vol. 31, no. 2

vol. 31, no. 2

PO Box 333

Roberts, Idaho 83444

Telephone: (208) 520-6461

Circulation: (503) 724-3581

CarrotCountry.com

CArrOT COUnTrY COnTACTS

editor

Denise Keller editor@ColumbiaMediaGroup.com

Publisher / Advertising Manager

Dave Alexander dave@ColumbiaMediaGroup.com

Director of Operations

Brian Feist brian@ColumbiaMediaGroup.com

eDiTOriAL inFOrMATiOn

Carrot Country is interested in newsworthy material related to carrot production and marketing. Contributions from all segments of the industry are welcome. Submit news releases, new product submissions, stories and photos via email to: editor@ColumbiaMediaGroup.com, or call (509) 697-9436.

ADverTiSinG SALeS

For information on rates, mechanics, deadlines, list rental, direct mail, inserts or other information, call (208) 520-6461 or email: dave@carrotcountry.net

SUBSCriPTiOnS

U.S. $20 per year

Canada $30 per year

Foreign $45 per year

Subscribe online at: www.CarrotCountry.com/subscribe or call (503) 724-3581

Email address changes/corrections to brian@ColumbiaMediaGroup.com or mail to: Carrot Country PO Box 333 Roberts, ID 83444

Bill Wirth, owner of Precision Seed Production, checks on a carrot seed crop growing near Ephrata, Wash., in late August 2022.

Learn what makes the area great for the seed multiplication business on pages 4-5.

Carrot Country magazine (ISSN 1071-6653), is published four times a year and mailed under a standard rate mailing permit at Idaho Falls, Idaho and at additional mailing offices.

Produced by Columbia Media Group PO Box 333, roberts, iD, 83444

Copyright 2023. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose without the express written permission of Columbia Media Group.

With a desert climate and abundant water, the Columbia Basin is prime real estate for carrot seed production. These conditions are key for companies such as Precision Seed Production that strive to consistently provide customers with a reliable seed supply.

Precision Seed contracts with 25 to 30 seed companies, multiplying seed on 6,000 to 7,000 acres around Ephrata, Washington. Carrot seed accounts for 300 to 600 of those acres and includes types such as Nantes, Imperator, Chantenay, Kuroda, Amsterdam and baby carrots. Sunflower and canola seed are important crops for the company, with other seed crops including arugula, corn salad, grass, wheat, beans and native seed.

“Our strength is we offer a diversified production area for all these different species that’s very reliable year after year. We have secure water, we have a dry climate, and our disease pressure is low,” says Precision Seed owner Bill Wirth. “We’re not the cheapest area, but most of the seed companies like to have a presence here just to have that reliable production year after year, and that’s what we offer.”

Even with the region’s ideal growing season of long, warm days and cool nights followed by a dry harvest season and relatively mild winter, hybrid carrot seed production requires intensive management, according to Wirth. The Precision team begins monitoring for insects weekly as soon as plants bolt and uses a fungicide and insecticide program in the carrot crop that is more intense than some other seed crops require. Insects can destroy the flowers, which hurts yield. Once plants are pollinated, insects can sting the developing seed and reduce germination.

Many other challenges are weather related. The area can get very hot during the pollination window and the seed fill period. At temperatures above 95 degrees

Fahrenheit, bee activity and pollen viability drop. On the flipside, a harsh winter can wipe out entire fields. Plus, in hybrid seed production, the loss of either parent (male or female plants) will result in the loss of the whole field.

“I like the seed business because it’s challenging, more so than growing grain corn or growing some of the other crops that are lower input or don’t take as much attention to detail,” Wirth says. “I enjoy a challenge, and seed crops are an evolving challenge all the time. There’s always something we could try to do better or try to improve on. I like getting up and going to work in the morning because of that. It’s never boring to me.”

To manage the carrot crop’s tendency to volunteer, Precision Seed maintains a long rotation of five to seven years. Generous isolation distances for each crop are also crucial for the company. Carrots of the same type are grown 1.5 miles apart, different types are kept at a distance of 2 miles, and carrots of different colors

have an isolation distance of 5 miles. Production companies work together to choose fields with proper isolation, and cooperative extension monitors the mapping system and notifies companies if their fields fail to meet isolation standards. This keeps strong integrity in the system that customers appreciate, Wirth says.

In 2022, 70 percent of Precision Seed Production’s carrot crop was direct seeded; 30 percent was grown root to seed.

The company seeds its direct-seeded carrots in August. As winter approaches, at least half of the acres are covered with Reemay, a cloth to protect the plants from winter kill. The cold and dormancy vernalizes the carrot plant into triggering its reproductive system. In April, the crew checks the survival rate and thins the plants if needed, cultivates, fertilizes and sprays for weeds before the crop blooms in late June. The rows of male

plants are removed, and the female plants are harvested in August. Then, the seed cleaning process begins and runs until the end of the year.

For the root-to-seed crop, a root bed is planted in the Imperial Valley of California in late September and grown through early February with a goal of 6- to 8-inch roots with a diameter of 1-1.5 inches. Roots are dug and moved into cold storage in Washington, where they’re kept at 35 degrees for six to eight weeks, vernalizing the plants. Carrots are planted in the field around the first of April, and seed is harvested in late August or early September.

The root-to-seed method offers several advantages to Precision Seed’s customers including a high germination rate and the option to make planting decisions later in the year. However, cost is a limiting factor. With the rising price of labor, water and transportation, the cost of root-to-seed production continues to increase, prompting a growing number of customers to choose direct-seeded production.

Always improving

Wirth has been in the seed business since the early 1990s. After working as a vegetable seed rep for Petoseed, a vegetable seed company acquired by Seminis, he and a colleague started Precision Seed in 1998. The company’s first crops included carrots, onions, radish and cabbage. The co-founder retired 15 years ago. Troy Hesse is now partners in the business.

“Carrot seed has been in the Columbia Basin longer than I have. I think it’s always going to be a crop that we work with and we keep growing over the years. We’re trying to get better at doing a few different things to try to make it better and more streamlined,” Wirth says, adding that the company has been experimenting with different female-to-male plant ratios, moving from 6:4 to 6:2 last year.

In the last couple of years, Precision Seed has also expanded its use of petiole sap testing in the carrot seed crop to determine what nutrients plants need. If plants need a minor element in a critical stage, Wirth can use a foliar feed all the way up to seed fill. He is still evaluating the most beneficial timing of the tests

and might begin utilizing more testing throughout the season.

“We’re excited about it,” Wirth says. “Normally at pollination, we stop doing petioles and let the crop finish out, and we’re trying to get a little more active all the way through the cycle and see if we can affect the germination rate by doing these sap tests and see if that ultimately affects the quality of seed in the end.”

In addition to trying new farming practices, Wirth likes building his own

equipment to meet the company’s unique needs and enjoys the challenge of figuring out how to do something that hasn’t been done before.

“I’m always on the lookout for new crops that would work in the Basin,” he says, noting that there are very few crops that won’t grow in the area. “That’s exciting to me, to try new crops that maybe haven’t been proven here and make them work through trial and error, mostly. That’s what’s fun to me.”

Photos courtesy Kevser Ozel and Michael Paulsmeyer, University of Wisconsin

Photos courtesy Kevser Ozel and Michael Paulsmeyer, University of Wisconsin

Acrowd of approximately 50 seed company reps, carrot growers, researchers and students gathered in El Centro, California, to check out the annual USDA carrot hybrid trial in early March.

“It was exciting to have so many people attend,” said Tom Horejsi with the USDAARS in Madison, Wisconsin, who helps set up the trial. “Due to the COVID pandemic, the number of people in the last three years was restricted. It was great to see people returning.”

The trial, planted at the University of California Desert Research and Extension Center in El Centro in mid-October 2022, featured 75 baby carrots, 75 cello types and 80 novelty types of different shapes and colors. Entries represented a wide range of carrot types on the market and in the research pipeline, providing a good sampling of what is available and soon to be available.

The growing season was unusually cold; however, most hybrids grew well, according to Horejsi. Carrots from each entry were dug and displayed with tops attached shortly before the evaluation. Attendees scored entries for traits such as uniformity, shape, color, size and percentage of marketable roots. This trial has been ongoing since the late 1960s.

Below, carrot breeder Phil Simon (center) evaluates carrots from the trial. The trial included 75 baby carrots, 75 cello types and 80 novelty types of different shapes and colors. Above, evaluators score each entry’s performance in the trial.

NAPOLI

Very full-sized Nantes with strong dark green tops and cylindrical, smooth blunt roots. A specialized variety with a sweet taste when sown in fall for winter harvest.

Resistance IR: Ar / Cc / Ps, Pv

YAYA

Similar to Nelson, with more uniform roots and plant vigor. The 5 1/2–6 1/2” roots have mild flavor and crisp, juicy texture with early sugar development. Strong, compact tops for bunching.

Resistance IR: Ar / Cc / Ps, Pv

Organic Lead, Home & Farm Market Manager : c.lenczyk@bejoseeds.com

NAVAL

A Nantes type that produces very shapely, uniform, hairless roots 7-9 inches long. Crisp and sweet, Naval resists cracking with an added bonus of a long shelf life.

Resistance IR: Ad / Ar / Cc

bejoseeds.com

In the Columbia River Basin region of Washington and Oregon, the phloemfeeding beet leafhopper vectors three pathogens to vegetable and seed crops. Beet curly top virus (BCTV) causes yellowing or slight reddening of leaves, leaf curling or cupping, and plant stunting in crops such as sugar beet, bean, coriander, tomato, pepper and cucurbits. Beet leafhopper-transmitted virescence agent (BLTVA) phytoplasma generally causes purpling of upper leaves and leaf curling in affected crops such as potato, tomato, pepper and carrot. BLTVA also induces aerial tuber formation and early plant senescence in potato and causes the over-proliferation of lateral roots in carrot. Spiroplasma citri can occur in carrot and causes infections characterized by leaf purpling or yellowing, stunting of shoots and taproots, and the overproliferation of lateral roots. Fields

infected with any of these three pathogens can see a reduction in yield and crop quality depending on the severity of infection.

All three pathogens have been found simultaneously in individual beet leafhopper specimens and in tissue from individual plants, highlighting the seriousness of these pathogens in the Columbia River Basin. There are currently no treatments that prevent or manage the pathogens themselves, so growers must manage the beet leafhopper by removing weedy hosts like kochia and wild mustard and by applying insecticides to their crops or the weedy hosts. These management strategies can be costly for a grower.

Information on pathogen distribution among crops, and on seasonal beet leafhopper population dynamics and associated pathogen prevalence, can

help growers assess the potential for damage to their crops and aid them in their integrated pest management (IPM) decisions. With funding support from the USDA Office of National Programs Areawide Pest Management Program and the Washington State Department of Agriculture Specialty Crop Block Grant Program, scientists at the USDA and Washington State University (WSU) have been working to generate this information.

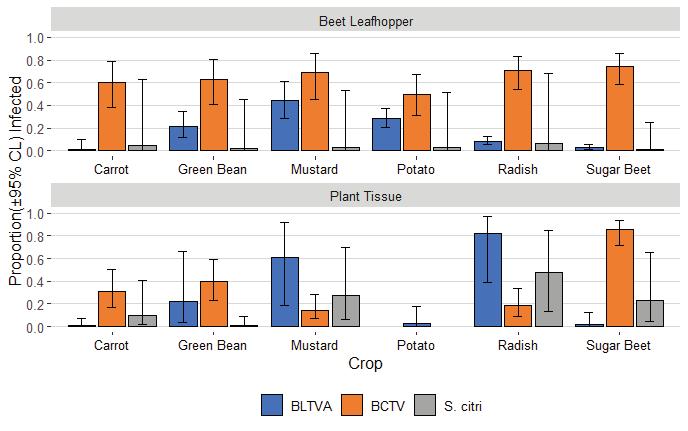

A replicated plot study with six crops (potato, green bean, sugar beet, radish, carrot, mustard) was conducted at the USDA-ARS farm in Moxee, Washington. Beet leafhoppers and plant tissue were collected from each plot on a bi-weekly basis. In beet leafhoppers, BCTV levels were the highest and S. citri levels the lowest among the three pathogens regardless of the crop where specimens were captured (Fig. 1a). BLTVA prevalence varied in beet leafhoppers collected from the different crops. Contrary to this, the levels of all three pathogens varied in plant tissue from the six different crops used in the study (Fig. 1b). These results indicate that pathogen transmission by the beet leafhopper to different plant species may not be equal. This trial will be replicated in 2023 to confirm these findings.

WSU Extension scientist Carrie Wohleb has been providing insect monitoring data on specimens, including the beet leafhopper, collected from potato fields across the Columbia Basin since 2009. In 2020, vegetable and seed fields were included in the pest monitoring network to increase the coverage of beet leafhopper captures across the region.

ACCURATE:

Precisely orients and sorts carrots

GENTLE:

Separates without damaging carrots

FAST:

Thirteen standard models custom-designed to meet your needs sort from 1000 lb/hr to 30,000 lb/hr

SIMPLE:

Effective but simple design provides a rugged, low cost, low maintenance machine at a high value to our customers. It can even be used in the field!

Since then, the total beet leafhopper population collected in a season has ranged from 24,942 in 2020 (from 45 potato and 24 vegetable/seed fields) to as many as 55,968 in 2021 (from 47 potato and 20 vegetable/seed fields).

Weekly beet leafhopper population results are disseminated to growers and crop consultants via an e-newsletter called WSU Potato Alerts. In collaboration with David Crowder, beet leafhopper monitoring data are interpolated and displayed as geographical contour maps that highlight areas of high to low beet leafhopper densities across the region to help growers with their IPM decisions. This data is displayed each week in WSU Potato Alerts but is also available at www. potatoes.decisionaid.systems.

New insect extraction and molecular diagnostic methods were developed and validated in the laboratory to enable the timely processing of insect specimens, so near-weekly pathogen prevalence data could be displayed alongside the beet leafhopper population data in 2022. A total of 33,775 beet leafhoppers were collected from 44 potato fields and seven vegetable or seed fields during the 2022 field season. Results consistently showed high levels of BCTV and low levels of S. citri over the 22-week season (Fig. 2a). Despite having high initial rates of BLTVA when the beet leafhopper population was low, the prevalence of this pathogen peaked at 25.35 percent in mid-July when beet leafhopper population rates were much higher. When pathogen prevalence was assessed by plant host, rates of BCTV were higher from beet leafhoppers collected from vegetable and seed fields as compared to potato (Fig. 2b). This indicates that there could be a previously unknown host-directed beet leafhopper response based on BCTV pathogen prevalence, though further research is needed to confirm this result.

Irrigated agriculture in the Columbia River Basin of Washington encompasses a wide geographic range. The 2022 beet leafhopper collection locations were divided into seven geographically defined regions to assess differences in pathogen prevalence based on geography. Regions were identified as the following:

Paterson, Snake River, Basin City, Othello, Mattawa, Royal City and Quincy. Average BCTV pathogen prevalence was lower in the southern Columbia Basin regions of Paterson and Snake River, while average levels were higher in the central regions of Mattawa, Royal City and Basin City (Fig. 3a). Average levels in northern Columbia Basin regions of Othello and Quincy were moderate, despite being the only two regions where traps were deployed in vegetable and seed crops. This suggests that location in the Columbia Basin could have a greater impact on BCTV pathogen prevalence than crop type alone. While BLTVA pathogen prevalence peaked at different weeks in July among the regions, the highest peak rates were at 40-41 percent in early to mid-July in the southern regions, and the lowest peak rates were at 17 and 21 percent later in July in the northern regions (Fig. 3b). Overall, these results suggest that BLTVA could be a higher threat in the lower Columbia Basin and BCTV a higher threat in the central region. Data from additional years is needed to confirm these results and determine if this is a consistent trend or simply a unique finding in the 2022 season.

During the 2022 season, BCTV, BLTVA and S. citri pathogen prevalence in beet

leafhoppers was incorporated into the WSU Potato Decision Aid System (www. potatoes.decisionaid.systems). Here, heat maps depict weekly rates of pathogen prevalence broken down by region, and visitors can toggle between the weekly data to observe pathogen changes over time. The goal is to have this information updated weekly throughout each growing season to help growers make more informed IPM decisions regarding timing

and number of applications for control of the beet leafhopper. This information, in addition to knowledge gained from field or greenhouse trials that explore pathogen dynamics across different crops and beet leafhopper movement in the landscape, should enable growers to improve management of the economically important beet leafhopperassociated pathogens.

To have your event listed, please email Denise Keller, at editor@ColumbiaMediaGroup.com. Please send your information 90 days in advance.

www.dewulfgroup.com

Dewulf has revealed the ZKIVSE as the second generation of its state-ofthe-art four-row self-propelled top-lifting harvester. This machine provides high capacity, maneuverability and stability in the field. The ZKIVSE is able to pick at a narrow distance of 38 cm and unload very smoothly thanks to the new elevator, unloading on the right-hand side. Users can opt for three different cleaning variants after the cutting set: a star cleaning module in combination with a hedgehog belt for maximum cleaning, a sieving web combined with a hedgehog belt for medium cleaning, or the product going directly into the elevator if no extra cleaning is required. The cutting set is also brand new, cutting faster than ever and respecting the product throughout the harvesting process.

www.kerian.com

The Kerian Speed Sizer sorts carrots by size accurately and consistently. The constantly rotating rollers help the turning flaps align the carrots with the rollers so that the carrots (with or without tops) are consistently sorted by diameter. The sizer is proven in use for fresh carrots, baby carrots and processing lines.

www.rietveldequipment.com

The Allround Polisher TD 350-18 has 18 rolls of brushes with an estimated capacity of 25 tons per hour. Three smaller models are also available. The polishers are available in stainless steel and feature a hydraulic lift for easy cleanout, variable speed control, a water recirculation system and water cleaning system. The machine also offers easy brush removal for changing the brushes, as well as several different types of brushes for each application.

Allround builds all of the machines required in a washing/grading line, and the machines are running in over 80 countries worldwide.

Rietveld Equipment offers free 2D and 3D drawings of full lines, or drawings of the available machines in users’ existing lines.

Parts and machines are in stock at the company’s Midwest facility, and service and support from certified technicians is available 24 hours a day, seven days a week.

www.univerco.net

With the addition of the G-Force model, a two-row three-point mounted on tracks, Univerco now offers a complete range of carrot harvesters. From the Mini-Veg that can be operated by a 60-hp tractor all the way up to the MAC Series of multiple-row, self-propelled and everything in between, Univerco can propose a solution for all needs and farm sizes.

The G-Force is unique in its category because it offers a compact, multiple-row, high performance machine, with a motorized track that will power it through the most difficult field conditions, at a much lower price than a self-propelled machine. State-of-the-art technology supports a user-friendly machine made to work every day for carrot growers.

www.vogel-engineering.com

Made in the U.S., Vogel Engineering harvesters offer features such as a precision computer-controlled planting population system and individual row head height adjustability. Plus, the company offers a new Extreme Super Cleaning System.

Harvesters are available in two-, three-, four-, six- and eight-row configurations. Other available options include conventional roller bars or high-speed crowning.

www.volmcompanies.com/equipment/visar-sortop-carrots

Volm Companies is proud to be the official distributor of the Visar Sortop Carrots in North America. This automatic and high-performance carrot sorter can sort any batch of carrots with maximum consistency and efficiency. Thanks to the mirror system and powerful circular lighting, each carrot undergoes a thorough 360-degree analysis at a rate of up to 15 carrots per second. This reliably detects any defects, as well as grades and weighs the carrots with great precision.

Stokes Seeds is promoting the carrot variety Caravel. This Nantes cultivar is used for fresh market and processing. It is described as a cylindrical jumbo/dicer with roots 10-11 inches in length with a slight taper and blunt tip. Roots are said to have attractive orange skin coloration and tops with strong attachment. Caravel has intermediate resistance to Alternaria leaf blight and root-knot nematodes, as well as tolerance to cracking.

Visit www.stokesseeds.com.

“Can you help me, Doc? My nose is running.”