QUALITYGRAPHICSWITHOUT COMPROMISE

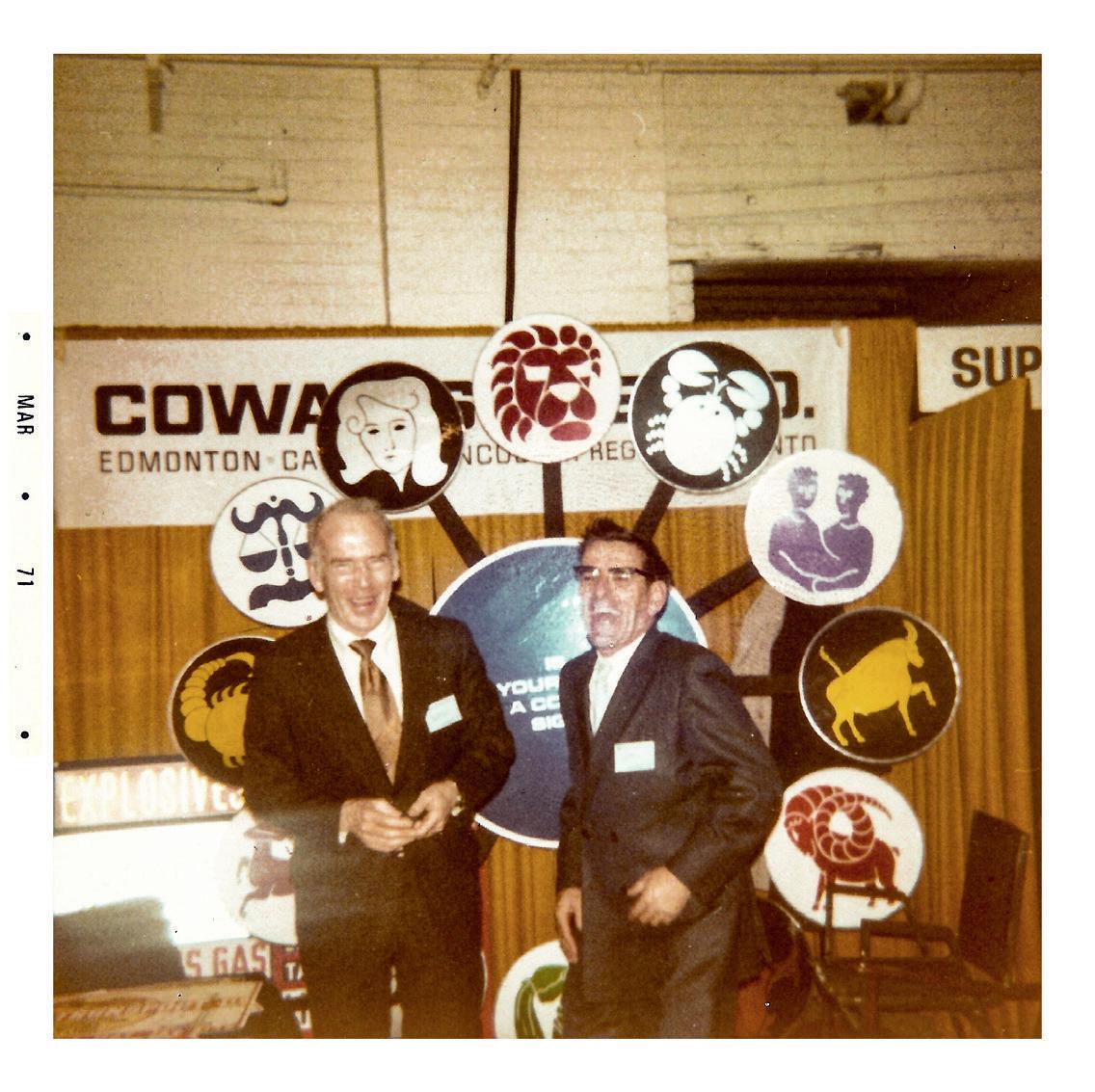

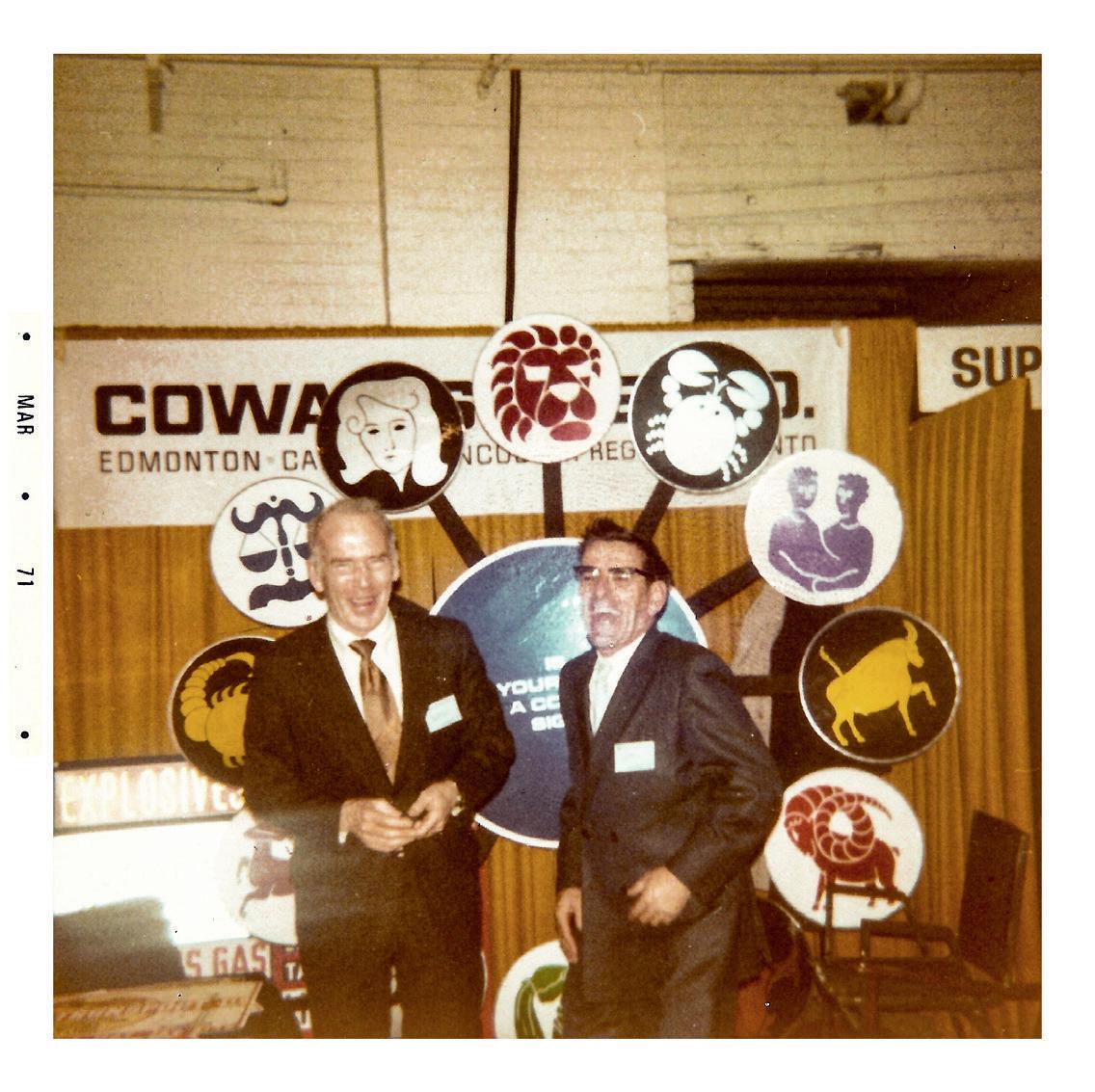

It wa s 1 945, and the b oys were coming hom e from th e war—l ooking for j ob s and ways to forget th e vagari e s of war. Muri el MacMi l lan was a young l ad y at Wood ward’s in d owntown

the weeke nd s . S he n o ticed that at the gam es, ma ny m en wou ld ma ke homemad e p enna nts to wave and sup port th ei r team s. A lig ht went on, and s he went to th e l ib rar y to le arn how to ma ke t he m and ta lked to her b oyf riend about how to s el l t he m.

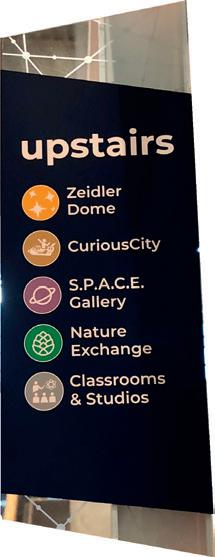

gir lf ri e nd was p roposing . So he re gi stered th e compa ny as th e C owan Cres t Com pany an d s tarted pri nting p enna nts. In s ea rch of mo re pro e products , they exp and ed to it ems li ke bronzing ba by s hoe s, wooden wall hanging s, and pri nting on ti e s, to nam e a few. This eventual ly le d t he C owan compa ny to focus on d e ca ls and ve hic l e markings in 1955, wh ic h remain a ma jo r p art of Cowan’s product l ine .

Muri el ’s b rot he r, Don, joined t he compa ny in 19 51 and p urchas ed a p art o f th e bu s ine ss in 1969. I n 197 7, he becam e t he sole own er.

In 1 98 5, after Don’s sudden pas sing, th e compa ny’s own ers hip shifted to six o f th e s even chi ldre n and t he com pany’s ma tria rch , Ruby—all of wh om wor ked fu ll time at the bu s in es s. The se were i nteres ting and exciting time s! The com pany co ntinu ed to g row

20 07, h e p urcha se d t he remaining s ha res in th e compa ny. W it h hi s s ta being his g reat es t ass e t, the compa ny co ntinu ed to g row, and in 20 16, the com pany m ove d i nto its cur rent

the p res id ent of th e o rganiz a tion

In 2 0 23 , Indu s trial G rap hic s in Calgar y be came a part of the Cowan Graphics fami ly.

To thi s day, Cowan Grap hi cs remain s a fami ly-owned busines s wit h an e m ph asi s on trea ting sta li ke p artn ers through pro t-sh aring and ad vanc e me nt wit h in th e compa ny.

EDMONTON

4864 93 Avenue N.W.

Edmonton, AB T6B 2P8

Ph 780-577-5700

Fax 780-577-5701

sales@cowan.ca CALGARY

#5565 - 56 Avenue S.E.

Calgary, AB T2C 3X6

Ph 403-233-9200

Fax 1-866-372-9078

salesc@cowan.ca SASKATOON

801A - 47 Street East

Saskatoon, SK S7K 8G7

Ph 306-652-9988

Fax 306-652-9962

saless@cowan.ca

Ph 1-866-372-9078

salesv@cowan.ca

• Humidity & Temperature Controlled

• Over 160 Employee

• 80 Years of Manufacturing

• Robotics Automation

• Over $10 Million in Equipment

• 24 Combined Digital/Screen

We currently are manufacturing out of four facilities: Delivering and supplying to multiple markets: small, corporate branding services such as Retail Signage, Promotional Products, Decals, Fleet Graphics, and Architectural Signage. We work closely with our manufacturer partners to ensure that new development in raw materials comply with our strict quality requirements and expectations prior to introducing them into the marketplace. Meeting and exceeding expectations in quality, service and delivery is our commitment to you, our respected customer.

/Dye Sub Printing Lines

• 13 Cutting Lines

• 10 Finishing Lines

• 6 Laminating Lines

• 4 Welding Lines

Our Commitment Is To Reduce Our Carbon Footprint.

Our dye sublimation process involves turning a solid directly into a gas. This process requires no water waste. Now, compared to screen printing for example, screen printing uses large amounts of water, which results in heavy water waste. Dye sublimation is an environmentally conscious choice for graphic solutions especially when combined with recycled polyester fabrics.

We have eliminated the use of harmful chemicals associated treatment plant for processing.

Our digital presses do not require plates and solvents (to clean the press between each job) and storage of paper itself, as you are cutting down trees to begin with.

The digital printing carbon footprint is far lower than traditional press work. In our digital print area, we have

mercury vapor curing methods. This is a large savings considering we run these presses on average 16 hours per workday.

being eco-friendly water based. All residual waste ink and cleaners are drained into enclosed containers and sent to a local waste company for processing.

We have replaced polyethylene print material wherever possible (determined by our client’s needs) and use

PROCESS OPTIMIZATION:

Historical knowledge plays a crucial role in process optimization, alongside utilizing the most advanced printing and converting equipment available in the industry. These technologies help streamline production processes, leading

•

•

Image max – 100% recyclable with 30%

recyclable product in this category of EPVA, making it the logical choice over any other

• Coroplast – uses polypropylene copolymers – recycles at the end of their useful life into

• Natural Packaging Corrugate –

•

• Falcon board – 100% recyclable, 95%

Our commitment is to minimize our carbon footprint as much as possible. Therefore, we continuously seek ways to reduce our environmental impact when supplying our products and services. We consider methods such as reusing and recycling wherever feasible. Currently, we manage waste by separating cardboard and paper containers, using trash compaction, and disposing of ink responsibly. Whenever possible, we sort waste plastics programs.

SUBSTITUTION, STANDARDIZATION, COST SAVINGS, AND DATA SHARING:

Cowan will, whenever feasible, make recommendations to substitute or standardize substrates. These recommendations are based on historical insights while also considering factors like costs, carbon footprint, and risk assessment. Cowan provides turnkey solutions, and

value-added services, particularly regarding data analysis on our customers and the substrates used.

gather this data and share it with our customers. This comprehensive analysis provides historical usage information, highlights any concerns or challenges that may have arisen, and demonstrates the cost savings achieved through a standardized production approach. Cowan predetermines times for these reviews over a 12-month period.