Clifford Imes

Clifford Imes

(585) 770-8913

cwimes6@gmail.com

Portfolio:

issuu.com/cliffordimes

archinect.com/cliffordimes

LinkedIn: linkedin.com/in/cliffordimes6

B.S. in Architecture University at Buffalo 2017 - 2021 | Buffalo, NY

First in class | GPA 3.91

- Excelled in architecture design and modeling

- Wrote on the development of sustainable housing

- Tau Sigma Delta Honors, Summa Cum Laude

- Placed 3rd in Senior Design Competition, 2020

- Academic Achievement Award 2018, 2020

- Rhino 3D

- AutoCAD

- Vectorworks

- SketchUp

- Lumion 3D Rendering

- Adobe Creative Suite

- Revit Architecture

- Microsoft Office

- Construction Documentation

- Shop Drawing

- Woodworking

- Model making

- Hand and Digital Drafting

- Collaborative

- Quick Learning

- Detail Oriented

A multitalented individual with skills in architecture, furniture design, acoustics, and scenery. Primary passion is architecture, while other passions include furniture design and acoustics. Excels in and enjoys 3D modeling and drafting, both computergenerated and by hand. Wishes to develop a career at the community scale while pushing the boundaries of traditional and new materials for practicality, inclusivity, and sustainability.

Technical Designer - Scenery Draftsperson Scenic Corporation of New York 2023 - Present

- Worked with designers and producers to develop and finalize scenery designs for technical drafting and production

- Had primary influence as designer/draftsperson of scenery, such as stages, flats, props, and furnishings

- Collaborated with project managers, scenic artists, and the workshop to ensure project accuracy

- Collaborated with managers to ensure maximum shop efficiency by standardizing shop drawing sets and operation procedures

Architectural Designer - Acoustics and Furniture Crossley Acoustics

2021 - 2023

- Worked with co-designers and clients to develop interior designs for acoustic treatment and isolation

- Standardized designs to greatly increase company efficiency

- Had primary influence in the furniture design and shop drawing divisions of the company

- Standardized the furniture shop drawing sets, making workshop efficiency double

- Designed a variety of furniture, from desks to shelves and recording studio equipment housing

- Coordinated with fabrication and installation teams to ensure project specifications and expectations

Personal Projects and Organizations

University at Buffalo

2017 - 2020

- Worked with the NYS Parks Department to design and construct the public outdoor installation, Ritual House

- Researched sustainable materials, and construction techniques

- Architectural Ceramic Assemblies Workshop (ACAW)

- AIAS 2017 - 2020

The project encompasses a conglomeration of multiple ideas into a museum of color. The initial ideas behind the project were inspired by James Turrell, who creates his effects through the use of curved and angled geometry so that there is a continuous surface and the user is unable to understand where the wall and ceiling meet.

Through various design phases and model making, the museum was developed from a ring to a spiraling circulation around and through shifting levels created by program arrangement. The user follows an endless ribbon of a wall that draws the user through the building while dissolving the sense of where the wall ends. The circulation narrows and widens to push the users up. Each floor has an exterior portion dedicated to views around the site and the ultimate goal is the top room dedicated to James Turrell.

Level One

UB Design Studio | 2020 | Tonawanda, NY

Inspired by Paul Rudolph’s Shoreline apartments, various sun-capturing sawtooth roof houses, and its relationship to the Erie Canal, the proposal is an off-the-grid house that captures the sun through south-facing sawtooth clerestories for natural sunlight and winter heat, while shifting down the site to give every room a view to the canal through a north facing slit window. The house has solid E and W walls for privacy and to prevent too much solar heat gain. The roof extends with overhangs to prevent summer sun and offer protection on the porches while the user enjoys the view toward the canal. The house is to be structured using CLT construction, a sustainable, strong, well-insulating building material to offer continuity in the interior spaces. To assist the passive heat and light, there will also be in-floor heating with clerestory ventilation and an on-site solar array.

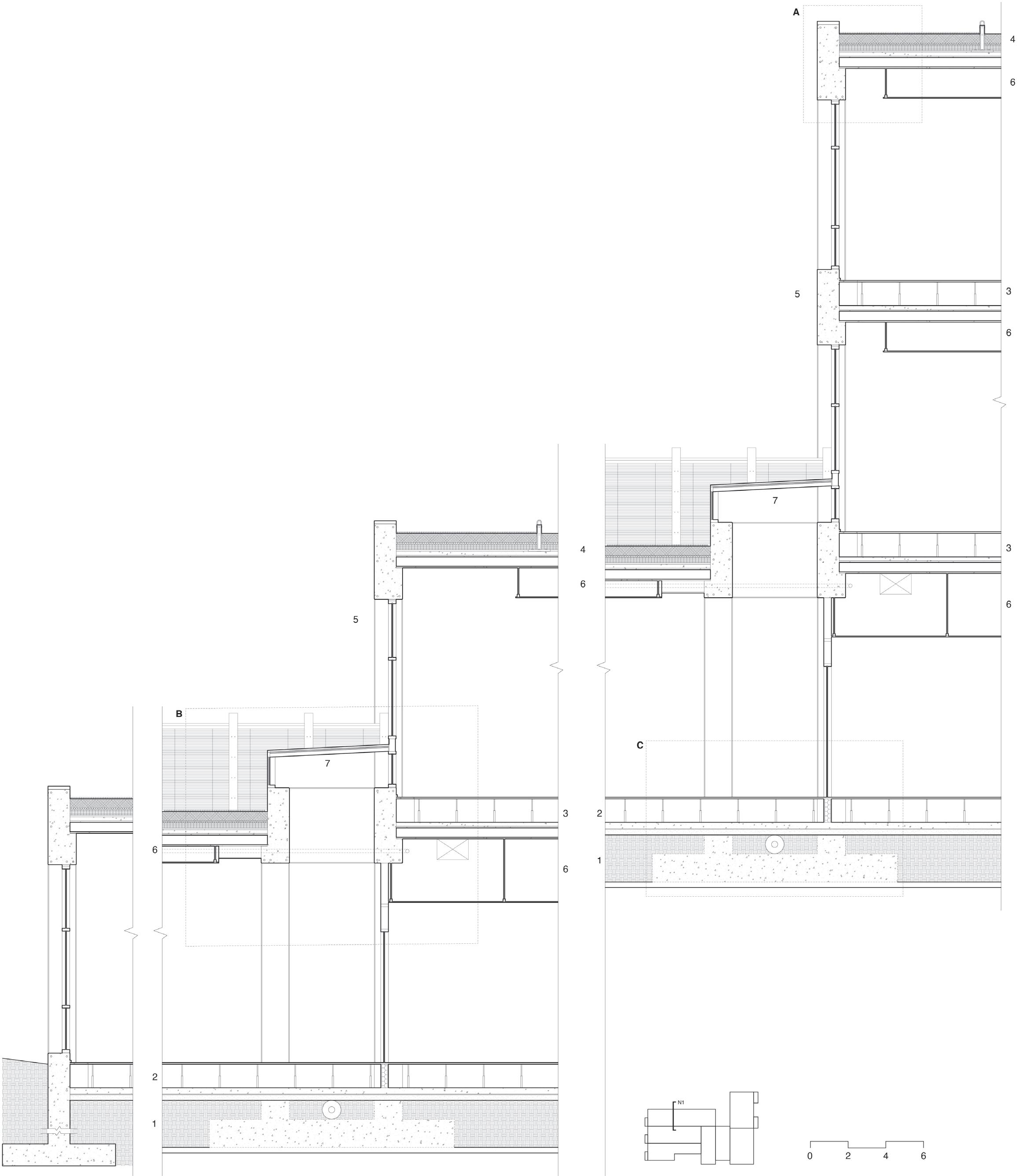

1. Foundation at perimeter wall

24 inch wide x 12 inch thick site cast concrete strip footing with (3)#5 reinforcement bars @ 3 inches from face

2. External wall below grade and ground level

Single wythe 8 x 16 x 12 CMU with #5 vertical reinforcement grouted solid at corners and sides of openings and horizontal joint reinforcement at 16 inches OC

3. External wall at upper levels

Single wythe 8 x 16 x 8 CMU with #5 vertical reinforcement grouted solid at corners and sides of openings and horizontal joint reinforcement at 16 inches OC

4. Ground level floor

4 inches compacted sand, Vapor barrier, 4 inch site cast concrete slab on grade with 8 bars (2) #5 @ 12x12 in wire mesh reinforcement or 12 in OC continuously with 3 inch clearance around

5. Floor at living room level

2 x 12 joists at 16 inches OC with blocking @ midspan, 2 x 6 tongue and groove finished decking

6. Loft floor

Steel beam W10x12 anchored to wall, 2 x 6 joists at 16 inches OC, 2 x 6 tongue and groove finished decking

The following projects are the result of a case study analysis of two existing buildings based on their structural and construction qualities. The two buildings are the Reid House by Clark and Menefee Architects and the Kitsap County Administration Building by Miller Hull Architects. For each project, a complete set of construction documents was provided and they were analyzed to recreate building sections and axonometric details of a portion of the building. The Reid House features wood and concrete masonry construction. The Kitsap County Administration Building features cast concrete and steel construction. Growth was gained in reading construction documents, using proper representational techniques, and a deep understanding of the specific elements that go into building construction.

7. Roof

Clips 16 inches OC, 2 x 6 rafters at 16 inches OC, 5/8 inch plywood sheathing, Built up roof membrane of vapor barrier and fiberglass roof shingles with underlayment

Ceiling

2 x 6 joists at 16 inches OC w/ ductwork, Vapor barrier, 3/8 inch plywood sheathing

8. Window at ground story

Site cast concrete sill, 8x16x12 inch bond beam lintel/header w/ (2)#5 reinforcement bars on top and bottom, Wood framed double glazed window

9. Large windows at upper floors

Site cast concrete sill, 16x8x8 inch ring bond beam lintel with 2-#5 reinforcement bars grouted solid, Steel frame with 5/8 inch insulated glass

10. Windows Under Roof

4x8x8 inch bond beam cap with 3/4 inch glass pocket, Frameless Glass, 2x10 beam header with anchor at corner, 2x6 blocking for top sash nailing

Detail Section B

1. Foundation

Site cast concrete footing with #8 reinforcement, 4-in gravel, 4-in site cast concrete slab with wire mesh reinforcement at 6-in OC, Concrete retaining wall

2. Ground Floor

4-in gravel, 6-in site cast concrete slab with 12x12-in mesh reinforcement, 24-in x 24-in x 15in raised floor panel system

3. Upper Floor(s)

8-in hollowcore pre-cast pre-stressed at 4-in OC, 2.5-in thick concrete topping with wire mesh reinforcement at 6-in OC, 24-in x 24-in x 15in raised floor panel system

4. Roof(s)

8-in hollowcore pre-cast pre-stressed at 4-in OC sloped at 1/4-in per ft, 2.5-in thick concrete topping with wire mesh reinforcement at 6-in OC, Fluid applied waterproofing system, Protection course, Root barrier, R-21 Rigid Insulation, Drainage and water retention mat w/ filter fabric, Vegetation w/ 6-in substrate soil

Detail Section C

5. External Envelope

Precast 8-in x 48-in concrete beams w/ 4-in ledge and #8 steel reinforcement bars, Manufactured aluminum storefront system with aligned vertical mullions

6. Ceilings

Exposed 8-in hollowcore pre-cast pre-stressed at 4-in OC, Acoustic Tile Ceiling w/ hangar clip, compression strut, 12 gauge lateral bracing wires within 2in of cross tee, 12 gauge vertical wire, and cross tee, all at 10-ft OC

7. Skylight

Aluminum storefront system w/ 1/4-in heat-strengthened glass, on 1/2-in airspace on 5/16-in laminated safety glass

To connect is to “join together to provide access and communication” and that’s what this project accomplished. This resilience hub/community center/bike shop is in a greatly impoverished area with little commercial or social infrastructure to support the community. The people of Black Rock needed a destination to be brought together as a community for access to education and recreation, and communication of present and future situations to and amongst the people. The building is also strategically linked to the community through publicly used recreational pathways that facilitate interaction with such a destination. This is done via a ramp, inspired by Le Corbusier’s Carpenter Center. The ramp divides the building into two main programs: recreation and education. Each portion is characterized by that program difference in material, structure, shading strategy, and form.

Top Roof for Solar Array Potential (approx 150,000 kwh)

Northwest Facing Overlook

Vegetated

Horizonal

Beams for Baskeball Court Span

Steel Mesh and Concrete Ramp for Transition, Transparency and Lightness

Paving for Gathering and Connection to the

UB Design Studio | 2020-21 | Black Rock, NY

3rd in Design Competition | Collaboration w/ Roberto Diurno

This is a public housing project in Brooklyn, NY dealing with wellness and affordability. With 100 units meticulously aggregated to provide the residents with a large outdoor area with a farmer’s market, cafeteria and a park, it provides dense housing with a large public space at the ground level. Each unit receives ample amounts of light, and natural ventilation through the skip stop circulation method throughout the towers. Cross-Laminated Timber is used for its ideal qualities for residents’ health and wellness through, both physical and mental. The massing takes the form of towers and slabs to provide generous collective spaces at the ground level. Through modulation, a wellness center and community market, housing can be affordable and dense, helping as many as possible in this urban environment.

Transitional/Single Units (Module and Extended Module)

Supports 1-2 people for transitioning purposes and relate to the health care facility for extended stays for patients. All are a single 25’ x 16’ module

Double, Shifted Module Units (Two Bedroom Duplex)

Facilitates low income tenants and families of 2-4 people. Shifted to create a vegetative balcony on the second levels. Some are extended for more space and shade.

Three Module Units (Three Bedroom Duplex)

Inserted as three structural modules, featuring three bedrooms, two bathrooms, a living, kitchen and dining room. Vegetative balcony and Community patio.

Cladding

Wooden Paneling, color coded to further express the variability of the facades of the towers

Two Bedroom Duplex

Cross Laminated Timber Sustainability, structural abilities, assembly and benefit on mental health were favorable

Exterior Cladding

On exterior units, the same wooden cladding that is applied to the anterior facades of the towers will be applied.