The project will require excavators, bulldozers, motor graders, asphalt finishers, road rollers, pavers, light towers and traffic

By Cindy Riley CEG CORRESPONDENT

With a goal of increasing roadway longevity and strengthening pedestrian safety, Florida’s Turnpike Enterprise (FTE) is widening Seminole Expressway/State Road (SR) 417 between

Aloma Avenue/SR 426 and north of SR 434 in Seminole County.

The $300 million project includes replacing five bridges and enhancing a dozen existing structures, as well as performing pavement milling and installing a drainage pond.

“Seminole Expressway serves as a critical cor-

ridor for both local and regional travel, providing a key alternative to the heavily traveled Interstate 4 and acting as an essential emergency evacuation route,” said Yasir Mercado, communications manager, FTE - Florida Department of Transportation

The parent company of Carolina Cat, Weisiger Group, announced Feb. 13, 2025, that Amanda Weisiger Cornelson was promoted to president, transitioning the company to its fourth generation of family leadership.

The upcoming ownership shift to Cornelson and her sisters, Marshall Weisiger Rodman and Grace Weisiger, will create one of the largest privately held women-owned businesses in the Southeast. Ed Weisiger Jr. will continue as chairman of the board.

“I’m excited for this new phase of the company as we position Weisiger Group and our companies for even greater success moving forward,” said Ed Weisiger Jr., chair of Weisiger Group Board. “We’ve worked through a

The U.S. Army Corps of Engineers (USACE), in partnership with three other federal and Virginia state agencies, has completed post-Hurricane Helene debris removal at Claytor Lake and demobilized the operations center at Claytor Lake State Park.

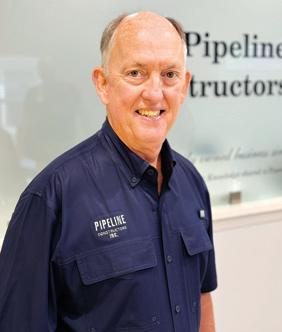

Ron Denmark, the owner and president of Pipeline Constructors Inc., founded the company in 1987 alongside his father, Roy. Based in northeast Florida, Pipeline Constructors started as a commercial site contractor, specializing in land clearing, earthwork, utilities, roadwork and paving.

Hills Machinery has opened a 14th location with its new full-service facility at 3235 U.S. Hwy 301 in Wilson, N.C. The new location includes full sales and rental operations, as well as Hills’ largest service center with massive service bays, overhead cranes and a large parts and components inventory.

The water pressure cannon on the small barge in the Cape Fear River was turned on and its firehose of water was soon pushing the fragments of broken concrete into the waterway at Carolina Beach State Park, south of Wilmington, N.C.

Hamilton Equipment Co. (HEC) is a prime example of an outfit that has used its many years of firsthand experience to create extremely durable water tanks and specialty trucks for use all over the world —from Africa to the Arctic Circle and Australia across North America to Europe.

Briggs JCB held a grand opening event Feb. 27, 2025, for its new dealership on John Young Parkway in Orlando. This new location is actually an expansion of its presence in the Orlando market and signifies an “evolution” from its original location on Orange Blossom Trail.

28

Herc Holdings Inc. and H&E Equipment Services Inc. announced Feb.19, 2025, that H&E has terminated its prior merger agreement with United Rentals Inc. and that Herc and H&E have entered into a definitive merger agreement under which Herc will acquire H&E.

Using multiple Liebherr piling and drilling machines, Superior Foundations Inc. completed 1800 ACIP piles for the Port Arthur liquefaction project, eliminating downtime and keeping the multi-phase job site on task. Superior Foundations Inc. is a full-service deep foundations contractor.

35

John Deere is enhancing the digital customer experience with new features in John Deere Operations Center. These customer-focused updates allow users to access comprehensive jobsite data and machine health information, empowering them to make real-time decisions that drive profitability.

70 WOA

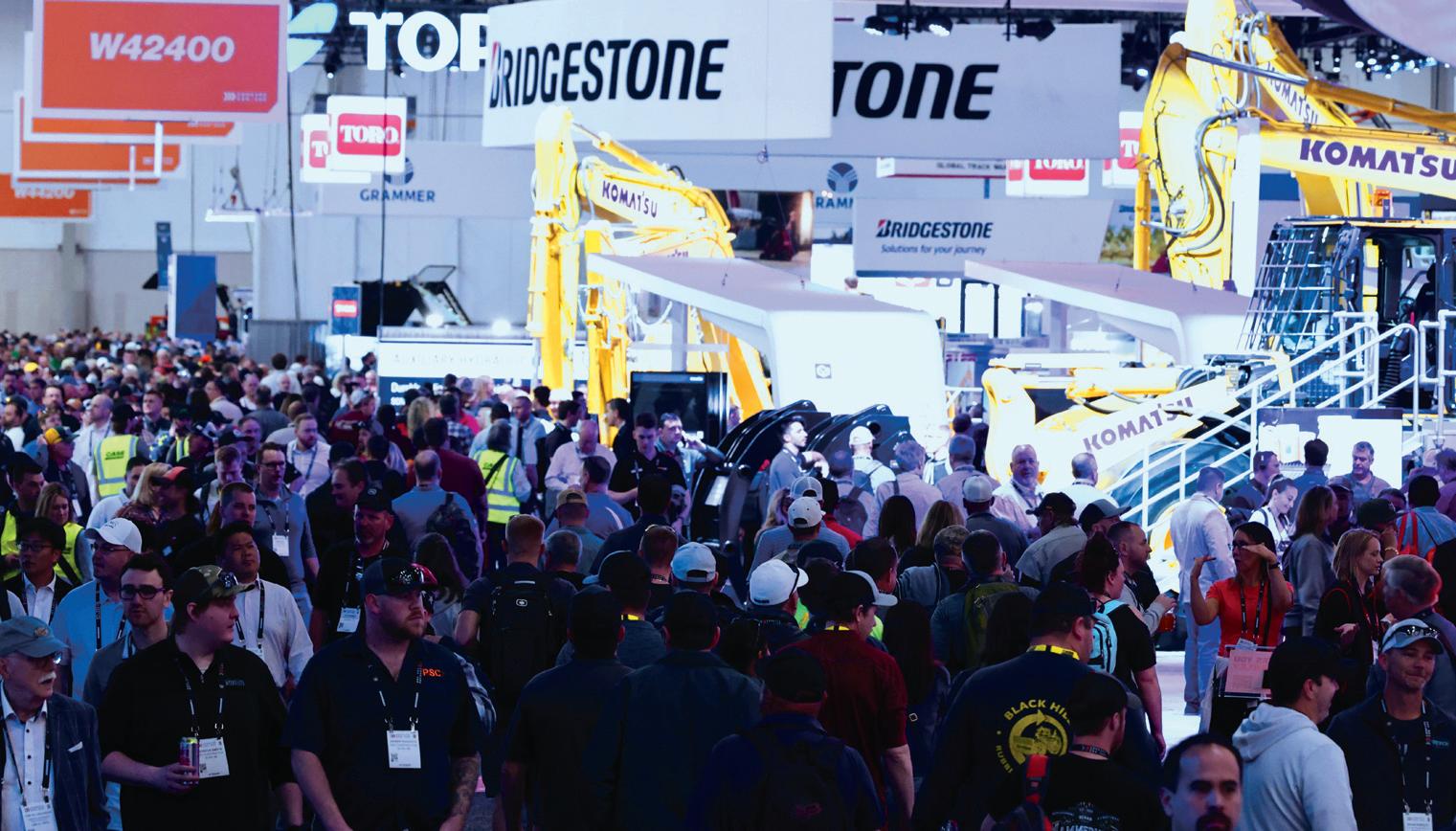

WORKFORCE PLANNING FOR INDUSTRY

With a tight labor market, a dwindling pool of skilled workers are increasingly scarce as people seek advancement opportunities, train in alternate industries or lack the necessary experience to fill skilled construction and infrastructure roles.

80 ARTBA MEMORIAL SCHOLARSHIP OPPORTUNITIES NOW AVAILABLE

The ARTBA Foundation is seeking eligible students for its 2025-26 “Lanford Family Transportation Construction Worker Memorial Scholarship Program.” The program provides post-high school financial assistance to children of transportation construction workers killed or permanently disabled on the job.

87 RB GLOBAL ANNOUNCES ACQUISITION OF J.M. WOOD AUCTION

RB Global announced it has entered into a definitive agreement to acquire J.M. Wood Auction Co. Inc. Founded in 1973, J.M. Wood has leveraged its culture of innovation and entrepreneurial thinking to build a strong reputation for providing a personal and professional auction experience for each of its customers.

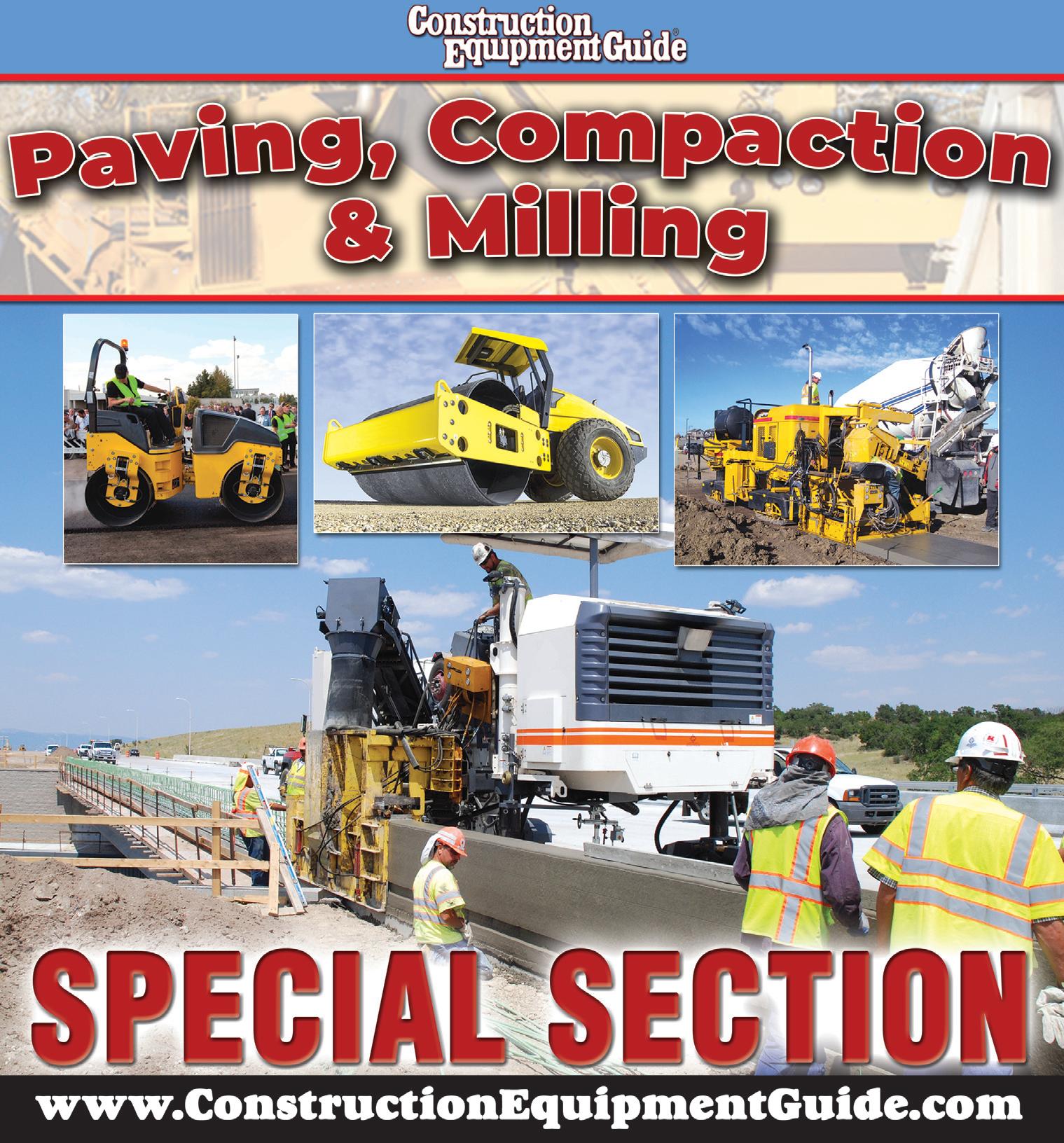

42 CEG’S PAVING, COMPACTION AND MILLING CHARTS

50 SARGENT MAKES KEY CONTACTS WITH DYNAPAC, DREAM ON 3 64 LEEBOY INTRODUCES ITS NEW 8680 ASPHALT PAVER

67 DEVELON BRINGS THREE HEAVY HITTERS TO WORLD OF ASPHALT

BUSINESS CALENDAR

IMPRESSIVE FROM A TO Z. Thanks to its robust design and extensive range of screen linings, the MSS 802 EVO can easily adapt to changing locations and new operating conditions – making it ideal for a wide variety of applications. The coarse screening plant features an intuitive system control that reduces the risk of operating error. And all relevant functions can be operated from a safe distance for increased work safety. The MOBISCREEN MSS 802 EVO –the heavy-duty, versatile solution in natural stone and recycling. www.wirtgen-group.com/kleemann

The U.S. Army Corps of Engineers (USACE), in partnership with three other federal and Virginia state agencies, has completed post-Hurricane Helene debris removal at Claytor Lake and demobilized the operations center at Claytor Lake State Park.

USACE worked closely with the Federal Emergency Management Agency (FEMA), the Virginia Department of Emergency Management (VDEM), Virginia Department of Conservation and Recreation (DCR) and the nonprofit Friends of Claytor Lake to get the popular state park, southwest of Roanoke, Va., ready for public use once again.

Helene’s rampage through the mountainous area in late September 2024 brought down hundreds of trees and scattered tons of debris in and around the lake.

Claytor Lake State Park sits on the northern shore of the reservoir and offers water access, 4 mi. of lake frontage, a swim beach and more than 470 acres of beautiful fields and woodland. The park served as the operations center for the USACE during the cleanup effort.

Debris was collected using modular barges, tugboats, excavators and a 40-cu.-yd. roll-off container before being sorted into categories: green waste, construction material, general trash and hazardous materials. Once that was completed, every bit of waste was transported to a designated dump site for disposal, the Virginia DCR noted in a March 3, 2025 news release.

“The U.S. Army Corps of Engineers takes pride in rapidly responding to natural disasters and restoring impacted areas,” said Lt. Col. Anthony Funkhouser, the acting commander of the agency’s Norfolk District. “Working closely with our federal, state and local partners, we successfully removed all floating and submerged debris [to return] Claytor Lake to its pre-storm conditions, ensuring it remains safe and accessible for the community. We appreciate the patience of residents and visitors as we completed this critical effort.”

With the operations center demobilized, the Claytor Lake State Park boat ramp and Virginia Department of Wildlife Resources (DWR) boat ramp located off Bear Drive are now operating as normal seven days a week.

“The cleanup of Claytor Lake is a testament to the resilience and dedication of our federal and state agencies, park rangers, and community members,” said DCR Director Matt Wells. “Their combined efforts have restored this natural space, demonstrating what can be achieved when we work together for the benefit of our public lands.”

Due to damage caused by large equipment working to clear the hurricane debris, the Virginia DCR noted that the park’s boat

ramps and parking lots still require repairs, as well as a regrading of the state DWR’s parking lot. This work will require temporary closures, which will be announced at a later date.

For the past 60 years, various methods have been used to connect the older College of William & Mary (W&M) campus in Williamsburg, Va., with the more modern one.

The most recent effort will be a pedestrian bridge/walkway that will link the school’s residential and dining facilities under con-

struction with the student life facilities of the Sadler Center and its neighboring wellness and career centers, according to a March 3, 2025, story in the Norfolk Daily Press.

Long ago, many of the ravines on the western part of campus were water-filled branches of Lake Matoaka. After the water receded, they became barriers that inhibited easy movement across the landscape that became William & Mary. At other times, they became conduits for campus rainwater runoff.

The first major connection came in 1963 as the campus developed around the Earl Gregg Swem Library. It was a highway bridge with sidewalks that were constructed

over a large ravine and was, at one end, simply a dirt wall.

Eventually, the bridge and walkway connected Dupont Hall and the Botetourt Complex with the rest of the W&M campus.

That was followed by the construction of what is today called the Crim Dell bridge, which was erected over a pond.

The new pedestrian bridge, the Daily Press reported, is expected to be completed this fall and is part of the university’s master plan “to enhance the student experience” with residential halls and dining centers, according to Amber Hall, an architect and senior project manager for William & Mary.

“The completion of the bridge is an exciting step towards connecting various districts of campus,” she said in a news release. “The William & Mary community will benefit from new walkways, which will enhance our existing pathway network.

Those wooded pathways in and around the university are now temporarily closed, and signage is posted to provide pedestrians with detour information. Vehicular traffic will not be rerouted, the school said.

The West Woods project includes four new residence buildings (Popular Hall, Maple Hall, Oak Hall and Pine Hall) that will provide 935 students with housing, and a 50,000-sq.-ft. dining facility.

These Phase One projects are expected to open for the 2025 fall semester.

The second part of the West Woods project, including the redevelopment of the Randolph housing complex, is expected to be completed in the fall of 2027, the Daily News noted.

Guidan Machine works

excavato or Module nce f

lo track t compac and rs b d n y a echnolog d t atente enables aderso d ea y- ustr in ware ar d h ge ug g r in

d l d o s t tor contrac Site Trimble® nd n a esig , d easurem

oday t t u h o Reac w t d be ove o be m t t ui ! ines ac e m tip u n m ee ites.s o n s a d j

NEW 2024 CAT 725

5,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

NEW 2024 CAT 730

6,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

(2) New 2024 Hydrema 922G 4x4

4,250 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

Equipment for Builds/Order

Rigid Water Tanks up to 18,000+ Gallons 4,500-6,000 Gallon Water for Tandem/6x6 Chassis, Heavy Duty Off-Road Construction

Complete NEW CAT Articulated & Rigid Builds (any size) available with HEC tanks/bodies

New Articulated and Rigid Water Tanks for all Sizes and Brands installation at our place or yours Current stock for CAT 725, CAT 730, CAT 740, CAT 773/775, Bell B30, Bell B40

Fuel, Fuel/Lube Builds available. Articulated or Rigid. Open for warm weather or Up to Arctic Level enclosed for extreme cold operation

Ron Denmark, the owner and president of Pipeline Constructors Inc., founded the company in 1987 alongside his father, Roy.

Based in northeast Florida, Pipeline Constructors started as a commercial site contractor, specializing in land clearing, earthwork, utilities, roadwork and paving, often working with school boards and military bases.

After transitioning to single-family projects around 2005, Pipeline Constructors faced a severe setback during the 2007 market crash, which reduced its workforce from 100 employees to just five. Despite this challenging period, the company survived and began recovering in 2011, fully returning to single-family projects by 2015.

“Our resilience during the market crash is a testament to our team’s dedication,” Denmark said. “We had to downsize significantly, but our core team remained strong. As the market recovered, we were fortunate to bring back many of the skilled workers we had to let go. Their loyalty and expertise are invaluable to us and are the reason we’ve grown to the point we are at today.”

Pipeline Constructors primarily focuses on sitework infrastructure for single-family homes and multifamily apartments, partnering with national homebuilders to prepare lots for new constructions. Pipeline Constructors strategically serves Duval, Clay, St. Johns and Flagler counties, which allows it to maintain a strong local presence and ensure highquality project delivery.

A significant contributor to Pipeline Constructors’ operational success has been its investment in Komatsu Intelligent Machine Control (iMC) equipment, which features factory-integrated GPS technology and grade control solutions.

“In 2015, we bought our first GPS machine, and the impact was immediate,” Denmark said. “From that point, our fleet expanded to include Komatsu iMC equipment. The transition from traditional methods to GPS has drastically increased our efficiency, allowing us to accomplish more with fewer resources. It’s hard to imagine returning to the old ways.”

The company’s fleet includes a range of iMC equipment, such as a Komatsu D51PXi-24 dozer and a Komatsu PC290LCi-11 excavator. These machines enable precise grading and digging, which can significantly reduce the need for rework.

“I love to run them,” Superintendent Evan Denmark said. “The visibility on the D51 is great, and the iMC excavator is amazing, especially when digging ponds. You don’t have to have a surveyor out here every day putting new grade stakes in the ground. The data’s right there on the machine, so you just lock it in and go.”

The integration of iMC equipment extends beyond just excavation and grading. Terry Qualls, who is responsible for construction layouts, highlighted how these machines have improved the company’s workflow.

“Since adding the iMC excavators to the fleet, we’ve seen an immediate increase in productivity of 10 percent to 15 percent,” he said. “The iMC excavators free up our dozers, especially for pond construction. The excavator can cut the pond’s slope to grade without relying on the dozer to contin-

uously monitor the grade. The dozer just slicks it off for grass seeding at the end, freeing up the dozer to work on other aspects of the job.”

Pipeline Constructors appreciates that the iMC machines are user-friendly and accurate.

“The operators prefer the iMC machines for laying pressure pipes because it removes the guesswork,” Qualls said. “The ability to collect as-built data on the spot and send it directly to the office also speeds up the process tremendously. It saves us both time and money.”

Incorporating iMC technology has not only streamlined operations but also elevated the quality of work.

“The data integration from our iMC machines allows for seamless communication between the field and office,” Denmark said. “Surveyors can download data directly from the machines, cutting out redundant steps and ensuring precision.”

To manage the data and monitor its fleet in real time, Pipeline Constructors recently adopted several of Komatsu’s Smart Construction solutions, including Smart Construction Remote, Smart Construction Drone and Smart Construction Dashboard. One of the key components of the Smart Construction solutions is that they can all be used together with My Komatsu, which helps boost the company’s productivity.

“Komatsu’s iMC and Smart Construction solutions have allowed us to exponentially grow our volume of business with significantly fewer people,” Denmark said. “If you go back to around ‘05, prior to using GPS, we were right at 100 employees. The volume of business that we were doing at that time compared to the volume of business we’re doing today is roughly eight to 10 times greater — but with only see KOMATSU page 78

Tim Bailey, branch manager; and Jay Terry, territory sales manager, all of Hills Machinery.

5-acre artificial oyster reef just off the state park's shoreline.

Hills Machinery has opened a 14th location with its new full-service facility at 3235 U.S. Hwy 301 in Wilson, N.C.

The new location includes full sales and rental operations, as well as Hills’ largest service center with massive service bays, overhead cranes and a large parts and components inventory to serve local heavy and compact equipment owners, according to the company.

The Wilson operation becomes Hills’ flagship Hitachi Construction Equipment facility in North Carolina, while also selling and servicing world-class manufacturers Case Construction Equipment, Astec, Rokbak, Sakai, RubbleMaster, FAE, Eagle Crusher, EDGE, Mauldin Paving and Midland Machinery.

“Wilson is growing in its own right, and our new facility sits at an important location in eastern North Carolina that will help us better serve the needs of the construction, paving, agricultural and environmental businesses in the region,” said Jim Hills, president, Hills Machinery. “This location is also built to be a service and parts destination

for equipment owners — whether they buy equipment from us or not — and features our 24/7 Hills Uptime Operations unit committed to providing premium aroundthe-clock field service and support.”

Hills Machinery Uptime Operations facilitates lifecycle fleet management and real-time equipment monitoring and service — both for its customers’ fleets as well as Hills’ own rental fleet. It also represents the dealer’s growing partnership with Hitachi, delivering high-quality earthmoving equipment to the region, according to the company.

“We understand that the equipment industry today relies on a fully connected network of equipment sales, rental, used equipment, parts and service capabilities and Hills Machinery and the new Wilson location will serve as that connection and cornerstone for business owners in the region,” “ said Hills.

Hills now operates 14 locations in the Carolinas, Virginia and Georgia.

The water pressure cannon on the small barge in the Cape Fear River was turned on and its firehose of water was soon pushing the fragments of broken concrete into the waterway at Carolina Beach State Park, south of Wilmington, N.C.

But this was not some kind of illegal attempt to dispose of unwanted material. In fact, it was the exact opposite — the reuse of a manufactured product to help protect and enhance the coastal environment.

The concrete shards pouring into the river will help build a 5-acre artificial oyster reef just off the state park’s shoreline, the Wilmington Star-News reported March 3, 2025.

The goal of the $1.9 million restoration work, a collaboration between the nonprofit North Carolina Coastal Federation and the state’s Division of Marine Fisheries (DMF), is part of a larger attempt — dubbed the Lower Cape Fear River Blueprint — to rebuild oyster habitats in the river’s watershed that, like in most of the state, has been devastated by decades of overharvesting, habitat destruction, declining water quality, disease and, in the case of the Cape Fear River, channel deepening projects.

The eventual aim is to take steps to build artificial reefs along much of the lower Cape Fear that enhance the waterway, improve water quality and provide important habitat for marine life.

“The completion of this reef is an important step in the implementation of the Cape Fear River Oyster Pathway,” said Ted Wilgis, a coastal scientist with the federation, in a news release.

Researchers call oyster reefs habitat multipliers since so many marine critters beyond oysters use them for foraging, spawning and living areas.

An acre of the artificial reef, which lies just south of the mouth of Snows Cut on the river, was constructed in 2017.

The latest project, which began in February, involves dumping 2,100 tons of recycled concrete to build the remaining 4 acres of the shallow reef, an effort that should wrap up in the coming weeks, the Wilmington newspaper noted.

Along with their reefs providing habitat for a host of other species, oysters also are vital to improving coastal water quality. Each oyster can pump up to 50 gal. of water through its body every day, removing nutrients and algae from the

By Eric Olson CEG CONTRIBUTING EDITOR

For a company to successfully build construction and mining equipment to withstand the toughest environments on Earth, it needs veteran experts and skilled fabricators to satisfy the demands of its customers.

Hamilton Equipment Co. (HEC) is a prime example of an outfit that has used its many years of firsthand experience to create extremely durable water tanks and specialty trucks for use all over the world —from Africa to the Arctic Circle and Australia across North America to Europe.

HEC had been selling those products, along with lube trucks, fuel tankers and tank kits since the company was created in Knoxville, Tenn., in 1996 by Bill Hamilton (by then a veteran at selling these machines, along with new and used heavy equipment) and son, Ryan McGuire.

For almost three decades now, he and his son have seen their operations in eastern Tennessee grow to where they are today with two locations in Knoxville and nearby Lenoir City.

McGuire said that when they were looking to grow the business and have some stability, HEC began to concentrate heavily on manufacturing water tanks and specialty bodies with the help of other fabricators for a couple of years, an experience that he said, “turned into a nightmare.”

As a result, HEC bought another facility and started up its own fabrication shop.

“The lead times and the quality of work from other folks just could not meet our schedules, our criteria and our customer’s demands,” he said. “We got to the point where we said, ‘If we are going to be in this business, we need to have total control of it.’”

Hamilton added, though, that his company no longer produces as many lube trucks on a regular basis as it used to because of the difficulty in keeping up with demand. Instead, HEC primarily focuses its attention on water equipment.

The water tanks that HEC manufactures in 2025 generally range from 4,500-gal. units for on-road trucks, up to 18,000gal.-plus tanks for off-road vehicles with a rigid cargo body fixed on the axles, such as a mining truck.

“These tanks are not used in residential projects but in

large scale construction and mining at quarries or in the oil sands of Fort McMurray in Canada, for instance,” McGuire said.

HEC’s products are designed to fit onto the chassis of any make or model of truck, either new or used. In addition, most tanks are mated with late-model, low-hour truck chassis — like-new, but not brand-new, McGuire clarified. They also come with a three-year warranty, and the components themselves carry the manufacturer’s warranty.

“Our tanks are built to fit specific chassis, another of Hamilton Equipment’s advantages,” he added. “We don’t just fabricate a one-size-fits-all tank like other people in the business; rather, all of our tanks are custom-mated to the truck brand.”

Everything HEC does to build its equipment must achieve the company’s primary objective, according to Hamilton, which “is to make our products a lot better than everybody else. We are probably the best out there when it comes to parts and service, too. As far as the quality of the manufacturing process, we know we are the best because that’s what our customers tell us.”

“The death of a good business is growing too fast and not being able to deliver to your customers,” McGuire added. “We have had a steady, organic build, if you will, that has lasted close to 20 years. We just want [HEC] to be where we have everything in line and to our standards before we deliver our products to customers.”

Briggs JCB held a grand opening event Feb. 27, 2025, for its new dealership on John Young Parkway in Orlando.

This new location is actually an expansion of its presence in the Orlando market and signifies an “evolution” from its original location on Orange Blossom Trail to expand the partnerships with respected storm clean-up companies, utility providers and construction contractors.

Briggs JCB vendors, partner companies, Briggs corporate and JCB factory representatives supported this event and approximately 300400 guests attended.

“Our customers have come to rely on our equipment and the services our dedicated team provides,” said Rocky Johnson, Orlando branch manager. “We understand the critical nature of their work and what a good partnership with their equipment provider means for their bottom lines and deadlines. We are excited to have this branch up and running as our second standalone JCB location in Orlando. This new facility not only represents growth, but also opens numerous opportunities for enhanced service and parts availability for our customers.”

The existing branch on Presidents Drive will continue to support industrial customers, while the new dealership at 3165 N John Young Parkway will be dedicated to all heavy equipment needs.

The event featured food trucks, giveaways, facility tours, games and a special appearance by Monster Jam’s ThunderROARus truck, as an extension of JCB’s corporate partnership with Monster Jam.

The “footprint” of the two buildings and equipment yard that make up this new Briggs JCB branch encompasses approximately 4 acres. The branch features eight service bays with an environmentally friendly wash bay to accommodate just about any machine. The facility also provides a high-volume parts stocking area, sales and rental offices and conference rooms.

see BRIGGS page 34

While everyone was enjoying the day’s activities outdoors, Nelson Jimenez kept the parts sales rolling in the spacious parts sales and warehousing facility.

JCB’s Kristian Mahrt (L) welcomes one of his customer-friends to the event, Compton

Orlando, Fla.

The Fayat and Mecalac Groups have signed an agreement for the acquisition of the Mecalac Group by the Fayat Group. The transaction is subject to regulatory approval by the relevant competition authorities and is expected to be completed by the end of the first half of 2025. In the meantime, the Mecalac Group continues to operate as usual and remains committed to supporting its customers and partners around the world, according to the two companies. Once the transaction is finalized, both groups will work to ensure a seamless transition and make this acquisition a complete success, the companies said in a combined statement. (Logos courtesy of Fayat and Mecalac.)

D5 – 2023 ZDA Series, 1,450 Hours, VPAT Blade, Rear Ripper, Trimble Earthworks $374,500

Cat 259D – 2022 CW9 Series, 1,450 Hours, Cab, G.P. Bucket

Cat 299D3 – 2023 DY9 Series, 700 Hours, Cab, High Flow Hydraulics, G.P. Bucket

Cat 306 – 2023 6G6 Series, 300 Hours, Hydraulic Thumb, Leveling Blade

Cat 310 – 2022 GWT Series, 860 Hours, Hydraulic Coupler, Rubber Pads, 36” Bucket

Cat 313GC – 2022 NFZ, 600 Hours, FRD Fx175 Hydraulic Breaker

Cat 315 – 2022 WKX Series, 1,400 Hours, Auxiliary Hydraulics, Hydraulic Coupler, Leveling Blade, 36” Bucket

Cat 320 – 2021 MYK Series, 1,428 Hours, Auxiliary Hydraulics, Hyd. Coupler, 48” Bucket

Cat 335 – 2022 XBE Series, 1,150 Hours, Auxiliary Hydraulics, Hydraulic Coupler, 60” Bucket

Cat 335 – 2021 XBE Series, 2,551 Hours, Auxiliary Hydraulics, Hydraulic Coupler, 54” Bucket

Cat 926M – 2019 LTE Series, 905 Hours, GP Bucket, Fusion Coupler, 20.5R25 Tires

Cat D6T XW – 2019 JNM Series, 1,929 Hours, EROPS, Sweeps, VPAT Blade, Rear Drawbar

Cat D8T – 2022 AW4 Series, 650 Hours, S/U Blade, Trimble Earthworks

$Call

$Call

$99,500

$Call

$Call

$174,500

$329,500

$Call

$204,500

$725,000

Cat CP56B – 2019 P56 Series, 2,175 Hours, Cab, A/C, Heat, 84” Padfoot Drum $Call

Dynapac CA30D – 2023 Model, 250 Hours, Cab, A/C, Heat, 84” Smooth Drum

Dynapac CA30PD – 2023 Model, 863 Hours, Cab, A/C, Heat, 84” Padfoot Drum $Call

Herc Holdings Inc., one of North America’s leading equipment rental suppliers, and H&E Equipment Services Inc. announced Feb.19, 2025, that H&E has terminated its prior merger agreement with United Rentals Inc. and that Herc and H&E have entered into a definitive merger agreement under which Herc will acquire H&E.

As previously announced on Feb. 18, 2025, under the terms of the Herc and H&E agreement, H&E shareholders will receive $78.75 in cash and 0.1287 shares of Herc common stock for each share they own, with a total value of $104.89 per share based on Herc’s 10-day VWAP as of market close Feb. 14, 2025. Following the close of the transaction, H&E’s shareholders will own approximately 14.1 percent of the combined company.

“The acquisition of H&E is a unique opportunity to accelerate Herc’s proven strategy for industry leading growth and delivering superior shareholder value,” said Larry Silber, Herc’s president and CEO. “We have great respect for the

Dothan, AL

334/794-8691

Troy, AL

334/566-4181

Riverview, FL (HQ)

813/620-1000

Miami, FL

305/592-5740

West Palm Beach, FL

561/848-6618

Orlando, FL

407/299-1212

Fort Myers, FL

239/334-3627

Lutz, FL

813/995-0841

Daytona, FL

407/299-1212

Riverview, FL

813/621-4902

Pompano Beach, FL

954/977-9541

Sarasota, FL

941/960-2004

Melbourne, FL 321-234-3344

Adairsville, GA

770/773-9857

Albany, GA 229/888-1212

Atlanta, GA

404/691-9445

Braselton, GA

770/965-1889

Brunswick, GA 912/264-6161

Columbus, GA 706/687-3344

Grovetown, GA 706/855-5440

Macon, GA 478/788-1586

Savannah, GA

912/964-7370

Valdosta, GA

229/474-6680

Andrews, SC

843/983-7337

Aynor, SC 843/358-5688

Ladson, SC

843/572-0400

Simpsonville, SC

864/963-5835

Walterboro, SC

843/539-1420

West Columbia, SC 803/794-9340

Using multiple Liebherr piling and drilling machines, Superior Foundations Inc. completed 1800 ACIP piles for the Port Arthur liquefaction project, eliminating downtime and keeping the multiphase job site on task.

Serving regions along the Gulf Coast, Superior Foundations Inc. is a full-service deep foundations contractor providing piling expertise and execution of turnkey projects throughout the Southeast.

Superior operates on the principle that the deeper the foundation, the stronger the build and the company leverage its extensive knowledge, skills and experience to address deep foundation challenges effectively, according to the company.

Specializing in a variety of foundation techniques, including auger cast piles, pipe piles, Hpiles and drilled shafts, Superior is well-equipped to handle complex projects.

On the Port Arthur liquefaction project, Superior used a range of advanced Liebherr deep foundation machines including the LRH 200 and LRB 355 piling and drilling rigs. In addition, Superior used the 110 D-K crawler concrete pump to ensure efficient and precise concrete placement, which pairs well with the deep foundation products.

Significantly impacting both the local economy and the global energy landscape, the Port Arthur liquefaction project will help meet demands of liquified natural gas (LNG), providing a reliable supply of LNG to markets around the world.

The Port Arthur LNG project will include two natural gas liquefication trains, two LNG storage tanks, additional marine facilities, extensive storage, truck loading and unloading zones as well as opportunities for further expansion of export in phase two.

To support this extensive project, Superior was responsible for drilling and pumping approximately 1,800 auger castin-place (ACIP) piles on site. To ensure efficiency and minimize downtime, even in challenging wet and cold weather conditions, Superior relied on Liebherr products.

These machines, including the LRH 200 and LRB 355 piling and drilling rigs and the 110 D-K crawler concrete pump, were highly versatile, capable of being used both individually and in tandem, which helped maintain high productivity levels.

This approach not only kept Superior on schedule, but also provided a strong and efficient foundation for future infrastructure developments, according to the company.

“The combined piling and drilling rig LRH 200 offers flexible leader kinematics that enable very high radii and inclinations of up to 18 degrees in all directions,” said Liebherr. “In addition, a flexible in-house hammer concept

allows for the use of tamper weights with varying weights. Therefore, varying materials such as concrete, steel or timber piles can be installed.”

“The new LRH 200 offers a full range of applications for Superior, including configured as a drilling rig, a high-performance rotary drive provides the necessary torque for the common single pass methods such as continuous flight auger, full displacement and down-the-hole drilling processes,” Liebherr added. “In addition, Superior uses Liebherr drilling assistant, which regulates the crowd force and speed of the rope crowd system, allowing Superior to ensure every pile is meeting their exact specifications.”

The LRB 355 piling and drilling rig also can be used for many applications including drilling with Kelly equipment, double rotary head, full displacement tool and continuous flight auger as well as soil mixing and piling jobs with a vibrator and hydraulic hammer. The multifunctional machine is designed for a reliable continuous operation and offers a powerful and fuel-efficient V12 diesel engine. Large vibrators and drilling equipment are operated by the machine’s own hydraulic system.

Due to the parallel kinematics, the piling and drilling rig has a large operating area and can be transported with the leader, multi-sledge and rope attached to the machine.

Superior also used the Liebherr 110 D-K crawler concrete pump, which offers the latest engine generation and can be easily transported due to its compact size. This pump has been specifically designed for concrete pile foundations in combination with Liebherr drilling rigs making it the perfect partner for Superior’s piling and drilling rigs.

REEF from page 16

water as it does so. That, in turn, creates clearer and cleaner water for marine life to grow and thrive.

Jordan Byrum, enhancement project manager of the North Carolina DMF, told the Star-News that oysters alone will not help solve a waterway’s water quality woes.

“But it’s certainly a step in the right direction,” he said, as another load of crushed concrete was loaded onto a barge from the state park marina’s parking lot.

Byrum added that while only concrete was being dumped to build the artificial reef, it would not take long for oyster larvae — or spat — floating in the Cape Fear River to find the reef and attach themselves to it.

“By the end of summer, we’ll probably see some oyster spat growing on there,” he said, adding that the reef, which is easily accessible by kayakers and canoers, also is expected to become a recreational fishing hot spot in future years.

Along with all of its habitat and water quality benefits, the artificial reef also will act as a natural breakwater to help protect Carolina Beach State Park’s shoreline that is regularly buffeted by the commercial and recreational boat traffic that travels along the Cape Fear.

Living shorelines like oyster reefs are increasingly gaining traction with scientists and officials looking to stabilize and protect eroding shorelines — a problem that is likely to increase as climate change supercharges sea-level rise and brings bigger and stronger tropical storms to coastal areas.

According to the National Oceanic and Atmospheric Administration (NOAA), living shorelines purify water, buffer floods, reduce erosion, store carbon and create habitat for a host of marine animals.

The move toward building natural coastline protection instead of more traditional bulkheads and riprap comes as officials focus more on resilience as they plan for how communities will adapt to climate change. Federal and local studies have found evidence that shorelines with intact natural coastal habitats not only see less damage but bounce back more quickly from severe storms.

Living shorelines can move with the water, rolling inland as water levels rise, the Star News noted. They also bounce back quickly, requiring little or no upkeep aside from removing trash and other debris that might harm the grass and marine life or limit sunlight.

Funding for the artificial reef project came as part of the clean-up agreement for the polluted Kerr-McGee Superfund site on the Cape Fear 15 mi. upstream from Carolina Beach State Park in the Brunswick County community of Navassa. Other parts of the restoration project include restoring 10 acres of wetlands in the state park and the construction of 2,000 ft. of living shoreline to help the park deal with erosion problems.

“This really is one of those projects that has multiple benefits for the environment, the park and for fishermen and we’re glad to be part of it,” Byrum said as another load of crushed concrete headed out to begin its second life submerged in the shallow waters of the Cape Fear River.

very thorough succession planning process, and Amanda has demonstrated her leadership in roles throughout our businesses by managing through challenging projects, successfully handling change management and, most importantly, taking the time and care to win the hearts and minds of our employees, customers and partners.”

“I’m honored to carry on our nearly 100-year history of excellence and continue to partner with our family of 2,300 talented employees, our partners at Caterpillar and Hyster-Yale and our customers to continue to build, power and move communities we serve,” Cornelson said. “It’s a rare opportunity and a tremendous privilege to collectively take this business into the fourth generation alongside my sisters, and I am committed to continuously improving and adapting to set us up for a successful future.”

Cornelson joined Weisiger Group in 2018 and has served in a variety of roles, working both front-line and office jobs across all of the company’s departments, serving most recently as vice president of sales of Carolina Cat. Before joining her family’s company, Cornelson co-founded and led a startup in the retail and e-commerce sector. She serves on Caterpillar’s international Dealer Digital Council as well as on multiple nonprofit boards, including Novant Health Presbyterian Medical Center Foundation, UNC Charlotte Foundation, Sullenberger Aviation Museum and Episcopal High School in Alexandria, Va. CEG

Wielding the big scissors for the official grand opening ribbon cutting are Rocky Johnson, branch manager, and John Hilberling, general manager, flanked by the entire staff of the Orlando branch.

BRIGGS from page 24

“This facility gives us incredible visibility in the Orlando market, and the investment is truly going to propel our business forward,” said John Hilberling, general manager. “Here in Florida, JCB has become a household name, and a brand that people recognize moreand-more. Up and down the I-4 corridor, JCB machines are working, and the population of these products is growing. Both JCB North America and Briggs corporate have been big supporters in our efforts and we’re just getting started here in this area.”

“We’re investing a lot into the future of both the earthmoving and ag machine business,” he added. “We’re going to continue to look at more stand-alone facilities to continue to grow our market share and presence.” CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

(L-R): FAE USA’s Tom DuRant goes over some of the features of the FAE RCU-75 remote controlled mulcher on display with Charles Feltner and Tommy Gaston of TTS Stump Grinding, Orlando, Fla., and Joey Guzman of Briggs JCB.

In addition to the JCB, ASV and FAE machines on the yard, the Monster Jam ThunderROARus became one of the instant stars of the show at this event.

John Deere is enhancing the digital customer experience with new features in John Deere Operations Center.

These customer-focused updates allow users to access comprehensive jobsite data and machine health information, empowering them to make real-time decisions that drive profitability.

Using feedback from John Deere customers, the added features and enhancements directly address challenges industry professionals face every day, according to John Deere.

“Our customers voiced their needs for solutions that help provide additional jobsite monitoring and analysis to manage costs, optimize productivity and ultimately increase profits,” said Katie Voelliger, product marketing manager, John Deere. “With the introduction of new features within operations center, our customers can now monitor their fleet more effectively than ever before. This not only helps maximize productivity, it empowers operators and fleet supervisors to fully leverage their technology investments on the job.”

• Custom Alerts: Customers can be alerted when idle time, speed or fuel levels exceed limits. These alerts enable proactive planning, ensuring fuel usage and maximizing jobsite productivity.

• Job Sites with Summary Cards: Monitors job sites in near real-time with Jobsite Manager and Summary Cards. Customers can easily create, track and optimize job sites to improve productivity and efficiency.

Paired with Summary Cards, customers can monitor progress, fuel consumption and machine locations, driving profitability and enhancing operational performance. Job sites also can be automatically created when the automatic toggle is on.

• Machine Analyzer Updates: Provides default customer reports to track operator use of grade control and its impact on productivity as well as payload weighing.

• Remote Display Access: Facilitates remote monitoring and operator support, allowing control of the display and adjustment of settings to enhance productivity and maximize machine uptime.

Regarding maintenance, there are a variety of new solutions available to customers to help keep the job site running smoothly. The Maintenance Plan Auto Assignment within Equipment Mobile empowers dealers to proactively plan and provide maintenance solutions with seamless communication to ensure customers’ equipment is readily available. With this feature, customers can add factory maintenance plans to their machines, see specific parts needed for service, streamline maintenance set up and empower customers to manage their machines efficiently, according to the company.

The John Deere Equipment mobile app helps customers manage their equipment with less effort. With this app, customers can look up information in the Operator’s Manual, quickly find parts and maintenance schedules, track past or upcoming service and more, according to John Deere. For more information, visit www.deere.com.

Hamilton is proud to say that all the steel that goes into fabricating HEC’s equipment is “U.S. prime and comes from American mills. We get some foreign made stuff because we can’t get it anywhere in the states, like a spray head component or something like that. Most all of our plate and pipe suppliers are also U.S.-based.”

He also noted, “We process every bit of it ourselves, but we don’t burn it to process the patterns anymore. We have that done by others because the machines to do it became too expensive to operate —the burn tables and all that equipment. But the rolling and breaking and pipe welding are all still accomplished by us.”

HEC also is proud of the long lifespans of its tanks and equipment.

“The first water tank that we ever built ourselves in our shop was, I think, about 18 years ago, and just a couple months ago, we got a call from the customer asking for parts for that same machine,” McGuire said. “As far as I know, we have not had a tank fail or go out of service. The vessel and its structure are overbuilt, and our components are the best we can get, but at the same time it is the simplest system we can build.”

While some of HEC’s competitors put computer systems on their tanks, which he said end up needlessly overcomplicating the product, HEC aims for making its products simple and rock-solid, which his customers really appreciate.

“A water tank is not a production machine, but it is still a high-use product,” McGuire said. “We know the various environments that it is going into, how it is going to be used and when it needs to be fixed. The tank must be one where anyone at any time can repair it to make it operate properly, and we have been successful building them that way.”

Over the years, HEC also has worked diligently to make its tanks and truck bodies easy for transport.

“Our heights are down, and we emphasize a low center of gravity to make them safer on the job,” he said. “We still cut out the fenders, and our subframes are lower than most other manufacturers in the industry for safety reasons and for transport. The tanks are usually either right at the OEM’s cab or just below it, so we don’t have height issues.”

McGuire added that operators have no need to climb on top of HEC’s tanks as the access to them is through the bottom.

“That makes the safety man on the job really happy and fulfills our desire to make our products easy and safe to use,” he said.

For the past several years, HEC has limited its manufacture of fuel lube trucks to custom builds, but a lot of that equipment ends up serving mining customers working in the Arctic and at Fort McMurray, located in northeastern Alberta.

Although the Arctic is usually described as a frozen wasteland, below its land surfaces are large quantities of oil, natural gas and various minerals, including phosphate, bauxite, iron ore, copper and nickel.

“I have been up there to the northernmost open mine in the world putting on a fuel lube body when it was 50 degrees below zero and having to sleep in a tent,” McGuire said.

As a result of the region’s often harsh conditions, he said those work sites are regarded as outstanding proving grounds for testing the durability of HEC’s products.

“We built machines to work up there in

that environment and in various applications. We saw that they could stand up and operate as they should to pump out oil when it’s 70 to 80 degrees below zero due to their being insulated and kept warm with redundant heaters.”

In addition, he said that the work sites are often full of 4- to 5-ft.-deep ruts made by huge Cat 797 mining trucks with 8- to 10-ft.-high tires that articulated trucks must drive through, meaning any fabricated bodies in use there have to withstand often punishing terrain.

“Once we saw that our products could survive those proving grounds, then we knew we had an excellent body,” McGuire said.

According to Hamilton, HEC’s parts and service business mimics what he learned many years ago working as a shop mechanic for Rozier Machinery, a Cat dealership in Tampa, Fla. While there, he took note of how hard one was expected to work to satisfy customer needs and has instilled that same ethic into his Tennessee business.

“I learned the old way that when a call came in, you took care of the customer,” he said. “At HEC, we’ve left out of here at 4 o’clock in the afternoon to fix somebody’s water truck that is three or four hours away so it could be ready for work the next morning. That’s the whole key to product support. We have young people here that know when to get in a service truck and quickly get out to where the repair is needed.”

His company does business with several Cat dealers and with James River Equipment, the latter of which recently sent some brand new 410-P 40-ton John Deere articulated dump trucks to Knoxville for HEC to fit new tanks onto for use at a massive phosphate mine located near the North Carolina coast.

“They need equipment that will run seven days a week,” said Hamilton, “mean-

ing we need to send a guy over there to put them in service. We have dealt with [the mine’s operators] a long time and they are a good customer.”

Training people to run its machines is another key function of HEC’s customer support.

“That is especially so with new customers,” according to McGuire. “Our people help familiarize them with the machine, demonstrate how everything works, explain how they can handle any potential issues that may come up and make ourselves available if they cannot.

“Everybody at Hamilton is accessible and that is one of our biggest strengths,” he added. “I have my phone on 24 hours a day and we have a technician that lives in Idaho, Zane Pilakowski, who does a lot of our field installs out west, and is usually accessible to customers, as is our parts and service manager, Brad Howard, located at the Lenoir City shop. If you call us, you will get hold of somebody.”

If there are issues with an HEC product in remote, far-flung locales like Australia or East Africa —places that the company’s people cannot easily reach, Hamilton said that his customers’ technicians have been fully trained by HEC’s service experts to handle any problems.

Because of its outstanding products and service over the past few decades, it is no surprise to learn that most of HEC’s success comes from repeat business, a testament to how well regarded it is among its customers.

“At the beginning of the year, we know that our order board is going to be 80 to 90 percent full of repeat business, and a lot of those customers have bought from us for 15 to 20 years,” McGuire said.

Hamilton has tremendous pride in the reputation his company has established within the construction and mining industries but gives the credit to his team of professionals, many of whom have been with him since they were young adults. Each one, he said, understands that they must adhere to HEC’s high standards in order to remain with the company.

“Some of the fabricators and welders come and go, but we pay our people well,” Hamilton said. “If they can’t do their best, they don’t stay here long — we’re not going to have it. The products that go out of here have to be the best this little family business and the people within it can make.”

For more information, visit www.hamiltonequip.com. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

H&E team and the high-quality platform they built. We look forward to welcoming H&E’s talented employees to Herc and working together to realize the substantial benefits that this transaction will create for the shareholders, employees and customers of both companies.”

John M. Engquist, executive chairman of H&E, added, “This is an outstanding transaction for H&E shareholders, providing both immediate, premium value and the opportunity to participate in the substantial upside value that will be created through this combination. With Herc, we have found a partner who shares our dedication to a higher standard of work.”

• Increased scale with complementary footprint and fleet mix: The transaction strengthens Herc’s position as the third largest rental company in North America. The combined company will have a leading presence in 11 of the top 20 rental regions and increased urban density in seven of the top 10 rental regions. In addition, it will have a larger, younger fleet, offering a variety of specialty equipment solutions and a broad range of general rental products.

• Approximately $300 million of annual EBITDA synergies are expected to be achieved by the end of year three following the close of the transaction, including approximately $125 million of cost synergies and approximately $175 million EBITDA impact from revenue synergies.

• Highly accretive: The transaction is expected to be high single digit accretive to Herc’s cash earnings per share in 2026 and ramping to greater than 20 percent as synergies are fully realized. In addition, the transaction is expected to generate ROIC in excess of Herc’s cost of capital within three years of closing.

• Attractive financial profile: The combination creates a company with revenue and EBITDA of approximately $5.2 billion and $2.5 billion respectively, with an expectation for continued revenue growth in excess of the market and improved adjusted EBITDA margins.

• Financial strength and flexibility with net leverage of 3.8x at close, prior to synergy realization, and projected to be below 3.0x and in Herc’s targeted range within 24 months of closing. Herc’s dividend will be maintained.

• Valuation multiple re-rating warranted for combined company that is more consistent with comparable company valuation multiples in the sector given the powerful growth platform, increased liquidity and greater investor interest that comes with a scaled company.

The transaction is expected to close mid-year 2025, subject to the majority of H&E’s shares being tendered into the offer, the receipt of customary regulatory approvals and closing conditions. Herc has obtained committed financing for the cash portion of the transaction.

In accordance with the terms of H&E’s prior agreement with United Rentals Herc, on behalf of H&E, has paid a termination fee of $63,523,892 to United Rentals.

(FDOT). “With increasing population and tourism growth in Florida, the expansion from four to eight lanes is designed to accommodate rising traffic volumes, improve mobility and enhance overall safety. The project also will contribute to more reliable travel times, better connectivity and future-proof the corridor for long-term growth.”

State Road 417 (SR 417) is a controlled-access toll road forming the eastern beltway around the city of Orlando. It is owned and maintained by the Central Florida Expressway Authority (CFX) and FTE.

According to Mercado, the project is the result of comprehensive planning, including traffic studies, environmental impact assessments, community engagement and coordination with various agencies.

“This project will serve residents, commuters, businesses and tourists by improving travel efficiency and reliability. It will benefit both commercial and personal transportation, ensuring smooth logistics for freight movement and daily commutes in Central Florida.”

Construction will take place during daytime and nighttime hours. Mercado said the project’s contractor is a good fit for the work taking place.

“Lane Construction is an FDOT pre-qualified contractor with extensive experience in complex transportation infrastructure projects. This includes highways, bridges and interchanges.”

The project aims to relieve congestion and improve travel times through updated infrastructure. It will increase roadway resilience and longevity by upgrading 17 bridges and adding pedestrian safety features to support

future population and economic growth in the state. Construction began in August 2024 and is on track to be completed by 2030.

“The primary challenge to this and many projects in Florida is weather impacts, such as frequent rain and fluctuating temperatures, which can delay activities like asphalt paving and concrete pouring by affecting curing times,” said Mercado. “To mitigate this, the construction team closely monitors forecasts, adjusts schedules as needed and incorporates contingency plans to minimize delays.”

Mercado noted that managing traffic along an active roadway also presents challenges.

“Construction will involve lane closures and temporary detours, but efforts are being made to minimize impacts. Most lane closures will occur during off-peak hours, and updates will be provided regularly through central and west central Florida weekly lane closures and work zone advisory.”

Widening the expressway includes clearing and grubbing vegetation along the corridor; relocating existing utilities; excavating and grading to prepare the roadbed; paving new lanes and shoulders; enhancing turnpike bridges; and providing proper lighting and new pavement markings.

Phase 1 of the project is under way and involves both northbound and southbound clearing and grubbings. Specialized crews have begun relocating utilities, including overhead power lines and gas mains along Aloma Avenue.

Major upcoming tasks include excavating and grading large volumes of earth to create the expanded roadbed; reconstructing five bridges and enhancing 12 existing ones; paving the new lanes; and implementing

safety features.

Excavation will involve removing 430,000 cu. yds. of material and placing 570,000 cu. yds. to build the roadbed. Approximately 140,000 cu. yds. of material will be brought in from nearby sources to support construction needs. A total of 1 million cu. yds. of earthmoving activities are expected.

In addition, Aloma Avenue/SR 426, Red Bug Lake Road and SR 434 will undergo minor resurfacing, new pavement markings and signalization upgrades.

The project will require excavators, bulldozers, motor graders, asphalt finishers, road rollers, pavers, light towers and traffic control devices. Key materials include asphalt, concrete and structural steel for bridges.

Although construction is in its early stages, Mercado said the progress being made is rewarding for everyone involved.

“This project exemplifies our mission to provide safe, reliable and resilient transportation options for Florida’s residents and visitors. By addressing congestion, enhancing safety and planning for future growth, this effort will have a lasting impact on the region’s

see CHART page 44

from page 44

see CHART page 48

Powell, Ashton Kelly, Tim Powell, Travis Hendrick and Chris Horn, all of Sargent Corp., and Jennifer

stand

front of a Dynapac CA2500D seismic single-drum roller wrapped with the Dream On 3 logo.

By Eric Olson CEG CONTRIBUTING EDITOR

Sargent Corp., an infrastructure builder in central North Carolina, is currently in the process of completing a project on the grounds of Greensboro’s Piedmont Triad International Airport (PTI).

Headquartered in Orono, Maine, Sargent operates two locations in the Northeast and two in the Mid-Atlantic states, the latter of which includes its Greensboro office.

According to Chris Horn, regional manager of Sargent’s Piedmont Triad region in the Tarheel State, the building site at PTI is being prepared for future non-runway expansion.

“I think it is more about building pads for hangars and more airport development, as well as for a roadway extension of Worldwide Drive [just northeast of the PTI passenger terminal],” he said in mid-January.

Sargent’s crews have been working at the airport property site for approximately a year, Horn said, and could be finished later in February.

Among the many types of earthmoving equipment being used at the PTI site is a new Dynapac CA2500D seismic sin-

gle-drum roller that Sargent just took delivery of in early January.

Manufactured by Dynapac in Fort Mill, S.C., the European-based company is well known among construction professionals for turning out a line of high-performance compaction, paving, and light equipment, according to the company.

At last November’s Dirt World Summit leadership forum in San Antonio, officials from both the equipment maker and Sargent got together for the first time with the end result being that the contractor was supplied with the new Dynapac.

“Taking delivery of the Dynapac roller through Jennifer Bishop, [the manufacturer’s dealer sales manager of the Southeast] was a pleasure,” said Horn. “We had not met previously, but she knew the roller and the technology in detail.”

He added that so far, the model CA2500D roller is the first and only piece of Dynapac equipment in Sargent’s North Carolina fleet, but the contractor hopes to add more of the maker’s products in the future.

www.stoneequipmentco.com

www.richmondmachinery.com

2350 Greystone Ct. Rockville, VA 23146 (804) 359-4048

www.reynoldswarren.com

1945 Forest Parkway Lake City, GA 30260 (800) 875-5659 (404) 361-1593

180 Thunderbird Drive Richmond Hill, GA 31324 (912) 445-2880

(844) 4 MY DOBBS www.dobbsequipment.com

2730 Falkenburg Road HQ Riverview, FL 33578 (813) 620-1000

4343 Northwest 77th Ave Miami, FL 33166 (305) 592-5740

3933 Martin Luther King, Jr. Blvd West Palm Beach, FL 33404 (561) 848-6618

4333 North John Young Pkwy Orlando, FL 32804 (407) 299-1212

3005 Hanson Street Fort Myers, FL 33916 (239) 334-3627

4618 Scarborough Drive Lutz, FL 33559 (813) 995-0841 1730 N. Nova Road Holly Hill, FL 32117 (407) 299-1212 1705 Columbia Lane Melbourne, FL 32904 (321) 234-3344

2710 Falkenburg Road Riverview, FL 33578 (813) 621-4902 - Parts

1751 Copans Road, Unit 8 Pompano Beach, FL 33064 (954) 977-9541 - Parts 6265 E Sawgrass Road Sarasota, FL 34240 (941) 960-2004 - Parts

Booth# 4731

www.tec1943.com

150 Piper Lane Alabaster, AL 35007 (205) 621-2489

5336 Messer-Airport Hwy Birmingham, AL 35212 (205) 591-2131

800 Church St. N.E. Decatur, AL 35601 (256) 355-0305

4307 Reeves Street Highway 431 North Dothan, AL 36303 (334) 678-1832

243 South Jackson St. Grove Hill, AL 36451 (251) 275-4158

108 Skylab Drive NW Huntsville, AL 35806 (256) 851-2222

2100 East I-65 Service Rd. North Mobile, AL 36617 (251) 457-8991

3285 Selma Highway Montgomery, AL 36108 (334) 288-6580

309 Hamric Drive West Oxford, AL 36203 (256) 831-2440

3820 Greensboro Ave. Tuscaloosa, AL 35405 (205) 752-0621

3305 Highway 77 Panama City, FL 32405 (850) 763-4654

9036 Pine Forest Rd. Pensacola, FL 32534 (850) 505-0550

www.powerequipco.com

3300 Dozer Lane Knoxville, TN 37920 (HQ) (865) 577-5563

4295 Bonny Oaks Drive Chattanooga, TN 37406 (423) 894-1870

1487 Rock Springs Road Kingsport, TN 37664 (423) 349-6111

320 Waldron Rd. LaVergne, TN 37086 (615) 213-0900

3050 Ferrell Park Cove Memphis, TN 38116-3502 (901) 346-9800 1545 Highway 45 Saltillo, MS 38866 (662) 869-0283

beardequipment.com 6870 Philips Highway Jacksonville, FL 32216 (904) 296-5000

2578 SE Baya Drive Lake City, FL 32025 (386) 752-9544

4539 NW 44th Avenue Ocala, FL 34482 (352) 732-4646

356 N. Hwy 17 Palatka, FL 32177 (386) 326-6268

3033 US Hwy 27 E. Perry, FL 32348 (850) 584-9200

7566 W. Tennessee St. Tallahassee, FL 32304 (850) 575-5600

see CHART page 56 CHART from page 48

beardequipment.com

ALABAMA

Mobile: 800-848-8563

FLORIDA

Freeport: 850-835-3337

Jacksonville: 904-296-5000

Lake City: 386-752-9544

Ocala: 352-732-4646

Palatka: 386-325-6268

Panama City: 850-769-4844

Pensacola: 850-476-0277

Perry: 850-584-9200

Tallahassee: 850-575-5600

Delivering the Industry’s Greatest Impulse Forces with Overall Superior Performance!

dobbsequipment.com

ALABAMA

Dothan: 334-794-8691, Troy: 334-566-4181

FLORIDA

Daytona: 386-492-4480, Fort Myers: 239-334-3627

Lutz (New Tampa): 813-995-0841

Melbourne: 321-234-3344, Miami: 305-592-5740

Orlando: 407-299-1212

West Palm Beach: 561-848-6618

PARTS ONLY:

Pompano Beach: 954-977-9541

Riverview: 813-621-4902, Sarasota: 941-960-2004

GEORGIA

Albany: 229-888-1212, Atlanta: 404-691-9445

Braselton: 770-965-1889, Brunswick: 912-264-6161

Cartersville: 770-773-9857, Columbus: 706-687-3344

Grovetown: 706-855-5440, Macon: 478-788-1586

Savannah: 912-964-7370, Valdosta: 229-474-6680

SOUTH CAROLINA

Andrews: 843-983-7337, Aynor: 843-358-5688

Ladson: 843-572-0400, Simpsonville: 864-963-5835

Walterboro: 843-539-1420, West Columbia: 803-794-9340

jamesriverequipment.com

NORTH CAROLINA

Ahoskie: 252-332-5550, Asheville: 828-667-0176

Charlotte: 704-597-0211, Elizabeth City: 252-679-7590

Fayetteville: 910-424-1200, Greensboro: 336-668-2762 Greenville: 252-758-4403, Monroe: 704-220-2575

Mt. Gilead: 910-439-5653, New Bern: 252-638-5838

Raleigh: 919-772-2121, Statesville: 704-872-6411

Wilkesboro: 336-973-8201, Wilmington: 910-675-9211

SOUTH CAROLINA

Rock Hill: 803-325-1555

linder.com

VIRGINIA

Bealeton: 540-439-0668, Chesapeake: 757-485-2100

Chester: 804-748-6411, Fishersville: 540-887-8291 Salem: 540-380-2090

mccoycf.com

TENNESSEE

Chattanooga: 423-855-0633, Kingsport: 423-349-5001

Knoxville: 865-546-3207, Nashville: 615-501-8600

striblingequipment.com

ARKANSAS

Arkadelphia: 870-246-8678, Camden: 870-574-0290

Fort Smith: 479-646-8381, Jonesboro: 870-268-9900

Little Rock: 501-455-2540, Monticello: 870-367-3496

Springdale: 479-756-9779, Texarkana: 870-772-9321

MISSISSIPPI

Biloxi: 228-396-2300, Brookhaven: 601-835-4400

Columbus: 662-328-0820, Hattiesburg: 601-544-3000

Jackson: 601-939-1000, Meridian: 601-482-5575

Natchez: 601-442-3613, Philadelphia: 601-656-1997

Tupelo: 662-844-3212, Winona: 662-453-7556

TENNESSEE

Jackson: 731-422-2542, Memphis: 901-345-5294

warriortractor.com

ALABAMA

Graysville: 205-675-9045, Madison: 256-233-1914

Monroeville: 251-575-7111, Montgomery: 334-277-7260

Northport: 205-339-0300, Oxford: 256-831-0921

Pelham: 205-988-4474

CHART from page 54 see CHART page 58

Track Asphalt Pavers

NOTE: weights without screeds. NOTE: paving widths can vary depending on screed.

Backhoe Road NE Leland, NC 28451 910-371-6301

Springs Rd. Washington, NC 27889 252-946-1081

Thompson Machinery TMCat.com

500 World Commerce Pkwy St. Augustine, FL 904-737-7730 14300 Ponce De Leon Blvd Brooksville, FL 352-796-4978

401 N Tomoka Farms Rd Daytona Beach, FL 386-947-3363

4900 N Main St Gainesville, FL

352-371-9983 330 Pecan Park Road Jacksonville, FL 904-714-2600

390 SW Ring Ct Lake City, FL 386-755-3997 3425 Reynolds Rd Lakeland, FL 863-606-0512

6200 North US 301/441

6969 US-31 Tanner, AL 256-353-7721 118 Vulcan Way Dothan, AL 334-671-1040 6307 Co Rd 490 Hanceville, AL 205-283-0128

Ocala, FL 352-732-2800 9901 Ringhaver Dr, Orlando, FL 407-855-6195 415 Community College Pkwy SE Palm Bay, FL 321-952-3001 7500 26th Ct E Sarasota, FL 941-359-6000

32000 Blue Star Hwy Tallahassee, FL 850-562-2121 10421 Fern Hill Dr Tampa, FL 813-671-3700

from page 50

“We have a 300,000-cu.-yd. fill site out at PTI, and that roller has fallen in line with the rest of our equipment,” he said. “It is a line of sight for the control tower. We had to do a lot of demolition on one side of the taxiway and remove all that material in order to bring it to the opposite side of the taxiway to fill in a 40-acre site.”

During the time working on the current airport project, Sargent’s crews have encountered many distinct types of soil across the site’s footprint, according to Horn, which led them to conduct a total of 52 different Proctor compaction tests, a process that determines the optimal moisture content at which a given soil will reach its maximum dry density.

He admitted that so many tests are “very unusual for a job this size,” but added that the earth Sargent moved from the side of the taxiway had different soil conditions, a problem the company needed to resolve.

It did so, Horn said, “through our experience and just overcoming the weather conditions that we worked in, as well as bringing in expertise from other areas of the country to deal with the various soil types.

“It is all in how you handle the existing soil,” he added, which led Sargent to call in experts from its Richmond, Va., area that have long worked with a variety of site conditions.

Eventually, the company found a solution after “understanding what we were working with and what to do with the soil types that have both a high plasticity and high moisture content to them.”

The PTI site work is the third project that Sargent has contracted with the airport over the years, Horn said, adding that the airport’s owners and officials have been wonderful clients for whom to work.

“We hope to continue making long-term investments and work with PTI for many more years,” he said.

Attending the Dirt World Summit last fall also proved advantageous for Sargent in that it gave Travis Hendrick, in charge of Sargent’s growth and strategy leader in North Carolina, the opportunity to be introduced to Brandon Lindsey, the founder and board president of Charlotte-based Dream On 3.

The nonprofit is dedicated to helping make sports dreams come true for young people aged 5-21 with life-altering physical, intellectual and developmental disabilities. Through what are known as “Dream Experiences,” kids are connected with sports-related trips and are able to meet their athletic heroes thanks to Dream On 3.

In learning more about the organization, Hendrick discovered that Dream On 3 also is heavily supported by contractors and the construction industry in general. Indeed, without that support, the nonprofit’s expansion and services over the past 10-plus years would likely not have been possible.

Dream On 3 has benefited from generous funding and support from several equipment dealers and manufacturers in the two Carolinas, including Dynapac.

“I think that supporting organizations like Dream On 3 is ingrained in our company’s DNA back to our founder, and in Herb Sargent, our current CEO,” Hendrick said. “He has

taught us that we need to give back and serve others, especially those who are less fortunate than ourselves. We are very proud of the fact that Dream On 3 is backed by other construction companies. That was the connection for us and led to our involvement with the nonprofit.”

When Sargent and Dynapac crossed paths at Dirt World, where the Dynapac roller was going up for auction, Hendrick said he knew Dream On 3 presented the “perfect opportunity” for his firm to help enrich the community.

“Through Dream On 3, we can help support kids with lifealtering conditions that are being robbed of what we would consider a normal childhood and help them to see their dreams come true,” he said. “I was recently on a call with [Lindsey] and Ben Allred, Dream On 3’s CEO, where I learned about all the college teams that they have set up within the program and how fast this is growing. It is something that we’re excited about and I, personally, am getting involved with it.”

In 2026, Sargent will celebrate its 100th anniversary, and during the century since its founding in rural Maine, it has seen a tremendous expansion from the one-man, one-truck operation of company founder Herbert E. Sargent to today’s team of more than 500 employee-owners.

The modern version of Sargent builds infrastructure that includes renewable energy projects, highways, commercial site work, landfill cells, and underground work — just to name a few examples — from the Canadian border south to the two Carolinas.

Besides the company’s headquarters in Maine, and the North Carolina location, Sargent also has a second New England office in Fremont, N.H., and its Mid-Atlantic operations are in Ashland, Va.

One of the company’s keys to success has been its intense focus on its employee owners — those folks who put their boots and hard hats on each day to brave the elements in the field.

Hendrick said that Sargent’s goal has been to make them feel that they are listened to, not simply heard. When they are working, he said, it is communicated to them that support services are ready to support their field operations. In addition, crew members are empowered to be creative and solution-oriented in order to tackle the challenges they face on the job.

Being completely employee owned has allowed Sargent’s front office to create a culture where its people are encouraged to build trusting relationships with clients and customers, stretch and refine their capabilities, and learn from any mistakes made in the course of their duties.

Eventually, Hendrick added, the contracting firm’s goal for the future is to keep it in the hands of its people so as to “foster an environment and a purpose much larger than the individual.”

“It's on us to make successful transitions in leadership so that we don't lose, replace, or erode this valuable foundation,” he said. “That will help drive the next 100 years of success for Sargent. The fact that what I can contribute to the value of this company drives rewards for hundreds of other people is extremely rewarding and satisfying.” CEG

www.richmondmachinery.com

2350 Greystone Ct. Rockville, VA 23146 (804) 359-4048

www.reynoldswarren.com

1945 Forest Parkway Lake City, GA 30260 (800) 875-5659 (404) 361-1593

180 Thunderbird Drive Richmond Hill, GA 31324 (912) 445-2880

6870 Philips Highway Jacksonville, FL 32216 (904) 296-5000

2578 SE Baya Drive Lake City, FL 32025 (386) 752-9544

4539 NW 44th Avenue Ocala, FL 34482 (352) 732-4646

356 N. Hwy 17 Palatka, FL 32177 (386) 326-6268

3033 US Hwy 27 E. Perry, FL 32348 (850) 584-9200

7566 W. Tennessee St. Tallahassee, FL 32304 (850) 575-5600

150 Piper Lane Alabaster, AL 35007 (205) 621-2489

5336 Messer-Airport Hwy Birmingham, AL 35212 (205) 591-2131

800 Church St. N.E. Decatur, AL 35601 (256) 355-0305

4307 Reeves Street Highway 431 North Dothan, AL 36303 (334) 678-1832

www.tec1943.com (844) 4 MY DOBBS www.dobbsequipment.com

243 South Jackson St. Grove Hill, AL 36451 (251) 275-4158

108 Skylab Drive NW Huntsville, AL 35806 (256) 851-2222

2100 East I-65 Service Rd. North Mobile, AL 36617 (251) 457-8991

3285 Selma Highway Montgomery, AL 36108 (334) 288-6580

309 Hamric Drive West Oxford, AL 36203 (256) 831-2440

3820 Greensboro Ave. Tuscaloosa, AL 35405 (205) 752-0621

3305 Highway 77 Panama City, FL 32405 (850) 763-4654

9036 Pine Forest Rd. Pensacola, FL 32534 (850) 505-0550

2730 Falkenburg Road HQ Riverview, FL 33578 (813) 620-1000

4343 Northwest 77th Ave Miami, FL 33166 (305) 592-5740

3933 Martin Luther King, Jr. Blvd West Palm Beach, FL 33404 (561) 848-6618

4333 North John Young Pkwy Orlando, FL 32804 (407) 299-1212

3005 Hanson Street Fort Myers, FL 33916 (239) 334-3627

4618 Scarborough Drive Lutz, FL 33559 (813) 995-0841

1730 N. Nova Road Holly Hill, FL 32117 (407) 299-1212

1705 Columbia Lane Melbourne, FL 32904 (321) 234-3344

2710 Falkenburg Road Riverview, FL 33578 (813) 621-4902 - Parts 1751 Copans Road, Unit 8 Pompano Beach, FL 33064 (954) 977-9541 - Parts

6265 E Sawgrass Road Sarasota, FL 34240 (941) 960-2004 - Parts

LeeBoy photo

The 8680 has a 210 hp Kubota Tier IV diesel engine paired with a four-speed drive system, capable of going 6 mph. To connect that power to any kind of terrain, the paver features high-speed smooth rubber tracks with oscillating bogeys, which allow for easy maneuverability.

LeeBoy photo

LeeBoy introduced its 8680 asphalt paver, which is designed to meet the demands of heavy commercial and main line contractors.

LeeBoy introduced its 8680 asphalt paver, which is designed to meet the demands of heavy commercial and main line contractors.

The 8680 has two screed options, the LB5 screed, which weighs 5,400 lbs., and the LB7 screed, which carries up to 7,400 lbs.

The 8680 offers a range of new updated features, including taller hopper wings to accommodate the new hopper capacity of 15-tons compared with 12.5-tons on the original design. A hydraulic lift, front apron and a 16-in. auger with no cut-off are some other notable features being introduced on the 8680. The 8680 also features optional power outlets and a pole to accommodate balloon lights. Along with these new features, the 8680 LB7 also features a streamlined control box, with easy access to a lever for extension, controls for the auger and conveyer and pile height settings.

“We experienced over 91 percent compaction with most

LeeBoy photo

The 8680 has two screed options, the LB5 screed, which weighs 5,400 lbs., and the LB7 screed, which carries up to 7,400 lbs.

mixes,” said Chris Broome, senior product manager of LeeBoy. “The LB7 is big enough and heavy enough to get the job done.”

Some more performance features of the 8680 include:

• paving widths up to 15 ft., 6 in.;

• dual electronic steering and adjustable operator platforms;

• two 18-in. feeding conveyers;

• hydraulic extending power tunnels;

• automatic temperature control (ATC); and

• actuator driven lift hood

The 8680 has a 210 hp Kubota Tier IV diesel engine paired with a four-speed drive system, capable of going 6 mph. To connect that power to any kind of terrain, the paver features high-speed smooth rubber tracks with oscillating bogeys, which allow for easy maneuverability. For more information, visit https://www.leeboy.com/products/8680/