A dverti $ er Component manufaCturing Serving the Structural Building componentS induStry S The “Setting the Goal of One Thousand Pieces per Hour” See cover story by LimTek Solutions on page 48

www.todd

The number one expert for process improvement in all departments of wood truss and wall panel manufacturing using proven and practical lean manufacturing methods combined with industrial engineering.

√ Labor Time Standards for Accurate Wood Truss Labor & Pricing Estimations

120+ Different time elements to input into any wood truss programs.

Based on the equivalent measurements called work minutes, work hours, realistic expectancy (RE), or scheduled units (SU).

√ 100+ Different Companies Using Them Every Day

Productivity scheduling, efficiencies measurement, productivity incentive programs, labor cost estimations, and Pricing based on Labor Units.

√ Three Offerings With or Without Onsite Consultation Services

1) Wood Truss Time Standard

2) Lean Manufacturing TDC Training Material — All the TDC lean manufacturing training material best practices, without an onsite consultation. Most clients are shocked by the depth and scope of the TDC best practice training materials, which are very clear, concise, and without bias to enhance their operations.

3) Consultation & Training — Full onsite consultation with all the lean manufacturing best practices training material and time standards included. A Minimum Gain of 3 Net Profit Points is a Very Low bar for TDC

“... It was an investment well spent because I not only learned a completely different way to view labor metrics, but I came out of it with a completely different mindset on pricing, scheduling, and staffing...”

Shane Soule, President Bremen, IN

“….Your time standards are perfect. They are far more accurate than BF. We are much more comfortable with the work minute for estimation of labor for both the pricing and shop scheduling. BF is just too unreliable for our needs.”

Keith Myers, Truss and Panel GM – Lakewood, NJ Written testimonials provided by dozens of clients on the TDC website.

drummond.com todd@todd drummond.com

(603) 748 1051

Anna Stamm – Advertiser Forum: Expecting an Instantaneous Answer

Joe Kannapell: The Development of the Truss Plate, Part VII: Contentious Competition

Wendy Boyd – Spida Machinery: Creating Solutions with Labor-Saving Equipment

Todd Drummond Consulting, LLC: Money Hides Many Sins (Waste)

Glenn Traylor: Has Your Guideline Shifted?

Tracy Roe – Eagle Metal: Dependability in an Uncertain Environment

Edmond Lim, P.Eng. –LimTek Solutions: Setting the Goal of One Thousand Pieces per Hour

Rob Bellian – Vekta: Increase Truss Production Quality and Efficiency with Precision Printing

Steve Shrader – Hundegger USA: Increasing CLT Options and Supply

Carl Villella – Acceptance Leasing: Forecasting Inflation and Interest Rates

Frank Woeste – All Things Wood: Design of Wood Structures—an Introductory Course

Thomas McAnally – The JobLine: Is 2022 Like 2006?

Geordie Secord – Design Connections: Building Information Modeling for the Component Business?

Lesko Financial Services Team: First Quarter Brings Hints of Later-Year Move Toward Recovery

MiTek Staff:

Effects of Ripping Structural Truss Lumber

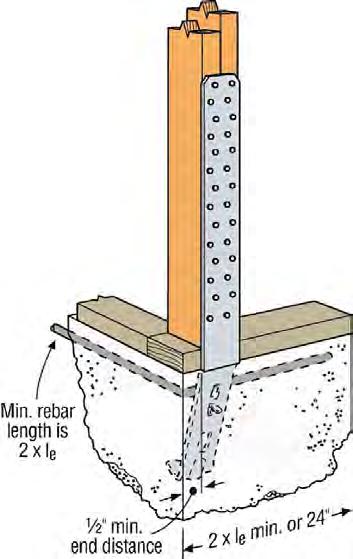

Randy Daudet – Simpson Strong-Tie: Top Structural and Wood-Related Changes in the 2021 IRC, Part 2

Joe Kannapell – The Last Word The

$ er Component manufaCturing Serving the Structural Building componentS induStry S The Inside Articles 6 10 17 24 35 42 48 55

A dverti

Last Pioneers 62 69 74 78 84 90 112 114 136

Design and build faster than ever. Learn

From plans, to walls, to panels, and everything above. Introducing a new level of design tools, built from the ground up.

more a t EagleMetal.com

Publisher Thomas McAnally twm@componentadvertiser.org

Editor Anna L. Stamm 800-289-5627 x 3 anna@componentadvertiser.org

Distributed FREE Via e-mail subscription Download PDF or Read on line at www.componentadvertiser.com

News of Interest and Advertising inquiries can be submitted to: anna@componentadvertiser.org An Open Forum for many sources. Deadline 20th of each month. Articles, Trade Names, and Logos are the property of their respective owner or creator unless otherwise noted

Disclaimer: We reserve the right to refuse any advertisement or material that we deem not in the interest of the industry or the Advertiser. Permission to use content is the responsibility of the contributor including permissions to use any likeness of persons.

The Advertiser is provided “As Is” including typographical errors, omissions, and mistakes both intentional and unintentional.

30,55,64,72 Copyright 2008-2023 Component Manufacturing Advertiser The Advertiser 411 Walnut Street #12250 Green Cove Springs, FL. 32043

&

Wolf X Machina

Tech Systems .............................................................. 14,101,126 .................................................. 13,51,69 .............................................................................................. 58,98 ................................................................................. 31 ............................................................................................ 22,80 ............................................................................. 8,64 ................................................................... 4,42,72 .................................... 32,66 ............................................................. 38,108,120 .................................................................................. 19,61 ................................................................................... 21,87 .............................................................. 9,33,41,62,94,121 ......................................................................... 1,30,48,50 ........................................................................................ 12,112,135 .......................................................................................... 83,138 ........................................................................ 46,47 ............................................................. 13,93 ....................................................... 20,60,114,119,120 ............................................................................ 16,17,52,82,88 ................................................................. 9,26,39,94,97 ...................................................................... 33,59,61,78,84,109 ............................................................... 34,102 ...................................................... 2,24 ................................................. 40,70,106 ........................................................................... 27,54,55 ............................. 7,15,19,31,61,65,67,68,71,83, 89,92,93,99,105,107 ................................................................................ 59,104 ....................................... 15,19,23,28,29,39,41,44,45, 51,53,59,65,67,71,73,76,77,79,81,83,86,89,96,107 Published Monthly

Wasserman

Associates

Wood

Believe it at your own risk!

reproduction in whole or in part

Archive Copies Available On Line www.componentadvertiser.com Inside ................................................................................................ 7 .............................................................................61 .............................................................................72 ............................................................................93 ............................................................................95 ...............................................................105 ................................................105 .................................................................................100 ............................................................................................103 ...............................................................................104 .........................................................................................119 .................................................................................................132 ............................................................................................134

no

without permission from the component manufacturing advertiser

Anna L. Stamm Director of Communications and Marketing Component Manufacturing Advertiser.

Advertiser F Forum

Expecting an Instantaneous Answer

I’m always amazed, and irritated, when people expect an instantaneous answer. In these days of instant electronic communication, the fact that replies could be immediate is often conflated with the thought that they will be immediate. This leads to unnecessary aggravation for everyone involved.

How many times have you been asked a question, only to have the person asking it move on before giving you an opportunity to answer? Whether they’ve escalated the situation by looping in more people or simply made a decision without all of the facts you could have provided, now you’re both on the defensive.

I realize this list will not live on past this article, but it sure would be nice if it could avert some of these avoidable conflicts for me or someone else in the future.

When communicating electronically, please remember:

1. Just because you are sitting at your computer, the other person may not be sitting at theirs.

2. Just because you are working on that specific topic, the other person may be working on a different critical issue at that same moment in time.

3. When you haven’t received an answer within 5 minutes, 2 hours, etc., that doesn’t mean you will never receive an answer.

4. If it was important enough for you to ask the question, isn’t it also important enough to wait for an answer?

With a good dose of patience and understanding, everyone can accomplish what needs to be done. Replies can be made in a timely manner, even when they’re not instantaneous.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #6 A dverti $ er Component manufaCturing m The

Monet DeSauw FWA 500 Floor Web Cutter

• Push Button Powered Blade Angulations

• Single Push Button Setting for 2 Blades per Side

• Electronic Digital Readouts

• Backup Mechanical Indicators

• Cuts 4 Angle Webs, Cantilever Webs (2 piece webs) & Square Blocks

• Magazine Lumber Feed for 3x2, 4x2 and 6x2 Lumber 12 1/2” to 48 1/2” Length Capacity (7” Minimum on Square Blocks)

• 60 Pieces per Minute

• (4) Internal 16” Blades & (1) External 16” Cut-Off Blade

• Pneumatic Blade Brake on External Blade

• Dust Hoods

• Belt Waste Conveyor (under saw)

• Add $4,200 for 12’ Incline Waste Conveyor (adjacent to saw)

• Add $1,900 for Extra Set of Blades

• 480 Volt / 3 Phase FOBMO

Call For Pricing

Monet DeSauw DeRobo

Linear Saw

• Automated (Truss Design Software Download) or SemiAutomated (Touch Screen Entry) Operation

• All Movements are Computer & PLC Controlled

• Comprehensive Setup Screens Display Each Piece with Setup

Data

• 22” x 40 Tooth Blade on PAE Cut 1 or 2 Boards up to 20’ (2 Second Plunge Cut)

• Cut Chords, Webs, Rafters, Wedges & Stair Stringers

• Cut Long Scarfs by MultiPlunging

• Servo Positioning on Infeed, Angle & Outfeed Pusher

• Over Travel Protection

• Ink Jet Printer

• Lumber Optimization Program

• Belt Waste Conveyor

• 480 Volt / 3 Phase / 60 Amp

• Includes 5 Day Onsite Installation & Training

• Optional Monet DeSauw Live Deck, Bunk Feeder & Incline Belt Waste Conveyor FOB MO Call For Pricing

Monet DeSauw DeSawyer

2000 Automated Saw

• Touch Screen User Interface with Backup Mechanical Controls

• 3 Operating Modes: Auto, SemiAuto & Manual

• All 20 Axes of Movements are Computer & PLC Controlled

• Comprehensive Setup Screens Display Each Piece with Setup Data

• Anti-Collision & Optimizing Programming

• Auto Calibration Productivity & Time Tracking

• Maintenance Diagnostics

• Variable Speed Conveyor (0-50 Flights per Minute)with Powered Hold Downs

• (1) 30” x 80 Tooth Blade (27 3/4”

Scarf on PAE)

• (4) 16” x 40 Tooth Blades (13 1/2”

Scarf on Centerline)

• Pneumatic Blade Brakes on all 5 Blades

• 16 1/2” to 20’ Length Capacity (11” Minimum on Square End Blocks)

• Vibrating Waste Conveyor Under Saw

• 480 Volt / 3 Phase

• Includes 4 Day Onsite Installation & Training

• Add $2,900 for Extra Set of Blades

• Optional Live Deck, Label Printer, Ink Jet Printer, Catcher Display & Incline Belt Waste Conveyor.

Call For Pricing FOB MO

Buy Factory Direct From Wasserman & Associates at the same price as the Manufacturer, and get the added support and care you need to be up and running FAST! WE’LL EVEN HELP SELL YOUR USED EQUIPMENT TOO!

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #7 A dverti $ er Component manufaCturing m The 800-382-0329 | www.wasserman-associates.com

NEW! NEW! NEW! NEW SAWS!

CONSIDERING EQUIPMENT? CONSIDER CLARK.

EZ-SET AUTO JIGGING EXCLUSIVE & PATENTED DESIGN

Automatic Truss Jigging System to drastically reduce setup times. Allows for 100% embedment on the table, with top & bottom chord pucks in the same slot. TopSider or standard configurations available for conventional kick-leg, walk-thru, or our new trackless 8' and 10' continuous table systems. Systems for other roller & hydraulic gantries are coming soon. Available in new machine installations or for retro-fitting your existing table. The TopSider is exclusively applicable for “kick or flip leg” style truss presses such as the Tri-Axis & Lumbermater®

FEATURES / APPLICATIONS

• Capable of 100% On-Table Nail Plate Embedment

• Two Pucks Per Slot

• 24", 26", and/or 30" Spacing

• Compatible with all current major design software

• Multiple Simultaneous Layouts

Lumbermater® is a registered trademark of Illinois Tool Works, Inc., or ITW.

EQUIPMENT FOR TRUSS & COMPONENT MANUFACTURERS WWW.CLARK-IND.COM / GENERAL@CLARK-IND.COM LOCAL 417-235-7182 • US TOLL FREE 800-743-9737

2Seconds

That'sallthetimeittakes

todrillstudsforrunningRomexorotherelectricalwireinthewallpanels

Motor: HeavyDuty5HP-3phase-220vor440v(Pleasespecifywhenordering)

MotorcarriagebearingandspindleassemblymountedonBlanchardgroundsteelplate

LinealmotionishardenedandgroundVbearingsandrails

BlockSizes: 2x4through2x12infiniteheightsettingtocenter

AirSupply: 100psi10CFM

Drills: 2wing3/4'”CarbideTippedcanaccommodatesmallerorlarger

Spindles: AlloySteelpolishedandgroundprecisionshafting

Frame: 2"SteelWithPowderCoatFinish

Covers: 10Gauge(1/8"Thick)Aluminumremovable

Dimensions: Height-60inches,Width-33inches,Depth-33inches

Shippingweight: 750lbs.-(Includingcrate)

MADEINAMERICABYAMERICANS

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #9 A dverti $ er Component manufaCturing m The 916-508-3558• ww w.thehaincompany.com SeetheStudDrillerinaction! Goto https://youtu.be/AnODX5vPesE forademonstration

Work Smar ter

The Development of the Truss Plate, Part VII: Contentious Competition

By Joe Kannapell

By Joe Kannapell

The plated truss industry went bonkers around 1961. Truss fabricators were besieging suppliers for product and were willing to try nearly any plate or machine. Plate suppliers had to conform to the new testing and QC required by TPI-60, but machinery vendors had no guidelines beyond satisfying customers. Many of these early suppliers followed the lead of Sanford and Jureit in obtaining patents to protect their inventions and their eventual sales – or so they thought. Among those were Interlock Steel in Pennsylvania, Clary Corporation in Texas, and Bill Black, Sr. in Florida, each entering the business with a unique perspective and each making their mark.

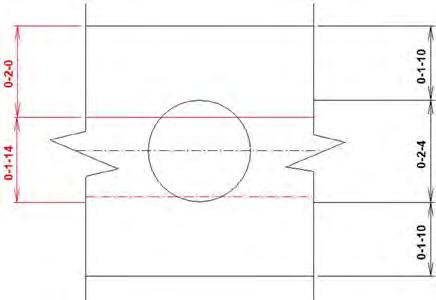

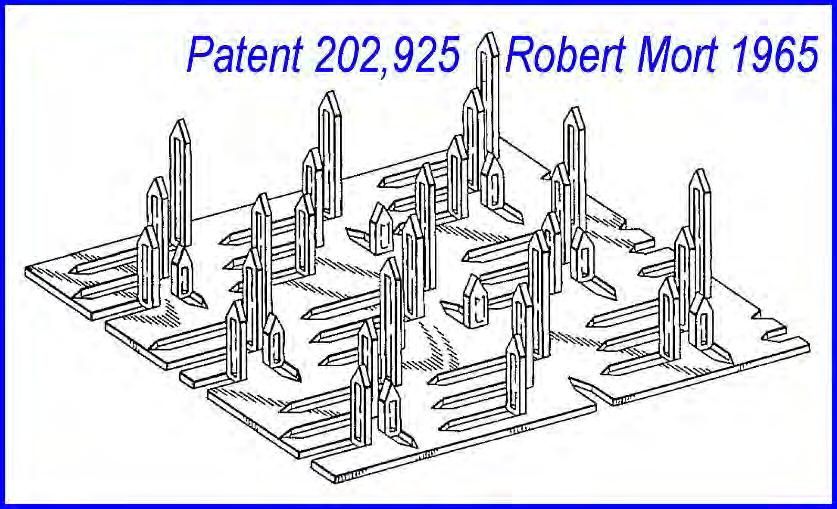

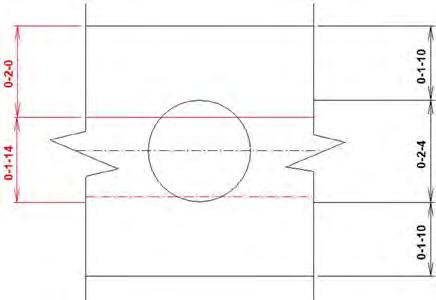

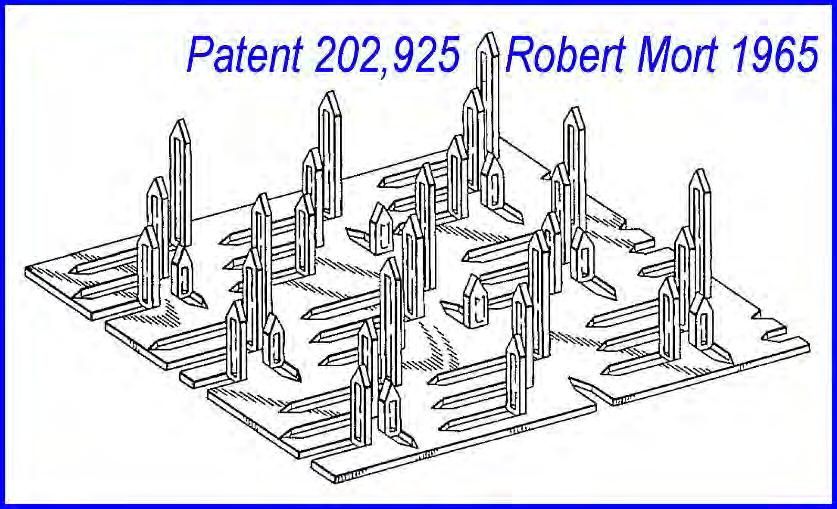

Interlock Steel : Edgar Mort knew right away that a truss plate with integral nails would sell much better than those he was stamping with only holes for nails. He encouraged his CPA brother, Bob Mort, to join him in developing a truss plate business. Edgar then devoted the resources of his Standard Aluminum Co. to developing a plate, while Bob engaged Dr. Jack Ritter at nearby Youngstown State University’s Civil Engineering Lab to assist. After testing several configurations, they settled on a unique design, for which Mort received a patent in 1965. With a viable product in hand, the Morts incorporated Interlock Steel Company, and went on to become a full-service supplier of plates, engineering, and machinery.

Clary: The Clary Corporation had been a manufacturer of mechanical office machines, but somehow got into the saw business through the work of a prolific inventor, George Mayo. Mayo’s first remarkable rendition of a component cutter incorporated mechanisms that survive to this day, including a rack and pinion drive for the moveable head, and a square drive shaft for the lumber conveyor. Mayo kept innovating for the next twenty years, finally conceiving the Timbermill for Speed Cut, Inc., the first component saw with more than four heads.

Clary was also the first to provide tabular books of cutting angles and lengths, authored by future SBCA President Gary Sweatt, PE. Later, Clary persuaded Dan and Camilla Hurwitz to move to Texas to provide cutting software. Though that venture was short-lived, the Hurwitzs went on their own to create On-Line Data, the most successful independent software provider.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #10 A dverti $ er Component manufaCturing m The Continued next page

Bill Black Sr., father of TeeLok founder Bill Black, Jr., devised a machine to build trusses, “of unusually uniform structural characteristics.” As this was the earliest truss machinery patent granted, it was necessary to establish the advantages of offsite construction over conventional framing which, “…requires much climbing about the upper portion of the house being erected, limiting this phase of the work to the stronger and more agile carpenters.”

Unfortunately, this very detailed multi-head machine design, perhaps never built, didn’t anticipate the tens of thousands of pounds of force required to embed most truss plates. But as this concept evolved through the next 20 years, it finally resulted in Hydro-Air’s Glide-Away, which set the world production record that stands to this day (see The Last Word: Vertical Presses—The World Record, in the February 2020 issue).

The three patents described here and in my previous articles set the stage for a contentious competition to either work around or to one-up these patents. By their nature, patents required the inventor to reveal the details of his invention to the public in exchange for gaining a monopoly position for the next 17 years in 1960. For example, Mayo’s 12,800-word patent description was sufficiently detailed to enable imitators to evade it with the help of skilled patent attorneys and skeptical courts-of-law. And, over the next decades, it was the courtroom that would largely shape the future of the industry. But, in the near term, a pivotal decision was forthcoming that would become the most far-reaching.

Next Month: Patent Skirmishes

Since 1970, Joe Kannapell has worked as programmer, Chief Engineer, Marketing Manager, and Sales VP for MiTek, plus 7 years at truss plants, retiring at the end of 2020.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #11 A dverti $ er Component manufaCturing m The

TIME COPYRIGHT © 2020 MITEK INDUSTRIES, INC. ALL RIGHTS RESERVED IDEAL FOR LARGE RESIDENTIAL OR MULTI-STORY PROJECTS

Prefabricated to meet builder’s specifications

Ability to be sheathed with most flooring surfaces

Utilizes top chord support for ease of installation

Allowances for deflections, reactions, plumbing locations, waste and duct chases at the design stages Contact your Sales Representative or Contact MiTek at 800-325-8075. FLOOR CASSETTES SAVE TIME ONSITE AND SHORTEN THE INSTALLATION CYCLE Open web design for easy installation of HVAC, Electrical & Plumbing Crane onsite and install in minutes Open web trusses eliminate the need for soffits and dropped ceilings, providing new design possibilities Safe to walk on immediately, improving safety at heights Reduced onsite storage

INSTALL MORE SQUARE FEET IN A FRACTION OF THE

→

→

→

→

Used Razer S5 Linear Saw

S5 Razer saw modules configured for either left-to-right cutting and/or “Z” shaped layout. AIT auto infeed tables. Vekta user interface software complete with the full version of the optimization algorithms. Stack cutting and side by side cutting

Contact for Pricing

Eide Integrated Systems, LLC 612-521-9193

www.eidemachinery.com

Safety Speed Manufacturing Model

7400 XL Panel Saw

Safety Speed Manufacturing, model 7400 XL*, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 1/8" maximum thickness, accuracy within 0.005 inches, 13 foot long welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include digital readouts for vertical cuts, automated length measuring, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00).

$13,149 Base, FOB MN. Wood Tech Systems 765-751-9990

www.woodtechsystems.com

2019 MiTek Blade Linear Saw (# 1)

MiTek Blade model: 89060-501, with 20′ infeed, face printing via Matthews printer model DOD 8000+ Maxi. Features 17″ saw blade powered by 5HP motor to cut 2×3 through 2×12 boards. Left to Right in-feed in “Z” configuration with 18′ out-feed conveyor. Includes any available spare parts, 230v/3Ph electrical power required, 110 PSI at 4-50 CFM air pressure as specified by the OEM.

$364,990 FOB CA

•

765-751-9990

•

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #13 A dverti $ er Component manufaCturing m The SAWS National Crane 680-HTM Tractor Mount, Multiple Units Available Call Dan at 800-824-6704 www.runnionequipment.com

20 ton capacity

80’ boom – 90’ tip height

Out and down outriggers

•

•

•

Single front outrigger for 360 degree stability

Continuous rotation

Adjustable swing speed control

5th Wheel

Freightliner and Peterbilt

OSHA and DOT Certified

•

•

•

•

A dverti$er Component manufaCturing S erving the S tructural B uilding c omponent S i ndu S try The

NEW!

www.woodtechsystems.com

Start smarter... Grow faster... Achieve more... cvillella@acceptlease.com | www.acceptlease.com 894 Beaver Grade Road, Suite #304 - Moon Township, PA. 15108 Phone: 412-262-3225 Fax: 412-262-1154 Keep More of Your CASH Eliminate Yearly Financial Reporting Low Fees Fixed Payment Programs No Additional Collateral Now offering short term Working Capital Loans

the Component Industry Since 1996” Start smarter... Grow faster... Achieve more...

“Serving

We have recently experienced unprecedented lead times, materials costs and home prices which seem to be receding as quickly as they arose. These cycles are not unique to our industry and will continue to ebb and flow. The one constant is the need to know how these factors affect your business. At 4Ward Solutions Group we help you figure out your costs per component group, minimum working inventory, plant capacity, and labor levels.

In-House Experts! Never

What do you need? How can we help?

Our values are integrity, safety, teamwork, and continuous improvement and we are here to serve. If you have questions about your business and would like our help in achieving operational excellence, please contact our team.

Our solutions are tailored to your business.

PROUDLY SERVING: LUMBER DEALERS, BUILDING MATERIAL DISTRIBUTORS, COMPONENT & PANELIZERS, MODULAR & VOLUMETRIC, MILLWORK & BUILDING INDUSTRY

250+ YEARS OF COMBINED EXPERIENCE IN-HOUSE EXPERTS TECHNOLOGY LEADERS

300+ HAPPY CUSTOMERS

Roger Wagner, Design Manager

Owen Eldridge, Consulting Manager

Ben Hershey, CEO

Jordie Puchinger, CTO, Founder of Moducore

Dylan Thomas, Labor Manager Tomasz Cwik, Robotics / New Products Expert

Mike Ruede Jr., Automation & Robotics Expert

Darren Hamar, Offsite Expert

Christ Weintraut, Offsite Expert

Roger Wagner, Design Manager

Owen Eldridge, Consulting Manager

Ben Hershey, CEO

Jordie Puchinger, CTO, Founder of Moducore

Dylan Thomas, Labor Manager Tomasz Cwik, Robotics / New Products Expert

Mike Ruede Jr., Automation & Robotics Expert

Darren Hamar, Offsite Expert

Christ Weintraut, Offsite Expert

outsourced.

CONNECT WITH OUR EXPERTS INFO@4WARDSOLUTIONSGROUP.COM - 4WARDSOLUTIONSGROUP.COM

Equipment Wanted!

Saws

• Automated Component & Linear Saws (2010 & Newer)

• Monet DeSauw or TimberMill

Manual Component Saws

• Floor Web Saws

• Spida (Apollo) Saws with Truss Automation

• Bunk Cutters

Truss Equipment

• Roller Gantry & Hydraulic Press Systems

• Finish Rollers

• Truss Stackers

• Floor Truss Machines

• Lumber Splicers

• Jack Tables

• C-Clamp Presses

Trucks & Trailers

• Stretch Roll-Off Trailers

• Go oseneck Roll-Off Trailers

Modular Equipment

• Pacific Automation or MiTek Mobile Home Press

Contact Wasserman & Associates for a Fair Market Value Assessment of your Used Equipment Operational, Needs Work, and Parts Only equipment will be considered!

800-382-0329 | www.wasserman-associates.com

Terminailer XP

Price: $224,000

FOB: MN

Don’t just do it, nail it. It’s a brand new day in wall-panel production, with a whole new way of doing things better.

Terminailer®, a revolutionary, event-driven, nailing machine that completely defies any preconceived notions about sub-component assembly.

1994 Clary Master Component Saw

1988 Clary Master 5-Blade Component Saw

1988 Clary Master, 5-blade component saw, rebuilt by seller in 2013. Cuts dimensional lumber from 1′-6″ at 90/90, to 20 ft lengths, 2×2″ through 2×12″. Includes analog displays for angles and length, powered angulation and length, shaker pan undersaw waste conveyor, (1) 32″ blade, (1) 22″ blade & (2) 18″ blades & (1) 16″ blade. Cuts 4-angle floor webs at 3′-0″ minimum. In working order when decommissioned in October of 2022. Includes belt incline, schematic drawing and all available spare blades. 480 volt, 3 phase electrical required.

$8,497 FOB ID

Wood Tech Systems

765-751-9990

www.woodtechsystems.com

5 Blade Component Saw (Model 340). Powered Angulation & Carriage. Pneumatic Blade Brakes. Waste Conveyor (under saw). Excludes Incline Waste Conveyor (adjacent to saw). In working condition but has several issues that need to be addressed (reference photo #6).

$7,500 NOW $5,000 - FOB AL

Wasserman & Associates

800-382-0329

www.wasserman-associates.com

Terminailer all but shatters the stereotypical myth that subcomponent equipment is essentially peripheral – unimportant. And it does so by quickly and accurately driving far more framing nails in your wall panel jobs than ever before. Whether in your shop or in the field, one operator sets the pace for production and quality. And that reduces labor costs and other aspects of overhead.

Terminailer is an event-driven, sub-component assembler that will quickly and accurately drive 30% to 70% of the framing nails in any wall panel job. In your shop or in the field, one operator sets the pace for production and quality. The Terminailer functions independent of design software, requires zero set-up time when switching between any configuration, and requires no special operator training.

The Terminailer is easy to move around the shop so it’s location can evolve as your shop evolves. With all of the nailing occurring in the closed main chamber, nail injuries and nail location miss-fires are eliminated, making your plant that much safer.

With nearly ten years of development from people that know machinery it is assembled to exacting standards, well supported, and it is easily maintained with shelf-item parts. Terminailer: vetted, tested, and ready to drive maximum productivity for you. Be sure to check out our videos below for a quick review of this revolutionary machine!

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #15 A dverti $ er Component manufaCturing m The A dverti$er Component manufaCturing S erving the S tructural B uilding c omponent S i ndu S try The 765-751-9990 www.woodtechsystems.com NEW!

SAWS

Creating Solutions with Labor-Saving Equipment

By Wendy Boyd Chief Customer Officer –Sales, Service & Marketing

By Wendy Boyd Chief Customer Officer –Sales, Service & Marketing

hen arriving back to work after Christmas holidays, I had a few hundred emails to work through and a multitude of other tasks to conquer so I’d be up to speed again for 2023. One of the most compelling emails I had was from a Truss and Wall Fabricator who was appealing to me to help solve an age-old problem. The email went something like this:

WWendy, I want to talk to you about some machinery for my factory. I can’t get my workers to come to work, they are either away on holidays, they are sick, or their family is sick – hence I only have half my staff come to work daily – what can Spida do to help?

My first thought was: wow, where do I start? Better cutting, better automation – Spida has so many options that could help!

Immediately I looked at my stock on hand to see if I had a quick solution to his cutting problems. With quite a few Spida saws in stock, we had a conversation on cutting requirements for his factory and how we could increase his cutting capacity with just one new saw. Could one saw make a huge difference? (Hint: the answer is YES.)

He also had a completely manual wall framing line with 10 men who would work on it – but on average only 5 would show up to work on any given day. Could we redeploy the dependable workers so that they were productive and efficient every day? (Hint: the answer is YES.)

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #17 A dverti $ er Component manufaCturing m The

Continued next page

Chatting about output, he understood that the Spida Wall Line’s capability eclipsed that of his current planned lineal feet per day of wall frames. He looked at where this wall line could fit in his plant and who he needed to make it work. He had 4 men that he knew were the workers who showed up every day – and that’s all he needed to operate the wall line we were discussing and to keep the production promises made to keep his factory running. I could see his mind ticking over about the possibilities going forward. Could he increase his production numbers and start getting more market share in his city? (Hint: the answer is YES.)

We were well on the way to helping him solve the issues he was having, but there was one more thing to add to his list that would be an easy way to increase his truss production. We discussed the capabilities of a Mini 8 or Mini 10 table press to help his already overburdened truss line. With a couple of dedicated workers –that were repurposed from around the factory (he didn’t need 5 of those men on the wall line anymore), he planned on pushing quite a few trusses to one of these tables. Easy to install and just as easy to learn with a little training, the Mini 8 or 10 can do anything from small to large trusses with just a few men. Would this help him increase his production even more? (Hint: the answer is YES.)

So with just a few conversations, I was able to provide a multitude of options to help the sender of that 1 email. Only 199 more emails to go….

If we can help you with your 2023 requirements, please let us know. We have Tony in South Central, Dan in the Southeast, Bill in the Northeast, and Mike in the West – all can be contacted via our Spida office or via the contact page on our website. Happy 2023!

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #18 A dverti $ er Component manufaCturing m The

priority, Call Me. If the salesman will do - we'll talk later...

Also, don't let Financing Deals influence your best solution. FitzGroup can arrange – Zero down & No payments for 90 Days!

Please be assured that your investment with any of our selected partners will not cost one penny more with the Fitzgerald Group as your purchasing contact. In addition, you will receive the full advantage of our Partner Relationships and Services NOT offered elsewhere.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #19 A dverti $ er Component manufaCturing m The REPRESENTATIVES 765-751-9990 www.woodtechsystems.com Monet FWA 500 Floor Web Saw New, Monet five-head, floor truss web saw, cuts 4-angle, 4x2 floor truss webs from 16 inches and 90-90 blocks from 12 inches to four foot long maximum length. Features 10-board magazine feed, powered, fixed-quadrant angulation, manual carriage standard, shaker-pan scrap conveyor with short incline conveyor and cut-off blade. Option for longer carriage length, single-sided setup (shown in pictures, but not standard), dust hood and horizontal scrap conveyor. 480 volt, 3 phase. Call for pricing, FOB MO. NEW! 800-382-0329 | www.wasserman-associates.com

LLC a blending of excellent services and products, with answers that work...!© Not producing the results you need or want – getting conflicting info about what to do and the equipment and the systems you may need? Before you Buy - Ask yourself –do I need a salesman or a guide? If you want an Independent Guide that has your bottom-line results as the #1

Fitzgerald Group,

RFitzgerald@FitzGroup.com

www.FitzGroup.com A dverti$er Component manufaCturing S erving the S tructural B uilding c omponent S i ndu S try The Hiring Zone Building Component Industry's Job Board Employer to Candidate Direct Hiring No Recruiting Fees! Post your Opportunity... Candidates respond directly to you! For Additional Information Contact: twm@componentadvertiser.org or Call: 800-289-5627 x1 Visit our website: www.componentadvertiser.com/Hiring-Zone 2021 Hain 20' Powered Measuring System & 2 Dewalt Saws • 20' Hain Powered Measuring System • Feet & Inches System (Stops at 12" Centers) • Motor: 1/4 HP Linear Actuator (110 Volt) • Infeed/Outfeed Roller Conveyor with Stands • (2) DeWalt Sliding Compound Miter Saws Details

719.528.5445

Leverage the power of a strong network.

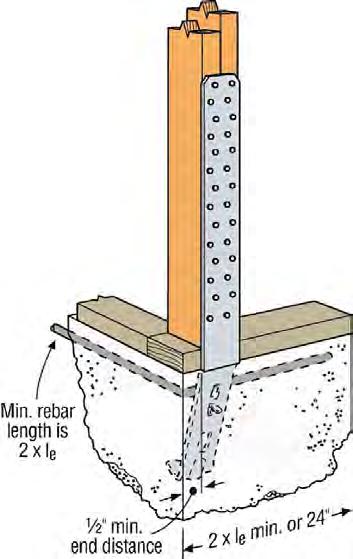

As a truss component manufacturer, you already know Simpson Strong-Tie as a reliable partner in the construction industry. But our connections go beyond the products we make. Our people can help reinforce your network of builders, engineers, contractors, equipment manufacturers and suppliers, strengthening your existing relationships. Also, our open-platform software is integrated with the most widely-used systems, and can be customized to work with the machinery you choose. Backed by our expert service and support, you’ve got all the resources to succeed.

Grow your business ecosystem with a well-connected partner. To learn more, visit our website at go.strongtie.com/componentsolutions or call (800) 999-5099.

© 2022 Simpson Strong-Tie Company Inc. TRUSS23PART

Simpson Strong-Tie® Building Technology | Software and Service for Smarter Business

IntelliVIEW Suite Manage. Design. Build.

The industry’s most powerful integrated component design, engineering, and management software for steel and wood-framed structures.

iCommand

Manage projects, customers, materials, pricing & inventory

iModel

Design truss layout & profiles

iDesign

Optimize material usage & engineer trusses

iPanel

Design wall layouts, panelize, bundle, break & stack

eShop

Maximize crew productivity & improve manufacturing efficiency

The IntelliVIEW Suite is a fully integrated software solution for the layout and design of a building’s rough framing elements—including roof and floor trusses, wall panels, solid sawn, EWP, sheathing and various ancillaries.

The IntelliVIEW Suite provides the industry’s most complete analysis of the design, cost information and bill of materials—promoting increased profits by reducing plate and lumber use.

Ask those who know. They’ll tell you about the people at Alpine who make a difference.

BUILD MORE. alpineITW.com | 800.521.9790

USED ALS 276 LINEAR SAW

PARTS & COMPUTER

• Used Servo Star CR10251 (2 Available) -$1,100 Each

• Used Servo Star CR06251 (2 Available) - $1,100 Each

• Used ALS Windows XP Computer - $1,500

• Used parts were removed in "working condition" from the ALS 276 during a saw upgrade FOB AL Wasserman & Associates 800-382-0329 www.wasserman-associates.com

2002 Koskovich Auto Omni component saw, 5-blade automated saw includes [3] 20 inch blades, [1] 30 inch blade, [1] 12 inch blade and shaker waste conveyor with factory side pans. Fully automated setup with full power length and all axis angulation, single-sided setup from operator console, 2×3 through 2×12 and 4×2, 20’ to 9” @ 90°/90°, Exair cabinet coolers, remote monitor, no spares. In operation until Aug. ’21. 208/240/480 volt, 3 phase, 100 Amp saw electrical required. 120 volt, 1 phase PC electrical required.

$13,970 NOW $9,997 FOB OH Wood Tech Systems

765-751-9990

www.woodtechsystems.com

Safety Speed Cut Model 7000 Panel Saw

Safety Speed Manufacturing model 7000, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 inch maximum thickness, accuracy within 1/64th of an inch, 10 foot welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include lower frame extensions, digital readouts, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00). $9,332 Base, FOB MN.

New L-M Equipment

Verticut 2000 PET / Bunk Saw Station

The L-M Verticut 2000 is a true Precision End Trim (PET) saw that is capable of holding a 1/16th accuracy all day long. Made in the USA, the V2k comes equipped with a 15 HP 460/230 volt High-E three phase TEFC motor driving a Double ended Premium “Stellite” inlaid saw bar with a spring loaded chain tensioner and an automatic oiler to lubricate the .404 pitch custom profile semi chisel saw chain.

Rather than a single pivot-point, the saw assembly is mounted on a mandrel box that is guided by cam followers on a steel frame that is raised and lowered by a hydraulic cylinder. A console with the saw controls moves with the saw assembly along a track positioned using a manual “V” wheel geared drive or optional Hydraulic drive

The V2k is unlike other imported systems that are basically a Portable Yard Saw on a cutting rack with a best cutting accuracy of +/- 1/8″ (meaning up to ¼” accuracy variance between units of lumber). The V2k from L-M provides +/- 40 thousands, assuring consistent PET precision from unit to unit.

Another advantage L-M has over the competition is their commitment to personal service with unlimited phone assistance and technical help. Their team has traveled the country working on crosscut saws for many years and they know their equipment inside and out. L-M is a familyowned business that prides themselves in doing the job right and building long term relationship that is vital to their business: “Built to last as long as our customers since 1946”.

Price based on configuration

FOB OR

765-751-9990

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #23 A dverti $ er Component manufaCturing m The SAWS 765-751-9990 www.woodtechsystems.com

NEW!

2002 Koskovich Auto Omni 5-Blade Component Saw

www.woodtechsystems.com

NEW!

SERVO

Money Hides Many Sins (Waste)

Atrending DIY post shows a long sequence of nail holes alongside a wall-mounted TV with a caption that says, “I knew that stud was in there somewhere.” Meant to be a humorous poke at the times when we’ve attempted new projects, it reveals how sometimes we might not have been as skilled as we believed. We are all guilty of trying to do projects that go horribly wrong. Often these projects cost us far more than if we had just listened to a professional.

The past few years have been a tremendous boon for the building industry. This type of success can easily cause a perception of ourselves that can be unrealistic when we are on top of the proverbial success hill. We tell ourselves that when the money flows like a river, we must be the unqualified expert. TDC is witnessing hidden mistakes that will cost so many component manufacturers (CM-wood truss and wall panel manufacturers) hundreds of thousands, if not millions, of dollars with the decisions being made today. As I explain in my January article, Don’t be Blind to Simple Truths for the 2023 Build Season, maintaining sales and margins will become more challenging in the coming months and years.

The tight labor market is causing many to make expensive bad decisions. In a rush to provide equipment to lower labor costs, some vendors are losing sight, or are blind, to the basic tenets of lean and time and motion principles. By far, the Just-In-Time tool in the lean manufacturing toolbox is the most misunderstood one. In an effort to lower labor costs, expensive equipment is being sold to CMs that, in the end, will cost the CMs millions of lost sales. The latest example is a floor truss assembly table made by a reputable truss equipment vendor which is the most ergonomically poor design TDC has witnessed in twenty years of professional consulting. My recommendation to my client, where I saw this brand new table, was to sell it and purchase a used or new floor truss table for better results. The cost of lost sales from the poorly designed table will be substantially higher than the cost of the table itself. Numbers do not lie, and the end results will clearly show that the overall output will be dramatically lower.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #24 A dverti $ er Component manufaCturing m The

Continued next page

Todd Drummond

New equipment installs and new manufacturing facilities are being built with preventable constraint costs that can never be removed. In other words, they would have been able to produce far greater output with the same equipment had it not been designed with seriously flawed bottlenecks in their overall systems. I cannot emphasize enough how poorly some new manufacturing buildings are being designed with no future expansion capabilities. Also, very expensive new truss tables are being positioned and combined with equipment that will forever constrain the total capabilities that would be possible. Even when a vendor is very successful with their sales, and is honorable in their advisement, they may be mistaken as to their recommendations of what is best for your needs. TDC cannot emphasize the importance of properly understood lean principles and industrial engineering practices in all areas of your operation, not just manufacturing.

When a company truly understands and follows lean manufacturing principles, one can find areas that need improvement, and the barriers that block improvement cannot be an excuse for a needed change.

Another example is that so many LBMs and CMs are struggling with their company’s existing communication and tracking enterprise resource planning (ERP) systems provided by plate and accounting vendors. The most common statement by most is that it is “good enough” or “just takes a little bit more training and investment” to get their system to where all their sales teams will use it. Too often, their systems do not connect all the information from every division within the company. The apps are too complicated for many sales team members, and not all the information is updated or available. Suppose your salespeople cannot find all of an order’s needit-right-now information, such as all relevant emails, documents, schedules, automated reminders, all various departments information beyond the CM operations, and detailed status of every stage via a web browser on the cellphone without calling someone. What kind of time-wasting events do you think are happening within your company in every department every day? When a salesperson has to interrupt someone else’s work to get an answer to 95% of the repeated typical questions being asked, why in the world does your company feel this is acceptable? If your current vendors are not resolving this never-ending time-wasting problem, perhaps it is time to look for another solution.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #25 A dverti $ er Component manufaCturing m The

Continued next page

Current success is not a guarantee of future success. Properly understood lean principles combined with industrial engineering practices can prevent many current and future potentially costly errors within your company’s system. It applies in every area, not just manufacturing.

The team of TDC is your best source for learning about proven and practical lean manufacturing best practices combined with industrial engineering principles to keep your company at the leading edge of competitiveness. No one is better at providing your team with proven results for good employee practices, pricing, truss labor estimation, and so many other best-in-class practices. TDC’s tailored solutions are for the client’s specific needs. Go beyond the typical software and equipment vendor recommendations for your operations and do what many have dared to do. Embrace the Drummond Method, and your company can experience cost savings, and net profit gains that usually take months or years can be accomplished in weeks or months, resulting in an average of 3 to 6-point net profit gains for CMs. All areas are addressed, not just the manufacturing. Please do not take my word for TDC’s services, though. Read the public testimonials many current and past clients with decades of expertise and experience have been willing to give: https://todd-drummond.com/testimonials/

Website: www.todd-drummond.com

Phone (USA): 603-748-1051

E-mail: todd@todd-drummond.com

Copyrights © 2023

Work Smar ter

2Seconds

That'sallthetimeittakes

todrillstudsforrunningRomexorotherelectricalwireinthewallpanels

Motor: HeavyDuty5HP-3phase-220vor440v(Pleasespecifywhenordering)

MotorcarriagebearingandspindleassemblymountedonBlanchardgroundsteelplate

LinealmotionishardenedandgroundVbearingsandrails

BlockSizes: 2x4through2x12infiniteheightsettingtocenter

AirSupply: 100psi10CFM

Drills: 2wing3/4'”CarbideTippedcanaccommodatesmallerorlarger

Spindles: AlloySteelpolishedandgroundprecisionshafting

Frame: 2"SteelWithPowderCoatFinish

Covers: 10Gauge(1/8"Thick)Aluminumremovable

Dimensions: Height-60inches,Width-33inches,Depth-33inches

Shippingweight: 750lbs.-(Includingcrate)

MADEINAMERICABYAMERICANS

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #26 A dverti $ er Component manufaCturing m The

916-508-3558• ww w.thehaincompany.com SeetheStudDrillerinaction! Goto https://youtu.be/AnODX5vPesE forademonstration

4,001,398

That’s the total trigger count from all six nail guns combined on an installed Terminailer.® For a machine that was a little over two years old, that is a big number; a real tribute to the durability of the machine’s components and engineering.

Yes, that number represents a pretty darn impressive mechanical milestone to be sure, but what is really impressive is that human hands were saved from millions of repetitive motions and potentially costly nailing accidents.

With just a sole operator, Terminailer drives a whole lot of improvement in efficiency and output. This amazing sub-component assembler quickly and precisely drives 30% to 70% of the framing nails in any wall panel job—be it batch, or just–in–time production. All with no complicated training, software or set-up time required when switching configurations. Add increased safety and easy maintenance with off-the-shelf parts, and you can see why Terminailer should be driving greater productivity in your plant.

Put things together like never before.

www.TERMINAILER.com 765-751-9990 Terminailer ® is a registered trademark of Construction Industry Innovations, LLC Copyright 2023 All Rights Reserved

Terminailer® and

Terminailer XP

Call

Condition: New Location: MO

New, Monet DeSawyer 2000, computerized, five-bladed component saw, sets up in 15 to 17 seconds, can run in manual mode, downloads projects from a network or manually using display screen controls. Features all powered movements, cuts from 15" 90/90 cuts to 20 foot length, 2 x 3" to 2 x 12" lumber depths and internal brakes are standard. Options include enhanced servo controls featuring autocalibration, catcher's display and either shaker or belt scrap conveyor and incline. 440 volt, 3 phase electrical.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #29 A dverti $ er Component manufaCturing m The 765-751-9990 www.woodtechsystems.com

NEW!

New Monet DeSawyer 2000 Component Saw

for

Pricing

One month after installing a Double Lumber PickLine to feed two TCT Linear Saws:

"We are getting 3,000 to 5,000 bdft more each saw, than we were getting before the install.

We have shut down one Cybersaw and one TCT chord saw.

This equals about 3 less people 10 hours, and 2 less forklifts 10 hours.

Overall, it is a major improvement to our operation. We hope to have the chance to run it two shifts to further accelerate the payback.”

Tom Hollinshed, Owner

LimTek Solu�ons Inc.

6021 Yonge St., Unit 1019

Toronto, ON M2M 3W2

Tel: (416) 888-4457

Edmond.Lim@LimTekSolutions.com

Edmond.Lim@LimTekSolu�ons.com

LimTekSolu�ons.com

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #31 A dverti $ er Component manufaCturing m The Your Solution for Lack of Technical Staff ● PlanSwift Lumber and Building Material Takeoffs ● Truss and Wall Panel Design Experienced Staff ● EWP Layouts and much more! All Points was launched by Industry Veteran Dave Walstad with over 20 years of Offshore Experience to create the Gold Standard in Technical Support Teams. 1-941-713-4395 www.AllPoints.Tech Dave.AllPoints@gmail.com Offices in: Panama City Beach, FL USA HCMC (Saigon), Vietnam Bengaluru, India Eliminate your lack of technical resources to grow sales and increase the clock speed of your company. We have the network and experience you can count on Deploy Technical Teams from All Points! 800-382-0329 | www.wasserman-associates.com 2000 Alpine AutoMill Automated Component Saw • Automated Setup via Download or SemiAutomated Setup via Touch Screen Input • 19 Axes of Automation • Five Blades cut 2x3 thru 2x12 from 18" to 20' • Waste & Incline Conveyor • Out of Service in 2018 • 480 Volt / 3 Phase • Price is in US Dollars $29,500 FOB ON Details

PERFECT Heels,Angles, & Lengths

Safe, accurate cutting of any component with the ProCut™ UC Linear Saw Series

Roof, Floor, and Wall components: Webs, Chords, Sliders and Wedges – up to 4-boards high! The ProCut™ Linear Saw Series is configurable to any assembly line – providing a safe, accurate way to cut your lumber, while keeping your materials moving on your line.

Maximize your output with ProCut™ Material Handling Systems

Feed the ProCut™ with bulk lumber staged around the Linear Infeed Conveyors. Materials are picked and placed in the order which it is to be processed. Lumber is fed to the ProDeck™ Lumber Infeed - where it accumulates and is dispensed to the sawyer.

From the ProCut™, the cut material is conveyed to an accumulator where it is grouped and placed together with all components for the job. The material is conveyed to the staging area at each truss assembly workstation. The staging areas at the table provide an uninterrupted supply of perfectly cut and organized material.

Eliminate the carts and congested staging areas in your plant. The ProCut™ saw, when used in combination with the ProDeck™ and our Custom Material Handling Systems, can be configured to improve the flow of perfectly cut parts and materials directly to your assembly stations.

The ProCut™ UC Linear Saw Series offers many variations to suit your plant and assembly line. Let us design a system for you.

UC LINEAR SAW SERIES ™ UC LINEAR SAW SERIES ™ ProCut LLC (612) 521-9193 www.eidemachinery.com/emsi-procut/

ProCut™ UC-4 shown.

ProDeck™ Options Available.

•

Used

•

2018 Hornet MC-19 Cutting Stations (Qty of 2)

•

Motors: Two 1 HP / 220 Volt or 440 Volt / 3 Phase

Saw Blades: 7 1/4"

Carbide Tipped (set

Angle Adjustment: Manual Rotation with Air Brake

Carriage: Steel Rails with Steel Dual V Rollers

Pedestal: 3/16" Formed Steel

• Covers: 10 Gauge (1/8" thick) Steel

Fully Enclosed for Safety

2018 Hornet model MC-19 chop saw version cutting stations, include 25 ft long infeed and 10 ft long outfeed. Two available at this location. Price is per each. Each station includes infeed pusher, chop saw, marking device, automated controls, outfeed, control panel and CutBuild Automation software. Sold for $59,500 new. 220 volt, 1 phase electrical required for station. 110 volt, 1 phase electrical required for computer.

$47,993 FOB NV

Wood Tech Systems 765-751-9990

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #33 A dverti $ er Component manufaCturing m The SAWS

Hain Quick Rafter Cutter

www.woodtechsystems.com Reconditioned in December 2020

Board Sizes: 2x4 and 2x6

•

•

at 45 degrees)

•

•

• Air Supply: 90 PSI

•

• Saw Housing: 1/2" Billet Aluminum

$12,500 FOB MN Wasserman & Associates 800-382-0329

800-289-JOBSJobLine.com, inc. Time To Hire? We’re here when you need help! visit: www.thejobline.com email: twm@thejobline.com STRICTLY CONFIDENTIAL! The

www.wasserman-associates.com

The truss industry relies on 3rd party quality assurance services to provide random visits to review the plants Quality Assurance program along with their operations. If your plant needs to comply with the IRC, IBC and to those who depend on solid, experienced QA expertise, we ask you to consider selecting Timber Products Inspection, Inc. (TP) as your choice for 3rd party inspections.

Proudly serving the forest products industry for over 50 years, TP brings the expertise you need to ensure your business is successful. As a responsible partner, TP delivers to clients, employees, and the industries we serve the confidence to drive value through the effective use of our diverse professional team.

TP would like to welcome the following authorized agents to our inspection team, each of whom have many years of experience in the truss industry!

• Al Coffman

• Jean Hart

• Curt Holler

• Chuck Ray

• Glenn Traylor

• Elliot Wilson

If you have questions about how you can make this selection, please contact your authorized agent above or Glenn Traylor at 919-280-5905 or trusguy@gmail.com.

https://www.tpinspection.com/ https://www.tpinspection.com/auditing-services/truss

Read/Subscribe online at www.componentadvertiser.com

Has Your Guideline Shifted?

By Glenn Traylor

By Glenn Traylor

Recently after receiving a phone call from a client, I reflected on our conversation. I was a little caught off guard with the direction the conversation took and felt like I needed to make a few issues clear. And, it has led me to reflect on boundaries and guidelines – why they exist and how they can shift over time.

The call started out as a basic call: “I need some assistance on a project.” My response was OK, what is it that we need to address? The caller explained that, during in-house inspections, it was determined that some lumber was substituted incorrectly, resulting in non-conforming lumber grades in some trusses. I asked: “How many trusses are we talking about?” The response: “Why does that matter?” I responded: “Well, depending on the quality of trusses, it would impact the potential solution.” My client responded: “Well, I have no idea how many trusses… I’m not sure how many jobs are involved. All I know is that my guys have been substituting #2 Southern Yellow Pine for drawings that called for #1.”

My first priority was to get a handle on the scope of the problem. Is it a problem with trusses in the yard? Trusses just built? Were the trusses delivered? Installed? Each of these scenarios could require a different solution.

The photograph of the errant white line on the pavement is a good metaphor for this situation. The manufacturing plant has correct protocols in place, but over time they were not followed successfully. Initially this road accurately followed the gradual curve of the highway. Eventually though, because of a soft area under the roadbed, the road pushed out toward the shoulder, creating a bulge in the white line. Although the line has remained intact, it is no longer a good indicator to a driver as to where to aim his vehicle. Within the context of the road, the line provides a guide to the driver to keep his vehicle out of the ditch, but anyone looking at the line will know it no longer defines that driving lane.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #35 A dverti $ er Component manufaCturing m The

Continued next page

In this plant, there are four production individuals who had the opportunity to verify and catch an improper substitution of lumber.

1. The lumber picker

2. The sawyer

3. The catcher

4. The truss builder

Then, if all that failed, the in-house inspector should have caught the problem on their weekly inspections. Statistically speaking, three inspections are supposed to be adequate to catch this sort of error. But is that enough? My answer might surprise you.

Even though five individuals failed to catch this situation promptly, that does not mean the frequency of inspections should be increased unilaterally. Consider this:

• Manufacturing that is solely dependent on an inspection to catch problems would require a 100% inspection.

• The ANSI/TPI 1 Chapter 3 procedure does not require 100% inspection. It does not need to require this type of inspection.

The reason is because the Quality Assurance Program is more than just inspections. It’s a review of procedures and processes that take place in the truss plant. It’s a review of the lumber selection process, the process of the catcher and sawyer. It involves walking through the entire plant identifying problems and areas that can create problems. This is specifically why in-house inspectors must do their job. It’s to check the process, not a specific truss inspection. The same is true with the thirdparty inspector. Without boots on the ground, scanning the shop floor, viewing lumber inventory, walking the aisles, the QA process is critically flawed. There has got to be a perspective view from different angles to get an accurate grasp of the situation.

An ANSI/TPI 1 3rd Party Quality Assurance Authorized Agent covering the Southeastern United States, Glenn Traylor is an independent consultant with almost four decades of experience in the structural building components industry. Glenn serves as a trainer-evaluator-auditor covering sales, design, PM, QA, customer service, and production elements of the truss industry. He also provides project management specifically pertaining to structural building components, including on-site inspections and ANSI/TPI 1 compliance assessments. Glenn provides new plant and retrofit designs, equipment evaluations, ROI, capacity analysis, and CPM analysis.

Glenn Traylor Structural Building Components Industry Consultant http://www.linkedin.com/in/glenntraylor

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #36 A dverti $ er Component manufaCturing m The

“I would encourage other component manufacturers to attend the workshop because it is an opportunity to gain a better understanding of MSR and how it can be used. That makes you a more responsible customer because you know how to maximize its use in the design of your product.”

—Porter Clark, Hiwassee Builders Supply Inc., Athens, TN

“Unless they can say they have their business running perfectly, I believe there’s something any CM can take back from the workshop to improve their business. I know our business will be better because we attended.”

—Adam Beck, Drexel Building Supply, Campbellsport, WI

—Adam Beck, Drexel Building Supply, Campbellsport, WI

Hotel Valencia Riverwalk

East Houston St. San Antonio, TX 78205 Hotel

April 5 Register Today!

4/26 Golf Outing Social Hour Independent Dinner

4/27 Educational Sessions Tour Hosted Dinner Friday, 4/28 Educational Sessions A PRIL 26-28 San Antonio, TEXAS Learn more at msrlumber.org/workshop

WORKSHOP

150

Deadline:

Wednesday,

Thursday,

2023

Electrical Supply: 110 VAC

Motor: 1/4 HP, 110 VAC, Linear Actuator

Highly Accurate: +/- .010 Inches

Stop Rail: 2 x 4 x 1/4 Aluminum Extrusion

Stops: Jig Bored Steel

Stop Blocks: Machine Billet Aluminum

Internal Components: Hardened, Ground and Polished Steel and Billet Aluminum

Dimensions:

Length: 5 feet (60”) to 60 feet (720”)

Height: 12 inches

Depth: 12 inches

If you are looking for the fastest, most consistent way to measure and cut your product, then the Hain Measuring System (MEA) is your answer. The MEA changes from one length t any length instantly, up to 60’, without changing the operator’s position on the line. It is also highly accurate (+/- .010) and quickly moves from one length to the next in seconds. The MEA is designed for quick and easy setup and is simple to use. Even a first time user will be productive with little or no training required. It can adapt to any saw and can be mounted to any surface so that you can integrate the MEA with your existing setup. The MEA is versatile allowing “left” or “right” handed operation and measurement in “feet and inches” or “inches” depending on your preference. The MEA is also available in a “Skid Mounted” version.

theHAINCOMPANY 6125 Enterprise Drive, Unit 9 | Diamond Springs, CA 95619 530.295.8068 | sales@thehaincompany.com

Spida Automated Apollo Saw

The Spida Apollo saw with Automation is a computerized, pull-arm type saw used for cutting either wood truss components or wall panel cutting and represents the lowest-cost way to add an automated single-blade saw to your operation. Features include angle cutting from 10 to 170 degrees, 36 inch scarf cuts, patented variable stroke limiter for safety, solid frame and arm design, 17 inch industrial touch screen with enclosure, 7.5 HP motor, plug and play wiring making installations easier and includes cowls for adding a dust extraction system.

Available options include software is available for both trusses and wall panel cutting, laser guide showing exactly the path of the blade before the blade moves, Safe Grip™ Clamp for cutting smaller pieces, clamping table, Plate Marker template providing automated set up for marking joint locations (studs, sub-component locations, etc.) on top/bottom plates, Chop Saw Table for adding another saw for miter/compound or end cuts, prior to feeding the Spida Apollo saw, Portable Dust Extractor and spare blades.

Saw is available in 240 volt, 20A or 460 volt, 15A 3 phase electrical. Computer requires 110 volt, 1 phase, 20A.

$64,500

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #39 A dverti $ er Component manufaCturing m The 765-751-9990 www.woodtechsystems.com

FOB NZ/IN NEW!

Prestage Tabl

Capabilities*

Wall Heights: 7' 11 ½" to 10' 3" - 12 ' 3" - 14' 3" or 16' 3"

Wall Lengths: 16', 20' or 24'

Pre-Stage Area: 16', 20' or 24' (matches wall length)

*Subject to change without notice

Why a Prestage Framing Table?

The new field-tested Triad PreStage Framing Table, designed and built with customer input, can bring increased productivity to your panel shop.

Triad's exclusive and unique design merges a pre-layout material-staging area with a fast and efficient framing station -- into a single unit that can assist with rapid throughput in your plant.

A powerful, built-in continuous track system lifts and conveys components and material to framers and then the finished panels to your next station.

Initial customer field production, from a Texas plant, has shown an average of 3600 linear feet per day (8 hr shift) of framed walls in their facility!

Cal I to learn more about this approach! Experience you can trust. www.TriadMachines.com I P.O. Box 130 Alda, NE 68810 I 800-568-7423 Ext. 133

New Monet DeRobo Linear Saw

New, DeRobo linear saw by Monet organizes "fill" boards to increase optimization of each board, can produce unlimited scarf cuts, cuts 1 or 2 boards at a time and cuts webs, chords, wedges, rafters and open-stair stringers. Works with all major connector plate manufacturer's software. Features include 22 inch blade, left-to-right feed direction standard, lumber push and pull grippers for more accuracy, ink marking on the 1 1/2" face of the incoming boards and small piece capture and delivery to the front of the saw for easy access. Infeed deck and bunk feed are shown as options only. 480 volt, 3phase. Call for pricing, FOB MO.

765-751-9990

REPRESENTATIVES

New Spida Rolsplicer

New Square 1 Rolsplicer, splices 2"x3", 2"x4" and 2"x6" lumber with a 3 to 4 second cycle time. Presses the lumber together prior to imbedding plates. Embeds plate lengths up to 19 inches. Features two, recessed, simultaneous-activation buttons, guarded motor and sprockets, external lubrication points, 3 HP motor and a footprint of 59" long x 42" wide. Optional 20' infeed and 10' outfeed conveyor available. 480 volt, 3 phase electrical. Other voltages available.

765-751-9990

$29,800 FOB IN

www.woodtechsystems.com

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #41 A dverti $ er Component manufaCturing m The REPRESENTATIVES

www.woodtechsystems.com

NEW!

NEW!

By Traacy Roe

Dependability in an Uncertain Environment

The most popular outlook for 2023 that I have heard is uncertainty. Nobody has a clear picture of what the new year will bring for our industry. Large investments have been made in talent, equipment, and infrastructure to capitalize on the increased demand over the past two years. What about your software? Have you had to adapt your process to fit the capabilities of your current offering? Could you use some additional enhancements to really get every ounce of productivity from your process?

The TrueBuild® Job Management application by Eagle Metal offers a level of adaptability and customization far beyond what the industry is used to. Imagine a scheduling platform that gives you everything you need and nothing that you don’t. Do you want to track deliveries only? Do you want a calendar and tracking for EVERY step in your operational process? This calendar was designed from the ground up to give you exactly what you need.

Now that you have things being scheduled and tracked the way you need them to be, how can you determine if you are doing any good? Job Management from TrueBuild® offers an instant, sortable, customizable snapshot of all of YOUR key metrics. You decide what you see and who sees it inside your operation. Break down your sell price and volume the way you want to see it. You are in control and the information is presented in the format you want for the date range you need.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #42 A dverti $ er Component manufaCturing m The

How do you know if your labor costing scheme is accurate? Data, of course. TrueBuild® Job Management gives you complete insight into your estimated labor costs from your labor pricing schemes and compares that to your input actual labor costs. All of this information on an easy-toread screen in real time. Gone are the days of having to adjust pricing for difficulty by feel and experience. Let this software do it for you.

Straight forward software for people who get things done developed by people who have done it. Everything you need and nothing that you don’t. Don’t compromise your process or limit your productivity because your software won’t support it or it isn’t dependable. You have invested too much to settle for anything less than exactly what you need. Visit eaglemetal.com to learn more or contact us at 800-521-3245. It’s time for an upgrade.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #43 A dverti $ er Component manufaCturing m The

NEW!

Component Saw

2002 Auto Omni 5 blade automated component saw includes shaker waste conveyor with factory side pans, [3] 20 inch blades, [1] 30 inch blade and [1] 12 inch blade. Fully automated setup with full power length and all axis angulation, single sided setup from operator console, 2×3 through 2×12, 22’ to 3′ @ 90°/90°, and spare blades. 208/240/480 volt, 3 phase, 100 Amp and 120 vac, 90 Amp electrical required.

Price: $19,990 FOB PA

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

2008 Alpine PF90 Wall Panel Saw

2008 Alpine PF 90 wall panel cutting and marking system. 3.5″ x 12″ maximum cutting profile, Inkjet option, cuts to 16 ft long. From the OEM’s literature, “Effortlessly handles two of the most critical and difficult processes in any wall panel operation – plate cutting and panel layout. At the rate of 1,000 linear feet per hour or more, uses data from the design software and accurately marks stud, cripple and jack locations, job and panel number, subcomponent and window/door locations, and even sheathing locations on both top and bottom plates simultaneously with ink-jet printing.

MORE INFORMATION HERE

$8,499 FOB NY

Wood Tech Systems

765-751-9990

www.woodtechsystems.com

REPRESENTATIVES

Safety Speed Manufacturing Model 6400 Panel Saw

Safety Speed Manufacturing model 6400 vertical panel saw, 3 HP worm drive motor, 64 inch crosscut, 1 3/4" inch maximum thickness, accuracy within 1/64th of an inch, 10 foot welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include lower frame extensions, digital readouts, laser guide, stop bar, vacuum and midway fence. 120 volt. Starting at $5,169 FOB MN.

2019 MiTek Blade Linear Saw (# 2)

MiTek Blade model number 89060-501, with 20′ infeed, face printing via Matthews printer model DOD 8000+ Maxi. Features 17″ saw blade powered by 5HP motor to cut 2×3 through 2×12 boards. Left to Right in-feed in “Reverse U” configuration with 18′ out-feed conveyor. Includes any available spare parts, 230v/3Ph electrical power required, and 110 PSI at 40-50 CFM air pressure as specified by the OEM.

$364,990 FOB CA

765-751-9990

www.woodtechsystems.com

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #45 A dverti $ er Component manufaCturing m The SAWS REPRESENTATIVES 765-751-9990 www.woodtechsystems.com New Monet FWA-500 AC Automated Floor Web Saw Call For Pricing FOB MO Additional Information Here NEW! 765-751-9990 www.woodtechsystems.com

2002 Koskovich Auto Omni 5 Blade

Setting the Goal of One Thousand Pieces per Hour

A“Thousand Pieces an Hour” is a golden truss production metric and a lofty goal for many component plants. If one thousand is the magic number, even at 75% efficiency, in a 7-hour shift (7 hours x 1,000 pieces/ hour, at 75%) that would be 5,250 pieces with potential to achieve 7,000 pieces. So, let’s use 750 pieces per hour as a production rate goal.

For a truss plant, pieces per hour is easily measured and/or extracted for every labor process and every machine utilized in truss production. For example, how many pieces of lumber can be picked in an hour? How many pieces are cut on a saw in an hour? How many pieces of lumber can be stacked behind a saw in an hour? How many trusses can be built on a jig in an hour?

Material handling, process organization, machinery, and the labor required can all be measured. I’m asked all the time how much production should be expected, or in other words what does it take to “Feed the Beast.” Fortunately, through videos/pictures and better yet by attending a plant tour, one can see how Enventek’s Process Organization Technology can achieve “A Thousand Pieces an Hour.”

How We Feed the Beast

Although I could go into great detail on all aspects of our process improvement, it’s always best to highlight these three. Individually or in combination, they will get you well on your way to the thousand pieces per hour goal.

Lumber intake: With a Lumber PickLine, if a board is dropped every 5 seconds into the chaindriven lumber trough, that would be a picking rate of 12 boards a minute (720 pieces an hour) for a total of 5,040 pieces in 7 hours. Organizing your lumber with a Lumber PickLine eliminates excessive forklift lumber picking and reduces operating costs significantly. And, picking lumber using our ingenious symmetrical batch mode makes the process essentially cut-by-truss when the autofill carts are positioned in sequence in front of the truss build tables.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er February 2023 #15283 Page #48 A dverti $ er Component manufaCturing m The

Continued next page

Edmond Lim, P.Eng. LimTek Solutions Inc.

Cutting: The amazing RetroC is a marvel to watch as the truss industry’s only auto-feeding component saw capable of cutting lumber at a rate of over 90 pieces per minute. Even with a 50 ft live deck, you will never be able to keep Feeding the Beast at this rate for long. Using the industry standard feed rate of 18 pieces per minute already yields more than one thousand pieces an hour. Having this much wiggle room is why the RetroC can be fed lumber collated for cut-by-truss to speed up truss production at the tables and also organize the cut lumber for left and right of table.