OEMs reference specific products and tools to complete the repair for a reason. They have been rigorously tested to OEM’s performance requirements for strength and corrosion resistance.

3M is more often referenced in OEM repair procedures for panel bonding and impact resistant structural adhesives than any other adhesive supplier.

Want to know more about OEM recommended products?

Get started here: 3MCollision.ca

At ALIGN 2025, ACX unveiled its revitalized identity and digital roadmap—marking a pivotal moment of growth, clarity and connection across its expanding collision network.

At the 2025 IBIS Global Summit in Istanbul, more than 350 collision repair leaders from over 30 countries gathered to confront global challenges—and shape the future of the industry through collaboration.

If you’re not at the table, you might be on the menu

BY DARRYL SIMMONS, PUBLISHER

There was a time when writing an estimate meant grabbing a clipboard, walking out to the lot, squinting at the damage, and jotting down a few numbers based on a combination of memory, gut instinct, and time spent on the floor. You’d punch it into the computer, fax it over (if the machine worked), and hope no one asked too many questions.

That era is—for the most part—behind us.

Today’s vehicles are smarter, more complex, and packed with systems that simply can’t be assessed visually or estimated loosely. We’re dealing with radar, lidar, battery packs, and more onboard computing power than the original space shuttles. And yet, some shops still treat estimating like it’s just a formality, something to get through on the way to the “real” work.

But here’s the truth: estimating is the real work. It always has been—and now, more than ever, it’s also the key to a healthy bottom line.

and justify their line items with documentation, have more influence than they think.

AI has the potential to dramatically improve estimating speed and accuracy. It may be able to recognise damage from images, flag calibration needs, and even recommend repair procedures. That’s helpful—especially when time is tight and vehicles are complex.

But it’s not infallible. AI doesn’t know what’s behind a bumper until you take it off. It doesn’t always account for rust, prior damage, or the judgment of an experienced tech. That’s why human insight still matters.

It’s also worth noting that many AI estimates— particularly those used early in the claims process—are designed more for triage than for teardown accuracy. Shops that take these estimates at face value may find themselves underpaid or overexposed.

Artificial intelligence is transforming estimating standards. The question isn’t whether it’s happening—it’s whether shops will help shape the rules.

Where estimating was once about quoting visible damage, today it’s about designing a repair strategy that accounts for unseen systems, safety protocols, and a growing list of OEM-specific requirements.

Modern estimating platforms now claim to offer features like real-time parts sourcing, calibration prompts, repair vs. replace suggestions, and even blueprint-level breakdowns based on a vehicle’s VIN. Some systems use artificial intelligence to analyse photos and flag damage patterns. Others integrate with scan tools, repair databases, and parts distributors to help streamline workflow.

Whether or not they always deliver on those promises is still a matter of debate—but the potential is there. And the more your team understands how to harness that potential, the more accurate, efficient, and profitable your estimates can become.

It’s no secret that many estimating systems are developed with insurers in mind. That means certain rules, defaults, or cost-saving measures may be built into the software itself.

Does that mean they’re inherently biased? Not necessarily. But it does mean shops need to be aware of what’s influencing the numbers behind the screen.

That doesn’t mean shops are powerless. Far from it. Estimators who understand how to navigate these systems, override defaults when necessary,

As the repair industry evolves, estimating is no longer something to rush through or hand off without care. It’s becoming a core competency— one that touches profitability, cycle time, liability, and customer satisfaction.

Done well, modern estimating tools have the potential to reduce unnecessary supplements, streamline parts ordering and scheduling, improve communication with insurers, and support better outcomes for both safety and customer service.

But only if they’re used properly. That means ongoing training, active oversight, and a willingness to challenge the system when it doesn’t reflect reality.

If you’re an owner or manager, don’t fall into the trap of treating estimating like a back-office task. Get involved. Understand how the tools work. Ask where the numbers are coming from. Question why a labour operation is missing or why a procedure wasn’t included.

The future of estimating isn’t just faster—it’s smarter. But only if the people using the systems are, too.

So don’t fear the technology. Learn it. Shape it. And make sure it serves your shop’s commitment to safe, complete, and properly paid repairs.

PUBLISHER

Darryl Simmons publisher@collisionrepairmag.com

ASSOCIATE PUBLISHER

Orest Tkaczuk | orest@mediamatters.ca

EDITOR

Allison Rogers | allison@mediamatters.ca

ART DIRECTOR

Yvonne Maschke | yvonne@mediamatters.ca

STAFF WRITERS

Mackenzie Grant | mackenzie@mediamatters.ca

Sadie McDonald | sadie@mediamatters.ca

VP OF INDUSTRY RELATIONS & ADVERTISING

Gloria Mann 647.998.5677 | gd.mann@rogers.com

INDUSTRY RELATIONS ASSISTANT

Wanja Mann 647.998.5677 | wanjamann1@gmail.com

DIGITAL OPERATIONS MANAGER

Cassie Doyle | cassie@mediamatters.ca

ONLINE EDITOR

Gideon Scanlon | news@collisionrepairmag.com

AUDIENCE ENGAGEMENT MANAGER

William Simmons | william@mediamatters.ca

MEDIA PRODUCTION SPECIALIST

Dayna Dicuangco | dayna@mediamatters.ca

CONTRIBUTORS

Abdallah Amro, Corey Carlaw, Greg Horn, Stefano Liessi, Jay Perry

SUBSCRIPTION

Single edition $7.99 One-year $39.95 ( 6 issues) Collision Repair™ magazine is published bimonthly, and is dedicated to serving the business interests of the collision repair industry. It is published by Media Matters Inc. Material in Collision Repair™ magazine may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions and statements appearing in this publication have been compiled and included with the permission, though not necessarily the endorsement, of the editor, or of independent columnist contributors, and are in no way to be construed as those of the publisher, or as endorsements of them.

PRINTED IN CANADA ISSN 1707-6072

CANADA POST CANADIAN PUBLICATIONS MAIL

SALES PRODUCT AGREEMENT No. 40841632

RETURN POSTAGE GUARANTEED

Send change of address notices and undeliverable copies to: 317 Reid St., Peterborough, ON K9J 3R2

“We acknowledge the financial support of the Government of Canada”

Collision Repair magazine is published by Media Matters Inc., publishers of:

Fix Network has appointed Sonia Bouthillette as its new vice-president of sales and operations in Canada. In her expanded role, she will lead national sales and operations for Fix Auto, NOVUS Glass, and ProColor Collision, reporting directly to president and CEO Steve Leal. Bouthillette joined the company in 2009 and most recently served as vice-president of operations, overseeing field support and training across the country. She succeeds Jeff Labanovich, who was credited with strengthening Fix Network’s Canadian presence. “Sonia’s dedication and operational expertise have been key to our success,” said Leal. “We’re confident she’ll continue driving our growth across Canada.” Prior to joining Fix Network, Bouthillette held executive roles in the automotive and franchising sectors. Fix Network operates over 2,000 locations in 20 countries, with a strong presence in Canada’s collision, glass and mechanical repair markets.

Martin Smith announced the new role in a social media post. “I’m very happy to share that I’ve started a new position as business development specialist for Manitoba/Saskatchewan with SATA Canada Inc! Looking forward to seeing many familiar faces and meeting new ones. See you soon.” Alongside many other well wishers, Joern Stoever, general manager of SATA Canada, offered his congratulations to his new colleague. “Martin, great to have you on board! Welcome to the SATA family—with family members around the world. I am sure that you will bring us forward and be a great asset for your customers.” Smith was previously head painter at Connexion Truck Centre and held business development roles with the TED Group. He holds a Red Seal journeyman certification in autobody collision and repair technology from Red River College Polytechnic.

AkzoNobel has named Fredrik Westin as its next chief financial officer, effective Jan. 1, 2026. He will succeed Maarten de Vries, who is set to retire in April 2026 after two terms with the company. Westin, currently CFO at Autoliv, brings over 25 years of experience in the industrial and automotive sectors, including senior roles at Sandvik and Johnson Controls. “Fredrik is a proven financial leader, well-equipped to build on Maarten’s strong legacy,” said supervisory board chair Ben Noteboom. CEO Greg Poux-Guillaume praised Westin’s global and operational expertise and thanked de Vries for his lasting impact. Westin’s appointment is subject to shareholder approval at the 2026 AGM.

SATA products help guarantee perfect finishes through their excellent precision and highest quality.

SATA products help guarantee perfect finishes through their excellent precision and highest quality.

You think nothing beats a perfectly finished surface?

You think nothing beats a perfectly finished surface? We agree. We have been developing spray guns, breathing protection systems and accessories to meet the highest standards for decades.

We agree. We have been developing spray guns, breathing protection systems and accessories to meet the highest standards for decades.

You are welcome to judge us by the results you achieve with them.

You are welcome to judge us by the results you achieve with them.

Canada catalogue

Canada catalogue

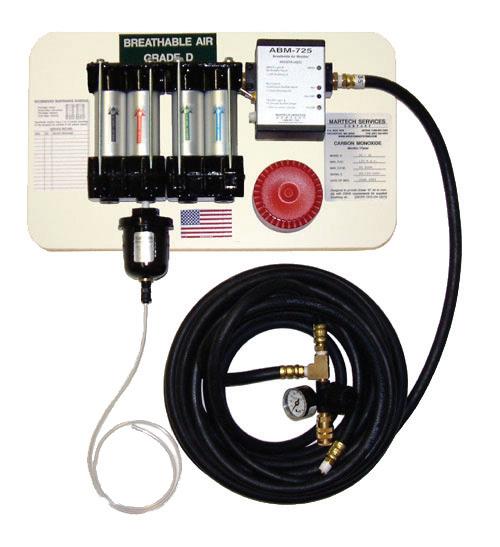

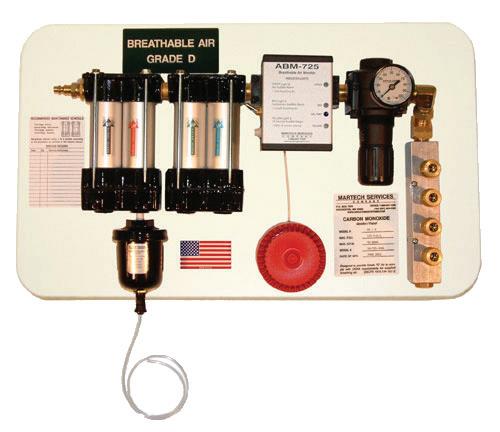

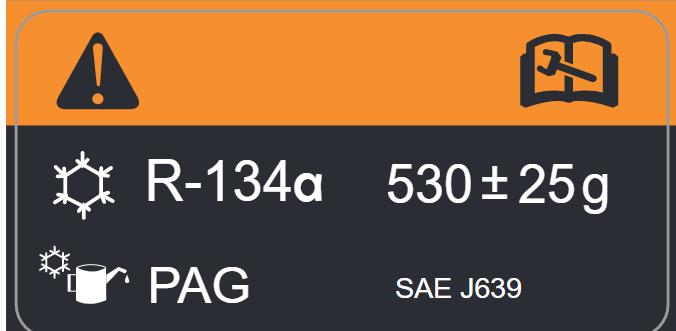

When spraying a catalyzed paint or waterborne paint product inside a spray booth or prep deck, the proper personal protection equipment is an air-supplied respirator. Air supplied respirators must be supplied with Grade “D” Breathable Air.

Quality Air Breathing Systems are designed to provide Grade “D” Breathable Air from your existing compressed air system, for compliance with current CSA Standards when using an air supplied respirator. Systems sized from one person to twelve persons at the same time. We offer complete systems, with proper filtration and carbon monoxide monitors, panel mounted, and ready to use. Available in belt mounted, wall mount, and portable versions.

Marian Van Hoek has been appointed managing director of BASF Canada, headquartered in Mississauga, Ontario. A BASF Canada team member since 2015, Hoek most recently served as general counsel and chief compliance officer, and sits on the Canadian Leadership Team and Executive Committee. With over 20 years of legal experience, including roles at BlackBerry and BASF, Hoek brings extensive expertise to her new position. In a LinkedIn post, she expressed her commitment to driving innovation and sustainable growth for BASF Canada.

Mazda Canada has announced Amy Fleming as its next president and CEO, succeeding David Klan, who will retire on September 30 after 33 years with the company. Fleming, currently chief operating officer, will officially take over this fall. Fleming will be the first woman to lead Mazda’s Canadian operations. Originally from Antigonish, N.S., she joined Mazda Canada in 2006 and has held leadership roles across sales, marketing, operations and customer experience. “It’s an incredible honour to lead Mazda Canada at such a pivotal time,” said Fleming. “I’m committed to building on the strong foundation Dave established.” Klan, who became president in 2019, led the company through a period of record performance and industry recognition.

Advantage Parts Solutions has named Adam Tolowitzki as its new vice-president of strategy. The former OEC executive will lead efforts to expand the company’s presence in the collision and mechanical repair sectors.Tolowitzki brings deep experience in strategic development and cross-sector collaboration, having led growth initiatives across the OEM and aftermarket spaces. In his new role, he will align strategy, sales and customer success while strengthening partnerships across North America. CEO Bob Kirstiuk called Tolowitzki a “thoughtful, strategic and people-centered” leader whose values align with Advantage’s mission. Tolowitzki, while excited for the opportunity, expressed gratitude for his time at OEC.

In a rapidly evolving industry driven by technology, Louie Riccelli exemplifies resilience and innovation. With deep family roots and decades of experience, he has transformed his longstanding collision locations—North Seven Auto Body and York Mills Automotive Centre—into integrated, futurefocused destinations. As a new member of Fix Network, Louie is leading his legacy into the future, blending traditional family values with cutting-edge services.

For Riccelli, this isn’t just about rebranding; it’s a strategic evolution. His shops—already well-established in the community—are now comprehensive centres that uphold trust, quality, and service excellence. By fusing history with innovation—such as advanced diagnostics, OEM repair standards, and integrated glass services—Louie is advancing Fix Network’s “Shop of the Future” vision, one repair, family, and generation at a time.

Louie’s journey began in 1973 at North Seven Auto Body, a cornerstone of Vaughan’s community, founded by his father, Elio Riccelli. Growing up alongside his father, he developed a passion for cars and a drive to innovate. At 18, he managed the shop alone when staff unexpectedly left, learning resilience and humility—lessons he still values today.

Reflecting on that pivotal moment, Louie shares: “I learned how valuable every employee and customer is, and I realized the grit it takes to lead when the odds are stacked against you. Those lessons have stayed with me ever since.”

Over the years, Louie transformed North Seven Auto Body into a successful collision shop and expanded York Mills Automotive Centre into a thriving hub for mechanical and collision repairs. Recognizing the significance of strong brand identities, he strategically rebranded the time-honoured family businesses under the Fix Auto and ProColor Collision brands—names trusted within the collision community that harness the strength of the Fix Network. With both locations now rebranded as ProColor Collision Vaughan Central and Fix Auto York Mills, Louie has established top-tier shops within the Fix Network.

His leadership has been recognized industry-wide: “Louie Riccelli is a true example of a successful entrepreneur who brings great value to our network,” says Amin Youssef, Regional Vice President of Fix Network Canada. “His ability to adapt and innovate while respecting his roots sets a benchmark for excellence across the entire Fix Network.”

He then acquired and revitalized a second location, doubling output with the same team, proving that tradition fused with innovation drives success.

Louie’s success isn’t just about preserving legacy; it’s about continuous evolution. His shops now serve as reliable, comprehensive centres offering both mechanical and collision repairs, fostering trust and loyalty across generations.

Recently, Louie made a strategic investment in top-of-the-line Hunter Engineering wheel service equipment, ensuring his shop can provide the best service for high-end vehicles in the York Mills area. The addition of NOVUS Glass complements his collision services, supporting both his collision clients and retail customers with advanced glass repair and calibration, especially critical for vehicles equipped with ADAS.

“Louie has effectively integrated auto glass repair into his existing operations, emphasizing safety and technology,” notes Zakari Krieger, Vice President of Prime CarCare. “His focus on calibration equipment and staff training highlights how a modern, high-quality shop should operate—delivering safety, efficiency, and peace of mind to clients.

Louie’s shops feature in-house scanning, OEM repair software, and certified calibration tools—reducing cycle times, improving quality, and elevating customer satisfaction. His proven success in retail service now extends further with the addition of glass, demonstrating a comprehensive approach to serving both collision and retail clients.

His core values—humility, respect, and embracing change—are the foundation of his leadership. With credentials like I-CAR Gold Class and multiple OEM certifications, Louie continues to inspire his team and push for continuous improvement.

Partnering with Fix Network was a strategic move to accelerate Louie’s growth and innovation. The alliance with trusted brands like Fix Auto, NOVUS Glass, and ProColor Collision allows him to expand service offerings, strengthen insurer relationships, and leverage co-marketing initiatives— creating a full-service automotive destination.

His core values—humility, respect, and embracing change— are the foundation of his leadership. With credentials like I-CAR Gold Class and multiple OEM certifications, Louie continues to inspire his team and push for continuous improvement.

Louie’s shops are community pillars, with loyal clients trusting decades of high-caliber service. From supporting local initiatives to welcoming co-op students, giving back is second nature. “Our door’s always open,” Louie says, reflecting on the families he’s helped keep on the road.

Family is central to his community focus. His wife, Chiara, is an active partner, fostering a culture of trust and support that extends to staff and clients alike.

Louie’s advice for family-business owners: “Don’t let small issues snowball. Set boundaries, prioritize family, and embrace change. When family businesses work, nothing beats it.”

Through his leadership rooted in tradition and innovation, Louie Riccelli continues to steer his shops—and the industry— toward a sustainable future that honours his legacy while embracing the opportunities ahead.

On Sunday, June 15, the Fix Network team cheered on the Stake F1 Team Kick Sauber during the Canadian Grand Prix.

“Our franchisees, partners and members of the Fix Network team experienced an extraordinary day at the Canadian Grand Prix, thanks to our partnership with the Stake F1® Team KICK Sauber,” the franchise wrote in a social media post. “Under perfect sunshine, [members of the Fix Network team] enjoyed exclusive paddock access, met the drivers and watched the race from breathtaking VIP seats. Some of our Atlantic franchisees even made the trip to Montreal to be part of this once-in-a-lifetime experience!”

Kick Sauber is a Swiss Formula One team operating with Ferrari engines. It entered a partnership with the Fix Network in 2024. The auto repair franchise’s logo features prominently on the team’s C45 car, appearing on the inner rear wing and nose.

According to its members, the partnership reflects shared values of performance, precision and forward-thinking innovation, while also giving Fix Network international brand visibility through its association with the global F1 platform.

The Stake F1 Team Kick Sauber had a solid showing. Nico Hülkenberg finished eighth, earning valuable points, while teammate Gabriel Bortoleto crossed the line in fourteenth, one lap down.

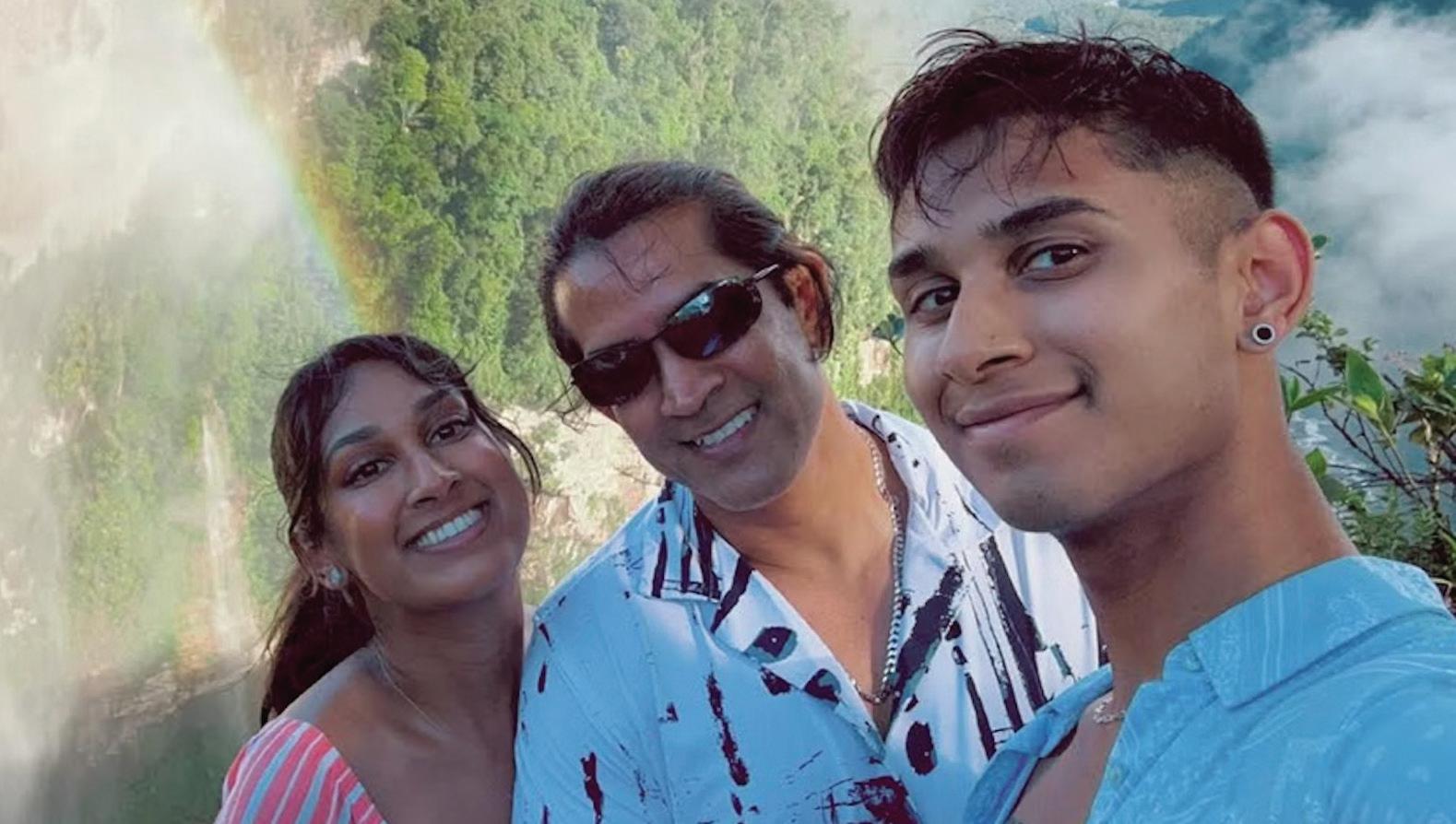

CARSTAR recently highlighted the story of a father-daughter duo making an impact at one of its Greater Toronto Area locations. Ashley and Bisram Deokinandan are both part of the family behind CARSTAR Newmarket, which first opened its doors in 2012. Now in its 13th year of operation, both Deokinandans are working at the shop alongside Bisram’s wife, Romena, and his son, Ryan. The report highlighted how Ashley had come to admire her father’s work ethic, kindness and willingness to make sacrifices for loved ones as a result of her time working beside him.

“We had no idea then how hard he worked all day, often juggling multiple jobs,” she said in the press release. “But no matter how tired he was, he never skipped those moments with us. That time together is one of our fondest memories. He’s a real hero in our hearts.”

She also talked about how her father had begun preparing them for positions of responsibility in business from a very young age.

“When my brother Ryan and I were younger, our dad would bring out Monopoly almost every night—it was our greatest joy” said Ashley. “He taught us every strategy —and made sure we knew whoever bought Boardwalk would always win!”

Ashley added that she hopes to see the business continue to thrive in the future.

“CARSTAR is part of our family’s legacy,” Ashley said. “We hope to continue sharing in the experience of being franchise owners for generations to come.”

A survey by Collision Repair magazine found that 74 percent of Canadian collision repair businesses are family-owned. Of those, 83 percent were started by a parent’s generation and 13 percent by grandparents.

According to Collin Welsh, senior director of CARSTAR, the Deokinandans’ story is a “perfect example of what makes CARSTAR so special.”

“The Deokinandans truly embody what it means to be a family business,” he said. “Bisram’s dedication and values have not only built a strong store, but a strong culture rooted in kindness and service. Their story is a perfect example of what makes CARSTAR so special and it’s a privilege to work alongside them.”

While the banner is well-known for providing family businesses with the support needed to compete against MSOs, many other collision repair shops have been passed down through multiple generations in Canada.

A survey by Collision Repair magazine found that 74 percent of Canadian collision repair businesses are family-owned. Of those, 83 percent were started by a parent’s generation and 13 percent by grandparents.

In Regina, Western Autobody was founded in 1944 by Nickolas Hauck. His son joined in 1952, and now the business is run by Hauck’s grandchildren.

Parr Auto Body in Saskatoon began in 1952 and remains a family-led shop. Its current team includes several relatives of the founder, along with long-time staff.

Even some larger networks like Distinctive Auto Works and Craftsman Collision also remain under family leadership.

ABritish Columbia collision repair facility is celebrating its 45th birthday. Founded on June 12, 1979 as Terminal Autobody by Al Descoteau in Nanaimo, B.C., the facility was later moved to Parksville, where the Descoteau family set up a 465 square metre (5,000 square foot) shop. Al, along with his children, Marc Descoteau and Sari Smith, and his daughter-in-law, Christina Descoteau, continue to provide outstanding service to the community, though the business has now moved into a state-of-the-art, 1,115 square metre (12,000 square foot) facility. Terminal joined the CARSTAR network in 2017. The franchise highlighted the location’s anniversary in a social media post.

“Please join us in celebrating Al Descoteau and the entire team at CARSTAR Terminal Autobody on this remarkable milestone of service, innovation and leadership. Here’s to many more years of success!”

Speed of a faster grit, Finish of a finer grit A K-2500 cuts as fast as P2000, but finishes like P2500 or finer K-SYSTEM FOR TOPCOAT FINISHING

Ultra-Uniform Finish Less Re-work & No Deep Scratches

Flexible Bonding Fast Sanding Coverage THAT BENEFIT FROM THE MOST ADVANCED

Replace costly and messy multi-pad and multi-compound buffing to leave a finish that can be buffed to final shine in a single polishing step. The entire K-System is Total DRY which means instant progress monitoring without the mess, prep and waiting of wet sanding.

Still taking razor blades and nib files to delicate clearcoats? Repair paint nibs, runs and texture even faster with Tolecut, while leaving a shallow, uniform finish that can be buffed out in a fraction of the time.

As part of its ongoing commitment to community impact, Simplicity Car Care is announcing a $10,000 donation to the Windsor Regional Hospital Foundation.

The donation was generously made by two Simplicity Car Care Windsor franchisees, brothers Sia and Arash Mokhtari.

The funds will be allocated by the hospital toward areas of greatest need, which may include essential equipment purchases, facility renovations or enhancements to patient care programs.

“At Simplicity Car Care, we believe that real success is measured not only by business growth but by the positive impact we make in the communities we serve,” said Paul Prochilo, chief executive officer of Simplicity Car Care.

“Supporting Windsor Regional Hospital allows us to give back to a community that has welcomed and supported us, and we’re proud to play a small part in helping deliver high-quality healthcare to families across the region.”

Simplicity Car Care’s Windsor locations have long been supporters of the local Windsor community. This donation reflects their shared dedication to helping improve the lives of residents and strengthening vital public services like healthcare.

“Healthcare is the backbone of a thriving community. We’re proud to stand behind

our local hospital and the incredible team that works tirelessly to care for our friends, neighbours and loved ones,” said Sia Mokhtari.

“For us, giving back isn’t just a responsibility—it’s a privilege,” Arash Mokhtari added. “We’re humbled to support our hospital and the dedicated professionals who deliver hope and healing every single day.”

Windsor Regional Hospital Foundation expressed its appreciation for the unrestricted nature of the gift, which provides flexibility to meet urgent and evolving needs within the hospital.

The contribution is part of Simplicity Car Care’s broader commitment to community investment, corporate responsibility and supporting the pillars that keep Canadian communities strong.

The Mokhtari brothers are the co-owners of Simplicity Car Care Windsor, Windsor East and Windsor LaSalle. Sia serves as the general manager of Simplicity Car Care Windsor and Windsor East locations while Arash manages the Windsor LaSalle location.

Earlier this year, the Mokhtari brothers were featured in the cover story for Collision Repair.

Ukraine’s Miroslav Hubenko claimed top honours at Camauto’s 2025 PDR & GPR International Competition, held in Montreal from July 11 to 13.

The event brought together 10 technicians from around the world for a weekend of live repairs, tool demonstrations and friendly rivalry. Sponsored by Anson PDR, competitors were selected through public voting. Over two days, each was tasked with repairing a dent under the gaze of judges and a crowd of fellow technicians and toolmakers.

The competition kicked off with demonstrations from Camauto Pro Tools, giving attendees a look at new equipment and repair techniques. Competitors were introduced and assigned their repair panels by random draw.

While techniques varied, their goals did not—to make clean, complete repairs under strict time constraints. Repairs continued through Sunday.

Judging was handled by four industry veterans: Arilson Guedes (Brazil), Charles Aoun (Canada), Ken Clark (U.S.A.) and Craig Dyer (U.S.A.). Scores were sealed until the evening Gala Dinner, where results were announced.

Second place was awarded to Menfis Hurachi of Brazil. All 10 competitors received certificates of participation and gift packages from Camauto.

Also competing were:

• Gene Fetty (U.S.A.)

• Martin Sadler (U.K.)

• Oleksandr Doronin (Canada)

• Pak Narlin (Canada)

• Pablo Rocha (Mexico)

• Vladimir Polacek (Czech Republic)

• Wei Wu (China)

• Zeeshan Anjam (Germany)

Simplicity Car Care is announcing its expansion into the United States with the launch of its U.S. brand, Clarity Car Care.

The move marks a significant step in the company’s continued vision to make car care simple and affordable for every vehicle owner in the world.

“The launch of Clarity Car Care in the U.S. marks an exciting new chapter in our growth journey,” says Paul Prochilo, Simplicity Car Care’s chief executive officer.

“This expansion reflects our commitment to delivering a consistent, high-quality customer experience while empowering independent

collision repairers with a proven system. We’re proud to bring our unique value proposition to a broader market and continue transforming the car care industry across North America. We believe there’s a real opportunity to support collision repairers with a modern platform that drives performance at scale.”

Simplicity Car Care’s expansion is the result of a thoughtful, long-term strategy grounded in value creation and modernizing the collision repair industry.

As the industry continues to evolve, Clarity Car Care will bring forward a scalable model that supports both independent collision repairers and large-scale partners with the

resources they need to thrive.

The US expansion will be led by the company’s president, Domenic Ieraci, who will oversee the strategy and growth plan with the support of its US-based team, as Clarity Car Care expands in key regions.

“This expansion is an extension of the foundation we’ve build alongsideour franchisees, employees and customers,” says Ieraci. “A stronger, more diversified platform allows us to greatly improve our value proposition on both sides of the border.”

Founded in 2017, Simplicity Car Care is one of North America’s fastest growing colliion repair networks.

Toyota has released the latest in a threepart retrospective detailing how its advanced safety features—now standard in most of its vehicles—were developed and rolled out between 2010 and 2015.

The most recent article, released on June 24, details how Toyota engineers overcame the challenge of balancing advanced safety functionality with affordability. It outlines how systems like automatic emergency braking, lane-departure alert and adaptive cruise control were developed to meet regulatory standards while remaining feasible for largescale production.

“In the future, we’re hoping to be able to cover more speeds and extend protection to increasingly difficult crash scenarios,” said Derek Caveney, senior executive engineer at Toyota Motors North America.

This release follows one from earlier in June,

which outlines Toyota’s shift from passive to active safety. The first release traced early innovations to hybrid vehicles like the Prius, where engineers trialed emerging technologies before broader deployment.

For shop owners and technicians, the wide

adoption of active safety systems like TSS means re-calibration and repair considerations are increasingly a part of routine collision work—particularly as sensor-equipped vehicles become more common across all market segments.

Axalta Coating Systems has been awarded the 2025 Diamond Supplier Award from International Motors, LLC., an Illinoisbased commercial vehicle manufacturer and developer of Fleetrite aftermarket parts.

Axalta employees Hadi Awada, president of mobility coatings; Dan Naugle, vice-president of mobility Americas; Phil Henriques, business director and Paul Davenport, heavy duty truck sales director, accepted the award on behalf of the company.

In an announcement post on social media, Axalta stated that “this prestigious honour celebrates our commitment to innovation, quality, sustainability and collaboration.”

International announced the award recipients on July 14, stating in the press release that the award “recognizes suppliers who have consistently demonstrated a commitment to excellence and collaboration across key areas such as technology, quality, delivery, cost, sustainability and people.”

Suppliers were evaluated on their ability to deliver advanced technological solutions, reliable delivery performance and

commitment to zero-defect quality. According to International, winners demonstrated strong cost leadership through innovative efficiency improvements in alignment with International’s strategic focus on sustainability.

Six suppliers won the award in addition to Axalta: HG Transportaciones SA de CV, Renaissance Manufacturing Group, Superior Trim, Toyota Credit Canada Inc., VCST International and W.W. Grainger, Inc.

“This year, we are proud to recognize those suppliers who have not only met, but exceeded expectations through exceptional performance, innovation and dedication,” said Peter Friberg, International’s chief procurement officer, in the press release. “I’d like to personally thank each International 2025 Diamond Supplier Award winners for their continued partnership in providing solutions that move our customers forward.”

ACCUWELD®3

ACCUWELD®

ACCUWELD® 2

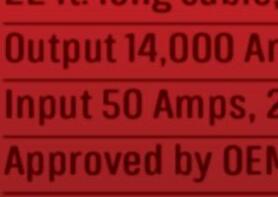

Output 14,000 Amps, 450 daN or 700 daN

Input 50 Amps, 208-240V, 3 Phase Approved by OEMs

BY GIDEON SCANLON

BEMAC Auto Body is celebrating 50 years as family-owned collision repair business.

Founded in 1960, the business was purchased by Gaetano Frangione and his brother-in-law Frank Palermo in 1975. Now led by Gaetano and his sons, Danny and Joe, the business is part of the BEMAC Collision Group, which also boasts seven other collision facilities, as well as two satellite locations and two dedicated calibration facilities.

In a speech delivered during an anniversary celebration held at the flagship location last week, Joe credited his father and uncle

with establishing a firm foundation on which the company was able to flourish.

“[Frank and Gaetano] brought with them a simple philosophy: treat people right, do quality work and always stand behind your word.”

“On a personal note, I feel incredibly fortunate to have worked side-by-side with my father since 1994, with my brother Danny since 2009 and now with my son since 2022,” Joe added. “The same passion and values that Gaetano and Frank instilled in us continue to drive our work today.”

Joe went on to thank the company’s loyal

customers, business partners and employees.

“To our customers and industry partners, thank you for your continued trust. To our team members—past and present— your dedication and passion have shaped everything we’ve built. To our families, your unwavering support has carried us through every challenge and triumph.”

Joe added that the company would remain committed to innovation, excellence and serving the Ottawa community with integrity and a personal touch in the future.

“Thank you for being part of this journey,” he said. “Here’s to the road ahead!”

BY GIDEON SCANLON

After a 15-year hiatus, the Consolidated Dealers Customer Appreciation Trade Show returned on May 27.

“The whole team was behind bringing it back,” said Mike Beier, president and chief executive officer of Consolidated dealers. “They felt it was important to do something to bring everyone together, showcase what we have to offer and to show off our head offices in Woodbridge. It was a very good call!”

This year, about 200 people attended the trade show, which featured more than 40 exhibitors, including 3M, BASF, Consolidated Collision Services, Hunter Engineering, SATA, Kent Automotive and LKQ. These partners showcased the latest in collision repair tools, refinishing products, diagnostic technologies and shop management solutions.

Guests were also invited to enjoy refreshment served by the two food trucks, ice cream truck and mobile beer-and-wine bar brought onto Consolidated Dealers’ campus. With so many people enjoying the food, the picnic tables presented an excellent networking opportunity for anyone in the automotive aftermarket.

“It was a great day. People had a lot of fun and got to learn a whole lot as well,” said Beier. “I’m looking forward to our team hosting the next one, and grateful for the contributions of everyone that helped made this event a success.”

Consolidated Dealers, Canada’s first national auto dealer buying group, was founded in 1979. Owned entirely by new car dealers, the co-operative serves over 2,800 customers nationwide, providing products and programs aimed at enhancing dealership and collision centre profitability and ensuring operational success.

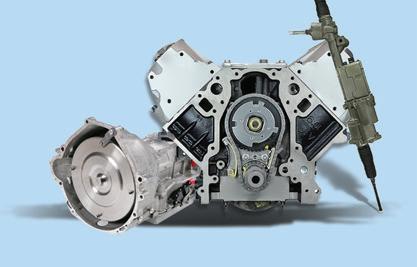

Paint | Aftermarket | Recycled | Transmissions & Engines

At LKQ, the “R” in P.A.R.T. stands for Recycled OEM parts. LKQ first began 25 years ago through the acquisition of several auto salvage yards, and through the years, LKQ has grown to become the largest recycler of vehicles in the industry. LKQ now operates more than 125 auto recycling yards across North America. Through its state-of-the-art processes, LKQ recycles or re-sells more than 90% of the materials from end-of-life vehicles that would otherwise end up in landfills. Engines, Drivetrain, Suspension, Body, Cooling/HVAC, Electrical, Emissions, Exhaust, Audio, Fuel Delivery, Interior, Power Steering, Restraint System Parts and More…LKQ

BY MACKENZIE GRANT

Rob Kember’s workdays are never the same—but that’s exactly how he likes it.

On any given morning, you’ll find him pulling into one of Centennial CARSTAR’s 12 locations across Atlantic Canada. It might be Dartmouth— or it could be a quick drive to New Glasgow. Regardless of where he starts, Rob’s schedule centres on showing up, listening in and lending a hand.

“I like to be at the store for opening,” he said. “I usually get involved with the management staff to see what’s going on—if there are any hot issues. I like to be at the production meetings just to hear how they’re carried out.”

From there, he says the rest of the day unfolds based on who needs him. Moving through operations, reviews analytics with teams and leans into one of his greatest thrills—helping shops perform better.

“I like running the business by the numbers,” he said. “I bring analytics to the team every day—targets, areas that need improvement. That kind of work excites me.”

It’s a detail-driven passion that’s helped Rob and his managing partners guide Centennial CARSTAR through remarkable expansion: more than 15 acquisitions in the last nine years. But for Rob, the real story isn’t the growth. It’s the people—starting with his own family.

Centennial CARSTAR traces its roots back to Kember’s father, Ezra, and uncle, Ira who first found success in automotive retail and repairs decades ago.

“It’s nearly impossible to overstate the value of experience. Not the kind measured in weeks or months, but the nearly five decades of experience from which Centennial benefits,” Rob said.

Today, Ezra still works on the shop floor, training members of the third generation— Rob’s cousins’ kids, with his own not far behind, set to receive the same training from their grandfather.

“There’s just a lot of pride in knowing we have this option to include more family,” he

“It’s nearly impossible to overstate the value of experience. Not the kind measured in weeks or months, but the nearly five decades of experience from which Centennial benefits.”

— ROB KEMBER, MANAGING PARTNER, CENTENNIAL CARSTAR

“We thrive off the daily business. I want to see steady growth— manageable, measurable growth that supports our team and keeps the brand strong in Eastern Canada.”

said. “And we’re focused on keeping the values aligned, from top to bottom.”

That family-first approach doesn’t end with bloodlines. Rob makes a point of inviting staff families into the fold—through everything from community fundraisers to seasonal hiring.

“If a staff member’s kid needs a summer job, we find something. Maybe with the maintenance crew, mowing lawns or just being around the business. It introduces them to the industry.”

Though his job title may read “Managing Partner,” Rob keeps his boots on the ground. His leadership philosophy borrows from RISEN From The Shop Floor: Lessons from an Entrepreneur, a book by Sam Mercanti, founder of CARSTAR. The theme of the book is servant leadership and its effectiveness in serving those around you to make the greater whole.

“Servant leadership really resonates with me,” he said. “You lead by serving others— but you also lead by doing what you expect. If I’m going to jump up to greet a customer or take a call, I want my staff to see exactly how I would expect that interaction to go.”

His early days as an estimator left a lasting impression. Even now, if a customer walks into a shop needing an estimate and the schedule’s full, he’ll grab a clipboard and jump in.

“I still get a thrill from customer service and selling,” he said. “That never left me.”

Rob’s dedication to operations is just as strong as his customer focus. Over the past five years, he’s helped lead the development of Centennial’s management structure, supplier partnerships, SOPs and customer experience protocols.

“Executing on those focal points has noticeably improved our group’s overall stability and consistency,” he said. “There’s greater trust with our insurance partners. And we’re now much more able to measure and quantify our goals and achievements.”

With locations in Prince Edward Island, Nova Scotia and New Brunswick, keeping performance consistent across stores takes effort—but it’s effort Rob welcomes.

“We bring our entire leadership team together frequently—in person—so we can all learn from each other,” he said. “This is where our SOPs are built and put into practice, then shared with each store.”

For Rob, business success is driven by team success. Centennial’s leadership group includes standout contributors like Charlie Yorston, director of parts departments, who says the company’s commitment to growth has been central to his own journey.

“This is the best group of people I’ve had the privilege of working with,” Charlie said.

There’s also Joe Potter, director of processes and standards, whose belief in the company’s vision has only grown stronger with every role.

“There are challenges,” said Joe, “but those challenges are really just opportunities for continual improvement.”

Then there’s Cory Gallupe in Dartmouth, who has grown alongside Centennial’s regional expansion.

“This isn’t a company that wants to sit back and rest on its laurels,” he said. “It’s great to be part of a team that is constantly pushing forward.”

Newcomer Courtney Barber, store manager at the Dartmouth TD Auto Centre, agrees.

“There’s a level of transparency around goals and finances that’s really refreshing,” she said. “Centennial truly stands behind the values they promote.”

Centennial CARSTAR doesn’t just operate in Atlantic Canada—it contributes to it. Whether it’s food bank drives, cystic fibrosis fundraisers or school playground builds, the team prioritizes giving back.

“We do a lot of work locally—sponsoring sports teams, organizing Christmas drives or partnering with schools,” Rob said. “We even send staff to help build playground equipment. When staff get involved in those projects, it builds a real connection.”

“If

That community-first mindset is reinforced by CARSTAR head office support, he says, especially when it comes to matching donations or helping fund local initiatives.

Rob isn’t slowing down. With more than 350 employees and a growing management infrastructure, he’s thinking in decades—not quarters.

“We’re not interested in selling,” he said. “We thrive off the daily business. I want to see steady growth—manageable, measurable growth that supports our team and keeps the brand strong in Eastern Canada.”

He also hopes to see Centennial continue to offer opportunities for the next generation— whether they’re family or not.

“We’re always coming across people who have no idea the collision repair industry offers this kind of earning potential—or personal satisfaction,” he said. “If you prioritize great customer service, there’s no reason you can’t be successful.”

At the core of that vision is the idea of passing things on. Rob encourages today’s technicians, especially those approaching retirement, to take an active role in mentoring younger staff.

“I always say: help make the next apprentice a rock star. Treat them like family, and set them up for success,” he said. “That’s how you build a legacy—and keep it going.”

We’ve been proud to be part of the CARSTAR team since 2014. The brand’s strong visibility and trusted reputation have been key drivers in growing our repair volume and revenue, enabling us to expand our shop several times. The ongoing support from CARSTAR — across certifications, marketing, training, and more, has been essential to our continued success and growth.

– Patrick Flibotte, owner of CARSTAR Charlesbourg

BY JAY PERRY

Asmall misconception can lead to growth-stunting errors. That misconception is that taking responsibility is the same thing as being blamed. True leaders take full responsibility for whatever shows up in their businesses. That means the good stuff, like financial success, awards for performance, recognition in the community, etc. They also take responsibility for the not-so-good stuff that shows up in the business. Where is can get deceptive is when we have a “team-fail”.

When we have one of those team-fails (and they happen to everyone occasionally) in taking responsibility the leader is not assigning blame to anyone individual. Let’s face facts. When a team does fail there is usually an individual that played a primary role in that fail. It is easy to blame that person. The problem is that learning stops once blame is assigned.

When a leader takes full responsibility they go beyond what happened and who made it so, to a stage of self-examination. They look

JAY PERRY

to see where improvement could be made in their performance as the leader. They ask questions like, “Did I provide enough training for the team-member(s)?” “Did I give them too much before they were ready to be on their own?” “Should I have been more available to help guide the team?”

That’s taking responsibility and not taking blame or assigning blame and that’s when learning can transpire. Those same types of questions can be asked of the team members, such as, “Did you feel fully prepared for what we were supposed to do?” “When you look back at the situation, is there something else we could have done to prepare for a better outcome?” “If we could roll back the clock on this, what would you do differently?”

These types of questions get people into a frame of mind we call solution-mode. This is where creativity lives. It squashes any desire to do better or be creative when we say things like, “I told you that wouldn’t work. Follow what I say next time.” Think about your own

Jay Perry is the founder of Ally Business Coaching, a process improvement and leadership development firm, and co-author of the book Success Manifesto with Brian Tracy. Jay is also an education partner with California Coast University in Santa Ana, California. He can be reached at jayperryally@gmail.com.

When a leader takes full responsibility they go beyond what happened and who made it so, to a stage of self-examination. They look to see where improvement could be made in their performance as the leader.

experience with leaders you had earlier in your career. If they said those types of things you feel gutted and totally uninspired to offer any alternatives that could improve things for the company. It is dispiriting.

By having these proper kind of conversations with our team, we plant the seed for engagement. We must display a responsible attitude not one that looks to assign blame if we want people to grow with us. People do not screw up on purpose. No one wakes up in the morning and says,”Let’s get to work and see what I can mess up today!” No, everyone has a desire to be considered a valuable part of the team, a contributor to its success. So we as leaders must guide team members down this path of taking responsibility so they can grow which in turn helps us to be the one who’s driving! .

In this third edition, we explore the challenges behind inconsistent apprentice success and the key role employers play. From outdated training methods to mismatched expectations, this conversation offers fresh insight into creating more transparent, personalized and effective apprenticeship experiences.

SHE: So, what would you like to explore today?

HE: Today I’d like to explore why my current strategies in training and developing apprentices are inconsistent in their successes.

SHE: Ok, tell me a little bit about why you feel your current apprenticeships haven’t been successful enough for you.

HE: Over the years I’ve had many apprentices and mentors throughout the company. Many of them were successful to some degree but many were not.

SHE: What made the successful ones, successful?

HE: They achieved their skills goals. Well, more like the industry’s skills goals for new apprentices.

SHE: Interesting. Are you saying that currently you are measuring the success of your apprenticeships based on an apprentice’s ability to reach the skills goals set for them by your industry? Sounds like it’s all been figured out for them: a pretty one-sided approach. Why don’t you think it’s working?

HE: When you say it like that, I don’t think we as an industry even bother to ask the apprentice what they want to learn or how they want to learn. We just set out skills, goals and timelines and even choose their career paths for them. Often choosing the paths we feel will best suit the shop.

SHE: I’m curious, how are employers making those career path choices? Are new apprentices undergoing an assessment process or something like that?

HE: No, that normally doesn’t happen, but I think it would help. But more than that, I don’t believe that all the skills required even come in the same personality.

SHE: Can you give me an example?

HE: Take the body technician role. Our trade requires them to be welders, electricians, computer programmers, HVAC technicians, mechanics and painters all to a certain various degree. If I renovate my house that would represent a greater

number of people. We are looking for all these skills in each successful candidate. If an apprentice lacks aptitude in one area they aren’t “successful”.

SHE: Wow, I can see how those factors certainly influence the success rate for an apprentice in this industry. I’m curious, are new apprentices aware of all these skill development expectations from the start?

HE: I don’t know, that’s a good question! I don’t think most people know to ask or most employers even think to mention it. I know we like to mention all the cool stuff about working with cars, to help create excitement about the industry. We don’t normally share all the challenging parts about being in this industry. They normally find out later.

SHE: What normally happens when they find out about all the challenges?

HE: We see them leave the trade or hop from shop to shop thinking it will be different.

SHE: Do you see opportunity for change when it comes to starting these new relationships off on a more open and transparent level?

HE: Yes, I feel starting with a simplified and honest conversation with new apprentices about the skills expectations and timelines for each role would be better. This will help set expectations together.

SHE: Sounds great, start building trust right from the beginning. Are there any changes you feel you would like to make when it comes to your future apprenticeships?

HE: I’d like to assess aptitude for each skill and reframe success by each learned skill rather than all or nothing.

SHE: Do you feel that will raise the success rate of your apprenticeships?

HE: I think it will help end the conversation from being one sided.

SHE: Absolutely, these types of conversations will help both sides set themselves up for success by agreeing how future successes will be measured. Is there anything else you feel is blocking more apprentices from being as successful as possible?

HE: Well, our mentors struggle with motivation.

SHE: Why do you think mentors struggle to stay motivated? What do you think that’s about?

HE: Well yes, they do struggle with that as well, but I meant that they see apprentices’ motivation wane. But now that we are saying it out loud, I don’t know which one goes first?

SHE: Ok, so whose motivation would you like to discuss first? Mentors’ or apprentices’?

HE: Let’s go with mentors.

SHE: Ok. How are you picking your mentors? How are you ensuring that your mentors want to be mentors in the first place?

HE: Generally, it’s a senior tech and we ask if they will do it.

SHE: How do you think your current selection system works for the teamed-up mentor/apprentice’s level of engagement?

HE: Sometimes the personalities don’t vibe. Some apprentices are super self motivated. Really eager to learn. They just go with whoever they are given as a mentor, and despite any personality differences they make it work. Some apprentices though need a lot more encouragement and explanation. They’re more difficult to find successful pairings.

SHE: It sounds as though a good personality match between mentor and apprentice is an essential part of this process.

HE: Yes, but the technical learning is one part. The encouragement and motivation and accountability really drain the mentor.

SHE: Do you think you might find the motivation of the mentors would be higher if they didn’t need to provide all the soft skills too?

HE: Could I have someone who can be the motivational support, or accountability partner so the mentors don’t need to be?

SHE: Yes. I would still suggest doing the personality and learning style assessments for all mentors and apprentice candidates. The results from these assessments will help you pair the ideal mentor’s training style and personality to each apprentice’s learning style and personality for more consistent success.

BY STEFANO LIESSI

Let’s say you have a perfectly tuned facility. You repair plan like a trooper, and you line-item everything you do to put that vehicle back on the road to OE spec, in its pre-loss condition.

Let’s say all your technicians are top-grade Canadian triple-‘A’ quality. So, what can you do to drive more business through the door? Marketing? Plaster your name on billboards and bus stop benches? Advertise on the radio? TV? Gift with purchase? Maybe a certification… that’s it. If you get OE certified, that should do it. Sounds like a very logical approach. Brilliant—or is it?

There is a thought process out there (prevalent with some U.S. outlets) that OE certifications are a waste and non-binding—they don’t hold their weight in water. This ideology may have you thinking twice about OE certifications. I understand how one might think this way; however, I don’t share this sentiment.

On that note, let’s discuss the OE certification playing field. The perception generally held of these certifications is that without that OE brand of certification—i.e. permission—you can’t fix that brand of vehicle. Sounds tough; however, it’s a wee bit misleading.

If you repair a vehicle without a certification, could there be negative repercussions? Yes, possibly. For example, the use of non-OEM parts may void a warranty, and the vehicle’s

owner may be upset. Additionally, you may find it challenging to obtain certain parts, such as structural components—which makes it difficult to repair without them. Tooling may also be a factor; without proper tooling, the job just got more difficult.

The OE is implementing a degree of the required skill set needed to fix these vehicles. After all, no hospital wants a doctor who was in the 50th percentile upon graduating with their degree—why should an OEM expect any less? As an OE, they implement specific repair procedures to ensure the vehicle is repaired correctly. Access to these procedures is sometimes limited without a certification.

The misleading part is that you can fix them —if you can get around a few hurdles. So, how can an OE implement the criteria that you will be required to follow?

They can host a training and testing session in their facilities, where they put on a series of brand-specific sessions with their own trained instructors, grading and testing technicians. Another approach is similar but allows the use of third-party instructors within their facilities.

The final option involves subletting the certification process to a third-party company, which would oversee it under licence from the OE—including audits, strategies and training also sublet to a third party.

As you can see, there are a few caveats re-

garding certifications to contend with from the OE level; hence, the negative perception regarding certifications.

Do I think certifications are a good idea? Yes, I do. However (here it comes), a few things need to be clarified.

First—everyone NEEDS to be in it together. Yes, everyone. If one party decides not to abide by the rules, it doesn’t work, and you are wasting your time—and others’.

Who are the players? The shop—from front end to detail—everyone needs to be on board and adhere to the guidelines. Payees need to understand that for this to work, they cannot selectively choose what applies and what doesn’t. The world doesn’t work this way. Sorry, it just doesn’t.

OEMs, you also need to be realistic in what you put out there. Mandating OE-only parts that you can’t supply—or that are discontinued—doesn’t cut it. Aftermarket and salvage are here to stay. They’re a multi-billion-dollar industry. OE-only is not viable or sustainable.

Anyone who thinks otherwise is delusional. You think delays are bad now? Try running the industry on OE-only and let me know how that works out.

How many vehicles are in your shop right now, waiting on an OE part? OEs need to work with the aftermarket and salvage companies— not against them.

If I go into a dealership, it’s not uncommon for them to use aftermarket brake pads and shocks on a vehicle—or front-end bushings. (All safety components.) But if I put an aftermarket fender or salvage headlamp on a vehicle in the bodyshop, would I suddenly be a hack? Please.

To my point—certifications can serve a purpose: regulation. In our industry we have NONE—zero—nada.

A plumber, electrician, carpenter, welder and HVAC professional all have a governing body that implements a code written specifically for their respective industry. It is not to be questioned that if you need outlets in the kitchen, they must meet code. If you want to install a second bathroom, it needs to meet code. If you’re going to change the landscape and parking at your business, it needs to meet code.

If Joey Francoscarapini decides to set up a Quonset hut in Greenacres, Alberta, and repair vehicles—have at it, Joey. Make sure the Quonset hut meets the code.

Sure, Joey has a licence he’s had since ’84, but no one is overseeing his contribution. Has he kept up? Is he repairing the vehicle to meet the OE requirements of a safe repair?

Who is guiding Joey in what he needs to keep up with? Who is watching over the process? Nobody.

Now you can see why everyone needs to be on board.

Without some form of regulation—such as OE certifications—we are living in the wild, wild west.

Are certifications the answer to all our troubles? Likely not. Are certifications a start? Yes,

they are. Should they be regulated as well? Absolutely.

In my opinion—and you are entitled to my opinion—what we have been doing is not working. Customers are mainly unaware of vehicle repair, and most couldn’t care less. All they know is that they should be able to trust that it is repaired properly.

They assume there are checks and balances in place. The plaque on the wall serves as a sign to the customer that you have this under control. Unfortunately, many businesses display it on the wall and then revert to the status quo—failing to follow through.

Take the opportunity to make a change in our industry for the greater good. If you have that OE certification, do yourself, the payee, and your customers a favour… Prove it.

Stefano Liessi is the Training and Curriculum coordinator for Color Compass Corporation. He is also a Red Seal technician and refinisher. Stefano enhances his 40 years of experience with 15 years of I-CAR instruction and a post-secondary degree. He also trains Skills Alberta students and has brought home 11 medals for the province, and taught high school students in the auto shop for six years. He can be reached at sliessi@colorcompass.com.

SALES PLUMMET, CREDITS CUT AND CYBERTRUCK CONUNDRUM

As political backlash, EV policy changes and consumer confidence collide, Tesla faces a critical moment — with implications for Canada’s collision repair sector.

Tesla sales in Canada were already declining prior to the federal government’s suspension of $43 million in EV rebates in March 2025 —an action that accelerated the downturn.

BY GREG HORN

Tesla’s recent turbulence may seem like Silicon Valley drama, but its effects are already rippling through collision centres across Canada. With plummeting sales, a potential collapse of critical EV tax incentives and a glut of unsold Cybertrucks, the future of North America’s most high-profile EV brand is suddenly in question—and the impact on repair volumes, parts availability and longterm viability of Tesla-certified bodyshops could be profound.

Elon Musk’s car company has made headlines recently, with global sales hitting the skids.

While many point to Musk’s shortterm stint as head of the Department of Government Efficiency, his very public feud with President Trump and his support for far-right political parties in Germany as the cause, there are several more—and far more severe—problems on the horizon for Tesla.

Before his affiliation with Trump, Musk made several decisions that are now negatively

impacting the company. Tesla initiated significant price cuts across its models on Jan. 13, 2023, in the U.S. and other markets —in some cases reaching up to 20 percent— affecting vehicles like the Model 3 and Model Y. This angered buyers who had ordered a vehicle at the original price, only to see that by the time they took delivery, the identical car was priced significantly lower. These price reductions hurt resale values and damaged the brand’s perception. Additionally, the unusually styled Cybertruck reached peak production just as sales began to slow, resulting in a glut of unsold inventory.

Tesla sales in Canada were already declining prior to the federal government’s suspension of $43 million in EV rebates in March 2025 —an action that accelerated the downturn. The decline is especially evident in Quebec, where sales plummeted by 85 percent in the first three months of the year compared to the end of 2024.

Despite this sharp drop in sales, Tesla

posted a $409 million profit for Q1 2025. However, that figure included $595 million in revenue from selling U.S. regulatory tax credits to other automakers. Without that $595 million, Tesla would have reported a $189 million loss. In 2024, Tesla generated $2.76 billion from these credit sales—a major concern, as the Trump administration has made it clear it wants to eliminate those tax credits altogether.

In addition, the Trump administration’s “Big Beautiful Bill,” recently signed into law, eliminates the US$7,500 tax credit for new EVs and the US$4,000 credit for used EVs as of Sept. 30, 2025—a change that will further impact Tesla sales.

Now, Tesla is facing a dramatic fall in sales, the possible elimination of a $2.76 billion revenue stream, a glut of its most expensive vehicle—the Cybertruck—and a damaged public reputation due to its CEO’s actions. Those are significant headwinds to overcome.

The question is: will Tesla survive?

Greg Horn is the chief industry relations officer at PartsTrader and writes collision industry articles and blogs, in addition to creating quarterly webinars for the industry. He is frequent keynote speaker at collision repair conferences across North America. Horn previously served as Mitchell International’s vice president of industry relations and data analytics, where he published the company’s Industry Trends Report.

A true ‘car guy’—he has owned more than 62 cars—Horn began in the industry working in Volkswagen and Porsche parts departments in high school and college. He began his auto claims career at Safeco and went on to hold senior leadership positions at many large insurance companies. He has also served on the I-CAR Education Foundation; the General Motors Safety Council and GM Fixed Operations Advisory Council. Horn also recently served two years as trustee with the Collision Industry Foundation. He studied at the University of Heidelberg in Germany as well as California State University, Long Beach, and holds degrees in Business Administration and German.

Anew report from Electric Mobility Canada predicts the nation’s transportation sector is about to undergo a major transformation.

According to the report, electric mobility’s slice of transportation-sector GDP is set to climb from a modest 17 percent in 2026 to a commanding 47 percent by 2035. This means more electric vehicles (EVs) on Canadian roads—and by extension, in collision bays.

The EMC report estimates EVs could account for anywhere from 21 percent of the light-duty fleet in Nunavut to a whopping 75 percent in Quebec by 2035.

During the same period, employment in the electric side of the mobility sector is expected to grow from 16 percent to 45 percent.

Canada’s electric vehicle adoption rates remain significantly behind that of the European Union. According to a recent report from Clean Technika, Europe saw a 28 percent in EV sales in April. Excluding Tesla, which saw a 50 percent year-over-year decline, the

market grew 33 percent.

Battery electric vehicle sales reached 184,000 units, up 26 percent year-over-year. Plugin hybrid electric vehicle sales increased 30 percent year-over-year to 98,000 units, and are up 12 percent year-to-date at 368,000 units.

Plugin vehicles accounted for 26 percent of the European auto market in April, with 17 percent from battery electrics and 9 percent from plugin hybrids.

Battery electrics made up 67 percent of all plugin sales this year, while plugin hybrids

comprised 33 percent, identical to the 2024 breakdown. Diesel vehicle sales declined 25 percent and now hold 9 percent of the market. Petrol vehicles dropped 22 percent year-overyear and represent 28 percent of the market.

Hybrid electric vehicles grew 17 percent year-over-year in April, with a market share of 35 percent. Altogether, 61 percent of all vehicles sold in Europe that month had some form of electrification.

At the current rate of expansion, 100 percent of all vehicles sold in the EU should have some level of electrification by 2032.

Non-operational electric vehicles are now barred from boarding boats operated by British Columbia Ferry Services Inc. making it very difficult for Gulf Island residents to secure repairs.

B.C. Ferries’ new rules prohibit EVs with significant damage—such as exposed batteries, fluid leaks and wiring issues—from boarding ferries. EVs with minor damage can still be transported, but require approval from the ship’s captain.

According to Southern Gulf Islands Tourism, the latest statistics from the Insurance Corporation of British Columbia state that 6.5 percent of residents on Salt Spring Island own an EV and 4.1 percent of residents across the rest of the Southern Gulf Islands own an EV.

Village Bay Repairs, an auto repair and maintenance shop on Mayne Island, doesn’t do EV repairs, and owner Mike Maxwell says that “Owners are certainly going to be in trouble though. How would they get them off the island, I wonder?”

The updates to B.C. Ferries’ internal policies come in response to Transport Canada guidelines on the fire risk posed by the lithium-ion batteries in EVs. Transport

Canada’s policy, which requires damaged or defective batteries to be removed for transportation, has been in place since 2014.

In a statement to Black Press Media, B.C. Ferries said “We recognize this presents challenges for customers and commercial operators, particularly as EV adoption increases. However, the safety risks associated with transporting potentially damaged highvoltage batteries, especially when the vehicle cannot be assessed under its own power, require a cautious approach.”

Langley-Abbotsford MLA Harman

Bhangu has raised “serious concern” over Transport Canada’s new rule banning nonoperational electric vehicles from BC Ferries. In a June 30 letter to federal and provincial transport ministers, Bhangu said the policy is “trapping” island residents, forcing them to pay for costly repairs even when no local services are available. He called it a “failure in planning” and claimed tow truck operators are now refusing EV jobs. Peninsula Towing, which handles 10–15 EVs daily, says the ban threatens their work. BC Ferries says it’s seeking clarification on safe transport options.

Montreal’s luxury collision scene just got a bold new boost.

After decades as a cornerstone of the city’s high-end repair market, AutoLux has evolved as part of the rebranded group of ACX collision centres—sleek, sophisticated and unapologetically reimagined. The grand reopening wasn’t just a ribbon-cutting—it was a statement.

“We’re very honoured to align the ACX brand with AutoLux,” said Tim Loehn, Director of Operations at AutoCanada. “It’s one of the most recognized names in the Montreal market.”

The transformation is more than a fresh coat of paint. The facility now boasts modernized customer spaces, a striking new exterior and elevated branding aligned with both ACX and Mercedes-Benz standards. The relaunch event drew more than 150 guests, stopping traffic and turning heads with a parade of ultra-luxury vehicles, curated décor and an unmistakable air of prestige.

“There was a lot of excitement, some

suspense, even,” said Loehn. “But the respect for the legacy of AutoLux is there—and the future under ACX is looking just as strong.”

The new design includes a MercedesBenz exclusive lounge with luxe finishes,

preserving the brand’s customer experience while blending it with ACX’s forward-thinking vision. Completed in two meticulous phases, the transformation pays homage to AutoLux’s roots while steering confidently into the future.

Ottawa just got a jolt of high-voltage innovation.

ACX 417 has officially opened its bay doors—and with it, a bold new era for electric vehicle collision repair in the capital. Rising from a site with nearly four decades of collision repair history, this brand-new, purpose-built facility doesn’t just represent progress—it accelerates it.

“It took us four years from design to completion,” said Mike Li, General Manager. “This moment means everything to us.”

ACX 417 is built with the future in mind, tailored for the specialized demands of OEM-certified EV repair. Tesla tops the current roster, but the roadmap ahead includes names like Rivian, VinFast and beyond. From the first customer handshake to the final delivery, every step is engineered with meticulous precision.

“We want to offer customers true attention to detail—and set a new standard in Ottawa,” said Li.

But ACX 417 isn’t just a local play—it’s a key part of a national strategy.“There’s only

one true way of performing collision repairs, and it’s through OEM certification,” said Tim Loehn, Director of Operations. “And this location embodies that philosophy.”

This new brand identity reflects their commitment to innovation, excellence and customer satisfaction. ACX 417 is more than a shop. It’s a statement.

BY WILLIAM SIMMONS

They came for the strategy, stayed for the scenery and left with a whole new sense of direction.

ACX’s annual conference, this year titled “ALIGN 2025 – Enhanced Vision” brought AutoCanada’s collision and hail repair crew to new heights—literally and figuratively—at the Fairmont Tremblant. Nestled in Quebec’s Laurentian Mountains, this year’s event wasn’t just about looking back at the numbers. It was about planting a flag for what comes next.

There’s no mistaking it: ACX is changing. The clearest sign came as the curtains lifted— figuratively—on the network’s new identity. Sleek visuals, a revitalized logo and a dynamic online rollout are just the surface. Behind it all was a months-long effort that Keven Lupien described as more than a rebrand—it was a reframing of purpose.

The redesigned ACX isn’t just meant to look modern. It’s meant to move. A new website and a full digital ecosystem are set to follow, aiming to create a stronger, clearer bridge between the teams doing the work and the customers relying on them.

Throughout the conference, one theme came up again and again: clarity. And perhaps no one challenged perceptions more than Dr. Niree Kodaverdian, who walked the room through the stories we tell ourselves about the economy—and why so many don’t hold up. Labour shortages, recession whispers, spiking insurance rates—each headline has a backstory, and often, a more complex reality. Kodaverdian connected the dots between rising U.S. debt, shrinking exports and increased household spending, all while showing how these forces subtly shape the future of collision repair.

Sean Carey reminded everyone why the word “rollercoaster” isn’t just a metaphor— it’s a business model. With OEM programs shifting, DRP contracts evolving and IT systems still catching up, collision operators face more curveballs than ever. But Carey wasn’t there to warn—he was there to point out where opportunity still lives. Services many shops overlook, from tire work to recalibrations, may be the key to weathering turbulent market cycles.

At the same time, Jeremy Miller challenged attendees to think bigger about positioning. Branding, he argued, isn’t just about slogans or colours—it’s about controlling the narrative in your customer’s mind. Miller’s workshop cracked open how certifications and culture can become selling tools, not just checkboxes. The energy in the room made it clear: ACX is ready to compete not only on quality, but on identity.

Jacques Villeneuve, Canadian racing legend and former IndyCar and F1 world champion, arrived as a surprise guest speaker. With the perfect blend of horsepower and humility, Villeneuve shared stories from the track that echoed themes from the conference: precision, discipline and the power of a great team.

Arthur Crawford spotlighted ACX’s drive to elevate its people—with leadership training, technical skills and a sharp focus on safety as a differentiator.

And AutoCanada President Jeff Thorpe put it plainly: the reason this network keeps breaking records isn’t luck—it’s people. With over 5,000 members across the country

and growing, ALIGN 2025 served as both celebration and recommitment.

Before the final evening’s celebration began, Paul Antony brought the message home in a closing address that hit both the head and the heart.

“Collision repair is one of the only industries where doing things right means the customer never comes back,” he said. “As odd as that is—we want them to return, but for coffee and visit, not because of another accident. So we set the standard: do it once, do it right and make sure they tell everyone else.”

He continued:

“Every number we report, every milestone we hit, every ounce of momentum—we owe it to the people. The ACX team delivers exceptional results, day in and day out.”

This three-day, high-impact conference wrapped up in style with a gala dinner and awards celebration that felt more like a championship win than a closing ceremony. Attendees gathered for one final night of connection and recognition as the ACX management team presented gifts to top performers and standout leaders across the network.

In the quiet hours that followed the final toast, some attendees lingered over late-night snacks and last laughs, maybe not wanting to let go of the mountain air just yet.

But come morning, they’d be back in their shops and offices. Realigning—again—with a little more perspective in their pocket and a clearer view of the road ahead.

For a look at the new ACX website visit www.acx.auto

BY WILLIAM SIMMONS

Rain clouds and scattered showers didn’t dampen spirits at Glen Abbey Golf Club, where Fix Network Canada hosted its 16th annual Fix Masters Golf Tournament on June 19, 2025. With teams made up of insurance representatives, franchisee members, vendor partners and friends, the tournament was once again a sold-out success, raising more than $5,000 in support of Ronald McDonald House Charities (RMHC) Canada.

Despite a grey sky and a few umbrellaworthy moments, attendees arrived in high spirits, ready to play and give back. Between bouts of drizzle, participants enjoyed oppositehand drives, beat-the-pro challenges and hole-in-one contests, all designed to test their skills—or at least their patience.

“The Fix Network Ontario annual charity golf tournament was another great success this year,” said Amin Youssef, regional vice president – Ontario at Fix Network. “Hosted at the beautiful Glen Abbey golf course, it was a sold-out event that brought together our network’s strategic partners, vendor partners, insurance partners and media partners—all in the spirit of having fun while making a meaningful impact at the same time. And a meaningful impact we collectively delivered. We thank our industry partners for joining us and eagerly look forward to another great tournament in 2026.”