11 minute read

Aggregate & Recycling Section

Pages 17-24 Aggregate Production and Recycling Section

For more information on crushing, screening and recycling equipment, visit CEG's Web site at www.constructionequipmentguide.com.

Kleemann Designs EVO2 Generation for Sustainable Use

Kleemann’s jaw crusher MOBICAT MC 110(i) EVO2 and the cone crusher MOBICONE MCO 90(i) EVO2, with their efficient crusher direct drive, have a holistic drive concept that forms the basis for high cost-effectiveness.

Both machines of the new EVO2 generation are equipped with a power train. The crusher is driven directly, and thus with high fuelefficiency, via a reliable fluid coupling. Conveying components, such as the vibrating feeder, the doubledeck prescreen or the discharge conveyors, are all-electric.

A robust and easily accessible transmission guarantees efficient power transmission. It not only operates with a high level of efficiency but also has increased protection against dust.

The power and load-dependent fan drive also ensures low-noise and economical operation. Operation in ECO mode can additionally reduce fuel consumption as well as wear in idle phases.

The plants can be optionally equipped with a heat package (-15 to + 50 C) or cold package (-25 to +40 C). The cold package has an autonomous auxiliary heater with a convenient timer function.

Environmentally Sound Operation — Less Noise, Dust

In the new drive concept, the speed of the cooler fan and thus also the cooling capacity is controlled automatically, which considerably reduces the noise level. Apart from less dust penetration due to a lower volume of moved cooler air, work near to the machine is a lot more agreeable for the operator, the manufacturer said.

For the jaw crusher MOBICAT MC 110(i) EVO2, which is frequently used in urban environments, an optional noise protection package also is available. The considerably reduced noise level would even permit work without special ear protection — depending on the material to be processed, further environmental conditions and local regulations.

To reduce dust, the machines are equipped in the standard series, among other things, at the crusher inlet and crusher discharge conveyor with water nozzles and the corresponding technical infrastructure. As a result, an optionally available water pump or an external water source, if available, can be used. Optional belt covers also contribute to an improvement of the air quality during crushing.

These measures benefit the machine operator, the further peripheral devices on the work site, local residents and the environment.

For more information, visit www.wirtgen-group.com.

The optimized crusher direct drive of the new EVO2 generation from Kleemann.

Page 20 • June 19, 2022 • www.constructionequipmentguide.com • Recycling Section • Construction Equipment Guide Epiroc Launches New 24/7 Self-Service Videos to Maximize Equipment Uptime

Epiroc USA currently has 50 instructional videos in its online library, which cover a variety of topics related to troubleshooting, maintenance issues and repairs, including troubleshooting sensor failure, winterizing, prewalk inspection, e-stop and more.

Epiroc, a productivity partner for the mining and infrastructure industries, is launching a 24/7 self-service video series designed to help operators and service technicians maximize their uptime of Epiroc equipment.

The instructional how-to videos bring Epiroc’s extensive machine and application knowledge right to customers’ fingertips on their web or mobile devices. This allows the operators and service technicians to be as safe and efficient as possible.

The new 24/7 video series addresses the needs of many customers who prefer to have quick and easy access to information that would help them take care of their mining and construction equipment anytime, anywhere, to keep the production running smoothly.

With the 24/7 self-service videos, Epiroc simplifies the troubleshooting, maintenance and repair process for customers who prefer to complete their own routine maintenance and minor repairs on Epiroc equipment in their fleet. The videos include answers to frequently asked questions and feature experienced Epiroc Product Experts who walk through step-by-step instructions and recommend parts and tooling for completing specific service work and a range of common repairs on various Epiroc machines.

“Customers’ productivity is our top priority,” said Floris Timmers, business line manager of the parts and services division at Epiroc USA. “When it comes to heavy equipment in the mining and construction industries, time is money. Having just one machine down can bring an entire job site to a standstill, but there’s no need to wait for help on typical repairs. Sometimes it’s possible to do the troubleshooting, repairs and maintenance yourself so you can get up and running as quickly as possible. That’s why we offer our 24/7 self-service videos.”

The self-service videos are available 24 hours, 7 days a week so operators and service technicians can access the information they need, right when they need it. In addition, each video is closed captioned, so if conditions don't allow for the users to hear clearly, they can still utilize the videos to help resolve their issue.

“Epiroc considers these videos to be an integral part of customer service,” said Jon Torpy, president and general manager Epiroc USA. “Our customer support team is realizing the impact that instructional videos can have in building customer relationships by offering assistance with a personal touch. Many times, it is quicker, easier and more convenient for an operator or service technician to watch a video explaining how they can solve their equipment issue than it is to figure it out through phone calls or texts.”

Epiroc USA currently has 50 instructional videos in its online library, which cover a variety of topics related to troubleshooting, maintenance issues and repairs, including troubleshooting sensor failure, winterizing, pre-walk inspection, e-stop and more. The series focuses on the SmartROC D65, D60, D55 and PowerROC T45, T35, with plans to expand to all equipment offerings, including other rock excavation and drilling equipment, hydraulic attachments, underground machinery, tools for surface and underground applications, and automation technology solutions.

Epiroc’s 24/7 self-service videos can be found at 247selfservice.epirocmarketplace.com/ and on Epiroc’s YouTube channel.

Mineral Processing... Metso Outotec Debuts Horizontal Mill Plant Units

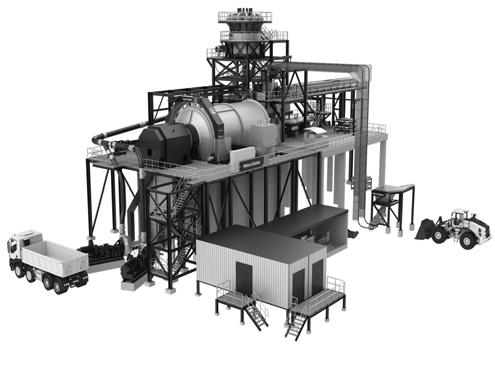

Metso Outotec is launching yet another unique solution in its range of minerals processing plant islands: the horizontal mill plant units.

The pre-engineered plant units provide optimized grinding performance and simplify project management through easy circuit selection and flowsheet implementation. At the same time, they ensure safe operability and maintainability due to their design, according to the manufacturer.

The plant units feature Metso Outotec’s industry-leading technologies including grinding mills, slurry pumps, hydrocyclones, conveying equipment, automation and service support. The scope of the unit can be tailored according to project requirements (brownfield or greenfield, open or closed circuit).

The horizontal mill plant units combine Metso Outotec

horizontal mills, classification, pumping and automation technologies with a wide range of services and operation support. It takes sustainability and grinding performance to a new level by optimizing the usage of energy, water, grinding media and consumables, according to the manufacturer.

Benefits • Grinding and classification expertise to support flowsheet implementation • Pre-engineered modules for simple and rapid execution • Process performance guarantee • Easy process optimization due to comprehensive automation and digitalization features • Sustainable technology with safe operability and maintainability • Lifecycle service support For more information, visit www.mogroup.com.

Due to its modular belt-over-apron design, the Metso Outotec Crossover feeder delivers increased levels of availability and reliability for bulk material transportation at lower overall costs, according to the company.

From Reduction to Shaping

Yo our ability to turn virgin material and waste pr h h roduct into high quality aggregates requires equipment with unmatched d d power and precision. From reducing shot rock to sizing and shaping fine sand, we design and manufacture the most versatile and efficient cru ushers. Not sure what you need? Let our experts partner with you to apply y the ideal solution.

astecindustries.com

1158 ithEd dBoulevar NE 7017que, NM 8Albuquer 30044-1505-3 .com oupsw pewesterngr.th gwww

z Blvd. asque5000 V 61, CO 802Denver 55-5900 303-3

cial Blvd.9 Commer322 ado Springs, CO 80906Color 1 46-5579-517

d.ntage Ronr0 F40 I-732 5051CO 8and Junction, CGr 550 1 1-140-279 5 1 Old Highway 94521 Boulder Cit 9006, NV 8y 902-27 3- 4 5075 7 280 . W. W oad alley RV 6 7632Rialto, CA 9 7 0074-274909-87 . Butler DriveW.6321 9 W age, AZEl Mir 1404-53-5926 eet2 South Jackson Str14 1019Amarillo, TX 7 327800-699-1 82 226

eetth Str Lubbock, 4409TX 7 4 4 74806-7 79-568

ve3 S. 4th A16 606376Mansfield, TX 7 0113-277-418

est 000 W90 N. 23 2440Lindon, UT 8 6216-691-780

ve.ent Ar8 East T244 A WASpokane, W 21299 45 751-04800-5 7 ginia St80 N. Vir77 eno, NVR 5-7577 4211-979

.goodfellowcorp.com g pwww 02 Nor1

eetth Main Str 4590d, TX 7eforHer 7 806-364-568 est Ind#6 W cledustrial Cir Odessa, 16 769TX 7 7 32-343 7883-2

.texasbwww g bearing.com

. 0 W1 IH -1738 3eeway Exit 69rF 4398Columbus, TX 7 2-690239-77 9

ve. S.d A1 83r4322 A WAKent, W 28039 524800-669-2 Weet S444 Ivan Str91 A WAr,ochR ester, W 97589 124-44800-30 0 Cloudbu146 ayWarst W Eugene, OR 9 40274 7 6-92800-8 118 ve.2nd A1 NE 8425 orP 0227tland, OR 9 97750-7800-9 1 International D01 .Dr 8Missoula, MT 59 08 3 S.55 Highway 913 1alispell, MT 5990K 9014-4800-43 d.ontage Rr50 S. F87 101Billings, MT 59 9585-23 73800-7

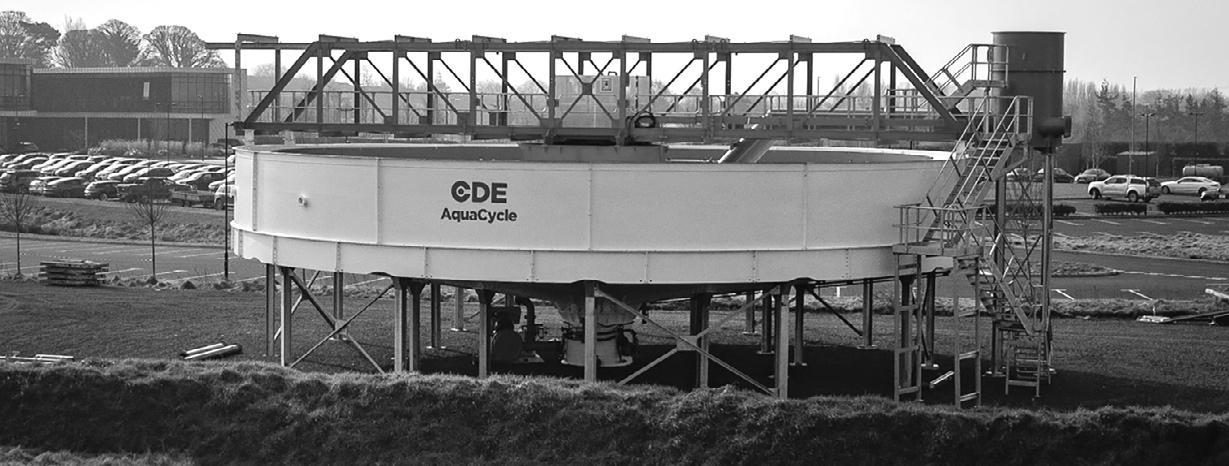

CDE, a supplier of wet processing solutions for the natural processing and waste recycling sectors, has revealed its new AquaCycle A2500 thickener, the latest addition to its water management and recycling systems.

With a capacity of 11,000 gpm, the new A2500 is CDE’s largest and most advanced water management system to date.

It has been developed in response to calls from materials processors operating in high tonnage markets for water management solutions equipped to supply their operations with sufficient water supplies while ensuring optimal production efficiency, minimum loss of fines and maximum water recycling.

Darren Eastwood, business development director of the Americas at CDE, said, “It is increasingly important for materials processors to invest in an effective water management system that ensures a steady supply of clean water to their plants through cost-effective means.

“The continued advancement of our pioneering wet processing solutions and leading-edge water management systems is supporting operators working in the natural processing and waste recycling sectors worldwide to overcome the challenges of washing in water-pressured or water scarce areas today.”

Where CDE bridged the gap in 2018 with the launch of its A900 and A1500, providing a median alternative to its 2,642 gpm and 6,604 gpm models, the new A2500 expands the range with a 11,000 gpm option to fit the requirements of sites processing high tonnages. The increased capacity also provides a lower rise rate, enabling operators to process challenging, harder to settle materials, according to the company.

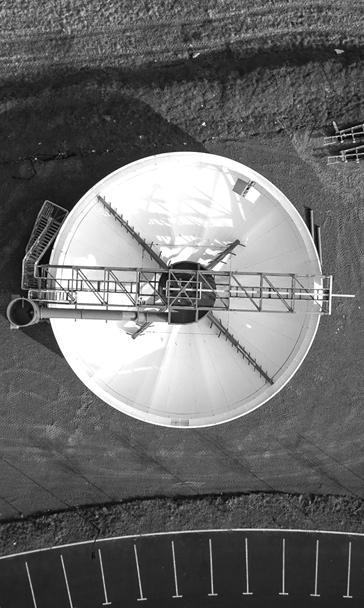

Designed for easy use and safe access for efficient maintenance, it boasts the first lattice bridge structure on any CDE thickener. An integrated monorail also provides enhanced access to the motorized rake, gearbox and motor.

With a sludge capacity of 138 tons/hour, the A2500 includes an adjustable rake lifting mechanism. Featuring passive torque control, the automatic raise and start sequence is designed to protect rakes from surge pressure from dense sludges. The rake itself also has been reimagined, with optimally spaced and redesigned blades for improved sludge conditioning.

Powered by the motorized rake arm, the introduction of a new floating scum scraper, which is independent of the rake’s height, allows for the easy removal of unwanted foam, oil and light weight trash. And, creating even radial flow to all regions of the A2500, a redesigned volute feedwell optimizes the incoming flow for improved flocculant performance.

Another key feature of the new A2500 is its feed height. Sitting at almost 22 ft, it simplifies upstream plant design complexity as it eliminates the need for expensive civils, helping to expedite the commissioning process of entire plant solutions.

With a tank diameter of 65.6 ft and a weight of 97 tons when empty and 1,268 tons when full, the A2500 features a small footprint while packing a punchy 11,000 gpm and a solids capacity of 138 tons/hour.

An alternative to water extraction from natural sources and the costly process of pumping water to the plant, CDE’s A2500, like the full AquaCycle range, significantly reduces costly water consumption by ensuring up to 90 percent of process water is recycled for immediate recirculation, according to the company.

Eastwood said the development of the new A2500 delivers all the benefits of CDE’s existing AquaCycle range on a much larger scale.

“It responds directly to the needs of materials processors operating in high tonnage markets. These operations, primarily in the areas of C&D waste, specialist sands and heavily clay-bound aggregates, require higher volumes of water resources; they need flexible water management systems with the capacity to supply their operations without compromising on footprint; and they need a system that can deliver this in a way that improves efficiency, driving down operational costs to maximize profitability and

With a capacity of 11,000 gpm, the new A2500 is CDE’s largest and most advanced water management system to date. Designed for easy use and safe access for efficient maintenance, the A2500 boasts the first lattice bridge structure on any CDE thickener. The A2500 has been developed in response to calls from materials processors operating in high tonnage markets for water management solutions equipped to supply their operations with sufficient water supplies while ensuring optimal production efficiency, minimum loss of fines and maximum water recycling.

enable fast return on investment. These are the guiding principles that underscore the design and development of the new A2500.” For more information, visit cdegroup.com.