‘I love running the Komatsu dozers’ . . . continued

northern-most quadrant of the GNTL, Northern Clearing turned to Komatsu equipment from Road Machinery & Supplies Co. From a temporary 10-acre equipment yard in Salol, Minn., that doubles as the section’s centralized headquarters, Grubisic and his crews are responsible for creating access to the GNTL’s first 262 structures between the border and Baudette, Minn., – a nearly 100-mile stretch. The machines of choice for the job are Komatsu D61PX and D65PXi dozers and a WA470 wheel loader. “We’re working on the coldest and nastiest elements on the project, and we need equipment that we can trust,” noted Grubisic.

“Komatsu has proven itself over and over again. We know that our dozers in the field and the WA470 in the yard are going to start and perform all day long and not experience any DEF issues. We’ve had other brands up here, and they couldn’t cut it.” “I love running the Komatsu dozers,” said Operator Jim Erickson. “We operate on rugged terrain, but the ride of the Komatsu D61 and D65 is very comfortable, the visibility is great and the controls are operator-friendly.” Komatsu’s performance made it an obvious choice for the segment, but coupling it with service from RMS made the decision a clear winner. “The level of commitment we have received from RMS has been above and beyond,” shared Grubisic. “Mike Stephani, an RMS Technician, is here full-time. We’re his only responsibility. That is a game-changer for us. If anything does happen, we know he is here to take care of it right away, instead of waiting for someone to come from a few hours away. RMS also has a dedicated parts warehouse on the yard. We’re pretty isolated, and RMS has worked really hard to ensure that we have parts and service available.

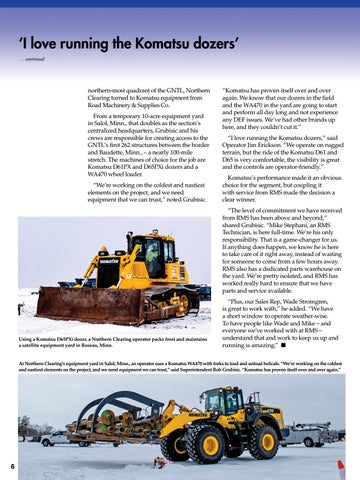

Using a Komatsu D65PXi dozer, a Northern Clearing operator packs frost and maintains a satellite equipment yard in Roseau, Minn.

“Plus, our Sales Rep, Wade Stromgren, is great to work with,” he added. “We have a short window to operate weather-wise. To have people like Wade and Mike – and everyone we’ve worked with at RMS – understand that and work to keep us up and running is amazing.” ■

At Northern Clearing’s equipment yard in Salol, Minn., an operator uses a Komatsu WA470 with forks to load and unload helicals. “We’re working on the coldest and nastiest elements on the project, and we need equipment we can trust,” said Superintendent Rob Grubisic. “Komatsu has proven itself over and over again.”

6