By David Holzel CEG CORRESPONDENT

Austin Water, in Texas’ capital city, has begun work on a $1.2 billion project to update and expand its Walnut Creek wastewater treatment facility.

Approved by the Austin City Council in May 2024, construction on the facility began in October 2025 to increase the facility’s capacity from 75 million gal. per day to 100 million.

Austin, with a rapidly growing population — from 297,000 residents in 1974 when Walnut Creek went into service to 980,000 in 2023 — and facing ncreasingly extreme weather, needs more from its wastewater treatment plants than it did 50 years ago.

In addition to a larger capacity, Walnut Creek will have, among its updates, modern equipment, advanced odor control technologies and improved flood resistance.

MWH is the prime contractor. A U.S. contractor in water, wastewater and industrial water construction projects, MWH was selected after a competitive process, said Austin Water Managing Engineer Lauren King.

The project will be delivered by the construction manager at risk method, or CMAR, King said.

“CMAR has advantages in that it allows the design team and the contractor to work together to achieve a more constructable and efficient final product,” she said.

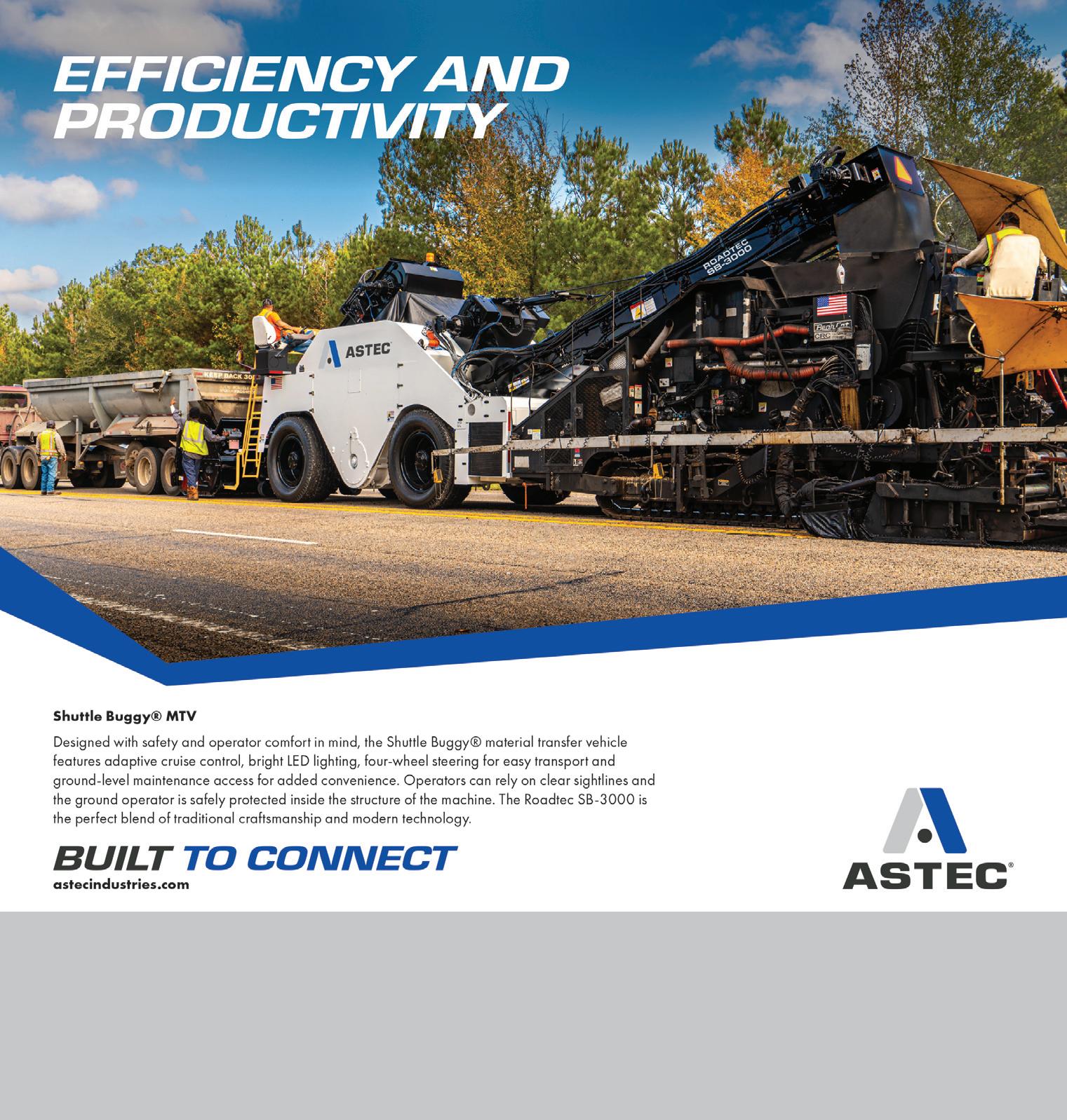

By Lucy Perry CEG CORRESPONDENT

expert evaluation of your construction site, from fleet staging to safety practices, can offer a new perspective on operations, a better way to perform rudimentary tasks, plans to save costs in fuel, labor and equipment maintenance. The process can be as cursory or as detailed as you need.

page

2018 Bomag BW145D-5, Stk#: HR1669, 54" Smooth Drum w/Pad Drum Shell Kit, 889 hrs. $42,500

2024 John Deere 210P, Stk#: HR1593, EROPS, A/C, 2,247 hrs., GP Bucket $189,500

2023 John Deere 700L LGP, Stk#: HR-1461, EROPS, A/C & Heat & Heat, Radio, 2,686 hrs., 6 Way Blade, 30" Pads, 12 ft. Wide ..............$189,500

2021Linkbelt 145X4LC, Stk#: HR1733, EROPS, A/C & Heat, Radio, 2,938 hrs., 60% U/C, 36" Bucket w/Hyd. Thumb, 24" Pads, Aux. Hyd. ............................................$78,500

2023 John Deere 450P LGP, Stk#: HR-1531, EROPS, A/C & Heat, 985 hrs., 6 Way Blade, 24" Pads, 9' 7" Wide ..................................$119,500

2022 Skytrak 6036, Stk#: HR-1389, OROPS, 6,000 lbs., 36 ft., 802 hrs., 60" Forks, 74" Frame, 370/75-28 Foam Filled Tires $99,500

2023 John Deere 650P LGP, Stk#: HR-1555, EROPS, A/C & Heat, Radio, 1,176 hrs., 6 Way Blade, 24" Pads, 10' 4" Wide ..............$159,500

2023 John Deere 75G, Stk#: HR1465, EROPS, A/C & Heat, Radio, 1,443 hrs., 24" Bucket, 91" Blade, 17" Rubber Pads. $89,500

2023 John Deere 26G, Stk#: HR1493, OROPS,

The 150th anniversary of the Battle of the Little Bighorn occurs on June 25, 2026, and a tribally owned construction company is hoping to complete work on a new $14 million visitors’ center at the national monument.

CONSTRUCTION FOR MAPS 4 STADIUM

The Oklahoma City Council voted on Jan. 13, 2026, to approve a construction management services contract with Lingo Construction of Oklahoma City for the new $121 million MAPS 4 Multipurpose Stadium.

Epiroc USA, a productivity partner of the mining, drilling and infrastructure industries, announced the appointment of G.W. Van Keppel Co. as its authorized dealer partner in Oklahoma, Texas, Kansas and Missouri.

12 WYOMING TRANSPORTATION BOARD AWARDS EIGHT HIGHWAY CONTRACTS

The Wyoming Transportation Commission awarded eight contracts valued at approximately $60 million for Wyoming Department of Transportation construction projects at its regular December business meeting.

14 SCHWEISS BIFOLD DOORS: BUILDING

If you want to get around Alaska, your best bet is by air. The vast majority of the state isn’t reachable by road, making flying a necessity. There are more than 9,100 licensed pilots in Alaska.

The U.S. Army Corps of Engineers, Tulsa District awarded a construction contract to replace the State Highway 251A bridge over Fort Gibson Dam near Fort Gibson, Okla., on Dec. 15, 2025.

The construction of the Juneau Creek Bridge with a span of 951 ft. is the centerpiece of one of the largest infrastructure projects in Alaska. The bridge will significantly increase the traffic capacity on the Sterling Highway.

20

Caterpillar Inc. unveiled a set of AI-powered and autonomous innovations that mark a major step forward for heavy industry, transforming machines into intelligent, connected systems.

20

Ecker brings extensive executive leadership experience across the construction equipment and heavy machinery industries, with a strong background in operations, sales and strategic organizational growth.

24

2026

Equip Exposition announced a new addition to the 2026 show, slated for Oct. 20-23: a closing party at Paristown Point Oct. 22, one of Louisville’s most dynamic new developments and a historic district.

42 JLG ADVANCES FUTURE JOB SITE VISION WITH CANVAS ACQUISITION

JLG Industries Inc. announced the acquisition of the core technology developed by Canvas, a San Francisco-based construction robotics technology company known for pioneering robotic solutions for interior construction applications.

46 RDO EQUIPMENT’S MACHINE HEALTH DETECTIVES AT WORK

During this era of tight profit margins and competing demands on people’s time, a machine monitoring system plus planned maintenance builds confidence in machine operators’ ability to get the job done.

56 SMART TECH FOR JOB SITES: COMPACT EQUIPMENT PERFORMANCE

In today’s construction industry, efficiency isn’t just a buzzword — it’s a competitive advantage. Contractors face tighter deadlines, rising costs and increasing pressure to deliver precision work.

58 AEM INDUCTS THREE INTO AEM HALL OF FAME FOR 2025 CLASS

The AEM Hall of

Robert “B.R.”

founder of LeeBoy; Art and Panny McElroy, founders of McElroy Manufacturing; and Nicolaus August Otto, engineer and inventor of Deutz, into this prestigious group.

After years of dedicated service to the country, United States military members leave their enlistment to return to civilian

but many veterans find this transition incredibly difficult, especially when it comes to finding employment.

The 150th anniversary of the Battle of the Little Bighorn occurs on June 25, 2026, and a tribally owned construction company is hoping to complete work on a new $14 million visitors’ center at the national monument south of Crow Agency, Mont., according to bozemandailychronicle.com.

The new 9,000-sq.-ft. building at the Little Bighorn Battlefield is rising on the footprint of the prior visitor center, which was torn down in late 2024. The new building will feature environmental controls, a contemporary design that blends with the landscape, large windows and a roof terrace that provides an elevated battlefield view.

Nomlaki Technologies LLC of West Sacramento, Calif, is building the visitors center, bozemandailychronicle.com reported. That company is owned entirely by members of the Paskenta Band of Nomlaki Indians.

It is uncertain whether the new visitors center will be finished in time to mark the anniversary of the 1876 battle between the U.S. 7th Cavalry and the Crow scouts and Lakota and Cheyenne warriors.

Visitors to the National Park Service’s website are advised to plan on limited access and parking through June 2026.

Completion of the work in time for the anniversary would be a boon to the region’s economy, according to bozemandailychronicle.com.

The University of Montana’s Institute for Tourism and Recreation Research said in 2025 that the national monument is the most-visited site by nonresidents who travel to eastern Montana, according to a 2025

study by the University of Montana’s Institute for Tourism and Recreation Research.

Site visitation peaked in 2002 at more than 425,000 visitors, but only 111,800 tourists stopped by in 2024. That was the lowest total since 1953, excluding the 2020 pandemic year, according to bozemandailychronicle.com.

And in 2025, attendance dwindled to approximately 42,700 because the site is only open Friday through Sunday.

Building a new visitor center has been a lengthy process.

May 2011 flooding at the old visitors’ center prompted the removal of millions of dol-

lars’ worth of artifacts, documents and rare books — including documents President Abraham Lincoln signed and items from Lt. Col. George A. Custer’s uniform wardrobe — that were relocated to a park service storage and conservation center in Tucson, Ariz. When the new building is complete, the park services has promised to return the artifacts, according to bozemandailychronicle. com.

Before the flood, there were nearly three decades of stalled negotiations caused by a standoff between the Custer Battlefield Preservation Committee and the Crow Tribe, according to bozemandailychronicle.com.

In 1982, the committee started buying Crow Reservation land with the intention to donate it to the park service. More than 3,000 acres were acquired, but the park service needed congressional approval to accept it. Plans weren’t approved for decades.

A $4.5 million grant from the Leona M. and Harry B. Helmsley Charitable Trust in 2020 is helping to pay for the project, with the remainder coming from donations to the Centennial Challenge program and the National Park Foundation, according to bozemandailychronicle.com.

(All photos courtesy of National Park Service.)

The Oklahoma City Council voted on Jan. 13, 2026, to approve a construction management services contract with Lingo Construction of Oklahoma City for the new $121 million MAPS 4 Multipurpose Stadium, set to anchor a future sports and entertainment district just south of Bricktown.

“Selecting a construction management firm is a significant step forward for the multipurpose stadium project,” said David Todd, MAPS program manager. “The Lingo team brings valuable local expertise and a strong track record delivering complex venues and community spaces.”

Construction is expected to begin this spring, with the stadium scheduled to open in early 2028.

“Lingo is excited to be part of this significant project that will serve the community in many ways,” said Stan Lingo, Lingo Construction president. “The stadium is designed to be more than a sports venue — it will serve as a gathering place that welcomes visitors from across the nation, supports local teams and events and creates lasting memories for generations to come. We’re honored to work alongside the city and our project partners to help bring this vision to life.”

The multipurpose stadium was designed by Populous and will be operated by Echo Investment Capital. A first look at the stadium design was announced in December.

The project is funded by

MAPS 4, the 2025 OKC Bond, Tax Increment Financing (TIF), private contributions and other economic development sources.

The site is east of the Oklahoma City Convention Center and south of Bricktown near Interstate 40. The stadium will feature a United States Soccer Federation-approved field and serve as the home to both women's and men's teams. The 10,000-seat venue will feature a club section, supporters’ section, locker rooms and suites.

While soccer will be its primary function, the stadium is poised to host football, youth sports, concerts and community events.

For details, visit okc.gov/MAPS4.

Epiroc USA, a productivity partner of the mining, drilling and infrastructure industries, announced the appointment of G.W. Van Keppel Co. as its authorized dealer partner in Oklahoma, Texas, Kansas and Missouri.

G.W. Van Keppel is an established distributor in the equipment industry with an extensive history.

Founded in 1926 and headquartered in Kansas City, Mo., G.W. Van Keppel is a distributor of heavy equipment, drilling systems and consumables with multiple branch locations.

The company said it brings many years of industry experience, strong customer relationships and a commitment to quality service. G.W. Van Keppel is still owned and managed by third- and fourth-generation Van Keppel family members.

G.W. Van Keppel serves customers through branch locations in Fort Worth and New Braunfels in Texas; Tulsa and Oklahoma City in Oklahoma; Garden City, Kansas City, Topeka and Wichita in Kansas; and Joplin, Kansas City and Springfield in Missouri.

The company said it can supply local service expertise, fast parts delivery and proactive service for Epiroc customers in aggregates, construction and drilling markets.

“G.W. Van Keppel’s strong reputation, customer loyalty and focus on the aggregates market make them an outstanding partner for Epiroc,” said Todd Courtney, Epiroc USA sales manager — construction and partners. “We are excited to welcome them to our network and look forward to the value they will bring to our customers in these regions.”

“Van Keppel is excited to partner with Epiroc,” said Sam Hayes, G.W. Van Keppel’s aggregate division manager. “Integrating Epiroc’s lineup into our existing portfolio

allows us to better support our entire customer base. By bridging Van Keppel’s renowned service with Epiroc’s innovative technology, we’re delivering a solution that delivers maximum value to our customers.”

Effective November 2025, G.W. Van Keppel assumed the dealer responsibilities in the dedicated territories. Together, both organizations said they are committed to maintaining uninterrupted support for customers throughout the territory, with an emphasis on responsive service, reliable parts avail-

ability and long-term partnerships.

As the new distribution structure takes effect, Epiroc said it remains focused on strengthening its dealer network, expanding local expertise and delivering products and solutions.

For more information about G.W. Van Keppel, visit vankeppel.com.

For more information about Epiroc USA, visit epircoc.us or call 844/437-4762.

The Wyoming Transportation Commission awarded eight contracts valued at approximately $60 million for Wyoming Department of Transportation construction projects at its regular December business meeting.

The commission awarded a bid valued at approximately $42.9 million to Utah-based W.W. Clyde & Co. for the combined reconstruction on one bridge and five overhead sign structures; bridge replacement on two structures; the replacement of water and sewer mains; and enhancements.

The projects involve placing concrete pavement, installing median barrier, placing road base, installing shoulder barrier, applying pavement markings, erecting structural steel, placing MSE wall, excavating, replacing overhead sign structures, removing concrete pavement, placing structural concrete and installing a traffic signal system on Interstate 25 at the Casper Marginal section (McKinley — Yellowstone) beginning at mile marker 187.99 and spanning approximately 2 mi. in Natrona County.

The contract completion date is June 30, 2028.

The commission awarded a bid valued at approximately $10.5 million to Worland,

Wyo.-based McGarvin-Moberly Construction Co. for a combined mill and overlay project with isolated areas of reconstruction.

The project involves placing asphalt pavement, placing road base, installing box beam guardrail, installing MGS guardrail, excavating, applying chip seal, milling plant mix, placing geotextile, installing fence and installing plant mix curb on U.S. 16 for approximately 15.20 mi. at various locations between Buffalo and Ten Sleep in Johnson County. The contract completion date is Sept. 30, 2027.

The commission awarded a bid valued at approximately $2.3 million to Cheyenne, Wyo.-based Reiman Corp. for the installation of a pedestrian underpass.

The project involves placing precast box culverts, excavating, installing storm sewer components, installing precast walls, placing a concrete bike path and placing road base on the U.S. 287 bypass at mm 1.87 (Higley Boulevard) in the city of Rawlins in Carbon County. The contract completion date is Oct. 31, 2026.

The commission awarded a bid valued at approximately 1.8 million to Montanabased RoamMT LLC for a bridge replace-

ment project involving installing temporary shoring, placing structural concrete, erecting structural steel, removing one steel bridge, laying asphalt pavement, machine placing riprap, excavating, installing box beam guardrail, installing reinforcing steel and placing road base on County Road 78 (Barnum Road) at mm 10.205 at the bridge over Middle Fork Powder River in Johnson County. The contract completion date is Oct. 31. 2026.

The commission awarded a bid valued at approximately $995,000 to Casper, Wyo.based Modern Electric Co. for electrical and Americans with Disabilities Act upgrades involving installation of traffic signal system, placing concrete sidewalk, removing a traffic signal system, placing curb and gutter, drilling shaft foundations and applying pavement markings on approximately .10 mi. on U.S. 26/89/191 (Broadway Avenue) beginning at mm 154.28 in the town of Jackson from Jackson Street to Millward Street in Teton County. The contract completion date is Dec. 31, 2026.

The commission awarded a bid valued at approximately $706,900 to Reiman Corp. for bridge rehabilitation on two structures.

The project involves application of bridge deck overlay, repairing the bridge deck and placing structural concrete on I-25 at mm 8.44 just south of Cheyenne in Laramie County. The contract completion date is Oct. 31, 2026.

All the above projects are funded primarily with federal dollars.

Funded primarily with state dollars, the commission awarded a bid valued at approximately $691,900 to Rock Springs, Wyo.-based Mountain Works for a stockpiling and screening project involving stockpiling chip seal aggregate and screening existing aggregate stockpiles at various locations in Fremont and Park counties. The contract completion date is Oct. 31, 2026.

Also funded primarily with state dollars, the commission awarded a bid valued at approximately $113,000 to Reiman Corp. for bridge rehabilitation on one structure, involving timber bent cap replacement and excavation on Wyoming 211/Horse Creek Road between Cheyenne and Horse Creek at mm 17.29 in Laramie County. The contract completion date is March 31, 2026. Almost all WYDOT projects are awarded to the lowest bid.

If you want to get around Alaska, your best bet is by air. The vast majority of the state isn’t reachable by road, making flying a necessity. There are more than 9,100 licensed pilots in Alaska, the most pilots per capita than anywhere else in the United States.

To serve these pilots, Alaska has a massive system of airports, airstrips and landing spots for aircraft; more than 760 recorded landing areas. Nearly 400 are public-use airports, while the rest are owned by private entities or the military.

One such privately owned airport is Airkat Airpark 9AA9, located outside Haines. Owned and operated by George and Lynette Campbell, the runway is approximately 1,100 ft. long and 130 ft. wide. Airkat also had a brand new hangar, approximately 60 ft. by 80 ft., with many nice features, including a liftstrap bifold door from Schweiss Doors, measuring 55 ft. by 15 ft.

“We’re not big into buying expensive cars or going on cruises,” said Lynette Campbell. “That just doesn’t suit us. So, we decided if we’re going to build a hangar, let’s build a really nice hangar.”

Both Campbells have had long careers in Alaska aviation. Lynette Campbell, now retired, worked for the Alaska Department of Transportation Aviation Division, managing airport lands in southeast Alaska. George Campbell is a bush pilot, flying various types of aircraft throughout the state. He has offered flight tours of glaciers, fishing and bear watching as well as providing air taxi services.

“Both of us come from aviation, him from the pilot side and me from the management, operations side,” Lynette Campbell said.

At one point, the couple owned a home near a glacial river where they would clear some space on the bank to be used as a landing strip for George Campbell. However, with the glacial rivers always changing and washing away the landing area, the couple decided to find a spot where they could build a more permanent setup.

They also wanted to create a landing area that could be used by other pilots in case of an emergency, such as a lowfuel incident or bad weather. Alaska’s small, rural airports and landing strips act a lot like a gas station does in the rest

of the United States. The Campbells decided to register their landing strip with the Federal Aviation Administration as an airport, so it would be part of the larger network.

“You want to strategically place airports along the way, to fill in gaps so a pilot is never more than a few hours away from one,” Lynette Campbell said. “This airport does help fill a hole in the aviation system in the state. I’m real passionate about Alaska and Alaskan aviation and I feel like this is my contribution.”

Like the majority of building projects, what started as a

simple runway soon turned into a much larger project.

“As we talked about what this would look like, it got more and more elaborate,” Lynette Campbell said, adding that work is continuing to extend the runway to 2,300 ft.

The hangar has a bunk room for visiting aviators to use and a more complete apartment above the hangar floor that may eventually be used to lodge visitors for extended visits. The building is clad in dark metal sheeting and includes several windows to let in the natural light.

see SCHWEISS page 54

Cleveland Tank, a manufacturer of diesel fuel and hydraulic tanks, announced that it has successfully been recertified to ISO 9001:2015, the internationally recognized standard for quality management systems.

This recertification reflects Cleveland Tank’s ongoing commitment to consistent quality, process-driven excellence and customer satisfaction across all aspects of its operations. By meeting the rigorous requirements of ISO 9001:2015 once again, Cleveland Tank reaffirms its ability to provide reliable, high-performing products and services to OEMs, distributors and end-users, according to Cleveland Tank.

“Maintaining ISO 9001:2015 certification is a powerful validation of the systems we have in place and the dedication of our entire team,” said David Wilson, general manager.

For decades, Cleveland Tank has provided direct-fit diesel fuel tanks, hydraulic tanks and accessories designed to reduce down-

“Maintaining ISO 9001:2015 certification is a powerful validation of the systems we have in place and the dedication of our entire team.”

David Wilson Cleveland Tank

time and deliver lasting performance. The ISO 9001:2015 recertification demonstrates the company’s continued focus on quality and continuous improvement to support customers across industries.

For more information, visit clevelandtank.com.

“Our customers trust us to deliver tanks and components that meet the highest standards, and this recertification reinforces that trust.”

On Dec. 17, the U.S. Senate approved the National Defense Authorization Act (NDAA), sending it to President Trump for his signature, following passage by the U.S. House of Representatives.

Importantly, the final bill did not include right to repair provisions that AED actively lobbied against, representing a significant victory for the industry and a setback to those seeking to impose these mandates on products, including off-road equipment.

AED members actively engaged lawmakers regarding the equipment industry’s concerns with language originally included in the house and senate NDAAs passed by both the house and senate, and it was a top priority during the AED policy conference and advocacy day in October 2025.

“Thank you to equipment dealers and manufacturers for educating lawmakers about the impact misguided right to repair proposals have on the industry,” said AED president and CEO Brian P. McGuire. “This

was not a time for the equipment industry to be passive. Ensuring that right to repair provisions were removed from the National Defense Authorization Act prevents off-road equipment from inclusion in legislation pertaining to military and weapons systems, and assists in our efforts to defeat similar proposals that apply directly to the products AED members distribute, service and manufacture.”

Throughout the process, AED led the charge on behalf of equipment dealers against the NDAA right to repair provisions, as outlined in an article by AED’s Senior Vice President of Government and External Affairs Daniel B. Fisher that was published in Farm Equipment in July 2025.

For more information, visit aednet.org.

The U.S. Army Corps of Engineers, Tulsa District awarded a construction contract to replace the State Highway 251A bridge over Fort Gibson Dam near Fort Gibson, Okla., on Dec. 15, 2025

The Tulsa District awarded the $63.8 million contract to Alberici Constructors of St. Louis.

The construction contract calls for demolition and replacement of the bridge. The SH-251A bridge was constructed concurrently with the Fort Gibson Dam from 1942 to 1949. With 30 spans, the Fort Gibson Spillway Bridge is the longest bridge in Tulsa District’s inventory.

The Tulsa District closed the Highway 251A bridge, which spans the Fort Gibson Dam spillway over the Grand-Neosho River, on April 22, 2025, after a bridge safety inspection identified critical findings. The bridge runs on the line separating Wagoner County and Cherokee County.

“We have been tracking and addressing

deficiencies at the Fort Gibson Spillway Bridge,” said Patrick Shoopman, Tulsa District bridge safety program manager. “We were surprised at the speed of degradation since the last inspection in November 2024.”

The bridge condition does not pose an immediate dam safety risk, nor does it affect powerhouse operations at Fort Gibson Dam.

Tulsa District engineers had conducted frequent inspections at the Fort Gibson Spillway Bridge due to deteriorating conditions.

In 2021, the Tulsa District posted load limitations to prohibit vehicles exceeding 15 tons from using the bridge. In 2023, USACE inspectors recommended closing a portion of the downstream lane on the bridge and, in 2024, the full downstream bridge lane was closed.

A project delivery team from the Tulsa District completed a full design for the replacement of the Fort Gibson Spillway Bridge in 2024.

Re-powering a mobile machine with a Tier 4 Final engine is a cost effective way to achieve a second life for your equipment while meeting CARB emissions standards.

At Smith Power Products, Inc. we understand the rigors of off-highway diesel engines and mobile machinery. Which is why our industrial products are designed to meet these tough everyday standards. We emphasize performance and reliability to provide you with a product that maximizes your production and profitability.

Our re-power capabilities cover a vast range of mobile machinery and our years of experience has taught us that proper installation is a key component in the second life of a machine.

All of these re-powers were completed using FPT and MTU

4 Engines which DO NOT USE

technology!

The construction of the Juneau Creek Bridge with a span of 951 ft. is the center piece of one of the largest infrastructure projects in Alaska.

The bridge will significantly increase the traffic capacity on the Sterling Highway between Anchorage and the Kenai Peninsula and improve safety. Traylor Bros Inc. relies on two Liebherr LR 1300.1 SX crawler cranes that are playing a crucial lifting role during the assembly of the bridge sections.

The steel girders of the bridge are assembled on one side of the canyon and then gradually pushed over the deep Juneau Creek Canyon to Cooper Landing with hydraulic presses using the bridge launch technique. Using this technology, the massive individual sections can be positioned precisely without the need for complex scaffolding across the chasm.

“The most challenging lift for us was the first girders of the bridge,” said Travis Ludlow, crane driver of one of the LR 1300.1 SX of Traylor Bros Inc. “They were very heavy, and I had to rely on a lot of ground people because wind was coming in. We could see up to 40 mile per hour winds. So I am very happy that we therefore have two Liebherr crawler cranes — one on each side of the project.”

He was particularly pleased with the cranes’ Gradient Travel Aid for safely negotiating slopes, which is challenging due to the topographical conditions of the project. The crane’s control system automatically calculates the center of gravity and warns the operator before the crane leaves the safe area. While travelling, the operator receives real-time information about the permissible and actual gradient, and the crane’s overall center of gravity at all times. If necessary, the main boom angle can be altered so that the machine remains in the safe area.

Only solid steel girders are being used for the Juneau Creek Bridge. These allow for wide spans and a high load-bearing capacity with minimum material weight. The girders must be aligned with millimeter precision to achieve the necessary stability for the bridge. Traylor Bros Inc. are carrying out this job with the two crawler cranes LR 1300.1 SX, so that the bridge can grow safely and efficiently across the canyon.

“There were several factors that went into the decision to choose the LR 1300.1 SX,” said Tyler Becker, senior field engineer of Traylor Bros Inc. “The reliability of the crawler cranes is incredibly important for our project site. We have a small window before the weather kicks us out. Any malfunctions would cause massive schedule delays. The LR 1300.1 SX works when we need it. It has the versatility and the capacity to handle all the lifts we need to do.”

The bridge has to withstand the extreme weather conditions in Alaska: strong snowfall, biting winds and great temperature swings. The seismic activities in the region also were considered in the technical calculations, in order to provide sufficient safety in the event of earthquakes.

The remote location and the surrounding natural habitats required careful planning of the project so that the ecological impact could be minimized. Steep slopes and limited access roads make the positioning of large bridge components extremely difficult. Traylor Bros Inc. planned the whole deployment of the two crawler cranes in advance and also during the work using Liebherr’s 3D software Crane Planner 2.0. By simulating the lifts, the company is supported in taking all scenarios into account and finding solutions for them in advance so that the bridge project can be completed safely, efficiently and on time.

The crawler crane type LR 1300 just celebrated its 18th birthday. With the construction of the Juneau Creek Bridge, the two LR 1300.1 SX — the two newest models of the type — have found a spectacular anniversary project in breathtaking surroundings.

Caterpillar Inc. unveiled a set of AIpowered and autonomous innovations that mark a major step forward for heavy industry, transforming machines into intelligent, connected systems that help customers build and power the world’s critical infrastructure, according to Caterpillar.

Caterpillar CEO Joe Creed took the CES keynote stage with Ogi Redzic, chief digital officer, and Jaime Mineart, chief technology officer, for a futurefacing keynote to showcase how AI, autonomy and edge computing are converging to create the next generation of heavy equipment — and committed $25 million to the future workforce who will help build it.

As AI accelerates transformation across industries, it depends on the physical world — an invisible layer of the tech stack that provides the foundation for modern technology. Caterpillar builds, powers and now makes more intelligent the machines that enable that progress, from the equipment that mines for critical minerals used in semiconductors and batteries to machines used to construct roads, bridges, data centers and energy systems.

At CES 2026, the company demonstrated how it is advancing Industrial AI, moving it from vision to reality.

Caterpillar introduced Cat AI assistant, a powerful AI solution that unifies Caterpillar’s diverse portfolio of digital applications and high-quality data into one simple, conversational experience. Using Caterpillar’s own trusted data stored on the Helios unified data platform, the Cat AI assistant provides customers with reliable, context-rich information to make daily work easier.

The goal is to help customers stay one step ahead from the office to the job site, and soon even into the cab of the machine.

Caterpillar and NVIDIA announced an expanded collaboration aimed at accelerating an AI-enabled future including on-board AI features, AI

Caterpillar introduced Cat AI assistant, a powerful AI solution that unifies Caterpillar’s diverse portfolio of digital applications and high-quality data into one simple, conversational experience.

agents at the scale of its products and industries, as well as safer, leaner, more resilient production systems. The collaboration leverages NVIDIA AI Infrastructure and Caterpillar’s century of building and maintaining the physical world to set a new standard for industrial innovation.

Caterpillar highlighted how decades of leadership in autonomous mining equipment and support from AI will now revolutionize the construction industry. After more than 30 years of deploying autonomous machines in some of the world’s most demanding mining environments, Caterpillar is expanding that expertise to the yellow iron seen on everyday construction sites.

The company previewed five autonomous machines designed to operate safely and reliably in complex construction environments.

While technology is transforming operations, Creed reaffirmed the company’s commitment to the most important part of the invisible layer of the tech stack — people.

To ensure employees and customers are equipped to use advanced technologies as new roles emerge, Caterpillar is pledging $25 million over five years to launch a global innovation prize. The initiative will identify, test and scale solutions that help workers with the skills needed to thrive in an increasingly digital and autonomous environment.

With $30 billion invested in research and development over the past 20 years and plans to increase investment in digital and technology by 2.5 times through 2030, the company is delivering advanced technology solutions to help solve its customers’ toughest challenges.

For more information, visit caterpillar.com/ces.

Mellott announced that Nick Ecker has been appointed as the company’s next president.

Ecker brings extensive executive leadership experience across the construction equipment and heavy machinery industries, with a strong background in operations, sales and strategic organizational growth. His leadership approach and focus on continuous improvement align with Mellott’s core values and long-term strategic vision.

In conjunction with this appointment, Rich Blake will continue to serve as chief executive officer (CEO) of Mellott. In this capacity, Blake will maintain responsibility for the company’s overall strategic direction, long-term industry relationships and future growth initiatives, including the evaluation of synergistic acquisition opportunities.

“We are excited to welcome Nick to Mellott,” said Blake. “His industry experience and leadership style will be an asset to the organization as we continue to strengthen our market position and pursue new opportunities for growth.”

Mellott looks forward to Ecker’s leadership and contributions as the company continues its commitment to operational excellence, customer success and strategic growth.

For more information, visit mellottcompany.com.

Niece 8,000 gallon water tanks

installed on 40 ton Articulated Off Highway chassis. This combination is the workhorse of the dust control and water needs for quarries and large construction sites

The NWT9500 9500 Gallon water tank mounted on articulated truck. Pictured: Deere 460E with 9,500 gallon tank. Tanks come with 6X5 pumps.

The NFL3000 Off Road, Fuel and Lube Bed offers 3,000 gallons of diesel fuel.

The NFL10000 Fuel & Lube Can be mounted on any 100,000 lb rigid frame truck. Holds 10,000 gallons of diesel. 5 additional fluid tanks. Holds up to 3,000 gallons of oil.

Equip Exposition announced a new addition to the 2026 show, slated for Oct. 20-23: a closing party at Paristown Point Oct. 22, one of Louisville’s most dynamic new developments and a historic district.

The new closing event is designed as a relaxed, open-air opportunity for attendees to unwind, connect and celebrate the close of the industry’s largest gathering. The celebration will feature live music in the Old Forester Paristown Hall, food vendors from across Louisville, outdoor gathering spaces and a distinctly local experience curated specifically for Equip attendees.

“This closing party has something for everyone,” said Kris Kiser, president of OPEI. “It’s an opportunity to get together with friends you brought and people you met at Equip in a relaxed environment and build on those connections made on the show floor.”

A highlight of the evening will be a bourbon tasting hosted by Uncle Boojie’s Distilling Co., offering attendees an authentic, on-site barrel tasting experience. Uncle Boojie’s also will serve as the show bourbon for Equip Exposition 2026. Attendees can sample the bourbon at the show, then enjoy full pours — and even purchase a bottle to take home — during the Thursday night event.

“We’re constantly listening to attendees and remaking the

show to give them what they ask for: more opportunities for peer-to-peer engagement and to learn from one another,” Kiser said. “This is a brand-new opportunity for attendees to experience one of Louisville’s unique, historic places.”

As previously announced, Equip Exposition will remain in Louisville during the Kentucky Exposition Center’s reno-

vation planning window, with the show committed to the city for both 2026 and 2027. New programming and attendee experiences will continue to enhance the show’s value for all audiences.

Also coming in 2026, Equip will launch several new and returning features, including new events, education and networking opportunities:

• Dealer breakfast returns — a refreshed version of the popular Dealer Breakfast returns, offering an exclusive networking opportunity ahead of the dealer-only show floor hours.

• Opening reception at Churchill Downs — Opening night kicks off at the First Turn Club at Churchill Downs, offering a uniquely Kentucky welcome experience.

• Concert at 4th Street Live! — Equip brings back a high-energy nighttime concert in one of Louisville’s premier entertainment districts.

• Expanded pro education series — More advanced education for landscapers, hardscapers, outdoor power equipment dealers and service professionals.

• More Education in tree care, irrigation and other new business segments — Responding to demand, Equip will offer new in-depth sessions tailored to these fast-growing sectors.

Here is a picture of what you can expect and suggestions for how to approach a job site evaluation.

Taking the time to schedule a site consultation can make a big difference in the success, efficiency and value of your project, said Survey Systems Atlanta.

Site consultants “serve as an essential foundation for planning, budgeting and mitigating potential issues that might otherwise cause costly delays,” said the company.

“A professional site consultation is a structured evaluation of a proposed construction site conducted by experienced experts,” according to a Survey Systems article.

A thorough review of the property includes its natural characteristics, existing structures and any potential challenges that could affect the build.

Survey Systems said the goal is to provide property owners, developers and construction teams a comprehensive understanding of the site’s conditions.

“By assessing critical factors early on, site consultations allow decision-makers to make informed choices,” the company’s article said.

The decision-making process, then, ensures that the project is feasible, safe and aligned with the desired goals.

No operation is too small to benefit from a professional site consultation, preaches Caterpillar. The company asks contractors to consider the following:

• Do you wonder if you’re getting the most out of your equipment?

• Are you frustrated by how much it costs to keep equipment working?

• Do you spend too much time on things other than getting the job done?

“You could benefit from the second set of eyes — and expert recommendations — a site evaluation brings,” according to Cat.

In an article on professional evaluations, the company wrote that you don’t have to run a massive operation to benefit from an expert site evaluation.

“Even the smallest sites can take advantage of a fresh perspective, best practices and lessons learned from around the world,” said the company.

“And even minor changes can make a big difference to your bottom line” in a typical site evaluation, which starts with information gathering.

As the contractor, you provide the background about your fleet and operation. That includes any “pain points” or problems you want to solve. A small team of system application specialists visits your site for a couple of days working with you to collect and analyze data and set benchmarks.

“When they’re done,” wrote Cat, “you receive a report with results and site-specific recommendations.”

Those recommendations can include “quick wins, long-term improvements and hard data to help you measure results.”

What you choose as the focus of your jobsite evaluation depends on your specific needs. A consultant can help you home-in on that before you start.

During Cat site evaluations, the company looks at the contractor’s fleet system, match and utilization as well as his or her load and hauling tool systems.

The company also will evaluate jobsite layout and haul roads; technology match; equipment operation; and fuel consumption and idle management.

Finally, the consultant will study the contractor’s equip-

When you have your site evaluated, you, the contractor, get to decide what you want the consultant to focus on. You provide the background about your operations including any solutions you seek to the challenges you face.

A team of application specialists will visit your job site for the evaluation. Over a couple of days, they’ll work with you to collect and analyze operations data before setting benchmarks for you and your team.

ment, work tool and ground-engaging tool configuration.

“A consultation can tell you if you’re operating the right (and right amount) of machines,” said Cat.

It can reveal ways to streamline maintenance, burn less fuel or save on repairs, the company added. “And it can uncover opportunities to make your site more efficient and your operators more productive.”

Survey Systems said the consultation starts with a professional walking the property, taking detailed notes.

The consultant might use specialized equipment to examine soil quality, topography, drainage and existing utilities, the company said.

“This insight forms the basis for a more strategic approach to the construction process,” said Survey Systems.

It also helps to identify obstacles before they become expensive problems, the survey company stressed.

“Professional site consultations are becoming a standard practice for those serious about efficiency and long-term planning,” the company said.

Construction consulting firm zumBrunnen offers five reasons to hire a construction management consultant. The number one reason is cost savings.

The construction management firm recognizes that one of the most pressing challenges to any construction project is staying on budget.

“When a major construction project is in full swing, it can become very easy to lose sight of your financial constraints,” the company wrote. “This consideration has been a particularly concerning issue in light of the soaring costs of construction materials.”

A construction management consultant can help alleviate these challenges by documenting costs associated with the project, said zumBrunnen.

A consultant will monitor a projects progress through each phase, said the construction consulting firm. “They will ensure that the various contractors … involved in the project are doing their part to produce a quality structure.”

And if an issue arises, the consultant will address it immediately before notifying stakeholders so they can take appropriate action, said zumBrunnen.

A site consultant offers the contractor access to valuable industry knowledge, can answer questions and address concerns.

“They can also help you more effectively relay information to key stakeholders by providing … detailed reports on the state of the project,” said zumBrunnen.

A consultant can “significantly” reduce the chances you as the contractor will experience a major project delay.

“Construction consultants are well versed in managing all facets of large-scale projects,” said zumBrunnen.

“Finally, a construction management consulting firm will take the weight of the world off of your shoulders,” added the company. “They will serve as a buffer” among stakeholders, subcontractors, engineers and the site owner.

This role makes the entire construction project far less stressful, noted zumBrunnen.

“If an issue does come about, the consultant can guide you to the most appropriate resolution.”

Survey Systems believes engaging in site consultations before construction begins offers numerous advantages, including early assessment and planning. Understanding the site’s characteristics from the outset allows stakeholders to make strategic decisions about project layout, material selection and construction methods.

“This foresight can prevent costly changes during the building process, saving both time and money,” said the company. “Site consultations also provide an opportunity to identify environmental and regulatory considerations that may affect the project.”

These considerations might include local zoning requirements, floodplain restrictions or protected vegetation, according to the article.

Addressing these factors early can streamline permitting processes and reduce the risk of future legal or regulatory complications, the company said.

“By incorporating expert recommendations from the consultation, project teams can establish a more efficient workflow.”

These teams also have the advantage of anticipating challenges that might otherwise delay construction, believes Survey Systems.

Vögele has announced the Super 800-5 P-Tier mini-paver. With its new material hopper, new paver operator’s platform and new lighting concept, the Super 800-5 P offers a high level of operating comfort and optimum visibility, according to Vögele.

As with all pavers of the Dash 5 generation, Vögele also focuses on high operating convenience and short setup times with the new Super 800-5 P. In combination with the AB 200 V and TV and AB 220 V and TV extending screeds, it offers pave widths from 1.6 ft. to 11.5 ft. — making it ideal for narrow construction projects, according to Vögele.

The successor to the Super 700 and Super 800 has an engine output of 74.3 hp, a laydown rate of up to 300 tons per hour and is compact with a width of 4.6 ft. and a length of 14.4 ft. Compared to its predecessors, the Dash 5 model also integrates numerous practical innovations.

An advantage of the mini-paver is the newly developed material hopper: as before, both hopper walls can be hydraulically adjusted separately or together. In addition, the asymmetrical setting, for example for paving along a

both sides.

Blue Diamond Attachments announces its new line of self-leveling extreme-duty Series 2 cold planers, designed for road surface milling, concrete scarification and asphalt removal applications. The comprehensive line includes eight models ranging from 14 in. to 48 in. in milling width, compatible with skid steer and compact track loaders and the attachments are available in both low and high flow.

The new cold planer line features several design elements that enhance performance and precision:

• a patented self-leveling system ensures constant milling depth regardless of ground contour or machine position;

• independent right and left depth adjustment capability, available in both mechanical and hydraulic configurations, enables precise surface matching and perfect side-by-side passes;

• standard hydraulic side shift functionality allows flush milling against walls and other obstacles; and

• multiple drum options with different widths and teeth layouts accommodate various applications from asphalt to concrete milling.

“Our extreme-duty Series 2 cold planer line represents a significant advancement in road maintenance and construction capabilities for contractors and municipalities,” said Drew Truan, chief operating officer of Blue Diamond Attachments. “By combining precise depth control with exceptional stability and versatility, we’re enabling operators to achieve superior results across a wide range of applications, from pothole repair to complete surface removal.”

The cold planers feature milling depths from 4.3 in. to 6.7 in., depending on model and working speeds of up to 16.4 ft. per minute. All models have an optional dust suppression spray system and clear depth indicators for precise control. The line’s robust construction and direct-drive hydraulic motors ensure reliable performance while minimizing maintenance requirements, according to the manufacturer. CEG

JCB continues to invest in American infrastructure and innovation with the introduction of the CT380 and CT430 vibratory tandem rollers at Pave-X 2025.

Designed to meet the demands of U.S. paving professionals, these high-performance machines represent JCB’s dedication to delivering robust, dependable solutions

for asphalt paving and site preparation, the company said.

“Our new rollers underscore JCB’s longterm investment in North America,” said James Gill, JCB product manager. “From our new manufacturing facility going up in San Antonio to the launch of products like the CT380 and CT430, we are laser-focused

on meeting the needs of U.S. contractors with machines that are reliable, easy to operate and built to perform.”

With the addition of the CT380 and CT430, JCB has expanded its tandem roller lineup to four models, providing versatile options to match the diverse needs of American job sites. The lineup, which also includes the compact CT160 and mid-size CT260, ensures that contractors have the right tools for any paving or compaction task, whether working on tight urban spaces or large-scale infrastructure projects.

The CT380 and CT430 are equipped with features to tackle the toughest jobs, offering reliable compaction and operator-focused design, with:

• Versatile Compaction Power: Dualdrum widths of 51 in. (CT380) and 55 in. (CT430) deliver centrifugal forces of up to 13,800 lbs. and 14,600 lbs. per drum, ensuring superior compaction.

• Efficient Operation: Both models feature maximum travel speeds of 6.2 mph, enabling swift, efficient movement across work sites.

• Exceptional Maneuverability: With a

±34-degree steering angle and ±13-degree oscillation angle, the rollers navigate tight turns and uneven terrain with ease.

• Operator-Centric Design: Adjustable seats, intuitive controls and exceptional visibility reduce fatigue and enhance operator productivity.

• Low Maintenance, High Uptime: Simplified service points and reduced maintenance intervals keep machines on the job longer.

• Smart Security: JCB LiveLink telematics provides advanced tracking and monitoring for added peace of mind.

Powered by efficient 48.9-hp, 3-cylinder engines, the CT380 and CT430 are built to handle rigorous daily use. Their operating weights — 8,820 lbs. and 9,920 lbs. respectively — strike a balance between easy transport and heavy-duty performance.

“Our philosophy is robust simplicity,” Gill explained. “These machines are easy to operate, easy to maintain and ready to work whenever you are. That’s what makes the

For more information, visit jcb.com.

ARNOLD MACHINERY COMPANY

www.arnoldmachinery.com

Las Vegas, NV

702-642-9000 Phoenix, AZ

602-414-1900 Tucson, AZ

520-294-7677

Albuquerque, NM

505-895-1565

www.ascoeq.com

Beaumont, TX 409-212-8100 Brenham, TX 979-836-6641 (North) Houston, TX 281-987-1990 (South) Houston, TX 713-649-0940

CLOSNER www.closner.com

Schertz, TX 210-732-2131

Rhome, TX 817-708-9108

Elgin, TX 512-272-8200

Waller, TX 936-525-9949

www.romco.com

Artesia, NM 575-746-6592 Austin, TX 512-388-2529

Carmine, TX 979-278-3570

Corpus Christi, TX 361-881-4891

Dallas (Carrollton), TX 214-819-4100

El Paso, TX 915-772-0613

Ft. Worth, TX 817-626-2288

Houston, TX 713-937-3005 Longview, TX 903-758-5576

Lubbock, TX 806-745-1511

Midland, TX 432-234-9409

Rio Grande Valley, TX 956-565-0100

San Antonio, TX 210-648-4600 Stephenville, TX 254-266-2871

www.nixonegli.com

Ontario, CA 91761 909-930-1822

Tracy, CA 95304 209-830-8600

2015 Etnyre Centennial II distributor, 2000 gal, BT-1 computer, 12 ft spray bar, propane burners,PTO pump, Ford F750XL, Cummins 6.7L dsl eng, auto trans, 2 spd axle $120,000

2012 Etnyre Centennial II distributor, 2000 gallons, BT-1 computer, 12 ft spray bar, spray wand & hose, diesel burners, PTO pump, Ford F750XL, Cummins 6.7L dsl eng, push button auto trans, 2 spd axle $100,000

2019 Rosco Max 2B distributor, 1950 gallons, Max 2B computer, 12 ft spray bar, diesel burners, Freightliner M2, Cummins 6.7L dse eng, auto trans, front tires new $149,000

New Marathon TPS500PT tack distributor, Briggs gas eng, 18GPM pump, 500 gal, spray wand w/50 ft hose, hose reel, hand wand recirculation plumbing, 12 gallon recovery tank, 6 ft spray bar, operator’s platform, propane burners, overnight heater, flushing system, dual material baffles $34,550

The successor to the Super 700 and Super 800 has an engine output of 74.3 hp, a laydown rate of up to 300 tons per hour and is compact with a width of 4.6 ft. and a length of 14.4 ft.

2022 Volvo PT125C pneumatic roller, 9 wheels, Volvo dsl eng, water system, tires 90%, 365 hrs $62,000

In addition, the hopper walls of the new Super 800-5 P can be folded twice. Together with the flat engine hood, the low hopper height and the raised operator’s platform, this gives the operator an unrestricted view to the front. This makes maneuvering and loading the new Dash 5 paver much easier, according to Vögele.

New Marathon TPS250PT tack distributor, Briggs gas eng, 18GPM pump, 250 gal, spray wand & hose, hose reel, 6 ft spray bar, operator’s platform, propane burners, flushing system $22,550

Vögele also has improved the operating system: As before, the new operator’s control console can be moved horizontally. In addition, its angle can now be adjusted in four stages and ergonomically adapted to the height of the operator.

The new ErgoBasic 5 operating concept follows the operating logic of the larger machines but has been specially adapted to the mini paver. For the first time, the paver operator’s console incorporates a display that allows the operator to view the machine’s operating data. In addition, Vögele has fully integrated the operation of

the auto grade basic system for automated grade and slope control into the screed control system.

This enables screed operators to control the Super 800-5 P with just one compact console — just like on large Vögele pavers. A new storage system with a tool and drink holder, coat hooks and 24-volt socket for mobile devices also ensures organization and more convenience.

With light package or light package plus of the Dash 5 generation, users can pave safely, relaxed and precisely even in the dark or in poor visibility conditions. The light package for the Super 800-5 P includes LED lighting for the paver operator’s console, the tow point cylinder and the auger tunnel. This ensures that all points relevant to the paving are specifically illuminated without casting shadows. The optional light package plus also offers two LED floodlights that optimally illuminate the entire working area. For more information, visit wirtgengroup.com.

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

Closner Equipment

www.closner.com

Rhome, TX 817-708-9108

Schertz, TX 210-732-2131

Manor, TX 512-272-8200

Waller, TX 936-525-9949

PacWest Machinery

www.pacwestmachinery.com

Seattle, WA 206-762-5933

Spokane, WA 509-534-5933

Pasco, WA 509-547-5933

Mt Vernon, WA 360-588-3083

Portland, OR 503-252-5933

Eugene, OR – Branch 541-302-3762

Power Equipment Company

www.power-equip.com

Farmington, NM 505-326-1413

Durango, CO 970-247-8830

Denver, CO 303-288-6801

Colorado Springs, CO 719-392-1155

Grand Junction, CO 970-243-0722

Greeley, CO 970-353-1224

Albuquerque, NM 505-345-7811

RDO Equipment Co. www.rdoequipment.com

West Haven, UT 801-627-0049

Salt Lake City, UT 801-262-744

St. George, UT 435-652-8003

Billings, MT 406-259-5536

Kalispell, MT 406-752-2828

Missoula, MT 406-549-4171

Bozeman, MT 406-551-2141

Idaho Falls, ID 208-523-9915

Casper, WY 307-266-4474

Gillette, WY 307-685-4288

Cheyenne, WY 307-316-9800

Rock Springs, WY 307-382-5284

Phoenix, AZ 85009 602-415-4700

Chandler, AZ 602-845-1800

Prescott, AZ 928-776-8300

Riverside, CA 951-778-3700

Shafer Equipment

wwwshaferequipmentco.com

Sparks, NV 208-801-7772

Boxcer Equipment

www.boxcerequipment.com Tulsa, OK 918-272-7237

closner.com

6532 East Highway 114 Rhome, TX 76078

817-708-9108

21910 FM 2252 Schertz, TX 78154 210-732-2131

778 US Highway 290 E Elgin, TX 78621 512-272-8200

18851 GH Circle Waller Industrial Park Waller, TX 936-525-9949

ascoeq.com

5980 S M L King Jr Pkwy Beaumont, TX 77705 409-746-5102

202 I-35 Frontage Road Belton, TX 76513 254-613-1500

2800 Hwy 290 E Brenham, TX 77833 979-836-6641

1875 N Earl Rudder Fwy Bryan, TX 77803 979-779-8942

1512 Neptune Dr. #9706 Clinton, OK 580-323-3422

2019 Airport Fwy Euless, TX 76040 817-283-2844

980 N Sam Houston Pkwy E Houston, TX 77032 281-987-1990

6203 Long Drive Houston, TX 77087 713-649-0940

27500 E University Drive Aubrey, TX 76227 972-441-2726

12805 US-290 E Manor, TX 78653 512-272-8922

7100 SW 3rd Street Oklahoma City, OK 73128 405-789-6812

902 SE 9th Avenue Perryton, TX 79070 806-435-7773

1920 S East Loop 410 San Antonio, TX 78220 210-333-8000

3600 US-82 Sherman, TX 75090 903-893-7586

401 FM 148 Terrell, TX 75160 972-563-2171

12210 E 1st Street Tulsa, OK 74128 918-437-5085

2602 E Front Street Tyler, TX 75702 903-593-0201

2900 Henry S Grace Fwy Wichita Falls, TX 76302 940-687-2726

nixonegli.com

2044 S. Vineyard Avenue Ontario, CA 91761 909-930-1822

800 E. Grant Line Road Tracy, CA 95304 209-830-8600

2750 Marion Drive Las Vegas, NV 89115 702-342-8100

Place Las Cruces, NM 88005 575-524-1671

5050 East 58th Avenue Commerce City, CO 80022 720-386-6040

2950 W. Durango Street Phoenix, AZ 85009 602-454-9808

JLG Industries Inc. announced the acquisition of the core technology developed by Canvas, a San Francisco-based construction robotics technology company known for pioneering robotic solutions for interior construction applications.

Through this strategic investment in intelligent automation for the job site of the future, the acquisition will advance JLG’s strategy to support customer needs beyond enabling jobs to actively executing them with autonomous, connected equipment, according to JLG.

The relationship between the companies began six years ago when Canvas selected a JLG platform to develop its robot, and since then, the technology has advanced to automate repetitive tasks and enable consistent, high-quality results — helping shape safe, efficient and productive job sites.

“By integrating robotic

technology that delivers moments of autonomy, we’re helping crews get more work done in today’s challenging labor environment,” said Mahesh Narang, executive vice president, Oshkosh Corp. and president of the Access segment.

“This investment expands what

customers will be able to accomplish with JLG equipment.”

“Robotics and automation will play an increasingly important role in the future of construction, especially as the industry looks for practical ways to deliver greater efficiencies, improve productivity and enhance consistency on job sites,” said Shashank Bhatia, access chief technology officer.

“This acquisition strengthens our technology roadmap and accelerates our ability to deliver solutions that create real, measurable value for customers in the field.”

Canvas is best known for developing the world’s first drywall finishing robot, which combines robotic precision with the skills and expertise of trained tradespeople. The system streamlines interior finishing workflows by automating fit-and-finish tasks, reducing rework and delivering consistent quality while minimizing physical demands on workers, according to the company. Through the acquisition, Canvas technology will advance robotic end-effec-

tor capabilities and autonomy, enabling pairing with JLG access equipment to support a range of interior construction applications. These solutions are designed to assist skilled workers by handling repetitive, physically demanding tasks and allowing crews to focus on higher-value work.

With this acquisition, the Canvas team will help JLG develop new robotic and autonomous solutions for customers to get more done with the equipment they rely on, increasing productivity and shaping the future of job sites.

“We welcome the Canvas team members to the company,” Bhatia said. “They bring a strong combination of technical depth, creativity and a clear understanding of job site challenges. We see tremendous opportunity to apply their expertise to the next generation of purposebuilt solutions.”

For more information, visit JLG.com.

www.cpower.com

9200 Liberty Drive

Liberty, MO 64068

816-781-8070

Wichita, KS

316-943-1231

Great Bend, KS

620-792-1361

Liberal, KS

620-624-7274

Woodward, OK

580-256-6014

Salina, KS

785-825-8291

Colby, KS

785-462-8211

Springfield, MO

417-865-0505

Joplin, MO

417-726-5373

Riverside, MO

816-415-6787

Wichita, KS

316-789-7370

Yukon, OK 405-324-2330

Maryland Heights, MO

314-427-4911

Liberty, MO

806-415-6700

Tulsa, OK 918-984-6565

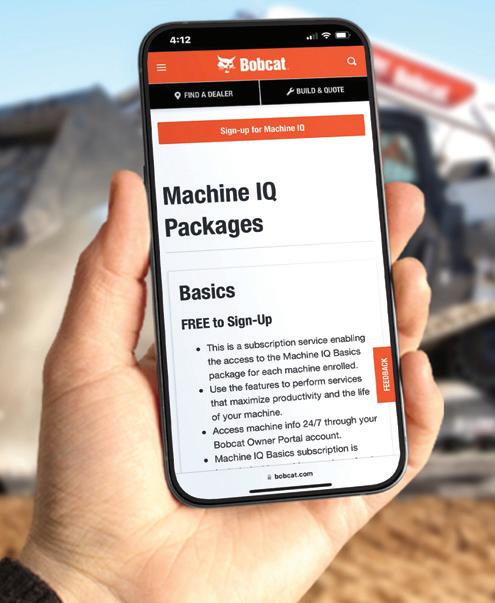

Unexpected downtime can quickly become complicated, disrupting not only production hours but also people’s schedules and workloads.

During this era of tight profit margins and competing demands on people’s time, a machine monitoring system plus planned maintenance builds confidence in machine operators’ ability to get the job done.

Telematics — technology like GPS and sensors — started gaining traction in the early 2000s, helping contractors and farmers track equipment remotely. A decade later, manufacturers such as John Deere developed fleet management software (FMS) to help business owners make data-informed decisions about their machines.

Heavy equipment owners add a modular telematics gateway (MTG) like a JDLink modem and install fleet management software like John Deere operations center to track vital operational data, including production hours, fuel usage and GPS location. Today, many heavy equipment owners rely on telematics data for planned maintenance, accurate budgeting and machine health decisions.

“Machine health means staying ahead of problems and being proactive,” said Derrick Rygg, RDO Equipment Co.’s machine health manager. “By connecting to a telematics gateway, an FMS and a trusted remote support team, owners can get a bird’s eye view on the wear and tear on a machine to treat it before issues occur.

Just Google’s search trends can tell us something about what people are thinking about, a machine’s data sets like engine hours and fuel usage can help to inform its owner about possible persistent issues before planned maintenance.

“I work with several team members to monitor more than 55,000 machines on a daily basis, so we catch fault codes and triage the higher priority fault codes like engine oil pressure,” Rygg said.

When RDO’s machine health team notes a priority fault code, they reach out to that heavy equipment owner’s service provider, which in turn notifies the customer to allow them to make informed decisions on their machines. Whether it may be something fixable with a simple solution or more complex that requires a trained service technician.

“We work with the service technicians and parts specialists to quickly address the issue, whether that’s as simple as filter replacement or complex, like a failed engine oil pump,” Rygg said.

Rygg explained that service technicians work like detectives to examine a machine’s fault codes and talk with the owner to provide prompt service. RDO’s connected support team helps to prep our technicians with accurate information, limiting downtime and delivering the right parts when a machine needs them.

When equipment owners sign up for pay-as-you-go or prepaid planned maintenance plans, they receive the following automatically:

• service reminders from their local RDO service department;

• coordinated scheduling with local service teams; and

• parts ordered ahead of time to reduce downtime.

“When a maintenance program can be made simple and predictable, it ensures machines stay ready when they are needed in the field,” Rygg said.

Equipment owners can also sign up for PM notifications using their operations center account. If a person purchases a machine at RDO and connects it to the operations center, their machine can be enrolled in a planned maintenance program at no extra cost. Equipment owners also can sign up for planned maintenance program right in their operations center account. During every planned maintenance appointment, a service technician will perform the following tasks:

• oil and filter changes;

• fluid and coolant checks;

• belt, hose and electrical inspections; and

• component adjustments or replacements as needed.

Much like how a detective can solve the case faster when he has access to call logs, a service technician can eliminate potential common issues when they know the machine has received regular service, Rygg said.

“Even when a machine has unplanned downtime, a connected machine’s data, a remote support professional and a skilled service technician all work together to fix the problem so the operator can get back to work,” Rygg said.

Hardware, software and expert support come together to create a system you can trust. When service technicians receive these clues from the machine’s data, they can start to build their case and uncover the machine’s error culprit.

“RDO’s remote support teams work as a silent partner to flag potential issues,” Rygg said. “Working together across our 12-state network, we’ve saved more than 100 engines from failure during the last year.”

Once a detective solves a case, others accept the argument due to the trust the detective has built over time with the courts and the community he serves. Similarly, fleet managers can trust their equipment service provider through a blend of remote monitoring and real-world expertise.

“We’ve experienced the value of proactive service for heavy equipment service repairs,” Rygg said. “When our team receives John Deere’s expert alerts, we know what parts to send with the technician and how long it may take to repair the issue,” Rygg said.

Over time, Rygg said his team can be 95 percent certain they have the solution to fix the machine before a service technician is in the field or a machine is in the shop.

“When we saw a low engine oil pressure alert on a wheel loader, we knew it could be the oil pump, crossover tube or pickup tube,” Rygg said. “We got a loaner machine to the field and brought the wheel loader into the shop. It turned out the oil pump just needed recalibration, which avoided costly downtime.”

Downtime can cause a world of problems in a hurry, but with boots-on-the-ground support, machine data and a trusted equipment service provider, problems don’t have to become expensive delays. Don’t wait for a breakdown, schedule planned maintenance and find your trusted detective.

(Article reprinted with permission from RDO Equipment Co. Jake Livingston is the director of connected support of RDO Equipment Co.)

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191

Corpus Christi, TX 361-884-8275

Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056

Pflugerville, TX 512-251-0013

Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900

Colorado Springs, CO 719-576-5541

Grand Junction, CO 970-241-1550

Milliken, CO 970-587-1188

www.powermotivecorp.com

Cheyenne, WY 307-634-5149

Durango, CO 970-259-0455

Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601

Carlsbad, NM 505-485-1700

El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

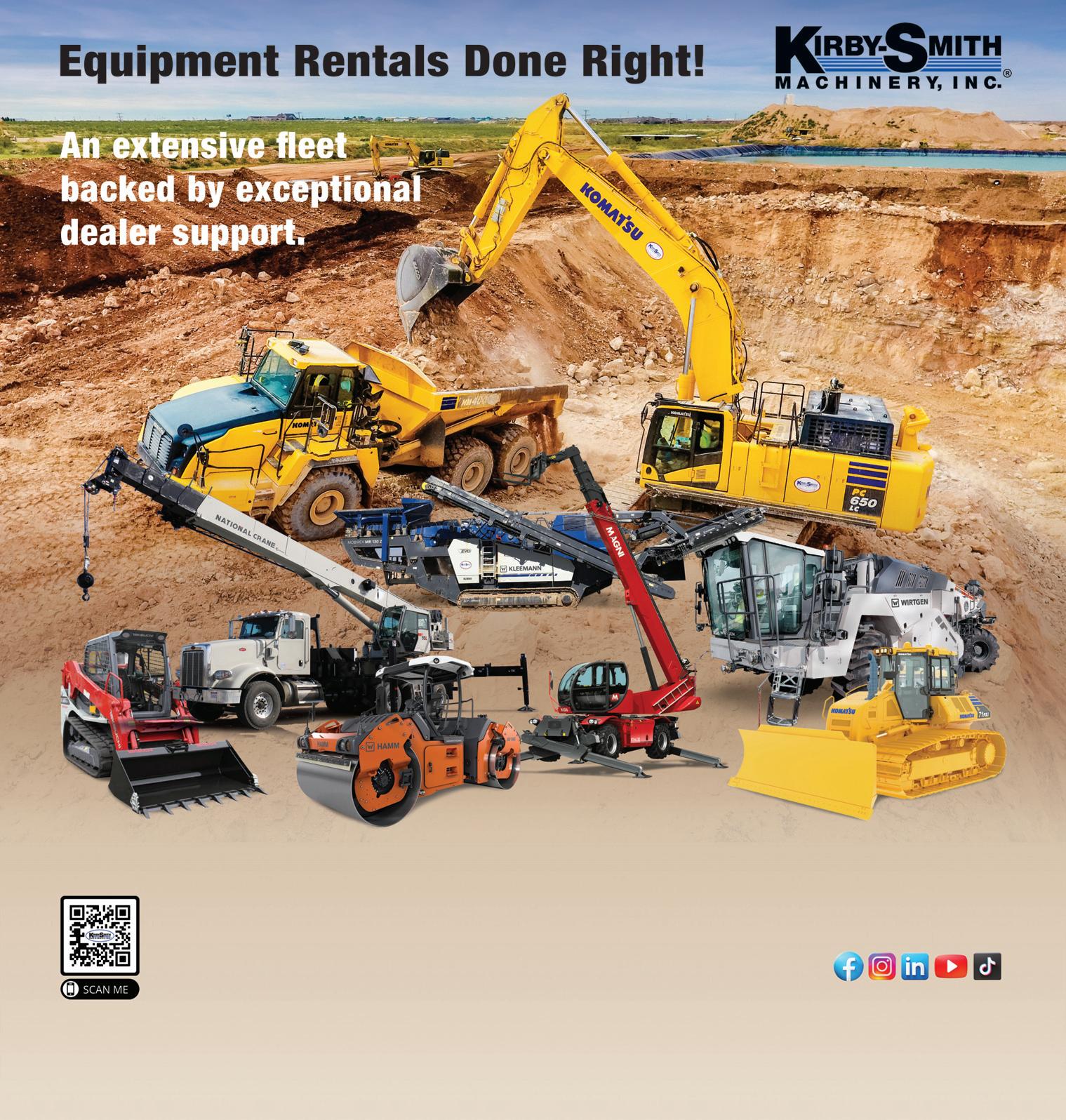

www.kirby-smith.com

Oklahoma City, OK

405-495-7820

McAlester, OK

918-310-1550

Tulsa, OK

918-438-1700

Abilene, TX

325-692-6334

Amarillo, TX

806-373-2826

Chico, TX

940-678-5046

Dallas, TX

214-371-7777

Ft. Worth, TX

817-378-0600

Hewitt, TX

254-261-1370

Lubbock, TX

806-745-2112

Odessa, TX

432-333-7000

www.modernmachinery.com

Corporate Office

Missoula, MT

409-842-1754

Boise, ID

208-336-8670

Jerome, ID

208-324-4522

Pocatello, ID

800-829-4450

Billings, MT

800-735-2589

Columbia Falls, MT

800-434-4190

Eugene, OR

800-826-9811

Portland, OR

800-950-7779

Kent, WA

800-669-2425

Rochester, WA

800-304-4421

Spokane, WA

800-541-0754

www.clairemontequipment.com

San Diego, CA

858-278-8351

Escondido, CA

760-739-9100

Fontana, CA

909-429-9100

Imperial, CA

760-355-7700

Indio, CA

760-863-5558

San Diego, CA

858-278-8338

CMAR contracts are broken into individual packages of guaranteed maximum price, or GMPs, she said.

Equipment used on the project includes: a tower crane on site; rough terrain cranes and crawler cranes; 150-kilowatt and 45-kilowatt generators; water trucks; street sweepers; skid steers; and lights.

Builders also will use forklifts, front loaders, scissor lifts and side-by-side buggies.

“There will be a lot of concrete,” King said.

That include post-tensioned concrete and peak cast concrete for basins and buildings and structures, as well as piping, pumps, control panels, clarifier mechanisms, electrical equipment, motor control centers, programmable logical controllers, different tanks for chemicals and storage, steel, reinforcement and valves.

Walnut Creek is one of Austin’s two wastewater treatment plants. It treats about half of the city’s wastewater. Opened in East Austin in 1974, it was most recently expanded in 2000.

The project will benefit Austin in five ways, King said. Greater capacity. 75 million gal. per day will increase to 100 million gal.

“The main way that we're going to accomplish the increase is by building the 25-million-gallon expansion portion of the plant first, thereby increasing our total treatment capacity,” King said. “And that will allow us to take portions of the existing plant down to be upgraded and retrofitted for the new treatment technology.”

Replacing aging equipment. “We will rebuild and replace aging parts of the existing plant,” King said. “So that's various mechanical equipment and electrical systems and control systems; and piping.”

In addition, screening machines will remove trash, rags, wipes and other debris from raw sewage to ensure clean water.

Updating wastewater treatment. After the new part of the plant is expanded, the existing plant will be retrofitted to reduce the nutrients that are discharged from the facility, phosphorus and nitrogen being the primary ones, King said.

Those nutrients contribute to algae growth.

“The nutrient removal process requires modifications to our aeration basins. And, so, we will have a more complex microbiology that we maintain to treat the water,” King said. “That

Austin Water is still “actively bidding some packages, so we don't have final costs for every- thing yet,” said Austin Water Managing Engineer Lauren King about the upgrade and expansion of the Walnut Creek wastewater treat- ment“Thesefacility. are the estimates that we're working off of and that the contract is based off of,” she said.

Renewal projects - $270 million

• $160 million — Rehabilitation of primary and flow equalization basin rehab

• $90 million — Rehabilitation of headworks No. 1

• $20 million — Replace and upgrade influent lift station

Expansion projects — $440 million

• $380 million — 25 MGD capacity expan- sion with nutrient removal and UV disinfection

• $60 million — New influent and outfall pipelinesTreatment conversion projects - $220 million

• $220 million — 75 MGD process treatment conversion to nutrient removal and UV disinfection

Protection of plant projects - $120 million

• $80 million — Wet weather facility for high flows during rain events

• $40 million — Flood wall around plant

Source: Austin Water

benefits the ecology of the Colorado River that we discharge into.”

Odor control. “We're including improved odor control for our facility as part of the expansion,” King said. Those improvements include biofilters, activated carbon filters and basin covers.

Improving flood resistance. “The plant was not in a floodplain when it was originally built,” King said. “But as climate change and urbanization have impacts on our watershed, the new floodplain maps do have the plant in the floodplain.”

To bolster the plant's resilience, a flood protection wall will be constructed around the facility.

“The Walnut Creek plant and all of our wastewater treatment plants here in Austin require tertiary wastewater treatment, which disinfection is a component of,” King said.

Walnut Creek disinfects using chlorine, which King said is “a very effective, cost-effective and robust process. It does require that the water be dechlorinated before being discharged into the water body.”

As part of the expansion and upgrade, the facility is switching to ultraviolet light disinfection.

“The water is essentially passed over UV light-emitting bulbs — specialized bulbs that kill the pathogens.”

UV technology is safer for the staff, as well as the surrounding community and environment.

Construction is expected to be completed in 2031.

Eight construction packages are going out for bidding. Package one includes the head works and the influent lift station.

“We'll start construction in June on package two, which is mobilization and site service, so that's construction trailers and whatnot,” King said.

The plant must remain in operation during construction, she added.

“People will keep taking showers and flushing toilets and using sinks,” King said. “So, we must keep treating the wastewater.

“And the sequencing of tasks in the construction project, as well as the planning around making it constructable, has been part of the design from the beginning, with the aim of ensuring that our plant is able to meet permit requirements through the construction phase.” CEG

(All photos courtesy of Austin Water.)

As land clearing, forestry and recycling operations continue to overlap on today’s job sites, contractors are looking for attachments that deliver flexibility beyond a single task. NPK Construction Equipment’s Demo Grabs are designed to support that need by providing a rugged, multipurpose solution for handling, sorting and processing materials generated during wood and brush clearing operations.

Demo Grabs play a key role after initial clearing, allowing operators to efficiently handle brush, logs, demolition debris and mixed materials. Their 360-degree continuous rotation gives operators precise control for positioning loads, improving productivity when sorting reusable material, feeding grinders or loading trucks.