By Chuck MacDonald CEG CORRESPONDENT

Maryland’s Route 4 in southeastern Maryland services Prince George’s, Anne Arundel and Calvert Counties. This thoroughfare has important neighbors including Washington D.C., and I-

495, the busy beltway around the nation’s capital.

Economic activity has been growing, especially near MD Route 4’s connection with Suitland Parkway (MD 337). The biggest and most influential neighbor is Joint Base Andrews, formerly known as Andrews Air Force Base.

By Lucy Perry CEG CORRESPONDENT

This military facility is home to more than 16,000 people and hosts the 316th Wing, which supports six Wings, two headquarters and some 50 tenant organizations. The base generates an estimated $1 billion in economic impact to the area.

MARYLAND page 32

Outback Parts is linked nationwide with three used parts networks, so finding

Outback Parts also supplies replacement parts for Non-Cat® machines. So when you’re needing parts, call or visit us on-line.

8 AGC WELCOMES MEMBERS TO CONVENTION IN COLUMBUS, OHIO

The Associated General Contractors of America (AGC) hosted its 2025 annual convention in Columbus, Ohio, April 8–10 at the Greater Columbus Convention Center.

After eight years as CEO and nearly 45 years of service, Caterpillar Inc. Chairman and CEO D. James Umpleby III will become executive chairman of the board effective May 1, 2025.

R&D Paving, a family-owned paving and snow contracting business, has become a trusted name across New Hampshire, serving residential, commercial and municipal clients.

16

The $384.5 million contract focuses on the southern interchange of Business Loop 81 and I-81, modifying the new I-81 interchange with New York Highways 5/92 in DeWitt, and expanding the corridor between I-690 and Kirkville Road.

18

The North American Steel Construction Conference (NASCC) was held in Louisville, Ky., April 2-4, 2025, at the Kentucky International Convention Center. Organized by the American Institute of Steel Construction (AISC).

20 TRACEY ROAD EQUIPMENT EXPANDS WITH THREE NEW LOCATIONS

Tracey Road Equipment recently expanded its service area beyond New York State to Wilkes-Barre, Pa., to add locations in Pittsburgh, Du Bois and Erie, Pa.

22 BRIDGE BEAMS BEING SET ACROSS I-83 AS PART OF PROJECT IN PA.

PennDOT announced that bridge beams were scheduled to be set on the new 29th Street bridge being constructed in Swatara Township over Interstate 83 and the Norfolk Southern railroad tracks.

22

Contractors will start removing Pennsylvania Turnpike toll plazas and reconfiguring entrance and exit ramps on the highway in the eastern part of the state in April 2025, the Pittsburgh Union Progress reported March 23, 2025.

Cleveland Brothers Equipment Co. Inc., a Cat dealer serving Pennsylvania, northern West Virginia and western Maryland, has acquired BCI Rentals in Altoona, Pa.

90 BOBCAT NAMES 2025 LEADERSHIP GROUPS, HONORS 55 NA DEALERS

Bobcat Company has announced its 2025 Dealer Leadership Groups. The 55 Bobcat dealerships honored this year are the company’s highest-performing dealers across respective business divisions in North America.

100 YANMAR APPOINTS ANNA CHRISTINE SGRO ITS NEW PRESIDENT

Effective April 14, 2025, Anna Christine Sgro was appointed president of Yanmar Compact Equipment North America. In her new role, Sgro will focus on organizational integration, financial performance and driving customer success.

105 ARTBA: FATALITIES, INJURIES IN HIGHWAY, BRIDGE SECTOR DECLINE

The highway and bridge sector is making measured progress in reducing worker deaths and injuries compared with the broader construction industry, according to an analysis of U.S. Bureau of Labor Statistics data released April 23.

113 KUBOTA TRACTOR ANNOUNCES

WITH POST MALONE

The collaboration will see Kubota provide a range of equipment to manage Post Malone’s expansive property, while also becoming an official sponsor of the artist’s highly anticipated “Travelin’ Tailgate.”

BLUE DIAMOND DEBUTS DRUM MULCHER FOR SKID STEERS, CTLS

BUCKETS HOLD

The Associated General Contractors of America (AGC) hosted its 2025 annual convention in Columbus, Ohio, April 8–10 at the Greater Columbus Convention Center. This event offers construction professionals an opportunity to enhance their knowledge, forge critical industry connections and navigate the evolving landscape of construction regulations and innovations.

Attendees participated in more than 30 expert-led educational sessions covering a broad spectrum of topics, including emerging technologies, workforce development, risk management and industry regulations. These sessions are designed to provide valuable insights that help contractors position their businesses for success in a competitive market.

A highlight of the convention was the Buckeye VIP Lounge, an exclusive area for AGC Ohio members to network, recharge devices and enjoy refreshments. Additionally, AGC of Ohio members were invited to a special reception at Parlay Kitchen & Bar on April 8, sponsored by Taft Law.

The convention also featured a comprehensive expo with hundreds of exhibitors showcasing the latest in construction technology, equipment and services. This provided attendees with hands-on experiences and opportunities to discover innovative solutions to enhance their operations.

Construction professionals were able to take advantage of the wealth of knowledge, networking opportunities and industry insights that this event promises.

For more information, visit agc.org. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Tommy Watkins (L), vice president of safety sales, and Phil Collier, business development manager, of Charles Taylor Safety Services connected with industry professionals, highlighting comprehensive safety solutions — from onsite staffing and OSHA compliance to customized training programs — designed to help contractors enhance safety and reduce jobsite risk.

Doug

Pierre Gleize (L) and Dash Natale of OTH Pioneer Rigging introduced attendees to the company’s remote-controlled lifting technology, emphasizing enhanced safety and efficiency in construction operations. The LudwigHook is a radio-controlled quickrelease hook designed to streamline rigging processes and reduce manual intervention.

(L-R) are Cassidy Bruns, communications coordinator of OCA; Dave Coniglio, director of labor relations and safety affairs of OCA; Parker Brown, director of the education foundation of the AGC of Ohio; Daniel Edwards, CEO of AGC of Ohio; and Carissa Hershey, director of communications and membership of AGC of Ohio. The Buckeye VIP Lounge, hosted by AGC of Ohio and Ohio Contractors Association offered a premier networking space at the AGC Convention, welcoming current and prospective members.

Tim Isaac (L), sales territory manager and Tony Little, territory sales manager, both of Company Wrench, drew attention highlighting the company’s robust lineup of demolition and construction equipment, including their full line of JCB machines. Attendees engaged with the Company Wrench team to learn more about solutions designed to tackle the toughest jobsite demands.

and Tim

(L-R): CMiC’s Matthew Lasher, Michael Ranucci and Luke Varrasso engaged attendees with the company’s cloud-based construction ERP platform. Visitors explored how CMiC’s integrated financial and project management solutions help streamline operations and improve collaboration across construction teams.

The Dumpsters.com team connected with contractors at the 2025 AGC Convention in Columbus, Ohio, showcasing its nationwide dumpster rental and jobsite service solutions. With a focus on efficiency and customer support, the team highlighted how its streamlined waste management services keep construction projects on track.

Cintas and Core Affinity partnered to provide AGC members with exclusive discounts and comprehensive safety solutions. Cintas emphasizes its commitment to supporting construction professionals with essential services, including uniform rentals, facility services, first aid and safety supplies and fire protection.

New Model TAG25, 24’ or 26' deck with 6' Tail, Safety Lighting Pkg., Bucket Pocket' in Deck & Tail, Black Paint In Stock!

Rogers TAG21XXL, 24' deck, 6' tail, 235's on aluminum outers, 8' Air Ramps. Safety Lighting Package. Red Paint.. IN STOCK!

Rogers 55 Ton CobraNeck, Severe Service Design. 2-position pin, ratchet ride height, adjustable width bi-fold steel ramps, 26' clear deck, deep well pocket, chain bins, tool boxes, 275's, alum. outers, side reinforcing, extra lights, strobes, night light pkg. Air Lift 3rd Air Lift 4th axle, Black Paint..........IN STOCK!

New Rogers 55 ton, CobraNeck, 2-position pin, Ratchet Ride Height, 26' deck, 18" ride height, deep well pocket, 275's on aluminum outers, air lift 3rd,& 4th. Night Light Pkg., Strobes, 3 or 4 Axles............ IN STOCK!

Rogers TAG21XL, 22’ + 6’ Tail & TAG21XXL, 24’ + 6’ tail, 235's on Aluminum, Air Ramps, Safety Lighting Pkg. with Strobes. Black Paint.. IN STOCK!

Rogers 40 ton Tandem, No-Foot Neck, 24' deck, adjustable width

bucket pocket, 275's, aluminum outers, night lights, work lights, strobes. Rogers Black............ IN STOCK!

Rogers TAG25XXL, 25 Ton Capacity, Premium Specs, Superior Quality, 235’s Aluminum, 7-Year Warranty, Black Paint, 24’ deck + 6’ tail, 8’ Air Ramps IN STOCK!

After eight years as CEO and nearly 45 years of service, Caterpillar Inc. Chairman and CEO D. James Umpleby III will become executive chairman of the board effective May 1, 2025.

Chief Operating Officer (COO) Joseph E. Creed, a 28-year Caterpillar veteran, will succeed him as CEO and join the board of directors May 1, 2025.

interim chief financial officer for Caterpillar in 2018. He then became vice president of the oil and gas and marine division and the electric power division. In 2021, he was promoted to group president of energy and transportation. Effective Nov. 1, 2023, Creed was appointed to the newly created position of chief operating officer.

After assuming the role of CEO on Jan. 1, 2017, Umpleby led the development and execution of a new strategy for long-term profitable growth, creating significant shareholder value. In 2024, Caterpillar achieved record full-year adjusted profit per share, which increased more than sixfold during Umpleby’s tenure as CEO.

“I’m grateful to have had the opportunity to work with Caterpillar’s dedicated global team of employees and dealers for my entire career,” said Umpleby. “As we celebrate our 100th anniversary, we honor those who came before us establishing a culture of excellence serving our customers. I have great confidence in my successor Joe Creed and the entire executive office to lead our global team as Caterpillar embarks upon our second century of helping our customers build a better, more sustainable world.”

“For 100 years, our incredible people have been the foundation of Caterpillar’s success,” said Creed. “I’m proud to work alongside our talented Caterpillar employees and dealers as we continue to support customers across our diverse businesses, from disaster recovery and building the world’s infrastructure to delivering critical minerals and reliable energy. I look forward to leading this amazing team as we build upon Caterpillar’s legacy of excellence.”

Debra L. Reed-Klages, who has served as a director since June 2015, will remain on the board as independent presiding director, a position she has held since June 2022.

Creed joined Caterpillar in 1997 and has held numerous positions of increasing responsibility across multiple divisions of Caterpillar. He was promoted to chief financial officer for Caterpillar’s energy and transportation business segment in 2013, then to vice president of Caterpillar’s finance services division in 2017. Creed also served as

“We are deeply grateful for Jim’s leadership and appreciate the outstanding results he achieved during his tenure,” Reed-Klages said. “His impact on our customers, dealers, shareholders and employees will continue for years to come. Joe’s selection as CEO is the result of a multi-year succession planning process by the board of directors. He is a proven leader with significant experience in Caterpillar’s global businesses. We are confident Joe will position Caterpillar for continued future success.”

For more information, visit caterpillar.com

R&D Paving, a family-owned paving and snow contracting business, has become a trusted name across New Hampshire, serving residential, commercial and municipal clients.

What started as a humble operation in 1990, founded by Richard, Donald and Nancy Dubreuil in the basement of their home, has grown into a well-respected company under the leadership of Richard’s sons, Matthew and Joseph Dubreuil.

Over the decades, R&D Paving has expanded significantly, building a team of highly qualified professionals with decades of combined experience and investing in a fleet of cutting-edge paving equipment. Despite their growth, the Dubreuil family has remained steadfast in their commitment to honesty, trustworthiness and expert craftsmanship. Each project, no matter the size, receives the full dedication and attention it deserves.

Customer satisfaction is a cornerstone of R&D’s philosophy. The company guarantees fair pricing, ensures projects are completed on schedule, and stands behind every job with a 100 percent satisfaction guarantee. Whether working with homeowners, business owners, or municipal representatives, R&D has built a reputation for reliability and excellence.

A significant portion of R&D’s business involves serving municipalities, a sector where precision and professionalism are paramount.

“Our primary focus when dealing with municipalities is flexibility, professionalism, and executing the project exactly right,” said Matthew Dubreuil. “When we achieve that, we build customer loyalty. Highway superintendents and municipalities repeatedly choose us because they know they won’t be disappointed. That’s when we know we’re doing something right.”

Given the substantial investment required for paving projects — whether for a town, a business repaving its parking lot or a homeowner paving their driveway — customer trust is crucial.

“It’s also essential that our employees share the same passion and commitment to customer satisfaction that we do,” said Joseph Dubreuil. “From administrative staff to sales representatives, laborers and superintendents, we encourage everyone to take ownership of the company’s success.”

Building a company of R&D’s scale and reputation has been a rewarding journey for

R&D Paving, a family-owned paving and snow contracting business, has become a trusted name across New Hampshire, serving residential, commercial and municipal clients.

the Dubreuil brothers.

“We take pride in what we’ve built,” said Matthew. “There’s a fine line between pride and cockiness, and we strive to remain humble. We know there are other great companies out there, but we take pride in how we run our business and how our employees represent us.”

Both brothers have dedicated their lives to the company, having started working in the business as pre-teens. With more than two decades of experience, they are already planning for the next generation.

“One of our primary goals is to smoothly transition this second-generation company to the third generation,” Matthew said. “Our sons and daughters are already getting involved in different aspects of the business. We have about 15 years before we retire, and by then, our children will be running the show.”

Running a family business comes with its challenges, but the Dubreuil brothers have always found ways to make it work. Their father, a former Marine, instilled in them a rigorous work ethic and attention to detail that continues to define the company.

“He expected 100 percent effort and demanded professionalism,” said Matthew. “He made us the men we are today.”

To ensure top-tier results, R&D places a strong emphasis

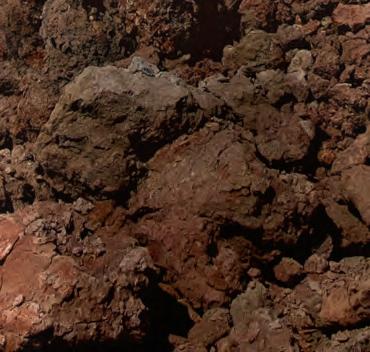

R&D Paving uses its Dynapac CC1200 to meet maximum compaction levels.

on investing in the best equipment. Much of their fleet has been purchased from Ambrose Equipment, headquartered in Hooksett, N.H. Over the years, R&D has acquired numerous LeeBoy pavers and Rosco asphalt maintenance equipment for residential and commercial work, along with Sakai and Dynapac rollers, and the company just purchased its first Roadtec paver for municipal projects.

One of R&D’s recent investments was a new Roadtec paver for large-scale commercial and municipal projects. They traded in a competitor’s machine, trusting Ambrose’s recommendation.

“The Roadtec has exceeded our expectations,” said Matthew. “Our team loves it.”

Joseph Dubreuil highlighted the critical role Ambrose plays in their success.

“Our relationship with Ambrose isn’t just about the equipment — it’s about the service and support they provide,” he said.

“Downtime is a major issue in our industry, and Ambrose understands that. When a machine goes down, we’re losing time and money, and we have customers depending on us. Ambrose has always responded immediately to our needs.”

see R&D page 106

BACKHOES:

EXCAVATORS:

SKID STEER LOADERS:

2019 NEW HOLLAND B110SPC, 747 HRS, CAB HVAC, QUICK TACH FRONT BKT, EXTENDAHOE, FRONT HYDRAULICS........................................

$88,995

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXTENDAHOE, TOOL CARRIER..................................................................................

$32,995

2017 HITACHI ZX135-6, 3900 HRS, HYD THUMB, FRONT BLADE, COUPLER, PATTERN CHANGER......................................................

2023 KOBELCO SK130LC-11, 516 HRS, CAB, HVAC, HYD THUMB, COUPLER........................................................................................

$105,000

$149,995

2021 KUBOTA SVL97-2 TRACK SKID STEER, CAB, HVAC, 905 HRS, STD FLOW HYD, HYD COUPLER, 78” BKT, BACKUP CAMERA................$69,000

2012 KUBOTA SVL90-2 TRACK SKID STEER, 1446 HRS, CAB HVAC, HIGH FLOW, LEXAN DOOR, COMES W/BKT, FORKS..................................$45,000

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXT HOE, TOOL CARRIER, TURF TIRES, BHOT SET TO CAT......................................

$29,995

2021 NEW HOLLAND B95C TLB, 139 HRS, CAB, HVAC, 4 IN 1, EXT HOE....

CHIPPERS:

$99,995

2019 KOBELCO SK140RLC, 2192 HRS, CAB, HVAC, HYD THUMB, FRONT BLADE, RUBBER TRACK PADS......................................................

$109,995

2023 KOBELCO SK140RLC-7, 288 HRS, CAB, HVAC, BLADE, THUMB, COUPLER........................................................................................

$169,995

2022 KOBELCO SK170LC-11, 256 HRS, CAB, HVAC, HYD THUMB

$169,995

TRACTORS:

2012 CASE MAX110, CAB, HVAC, 6380 HRS, 4WD, LOADER, 3PT HITCH, 3 SETS REAR REMOTS, AG TIRES......................................................$42,000

2013 BANDIT 1390XP CHIPPER, 15” CAPACITY, 142 HP PERKINS DIESEL ENGINE, 2511 HRS, AUTOFEED, WINCH..........................................

$29,995

2023 KOBELCO SK350LC-11, 397 HRS, CAB, HVAC, 54” BUCKET, PLUMBED........................................................................................

$295,000

MISCELLANEOUS:

2017 BANDIT 250XP 12” CHIPPER, CAT 120HP DIESEL ENGINE, 2305 HRS, AUTO FEED, WINCH..........................................................................$41,995

2022 BANDIT 250XP CHIPPER, 400 HRS, WINCH, 12" CAPACITY, CAT 120 HP......................................................................................................

SCREENERS:

2021 VIBROSCREEN SCM40

2021 VIBROSCREEN SCM27

$64,995

$79,995

$62,995

NEW VIBROSCREEN SCM75C BOX SCREEN W/CONVEYOR, TIER 3 ENGINE................................................................................$195,000 NEW VIBROSCREEN SCM115T TROMMEL, NO DPF, NO DEF........$179,995

2003 TEREX HR16 MINI EXCAVATOR, CAB, HEAT, 3253 HRS, HYD THUMB, RUBBER TRACKS, 4 TON..................................................................

2018 YANMAR VI080-1A, CAB, HVAC, 1351 HRS, THUMB, RUBBER TRACKS............................................................................................

$19,995

$59,995

WHEEL LOADERS:

2022 AVANT 528LX, 40 HRS, CAB W/HEAT, 51” BUCKET, 43” ROTARY BROOM, LIKE NEW CONDITION........................................................$46,995

2002 DAEWOO MEGA200V, 2YD 4IN1 BKT, 2283 HRS, HYD COUPLER........ $39,995

AFE ROTARY FORESTRY HEAD, SKID STEER MOUNT $17,995 HLA 96” SNOW BUCKET, SKID STEER MOUNT, 47.3 CU. FT. HEAPED$3000 KUBOTA KX080 EXCAVATOR TO SKID STEER COUPLER ADAPTOR $3,199 48” REVERSE LUG GRADING BUCKET, FITS KUBOTA 57&55, NEW CONDITION..........................................................................................$2,500 2024 WERKBRAU CEMETERY 36” BUCKET, FITS BACKHOE................$2,200

Interstate 481 over the CSX rail yard in DeWitt, N.Y., just outside Syracuse, is being widened as part of the ongoing $2.25 billion I-81 viaduct project.

The $384.5 million design-build contract focuses on constructing the southern interchange of Business Loop 81 and I-81, modifying the new I-81 interchange with New York Highways 5/92 in DeWitt, and expanding the corridor between I-690 and Kirkville Road.

As part of the effort, a pair of gantry cranes have been dispatched to the work site to carry steel beams into place between existing bridges on the freeway.

The bright yellow machines have caused plenty of motorists to slow down to gawk at the three-story tall structures. In fact, they are so big they had to be assembled on site, the Post-Standard reported March 10, 2025.

For the uninitiated, gantry cranes can usually be found working at rail and shipping yards, where they can lift a shipping container.

But their use on the I-481 project is all about providing an engineering solution to a tricky construction dilemma.

Picture two existing 2,100-ft.-long bridges side-by-side over a functioning railroad. The northbound and southbound

bridges are separate structures with a little space in between.

Contractors of CNY Alliance, a joint venture made up of three construction firms based in the state, are working on the design-build project. With the gantry cranes, they are adding one lane to each side of the bridge structures, as well as building new lanes in the middle space, the Syracuse news source noted.

As a result, there is not much room to maneuver construction equipment between the two bridges, said Jim Harmon, the engineer in charge of the New York State Department of Transportation (NYSDOT).

NYSDOT photo

A pair of gantry cranes have been dispatched to the work site to carry steel beams into place between existing bridges on the freeway.

Enter the gantry cranes, each with wheels taller than a human being.

The two cranes will roll over the lanes with one wheel on each existing bridge. In their giant hooks, the Post-Standard said, they will carry the heavy steel beams needed to support 15 spans of new bridge deck.

“It’s very tight down in the middle where the cranes would have to sit to set the beams, so these [machines] carry the load differently than a traditional crane,” Harmon said.

Over the next six or eight months, he added, the cranes will roll back and forth with 60 beams, each one weighing 68,000 lbs., roughly the weight of 19 Subaru Outback cars.

It took approximately a week for workers to haul in the crane parts and build them on site, according to Harmon, and several more days for operators to learn how to run the cranes in this unusual configuration, he said.

One critical advantage to using the gantry cranes at this specific site on the I-481 proj-

ect is that the machines can walk the beams into place above the bridges without touching the fragile wetlands or the railroad lines below.

The idea to use the gantry cranes in this manner came from CNY Alliance, which is responsible for this particular section of the project, said TeNesha Murphy, a NYSDOT spokesperson.

The companies making up the joint venture are the Rifenburg Companies, in Troy, N.Y.; A. Servidone/B. Anthony Construction, located in Castleton; and Cortland-based Economy Paving Company Inc.

The work is part of the massive effort to tear down the elevated Interstate 81 in downtown Syracuse and build up I-481 to handle more high-speed traffic around the east side of the city.

Drivers will continue to have a close-up view of the DeWitt work for at least the next two years until that portion of the overall I81 rebuild is completed. In the meantime, traffic will continue to flow on two lanes north and south during the construction, according to NYSDOT.

The North American Steel Construction Conference (NASCC) was held in Louisville, Ky., April 2-4, 2025, at the Kentucky International Convention Center. Organized by the American Institute of Steel Construction (AISC), this annual event is a cornerstone for professionals involved in the design and construction of steel structures.

The Steel Conference offered an extensive program featuring more than 270 technical sessions providing attendees with up to 16 professional development hours (PDHs). A specialized short course was available offering an additional four PDHs.

The conference also included a vast exhibition hall with more than 300 exhibitors showcasing the latest in steel construction products and services. This year’s conference hosted several co-located events,

including the World Steel Bridge Symposium, QualityCon, NISD Detailing Conference, SafetyCon, Architecture in Steel and the SSRC’s Annual Stability Conference. These events provided attendees with a comprehensive view of the industry’s latest advancements and best practices.

The conference attracted more than 6,000 industry professionals, including designers, fabricators, researchers and contractors. It also provided networking opportunities, allowing attendees to connect with peers and industry leaders.

For more information, visit nascc.aisc.org. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Steel Dynamics drew a steady crowd at its bustling booth during the 2025 NASCC. As a sponsor of the event, the company showcased its latest advancements in steel production and construction solutions, engaging with industry professionals throughout the conference.

Sean Smith, market development manager of New Millennium Building Systems, introduced the company’s RED (rolling electric deck), designed to streamline and improve installation of interlocking steel B-deck.

Lincoln Electric’s booth was a lively hotspot at the Steel Conference, where attendees explored welding and automation solutions while enjoying fun beverages and vibrant networking opportunities with industry peers.

Sherwin-Williams’ Nate Brulport (L), product manager, and Russell Norris, market segment manager, fire protection, made a strong impression at the 2025 Steel Conference in Louisville, Ky., with a vibrant and engaging booth. Showcasing advanced coating technologies designed for structural steel protection, the team connected with engineers, fabricators and specifiers.

Dale Olson (L), technical training specialist, and Paul Bilson, director of dealer development, both of Baumann USA in Brookville, Ohio, showcase the Baumann EGX 80L electric sideloader. This machine has a load capacity of up to 17,600 lbs., platform widths from 48 in. to 98 in., lift heights up to 295 in. and dual 120v electric drive motors.

Encon Equipment, a distributor of Magni Telescopic Handlers, showcased a lineup of material handling solutions. The booth highlighted the strength and versatility of Magni machines, drawing in industry professionals looking for equipment for steel construction projects. (L-R) are Dalton Duane, marketing, Magni Telescopic Handlers; Nick Newbury, regional sales manager, Magni Telescopic Handlers; Jay Jude, regional sales manager, Magni Telescopic Handlers; Rachel Judd, marketing, Encon Equipment; Todd Pennycuff, sales Encon Equipment; and Casey Shepherd, sales, Encon Equipment.

MANASSAS, VA

Dealer Imprint Arrea

6918 Wellington Rd. Manassas, VA 20109 703/257-2381

JESSUP, MD

10421 Guilford Road, Jessup, MD 20794

410/792-9134 from Washington D.C. 301/725-7394

DELMAR, DE

38420 Sussex Highway Delmar, DE 19940

302/846-3033

HARRISBURG, PA 6680 Allentown Blvd., Harrisburg, PA 17112 717/652-5430

KING OF PRUSSIA, PA

450 E. Church Road, King of Prussia, PA 19406 610/279-5200

Tracey Road Equipment, a longtime dealer providing sales and service for HD Hyundai Construction Equipment North America, recently expanded its service area beyond New York State to Wilkes-Barre, Pa., to add locations in Pittsburgh, Du Bois and Erie, Pa.

The dealership, which began operations in Syracuse in 1976, specializes in heavy trucks and equipment.

“We are now able to provide sales, parts and service to customers across all of northern, central and western Pennsylvania,” said Christine Tracey Julka, vice president of Tracey Road Equipment. “Hyundai is a primary equipment brand for us. By carrying the full line of Hyundai construction equipment, we have machines for each of our different customer bases. Hyundai’s aftermarket support and training for our people is tremendous and really helps us with our customer relationships.”

Julka noted that her father, Jerry Tracey, built the still-growing dealership from the ground up and remains active in every aspect of the business.

“At Tracey Road, the customer has come

first from Day One,” she said. “We have great business and personal relationships with our customers and we bring that same spirit and commitment to our business oper-

ations in Pennsylvania.”

“We are happy that Hyundai customers in Pennsylvania will receive the same exceptional service and support as Tracey Road

customers in New York,” said Brian Slavinski, HD Hyundai Construction Equipment North America’s Northeast district manager.

generator, Deutz diesel, stk#AE376.......... $27,500

2016

2,531 hours, 41 ft

2018 Peterbilt 567, 272,016 miles, 10 wheel, 15 ft steel Brandon body w/ 3 chutes, Paccar MX13, 455 hp, Allison automatic, 20k f, 46k r, spring suspension, hitch, stk#TK997 $139,500

2017 Doosan DX140LCR-5, 4,288 hours, 32" bucket, hydraulic thumb, a/c, 4 cyl Perkins turbo, 2 speed, backup camera, 33k lbs, stk#XC730....................................$77,500

2017 John Deere 410L, 5,909 hours, 4x4, x-hoe, cab w/ a/c, ride control, pilot controls, 4-in-1 bucket, 1-way rear aux hyd, new 24" digging bucket, stk#BH191..........$49,500

2016 MEC 60J, 3,037 hours, 60 ft boom lift, 8 ft basket, skypower, 4 cyl Kubota turbo, stk#AE044................$23,500

2005 Caterpillar D8T, 17,631 hours, 12'9" semi-u blade w/ tilt, cab w/ a/c, diff steer, 6 cyl Cat C15 Acert turbo, 87k lbs, stk#DZ577..................................................................$129,500

Contractors will start removing Pennsylvania Turnpike toll plazas and reconfiguring entrance and exit ramps on the highway in the eastern part of the state in April 2025, the Pittsburgh Union Progress reported March 23, 2025.

Dismantling 10 sets of closed toll booths on the turnpike’s Northeast Extension is the latest step in the agency’s conversion to open-road tolling, where motorists pay when they pass under gantries that read their EZPass transponder or photograph their license plate and send them a bill in the mail.

The agency switched to that system in January 2025 on the turnpike’s mainline from east of Reading to the New Jersey border (which has 10 new gantries) and on the Northeast Extension (which has nine). Ten more are nearing completion in central Pennsylvania, and construction started on 11 others in the west earlier this year between the Fort Littleton interchange in Fulton County and the Ohio border.

The agency changed to all-electronic tolling in spring 2020, when it laid off toll collectors during the pandemic to reduce contact between drivers and collectors. Initially, electronic and photographic equipment were added to the plazas to collect tolls, so drivers still had to slow down, but as

the gantries are installed on the roadway, the plazas are no longer needed and traffic will again be free flowing.

The first area where plazas are slated to be eliminated is on the northern end of the turnpike’s Northeast Extension, where six interchanges will be removed from the Pa. Highway 903 interchange north to Clarks Summit, near Scranton.

New Enterprise Stone & Lime Co. Inc. won the bid for that particular $13.45 million contract. The New Enterprise, Pa., company will work to rebuild the ramps to narrow the roadway where the booths used to be and create smoother entry and exit ramps.

The Pennsylvania Turnpike Commission also awarded a $13.21 million contract earlier in March to Atglen, Pa.’s J.D. Eckman Inc. to remove toll plazas and upgrade the ramp system on four interchanges from Lansdale to Mahoning Valley.

The conversion of all the plazas in the eastern part of the state should be finished by the end of 2026.

Marissa Orbanek, a Pennsylvania Turnpike spokesperson, told the Union Progress that the redesign of each toll plaza will be unique because of their differing physical settings. In addition to providing a free-flowing entry and exit for the highway, she said the revised road system also should improve safety because motorists will no longer have to weave into and out of traffic

lanes to find their appropriate toll booth.

In addition, motorists will not have to slow down to pay tolls, thus reducing rear-end collisions. The revised ramps should increase the line of sight for drivers, as well and cut down on the potential for drivers to travel the wrong way. The removal of toll plazas also will eliminate the amount of land PennDOT needs for an interchange and allow it to create more entry and exit points along the toll road.

The first turnpike plaza without toll booths to be designed in the Pittsburgh area is slated to be a new interchange with PA 130 in Westmoreland County’s Penn Township, but that project likely will not be built until the mid-2030s.

Work to revise interchanges in the western part of the state should begin after the gantries are put into service in January 2027, according to the Union Progress.

The Pennsylvania Turnpike said that it expects the shift to open-road tolling to save about $25 million annually.

The Pennsylvania Department of Transportation (PennDOT) announced that bridge beams were scheduled to be set on the new 29th Street bridge being constructed in Swatara Township over Interstate 83 and the Norfolk Southern railroad tracks.

The procedure was set to be carried out on consecutive evenings, March 24-25, 2025. This work was not expected to impact traffic on the I-83 mainline, PennDOT noted, but brief, intermittent stoppages on Derry Street while the beams are put into place was likely, the state agency said in a news release.

I83 Beltway Project photo

Bridge beams were scheduled to be set on the new 29th Street bridge being constructed in Swatara Township over Interstate 83 and the Norfolk Southern railroad tracks.

Following that work, more bridge beams are expected to be set over northbound and southbound I-83 on the evenings of March 27-28, 2025. Then, PennDOT will oversee additional beam installations over the widened portion of the freeway on the night of March 31, 2025.

All of the current work is associated with the first of two contracts for East Shore Section 3 of the larger I-83 Harrisburg Capital Beltway Project, which is being built to surround the city’s downtown.

It includes widening and reconstructing portions of the I-83 roadway; construction of

overhead bridges at 29th and 19th streets; building the new Cameron Street interchange; removing the 13th Street interchange; and roadway improvements along Swatara Township’s Cameron Street, 19th Street and 29th Street corridors.

PennDOT said that there may be significant impacts to traffic during the life of this portion of the project, including traffic shifts, lane restrictions and road closures/detours. New Enterprise Stone and Lime Co. Inc., located in New Enterprise, Pa., is the con-

tractor on the $154.6 million road and bridge project.

All work on the East Shore Section 3 contract is expected to be completed by Oct. 12, 2027, according to the state transportation agency.

The Harrisburg Capital Beltway encircles the Harrisburg, Pennsylvania’s state capital and its surrounding municipalities, including Swatara. The Beltway includes a section of not only I-81, but a portion of I-83 and Pennsylvania Highway 581 and is a limited-access facility.

PennDOT describes the Capital Beltway as “vital to the economy of the Harrisburg region and is an important hub in the transportation network of the northeastern United States.”

The I-83 section of the Capital Beltway extends from a junction with I-81 northeast of Harrisburg to the interchange with Pa. 581 to the south of the city. An I-83 Master Plan was prepared by the PennDOT in 2003 for this section of the Capital Beltway to identify, plan and program future transportation improvement efforts.

The beltway includes five projects in the Harrisburg region: East Shore Section 1, East Shore Section 2, West Shore Section, East Shore Section 3 and the I-83 South Bridge.

The second East Shore Section 3 contract is expected to be under construction from later this year to 2028 and includes the widening and reconstruction of I-83, construction of the 13th Street bridge and approaches, the work to build the 17th Street interchange and a widening of 17th Street.

According to PennDOT, the I-83 Capital Beltway has three major issues that the construction efforts will address:

• Worsening roadway conditions. Most of the pavement in the I-83 corridor is more than 50 years old and has been repeatedly patched and overlaid while the base pavement continues to age;

• high traffic volumes and congestion, two problems that will only be compounded as the existing traffic and the predicted traffic to use I-83 in the future become more than the roadway can effectively carry; and

• safety concerns, due to the fact that the interstate was designed decades ago and does not include the modern safety features needed for roadways that have many vehicles traveling at high speeds.

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR . .$195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires

$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote

$4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs .

$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

185’s, JD diesels

CALL

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

$224,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$179,000

$122,500

$72,500

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition

CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent

$229,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

Cleveland Brothers Equipment Co. Inc., a Cat dealer serving Pennsylvania, northern West Virginia and western Maryland, has acquired BCI Rentals in Altoona, Pa.

This addition marks the heavy equipment dealer’s first location in Blair County, bringing equipment rental solutions to the area beginning June 2, 2025.

“We’re proud to welcome the BCI Rentals team and their loyal customer base into the Cleveland Brothers family,” said Jay Cleveland Jr., Cleveland Brothers president and CEO.

“This expansion is a key step in our mission to provide easier access to rental solutions across the region, backed by the service excellence and top-tier equipment Cleveland Brothers is known for.”

The existing BCI Rentals facility will become a One Call Rentals location featuring equipment from Caterpillar and other leading manufacturers, such as JLG, Toro, Sullair, Magni and more. The location also will feature a parts counter, hydraulic hose press and service for rental and small Cat equipment.

The acquisition extends the Cleveland Brothers footprint to 30 locations, including 11 One Call Rentals stores, further increasing the company’s capacity to meet the growing demand for reliable equipment and support in central Pennsylvania.

“This is more than a new location,” said Cleveland. “It’s an opportunity to better serve our customers with greater convenience, availability and trust. We look forward to growing with the Altoona community.”

Cleveland Brothers, headquartered in Murrysville, Pa., offers equipment sales, rental, parts and service to a diverse customer base that spans the construction, oil and gas, mining, power generation and transportation industries.

ROKBAK MODEL RA30 OFF ROAD TRUCK: 30 TON CAPACITY WITH TAIL GATE, 276HP SCANIA ENGINE. AVAILABLE FOR SALE OR RENT! +N5027..........AVAILABLE FOR RENT OR PURCHASE

NEW ASV RS75 WHEEL SKID STEER: OPEN ROPS, SUSPENSION SEAT, 74" BUCKET, 21.3 GPM, ELECTRIC PLUG ON BOOM FOR ATTACHMENTS, MAX CAB, UNIT# N4200......CALL FOR PRICE

ANACONDA DF410 SCALPING SCREEN: 2 DECK TRACKED SCREENING PLANT WITH LOW HOURS, UNIT# AG1381........................................................................................CALL FOR PRICE

ANACONDA TR75 TRACKED CONVEYOR: 42” X 75’ CONVEYOR, IT ALLOWS FOR STOCKPILING OR FEEDING OF A RANGE OF APPLICATIONS. THE TR75 HAS A VARIABLE SPEED CONVEYOR IN ORDER TO FACILITATE FOR DIFFERENT APPLICATIONS SUCH AS SAND, GRAVEL, AGGREGATES, COMPOST, COAL AND WOOD CHIP. WE STOCK A FULL RANGE OF SPARE PARTS AS A DISPLAY OF OUR COMMITMENT TO PROVIDE A DEDICATED AND RESPONSIVE SERVICE TO ALL OUR CUSTOMERS, 6 UNITS IN STOCK........................................................CALL FOR PRICE

ANACONDA FTR150 UNIT AG1353: MID SIZE FEED LOADER RANGE. FULLY EQUIPPED WITH 50' STOCKPILING CONVEYORALLOWS DFOR STOCKPILING OR FEEDINGA WIDE RANGE OF APPLICATIONS. INCLUDES OPTIONAL 2 DECK VIBRATING GRID......................CALL FOR PRICE

ASV MODEL RT50: ALL WEATHER CAB WITH HEAT AND AC, SUSPENSION SEAT, 15” RUBBER TRACKS, 60” BUCKET WITH BOLT ON EDGE, UNIVERSAL SKID STEER COUPLER, YANMAR TURBO DIESEL ENGINE, BLOCK HEATER, ATTACHMENT CONTROL KIT, REAR VIEW CAMERA, APPROXIMATELY 300 HRS, UNIT# 4310............................................................CALL FOR PRICE

SIMEX PLC-24 24" WIDE COLD PLANER WITH REVERSIBLE DISCHARGE CONVEYOR: CUTTS UP TO 7" DEEP, 16 DEGREE TILT, 27-40GPM DISSCHARGE CONVEYOR HELPS LEAVE A CLEANER CUT, WINDROWS MATERIAL BEYOND THE CARRIER FOR EASIER CLEAN UP, UNIT# AT4540...... $25,400

2020 BOBCAT T740: WITH CAB, HEAT & AIR EXCELLENT CONDITION, 1600 HOURS, HYDRAULIC COUPLER, 2 SPEED, UNIT# U5863................................................................$39,000

KOBELCO SK350LC-10, APPPROXIMATELY 2400 HOURS, 31.5” TRACK SHOES, 10’10” ARM, 2 WAY AUXILLIARY HYDRAULICS, HAND CONTROL PATTERN CHANGER, HEATED AIR RIDE SEAT, VERY GOOD CONDITION, UNIT# N3651................................................................$183,000

AG1359, ANACONDA J12 JAW CRUSHER: IS AN AGGRESSIVE & POWERFUL MOBILE JAW CRUSHER. WITH THE PROVEN ABILITY OF THE UNIVERSAL CRUSHERS JAW CHAMBER 28" X 44" WITHIN AN INNOVATIVE ANACONDA TRACKED SOLUTION........................CALL FOR PRICE

30”X50’ ELECTRIC RADIAL STACKERS: 5 IN STOCK..........................................CALL FOR PRICE

2020 KOBELCO SK210LC-10: 2 WAY AUX HYDRAULICS, 31.5” SHOES, PATTERN CHANGER, 850 HOURS, 1 OPERATOR. UNIT# U5865............................................................CALL FOR PRICE

MCLANAHAN 44” X 33’ FINE MATERIALS WASHER: IN STOCK & READY FOR IMMEDIATE DELIVERY, UNIT# AG1402....................................................................$94,500

BOMAG BW120SL-5: FOLDING ROPS, 47.2” WIDE DRUMS, 5511LBS. OPERATING WEIGHT, KUBOTA

24.8HP DIESEL, FRONT & REAR VIBRATORY, 4320 VPM, .020 IN AMPLITUDE, UNIT# N4538..$45,995

2023 ANACONDA TR100 TRACK CONVEYOR: 42”X100’ TRACK MOUNTED CONVEYOR, LESS THAN 500 HOURS, INCLUDES A WEIGHT SHARK BELT SCALE................................$CALL FOR PRICE

used PA140

Just in for Teardown, TL1225D

ML701857 telehandler, Machine had 3800 hours when torn down

This spring, when the application window for the federal Safe Streets and Roads for All program opened, it was considered by many to be tight.

Criteria for the DOT’s $1 billion grant program read that less consideration would be given to safety projects that reduce lane capacity for vehicles.

According to Streetsblog, in the past, the funds have gone to a mix of planning grants and hard infrastructure projects “aimed at saving lives.”

Historically, those projects include bike lanes, sidewalk expansions and road diets.

But the new grant criteria read that projects including infrastructure reducing lane capacity for vehicles would be viewed less favorably by the department.

Traffic reduction advocates fear the agency will drop road diets from its most critical safety program. In doing so, say advocates, the fed will forfeit one of its most important tools to save lives in and out of automobiles.

“Excess road capacity leads to excess speed,” Chris Forinash of design firm Nelson\Nygaard, told Streetsblog.

He believes the much-needed modernization of many roads must “include how we allocate our public right of way for maximum public benefit.”

Others are concerned that safety might take a backseat to maintaining space for cars no matter how busy the road. But road diet opponents believe traffic calming methods only serve to bog drivers down and can threaten the effectiveness of emergency vehicles.

For many years, the DOT has recognized road diets or road rebalancing as a way to save lives. With the design concept, corridors are reconfigured to make more room for bike lanes, sidewalks, bus lanes, train lines or other infrastructure.

The goal is to make more room for people outside cars and to encourage motorists beside them to slow down, said Streetsblog.

Road diets encourage people to leave their cars at home and streamline turning movements for drivers that frequently cause back-ups.

Streetsblog said studies show the concept can actually decrease congestion often without adding extra traffic to adjacent side streets.

“Studies show that converting a four-lane road to three lanes can cut crashes as much as 47 percent,” said the blog.

Simply narrowing existing lanes from a highway-style width of 12 ft. to a neighborhood-appropriate 9 ft. can cut crashes significantly, said Streetsblog.

These approaches can create room for other modes, linear parks, outdoor dining and retail, it said.

Road diets that reclaim a lot of lanes like highways-toboulevards conversions, even housing and businesses result.

Road diets are the redesign of road corridors to make room for bike lanes, sidewalks, bus lanes, train

or other infrastructure.

Orange County, Fla., rationalized the road diets by explaining that they are an effort to keep up with shifts in modes of transportation. The county’s busiest thoroughfares were developed back when cars ruled the road, the agency said.

“But in recent years, people have changed how they get around. Mass transit, bicycles, scooters and other micromobility devices have become more popular.”

State-of-the-art engineering down to the smallest detail. The new gen 8 mid size wheel loaders feature a dynamic travel drive for increased productivity a d improved fuel consumption. www.liebherr.com

MARYLAND from page 1

Maryland’s State Highway Administration (SHA) has determined to reduce congestion in this area and increase safety by taking on an ambitious revamping of the road system with a nearly $300 million project. The work is expected to be complete by fall 2028, weather permitting.

The project will include a new diamond interchange and five new bridges. The average daily traffic here is 66,000 vehicles with a large volume of trucks. Concrete General is the main contractor for the project.

Often projects like this are composed of many smaller units, each one tasked with improving traffic patterns, reducing overall congestion and providing greater safety for motorists and pedestrians.

The Route 4-Suitland Parkway project will include:

• rebuilding the on and off-ramps to Joint Base Andrews;

• building a new two-lane ramp over MD 4 to connect to northbound Route 4 and westbound Suitland Parkway;

• widening Route 4;

• reconfiguring Pennsylvania Avenue Service Road and Armstrong Lane;

• realigning Presidential Parkway with Suitland Parkway;

• building a new signalized intersection at Presidential Parkway and Central Park Drive, including new sidewalks; and

• adding a new shared-use path across Suitland Parkway bridge.

The project is supervised by Ryan Doran, acting assistant district engineer, construction of SHA’s District 3. Concrete General’s Mike Higgins provides direction for the Concrete General team. The project is 13 percent complete and has now started phase two of six phases of the work. Workers are relocating utilities, installing wick drains, placing roadway fill in the surcharge areas and driving the support piles for the proposed bridge over MD 4.

“Working closely to the base has added some challenges,”

see MARYLAND page 38

Caterpillar 528 Log Skidder, 1:50 scale - $110 Caterpillar D8N Track-Type Tractor, 1:50 scale - $110

Allis Chalmers Forty-Five Motor Grader,1:50 scale................................

Allis Chalmers TS300 Motor Scraper, 1:50 scale..................................$80

Bantam Lattice Truck Crane on White WC Carrier,1:50 scale..............$160

Bucyrus Erie 22B Dragline,1:50 scale....................................................

Bucyrus Erie 22B Cable Shovel,1:50 scale............................................$215

Bucyrus Erie 22B Cable Backhoe,1:50 scale..........................................$215

Case 580D Backhoe/Loader, 1:35 scale................................................$100

Case 580E Backhoe/Loader,1:35 scale....................................................$65

Case 580SR Backhoe/Loader,1:50 scale................................................$150

Case 850B Angle/Tilt Dozer,1:35 scale..................................................$100

Case 1845B Uni-Loader,1:35 scale..........................................................$35

Case DH4B Trencher,1:35 scale..............................................................$75

Case 9030B Excavator,1:50 scale............................................................$50

Caterpillar AP-1000 Asphalt Paver,1:50 scale......................................$100

Caterpillar C-591 Pipelayer,1:70 scale....................................................$70

Caterpillar CB534 Double Drum Roller, 1:50 scale................................$40

Caterpillar D3 Track-Type Tractor,1:50 scale........................................$110

Caterpillar D4E Track-Type Tractor, new color,1:50 scale......................$60

Caterpillar D4E Track-Type Tractor, old color,1:50 scale......................$60

Caterpillar D6H Track-Type Tractor,1:50 scale........................................$90

Caterpillar D9N Track-Type Tractor w/black Tracks,1:50 scale............$100

Caterpillar D9N Track-Type Tractor w/yellow Tracks,1:50 scale..........$100

Caterpillar D8L Track-Type Tractor,1:50 scale......................................$100

Caterpillar D7C Track-Type Tractor,1:50 scale......................................$110

Caterpillar D10 Track-Type Tractor w/ ripper,1:50 scale......................$100

Caterpillar D10N Track-Type Tractor,1:50 scale......................................$40

Caterpillar D11R Track-Type Tractor,1:50 scale......................................$75

Caterpillar 225 Excavator,1;70 scale........................................................

Caterpillar 225 Crane w/clamshell

Caterpillar 555D Log Skidder,1:50 scale..............................................

Caterpillar 631 Tilting Dumper,1:70

Caterpillar 773B Off-Highway Truck, 1:70 scale

825B

said Doran. “Before bringing in some of the cranes to the job, we had to get FAA clearance to make sure there would be no interference on the flights. However, we kept a steady flow of communication with Joint Base Andrews to get the waivers approved in an expedited manner and by doing so we were able to avoid any major delays.”

The cranes will be vital as the construction team assembles the five steel-girder bridges. The bridges will require approximately 2,200 tons of steel with sections of the bridges preassembled at the factory.

The construction team is taking extra steps to combat a relatively high water table in the area.

“We will install wick drains in several locations,” said Doran. “We will drill holes from 100 to 200 feet deep into the ground and then place our roadway fill on top of those surcharge areas until the final elevation is reached. The wick drains will enable us to draw out the water and build on a drier surface.”

The wick drains will use prefabricated geotextile filter wrapped strips to channel the water as it ascends to the surface.

“We will also be using lightweight permeable low density cellular concrete (PLDCC) in multiple areas to limit ground settlement,” said Doran. “This type of concrete is not frequently used on SHA projects, but we will be using it on this project because it is lighter in weight than normal concrete but still retains strength.”

The construction team will be using approximately 44,000 sq. yds. of concrete on the flyovers and 90,000 tons of asphalt for significant road construction.

In addition to the cranes, the construction team will be using paving machines, material transfer vehicles and rollers to produce a smooth highway and surface roads. The team also will use dozers, excavators and front-end loaders to prepare the ground for final construction.

The construction team will deliver significant savings by reusing material from a previous project that was halted because of utility conflicts.

“Concrete pipe and steel for bridges had already been delivered, so we are able to use that for our project,” said Doran.

The construction team will use message boards to com-

municate changing traffic patterns and establish work zone areas. However, the ramps and surface streets received special attention.

“We added a temporary turn signal on MD 4 southbound at Dower House Road to safely navigate onto the highway and will restripe certain roads so motorists could easily understand what is happening. We have also added stop signs, stop bars in the roadway and some temporary concrete barrier walls for worker safety. In addition, we have a robust community outreach program in place to inform the traveling public well in advance of the construction activity as well as changes to traffic patterns.”

As the project is finalized, Doran and his team expect to see smoother traffic through this critical juncture. “We are making it safer for commuters and eliminating congestion. It’s exciting to see that we will be making a difference.” CEG

(All photos courtesy of Maryland State Highway Administration.)

Baschmann Services, Inc. www.baschmann.com

1101 Maple Road Elma, NY 14059

716-219-7045

Drobach Equipment Rental www.drobach.com

2240 Route 22 E Union, NJ 07083

908-686-0018

Equipment East www.equipmenteast.com

61 Silva Lane Dracut, MA 01826 978-454-3320

196 Manley Street Brockton, MA 02301 508-484-5567

250 Washington Street Auburn, MA 01501 508-635-5058

Heavy Machines, Inc. www.heavymachinesinc.com

2401 Broadway, Bldg. #3 S. Portland, ME 04106 877-202-1275 207-550-0014

159 North Avenue Skowhegan, ME 04976 888-875-3954 207-858-0051

Jersey Rents www.jerseyrents.com

252 Atlantic City Blvd. Bayville, NJ 08721

732-606-1002

Hoffman Equipment www.hoffmanequip.com

300 South Randolphville Road Piscataway, NJ 08854 732-752-3600 1330 Hurffville Road Deptford, NJ 08096 856-227-6400

22 Peconic Ave. Medford, NY 11763 631-207-2900

1144 Zerega Ave. Bronx, NY 10462

718-822-1180

1440 Route 9W Marlboro, NY 12542 845-236-3000

120 Gordon Drive Lionville, PA 19341 610-363-9200

During World of Asphalt 2025, Joseph Vögele AG presented the new VR 500 with rear-mounted extensions. It has been redesigned from the ground up and offers paving widths between 8-ft. 4-in. and 20-ft. 12-in.

For the first time, Vögele presented a VR 500 screed for the 8-ft. class pavers. The new VR 500 is equipped with extending units that can be sloped by up to 10 percent and is precisely tailored to the paving requirements of the North American market.

In combination with the SUPER 1700-3i and SUPER 1703-3i pavers, it achieves pave widths of between 8-ft. 4-in. and 20-ft. 12-in. This makes it particularly suitable for the construction of roadways and for medium to large paving jobs. In conjunction with the vibration compaction unit, it achieves optimum smoothness and pre-compaction, according to Vögele.

Vögele has developed the screed from a clean-sheet perspective: It has a low design, is extremely compact and offers an optimum view of the entire auger tunnel. The two-stage telescopic guidance system enables particularly smooth and precise width adjustment. The robust center joint for hydraulic adjustment of the crown also ensures a high level of stability, even with larger pave widths, according to Vögele.

The height of the VR 500’s end gates can be adjusted hydraulically at the touch of a button. Another feature of the new VR 500 is the adjustable edge which allows the operator to continuously adjust the angle of the edge from 0 degrees to 90 degrees.

The electric screed heating also ensures high paving quality, bringing the VR 500 up to temperature quickly and evenly. All components that come into contact with the material are constantly heated, which ensures a homogeneous surface structure.

The additional heating integrated into the leading edge of the screed plate prevents buildup and results in a superior finish texture. In addition, smart generator management reduces energy requirements and fuel consumption during operation, according to Vögele.

The new VR 500 is precisely tailored to the needs of users. The ErgoPlus 3 operating concept provides a clear layout of all functions and symbols. Operators can define, view and change all relevant paving parameters, including the Niveltronic plus system for automated grade and slope control, at the screed operating consoles.

Vögele introduced the new VR 500 for the SUPER 1700-3i and SUPER 1703-3i road pavers.

The screed width be conveniently adjusted with the SmartWheel. In addition to the screed control consoles, Vögele provide users with two remote control units featuring practical magnetic mountings, so they can operate the key screed functions from the optimal location at all times, according to Vögele.

39 Jersey Street West Babylon, NY 11704

631/643-2605 www.allislandequipment.com

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave.

S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38

Lumberton, NJ 08048

609/267-2020 www.jesco.us

1401 Hookset Rd. Hooksett, NH 03106 603/644-8787 ambroseequipment.com

1440 Route 9W Marlboro, NY 12542

845/236-3000 www.hoffmanequip.com

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492 203/265-6781

17 Eagle Road Danbury, CT 06810 203/775-1203

80 Pratt Rd. Plainfield, CT 06374 860/546-4808 www.wiclark.com

2350 Greystone Ct. Rockville, VA 23146 804/359-4048 www.richmondmachinery.com

1001 Lehigh Station Road Henrietta, NY 14467 585/334-3867

5035 Genesee Street Buffalo, NY 14225 716/681-7100

8194 State Route 415 Campbell, NY 14821 607/739-8741 monroetractor.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455

Wilkes-Barre, PA 600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA

796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA 135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057 800/692-7600

Ebensburg, PA 2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY

3 Industry Drive Waterford, NY 12188 518/357-2200

Syracuse, NY 6018 Drott Drive East Syracuse, NY 13057 800/368-6455

www.stephensonequipment.com

Northern, VA (DC) 8192 Euclid Court Manassas Park, VA 20111 703/330-5579

Hagerstown, MD 20332 Leitersburg Pike Hagerstown, MD 21742 301/733-7414

Baltimore, MD

1109 Middle River Rd Middle River, MD 21220 800/633-5077

Volvo Construction Equipment is enhancing its soil and asphalt compaction product lines with upgrades to multiple models and a forthcoming electric model.

The latest machines were on display at World of Asphalt/AGG1 in St. Louis.

Updates to the SD75 and SD45 soil compactors and the PT125 pneumatic tire roller include features that enhance safety, serviceability and the user interface for operators, according to Volvo. Show attendees also got the first look at a DD15 electric asphalt compactor.

At a press conference, Scott Young, president of Region North America, said that the upgrades demonstrate Volvo’s ongoing commitment to offering a diverse product range for those in the aggregates and roadbuilding industries.

“We’ve been designing, refining and manufacturing compactors in Shippensburg for decades,” said Young. “So we understand what helps contractors get their jobs done right, as safely and efficiently as possible. These machines are a testament to that.”

The SD45, SD75 and PT125 are now equipped for over-the-air software updates as they become available. Their wiring design has been optimized for commonality, cost-effectiveness and ease of service, according to Volvo.

At a press conference, Scott Young, president of Region North America, said that the upgrades demonstrate Volvo’s ongoing commitment to offering a diverse product range for those in the aggregates and roadbuilding industries.

Updates to the SD75 and SD45 soil compactors and the PT125 pneumatic tire roller include features that enhance safety, serviceability and the user interface for operators, according to Volvo.

To maximize uptime, Volvo doubled the diesel particulate filter (DPF) replacement intervals on these machines from 3,000 to 6,000 hours.

LED work lights and beacons replace halogen lights and telematics systems now include GSM/GPS and SATCOM antennas for optimized machine connectivity.

Operators will appreciate several human-machine interface (HMI) upgrades, including new software, advanced keypads, a USB charging port and a 5-in. full-color LCD display — the same display available on the Volvo compact double drum compactor and excavator models. Additional HMI improvements include auto idle and auto engine shutdown to reduce fuel consumption and an indicator for remaining hours of fuel.

The HMI on the updated SD75 now includes a fan reverse menu selection and an optional five-frequency selection feature that allows the operator to select by surface type rather than frequency number.

The upgraded PT125 also has a new drive motor with an integrated speed sensor for optimal performance.

The 1.5-ton DD15 Electric asphalt compactor is a double drum machine with features similar to the 2.5-ton DD25 Electric. Its size fits small-scale jobs like parking lots, driveways and municipal work.

The DD15 Electric can fully charge in three-and-a-half hours with a 240-volt level two charging setup or in 12 hours with a 120-volt Level 1 outlet. Customers will get a full day’s work from the compactor on a single charge with typical light usage, especially considering that electric machines don’t accumulate idle hours like diesel machines do.

For more information, visit volvoce.com/united-states/ en-us/products/compactors/.

LESLIE EQUIPMENT COMPANY www.lec1.com

6248 Webster Road Cowen, WV 26206 304/226-3299

2098 Lillian Lane Pleasant Valley, WV 26554 304/534-5454

19 Goff Crossing Drive Cross Lanes, WV 25313 304/204-1818

80 John Deere Lane Norton, WV 26285 304/636-6421

www.monroetractor.com

1001 Lehigh Station Road Henrietta, NY 14467 585/334-3867

5035 Genesee Street Buffalo, NY 14225 716/681-7100

7300 Eastman Road N. Syracuse, NY 13212 315/452-0000

8194 State Route 415 Campbell, NY 14821 607/739-8741

6 Equipment Drive Binghamton, NY 13904 607/754-6570

GROFF TRACTOR & EQUIPMENT www.grofftractor.com

800-33-GROFF 800-33-(47633)

136 Clifftop Drive Beaver, WV 25813-1525 304/255-1525 6779 Carlisle Pike Mechanicsburg, PA 17050

Rolling Ridge Drive Bellefonte, PA 16823 963 South Center Ave

Stanton, PA 15672 179 Perry HWY Hamony, PA 16037 2550 East Cumberland St.

www.unitedequip.com

80 Southbridge Rd. • Route 20 North Oxford, MA 01537 508/987-8786

2397 GAR Highway • Rte 6 & 136 North Swansea, MA 02777 508/379-9810

88 Camelot Drive • Unit 42 Plymouth, MA 02360 508/830-9997

1620 Page Blvd Springfield, MA 01104 413/543-5595

4 Sterling Road North Billerica, MA 01862 978/667-4345

34 Page Road West Hermon, ME 04401 207/947-6786

106 North Street Houlton, ME 04730

207/532-6517

1505 Caribou Road New Canada, ME 04743 207/834-6701

396 County Road Westbrook, ME 04092 207/773-3777

98 Sheep Davis Road Pembroke, NH 03275 603/225-2769

300 Clinton Street Springfield, VT 05156 802/885-6840

ALL ISLAND EQUIPMENT

39 Jersey Street West Babylon, NY 11704

631/643-2605

allislandequipment.com

AMBROSE EQUIPMENT / ALTA EQUIPMENT

1401 Hooksett Rd. Hooksett, NH 03106

603/644-8787 ambroseequipment.com

HOFFMAN EQUIPMENT COMPANY

1440 Route 9W Marlboro, NY 12542

845/236-3000 www.hoffmanequip.com

JESCO, Inc.

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave. S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38 Lumberton, NJ 08048

609/267-2020 www.jesco.us

MONROE TRACTOR

1001 Lehigh Station Rd. Henrietta, NY 14467

585/334-3867

5035 Genesee Street Buffalo, NY 14225

716/681-7100

8194 State Route 415 Campbell, NY 14821

607/739-8741

www.monroetractor.com

RICHMOND MACHINERY

2350 Greystone Ct. Rockville, VA 23146

804/359-4048 www.richmondmachinery.com

W.I. CLARK COMPANY

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492

203/265-6781 17 Eagle Road Danbury, CT 06810

203/775-1203

80 Pratt Rd. Plainfield, CT 06374

860/546-4808 www.wiclark.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455

Wilkes-Barre, PA

600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA

796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA

135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057

800/692-7600

Ebensburg, PA

2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY

3 Industry Drive Waterford, NY 12188 518/357-2200

Syracuse, NY

6018 Drott Drive East Syracuse, NY 13057

800/368-6455

Northern, VA (DC)

8192 Euclid Court Manassas Park, VA 20111

703/330-5579

Hagerstown, MD 20332 Leitersburg Pike Hagerstown, MD 21742

301/733-7414

Baltimore, MD

1109 Middle River Rd Middle River, MD 21220 800/633-5077

CM Labs Simulations announced the launch of the Intellia Single Drum Roller Simulator Training Pack.

Designed to equip new operators with essential skills, the simulator training pack integrates with CM Labs’ Intellia training platform and joins a full equipment catalog — including training packs for motor graders, dozers and excavators — for a complete training solution for operators of all levels.

Built by subject matter experts and designed to address the growing labor shortage, the new training solution delivers a highly realistic training experience tailored to beginners with no prior experience operating heavy equipment.

As the most beginner-friendly training pack to date, the Single Drum Roller simulator training pack features a comprehensive nine-exercise curriculum designed to build a strong foundation in operating heavy equipment. With the training pack, trainees learn the foundational lessons of turning on, shutting down and operating the roller, as well as more advanced lessons such as compacting dirt in a J pattern, compacting in a Y pattern and how vibration settings affect operations, according to CM Labs.

“Because rollers are often the first piece of heavy equipment operators learn, we wanted to design a training solution that starts with the very basics of operation,” said Alan Limoges, manager of product growth and

partnerships. “Even if a trainee has never operated heavy equipment before, our roller training pack can meet them where they are and bring them up to proficiency quickly.”

With the Intellia Single Drum Roller Simulator Training Pack, trainees and instructors benefit from the following:

Detailed Metrics: Trainers gain access to data-driven insights that are impossible to measure in live environments, providing enhanced training effectiveness and skills assessment.

A Comprehensive Training Approach: Through dedicated exercises, the training pack introduces new operators to the fundamentals of articulated machinery, helping them master the complexities of roller operation in a risk-free environment.

Sandbox Modes for Custom Training: With two sandbox exercises — an open space and an enclosed environment — trainers have the flexibility to conduct training sessions that meet their specific needs.

Advanced Learning Features: The inclusion of an overhead view, as well as instant playback capabilities, allows instructors and trainees to analyze performance and improve learning outcomes.

Intellia Integration: The training pack is a fully integrated solution that works seamlessly within the Intellia ecosystem and is compatible with CM Labs’ full suite of Intellia training management and instructor support tools.

2026

TMA2

6.7L Cummins, Allison Automatic AIR Brakes, NEW Scorpion MASH TMA2, 15-Light Arrowboard, Light Kit. Road Work Signage. $147,500 EA

2026 Freightliner M2 18’ MAN POD STAKE TMA2

250HP 6.7L Cummins, Allison Automatic w/ AIR Brakes, NEW Scorpion MASH TMA2, Vertical Lift Arrowboard, LED Light Kit. Road Work Signage. $152,500 EA

Leica Geosystems and Dynapac announced the compatibility of auto-steering and screed edge control features on Dynapac asphalt pavers with the Leica iCON pave solution.

This solution will be available on the Dynapac SD25 and XD25 highway paver series, a line of paving machines set to debut at bauma.

This partnership aims to enhance the precision and efficiency of asphalt paving operations by combining Dynapac’s paving machinery with Leica Geosystems’ machine control technology.

In addition, the integration of new auto-steering and edge control features will enable pavers to follow stringline design models with millimeter accuracy, eliminating the need for traditional strings-and-pins methods and reducing costs, while improving productivity, according to the companies.

“Our collaboration with Leica Geosystems marks a significant milestone in advancing paving technology and, as a result, providing even more functionality to our customers,” said Soenke Demuth, head of global product management paving of Dynapac.

With the Leica iCON pave machine control system, operators benefit from automated guidance and precise screed width adjustments based on a digital stringing design, according to the companies. The system enhances site sustainability by optimizing material usage, minimizing waste and ensuring more accurate material estimation throughout the paving process. In addition, it enhances safety by eliminat-

ing physical hazards such as stringlines, pins and other marking materials from the job site.

“As infrastructure projects continue to expand globally, meeting the high standards of modern construction requires even greater precision and efficiency in asphalt paving,” said Neil Williams, president, machine control division of Leica Geosystems.

“Manually steering a paver while ensuring the screed maintains its optimal width demands constant adjustments to adapt to varying site conditions and maintain consistency. By introducing automated steering and screed control, we alleviate this burden on operators and enhance their ability to deliver superior paving results with greater ease and reliability.”

For more information, visit leica-geosystems.com.

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

www.traceyroad.com 6803 Manlius Center Road East Syracuse, NY 13057 315-437-1471 • 800-872-2390

Albany, NY 518-438-1100 866-740-8853 Kirkwood, NY 607-775-5010 800-370-9488

Queensbury, NY 518-793-9688 833-817-2917

Henrietta, NY 585-334-5120 866-950-6210

Utica, NY 315-765-8746 800-872-2390

Adams Center, NY 315-788-0200 888-335-0200

Wilkes-Barre Township, PA 570-410-2123 • 800-872-2390

AdClosingDate May21,2025

PublishingDate June4,2025

AdClosingDate June19,2025

PublishingDate July2,2025

AdClosingDate July17,2025

PublishingDate July 30,2025

AdClosingDate August14,2025

PublishingDate August272025

AdClosingDate September11,2025

PublishingDate September24,2025

Murrysville, PA

724-327-1300 Erie, PA

814-898-3388 Somerset, PA 814-445-7915

Clearfield, PA 814-765-1611

Mansfield, PA 570-662-7171 Kane, PA 814-778-5250

Mt. Pleasant, PA 724-696-4080 Watsontown, PA 570-538-2551

Ephrata, PA 717-859-4905 State College, PA 814-237-8338 Harrisburg, PA 717-564-2121 Pittston, PA 800-922-8630

Bridgeport, WV 304-842-2222

Shinnston, WV 304-592-5855 Bellefonte, PA 814-353-2800 Blawnox, PA 412-828-7810 Camp Hill, PA 717-730-7435 Cranberry Twp, PA 724-776-7660

hopenn.com

Ebensburg, PA 814-471-1710 Indiana, PA 724-463-8743

Barnesville, PA 570-773-1720 Howard, PA 814-355-3500

Hunker, PA 724-861-6080

Eighty Four, PA 724-325-9297

Piscataway, NJ 732-885-5555 Hammonton, NJ 609-561-0308

Bensalem, PA 215-639-4300 Whitehall, PA 610-261-4887 Bear, DE 302-328-4131

Poughkeepsie, NY 845-452-1200 Bronx, NY 718-863-3800 Bloomingburg, NY 845-733-6400

Richmond, VT 802-434-4228

Londonderry, NH 603-665-4500

Brewer, ME 207-989-1890

Scarborough, ME 207-883-9586

Binghamton, NY

607-772-6500

Clifton Park, NY 518-877-8000 Syracuse, NY 315-476-9981