April 2024 A publication for and about Kirby-Smith Machinery Inc. customers www.KirbySmithConnection.com WEAVER EXCAVATING & SEPTIC LLC Contractor brings experience to East Texas, becomes one of the area’s top sitework companies

Jeffrey Weaver, Owner

MESSAGE FROM THE PRESIDENT

Dear Valued Customer:

I hope 2024 is off to a great start for you. The forecast looks promising across most sectors of the construction industry, and my hope is that your year is filled with numerous projects.

Recently, Komatsu's Quarry Days took place at Komatsu's Arizona Proving Grounds. Quarry Days offered attendees a chance to see and operate more than a dozen machines, including a Komatsu PC2000-11 surface mining excavator and Komatsu’s new GD955-7 motor grader with a standard 18-foot blade. In addition to equipment, Komatsu representatives from its Smart Quarry solutions and My Komatsu teams were available to show customers the advantages of incorporating technology into their operations. On page 32, you can read all about the equipment and products that were on display at the event.

No matter your machinery or fleet size, My Komatsu can help you manage it better. Now even easier to navigate, My Komatsu lets you get the critical information you need in fewer clicks. You can also see manuals and order parts, including Reman items that could potentially provide you with significant savings. Learn more on page 37.

Additionally, you can access Komatsu’s Smart Construction solutions through your My Komatsu account. Smart Construction solutions can help you maximize productivity and efficiency, and you can incorporate them at practically any stage of the construction process, from pre-bid to production to final closure. Be sure to check out the article on page 22 to find out how to choose the best solution for your business.

There are several other articles that I believe you will find valuable as you work on projects now and look to the future.

As always, if there is anything we can do for you, please reach out to your nearest Kirby-Smith Machinery location, where our knowledgeable staff and I will be happy to support you in any way we can.

Sincerely,

John Arapidis President & CEO, Kirby-Smith Machinery Inc.

John Arapidis President & CEO, Kirby-Smith Machinery Inc.

2 Printed in the U.S.A. © 2024 Construction Publications Inc. Not all products represented at all locations.

John Arapidis

FEATURED ARTICLES...

WEAVER EXCAVATING

& SEPTIC LLC pg. 4

Read about how this contractor offers large-scale site packages that involve everything from clearing to paving.

BRISON

EXCAVATING LLC pg. 8

Meet the Brisons, whose business focuses on the commercial market around the Kansas City area.

HIVE

SERVICES LLC pg. 10

See how a wealth of experience helps this company deliver quality pipeline services to customers in Oklahoma and beyond.

MAKING

THE GRADE pg. 18

Discover how Komatsu's Smart Construction solutions can help increase efficiency.

PAVING

CORNER pg. 26

Check out the new WIRTGEN WRC 240i rock crusher.

CRANE

CORNER pg. 29

Take a look at the new Grove GMK4070L all-terrain crane.

COMMITTED TO THE FUTURE

pg. 43

Learn about KSM's contribution to the Associated Equipment Distributors Foundation's Vision 2025 initiative.

ASK THE PSSR pg. 45

Gain knowledge from KSM's experienced product support sales representatives (PSSRs).

FACES OF KIRBY-SMITH

MACHINERY pg. 28, 47, 49, 51, 53

Get to know KSM's featured employees: Kelly Shuffield, Paul Bell, Roddy Conner, Jennifer Smith, Matt Heisel, and Richard Graves.

NEWS & NOTES pg. 54

Stay up to date on KSM's news.

YOUR CONSTRUCTION EQUIPMENT AUTHORITY www.kirby-smith.com

Published by Construction Publications Inc. for 3 OKLAHOMA CITY, OK 6715 W Reno, Oklahoma City, OK 73127 405.495.7820 405.787.5973 fax TULSA, OK 12321 E Pine St, Tulsa, OK 74116 918.438.1700 918.437.7065 fax MCALESTER, OK 4617 Powell St, McAlester, OK 74501 918.310.1550 ABILENE, TX 12035 Interstate 20 W, Abilene, TX 79601 325.692.6334 325.672.4435 fax AMARILLO, TX 3922 I-40 E, Amarillo, TX 79103 806.373.2826 806.373.4841 fax DALLAS, TX 8505 S Central Expy, Dallas, TX 75241 214.371.7777 214.375.7903 fax FT. WORTH, TX 1450 NE Loop 820, Ft. Worth, TX 76106 817.378.0600 817.378.0080 fax LUBBOCK, TX 3419 East Slaton Road, Lubbock, TX 79404 806.745.2112 806.745.2102 fax ODESSA, TX 7301 E Interstate 20 E, Odessa, TX 79765 432.333.7000 432.333.7010 fax WACO, TX 415 Enterprise Blvd., Hewitt, TX 76643 254.261.1370 ST. LOUIS, MO 12920 Gravois Rd, St. Louis, MO 63127 314.729.0125 314.729.1317 fax KANSAS CITY, KS 8320 Ruby Avenue, Kansas City, KS 66111 913.850.6300 913.850.6319 fax NORTH TEXAS – COMING SOON

WEAVER EXCAVATING & SEPTIC LLC

Contractor brings experience to East Texas, becomes one of the area’s top sitework companies

Jeffrey Weaver discovered his calling when he was young by working for his dad’s construction business in Illinois.

“We built houses from the ground up and did all the dirt work ourselves,” recalled Weaver. “I really enjoyed it, and I knew that’s what I wanted to do for a living.”

Weaver took a job at a friend’s business and moved to southern Missouri to perform earthwork

services around the Lake of the Ozarks. While he was building his career, his future wife, Judith — who grew up just a few miles from him in Illinois — was doing the same, teaching at a Christian-based school in East Texas. Weaver visited her monthly, and as the couple’s love for each other grew, so did their fondness for the area.

“We believed this area was right for us, and that’s proven to be the case,” stated Weaver.

In 2006, Weaver founded Weaver Excavating & Septic LLC in Eustace, Texas.

“When I moved here from Missouri, I brought my septic license with me, and that was a field I could jump into right way,” said Weaver. “It was a wide-open market with lots of housing being built around that time. I started with myself, a skid steer and a mini excavator, and I just kept growing from there. I worked with several contractors, putting in septic systems for them, and doing some finish grading around houses. I knew how to do house pads and was already working with developers, so it made sense to add that service. Then, I built some retention ponds and that got us into the dirt work side.”

Today, Weaver Excavating & Septic offers large-scale site packages that involve everything from clearing to paving. Its crews self-perform nearly every task — including stripping, road base prep, mass earthwork, finish grading, utility installation, and asphalt paving — to complete projects on time and on budget for a variety of clients, such as residential and commercial developers. The company subs out concrete and specialty items. Key staff members include Vice President of Operations Duane Wadel, Estimator/Project Manager/CAD Designer Scott Shelton, Septic Service Coordinator Shannon Steadham, Septic Installation Coordinator Mike Reed, Supervisor Brendyn Zook, and Receptionist Ashley Vargas.

Increased productivity with IMC

Weaver noted that the company started to do larger dirt work projects after hiring some employees with GPS experience. One of those hires was Shelton, who builds the company’s

An operator grades a slope with a Komatsu D61EXi-24 Intelligent Machine Control (IMC) dozer.

4

Jeffrey Weaver is the founder and owner of Weaver Excavating & Septic LLC. Weaver’s twin sons have shown a keen interest in the business, and he hopes they will be involved in the future.

GPS models. Weaver emphasized that Shelton’s background and expertise paid off right away.

“It gave us an edge in the market,” declared Weaver. “Our initial subdivision had 2 miles of roadway and 120 lots, and we did it with a laser. It worked out, but since then, we have done all the others with GPS. They were so much easier, smoother and more efficient. We knew exactly how many yards of dirt we were moving as opposed to the guesstimate we had with the first one.”

Shelton typically uses two methods when building GPS models for the company. One option is to do a topography of a site, then make a grading plan. The other is to make a model off of an engineer’s CAD file. In either instance, he’s uploading the final models to the company’s Komatsu Intelligent Machine Control (IMC) dozers and excavators.

Once the model files are loaded into the IMC machines, it’s a matter of simple calibration and getting to work. The machine always knows where final elevation is and works to get there as productively and efficiently as possible. Weaver added that the IMC machines have increased productivity by up to 30% on most projects.

“We use the excavators to dig utility trenches,” noted Weaver. “A great feature is that once the target depth is reached, the machine won’t let you dig any further. Put in the bedding, set the pipe, and that’s it. It’s a very smooth operation. The dozers are used for road and pad construction. They know the final grade and automatically get to it. We also use them to put down subbase. There are no material overages, and we don’t have to redo work that was done incorrectly. The precision and accuracy are spot on.”

Weaver Excavating & Septic also has a Komatsu PC88MR short tail swing excavator, which is used to put in septic systems and to complete other tasks in confined spaces.

“We use the PC88 on practically every job, and it does great,” said Reed. “In addition to digging, we use it to lift and set 500-gallon tanks.”

Support from KSM

Weaver Excavating & Septic purchased all of its Komatsu equipment from Kirby-Smith Machinery Inc. (KSM) with the help of Territory Manager Craig Doran. Weaver noted that he bought his first piece of Komatsu equipment in 2010.

“I learned about Komatsu and Kirby-Smith through a neighbor,

Continued .

Discover more at KirbySmithConnection.com 5

. .

An operator digs to grade and loads trucks with a Komatsu PC360LCi-11 IMC excavator on a subdivision site near Eustace, Texas.

‘I absolutely enjoy working with Kirby-Smith’

. . . continued

who was a Komatsu service tech, and he introduced me to Craig,” recalled Weaver. “Our relationship continues to grow because they always take care of us. Craig helps us determine what machines we need to be most effective, and Kirby-Smith backs them up with exceptional service. We love that they track the newer machines with Komtrax and do the routine services for a certain period of time, or they alert us if a code pops up, so we can address it quickly.”

KSM Smart Construction Specialist Eddie Garcia and KSM Director of Smart Construction Dennis Cox support the company’s IMC needs.

“I absolutely enjoy working with Kirby-Smith,” said Shelton. “We have a good relationship. They train our staff when needed to get them up to speed on everything and offer ongoing support. If I have a problem, I call them up, and they get me the answers I need.”

Still passionate about dirt

Even though he doesn’t run equipment as much as he used to, Weaver hasn’t lost his passion for earthmoving.

“People ask me why I do dirt work, and I tell them that I thoroughly enjoy working with people and taking care of their needs,” he said. “Taking a piece of property and turning it from a concept to a finished piece is what I love doing. We have gone from doing small septic installs to jobs as big as $2 million to $3 million. That’s a decent range, and this area continues to grow, so I think there is plenty more jobs out there that fit into that.”

Weaver is optimistic about passing down his love for the business to his twin sons.

“They love the equipment,” Weaver said. “They are still pretty young, but I’d love to be able to work with them as they get older, and they have a fascination for equipment operation. It’s up to them, but it would be great if they keep that same interest and do join on some day.” ■

*The opinions expressed here are from the end user as quoted. The results described herein are those of these end users under certain conditions. Your results may vary.

6

Mike Reed, Septic Installation Coordinator

(L-R) Weaver Excavating & Septic’s Jeffrey Weaver, Brendyn Zook, and Scott Shelton meet with KSM’s Craig Doran, Jordan Washam, Eddie Garcia, and Dennis Cox at Weaver’s office in Eustace, Texas.

Operator Kyle Mast backfills a new septic tank install with a Komatsu PC88MR excavator. “It handles really well and does good in tight spots,” said Mast.

PLEASE CONTACT YOUR LOCAL KIRBY-SMITH MACHINERY BRANCH: Scan the QR code for more info npkce.com ALL THE RIGHT ATTACHMENTS NPK MANUFACTURES AND MARKETS THE GREATEST SELECTION OF: Hydraulic Hammers • Compactors • Sheet Pile Drivers Concrete Crushers • Material Processors Demolition Shears • Demolition Grabs • Pedestal Boom Systems PLEASE CONTACT YOUR LOCAL KIRBY-SMITH MACHINERY BRANCH: Scan the QR code for more info npkce.com ALL THE RIGHT ATTACHMENTS NPK MANUFACTURES AND MARKETS THE GREATEST SELECTION OF: Hydraulic Hammers • Compactors • Sheet Pile Drivers Concrete Crushers • Material Processors Demolition Shears • Demolition Grabs • Pedestal Boom Systems Tulsa, OK • (918) 438-1700 Oklahoma City, OK • (405) 495-7820 McAlester, OK • (918) 310-1550 Amarillo, TX • (806) 373-2826 Dallas, TX • (214) 371-7777 Fort Worth, TX • (817) 378-0600 Abilene, TX • (325) 692-6334 Lubbock, TX • (806) 745-2112 Odessa, TX • (432) 333-7000 Waco, TX • (254) 261-1370 www.kirby-smith.com

BRISON EXCAVATING LLC

Couple’s dreams come true as they get married, start a business at the same time

About six years ago, Jake and Kendall Brison were busy planning their wedding. They decided that if they were going to get hitched, they should try to make another dream come true as well.

“We knew we were getting married, and we had talked about being in business for ourselves,” recalled Jake. “We figured we might as well jump in with both feet and see if we can make it work. That’s how Brison Excavating LLC came to be.”

Before officially launching Brison Excavating in 2018, the couple had been doing some “weekend warrior work” with a few pieces of equipment Jake had acquired over the years while working for other companies. The projects included

concrete removal, pond construction, tree clearing, and building barn pads.

“I would run a loader, and Kendall would run the dump truck or roller; whatever we could do together to make it happen, and things kept evolving,” explained Jake. “We decided to focus on the commercial market around the Kansas City area because that’s where my background was. Our services are extensive, including structural concrete from paving to walls, footings, utility installation and site grading, and our projects tend to be fairly sizable and comprehensive in scope.”

at any one time. Jake oversees projects as the field superintendent, and Kendall handles everything from bidding to billing as the owner of the company.

Versatility with Takeuchi

Brison Excavating is committed to ensuring its operators have top-quality equipment and has worked with Kirby-Smith Machinery Inc. (KSM) Territory Manager Jason Woods to acquire Takeuchi TL12R2 compact track loaders as well as Takeuchi TB280 and TB290 compact excavators. Woods has also assisted Brison Excavating with rentals such as Link-Belt excavators.

He added that Brison Excavating typically has about six jobs going

“Jason goes above and beyond to make sure we have what we need and always checks in on us,” said Jake. “We love doing business with Jason. He’s part of a really good team at Kirby-Smith that takes care of us with machinery, parts and service. They’re honest and easy to deal with.”

The Takeuchi equipment has helped Brison Excavating complete jobs efficiently.

“Takeuchi is reliable, it’s rugged, and we have zero downtime,” stated Jake. “Our operators keep asking for Takeuchi, so we know it’s the right brand. As our jobs have gotten bigger, we have added equipment to meet the needs. The TB290 is a perfect example. It’s a 19,000-pound excavator that lets us dig large footings and utility trenches, as well as doing smaller work, while still having the ability to quickly move them on a trailer behind a heavy-duty pickup. It’s just a great all-around machine.”

Jake added, “The TL12R2’s design has been around a long time, and it’s proven to be tough while also being comfortable for the operator.

8

Brison Excavating Field Superintendent Jake Brison levels dirt with a Takeuchi TL12R2 compact track loader.

Jake Brison, Field Superintendent

Kendall Brison, Owner

The versatility is great because we can move dirt with a bucket, then switch over to forks and carry pipe, conduit, forms, lumber and more. It allows us to run additional attachments too, such as mowers, augers, forks and brooms. It will handle anything we put on it and handle it well.”

Bright future

Brison Excavating recently completed some sitework for a general contractor at a health facility in Olathe, Kan., and is currently working on the installation of more than 10,000 feet of pipe at a bottling facility for another customer.

“We always make sure we have plenty of manpower on our projects, and we strive to have a great work environment as we believe that directly relates to productivity and customer satisfaction,” said Jake. “We have built a great group of people who do a wonderful job. They deserve a huge amount of credit for our success and ability to complete work on time and on budget.”

The Brisons are looking to increase their staff to about 15 employees in the near future.

“That’s manageable and will allow us to take on additional work without sacrificing quality,” said Jake. “Our plan is also to continue to concentrate

on the Kansas City area as there is plenty of work here and keep our employees happy.” ■

Discover more at KirbySmithConnection.com

Brison Excavating Field Superintendent Jake Brison (left) meets with KSM Territory Manager Jason Woods on a job site in Olathe, Kan.

9

Operator Anthony Mullin digs a utility trench with a Takeuchi TB290 compact excavator. “It has good power to handle any dig we have, and I like that I can work in open areas or in tight spots productively,” said Anthony.

HIVE SERVICES LLC

A wealth of experience helps Hive Services LLC deliver quality pipeline services to customers in Oklahoma and beyond

Dustin Myrick and Derek Crawford had spent more than a decade in the oil and gas fields installing pipe, setting pumps, and overseeing projects for other companies before teaming up in 2021 to start Hive Services LLC in El Reno, Okla. Even though they had extensive experience and contacts in the pipeline industry, they admitted that starting a new business was tough. However, they were confident that their knowledge, along with their perseverance, would pay off in the long run.

“We were knocking on doors and trying to set up meetings before we

(L-R) Hive Services’ ownership team includes President Dustin Myrick and General Superintendent Derek Crawford. Based in El Reno, Okla., Hive Services performs all facets of pipeline work and is branching out into civil construction and the renewable energy sector.

got our initial job,” said Myrick. “We questioned ourselves, but we were determined to make it work. Our experience and reputations helped us get a foot in some of those doors. Our first job was a little truck offload. It wasn’t much of anything, but it was an opportunity. It was just us doing it — we were the labor hands, equipment operators, concrete guys — and we were on that job for a couple weeks.”

Myrick noted that Hive Services is a “pipeline company first and foremost,” so pipeline services have remained a constant on the

company’s resume, including connecting wells and gathering pipe, station and facility construction, integrity checks, maintenance, and emergency response.

“We can provide a complete project, from start to finish,” said Myrick.

“Growth was fairly quick after we got our feet under us and were established with our customers,” commented Crawford. “In a short period of time, we added about 50 employees and moved from doing that first project, which didn’t have much pipe to it, to installing a couple miles of 16-inch steel.”

During the past few years, Hive Services has expanded into civil construction, including turnkey dirt work for commercial, residential and industrial projects; right-of-way maintenance and restoration; rock hauling; and more. Hive Services also offers work in the renewable energy sector such as solar array installation and sizing; support structures and framework fabrication; storage, inverter and charge switch/tracking equipment installation and procurement; as well as oil- and gas-related solar power equipment repair, procurement and installation.

“I feel like we’ve been successful so far because of our foundation,” said Myrick. “We are really focused on quality and building relationships, and I think that’s kind of built us to where we are today.”

Tackling tough projects

For a recent project, Hive Services installed 8-inch gas line in two sections, which involved putting in new pipe and hooking it up to a well. Along the way, the crew had to navigate around existing live and abandoned lines to put in about 2,500 feet of new line.

10

An operator moves material with a Komatsu PC210LC excavator.

“It’s challenging to work around those old lines, and in many cases, the abandoned ones that are no longer in service are not marked,” said Crawford. “Fortunately, we have the experience to make sure it’s done safely and efficiently.”

That was the case on Hive Services’ largest project to date, which involved installing 4 miles of 12-inch water line with nine well connects in south central Oklahoma over a two-month period. While most of it was open-cut trench, about 3,000 feet involved boring, which Hive Services subbed out.

“Those bigger, more comprehensive projects — not just in pipeline — are really what we are looking for,” said Crawford. “We have always had the ability to do them, but not the capability due to our size. With a staff of around 60 people, now we do. They are a great group that’s a big part of our success.”

Myrick added that another advantage of Hive Services’ staff is

a willingness to travel because the company has expanded its territory from beyond the immediate central Oklahoma area to “anywhere there’s pipeline.” He noted that Hive Services was recently awarded a project in Kansas, and the company is currently looking at work from North Dakota to southern Texas.

Outstanding versatile equipmentservice,

The ownership team at Hive Services emphasized that as their company has grown, so has their relationship with Kirby-Smith Machinery Inc. (KSM). Territory Manager Josh Lee and Rental Representative Brandon Haddad have helped Hive Services purchase Komatsu and Takeuchi equipment, as well as rent additional units as needed.

“We knew Brandon from before we started on our own, and he reached out to see how he and KSM could help,” recalled Myrick. “He helped us get a credit line. Us being a new company, it was hard to get rolling in the financial world.

KSM stepped up, gave us a chance, and we appreciate it. If we need anything, they are right there, whether it’s machines or parts or service.”

Crawford added, “We really like that they are tracking the machines with Komtrax, so they can do the routine services under Komatsu Care. It ensures they are done on time, and the fact that they are complimentary for a certain period of time or hours is great. KSM does a great job.”

Hive Services prefers Komatsu PC210LC-11 excavators and uses the 165-horsepower machines to dig and set pipe.

“They are real versatile machines, and they’re fast,” stated Myrick. “Currently, we deal with up to 16-inch pipe, and the PC210s can easily handle anything up to that size. They have the power we need to dig

11 Continued

. . .

Operators use Komatsu PC210LC-11 excavators to set pipe and dig around an abandoned line on a pipeline project in southern Oklahoma.

‘They've

been great machines’

trenches, and the lifting capacity to set the pipe. The other aspect we like is that their size allows for us to get into some tighter areas, as well as easily transport them. If we get into anything bigger, we will rent what we need such as a PC240. As we progress, we see ourselves purchasing those bigger class sizes.”

In addition to excavators, Hive Services uses a Komatsu D39 dozer with a side boom to handle smaller pipe.

“It’s the perfect combo for laying out and setting 4-inch to 8-inch,” said Myrick. “We pick up each joint, line it up, and hold it for our welders before we install the line. Like the PC210s, it’s easy to move and gives us versatility. After the pipe is set, we backfill with the six-way blade. It’s perfect for our needs.”

Hive Services also has Takeuchi TL12R2 compact track loaders.

“They’re equipped so that we can easily change attachments,” said Crawford. “We have buckets, forks, augers, and mowers. They’ve been great machines. We also have a TB260 compact excavator we use for small lines and anomaly digs.”

Bright future

As Hive Services moves forward, the ownership team would like to take on larger pipeline jobs as well as increase the company’s presence in the renewable energy and civil sectors.

“It’s full steam ahead,” said Myrick. “Our focus for now is continuing to build on our pipeline side first. It’s our intent that within the next five years that we are doing more mainline work, knocking out 30- to 40-mile jobs and doing them on time and on budget. As we continue to build our capabilities and staff, we’ll branch out more.” ■

*The opinions expressed here are from the end user as quoted. The results described herein are those of these end users under certain conditions. Your results may vary.

12

. . . continued

An operator places pipe on a cradle with a Takeuchi TL12R2 compact track loader at the Hive Services’ yard in El Reno, Okla.

Discover more at KirbySmithConnection.com

(L-R) KSM Territory Manager Josh Lee talks with Hive Services owners Dustin Myrick and Derek Crawford.Derek Crawford.

Hive Services uses a Komatsu D39 dozer with a side boom for smaller pipe installation.

TL8R2 There’s only one member of your crew that will never quit, complain, ask for breaks or wish the day would end. The TL8R2 track loader just wants to work. For those who value uptime above all, nothing else comes close. In fact, anything else is probably in the shop. THE MARK OF TOUGHNESS ROBUST DEALER NETWORK TAKEUCHI FLEET MANAGEMENT GENUINE PARTS » DIG IN AT TAKEUCHI-US.COM CLOCKS IN, NEVER OUT. www.kirby-smith.com Abilene 12035 Interstate 20 W. Abilene, TX 79601 Amarillo 3922 I-40 E. Amarillo, TX 79103 Lubbock 3419 East Slaton Road Lubbock, TX 79404 Odessa 7301 E. Interstate 20 E. Odessa, TX 79765 Waco 415 Enterprise Blvd. Hewitt, TX 76643 Kansas City 8320 Ruby Avenue Kansas City, KS 66111 McAlester 4617 Powell St. McAlester, OK 74501 Oklahoma City 6715 W. Reno Ave. Oklahoma City, OK 73127 Tulsa 12321 E. Pine Street Tulsa, OK 74116

NEW! 4-IN-1 SKID STEER BUCKET EXCAVATOR NEW! BUCKETS & THUMBS DRUM CUTTER NEW! NEW! CONE CRUSHER BUCKET SKID STEER HYDRAULIC REAR RIPPERS 800-419-8090 www.solesbees.com GET CONNECTED @ 0 flm 0 @solesbeesequipment Available Through Kirby-Smith Machinery Inc.

CONSTRUCTION OUTLOOK

Fed rate pause could have positive effect on housing market in 2024, economists predict overall growth

Late last year, the Federal Reserve indicated it was likely done raising rates in its efforts to bring inflation under control and avoid a recession.

Construction forecasters were expecting the news even before it was announced, which led to a primarily optimistic outlook for construction starts in 2024.

According to Dodge Construction Network, overall construction starts are expected to rise 7% this year, following a 1% increase in 2023. That projection would bring total starts to $1.206 trillion in 2024. Dodge sees all regions of the country making gains, led by the Northeast at 16% and the West at 10%.

“As we go into 2024, we’re starting to see economic growth become more consistent and accelerating by the end of the year,” said Dodge Chief Economist Richard Branch in the article “2024 Forecast: Non-Building, Manufacturing

Lead the Way” by Engineering News-Record.

Branch added that the outlook is dependent on the assumption that the Federal Reserve is done raising interest rates. Dodge expects rates to begin falling in the middle of 2024, according to the Engineering News-Record article.

A rate increase freeze and expected drop later would bode well for the housing market, according to Dodge and other forecasters. Dodge predicts an overall 11% increase, with a rise of 9% in single-family and 14% in multifamily. ConstructConnect predicts a 4.4% increase in overall residential. The National Association of Home Builders forecasts single-family rising 3.7%.

“As interest rates stabilize and then begin to decline after Q1 or Q2, the

homebuilding sector will revive,” said Alex Carrick, Chief Economist at ConstructConnect.

Transportation’s continued surge

While overall construction was relatively flat in 2023, the transportation sector, which includes public highway, pavement and street construction, was a standout with double-digit growth that saw it reach $108.6 billion. The American Road & Transportation Builders Association (ARTBA) expects the trend to continue and increase another 16% in 2024 to nearly $126 billion, according to Alison Black, Chief Economist at ARTBA.

Black indicated that the rise was influenced by the Infrastructure Investment and Jobs Act (IIJA) because many of the projects supported by IIJA are in the construction phase.

Potential interest rate cuts in 2024 could spur the housing market, according to construction industry forecasters. Dodge Construction Network sees an overall 11% increase, with a rise of 9% in single-family and 14% in multifamily. The National Association of Home Builders forecasts single-family rising 3.7%.

15 Continued . . .

Positive outlooks for the non-building sector

Plus, many states are increasing their own revenues to match federal funds and make additional transportation investments, using a combination of general fund transfers, bond issues, business taxes, and other user-fee increases.

Considering IIJA’s impact on starts, along with states’ increased revenue, ARTBA predicts the total value of overall transportation to grow to $214 billion, a 14% increase. That includes sectors such as airport construction, bridges, public transit, rail, and ports.

Both Dodge and Fails Management Institute (FMI) have positive outlooks for the non-building sector, which

includes transportation. Dodge sees overall growth at 7% with highways and bridges up 23% and environmental public works rising 10%. It only predicts power plants/gas/communications to fall, dropping 17%.

FMI’s outlook is more modest at 7.7% overall with highways and streets at 8.6%, sewer systems at 9.1%, and water supply at 7%. In contrast to Dodge, FMI predicts power will have an increase of 6.2%.

Sector gains

Manufacturing is expected to see double-digit growth within the overall non-residential market, according

to both Dodge and FMI, with Dodge predicting 16% and FMI 15.1%. Both have an overall outlook for non-residential at about 4%.

Dodge predicts as much as 17% growth in the hotels and motels sector, and 9% in stores and shopping centers. It also sees a rise in educational buildings and health care facilities, with drops in office buildings and warehouses. Other non-residential is predicted to be flat.

While FMI predicts office and commercial will fall, it anticipates growth in amusements and recreation, religious, education, health care, and public safety. ■

. .

16

. continued

The American Road & Transportation Builders Association predicts the total value of overall transportation to grow to $214 billion, a 14% increase.

Your one-stop supplier. A JOHN DEERE COMPANY CLOSE TO OUR CUSTOMERS ROAD AND MINERAL TECHNOLOGIES. With leading technologies from the WIRTGEN GROUP, you can handle all jobs in the road construction cycle optimally and economically. Put your trust in the WIRTGEN GROUP team with the strong product brands WIRTGEN, VÖGELE, HAMM, KLEEMANN www.wirtgen-group.com www.wirtgen-group.com/technologies www.kirby-smith.com OKLAHOMA CITY, OK 6715 W. Reno • (405) 495-7820 FT. WORTH, TX 1450 NE Loop 820 • (817) 378-0600 MCALESTER , OK 4617 Powell St. • (918) 310-1550 DALLAS, TX 8505 S. Central Expwy • (214) 371-7777 TULSA, OK 12321 E. Pine St. • (918) 438-1700 ODESSA, TX 7301 E Interstate 20 E • (432) 333-7000 AMARILLO, TX 3922 I-40 East • (806) 373-2826 WACO, TX 415 Enterprise Blvd. • (254) 261-1370 ABILENE, TX 12035 Interstate 20 W • (325) 692-6334 LUBBOCK, TX 3419 East Slaton Road • (806) 745-2112

MAKING THE GRADE

KSM showcases how Komatsu’s Smart Construction solutions can help increase efficiency and potentially lead to greater profitability

Achance to operate Komatsu’s Intelligent Machine Control (IMC) equipment and learn more about its advanced Smart Construction solutions that help increase job site productivity and efficiency drew hundreds to Smart Construction Demo Days, which were hosted by Kirby-Smith Machinery Inc. (KSM) and held at the company’s Dallas and Lubbock locations in Texas, as well as its Oklahoma City, Okla., branch.

light on the numerous benefits. We wanted to give them all an opportunity to see how it can fit into their business, streamline their operations, and potentially increase profitability.”

In addition to Cox, Komatsu IMC Product Manager Neal Rogers and several of KSM’s technology solutions experts (TSEs) were on hand to answer questions and help attendees understand how they can incorporate both machinery and technology into their operations.

proactive in making decisions and adjustments in their practices that can potentially lead to significant increases in time and cost savings.”

IMC equipment in the spotlight

At each event, attendees could get in the cab and run several Komatsu IMC 2.0 dozers and excavators with integrated GPS grade control. Both allow plan models to be uploaded into the machines and have been proven to reduce costs associated with surveying and staking.

“Some customers are brand new to the technology, and some already have it and are interested in adding more,” said Dennis Cox, Director of Smart Construction, KSM. “I think one of the things that prevents the adoption of technology is fear of the unknown. These events shed

“Events like this are a great way for us to understand where customers are in their adoption of technology and how we can help at each step along the way,” said Rogers. “With IMC equipment and our other solutions, customers get the benefit of viewing data at practically any given time every day. That leads to the ability to be more

“Because the GPS is integrated, there are no masts or cables to put up and take down, so production time is increased, and there are cost savings in not having to replace those items,” said KSM TSE Austin Briner. “The dozers are especially helpful for new operators. They automatically work to maximize the material on the blade, so even a novice can be productive right away. We put a guy in one a few weeks ago, and within days, you would have thought he had five years of experience.”

The Komatsu IMC 2.0 dozers allow operators to use automatics from first pass to last. They include proactive dozing control, which enables operators to cut/strip from existing terrain, regardless of their experience level. IMC 2.0 dozers also feature technology such as lift layer control, tilt steering control, quick surface creation, and added satellite systems that improve satellite coverage, allowing operators to work in more challenging areas such as near woods or on urban job sites.

“I’ve never run a dozer in my life and didn’t think it would be this simple to operate,” said Ryan Guerra, a transportation technician with Caddo Nation of Oklahoma, after running a Komatsu D71EXi-24

18

Dennis Cox, Director of Smart Construction, KSM

KSM TSE Bret Johnson (right) shows Cody McGuire of Constructors Inc. the features of a Komatsu GD655-7 motor grader with a Trimble dual GPS system at Smart Construction Demo Days in Lubbock, Texas. “GPS-equipped machines are user-friendly and easy to learn,” said Johnson.

IMC 2.0 dozer. “They did a great job of explaining the technology and walking me through it to get started. Once it’s set up, all you have to do is lower the blade and go forward. The machine will grade out exactly where it’s supposed to. I was definitely impressed by that.”

Komatsu IMC 2.0 excavators virtually eliminate wasteful overdigging as they let you dig straight to grade, and once target elevation is reached, the machine won’t allow the operator to go past it. Additionally, you can accurately excavate slopes and finish grade tasks such as ponds with limited movement. Testing has shown that IMC 2.0 excavators can help improve production by up to 33% and efficiency as much as 63% compared to conventional excavation and grading methods.

“I’m used to stringline and grade stakes to get to grade; with the IMC excavator, you set it to automatic, get to grade, and you can’t dig anymore,” Continued . . .

said Rogers Group Plant Manager Ricky Dunn, who tested out a Komatsu PC210LCi-11 IMC 2.0 excavator at the Lubbock event. “You don’t have to

Rogers Group Plant Manager Ricky Dunn tests out a Komatsu PC210LCi-11 Intelligent Machine Control (IMC) 2.0 excavator at KSM’s Smart Construction Demo Days. “With the excavator, you are on grade every time,” Dunn commented.

Caddo Nation of Oklahoma Transportation Technician Ryan Guerra operates a Komatsu D71EXi-24 IMC 2.0 dozer at KSM’s Smart Construction Demo Days. “Once it’s set up, all you have to do is lower the blade and go forward,” said Guerra.

19

Watch the video

‘Easy to add on, easy to use’

. . continued

worry about digging too far and then having to fill it back in or moving too much material and hauling material back. With the excavator, you are on grade every time. That’s a great advantage.”

Smart Construction Retrofit

KSM showcased machines with add-on systems as well, such as Komatsu’s Smart Construction Retrofit for standard excavators. Retrofit is an entry-level, indicate-only system that’s three-dimensional and gives operators the advantage of seeing where they are on a project and their relation to target elevation.

“Retrofit is a good introduction to using GPS on an excavator,” said KSM TSE Zane Miller. “It can’t do everything an IMC machine can, but it’s a nice bridge between a standard machine and a fully integrated one. It’s easy to add on, easy to use, and has the potential for big savings just like all the Komatsu Smart Construction solutions.”

Once Retrofit is installed, users download the Smart Construction Pilot app and use it with their connected device. They can set audio alerts that will change tones the closer they get to finish grade, and the visual representation on the app helps keep operators from digging too deep.

Additionally, attendees could operate a Komatsu D51EX-24 dozer with a Topcon aftermarket system and a Komatsu GD655-7

motor grader with a Trimble dual GPS system.

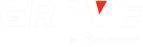

Project management at every stage Attendees also learned how Komatsu Smart Construction solutions can be beneficial in building site models, keeping track of production and labor hours, and remotely monitoring and troubleshooting machinery.

“IMC and Retrofit are great introductory ways to bring technology into your operations at the field level,” said Cox. “Additional solutions such as Smart Construction Fleet, Remote, Drone, Office and Dashboard bring connectivity from the field to the office and help make estimating, bidding and project management so much more efficient, and we were excited about sharing that with those who attended the events.”

Smart Construction Drone provides survey technology that builds an accurate topography of a site safely, quickly and easily. Preconstruction flyovers let you see things you can’t with paper plans, and consistent drone flyovers throughout a project give you information about progress across the entire site and assist with project tracking.

By combining 3D design data with aerial mapping and intelligent machine data, you can confirm quantities and visualize progress with Smart Construction Dashboard. 3D designs can be directly uploaded into IMC machines with Smart Construction Remote.

“Remote is one of the most popular solutions because it allows you to directly upload design files and updates to machines without driving to the job site, as well as remotely support operators who may have questions about the plans,” elaborated KSM TSE Eddie Garcia. “It lets GPS and project managers remotely connect with the machine and see exactly what the operator does on their monitor. It saves valuable time and costs such as decreased fuel usage.”

.

20

Komatsu IMC Product Manager Neal Rogers (right) shows a customer how Komatsu Smart Construction solutions can be implemented into his operations.

At KSM’s Smart Construction Demo Days, an attendee checks out a Komatsu PC138USLC excavator equipped with Komatsu's Smart Construction Retrofit.

Garcia added that all solutions can help increase savings, production and efficiencies. For instance, Smart Construction Design lets you make the leap from 2D to 3D and quickly move from rolled-up paper plans to digital design files with data that can be shared, replicated and updated.

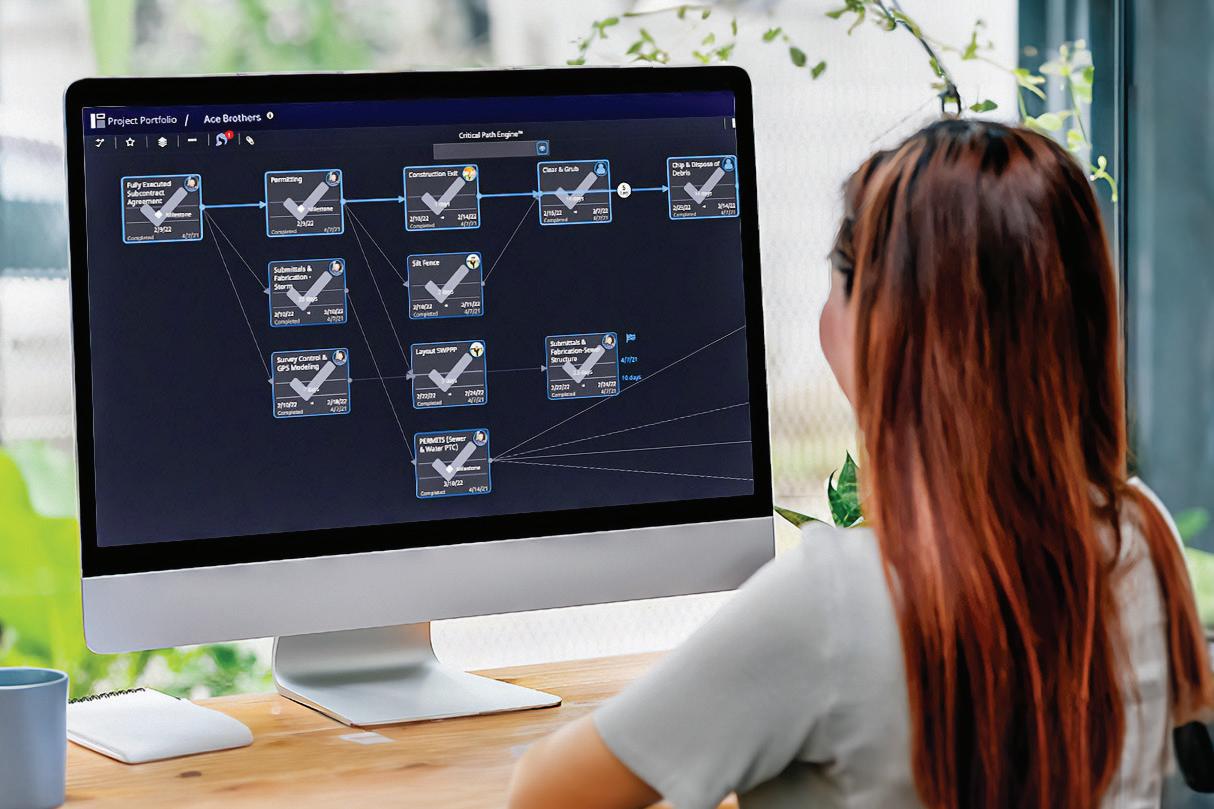

Smart Construction Fleet lets you track load counts with a mobile app and works with any brand of equipment. Smart Construction Field connects humans, machines and materials to automate data collection at the job site for accurate analyzation of operational costs and efficiencies in real time. Smart Construction Office is a project scheduling and management solution that serves as a central hub for all your jobs and can help replace manual production and cost tracking with streamlined daily automation.

“There really is a solution for everyone, no matter the size of their operation,” stated Cox.

“Events like this highlight that, and we encourage anyone who wants to improve their production and efficiency to contact us, and our TSEs can help guide them to which solution is best for their

operation and show them how to implement it.” ■

*The opinions expressed here are from the end user as quoted. The results described herein are those of these end users under certain conditions. Individual results may vary.

21

At KSM's Smart Construction Demo Days, attendees look at some of the technology behind GPS, IMC and Komatsu Smart Construction solutions.

Attendees move material with a Komatsu D71EXi-24 IMC 2.0 dozer and a Komatsu D51EX-24 dozer equipped with a Topcon aftermarket system.

SMART CONSTRUCTION

Smart Construction solutions can help you increase productivity, track it and make faster critical decisions

Technology use in the construction industry has grown rapidly during the past decade and includes both on-machine technology as well as software designed for each stage of project management. Choosing the right technology to move your business forward comes with many questions, and the correct answers depend on what technology your company has already adopted.

additional comprehensive information that helps with proactive fleet management, to help reduce downtime as well as owning and operating costs.

“For our customers, Komtrax was a great introductory option down the technology path, and it continues to be a great feature,” said Jason Anetsberger, Director of Customer Solutions, Komatsu.

are at the moment. We offer solutions that can support a small operation that is currently not using any technology, as well as solutions for large multinationals that have fully embraced machine control and project management systems.”

Anetsberger provided some helpful tips for how to determine which Smart Construction solutions could be beneficial and when the right time to add them is. All of the solutions can be accessed and viewed through your My Komatsu account.

Komatsu has long been a technology proponent. It was among the first manufacturers to incorporate telematics into its machinery, with its Komtrax remote monitoring system that enabled customers to monitor fuel usage, idle time, location and more. During the past two decades, Komtrax has expanded to include

“On our new machines, it’s easily accessible through our My Komatsu platform and lets you monitor any piece of equipment.”

Anetsberger continued, “Now, the question is: what’s the next step that is right for you in this technological journey? Fortunately, we have many Smart Construction solutions depending on where you

No solutions? IMC is a good introduction

If you are not using any of Komatsu’s Smart Construction solutions, Intelligent Machine Control (IMC) dozers and excavators may be a good starting point, according to Anetsberger. When Komatsu introduced its first IMC dozer more than a decade ago, it was the original

If you already have IMC equipment in your fleet, the next step may be to add solutions that help you better track and manage progress. Smart Construction Dashboard allows remote visualization of job site terrain progress with the aim to have a digital twin of the job site material movements. 22

Jason Anetsberger, Director of Customer Solutions, Komatsu

Smart Construction solution. Several new models and next generation machines have been added that feature fully factory-integrated GPS machine control, which helps increase productivity and efficiency by reducing surveying and staking costs and eliminating the masts and cables of traditional aftermarket GPS add-on systems.

With seven sizes of IMC dozers, ranging from the 105-horsepower D39i-24 to the 354-horsepower D155AXi-8, there is a fit for practically every construction site application.

The IMC 2.0 dozers have advanced features such as proactive dozing that enables operators to cut/strip automatically from existing terrain as well as lift layer control, tilt steering control, and quick surface creation.

On the excavator side, there are IMC machines ranging from the 20-ton-class PC210LCi-11 to the 50-ton-class PC490LCi-11.

All have semi-automatic functions that go beyond simple guidance to semi-automatically limit over-excavation and trace a target surface. Once target elevation is reached, even if the operator tries to move the joystick to lower the boom, the excavator doesn’t allow it, reducing wasted time and the need for expensive fill material.

IMC 2.0 excavators feature bucket angle hold control, which automatically holds the bucket angle to the design surface during arm operation. It’s less fatiguing for operators, so they can be more productive, and it produces a better finish-grade surface. Plus, auto tilt bucket control assists operators by aligning the bucket parallel with the slope, so that finish grading can be accomplished without needing to align the machine with the target surface. Testing has shown that these latest generation models help

improve accuracy by up to 33% and efficiency as much as 63% compared to conventional excavation and grading methods.

“We have more than a decade of proven success with IMC machines saving time and material costs, to help increase profitability,” said Anetsberger. “IMC was our first Smart Construction solution, and we have built a suite of additional beneficial solutions, including our Smart Construction Retrofit for standard excavators. This technology is a good entry-level system for someone who may be considering GPS but is not ready to fully commit to integrated machine control.”

Smart Construction Retrofit is an add-on, indicate-only system that offers many of the benefits of IMC. It’s three-dimensional, so operators get the advantage of seeing where

Continued . . .

23

Intelligent Machine Control (IMC) dozers can help increase productivity. For those looking for an introduction to Smart Construction, IMC equipment may be the best fit.

‘Easy to implement, user-friendly’

. . . continued

they are on a project, as well as their relation to target elevation. They can set audio alerts that change tone the closer they get to finish grade. That, along with the visual representation on the app, helps keep operators from digging too deep, saves time and lowers costs.

From site to office and vice versa

Additional Smart Construction solutions can help customers better manage their projects from pre-bid to final close out.

“Knowing which one to use is a matter of assessing your goals,” Anetsberger stated. “Do you want faster, more accurate mapping and progress tracking? Do you want to move to 3D digital plans and combine drone data with 3D design data to confirm quantities? Do you want better labor management and cost tracking and to be able to do it remotely?”

A couple of solutions Anetsberger suggested for those who now have IMC machines are Smart Construction Remote and Smart Construction Dashboard. Remote allows users to

remotely send design files to targeted machines in the field and remotely support operators without driving to the job site, saving time and fuel expenses. With remote access, contractors can help their operators troubleshoot issues in real time by viewing the same visuals as in the machine.

To help users with tracking cut/fill progress, Dashboard allows remote visualization of job site terrain progress, with the aim to have a digital twin of the job site material movements. It combines data from multiple sources into one comprehensive picture and provides a 3D graphic visualization of all design, drone and machine data to measure cuts/fills, quantities and productivity. Users can confirm pre-bid and topographical map data, track site progress in near real time, document job site conditions as evidence for change orders, and quickly and easily measure quantities.

“Dashboard and Remote are complementing solutions to IMC,” said Anetsberger. “The visual representation and the ability to track

job site progress more easily from practically anywhere, can lead to faster decisions and potentially better bottom-line outcomes. They are easy to implement, user-friendly, and the cost savings have been significant for companies using them.”

Further building your solutions portfolio

As any project manager knows, job sites often evolve and plans change, which makes staying on schedule and on budget a challenge. Smart Construction Office is a project scheduling and management solution that serves as a central hub for all your jobs and can help replace manual production and cost tracking with streamlined daily automation. It delivers timely updates, insights and auto-forecasting schedules, and cost estimates throughout a project’s life cycle.

“Office is a project management tool that gives you reliable forecasting and insight into budget versus actual costs,” explained Anetsberger. “Another consideration is Smart Construction Field, a mobile app that uses data to track spending and allows contractors to quickly view current conditions and progress. You can break it down by labor, equipment, materials, receipts, timecards, and much more. Both Office and Field are brand-agnostic, so they can be a great solution for contractors with mixed fleets.”

Additional Smart Construction solutions include Design, Drone and Fleet, which can help replace paper plans with digital files, accurately map job sites, and collect data for fleet optimization.

“There are so many easy ways to implement technology solutions into your operations,” concluded Anetsberger. “We encourage anyone who wants to streamline and optimize their operations to learn about Smart Construction solutions by talking to their distributor about how to get started.” ■

24

Cost tracking is essential. Smart Construction Office is a project scheduling and management solution that serves as a central hub for all your jobs. It can help replace manual production and cost tracking with streamlined daily automation that delivers timely updates, insights and auto-forecasting schedules, and cost estimates throughout a project’s life cycle.

Whether you need training to get the most out of your intelligent machines, or support on your digital transformation, we are here to help. Our team of Komatsu-certified solution experts are on the phone, online or at your job site to make sure you get the most out of your investments. Abilene Amarillo Dallas Ft. Worth Lubbock Odessa Waco Oklahoma City Tulsa McAlester Kansas City St. Louis 325.692.6334 806.373.2826 214.371.7777 817.378.0600 806.745.2112 432.333.7000 254.261.1370 405.495.7820 918.438.1700 918.310.1550 913.850.6300 314.729.0125 www.kirby-smith.com Solutions: • Dashboard • Design • Drone • Field • Remote • Retrofit • Intelligent Machine Control Zane Miller N. Texas / S. Oklahoma zmiller@kirby-smith.com 469-873-0048 Eddie Garcia DFW Area egarcia@kirby-smith.com 469-540-8368 Austin Briner DFW Area abriner@kirby-smith.com 469-584-7602 Bret Johnson West Texas bjohnson@kirby-smith.com 806-782-2380 Keith Graham Oklahoma kgraham@kirby-smith.com 918-210-8590

PAVING CORNER

New WIRTGEN WRC 240i crushes in place, processes homogenous grain sizes in all applications

Do you want to increase sustainability by using existing materials while reducing costs associated with trucking?

WIRTGEN’s new WRC 240i rock crusher breaks course rocks in situ, such as pavement layers and stony soils, and produces a homogenous mix in a continuous process that shortens construction times, conserves resources, and lowers CO2 emissions.

With a working width of 7 feet, 10 inches and a working depth of 20.1 inches, the WRC 240i has an output of up to 600 tons per hour. In addition to crushing rock and stones with an edge length of up to 11.8 inches and a compressive strength of up to 200 MPa, the machine can add cement and water in the same pass. It can also be used for soil stabilization, transforming undesirable soils into a high-grade construction material and depositing it evenly behind the machine.

The WRC 240i offers several setting options that enable the achievement of the desired grain size and consistent uniform

distribution in a wide range of applications. Nine rotor speeds, a variable crushing stage, exchangeable screens with a range of clear mesh sizes and adjustable distance from the rotor, adjustable rotor plate pressure, and the machine advance rate enable the configuration of the machine to meet the demands of actual site conditions and the desired application.

Newly developed crushing and mixing rotor

The rugged and resilient crushing and mixing rotor with toolholders developed especially for crushing applications enables optimal results when working in stony ground. The tools are fitted with large, impact-resistant carbide cutting edges, and the holder bases are protected by wear-resistant protective elements made from high-tensile steel. This ensures high machine utilization rates and process reliability in demanding applications. Robust edge protectors reduce wear on the edge ring segment of the rotor, which is driven via a transmission

The WIRTGEN WRC 240i rock crusher enables the crushing, processing and homogenization of hard-core concrete fragments, cobblestones and stony ground with an output of up to 600 tons per hour. It can also be used to stabilize soils.

developed especially for the WRC that enables high rotor speeds.

For long-term resistance to the stress encountered when crushing rocks, the rotor housing is lined with abrasion-resistant wearing plates made from tough high-tensile steel. These guarantee a longer service life and increase the overall stability of the housing. The entire mixing chamber is lined with these wearing plates, which can be individually replaced if and when required.

By enabling precise, automatic steering, the satellite-based AutoTrac system helps the WRC to achieve greater process efficiency and a high degree of environmental compatibility. It steers the machine accurately within tolerances of a few centimeters on the basis of a previously calculated reference strip and a specified overlap of adjacent strips for consistent utilization of the machine’s ideal working width. The WIRTGEN PERFORMANCE TRACKER registers all relevant location-specific working parameters to provide a comprehensive database for the analysis and documentation of the construction site. ■

26

The Kirby-Smith Machinery Road Construction & Minerals Division is here to partner with our customers to maximize their equipment performance and assist with:

• Best practices for Machine Alications • Start-us and product Demonstrations

• Oerations & Oerator raining • Machine Insections • eneral Q&A on Machines and echnology

Meet Our Product Specialists

Carlos Vega Crushing & Screening Product Specialist (KLEEMANN and Masaba) cvega@kirby-smith.com

806.640.7708

• Industry Exerience: 20 Years

• Extensive exerience running sand & gravel oerations

Brian Evans Crushing & Screening Application Specialist (KLEEMANN and Masaba) bevans@kirby-smith.com

682.816.5344

•Industry Exerience: 30 Years

•Significant exerience for both tracked and stationary units

•Millions of tons of crushed material

Robert Perkins Sr. Paving & Compaction Product Specialist (VÖGELE, HAMM, LeeBoy +WIRTGEN in Oklahoma)

rerkins@kirby-smith.com 501.514.4156

• Industry Exerience: 19 Years

• VöELE Alications Secialist for WI

• project Manager/EstimatorCivil and private Sectors

Chris Brenz WIRTGEN Product Specialist (WIRTGEN) CBrenz@kirby-smith.com 254.447.0774

• Industry Exerience: 7 Years

• Milling, stabilization, and sliform aving

•Extensive service and alication knowledge

405.508.0054

• Industry Exerience: 15 Years

• Over 7 years of exerience in service oerations for

Op

E

Jason Edens WIRTGEN GROUP Technical Specialist jedens@kirby-smith.com

WIE Op line

strategic oversight of all crane support operations throughout KSM’s territory. KSM is an authorized crane dealer for Manitowoc, Grove, National Crane and Broderson — with lines varying by location — and offers sales, rentals, parts and service.

Kelly Shuffield, Vice President, Product Support, Cranes & Lifting, KSM

Kelly Shuffield, Vice President, Product Support, Cranes & Lifting, KSM

Shuffield brings over 30 years of equipment product support experience to this new position, as well as an unmatched understanding of what it takes to support customers.

Response Team. He credits his time at KSM and his prior crane OEM experience for preparing him for this moment.

“I’m excited about the future and look forward to the challenges of this new opportunity,” said Shuffield. “We understand how crucial uptime is to the crane industry and will continue to provide our customers with industry-leading product support that helps them meet their goals. I am grateful for the highly trained

and has the necessary vision and dedication to customer support and employee development to lead KSM to new levels of success, according to Rickey Bailey, Vice President, Crane Division, KSM.

“Kelly’s leadership will continue to be invaluable as we expand our business and find new ways to support our customers,” said Bailey. “He has always been a perfect example of everything KSM stands for, and I have no doubt that will continue as he takes on this expanded role.” ■

28

CRANE CORNER

Strongest load chart, longest boom in 75-ton all-terrain crane class makes new Grove GMK4070L a solid choice

Manitowoc strengthened its four-axle all-terrain crane lineup with the addition of the new 75-ton Grove GMK4070L. The crane offers the strongest load charts and longest boom length in its class, according to Manitowoc. At its full 197 feet of main boom, the GMK4070L can lift nearly 5 tons, while at 160 feet, it is capable of picking loads of up to approximately 9 tons. When working at its maximum radius of just under 151 feet, it will lift 1 ton.

“The Grove GMK4070L offers an improved engineering design and adopts several of the latest technologies to deliver a new level of performance, operation, serviceability and fuel efficiency,” said Andreas Cremer, Vice President of Product Management for Mobile Cranes at Manitowoc. “It’s a crane that will be a true game changer, surprising many customers with just how much more a 75-ton all-terrain crane can achieve.”

Power for both the carrier and the superstructure comes from a single 430-horsepower engine that’s clean, efficient and approved for use with HVO (hydrotreated vegetable oil) diesel for those looking to further reduce their carbon dioxide emissions or meet tight environmental job site requirements. The engine’s ECO mode can be used in conjunction with the transmission’s Fuel Saver mode for greater fuel efficiency.

The optional MAXbase feature helps users reduce setup time and gives them a wider choice of outrigger positions. With this option, the crane becomes an ideal choice for confined spaces or projects where obstacles are preventing setup

in the preferred location. It allows the four double hydraulically telescoping outriggers to be easily extended to a range of symmetric and asymmetric positions, maximizing flexibility and enabling lifting work to continue in less-than-ideal conditions.

Features Grove CONNECT

At a configuration of about 18 tons per axle, the crane will carry 19.6 tons of counterweight, just shy of its full 20.9-ton complement. In situations requiring 13.2 tons per axle, it will carry up to 14.6 tons, while for 11-ton per axle configurations it will travel with 5.8 tons of counterweight.

A Telma retarder package in the carrier design reduces the risk of overheating and overall wear

and tear on the conventional service brake system. The frictionless, maintenance-free braking system remains effective even after the engine is switched off, or when the gearbox is in neutral, ensuring full braking power is available regardless of the crane’s speed.

The GMK4070L is also one of the first Manitowoc cranes to feature the Grove CONNECT digital platform that provides owners with real-time access to fleet data. Through Grove CONNECT, fleet managers can get instant insights into the crane’s performance with just a couple of taps on a screen. Service technicians are supported with remote, optimized troubleshooting, which reduces the frequency of on-site trips and strengthens preventive maintenance programs. ■

The Grove GMK4070L all-terrain crane has a maximum tip height of 253 feet when the approximately 197-foot main boom is paired with the 49-foot swingaway jib option. These capabilities are more commonly associated with 110-ton models and allow the GMK4070L to take on jobs that would typically require larger cranes.

29

Support

Standard and custom units available as sales or rentals and built to conquer any jobsite regardless of what you specialize in. Each machine is backed by our highly trained service and support professionals to keep you up and running. IT’S MORE THAN A DUMP TRUCK. IT’S UNMATCHED VERSATILITY. Find a Kirby-Smith location near you! www.kirby-smith.com/branches/locations www.terramac.com Equipment Support

Standard and custom units available as sales or rentals and built to conquer any jobsite regardless of what you specialize in. Each machine is backed by our highly trained service and support professionals to keep you up and running. IT’S MORE THAN A DUMP TRUCK. IT’SUNMATCHED VERSATILITY. Find a Kirby-Smith location near you! www.kirby-smith.com/branches/locations www.terramac.com

Equipment

Videos

Videos

PRODUCT SPOTLIGHT

New GD955-7 is designed to build and maintain haul roads for truck fleets of 100 tons and up

Solid and smooth haul roads are essential for maximum productivity. To build and maintain them for fleets of 100 tons and up, Komatsu’s new GD955-7 motor grader offers operators the control and precision necessary.

The GD955-7 stands out with its ample horsepower and powerful blade downforce pressure for efficient grading performance. With faster working travel speeds compared to the previous model, Komatsu engineered the GD955-7 to increase grading efficiency while helping reduce maintenance requirements and total cost of ownership.

“With significant increases in operating weight, blade downforce pressure, and working travel speeds, this new size class motor grader will be a smart choice for increased efficiency on our customer’s mine sites,” said Joseph Sollitt, Director of Mining Support Equipment at Komatsu.

Tight turning radius

Despite its large size, the GD955-7 offers excellent maneuverability. It can execute tight U-turns on a standard 100-ton class haul road without the need to fully cut the wheel or course correct. The long wheelbase and large, 27-degree articulation angle allow a tight turning radius and provide maneuverability

for narrow haul road applications in confined spaces and around obstacles.

The newly adopted, long-life circle bearing allows for smooth and precise rotation of the moldboard while eliminating the need for circle play adjustments or replacing wear plates. Coupled with a standard auto-lubrication system, the GD955-7 is engineered to help reduce planned and unplanned maintenance downtime while helping to extend life to overhaul.

“The GD955-7 comes standard with an 18-foot moldboard, and there is a 20-foot optional moldboard available,” said Sollitt. “We encourage anyone who has a larger fleet of trucks and wants to build and maintain their haul roads to contact their Komatsu distributor for additional information.” ■

31

Komatsu’s new GD955-7 motor grader offers operators the control and precision needed to build and maintain haul roads for truck fleets of 100 tons and up.

Model GD955-7 Quick Specs Operating Weight 104,323 lbs. Horsepower 426 hp Moldboard 18 ft. standard, 20 ft. optional

Joseph Sollitt, Director of Mining Support Equipment, Komatsu

DEMO IN THE DESERT

Meaningful conversations, ability to operate equipment stand out at Komatsu’s Quarry Days held at Arizona Proving Grounds

One of the highlights of Komatsu’s Quarry Days is the ability to get in the operator’s seat and put equipment to the test.

“I think it’s a very good thing for Komatsu to do for operators and businesses that are looking for equipment,” said Brad Disrud, an operator with North American Coal at its Coyote Creek Mine in Zap, N.D. “I currently run an older PC2000 that we are looking to replace down the road,

and the ability to get in the new one and make a comparison is valuable. It’s quieter, and the productivity is definitely there. The electronic over hydraulic controls is nice.”

The 1,046-horsepower PC2000-11 surface mining excavator was one of more than a dozen Komatsu machines that attendees could operate or see in action at Komatsu’s Quarry Days, an event that took place at Komatsu’s Arizona Proving Grounds.

Among the machines was Komatsu’s new GD955-7 motor grader with a standard 18-foot blade.

“You can definitely tell the GD955 is a game-changer,” said Mauricio Vallejos with Titan America. “The palm steering is something completely different. In the long run, I think it’s going to benefit a lot of operators because it will cut down fatigue. Your hands are always on the controls. I think it has several uses — padding, the finishing touches, making sure our dragline shoes sit on the ground and don’t bend, and road maintenance for the haul roads our HD785s run on. It could allow us to do that in fewer passes.”

Popular PC900LC-11

In addition to the PC2000-11 and GD955-7, attendees were able to operate several other Komatsu machines, including a PC900LC-11 excavator; an HB365LC-3 hybrid excavator; WA900-8 and WA475-10 wheel loaders; a D475A-8 surface mining dozer; a D71PXi-24 Intelligent Machine Control (IMC) dozer; and HM400-5, HD785-8 and HD1500-8E0 trucks. A ZT44 drill and an RF-5 reclaim feeder were on display as well. Attendees could also talk with product experts from Montabert and Tramac about breakers and Hensley Industries about its Kprime tooth system. Montabert, Tramac and Hensley are all Komatsu-owned companies.

“We have solutions at Quarry Days that represent every application within a customer’s job site — from stripping, to loading and haulage, to drilling, blasting, breaking, processing, and dozing, it’s all here,” said Joseph Sollitt, Director of Mining Support Equipment, Komatsu. “It gives customers a chance to put the machinery to the test and see firsthand what it can do in a real-world setting. The feedback has

32

David Ritter (left) of Heidelberg Materials and KSM’s Jason Wolfe explore Quarry Days.

Arcosa Aggregates Texas LLC’s Ruel Wortham (left) and KSM’s Braxton Britting learn about a Komatsu HM400 articulated haul truck.

been overwhelmingly positive. These types of events are beneficial for the customer, as well as for us to learn more about them and what we can do to improve their operations.”

James Van Remmen with Interstate Earthworks LLC specifically wanted to operate the recently introduced 204,148-pound, 543-horsepower PC900LC-11 excavator that’s designed for heavy construction, demolition, material handling, deep digs, large mass excavation and quarry/mining applications.

“We wanted to compare it to a competitive brand of a similar size,” said Van Remmen. “The speed was very fast for a machine that big.”

With more bucket and lifting capacity, the PC900LC-11 increases productivity up to 40% compared to its predecessor, the PC800LC-8.

“The PC900LC-11 is ideal for those working in applications that involve moving large amounts of

material efficiently,” said Casey Zbinden, Product Marketing Manager, Komatsu. “It’s been a popular attraction at Quarry Days because customers see so many potential uses for it. With an optional counterweight removal system, it’s more easily transported.”

Smart solutions

In addition to equipment, Komatsu representatives from its Smart Quarry solutions and My Komatsu teams were available to show customers the advantages of incorporating technology into their operations.

“Smart Quarry is designed to improve and optimize production, which includes site studies and our new Smart Quarry Site,” said Craig McGinnis, Senior Business Solutions Manager, Komatsu. “What’s great about Site is that it’s brand-agnostic, so it can be used with Komatsu and non-Komatsu equipment. It’s plugged into the machine and transmits actionable data that can

be used to improve practices and increase productivity.”

McGinnis continued, “For example, we did a case study and identified that a quarry was only putting about 89 tons on a 100-ton truck during loading. We determined that if they added about six more tons that it would equate to more than 13,000 tons per month in added production with the same fuel burn and time. The savings are significant.”

Great conversations

The ability to network with other contractors doing similar work is another advantage of events like Quarry Days, according to Moroni Wardell, who along with his three brothers owns and operates Wardell Brothers Construction in Morgan, Utah. The full-service construction company manages two gravel pits and

Continued

33

. . . Watch the video

Attendees test out Komatsu excavators at Quarry Days, including a PC2000-11, a PC900LC-11, and an HB365LC-3 hybrid model. Product Marketing Manager Casey Zbinden (right) answers a question about the PC900LC-11.

‘The savings are significant’

Komatsu personnel provide information about technology such as Smart Quarry Site, which is designed to help increase efficiency and production.

currently runs several Komatsu loaders and excavators.

“Sharing information is very valuable because it gives us insight into how others are using the equipment and the production they get from it,” said Wardell. “All new iron looks pretty and runs really well — but talk to a customer that has 10,000 or 12,000 hours, and you will see where the results really are. We have been able to network with a lot of other customers that stand behind Komatsu equipment.”

Attendee Chad Mikulec said the ability to talk with Komatsu personnel was another positive aspect of Quarry Days.

“The attentiveness of the people out here, wanting to talk to us and hear what we have to say and be actively engaged is very meaningful,” said Mikulec. “It makes me feel good as an end user that they listen to us. Our opinion matters, and what we say is taken into consideration for new products.” ■

*The opinions expressed here are from the end user as quoted. The results described herein are those of this end user under certain conditions. Your results may vary.

. .

34

. continued

Watch the video

KSM’s Justin Ashlock (left) checks out all of the equipment on display at Quarry Days with Interstate Earthworks LLC’s James Van Remmen.

The opportunity to see and operate several pieces of equipment brought KSM’s Britt Stubblefield (left) and Rogers Group’s Ron Caldwell to Komatsu’s Arizona Proving Grounds for Quarry Days.

TRUST LEEBOY. You work hard—and for all the right reasons: pride, quality, reputation, prosperity. You expect your equipment to work as hard as you do, to be every bit as tough, productive and reliable as you are. We are LeeBoy. The name behind the world’s most dependable and productive commercial asphalt paving equipment. www.kirby-smith.com OKLAHOMA CITY 6715 W. Reno 405.495.7820 KANSAS CITY 8320 Ruby Ave 913.850.6300 TULSA 12321 E. Pine St. 918.438.1700 MCALESTER 4617 Powell St. 918.310.1550

Have you seen what’s new in My Komatsu?

We’ve made some exciting changes! An all-new mobile app, simplified ordering through the Online Parts Store, Komatsu Care Program (KCP) integration and more have been added to enhance the My Komatsu user experience.

Log in to your My Komatsu account to see the full range of new features. Don’t have a My Komatsu account? Go to mykomatsu.komatsu to sign up.

OPTIMIZED EXPERIENCE

My Komatsu updates, new features improve fleet management to help you get the critical information you want in fewer clicks

Fleet management is essential to maintaining your equipment’s health. Properly maintained equipment helps increase uptime and lower overall owning and operating costs. Staying on top of fleet management can be challenging, especially if you are still relying on end-of-day field reports or drives to the job site to check hour meters.

Andrew

Casey, Digital Solutions Analyst, Komatsu

Digital solutions such as My Komatsu can change the game by giving you real-time machine data

that can be accessed from practically anywhere, as well as tools that give you the capability to order parts and more. Recent updates make it easier to navigate, so you can quickly get the information you need to help make proactive fleet management decisions.

“Filtering capabilities have been updated to help users more quickly access the information they are looking for,” said Andrew Casey, Digital Solutions Analyst, Komatsu. “It’s more

like a dashboard where you can get information in fewer clicks, which is something our customers wanted. Using their feedback, we made changes to make the interface more user-friendly. Customers who already have a My Komatsu account will see the updates automatically.”

Casey said one of the priorities based on customer feedback was a redesign of the My Fleet page, emphasizing that its substantially different look and easier navigation enable users to see their entire

My Komatsu lets users monitor their fleet from anywhere at any time and helps optimize fleet management — with real-time data that can help you make proactive decisions.

37 Continued . . .

Easier, faster and more efficient

fleet of registered machines all on a single page without having to go through multiple tabs.

“We also expanded the ability to filter by idle time percentage, SMR range, model type, manufacturer, and much more,” Casey added.

“A new sync map feature lets users zoom in on a particular territory, click the sync map to list button, and see machines just in that territory.”

Component tracking capability

Another major change is the addition of component tracking, according to Casey. The new functionality allows users to monitor component health, so they can more proactively plan for replacements.

“Users can set an interval based on last service date or SMR hours of the machine, then create an alert that notifies them when a component is due for replacement,” Casey explained.

Machine health and fleet monitoring are now easier, faster and more efficient with new alerting features, including additional alert types for abnormality codes, coverage, Komatsu Oil and Wear Analysis (KOWA) samples, and more. Consolidated and customizable views of your alerts can be set with the alerting dashboard. With My Komatsu, you can choose how to receive notifications — by web, mobile app, email or SMS.

Telematics information (Komtrax) in My Komatsu remains a vital feature that works with Komatsu and other brands that you have registered in your My Komatsu account. You can view machine location, fuel consumption, and machine health, which includes maintenance history.

Additional features available in My Komatsu include:

• Publications – View parts and support manuals for your machines

• E-commerce parts stores – Easily order parts and solutions that you can pick up in store, have shipped to your shop, or get delivered directly to your job site

• Digital solutions – Sign up for and access your Smart Construction accounts such as Dashboard, Design, Drone, Field, Fleet, Office and Remote