NICKEL THE SOCIABLE METAL Remember back to your early days in school when the teacher might include the statement “plays nicely with others” in a report card? This also describes nickel, a versatile element which will alloy with most metals. The breadth of nickel-containing alloys and their applications is unmatched.

Nickel readily mixes with iron, copper, chromium, molybdenum, titanium, cobalt, and tungsten producing useful and critical engineering alloys.

Nickel forms binary (two element) alloys with copper, molybdenum, titanium, iron and chromium. It also forms tertiary alloys where iron is the third element either because iron is essential to the alloy’s properties, or the presence of iron is not objectionable to the alloy’s properties and thus is added to reduce cost. Then there are multi-element alloys which contain many of the aforementioned elements, in particular the corrosion-resistant stainless steels and nickel-based alloys. The presence of

Corrosion resistant stainless steels and nickel-base alloys

Multielement alloys

Tertiary element alloys

Binary element alloys

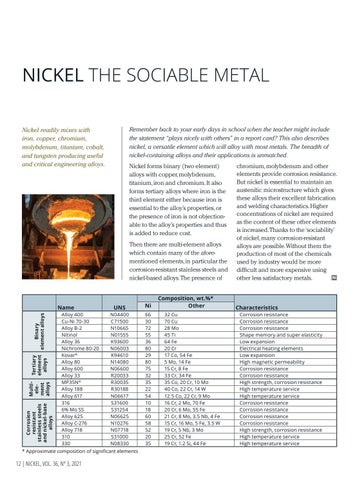

Name Alloy 400 Cu-Ni 70-30 Alloy B-2 Nitinol Alloy 36 Nichrome 80-20 Kovar ® Alloy 80 Alloy 600 Alloy 33 MP35N® Alloy 188 Alloy 617 316 6% Mo SS Alloy 625 Alloy C-276 Alloy 718 310 330

UNS

Ni

N04400 C71500 N10665 N01555 K93600 N06003 K94610 N14080 N06600 R20033 R30035 R30188 N06617 S31600 S31254 N06625 N10276 N07718 S31000 N08330

66 30 72 55 36 80 29 80 75 32 35 22 54 10 18 60 58 52 20 35

* Approximate composition of significant elements

12 | NICKEL, VOL. 36, Nº 3, 2021

Composition, wt.%* Other 32 Cu 70 Cu 28 Mo 45 Ti 64 Fe 20 Cr 17 Co, 54 Fe 5 Mo, 14 Fe 15 Cr, 8 Fe 33 Cr, 34 Fe 35 Co, 20 Cr, 10 Mo 40 Co, 22 Cr, 14 W 12.5 Co, 22 Cr, 9 Mo 16 Cr, 2 Mo, 70 Fe 20 Cr, 6 Mo, 55 Fe 21 Cr, 8 Mo, 3.5 Nb, 4 Fe 15 Cr, 16 Mo, 5 Fe, 3.5 W 19 Cr, 5 Nb, 3 Mo 25 Cr, 52 Fe 19 Cr, 1.2 Si, 44 Fe

chromium, molybdenum and other elements provide corrosion resistance. But nickel is essential to maintain an austenitic microstructure which gives these alloys their excellent fabrication and welding characteristics. Higher concentrations of nickel are required as the content of these other elements is increased. Thanks to the ‘sociability’ of nickel, many corrosion-resistant alloys are possible. Without them the production of most of the chemicals used by industry would be more difficult and more expensive using other less satisfactory metals.

Characteristics Corrosion resistance Corrosion resistance Corrosion resistance Shape memory and super elasticity Low expansion Electrical heating elements Low expansion High magnetic permeability Corrosion resistance Corrosion resistance High strength, corrosion resistance High temperature service High temperature service Corrosion resistance Corrosion resistance Corrosion resistance Corrosion resistance High strength, corrosion resistance High temperature service High temperature service