Images of inspiration to keep your workplace safe.

From your request for quote to final installation, our goal at Cogan is to make working together so seamless, it’s effortless. Our engineers are among the finest in the business, while our experienced staff and extensive network of design consultants and authorized installers are committed to keeping you satisfied by providing the smartest, most cost-effective solutions to your specific needs.

No other team can deliver a higher level of service or support than Cogan. Our 100 years of experience means we know what it takes to think, build and design for the long term. Family-owned and operated for four generations, customer satisfaction is more than just our goal, it’s our tradition – a tradition we’ve maintained for over a century.

Derek Goddard President/CEO

A Safe Workplace

Your first line of defense against dangerous collisions and accidents.

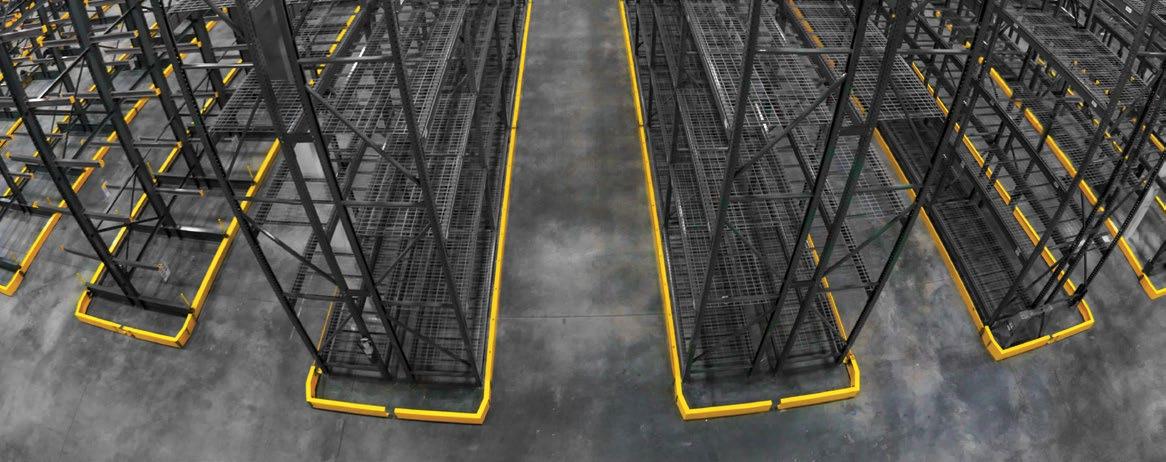

Protect your Racking

Shield critical rack supports and prevent pallet spills.

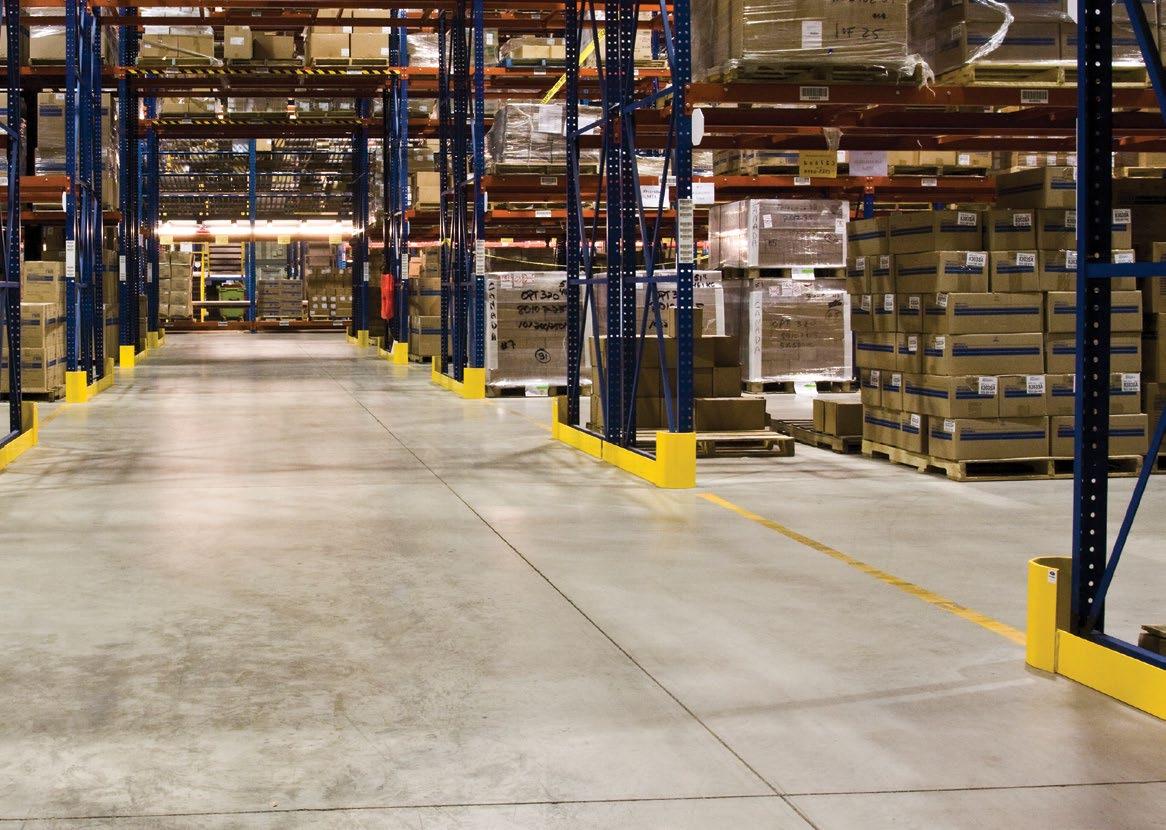

Protect your people and your property from the ground up with Cogan guardrails and safety rails. Every employee has a right to a sound work environment free from occupational hazards that may cause injury. Install a Cogan guardrail system and create a protective shield between your workers and your equipment.

When working with heavy equipment and moving machinery, there is little margin for error. Operators must be 100% vigilant at all times. One wrong turn in a 5-ton fork truck can inflict a lot of damage. This is why investment in proper safety equipment is one of the best business decisions you can make. Distractions are everywhere and accidents likely to happen. Adequate safeguarding not only prevents costly repairs, but attention to safety means so much more than money saved. Improve employee well-being, reduce job-related stress, avoid injuries and limit downtime. A healthy work environment means a productive workforce and a profitable business.

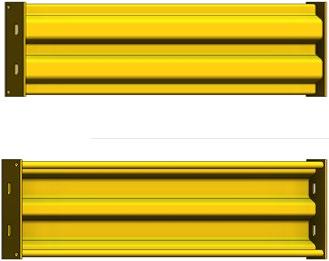

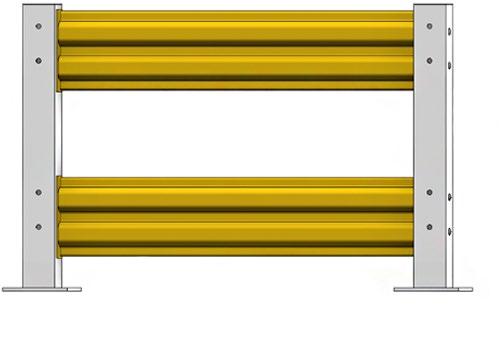

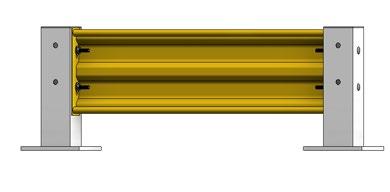

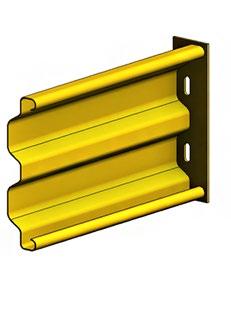

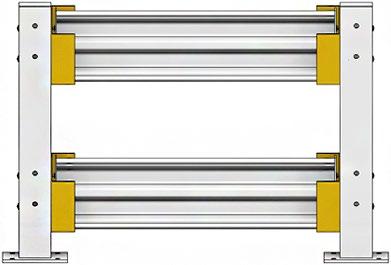

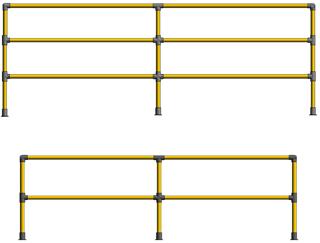

With modular components and fast installation, Cogan guardrail controls, defines and protects important areas in your warehouse. Available in a variety of lengths with single and double-rail options. Choose either standard rails or easy-to-remove lift-out rails that slip into specially designed “saddles” attached to each post. Cogan guardrail is powdercoated in safety yellow for maximum visibility and code compliance.

Use heavy-duty guardrail to safeguard manufacturing equipment, electrical panels, computer stations, staircases and walkways, in-plant offices, first aid and restroom areas, or anywhere else crash protection is required.

With over 11% of forklifts in the United States involved in some kind of accident each year, the potential for workplace injury is high. Add conveyor systems and other moving equipment to the mix and the threat to occupational safety becomes even greater. Promote a safe and efficient work environment with Cogan heavy-duty guardrail.

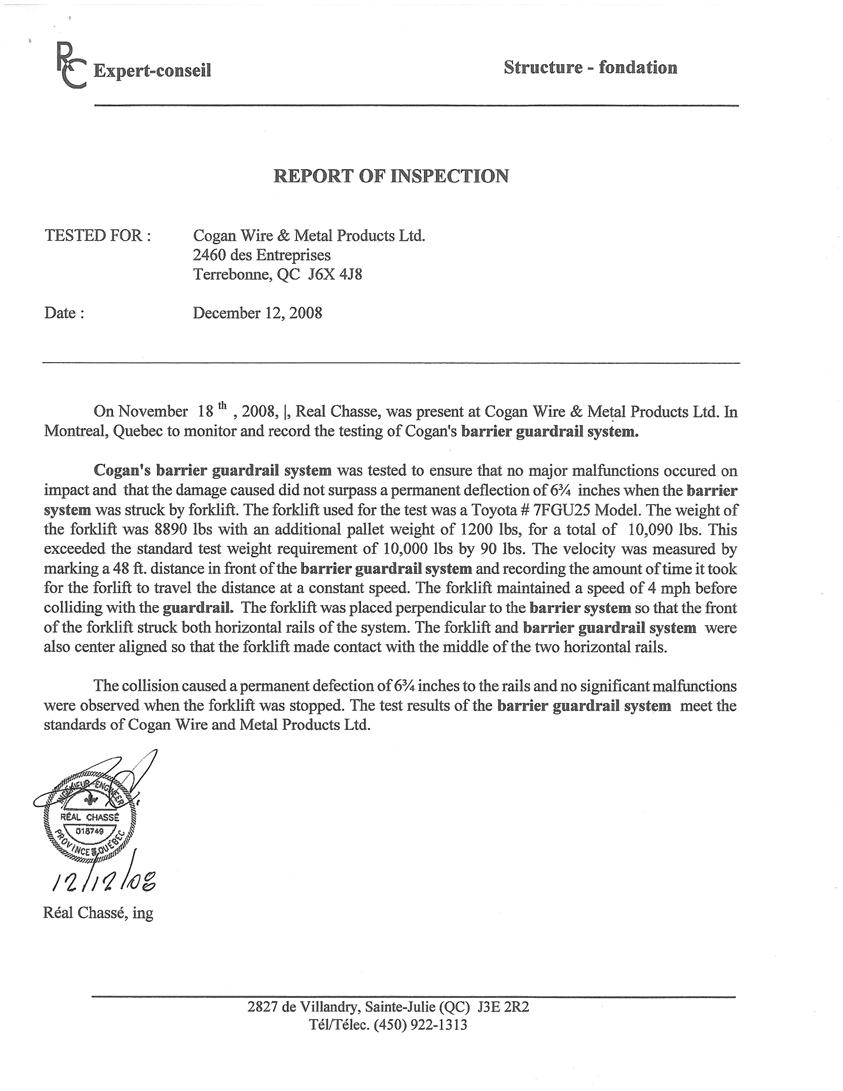

Built from the best quality materials, our guardrail is strong, adaptable and, when properly installed, engineered to withstand a 10,000-lb impact at 4 mph. Avoid downtime and costly repairs. Create a protective wall of steel between your workers and your equipment. It’s the trouble-free solution to your peace of mind.

Ideal when you need a sturdy barrier between processes, our guardrails create secure aisle ways to guide in-plant traffic around the separate sections in your warehouse.

Forklift accidents are a common and costly occurrence. Divide and control storage zones and

protect manufacturing equipment and work cells from collision damage.

The corrugated steel construction gives our guardrail extra durability while minimizing width to maximize floor space. You benefit from increased efficiency, enhanced aisle flow, and improved worker safety.

Protect staircases and other entranceways from collision accidents with Cogan heavy-duty guardrail.

Unimpeded access to your mezzanine platform is essential to maintain productivity. Damaged staircase components are not only costly to repair but can pose a number of safety hazards. When an elevated work area is structurally compromised, your employees are much more susceptible to fall accidents and personal injury. With over 11% of forklifts in the United States involved in some kind of accident each year, the potential for such occurrences is high. Cogan heavy-duty guardrails shield vulnerable property to promote a safe and efficient work environment.

Every employee has the right to a sound work environment that provides adequate measures to treat and prevent injury.

Improved on-site safety by securing your first aid area and restroom areas with Cogan guardrail barriers. According to OSHA, approximately 85 workers are killed and another 34,900 are injured in fork truck collisions each year in the United States. Engineered to absorb heavy impact, our guardrail barriers reduce the occurrence and costly effects of such accidents.

Use Cogan guardrails to guide in-plant vehicles away from employee rest areas. Avoid damage to plumbing equipment and shield personnel from collision accidents when entering and exiting the restroom. You benefit from increased productivity and employees who know that their well-being is a top priority.

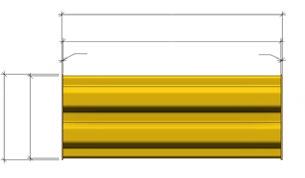

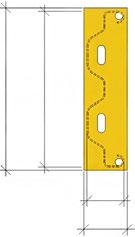

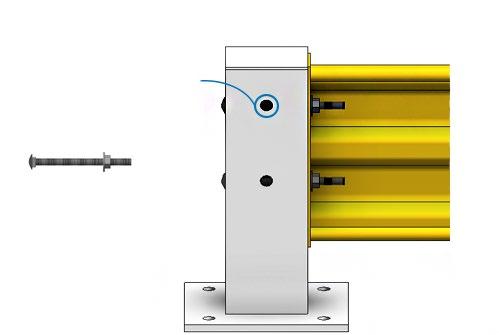

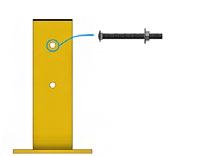

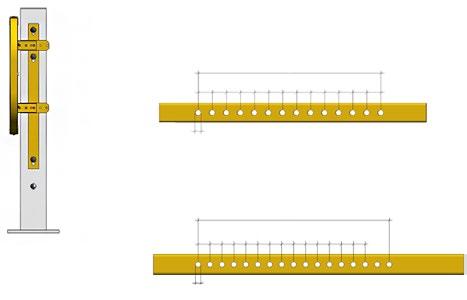

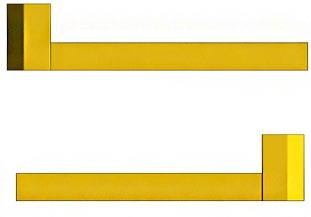

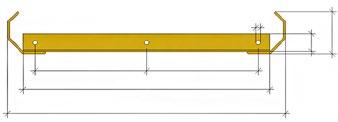

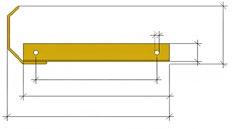

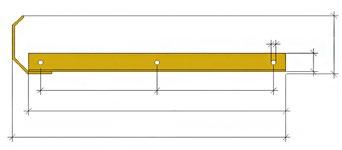

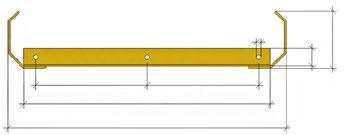

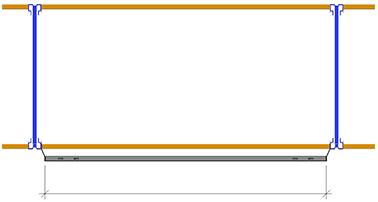

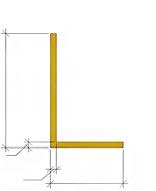

Guardrails are assembled either individually or in pairs according to column height. The standard 12” high rail is welded to two 12 1/2” x 3” plates on each side.

These plates are punched with two 9/16” connection holes and bolted to the column using Ø1/2” x 7” carriage bolts.

Specifications

Construction

Material

Rail Height

Overall Height

Rail Width

Overall Width

Thickness

Finish

Requires Unassembled Components

ASTM A607 Grade 50 Corrugated Steel

1/2” (includes end plate)

Rail Front

Safety Yellow

(includes endplate)

Powder-Coated Safety Yellow

ø1/2” x 7” Carriage Bolts

Rail Back

Item Description

2’ Heavy-Duty Guardrail with 12” Rail Height

3’ Heavy-Duty Guardrail with 12” Rail Height

4’ Heavy-Duty Guardrail with 12” Rail Height

5’ Heavy-Duty Guardrail with 12” Rail Height

6’ Heavy-Duty Guardrail with 12” Rail Height

7’ Heavy-Duty Guardrail with 12” Rail Height

8’ Heavy-Duty Guardrail with 12” Rail Height

9’ Heavy-Duty Guardrail with 12” Rail Height

10’ Heavy-Duty Guardrail with 12” Rail Height 3. Standard Sizes

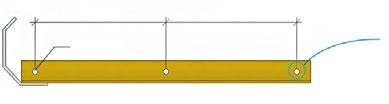

Front View

Exact rail length including end plates

1/4” thlck steel / Overall rail height 12 1/2”

Overall rail length including end plates

G-GR2

G-GR3

G-GR4

G-GR5

G-GR6

G-GR7

G-GR8

G-GR9

G-GR10

All sizes in blue are kept in stock. Refer to Delivery Dates for details.

Custom sizes also available.

Side View

Rail is welded to a 12” 1/2” x 3” x 1/4” thick end plate on each side.

Exact rail length 1/4” thick endplate 1/4” thick endplate Overall rail height Rail height 12 1/2” 12”

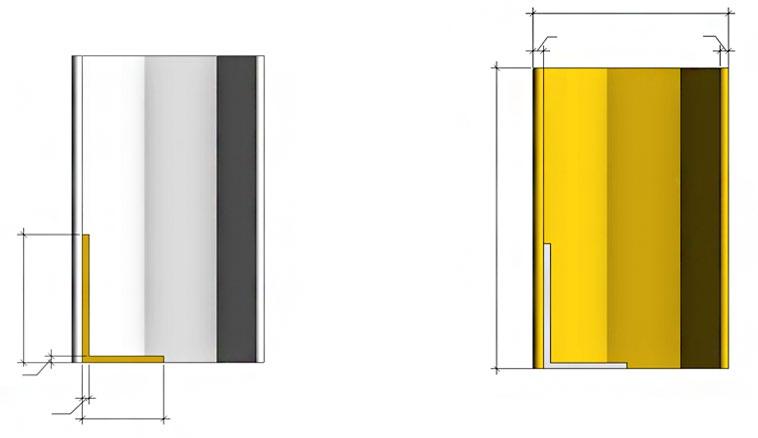

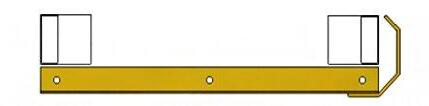

Double Heavy-Duty Guardrail Front View

Heavy-Duty Guardrail Connection Detail

The heavy-duty guardrail is connected to the columns using 2 - ø1/2” x 7” carriage bolts.

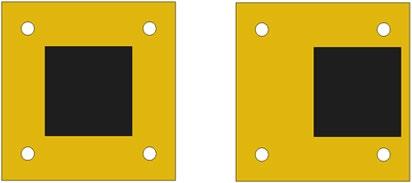

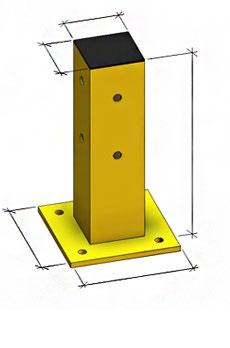

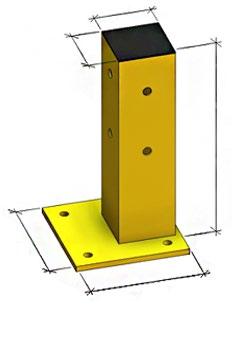

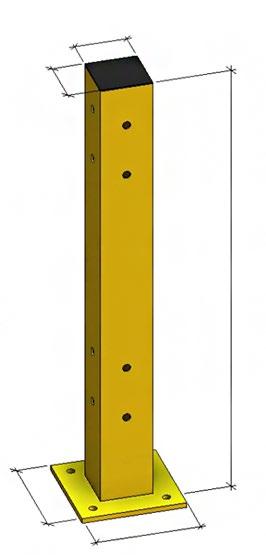

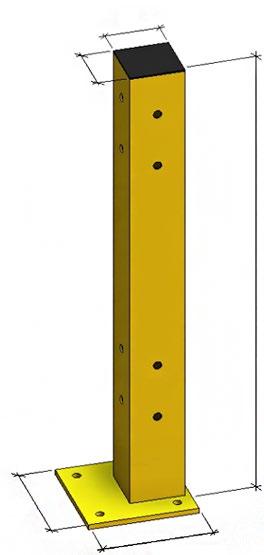

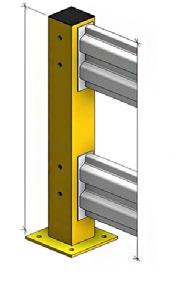

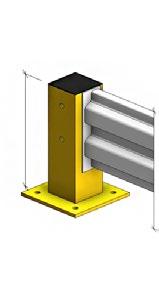

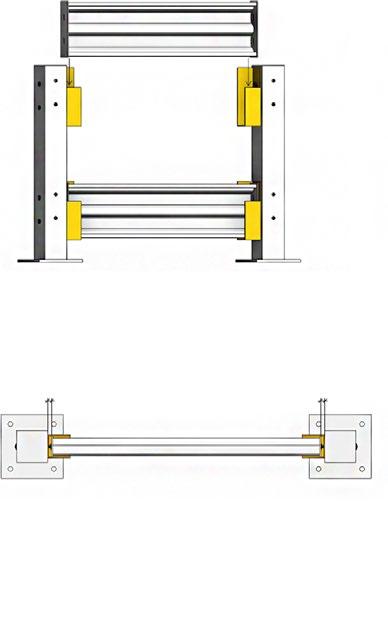

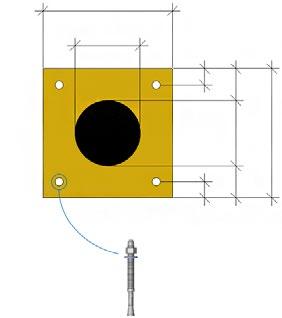

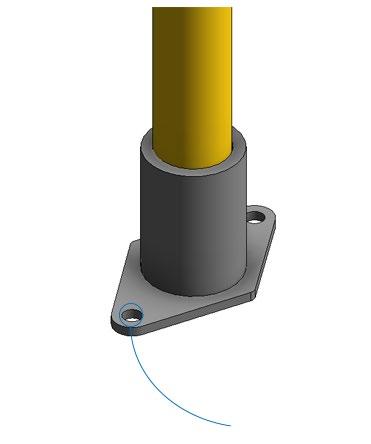

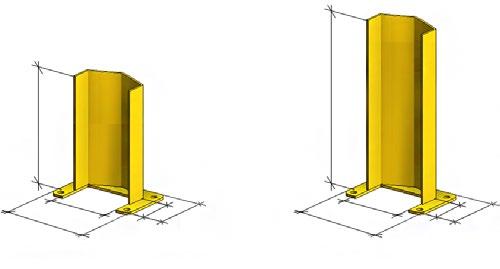

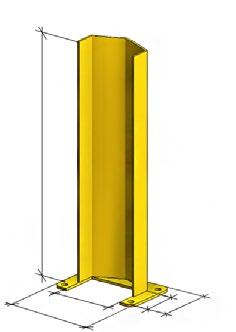

1. Product Information

Double Guardrail: The standard 44”column is made of steel and is designed to support two parallel guardrails. Each column is equivalent to 5” x 5” x 1/8” thick and has 4 punched holes with a diameter of 3/4” on e ach side. The column is secured at the top with a customized plastic black cap and is welded to a 10” x10” x 1/2” baseplate consisting of 4 evenly spaced 3/4” diameter hole at each corner. The columns are powder-coated Safety Yellow and weighs a total of 45 lbs.

Single Guardrail: The 18” single guardrail column is punched with 2 holes with a diameter of 3/4“on each side. Each column weighs a total of 27 lbs. When properly installed-engineered to withstand a 10, 000-lb impact at 4mph.

Specifications

Column Height

Type of Coulmn

Size

Finish

Base Plate

Requires

18”, 44”

Centered or Offset

5” x 5” x 1/8” Thick

Powder-Coated Safety Yellow

10” x 10” x 1/2” Thick

5/8” x ø 4 1/2” Floor Anchors (sold separately)

Type of Column

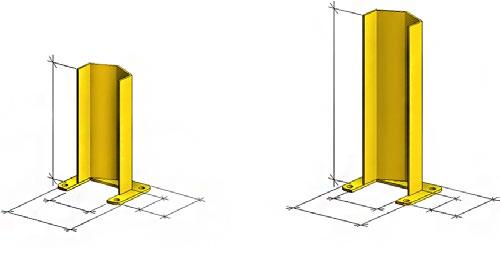

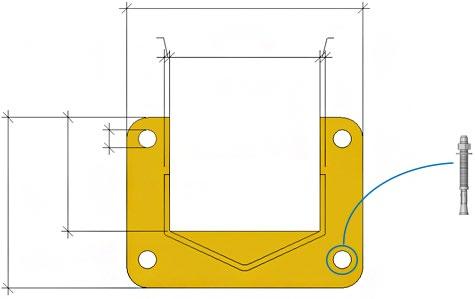

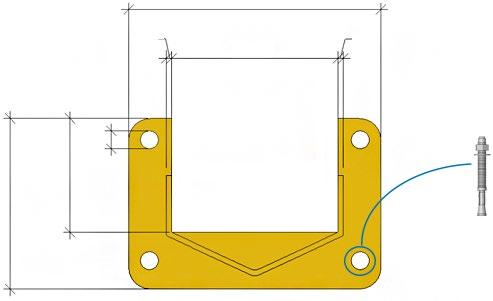

Centered Base Plate Offset Base Plate

Finish

Safety Yellow

Item Description

Single Rail Column (5” x 5” column + centered 10” x 10” baseplate)

Single Rail Column (5” x 5” column + offset 10” x 10” baseplate)

Double Rail Column (5” x 5” column + centered 10” x 10” baseplate)

Double Rail Column (5” x 5” column + offset 10” x 10” baseplate)

All sizes in blue are kept in stock. Refer to Delivery Dates for details. Custom sizes also available. Item #GPSC

Single Rail Column

5” x 5” Column & Cenetred

10” x 10” Base Plate

#GPSO

Single Rail Column 5” x 5” Column & Offset 10” x 10” Base Plate Item #GPDC

Double Rail Column 5” x 5” Column & Cenetred 10” x 10” Base Plate

#GPDO

Double Rail Column

5” x 5” Column & Offset

10” x 10” Base Plate

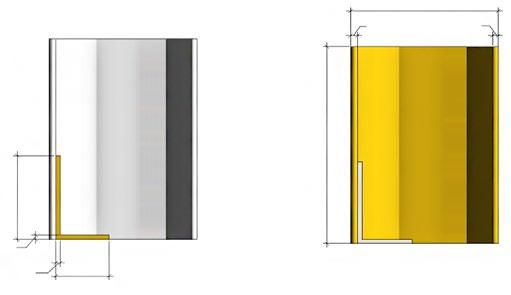

Column Sizes

Height: 18”

Columns are made of 5” x 5” x 1/8” thick steel tube.

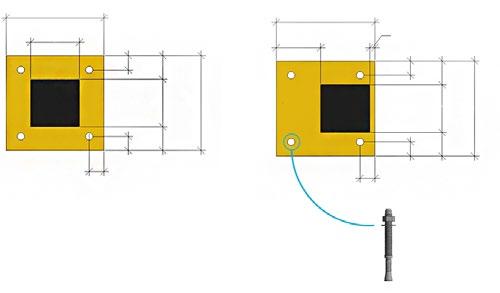

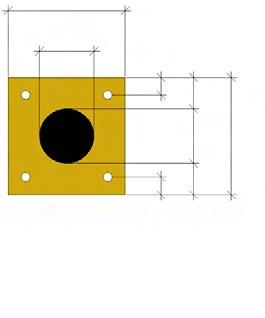

Base plates are made of 10” x 10” x 1/2” thick steel and are punched with four holes for 5/8” ø x 4 1/2” floor anchors.

Height: 44”

Columns are made of 5” x 5” x 1/8” thick steel tube.

Base plates are made of 10” x 10” x 1/2” thick steel and are punched with four holes for 5/8” ø x 4 1/2” floor anchors.

Plan View

Centered Base Plate

Plan View

Offset Base Plate

3/4” diameter

Requires 5/16”ø x 4 1/2” carriage bolt with nut and washer.

3/4” diameter

Requires 4 - 5/8”ø x 4 1/2” floor anchors.

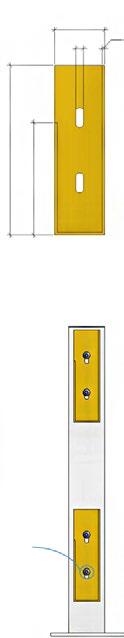

Description Lift-Out Brackets (sold in pairs)

Bracket (sold individually) Lift-Out Bracket (sold individually)

Plan View

Lift-Out Bracket

Plan View

Lift-Out Section

Add 1” nominal distance in between columns and lift-out section

Dimension Details Left Bracket

Connected with 5/16ø x 5 1/2” carriage bolt with washer and t-nut head tork socket. 3 5/8” 3/16” 9/16”

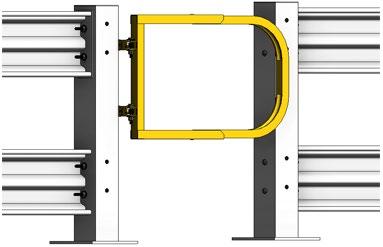

1. Product Information

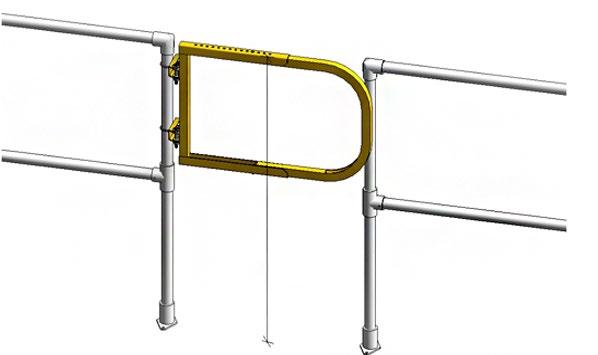

Specifications

Height

Sizing

Mouting Adapter

Hinge Springs Finish

Gate Operation

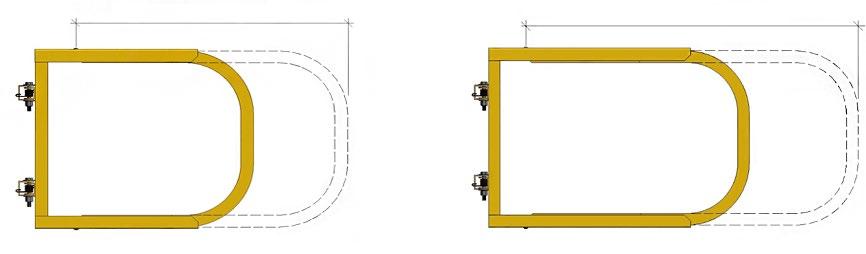

Closing Method 22.75” Adjustable Length Exclusive Universal Adapter

Torision Type Includes Two Springs Per Gate

Powder-Coated Safety Yellow

90° Reversible Swing Spring Loaded and Self-Closing

Self-Closing Safety Gate

Item Description

Adjustable Self-Closing Safety Gate

Adjustable Self-Closing Safety Gate

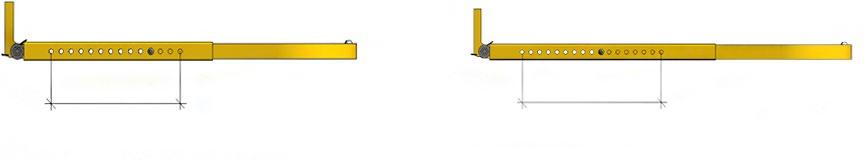

Adjustable Length 24” - 36” 33” - 48” Bolt Spacing 14 punched holes at 1” C/C 17 punched holes at 1” C/C

All sizes in blue are kept in stock. Refer to Delivery Dates for details.

Bolt Spacing

Custom sizes also available.

Overall Length

Adjustable gate length 24” - 36”

Adjustable gate length 33” - 48”

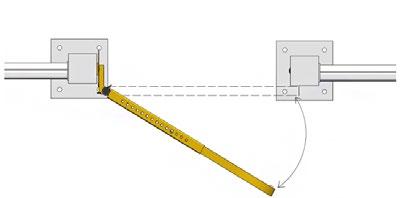

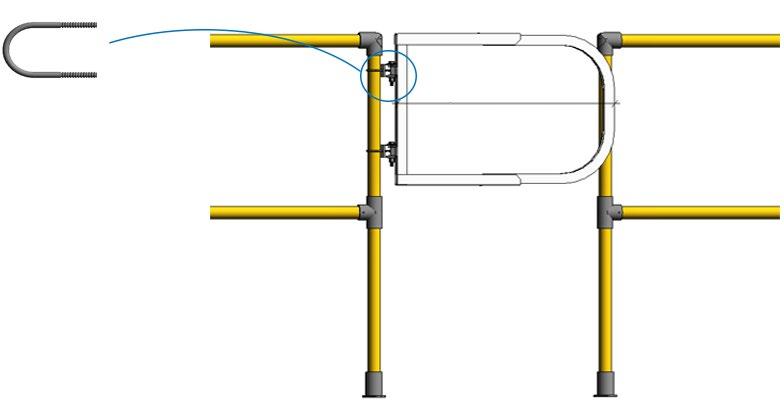

Self-closing safety gate with 2 - spring-loaded hinges. Allows for 180° reversible rotation.

Standard Dimensions

The standard height of the gate is 22 3/4”.

The gate is connected to the column using 1/2”ø x 7” carriage bolt and connected to the adapter using a 1/4”ø x 3/4” carriage bolt. Spacing Detail

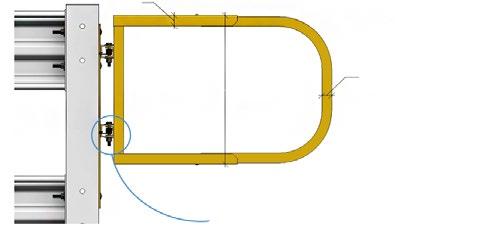

The self-closing safety gate can be used witha heavy-duty guardrail system, a pedestrian rail system, and a mezzanine system.

When installed on a mezzanine system, the top of the gate must be 44” high from the ground.

When installed with a mezzanine staircase, the top of the gate must be 41” - 42” high from the top of the deck.

When installed with a pedestrian rail system, the top of the gate must be 42” high from the ground.

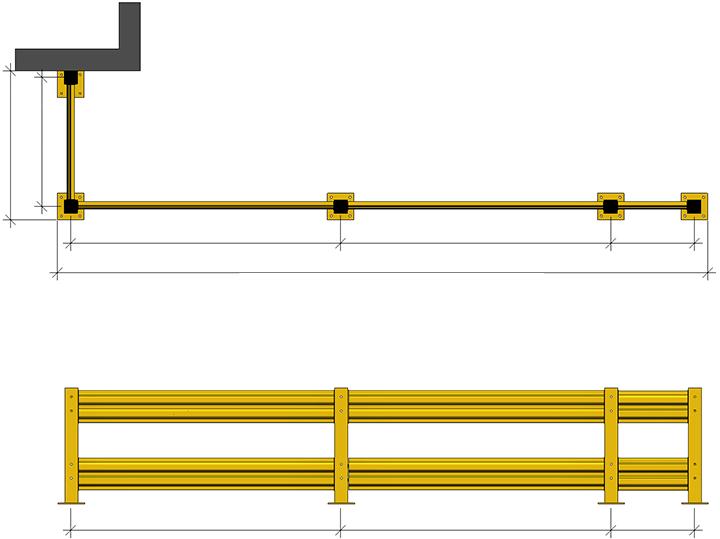

Material Required for this Double Rail Guardrail

4x: Double rail column with centered baseplate

1x: Double rail column with offset baseplate

4x: 10’ rail

2x: 3’ rail

2x: 2’ rail

Layout Example - Plan View

Overall dimension (including baseplates)

Layout Example - Elevation View

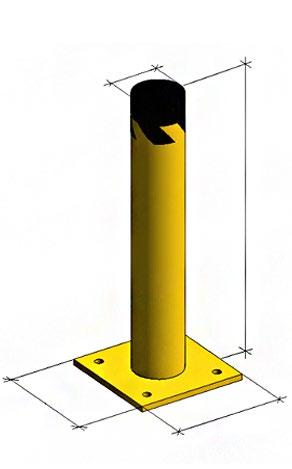

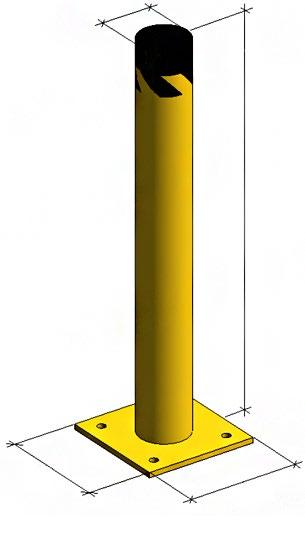

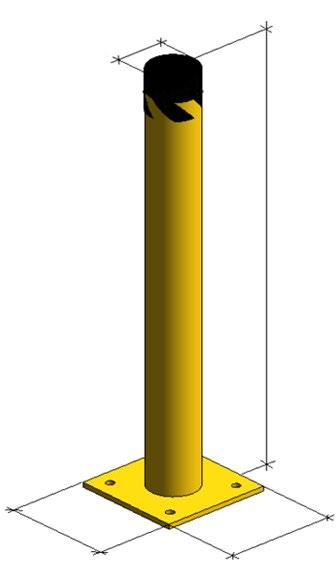

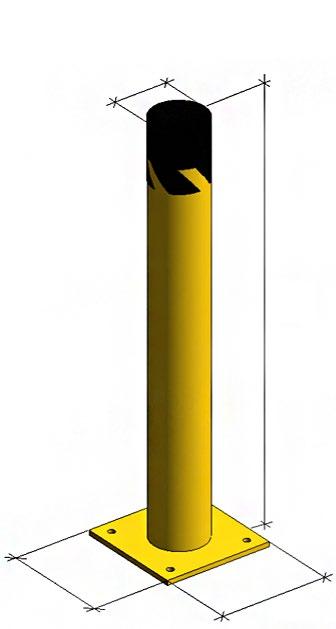

The no-nonsense solution for directing traffic and protecting your assets, our bollards absorb impact to increase safety and security in your facility. Ideal for protecting loading dock doors from collision damage, bollards can also be used to define perimeters and keep pedestrians away from moving vehicles.

Our standard 4 ½” diameter steel tube bollard is welded to a 10” x 10” baseplate. If heavy-duty protection is required, we also offer an oversized 6” diameter bollard welded to a 12” x 12” baseplate. All bollards are sealed in a durable, powder-coated safety yellow paint finish for clear visibility.

1. Product Information

Specifications

Construction

Heights Thickness

Diameter

Finish

Base Plate

Requires

Top Cover

Assembled Components

24”, 36”, 42”

1/8”

4 1/2” and 6”

Powder-Coated Safety Yellow

10” x 10” x 1/2” Thick for 4 1/2” ø

12” x 12” x 1/2” Thick for 6” ø

5/8” ø x 4 1/2” Floor Anchors (sold separately)

Black Plastic Cap

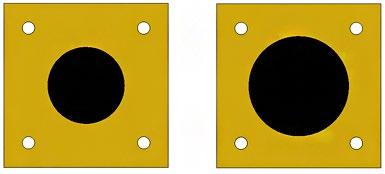

Type of Bollard - Plan View

4 1/2” ø Bollard with 10” x 10” x 1/2”

Thick Base Plate

6“ ø Bollard with 12” x 12” x 1/2”

Thick Base Plate

2. Finish

Safety Yellow

Item Description

Standard High Bollard

Standard High Bollard

Standard High Bollard

Standard High Oversized Bollard

Item #B24

Standard High Bollard

Custom sizes also available. Base

Standard High Bollard

All sizes in blue are kept in stock. Refer to Delivery Dates for details.

#B42

Standard High Bollard

#B642

Standard High Oversized Bollard

Plan View

Base Plate 10” x 10” x 1/2”

ø4 1/2”

Plan View

Base Plate 12” x 12” x 1/2”

3/4” diameter

Requires 4 - 5/8 ø x 4 1/2” floor anchors.

In a busy industrial setting, it is crucial that your employees, visitors and customers are clearly able to identify safe walkways at all times. Cogan pedestrian barriers create safe corridors and separate pedestrian traffic from dangerous areas in your factory or warehouse.

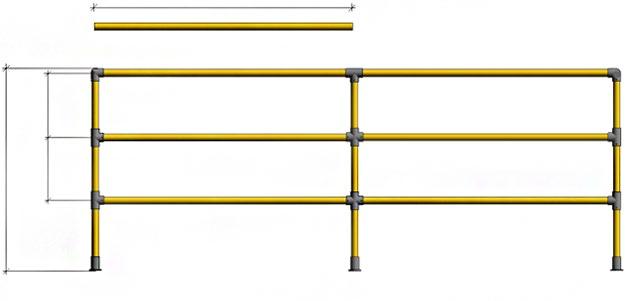

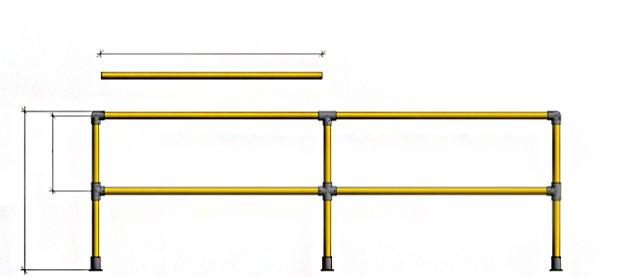

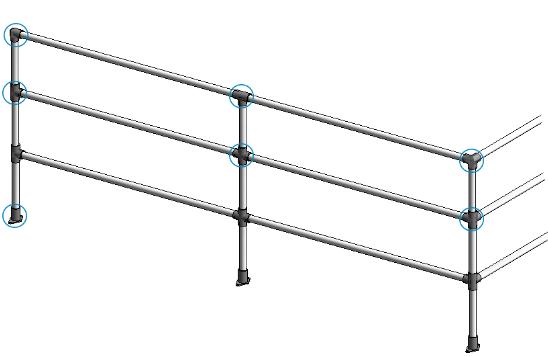

All Cogan pedestrian barriers are designed with 2-rail or 3-rail options to meet code safety standards. Multi-directional pipe connections and

cut-to-size rails can be arranged in countless configurations to match the exact shape and size of the protected area. No welding, threading, drilling or bolting required for assembly. This means our pedestrian barriers are extremely easy to install and repair. Damaged components can simply be removed and replaced without affecting adjacent rail sections.

Use pedestrian barriers to delineate passageways around storage areas, manufacturing equipment, moving machinery and other potential hazards. The bright yellow paint finish ensures maximum visual impact. Your employees will be immediately able to recognize which areas are safe and which ones are not.

1. Product Information

Specifications

Length

Height System

Outer Diameter

Material

Finish Requires Standards

OSHA

2’, 4’, 6’, 8’, 10’

42” (From Bottom to Top of Highest Rail)

2-Rail System and 3-Rail System

19/10”

Tubular Steel Rails

Powder-Coated Safety Yellow

ø 3/8” x 2 3/4” Wedge Bolt Anchors

All rails meet OSHA standards when properly installed

Occupational Safety and Health Administration

Pedestrian Barriers

3-Rail System

2-Rail System

Disclaimer: Please note that this product is for pedestrian traffic control only. It has not been rated for lateral load capacity and should never be used as fall protection or as a crash barrier. All pedestrian barriers must be installed on ground level only and can never be used as mezzanine handrail.

2. Finish

Safety Yellow Rails Electro-Galvanized Fittings

Starter Units

Item # - 2-Rail System

GHSU2O

GHSU4O

GHSU6O

GHSU8O

GHSU10O

Item # - 3-Rail System

GHSU2B

GHSU4B

Add-On Units

Item # - 2-Rail System

GHAU2O

GHAU4O

GHAU6O

GHAU8O

GHAU10O

Item # - 3-Rail System

GHAU2B

GHAU4B

GHAU6B

GHAU8B

GHAU10B

* When ordering, please specify the number of corners.

Refer to Delivery Dates for details. Custom sizes also available.

3-Rail System

2-Rail System

4. Fittings

Specifications

Material

Inner Diameter

Outer Diameter

Thickness Requires Electro-Galvanized Steel 19/10” 12/5” 1/4” ø 1/4” Screw

90° Elbow Openings: 2

4

Three Socket Tee Openings: 3

Railing

Openings: 1

Side Outlet Elbow Openings: 3

3

4

Cross Section Tube Rail

Total outer diameter 12/5”

Railing Flange 2 1/2” punched holes

1/4” 1/4”

ø19/10” inner diameter

Pedestrian Rail Safety Gate Assembly

Requires spring bracket connection with bolt and washer.

Requires 2 - ø3/8” x 2 3/4” wedge bolt anchors.

Please contact a Cogan Engineer to determine which floor anchor is needed if the barrier is being used on a mezzanine or other application where the barrier must meet a specific load capacity by code.

Adjustable from 24”-36” or 33”-48” (exact gate width)

Shield critical rack supports and prevent pallet spills with Cogan’s line of rack protection products. The allsteel construction provides around the clock protection to guard your investment without interrupting aisle flow patterns or limiting access to your pick area. Your workers are kept safe and your property secure.

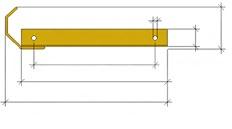

Effective protection close to the ground, Cogan rack protectors shield sensitive rack-aisle-ends from warehouse traffic. Prevent collision damage should a fork truck or other in-plant vehicle steer off-course and accidentally bump the racking. When properly anchored to the floor, Cogan rack protectors help guard your investment without interrupting aisle flow patterns or limiting access to your pick area.

Available in single or double-sided configurations, rack aisle crescents are 12” high and 3/8” thick. Floor angle is made of 5” x 3” x 1/4” structural steel and is available in standard lengths of 24”, 42”, 48” and 54”. These design options ensure the entire depth of racking is protected from impact damage.

Our powder-coated safety yellow paint finish offers maximum visibility and is resistant to the wear and tear inflicted by rolling carts, pallet jacks and forklifts. Ideal for intersecting aisles or any location in your warehouse where traffic circulation is at its heaviest.

Specifications

Model

Single Sided Wrap Around 12” L5 x 3 x 1/4”

Powder-Coated Safety Yellow

5/8”ø x 4 1/2” Floor Anchors (sold separately)

Model

Overall Height

Angle

Double Sided Wrap Around 12”

L5 x 3 x 1/4”

Powder-Coated Safety Yellow

5/8”ø x 4 1/2” Floor Anchors (sold separately)

Item Description

24” Left “Wrap Around Rack Pal”

24” Right “Wrap Around Rack Pal”

42” Left “Wrap Around Rack Pal”

42” Right “Wrap Around Rack Pal”

48” Left “Wrap Around Rack Pal”

48” Right “Wrap Around Rack Pal”

54” Left “Wrap Around Rack Pal”

54” Right “Wrap Around Rack Pal”

42” Double-Sided “Wrap Around Rack Pal”

48” Double-Sided “Wrap Around Rack Pal”

All sizes in blue are kept in stock. Refer to Delivery Dates for details.

Custom sizes also available.

Type

Single Sided Wrap

Single Sided Wrap

Single Sided Wrap

Single Sided Wrap

Double Sided Wrap

Double Sided Wrap

Sided Wrap Around (Large Crescent)

x 3 x 1/4”

Safety Yellow

x 4 1/2” Floor Anchors (sold separately) Model

Sided Wrap Around (Large Crescent)

x 3 x 1/4”

Safety Yellow

x 4 1/2” Floor Anchors (sold separately)

Description

24” Left “Wrap Around Rack Pal” (Large Crescent) 24” Right “Wrap Around Rack Pal” (Large Crescent)

42” Left “Wrap Around Rack Pal” (Large Crescent)

42” Right “Wrap Around Rack Pal” (Large Crescent)

48” Left “Wrap Around Rack Pal” (Large Crescent)

48” Right “Wrap Around Rack Pal” (Large Crescent) 54” Left “Wrap Around Rack Pal” (Large Crescent) 54” Right “Wrap Around Rack Pal” (Large Crescent)

42” Double-Sided “Wrap Around Rack Pal” (Large Crescent)

48” Double-Sided “Wrap Around Rack Pal” (Large Crescent)

RP24L-LC

RP24R-LC

RP42L-LC

RP42R-LC

RP48L-LC

RP48R-LC

RP54L-LC

All sizes in blue are kept in stock. Refer to Delivery Dates for details.

Type

Single Sided Wrap

Single Sided Wrap

Single Sided Wrap

Single Sided Wrap

Double Sided Wrap

Double Sided Wrap

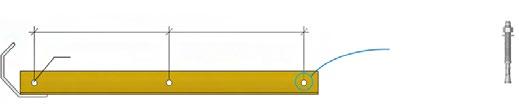

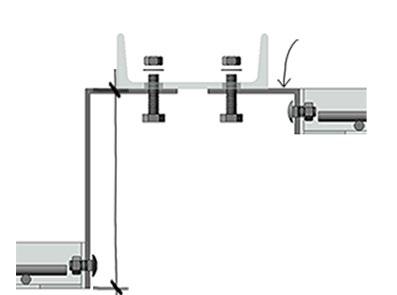

Floor Angle L5 x 3” x 1/4” - Detail Single and Double Sided Wrap Around

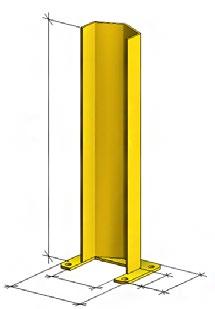

Rack posts, the most critical part of any racking system, are also the most vulnerable. It only takes one damaged rack post to compromise the structural integrity of an entire racking unit. When left exposed along busy aisles, rack posts can be easily struck by a forklift or other in-plant vehicles. Repairing damaged racking is both expensive and time-consuming. Stored materials must be removed and kept elsewhere, while the damaged components are replaced. Your operations are interrupted causing costly downtime.

Easy-to-install and economical, our rack post protectors provide just the right amount of protection around individual racking posts. Available in sizes 12”, 18” and 24” high, the structural steel design wraps around the full circumference of the rack post to shield it completely from impact. Your racking will remain intact and your workflow productive.

Safety Yellow 1/2 ø x 4 1/4” Wedge Type Floor Anchors (sold separately)

12” Rack Post Protector

Rack Post Protector

Plan View

The rack post protector shields a maximum rack post of 5”.

Crescent Wrap around crescent is made of 3/16” thick steel.

Base Plate

The base plate is made of 1/4” thick steel plate punched with four 5/8ø holes for floor anchors.

Requires 1/2” ø x 4 1/4” wedge type floor anchors

Specifications Height

Base Plate

Information Back View Front View Rack Post Protector (Large Crescent)

12”, 18”, 24” 3/8” For Maximum Rack Post of 8” 8 1/4” Powder-Coated Safety Yellow 1/2 ø x 4 1/4” Wedge Type Floor Anchors (sold separately)

Description Rack Post Protector (Large Crescent) Rack Post Protector (Large Crescent) Rack Post Protector (Large Crescent)

All sizes in blue are kept in stock. Refer to Delivery Dates for details.

12” Rack Post Protector (Large Crescent)

18” Rack Post Protector (Large Crescent)

Plan View

The rack post protector shields a maximum rack post of 8”.

Crescent Wrap around crescent is made of 3/16” thick steel.

Base Plate

The base plate is made of 1/4” thick steel plate punched with four 5/8ø holes for floor anchors.

24” Rack Post Protector (Large Crescent)

Requires 1/2” ø x 4 1/4” wedge type floor anchors

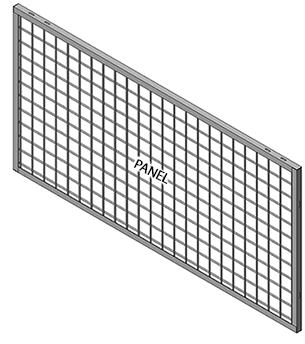

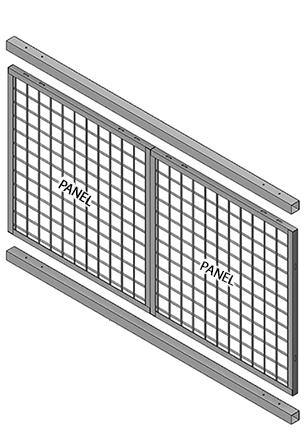

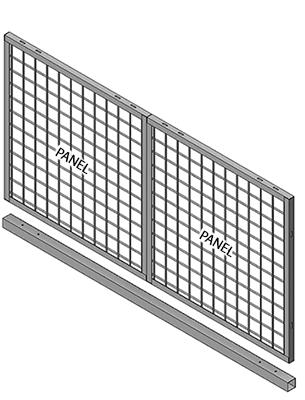

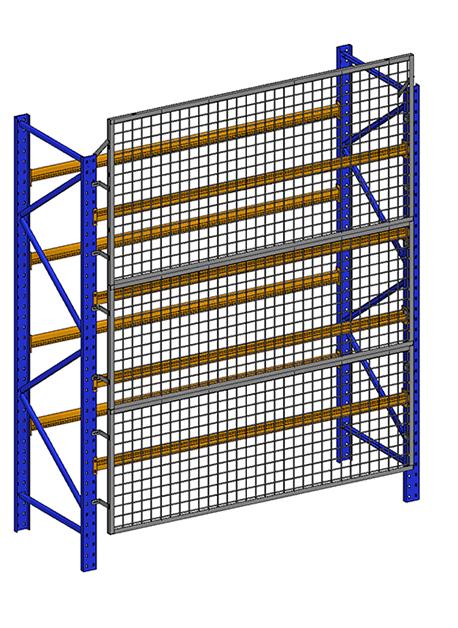

Form a sturdy wall of protection between your employees and your inventory with Cogan back-of-rack guards. Rigid and resilient, our rack guards bolt directly to racking uprights, effectively placing a barrier between stored materials and the picking aisles below. Your workers remain safe from falling debris should a forklift bump the racking or if a pallet breaks.

Boasting an exceptional all-welded angle frame, sturdy wire mesh panels are wear-resistant for dependable, long-lasting protection. The wire mesh construction also means your inventory remains visible at all times for fast visual assessment and proper ventilation.

Wire Mesh Rack Guards

1. Product Information

Specifications

Panel Height

Finish

Mesh Size

Panel Material

Frame Material

Stiffening Profile

3. Standard Sizes

Plan View

3’-5’

Powder-Coated

2” x 2” x 10GA

Steel Wire

Structural Angle 1 1/4” x 1 1/4” x 12GA

None

Panel Width

2. Finish

Cogan Grey Panels

Electro-Galvanized Brackets

Standard Width

94” panel for 96” rack beam

106” panel for 108” rack beam

118” panel for 120” rack beam

130” panel for 132” rack beam

142” panel for 144” rack beam

Oversized

Started and Add-On Units

Width

154” panel for 156” rack beam

166” panel for 168” rack beam

178” panel for 180” rack beam

190” panel for 192” rack beam

Standard Panel Sizes

8’ x 3’

8’ x 4’

8’ x 5’

9’ x 3’

9’ x 4’

9’ x 5’

10’ x 3’

10’ x 4’

10’ x 5’

11’ x 3’

11’ x 4’

11’ x 5’

12’ x 3’

12’ x 4’

12’ x 5’

94” x 35”

94” x 47”

94” x 59”

106” x 35”

106” x 47”

106” x 59”

118” x 35”

118” x 47”

118” x 59”

130” x 35”

130” x 47”

130” x 59”

142” x 36”

142” x 47”

142” x 59”

All sizes in blue are kept in stock. Refer to Delivery Dates for details.

Item #

P-W83

P-W84

P-W85

P-W93

P-W94

P-W95

P-W103

P-W104

P-W105

P-W113

P-W114

P-W115

P-W123

P-W124

P-W125

Custom sizes also available.

Standard

Nominal Panel Size (WxH)

13’ x 3’

13’ x 4’

13’ x 5’

14’ x 3’

14’ x 4’

14’ x 5’

15’ x 3’

15’ x 4’

15’ x 5’

16’ x 3’

16’ x 4’

16’ x 5’

154” x 35”

154” x 47”

154” x 59”

166” x 35”

166” x 47”

166” x 59”

178” x 35”

178” x 47”

178” x 59”

190” x 35”

190” x 47”

190” x 59”

Item #

P-W-SU-133

P-W-SU-134

P-W-SU-135

P-W-SU-143

P-W-SU-144

P-W-SU-145

P-W-SU-153

P-W-SU-154

P-W-SU-155

P-W-SU-163

P-W-SU-164

P-W-SU-165

Refer to Delivery Dates for details. Custom sizes also available.

Starter Unit

Add-On Unit Sizes

Nominal Panel Size (WxH)

13’ x 3’

13’ x 4’

13’ x 5’

14’ x 3’

14’ x 4’

14’ x 5’

15’ x 3’

15’ x 4’

15’ x 5’

16’ x 3’

16’ x 4’

16’ x 5’

154” x 35”

154” x 47”

154” x 59”

166” x 35”

166” x 47”

166” x 59”

178” x 35”

178” x 47”

178” x 59”

190” x 35”

190” x 47”

190” x 59”

Item #

P-W-AU-133

P-W-AU-134

P-W-AU-135

P-W-AU-143

P-W-AU-144

P-W-AU-145

P-W-AU-153

P-W-AU-154

P-W-AU-155

P-W-AU-163

P-W-AU-164

P-W-AU-165

Refer to Delivery Dates for details. Custom sizes also available.

Add-On Unit

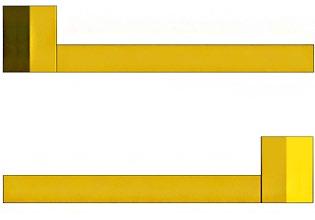

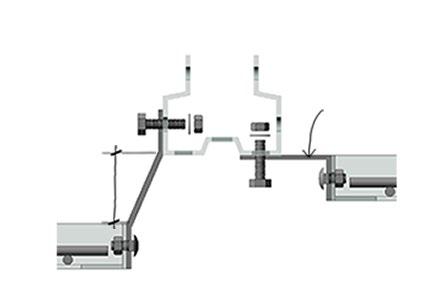

Top View of Roll Formed Racking Upright

Top View of Structural Racking Upright

6”, 8” or 12” offset installation

Flush mount installation

6”, 8” or 12” offset installation

Flush mount installation

Mounting Brackets

Offset bracket for roll formed racking uprights

Flush mount bracket (used for roll formed or structural uprights)

Offset bracket for structural racking uprights

Angled extension bracket (used for both roll formed and structural uprights)

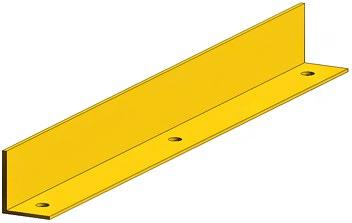

Cogan floor angle guide provides continuous, uninterrupted protection low to the ground. Easy-to-install and cost-effective, our floor angle guide keeps traffic away from critical rack supports, pallet flow rails, walls, offices, storage partitions, and other work areas. Cogan floor angle guide can also be used for narrow aisle storage applications. Prevent narrow aisle fork trucks, lifts and order pickers from coming into contact with the rack. Your racking remains intact and your assets undamaged.

Our floor angle guide is ideal where long, straight sections of protection are required. Made from 5” x 3” x 1/4” structural angle, the sturdy, all-steel construction stands up to warehouse traffic. Available in standard lengths of 12”, 24”, 36”, 42”, 48”, 60”, 96” and 120”. Custom lengths are also available. Angle is punched with ø5/8 bolt holes, evenly spaced to securely anchor floor guide directly to concrete.

All Cogan floor angle guide is sealed in a durable, powder-coated safety yellow paint finish for maximum visibility.

L5 x 3 x 1/4”

12”, 24”, 36”, 42”, 48”, 60”, 96”, 120” 3” 5” 1/4”

Powder-Coated Safety Yellow

5/8”ø x 4 1/2” Wedge Type Floor Anchors (sold separately)

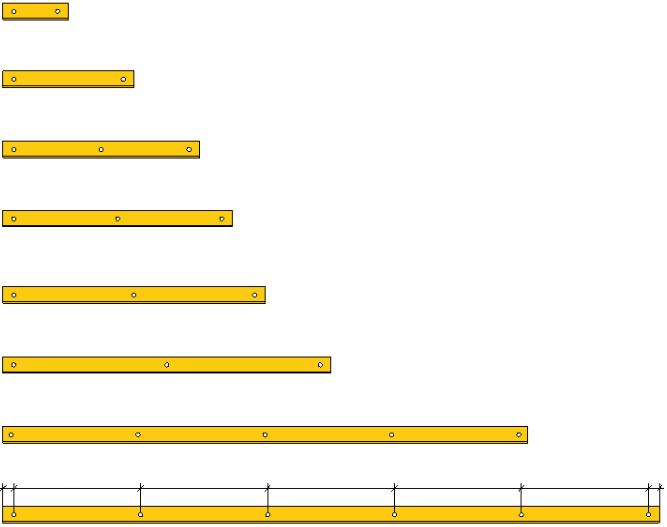

Item Description

Floor Angle Guide

Floor Angle Guide

Floor Angle Guide

Floor Angle Guide

Floor Angle Guide

Floor Angle Guide

Floor Angle Guide

Floor Angle Guide

Item #

RPFAG12

RPFAG24

RPFAG36

RPFAG42

RPFAG48

RPFAG60

RPFAG96

RPFAG120

Refer to Delivery Dates for details. Custom sizes also available.

Requires ø5/8” x 4 1/2” wedge type floor anchors

Please refer to the guidelines below for delivery estimates when placing your Ready Made or Custom Made order.

$0 - $5.000

For orders with a total dollar value of $5,000 and under.

Standard sizes in blue are kept in stock. Allow 1-2 weeks for delivery.

For all other standard sizes, allow +1 extra week for delivery.

For all custom sizes, allow +1 extra week for delivery.

$5.000 +

For orders with a total dollar value of $5,000 and over. +

For all standard and custom sizes, allow 3-4 weeks for delivery.