HM LINERFREE®

HM Linerfree is a patented Print & Apply labelling solution that does not require the use of backing paper.

Every year 36 billion m2 of liner is wasted - enough to cover almost the entire area of Switzerland*

In the search for new and innovative ways to reduce global CO2 emissions, HM Systems offers a sustainable and resource-efficient labelling solution that eliminates waste.

The HM Linerfree® solution offers all companies with industrial production and packaging operations a sustainable alternative with zero waste and maximum flexibility.

HM Linerfree® makes a meaningful contribution to your company’s CSR activities to reduce CO2 emissions and waste.

It uses 100% of the label material, unlike conventional systems, where up to 50% of the material remains as waste to be discarded.

• Sustainability

- No backing paper = zero waste

• Double operating time - less downtime

- 50% more material per label roll

• Label flexibility

- Different label sizes possible on the same label roll

• Reduction in label stock costs

- Fewer and faster roll changes

• One-Stop supplier

With HM Linerfree® the need for die-cut labels is eliminated and reduces the amount of label stock required as all labels can be printed in one label format on the fly.

With a single HM Linerfree® label roll, 5,000 labels (100 mm label length) can be printed and applied - compared to approx. 2,500 labels on a conventional label roll with backing paper.

• 50-70 % reduction in label stock costs

• Twice the uptime - less downtime

• Variable label length on the fly

• Double printhead life

• 50 % less shipping costs

• Fewer and faster label roll changes

A systematic analysis of the environmental impact throughout the life cycle of a product, material, process or other measurable activity, is increasingly being used in the labelling industry. LCA calculates the environmental impact of the many interacting processes from cradle-to-grave.

The main difference between a conventional label and a linerless label is the absence of a liner. Conventional labels have four layers, while linerless labels have only three.

The absence of the layer discarded during use (liner) minimises waste and allows for more labels per roll.

Through a comprehensive LCA in accordance with ISO 14040 and ISO 14044 standards, the linerless solution shows: An impressive 35% reduction in carbon footprint compared to a product with a liner for the same application.

By eliminating the need for a liner, linerless labels achieve a significant 38% reduction in post-consumer waste at end-of-life.

When performed accurately, it can provide valuable data that decision-makers can use to evaluate sustainability initiatives and technologies.

Switchmode power supply

120V/240V

Easy changeable wear parts without tools

Typically used for applications where the products to be labelled have the same or few different reference points when the label is applied. It is an ideal application for applying unique traceability information to the label.

Icon-based interface

Intuitive & user-friendly

Same base unit for all applications

• Higher capacity - compared to tamp-on application

• Side or top labelling

• Suitable for corner, bottom and wraparound labelling

• Available with different applicator lengths

• Ideal for products that can be aligned to a side guide

Optimized brake system for smooth label application

High quality label material - Proven & tested

Reduced weight

Typically used for applications where the products to be labelled have different sizes. The tamp applicator is able to reach products of varying heights. It is an ideal application for applying unique traceability information to the label.

Dashboards for operational data & remote service

Tamp applicator available – Quick & easy change between label applicators

• Maximum flexibility for different sizes

• Typically used for top and side labelling

• HM flow vacuum pad for many label formats

• Optimised label loop for higher capacity & minimum distance to product

• Optimised high safety with closed cylinder

Industry 4.0

The HM Linerfree® controller has an extremely user-friendly touch panel with many intelligent features such as alarm overview, fault analysis, recipe control and OEE data that can be used to significantly improve line performance.

For example, the controller holds numerous recipes, all of which can be quickly set up and modified.

HM Linerfree® can communicate with a line control PLC, receiving production data and error messages to optimise the production. Has the ability to provide operating data to a line controller.

HM Linerfree® machines can be accessed worldwide via the Smart Controller and the HM Technical Support Centre. It is possible to view data, edit machine settings and update firmware remotely.

The HM Linerfree® controller uses an integrated touch panel with an icon-based user interface. Different pages and settings can be accessed with just a few clicks.

Optionally, all operating data can be viewed via external web devices such as PCs, tablets and smartphones.

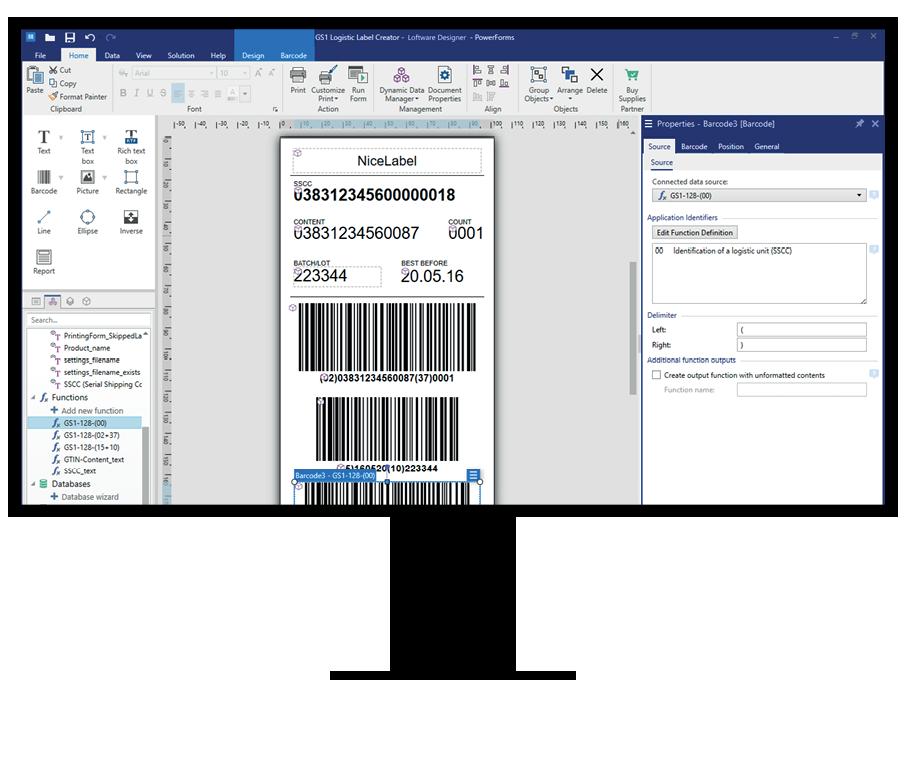

HM Systems offers a wide range of software solutions for label design and printing using leading software applications, such as NiceLabel, Codesoft and Bartender.

These design software solutions, both standard and customised, enable the control and monitoring of printing processes throughout a factory.

Simplifying printing and labelling processes with a label management system centralises data and label management, reducing risk, cost and errors.

Automation allows you to streamline complex printing processes and integrate printing with existing business systems and hardware devices, such as PLCs or scales.

To optimise the user experience, HM has developed a unique Windows printer driver that can be used on Windows based operating systems.

• Printer drivers for all types of printers

• Interface customisation - NiceLabel Power Forms

• Professional design with minimal training requirements

• Connectivity to ERP systems

HM Linerfree labels enable traceability with detailed data capacity

2D & Datamatrix Barcodes

Extensive texts & titles in different formats

HM has partnered with Zebra Technology to develop the latest HM Linerfree Generation 4.

Superior printing platform

Zebra is the world’s leading supplier of label printers and together we have developed a special firmware that optimises printing performance and stability.

One of the advantages of using Zebra is the availability of true ZPL protocol, which is the leading standard in the logistics industry.

As a standard, HM Linerfree has a “real time clock” build into the printer, to be able to print real time and date stamps to ensure traceability.

Applicators Wipe on, Tamp, Corner

Approval

Communication

CE

Ethernet Industry 4.0

Serial

Smart control

Design Software Nicelabel Loftware Codesoft Bartender Windows driver

Applicator Modules

Label reel diameter

Max. label length

Max. Passage Width

150 mm, 350 mm

240 mm, 300 mm

150 mm, 350 mm

100 mm

Options Non Stop Mode

Print Technology

Resolution

Printer

Standard label width

Settings

Direct thermal

203 dpi, 300 dpi

Integrated 4” Zebra Printer

49 mm, 70 mm, 98 mm

Intuitive touch panel with icon based user interface

Version Right or left

Capacity Up to 40 labels pr. minute

Weight