By Larry Bernstein CEG CORRESPONDENT

Travel between countries in Europe is like traveling between American states. Yet, some connections are not so simple. Hence, the Fehmarnbelt tunnel, which will connect Germany to Denmark. Upon completion, the 18-km (11.2 mi.) long tunnel will be the world’s longest immersed tunnel connecting the northern German island of Fehmarn and the south Danish island of Lolland. The tunnel will be a game changer in terms of traveling within the European Union, and its complex construction is worthy of study.

By Lucy Perry CEG CORRESPONDENT

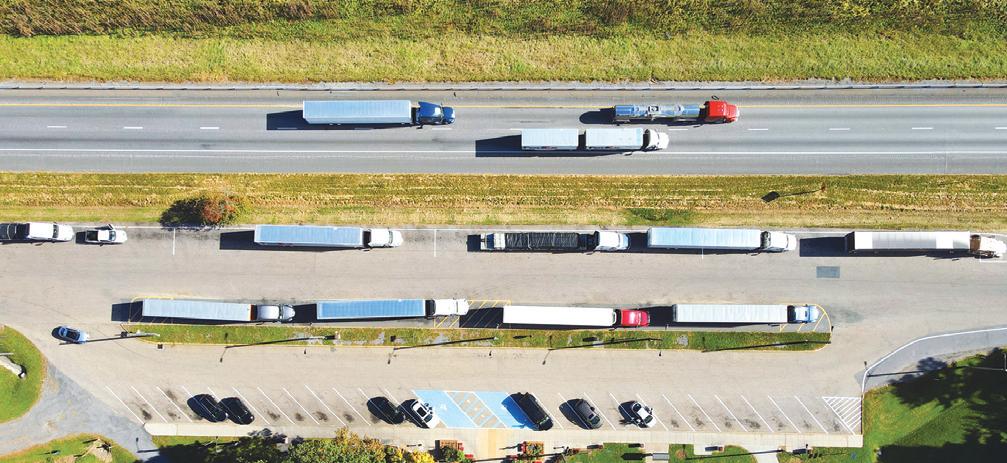

trucking industry is overjoyed congressional transportation committee members have recognized the safety needs of truckers. Legislation was introduced this winter to authorize $755 million in

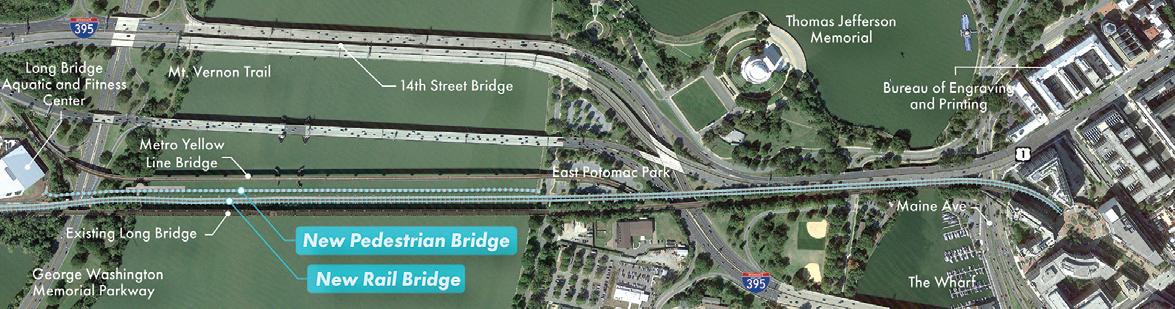

LBRP was selected to deliver the South Package of Virginia’s $2.3 billion Long Bridge Project, which includes construction of a new two-track railroad bridge and an adjacent bicycle pedestrian bridge over the George Washington Memorial Parkway and Potomac River.

The Jacksonville, Fla., District of the U.S. Army Corps of Engineers (USACE) announced March 27, 2025, that it has awarded an approximately $20 million contract to Marinex Construction Inc. for the second periodic renourishment of Fernandina Beach for the Nassau County Shore Protection Project (SPP).

The challenge drew a great turnout of contestants to enjoy a catered event, view machine displays and to see some of the best operators in the area compete for an opportunity to move on to the Caterpillar regional finals with the potential to advance to the Global Operator Challenge Finals

Dassault Falcon Jet officials expect their new service complex at Melbourne Orlando International Airport to welcome its first aircraft summer 2025 — launching plans to eventually employ approximately 350 well-paid workers.

John Coughlin, who has served as president and chief executive officer since 2010, will transfer responsibilities to Executive Vice President of Operations Travis Mullins, who was appointed president and chief executive officer on April 1, 2025.

FAE USA celebrates a significant milestone as Giorgio Carera marks his 20th anniversary as CEO. Under his guidance, the company has grown from a small North American subsidiary into a trusted industry leader in land management and road construction.

22

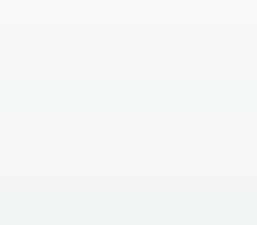

The event, which was held at America’s Center Convention Complex, featured a record of more than 230,000 sq. ft. of display space, giving 430 asphalt industry manufacturers a chance to display equipment and tout their services.

26

The survey found that 27.2 million Americans planning digging projects in the next year will not contact 811, putting themselves and their communities at risk of utility service disruptions, costly fines and more.

30 EQUIP EXPO NAMES SAVANNAH BANANAS’ JESSE COLE AS KEYNOTE

Marketing challenges face every business owner, and Equip Exposition attendees will learn from one of the most well-known marketers and entrepreneurs in the United States: Savannah Bananas founder Jesse Cole.

34 MECALAC SHOWCASES NEW REVOTRUCK SERIES DUMPERS AT NDA

During the National Demolition Association show, Mecalac debuted its new Revotruck Series dumpers, which feature a unique new design that combines the revolution of the cab with off-road truck capabilities.

56 MANO ENGINEERING OFFERS ROPS, FOPS RE-CERTIFICATION

Specializing in the restoration and certification of damaged cabs on heavy-duty machinery, the company provides OSHA-compliant solutions that help businesses meet regulatory standards while maintaining operational safety.

LIEBHERR

In his role, Hirohito Imakoji will oversee the strategic planning and execution of growth strategies for all corporate, finance and administrative functions integrated in the shared services at Liebherr USA Co.

The Jacksonville, Fla., District of the U.S. Army Corps of Engineers (USACE) announced March 27, 2025, that it has awarded an approximately $20 million contract to Marinex Construction Inc. for the second periodic renourishment of Fernandina Beach for the Nassau County Shore Protection Project (SPP).

Based in Charleston, S.C., the marine contractor is set to undertake the project in a continuing effort to replenish the beachfront following damage done to it by Hurricane Nicole in 2022.

The Nassau County SPP is a federally authorized, 50-year project designed to provide sustainable shore protection for property, critical infrastructure and environmental habitat while simultaneously providing recreational opportunities for residents and tourists, energizing the local economy.

ly 3 mi. offshore of the south jetty.

USACE will cover 100 percent of the total project costs.

The plan calls for renourishing approximately 4 mi. of shoreline on Fernandina Beach south of the St. Mary Entrance Channel south jetty, located between the Florida Department of Environmental Protection’s R-19 and R-33 range monuments, or coastal survey markers, established by the FDEP to track beach erosion and accretion and to assist in coastal management and mapping.

Beach compatible sand for the project will be dredged from the South Channel Borrow Area, located approximate-

Once constructed, the USACE-managed project will provide a holistic defense against future storms, beach erosion and sea level rise, the agency said in a news release.

In addition, it will foster a more resilient coastline, allowing more efficient and less costly recovery in the wake of any future severe storm impacts, significantly increasing the protection of homes, businesses and infrastructure from coastal storms, while saving the taxpayer’s money.

The project, under the Stafford Act, is eligible for emergency beach renourishment following significant storm events at 100 percent federal cost.

Initial work at Fernandina Beach, northeast of Jacksonville, had been projected to start in June, the federal agency noted, but could commence as soon as mid-April 2025, depending on the contractor’s readiness and ability to mobilize.

Marinex Construction plans to stage its equipment at the Dolphin Avenue parking lot in the beach town. As a result, the Sadler Road beach access may be temporarily blocked for equipment delivery and removal.

The construction will likely occur around the clock, seven days a week until completed, USACE said, and will undoubtedly include backup alarms, lights and other noise associated with active work zones.

Sand will be pumped onto the beach from offshore and graded into place by dozers and other equipment. Crews will be working within approximately 1,000-ft. intervals, which will lead to sections of the beach being closed off.

To ensure public safety, beach access will be restricted in the active construction zone but will remain open elsewhere along the shore. The federal agency noted that safety personnel will be on site to direct the general public away from potential hazards.

The latest renourishment of Fernandina Beach is estimated to conclude November 2025 and periodic upgrades are expected to occur in five-year cycles determined by the extent of storm impact, wave erosion and sea level rise.

Long Bridge Rail Partners (LBRP) — a joint venture of Trumbull Corp.; Fay, S&B USA Construction (Fay); and Wagman Heavy Civil Inc. — announced their selection by the Virginia Passenger Rail Authority (VPRA) as the design-build contractor for a key component of the Long Bridge Project to provide increased capacity for passenger rail over the Potomac River between Washington, D.C., and Arlington, Va.

The project will help the Commonwealth of Virginia to modernize critical infrastructure to meet the needs of growing communities and industries.

LBRP was selected to deliver the South Package of Virginia’s $2.3 billion Long Bridge Project, which includes construction of a new two-track railroad bridge and an adjacent bicyclepedestrian bridge over the George Washington Memorial Parkway and Potomac River. The work site will be upstream of the existing Long Bridge, spanning from south of the Jefferson Memorial by Ohio Drive SW to Arlington County south of the George Washington Memorial Parkway.

At completion, the two new tracks will enable separation of passenger and freight rail traffic across four tracks to enhance

transportation connectivity and efficiency in the region. The new infrastructure will benefit Amtrak travelers from Boston to Miami and regional commuters using the Virginia Railway Express. Additionally, the bicycle-pedestrian crossing will connect regional residents and visitors from the Jefferson Memorial and East Potomac Park to the Mount Vernon Trail and other northern Virginia amenities. Following design of the new bridges, heavy construction on the South Package is expected to begin in the fall of 2026 and estimated for substantial completion in 2030.

The lead designer on this project is STV, a leading professional services firm that plans, designs and manages infrastructure projects across North America.

“The LBRP team is committed to delivering this cornerstone project of regional infrastructure improvements to enable expansion of Virginia rail service to meet future demand,” said Mark Gentile, president of Trumbull Corp.

“With more than 75 years of heavy civil construction experience and extensive design-build expertise in bridges, rail projects and other complex infrastructure, Fay

brings innovative solutions for design, efficient construction and safety that will help LBRP deliver this transformational project on time and on budget for the VPRA,” added Ryan Surrena, president of Fay.

“Wagman relishes the opportunity to partner in the delivery of this generational project,” said Greg Andricos, president and COO of Wagman Heavy Civil Inc.

For more information, visit www.trumbullcorp.com, www.shikunusa.com and www.wagman.com. (Photos courtesy of Virginia Passenger Rail Authority.)

NEW 2024 CAT 725

5,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

NEW 2024 CAT 730

6,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

(2) New 2024 Hydrema 922G 4x4

4,250 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

Equipment for Builds/Order

Rigid Water Tanks up to 18,000+ Gallons 4,500-6,000 Gallon Water for Tandem/6x6 Chassis, Heavy Duty Off-Road Construction

Complete NEW CAT Articulated & Rigid Builds (any size) available with HEC tanks/bodies

New Articulated and Rigid Water Tanks for all Sizes and Brands installation at our place or yours Current stock for CAT 725, CAT 730, CAT 740, CAT 773/775, Bell B30, Bell B40

Fuel, Fuel/Lube Builds available. Articulated or Rigid. Open for warm weather or Up to Arctic Level enclosed for extreme cold operation

Kelly Tractor held a Cat Operator Challenge March 28 and 29, 2025, adjacent to the construction of its new Ft. Pierce branch next to I-95 in South Florida. The challenge drew a great turnout of contestants who brought their families to enjoy a catered event, view machine displays and to see some of the best operators in the area compete for an opportunity to move on to the Caterpillar regional finals with the potential to advance to the Global Operator Challenge Finals at ConExpo-Con/Agg 2026 in Las Vegas where Caterpillar will crown one operator as World Champion.

(L-R): A big group from ATC Engineering, based in Miami, Fla., came out to watch their expert operator compete and included Luis Romero, Lidis Burgos, Ildelys Alvarez, Elizabeth Alvarez, Yerandi Legra and Alvaro Martinez.

Checking grade accuracy of a contestant’s trenching work in the

At the event’s conclusion and the score sheets were tabulated, the winners were:

• First place — Christopher Dial, Capling Leveling, Vero Beach, Fla.

• Second place — Carmen Costa Jr., Tomahawk Construction, Labelle, Fla.

• Third place — Carmen Costa Sr., Kater Company of Estero Inc., Estero, Fla.

Overall, 47 contestants competed. Company representatives also said they sold a Cat 255 compact track loader and a 302 mini-excavator because of the exposure and the vari-

Under the watchful eye of one of Kelly Tractor’s Certified Dealer Instructors, Chad Thompson (L), Alexander Bryan of Stewart Materials, Ft. Pierce, Fla., made his way through the “Stay on Track” compact track loader course.

Kelly Tractor’s Bill Colosi (L) and David Erkelens (R) welcome customer-friend Jim Heimer of Dickerson Infrastructure, Ft. Pierce, Fla., to the event.

Kelly Tractor sales representative Jason Slinker (C) and Yaisbel Cruz, sales manager of utility equipment sales for Miami-Dade and Broward counties, speak with customers about some of the compact machines on display.

ous contractors in the area stopping by to visit. Lunch consisted of a fantastic BBQ lunch with all the sides. Jamie Hoffman and the Kelly Tractor Certified Dealer Instructors team put together a course that expanded on the difficulty from the previous challenge competitions and proved to be quite a test for even the most experienced operators. It was a total team effort from marketing to demo instructors to company ownership. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.) see CHALLENGE page 78

(L-R): Jim Holman, Joseph Holman, and two-year-old Wyatt Holman, all of Precision Site Contracting, Jensen Beach, Fla., enjoy some great conversation with their

(L-R): Jamie Hoffman, Kelly Tractor Certified Dealer Instructor (CDI) talks with Hunter Curtis and his dad, Allen Curtis, subcontractors working in Ft. Myers, Fla., but based in Winchester, Ky. At the event’s conclusion, they drove two trucks pulling two trailers more than 1,000 miles back to Kentucky.

Another contestant makes a go at the “Big Dig” competition operating a Cat 323 excavator.

Dassault Falcon Jet officials expect their new service complex at Melbourne Orlando International Airport to welcome its first aircraft summer 2025 — launching plans to eventually employ approximately 350 wellpaid workers and attract “ultra-high-networth customers” to Florida’s Space Coast for weeks at a time.

Boasting a multi-billion-dollar worldwide backlog of aircraft orders, the French aviation giant also is scrambling to meet heavy demand from existing customers to maintain, repair, paint and overhaul their business jets — which can cost north of $60 million.

As part of a global jet-maintenance expansion, DFJ is wrapping up construction of a $115 million white-and-blue hangar facility

Boulevard still refers to DFJ’s future facility by its code-name, Project Vista, a oncesecretive economic development undertaking. The mystery company was publicly identified in October 2022, and a dedication ceremony took place 13 months later on the Hyatt Place Melbourne Airport rooftop deck.

The complex will accommodate all current Falcon models, including the new ultralong-range Falcon 10X, the largest purposebuilt business jet, and be capable of performing major work and modifications on up to 16 Falcon models simultaneously.

Employees are expected to earn average salaries of $86,120, the Economic Development Commission of Florida’s Space Coast reported. Partners on the project included Space Florida, Enterprise Florida and CareerSource Brevard.

taking shape off Apollo Boulevard in Melbourne, Fla., Florida Today reported March 31, 2025.

The 235,000-sq.-ft. structure will serve as a troubleshooting hub for mechanical, hydraulic, electrical and electronic systems on all models of Falcon corporate aircraft from the United States East Coast, Mexico and Latin America.

“Airplanes arriving on site will be a mix,”

Andy Alberti, DFJ’s vice president of maintenance, repair and overhaul (MRO) in the Americas, told the Viera-based news source. “You’ll have aircraft that have a part failure, [or] that need that one part changed. [After they] show up, the next morning they go back into service.”

He noted that the Brevard County facility also will handle standard annual maintenance, which lasts one to two weeks and its crew can do full paint jobs, interior work, avionics updates and all major maintenance.

“So that could be up to a three-month input,” Alberti said.

A construction sign facing Apollo

“Dassault Falcon Jet’s presence will not only create hundreds of high-paying jobs but also strengthen Melbourne Orlando International Airport’s position as a global leader in aviation services,” Greg Donovan, airport executive director, said in an e-mail to Florida Today. “Over the past decade, MLB has reinvested airport revenue into major infrastructure improvements — the very same improvements that are central to attracting new companies like DFJ.”

Bolstering the Space Coast’s economic impact, DFJ’s “ultra-high-net-worth customers,” including corporate pilots and crew chiefs, will be encouraged to stay in Melbourne-area hotels for weeks, if necessary, to monitor progress while their aircraft are revamped. In fact, the service facility will feature 14 offices and a conference room, lounge and other amenities for customer use during their layovers, according to Florida Today.

The prime contractor for the new jet maintenance hangar is the Haskell Company, based in Jacksonville, Fla.

Inside the sprawling, white-painted maintenance and overhaul hangar on a recent day, construction workers soared upward on scissor lifts while finishing tasks near the 57-ft. ceiling.

Cat 259D – 2022 CW9 Series, 1,450 Hours, Cab, G.P. Bucket $59,500

Cat 299D3 – 2023 DY9 Series, 700 Hours, Cab, High Flow Hydraulics, G.P. Bucket

$84,500

Cat 306 – 2023 6G6 Series, 300 Hours, Hydraulic Thumb, Leveling Blade

$99,500

Cat 310 – 2022 GWT Series, 860 Hours, Hydraulic Coupler, Rubber Pads, 36” Bucket

$119,500

Cat 315 – 2022 WKX Series, 1,400 Hours, Auxiliary Hydraulics, Hydraulic Coupler, Leveling Blade, 36” Bucket............................................$174,500

Cat 320 – 2021 MYK Series, 1,428 Hours, Auxiliary Hydraulics, Hyd. Coupler, 48” Bucket

$Call

Cat 330 – 2023 WCH Series, 250 Hours, Warranty Remaining, Auxiliary Hydraulics, Hydraulic Thumb, 54” Bucket $309,500

Cat 336 – 2019 YBN Series, 4,250 Hours, Auxiliary Hydraulics, Hydraulic Coupler, 60” Bucket

Cat D3 – 2022 XKW Series, 750 Hours, Sweeps, Winch

$189,500

Cat 745 – 2019 3T6 Series, 45 Ton Capacity, Good Tires $194,500

$179,500

Cat D3 – 2023 XKW Series, 950 Hours, Sweeps, Rear Ripper $179,500

Cat D5 – 2024 ZDA Series, 125 Hours, VPAT Blade, Sweeps, Rear Drawbar

$Call

Cat D6T XW – 2019 JNM Series, 1,929 Hours, EROPS, Sweeps, VPAT Blade, Rear Drawbar $Call Cat D7 – 2021 CM9 Series, 4,000 Hours, S/U Blade, Rear Drawbar, Trimble Earthworks GPS

Deere 350P – 2022 Model, 700 Hours, Auxiliary Hydraulics, Hydraulic Thumb, 54”

Linder Industrial Machinery has announced a leadership transition.

John Coughlin, who has served as president and chief executive officer since 2010, will transfer responsibilities to Executive Vice President of Operations Travis Mullins, who was appointed president and chief executive officer on April 1, 2025. In tandem with this change, Richard Fikis, current executive vice president of construction sales, was appointed chief operating officer.

John Coughlin has been an integral part of Linder for 22 years, guiding the company through substantial growth and transformation. Under his leadership, Linder has expanded its market presence, strengthened relationships with key manufacturing partners and enhanced its commitment to customer service and innovation. “Leading Linder has been an incredible journey, and I am deeply grateful for the dedicated team and valued customers who have made our businesses mutually successful,” Coughlin said,

Ichiro Murofushi, chairman of Linder’s board of directors, said, “On behalf of Linder’s employees, manufacturing partners and the board, I would like to thank John for his outstanding leadership and resolve during his 15 years as president and CEO. John’s strategic vision has positioned our company as a well-diversified, premier equipment and solutions provider across the southeast. We are excited to support Travis, Rich and the leadership team in driving the next level of growth for Linder and its stakeholders.”

Mullins brings extensive industry experience and a strong track record of leadership to his new role as president and chief executive officer. Having served in several executive positions at Linder for nearly 10 years, Mullins has played an essential role in driving operational excellence and executing

Coughlin see LINDER page 24

FAE USA celebrates a significant milestone as Giorgio Carera marks his 20th anniversary as CEO.

In an era where leadership is often distant, Carera’s “boots on the ground” approach has set him apart, cultivating a culture of connection and excellence that extends from his team to customers across North America, according to FAE.

“Under his guidance, FAE USA has grown from a small North American subsidiary into a trusted industry leader in land management and road construction,” said FAE. “Giorgio’s hands-on leadership style and commitment to being present at every level — from team meetings to customer job sites — has fostered a top-down attitude of dedication and accountability. His approach resonates throughout the organization and sets the standard for customer-first service and innovation.”

“Reflecting on these 20 years, I am incredibly grateful to be part of this journey alongside our talented team, dedicated dealers and loyal customers,” said Giorgio Carera. “Our success is built on strong partnerships and a shared commitment to excellence. Presence and genuine connection with our customers are at the heart of everything we do, and that will continue to drive our efforts moving forward.”

FAE’s product line has continuously evolved to meet the changing needs of the industry. Many of these are a direct response to customer feedback and realworld challenges. By staying connected

to the people who use the company’s products and truly understanding their needs, FAE has been able to develop solutions that enhance productivity and efficiency across land management, forestry, agriculture, construction and road maintenance sectors, according to FAE.

“Giorgio’s leadership philosophy emphasizes teamwork, integrity and growth,” said FAE. “His ‘boots on the ground’ presence sets the standard for FAE USA’s customer-first approach, inspiring every team member to prioritize genuine connections and exceptional service.”

By empowering employees and fostering a collaborative work environment, FAE USA has built a team that is dedicated to supporting its dealers and end users. Carera’s commitment to presence and availability — whether at dealer meetings, trade shows, or customer demonstrations — reinforces the company’s dedication to building trust and long-term relationships, according to FAE.

“Our mission is to provide the highestquality equipment backed by exceptional service,” said Carera. “We are driven by the feedback from the people who use our products every day, and we are constantly looking for ways to help them work more efficiently and effectively.”

For more information, visit faegroup.com.

The World of Asphalt Show & Conference and AGG1 Academy and Expo visited St. Louis, Mo., for the first time, drawing more than 11,500 industry professionals between March 25-27, 2025.

The event, which was held at America’s Center Convention Complex, featured a record of more than 230,000 sq. ft. of display space, giving 430 asphalt industry

manufacturers a chance to display equipment and tout their services.

“This success is a direct result of the collaboration and hard work of all our partners, exhibitors, and staff,” said Brittany Schmidtke, World of Asphalt show director. “The momentum and growth in the asphalt and aggregates industry is evident by what we saw exhibited on the show floor

and ultimately provided a richer experience for our attendees.”

Fifty-nine percent of the attendees were under age 45, and 10 percent were women. Visitors traveled from across the country and abroad, some traveling as far as Australia, England, Argentina, Mexico and Nigeria.

Attendees engaged in more than 120 educational sessions

occupied a prime location at World of Asphalt 2025.

through the People, Plants and Paving and AGG1 Academy. These conferences covered a range of topics essential to the asphalt and aggregates industries.

A few of the most popular sessions included “Lean Principles: It’s About People, Process and Change,” “Unleashing the Power of Intentional Leadership: Leading Yourself to Lead Others,” “Autonomous Quarry Trucks

(L-R): At the Komatsu booth in front of WA 485 yard loader are Jimy Joseph, senior vice president of sales of Roland Machinery Co. of Springfield, Ill.; Jenkins Davis, senior district manager of Komatsu, who has more than 50 years in the industry; and Frank Pagura of Walkesha Pearce Industries of Houston, Texas.

Caterpillar is celebrating its 100th anniversary. Much of the equipment and its display was adorned with the100th anniversary commemorative logo.

101,” “Extreme Ownership for Business and Life,” “Laydown Best Practices” and “Compaction 101: Doing the Right Things, the Right Way.”

Running concurrently with AGG1 was the NSSGA annual convention, which featured the announcement of the 2025 NSSGA leadership, including board chair Ted Baker II of Blue Water Industries, and the presentation of the Barry K.

Komatsu’s HM 400 articulated truck (foreground) and mid-sized excavator were featured at the company’s space.

Wendt

Commitment

The annual membership meeting keynote was a moderated discussion by football legend Archie Manning. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.) see WOA page 38

A Liebherr L566 wheel loader beckons to passersby.

strategic growth and customer success initiatives. His deep understanding of the business and his commitment to innovation and excellence positions him exceptionally well to lead Linder into its next chapter.

“I am honored to step into this role and build upon the legacy that John established,” said Mullins. “Linder is a company with a rich history and a bright future. I look forward to working with our talented team to continue delivering exceptional value to our customers and partners.”

Fikis was vice president of sales of Linder for three years before his promotion to an executive vice president position in 2024. Prior to joining Linder, Fikis held several senior leadership roles with Komatsu North America, contributing to that company’s success for more than 20 years. His deep industry experience, proven leadership and customer-centric approach will serve him well in his new role as chief operating officer.

“Linder has a strong legacy of excellence, and I look forward to working with Travis and our incredible team to drive innovation, efficiency and continued growth for our customers and partners,” said Fikis.

As part of the transition, Coughlin will stay on as senior advisor over the next year to ensure a seamless transition and successful integration of recent acquisitions.

“I have complete confidence in Travis, Rich and the leadership team to continue building on our strong foundation,” said Coughlin.

Linder launched a material handling and port solutions division in 2014. Four years later, Linder Turf & Tractor was established, which now has seven locations in three states. In 2024, Linder expanded into Virginia making Linder the largest Komatsu dealer in the country. Linder remains committed to its mission of delivering top-tier products and

to its customers

In observance of National Safe Digging Month in April, Common Ground Alliance announced results from a recent national survey.

The survey found that 27.2 million Americans planning digging projects in the next year will not contact 811, putting themselves and their communities at risk of utility service disruptions, costly fines and repairs and even serious injury or death.

“As we work to unleash American energy, the Department of Transportation will continue to educate the public on free resources they can use to enhance safety,” said U.S. Secretary of Transportation Sean Duffy. “Whether you’re a homeowner planting a garden or a contractor

breaking ground on a major project, we encourage you to contact 811 prior to any excavation activity to ensure a safe dig every time.”

Digging without knowing the location of underground utilities can lead to serious injuries, service outages and expensive repairs.

Accidentally striking gas, electric, communications, water or sewer lines can cause significant disruptions to homes and businesses. A free 811 request is available by calling 811 or submitting a ticket online. Your dig request ensures that underground utility lines are properly marked before digging, preventing accidents and keeping communities safe.

“Our survey found that 46 percent of Americans don’t plan to notify 811 before digging, with most believing their project is too shallow to merit an 811 request,” said CGA President and CEO Sarah K. Magruder Lyle.

“This misconception puts homeowners and their neighbors at risk of injury and utility service interruptions. The reality is that utility lines can be buried just inches below the surface, which is why everyone must contact 811 before every digging project — whether it’s installing a patio or major construction.”

Even common do-it-yourself projects — such as planting a garden, installing a mailbox or setting up a fence — can pose risks, as the depth of buried utilities can vary.

To keep homeowners,

families and communities safe, a few days before breaking ground, make a free request to have the approximate location of underground lines marked with flags or paint by calling 811 or visit 811beforeyoudig.com. This National Safe Digging Month and all year long, take the following steps when planning a digging project:

• Always contact 811 a few days before digging, regardless of the depth or familiarity with the property;

• Plan ahead. Make a free 811 request on Monday or Tuesday for work planned for an upcoming weekend, providing ample time for the approximate location of lines to be marked;

• Confirm that all lines have been marked;

• Consider moving the location of the project if it is near utility line markings; and

• If a contractor has been hired, confirm that the contractor has contacted 811. Don’t allow work to begin if the lines aren’t marked.

Everyone who contacts 811 a few days before digging is connected to a local 811 center that collects the information and communicates it to local utility companies. Professional locators will then visit the dig site to mark the approximate location of underground utility lines with spray paint, flags or both. Once a site has been accurately marked, it is safe to begin digging around the marked areas.

HUB from page 15

The 46-acre site is located on the airport property between Sheltair Aviation’s fixed-base headquarters and General Aviation Drive, a gated roadway leading to Embraer’s jet manufacturing campus.

Besides the Falcon 10X, the Melbourne complex is geared to accommodate every other Falcon model, including Dassault’s latest — the Falcon 6X — a widebody jet introduced in 2023; and the Falcon 8X, designed for long-range flights. Both are designed to carry as many as 16 passengers.

The jumbo-sized Falcon 10X business jet remains under development, with first deliveries expected in 2027.

According to the company website, the Falcon 10X is so large it can include “an expanded dining/conference area, an entertainment area with a large-screen monitor, a private stateroom with a true queen-size bed or a master suite with a private stand-up shower.”

Not far from the primary DFJ maintenance facility in Melbourne, a smaller hangar is home to a 54,000-sq.-ft. paint shop. Standing 49 ft. high, it is split into a strip-prep bay on one side and a paint bay on the other. Both have separate ventilation systems.

In speaking with Florida Today, Alberti said it takes approximately four weeks to repaint a jet as the old paint must first be stripped down to the raw metal via hand sanding (composite materials) or a chemical process (aluminum).

A $6.6 million Florida Department of Transportation (FDOT) grant helped to kick start the DFJ project by financing an environmental assessment, land-clearing, apron construction, utility extensions, stormwater drainage, an Apollo Boulevard median cut and security equipment for the work, per a Melbourne City Council memo.

During a meeting of the Melbourne Airport Authority on March 26, 2025, David Perley, its director of capital improvements, said underground utility work along Apollo Boulevard is nearing completion. Crews will soon shape driveways and median crossovers, and base rock is being installed so the concrete apron can be poured outside the buildings.

DFJ’s other major service centers in the Western Hemisphere are in Little Rock, Ark., Reno, Nev., and Sao Paulo, Brazil.

It also operates a smaller, 25,000-sq.-ft. service facility in Stuart, Fla., approximately 75 mi. down the coast from Melbourne at Martin County Airport/Witham Field. There, DFJ technicians handle the Falcon 50, Falcon 2000, Falcon 900, Falcon 7X, and Falcon 8X jets.

DFJ spokesperson Andrew Ponzoni said the company expects demand for drop-in and light maintenance in Stuart to remain high, while traditional long-term heavy maintenance gets transitioned northward to Melbourne.

After bringing in a nucleus of approximately 70 mechanics and employees from other DFJ facilities bolstered by new hires — with applicants hailing from as far away as Japan — Dassault Falcon Jet CEO Thierry Betbeze said the Melbourne aviation complex should serve its first aircraft in July 2025 and employ approximately 150 workers by the

Marketing challenges face every business owner, and Equip Exposition attendees will learn from one of the most well-known marketers and entrepreneurs in the United States: Savannah Bananas founder Jesse Cole.

Founder of the popular baseball team, Cole will deliver the keynote address, sponsored by Kress, at the blockbuster trade show for landscapers, dealers, contractors, hardscape experts and outdoor power equipment manufacturers. The trade show drew 28,500 attendees last year.

Known for his banana yellow suit and marketing ideas, Cole will share what it takes to develop a great idea into a brand that people embrace and love. His story will delve into marketing brands and how to keep creativity flowing.

Those are lessons smart industry business owners are seeking to learn.

“There’s just so much to learn from being around a group of growth-minded people who are really, truly just trying to better themselves and their businesses,” said Mark Bradley of LMN and TBG Landscape, when asked what draws him to Equip Exposition.

Ideas from Cole will likely be hot discussion points for the trade show’s legendary networking opportunities, which span a welcome reception at Churchill Downs where a new signature bourbon will debut this year, two concerts, a women’s leadership reception sponsored by Belgard, Hunter Industries and SiteOne and more peer-to-peer activi-

ties.

Country stars Big & Rich and solo country artist Gretchen Wilson will perform an exclusive concert for show attendees at the Kentucky International Convention Center the Thursday night of the show. The concert is included with the registration to Equip Exposition.

“We offer a number of social opportunities at Equip but they’re created with purpose,” said Kris Kiser, president and CEO of the Outdoor Power Equipment Institute (OPEI), an international trade association representing manufacturers and suppliers of power equipment, small engines, battery power systems, portable generators, utility and personal transport vehicles and golf cars, which owns and manages the blockbuster show. “Unlike any other time of year, peers can talk with one another, get to know each other, at the show. It’s especially a great opportunity for team building.”

With more than 1.2 million sq. ft. of indoor and outdoor exhibit space, Equip Exposition is a “must see” for dozens of reasons, including the 30-acre Outdoor Demo Yard, networking events, education and technical training in English and Spanish.

“Anything that has anything to do with marketing, it’s here,” said Keith Kalfas, a leading lawncare podcaster. If you’ve never been to the [Equip] Expo, you have to come at least once. Be committed, because once you get here, you’re going to be

Alabama Heavy Machines Inc.

www.heavymachinesllc.com

THEODORE (251) 653-5955

BIRMINGHAM (205) 323-6108

DECATUR (256) 898-0550

Arkansas LiftTruckServiceCenterInc

Lift Truck Service Center, Inc.

www.lifttruckservicecenterinc.com

LITTLE ROCK (501) 568-3330

Florida Heavy Machines Inc.

www.heavymachinesllc.com

PENSACOLA (888) 366-9028

Great Southern Equipment, LLC. www.gsequipment.net

T

AMPA FT. MYERS

(813) 248-4971

ORLANDO (407) 859-9160

JACKSONVILLE (904) 268-4400

OCALA (813) 248-4971

Georgia Heavy Machines Inc.

www.heavymachinesllc.com

COVINGTON (770) 788-0888 (239) 334-6063

Louisiana Heavy Machines Inc.

POMPANO BEACH (954) 327-8808 MIDWAY (850) 574-0892

www.heavymachinesllc.com

SHREVEPORT (318) 621-0854

State Machinery & Equipment Sales, Inc. www.statemachineryco.com

KENNER (504) 464-0431

North Carolina

Liebherr r Equipment Source libh www.liebherr.com

RALEIGH (919) 329-0080

RECO Equipment, Inc. www.recoequip.com

CHARLOTTE (704) 399-7555

Tennessee Heavy Machines Inc. www.heavymachinesllc.com

MEMPHIS (901) 260-2200

RECO Equipment, Inc. www.recoequip.com

LaVERGNE (615) 610-7326

VIRGINIA Liebherr r Equipment Source www.liebherr.com

MANASSAS (703) 392-0111

(757) 240-4250 LOUDON (865) 686-8686 material handling equipment and technology in th components are developed and manufactured in-h or in close collaboration with our partners to ensu possible quality standards.These components inc drive and controltechnology, diesel engines, and a components for hydraulics, gearboxes and electro Reach out to your local Liebherr distribution partne nformation. e USA Main ouse by Liebherr re the highest lude the entire variety of nic systems. rfor more

Currently, it takes approximately 60 minutes to cross between the two areas and over the Baltic Sea. When the tunnel is complete, the trip will be just seven minutes by train and 10 minutes by car.

The tunnel will be heavily trafficked if the owner’s projections are correct. They anticipate the ADT will be more than 12,000. In addition, they expect 111 trains to travel through the tunnel daily. It will have five tubes — two for a two-lane motorway in each direction; two electrified rail tracks; and one for a service passageway.

Speed is just one of the benefits the tunnel will provide.

“This project aims to address current transportation bottlenecks, improve logistics for freight transport, and pro-

vide a faster, more reliable route for both passenger and cargo traffic,” said Denise Juchem, spokesperson of the Danish project owner Femern A/S. “The tunnel also will contribute to the European Union’s goal of creating a seamless and sustainable transport network across Europe.”

Many technical and construction challenges come with building the world’s longest-immersed tunnel. Hence the lengthy construction schedule. Work began in 2020 on the Danish side and in 2021 on the German side, and the project is expected to be completed by 2029.

The first stages focused on extensive preparations. The team built a large work harbor on the Danish side, which serves as a way station for the sand, cement, steel and gravel that will be used to cast tunnel elements.

Hundreds of workers from the contracted international construction consortium Femern Link Contractors (FLC) are

building the elements in a huge tunnel factory located behind the work harbor close to the future tunnel entrance. In the factory, which has three production halls and six production lines, numerous teams are casting the tunnel’s elements. Work is taking place 24/7. Each of the 79 standard elements is 217 m (712 ft.) long and weighs 73,000 tons. The team projects that it will take nine weeks to produce each project element.

Working in the water has been a significant challenge for the Dutch construction consortium Fehmarnbelt Contractors (FBC). Dredging the tunnel trench, which began in 2021 and was completed in 2024, involved excavating 15 million cu m (19.6 million cu. yds.) of seabed.

“Large excavation vessels, including Magnor, the largest backhoe dredger in the world, was used as part of the process,” said Gerhard Cordes, project director of Femern A/S. “The dredged material has been used to construct new coastal areas on the Danish island of Lolland.”

see TUNNEL page 76

The National Demolition Association (NDA) recently held its annual conference and event in New Orleans, attracting more than 1,300 demolition professionals. Attendees engaged in informative meetings with industry vendors and had the opportunity to test their equipment operating skills in the live demolition area.

Mecalac, a manufacturer of construction equipment headquartered in France, capitalized on the show’s demolition

area to introduce its new Revotruck Series dumpers to the U.S. market.

The Revotruck Series dumpers feature a unique new design that combines the revolution of the cab with off-road truck capabilities. For the first time, operators can rotate the entire cab of the site dumpers at the touch of a button, allowing them to maintain their vision and focus on the job while avoiding obstacles on the construction site, according to Mecalac.

The exclusive chassis, which features central oscillation and four-wheel steering, provides stability and traction even under the most severe ground conditions. With Revotruck, material transport is smarter and safer than ever, said Mecalac. The trucks are available in six-ton and nine-ton payload capacities.

According to the U.S. general manager of Mecalac North America, Peter Bigwood, the introduction of the Revotruck Series at the National Demolition Show marks a significant milestone in the company’s expansion into the U.S. market.

This is not the first time that Mecalac has showcased its equipment at the NDA show. At previous expos and this year’s NDA show, Mecalac has demonstrated the Mecalac 6MCR, a skid steer excavator hybrid. The boom of the 6MCR features a unique configuration, allowing the excavator skid steer hybrid to access low clearance areas that would have been impossible with traditional machines. Demolition contractors have noted Mecalac’s ability to handle tasks that

larger machines could not, such as material removal in confined spaces.

Bigwood said that attendees of the show were “very impressed with the rotating cab feature of the Revotruck. Attendees commented that the improved safety, visibility and ease of operation were unique to anything they had seen in the market previously and offered significant advantages to demolition contractors.”

CEG

(All photos courtesy of Mecalac.)

Pages 36-55

During World of Asphalt 2025, Joseph Vögele AG presented the new VR 500 with rear-mounted extensions. It has been redesigned from the ground up and offers paving widths between 8-ft. 4-in. and 20-ft. 12-in.

For the first time, Vögele presented a VR 500 screed for the 8-ft. class pavers. The new VR 500 is equipped with extending units that can be sloped by up to 10 percent and is precisely tailored to the paving requirements of the North American market.

In combination with the SUPER 1700-3i and SUPER 1703-3i pavers, it achieves pave widths of between 8-ft. 4-in. and 20-ft. 12-in. This makes it particularly suitable for the construction of roadways and for medium to large paving jobs. In conjunction with the vibration compaction unit, it achieves optimum smoothness and pre-com paction, according to Vögele.

Vögele has developed the screed from a clean-sheet perspec tive: It has a low design, is extremely compact and offers an optimum view of the entire auger tunnel. The two-stage tele scopic guidance system enables particularly smooth and pre cise width adjustment. The robust center joint for hydraulic adjustment of the crown also ensures a high level of stabil ity, even with larger pave widths, according to Vögele.

The height of the VR 500’s end gates can be adjusted hydraulically at the touch of a button. Another feature of the new VR 500 is the adjustable edge which allows the operator to continuously adjust the angle of the edge from 0 degrees to 90 degrees.

The electric screed heating also ensures high paving quality, bringing the VR 500 up to temperature quickly and evenly. All components that come into con tact with the material are constantly heated, which ensures a homogeneous surface structure.

The additional heating integrated into the leading edge of the screed plate prevents buildup and results in a superior finish texture. In addition, smart generator management reduces energy require ments and fuel consumption during operation, according to Vögele.

The new VR 500 is precisely tailored to the needs of users. The ErgoPlus 3 operating concept provides a clear layout of all functions and symbols. Operators can define, view and change all relevant paving parameters, including the Niveltronic plus system for automated grade and slope control, at the screed operating consoles.

The screed width be conveniently adjusted with the SmartWheel. In addition to the screed control consoles, Vögele provide users with two remote control units featuring practical magnetic mountings, so they can operate the key screed functions from the optimal location at all times, according to Vögele. Vögele introduced the new VR 500 for the SUPER 1700-3i and SUPER 1703-3i road pavers.

Cimline of Plymouth, Minn., showcased its M-series crack sealer machine. The team included (L-R) Tom Rollo, Midwest regional sales manager; Dale Daugherty, regional sales manager; Matt McCormick, director of international sales; Tim Oustrich, sales; Bill Ganger, product support specialist; Amy Dinkel, marketing and brand manager; Ben Thielbar, director of sales; Jared Jamieson, regional sales manager; Jimmy Barthel, sales; and Lance Hartmann, president and CEO of Plymouth Industries, the parent company to Cimline.

WOA from page 23

NPK displayed its GH15 hydraulic hammer, promoting its power and efficiency for heavy-duty demolition applications. (L-R) are Scott McEver, district manager; Ben Moskowitz, pedestal boom specialist; and Ryan Crookham.

and Kelly

At the Odra Sweepers of Grand Forks, N.D. booth, Alan Christy (L) of Superior Roadway Services of Ocoee, Fla., visited with Jason Coover, a territory manager of Odra Sweepers.

Niel Maus, marketing manager of Okada, showcased the Okada ORV 1500 hydraulic breaker as a robust and efficient attachment designed for heavy-duty demolition and construction tasks.

(L-R): Skip Barnes of Berry Tractor & Equipment of Topeka, Kan.; Kaitlyn Ray of Berry Tractor; Ken Bulthuis of Montabert; Aaron Scarfia of Montabert; Clint Golay of Berry Tractor; Jason Cole of Berry Tractor; and Anthony Arellano of Berry Tractor check out the Montabert HCP 850 pulverizer.

Ian Harvey, retired director of product marketing and communications of Volvo of Shippensburg, Pa., appeared with Tony Beets, known from the TV show “Gold Rush,” to discuss mining and his favorite Volvo equipment, specifically the A50 articulated hauler.

Trail King Industries Inc. of Mitchell, S.D., is a North American manufacturer of a comprehensive range of trailers. (L-R): The team includes Cassidy Black, district sales manager; Eric Thomas, director of sales; Mark Hartman, district sales manager; Adam Risher, district sales manager; and Steve Workmeister, district sales manager.

McLanahan is celebrating its 190th anniversary and launching its rapid filter cloth changeout system. (LR) are Alistair Forsyth, group president and managing director of Anaconda Equipment, a McLanahan Company; Mark Krause, vice president of business development of North America; Sean McLanahan, president and CEO; and Cory Jenson, executive vice president of sales and business development, all of McLanahan.

Julie Andreas (L) and Wilm Schulz of Haver & Boecker show off the Niagara F-class portable plant used primarily in aggregate and mining. It offers customizable features and is sold directly in North America.

KAGE Innovation of Oceola, Wis., offers a range of snow and ice removal attachments and accessories that are ideal for professional snow fighters. Team members Kyle Melin (L), inside/outside sales, and Joe Boles, sales, show the features of KAGE plow systems.

www.richmondmachinery.com 2350 Greytone Ct. Rockville, VA 23416 804-359-4048 800-662-6485

SAKAI America announced the release of its new Echelon Mode for the Guardman automatic brake assist system.

This feature, developed in response to customer feedback, enhances the safety and efficiency of tandem asphalt rolling operations.

Guardman uses millimeter-wave radar or 3D LiDAR (depending on the model) to detect potential collisions with personnel or equipment, warn the operator progressively and automatically brake to prevent accidents if needed. The new Echelon Mode builds upon this foundation by specifically addressing the unique challenges of echelon rolling, a common technique used in highway-class paving, according to SAKAI.

“We listened to highway contractors who expressed the need for a solution that would allow for closer, more efficient tandem rolling while still allowing the benefits of Guardman’s automatic braking if necessary,” said Brad Belvin, manager of sales and marketing. “Echelon Mode is the result of that feedback, and we’re proud to offer this advancement to the industry.”

Echelon Mode allows two SAKAI SW884 (79 in.) or SW994 (84 in.) asphalt rollers, equipped with Guardman, to operate in proximity without generating false alarms but still protecting against collisions. The system intelligently monitors distance to the lead roller, ensuring

that both operator warning and braking is only initiated when an imminent collision risk is detected, according to SAKAI.

According to SAKAI, some key features of Echelon Mode include:

• Optimized tandem rolling: Enables closer, more efficient echelon formation.

• Reduced false alarms: Minimizes unnecessary braking interruptions.

• Enhanced safety: Maintains the core Guardman functionality, providing reliable collision prevention.

• Proximity indicator: Provides operators with real-time feedback on the distance between rollers, allowing for proactive adjustments and preventing unwanted braking.

• Easy activation: Echelon Mode can be toggled on and off via the Guardman display screen with one button press.

“Safety is our top priority at SAKAI America,” said Kevin McClain, vice president of operations. “Echelon Mode is a testament to our commitment to continuous improvement and our dedication to providing our customers with the most trustworthy compaction equipment.”

The Echelon Mode update is now available for SAKAI SW884 and SW994 asphalt rollers equipped with the Guardman automatic emergency braking system.

The LeeBoy Rosco NV55 self-propelled broom is designed for heavy sweeping applications including milling, paving, airport and construction site cleanup. The NV55 is the go-to for contractors looking for simple operation and superior sweeping, according to the company.

The NV55 is equipped with a 74 hp (55 kW) Hatz Tier IV diesel 4H50TIC engine, 30-gal. fuel tank, 7-ft., 6-in. HD brush head (with optional 8-ft. head), quick change brush system, variable down pressure and brush speed controls, suspension seat and tilt column, joystick control for travel and broom functions, options include HD side shift brush head and foot pedal transmission.

The NV55 has an operator-centric cab, built for ergonomics and safety. Some features of the cab include a roll over protection system, high visibility mirrors, sliding glass windows, seat belts and 12V outlets. Options include cab heat and air conditioning, backup camera, cab air filtration and AM/FM radio with Bluetooth.

For more information, visit https://www.leeboy.com/products/nv55/.

The NV55 has an operator-centric cab, built for ergonomics and safety. Some features of the cab include a roll over protection system, high visibility mirrors, sliding glass windows, seat belts and 12V outlets .

Leica Geosystems and Dynapac announced the compatibility of autosteering and screed edge control features on Dynapac asphalt pavers with the Leica iCON pave solution.

This solution will be available on the Dynapac SD25 and XD25 highway paver series, a line of paving machines set to debut at bauma.

This partnership aims to enhance the precision and efficiency of asphalt paving operations by combining Dynapac’s paving machinery with Leica Geosystems’ machine control technology.

In addition, the integration of new auto-steering and edge control features will enable pavers to follow stringline design models with millimeter accuracy, eliminating the need for traditional strings-and-pins methods and reducing costs, while improving productivity, according to the companies.

“Our collaboration with Leica Geosystems marks a significant milestone in advancing paving technology and, as a result, providing

Boone, NC 828-268-9992 BLANCHARD MACHINERY www.blanchardmachinery.com/paving Columbia, SC 803-791-7100

Florence, SC 843.678.8520

Rock Hill, SC 803.324.9600

Simpsonville, SC 864.963.3645

Myrtle Beach, SC 843-399-2074

Summerville, SC 843.871.2001

Hilton Head, SC 843-784-6766

CAROLINA CAT www.carolinacat.com

Charlotte, NC 704-596-6700 Asheville, NC 828-251-2500 Greensboro, NC 336-294-5240

Hickory, NC 828-464-7045

Monroe, NC 704-292-1555

even more functionality to our customers,” said Soenke Demuth, head of global product management paving of Dynapac.

With the Leica iCON pave machine control system, operators benefit from automated guidance and precise screed width adjustments based on a digital stringing design, according to the companies. The system enhances site sus-

tainability by optimizing material usage, minimizing waste and ensuring more accurate material estimation throughout the paving process. In addition, it enhances safety by eliminating physical hazards such as stringlines, pins and other marking materials from the job site.

“As infrastructure projects continue to expand globally, meeting the high standards of modern construction requires even greater precision and efficiency in asphalt paving,” said Neil Williams, president, machine control division of Leica Geosystems. “Manually steering a paver while ensuring the screed maintains its optimal width demands constant adjustments to adapt to varying site conditions and maintain consistency. By introducing automated steering and screed control, we alleviate this burden on operators and enhance their ability to deliver superior paving results with greater ease and reliability.”

For more information, visit leica-geosystems.com.

Chattanooga, TN 423-698-6943

Crossville, TN 931-484-4040

Knoxville, TN (East) 865-546-1414

Knoxville, TN (West) 865-218-8800

Sevierville, TN 865-595-3750

Tri-Cities, TN 423-323-0400

Hamm introduced Smart Compact Pro during World of Asphalt 2025.

For the first time, real-time density is used as a decisive parameter for qualitative assessment and integrated into automated compaction, said Hamm. Smart Compact Pro therefore makes a decisive contribution to extending the service life of road surfaces and reduces construction and renovation costs as well as potential additional expenditure at the contractor’s expense. The innovation is initially available in North America for tandem rollers from the HD+ series.

Despite advances in digitalization, asphalt compaction has been heavily dependent on empirical data and the experience of the driver. Consistent double passes and the correct use of dynamic compaction often depended on the driver’s knowledge.

Since 2022, the digital compaction assistant Smart Compact from Hamm has been simplifying the compaction process in asphalt construction by automatically and separately controlling the compaction modes and forces for both drums based on the selected course

www.richmondmachinery.com

2350 Greystone Ct. Rockville, VA 23146 (804) 359-4048

www.reynoldswarren.com

1945 Forest Parkway Lake City, GA 30260 (800) 875-5659 (404) 361-1593

180 Thunderbird Drive Richmond Hill, GA 31324 (912) 445-2880

(844) 4 MY DOBBS www.dobbsequipment.com

2730 Falkenburg Road HQ Riverview, FL 33578 (813) 620-1000

4343 Northwest 77th Ave Miami, FL 33166 (305) 592-5740

type — base course, asphalt binder course or surface course.

The physical properties of the asphalt, such as the temperature and stiffness, as well as the complex cooling behavior of the material, are continuously taken into account to achieve homogeneous compaction by using the optimum compaction energy and modes in each case. Local weather data also can be included as an option, according to Hamm.

Hamm is now expanding Smart Compact by adding a central measured value — the real-time asphalt density. Industry experts agree that it is the decisive parameter for qualitative assessment during the compaction process and is becoming the key parameter for precisely meeting regulatory requirements and minimizing financial deductions, according to Hamm.

Smart Compact Pro closes this gap by integrating the new “Realtime Density Scan” sensor into the automated compaction process. This determines the asphalt density in real time by measuring the dielectric conductivi-

ty of the asphalt mix to be compacted, forming the basis for the correlation with the asphalt density or the void content.

Both parameters are decisive for self-monitoring or control testing. With the help of real-time density, Smart Compact Pro is able to provide construction companies with a decisive advantage by accurately implementing regulatory requirements, according to Hamm.

“This can significantly reduce possible financial deductions due to insufficient quality in the construction work, and save costs for early refurbishment measures,” said Hamm. “The use of Smart Compact Pro also significantly reduces the effort involved in removing drill cores.”

“All in all, the initial integration of real-time density into automated compaction represents a significant step forward in the development of asphalt compaction,” added Hamm. “Even inexperienced operators can achieve optimum compaction results with Smart Compact Pro without any prior knowledge. This also is crucial support for construction companies in times of an increasing shortage of skilled labor.”

3933 Martin Luther King, Jr. Blvd West Palm Beach, FL 33404 (561) 848-6618

4333 North John Young Pkwy Orlando, FL 32804 (407) 299-1212

3005 Hanson Street Fort Myers, FL 33916 (239) 334-3627

4618 Scarborough Drive Lutz, FL 33559 (813) 995-0841

1730 N. Nova Road Holly Hill, FL 32117 (407) 299-1212

1705 Columbia Lane Melbourne, FL 32904 (321) 234-3344

2710 Falkenburg Road Riverview, FL 33578 (813) 621-4902 - Parts

1751 Copans Road, Unit 8 Pompano Beach, FL 33064 (954) 977-9541 - Parts

6265 E Sawgrass Road Sarasota, FL 34240 (941) 960-2004 - Parts

www.tec1943.com

150 Piper Lane Alabaster, AL 35007 (205) 621-2489

5336 Messer-Airport Hwy Birmingham, AL 35212 (205) 591-2131

800 Church St. N.E. Decatur, AL 35601 (256) 355-0305

4307 Reeves Street Highway 431 North Dothan, AL 36303 (334) 678-1832

243 South Jackson St. Grove Hill, AL 36451 (251) 275-4158

108 Skylab Drive NW Huntsville, AL 35806 (256) 851-2222

2100 East I-65 Service Rd. North Mobile, AL 36617 (251) 457-8991

3285 Selma Highway Montgomery, AL 36108 (334) 288-6580

309 Hamric Drive West Oxford, AL 36203 (256) 831-2440

3820 Greensboro Ave. Tuscaloosa, AL 35405 (205) 752-0621

3305 Highway 77 Panama City, FL 32405 (850) 763-4654

9036 Pine Forest Rd. Pensacola, FL 32534 (850) 505-0550

www.powerequipco.com 3300 Dozer Lane Knoxville, TN 37920 (HQ) (865) 577-5563

4295 Bonny Oaks Drive Chattanooga, TN 37406 (423) 894-1870

1487 Rock Springs Road Kingsport, TN 37664 (423) 349-6111 320 Waldron Rd. LaVergne, TN 37086 (615) 213-0900 3050 Ferrell Park Cove Memphis, TN 38116-3502 (901) 346-9800 1545 Highway 45 Saltillo, MS 38866 (662) 869-0283

beardequipment.com 6870 Philips Highway Jacksonville, FL 32216 (904) 296-5000

2578 SE Baya Drive Lake City, FL 32025 (386) 752-9544

4539 NW 44th Avenue Ocala, FL 34482 (352) 732-4646

356 N. Hwy 17 Palatka, FL 32177 (386) 326-6268

3033 US Hwy 27 E. Perry, FL 32348 (850) 584-9200

7566 W. Tennessee St. Tallahassee, FL 32304 (850) 575-5600

423/349-6111

901/346-9800

662/869-0283

from

“One of the most meaningful ways Congress can show its support for America’s professional truck drivers,” Chris Spear, ATA president said of the bill. “The chronic lack of truck parking poses an unacceptable risk to both truckers and the nation’s motoring public.”

Spear called on congress to provide a solution to the situation. He believes the legislation will increase supply chain efficiency and improve highway safety.

The ATA reports that for every 11 truck drivers on the road today, there is one truck parking space. The shortage of truck parking impacts supply chain efficiency, driver health and wellbeing, highway safety and the environment, said the association.

“Additionally, the lack of safe parking options is often cited as a deterrent to more women joining the industry,” he said.

Inadequate access to parking was second on the American Transportation Research Institute’s (ATRI) 2024 list of critical issues in the trucking industry.

ATRI believes until Congress acts, “states will need to apply for parking capacity expansion resources through DOT infrastructure investment programs.

According to ATA, for every 11 truck drivers, one truck parking space is available nationwide. Truckers report they frequently waste an hour a day searching for a spot to park, said the association. Parking spot shortages lead truckers to park alongside the shoulder of the highway, on off-ramps or in residential areas.

This habit of parking where they are able is resulting in hazards for both truckers and other drivers, the industry said.

“They stop early. That affects supply chain issues,” John Blair, president, Motor Transport Association of Connecticut, told the Middletown Press. “The truck parking shortage has plagued the trucking industry for decades. The consequences are as wide-ranging as they are severe.”

The nationwide scarcity of parking spaces decreases safety for everyone and exacerbates longstanding trucking industry workforce challenges, added Blair. It also diminishes trucking productivity, and results in unnecessary greenhouse gas emissions, he said.

Over-the-road truckers are required to drive for nine hours. They take 10 hours to rest.

Industry officials said because of that parking areas must be made secure and comfortable for drivers. Like in other states, it’s a critical issue in Connecticut.

“We’ve seen the trends of truck traffic continue to grow since 2020,” Garrett Eucalitto, Connecticut transportation commissioner, told the Middletown Press.

“Now we have a lot more truck traffic than we did before the pandemic,” he said, adding that people want things on demand.

“They order, and they want it delivered tomorrow ... the industry has shifted, so we just see trucks all the time,” said Eucalitto.

When truck drivers are unable to find safe, authorized parking, they’re stuck in a no-win situation, said the ATA. Truckers are forced to either park in unsafe or illegal locations, or to violate federal hours-of-service rules that regulate their daily drive-time.

ATA cites a U.S. Department of Transportation report that found 98 percent of drivers regularly experience problems finding safe parking. The truck parking shortage exists in every state and region and is most acute along major freight corridors, according to the report.

In fact, 70 percent of drivers have been forced to violate federal hours-of-service rules because of this common scenario, the association said. To ensure they can find a safe and legal space, truck drivers often park prior to exhausting available drive time,” reported ATA.

“The time spent looking for available truck parking costs the average driver about $6,800 in direct lost compensation — or a 12 percent cut in annual pay.”

see TRUCKS page 50

www.richmondmachinery.com

2350 Greystone Ct. Rockville, VA 23146 (804) 359-4048

www.reynoldswarren.com

1945 Forest Parkway Lake City, GA 30260 (800) 875-5659 (404) 361-1593

180 Thunderbird Drive Richmond Hill, GA 31324 (912) 445-2880

beardequipment.com

6870 Philips Highway Jacksonville, FL 32216 (904) 296-5000

2578 SE Baya Drive Lake City, FL 32025 (386) 752-9544

4539 NW 44th Avenue Ocala, FL 34482 (352) 732-4646

356 N. Hwy 17 Palatka, FL 32177 (386) 326-6268

3033 US Hwy 27 E. Perry, FL 32348 (850) 584-9200

7566 W. Tennessee St. Tallahassee, FL 32304 (850) 575-5600

150 Piper Lane Alabaster, AL 35007 (205) 621-2489

5336 Messer-Airport Hwy Birmingham, AL 35212 (205) 591-2131

800 Church St. N.E. Decatur, AL 35601 (256) 355-0305

4307 Reeves Street Highway 431 North Dothan, AL 36303 (334) 678-1832

www.tec1943.com (844) 4 MY

243 South Jackson St. Grove Hill, AL 36451 (251) 275-4158

108 Skylab Drive NW Huntsville, AL 35806 (256) 851-2222

2100 East I-65 Service Rd. North Mobile, AL 36617 (251) 457-8991

3285 Selma Highway Montgomery, AL 36108 (334) 288-6580

309 Hamric Drive West Oxford, AL 36203 (256) 831-2440

3820 Greensboro Ave. Tuscaloosa, AL 35405 (205) 752-0621

3305 Highway 77 Panama City, FL 32405 (850) 763-4654

9036 Pine Forest Rd. Pensacola, FL 32534 (850) 505-0550

www.dobbsequipment.com

2730 Falkenburg Road HQ Riverview, FL 33578 (813) 620-1000

4343 Northwest 77th Ave Miami, FL 33166 (305) 592-5740

3933 Martin Luther King, Jr. Blvd West Palm Beach, FL 33404 (561) 848-6618

4333 North John Young Pkwy Orlando, FL 32804 (407) 299-1212

3005 Hanson Street Fort Myers, FL 33916 (239) 334-3627

4618 Scarborough Drive Lutz, FL 33559 (813) 995-0841

1730 N. Nova Road Holly Hill, FL 32117 (407) 299-1212 1705 Columbia Lane Melbourne, FL 32904 (321) 234-3344

2710 Falkenburg Road Riverview, FL 33578 (813) 621-4902 - Parts 1751 Copans Road, Unit 8 Pompano Beach, FL 33064 (954) 977-9541 - Parts

6265 E Sawgrass Road Sarasota, FL 34240 (941) 960-2004 - Parts

TRUCKS from page 48 RJV Equipment www.rjvequipment.com

USDOT has logged 55 deadly accidents involving trucks near off ramps every year.

The bipartisan infrastructure act supports the construction of roughly 2,000 new truck parking spaces, noted ATA

“But much more progress is needed to make a measurable difference for truck drivers,” said the association. Members of Congress agreed.

The House Highways and Transit subcommittee had bipartisan support for the trucking industry in discussing the need for more parking nationwide.

“We must continue the safety investments we made in the IIJA,” said Eleanor Holmes Norton committee member from Washington D.C.

The trucking industry called for more parking in the next surface transportation funding package, on the table for next year.

“I strongly urge you to include the truck parking language in the next highway reauthorization bill,” said John Elliott of the Truckload Carriers Association.

Elliott noted that the bipartisan Truck Parking Safety Improvement Act has failed to advance through Congress.

It contains “must-have language” that should be incorporated into any upcoming highway policy bill, he said.

“The 2021 IIJA failed to allocate dedicated funding for truck parking initiatives,” Elliott said. “This oversight must be corrected to ensure the safety and efficiency of our nation’s trucking workforce.”

The lack of available parking forces truckers to choose between a potentially safe location or driving while they feel fatigued or out of hours-of-service time.

“These factors are also negatively affecting the safety of the driving public,” said Lewie Pugh of the OwnerOperator Independent Drivers Association.

States and private industry are answering the call for more and safer parking facilities for truckers.

In the Chicago, Ill., area, the first phase of what was billed as the largest-capacity truck stop in the country opened last fall. The 30-acre site, off I-90 in West Dundee, allows truckers to stage their trailers efficiently, reported abc7chicago.com.

The goal was to have 1,000 semi-truck parking spaces, adding nearly 10 percent more spaces to the statewide total, reported Outpost, site manager. Drivers book spots in advance in the yard, which is expected to bring lots more trucks to the mostly industrial area.

At the end of 2024, Connecticut DOT announced a $31 million project to increase the state’s public truck parking capacity by 44 percent. The project was to add 180 truck parking spaces over five key locations in the towns of Middletown, Madison, Southington, Southbury and Vernon.

According to cdllife.com, this project increases the state of Connecticut’s public truck parking spaces to approximately 600. The project launched with the addition of 11 parking spaces at the Middletown rest area on northbound I-91.

The rest of the project will be completed in phases over the next several years, said cdllife.com.

“During the COVID-19 pandemic, we heard truckers loud and clear when they called for more places to safely park along state highways,” said Eucalitto. “We are excited to begin these projects to improve safety for the trucking community, who keep our economy moving.”

Blair of the state motor transport association applauded the project: “The effort here in Connecticut will undoubtedly make our roads safer.”

Last fall, the DOT announced $4.2 billion in grant programs to fund 44 projects including three truck parking capacity expansions.

The expansions, in Ohio, Wisconsin and Nevada, are necessary to mitigate the hazards associated with the chronic lack of truck parking.

Ohio’s portion, a $17.9 million grant, will reopen and repurpose two closed rest areas as truck parking facilities. One site is located along I-70 eastbound near New Paris, Ohio. It will provide 100 truck parking spaces.

The other project, on I-80 eastbound near Hubbard, Ohio, with feature 38 truck parking spaces.

In 2022, Ohio DOT found that over a one-year period, 654 trucks parked in undesignated locations within 8 mi. of the I-70 location.

The department survey also found that 487 trucks parked in undesignated locations within 2 mi. of the I-80 site.

The facility repurposing projects will incorporate video surveillance. And the parking areas will provide real-time parking information to drivers.

In Wisconsin, $12.5 million in grant funding will replace rest areas along I-43 in Manitowoc County. The project will replace both the Maribel and Denmark facilities, including a new rest area building, maintenance garage and parking for cars and trucks.

The capacity of truck parking would increase by a total of 72 stalls, according to ccjdigital.com.

Lighting will be replaced and ingress/egress roadways will be reconstructed to accommodate the parking spot additions.

Pavement at both facilities will be improved and a substandard beam guard will be removed, according to ccjdigital.com.

And in Nevada, a $275 million grant will widen I-80 between the Reno/Sparks metro area and Tahoe Reno Industrial Center. The project also will include the creation of 50 new truck parking spaces along the corridor. Improvements to I-80 include one additional lane in each direction, shoulder widening, bridge reconstruction and new pavement.

Site manager Outpost hopes to bring parking expansions to other sites across the country. The company is growing its network of 18 parking properties and 8,000 spaces.

“Truck parking is essential infrastructure for our supply chain and the U.S. economy — no different from roads and bridges,” said Trent Cameron, CEO.

The infrastructure, he said, will evolve to include maintenance, electric vehicle charging, autonomous vehicle landing, office space and other services.

“The first step is building a nationwide network of outposts for truck parking, fleet positioning and drop trailer relays,” added Cameron. CEG

Knoxville, TN 865/970-2840

www.stoneequipmentco.com Montgomery, AL 844/786-6373

taylorconstructionequipment.com Philadelphia, MS 601-650-9600

Richland, MS 601-922-4444

1245 Bridgestone Blvd. LaVergne, TN 615-256-2424 4545 Columbia Pike Thompson’s Station, TN 615-744-7850 541 Alfred Thun Rd. Clarksville, TN 931-552-5496 667 Horace Lewis Rd. Cookeville, TN 931-646-3200 3565 New Tullahoma Hwy. Manchester, TN 931-461-5000 1291 Corporate Ave. Memphis, TN 901-332-3051

4350 US-641 Camden, TN 731-584-2732

Airways Blvd Jackson, TN 731-988-4240 1808 US-82 Greenwood, MS 662-453-5233

761 HWY 6 West Oxford, MS 662-371-4440 421 Wallace Dr Belden, MS 662-680-8948

3199 S Frontage Rd. Columbus, MS 901-401-7011

Ponce De Leon Blvd Brooksville, FL 352-796-4978

401 N Tomoka Farms Rd Daytona Beach, FL 386-947-3363

4900 N Main St Gainesville, FL 352-371-9983 330 Pecan Park Road Jacksonville, FL 904-714-2600

390 SW Ring Ct Lake City, FL 386-755-3997 3425 Reynolds Rd Lakeland, FL 863-606-0512 6200 North US 301/441 Ocala, FL 352-732-2800 9901 Ringhaver Dr, Orlando, FL 407-855-6195

415 Community College Pkwy SE Palm Bay, FL 321-952-3001

6969 US-31 Tanner, AL 256-353-7721 118 Vulcan Way Dothan, AL 334-671-1040

Pinson Valley Pkwy Tarrant, AL 205-841-8601 5749 John Givens Rd Crestview, FL 850-682-6510

6307 Co Rd 490 Hanceville,

7500 26th Ct E Sarasota, FL 941-359-6000

32000 Blue Star Hwy Tallahassee, FL 850-562-2121 10421 Fern Hill Dr Tampa, FL 813-671-3700

800-239-2694 | COWIN.COM

5710 Riverview Road SE Atlanta, GA 30126 (404) 696-7210

2238 Pinson Valley Parkway Birmingham, AL 35217 (205) 841-6666

STONE EQUIPMENT CO., INC. www.stoneequipmentco.com 210 West Boulevard Montgomery, AL 36108 844-786-6373 334-625-6585

15101 AL-20 Madison, AL 35756 (256) 536-9390 35 Schillinger Road North Mobile, AL 36608 (251) 633-4020

4325 Northern Blvd. Montgomery, AL 36110 (334) 262-6642 1501 Highway 78 East Oxford, AL 36203 (256) 832-5053

1797-A Fulton Springs Rd Alabaster, AL 35007 844-786-6373

7950 Pittman Avenue Pensacola, FL 32534 (850) 479-3004

1800 Culver Road Tuscaloosa, AL 35401 (205) 848-4147

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

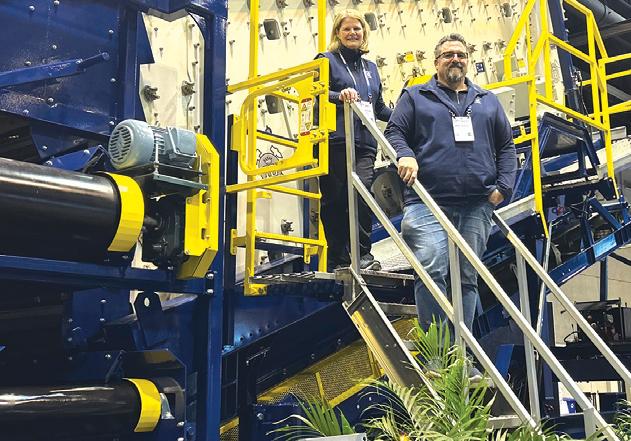

In industries where heavy equipment is essential, safety remains the top priority. Mano Engineering, in collaboration with Hurst and Henrichs MN Ltd. Structural Engineers, is at the forefront of ensuring the protection of machine operators through its Rollover Protective Structure (ROPS) and Falling Object Protective Structure (FOPS) re-certification services.

Specializing in the restoration and certification of damaged cabs on heavy-duty machinery, the company provides OSHAcompliant solutions that help businesses meet regulatory standards while maintaining operational safety.

Mano Engineering has successfully recertified equipment from leading manufacturers such as Caterpillar, Komatsu and John Deere. Its expertise and commitment to safety ensure that equipment operators remain protected from the risks associated with rollovers and falling objects, according to the company.

Replacing an entire cab can be an expensive and time-consuming process, often leading to significant equipment downtime. Re-certification is a much better way to restore structural integrity while keeping costs low and minimizing disruption to operations. Mano Engineering’s streamlined process ensures that businesses can maintain safety standards without the burden of full cab replacement.

Before and after pictures of a cab that was repaired and re-certified.

According to Mano Engineering, it follows a meticulous, fourstep process to ensure that each ROPS and FOPS system meets stringent safety regulations. These include:

• Pre-Check Evaluation — The process begins with a thorough initial assessment. Clients are required to submit images of the unit that needs re-certification. A highly experienced structural engineer carefully reviews the images to determine if re-certification is viable. If the unit is deemed repairable, the process moves to the next stage.

• Onsite Collaboration and Repairs — Once the unit is approved for re-certification, the Mano Engineering team schedules an onsite visit. Certified welding professionals conduct necessary repairs under close supervision, ensuring that all work adheres to OSHA and industry safety standards. Throughout this stage, the team provides real-time photo updates to the structural engineer for continuous monitoring.