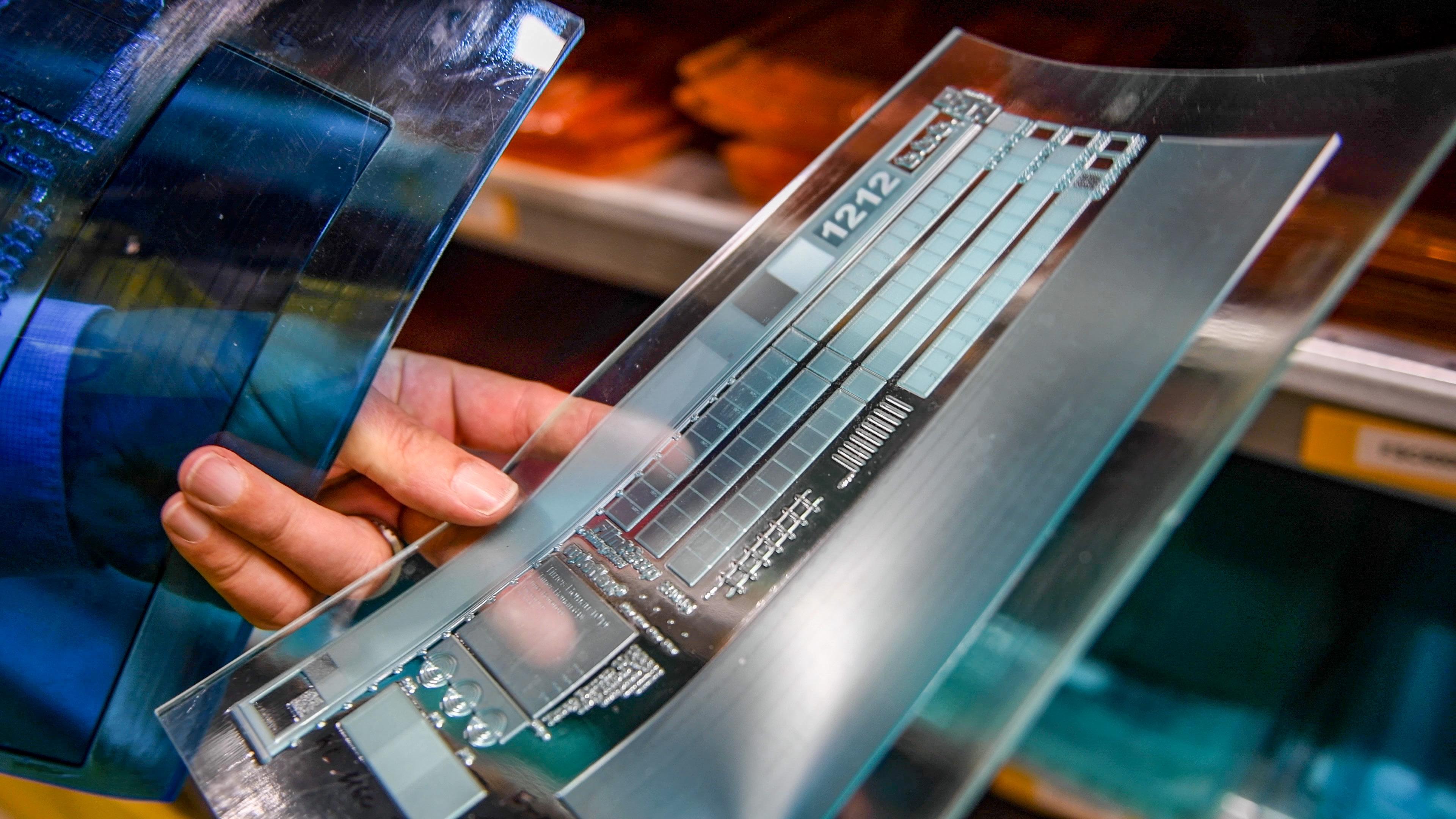

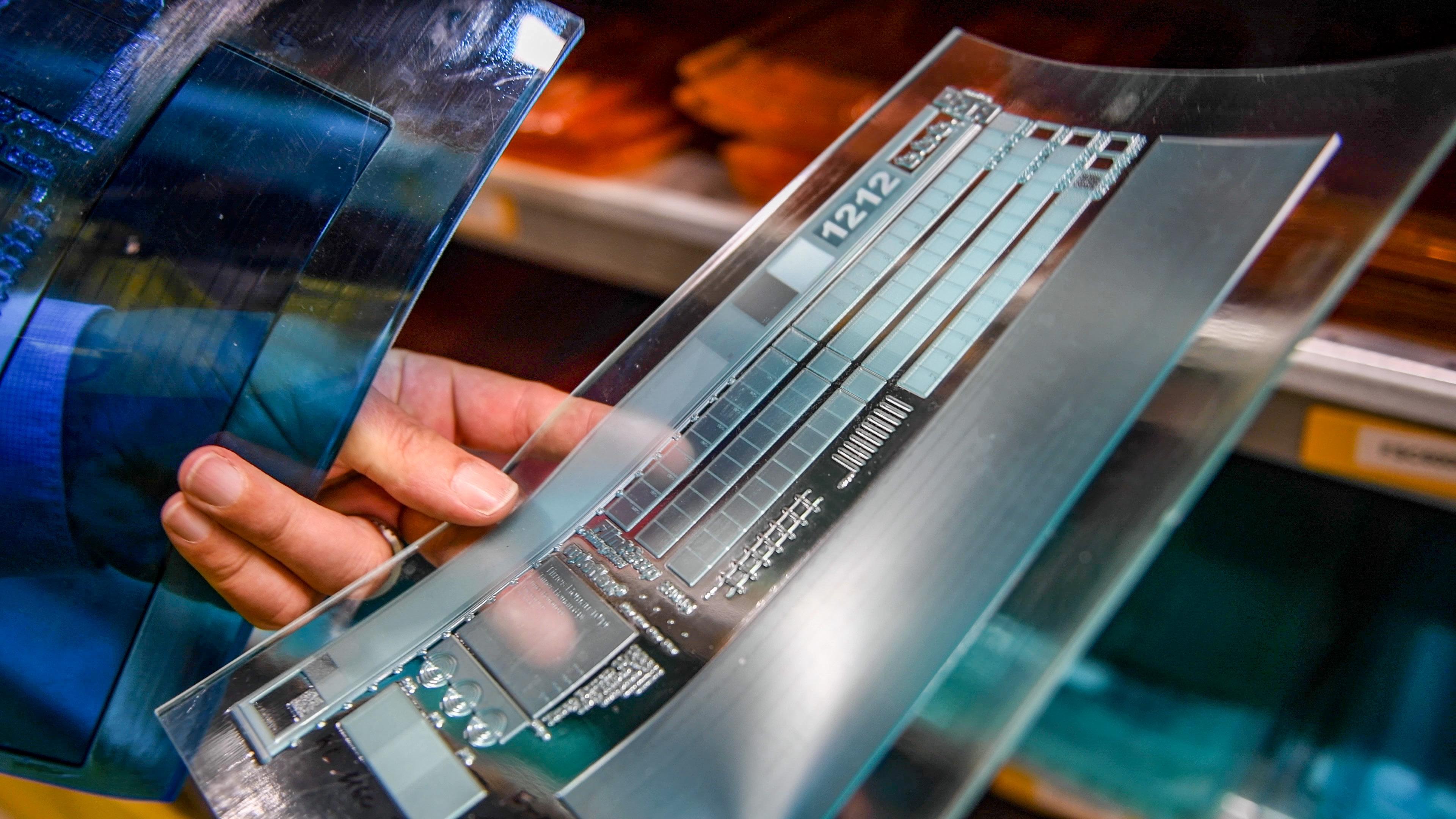

XSYS is also proud to introduce ThermoFlexX Catena-BE 48, the company’s latest innovation designed to increase efficiency and decrease waste in flexographic platemaking. The CatenaBE48, incorporating both hardware and software components, allows a seamless integration with the ThermoFlexX TFxX 48 Imager. This integration is facilitated

Print Innovation Asia Issue 4 2024 24

C M Y CM MY CY CMY K

Print Innovation Asia Issue 4 2024 25

products and services for brilliant print results and business success. PrePress Plates Sleeves & Adapters www.xsysglobal.com Visit us at DRUPA 2024

Brilliant

by a bridge that enables this automation, creating an efficient, and touch free workflow. Catena-BE 48 employs a precision gripping system which ensures zero waste of plate material during transport.

With this innovative method, the TFxX 48 Imager can be pre-loaded and prepared for the next job while the previous plate is transferred autonomously to the Catena-E 48 LED exposure unit. This automation not only saves significant time but also guarantees that job presets are maintained throughout the process, ensuring that there are no configuration errors, to prevent waste and enhance efficiency.

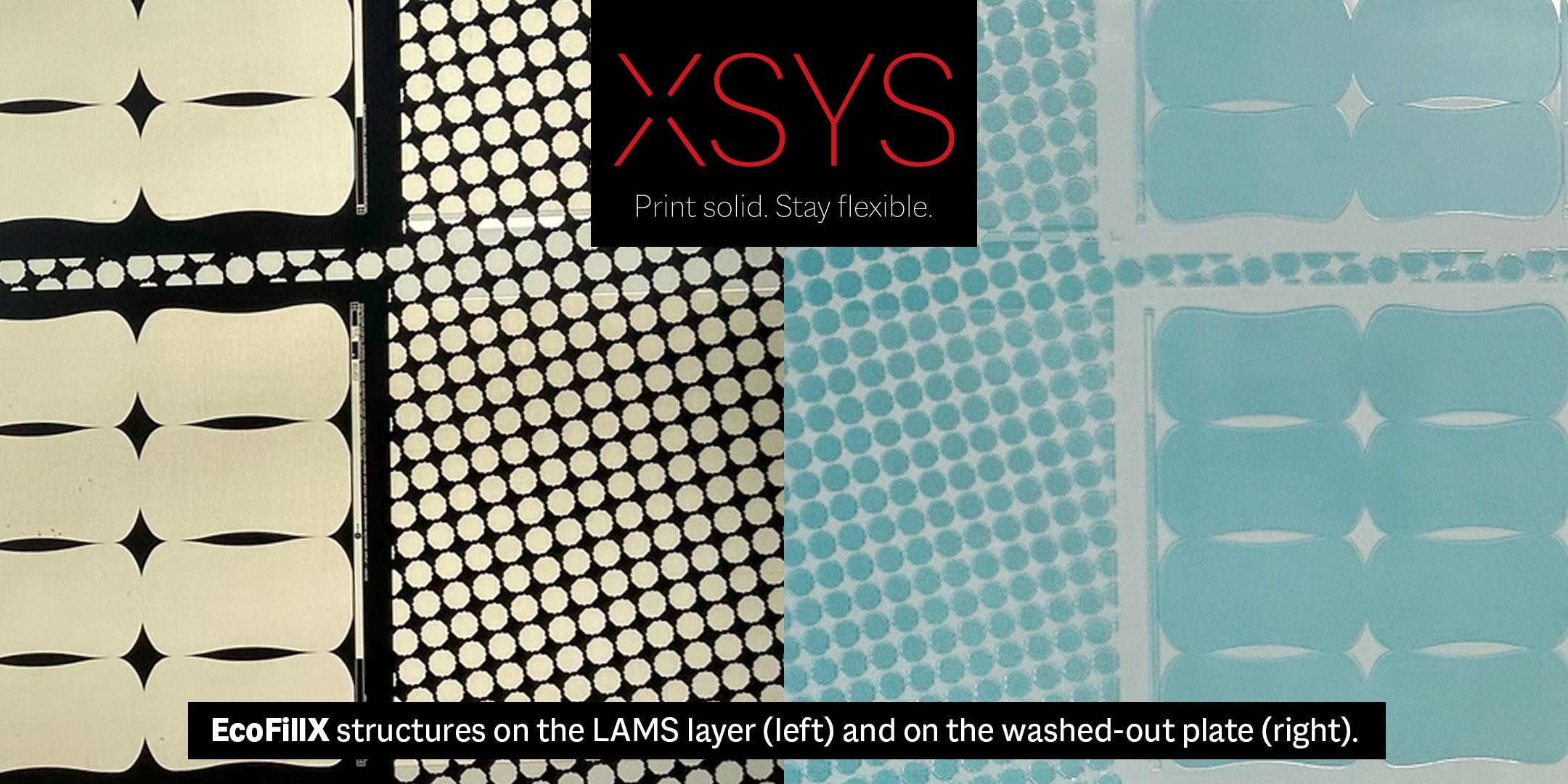

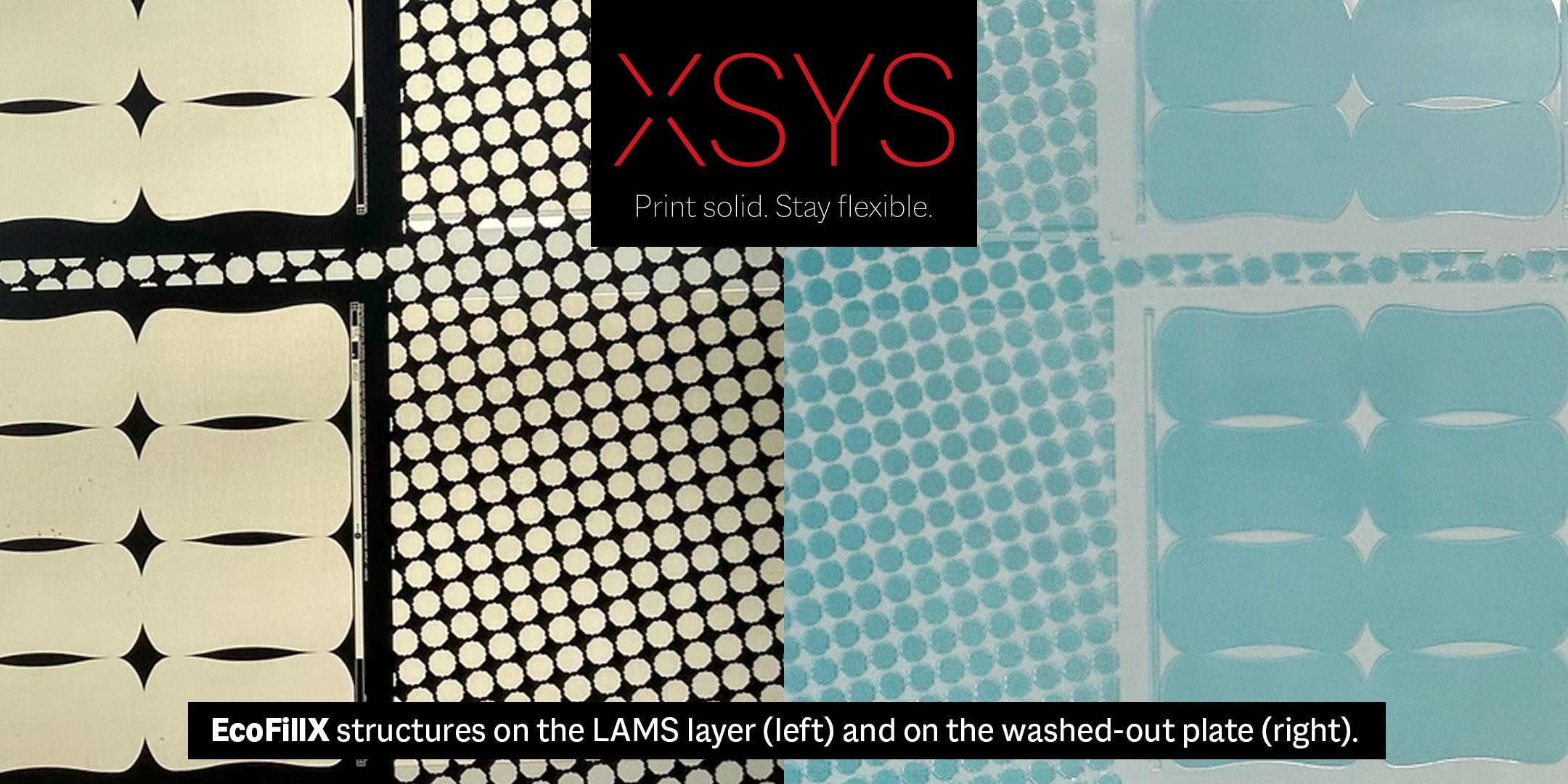

XSYS also launches EcoFillX in support of extended sustainability commitment

New EcoFillX software feature for ThermoFlexX imagers targets nonimage areas of flexographic printing plates to actively reduce the amount of polymer material washed out during processing. Reducing the amount of solid washed out, this innovation lowers solvent consumption by up to 30%, combining a real ecological advantage with considerable cost saving.

Targeting the non-image areas of photopolymer printing plates, EcoFillX represents another important step

towards improving the sustainability of the flexographic platemaking process. “Sustainability is a central responsibility for any manufacturer today; a responsibility XSYS places at the forefront of innovation by developing more eco-conscious ways to support our customers in their ‘ Environmental friendly’ endeavors,” said Dirk De Rauw, Senior optical designer. “EcoFillX joins a host of other environmental initiatives from XSYS that together can have a big impact of the carbon footprint of the plate processing operation.”

As a new add-on feature within MultiPlate software for ThermoFlexX imagers, EcoFillX incorporates imageable structures into the non-printing areas of the flexographic plate. Through intelligent image analysis, EcoFillX swiftly populates those areas in the LAMS layer with the designated pattern, leveraging the versatile ThermoFlexX optics to expedite imaging.. As a result, more polymer material stays on the final imaged plate, effectively reducing the accumulation of solid content in the washout solvent. Consequently, this prolongs the durability of washing solvent used in circulation and reduces the frequency of solvent replenishment.

During recent successful tests at a customer site, EcoFillX demonstrated a remarkable 30% reduction in weekly solvent usage. The extent of these

savings will naturally vary depending on several factors such as plate image filling, the type of plate and its thickness, as well as the requested washout depth.

For customers that do not operate with inhouse distilling units, the reduction translates directly into significant economic gains. Customers equipped with distilling units will experience noticeable decreases in both power consumption and the quantity of additives required to maintain optimal solvent conditions and balance.

“XSYS is very proud to present this very exciting innovation which comes with benefits that extend beyond mere cost savings. EcoFillX is not simply a new software feature; it’s a significant sustainable solution that enhances both economic efficiency and environmental stewardship,” concluded Dirk De Rauw.

“XSYS is deeply committed to sustainability, and we invite you to our booth [A30 in hall 8b] to explore, experience, and acquire our innovative products. Embracing the concept that the new green is blue, we’re eager to showcase our suite of solutions that are driving a sustainable future, helping our customers to ‘Be Brilliant’.”

Print Innovation Asia Issue 4 2024 26

Mockup Labels All Process

YOUR FREE ENTRY FORM

INSIDE ON HOW TO ENTER WITH ALL THE CATEGORIES CLOSES SEPTEMBER 27TH 2024

Asia

Flexo Gravure Offset Digital Embellishment Hybrid

THE 2024 ASIAN PAC GING EXCELLENCE AWARDS

SEE

Design Win Gold

THE 2024 ASIAN PACKAGING EXCELLENCE AWARDS

The Asian Packaging Excellence Awards is the only regional Independent Packaging Print competition. Since 2001, awarding Gold Silver and Bronze for packaging printers who have excelled in producing world class quality. The judges are non-supplier but are retired educators or production professionals and come from all over Asia/Europe/Australia.

* We MUST have 2 consecutive samples for each job in ALL catergories you enter (If 1 is damaged)

* ONLY 3 jobs allowed for each catergory that you enter.

FLEXO

1. Narrow Web Flexo (up to 500mm width only)

1a Paper/Board

1.b Film

2. Mid Web Flexo (501mm to 914mm width only)

2a .Paper/Bpard

2b Film

3. Wide Web Flexo (915mm and over)

3a . Paper/Board

3b Film

4.Carton & Cups

GRAVURE

LABELS

1. Flexo

2. Letterpress

3. Offset Labels

4. Gravure Labels

5. Combination Printing (Many different processes)

6. Non Pressure Sensitive material

7.Digital Labels

7a. Up to 4 colours

7b. 4 to 5 colours

7c. 5 to 6 colours

7d. 7 + Colours

WIN THE BEST IN SHOW 2024 AWARD

5.Post Print for Corrugated

6.Pre Print for Corrugated

Metallised

Aluminium Foil Surface Print 3. Film 3a.. Surface Print 3b. Reversive Print

Gravure (Must provide written explanation) OTHER PROCESS 6. Embellishment 7 Mockup/Sample 8 Digital Packaging 9 Hybrid Printing 10 Offset Packaging Singapore - Malaysia - Hong Kong - China - Thailand - Vietnam - Japan - Korea - Indonesia - Philippines - IndiaPakistan - Cambodia - Taiwan - Bangladesh - Sri Lanka - Myanmar - Brunei

1. Paper/Board 2.

Paper/

4.Speciality

PLEASE READ: Asian Packaging Excellence Awards are open to all packaging compnaies across Asia. It is free to enter and winners will be presented Gold Silver Bronze awards live on stage in Vietnam 8th November 2024. If you do not attend, we will not send awards to you. Jobs must have been produced from November 2023 till September 20th 2024.

*Brand of Machine

*Plate Supplier

*Pre Press by

*Paper/Board/Film/Label supplier

*Ink Supplier

*Tape Supplier

*Printed Quanity

*Web Width ___________________Other detials_______________________________________

If you would like to supply more information, please attach this to Section A above

Please send your entries to: Send your best work to:

ATT Asian Packaging Excellence Awards c/o PRINT & MEDIA ASSOCIATION OF SINGAPORE

627A Aljunied Road, Biztech Centre, #04-07, Singapore, 389842

Telephone: +65

DEADLINETOENTER27thSEPTEMBER24

Free

FORM

A - This is seen by the

ONLY 3 JOBS PER CATERGORY PLEASE SELECT 5 FLEXO 5 LABELS 5 GRAVURE 5 MOCKUP 5 DIGITAL PACKAGING 5 HYBRID 5 OFFSET PACKAGING

Name_____________________________Contact Person________________________ Compnay Address________________________________________________________________ Country________________Contact Number _______________e-mail ______________________ Name of Entry_____________________________Printing Company_______________________ Your Name ________________________________Signature_____________________________ _ _ _ _ _ # _ _ _ _ _ _ _ _ _ _ # _ _ _ _ _ _ _ _ _ _ # _ _ _ _ _

B - CUT AND TAPE THIS TO THE BACK OF THE JOB ENRTY - *fill out each process

ENTRY

SECTION

Judges

Catergory Entered for this job (See catergories opposite page) Company

SECTION

Catergory Entered_____________Print Method_______________Number of colours__________

6336 4227 THIS IS YOU FREE ENTRY FORM. PLEASE WRITE CLEARLY SO WE CAN READ IT

THE SHIFT 24 Conference will be held in Ho Chi Minh Vietnam on the 7th and 8th November 2024 and the Asian Packaging Excellence Awards dinner will be the 8th after the SHIFT Conference

The SHIFT 24 conference (now in its 21st year) is designed to give Packaging companies, no matter what area of production they are involved in, a view on the trends and technologies that effect business today.

Supported by the leading manufacturers and suppliers, the event offers you the chance to hear from world leading speakers on a whole range of industry topics. Also meet and network with other companies like yours at this intensive one-day event.

More detailed information will be available in the coming weeks so mark this date in your calendar, 7-8th November 24, Ho Chi Minh - Vietnam..

And if you enter the Asian Packaging Excellence Awards, we hope to see you on stage receiving your Awards for excellence in packaging live on stage. See you then!

VIETNAM

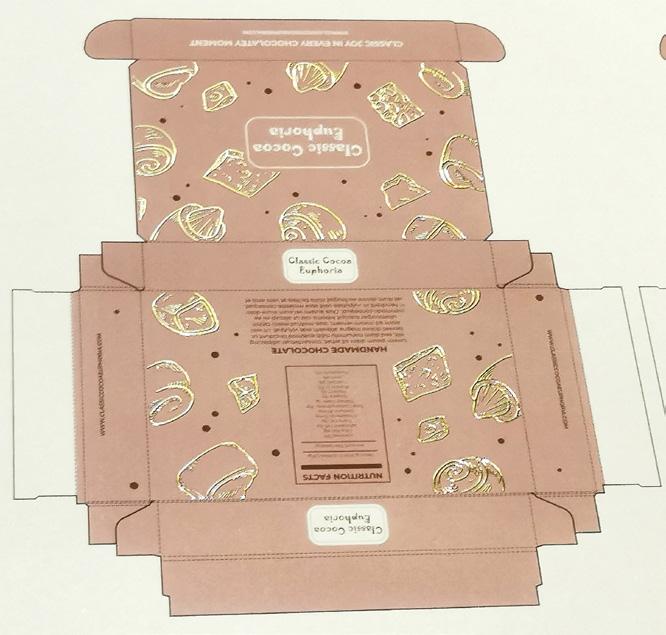

Miraclon - drupa line-up that guarantees packaging printers a path to modern flexo

Miraclon announced its plans for drupa 2024, guaranteeing to bring the benefits of modern flexo to packaging printers by enabling them to achieve their efficiency, sustainability and quality goals and maximize returns on flexo press investments.

Exhibiting in Hall 15, Booth 50, visitors to the booth will learn how Miraclon, through the delivery of critical technology and knowledge, is a key enabler of the transformation to modern flexo; facilitating consistent, highly capable, efficient, sustainable printing.

Leading with real-world examples, the booth will showcase 12 case studies of commercial success, highlight nine new product innovations that build on the strength of core FLEXCEL NX technology, and provide access to Miraclon technical and commercial experts that can demonstrate the Miraclon difference and leverage firsthand experience to help customers navigate to business success.

Chris Payne, Chief Executive Officer, said: “Flexo is an attractive and growing

segment of the packaging printing industry and is evolving from its traditional capabilities, practices and processes to a new era of modern flexo that is a standardized, sustainable manufacturing process.

And, with printers under increasing pressure from brands to be more efficient and sustainable in their production, we invite them to visit the Miraclon booth to see, learn and experience how Miraclon, together with our network of valued partners including prepress providers, technology suppliers and channel partners, can help them develop a practical plan for success. We guarantee it will be worth their time.”

On the Miraclon booth, visitors will see, learn and experience:

• Champions of Modern Flexo: Real life case studies of 12 printers that have met challenging brand client needs and achieved dramatic financial and sustainability goals after successfully implementing FLEXCEL NX technology,

Print Innovation Asia Issue 4 2024 32

FLEXCEL NX: An Ecosystem of Technology Continuously raising the bar within the same platform maximizing investment protection. 2008 2010 2016 2018 2021 2022 2023 FLEXCEL NX System DIGICAP NX Patterning Advanced DIGICAP NX Patterning (NX Advantage) FLEXCEL NX Ultra Solution PureFlexo Printing FLEXCEL NX Central Software UV Choice Printing ONGOING Innovation journey addressing fundamental customer challenges 2024 and beyond INCREASED Performance, Efficiency & Profitability Next Generation FLEXCEL NX and FLEXCEL NX Ultra Plates FLEXCEL NX Ultra 42 Processor Technical Support Plans Halftone Screening Shine LED Lamp Kit

Chris Payne, Chief Executive Officer,

Cut complexity and costs with FLEXCEL NX Solutions.

Simply consistent

Decrease waste and setup with predictable plates

Simply efficient

Increase on-press performance with a robust plate

Simply sustainable

Support sustainable inks and substrates all with the same plate

Simply better

Address your most demanding brand and quality requirements

From prepress to on-press, deliver the efficiencies and productivity needed from your plates to maximize your bottom line.

MIRACLON.COM © 2023 Miraclon Corporation. FLEXCEL is a trademark of Miraclon. The Kodak trademark is used under license from Kodak. 230501

NX Technology to put printers on a clear path towards modern flexo, including:

o The FLEXCEL NX Ultra 42 Processor: Miraclon is the leader in high-performing, water washable plate technology. Building on the success of the FLEXCEL NX Ultra 35 processor for narrow-web applications, the new FLEXCEL NX Ultra 42 Processor offers a key proof point for achieving this in a high-volume, low maintenance plate production environment. Our water washable plates offer the same benefits as our solvent processed plates in the transition to Modern Flexo.

aided by the technical expertise of Miraclon and its valued prepress partners.

• Expert knowledge-based services: Including consultancy, savings tools & calculators, and technical & applications

support to enable printers to maximize their returns in the press room.

• Product Innovation: Showcasing nine of its newest innovations that that build on and strengthen the core FLEXCEL

o Shine LED Lamp Kits: Shine LED Lamp Kits, innovated by Miraclon, are a simple and cost-effective path to UV LED plate exposure that makes an even more consistent flexo plate. Increased plate consistency leads to even greater efficiencies in printing.

o A preview of next generation FLEXCEL NX Plate and FLEXCEL NX Ultra Plate Technologies: LED optimized plate technology that offers even cleaner printing for greater efficiency and sustainability benefits.

Payne concludes: “Any visitor to our booth during drupa is guaranteed to see how FLEXCEL NX Technology, together with our team’s knowledge and expertise, can optimize the flexo print production process and help maximize the return on press investments. We look forward to showing them why partnering with Miraclon should be the first step in their journey to modern flexo success.”

9th INTERNATIONAL PACKAGING AND PRINTING EXHIBITION FOR ASIA 10th International Packaging And Printing Exhibition For Asia SOARING TO NEW HEIGHTS www.pack-print.de 17 – 20 Uncovering Total Solutions for the Packaging and Printing Industries The Thai Printing Association For enquiries : Within Thailand Exposis Co., Ltd Tel (66) 2559 0856-8 info@exposis.co.th Overseas Messe Düsseldorf Asia Pte Ltd Tel (65) 6332 9620 ppi@mda.com.sg Jointly organized by : Book Your Booth Space NOW! SEP 2025 BITEC • Bangkok

Workflow Automation Drives

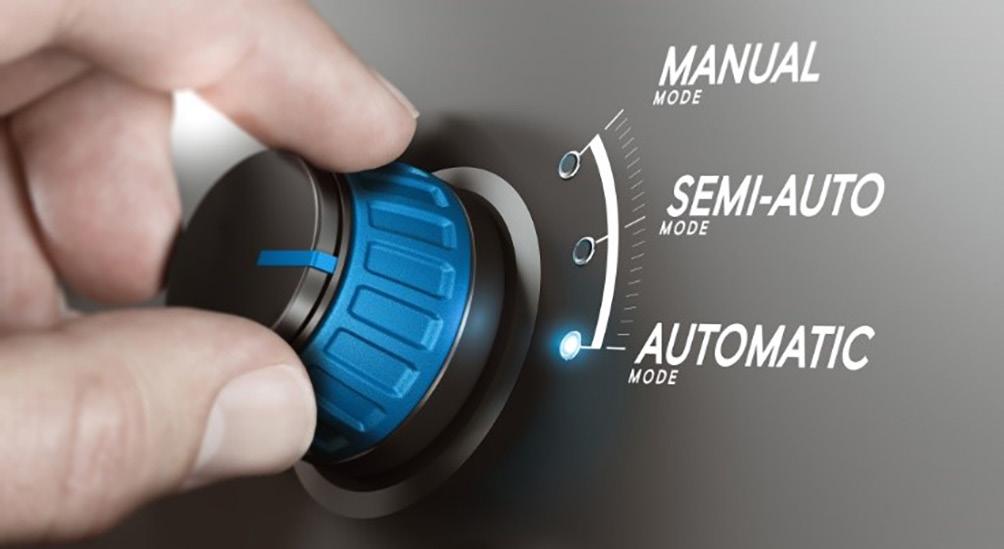

For more than 60 years, we have talked about workflow automation, driven by data, to add efficiency, reduce costs, manage labor challenges, and increase margins.

In this century, we stepped up the volume, embracing the Fourth Industrial Revolution, branding it Industry 4.0, and demonstrating the value workflow automation brings to print manufacturing. With an efficient, scalable, automated workflow that begins before you sell the job, every printer can survive the pressures of increasing paper and consumables costs, demands for faster turnaround, labor challenges, and the requirements to support very long and very short print runs.

Automating workflows is the core of the future of all manufacturing, but the results can be dramatic for print manufacturing. In the print industry, we look at workflow as the rules, protocols, and processes that are defined, documented, repeatable, and auditable. Your print business has many workflows that guide work through your front office, back office, and production to delivery.

Each time you sell a product or service, one or more workflow routines manage the sales pitch, estimating, contracts, job onboarding, preparation, production, delivery, and payment.

Beginning when a customer agrees to buy print and delivers the job to the shop to when the work is handed over for delivery, and the job tickets are closed in production and sent to accounting, every step is at risk. Bottlenecks that add time and complexity to the job can happen at any and every step. Those bottlenecks cost time and money that eliminate

expected profits. Tuning and tightening print manufacturing workflows using automation tools adds efficiency and scalability and keeps more revenue in the business.

10 Steps to plan for automation

The current marketplace for workflow automation is vast. There are tools available for every size printer in every print segment. Spend the time to look at the software available for the market segments you serve. Many tools are built to serve the needs of multiple print technologies and products. However, before you go shopping, you need a clear understanding of your current workflow state.

Begin with an honest self-assessment, looking at all of your workflows.

1. Make a list of your production workflows and the workflows that touch them. If you produce a variety of print products, identify the workflows used for each one. If you have automated some or all of your workflows, note that on your list.

2. Who is responsible for the architecture of each workflow?

3. Who is responsible for solving bottlenecks in each workflow?

4. Where do workflows intersect?

5. What are the rules for Sales interacting with Production?

Drives the Future of Print

By Pat McGrew, Managing Director, McGrewGroup, Inc.

6. What are the rules for Customer Service Representatives to interact with Production?

7. Who is responsible for interacting with customers when there are problems with inbound files?

8. How are Change Requests managed?

9. How are Proofs and Approvals managed, and who monitors customer approvals?

10. How is accounting notified of additional charges and the final job costs?

You may want to add more items to your assessment list. Consider the areas that rarely experience bottlenecks and those that are more susceptible. Think about the people in the processes as well as the technologies. Look at any existing automation to determine if it is still providing the expected results.

Automate to eliminate friction

There are three fundamental reasons to spend the time and money to implement and tune automation:

1. Reduce the time to onboard work: There are dozens of whitepapers that pop up in searches related to job onboarding in print manufacturing, even where there are web-to-production and digital portals available. Walk your workflow and watch a range of jobs as they arrive and move

through the processes that get them into production. Record the time and the number of steps. How many loops do you see? Is everyone working by the same set of rules, or is everyone writing their own rules?

2. Reduce the time to make the job ready: How much time and effort is expended to move work into production? How many loops, delays, and reworks? Mistakes and misunderstandings reduce the margin on the job, so look at your averages. There may be a pot of gold waiting for you in an automated workflow.

3. Reduce production time: Your recipe for production has time elements, but also people and tasks. Count the manual steps and the loops in those tasks that extend the time to completion. How many tools are in use officially and covertly?

These three reductions open the door to less waste, fewer missed deadlines, more efficient production, and higher profit margins.

People Cause Friction

The print industry is actively working to bring back apprenticeships and find more efficient ways to train newcomers and those transitioning to new roles. While that is happening, people performing tasks create workflow friction. Tasks performed inconsistently may lead to job rework and reruns, missed specification changes, and mispriced work that erodes profit margins through a long series of minor incidents during production.

People are inconsistent. They may be wonderful teammates and enthusiastic workers, but that is not the same as repeating the same tasks daily with reliable precision. They are not robots, but that

is what you need – software robots that execute repeatable and auditable tasks in a manner that is predictable and auditable.

Use your data to understand where staff members spend their time, how long tasks take, and how many loops they make. Most shops don’t track their teams by the minute, so consider a quick survey to see what they think takes the most time in their day and the sources of frustration. Look at the number of touchpoints from when a file arrives in Production. How much time do they spend verifying inventory, resolving preflight errors, chasing missing assets, and handling color management or finishing questions by trading emails, text messages, phone calls, and chats? Automation can get much of that time back, freeing the team to handle more significant challenges.

Paper and consumables cause friction

Paper, film, vinyl, and the vast range of specialty substrates a shop may need to stock, along with the consumables that are part of the print process, like ink, toner, solvents, and cleaning tools, are a source of friction, but automation can be a lubricant.

Take stock of everything you keep in inventory and your replenishment rates. You may have a dedicated inventory management system for tracking, but you might be doing it manually using spreadsheets. Look at what has been sitting in stock for longer than average and what you regularly expedite. If you automate your orders based on agreed replenishment quantities and update received goods in your internal inventory

management system, you should find that material management becomes easier.

Take it a step further and integrate order and received goods management into the systems that feed your estimating and quoting to ensure that you have the raw materials you need to complete the work. Over time you should find that your stockholding becomes more efficient.

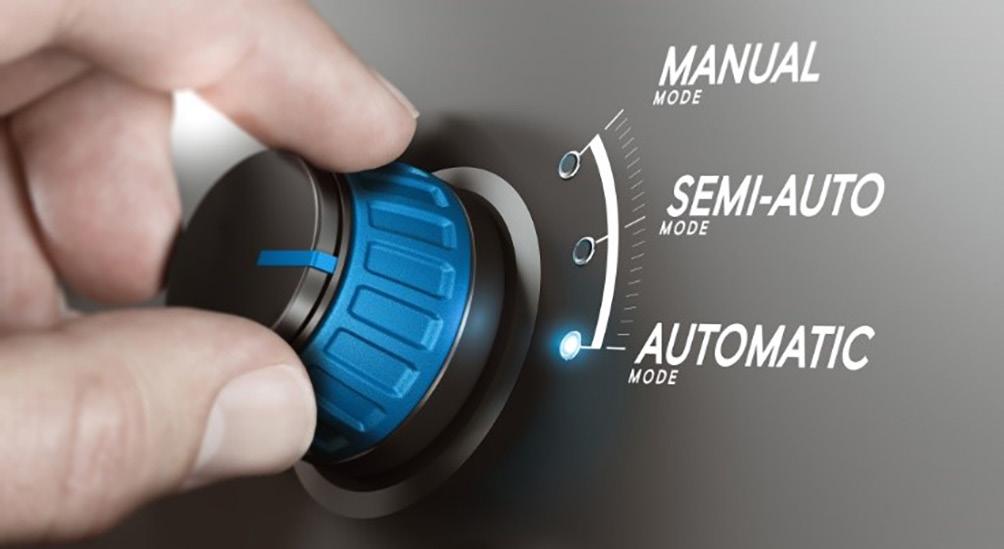

Deploy automation as the lubricant

Preparing for the future demand’s efficiency and optimization of every process. Islands of automation linked by manual processes is not a best practice. End-to-End workflow automation is the path to follow. Follow the Crawl-WalkRun rule!

If you have islands of automation, begin by reviewing those automation tools and the manual processes that link them. Review your installed software solutions. What are your options for expanding your adoption and deployment of adopting tools you own to achieve end-to-end automation?

Look at Job Onboarding, Prepress, Production, and Delivery. Anthony Thirlby at Venn Holding in Belgium shares his productivity numbers on LinkedIn. He says that 55% of the life of a job is spent in Estimating, Job Administration, and Scheduling. Focusing on these areas in your Crawl phase builds repeatable results that may save minutes to hours in bringing the job on board, adding money to the bottom line.

Even if you have a web-to-production portal or digital storefront, take a few steps back and review if they are still working for you or need a tune-up. If jobs arrive and seamlessly flow to prepress and production, great! But if there are still loops and bottlenecks, it is time to look at how your tools are set up and solve the bottlenecks.

If you are in a manual job onboarding environment, using hot folders and email, this is the time to stop. Your Crawl phase should be the development of a requirements and specification protocol to inform acquisition and implementation of automated job onboarding. Automated job onboarding will save time, create consistency and efficiency, and free team members to spend time on more valuable tasks.

After job onboarding, walk into automating customer approval management, change request and resolution, and then close the loop. Verify that every job is invoiced, including change requests—set policies for discounts. And use your production data to keep pricing up to date.

When all processes are connected and sharing data, you are ready to run. It may take two years to build the end-to-end process, but new automated step lifts your level of efficiency.

What happens when you embrace automation?

Print Innovation Asia Issue 4 2024 EXTRUSION | PRINTING | CONVERTING Best profitability at printing speeds up to 600 m/min. and fast job changes Highest quality with best register Connected to RUBY to digitize the value chain ... and many more! HELIOSTAR Ready to print MDO-PE Windmöller & Hölscher KG Lengerich / Germany Phone + 49 5481 14 - 0 · info@wuh-group.com www.wh.group/int/en/ 100% sustainable Print the future green!

Automation is not magic. Automation takes a well-defined plan that is transparent. It takes executive sponsorship and team leadership. It is part art and part science. Automation requires calming the fears of employees that their jobs may be eliminated. It requires a different type of conversation with the current array of software vendors. But if you do your assessment and have those conversations, the waste reduction, production efficiencies, and customer satisfaction that result can change the trajectory of the company.

If you need talking points for your team, here are the top reasons to embrace automation:

Eliminate manual and repetitive tasks: Automation eliminates repetitive tasks and errors, allowing faster processing, reducing turnaround times and increasing overall efficiency.

Integration enabling data sharing across applications: Integrating digital technologies with traditional print methods is the bridge to the future. It allows seamless integration between design software, content management systems, and data-driven workflow processes.

Easier to collaborate: Work rules are different in every country, but the global economy lets us sell print around the world. Automation paired with cloudbased workflow solutions fosters more efficient communication, faster approvals, and reduced lead times.

Enables waste reduction: By identifying workflow inefficiencies and eliminating them, reprints due to production mistakes become a thing of the past. Leveraging vendor data and integrating business workflows with production workflows minimizes waste through better inventory management. The ability to print ondemand and in smaller quantities reduces excess inventory and waste associated with outdated or unused materials.

Print manufacturing workflow automation brings increased efficiency, improved production quality, and more flexibility in scheduling. The business result is increased capacity through efficiency and higher available profit margin on each job.

Automation and management of the automation rules allow the print shop to adapt to changing customer demands, integrate with digital processes, improve efficiency, reduce costs, and deliver a better overall experience. The resulting optimized print workflows are essential to staying competitive in a digital age while still leveraging the unique benefits and tangible qualities of print.

UV ANALYZER FOR UV AND LED UV UNITS

The UV Analyzer is a app-based UV radiation measuering device.

The measuring is quite easy. Put the strip on your substrate, irradiate it with UV and measure the strip with the stick. The app will show you the measured dose in mJ/cm². This dose value can be compared with your reference value to determine aging.

Scope of delivery: UV Analyzer Stick and reference white, charging cable, lanyard, measuring strips

IST METZ SEA Co.,Ltd. • 1558/12 Baan Klang-Krung, Soi 4 • Bangna-Trad Road, Bangna, Bangkok 10260 • Thailand +66 2182 0043 • info@th.ist-uv.com • www.ist-uv.com/th

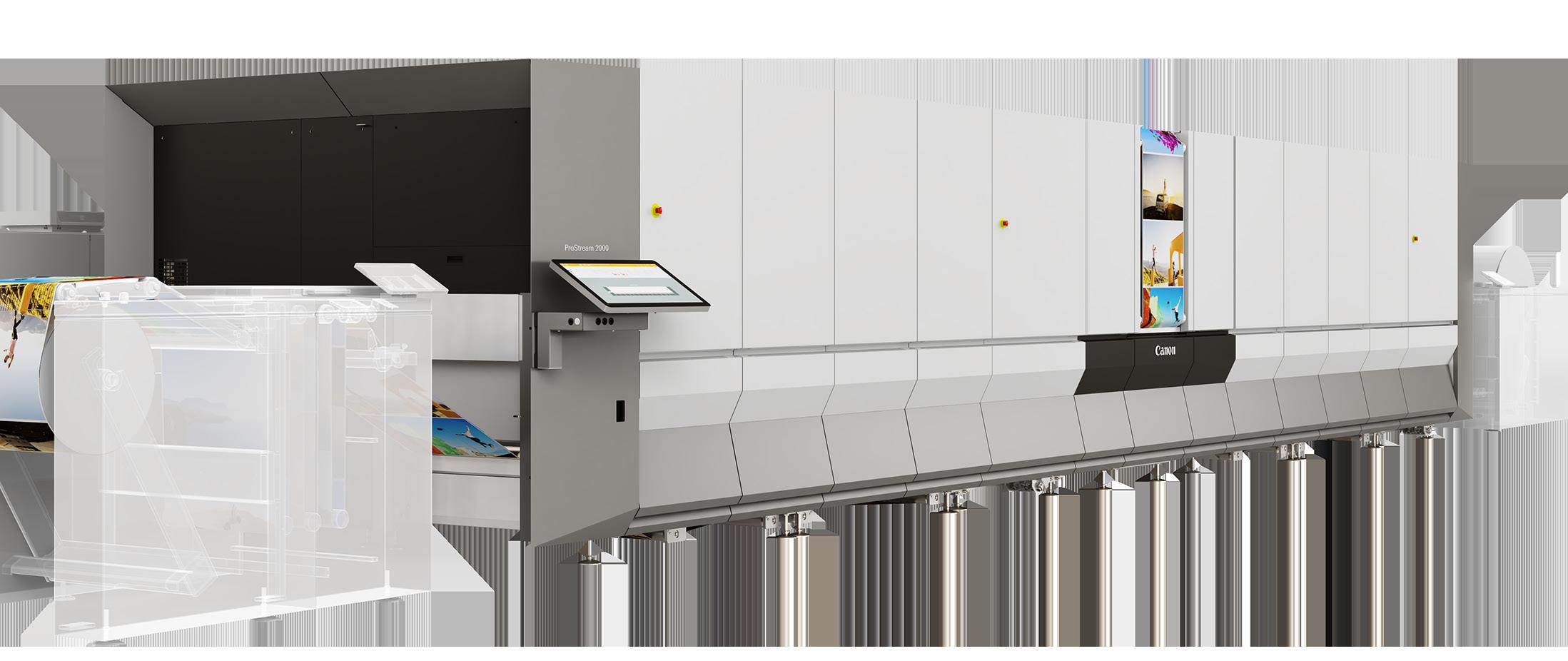

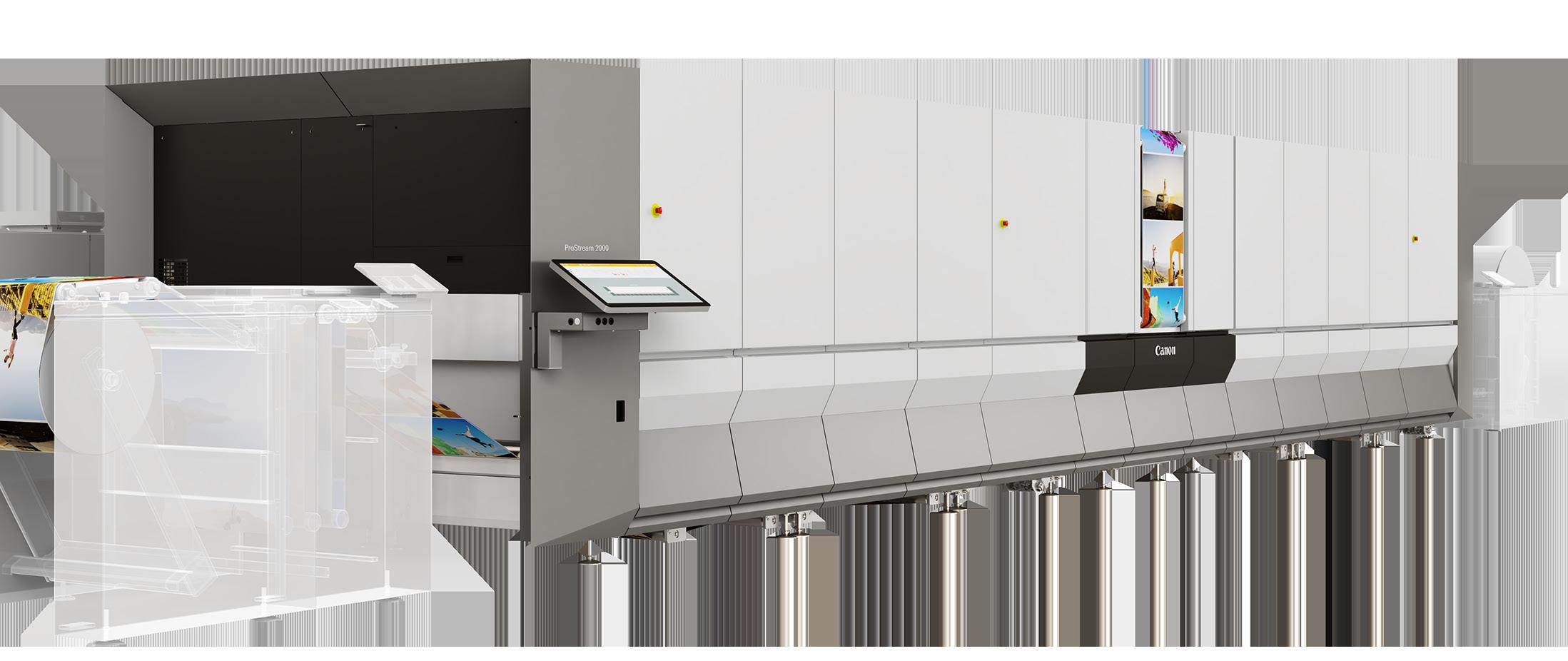

Canon demonstrates ‘The Power

At drupa 2024 Hall 8a, Stand B41-1 to B41-8) under the theme ‘The Power to Move’, Canon will demonstrate how its powerful combination of technology innovations, expert teams, excellent support services and dynamic collaboration empowers print service providers (PSPs) to transform their businesses.

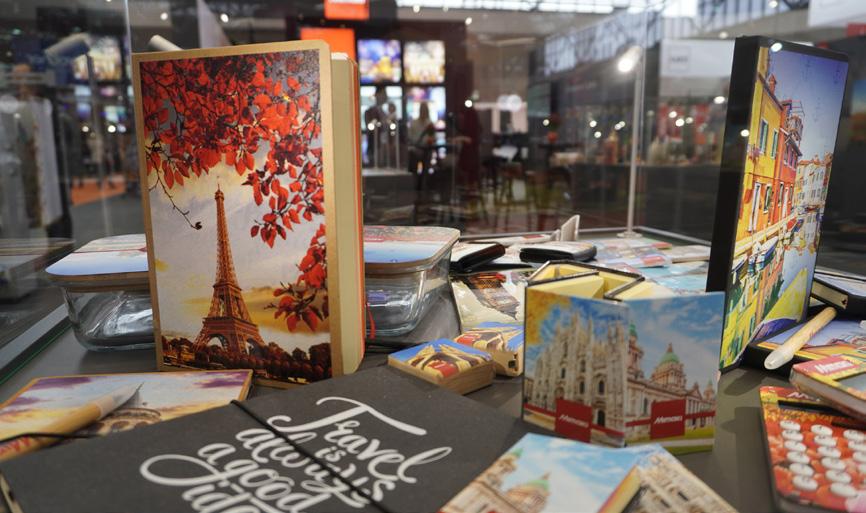

The full portfolio of Canon production print technologies will be showcased, including sheetfed inkjet and toner presses, high-speed continuous inkjet production lines, flatbed and roll-to-roll wide format printers, and digital label printers.

Simulating real-world operations, end-toend production solutions will combine Canon workflow productivity solutions, print media and presses with the preand post-processing equipment of more than ten technology partners. Through customer success stories, innovative applications and inventive business models, visitors will see the many creative and commercial possibilities of digital print-on-demand.

At the centre of the 4,600 sqm Canon exhibition and hosted hospitality space will be ‘The Core’, offering visitors an immersive, multi-sensory exploration of print’s emotional impact and how imaging experiences can enrich lives and businesses. ‘The Core’ invites attendees to get to know Canon from a less familiar perspective and to experience how print has the power to move.

Fanning out from The Core, Canon’s technologies will be arranged by industry segment: Commercial Print, Publishing (including books), Promotional Communications (including direct mail and retail), Labels and Packaging, Interior Décor, as well as Inhouse and CAD printing. Across the stand, production solutions will deliver a diverse range of live applications reflecting the work mix of customers in these segments.

Whether visitors are interested in inkjet or toner, colour or mono, small or wide format, Canon experts will be on hand to guide print businesses of all types and sizes to the best digital print technology, workflow and print media

choices for them - taking into account their operations, production volumes, customer profiles and growth aspirations.

A first at drupa, Canon will demonstrate its commitment to become a significant, trusted partner to the label and packaging markets, demonstrating live production of various label, corrugated and folding carton applications.

The ‘Printworks’ area of the stand is about ‘People, Planet and What’s Possible’. Visitors will gain inspiration from exploring the various strategies Canon customers have adopted for

successful sustainable growth and how Canon has successfully partnered with them to implement effective solutions.

This area also visualises Canon’s collaboration activities in the market to drive innovation and make a positive impact in the industry. ‘Printworks’ is also the designated area to connect with Canon business development, applications and operations experts. There, visitors will be able to explore how to accelerate their growth by accessing advice on everything from improving production efficiency, colour management and quality control to media selection, pre- and post-

Print Innovation Asia Issue 4 2024 42

Power to Move’ at drupa 2024

installation service and support models, and sustainability.

The importance Canon places on sustainability will also be reflected in every aspect of the stand, from individual product characteristics to the stand design and the choice of applications printed, many of which have a specific purpose with visitor or community projects. Environmental data relating to all solutions and substrates on the stand will be clearly displayed.