Aviation Expertise

We’ve completed airport/aviation design for clients around the nation using a holistic approach to address maintenance, reliability, and energy efficiency. We understand the importance of designing a space that supports state-of-the-art equipment and technology while focusing on safety and security. Whether designing a new terminal, a lounge renovation, hangar upgrades, or a flight operations facility, strategic collaboration among the design teams, owner, facilities staff, and code officials is key to project success. Due to the intricacies of these spaces, we encourage input from the owner and work directly with equipment suppliers to design systems specific to the owner’s needs.

Select Aviation Clients

Louisville Muhammad Ali International Airport — KY

Cincinnati/Northern Kentucky International Airport — KY

Memphis International Airport — TN

Minneapolis-Saint Paul International Airport — Minneapolis, MN

Hector International Airport — Fargo, ND

Dayton International Airport — Dayton, OH

John F. Kennedy International Airport — Queens, NY

Baltimore-Washington International Airport — Baltimore, MD

Portland International Jetport — Portland, ME

Wolf Point Airport — Wolf Pointe, MT

Columbia Metropolitan Airport — Columbia, SC

Charlotte Douglas International Airport — Charlotte, NC

Elizabeth City State University Aviation School Hangar — Currituck, NC

Fargo Jet Center — Fargo, ND

The Boeing Company — Charleston, ND

Boone National Guard Army Aviation — Frankfort, KY

Blue Grass Airport — Lexington, KY

Monoco Air — Duluth, MN

Dulles International Airport — Dulles, VA

Bill and Hilary Clinton National Airport — Little Rock, AR

Ronald Reagan Washington National Airport — Washington, DC

TSA - Transportation Security Administration

Norman Y. Mineta San Jose International Airport — San Jose, CA

Commercial + Private Aviation

Louisville Muhammad Ali International Airport Renovations

Louisville Regional Airport Authority (LRRA) | Louisville, Kentucky

In 2021, the Louisville Regional Airport Authority (LRAA) selected CMTA to execute design and manage construction of terminal improvement projects at their facilities, including the Louisville Muhammad Ali International Airport (LMAIA). As Construction Manager at Risk (CMaR), CMTA is responsible for the design, acquisition, installation, and overall execution of current and future planned improvement projects, including architectural upgrades, energy management, energy conservation measures, and construction reporting services.

LRAA selected CMTA for this important project due to our commitment to cost savings and pricing transparency, and our

track record of proven results in Louisville and throughout the US.

The approach to this multi-phased project was developed to enable the execution of currently designed and owner approved projects, while additional terminal improvement plans are developed and analyzed by LRAA with future work being approved as local and Federal funding allows. The total project cost with all planned work phases is estimated to be between $60M to $100M.

This has involved the following scope of services:

– Developed, reviewed and approved a comprehensive LMAIA MEP and Terminal Improvement (MEP/TI) phasing/task order plan

– Developed phase 1 true guaranteed maximum price (GMP) contract that includes 100% local contractor participation. In addition, current phase anticipates ~22% labor and material disadvantaged business enterprise (DBE) participation which is 120% higher than LRRA’s typical DBE project utilization goal.

– Developed multi phased implementation plan that is currently on schedule.

–

Central Generator Plant / Microgrid

– Terminal Tenant Office Renovations

– Terminal Tunnel Renovation

– Terminal Electrical Upgrades

– Terminal K5 and PR Gate Replacement

Continued

Louisville Muhammad Ali International Airport Renovations

Louisville Regional Airport Authority (LRRA) | Louisville, Kentucky

– Terminal Bag Belt Upgrades

– Terminal Security Checkpoint Addition and Renovation

– Terminal Graphics Addition

– Terminal Customs Office

– Terminal Retail Space Renovation

– Terminal Security Upgrades

– Replacement Bag Belt System

– Runway Lighting Upgrades

– Runway Lighting Assessment

– Roadway Signage Lighting Assessment

– Quick-Turn-Around Rental Car Facility and Parking Modifications

– Rental Car Renovation

– New Observation Waiting Parking Lot

– Airport Operations Center

Geothermal System

As part of this renovation effort, the team designed a geothermal system - the largest of any airport in the US. It includes 648 vertical wells each drilled 500 feet deep

into the earth. The system saves massive amounts of energy by using the earth’s natural temperature to heat in the winter and cool in the summer replacing the need for additional equipment. The HVAC system will increase the amount of outside air that is brought into the terminals and other spaces, which contributes to a healthier and more comfortable environment for travelers and airport staff.

With the geothermal system in place, old systems that require large, loud cooling towers and boilers will be removed, making space for needed future terminal expansion.

The geothermal project will cut carbon emissions by more than 80% and cut heating and cooling operating costs by nearly $400,000 per year. It will use 40% less energy than traditional heating and cooling systems and will require less maintenance over the course of system life. Geothermal systems have a much longer

life expectancy than traditional systems and contribute to a more resilient terminal overall.

Projects at a Glance

Various projects have stemmed from this contract as noted above. Ranges of thse task orders are as follows:

Construction Cost: $1M-$400M

Design Cost: $12,000 - $2M

Project Type: Renovations

Completion: Ongoing

80% Carbon Reduction

40% Energy Reduction vs. Traditional Systems

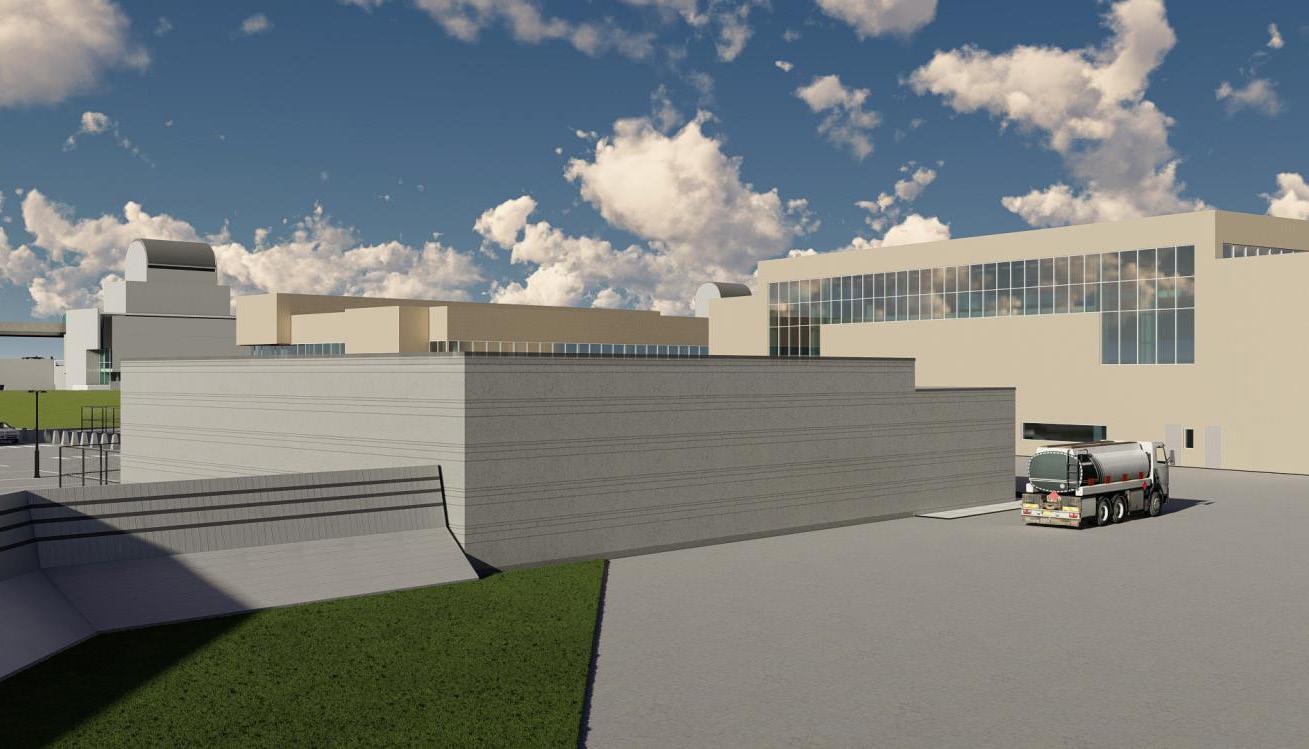

Generator Plant MicroGrid

Louisville Muhammad Ali International Airport | Louisville, Kentucky

The airport terminal building at LMAIA currently has insufficient generator capacity to operate safely in the event of a complete utility outage. This project will improve the resiliency of the terminal building by providing a centralized generator plant that will allow the entire terminal building to remain operational in the event of complete utility power failure.

The new generator plant has been sized to accomodate current and projected airport loads based on the airport improvement program currently underway. Provisions have been included for additional generation capacity to be added in the future as it becomes necessary. The new generator plant has been designed with resiliency in mind, including resistance to severe storms

as common for the region. Lastly, airport sustainability has also been considered, including photovoltaic (solar) generation, battery energy storage, and microgrid controls.

The scope of work includes:

– Generator Building to be constructed South of existing Main Switchgear Building

– (3) 2.25 MW 15kV Tier 4 Diesel Generator Sets, plus space for (1) Future

– Fuel Tanks sized to provide 72 hours of runtime at 75% rated load

– Integrates new 15kW Generator Paralleling Switchgear with Existing 15kV Switchgear

– Clean Agent Fire Suppression

Systems in 15kV switchgear and generator buildings

Removal of existing generators at Operations Center, Landside, and Airside Terminals

– 500 kW / 1.5MwH Battery Energy Storage System for Demand Reduction

– 80kWDC Photovoltaic (PV) System on East Baggage Building Roof for Carbon Reduction

Project at a Glance

Completion: 2025 Est.

Size: 6.75 MW (Expandable to 9 MW)

Power Generation

Cost: $18M Est.

Project Type: New Construction

Delivery Method: Design-Bid-Build

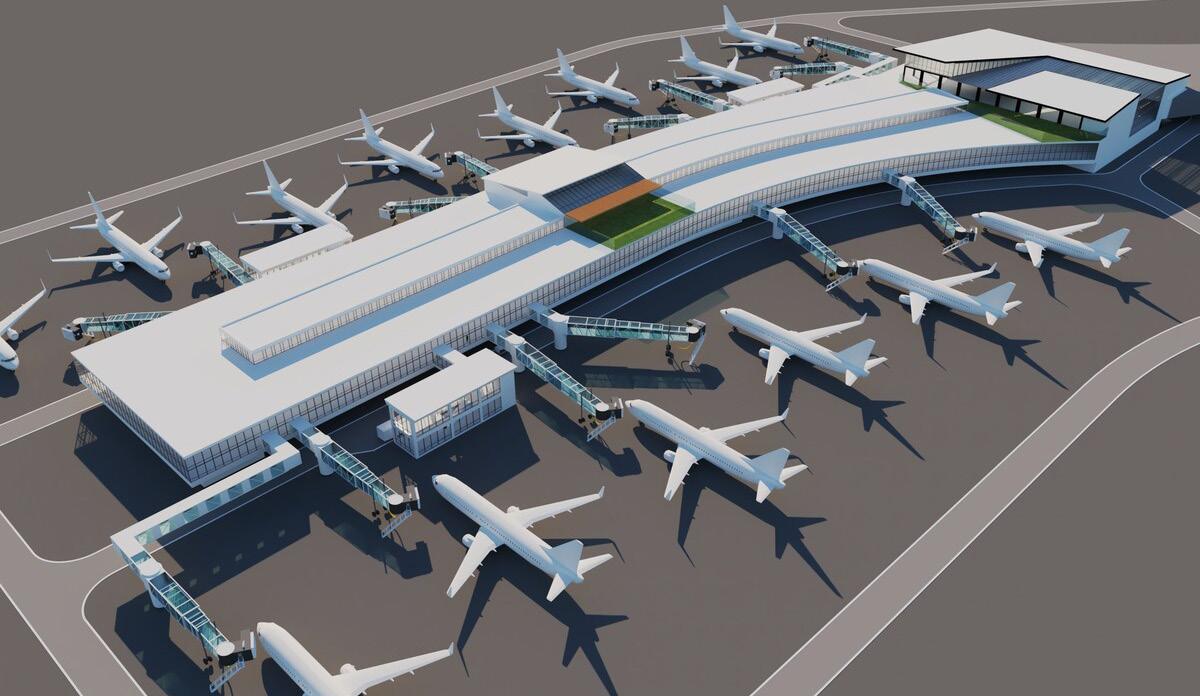

Dulles International Airport New Terminal

The Metropolitan Washington Airports Authority | Dulles, Virginia

This project includes a new concourse at Washington Dulles International Airport to replace outdoor boarding areas currently used by regional flights, upgrade aircraft service facilities, and bring new conveniences and amenities to passengers. It will replace gates built in the 1990s at the eastern end of Concourse A, where many regional-flight passengers currently go.

The new Tier-2 Concourse East will be a modern 14-gate facility with convenient access to the airport’s underground Aerotrain system and will include new shops, restaurants, and other customer services. Additionally, it will include the latest aircraft-servicing technologies to accommodate future needs.

The new concourse also meets additional

criteria required by the FAA grant program, including:

– More space for larger seating areas, concessions, airline lounges, ADA-compliant restrooms, and other amenities

– Larger operational areas for servicing aircraft, handling baggage and other airport and airline support functions

– Enhanced sustainability features, including EVs to service aircraft and carry passengers, increased usage of the electric Aerotrain to move passengers to and from the new gates; energy-efficient construction featuring LED lighting, high R-value insulation and high-efficiency climate control systems that will follow LEED Silver building standards.

The project included the implementation of displacement ventilation, a process

that delivers ventilation at the occupant level, as part of the 30% documents. CMTA went above and beyond to employ chiller control and pumping strategies, that were introduced to meet LEED standards, and resulted in effectively reducing the need for heat recovery and expensive heat exchangers. Furthermore, CMTA identified a more efficient and better location for the heating hot water plant, which reduced pump sizes, centralized equipment, and saved construction costs.

Project at a Glance

Completion: Est. 2026

Size: 410,000 SF (300,000 SF addition)

Cost: $674.7M ($60M HVAC/Plumbing)

Project Type: Renovation/Addition

LEED Silver Targeted

Terminal Modernization & Seismic Program

Memphis-Shelby International Airport | Memphis, Tennessee

The Airport is operated by the MemphisShelby County Airport Authority and is the headquarters for the FedEx cargo operation; an important destination for multiple airlines; and home of a state-of-the-art Air National Guard facility.

This multi-phased project focuses on updating the terminal buildings (A,B, and C)—which are nominally 60 years old—to accommodate future demand, improve ADA accessibility, increase energy efficiency, and improve life safety. Encompassing approximately 500,000 SF of terminal area, the renovated facility aims to provide modern amenities and meet the future needs of operations, various airlines, TSA, and other airport stakeholders.

The project scope will expand the face of

the building, reconfigure vertical circulation, reconfigure the ticket lobby, construct a Checked Baggage Inspection System (CBIS), expand the Security Screening Checkpoint (SSCP), construct an employee screening checkpoint, expand bag claim and prepare an area for a future new FIS. The team will focus on minimizing interruptions to operations and the traveler experience during this comprehensive phased renovation. In addition, the project will focus on reducing environmental impacts through sustainability measures. The design team has collaborated to create a sustainable and energy efficient modernization plan for Memphis International Airport. The goal is to enhance the terminal’s usability, safety, and comfort while minimizing costs and environmental impact. Through an integrative design process, we have

considered factors such as site design, water use, energy use, material use, and environmental quality. The intent is to optimize energy consumption and minimize maintenance costs, all within the available budget.

As a result, we reduced the EUI from 193 kBTU/SF to 157 kBTU/SF. We are transitioning from steam to heating hot water to increase efficiency by 30%. Combined with the heat recovery chiller, we are targeting a 991-ton reduction in greenhouse gas emissions. The project is targeting LEED Silver certification.

Project at a Glance

Completion: 2027-2028 Est. Size: 1,000,000 SF

Construction Cost: $950M

Clinton National Airport Terminal Modernization

Little Rock Municipal Airport Commission | Little Rock, Arkansas

The Little Rock Municipal Airport’s longterm plan aims to be a comprehensive expansion and renovation of its 430,000 square foot complex to meet increasing air service demand through 2030. The redevelopment program focuses on modernizing infrastructure and enhancing building performance and sustainability.

Key elements include the construction of a central utility plant, featuring a 750-well geothermal system for enhanced efficiency, which will support the expansion and aim for the reduction in greenhouse gas emissions. To ensure flexibility, this effort will align with the future growth of the new arrivals hall and concourse (including baggage claim and new bag claim devices) and upgraded security checkpoints.

Through the implementation of these sustainable initiatives, the project aims to achieve an 85-95% reduction in greenhouse gas emissions while also potentially saving $200,000 in annual utility expenses.

Transitioning the existing kitchen to electric equipment would enable the airport to achieve full electrification. The electric systems will substitute traditional combustion equipment, facilitating the incorporation of on-site renewable energy solutions such as solar power. The airport received a $17.5M (TBD) grant from the FAA VALE grant program to help fund this ground breaking system.

CMTA is providing mechanical engineering services for this project, including design of new geothermal central plant to back-feed the existing airport and future planned renovations/additions.

Projects at a Glance

Construction Cost: $40M

Project Type: Renovations and Expansion

Completion: 2026 Est.

Size: 206,987 SF

– Renovate and expand terminal facilities

– Decarbonization and Electrification

– Geothermal Central Plant

Owner

Suzanne Peyton

Director of Properties, Planning and Development speyton@clintonairport.com 501-537-1701

Rental Car Facility & Hourly Parking Deck

Charlotte Douglas International Airport | Charlotte, North Carolina

CMTA provided the plumbing, mechanical, fire protection, and electrical engineering for this combined project of the Charlotte Douglas International Airport (CLT) new 30,000 squarefoot Customer Service Facility and an adjoining 7-story, 3,500,000 square-foot parking deck.

CLT serves over 50 million passengers per year and is on a track for rapid growth. Airport officials wanted each of the parking decks to extend beyond the bounds of conventional design while focusing on user experience and accommodating future growth. Innovative materials and sophisticated design resulted in unique solutions that addressed the owner’s function, safety, and maintenance needs while preserving the architect’s aesthetic vision.

Project at a Glance

Completion: 2017

Size: 30,000 SF Customer Service Center / 3,500,000 SF Parking Deck

Construction Cost: $71,187,366

Project Type: New Facility

Elevate CVG - Terminal Modernization

Cincinnati/Northern Kentucky International Airport | Hebron, Kentucky

CMTA was proud to be part of the Elevate CVG campaign, a multi-year, $400M terminal redevelopment effort that will transform the Cincinnati/Northern Kentucky International Airport (CVG) into a modern, efficient hub for travelers.

As a subconsultant to Corgan and Pasley, our team contributed our expertise in mechanical, electrical, plumbing, fire protection, and technology to the project’s planning design documents, serving as a critical guide for the design-build teams in the upcoming phase of the redevelopment.

The Elevate CVG project is simple. It seeks to overhaul operational efficiency, enhance passenger experience, and modernize facilities that haven’t seen significant

renovations in decades. The project will breathe new life into the two existing concourses A and B, originally constructed in 1993, which had not undergone any major upgrades since 2012.

A key focus of the redevelopment is the modernization of the Welcome Pointe—the airport’s primary customer-facing area for arriving passengers. This redesign includes new security technology to streamline passenger flow and boost safety.

Additionally, CVG is aiming to create a more welcoming and regionally representative space with artwork and displays that celebrate the Greater Cincinnati area. This sense of place will be woven throughout the terminal, giving travelers a clear

connection to the region as they arrive and depart.

To accommodate this bold change, major mechanical and electrical infrastructure will need to be relocated and expanded. With this, operational efficiencies and maintenance, along with energy efficiency are a primary focus throughout the project.

This ambitious modernization effort, funded through a combination of the airport’s capital budget, general airport revenue bonds, and passenger facility charges, will position CVG as a leader in the aviation industry.

Project at a Glance $400M Terminal Redevelopment

CVG MEP On-Call Services

Cincinnati/Northern Kentucky International Airport | Hebron, Kentucky

As part of the growing passenger and cargo aviation needs in Cincinnati and Northern Kentucky, CMTA was selected as the prime contract holder for the MEP on-call project at Cincinnati/Northern Kentucky International Airport (CVG) to implement a host of enabling and remediation jobs for the airport. This project is a key component of the Elevate CVG program, a multi-year redevelopment plan designed to modernize the airport’s infrastructure, boost operational efficiency, and enhance the passenger experience.

Our role as the lead on the MEP on-call project positions us at the heart of this transformation, where we will be responsible for developing the airport’s Utility Master Plan. This crucial master planning effort will inform and support the broader Elevate CVG program, ensuring that CVG’s utility infrastructure is optimized to meet the growing demands of travelers and airlines alike.

In collaboration with a powerful team of national consultants, including Gresham Smith, Prime Engineering, Arora Engineers, and Motz Consulting Engineers, CMTA is in the process of delivering cutting-edge mechanical, electrical, plumbing (MEP), civil, surveying and fueling design services.

Together, we will assess the current infrastructure, plan for future utility needs, and contribute to the modernization efforts that will reshape the airport’s main terminal and concourses.

Our work on this project will also lay the groundwork for several other significant initiatives at CVG, including upgrades to fire alarm and PA systems, the installation of emergency evacuation systems, enhancements to cooling towers and chillers, and the integration of EV charging stations to support sustainability goals.

Additionally, we will provide essential support for the $100M baggage system modernization, a cornerstone of Elevate CVG’s efforts to streamline operations and improve the overall passenger journey.

Being awarded this MEP on-call contract is a testament to our expertise and commitment to delivering innovative, future-forward solutions. We are honored to play such a vital role in shaping the next chapter of CVG’s history, working alongside a renowned team of national experts to ensure that this redevelopment will set a new standard for airports across the country.

Project at a Glance

MEP On-Call Services

Utility Master Plan

Infrastructure Assessments

Baggage System Modernization

Alignment with Elevate CVG Program

Elevate CVG is not just about upgrading an airport—it’s about creating a world-class travel experience. Our contributions to the MEP On-call project will help make that vision a reality, ensuring that CVG continues to thrive as a leading gateway for millions of travelers.

CVG Energy and Sustainability Master Plan

Cincinnati/Northern Kentucky International Airport | Hebron, Kentucky

Airports today are challenged to manage safety, operational costs and capacity, reduce environmental risks and liability, ensure employee and customer satisfaction, while demonstrating a commitment to the economic impact, health, and vitality of the communities they serve. As the aviation industry establishes goals for decarbonization, key stakeholders and investors have high expectations for how airports reduce environmental impacts.

To address this challenge, the CVG Airport Authority enlisted the services of Donovan and CMTA to develop an Energy and Sustainability Master Plan. The plan aligns ongoing efforts and models how the CVG Airport Authority can adopt and adapt sustainable actions, innovative technologies and strategies.

This plan contains a comprehensive highlevel set of recommendations to achieve energy reduction, reduce carbon emissions, and water-use reduction, through enhanced land management, vehicle and equipment transitions, and sustainable design and construction practices.

Project at a Glance

Carbon Reduction Road Map

Sustainability Plan

Funding Plan

US Customs FIS Renovation & Concourse D Expansion

Charlotte Douglas International Airport | Charlotte, North Carolina

CMTA has been providing MEP/FP engineering on a continuous basis for this airport for over three decades. Projects range from small upfits to major terminal and concourse expansions and new parking decks.

CMTA recently provided the mechanical, electrical, and fire protection engineering design for the renovation and expansion of the existing U.S. Customs FIS facility and an expansion of the connector area between Concourses C and D. The project comprises the renovation of the existing Concourse D ticketing level and baggage

level. Work in the baggage level includes relocating, renovating, and adding the required custom and border protection spaces, restrooms, baggage claim devices, and altering the overall passenger flow.

The ticketing level work includes new hold rooms, restrooms and corridors. The total area for this expansion/renovation effort is approximately 225,630 square feet.

Project at a Glance

Completion: 2025

Size: 225,630 SF

Project Type: Addition/Renovation

MSP Energy Management Center Replacement

Metropolitan Airports Commission | Minneapolis, Minnesota

The Metropolitan Airports Commission is undertaking a major replacement and expansion of the Energy Management Center (EMC) at Minneapolis–Saint Paul International Airport’s Terminal 1.

Originally constructed in 1960 and expanded over multiple phases, the existing central utility plant is nearing the end of its service life. This modernization project will ensure reliable, energy-efficient heating and cooling for the entire Terminal 1 campus, including terminal buildings, support facilities, and parking structures, while advancing MAC’s aggressive sustainability goals.

Currently in the SD phase, the project will include a full replacement of the existing boilers, chillers, and associated systems with a hybrid solution that integrates high-efficiency and low-carbon technologies. The work includes comprehensive design services for mechanical, electrical, plumbing, fire protection, and technology systems, as well as integration with airportwide automation, metering, and sustainability initiatives.

The EMC replacement project is a key component of MAC’s long-term strategy to reduce greenhouse gas emissions by 80% and water use per passenger by 15% by 2030, with the ultimate goal of achieving

net-zero operations by 2050. The project will incorporate energy modeling, life-cycle cost analysis, and provisions for full system electrification in alignment with regional utility decarbonization targets.

Project at a Glance

Completion: 2030 Est.

Cost: $420M Est.

Project Type: Renovation

Hector International Airport Terminal Expansion

Hector International Airport | Fargo, North Dakota

CMTA has worked with Hector International Airport for nearly 30 years. We’ve completed projects varying in size and scope – ranging from food service upgrades to boiler replacements and terminal renovations. Recently, the team evaluated the existing mechanical systems to improve indoor aire quality to mitigate the spread of airborne pathogens.

Main Terminal Expansion

Currently, CMTA is providing MEP and fire protection design services for the main terminal expansion project. Many years in the making, the all-encompassing project expansion includes four additional pages (for a total of nine), a fourth security checkpoint, additional departure lounge spaces, and expanded accommodations for

travelers. Renovations include ticketing/ check-in areas, including self-service kiosks, baggage claim improvements, as well as overall aesthetic and operational efficiency upgrades.

Project at a Glance

Completion: 2027 Est. Size: 86,000 SF Addition; 113,000 SF Renovation

Project Type: Addition/Renovation

NOAA Hangar Renovation & Addition

Lakeland Linder International Airport | Lakeland, Florida

This project within the two-story existing space includes a renovation of the first-floor area that will be used for office space, maintenance support, and a parts room. The second floor renovation features updated workstations, office space, conference room, break room, with a future expansion. Our scope of work also includes mechanical, electrical, plumbing, and fire protection design. The NOAA project involves upgrading to a new Foam Fire Protection System to support the existing hangar and the new 46,115 square-foot hangar addition.

Project at a Glance

Size: 46,115 SF

Cost: $12 Million

Project Type: Mechanical, Electrical, Plumbing, and Fire Protection

San Francisco International Airport | San Francisco, California

CMTA serves the San Francisco International Airport under the architectural design teams of K2A Architects and Hamilton Aitken Architects. Our team provides mechanical, electrical, plumbing, fire protection, information technology and audio visual engineering design services. Our scope of work has included a diverse range of renovation projects, site and building surveys, testing procedures and upgrades to existing facilities under $4 million.

Project at a Glance Cost: $4 Million

Project Type: Mechanical, Electrical Plumbing, Fire Protection, and IT/AV

Car Rental Facility

Blue Grass Airport | Lexington, Kentucky

This project involved the design and construction of a new 2-story multi-tenant car rental facility. Components of the project include a 5,200 square foot fuel facility, an 8,000 square foot carwash building, a 12,040 square foot maintenance building, and a 7,040 square foot administrative office space.

The scope includes the demolition and restoration of the existing rental car campus, site utilities and provisions for the construction of the new campus, and all mechanical, electrical, plumbing, fire protection, and technology needs for the new facilities.

Other projects completed for the Lexington Blue Grass Airport include:

• Administrative Offices renovation

• ARF Building Study

• Chiller Replacement

• Customs Renovations Study

• Hangar/Office Building Addition

• Rental Car Facility

• Restaurant Renovation

• Roofing Project

• Runway 4/22 Expansion

• Security Upgrade

• ServAir Hangar Renovation

• Smoking Room Addition

• Terminal Renovation (size doubled)

• Vehicle Maintenance Facility/Fueling Station

Project at a Glance

Completion: 2017

Size: 32,280 SF

Cost: $12.4M

Project Type: New Construction

Delivery Method: DBB

Reference: Brent Perry

Environmental Specialist

859-425-3100

Orion Jet Center Terminal & Aircraft Maintenance Hangars

Opa-Locka Executive Airport | Opa-locka, Florida

This two-part phased project located between Ft. Lauderdale and Miami involved designing new 76,000-square-feet General Aviation Orion Jet Center Terminal and two large Aircraft Maintenance Hangars at Opa-Locka Executive Airport.

The second phase was an addition of two brand new hangars providing an extra 76,000-square-feet including and 7,300 -square-feet of office space with the latest in security technology. On site parking, site development and roadway lighting was included.

Project at a Glance

Size: 123,000 SF

Cost: $25 Million

Project Type: Mechanical, Electrical Plumbing, and Fire Protection

Aircraft Rescue & Fire Fighting Facility (ARFF)

Daytona Beach International Airport | Daytona Beach, Florida

This new 16,000-square-foot state-ofthe-art facility houses fire services staff 24 hours a day and includes Offices, Living Quarters, Fitness Facility, Decontamination and Storage Space, Gear Wash/Dry, Kitchen/Day room, Locker Room, Showers, Storage and a Multi-Vehicle Drive through Apparatus Bays. The new $5.7 million facility was completed in 2017.

CMTA was responsible for the complete design and construction administration of all mechanical, electrical, plumbing, fire protection and IT/AV/Communications Systems.

Highlights of IT/AV/Communications design include: Site Infrastructure, Voice and Data, Audio / Visual Systems, Access Control,

Intrusion Detection and CCTV Security and Station Alerting System and Paging Systems.

Commercial aircraft landing at Daytona Beach International Airport requires at least 126-feet in length but no more than 159-feet in length. This means the personnel at Station 17 must protect the lives of up to 250 passengers in the event of an emergency on-board a commercial aircraft arriving or departing Daytona Beach.

International Airport. Station 17’s personnel are also required by the FAA (Federal Aviation Administration) to be in place on the runway for a declared aircraft emergency within three minutes of notification.

These firefighters must have knowledge regarding the types of aircraft arriving/ departing, maximum number of passengers possibly inside, location of emergency exits on the aircraft, and location of critical systems on the aircraft which could increase the danger to passengers exiting the aircraft if it was on fire. As the thin walled aluminum exterior of a large commercial aircraft burns so hot and quickly, all lives on board can be lost in less than five minutes making immediacy of response critical.

Project at a Glance

Completion: 2014

Size: 16,000 SF

Cost: $5.7 Million

Project Type: Mechanical, Electrical Plumbing, Fire Protection, and IT/AV

Signature Flight Executive Flight Terminal

Norman Y. Mineta San Jose International Airport | San Jose, California

The 270,000-square-foot project include a 10,000-square-foot executive terminal, office space, hangars and aircraft servicing facilities. Within the FBO terminal is a large and small conference room, crew room, kitchen, locked storage room, passenger lounge, restrooms and showers. On site are seven private hangars with five occupied by Google executives.

The $82 million new development also features ramp space to accommodate large business jets, such as the Boeing Business Jet 737 and Boeing B767. Long term and short term parking with a Signature QTA and 24 hour surveillance. Completed in 2016, the facility is certified LEED® Silver

Project at a Glance

Size: 270,000 SF

Cost: $82 Million

Project Type: Mechanical, Electric, Plumbing, and Fire Protection

American Airlines Hangar & Office Renovation

Meacham International Airport | Fort Worth, Texas

This $20 million project was an ongoing phased project that involved a historic renovation of American Airlines 1933 hangar. The existing 26,000-square-foot building was renovated and updated to store the owner’s private plane. The second phase included the addition of two new 40,000-square-foot hangars and a new 7,000-square-foot fixed base operations (FBO) terminal. Completed in 2014 the total project was 113,000-square-feet.

Project at a Glance

Completion: 2014

Size: 113,000 SF

Cost: $20 Million

Project Type: Mechanical, Electric, Plumbing, and Fire Protection

Federal Aviation

Yokota Air Base Simulator Facility

US Army Core of Engineers | Yokota, Japan

CMTA, along with a joint venture between Woolpert and KZF, designed the Air Force Special Operations Command (AFSOC) Osprey Campus at Yokota Air Base. The USACE Japan Engineering District (JED) is the design and construction agent that managed and executed this project.

The Simulator Facility is designed according to the requirements set forth in the Facility Requirements Specification for a Flight Safety Design Simulator with Motion System, as prepared by the Flight Safety International Simulation Systems Division, September 2013 release.

CMTA design services for the 9,100 SF Flight Simulator Facility supporting the crew members of the Osprey aircraft to

conduct required training for both annual and semi-annual events, to support crew upgrade training, and to conduct specific mission rehearsals. A high-bay room is required to support a full-motion simulator. Additional space is required to support the large communications and the uninterrupted power supply (UPS) system dedicated to the simulator.

Other spaces within this facility include maintenance and system storage, office space for both government and contractor personnel, briefing/debriefing room, and a training classroom.

CMTA was the designer of record for Mechanical, Electrical, Lighting, Communication, Audio-visual, Security,

and Technology services. All systems were developed according to DoD Unified Facilities Criteria (UFC) such as the General Building Requirements per UFC 1-200-01, seismic design due to location per UFC 3-310-04, and DoD antiterrorism/force protection requirements per UFC 4-101-01. In addition, the designs adhered to the Osprey Facility Requirements Specification and AFSOC Facilities Requirements Specification.

Project at a Glance

Completion: 2023

Size: 9,100 SF

Cost: $7,900,000

Project Type: New Construction

Delivery Method: Design-Bid-Build

US Army National Guard Aviation Support Facility

USACE, Louisville District | Frankfort, Kentucky

The Boone National Guard Aviation Support Facility is the most energy efficient aviation hangar in the world, operating at 15 kBtu/ sf/yr. The project is Net Zero Ready, and easily achieved LEED Gold, by achieving all 19 points for EA Credit 1 – Energy Optimization, including an exemplary point and regional priority credit for a total of 21 points. The project bid under budget, and the Kentucky National Guard was able to install an 80 kW monocrystalline photovoltaic system. The 80 kW photovoltaic system will offset 20% of the total building energy usage. The building infrastructure is in place to increase the photovoltaic system and allow for 100% energy offset.

A radiant slab heating system was used in the maintenance bays, with ground source

heat pump water heaters for hot water generation. The 90°F hot water heating temperature increased the heat pump efficiency by 20%, operating at a COP of 5.4. High volume, low velocity fans were used for summer time ventilation. The two story administration and operation space is conditioned using an enhanced geothermal HVAC system with dedicated outdoor air unit with energy recovery. All LED lighting was used in the administration space, and high efficiency linear fluorescents in the maintenance bay. A building pressurization test was included in the project requirements, and the maintenance bays passed at an air leakage of 0.19 cfm per square feet of building envelope.

Project at a Glance

Completion: 2015 Size: 122,000 SF

Project Type: New Construction

Delivery Method: Design-Bid-Build Awards / Certifications: – LEED Gold

Reference: Steven King, Brigadier General 502-607-1481

Zero Energy Air Force Personnel Center, Wing B

Randolph Air Force Base, Joint Base San Antonio | Randolph, Texas

USACE, Ft. Worth District

This new facility replaces the original B Wing of Building 499. The total construction budget for this two-story, 68,000 SF project is $32,864,000. The project will provide new administrative space for an Air Force Personnel Center and was managed by USACE Ft Worth District.

CMTA was engineer of record for Mechanical, Electrical, Plumbing, Lighting, Communication, Audio-visual, and Technology. All systems have been designed to exceed the requirements of the high performance UFC 1-200-02.

CMTA leveraged our building science leadership to help the team find optimization opportunities. The results of this effort

found significant structural improvements that greatly improved the envelope while also reducing costs. The team continued to optimize the design to find additional savings opportunities; this allowed the team to design a zero energy facility within budget. This will be the first zero energy building on Randolph AFB.

Project at a Glance

Completion: 2024 Est.

Size: 68,000 SF

Cost: $32,684,000

Project Type: New Construction

Wright Patterson Air Force Base

US Air Force, USACE Louisville

Dayton, OH

CMTA played a pivotal role in several key projects at the NASIC campus, showcasing expertise in high-performance HVAC systems, mechanical design, and infrastructure modernization.

NASIC Intelligence Production Complex III

CMTA provided expertise on high-performance HVAC systems and cost-effective mechanical design for this new 5-story facility that includes secure space. An Active Chilled Beam System was selected to provide the optimum combination of simplicity, energy performance, cost, and most importantly, substantially fewer operation interruptions due to maintenance. This was especially important since all five floors have restrictive spaces which creates challenges for uncleared maintenance staff. The design ensured minimal maintenance requirements within secure spaces. The Active Chilled Beam will use 40% less energy than UFC minimum.

Rapid Reacting Laboratory

CMTA led a 14,420 SF renovation of research labs in Building 652 at Wright-Patterson AFB to support the AFRL’s Materials and Manufacturing Directorate. The project included upgrades to first-floor labs, second-floor Adhesives and Composites lab, and the conversion of Room G-18 into a high-bay area with a mezzanine for increased space and visibility. CMTA optimized lab layouts, upgraded electrical and telecommunications systems, designed new lighting, and implemented AV displays, NIPRNET, Defense Research network infrastructure, and wireless access points.

Wind Turbine Complex Study

Study to develop options to repair a steam line to address capacity concerns versus a new centralized boiler system.

Steam Line Replacements

CMTA provided a comprehensive solution to reduce energy loss by converting the existing steam lines C and D to natural gas-fired condensing boilers and steam generating boilers.

Component Research Air Facility (CRAF)

CMTA is conducting a study for the Air Force Research Laboratory at Wright-Patterson Air Force Base. The specific facility under review is the Component Research Air Facility (CRAF), a unique site that houses research cells, a robotics lab, a jet engine, and specialized systems for water and sanitary equipment, as well as a one-of-a-kind exhaust system. The study includes a comprehensive analysis of the existing exhaust system, which consists of four turbo exhausters, routing valves, piping, and connections to combustion research equipment. The outcome of the study will provide recommendations for improvements to increase capacity, along with an associated implementation plan.

District Cooling Plant (DCP)

Part of a series of Central Utility Plant projects aimed at expanding and modernizing the NASIC campus while improving the resiliency of its infrastructure, in alignment with ADP guidelines. The 19,000 SF, free-standing DCP features four 675-ton centrifugal chillers, providing N+1 redundancy.

Aerospace

+ Aviation Tech

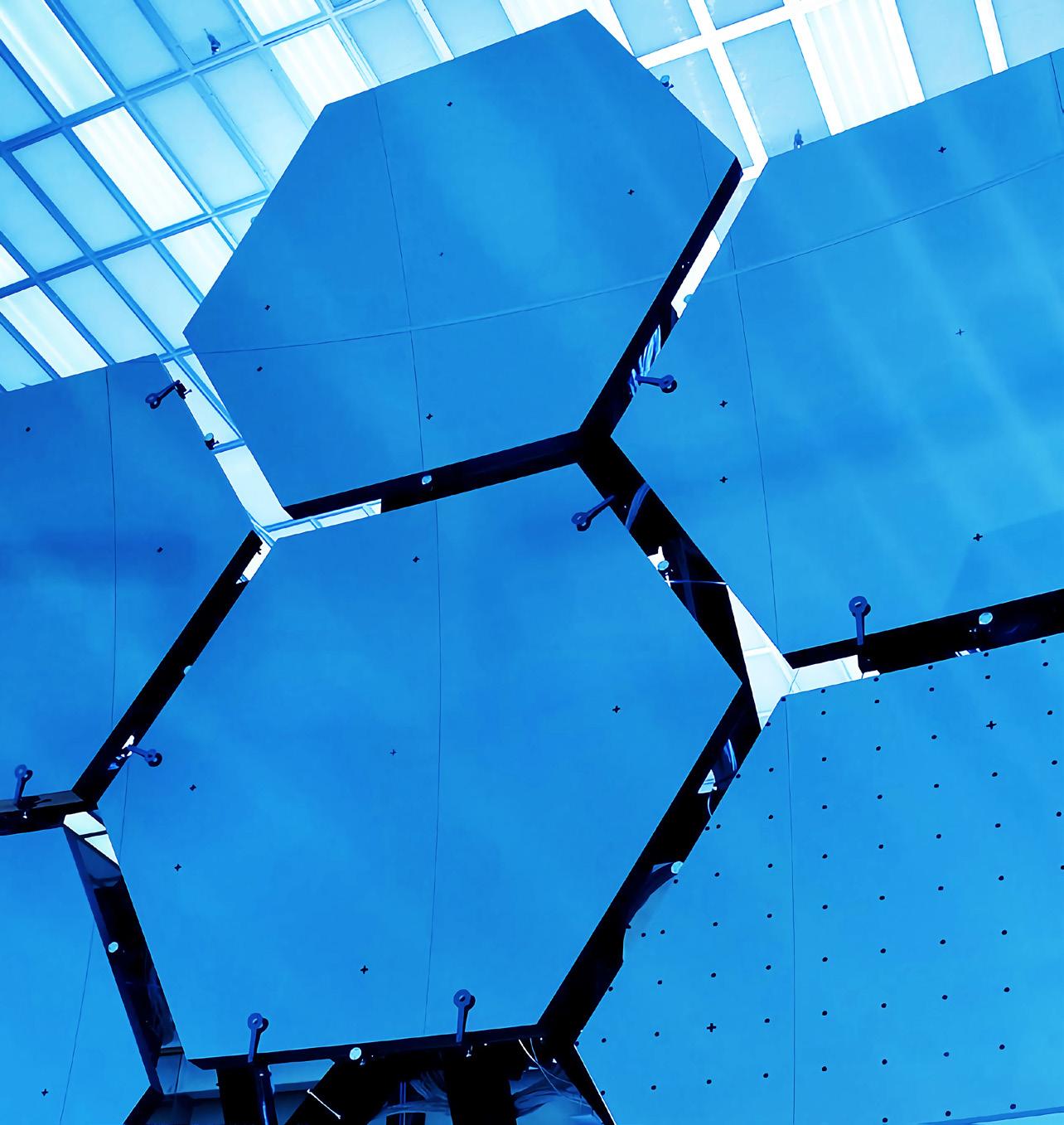

Aerospace Expertise

CMTA has performed services for many renowned aerospace companies, both public and private. The following includes a brief overview of this experience, which ranges from carbon reduction strategies to full MEP design services, demonstrating CMTA’s ability to deliver precise, resilient, and sustainable solutions in mission-critical environments.

Our background in aerospace projects allows us to anticipate operational priorities—optimizing manufacturing workflows, supporting secure facility operations, and advancing sustainability goals to ensure our client receives innovative, efficient, and forward-looking designs that strengthen long-term performance and competitive advantage.

Select Clients

The Boeing Company

60+ projects including a hanger launch support facility Association of Universities for Research in Astronomy (Aura) Mayall Telescope, Kitt Peak, Arizona

Confidential Aerospace Company

60+ projects including a hanger launch support facility, multiple rocket factories, manufacturing facilities, etc.

Fortune 50 Aerospace Manufacturing Company

Global Decarbonization Plan, 20 Sites US and International

Ball Aerospace/BAE

80+ Projects, multiple locations, Colorado

Northrop Grumman

Grand Forks Air Force Base, North Dakota, and Sterling, Virginia

Lockheed Martin

Peterson Space Force Base

Redwire Aerospace

The Boeing Company

Various Locations

Welcome Center and Delivery Center, Charleston, SC

In support of Boeing’s second 787 Assembly Line in Charleston, SC, Boeing provided a site Welcome Center to acclimate visitors and customers to the Boeing experience, and a 787 Delivery Center to accommodate its customers as they take delivery of their new 787 Dreamliner aircraft.

The Delivery Center is a 4-story/45,000 SF building located at the northeast corner of the campus. This is the last building seen by Boeing customers as they take possession of their 787 Dreamliner. The building features a roof top observation deck and jetways for direct entry into the customer Dreamliner. The building, which

was designed to LEED Silver standards, is comprised of customer offices, delivery lounges, conference rooms, and Boeing offices and support functions.

The Welcome Center is a 2-story/ 18,000 SF building located at the south end of the site, becoming the central location for many administrative functions. The building contains multiple offices, a tour center with theater and space for employee training.

Boeing’s Charleston Welcome Center was awarded a LEED Gold Certification.

Boeing SCIF project

Included design of 8,000 SF of ISO 5, 6 & 7 cleanroom

Boeing DOD Facility Design

Included the design of 3,000 SF of ISO, 6 & 7 cleanroom

Boeing SCIF Lab Design

Included the design of 7,000 SF of ISO, 6 cleanroom

Boeing Training Lab

Included design of 3,500 SF of ISO 5, 6 & 7 cleanroom

Boeing Building 531, Mesa, AZ Hydraulics Upgrades

Boeing Building 552, Mesa, AZ

Pump House Surge Protection

BAE/Ball Aerospace

Colorado

CMTA has demonstrated extensive expertise in supporting Ball Aerospace and BAE Systems with a wide range of complex projects across their manufacturing and research facilities in Colorado. From electrical upgrades, HVAC improvements, and generator installations to specialized lab expansions, cleanroom designs, and advanced testing chambers, CMTA has consistently delivered innovative and reliable solutions. These projects highlight CMTA’s ability to address the unique challenges of high-tech environments, including aerospace manufacturing, thermal analysis labs, and rapid prototyping areas. With a focus on precision, efficiency, and cutting-edge design, CMTA has played a critical role in enhancing the operational capabilities and infrastructure of these industry leaders.

Select Projects

Advanced Manufacturing Center (AMC)

The Aerospace Manufacturing Center (AMC) is a two-story structure housing Ball Aerospace’s antenna and video technologies (AVT) development, production, and test operations facilities. CMTA has provided numerous projects within this facility including:

– M&P Lab Expansion

– Ceramics Lab

– Lower Level Machine Shop

– DI Water Loop

– Outdoor Antenna Testing

– Robotic Paint Booth

– Conformal Coat Lab

– FHDL Ovens

– Rapid Prototype Area

– Paint Lab

– Tetra Etch Oven

– ESS Lab

AMC 2 Spherical Range

Electrical infrastructure design for spherical ranges, ranging in size from 10’ to 20’.

Ball Aerospace Headquarters Remodel, Broomfield, CO

MEP renovated an existing corporate building to meet the needs of the Ball executives and staff.

Chemistry and Material Testing Lab

MEP Renovation for existing chemistry and material testing laboratories.

Electrical Infrastructure Upgrades

Design of the replacement of the electrical services and emergency backup system for 3 manufacturing and test facilities.

Machine Shop

MEP design for CNC Machine shop that designs prototype hardware in the research and development building.

Cleanroom

MEP Renovation of an existing cleanroom.

EMI Chamber

MEP Redesign and expansion of an existing EMI chamber and anti-room.

Global Carbon Reduction and Sustainability Plan

Fortune 50 Aviation/Aerospace Manufacturing Company

CMTA, in partnership with Donovan Energy, has embarked on a multi-year evaluation of a global company’s domestic and international sites in the US, Italy, Singapore, Brazil, Europe, and India. The confidential company’s goal is to identify at least a 70% reduction in emissions across all the aviation division’s sites, which will encompass more than 10 million square feet. The reduction strategy will include infrastructure efficiency improvements and renewable energy procurement, ultimately aligning the company to their commitment to be carbon neutral by 2030.

At each site, the team will establish benchmarking by evaluating energy usage and utilizing baseline data. This will involve both

on-site walkthroughs and remote audits of select manufacturing sites and testing facilities. Infrastructure efficiencies that have the highest impact on carbon reduction will be identified along with the associated supporting cost estimates and a return on investment. The assessment and resulting report will also include potential renewable energy systems, with local market and regulatory requirements, procurement, PPAs, etc. in mind.

The overall strategic roadmap developed will consider timeline, procurement and progress milestones as well as opportunities to leverage federal, state and local incentives.

Project at a Glance 20 Domestic and International Sites

Carbon Reduction Roadmap

Sustainability Plan

120,000 MTCO2e

Annual savings potential identified through efficiency improvements and electrification opportunites.

26,000 Cars

Equivalent to 26,000 Gas-powered Cars Driven for One Year

Northrop Grumman at Grand Sky

Northrop Grumman | Grand Forks Air Force Base, North Dakota

Northrop Grumman opened a facility on the Grand Sky business and aviation park located at Grand Forks Air Force Base near Grand Forks, ND. The first phase included the office support area dedicated to fostering autonomous systems associated with Unmanned Aerial Systems.

The building features several individual office spaces as well as larger open office space environments which also include several conference rooms and break rooms for the support staff. The facility is a two story building with the main lobby/reception area open to the story above. Server rooms are spread throughout the facility to provide the computational service requirements for the program of the building.

The first phase was completed with an overall square footage of 36,000 square feet having an overall construction cost of $1,620,000 and there is currently an addition under design for the hangar and subsequent aviation support spaces. The first phase is a LEED Certified project and the second phase is striving for LEED Silver. Fire protection, plumbing, and HVAC design and construction administration services were provided for the project.

Project at a Glance Completion: 2018

Size: 36,000 SF

Cost: $1.62M

Project Type: New Facility

Awards / Certifications: – LEED-Certified