By Cindy Riley CEG CORRESPONDENT

Although still in the first phase of construction, the Improve I-70 Columbia to Kingdom City project continues making progress, as crews work to update the I-70 corridor in Missouri. The multi-million undertaking is one of several in the $2.8 billion Improve I-70 Program that will widen and modernize I-70 across the state from Blue Springs to Wentzville.

“The construction of I-70 began in 1956, making it the oldest interstate in the nation,” said Nicole Samer, Improve I-70: Columbia to Kingdom City deputy director. “The Missouri Department of Transportation [MoDOT] has been studying the existing I-70 corridor since the 1990s and is working to complete all required environmental re-evaluations. The Columbia to Kingdom City section was the first to complete its environmental re-evaluation, making it the ideal starting point for our program.”

see MODOT page 54

By Lucy Perry CEG CORRESPONDENT

The road and bridge construction sector observed the National Work Zone Awareness Week in April, recognizing the critical need to keep drivers, the public and construction workers safe in road construction zones.

In support of the industry, several states have announced the integration of smart technology into road and bridge projects to make sure everyone remains safe while navigating and working in these areas.

see ITS page 60

Connected work zone devices transmit real-time data that allows drivers to navigate apps that provide audio alerts as they near work zones.

Stoops Freightliner-Western Star dealerships took big steps forward with an aggressive construction plan aimed at improving customer experience, facilities and development opportunities.

Live equipment demonstrations and hands-on experiences gave attendees an up-close look at the company’s extensive fleet, guided by knowledgeable factory representatives and the expert Tri-State Bobcat team.

Magni Telescopic Handlers announced that RP Rents of Naperville, Ill., is the first United States dealer to add the all-new Magni TH 6.19 telehandler to its rental fleet.

This year, the open house featured 14 vendors, including RMS Hydraulic Solutions and Ruffridge Johnson, both of which also had booths showcasing their company’s full offerings and services.

M&D Truck and Equipment of Monroe, Wis., has added the Thunder Creek lineup of field fueling and service solutions to its product offering of construction, agricultural, turf and support equipment.

26 BROOKS TRACTOR HOSTS TECH OPEN HOUSE AT SUN PRAIRIE HQ

Customers visited Brooks Tractor’s headquarters in Sun Prairie, Wis., as the company hosted the last of its Technology Open Houses of the spring, showcasing the latest technology available on new John Deere machines.

28

Fabick Cat hosted its annual Open House event in Fenton, Mo., on May 2. Held at headquarters (One Fabick Dr., Fenton, MO 63026), the event also included the first local phase of Caterpillar’s Global Operator Challenge.

32 HARDINGS INC. TO OFFER HYUNDAI EQUIPMENT AT NEW LOCATION

Representatives of HD Hyundai Construction Equipment North America recently joined Hardings Inc. for the grand opening of its new location in Elwood, Ill., which expands its sales and service area for Hyundai construction equipment.

55 SMALL-TOWN ROOTS TO GLOBAL IMPACT: STELLAR CELEBRATES 35 YEARS

Over the past three and a half decades, Stellar has grown from a small-town operation in Garner, Iowa, to a global force in the construction, waste and work truck industries.

58 LEER GROUP STARTS U.S. PRODUCTION OF SNUGTOP PRODUCTS

The celebration at LEER’s Elkhart facility marks the full return of United States’ production for SNUGTOP, which manufactures a lineup of more than 400 truck cap products for a growing number of automotive brands.

62 ROAD MACHINERY & SUPPLIES OPENS NEW SIOUX CITY BRANCH

To celebrate the new facility in Sioux City, Iowa, RMS held a ribbon-cutting ceremony on Feb. 18 and an Open House for customers, vendors and employees on April 24.

64 RDO EQUIPMENT’S MANKATO, MINN. TEAM CELEBRATES FACILITY EXPANSION

Dan Lingen, RDO Mankato’s general manager, marked the completion of Mankato’s heavy equipment store and service shop expansion to meet area contractors’ needs as they continue to build their communities.

For half a century, Isuzu industrial engines have powered productivity across the United States. Isuzu diesel engines are known throughout the off-road equipment market for their reputation for reliability, durability and long-term value.

2021 Case TV450B, S/N JAFTV450KLM487291, 541 Hrs, CAB/AIR/HEAT, 2 SPEED, HYDRAULIC COUPLER, 84" GP BUCKET, HIGH FLOW PERFROMACE PACKAGE, SERVICED AND READY TO GO, UNIT WILL HAVE A NEW DOOR

$69,900

2022 Case SV280B, 171 Hours, S/N JAFSV280HMM403668, CAB/AIR/HEAT, HYDRAULIC COUPLER, 72" GP BUCKET, 2 SPEED, RADIO, EXCELLENT CONDITION FULL MACHINE WARRANTY UNTIL 11-22-24 $47,000

Mike Garrard • (630) 492-9115 Bolingbrook, IL Contact us at Used@McCannOnline.com

our complete Used & “Like New” inventory at McCannOnline.com

2017 Case 621G, S/N NGF240021, 13131 Hours, Cab/Air, Ride Control, ACS Coupler, 2.5 Yard GP Bucket, Forks, Z Bar, Heavy Counterweight, Limited Slip Diffs, Cold Weather Package

$94,000

2022 Case 321F, S/N NNHP04331, 241 Hours, CAB/AIR/HEAT, HIGH SPEED TRANSMISSION, SKID STEER STYLE COUPLER, 1.7 cu yd BUCKET, LIMITED SLIP DIFFERENTIAL, THIRD VALVE HYDRAULICS TIRES LIKE NEW, PREMIUM CAB

2023 Case TV370, S/N 2023 Case TR370B, 176 Hrs, CAB/AIR/HEAT, HYDRAULIC COUPLER, 84" GP BUCKET, DELUXE CAB, PREMIUM DISPLAY PANEL, GOOD TRACKS

$82,500

$72,500

2019 Case Cx130D, S/N DAC130K7NKS7D1558, 358 Hours, CAB/AIR/HEAT, HYDRAULIC COUPLER, 18" BUCKET, AUX HYDRAULICS

$109,900

2023 Case TR270B, S/N JAFTR270LNM421971, 281 Hours, CAB/AIR/HEAT, E-H CONTROLS, HYDRAULIC COUPLER, 78" GP BUCKET, RIDE CONTROL, SELF LEVEL, HIGH FLOW HYDRAULICS, REARVIEW CAMERA, PREMIUM DISPLAY MODULE, FULL MACHINE WARRANTY UNTIL 1-30-25, JUST SERVICED READY TO GO $54,900

2018 Case CX245DSR, S/N NJS7K1152, 1306 Hours, Cab/Air, Kent Coupler, Aux Hydraulics, No Bucket, Bucket available at additional charge, Rental Fleet Roll Out $193,500

McCann Rents a full line of heavy and light construction equipment. Call us today to supply your next rental.

THE BEST PARTS ALL IN ONE PLACE B N HE BE O T PAART EST P TS

Roadtec RX100e - ‘18, approx. 500 hrs. Includes grade controls $186,000 Sandvik CJ412 - ‘14, approx. 1400 hrs. Mobile jaw plant $795,600

Sakai R2H-4 - ’19, approx. 900 hrs. 83” triple drum static $93,800

ROADTEC RP195 PAVER - ’08, approx. 8890 hrs. Carlson EZIV 10 screed, Moba grade & slope controls ....................................$37,500

Liebherr A904C Wheeled Excavator - ‘16, approx 550 Hrs, 2-piece boom, pin grabber coupler, aux hyd

$P.O.R.

Liebherr R946 - ‘14, approx.. 800 Hrs, 12’6” stick, QC66 coupler, aux. hyd

$P.O.R.

- ‘16, 565 Hrs, 24” Drum, Load Out Conveyor $174,000

Roadtec RX-300 - ’18, approx. 600 hrs. 4’ drum $325,000

Roadtec RX-100 - ‘18 w/475 Hrs, 20” drum, #C001554 $185,900

ASTEC GT104 - ‘17, 325 Hrs, 5.25cyd Hopper, 4’x9’ Top & Bottom Screens, #C001154

KPI FT2650 – ’19, approx. 1800 hrs. Tracked jaw crusher

$161,700

$645,000

Mauldin 1560 paver – ’22, approx. 600hrs. 8-14’, electric screed heat $119,800

P.O.R. items may be on rent causing pricing and hours to vary.

ASTEC GT205MF, (’18), 3,296 Hrs, 5 x 20 top deck, 5x18 bottom deck, 8 cu. yd. hopper, 5' wide double deck multi-frequency screen w/hydraulic vibrators, #C005896 $229,900

HAUL TRUCKS

LIEBHERR TA230 LITRONIC, (‘23), 361 Hrs, #C005550 $CALL

LIEBHERR TA230 LITRONIC, (‘23), 367 Hrs, #C005511 $CALL

LOADERS AND EXCAVATORS:

$370,000

HAZEMAG APPH1515QL, (’93), Primary Impactor Portable Plant, 400HP electric crusher drive, 15 cu. yd. hopper, #C005559

HAZEMAG APS1315, (’10), 7'x20' triple deck screen, #C005792

$362,500

SIMPLICITY 6203, (’96), Dual Portable Screening Plant, 6’ x 16’ Triple Deck Primary Screen, 6’ x 20’ Triple Deck Secondary Screen, #4873

$295,000

LIEBHERR L550 XPOWER, (’17), 2,722 Hrs, innovative machine concept which combines performance, fuel efficiency, robustness and comfort. Power split driveline, #C003118 $146,499

LIEBHERR R920 COMPACT LITRONIC, (‘18), 667 Hrs, w/Werk-brau pin grabber coupler, medium & high pressure aux. hydraulic circuits, pattern changer, #C003330 $CALL

$32,500

SUPERIOR BROOM SM80K, (‘17) 2,250 Hrs, Enclosed Rops, AC, #C006107

SUPERIOR BROOM SM80K, (‘17) 2,090 Hrs, Enclosed Rops, AC, #C006106 $32,500

GROVE GHC85, (’23), 164 Hrs, #C005208 $CALL

LIEBHERR R934 LITRONIC, (‘23), 485 Hrs, The new R934 weighs approx. 35 tons, completely updated design is characteristic of the new range of "generation 8" machines, #C005399 $CALL

$1,099,000

GROVE GHC130, (’19), 932 Hrs, 130-ton lift capacity, #C004141

LIEBHERR R936 COMPACT LITRONIC, (‘18), 1,042 Hrs, Convenient and service-friendly, the R 936 Compact makes for safe working. With its tight slewing radius, this machine is especially well suited to urban applications, #C003377$CALL

$885,850

GROVE GRT880, (’22), 807 Hrs, 80-ton lift capacity, #C005002

GROVE GRT880, (’18), 2,476 Hrs, 80-ton lift capacity, #C004982

$628,750

LIEBHERR R956 LITRONIC, (‘22), 1,800 Hrs, 35' boom and 21' stick, #C004867 $CALL SAKAI SV544TB, (‘23), 2 Hrs, #C005470 $CALL

The new Stoops Freightliner-Western Star and Stoops Trailers regional headquarters

Ind., is a two-story, 215,000-sq.-ft. multiplex situated on 40 acres on the south side of

Stoops Freightliner-Western Star dealerships took big steps forward with an aggressive construction plan aimed at improving customer experience, facilities and development opportunities, including increasing employment opportunities and positively impacting the environment with a focus on energy efficiency.

The new Stoops Freightliner-Western Star and Stoops Trailers regional headquarters in Indianapolis is a two-story, 215,000-sq.-ft. multiplex situated on 40 acres on the south side of Indianapolis. The facility opened May 19, 2025, and a grand opening celebration is scheduled for June 19, 2025.

Halstead Architects designed the new headquarters, doubling the service capacity with 60 service bays that all have access to a 5-ton crane. The parts department is doubling its capacity, too, and will have a wider variety of parts with a drive-up will call, after-hours parts and a full set of amenities.

The new facility will feature a pet-friendly lounge, a dog park outside, a customer lounge with theater-style seating and a hush office. Business offices, advanced repair and maintenance bays, two expansive parts warehouses, training rooms and a dual-level parking garage were included in the design.

• Doubling of truck service bays from 30 to 60 bays — all bays will have full-service capabilities to handle all repair work.

• Eight drive-in, service department write-

up/check-in bays.

• Doubling the number of customer service stations in the parts department to expedite the throughput process.

• Tractor-trailer parking for parts retail customers is increasing from five to nine spots.

• An enhanced driver’s lounge, with the addition of theater-style seating, expanded restroom/shower facilities and a pet lounge where animals can be kenneled.

• The inclusion of an outdoor pet park. The company plans to increase staff and allow new opportunities for existing employees. New hires include diesel and maintenance technicians, body shop and trailer technicians, office administration, sales, parts and warehouse personnel, marketing coordinators, database and IT administrators, as well as other positions.

“We are excited about investing and expanding our current operations in Indianapolis,” said Brian McCoy, president of Stoops Freightliner–Western Star. “This investment is focused on giving our customers a best-in- class experience. The new facilities will provide even more capacity to train and mentor our employees. We anticipate adding 50 jobs and will have expanded employment opportunities. This state-of-theart corporate building and dealership will reinvigorate this side of Indianapolis, and we are excited about the future.”

For more information, visit truckcountry.com, mccoycf.com and foodliner.com.

JD 50G, A/C, Hyd Thumb, 5’7” Long Arm, Blade, Aux, #292872 ......................................$46,000

JD 300G, A/C, Hyd Thumb, 12’4” Arm, 32” Pads, Aux, #291372 ......................$215,000

JD 331G, A/C, Hi Flow Aux, 2 Speed, Ride Control, #262952 .. $66,000

JD 850K, A/C, LGP, 36” Pads, 6 Way 168” Blade, Trimble Ready, #292590 $175,000

JD 130G, A/C, Hyd Thumb, Aux, 9’11” Stick, 24” Shoes, #261469 ....................................$119,000

CAT 328D LCR, A/C, 32” Pads, Aux, Long Arm, # 291452 ......................................$64,000

JD 550K, A/C, XLT 18” Pads, 6 Way 105” Blade, 4th Function Aux, #262480 $109,000

JD 135G, A/C, 9’11” Arm, 24” Shoes, Reduced Tail Swing, #249203 ........................$87,000

JD 350G, A/C, 72’ Long Reach, Rev Fan, 32” Pads, 60” Bkt, #261824 ......................$139,000

JD 650K, A/C, LGP, 28” Pads, 6 Way 128” Blade, Rev Fan, IGC, #262371 $116,000

JD 950K, A/C, LGP 36” Pads, 6 Way 184” Blade, Trimble Ready, #250252 $418,000

JD 444K, A/C, JRB Coupler, Ride Control, #262773 ..$78,000

JD 210G, A/C, Hyd Thumb, Coupler, 9’7” Arm, Rev Fan, #261276 ......................$127,500

Volvo EC240BLR, A/C, 60’ Long Reach, 60” Ditch Bucket, #292240 ........................$84,000

JD 700K, A/C, LGP, 36” Pads, 6 Way 132” Blade, Rev Fan, #291338 $158,000 715-752-8112

JD 544K-II, A/C, Rev Fan, 20.5 Tires, Air Seat, GP Bucket, #262551 $129,000

JD 245G, A/C, Aux Hydraulics, 9’7” Arm, 32” Shoes, Air Seat, #262242 ......................$199,000

JD 317G, A/C, Joystick, Air Ride, PQT, Aux, #291038 ......................................$46,000

JD 750K, Cab, A/C, 34” Pads, Smartgrade, LGP, 6 Way 156” Blade, #251152 $179,000

JD 844K, A/C, 29.5 Tires, Scales, 2 Lever, 8 YD BKT, #261515 $229,000

Tri-State Bobcat, a familyowned and operated business, recently hosted two open house events, drawing more than 400 attendees between both locations.

The first event kicked off in Hudson, Wis., on April 29, 2025, followed by a second in St. Croix Falls, Wis., on May 2, 2025. Guests enjoyed a lively atmosphere complete with a complimentary barbecue lunch; exclusive event-only discounts on equipment and parts; and exciting door prizes.

Live equipment demonstrations and hands-on experiences gave

attendees an up-close look at the company’s extensive fleet, guided by knowledgeable factory representatives and the expert Tri-State Bobcat team.

Event giveaways included:

• six EGO trimmers

• two Toro blowers

• two STIHL chainsaws

• one RedMax blower

• six Bobcat sweatshirts

“We extend our heartfelt thanks to everyone who joined us and helped make these events a resounding success,” said Matt Courts, director of sales. “We’re already looking forward to future opportunities to con-

nect, celebrate and serve our incredible customers and community.”

Tri-State Bobcat has been a trusted name in equipment sales and rentals since 1983. With four convenient locations across Minnesota and Wisconsin, the company serves a wide array of industries, including construction, landscaping, agriculture, tree care, property maintenance and more.

For more information, visit tristatebobcat.com. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide, except where noted. All Rights Reserved.)

Attendees had an up-close look at Tri-State Bobcat’s extensive fleet, guided by knowledgeable factory representatives and the expert Tri-State Bobcat team.

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR $195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires . . . . . .$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote $4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$21,500 Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

$49,500 IR 185’s, JD diesels

CALL

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready $224,500

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR $179,000

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$122,500

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent From $5,200 Case 580L Rubber Tire Loader Backhoe, 1997, OROPS, std stick, 24" bkt

$24,500 (2) Balderson Broom Attachment for Cat IT Machines, 8' wide, good condition $4,000 Ea. NUMEROUS Rivinius R600’s, 10’ Wide, Mount on Dozer Blade

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

$72,500

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

$229,500

Over 100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent $4,000 Others Available Call Prices Are Negotiable - At Your Inspection

$152,500

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

Magni Telescopic Handlers announced that RP Rents of Naperville, Ill., is the first United States dealer to add the allnew Magni TH 6.19 telehandler to its rental fleet.

“RP Rents’ early move to bring the TH 6.19 to Chicago contractors shows exactly why they’re a leader in their market,” said Matt Lyons, chief sales officer of Magni America. “Their customers will be the first to experience the compact power, precision and reliability that only Magni can deliver.”

Compact, powerful and built for the toughest jobs, according to Magni, the TH 6.19 is a true game-changer for contractors needing serious performance in tight spaces.

With a 6,600 lb. maximum lift capacity, 19 ft. of reach and Magni’s advanced safety technology, the TH 6.19 is built to work smarter — and safer — on today’s demanding jobsites.

“We’re excited to welcome the Magni TH6.19 to our expanding fleet of Magni telehandlers, said Brian Scalet, director of sales of RP Rents. “Customers have been impressed by the spacious cab, 6,600 pounds lifting capacity and the user-friendly LMI display, making operation both efficient and intuitive. This is another step forward in delivering the best equipment for every job.”

RP Rents is fully trained on Magni's complete lineup, ensuring outstanding support and service for every machine in their fleet, according to the company.

For more information, call 800/732-2490 or visit gorprents.com.

The TH 6.19 is now available to rental companies across the United States. For more information, call 908/280-8899 or visit magnith.com.

(L-R) are Laura DeGross, territory manager (Savage heavy); DaleLyn Means, sales coordinator; Sara Dickinson, sales coordinator (Savage heavy); Sarah Bute, RMS Rentals rental coordinator; Larissa Indrebo, assistant rentals manager; Malia Oesterreich, RMS Rentals territory manager; Charlize Bistodeau, rental coordinator (Savage heavy); Justina Soller, rental manager (Savage heavy); Abby Sill, vice president of employee experience and marketing; Heather Jensen, RMS Rentals inside sales coordinator; and Jessica Tass, communications and brand manager.

RMS Rentals hosted its annual Open House on April 30, at its Savage, Minn., location. Customers, vendors and employees attended the event.

This year, the open house featured 14 vendors, including RMS Hydraulic Solutions and Ruffridge Johnson, both of which also had booths set up showcasing their company’s full offerings and services.

The annual open house is a great opportunity for RMS Rentals staff and customers to get a chance to connect in a setting different

(L-R) are Heather Jensen, RMS Rentals inside sales coordinator; Charlize Bistodeau, rental coordinator (Savage, Minn.); Dave Hosch, Ruffridge Johnson Equipment general manager; Sara Dickinson, sales coordinator (Savage, Minn.); and Tyler Marz, Ruffridge Johnson, territory manager.

from the job site and build a stronger relationship.

“Everyone appreciates a low-pressure environment where there’s no obligation,” said TJ Burns, general manager, rentals.

“They can come in, have a good meal, enter some drawings and interface with people from RMS they may see every day, but in a more casual environment.”

Attendees received a welcome bag, and lunch was catered by three local food trucks — The Purple People Feeder, El Taco Turro

and Pretty Great Cheesecake. A live Husqvarna DXR demolition robot demo capped the day.

Equipment manufacturers who participated in the event included Potain, Husqvarna, BOMAG, LeeBoy, Haugen Attachments, Multiquip, Cratos, Allen Engineering, Wacker Neuson, EDCO, Allmand, JLG, Werk-Brau, Terramac, Komatsu, BringFuel and AgriLands Division. Each had equipment on-site.

“Overall, this event was a success for us.

We were able to generate some small equipment sales and set up some rentals as a direct result of the open house,” said Burns.

To celebrate, RMS Rentals also featured an exclusive event blitz, offering some of the lowest prices of the year on select equipment. For more information, visit rmsequipment.com. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide, except where noted. All Rights Reserved.)

From BringFuel and AgriLands Division, Winterset, Iowa, Susie Larson (L), regional account manager, and Steve Clawson, regional account manager, were at RMS’s open house to let customers know BringFuel provides for energy and lubricant needs across the United States.

This Komatsu excavator with custom wrap — courtesy of Dirty Graphix, Stillwater, Minn. — welcomes customers to the RMS Rentals open house in Savage, Minn.

The prize table showed the

items

Dell Howen (L), director of product support of Terramac, Sugar Grove, Ill., and Scott Kropiwka, used equipment manager of Road Machinery and Supplies Co., showed customers the Terramac DS70 dumper.

Brad Ketcherside, territory sales representative of Allen Engineering, Paragould,

with the company’s newest products on

Fooralimitedtime,get0%for60months F

ths on CASE Mini Exca

e RPO (rental purchase o y? ob done right. t, control, and durabil or ting, digging, or grading f

g leasingplansthat

Ask about flexible ady to buy Not re jo need to get the comf delivers the Whether you’re li or 0% for 48 mon or a limited tim , g g g g tworkonyourtimelinea

e, get 0% for 60 months , andbudget option) and ity you g, CASE avators. s on CTLs leasing plans that y t work on your timeline a and budget.

M&D Truck and Equipment of Monroe, Wis., has added the Thunder Creek lineup of field fueling and service solutions to its product offering of construction, agricultural, turf and support equipment.

The company specializes in the resale of heavy, compact and support equipment into a variety of industries throughout southwestern and central Wisconsin. The dealer sells both new and used equipment, and represents such global brands as New Holland, Wacker Neuson and sells used Caterpillar, Volvo equipment and more.

construction and agricultural equipment, as well as landscape and site development contractors who need a diverse equipment offering,” said Aidan Lambert, sales manager, M&D Truck & Equipment. “The addition of the Thunder Creek field and fueling solutions provide our partners with an entirely new way to view how they look at field fueling and service — driving efficiency both in fleet management and site operations.”

Thunder Creek designs and manufactures fueling and preventative maintenance solutions that serve all of the industries that M&D Truck & Equipment supports, including the original No-HAZMAT fuel and service trailer (MTT), the multi-tank oil trailer (MTO) and service and lube trailer (SLT).

“We are at a unique area in the state of Wisconsin where we have demand for heavy

“Mike and Dan Lambert have built a business and a reputation on understanding the diverse needs of their local equipment managers,” said Larry Lea, vice president of sales, Thunder Creek Equipment. “They bring a unique understanding and perspective of how Thunder Creek can support fleets of all shapes and sizes drive efficiency in their operations and we are proud to partner with them in the region.”

For more information, visit mdtruckequipment.com.

Loved for the features. Trusted for the performance.

Hyundai articulated dump trucks have the power and performance — not to mention top-notch interiors, clear sight lines and handy tech — that make life on the jobsite easier. So you can do more without feeling like longtime fans.

See the Hyundai difference yourself at your local dealer or na.hd-hyundaice.com.

Customers visited Brooks Tractor’s headquarters in Sun Prairie, Wis., as the company hosted the last of its Technology Open Houses of the spring, showcasing the latest technology available on new John Deere machines May 14-15, 2025.

Live demonstrations with hands-on training of John Deere equipment, featuring SmartGrade (from 2D to 3D), SmartDetect and Topcon MC-Mobile, were conducted. Guests had the opportunity to try these machines with the help of members of Brooks Tractor and Brooks Positioning Systems, a division of Brooks Tractor.

Featured John Deere equipment included a 333G compact track loader with SmartGrade; the new 335P compact track loader; a 210P excavator with Topcon grade control; and a new 650P dozer with Next-Gen 2D and 3D technology.

Registered attendees were given deals that included exclusive pricing and discounts on John Deere SmartGrade and Topcon Machine Control systems.

Brooks Tractor is a family-owned and operated company, with seven locations throughout Wisconsin. The company is celebrating 80 years in business this year.

For more information, visit brookstractor.com. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Fabick Cat hosted its annual Open House event in Fenton, Mo., on May 2. Held at headquarters (One Fabick Dr., Fenton, MO 63026), the event also included the first local phase of Caterpillar’s Global Operator Challenge.

Welcoming more than 250 guests, the event brought together equipment operators, industry professionals and community members for a high-energy day of hands-on experiences and competition. Attendees enjoyed a complimentary lunch, door prizes and networking opportunities with Fabick Cat team members and Caterpillar representatives.

The event spotlighted the newest Cat equipment and technology while kicking off the first local phase of Caterpillar’s Global Operator Challenge — drawing skilled operators eager to test their abilities in speed, accuracy and precision. Spectators gathered to watch as competitors battled it out for a shot at advancing in this prestigious global competition.

After rounds of operating skills on display, Matt Froese of Baxmeyer Construction Inc., Waterloo, Ill., took home first place in the Fenton challenge. With the second event happening in

Wausau, Wis., in June, Fabick Cat will crown the overall winner between the two challenges — with one operator heading to the regional round to compete later this year.

Beyond the competition, attendees explored live equipment demonstrations and interactive displays, where Fabick Cat experts shared insights on how Cat machines and services are transforming productivity and efficiency across the industry. From compact machines to heavy-duty earthmovers, the event gave guests the opportunity to get up close and personal with the latest tools of the trade.

“We’re honored to host the Fenton Open House each year as a way to thank our customers and give them a closer look at the innovations shaping the future of construction and equipment technology,” said Kelli Fabick, vice president of Rents of Fabick Cat. “And to the operators who brought such energy and enthusiasm to this year’s event — your skill and passion truly made the day memorable.”

For more information, visit fabickcat.com. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Operators displayed their Cat 308

Carter of C&L Demolition competing in one of the challenges at Fabick Cat’s Fenton, Mo., phase of the Global Operator

Jamie Meyer of Fabick Cat; Harrison Stone and James McMullen of Commercial Retail Developers; and Tony Sciarratta of Fabick Cat posed for a photo with this Cat 246 D3 skid steer.

Roland Machinery Co. www.rolandmachinery.com

Bridgeton, MO

(314) 291-1330

Cape Girardeau, MO (573) 334-5252

Columbia, MO (573) 814-0083

Palmyra, MO (573) 769-2056

Portage, IN (219) 764-8080

Bolingbrook, IL (630) 739-7474

Carterville, IL (618) 985-3399

East Peoria, IL (309) 694-3764

Marengo, IL (815) 923-4966

Springfield, IL (217) 789-7711

DePere, WI (920) 532-0165

DeForest, WI (608) 842-4151

Eau Claire, WI (715) 874-5400

Franksville, WI (262) 835-2710

Schofield, WI (715) 355-9898

Slinger, WI (262) 644-7500

Escanaba, MI (906) 786-6920

Joplin, MO (417) 726-5373 Maryland Heights, MO (314) 427-4911 Springfield, MO (417) 865-0505 Colby, KS (785) 462-8211 Liberal, KS (620) 624-7274 Salina, KS (785) 825-8291 Wichita, KS (316) 789-7370

1801 Watterson Trail Louisville, KY 40299 (502) 491-4000

Bowling Green, KY (270) 780-3004

Corbin, KY (606) 528-3700

Lexington, KY (859) 259-3456

Paducah, KY (270) 444-8390

Stanville, KY (606) 478-9201

Evansville, IN (812) 425-4491

Fort Wayne, IN (260) 489-4551

Indianapolis, IN (317) 872-8410 Brandeis Machinery & Supply Company www.brandeismachinery.com

Representatives of HD Hyundai Construction Equipment North America recently joined Hardings Inc. for the grand opening of its new location in Elwood, Ill., which expands its sales and service area for Hyundai construction equipment from its original location in Lowell, Ind., covering northwestern Indiana, to serve customers across Chicagoland.

The new location in Chicago’s southwest suburbs offers the full line of Hyundai construction equipment, from compact excavators, compact loaders and crawler dozers to wheel loaders, excavators, articulated dump trucks, as well as specialty material handlers and hydraulic breakers.

Hyundai Construction Equipment photo

The new Hardings Inc. location in Elwood, Ill., includes a full-sized shop, with Hyundai-trained technicians working in a well-appointed maintenance bay, as well as a well-stocked parts department and a fleet of service vehicles.

“We have known since my family opened this business in 1916 that our main objective is to help lower our customers’ costs per hour,” said Clarence Harding, president and owner, Hardings Inc. “We work to achieve this by offering the best value in new equipment, rentals, parts and service. When that happens, we both win. That’s why Hyundai machines have been an excellent fit for us and our customers. Hyundai equipment is

very reliable, and we know that, together, Hardings and Hyundai are doing everything we can to ensure we keep our customers in solid equipment, with top-caliber support.”

“We are happy Chicago-area customers have the support of a strong, growing dealership in Hardings Inc., which just celebrated 20 years as a Hyundai dealer,” said Ed Harseim, north central district manager, HD Hyundai Construction Equipment North America. “Their new location in Elwood offers a full-sized shop, with Hyundaitrained technicians working in a well-

Construction Equipment photo

Mike Ross, senior VP, HD Hyundai Construction Equipment North America (center R), presents a plaque to Clarence Harding, president and owner of Hardings Inc. (center L), recognizing the dealership’s 20-year milestone as a Hyundai dealer, along with the opening of a new Hardings Inc. location in Elwood, Ill., that will serve customers in the greater Chicagoland area. Also pictured are Hardings and Hyundai team members (L-R) Rick Briggs, Kevin Reese, George Nikitaras, Dave Huppenthal, Sherry Harding, Alesia Harding, Vince Harding, Derrick Justice, Ken Jellema and Ed Harseim.

appointed maintenance bay, as well as a well-stocked parts department, and a fleet of service vehicles.”

Harding noted that the pace of growth in the collar counties around Chicago has been rapid in recent years.

“Our new shop in Elwood is well positioned to serve that customer base — with easy access to I-55 and I-80 and fewer traffic headaches,” he said.

For more information, visit na.hdhyundaice.com and hardingsinc.com.

PIRTEK USA kicked off 2025 with momentum, adding 20 new territories and opening 10 locations in the first quarter.

This early-year growth includes the brand’s expansion into Kansas and Delaware, strengthening PIRTEK’s coastto-coast coverage and presence in untapped markets.

Of the 20 new territories signed in Q1, 16 were awarded to new franchisees entering the system, while four represented expansions by existing owners capitalizing on PIRTEK’s proven model.

Meanwhile, the 10 new locations opened, included six launched by first-time franchisees and four by current owners expanding their operations.

“We’re seeing continued strong interest from entrepreneurs across the country who recognize the value and staying power of the PIRTEK model,” said John Dobelbower, vice president of franchise development, PIRTEK USA. “The combination of essential service, high demand and operational support makes this a compelling opportunity, whether you’re new to franchising or looking to grow an existing business portfolio.”

Among the expanding owners is John Baker, owner of PIRTEK Waco in Waco,

“We’re seeing continued strong interest from entrepreneurs across the country who recognize the value and staying power of the PIRTEK model.”

John Dobelbower PIRTEK USA

was a significant opportunity to expand throughout Central Texas,” said Baker. “The PIRTEK model has been incredibly effective, providing a much-needed service to businesses in our area. I’m excited to bring that same level of reliability and support to more businesses and communities throughout the region.”

“PIRTEK prides itself on quickly and efficiently filling customers’ hose service needs, having the widest variety of superior products and parts to keep essential projects running,” said PIRTEK. “Our quick turnaround time also is credited to the 1-Hour ETA on-site emergency hose service offered 24/7/365. This service enables customers to be up and running again quickly, minimizing equipment downtime due to a hose failure.”

Texas. In Q1 2025, Baker expanded his PIRTEK business by opening a second location in Temple, Texas, and signed an agreement to develop a third territory in

Tyler-Longview, Texas, with plans to open that location in Q4 of this year.

“After seeing the demand and success in the Waco market, it became clear that there

PIRTEK onboards potential franchisees who prioritize customer service and welcome driven individuals from all industries, regardless of technical experience. The initial investment ranges from $216,400 to $619,300. Franchisees can expect extensive in-person and online training, ongoing support and exclusive territories.

To learn more about PIRTEK franchise opportunities, visit pirtekusafranchise.com.

Diamond Mowers introduced the mini-brush cutter Pro X, delivering precision, power and reliability in one compact package.

Modeled after Diamond's brush cutter Pro X, the minibrush cutter Pro X is engineered to provide stand-on users — from farmers and construction contractors to landscapers and land management professionals — with another tool for their equipment toolbox.

This attachment transforms a stand-on or stand-behind track loader into a powerful land-clearing tool that tackles trees, cuts through dense brush and grinds stumps to groundlevel, empowering operators to take on a broader range of tasks and jobs, according to Diamond Mowers.

“This attachment is engineered specifically for the miniskid steer market and adds a new dimension of capability that empowers operators to clear land faster, reduce manual labor and maximize their equipment investment,” said Nate Cleveringa, vice president, engineering and product management of Diamond Mowers. “It packs all the power and performance of our brush cutter Pro X in a streamlined profile designed for those who value relentless durability and optimal versatility.”

The mini-brush cutter Pro X features a spindle-driven blade system with 25 percent more cutting capacity than standard models, enabling operators to slice through dense brush, thick vegetation, and trees up to 5 in. in diameter with ease. The 42-in. cutting width is ideal for tackling everything from landscaping and property reclamation to urban lot clearing and maintaining parks, trails and forest preserves. The direct-drive spindle also delivers smooth and efficient power from the motor to the blades for consistent cutting performance so operators can handle tough materials without compromising on precision.

“The spindle system replaces the more traditional gearbox, which can be prone to wear and tear under heavy loads,” said Cleveringa. “This design reduces mechanical complexity, resulting in greater durability during heavy-duty operations.”

The steel construction of the mini-Pro X is 25 percent thicker for enhanced durability, according to Diamond Mowers. Furthermore, the offset design of the bolt-on attachment plate allows operators to shift the plate across the front of their carriers to minimize track marks that would normally be left behind. This is particularly useful for precision tasks such as trail clearing or vegetation management near sensitive areas and affords greater flexibility when maneuvering in tight spaces and working near edges, fences or other obstacles.

said Cleveringa. “It replaces manual clearing and empowers operators to tackle a wide range of tasks efficiently and reliably without needing to call in additional trades,” said Cleveringa. “This versatility leads to greater productivity

and profitability.”

To help protect operators and ensure long-term usability, the mini brush cutter Pro X also features:

• universal safety guarding — to minimize the risk of

injury while working in challenging environments, polycarbonate safety glass shields operators from flying debris and other potential hazards during operation, according to the company.

• hydraulic hose protection — hoses are enclosed in a thin spiral wrap, offering safeguarding, an enhanced level of durability, and resistance to wear and tear, according to the company.

• castle nut fasteners — providing an added layer of protection, the castle nut system locks cutting blades in place and positions them closest to the ground during operation. Under significant stress or impact, the secure fit reduces vibrations and ensures that, in the event of a blade compromise, failure is isolated to the blade and the attachment continues to operate safely, according to the company.

“Reliability and performance are crucial for professionals working in challenging environments and were top priorities in the design of this attachment,” said Cleveringa. “Field testing has shown that the spindle-driven double blades and castle nut system perform well in rigorous conditions. The design handles heavy workloads and minimizes downtime by reducing the frequency of maintenance and repairs.”

Murphy Tractor & Equipment Co.

murphytractor.com

Park City, KS (316) 942-1457

Great Bend, KS (620) 792-2748

Humboldt, KS (620) 473-7020

Olathe, KS (913) 298-7373

Topeka, KS (785) 233-0556

Ulysses, KS (620) 356-1071

Dodge City, KS (620) 227-3139

Gering, NE (308) 436-2177

Omaha, NE (402) 894-1899

Lincoln, NE (402) 467-1300

Grand Island, NE (308) 381-0741

North Platte, NE (308) 534-7020

Kansas City, MO (816) 483-5000

Springfield, MO (417) 863-1000

Des Moines, IA (515) 263-0055

Fort Dodge, IA (515) 576-3184

Sioux City, IA (712) 252-2753

Waterloo, IA (319) 235-7085

Brunswick, OH (330) 220-4999

Cambridge, OH (740) 439-2747

Canton, OH (330) 477-9304

Cincinnati, OH (513) 772-3232

Columbus, OH (614) 876-1141

Jackson, OH (740) 688-4100

Lima, OH (419) 221-3666

Painesville, OH (440) 639-0700

Poland (Youngstown), OH (330) 629-6299

Rossford, OH (567) 352-7001

Vandalia (Dayton), OH (937) 898-4198

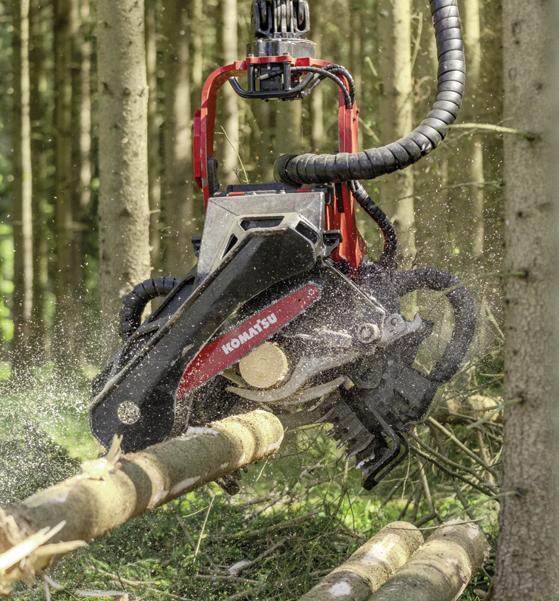

The Komatsu C124 has received significant upgrades for the 2025 model year, aimed at boosting productivity and user experience. Key improvements include a redesigned valve block and enhanced hydraulics for the feeding system.

Feedback from test customers who tried the prototype has been overwhelmingly positive, particularly noting the head’s smooth operation and efficient feeding.

The most notable upgrade is the introduction of a new valve bank, which offers improved durability, reduced wear and lower energy losses — resulting in fuel savings.

Additionally, the pressure control for the front and rear knives has been refined for greater precision, with adjustments now fully managed via software.

This allows operators to easily control settings like the knives’ opening pressure from inside the cab. The hydraulics for the tilt functions also have been improved, resulting in smoother operation and potentially

higher measurement accuracy during processing.

To ensure high and consistent measurement quality, Advanced length measuring is now standard on the C124. This update includes a stronger cylinder and a modified mechanical stop to reduce wear.

The saw unit has been redesigned with additional clearance between the saw bar and frame to prevent collisions. A reinforced, curved base plate enhances durability while reducing the unit’s ground footprint. The updated design also provides more space around the saw motor, making daily maintenance easier and more accessible.

The new feed system features high-flow motors that enhance performance and reduce energy losses.

The upgraded system also includes improved hose routing for easier

servicing and extended service life. An optional reinforced hose protection layer is now available to further increase hose longevity.

The 2025 model introduces the “Find End” option, which automatically resets length measurements without requiring a new cut, reducing waste. The option has been updated with a protected lens and debris-resistant design for longer service life.

Other enhancements include improved centering for small stems, stronger bushings with better sealing for front delimbing knives, and new feed rollers with spikes for better grip and measuring accuracy in challenging conditions.

These upgrades collectively make the Komatsu C124 more efficient, durable and user-friendly, offering operators greater control, reduced downtime and improved productivity even in the most challenging environments.

For more information, visit komatsuforest.com.

The new Cat tiltrotator line helps to deliver cost savings by reducing the number of machines and ground staff at the site.

The tilt rotate system allows the attachment to simultaneously rotate 360 degrees and tilt up to 40 degrees, allowing tracked excavators to perform a range of tasks — digging, grading and compacting — with more precise movements without repositioning the machine. Less machine repositioning helps to reduce undercarriage wear and lower costs, according to Caterpillar.

“Our fully integrated new TRS12, TRS17, TRS20 and TRS26 models reduce installation time and show up automatically on the machine’s monitor, allowing it to be easily controlled by the joystick,” said Scott Rosengaard, senior product consultant, Caterpillar. “Our tiltrotators can be used with a wide range of attachments like buckets, grapples, compactors and more, allowing for higher machine utilization and improved productivity. Plus, the new standard tilt sensor delivers precise tilt and rotation angles to the grading system.”

Caterpillar photo

The new Cat tiltrotator line helps to deliver cost savings by reducing the number of machines and ground staff at the site.

the locking cylinder to verify the tool is correctly connected and securely locked to reduce the risk of swinging or dropping tools, according to Caterpillar.

Cat TRS models feature a single grease point connection with the excavator’s autogrease system and the simple-to-use innovative lubrication system is developed to quickly distribute the right amount of grease to the appropriate points. Double-acting tilt cylinders fitted with a load holding valve ensure the load is securely in position, even in the event of the hydraulic system losing pressure. Providing maximum heat distribution, the worm gearbox is filled with oil for optimum lubrication.

With the new tiltrotator models, operators can change tools without leaving the cab when equipped with the full hydraulic coupler, enhancing safety, productivity, performance and efficiency.

New pressure compensated hydraulic valves manufactured with spools provide

These new models feature a standard high flow swivel, providing up to 200 l/min flow at 250 bar for use with high-flow work tools. Pairing the tiltrotator with a next generation Cat excavator that has a second hydraulic line boosts hydraulic flow and pressure to 250 l/min at 350 bar.

even better control of the hydraulic flow than previous designs, allowing the tiltrotator to maintain stable rotation speed regardless of tilt speed. A quick-connect interface provides fast hydraulic attachment changes. SecureLock uses sensor technology inside

A plastic cover with built-in electrical harness provides easy connection to the hydraulic valves and simplifies servicing. Frame modification on the new series reduces dirt exposure for the grading sensor, which is further protected by a metal cover. For more information, visit cat.com.

For almost three quarters of a century, the Duff family has produced and supplied crushed limestone, sand and gravel to all of west-central Ohio.

As the multi-generational family enterprise approaches its landmark 75th year in business, a new CDE wash plant, capable of processing up to 300 tons per hour (tph) of sand and aggregate, has been commissioned at the company’s Lewistown, Ohio, sand and gravel site.

“It’s an investment in the future of the business and in the future of the mineral production industry in the state,” said Ross Duff, president of Duff Sand and Gravel Inc. and vice president of Duff Quarry Inc. “It’s about honoring the history and heritage of our business and continuing that good work, ensuring we’re equipped and resourced to meet future challenges head on, and that we extract and utilize every valuable grain from our deposits. In short, it’s about longevity.”

In 2023, Ohio was ranked as one of the leading construction sand and gravel producing states, according to data from the U.S. Geological Survey (USGS). Of the 920 million tons of sand and gravel produced last year, the top 10 states by production volume accounted for more than 50 percent of the total combined output.

Similarly, USGS data shows Ohio as a top producer of crushed stone. Last year, an estimated 1.5 billion tons were produced. The 10 leading states, which included Ohio, accounted for more than half of the total output (54 percent).

An essential industry to support the continued economic development of the state, the Ohio Aggregates & Industrial Minerals Association (OAIMA), where Duff serves as an active board member, estimates raw mineral production in the state to be valued at more than $1 billion, employing more than 5,000 directly and up to 40,000 indirectly through associated construction activity, transportation and more.

Duff Quarry first discovered CDE at ConExpo-Con/AGG in 2020, where the

washing experts left a lasting impression on the family enterprise.

“We believed technology of this kind was beyond our reach,” Duff said. “It was everything we needed and more. When we left that show, we left with an impression of CDE and its equipment that would stay with us for the next few years. We knew it would be a major investment — one of the largest in the history of the company — but we knew just how impactful it could be.” It would be another three years before the two companies would meet again at ConExpo-Con/AGG in 2023.

“By then, we were ready to move forward with this project, and CDE was still the preferred supplier all those years later,” said Duff. “That second show just strengthened our resolve to bring this project to life with CDE by our side.”

4805 Scooby Lane NW Carroll, OH 43112

866-262-4181

4510 East 71st Street Cleveland, OH 44105 440-439-4567

920 Deneen Avenue Monroe, OH 45050 513-649-8105 1515 W. Epler Avenue Indianapolis, IN 46217 317-782-8850 1330 KY-151 Frankfort, KY 40601 502-699-2681

www.rolandmachinery.com

Escanaba, MI

906-786-6920

DePere, WI

920-532-0165

DeForest, WI

608-842-4151

Eau Claire, WI

715-874-5400

Franksville, WI

262-835-2710

Schofield, WI

715-355-9898

Slinger, WI

262-644-7500

www.rmsequipment.com

Savage, MN

800-888-9515

Des Moines, IA

800-555-1445

Cedar Rapids, IA

800-616-6615

Sioux City, IA

800-633-9104

East Moline, IL

800-633-9114

Duluth, MN

800-888-9535

Virginia, MN 800-752-4304

www.vlpco.com

4100 Gardner Avenue

Kansas City, MO

64120

866-928-4055

816-241-9290

Garden City, KS

800-511-1435

Joplin, MO

417-781-8222

Topeka, KS

785-267-4345 Wichita, KS

316-838-3346

www.brandeismachinery.com

Bowling Green, KY

270-780-3004

Corbin, KY

606-528-3700

Lexington, KY

859-259-3456

Louisville, KY

502-491-4000

Paducah, KY

270-444-8390

Stanville, KY 606-478-9201

Evansville, IN 812-425-4491

Ft. Wayne, IN 260-489-4551 Indianapolis, IN 317-872-8410

Ronan Duffy, CDE business development manager, said the solution engineered for Duff Quarry is born from proven solutions and designed specifically for its Huntsville, Ohio, quarry.

“Material gradings can vary from one day to the next, so any solution needs to be approached with real understanding of the customer, their needs and the material to be processed,” said Duffy. “A full site audit, including material testing in our lab, helped inform and develop the best possible solution for Duff Quarry as they begin washing material for the very first time. Equipment specification, site layout — it’s all considered in order to create an optimized site workflow that can help accelerate return on investment.”

The final solution includes CDE’s AggMax scrubbing and classification system, which combines pre-screening, washing, scrubbing, lightweight and organics removal and sizing on a compact chassis to produce a range of washed and graded aggregates ready for market straight from the belt, according to the company.

Alongside this, CDE’s M4500 modular sand washing plant, which integrates feeding, screening, washing and stockpiling, features customizable cut point control and patented Infinity technology to deliver consistent in-spec sand products, according to CDE.

“Seeing the first containers arrive on site for the build, that was pretty neat,” Duff said.

Increased Production

Processing up to 300 tph, the new CDE plant is helping Duff Quarry produce more material per year to better meet the demands

of the local construction market through proven design, efficient processing and optimized operations, according to the company.

A major construction boom is under way in central Ohio where the now $28 billion development of two Intel semiconductor manufacturing plants — the single largest private sector investment in the history of the state — is continuing at pace. A further $90 million has been committed by the Ohio Department of Transportation to improve and enhance infrastructure around the facility.

This is in addition to continued work on the development of a new lithium-ion EV battery plant in Jeffersonville, Ohio, as part of a $3.5 billion joint venture between LG Energy Solutions and Honda.

“Within a matter of hours of booting up the plant, material testing showed concrete sand output to be perfectly in-spec,” Duffy said.

The plant is producing a range of construction materials, including C33 coarse concrete sand, fine sand and three different aggregate fractions: 1-2-in., #57 stone and pea gravel.

“I was amazed,” Duff said. “The result was immediate. Right from the starting block we were producing great looking stockpiles. The plant is making sure we have a constant supply of concrete sand for our six ready-mix plants.”

Since initial commissioning in June last year, the geology and material quality of the limestone deposit at the company’s operation in Huntsville has changed significantly, but Duff said the CDE plant has been able to adjust easily to the new conditions.

“We’ve been extracting here for almost 75 years now. It’s a large deposit about 400 feet

deep, and it spans an area of approximately 400 acres. Given its size and scale, we know that the make-up of the material is going to vary and, down through the years, we’ve invested in new equipment and adapted our operation in response to this,” he said.

The deposit continues to evolve even today.

“It’s a different deposit now to what it was at the outset of this very partnership — however now we’re equipped with a CDE plant,” said Duff. “We’re really impressed by the adaptability of the plant and just how little intervention is needed from our side to make the necessary adjustments in response to variations in the material we’re processing.

“That versatility is keeping us up and running. It’s keeping us competitive and profitable.”

For more information, visit CDEGroup.com.

www.aisequip.com

3600 N Grand River Ave Lansing, MI 48906

517-321-8000

Grand Rapids

600 44th Street SW Grand Rapids, MI 49548

616-538-2400

Northeast Detroit 65809 Gratiot Avenue Lenox, MI 48050 586-727-7502

Saginaw 4600 AIS Drive Bridgeport, MI 48722 989-777-0090

Traverse City 8300 M-72 East Williamsburg, MI 49690 231-267-5060

West Detroit 56555 Pontiac Trail New Hudson, MI 48165 248-437-8121 800-457-8121

www.butlermachinery.com

3630 Miriam Ave Bismarck, ND 58502

701-223-0890

7910 US-2

Devils Lake, ND 58301 701-665-3800

2803 I-94 Business Loop E Dickinson, ND 58601

701-456-1400

3402 36th St SW Fargo, ND 58104 701-280-3100

1201 S 46th St Grand Forks, ND 58201 701-775-4238

1910 27th Ave SE Jamestown, ND 58401

701-251-1400

4950 U.S. Highway 12 Aberdeen, SD 57401 605-225-6240

3601 Deadwood Ave N Rapid City, SD 57702 605-342-4850

20571 Truck Stop Ave Pierre, SD 57501 605-224-5400

3201 N Louise Ave Sioux Falls, SD 57107 605-336-3010

603 10th St NW Watertown, SD 57201 605-954-7100

1715 US Hwy 14 W Huron, SD 57350 605-353-1200

1505 Hwy 2, Bypass E Minot, ND 58701 701-852-3508

www.centralsands.com

4219 E 50th St • Des Moines, IA 50317 800-247-2400 • 515-964-8600

www.rbscott.com

1011 Short St Eau Claire, WI 54701 715-832-9792

17403 County Road 75 NW Clearwater, MN 55320 320-558-8100

www.roadbuildersmachinery.com

1001 S 7th St Kansas City, KS 913-371-3822

4115 S 90th St Omaha, NE 402-331-9200

5601 Fletcher Ave Lincoln, NE 402-325-0447

4949 Juergen Rd Grand Island, NE 308-384-2620

1303 S Chestnut St Norfolk, NE 402-316-4640

DRILLS & COMPRESSORS

Coming In: (2019) Sandvik DX800, with approx 8700 hrs & 3100 impact hrs on HF820 hammer. Running & working currently.

#510134 (2004) Furukawa 1200ED hydraulic drill, w/ 12,043 hrs on 5.9 Cummins engine (approx 600hrs on factory Re-man) & 5590 impact hours (114 hrs since re-seal). New injection pump at 11,394 hrs. New main hydraulic pump at 11,078 hrs. Overall Good condition.

#510099-Tamrock DHA550 self-contained hydraulic drill, Deutz air cooled engine. Has 1185 impact hours. Good condition.

#580000-Furukawa HD712 drifter, approximately 4786 total impact hours and zero hours on complete reseal. Was used on 1200EDII.

Ready to be installed for operation.

#510128 Atlas Copco T45 Smartroc hydraulic drill, 9600hrs on Cat C9 engine and 3600 hrs on Copco 3060 drifter. Set up for 60mm steel. Drill running daily.

#530029 Ingersol Rand ECM370, self-contained rock drill w/ VL140 hammer & Cummins engine.

#1111085 Portable Pioneer 3042 jaw with 42"x16' VGG, 42" underconveyor, & 150hp motor on shopbuilt chassis.

#131026 Simplicity 36"x16' Vibrating Grizzly Feeder, 4' grizzly section. Very good condition.

#118000-New/never used Universal 2036 jaw crusher parts, including: Jaw plates, toggle seats, toggle plates, spring loaders, and all thread rods.

#111083 (2015) KLEEMAN MZ110i TRACK-MOUNTED JAW CRUSHER, (27X43″) with 5374 HRS

SCREENS & WASH EQUIPMENT

#1154001 Self-contained SMI portable wash plant w/ 4x8 3-deck wet screen. a hydraulic driven Greystone 36x25 sandscrew, & a 30"x40 hydraulic driven radial stacker.

#152027 Ortner model 3000 sandscrew. with 5hp electric motor.

Rated at 50-125 TPH capacity. Very Good Condition.

#141163 Allis Chalmers 6x16 2-deck Ripl-Flo incline screen with

structure, 1" screen in top deck & 3/4" screen on bottom. Good cond. #142003-Deister 5x16 2-deck horizontal, underslung screen with new bearings

#141164 Pep 6x18, 2-deck high frequency screen on factory chassis with electric motor & switchgear.

#141167 Deister BHT2616 (6x16 2-deck) screen, with polydeck top & bottom. Could be set up for wet screen.

#142004 Portable Cedarapids/El-Jay 6x20 3-deck horizontal screen, on 3-axle chassis (set up for two screens, but only one included). Has four (4) 30"x12' cross conveyors, two (2) 36"X12' cross conveyors, & two (2) 42" underconveyors.

#640055 (2021) Sany SY265CLR long-reach excavator (60'), 1750 hrs, Cummins QSB6.7 T4F engine, 190 hp, 70,000lb shipping weight. Has A/C, heat, & radio. Max reach at ground level 57' 9" & max digging depth 43'9", 31" track pads, 60" digging bucket, & plumbed for hydraulic mower. 1-owner machine. Remainder of 5 yr / 5000 hour warranty (though Jan 2026).

#640057 - 2007 Volvo 330BLC, 5800 hours on 6 cyl D12C, 198hp engine. 58" bucket with teeth and hyd. Thumb. 31" track pads, 78,000 lb operating wgt. Overall, good condition. #610137-1995 John Deere 644G Loader, unknown hours and 3 3/4 yard bucket. Good rubber and runs great, overall good condition. #410063-CAT D9H, EROPS cab w/ A/C, straight blade w/tilt. Single shank, 4-barrel ripper. 24" pads. U/C (overall approx 70%). Rebuilt engine, trans, and finals (HMR 2994) Left Trunnion is available but needs to be installed. Overall good condition.

#700001 CAT 12F MOTORGRADER

The Phoenix Center released its 2025 aggregates industry scorecard on April 9, 2025.

The scorecard assessed the aggregates industry’s impact on the U.S. economy at the national, state and county levels. This is an update to the Center’s 2017 Scorecard, as it provides a new look at the economic advantages after the passage of the Infrastructure Investment & Jobs Act (IIJA) in 2021.

The scorecard shares that the aggregates industry continues to be a significant contributor to our nation’s economic well-being. The implementation of IIJA, which included approximately $350 billion for federal highway programs over a five-year period in states and federal projects, showcases the positive effects on the United States economy. The industry supports $171 billion in national sales, $55 billion in national earnings (i.e., labor compensation) and nearly 729,000

jobs across a wide range of occupations and industries.

“Our members provide and support the aggregates materials used for residential, commercial and government construction projects, as well as transportation infrastructure including roads, highways, bridges and railroads,” said NSSGA Interim CEO Michele Stanley. “This scorecard proves that the growth of the aggregates industry is necessary for the growth of our overall economy.”

NSSGA logo

The industry’s economic impact creates a ripple effect on the broader economy. For every job in the aggregates industry, an additional 5.95 jobs across other industries are supported throughout the economy. Each dollar of earnings creates another $4.95 of earnings in other sectors, and each dollar of industry sales produces another $3.29 of sales in other industries.

Kobelco Construction Machinery USA introduced two new SK260DLC-11 models that are purpose built for the waste and recycling market.

The new SK260DLC-11 material handler and SK260DLC-11 scrap loader offers more standard features, optimal comfort and superior perform ance, according to the company.

Purpose built to meet the demands of the those who require durability, reliability and high performance; the Kobelco material handler and scrap loader models carry on a tradition of quality, according to Kobelco.

Powered by a Yanmar Tier IV engine, both versions of the SK260DLC-11 machine exceeds performance expectations and meet all EPA requirements. The four-cylinder Yanmar engine produces 194 hp at 2,200 rpm and minimizes fuel con sumption at the same time.

The two boom and arm combinations of the SK260DLC-11 provide the power-generating capacities and working ranges to complete the toughest jobs, according to Kobelco.

The hydraulic system is designed with functionality in mind, boasting an eight-spool main control valve, four pumps (two variable displacement axial piston pumps, one extra gear pump and one pilot gear pump) and a boom-to-arm regeneration feature that redirects hydraulic oil and pressure between the boom and arm. Both machines have a 106.5gal. fuel tank and a 115.7-gal. hydraulic oil tank (tank oil level and hydraulic system).

A heavy-duty level II overhead FOPS guard is stan dard and can be tilted open for easy cleaning of the top window. In addition, rear swing flashers and rear work lights, a KOBELCO USA exclusive, are integrated into the counterweight for added safety and visibility on busy job sites. Seven LED lights also are standard to provide addi tional visibility in low light conditions. A standard 270-degree view three-camera sys tem provides optimal visibility for the oper ator.

The cab interference prevention sdystem is another standard safety feature that pre vents the arm from contacting the body or cab of the machine, using multiple sensors to create an invisible barrier that neither the arm nor tool can cross. Multiple air conditioning and heater vents are directed toward the operator to maximize comfort, and the jog dial integrates multiple functions into a single user interface with the large 10in. color monitor. This menu screen facilitates reading of important information including work mode, maintenance intervals and fuel consumption.

Kobelco photo

The new SK260DLC-11 material handler features a bent boom and a two-pin linkage-type arm, allowing for both precise movement control and powerful lifting.

1200 East Highway 13 Burnsville, MN 55337 952-894-0894

open Saturday 8am-12pm CST

Minnesota Avenue Little Canada, MN 55117 651-407-3727

www.tristatebobcat.com

www.bobcat-ent.com

Kobelco photo

The new SK260DLC-11 scrap loader utilizes a straight boom and 1-pin droop nose arm that has a unique shape useful for smooth cargo vessel loading and unloading.

Using a hydraulic elevator cab that reaches a maximum lift height of 19 ft., 4 in., the operator has ultimate visibility. Other features include a tilting left console for easy entry and exit, adjustable pilot controls, a FM/AM/AUX/Bluetooth radio, smartphone holder, USB charger and a 12v power outlet. For more information, visit www.KOBELCO-USA.com.

Ashland, KY 606-327-1709

Cowen, WV 304-226-3299

Beaver, WV 304-255-1525

Cross Lanes, WV 304-204-1818

Pleasant Valley (Fairmont), WV 304-534-5454

Norton, WV 304-636-6421

Pikeville, KY 606-432-0321

Marietta, OH 740-373-5255

www.lec1.com

Madison (Sun Prairie), WI 608-837-5141

Milwaukee, WI 414-462-9790

Green Bay (De Pere), WI 920-336-5711

La Croose (West Salem), WI 608-786-2644

Stevens Point (Plover), WI 715-254-2777

Racine (Mt. Pleasant), WI 262-898-6700

Sparta, WI 608-351-2101

www.brookstractor.com

Recycled and scrapped materials play a pivotal role in society by promoting waste reduction, conserving natural resources and providing economic benefits to local communities.

By recycling ferrous and non-ferrous metals, plastic, paper and other materials, local scrap yards help reduce the amount of waste sent to landfills, decrease pollution across the nation and save significant amounts of energy compared to producing new materials from raw resources.

St. Louis-based Rimco Inc. is well-versed in the demanding requirements of maintaining efficient scrap operations.

Specializing in both commercial, industrial and residential scrap metal recycling, Rimco collaborates with a diverse range of clients to ensure that discarded ferrous and non-ferrous metals are handled properly. With more than 100 years of experience, Rimco has established itself as a leader in the scrap industry. The company relies on Liebherr material handling machines to tackle its toughest jobs, ensuring reliability and efficiency in its operations.

“Rimco and their leadership team continue to expand and elevate their family business, achieving increasingly impressive results each year,” said Hampton Wideman, regional business manager, Liebherr USA Co. “They are making strategic decisions and creating opportunities for continued influence in the St. Louis market and in the overall scrap and recycling industry. This enables Rimco to participate and excel in community activities, charitable giving and contribute to making the St. Louis area a better place for current and future generations. It has been a great experience getting to know the Rimco team and sharing their story.”

As one of the toughest applications in industrial goods handling, Liebherr said it understands the demanding working conditions of a scrap yard. Moving large scale, bulky and heavy loads with sharp edges requires extreme safety requirements. Liebherr machines not only offer the necessary strength required, but also maximizes safety and innovative technologies that optimize scrap handling processes. This includes a wide range of visibility in the cab, safety guards and numerous assistance systems including tool control and stabilization assistant allowing Rimco safer and more efficient working conditions, according to the company.

Liebherr offers a diverse portfolio of material handling machines that support sorting, transport and loading, as well as shredding and feeding of materials. In addition, Liebherr offers a wide array of attachments specifically developed for scrap handling to help maximize the efficiency, flexibility and performance of the entire scrap handling process including orange peel grabs, sorting grabs, hydraulic magnets, stick extensions and quick-coupling systems.

Rimco Inc. recently expanded its 12-acre St. Louis scrap yard fleet with the addition of two new Liebherr LH 40 industry material handling machines. One of these machines is equipped with a multi-tine grab, ideal for handling large, irregular scrap materials, while the other is fitted with a magnet, perfect for efficiently sorting and moving ferrous metals. The high-performance LH 40 industry material handling machine is a performer in its class. With the patented energy

recovery system (ERC), the maximum handling capacity is guaranteed while lowering the overall fuel consumption. This not only equips the machine with more power, but faster work cycles allowing Rimco to work efficiently day to day, according to Liebherr. In addition, the machines can be equipped with a variety of attachments, allowing Rimco to choose what fits their individual needs best.

Rimco worked closely with Liebherr dealer Central Power Systems & Services to find the right machines that meet its requirements. Central Power Systems & Services provides a wide range of Liebherr earthmoving and material handling technology equipment within the south-central United States.

Rimco has been a loyal customer of Liebherr since the early 1990s, consistently choosing Liebherr equipment due to its outstanding reliability and performance, according to the company. The company values the durability and efficiency of Liebherr machines, which is crucial for maintaining its operations. This long-standing partnership highlights Rimco’s commitment to using top-tier technology to optimize its scrap handling processes and ensure smooth, continuous operations, according to the company.

For more information, visit www.liebherr.com.

5255 N Deere Rd Park City, KS 67219 316-942-1457

325 S Highway 281 Great Bend, KS 67530 620-792-2748

1141 Kanza Drive, Humboldt, KS 66748 620-473-7020

15854 S US 169 Hwy Olathe, KS 66062 913-298-7373

1621 NW Gage Blvd Topeka, KS 66618 785-233-0556

1410 W Oklahoma Ave Ulysses, KS 67880 620-356-1071

10893 112 Rd Dodge City, KS 67801 620-227-3139

220810 Hwy 92 Gering, NE 69341 308-436-2177

9751 S 148th St Omaha, NE 68138 402-894-1899

6100 Arbor Rd Lincoln, NE 68517 402-467-1300

3204 S Engleman Rd Grand Island, NE 68803 308-381-0741

3701 S Jeffers St North Platte, NE 69101 308-534-7020

8600 NE Parvin Rd Kansas City, MO 64161 816-483-5000

1401 S State Highway MM Springfield, MO 65802 417-863-1000

5087 E Broadway Ave Des Moines, IA 50317 515-263-0055

1303 3rd Ave NW Fort Dodge, IA 50501 515-576-3184

4900 Harbor Dr Sioux City, IA 51111 712-252-2753

3469 W Airline Hwy Waterloo, IA 50704 319-235-7085

1801 Watterson Trail Louisville, KY 40299 502-491-4000

17000 Highway 41 North Evansville, IN 47711 812-425-4491

7310 Venture Lane Fort Wayne, IN 46818 260-489-4551

Although still in the first phase of construction, the Improve I-70 Columbia to Kingdom City project continues making progress, as crews work to update the I-70 corridor in Missouri.

In order to not overwhelm our industry partners, MoDOT has divided the expansion of I-70 across the state in sections following a schedule that would best allow for the best competition and contractor availability. The program will be broken into various contracts that will be awarded throughout 2029. Total completion of the corridor is anticipated by the end of 2030.”

The Columbia to Kingdom City project is a fixed-cost contract at $405 million. This number includes $123 million previously programmed by MoDOT for the I-70 interchanges at U.S. 63 in Columbia and U.S. 54 in Kingdom City.

Work began in July 2024. According to Samer, the need for new construction can’t be overstated.

“The safety and economic prosperity of Missourians depends, in part, on an I-70 that grows along with the state and nation. That’s why MoDOT is working to improve I-70. Today, many portions of the facility are strained beyond capacity, and outdated interchange designs increase delays and dampen economic activity.

“I-70 is a vital transportation corridor in Missouri, connecting the state’s two largest cities and carrying more rural daily traffic than any other route in the state. The 250 miles of I-70 through Missouri have been an engine for economic growth and prosperity. Missouri marks the distinction of being the birthplace to the interstate with the first interstate project under construction on I-70 in St. Charles County.”

Samer said traffic management is a chief concern for crews.

“The biggest construction challenge is keeping the traveling public moving with minimal delays. Anticipating impacts and

planning work to avoid disruption is a key focus for this project. Maintaining adaptability is one of the main ways this team is tackling this challenge.

“The Millstone Weber design-build team has committed to keep two lanes of I-70 open during peak travel times. Most work on mainline I-70 is occurring overnight, with various single lane closures. That said, traffic along I-70 is a dynamic situation. Motorists are quickly adjusting, and the design-build team is continuing to adapt to the needs of the traveling public. Overall traffic is responding well.”

Construction tasks include the reconstruction of the median of I-70. The current configuration has eastbound and westbound separated by a grass median with guard rail and guard cable in many areas, draining to the ditches. A closed median will require reconstruction of the median to include grading, base preparation, concrete paving, concrete barrier wall and reconfiguration of drainage.

“Seventeen bridges/structures will be impacted during the construction of this project for the I-70 expansion in this section alone. That includes a combination of bridge and culvert replacements, new bridge construction, rehabilitation and extensions. An additional six structures will be affected as part of the reconfiguration of the major interchanges at U.S. 63 and U.S. 54.

The project calls for traffic control, clearing and grubbing, erosion control, grading, hauling material, concrete paving, slip forming barrier wall, temporary and permanent pavement striping, bridge construction, culvert installation, MSE wall construction and relocating utilities.

Concrete paving in the median began in fall 2024. Winter weather has hampered the

contractor’s ability to pave during the colder months, due to specification restrictions.

“The freezing temperatures have affected concrete placement,” said Samer. “There is no efficient way to heat/control for freezing temperatures of large pavement sections. Bridge work outside of concrete placement continues through the winter.”

Work continues in Columbia on U.S. 63 to construct the two new bridges on U.S. 63 for the new underpass of U.S. 63 from Conley Road. Median grading has begun in different locations along this section, along with MSE wall construction and bridge work.

Approximately 450,000 to 500,000 cu. yds. of dirt will be moved during construction. Samer said minimal excavation has taken place.

“The only real areas that have started are off I-70 for the new underpass of U.S. 63 as a part of the interchange reconfiguration. Most of the excavation work on this project is related to the bridge and interchange work, rather than the addition of the third lane. This is due to the expansion occurring to the median, rather than on the outside.

Regarding the crossover in place along U.S. Route 63 between the Broadway overpass and the Conley Road underpass for bridge construction, currently south U.S. 63 traffic is being crossed over to the northbound side of U.S. 63 to allow for building the new U.S. 63 bridge. Once that structure is complete, traffic on the northbound direction will be moved to the south direction, using the new bridge, to allow for the construction of the new northbound bridge.

The bridges are necessary to allow additional mobility from Conley Road and provide an alternative to the existing triple left turn at the Conley Rd./U.S. 63 Connector intersection that’s being removed. To date,

traffic on Conley Road traveling to northbound U.S. 63, or to I-70 through the connector, takes a left in one of the turn lanes at that intersection. All of those turn lanes are being removed. Left onto Conley Road. from the connector and through to I-70 Drive will remain. The underpass will travel along the U.S. 63 lanes (east side) and merge back in at the connector.

A variety of heavy equipment being used on the I-70 Columbia to Kingdom City project.