2025-10-20

Classification: Open

2025-10-20

Classification: Open

Incidents occurring at customer sites are to be reported through the Company's 24/7 customer service number +47 55 22 95 01

Give a short and accurate statement with the following information:

• WHO - you are

• WHAT - has happened

• WHERE - has it happened

• The extent of damage

We prioritize safe work execution. Organizational, operational, and technical measures are put in place to safeguard our people, processes, and products.

When conflict arises between operational, economic, and safety issues, safety shall always have the highest priority.

All employees are responsible for prioritizing safe work procedures and execution for us to reach and maintain our zero serious incident ambition.

Together we shall establish an HSSE culture that makes us proud and helps us perform our best when delivering our work tasks.

We acknowledge that risks occur in our operations. Assessment and mitigation of risk shall be done as part of our work planning and execution. Stopping unsafe workplace behavior or dangerous conditions is everyone's responsibility.

This handbook provides a summary of HSSE guidelines including safe working instructions for all employees. Our formal requirements and regulations can be found in our governance documentation.

Let us create a safe and productive workplace together.

Safety is everyone's responsibility, if you see something, tell someone and DO something.

Our Values

We drive Innovation by developing industry leading technology.

We act with Integrity by being honest and ethical in everything we do.

We are Team Players and foster an open and collaborative environment. We are Passionate about health, safety, security and environment.

We commit to this by:

• Being passionate about our safety and the safety of others.

• Providing the best workspace for our people across the seven seas.

• Optimizing our resource management and organization across all departments.

• Acting with integrity to ensure compliance with all relevant laws and regulations, as well as our industry’s best practices.

• Maintaining our zero serious incident philosophy through innovative solutions.

• Being team players and driving continuous improvement through health and safety programs, procedures and initiatives.

• I take the time needed to understand the tasks I am about to perform.

• I always assess risks, identify requirements, and procedures before starting any work.

• I act when observing unwanted actions and conditions.

A good HSSE level prevents illness and injuries. It will strengthen the work environment and improve well-being.

If hazardous conditions are identified, everyone is responsible for addressing the situation and ensuring risk-reducing measures.

How well we succeed in HSSE work depends first and foremost on individuals and how the various roles and tasks are exercised. HSSE is a line responsibility. Be proactive and ensure correct risk understanding and awareness. All employees are responsible for registering observations and HSSE incidents to ensure learning and continuous improvement.

Leaders must ensure high HSSE standards, identify issues, and implement necessary measures. Prioritize safe work execution by allocating sufficient resources to the organization.

/ Health and Safety Representatives (Joint Health and Safety Committee – Canada & US)

This is the employees' representative in working environmental issues, and important roles for identifying hazards, inspecting the workplace, participating in investigations and making recommendations on safety measures.

Accidents can often be prevented through the implementation of multiple layers of defense, known as barriers. To ensure workplace safety, efficiency, and compliance, we must first identify hazards and then implement barriers to mitigate risks.

Hazards can be categorized into several types such as: Physical, Chemical, Electrical, Ergonomic, Organizational & Psychological Hazards.

To mitigate identified hazards, barriers, including organizational, technical and operational measures, should be implemented. By layering these barriers, the risk of hazards causing harm is minimized. If one barrier fails, others can still block the hazard from causing an accident.

Policies, procedures, and management strategies to reduce hazards, such as:

• Training and preparation

• Clear policies and instructions

• Strong safety culture

Physical or engineering controls that prevent exposure to hazards, such as:

• Machine guarding and design

• Personal protective equipment (PPE)

• Correct tools

Day-to-day practices and controls to prevent hazards from becoming incidents, such as:

• Work instructions (WI)

• Lockout-tagout-testout

• Planning (SJA, hazard- and risk analysis)

• Emergency preparedness

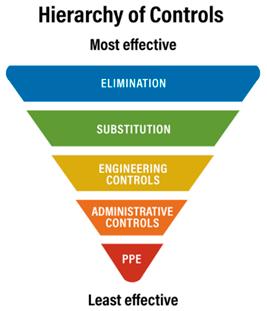

The hierarchy of controls is a method of identifying and ranking safeguards to protect workers from hazards ranked from the most effective to the least effective.

• Elimination makes sure the hazard no longer exists.

• Substitution means changing out a material or process to reduce the hazard.

• Engineering controls reduce exposure by preventing hazards from harming workers while still allowing the workers to do their jobs.

• Administrative controls change the way work is done or give workers more information by providing workers with relevant procedures, training, or warnings.

• Personal protective equipment (PPE) includes clothing and devices to protect workers.

Ensuring health, safety, security, and environmental (HSSE) standards in Corvus is paramount for protecting employees and the environment. The systematic reporting of HSSE incidents, observations, and near misses plays a critical role in this endeavor. Report an incident as soon and precisely as possible to your manager and in our incident reporting system.

Reporting helps us identify and understand the root causes of incidents, enabling Corvus to implement effective preventive measures. This proactive approach minimizes the risk of recurrence and fosters a safer work environment.

Documenting near-misses and observations to prevent future harm

Documenting near misses—events that could have led to accidents but didn't, often due to luck or

timely intervention—provides valuable insights into potential hazards. These “close calls” are often precursors to more severe incidents and addressing them can prevent future harm.

Observations are dangerous conditions or behavior in the workplace that can, if not properly addressed, contribute to or develop into an HSSE incident.

Fostering a culture of transparency and open communication around HSSE issues encourages employees to remain vigilant and take collective responsibility for safety. In conclusion, consistent and comprehensive reporting of HSSE incidents, observations, and near misses is fundamental for continuous improvement in safety standards and for safeguarding both personnel and the environment.

Behavior Based Safety (BBS) is a proactive approach toward increasing workplace safety by observing individual behavior, analyzing the consequences, and reinforcing desired safety behaviors. The main objective is to reduce unsafe behaviors and continuously improve safety performance.

Observation and feedback:

Employees observe each other in different work settings and give constructive feedback on safe an unsafe behavior.

Positive reinforcements: BBS focuses on the acknowledgement of safe behaviors, which often is a motivating factor to continue with the safe behaviors.

The BBS program involves employees at all levels, promoting ownership of a good safety culture.

Observations are registered and analysed to identify trends and implement targeted improvement measures.

BBS is a dynamic process which is adjusted based on feedback given and results.

Reduces accidents and injuries: By focusing on behavior, one often addresses the underlying causes of incidents.

Strengthens the safety culture:

Employees become more aware and engaged in the safety work.

Forwards positive collaborations: Observations and feedback are done in a supportive and non-punishing tone.

Gives valuable insights: Data from observations can be used to identify trends and areas of improvement.

Increases ownership and responsibility: When employees themselves are involved in observations and actions, they get an increased responsibility for safety.

Lean Manufacturing Overview

Focuses on maximizing productivity and minimizing waste.

Core principles:

• Value: Define from the customer’s perspective.

• Value Stream: Map processes to identify and eliminate waste.

• Flow: Ensure smooth processes to avoid bottlenecks.

• Pull: Produce only what is needed.

• Perfection: Continuously improve efficiency.

• Essential for protecting employees and ensuring regulatory compliance.

• Reduces accidents, injuries, and associated costs.

• Design workstations to fit operators and reduce physical strain.

• Implement proper lifting techniques and use mechanical aids.

• Schedule regular breaks and encourage stretching to manage fatigue.

• Use Lean tools such as 5S (Sort, Set in order, Shine, Standardize and Sustain) to organize workspaces and remove hazards.

• Employ Poka-Yoke (fail safe design) for mistakeproofing processes.

• Utilize standard work checklists for safe procedures.

• Conduct regular safety observations to reinforce safe behaviors.

• Balance workloads to prevent hurrying and enhance safety.

The working environment in our company is sur veyed regularly by the HSSE department, Safety Delegates, and JHSC members. Your insight into work tasks and whether you are exposed to chemicals, noise, or poor working conditions contribute to the quality of the surveys.

It is every employee's responsibility to contribute to a working environment that is inclusive and characterized by respect for each other. We have zero tolerance for bullying and harassment.

Exposure to noise in the workplace can lead to hearing loss. Injuries can occur from impulse noise or noise exposure over a long period of time. Hearing damage cannot be reversed and can significantly reduce quality of life.

Always wear mandatory hearing protection and adhere to information on length of stay and minimum protection requirements for your workplace.

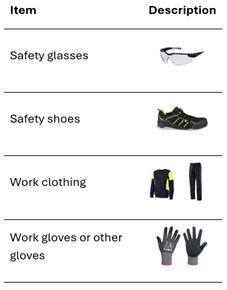

Personal Protective Equipment (PPE) refers to any equipment or clothing worn by individuals to minimize exposure to hazards that may cause injury or illness in the workplace, by creating a barrier between the person and potential hazards. The selection of PPE beyond the basic requirements depends on the specific hazards within the workplace and the tasks being performed. Additional PPE will usually be determined in the Risk Assessment or the Safe Job Analysis for a task.

Wearing PPE is crucial for several reasons:

PPE protects you from workplace hazards.

Proper use of PPE minimizes the risk of accidents and injuries by creating a barrier between you and the hazard.

Ensures adherence to legal and regulatory requirements for workplace safety.

Consistency

Ensures uniform safety practices across the organization.

Established PPE procedures help you react quickly and appropriately in emergencies, protecting yourself effectively.

Regular updates to PPE guidelines incorporate new safety practices and technologies, enhancing overall safety. By using the appropriate PPE, you contribute to creating a safer work environment for yourself and your colleagues.

In a Safe Job Analysis, we analyze which tasks are to be performed to identify dangerous situations that need to be controlled during work execution.

A Safe Job Analysis is required for a task when risk elements are not adequately managed and controlled through applicable procedures and methods.

Anyone involved in a work activity can demand a Safe Job Analysis. If the conditions described in the SJA changes during the work, the activity must be stopped, and the risk reassessed.

• Whether the work is described in procedures or routines or requires deviations from these.

• Whether all risk elements for the task have been highlighted and controlled.

• Whether undesirable incidents have occurred in this type of tasks in the past.

• If the work is assessed to have high risk, is complex or involves several professional groups/units.

• If new equipment or methods are used that are not covered by procedures or routines.

• Whether personnel involved in the work have experience with the work in question.

There are some fundamental requirements in place to ensure the effective implementation of the Life-Saving Rules:

• High risk work tasks will not be conducted without a pre-job safety discussion appropriate for the level of risk.

• All personnel will be trained and competent for the work they conduct.

• Personal protective equipment will be provided and worn in accordance with the requirements identified by the task risk assessment and work-site policies.

• Emergency response plans, developed from a review of potential emergency scenarios, will be in place with suitable and sufficient resources available before commencement of work.

• Everyone is authorized to stop work if they are in doubt about the safety of an activity.

I only perform tasks and use equipment for which I am authorized and trained.

I keep myself and others out of the line of fire, meaning I position myself to avoid moving objects, vehicles, pressure releases and dropped objects, and I respect barriers.

I obtain authorization before overriding or disabling any safety controls/barriers. This also includes deviating from a procedure or crossing a barrier.

I always follow safe driving rules at work, meaning I wear a seat belt where this is installed, follow speed limits, and stay focused while driving.

I verify isolation and zero energy before work begins. Meaning I have identified all energy sources, confirmed that hazardous energy sources have been isolated, locked, tagged, and tested to verify that there is zero residual stored energy.

I always control ignition sources and eliminate fire and explosion risk.

I plan lifting operations and control the area prior to starting. This includes checking that the equipment is fit for purpose, only using equipment for which I am qualified, respecting barriers and never walking under hanging loads.

I protect myself against falling when working at height, meaning I inspect the fall protection equipment prior to use and secure objects to prevent them from falling.

When approaching someone performing a task where it is likely that safety can be improved, initiate an Open Safety Dialogue.

All workers and managers have the right to have an informal safety conversation at any time for clarifications to ensure safe job performance. Make sure that you are standing in a safe place, and that the workplace is secure.

Ask open-ended questions when approaching workers at a workplace:

• What tasks are you doing?

• How do you perform the work?

• What could go wrong?

• What measures must be taken to prevent something from going wrong?

Seek more information if hazardous conditions are identified and implement risk-reducing measures before the work is resumed. Promote strong safety performance observed at the job site.

Our security measures are designed to deter, detect, delay, and stop illegal and criminal acts. They target a wide range of threats, from theft for profit to organized crime, industrial espionage, sabotage, and acts of terrorism.

We will prevent unauthorized people and goods from entering our controlled areas, and we will have a clear focus on security when we recruit and hire personnel.

The goal is that no one should succeed in harming us.

The security activities are divided into physical security, personnel security, and information security. In addition, our factories provide supply chain security. We have guidelines for securing the supply chain and securing critical infrastructure. We manage this in agreements with key suppliers and transport companies.

• Remain vigilant – register any suspicious activity or situations.

• Keep an eye out for anyone trying to enter behind you – tailgating.

• You are responsible for your visitors.

• Always be prepared to present your access card or other identification upon request.

• If someone attempts to enter at the same time as you, you should ask them to identify themselves.

Security is our shared responsibility, and we are dependent on a security-conscious organization. Your contribution to a robust security culture is to follow the work processes and report all suspicious conditions and security deviations immediately. We must be aware of the possibility that someone could try to harm us.

Protection of the environment is strongly integrated in Corvus Energy’s mission, Powering a Clean Future.

Our ambition is to design and develop products with minimum environmental footprint from a cradle to grave perspective, including reduction of greenhouse gas emissions, energy consumption and waste generation. Through our ISO 14001 certification, Corvus has established an environmental management system.

Protection of the environment is a cornerstone of HSSE practices, emphasizing sustainable solutions and ongoing improvement. Continuous efforts should be made to replace dangerous chemicals with safer alternatives, reducing harm to ecosystems and promoting workplace safety. This proactive approach minimizes risks and sets a foundation for sustainable operations.

Proper waste management, including effective recycling systems, are crucial for reducing waste and conserving resources. Employees are encouraged to segregate recyclables and prioritize reuse to lower environmental impact in their daily operations.

Maintaining a clean, organized, and environmentally conscious workspace is essential to:

• Increase efficiency, safety and productivity.

• Create a pleasant and healthy work environment for all employees.

• Set a standard for order and quality.

• Promote environmental awareness through responsible waste management and recycling.

Daily Cleaning:

Follow a developed schedule to keep work areas tidy. Organized Workspaces: Store tools and materials properly. Return items after use.

The purpose of the 5S method is to create a clean, organized, and efficient workplace that minimizes waste and maximizes productivity. By systematically sorting, arranging, cleaning, standardizing, and

sustaining workspaces, 5S helps teams work more safely, reduce time spent searching for tools or materials, and build a foundation for continuous improvement.

The 5S method consists of:

• Sort: Remove unnecessary items.

• Set in Order: Arrange tools for easy access.

• Shine: Keep areas clean.

• Standardize: Follow consistent routines.

• Sustain: Regularly review and improve.

• Use marked bins for recycling.

• Minimize waste.

• Regular inspections ensure standards are met.

• Feedback and suggestions for improvement are encouraged.

During an evacuation alarm, the first course of action all employees should do is to find the clear path of evacuation to the nearest emergency exit.

Frequent evacuation drills will be conducted to allow employees to familiarize themselves with an approved evacuation procedure.

When air horn is implemented one long blast signalizes evacuation of the area. When the building has its own alarm system this will also signal immediate evacuation.

When the evacuation alarm sounds, all employees shall evacuate the building immediately.

Employees must prioritize evacuation over all else, and this must be done effectively and in a calm way.

Employees should relocate to a designated muster point or leave the area in a safe way.

Employees are to remain outside the building at the muster point or the safest distance possible until given approval to re-enter the worksite. At some worksites this is when the evacuation alarm is switched off.

Notification of first aid, fire responders and evacuation of the area shall be done by using available air horn where this is implemented.

1 Long Blast for Evacuation

Incidents or situations resulting in a damaged battery module must be handled by 1 long blast to alert responders and evacuate the area.

When the air horn alarm sounds, designated responders shall immediately mobilize.

In the event of an earthquake:

• Remain calm.

• If inside – stay inside.

• Move away from glass, mirrors, or objects that may fall or shatter.

• Drop to your hands and knees before the earthquake knocks you down. This position protects you from falling but still allows you to move if necessary.

• Cover your head and neck (entire body if possible) under the shelter of a sturdy table or desk.

• Hold on to your shelter (or to your head and neck) until the shaking stops.

• If outdoors, move away from buildings, utility wires, sinkholes, and fuel and gas lines.

Once the shaking stops:

• Assess yourself. Assess others and assist as required.

• Assess the area for immediate damage and, if possible, clear away any hazardous debris.

• Be aware of the possibility of aftershocks.

• If there is to be an evacuation out of the building, proceed to the designated marshaling area and wait for further instructions.

To cordon off an area means to put up physical barriers to restrict access to that area. This can be done with barrier tape, fencing, cones, etc.

Such physical barriers are essential for maintaining safety and efficiency in the workplace as they help prevent unauthorized access, protect employees from hazardous areas, and ensure compliance with safety regulations.

Cordons can be either permanent fixtures, or temporary barriers. All cordons must be respected, and temporary cordons must be removed when they are no longer in use.

When cordoning off, one must also remember:

• To ensure the barriers are highly visible.

• To ensure that they are stable and securely placed to prevent them from being moved or knocked over.

• Use clear signage indicating what the hazards are and who put up the cordons.

• Ensure no cordons are blocking emergency exits.

Working alone means being the only worker on a site or in an area where assistance may not be readily available in case of injury or emergency. High-risk activities include working at heights, in confined spaces, and with hazardous energy or products.

There are a variety of scenarios where one might be working alone, all having different risks. It is therefore important to perform a risk assessment and assess these risks with a focus on:

Time

The duration and legality of working alone.

Communication

Availability and reliability of communication methods.

Location

Remoteness and emergency supplies.

Nature of the work

Training, PPE availability, and emergency access

Based on the risk assessment, risk-reducing measures should be put into place, and a check-in routine must be established.

Risk reducing measures could be:

• Avoid lone workers for high-risk jobs.

• Assess workplace hazards.

• Consult with colleagues.

• Investigate incidents and take corrective actions to learn.

• Provide training and education.

• Report all incidents and near misses.

• Schedule high-risk tasks during normal working hours.

Working at height generally refers to any work where a person could fall and be injured, typically from a height of 1.2 meters / 4 feet or more.

When performing work at height, one must:

• Perform a risk assessment to identify risks and mitigating actions.

• What equipment is to be used?

• Does everyone have the required training?

• Do we have the appropriate PPE?

• Is all the equipment in good working condition?

• What is the duration of the work?

• Is there a need for a Safe Job Analysis (SJA)?

• Is the risk assessment approved?

• Always prioritize fall restraint equipment (guardrails, fencing etc.) over personal fall arrest equipment (harness, etc.).

Work Execution:

• Ensure situational awareness.

• Secure the work area.

• Does everyone involved understand the task?

• Is the work situation changing during execution?

Do:

• A visual inspection.

• Make sure the equipment is set up properly, on a stable surface.

• Take breaks when necessary.

• Follow the manufacturer’s instructions.

• Keep emergency exits clear.

Do Not:

• Use damaged equipment.

• Fix damaged equipment of not trained.

• Excess the maximum load capacity.

• Use equipment for anything other than its intended use.

• Perform work at height when you are alone.

Work Evaluation:

• Are there any new risks?

• Was our initial plan sufficient?

• Is updating our processes or procedures needed?

Exposure to hazardous substances can lead to short-term and/or permanent damage. Most common are skin and respiratory injuries, but serious damage to internal organs can also occur.

Always familiarize yourself with the health hazards associated with activities where chemicals are used. Information on this can be found in the Safety Data Sheet (SDS) for the product. In the Safety Data Sheet, you will also find information about protective measures, Personal Protective Equipment, storage, and waste disposal.

A chemical register is established at your workplace containing Safety Data Sheets, risk assessments and requirements for Personal Protective Equipment.

Familiarize yourself with the regulations for handling chemicals by consulting your manager and by attending available training.

Always consider whether it is possible to avoid using substances that are hazardous to your health- are there good alternatives?

Ergonomics

Use proper lifting techniques – bend at the knees, not waist. Avoid twisting and use adjustable equipment to reduce strain.

Training

Conduct regular courses on safe material handling and the use of equipment. All forklift and pallet jack operators must have the relevant training and certification before operating the machinery.

Inspection

Perform routine checks and maintenance on equipment to prevent failures and ensure safe operation.

Route Planning

Keep work areas clear of obstacles, ensure proper lighting, and mark pedestrian and vehicle pathways.

Load Securing

Secure loads to prevent shifting or falling during transport. Do not overload equipment.

Proper Tools

Use appropriate equipment such as carts, hoists, and conveyors to minimize manual handling.

Protective Equipment

Wear safety glasses, gloves, safety shoes, and high-visibility vests/clothing. Regularly check for wear and tear.

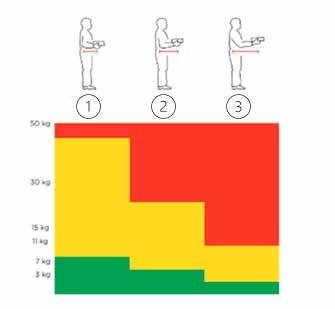

Correct lifting techniques protect your back. An incorrect lifting technique, together with a tendency to overestimate one's own strength, is to blame for many incidents.

Take the right precautions and plan before lifting.

1. When lifting close to the body, you may lift a maximum of 10 tons/20 000 pounds during a workday.

2. When lifting at a forearm distance, you may lift a maximum of 6 tons/12 000 pounds over a working day.

3. When lifting 3/4 arm's distance, you may lift a maximum of 3 tons/6000 pounds during a workday.

Musculoskeletal disorders are, in general, the cause of approximately 50% of workplace absences. Try to arrange your work so that you avoid stressful working positions, heavy lifting, and prolonged repetitive movements.

Use assistive devices that can reduce strain. If you think your workplace has an unfortunate ergonomic design or have suggestions for improvements, discuss it with your manager, safety delegate representative or HSSE personnel or JHSC member.

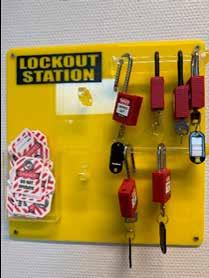

Lockout, tagout and test out is a safety procedure used to ensure that dangerous equipment is properly shut off and not able to be started up prior to the completion of maintenance or repair work.

Test out verifies that the lockout and tagout procedures have been effectively implemented by attempting to start the equipment or machinery. This ensures that the energy source has been completely isolated, and that the equipment cannot be accidentally energized while work is being performed.

Battery systems may be energized from multiple sources, such as:

• Power supplies

• Parallel Packs

• UPS, chargers or drives

Each source must be isolated separately!

Electrical hazards can cause injury, either directly or via arc flash. Key hazards include:

Arc Flash

Sudden energy releases causing burns and blindness.

Electric Shock

This can lead to burns, cardiac arrest, or respiratory issues.

Explosions

Electrical faults may ignite volatile materials.

Chemical Leaks

Failures can release hazardous substances.

Ensuring proper safety procedures, training, the use of appropriate tools, and personal protective equipment can mitigate these risks.

Only qualified personnel are permitted to perform electrical work on live Corvus systems. Before starting any work:

• Conduct Safe Job Analysis (SJA) to assess hazards.

• Use approved PPE and tools for working on or near electrical systems.

Communication

Ensure all relevant personnel are informed about planned work and associated risks.

Always use voltmeter or equivalent testing device to verify that the system is disconnected before beginning work.

Prevent unintended activation of the electrical system by using lockout.

Battery safety is crucial, including safe handling, operation, and disposal.

High-voltage batteries are always powered and pose an electrical shock risk.

Thermal Runaway (TR)

TR occurs due to insulation breakdown, leading to short circuits, overheating and potential fire and chemical exposure. Fire may spread internally in a battery system and to nearby areas. Chemical exposure from gases such as CO, hydrocarbons, hydrogen, and fluorides can be released. TR cannot be extinguished. Do not attempt to stop it but leave the area and let it burn out in a safe environment and evacuate.

Battery modules are heavy and may cause musculoskeletal injuries if mishandled. Damaged batteries can become a safety risk.

Batteries contain hazardous materials. Adhere to Corvus disposal and recycling practices.

Batteries are classified as dangerous goods and should only be shipped using Dangerous Goods Transportation guidelines.

Participate regularly in safety drills and training sessions related to battery safety. Attend assigned training on first aid, working on electrical systems, evacuation routes, and emergency shutdown procedures.

Hydrogen is a versatile and clean energy source. In Corvus, hydrogen is used as fuel for our fuel cells.

Hydrogen’s unique properties require strict safety measures. As a flammable gas with a wide explosive range in air, hydrogen must be handled with care to mitigate risks.

Key safety practices include:

Training and Awareness:

Only trained personnel are allowed to work with hydrogen.

All workspaces involving hydrogen are well-ventilated to prevent hydrogen accumulation, as it is lighter than air and can accumulate in enclosed spaces.

Hydrogen is colorless, odorless, and can easily diffuse through various materials due to its small molecule size. Proper leak detection is therefore essential. Equipment is inspected and maintained regularly.

Open flames, sparks, and other ignition sources are prohibited near hydrogen storage or handling areas.

Compressed hydrogen gas at 200 bars is stored in gas bottles. These shall be handled with caution and only by trained personnel. By adhering to these measures, specific work instructions and training material, we can ensure a safe working environment while handling hydrogen.

No employee is allowed to use any piece of machinery until they have completed the required training, and the record of training is on file in their personnel file, regardless of their prior experience with the machinery before working at Corvus Energy.

An administrative safeguard can be a training program or an available user manual. Employees are not required to use any machinery they are not comfortable with using or lack formal training to operate.

The machinery safeguards must be inspected and deemed to be operational before use of the machinery.

There are several solutions available to ensure the safe use of machinery, such as:

• Warning signs and labels

• Lights, beacons, and switches

• Computer warnings

• “Restricted Space” painted on floors

• Beepers

• Horns and sirens

Protection of our data and access to IT systems is everyone's responsibility. Every employee must be vigilant when handling our information systems and data.

Email phishing is a targeted cyber-attack using a disguised email. Text message phishing is a cyberattack using a disguised text message. Do

• Always check the address the email is sent from. Is it from someone you usually communicate with?

• Be wary of any email that you are cc’d on where you don’t personally know the other people it was sent to.

• Check the time an email arrived - did it arrive at an unusual time?

• Always check the subject line - is it a reply to something that you never sent or requested?

• Be careful what you post to social media, online forums, and web chats.

• Always hover your mouse over any link in an email and check that the link matches the address shown on screen. You should also check that the address is given correctly and isn’t a fraudulent copy.

• Do not use business email for personal use.

• When receiving a suspicious email or text message report as junk/phishing mail.

Protection of both digital and physical data and information shall be done according to the information classification.

• Only use accounts and passwords assigned to you (except for generic and group accounts).

• Ensure that logins for generic and group accounts are kept confidential and not shared with colleagues or third parties.

• Change your password immediately if you suspect your password is known by others.

• Ensure that printed information is protected according to its classification.

Our suppliers on site need to transfer instructions with a memory stick or portable storage media. It is your responsibility to ensure proper approval and scanning of the storage media before it is entered into Corvus infrastructure. Do

• Ensure approval of a supplier to connect their equipment to our IT infrastructure.

• Review our “Acceptable Use Policy” and request formal confirmation from the supplier that it is read and understood.

• Before entering portable storage devices such as memory sticks or portable disks, the medium must be scanned for viruses and confirmed free from malicious code.

All corporate travel shall be booked through the approved Travel Coordinator and/or partner for your location.

This ensures employees use airlines, hotels, and other providers that meet our safety requirements. In rare cases where you need to book travel outside of our approved partner and/or travel coordinators, you must ensure it is pre-approved and that your itinerary, mode of transport and accommodation are chosen with safety in mind. This may involve avoiding hazardous areas, choosing reliable transportation providers, and ensuring that accommodation meets satisfactory safety standards.

Check visa requirements and obtain any necessary permits well in advance of departure.

Where applicable, verify that you have adequate travel insurance coverage. Stay informed of local conditions during your trip, for example, by reviewing your government’s travel advisory website and taking appropriate measures to ensure your safety. As per corporate travel policy, preapproval from your manager is mandatory for all corporate travel bookings. In the event of delays or cancellations, ensure your manager is kept updated.

Regular workplace inspections are essential to maintaining a secure and healthy work environment. These inspections are intended to identify hazards and assess risk in the workplace. Through this, Corvus can address risks promptly and improve our safety culture.

A workplace inspection program may include daily inspections of equipment, initial startup inspections, walk-arounds of mobile equipment before use, daily and/or weekly supervisor inspections, and weekly and/or monthly departmental inspections.

In addition to regularly scheduled inspections, there will be a need to inspect the workplace after an incident or after implementation of a new work process or new equipment.

• In Canada & US the Joint Health & Safety Committee is responsible to conduct monthly inspections.

• In Norway the Safety Representatives will plan and perform workplace inspections.

The committee is held in the Norwegian part of the company consisting of representative from the company’s top management and main safety representatives from the employees. Meetings are held four times a year.

All employees, except for the top management, have the right to vote and be eligible for elections. The election should be conducted through a written and secret ballot, and alternate members should also be elected. The election is supervised by an electoral committee appointed by the local trade union.

• Issues concerning occupational health services and internal safety issues.

• Questions regarding training, instruction, and information about activities relevant to the working environment.

• Plans that may have a significant impact on the working environment, such as construction projects, purchase of machinery, rationalization, work processes, and preventive safety measures.

• Establishment and maintenance of the enterprise's systematic health, environment, and safety work.

• Health and welfare-related issues related to working hours arrangements.

• Be informed about re-organization projects that may have consequences for employees' working environment.

The committee is a collaborative group made up of employer and employee representatives to help identify and resolve health and safety issues in the workplace.

The role of the JHSC is to promote a safe working environment by reviewing incidents, recommending corrective actions, and ensuring compliance with health and safety regulations. JHSC serves as a key communication link between workers and management, fostering a culture of shared responsibility for workplace safety and ensuring that health and safety concerns are addressed promptly and effectively.

• Identify situations that may be unhealthy or unsafe for employees while advising effective solutions as a response.

• Consider, and promptly deal with complaints relating to workplace health and safety.

• Consult with workers and the employer on issues related to occupational health and safety as well as occupational environment.

• Make recommendations to the employer on educational programs promoting the health and safety of workers and compliance with regulatory bodies concerning worker health and safety while monitoring its effectiveness.

• Advise the employer on policies and programs required under the regulations for the workplace and monitor their effectiveness.

• Advise the employer on proposed changes to the workplace, including significant proposed changes to equipment and machinery, or the work processes that may affect the health or safety of workers.

• Ensure that required incident investigations and regular inspections are conducted.

Norwegian companies with over 40 employees in specific industries must establish an industrial safety system under "Regulations relating to industrial safety and emergency preparedness." An industrial safety system enables quick responses to fire, personal injury and the escape of gas or hazardous chemicals before the emergency services arrive.

The structure of the industrial safety system includes an industrial safety manager, on-scene commanders, and emergency response personnel. The industrial safety system is organized, equipped and trained based on findings from a risk assessment assessing possible incidents.

In the event of an emergency, the industrial safety system shall act according to the emergency plan and serve as contact with the emergency services.