PLUS POWERED ACCESS EXPERTS ON THE FUTURE FOR RENTAL E-MACHINES HOW CAN WE GET MORE IN THE REGION?

RAW POWER

REACH THE NEXT LEVEL

NEW HOLLAND GOES HEAVY TO SET A NEW BENCHMARK IN THE MARKET

PLUS POWERED ACCESS EXPERTS ON THE FUTURE FOR RENTAL E-MACHINES HOW CAN WE GET MORE IN THE REGION?

RAW POWER

NEW HOLLAND GOES HEAVY TO SET A NEW BENCHMARK IN THE MARKET

With its compact design and light weight the applicators reach challenging project sites with ease. The improved LWSE hi-frequency motor and the compact control unit are also suitable for expanding to wire sawing and core drilling units, handing out a wide range of applications to construction sites.

Excellent weight-to-performance ratio.

Lightest saw head for depths up to 705mm. Remote controlled operations for maximum safety.

Suitable to use 1600mm diameter blade guard. Special cooling bypass system for wet and dry cutting applications.

2023

6_NEWS

The latest news from across the region and further afield.

10_A

Mammoet’s operation is so big in Uzbekistan it needed to take over an entire port to get the job done.

14_THE

CMME talks to access experts to discuss the opportunities to be gained by opting to take your operation electric.

16_RENTAL IN REVOLUTION

CMME brings together some of the leading experts in rental to discuss their future and the market’s prospects in the years ahead.

20_ATLAS COPCO @ 150

A special look back Atlas Copco’s early forays into compressors to the multi-segment approach it takes today.

The Construction Machinery Awards were a personal highlight of mine last year, partly because it was great to catch up with a lot of old friends but also to see what was happening in the market after a few years away.

As I’m sure you have heard by now we are asking everyone who supplies machinery in the market to put their best equipment forwards to the construction, logistics and industrial communities of the region.

My best advice to manufacturers, distributors and rental experts is to get onto our Construction Machinery Middle East Awards 2023 site as soon as you can to make sure you don’t miss out.

We want to make product nominations for the regional vote as simple as possible for you, and have stripped down the uploading process as much as possible.

So now you just need to choose the Product Category for each of your products and in the appropriate boxes supply model information, weblinks and a description (which will used for the event and marketing campaign in the lead up to the big night) and then in the final page you will be able to upload up to two pictures for each entry.

I’m sure a lot of you will pleased to hear that much of the information just needs to be filled in once this time around. So, what are you waiting for, get on with it!

If you are wondering what are the major differences between this year’s Awards and the previous edition, well this is a much bigger focus on the most important cohort of all – the people actually using the machines in the wild.

Obviously, in such a diverse market as the Middle East, it would be impossible to

ask people to vote on individual companies operating in industries that may be very different from their area of expertise.

Instead we are looking for judges to take part in deciding who the best contractors and equipment users are in the region.

So, while equipment experts and professionals from across the region are invited to vote in the Suppliers and Product awards to decide the winner of those categories, the Contractor awards, are decided separately by an independent panel of judges from across the spectrum of the industry selected by the Awards organising team. (Please drop me a line if you do want to join our esteemed line-up).

Nominees are assessed by the appropriate experts who have a chance to assess nominations both individually, and in a group discussion.

I believe this ensures that winners are chosen on the basis of the work they do over the course of the year, and on the reputations they develop with the industry.

If you are operating on the supply side of the industry, please put your hands up if you would like to take part in the judging, and if you know a company that is setting bencmarks and raising standards in areas such as sustainability, efficiency and safety, please point me in their directiion.

GROUP

MANAGING DIRECTOR

RAZ ISLAM raz.islam@cpitrademedia.com

+971 4 375 5471

MANAGING PARTNER

VIJAYA CHERIAN vijaya.cherian@cpitrademedia.com

+971 4 375 5713

DIRECTOR OF FINANCE & BUSINESS OPERATIONS

SHIYAS KAREEM shiyas.kareem@cpitrademedia.com

+971 4 375 5474

PUBLISHING DIRECTOR ANDY PITOIS andy.pitois@cpitrademedia.com

+971 4 375 5473

EDITORIAL EDITOR

STEPHEN WHITE stephen.white@cpitrademedia.com

+44 7541 244 377

ADVERTISING

SALES MANAGER

BRIAN FERNANDES brian.fernandes@cpitrademedia.com

+971 4 375 5479

DESIGN

ART DIRECTOR SIMON COBON simon.cobon@cpitrademedia.com

DESIGNER PERCIVAL MANALAYSAY percival.manalaysay@cpitrademedia.com

MARKETING

EVENTS EXECUTIVE MINARA SALAKHI minara.s@cpitrademedia.com

+971 4 433 2856

SOCIAL MEDIA EXECUTIVE DARA RASHWAN dara.rashwan@cpitrademedia.com

CIRCULATION & PRODUCTION

DATA & PRODUCTION MANAGER PHINSON MATHEW GEORGE phinson.george@cpitrademedia.com

+971 4 375 5476

WEB DEVELOPMENT

ABDUL BAEIS UMAIR KHAN

FOUNDER DOMINIC DE SOUSA (1959-2015)

PUBLISHED BY

Stephen White Editor, CMMENow you can increase significant savings through a dedicated tool developed and managed by TotalEnergies.

Presenting, LubAnac is a Fleet Management System, to reduce your vehicle maintenance costs through oil analysis that:

Reduces downtime of your fleet

Optimizes the maintenance

Increases the lifetime of your vehicles

Reduces total cost of ownership (TCO)

totalenergies.ae

PROPERTY

Azizi Developments

launches Azizi Grand in Dubai Sports City

ANALYSIS: Is Partanna’s cement alternative the key to carbon negative projects?

FINANCE

Moody’s affirms A1 issuer rating for PIF

CONSULTANT

Egis in new partnership with EmiratesGBC

EXPERTS: What the 6th IPCC report means for the MENA region

FINANCE

$344.5mn in financing for electric express train project in Egypt

INTERVIEW: Women in Construction profile – ACCIONA’s Adelaida Fernandez

INFRASTRUCTURE

Two bridge and tunnel at Falcon Interchange now open says RTA

Honouring the Machinery at the heart of every project, rewarding outstanding performance

CONSTRUCTION

Contracts for Amaala’s Marina Village awarded says Red Sea Global

The first development phase of Amaala is underway and expects to welcome its first guests in 2024

CONSTRUCTION

Dar Al Arkan 3D prints

‘smart’ villa in Riyadh

Low-cost local materials were used to create the 3D printable concrete, which was the primary construction material for the walls of the 330sqm structure

CONSTRUCTION

Electric ship-maker to build plant in UAE

The announcement follows news of the company recently sealing a deal with Kuwait’s Badr Sultan Group

PROPERTY Aldar and Mubadala ink deal to develop commercial assets in ADGM

CONSTRUCTION

Digital District opens at Zayed Port First phase of Digital Harbour project now complete and ready to offer a dedicated digital ecosystem

CONSULTANT Hill wins 50,000-unit Al Fursan PMC contract

PROPERTY Contracts awarded for DAMAC Lagoons development

Several consultancies have each been allocated a portion of the delivery of the masterplanned community

PROPERTY Luxury marina community slated for Jubail Island

FINANCE

African Development Bank approves grant to boost Ghana’s use of renewable energy

PROPERTY Meraas launches Design Quarter residential hub in

The second Construction Machinery Middle East Awards includes an expanded list of contractor awards with the event recognising end-user excellence in an array of sectors, the organisers have announced.

The nomination process is now open to users of machinery and equipment across sectors such as construction, infrastructure, FM, as well as members of the logistics chain in the market. A judging panel will soon be appointed to oversee the shortlisting process of the contractor categories ahead of the event on June 8, 2023 in Dubai, confirmed Stephen White, Head of Content at Construction Machinery Middle East

As before, the Awards will also celebrate manufacturers, suppliers and dealers whose machinery plays a key role onsite in the projects at the heart of the GCC economy. Most importantly of all, in a competitive and contract-driven environment, the Awards are a snapshot

of the touchstone equipment enabling operational performance and safety.

To ensure complete objectivity, the Awards are judged by a mixture of public votes and a specially recruited judging panel for the contractor awards; they are influenced by one criteria only – the informed decision that they are truly the best-in-class.

Members of the construction and industrial communities in the region will be invited to decide the best equipment and players in the market through a special online vote which will begin on the April 10, 2023. This is scheduled to be concluded on May 10, 2023.

Companies wanting to take part can upload their nominations now, confirmed White.

“This year we have simplified the whole process of uploading product information on the site to make sure we get the best of the best putting themselves forward for the voting process,” he concluded.

A $217mn contract has been awarded by Dubai’s Roads and Transport Authority (RTA). The contract is for Phase 4 of the Al Shindagha Corridor Improvement Project, which extends 4.8km along Sheikh Rashid Road from the intersection with Sheikh Khalifa bin Zayed Street to the Falcon Interchange on Al Mina Road. The project aims to keep pace with the continuous development of the locality, while catering to the demands of urban expansion and population growth. The scope of work includes the construction of three bridges spanning 3.1km in total, capable of accommodating 19,400 vehicles per hour across all lanes.

The team at Byrne Equipment Rental have had a busy start to the year with multiple product open days held at their depots across the GCC. First up was KSA in February and March, with three successful open days held in the hub of the global O&G industry, Yanbu and Jubail as well as their facilities in Riyadh.

In Yanbu and Jubail, the KSA teams welcomed prospective and existing clients to their facilities to demonstrate their product offering for the upstream and downstream O&G industry and had a wide range of equipment on display from temporary buildings and cargo containers, to boom lifts, scissor lifts and steam boilers. Syed Zahid, assistant general manager KSA –Eastern & O&G KSA had only good things to say about the first of this kind event for Byrne in the region,

“At the tail end of 2021, we launched an enhanced product for our camp services, designed based on heavy duty and durability, and specifically designed for drilling / rig area working. It was great to showcase these and we received positive feedback from drilling contractors & sub-contractors alike.”

The Riyadh open day covered a wider range of equipment suitable for various sectors including but not limited to O&G, Construction and Events. The team arranged a set up of equipment including AC Units, Hoist & Access machines and a state-of-the-art accommodation unit custom made by Byrne’s sister company Spacemaker – SmartSpace. General Manager of Byrne’s KSA operations James Dodgson said:

“This is the first time we have held events of this kind in the Kingdom and they’ve all been a huge success.”

WE

new models from 25 to 58 HP designed to meet the different needs of customers in the EMEA region. Each model varies in size and engine horsepower, with the option to choose between manual and hydrostatic transmission, and between open canopies (ROPS) and cabs.

Bobcat is exhibiting at SaMoTer 2023 in May, the most important exhibition in Italy for the construction machinery sector, presenting several recently launched product lines and models for the first time in the country.

SaMoTer provides an ideal platform to show visitors the new Ground Maintenance Equipment (GME) range from Bobcat, which includes compact tractors, small articulated loaders (SAL), mini track loaders, mowers and turf equipment, says Bobcat: “Building

on the company’s success in the North American market, Bobcat aims to rank within the top.”

All Bobcat GME models are robust and versatile, providing excellent productivity and great comfort. Representing the range, a cabbed version of the new CT2535 compact tractor will be on display on the Bobcat stand at SaMoTer for the first time in the Italian market.

Bobcat is offering three Compact Tractor platforms – the 1000, 2000 and 4000 series – which feature nine

Bobcat’s proven Bob-Tach system comes as standard on all machines with the front-end loader option, enabling users to switch effortlessly between different Bobcat attachments, to carry out multiple jobs easily, delivering value and versatility for customers’ businesses.

Francesca Biagini, Italy, Greece & Iberia Attachments - GME Sales Manager, comments: “These machines are versatile tool carriers thanks to their total compatibility with a wide range of Bobcat attachments that allow users to maximize productivity in any application such as gardening, agriculture, construction, roads and snow clearing, to name a few.

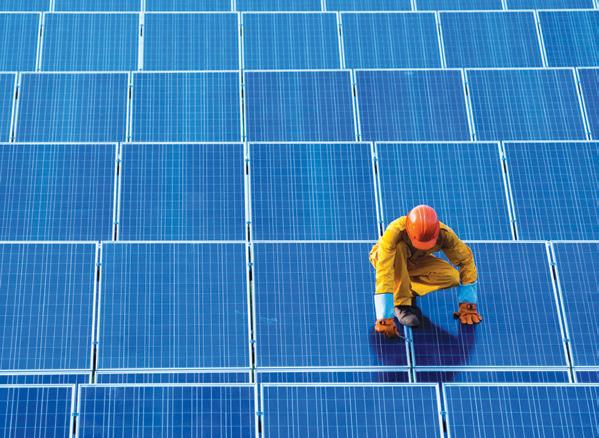

SirajPower has signed a deal with Fujairah-based Halwan Crusher that will see the deployment of its Solar Hybrid system. Through the agreement, SirajPower will develop a fully financed 3.9MVA solar-diesel battery. The firm says its system will enable Halwan Crusher to reduce fuel consumption at its latest project site in Fujairah.

According to SirajPower, its hybrid system will provide Halwan Crusher with reliable power through solar PV, diesel generators, and batteries. The generators will be utilised to fill the gap between the load and the electricity provided by the PV system on a consistent basis. The solution is estimated to offset over 1,500mt of CO2 emissions for the project’s remote location, enabling Halwan Crusher to reduce its fuel consumption, operational expenditures, and carbon footprint without making any upfront investments, the firm added.

A collective fine of US $37.32mn has been imposed on 14 cement companies in the Kingdom by the General Authority for Competition (GAC). The antitrust authority imposed a $2.66mn fine on each of the cement firms.

Bauer International has been as one of two contractors appointed for the development of the Wynn Resort in Ras Al Khaimah by Marjan, which is developing the integrated gaming resort in partnership with RAK Hospitality Holding and Wynn Resorts. ALEC Engineering and Contracting was awarded the main contract for the construction of the integrated resort development, while the German foundation specialist will undertake the piling and enabling works and has already begun construction preparation on the project site, located on the man-made Al Marjan Island, the flagship project of master developer Marjan.

The very first batch of modularly constructed villas for Red Sea Global’s Sheybarah Island Resort have been lifted into place by Mammoet and Demag. A total of four villas were loaded-in at the Port of Hamriyah, in Sharjah, and were shipped to the island be installed at the site.

A new milestone was achieved with the installation of the first prefabricated, stainless steel overwater villa orb on its foundation. For the installation, Mammoet used its 650t capacity Demag CC3800 crawler crane positioned on top of Mammoet’s modified barge, ALE 250. The shallow draft of the barge meant that there would be minimal disturbance to the sensitive marine environment of this unique and picturesque archipelago in the Red Sea.

At the construction jetty, the crane loaded and placed the first orb on the barge deck and sailed to the installation area. Once at the location, the barge was positioned using a hyper-accurate GPS system and the barge’s own winches, for precise alignment with the

foundation. The barge was then stabilized using a retrofitted 300t spud jacking system provided by Combifloat - Mammoet’s partner for floating and self-elevating marine equipment suitable for nearshore operations. Safe and efficient lifting, lowering and (re)positioning of

the barge was achieved through a locally controlled jacking mechanism and a 4-point mooring system.

The crane was raised to lift the orb into place - its superlift was replaced by a system designed specifically for the project where the back mast of the CC3800 is “tied back” to the barge.

This gave the crane enough capacity to skillfully place the orb onto the foundation without requiring the additional mass of a superlift tray.

Robert van Tinteren, Lead Project Engineer for Mammoet commented: “Creative engineering at its best. It has been an exciting nine months building up to this point, but it never gets tedious to see the incredible things we at Mammoet can do when we put our minds to it!”

When Mammoet was approached by Globalink Logistics to assist with the transportation of heavy items for the construction of a new power plant in the city of Shirin, Uzbekistan, it certainly wasn’t a case of “let’s cross that bridge when we come to it” when rising to the engineering challenge.

Developed by ACWA Power, the new 1.5GW combined cycle gasturbine (CCGT) power plant is part of the Uzbekistan Government’s plan to improve efficiency and capacity of its electricity production, while boosting economic growth and reducing environmental impact. Uzbekistan doesn’t have sea access, so typically Caspian Sea ports are chosen for receiving any Out of Gauge (OOG) cargo. For this project we have chosen Kazakhstan Port of Bautino. This cargo’s destination was the city

of Shirin in Uzbekistan, meaning once it arrived at the Caspian port it would face a 2200-kilometre road trip.

A team of engineers, headed up by Mammoet Operations Manager Marek Lysko, set to work on planning the best method to get the OOG components (ranging from 130t to 517t) from port to plant. It was decided that Port of Bautino, located on the coast of the Kazakh Caspian Sea, would be the best port to receive the cargo. Mammoet been in the Caspian region since 2004.

“We call it Mammoet Port, because it’s purely operated by us,’ says Ali Yoldashov, Mammoet’s Regional Manager – Caspian. “Bautino is a seaport and has sufficient draft, unlike other ports in the Caspian Sea. The ground-bearing pressure capacity on the port is sufficient enough to handle oversized cargo on the crane outreach. It also gave us the possibility to make customs clearance, and practically unlimited

storage space. We established it was the only solution.”

Most of the OOG items would be loaded straight from vessel to trailer and then driven to the site directly from the port. However, for the five heaviest items, most notably the 517t gas turbines, this wasn’t possible. Yoldashov, explains why: “The gas turbines can be transported on a rigid set of conventional trailers having large axle numbers, but because the load capacity of the majority of the existing bridges in Uzbekistan, the load spreading calculation entered the discussion.”

Even with this solution and 480 tyres distributing the load, there were still some bridges unable to handle the extreme axle loads. The team came up with a solution to add an additional 8 axles (64 tyres) directly under the hanging cargo to cross these critical bridges. Adding and removing additional axles was a

challenge in terms of engineering and operations, but proved to be the only way to protect the team, equipment, cargo and infrastructure. This required a specialist piece of Mammoet equipment: the AL600 Girder Frame. Designed to transport the next generation of power equipment exceeding weights of 500t; the AL600 is a globally unique product in terms of design and capacity. It can transport heavy loads to remote locations with road restrictions. These restrictions can be height, low bridges or, in this case, axle loadings – whereby a route or country legislation demands a need to spread heavier loads over more axles.

The AL600 sits on two independent trailers, towed by prime movers, and its modular design allows for up to 2 sets of 20 axle lines to carry exceptional weights, which are distributed using a load spreader system.

JCB have used their experience in designing tough, hardworking equipment to ensure their electric scissors range are also built to higher standards. With high quality paint finish and many unique features, the machines have higher levels of safety, ease of use, reliability and serviceability. Industry standard components across the range allow seamless integration into existing rental fleets. JCB also offer higher levels of support through an unrivalled dealer network with quick start guides, good parts availability, finance and technical advice.

For more information, please contact your local dealer.

www.jcb.com/access-platforms

Construction of the Sheikh Khalifa bin Zayed Al Nahyan Mosque - Al Ain was awarded to Arabian Construction Company (ACC) for AED 600 million over a decade ago. Works on the 15,684 sqm built area for the mosque, which designed with a dome adorned with the verses from the Quran, started in December 2013 and was initially scheduled for completion in 2016.

At the time, the biggest mosque in use in the city was that of Shaikhah Salamah mother of the late Sheikh Zayed bin Sultan Al Nahyan, the father of the UAE’s second president Sheikh Khalifa bin Zayed bin Sultan Al Nahyan. Despite its importance, the project was subsequently delayed

by a review of major projects that were at the time slowing the pace of development in Abu Dhabi. However, the project was finally completed in 2019 and recently Johnson Arabia was contracted for lifting services for the improvements on the Mosque that were initiated in 2022.

The project improvements included installing sensor-activated shade canopies for the outdoor prayer areas. To provide shading for such massive areas multiple 22t and 12m-high steel columns were needed to be erected at the mosque with minimal disturbance to prayer times.

Johnson Arabia was tasked as the expert lifting partner to complete this difficult task. The team had to obtain very special permits for the job due

to its high-profile nature and ensure that no work was attempted - or lifts performed - during prayer times. As prayer times occur five times a day, the engineers had to carefully plan lifts that could be performed in specific time windows or ensure the columns were secured at their midlift positions should there be a clash. The scale and precision required for the placement of the columns, in an essentially built environment, created the biggest challenges for the Johnson Arabia team. Based on the size of the columns and lifting plan, the team planned to use a TEREXDEMAG CC2200, 350t crawler crane loaded with a 108m straight boom in tandem with a 100t Liebherr crane. But first the parking space near the mosque had to be converted into

a high-load bearing area. This was achieved by the strategic placement of crane mats after ground pressure calculations had ensured full safety of the equipment and lifts.

Once the columns were able to be lifted off their flatbeds, the CC2000 was used to position the column upright and the Liebherr used to keep the bottom of the column off the ground for accurate positioning.

The crane operators being unable to retain full visibility on the ends of the columns presented a major challenge. The rigging team had to make sure they communicated with each other for every step of the lift, as well as consult the installation team for accuracy of placement to complete this stunning addition to the Al Ain skyline.

and secondary platform controls, the high specification performance with a tight inside turning radius for

In many ways, the powered access and handling sectors are ahead of the game when it comes to electrification in the region. That’s the good news. The less good news is that compared to other markets the utlitisation is far lower. The Access and Handling Summit last month was an opportunity to discuss why the market isn’t yet at the levels of Europe and China, where close to 80% of machines can be plugged in and charged.

According to Tim Whiteman, global branding director, Sinoboom, one of the major impediments is the lack of charging infrastructure in the market, and particularly on-site.

“It’s now become the norm in many countries to start from the construction site, and say “Okay, how are we going to provide the electric power?” He comments, adding that going electric doesn’t always have to mean that the power is coming from a battery.

“It might be a temporary diesel generator, because it’s still cheaper and more environmentally friendly to have a low power diesel generator than just charging the equipment,” he adds. “As counterintuitive as it seems, it actually can be a good option.”

Antony Chalissery, regional sales manager, ME & Africa/LGMG, Lingong Heavy Machinery Pvt Ltd, says that the market is shifting to electric but hasn’t yet fully appreciated the capabilities of the batteries that can bridge the gap in charging infrastructure that dogs the market. He is particularly enthusiastic about the potential of lithium-ion batteries which can sustain power for longer than other alternatives.

“We focus on lithium-ion batteries at LGMG. Why not a lead acid battery, which is much cheaper compared to the lithium battery? The reason is, there are a few technical aspects to it. For instance, if you charge a lead-acid battery, you may only end up using half of what is stored inside. So, if you say a battery has got a capacity of ‘10’, we have been using only a maximum six. On a lithium-ion battery, you end up using maybe 9, or 9.5. Number two: if you use a conventional lead-acid battery, your power rating, or the wattage output drops as the power goes out. But with lithium batteries, you’ve got a steady output and at a broad range.”

A common worry is that the batteries can’t cope in the heat of the summer. Chalissery draws a comparison with a well-known EV car brand: “Teslas are running in this weather and the power consumption of these machines are much lower than a Tesla going at full speed.”

Whiteman believes that it would be wise to hedge bets when it comes to which particular battery will prove the more popular in the market. Absorbent Glass Mat (AGM) batteries, for instance, which still use lead acid are able to reach temperatures as high as 80OC and are popular in some markets because of their fine glass fibre shielding design.

“On the discussion about what kind of battery to use, I would say the jury is still out,” says Whiteman. “We supply lithium in China, and we’ve got good experience in there as people are familiar with it. Our experience of the AGM batteries that we’re using in Europe has been that nobody ever talks about them... which is great.”

Rob Cavaleri, regional training, safety and compliance manager, Manlift Middle East, says that battery development is happening at such a fast pace that the market shouldn’t be deterred from opting for electric machines, even if there are concerns about the durability of lithium-ion batteries or the efficiency of the lead acid-based alternatives.

“I don’t think we should ‘get stuck’ on lithium and of course, we have more options coming soon. But the manufacturers can also change the compounds of lithium quite easily to suit a higher ambient temperature or a lower ambient temperature, and

they can change the parameters to make it less volatile, so on and so forth.”

Despite the problem of dealing with the more extreme temperatures that equipment has to be mobilised in the Middle East, Chalissery believes that electric machines could find a role even in roughterrain and off highway applications if contractors can shift their perceptions of what is possible.

“People tend to think that unless your machine makes a heavy noise, it’s not strong enough. Also, when we say an electric machine, they are bulkier but much more powerful than a comparable diesel machine.”

“The power is there,” emphasises Whiteman. “It’s a question about how often can you charge it? How often do you need to charge it? Have you got the power supply on-site? And then which kind of battery is most appropriate for your product?”

One frequent criticism of electric alternatives, is the upfront cost to purchase them. Chalissery says that buyers should look at the lifetime cost instead when weighing up a potential first electric machine purchase.

“If I speak about my product, and not about the other brands although I think they are the same for pricing, lithium-ion machines are slightly, let’s say 5-7%, more expensive than a same-sized diesel machine. But, when you look at the cost of ownership, if you’re talking also a typical lifespan in a fleet of five or six years, it’s much less compared to the diesel machine. And when you use an electric machine your maintenance requirements are lower, and your breakdowns are less because most of electric machine use an electric drive.”

Drawing on his own extensive experience, Whiteman recalls a buyer in the UK who was event frustrated that he still needed to buy non-electric equipment.

“He said to me on a diesel machine there are 20 touch points, that’s 20 points that need to be checked regularly. You don’t have those on an electric machine,” he says adding that an electric equivalent typically only has four. “Or one. The charging point,” jokes Chalissery.

Both agree that although charging is an issue, it

is worth considering that charging only needs to be scheduled once a day, and often longer, with proper planning.

Whiteman explains: “They’re designed like that. Absolutely designed with that in mind. Of course in our industry, what is a full day’s work? Because when the platform is up, it’s off. So generally speaking we say you can get two days on a full charge.”

“I’ll give you some data. A 28m boom, across all brands, typically uses a 60 kilowatt engine to run. On an electric machine, a 28m boom typically uses a 40-kilowatt battery, and once fully charged, it can comfortably support you for two to three days. And to charge a 40-kilowatt battery, using a normal 7kW charger, like you a normal all charger, it takes five or six hours.”

Although charging is seemingly not the insurmountable issue it is often betrayed as (“in Europe they have over half of their machines electric, how do they get charged?”) If companies are prepared to work plugging in into their routines, electric machines still lack their champions in the market. Many end-users will cite early models with high failure rates have made them resistant to adopting the latest machines.

Chalissery believes in a vicious circle that some people will not be convinced until they have seen an electric machine perform. And they won’t see them perform, until they have taken the plunge. To counter that, Whiteman argues that the rental sector can have a crucial role to play in changing the mindset of end-users and get more electric machines on sites.

“It is vital. It is crucial. I am trying to give the rental guys the confidence to believe that electric power and AWPs can deliver. They can do the work. Because if you’re thinking, “I’m not sure if it can really deliver on rough terrain”, you’re not going to recommend it.”

“The power is there. It’s a question about how often can you charge it?

How often do you need to charge it? Have you got the power supply on-site?”

“With lithium batteries, you’ve got a steady output at a broad range”

The Rental Roundtable: Striving for Higher Utilisation and Better Mobilisation session was an opportunity for the delegates at the recent Access and Handling Summit in Dubai to take a special look at the rental scene in the region. The panel comprising Joe Keely, Executive Manager – AWP/ Johnson Arabia; Rob Cavaleri, Regional Training, Safety and Compliance Manager | Manlift Middle East; and Martin Newton, Technical Director for International and Middle East, Rapid Access was an absolutely top-level array of rental experts and veterans. Together the panel moderated by CMME’s Stephen White discussed how we can strive for higher utilisation and better mobilisation in the market through the critical rental channel.

Stephen White (SW): Joe, I’ll start with you, what are your thoughts in terms of where we’re at now in terms of the market?

Joe Keely (JK): Well, AWP is my specialty and I think the market is growing but maturing. We at Johnson Arabia, are still very heavily involved in construction and we see some maturity there and in some other markets, and industries, and sectors.

SW: There was a feeling after the Expo that we might see a drop off. But the market seems to have beem stronger than I think a lot of people thought.

JK: Yeah, I think it did slow, definitely, but for us, it has picked up in residential construction areas.

Saudi Arabia is obviously a big draw for equipment. But one thing I would say is that the UAE has had what I would call a second wave of construction if you describe its first wave as 2008 to 2011 with big ambitious projects. The second wave saw a lot of infrastructure for Expo of course. I think potentially now there is a third wave. With the legislation that the government is releasing, they’re attracting the smaller and medium enterprises, and there’s a lot of work in terms of logistics, distribution, smaller commercial areas. This third wave of construction is very good for us because we can work on the smaller projects.

Martin Newton (MN): I totally agree. Ultimately, being based throughout the GCC we see a lot of fluctuations in the market. But it’s relatively easy for us to mobilise across the GCC, which is very good. The market in the UAE is very good at the moment. There’s a lot continuity on projects.

Rob Cavaleri (RC): The UAE is the most advanced as far as maturity of the market. And that means it’s moving away from construction and more than in the other GCC countries into what we call the outreach acquirers of access equipment. We are needing to supply to alternatives to construction. Every year, you need to say, “Okay, what have you got in the fleet? What’s the market going to ask for?” Then you order more of that type of kit. It can be depending on the height or reach capabilities, and so on. We have approximately 30-40% currently in the UAE of electric machines. And I think it will take another 10 years before they get to 50% or above that.

The UAE is the most mature market in the region , says Manlift’s Rob Cavaleri, with a shift away from demand being driven by the construction sector.

“I think what we haven’t yet done is found a voice that talks about what we can do in terms of sustainability. There are still barriers between us and having that conversation”

SW: That’s quite low compared to other markets…

MN: Yeah, I want to go all electric but that’s a challenge at this time. Where I think we’ll go is more into a hybrid model, which will probably take another 10 years. And then we’ll be going to full electric.

SW: It seems quite slow compared to the rest of the world. Joe, what do you think?

JK: I think I do disagree slightly. I think it’ll be slower than the rest of the world. But honestly, I think because of the maturity and the projects getting smaller. If you look at, for example, the redevelopment of some of the existing areas, like Al Quoz or Minah Port, for example, they are established areas and I think they will be quicker to take on electric. And if you factor in the fact that we are now regenerating areas of Dubai and Abu Dhabi…

SW: While you’re right, we are seeing regeneration, but is the infrastructure there?

JK: By 2025 the RTA say that they will have an all-electric fleet of taxi vehicles and you’ve got the use of hydrogen fuels - I think there is a big project being finished in Abu Dhabi – so, I think that it will very quickly come up. I think it will slow, but I’m not sure it’ll be 10 years, I think it will be quicker.

SW: Martin, you are obviously dealing across region as well. How do you see the rate of progress elsewhere?

MN: Yes there are some big challenges and there are two different models but Saudi Arabia seem to be doing a lot of things as well (because of the Saudi Vision 2030 programme), not just with construction,

but also generally and how the country is changing. I have been going to Saudi for 20 years and it is a very big market for us. So we have an understanding of new regulations such as SABR and all the rest of it. I would like think we’ve been in there long enough now to actually know what we’re doing. But even we get caught out sometimes.

JK: I think the energy demand globally is going to change and there will be a shift. And this region has always been the centre of global energy when you’re thinking of

its exports. I don’t think that they’ll change that for their future plan. It’ll be the future of energy in terms of solar, in terms of nuclear, in terms of renewables. We’ve said that it might be slower than the rest of the world because of the infrastructure, but I think their ambitions will lead them towards being as fast as possible as they want to retain that area of expertise, which is energy.

SW: Rob, you’ve been in this market a long too. Are you seeing your customers’ habits changing?

RC: We see changes in the sales of equipment. And I think the larger projects which you see in other countries have different requirements, to a degree, on what they ask for compared to here. If you look at the UAE government’s own strategy, and we were at a sustainability centre in Al Quoz recently, I think it’ll be more than 10 years before they think about going fully into renewables and stuff like that.

SW: There is a lot digitalisation in the sectors that you guys are serving, do you you think that and other emerging technologies like AI are re-shaping this industry too.

JK: All of us as rental companies have only have one responsibility or one reason for existence - and that is to maintain the availability of a solution for the customers. AI and IoT will be fundamental in improving how well we can maintain equipment, how well we can make equipment available. IoT will help us with all sorts of inputs and data intelligence in terms of how that machine is performing, what maintenance it requires. And then AI plugged into that will allow us to forecast demand in terms of repair of that machine for demand in terms of where that machine needs to be deployed. Those two things will fundamentally change the way we look at availability and maintaining the equipment.

SW: Is utilising these technologies being driven in-house, or does this come from the manufacturing side and then you incorporate it into your own operation.

JK: A mix of both. There’s plaforms developed by every manufacturer. There’s also wide availability of the IOT products from other third parties as well. You can already get the great information from these systems in terms of maintaining your equipment. The AI element is still probably a little way off. But it exists.

MN: We have purchased some of these products and manufacturer products, and we just upgraded one to a new version, so we can see tracking of the information and utilisation. We can give that to the customer as a report. We can also see battery voltages… That is something that’s an on-going project

I want to go all electric but that’s a challenge at this time. Where I think we’ll go is more into a hybrid model, which will probably take another 10 years”Martin Newton has seen many changes in the Saudi market over the past two decades, but the Kingdom is now undergoing rapid change.

for us and we’re looking at rolling it out on all of our fleet this year.

SW: Sometimes it’s lost in sort of translation that you still own this equipment, so you want to make sure this equipment is being used in the best way possible. Getting data from the equipment actually out in the field is useful obviously for the guys using the equipment, but also for you to make sure it’s being used properly. I assume, you can go back and then channel that feedback to the customer?

MN: I think it’s very useful from both sides. One, from the customer-side. We have a couple of large customers that use the utilisation reports. And they can actually save money by saying, Actually, we don’t need that machine. From our data side, it is really useful to monitor the machines particularly the batteries, and tires, and things like that.

RC: Telematics-wise, we have actually approximately 90% of the fleet using telematics. Don’t ask me to list them! And it’s potentially a list of 25 benefits for the customers, such as how many hours until the maintenance is due. At Expo 2020 we could extensively control who uses the equipment. Are they competent or not? Are they trained or not? Rather than asking on the phone where their equipment is, the customer can see where it is. With features geo fencing, if the machine goes outside an area where it’s not supposed to be, us or the customer can actually make a call and say, “Where are you taking this piece of equipment?” Geo fencing is not extensively used, but it’s used by bigger projects with

multiple contractors on one site. You want to keep your machines secure especially when it comes to safety. We also have apps where customers can actually look at the type of machines that are available: the models, and their availability, for example.

SW: I also want to touch on the Year of Sustainability in the UAE. Are you guys actively working out how to approach it?

RC: So we have internal measures. Sustainability is a much stronger focus and so we have KPIs, for example, on what we

can do. We pick ones that we can do well on. And at the moment, we have a strong focus on the quality of education and responsible production and energy consumption in workshops. One of the important things that rental organisations should be doing is educating and improving the performance of the suppliers as well the customers and bring awareness to them. So you may not be able to do everything yourself, but you can certainly spread the message.

SW: Given where you guys sit in the supply of machinery, the power is in your hands in terms to a degree?

JK: Yes, but there’s definitely more collaboration that’s required in terms of the rental industry. You look at America, you look at Europe, you look at India, they’ve all got rental associations. We require leadership like that I think. Well, not necessarily leadership but collaboration. For instance, there is a lack of representation in terms of the equipment rental’s position within construction.

I think what we haven’t yet done is found a voice that talks about what we can do in terms of sustainability. There are still barriers between us and having that conversation.

And while we can open the door, I don’t think we are brought in early enough, I don’t think we’re consulted with, because we don’t have that collaborative culture with them or with each other. And I think that’s important. I (actually) believe they (the construction industry) are looking for that sort of collaborative body in order to have a conversation about what can be done sustainably.

“There’s definitely more collaboration that’s required in terms of the rental industry. You look at America, you look at Europe, you look at India, they’ve all got rental associations”Joe Keely says that there needs be much more collaboration betwen the equipment sector and other stakeholders as seen in other markets globally.

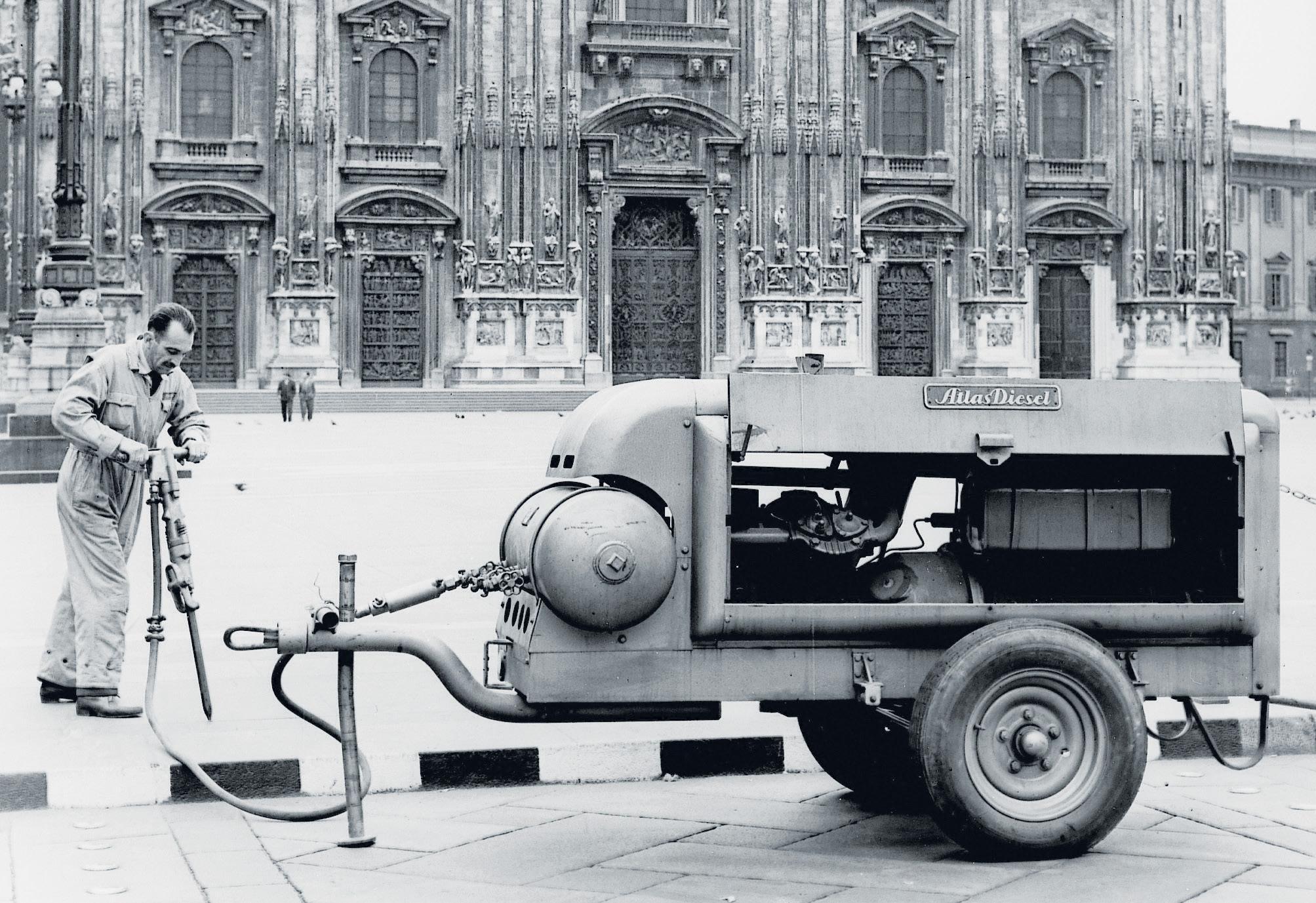

Compressors have been at the heart of the Atlas Copco Group’s success for over a century. Today it holds world-leading positions in many of industries.

“The world is always changing rapidly and companies that can follow along and contribute to the change will be successful. Atlas Copco is such a company, and it always has been”

2023 MARKS THE 150TH ANNIVERSARY OF THE ATLAS COPCO GROUP AND ONE AND A HALF CENTURIES OF PIONEERING INDUSTRIAL INNOVATION. STARTING WITH A SINGLE SWEDISH VENTURE, ITS HAS GROWN INTO AN EXPANSIVE GROUP OF BRANDS SPANNING THE ENTIRE GLOBE

Since the start in 1873 Atlas Copoc has strived to find new solutions to society’s challenges. The firm started by supplying products for the railway expansion in the late 1800s and from there expanded into compressors, tools and rock drills needed to industrialise the world. Today, it holds world-leading positions in many of the same industries, but also in completely new segments such as vacuum.

“Still, our purpose remains the same: creating a better tomorrow by empowering our customers to grow and drive society forward,” says the company in a new book detailing its history. “Throughout our history, our innovative spirit and our values – innovation, sustainability, doing business in an ethical way – have remained intact. However, most of all it’s about passionate people and their drive and ideas to find new and better ways to shape the future.”

In a planetary perspective, 150 years passes in the blink of an eye. For the people on that planet, though, the past 150 years have seen living conditions improve faster than ever before. A change propelled by the most remarkable developments in technology. In the process, humans themselves have also affected the world in unprecedented ways, for better or for worse. In 1873, the year that Atlas Copco Group was founded, the planet supported around 1.4 billion people. Today, it is home to more than 8 billion. Such growth could not happen without continuous technological development – but it also creates a whole new set of challenges.

The world has became smaller, the connections closer – including on an individual level. If railways and ocean liners had connected people and places in the 1800s, cars and airplanes now opened the world to more people. Globalisation has helped build material progress and mobility worldwide. Still, it didn’t bridge the difference between the industrialized world and developing countries.

The postwar years have proven successful for the company. Walther Wehtje, a previous department store manager, was now President and CEO and led the company in a more sales-focused direction. He didn’t neglect, though, to keep up the engineering expertise that was the company’s hallmark. One way to do this was to acquire other engineering companies, first domestically in Sweden, and then also abroad. The first strategically important international

acquisition was the Belgian compressor company Arpic Engineering in 1956. This also led to most of the company’s compressor production moving to Belgium.

The name Atlas Diesel had by now clearly past its best-before date. So, on the heels of the Arpic acquisition, the company changed its name to Atlas Copco. It replaced “Diesel” with an acronym of a Belgian sales subsidiary in French, Compagnie Pneumatique Commerciale.

As Atlas Copco, the company continued

to grow internationally, both through acquisitions and through inventive new processes. The so-called “Swedish method” for drilling, which allowed one man to operate a drilling machine where previously many were needed, brought the company global success during the 1950s. Another growth area was compressor technology, which the company and its customers kept finding new ways to use. Atlas Copco established factories and sales offices on continent after continent.

The oil crisis of the early 1970s and the following global recession of course meant restructuring and cutdowns in the company. At the same time, the crisis also opened up for strategic acquisitions. One such important purchase on the compressor side was French company Maugière. During the early 1980s, the company made several important acquisitions, among those Worthington Compressors.

Overall, this was another period of growth for Atlas Copco, which made the company the world leader in both rock drilling and compressed air. There was still untapped potential, however, in the field of industrial tools. Some key acquisitions helped Atlas Copco break into the important American, French, and British markets. One such acquisition was Chicago Pneumatic Tools, which was strong within the American industry and among car workshops. It made Atlas Copco the world’s largest manufacturer of compressed air tools and assembly systems.

More acquisitions came during the following decades, such as Desoutter Brothers Plc (UK), AEG Elektrowerkzeuge (Germany), and American Milwaukee Electric Tool (USA). They allowed Atlas Copco to both broaden its offering and strengthen its positions in various geographical markets.

The new millennium saw continued mergers and acquisitions. Two new key members of the Group were Edwards (UK) and Leybold (Germany). They brought longstanding heritages of their own and allowed the Group to form an extensive business in vacuum technology. In 2017, vacuum became a new business area of its own.

In 2019, Atlas Copco acquired 18 companies. It was a record that was thought hard to beat, but in 2022, the company completed 30 acquisitions. The Atlas Copco Group has grown to be a truly global industrial company, with a direct presence in over 70 countries and customers in more than 180. A primary driver for that worldwide footprint has been

a need and a willingness to operate close to its customers. It’s hard to offer good service in each market without good local knowledge and local experts. The result, especially after the past 50 years’ focus on strategic expansion, speaks for itself.

“The Atlas Copco Group has companies in some 70 countries. I have visited 50 of them. They were all different, working with widely differing local needs. Still, it always felt like coming home to Atlas Copco, wherever I went,” says Liselotte Duthu.

Duthu is a Group veteran with 36 years of service, 23 of those spent abroad. Her professional life mirrors the company’s globalization. She has been a manager in Sweden, France, Belgium, and China – all some of Atlas’ most important locations. She has also amassed a wealth of experience working with local expertise, not least in China.

When Liselotte became Vice President of Atlas Copco’s holding company in Shanghai in 2012, with responsibility for legal and administrative decisions for Group operations in China, the Group had about 30 companies in the country. The majority had non-Chinese general managers. Ten years later, almost all companies had Chinese general managers, and out of 6,700 employees, less than 30 were foreigners, mostly in specialist positions.

“Seasoned Atlas Copco managers of course come with Group experience. But local general managers have better contacts

with local authorities,” says Duthu. “Also, employees prefer native managers, because they know they stay longer than expats.” The globalisation journey has been a constant in the company’s history – but it gained extra speed when the giant China market opened. Liselotte joined the company at about the same time. Back then, Atlas Copco had 63% of its sales in Europe and the Middle East, 24% in the United States and 13% in Asia. Today, the distribution is closer to 30/30/40 percent

and with almost only local employees in each market.

The first licensing agreement in China was signed in 1983, with a compressor factory in Wuxi, 21 kilometers west of Shanghai. Ten years later, it was time for a first joint venture: a factory with Nanjing Construction Machinery Plant. More agreements and factories followed. The market was – and is – huge, and Atlas Copco believed, again, that it needed a local presence in order to be competitive. This is a strategy that the company continues to follow.

“Bengt Kvarnbäck, who was Business Area President for Compressor Technique, stubbornly pursued the investment in China,” says Liselotte. “It was farsighted, because it is among the best things that the company has done.”

Today, Asia accounts for over one third of Atlas Copco Group’s operations, with China as the most important market. Another reason to be there is to keep an eye on the fast-growing Chinese competitors. Atlas Copco Group believes it must meet them locally, head-on, in order to keep the company’s leadership position and secure continued growth.

All in all, Atlas Copco Group today has production in around 20 countries, 97% of its employees outside Sweden, and more than 5,000 significant subcontractors.

In 2007, Liselotte Duthu was asked by Ronnie Leten, then head of Compressor Technique business area and later President and CEO, to project-lead the creation

“Today, we are proud to be a leading force in the global energy transition, supporting emerging market trends in the shift away from fossil fuels”

of the Compressor Technique Service Division. This led to better focus and higher profitability in both production and service – and also to even more globalisation within the company. Because with increased service came, once again, closer contacts with the customers and thus an even better understanding of the local conditions.

Product demands also differ. In Asian countries, the requirements for compressors could be different than in, for example, European countries. To understand what customers need, local production is required.

In recent years, the Atlas Copco Group has built up more regional supply chains, as opposed to global chains. This has been done as a response to increased protectionism between countries, but even more so in order to stay close to customers. In the history of globalization, it is clearly a new phase. It is a phase, though, that Liselotte Duthu will not be a part of since she recently retired. She intends to still follow the company’s development closely and is convinced that it will be a favorable one.

“The world is always changing rapidly and companies that can follow along and contribute to the change will be successful,” she says. “Atlas Copco is such a company, and it always has been.”

Compressors have been at the heart of the Atlas Copco Group’s success for over a century. The Group has succeeded in transforming compressor technology many

times over by completely reimagining the way compressors are designed and how compressor R&D-teams work. This is now sparking yet another revolutionary shift with digital twin technology.

Atlas Copco first got into the compressor game in 1904 when it started making piston compressors in-house. Since then, it has played a major role in advancing compressor technology to meet new industry needs – a role that the Atlas Copco Group is intent on maintaining. Today, compressor technology

at the company is being reimagined – once again – by the Antwerp-based team led by Guy Mareels, Vice President Engineering at the Oil-Free Air Division.

“Atlas Copco has repeatedly made breakthroughs in oil-free air ever since the first oil-free series in the 1960s,” says Guy, who joined the Atlas Copco Group 15 years ago, starting out as a calculation engineer running simulations. “We are now making another quantum leap in energy efficiency with a new generation of oilfree screw compressors. I spend much of my time in meeting rooms as I stimulate co-breeding across teams, but my favorite time of day is when I get out and see the machines. After all, I’m still an engineer at heart and enjoy helping the product teams stay on the right track.”

Reinventing existing products is core to the Group’s operations. In the 1950s, Atlas Copco made two key moves that transformed its compressor business to meet new demands. The first was purchasing the rights to Swedish inventor Alf Lysholm’s screw compressor in 1954, a technology that greatly increased compressor capacity. The second was the acquisition of Arpic, a highly efficient Belgian compressor factory in 1956.

After designing the company’s first aircooled portable compressor in 1952 in collaboration with engineer Karl-Erik Hilfing, Iwan Åkerman relocated to Antwerp in 1956 to head up R&D at Atlas Copco’s new base for compressor operations.

A decade later, in the 1960s, Atlas Copco became the first company in the world to present a transportable piston compressor supplying oil-free compressed air. A parallel breakthrough was the launch of a stationary oil-free compressor, the Z series. It was named Z because it felt like a development “at the end of the alphabet” as far as you could imagine innovation. The Z series made compressed air viable for new markets, including the textile, food, and medicine industries.

“Today, we are proud to be a leading force in the global energy transition, supporting emerging market trends in the shift away from fossil fuels,” Guy explains. “For instance, the electric car and battery industries rely heavily on large amounts of compressed air. Another emerging market is the maritime industry, where our lowpressure turbo and screw blowers can be used for hull lubrication to increase ship fuel efficiency. We also have a new generation of compressors rolling out to empower low-carbon utilities and are working on higher-pressure solutions for compressing

“Energy efficiency has always been a strong focus and now we’re prioritizing it like never before”

hydrogen and CO2, which are poised to be a big wave of the energy transition.”

In the 1970s a company team set out to bring about the next phase in compressor technology. Their work initially led to making several compressor parts more energy efficient, especially motors. This laid the foundation for taking the promising variable speed drive (VSD) technology to new levels, making it even more efficient and also better adapted to customer needs.

Atlas Copco wasn’t the first company to introduce VSD technology. However, the Group played a major role in bringing it to market on a broad basis. The company’s VSD prototype was completed in the late 1980s and was launched on the market in 1994, rapidly becoming a bestseller and driving enormous energy savings. In 2000, the team working on VSD won the John Munck Award.

“VSD was a game changer,” says Guy, “and now we’ve recently leveled it up to VSD+ with two-stage compression. By powering each element with a separate motor, this further improves energy efficiency, performance, and uptime.

Just as the original VSD was combined with motor efficiency improvements, we are now also introducing more efficient motor technology to go hand in hand with VSD+. The two types of new and improved VSD+ motors are the permanent magnet

synchronous motor and the synchronous reluctance motor. At the Atlas Copco Group, energy efficiency has always been a strong focus and now we’re prioritizing it like never before to do our part to help our customers meet unprecedented sustainability and energy challenges.”

During its 150 years, the Atlas Copco Group has reinvented itself many times, at both the Group and product levels. It went from rail to compressed air and diesel motors at the turn of the 1900s, and then

Today’s Atlas Copco has operations on all continents except Antarctica. Its first non-Swedish operation was otherwise a sales office in 1913 in Russia, which at the time was an important business partner for many Swedish companies until the Russian Revolution. Instead it was in the United Kingdom that the company’s global expansion started in 1919. Its first African establishment was a sales office in Kenya in 1936, but it was in South Africa that the company began proper operations. As early as 1922, Atlas bought shares in Delfos, a drill bits and spare parts manufacturer, before eventually becoming sole owner.

Across the Atlantic, Canada became the company’s gateway into North America. In 1948, it introduced the Swedish method of rock drilling there. The company managed to conquer half the market in just a

couple of years during the 1950s.

In 1950, Atlas Copco established itself in Australia. The arguably oddest story to emerge from that market is about…a dinosaur. During digs in the 1980s, a number of bone fragments were found from several new and previously unknown species.

Atlas Copco had lent equipment to the excavations and, as thanks, the paleontologist named one of the new species Atlascopcosaurus loadsi. (“Loadsi” after Bill Loads, Atlas Copco’s manager in Victoria who was personally involved in the project.)

The first South American operation for Atlas Copco was a sales office in Peru in 1950. This was followed by Chile in 1954, Brazil in 1955, and Argentina in 1969. That year also saw the formation of the Andean Common Market (Ancom) between countries in the western parts of South America. Within Ancom, each country was

transformed again from Atlas Diesel to Atlas Copco in the 1950s. More recent examples are the creation of the Vacuum Technique business area in 2017 following strategic acquisitions and the spin-off of the Group’s long-time mining equipment operations into Epiroc in 2018.

Building on that legacy, the company is now completely reimagining the way engineers work with compressor technology. With connected, advanced telemetry from compressors, and digital twin technology, Compressor Technique engineers can now see exactly how machinery is being used by customers out in the real world.

In 2007, Liselotte Duthu was asked by Ronnie Leten, then head of Compressor Technique business area to projectlead the creation of the Compressor Technique Service Division.

“I’m excited about all the gains we’re seeing from our digital twin deployment,” says Guy. “For instance, we can leverage the data to discover issues before the customer even notices them – something that was unthinkable five years ago. The digital twin data is also a highly valuable tool for identifying sales and service needs. Young engineers joining us now will probably wonder how it was ever possible to design products without all this data. This is only the beginning, too. Imagine the possibilities in the future when customers can connect their ecosystems to our digital twin and open a whole new world of data-driven compressed utility room operations.”

assigned production of certain industrial products, which could then not be manufactured in any other Ancom country. Bolivia was given the manufacture of rock drilling machines and compressors – and chose Atlas Copco as its partner. In the spring of 1976, Atlas Copco Andina opened a completely new factory in the capital of La Paz. With its approximately 90 employees, it became one of the largest mechanical manufacturing industries in the country.

In 1960, Atlas Copco opened a sales office in India, after many years of selling through an agent. Two years later, it opened a newly built factory and soon became a significant supplier on the Indian market. When the Indian government passed a law in the 1970s mandating that all foreign companies must have majority Indian ownership, many international companies chose to leave the country.

Atlas Copco remained, though, now with fellow Indian owners, following a company tradition of remaining in established markets to take care of existing customers.

China first saw Atlas Copco products back in the 1920s. It wasn’t until 1983, though, that the company signed its first license agreement, this with a compressor factory in Wuxi, west of Shanghai. Two years later, Atlas Copco opened its own representative office in Beijing. In March 1993, Atlas Copco entered its first joint venture with Nanjing Construction Machinery Plant to manufacture and sell drilling rigs.

China has become one of Atlas Copco’s largest markets for mid- to large-sized oil-free compressors. In 2022, Asia/Oceania accounted for 39%, the Americas for 29%, Europe for 27%, and Africa/Middle East for 5% of the Group’s revenue.

The need for power is global and it is growing. From dense urban cities to remote communities, operations and industries of all types require robust, reliable, flexible and fully integrated power systems, that are available on demand.

Cummins Power Generation has looked beyond today’s challenges to help you meet your future needs by developing the next generation of power – an ever-expanding range of power system solutions that are reliable, flexible and user friendly. Supported by next-level global Cummins sales and service support that ensures you’re covered no matter where your business takes you.

Learn more at cummins.com/generators

FOR A WORLD THAT’S ALWAYS ONTM

The latest releases from the world of construction machinery.

How off-highway tyre gurus BKT are going to double their turnover.

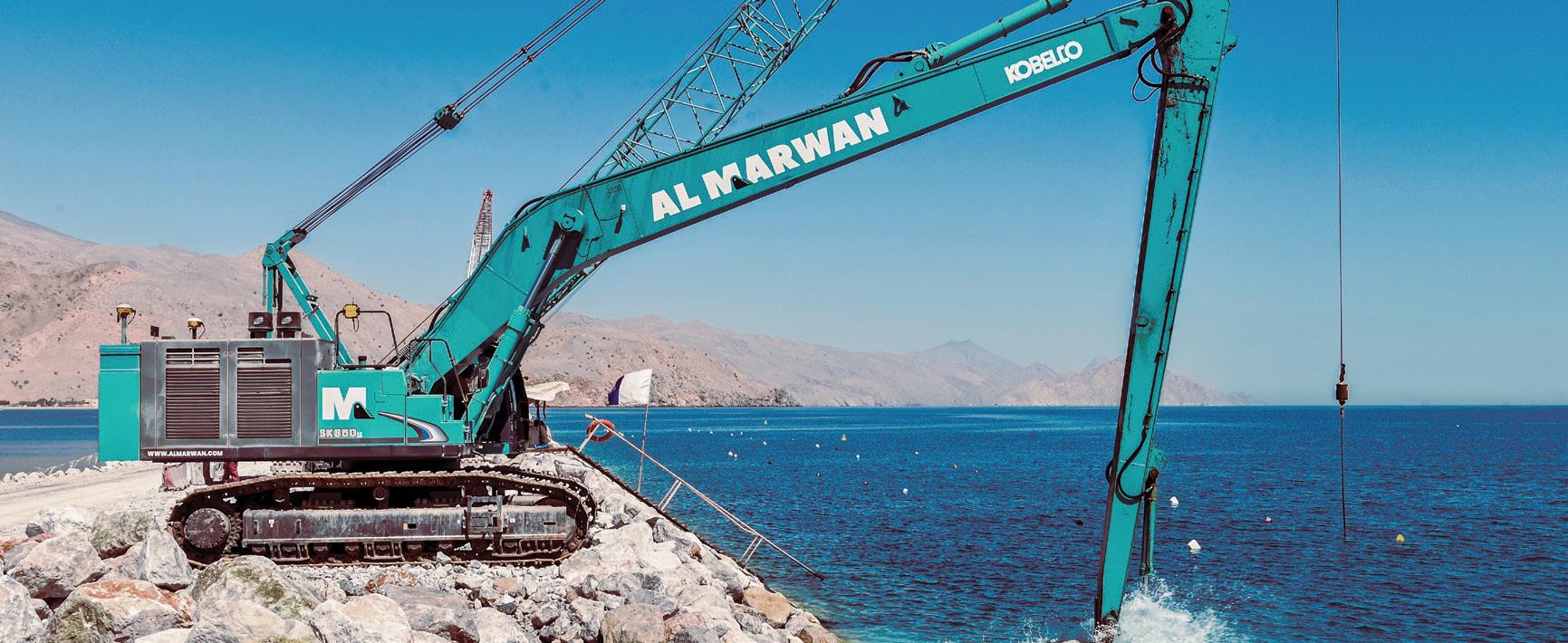

Al Marwan talks offering new service options across the region.

Seven tips to take care on site.

40_LUFFING LIFT COMING FOR THE CRANE MARKET

Luffing jib crane demand set to rise to a quarter of all sales.

connection, or via any gen set unit, in case there is no connection to the grid available.

The 61sT (55t) equipped R5e with a capacity up to 440 sT/h (400 t/h) is very mobile and can be transported in one piece, even equipped in closed circuit. The double deck pre-screen (7’x3’) (2.200mm x 1.000mm) ensures perfect screening and the material can be stockpiled by the side conveyors, or can go via the crusher bypass.

TRAILER OFFERS ENHANCED WEIGHT DISTRIBUTION OPTIONS AND A REINFORCED DECK FOR GREATER VERSATILITY.

Talbert Manufacturing’s 60CC-RC trailer, offers enhanced weight distribution options and a reinforced deck for greater versatility to meet load requirements in a variety of states. The fixed four-axle close-couple trailer incorporates an option to add a fifth axle for improved weight distribution to meet load restrictions in some markets.

Talbert recently exhibited the custombuilt 60CC-RC trailer during CONEXPO.

“Trailers are often an afterthought, but Bill Miller Equipment recognizes that purchasing a trailer that is custom engineered to meet ever-changing weight and height requirements is an investment that will put them ahead in the long run,” said Troy Geisler, vice president of sales and marketing for Talbert.

It features a ratchet gooseneck design and a 28ft deck length with a 114in swing radius, and a 24in flip-up and removable gooseneck extension for a 138in swing radius. The deck incorporates a 9ft, 6in-wide raised center deck with capabilities for an additional 4ft reinforced beam deck and 6ft raised center deck inserts. With a 60-ton capacity of just 13ft and with four axles close-coupled.

THE R5E USES ON AVERAGE 173 KW WHEN POWERED FULL ELECTRIC OR AROUND 10 GAL/HOUR (40L/H) WHEN DRIVEN VIA THE DROP OFF DIESEL ENGINE/GEN SET.

Keestrack says that the range of machines on display at CONEXPO 2023 event highlighted how it guarantees “sustainable performance at the lowest cost per produced ton”. During the Las Vegas show, the Texasbased manufacturer of mobile crushing and screening equipment showcased its extensive product range, including the completely newly designed R5e impactor of Keestrack is a full electric plug-in. It also has a plug-out connection to power additional equipment. The impactor used in aggregate production, recycling, quarrying and mining can be powered via mains

440t/h

The impact crusher with an inlet opening of 31”x41” (800mm x 1.050mm) (HxW) is driven by a 200kW electric motor and drives the rotor, with a width of 39” (1.000mm) and a diameter of 50” (1.260mm), with an extremely high mass moment of inertia, which gives high productivity and stability. The 2-deck precision screen, 15’7” x 5’ (4.760mm x 1.500mm) can be placed in closed circuit. The middle and fine fraction can be stockpiled as an additional option. The swivelling oversize conveyor can easily be changed to a stockpile conveyor if wanted.

The R5e shown at Conexpo has a drop off engine/gen set of 5sT (4,5t) which can be placed either on the chassis of the machine or it can be placed besides the machine, connected with a power cable. Being placed in a less dusty and vibrant environment it functions as a backup when there is no connectivity to the grid available.

WHICH IS ALSO A FULL ELECTRIC PLUG-IN

Despite its high performance R5e is very mobile and can be transported in one piece

MACHINE DEMOS NEW TECHNOLOGIES TO HELP OPERATORS WORK MORE PRODUCTIVELY AND WITH MORE SPEED, PRECISION AND CONSISTENCY, SAYS VOLVO CE

Volvo CE provided the first look at a pre-production model of its new EC500 excavator at the CONEXPO trade show in Las Vegas, North America. This heralds a new generation of excavator, with improvements across cab design and operator interface, safety and productivity.

A successor to the Volvo EC480E, the EC500 is a new 50-ton crawler excavator for the toughest applications, from building and construction, road construction, utilities, quarrying and aggregates to agriculture and landscaping and is the ideal partner for the Volvo A25G to A35G hauler. The biggest change can be seen in the cabin design and styling, with new layout and features including highdefinition co-pilot screen, keyless engine start, wired and wireless smart phone charging and new work mode switch.

A valuable new addition, Volvo Smart View with Obstacle Detection delivers significant safety benefits. Operators enjoy a 360° view thanks to an improved camera system and new radar detection system which provides automatic alerts when the excavator approaches any obstacle, identifying and classifying them as an object or human, and allowing the operator to take remedial action. Three-point access guard rails and a foldable top handrail for transportation are important new safety features.

This next generation of excavator is also set up to access a range of machine options to help operators complete their tasks faster, more easily and more safely, as well as boost their performance and productivity. These include the operator coaching app, Volvo Dig Assist - a suite of tools designed to help deliver excavator accuracy by eliminating the need to manually mark out a site and check depths and grades - and Volvo Lift Assist, all accessed via the Co-Pilot

screen in the cab. Volvo Active Control, an automated grading system and part of the Dig Assist suite of tools, will also be available for the first time on an excavator of this size.

Sejong Ko, Product Manager Excavators at Volvo CE North America, said: “With the EC500 and our next generation of excavators, we are utilising new technologies to help operators work more productively and with more speed, precision and consistency, to help them get the job done every time.”

The fixed four-axle closecouple trailer incorporates an option to add a fifth axle to meet load restrictions

Increased cooling capacity means the EC500 can handle the most extreme weather conditions and the excavator also benefits from longer service intervals – from 2,000 to 3,000 hours - for the hydraulic oil and filter, bringing both cost savings from reduced maintenance requirements and increased uptime. This means the customers’ machines stay out on the job site and work their best for longer and has a positive environmental impact without compromising on performance.

WHY GET THEM?

BASED ON THE NOTABLY RELIABLE AND DURABLE PC800LC-8, THE PC900LC-11 OFFERS MAJOR DESIGN ENHANCEMENTS COMPARED TO THE EARLIER MODEL.

Built for tough jobs that require high performance, the Komatsu PC900LC-11 excavator is a versatile machine. Designed for heavy construction, demolition, material handling, deep sewer, water, large mass excavation and mining/quarry, the 842 HP PC900LC-11 featured in Komatsu’s booth at CONEXPOCON/AGG 2023.

Taking productivity to a new level, the PC900LC -11 offers increased bucket and lifting capacity and higher performance with: Up to a 40% increase in productivity; 25% more arm crowd force; and 12% more swing torque Based on the notably reliable and

durable PC800LC-8, the PC900LC-11 offers major design enhancements compared to the earlier model. The new counterweight removal system helps make moving this large machine easier, and the boom configuration reduces transport height. A new service pass through area allows easy access to filters, oil level checks and sample ports. The major structures, booms and arms, with a redesigned revolving frame, were engineered to increase longevity.

To help operators improve situational awareness, tools such as the KomVision camera system come standard on the PC900LC-11. KomVision is a 360-degree monitoring system that uses six cameras for a real-time view of the surroundings. Smart Construction 3D guidance and payload monitoring are other available options.

At the show, the PC900LC-11 was displayed with Smart Construction Retrofit, an “affordable guidance” kit that gives operators in the field and managers in the office access to both 2D and 3D design and payload data to help drive accuracy, control load volumes and improve operations. Easily installed by a local Komatsu distributor, this technology upgrade is designed to improve grading performance and help drive productivity and profitability.

OUTSTANDING CONFIGURATIONS, FEATURES, QUALITY, EASE OF USE AND DURABILITY WILL MAKE THEM AN ASSET FOR THE REGION’S CONSTRUCTION OPERATIONS.

New Holland Construction and its dealer in the UAE, United Al Saqer Heavy Equipment LLC are launching the first ranges of the brand’s heavy line equipment in the Middle East region, the New Holland E215C Excavators and V110D Compactors, “strengthening its offering in the market,” it said in a statement. The outstanding configurations, features, quality, ease of use and durability will make them an asset for the region’s construction operations, added New Holland. The machines themselves are designed for tough applications such as quarrying, road works and earthworks, as well as general construction jobs.

The Excavator features a fuel-efficient FPT engine and a new cab design that provides a comfortable and safe environment with exceptional all-round visibility. According to New Holland, the “remarkably low” vibration and ergonomically designed seat with 8 different adjustments offer superior operator comfort and safety on long workdays. The 6-cylinder, electronic fuel injection engine delivers a highly fuel efficient performance. The high power reserve reduces transient times, making the hydraulic system immediately reactive to any load. It also comes with built-in serviceability, reliability and smooth control resulting in higher productivity and maximum uptime.

Pre-production model gives operators a 360° view thanks to an improved camera array

A diversified and rigorous testing process is essential to ensure a compressor can live up to quality standards and withstand the tough conditions of construction landscapes. New, updated, or repaired portable air compressors should be put through performance testing, which includes a leak, strength and temperature test. Tests cover a lifespan of use and replicate all the environments (f.e. low/high altitudes, low/high temperatures or dusty conditions) compressors might operate in to prevent setbacks in any eventuality.

Toughness can be optimised through adopting recent developments in material innovation. Atlas Copco portable compressors, for instance, feature canopies made using linear medium-density polyethylene (PE) HardHat, allowing them to be corrosion resistant, maintenance-free, and virtually indestructible. The canopy has been tested by both engineers and customers, who have dropped rocks and rubble on it – and it hardly suffered a scratch.

For portable air compressors to fulfill their tasks, they need to be able to withstand a broad range of heat and pressure levels. They should ensure long-lasting performance in every tough temperature you can imagine, from a freezing temperature of -20°C up to a tropical 50°C. A tough portable compressor should feature high-functioning cooling, enabling them to optimally perform in sweltering, dusty underground conditions. They also undergo full footprint data tests to track flow and pressure optimisation, contact surface temperature and starting capability.

Climate and environment are ever-changing variables in a portable compressor’s life, hence an inability to adapt will quickly affect machine performance. A truly reliable compressor can weather any terrain, and can continuously perform in high altitudes, snow, mud or rain. The most robust portable air compressors are designed, tested and certified with the most demanding conditions in mind, even in outdoor monsoon weather conditions.

Operators should feel assured that their compressors can perform reliably without putting themselves or any party at risk. An expertly crafted portable compressor will continue to operate safely, no matter how much strain it endures. Verified safety reports and testing documentation are available online for mant pressure components, allowing for absolute transparency and reassurance. All units are also equipped with digital panels to inform users about the status of the machine while operating.

To complement the machines’ physical resilience, ongoing checkups ensure that they remain tough enough to withstand all their arduous tasks. Atlas Copco’s teams consistently monitor its compressors using advanced FleetLink technology, to capture live data and oversee efficiency, but also offer various service plans to cater for any client concern. Tough machines are resilient enough to have a lower maintenance service interval. Atlas Copco’s electric portable air compressor range for example only needs maintenance every 2000 hours.

A hint as to how tough your portable air compressor is can be found in how much downtime it accumulates throughout the year. The robustness of the design and use of high-quality durable components are crucial for your machine’s uptime. A portable compressor that is built to work in extreme and challenging conditions will automatically have greater uptime and longer lifetime.