HYDROPONIC

AEE 22/23 INDONESIA

Clara Tian Yu Lie

COASTAL MANGROVES

CONTENTS

SITE

SITE

PROBLEMATICS

INFORMATION

GATHERING

INFOGRAPHICS

HYPOTHESIS DEVELOPMENT

HYPOTHESIS RESEARCH

PRE-TEST

DESIGN DEVELOPMENT

INITIAL DESIGN

HYPOTHESIS

ARTISTIC INTENTION

FINAL DESIGN

FABRICATION

PROTOTYPE COMPONENTS

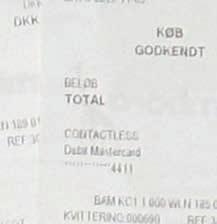

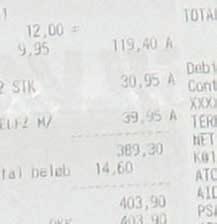

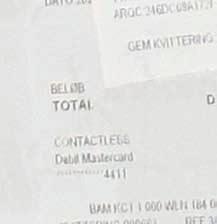

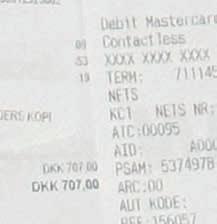

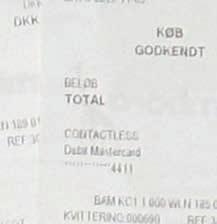

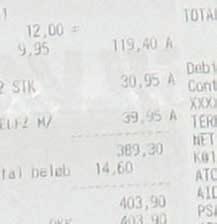

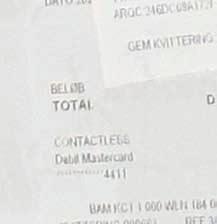

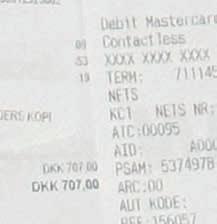

COST BREAKDOWN

FIELDWORK

PROTOTYPE SITE

LOCAL MATERIALS

DEPLOYMENT

SCIENTIFIC TESTING/RESULTS

ACKNOWLEDGEMENTS

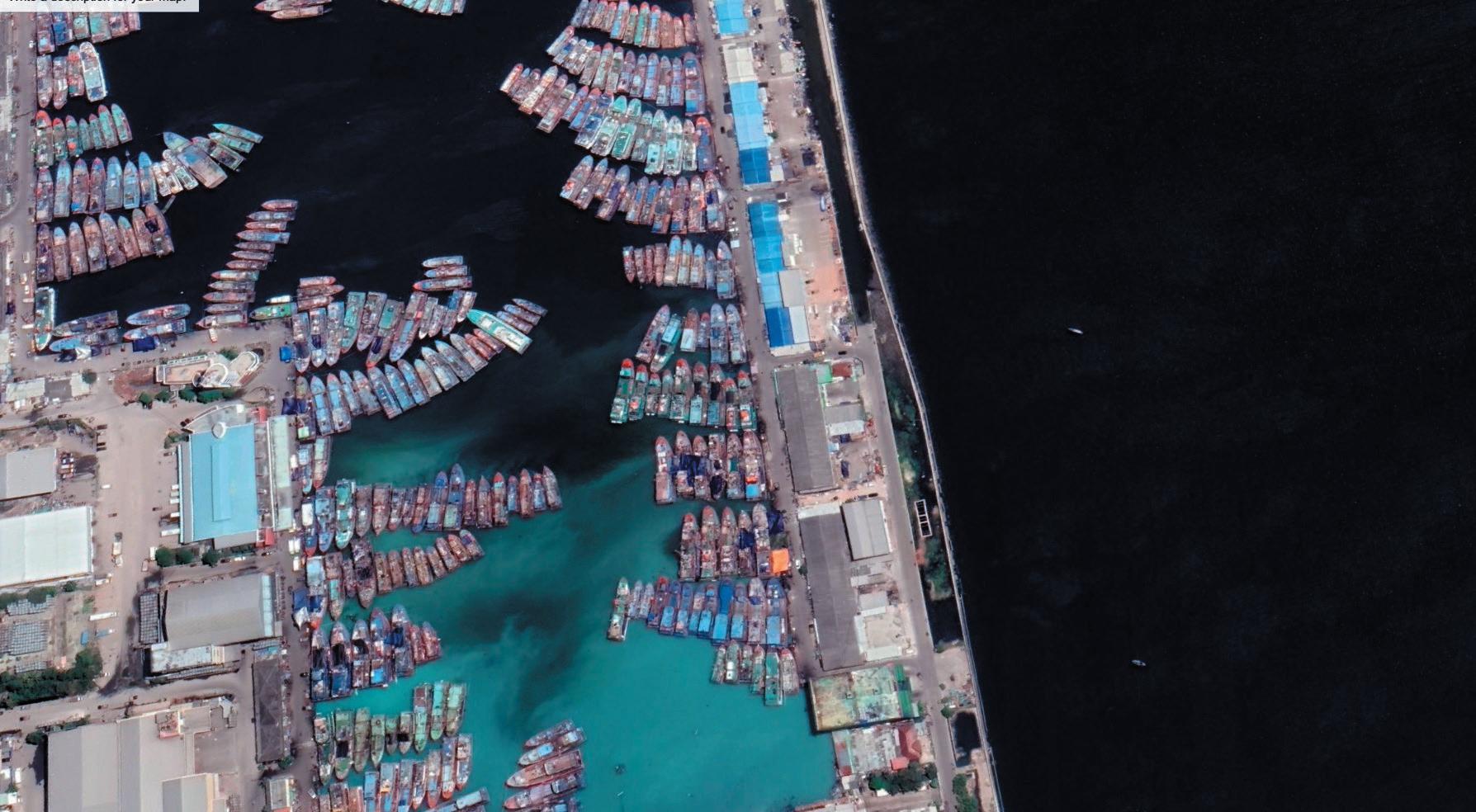

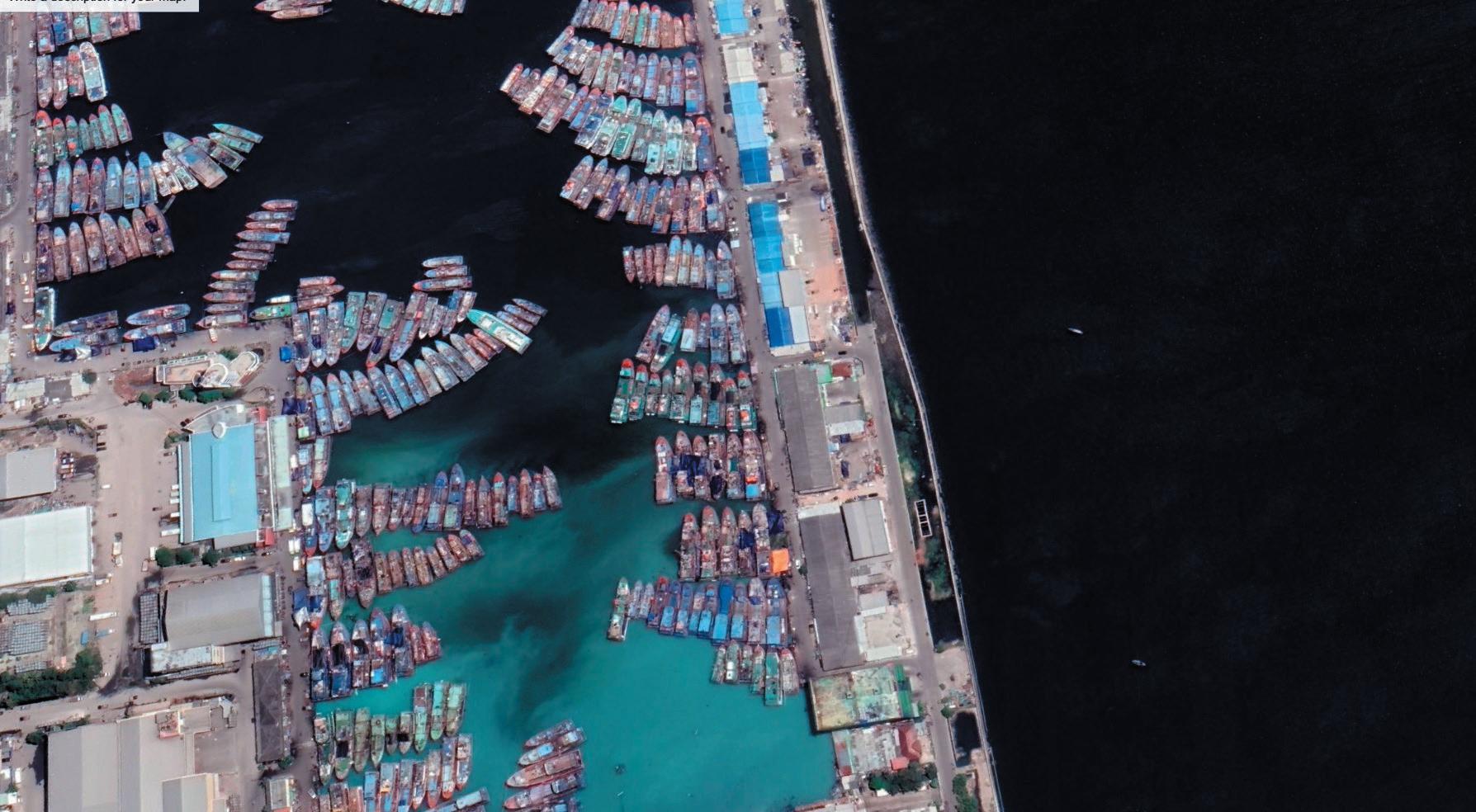

Indonesia | SITE

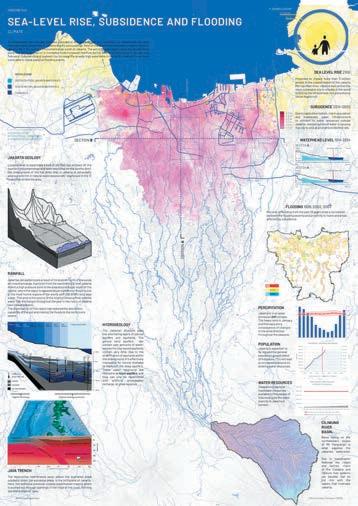

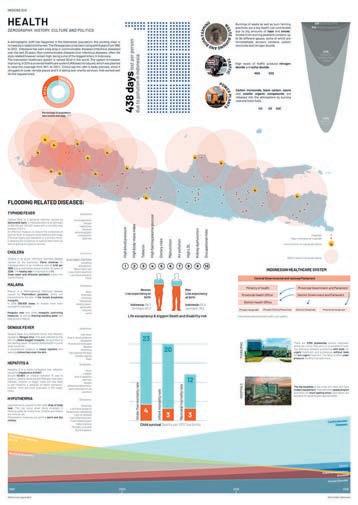

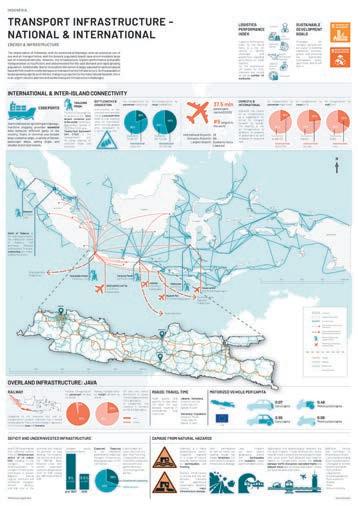

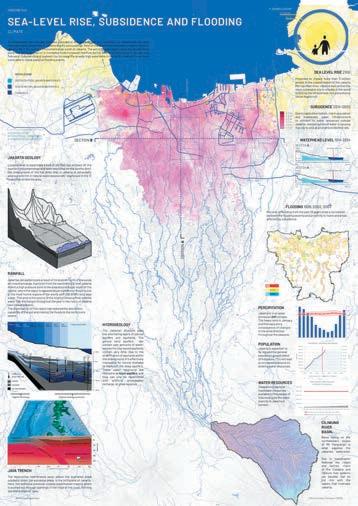

Jakarta, the capital city of Indonesia is one of the most densely populated cities in the world. With a population of 11.1 million, the city is a concrete jungle that struggles with climate change. Climate change has caused flooding and sea level rise to become a challenge for the residents of the city. Jakarta has also been projected to be completely submerged in water by 2050 as it is sinking at a rate of 1-15cm per year; with most of North Jakarta already sitting under sea level.

site | JAKARTA, INDONESIA population 11.1 million urban area 661.5 km² coastline (jakarta bay) 72km urban density 15,900 / km²

JAKARTA, INDONESIA

Sea level rise, mangrove forest degradation, land subsidence, and urbanisation contribute greatly to the exposure of coastal cities to threats which include flooding and soil erosion. These threats have caused great harm to coastal communities living in informal settlements. Many residents especially those living in informal settlements struggle to get out of poverty due to having no access to free clean water. The average amount spent on clean water from delivery trucks is approximately Rp 1,000,000 (US$71.10) over a third of their monthly income.

site | JAKARTA PROBLEMATICS mangrove forest loss 40% no acess to clean water 40% informal settlements 250,000 people flood height 40 - 200 cm

PROBLEMATICS

JAKARTA’S INFORMAL SETTLEMENTS

JAKARTA BAY

FLOODING DURING HIGH TIDE

3M HIGH CONCRETE SEA WALL

WATER TUBS

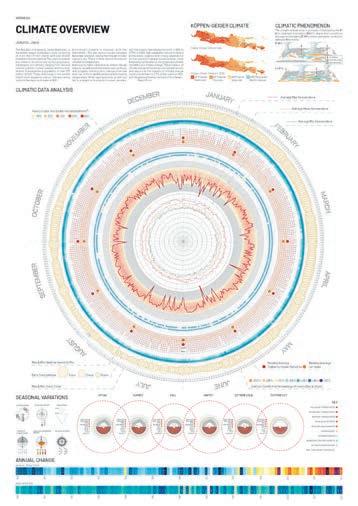

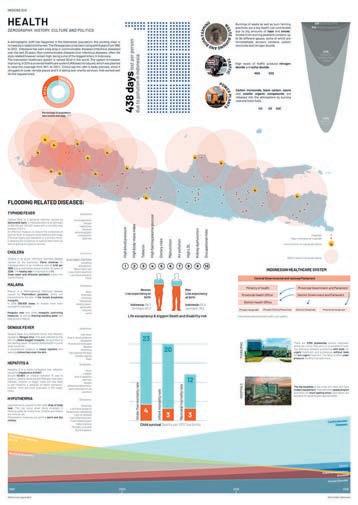

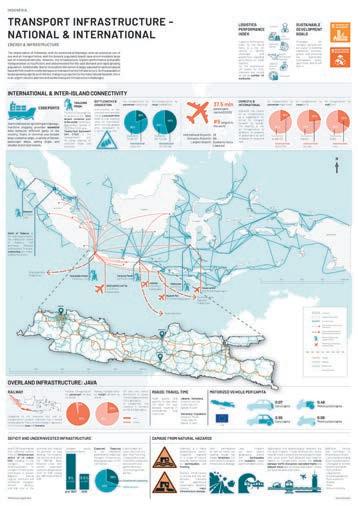

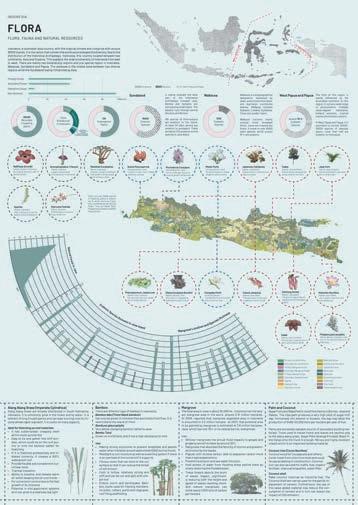

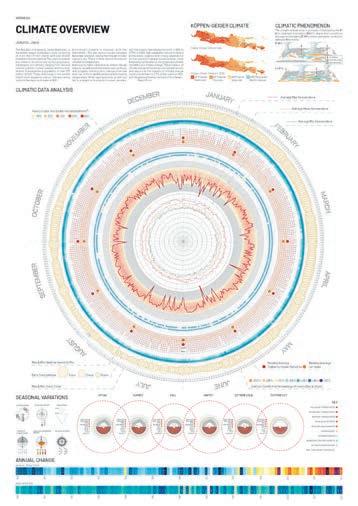

Information gathering | INFOGRAPHIC

INFORMATION GATHERING

information gathering | INFOGRAPHIC

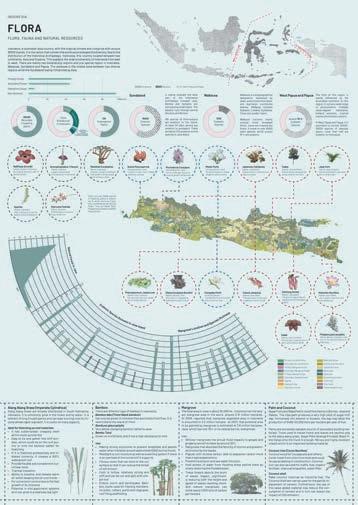

During the information gathering phase of the semester, we focused on gathering information on geography, landscape, climate, history, health, infrastructure and natural resources of Indonesia.

My infographic was on the urban development of Jakarta which was a great starting point in finding out what I was interested in to look into further during the hypothesis research phase.

hypothesis development | DESIGN EXPLORATION

hypothesis research | ELEMENTS OF INTEREST

Through research on Jakarta, these were some of the elements I found interesting and had the potential to develop. The intention of restoring mangroves along sea walls were also a key element I wanted to include in my project.

CONCRETE SEA WALL + MANGROVE RESTORATION + COCONUT WASTE

HYPOTHESIS RESEARCH

SEA LEVEL HIGHER THAN LAND

ABUNDANCE OF COCONUT WASTE

COASTAL FLOODING

MANGROVES COMPLEX ROOT STRUCTURE

THE CONCRETE SEA WALL

DENSITY OF MANGROVE FORESTS

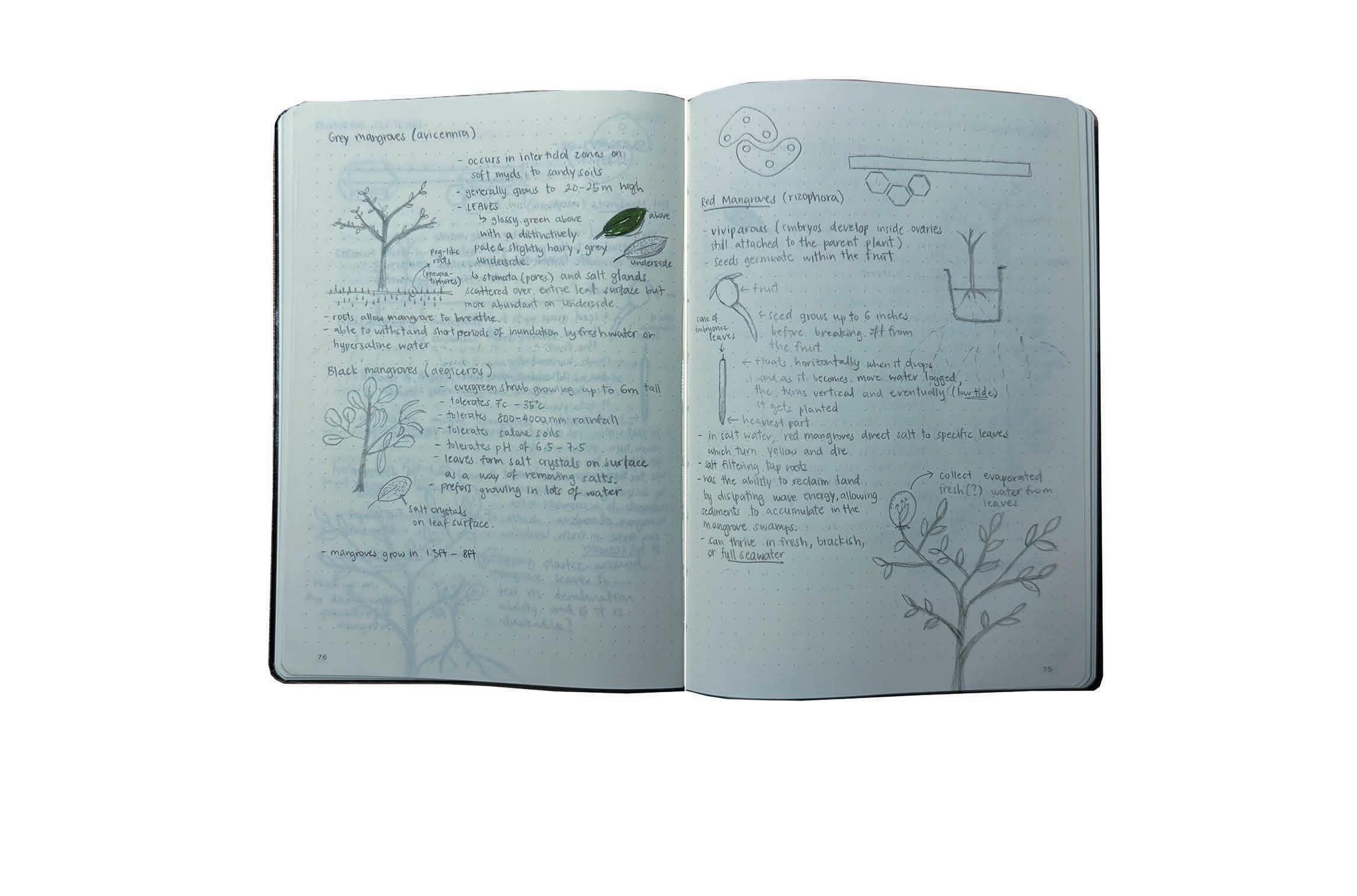

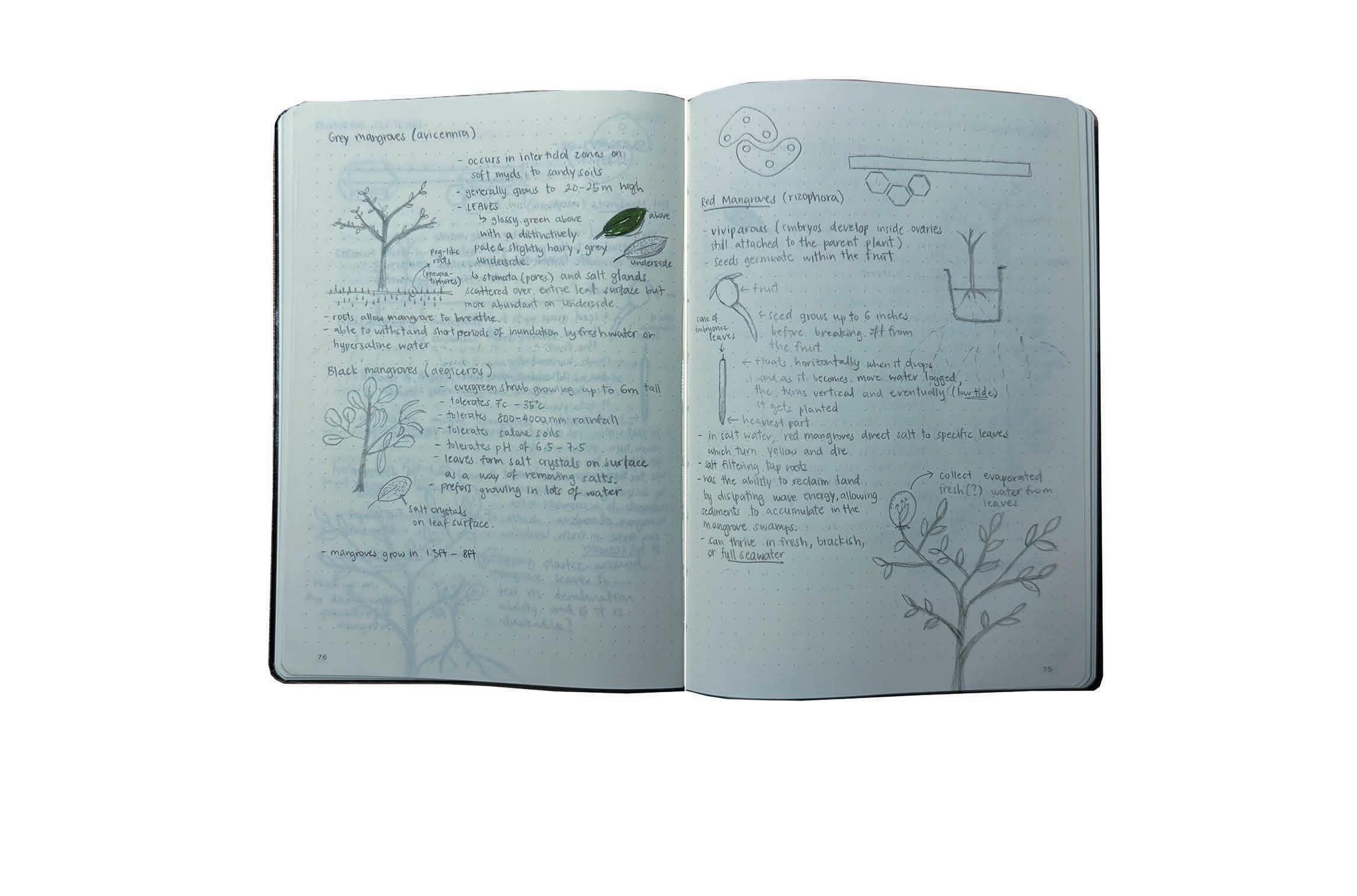

HYPOTHESIS RESEARCH

GREY/WHITE MANGROVES

Roots: peg-like roots (pneumatophores) that stick out of the ground

Leaves: oval, pointed with a pale and slightly hairy underside

Desalination: grey mangroves desalinate by having salt glands that excrete salt mostly on the underside of the leaf; to reduce rate of evaporation.

BLACK MANGROVES

Roots: peg-like roots (pneumatophores) that stick out of the ground

Leaves: silvery green with a blunt tip

Desalination: black mangrove leaves form salt crystals on the surface.

hypothesis research | MANGROVE DESALINATION

Indonesia has the largest different types of mangrove species in the world and they are categorized as red, black and grey/white mangrove. Although all mangroves are able to desalinate water, these different types have different methods of excreting the excess salts.

RED MANGROVES

Roots: above ground prop roots

Leaves: large and broad with a blunt tip

Desalination: red mangroves desalinate water by directing salt towards ‘sacrificial’ leaves which turn yellow

*The most common species in Indonesia is the red mangrove

PROP ROOTS

PNEUMATOPHORES

PROP ROOTS

PNEUMATOPHORES

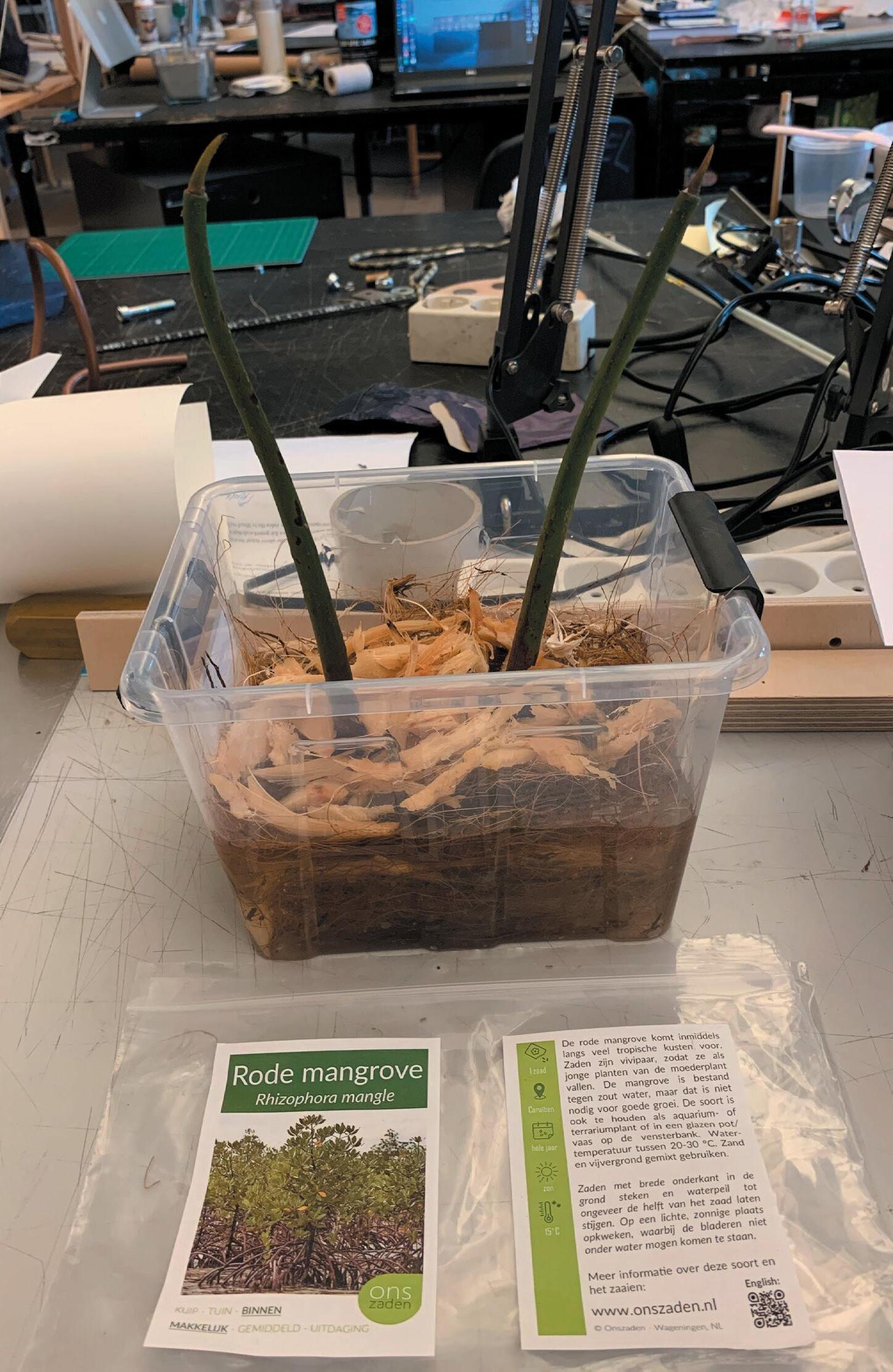

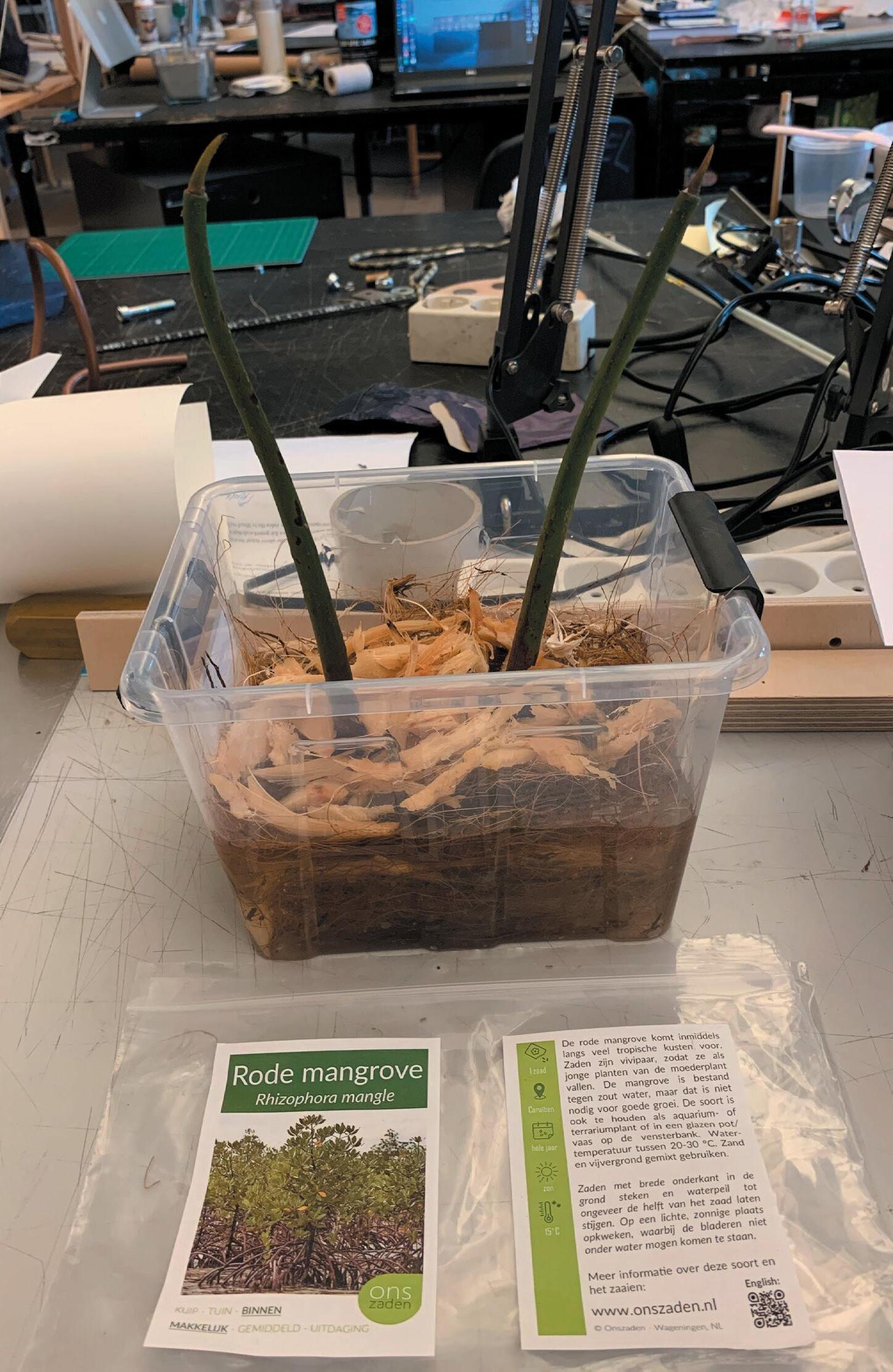

hypothesis research | PRE-TESTING ON USING FRESH HUSKS FOR GROWTH

After doing plenty of research on the benefits of coconut husks as a nutrient source, I wanted to do some preliminary testings to decide whether I would like to move forward with this idea as well together with desalination. In the two weeks, the seed in tub with fresh husk added seemed to have grown slightly faster than the one without. Thus, I decided to add this as a secondary hypothesis for the project.

HYPOTHESIS RESEARCH - PRE TEST

RED MANGROVES (RIZOPHORA MANGLE) FROM THE NETHERLANDS

USING COCONUT FIBRE AS THE PLANTING MEDIUM

USING THE LAMP TO GIVE IT LIGHT

FILLING 2 TUBS FOR THE COMPARISON TEST TESTING FRESH COCONUT HUSK AS A NUTRIENT SOURCE FOR GROWTH

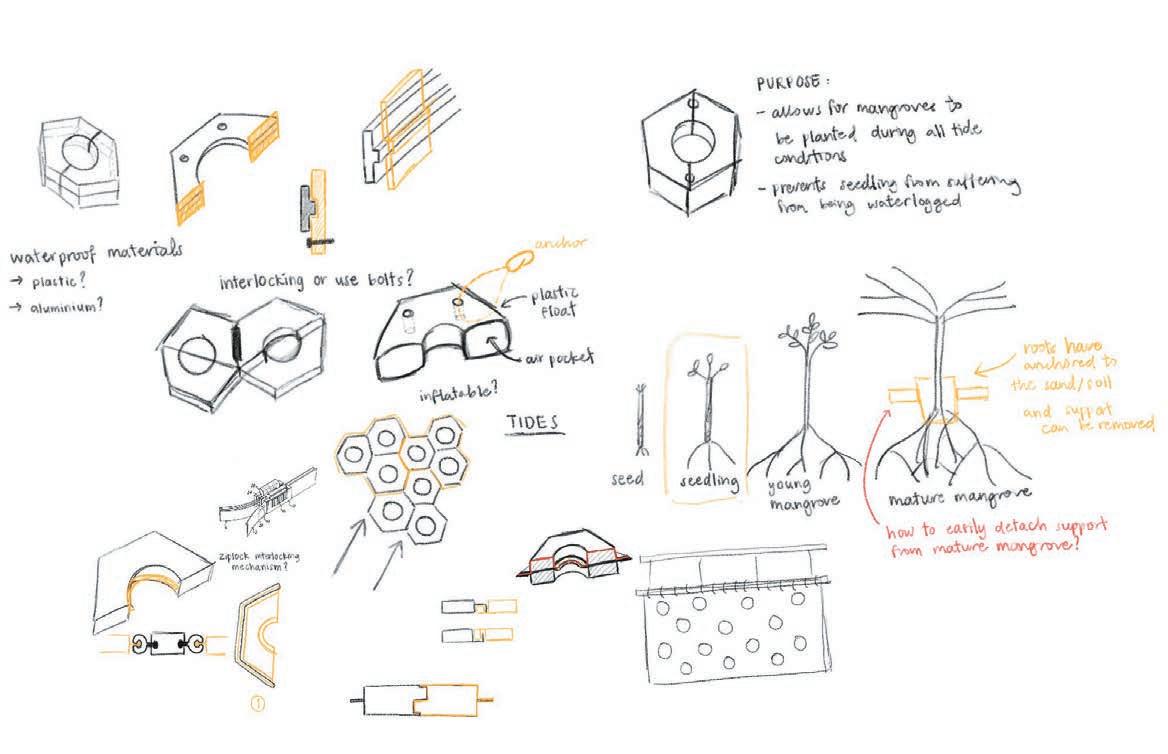

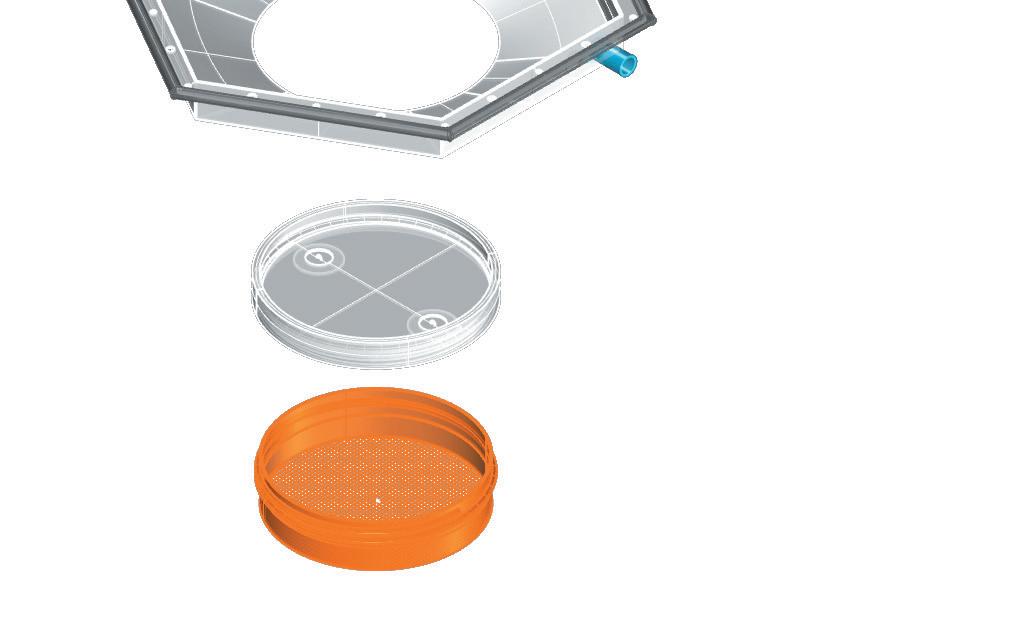

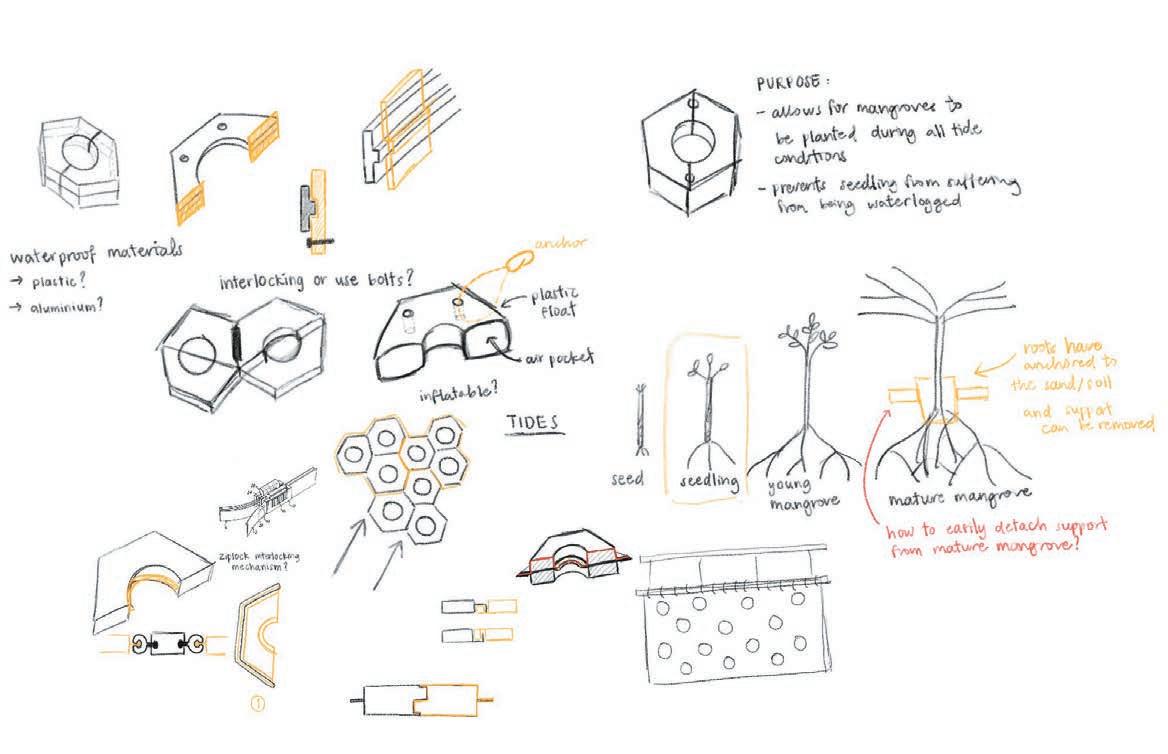

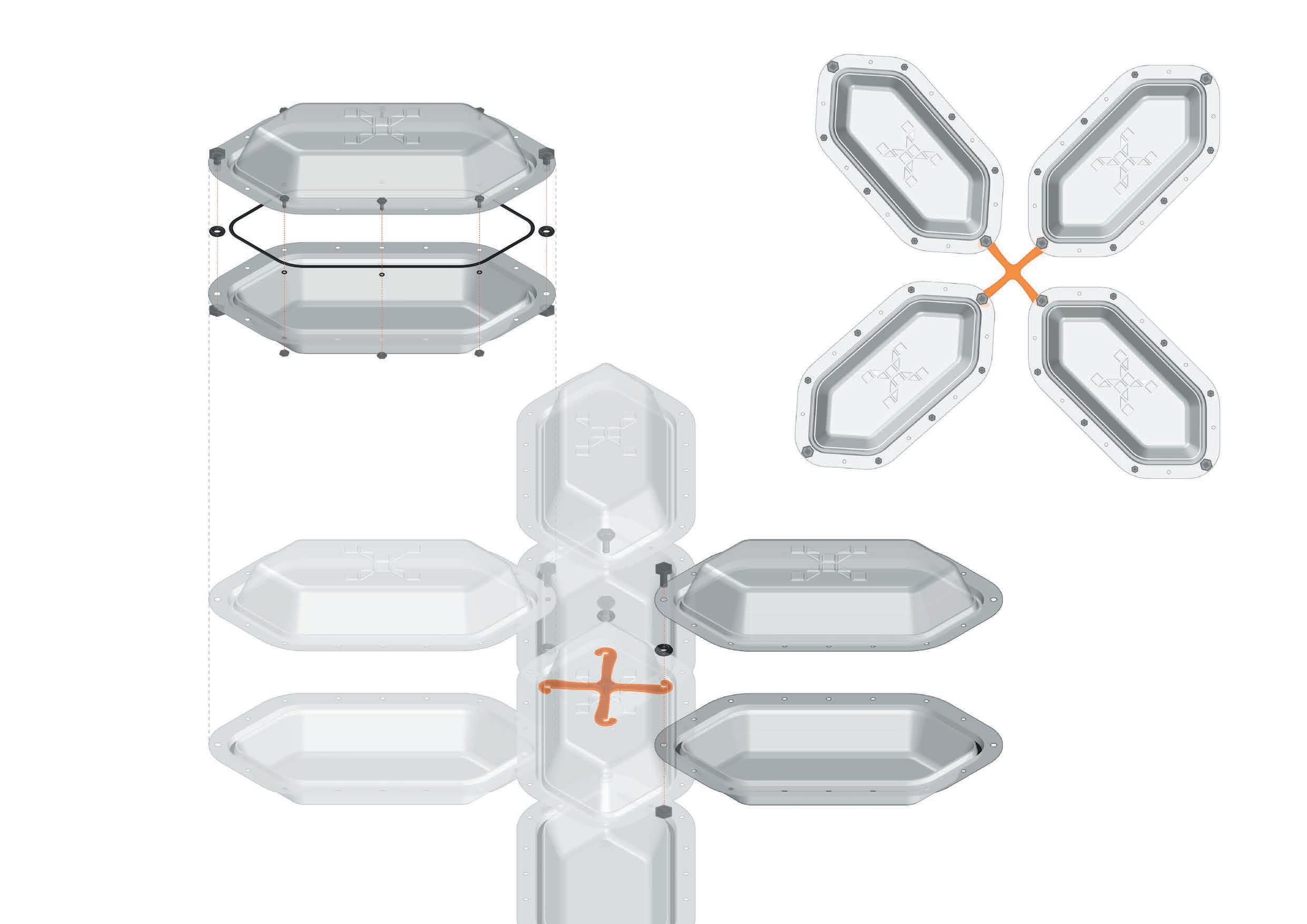

design development |

INITIAL

DESIGN

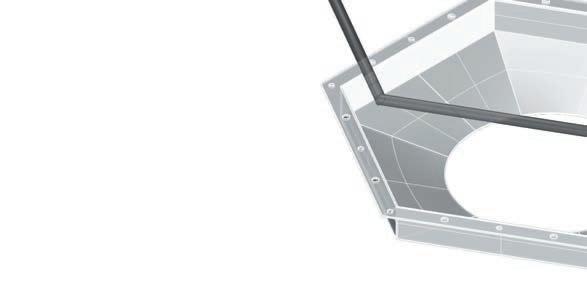

INITIAL DESIGN

initial design | sketches

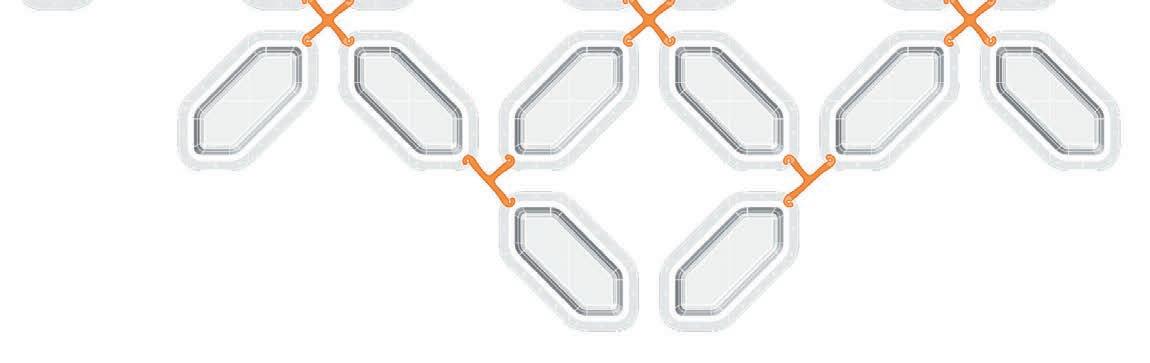

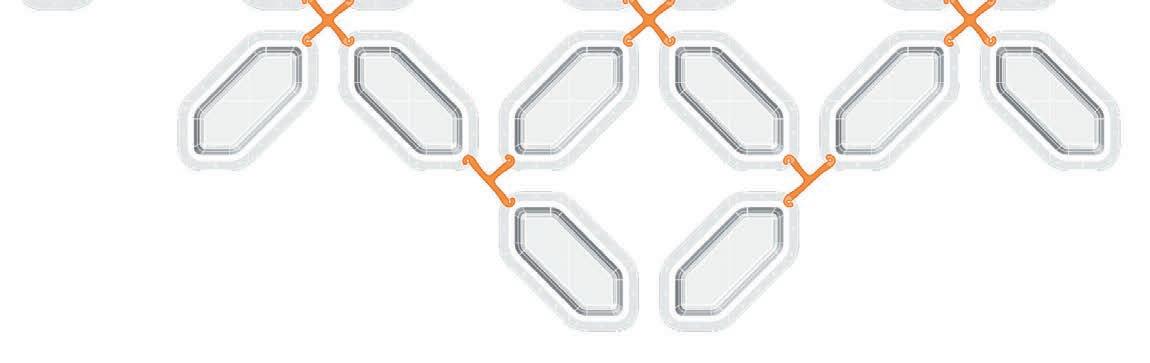

early sketches for the prototype based on the idea of creating a hydroponic mangrove system which explores the hexagon shape as the modular component. At this stage the hypothesis was still unclear but the sketches were done more for using the mangroves as a coastal defense to challenge the concrete sea wall in a way and also raise awareness on what urbanisation has taken from nature.

INITIAL DESIGN

INITIAL DESIGN WAS TOO COMPLICATED AND WAS DIFFICULT TO FABRICATE

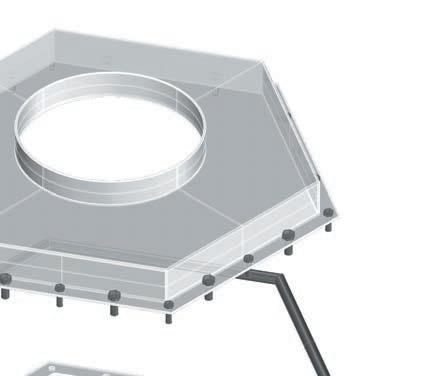

1. initial prototype exploded iso

2. initial float components

3. initial prototype module iso

1.

1.1. Coconut fibre pot

1.2. Plastic water collection chamber

1.3. Rubber seal

1.5. Valve

1.4. Silicone tube

1.6. Mesh

2.

3.

2.1. M6 bolt

2.2. M8 bolt

3.1. Parang joint

1. initial prototype exploded iso

2. initial float components

3. initial prototype module iso

1.

1.1. Coconut fibre pot

1.2. Plastic water collection chamber

1.3. Rubber seal

1.5. Valve

1.4. Silicone tube

1.6. Mesh

2.

3.

2.1. M6 bolt

2.2. M8 bolt

3.1. Parang joint

Can a floating hydroponic mangrove system be used to desalinate sea water in coastal flood-prone settlements where the only barrier between land and sea is the sea wall, to provide those of lower income with access to free clean water for daily use?

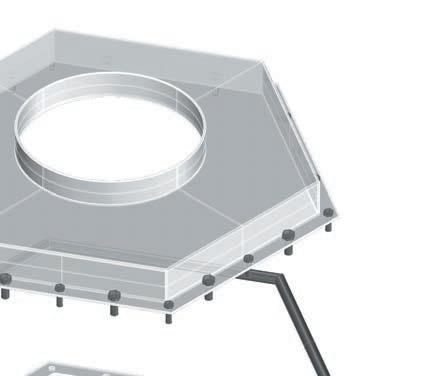

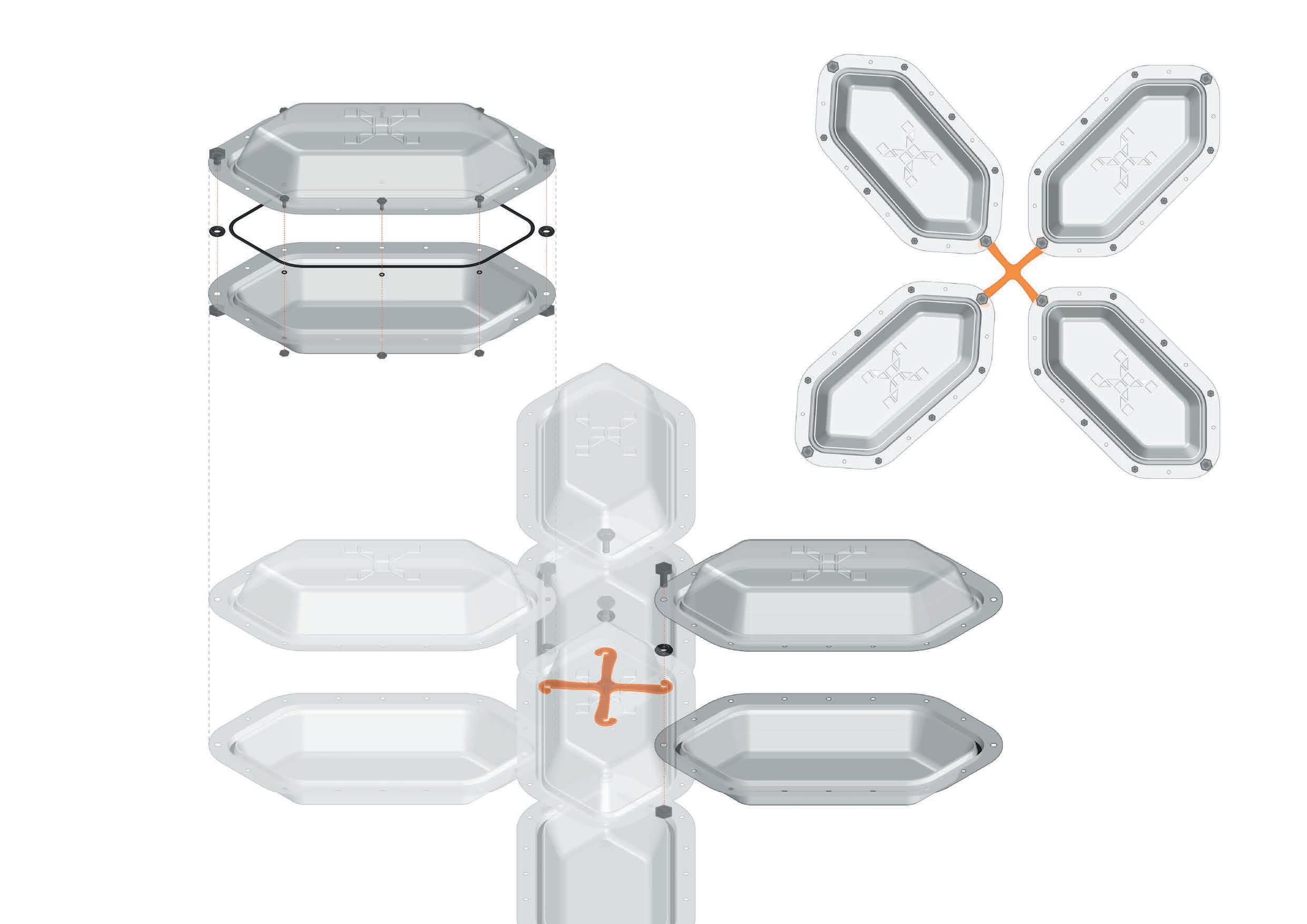

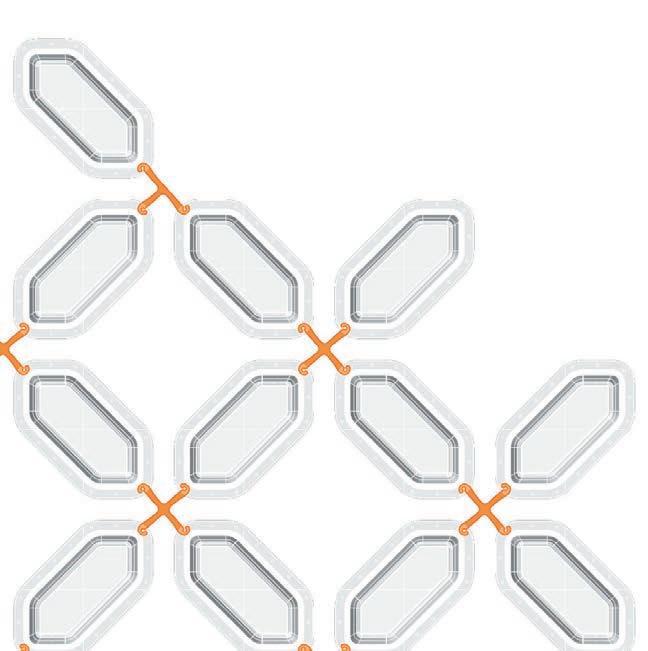

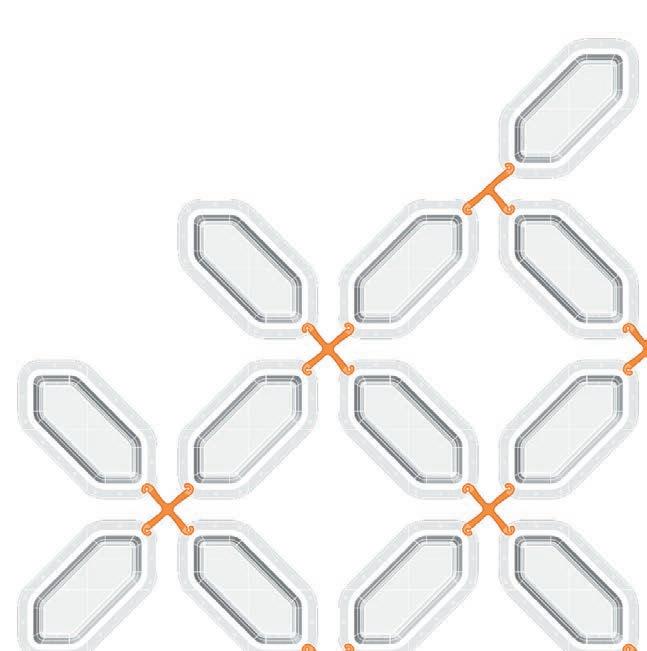

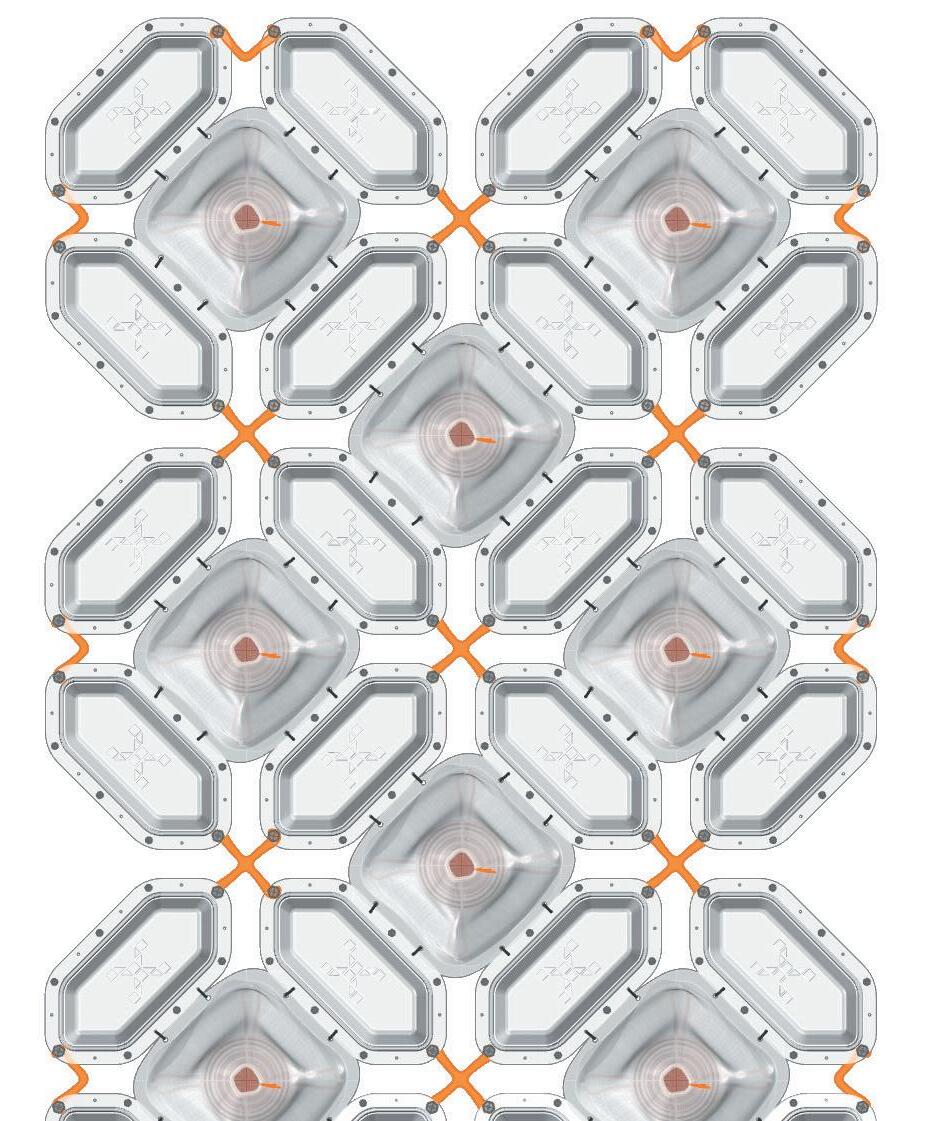

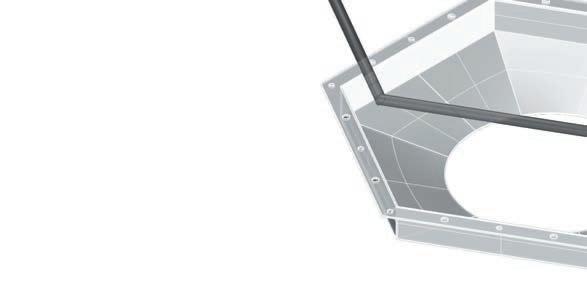

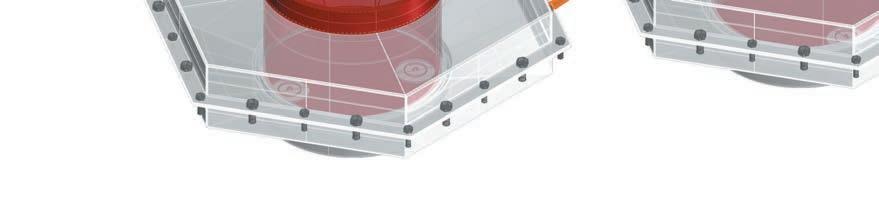

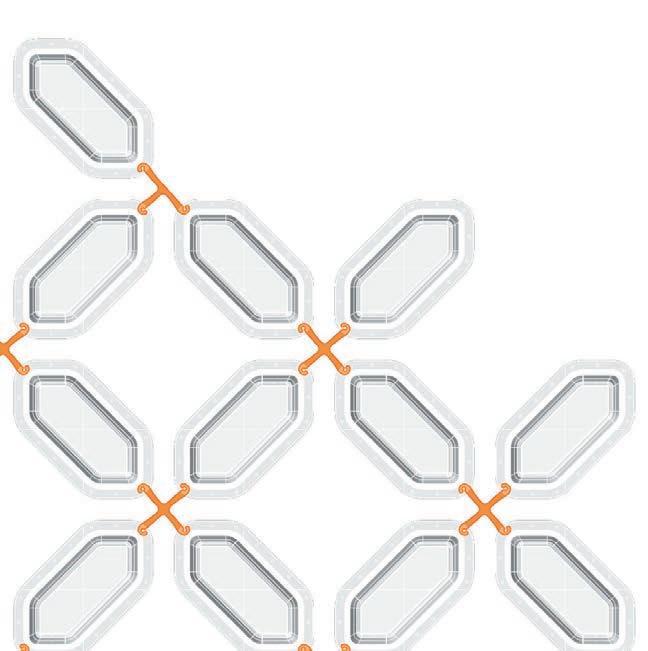

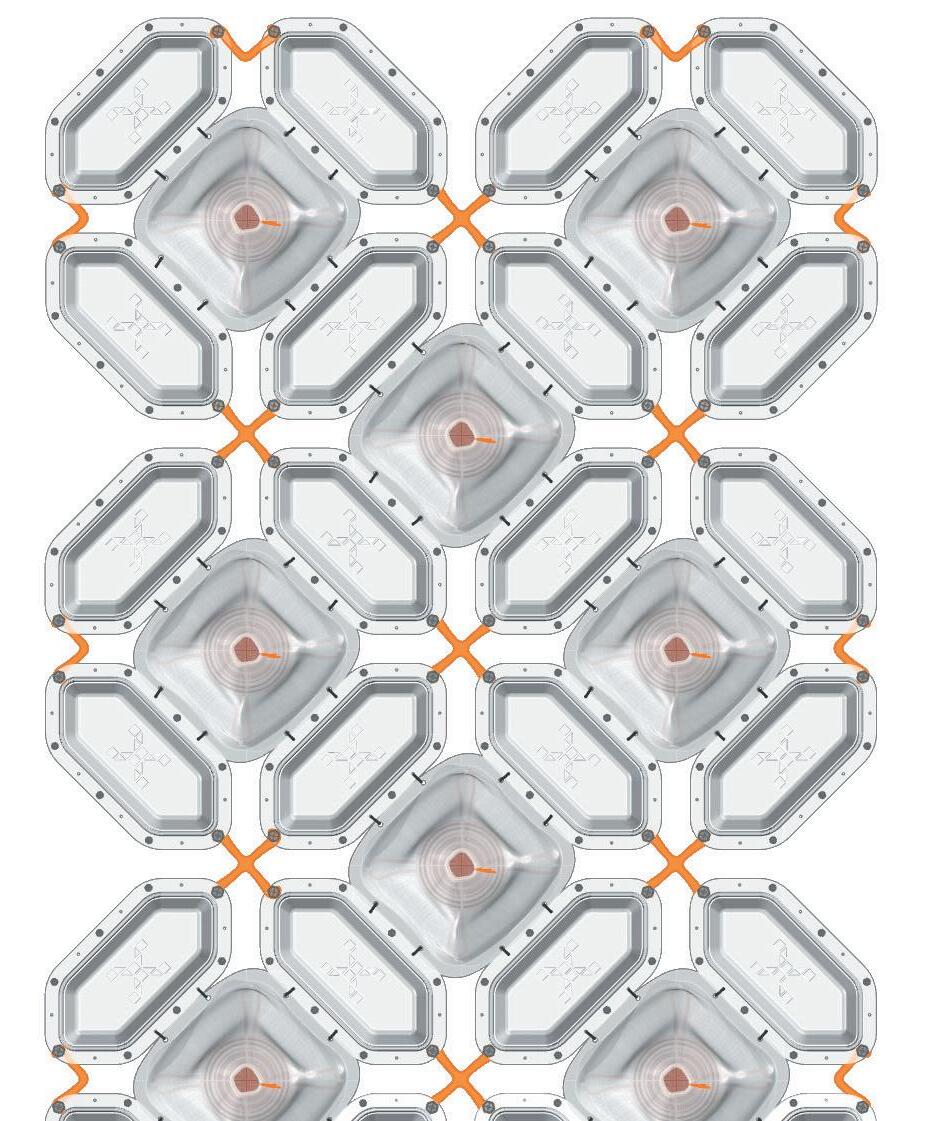

the hydroponic mangrove system | FINAL DESIGN

1. float components exploded iso

2. float joint connection exploded iso

1. float components exploded iso

2. float joint connection exploded iso

3. float module plan 0.5mm

1. 2. 1.8.

3. 1.6. vacuum formed plastic top float

thickness

1.5.

M8 bolt

1.7.

M6 rubber gasket

M8 nut

1.1. M4 bolt

1.3. M4 rubber gasket

1.4. M4 nut

0.5mm

1.2. rubber gasket 1.5mm

1.9.

vacuum formed plastic bottom float

thickness

3.1. powder coated steel joint

thickness

FINAL DESIGN - FLOAT

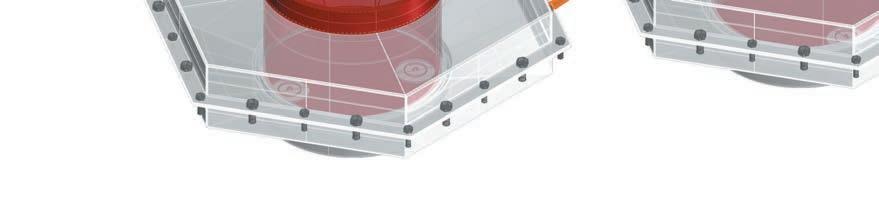

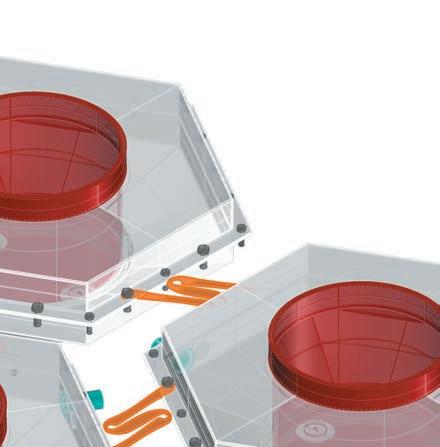

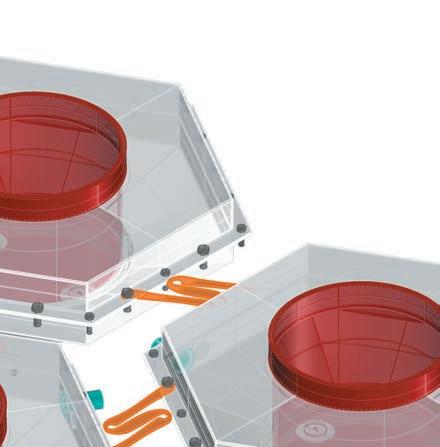

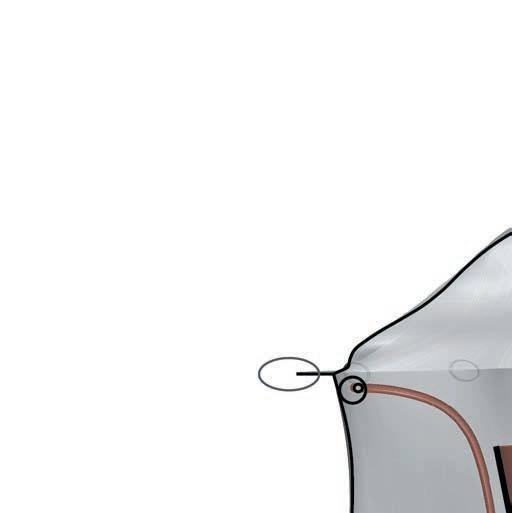

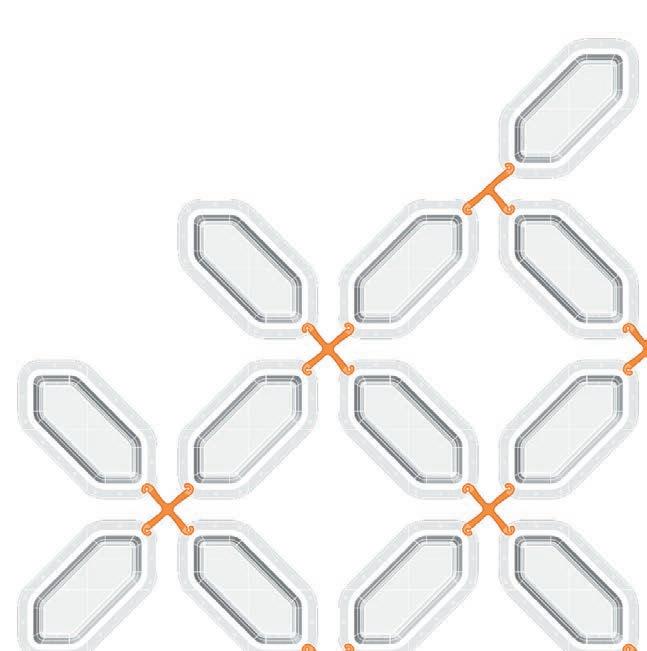

FINAL DESIGN - WATER BAG

RAFIA ROPE

COCONUT FIBRE POT

COCONUT FIBRE ROPE

4.

4.1 40x40x50cm water bag

220gsm transparent tarpaulin

4.2 5cm tab with holes to attach to floats

220gsm transparent tarpaulin

4.3 Adjustable drawstring opening 5mm diameter rope

4.4 2cm diameter ring 200gsm transparent tarpaulin

4.5 coconut fibre rope

4.6 coconut fibre pot

4. Water bag section drawing

5. Water bag components

6. 1 module of floats and water bag

5.

6.

5.1 coconut fibre rope 8mm diameter

5.2 coconut fibre pot 15cm diameter

5.3 tarpaulin water bag 220gsm transparent

5.4 rope 5mm diameter

RAFIA ROPE

COCONUT FIBRE POT

COCONUT FIBRE ROPE

4.

4.1 40x40x50cm water bag

220gsm transparent tarpaulin

4.2 5cm tab with holes to attach to floats

220gsm transparent tarpaulin

4.3 Adjustable drawstring opening 5mm diameter rope

4.4 2cm diameter ring 200gsm transparent tarpaulin

4.5 coconut fibre rope

4.6 coconut fibre pot

4. Water bag section drawing

5. Water bag components

6. 1 module of floats and water bag

5.

6.

5.1 coconut fibre rope 8mm diameter

5.2 coconut fibre pot 15cm diameter

5.3 tarpaulin water bag 220gsm transparent

5.4 rope 5mm diameter

1. 11 water bags configuration

2800x1400mm

2800x2100mm

2800mm 2100mm

1400mm 2800mm

FINAL DESIGN - MODULAR

1.

2.

2. 9 water bags configuration

the hydroponic mangrove system | FABRICATION

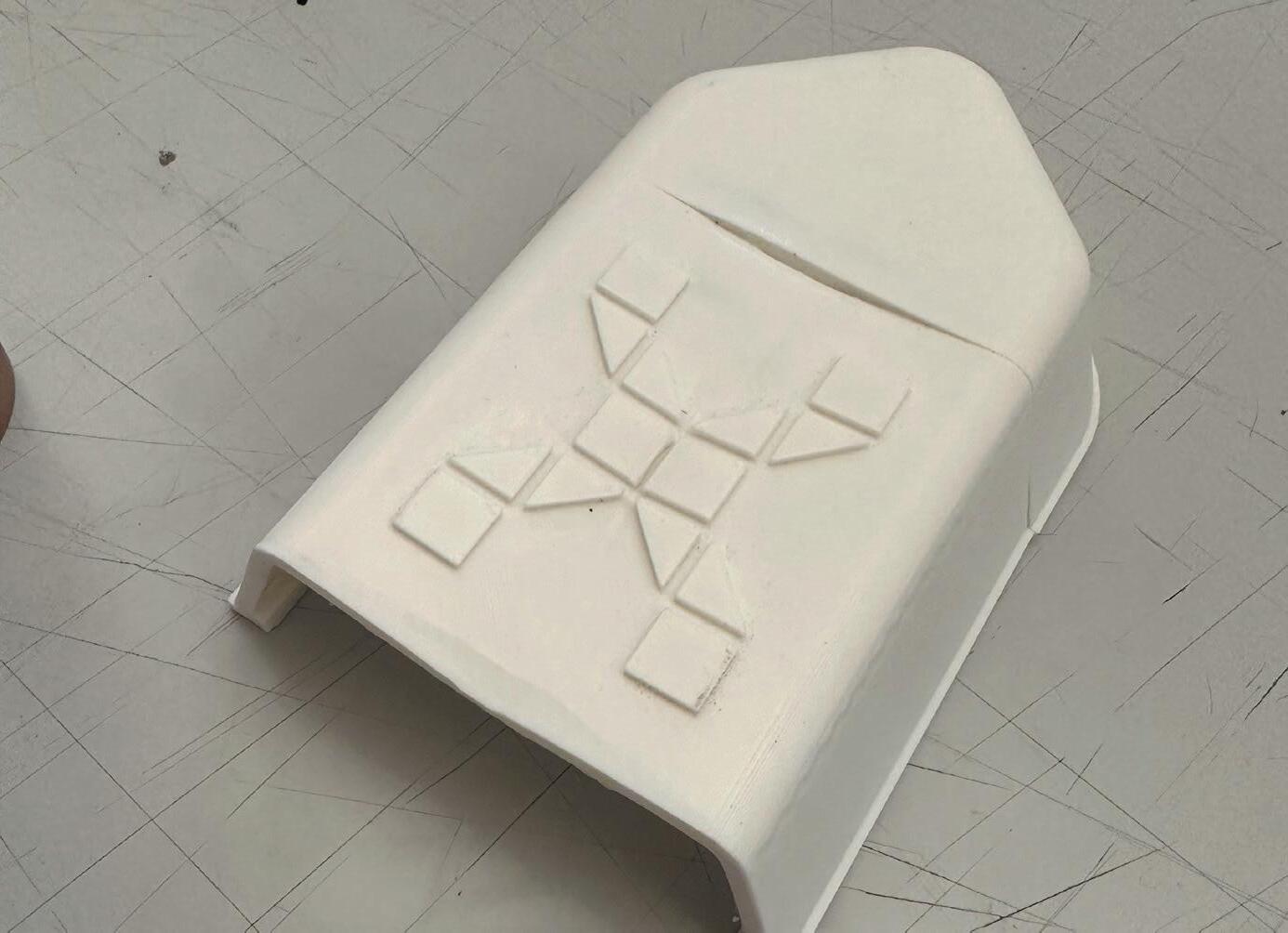

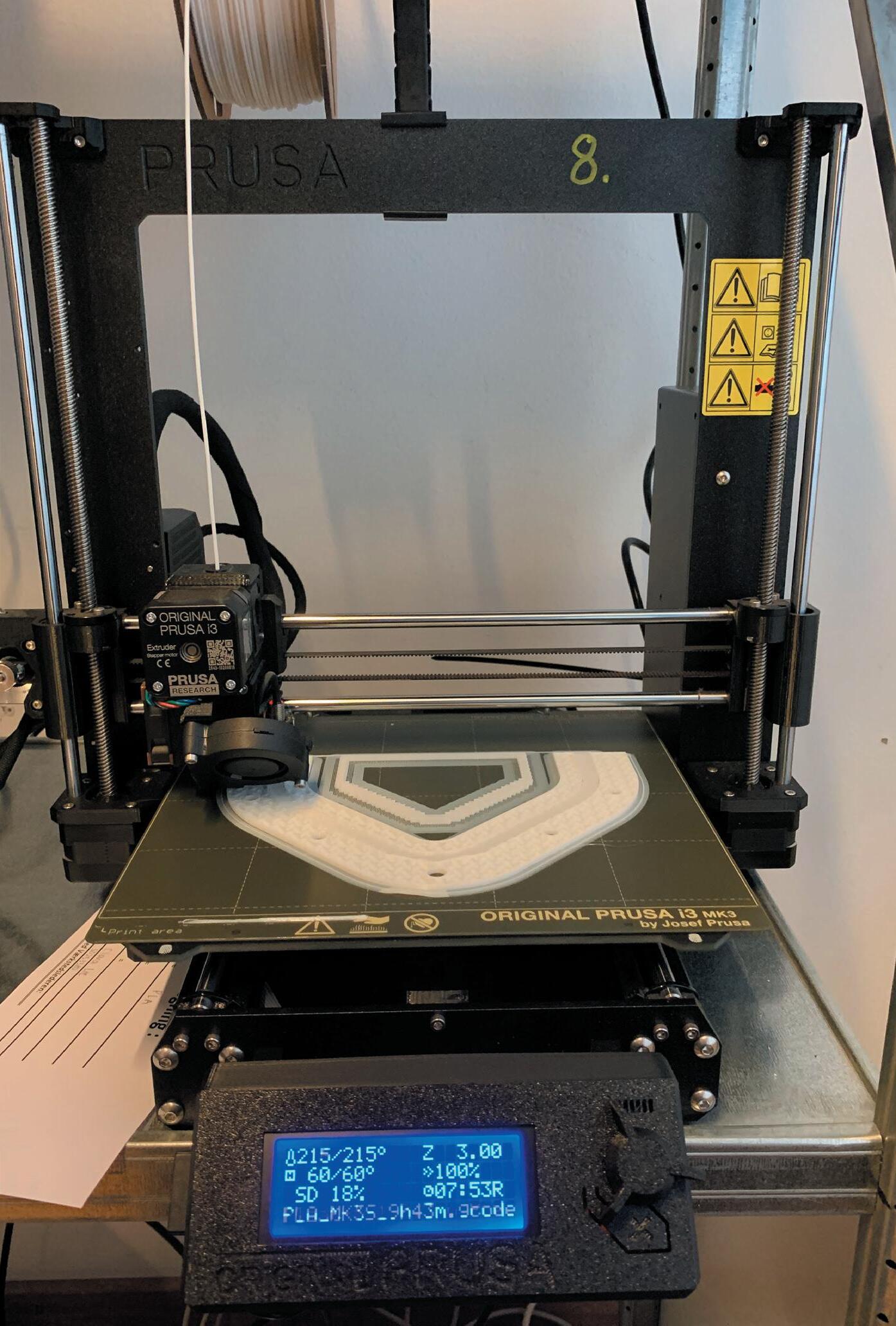

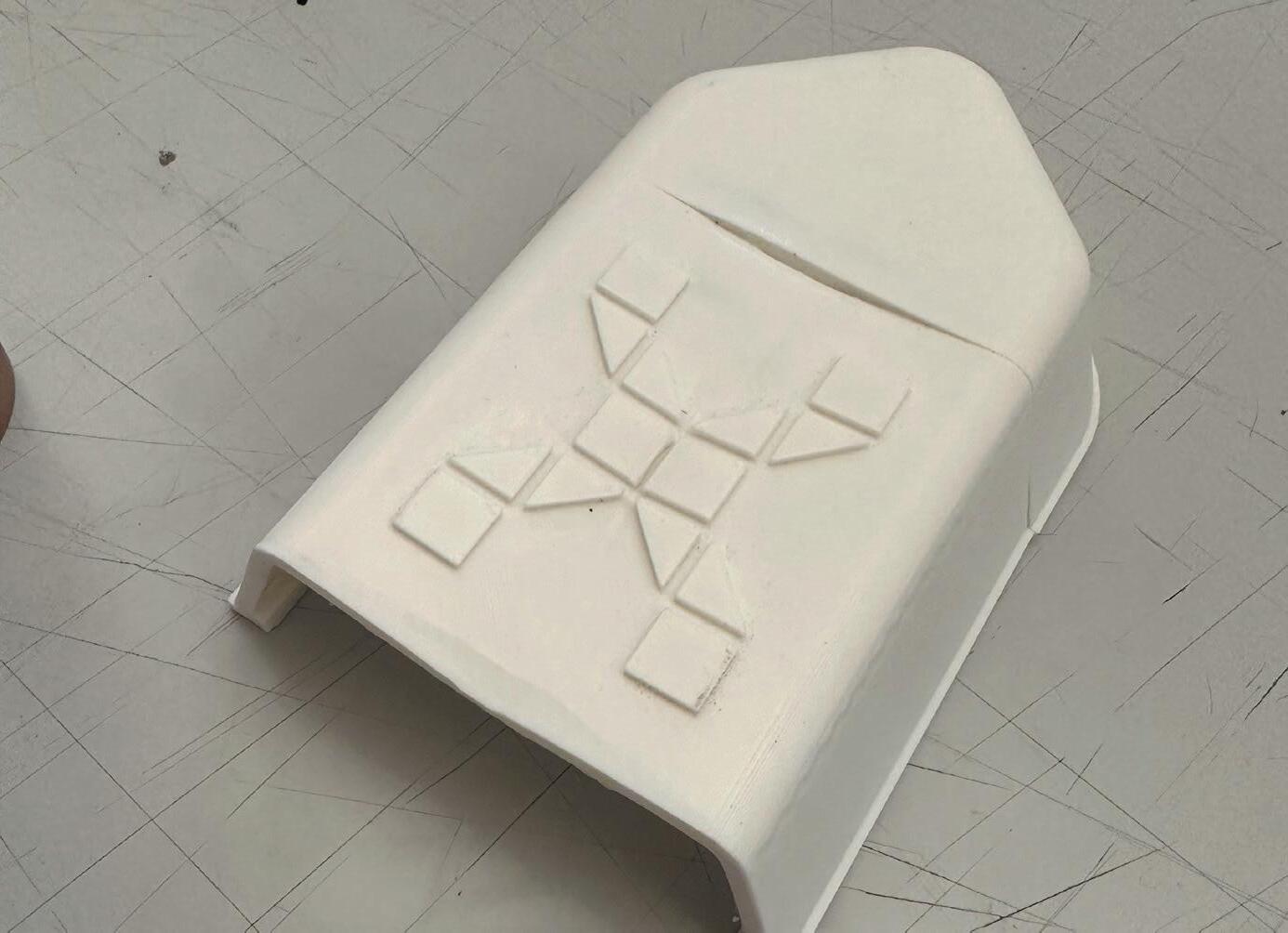

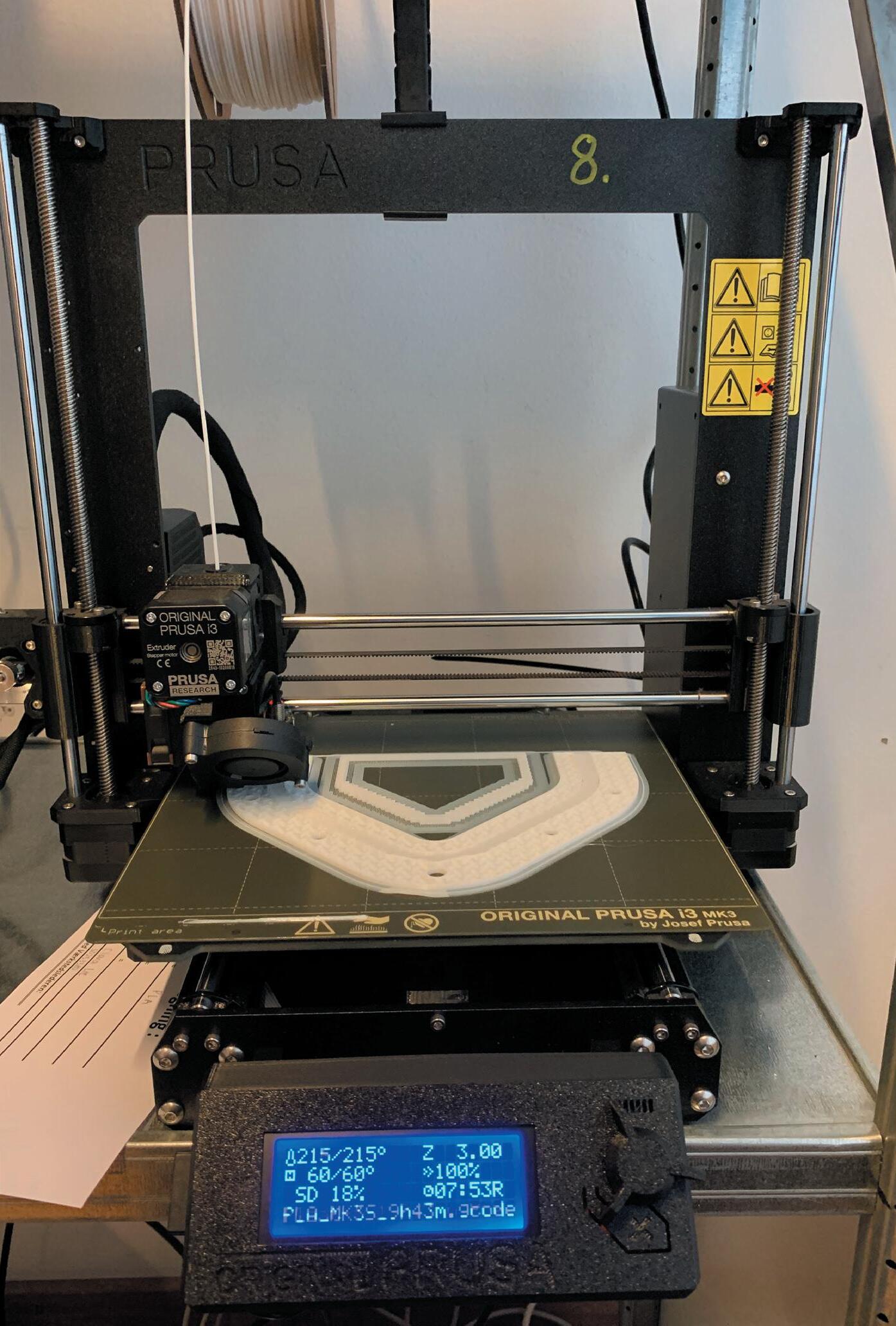

float mould fabrication | 3D PRINTING

The mould fabrication process was done with the top and bottom floats divided into three parts to accommodate to the 3D printing machine. The whole 3D printing was initially planned to take three days to complete with two mould being printed at the same time per day. However due to unforeseen circumstances (3D printer breaking down, mould not printing properly, etc.) the process took over a week to complete. Despite the troubles, since the top float mould was completed smoothly, the next stage of the float fabrication was able to happen together with the printing of the bottom float.

PRUSA i3 MK3 - 3D PRINTER

3D

HOLLOW MOULD DEFORMED MOULD AFTER VACUUM TEST COMPLETE TOP FLOAT MOULD PROTRUDING PORTION OF THE MOULD SOLID MOULD

1/3 OF THE BOTTOM FLOAT MOULD

PRINT SUPPORT SUNKEN PORTION OF THE MOULD

DEFORMATION

FABRICATION

FABRICATION

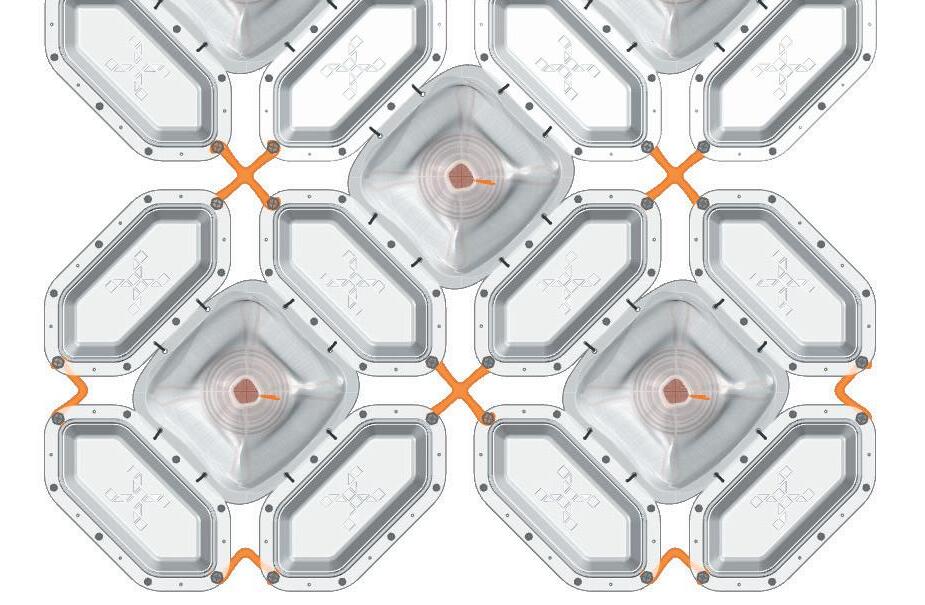

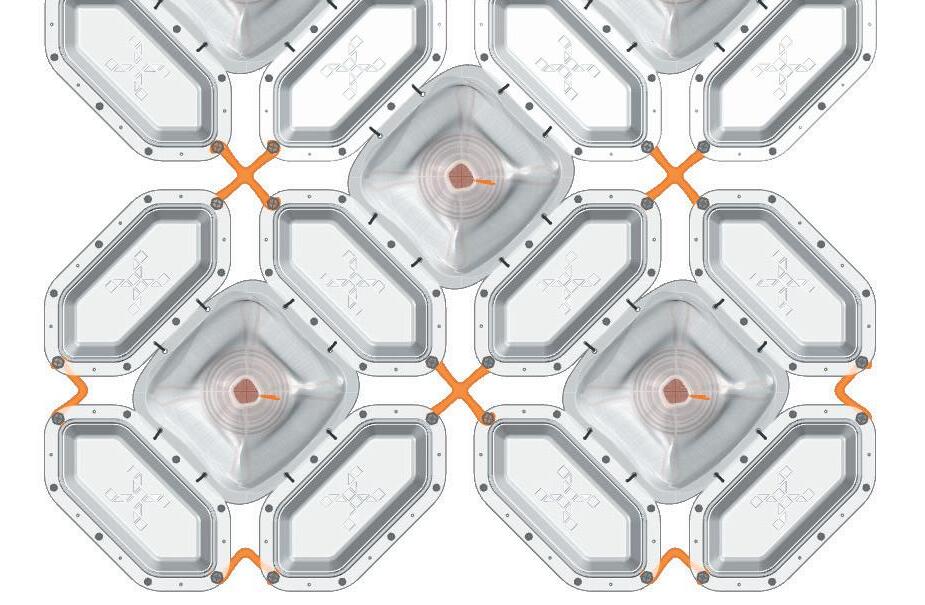

float mould fabrication | VACUUM FORMING

The prototype includes 32 floats which required a total of 64 vacuum formed plastic pieces. This was done using the smaller illig machine with a bed area of 45cm x 50cm allowing for one mould to be vacuum formed at a time. The test float was done using 1mm thick transparent VIVAK plastic sheet which was later replaced by the one with 0.5mm thickness; due to having to make 64 floats and the 1mm sheets were more difficult to cut and it was unnecessary extra cost. The vacuum forming lasted over five days with about 12 floats done everyday.

VACUUM FORM TEST USING 1MM THICK PLASTIC

COOLING THE PLASTIC

64 PLASTIC FLOATS CUT AND DRILLED

PLASTIC FLOATS BEFORE CUTTING

ILLIG VACUUM FORMING MACHINE

INDENTATION CAUSED BY USING HOLLOW MOULD

VACUUM FORM TEST USING 1MM THICK PLASTIC

COOLING THE PLASTIC

64 PLASTIC FLOATS CUT AND DRILLED

PLASTIC FLOATS BEFORE CUTTING

ILLIG VACUUM FORMING MACHINE

INDENTATION CAUSED BY USING HOLLOW MOULD

FABRICATION

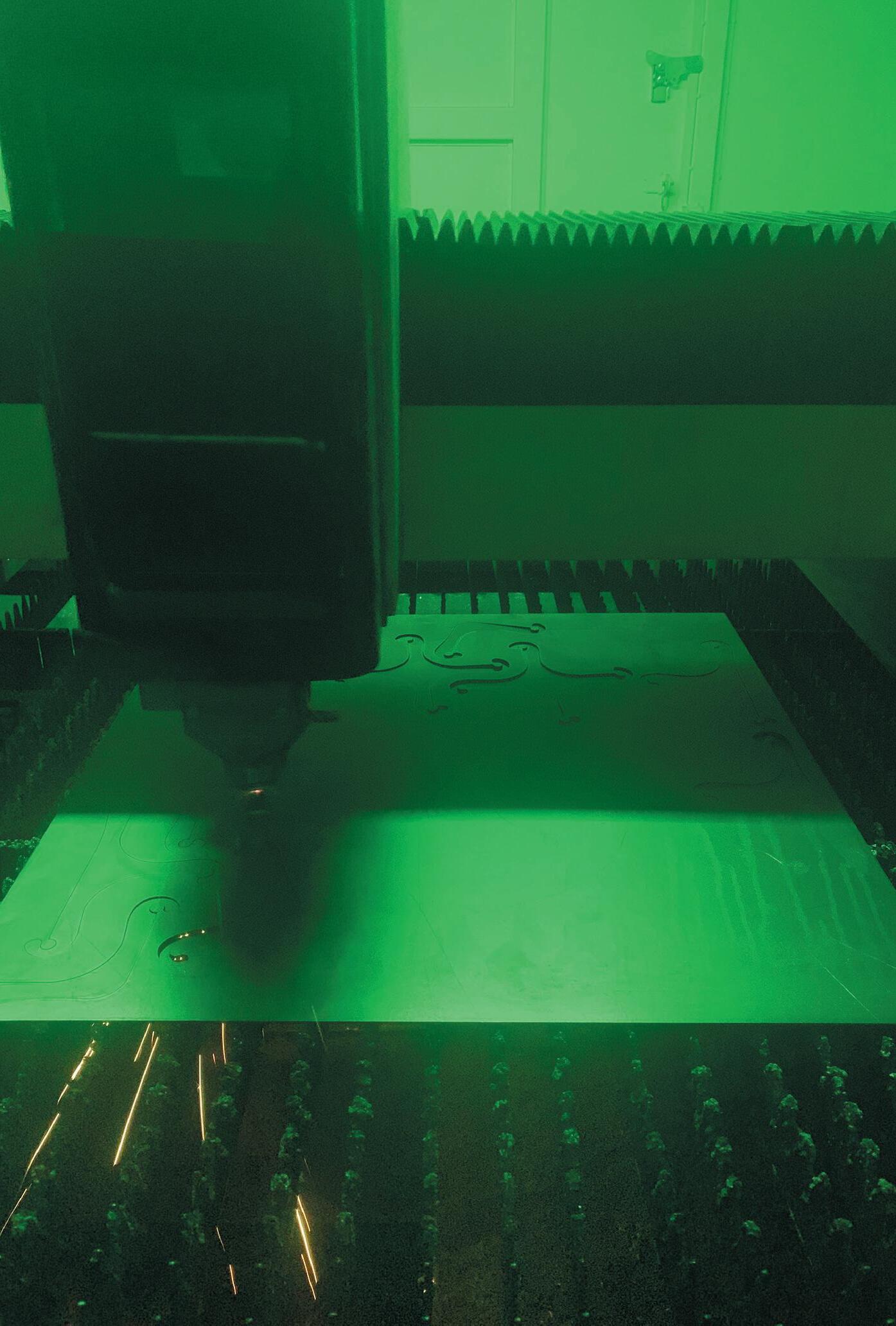

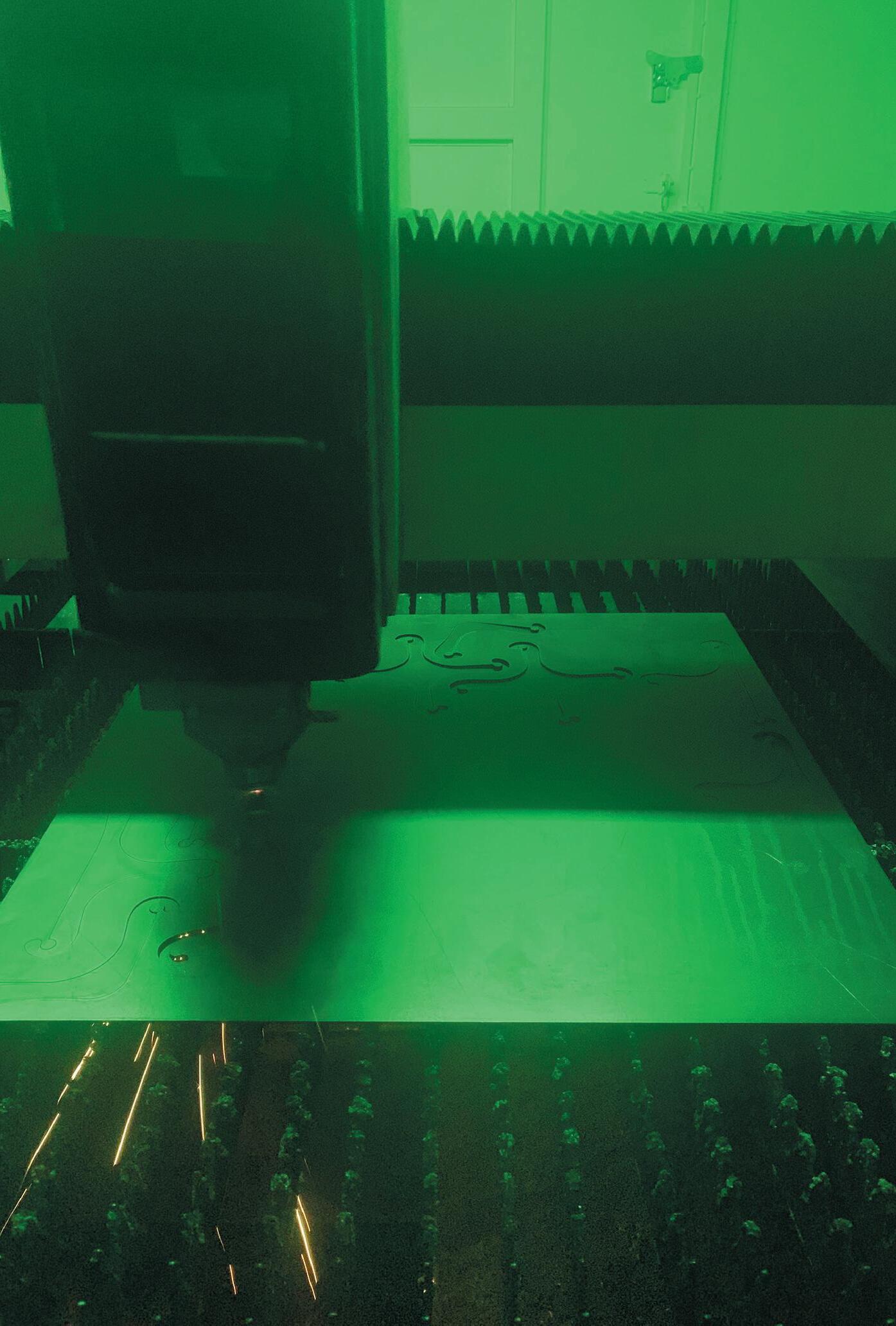

parang joints fabrication | LASER CUT

The float joints were made by laser cutting on a 1.5mm thick 50x50cm steel sheet. This created rough laser cut edges which were sanded down for a smoother finish. Despite being on the heavier end, steel was chosen over aluminium due to its strength properties over aluminium which would allow the slim joints to work and withstand the wave movements when in the field. This decision was made after consulting with experts in the metal workshop.

METAL LASER CUT - 50X50CM SHEET

SANDING ROUGH LASER CUT EDGES

SANDED PARANG JOINTS

4 FLOAT PARANG

2 FLOAT PARANG

3 FLOAT PARANG

METAL LASER CUT - 50X50CM SHEET

SANDING ROUGH LASER CUT EDGES

SANDED PARANG JOINTS

4 FLOAT PARANG

2 FLOAT PARANG

3 FLOAT PARANG

FABRICATION

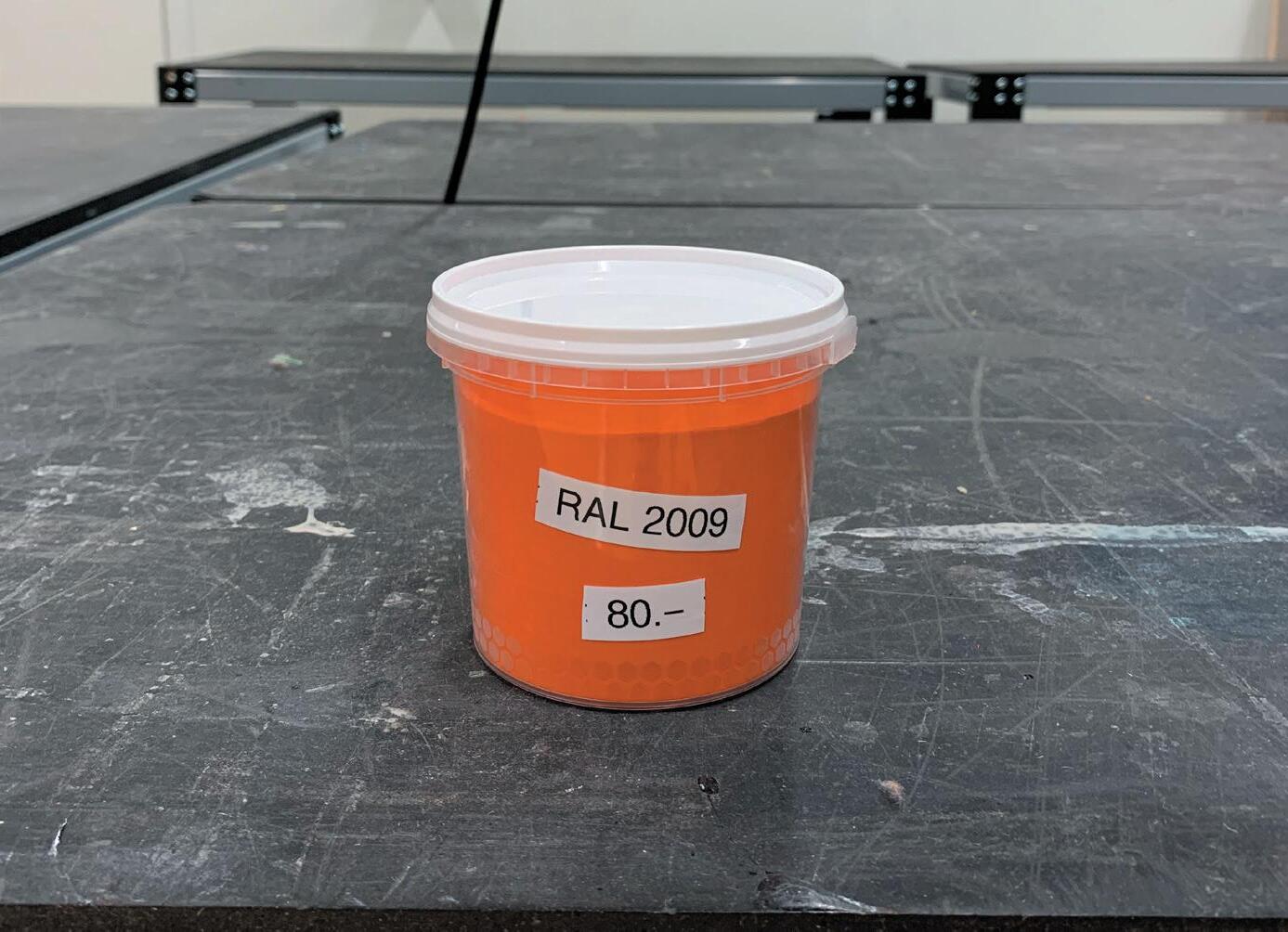

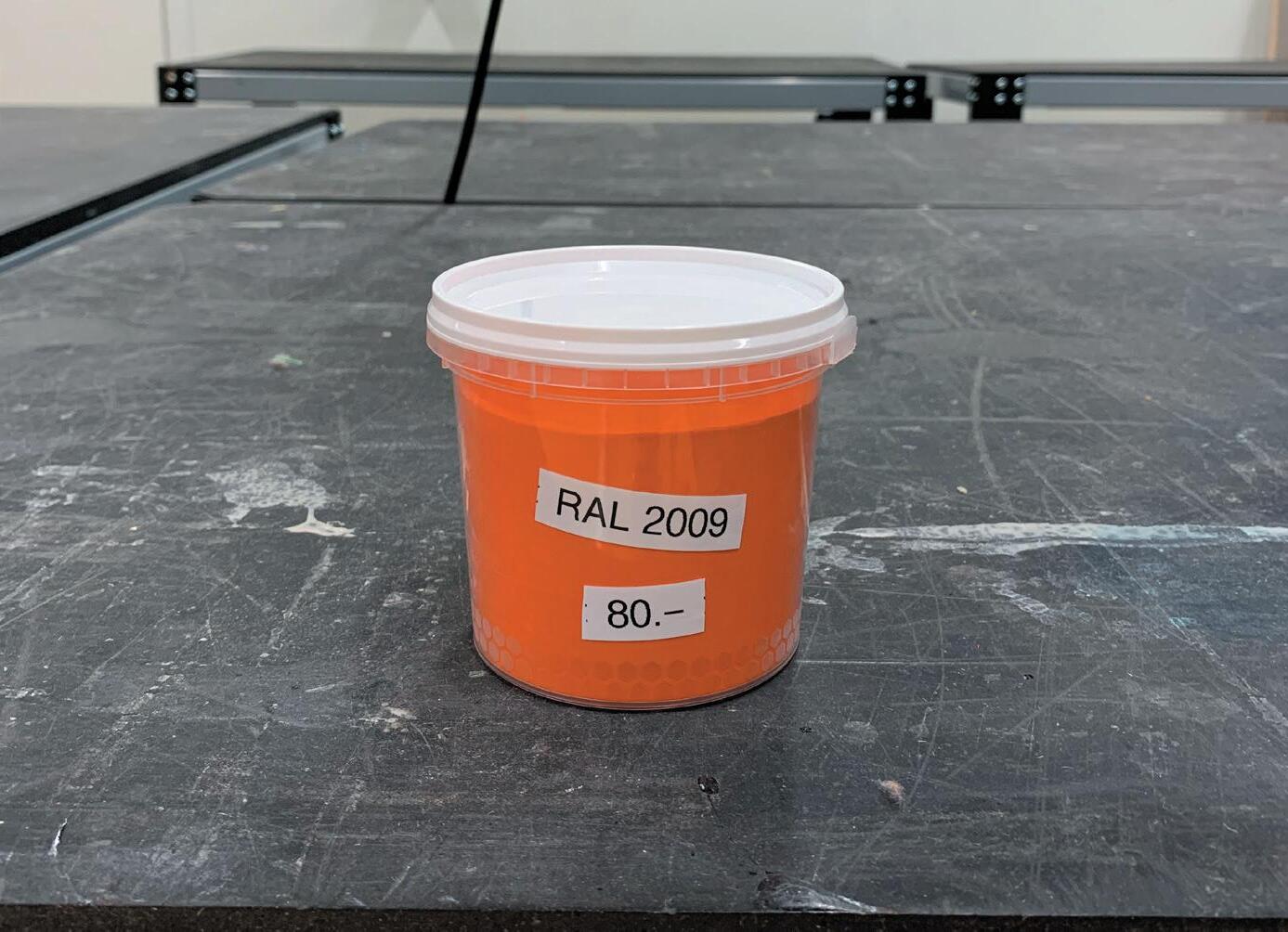

parang joints fabrication | POWDER COATING

Powder coating of the parang joints was the last step in the fabrication process. The parang joints were coated in orange powder to be able to stand out when in the field. Powder coating was also done to protect the steel from rusting when placed in sea water throughout the fieldwork. Two coats were given to all joints to ensure that they were well coated and protected.

POWDER COATING PARANG JOINTS

BAKING TO SET THE POWDER COAT

DRYING AND COOLING THE COATED JOINTS

ONE TUB USED TO COAT JOINTS TWICE

POWDER COATING PARANG JOINTS

BAKING TO SET THE POWDER COAT

DRYING AND COOLING THE COATED JOINTS

ONE TUB USED TO COAT JOINTS TWICE

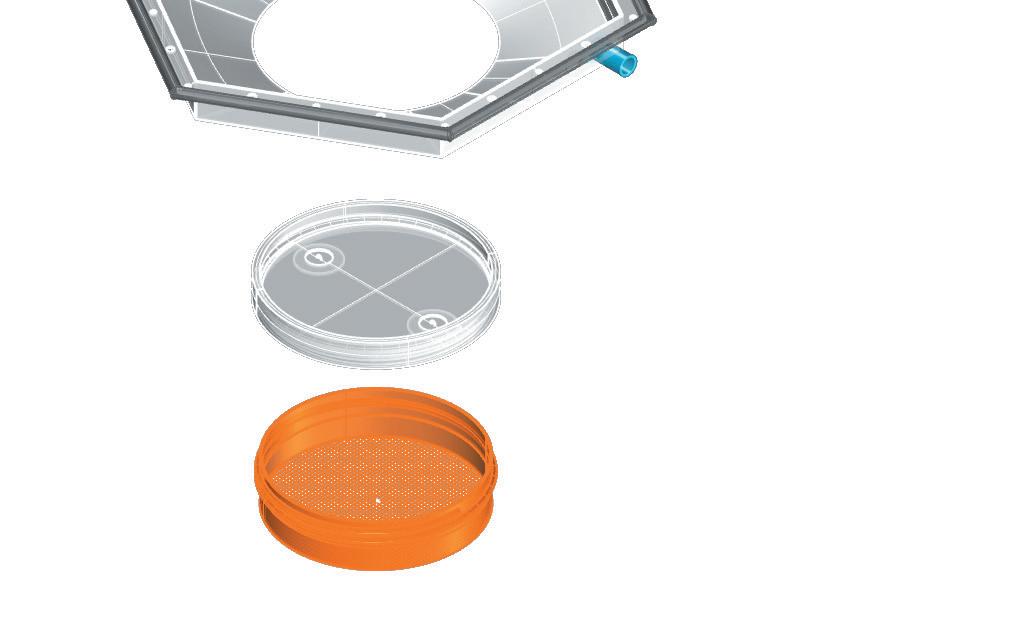

prototype | COMPONENTS TO BRING

PROTOTYPE 3 2 1 4 5 6 7 8 9 10 11 12 13

1. Tarpaulin fabric cut to size for water bags [x11]

2. Top plastic float [x32]

3. Bottom plastic float [x32]

4. White 5mm diameter flagline ropes [3x20m]

5. Adhesive rubber gasket 3mm thick [32m]

6. 2 float parang joint [x12]

7. 3 float parang joint [x8]

8. 4 float parang joint [x10]

9. Miscellaneous screws

10. Rubber gasket set

11. Salinity refractometer

12. White reflective tape

13. Silicone hose 16x21mm [2m]

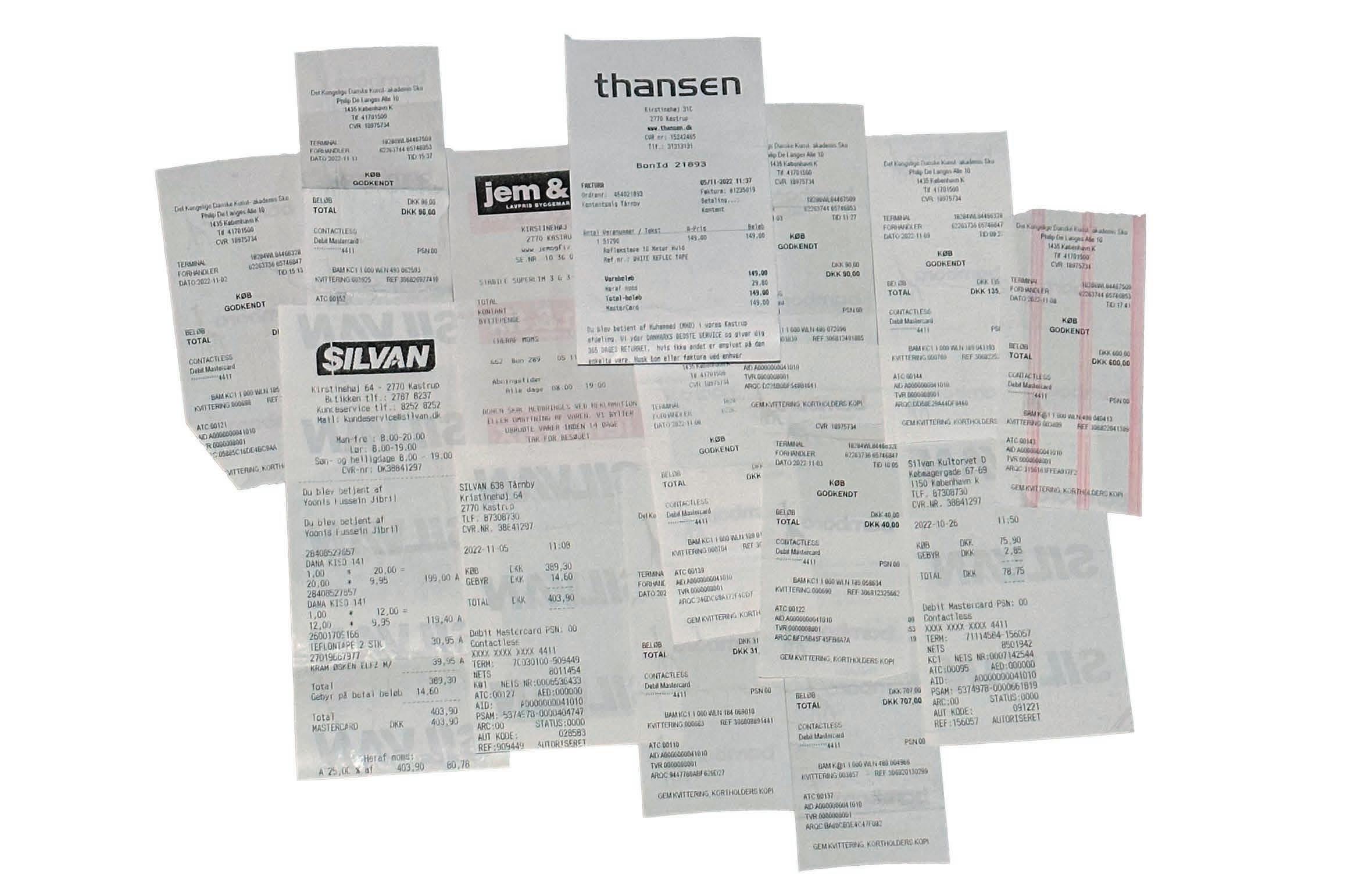

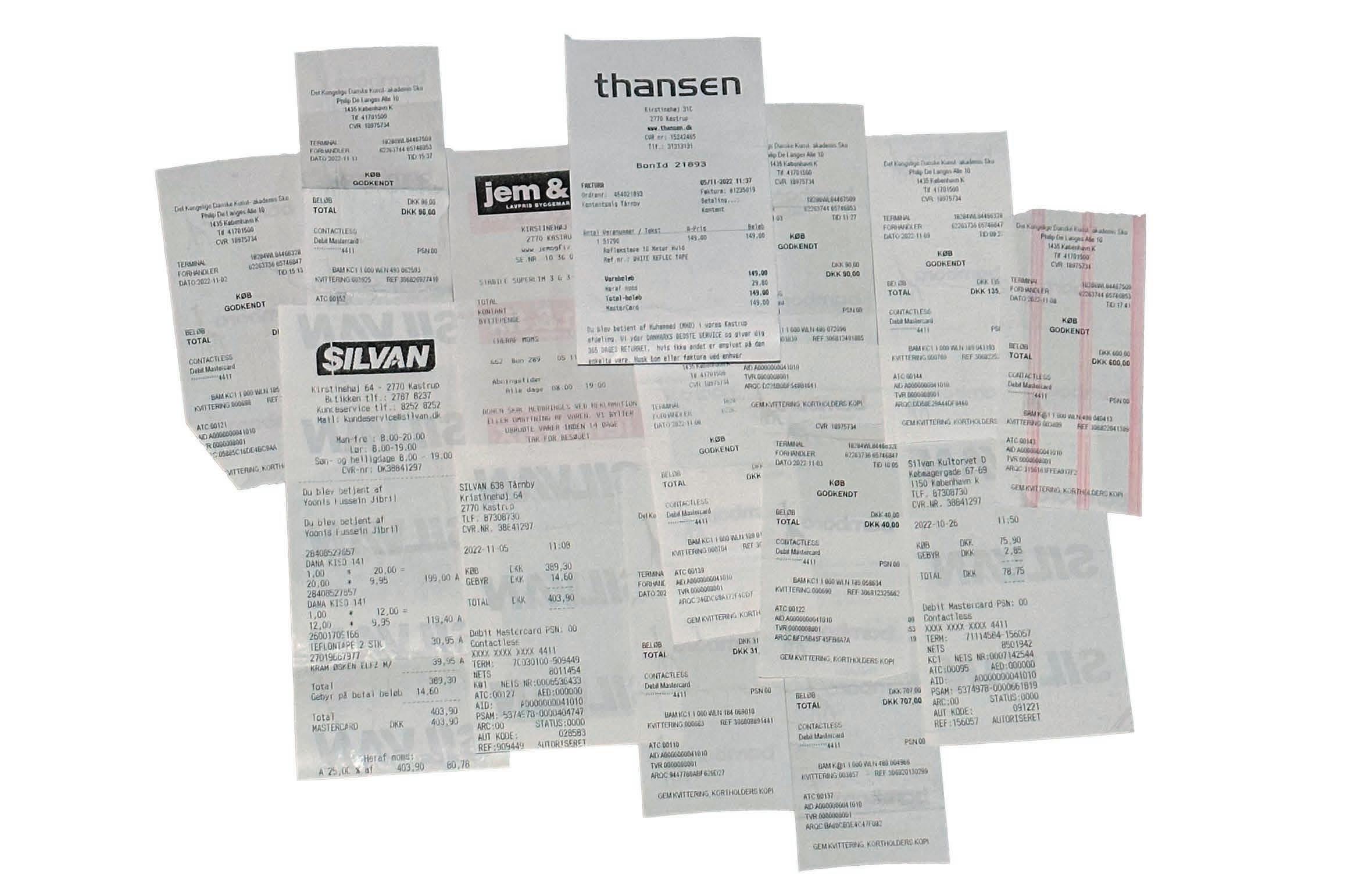

PROTOTYPE TOTAL COST = 4,105kr prototype | COST BREAKDOWN PLASTIC FLOATS 0.5mm VIVAK transparent sheet *32 1,920 kr 1.0mm VIVAK transparent sheet *1 90 kr STEEL PARANG JOINTS 1.5mm thick 50x50cm steel sheet 162 kr WATER BAGS 6x10m 200gsm transparent tarpaulin 783 kr ADHESIVE RUBBER GASKET 3mm thick *32m 318 kr RUBBER GASKET SET FOR BOLTS 800pcs box 126 kr FLAGLINE ROPE - WHITE 5mm diameter 20m long *3 120 kr POWDER COAT - ORANGE RAL 2009 80 kr 3D PRINT FILAMENT - WHITE PLA 0.3kr/gram 506 kr M4 BOLTS AND NUTS 4kr each *24 96 kr

the hydroponic mangrove system | FIELDWORK

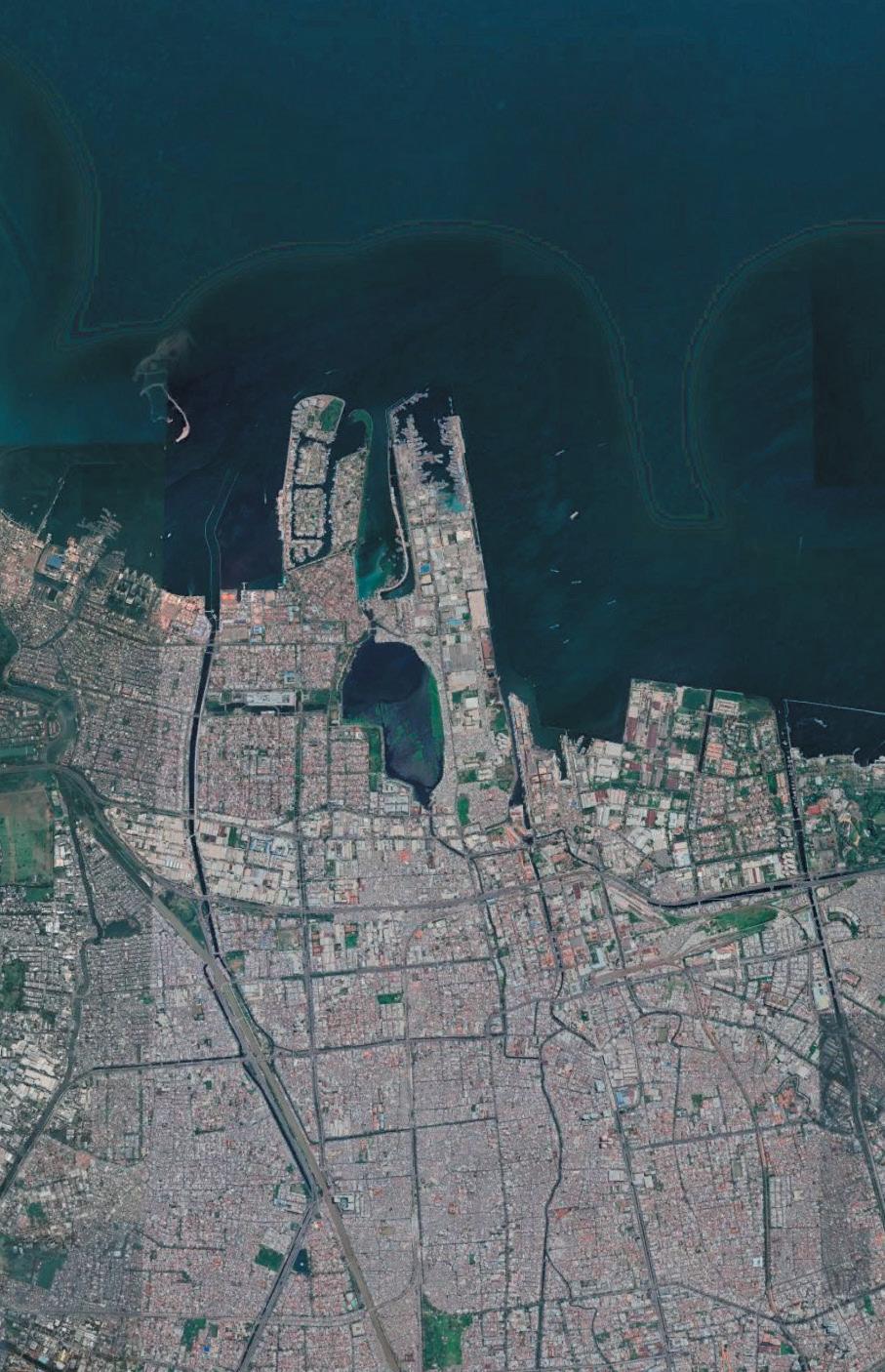

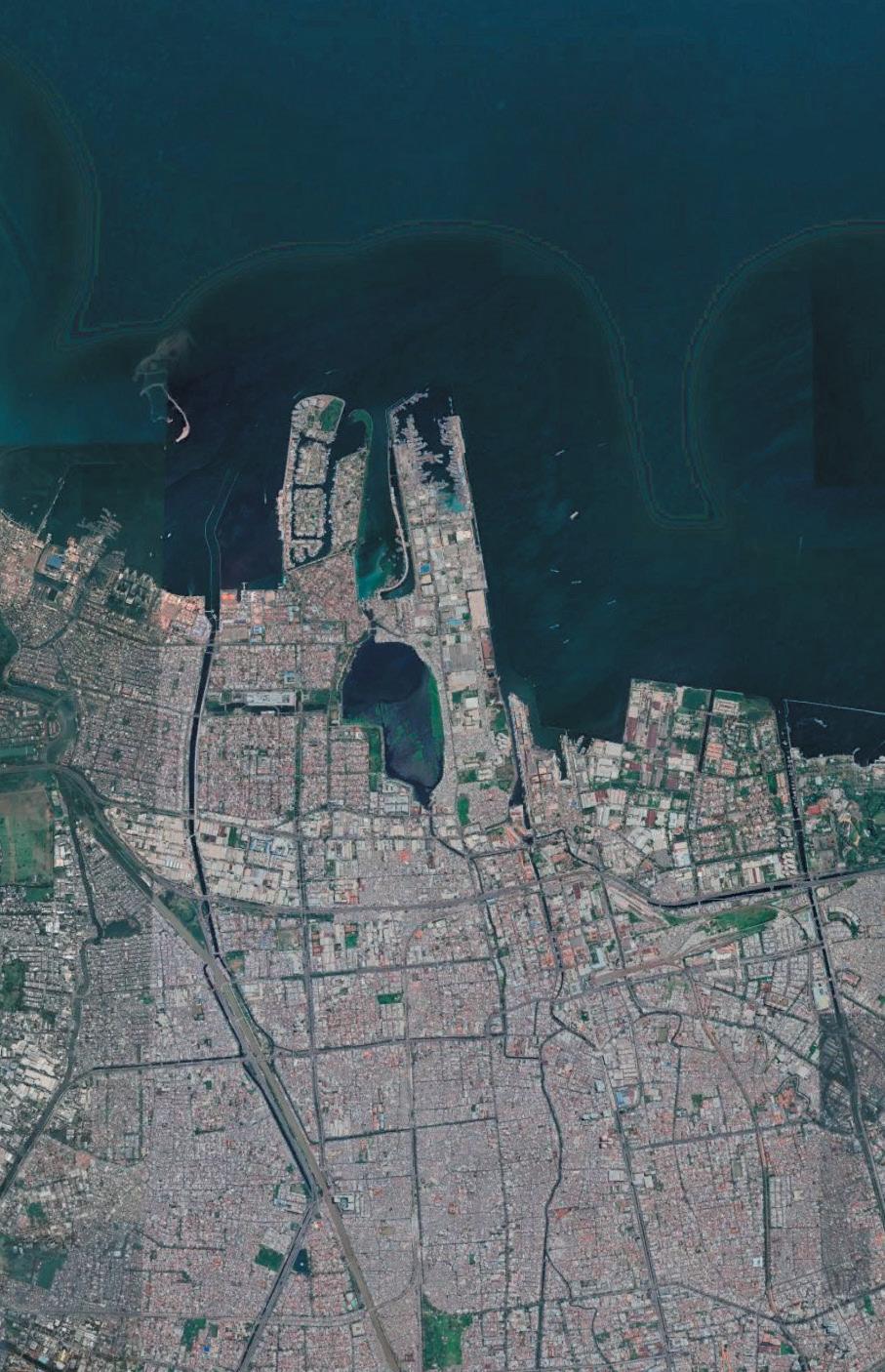

fieldwork | PROTOTYPE SITE

The prototype site is located on the inner side of the sea wall in Muara Baru port where the area is constantly flooded with sea water. This pool of water coincidentally has young mangroves planted in it which makes it an even more perfect site. Despite wanting to have the prototype sit on the outer side of the sea wall, the risks of strong waves and divers sabotaging the prototype were mentioned, and thus this site was suggested by one of the district administrator staff of Muara Baru.

Site coordinates: (-6.1006427, 106.8047560)

PROTOTYPE SITE

MUARA BARU PORT (-6.1006427, 106.8047560)

NORTH JAKARTA

WADUK PLUIT

PANTAI MUTIARA

MUARA BARU PORT

COLLECTION OF LOCAL MATERIALS

1st month

2nd month

3rd month

MANGROVE NURSERY - PANTAI INDAH KAPUK, NORTH JAKARTA

COLLECTING MANGROVES FOR THE PROTOTYPE MANGROVE SEEDLINGS

3-month-old rizophora mucronata

SITE EXPLORATION

POTENTIAL SITE 3

POTENTIAL SITE 2 MUARA BARU (-6.1109280, 106.8063110)

FISHING NET HUB (-6.1047206, 106.8053232)

POTENTIAL SITE 1 TAMAN WISATA ALAM ANGKE KAPUK

POTENTIAL SITE 3

POTENTIAL SITE 2 MUARA BARU (-6.1109280, 106.8063110)

FISHING NET HUB (-6.1047206, 106.8053232)

POTENTIAL SITE 1 TAMAN WISATA ALAM ANGKE KAPUK

PROTOTYPE DEPLOYMENT

ATTACHING WATER BAGS TO FLOATS USING RAFIA ROPE

JOINING FLOATS IN SECTIONS INDOORS BEFORE GOING TO SITE

TRANSPORTING PROTOTYPE TO SITE

PUTTING THE WHOLE PROTOTYPE TOGETHER ON SITE

ATTACHING WATER BAGS TO FLOATS USING RAFIA ROPE

JOINING FLOATS IN SECTIONS INDOORS BEFORE GOING TO SITE

TRANSPORTING PROTOTYPE TO SITE

PUTTING THE WHOLE PROTOTYPE TOGETHER ON SITE

TYING THE COCONUT FIBRE POTS TO THE WATER BAGS

PROTOTYPE GOES INTO THE WATER

PLANTING THE MANGROVES

FILLING THE WATER BAGS WITH SEA WATER

TYING THE COCONUT FIBRE POTS TO THE WATER BAGS

PROTOTYPE GOES INTO THE WATER

PLANTING THE MANGROVES

FILLING THE WATER BAGS WITH SEA WATER

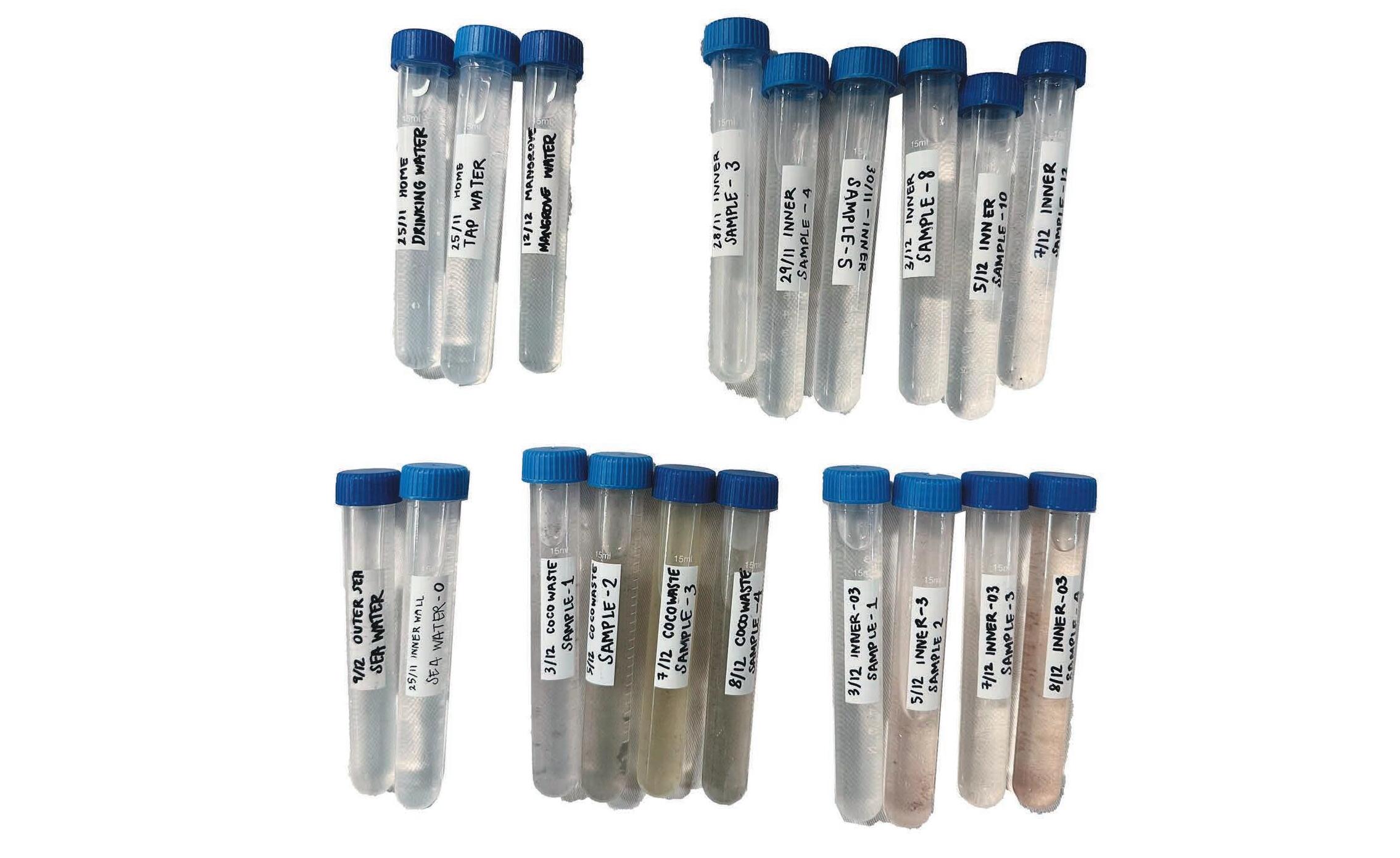

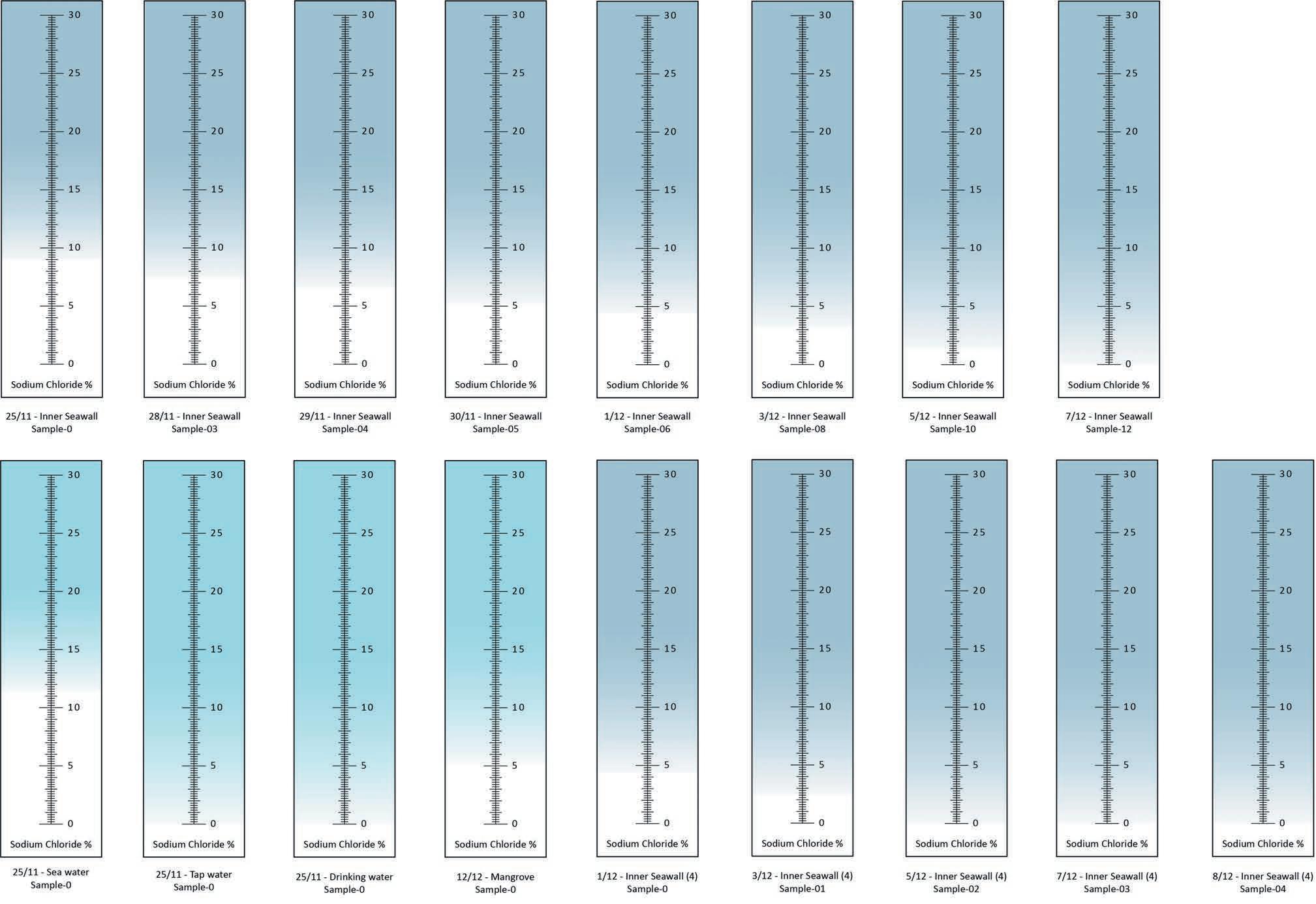

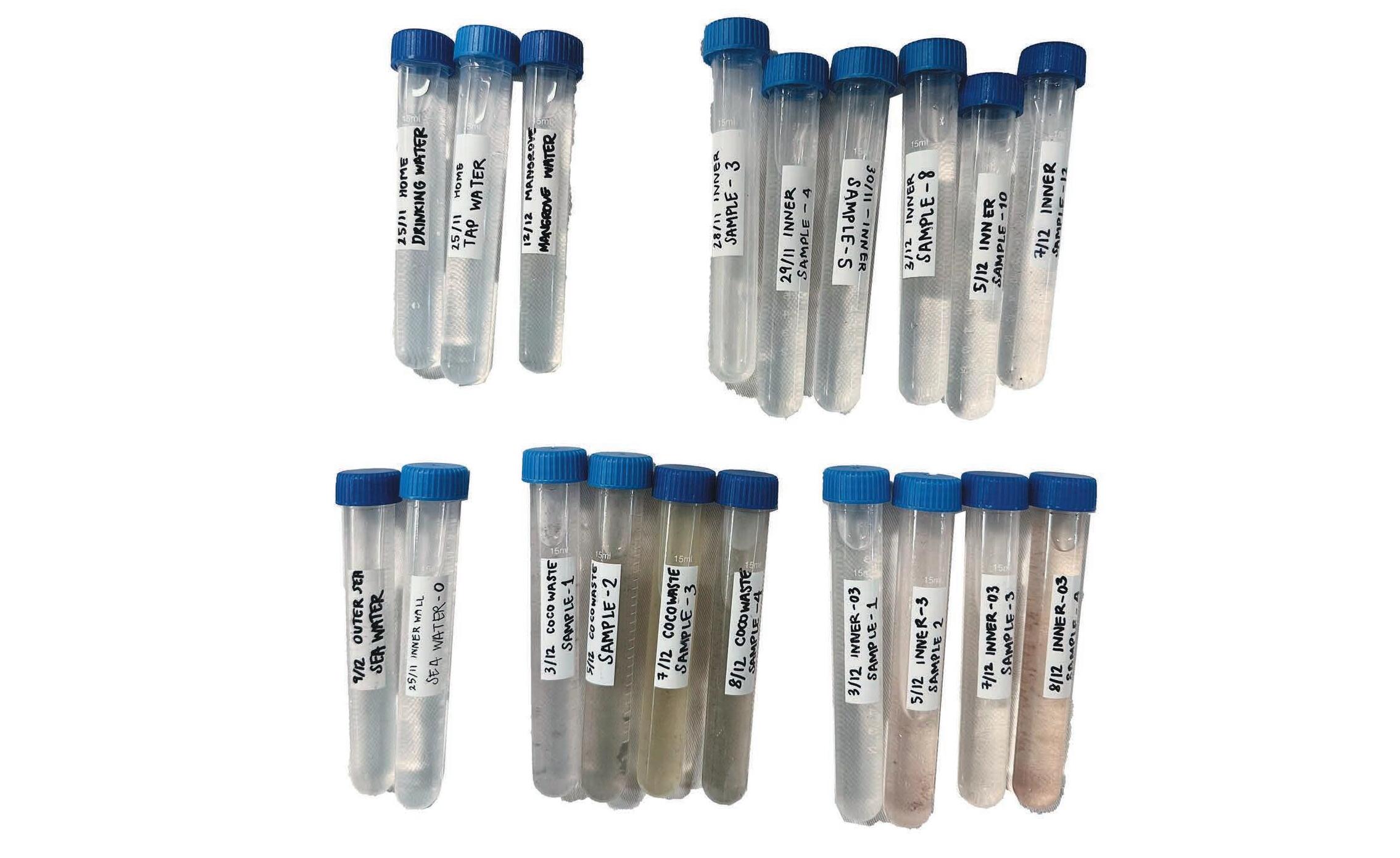

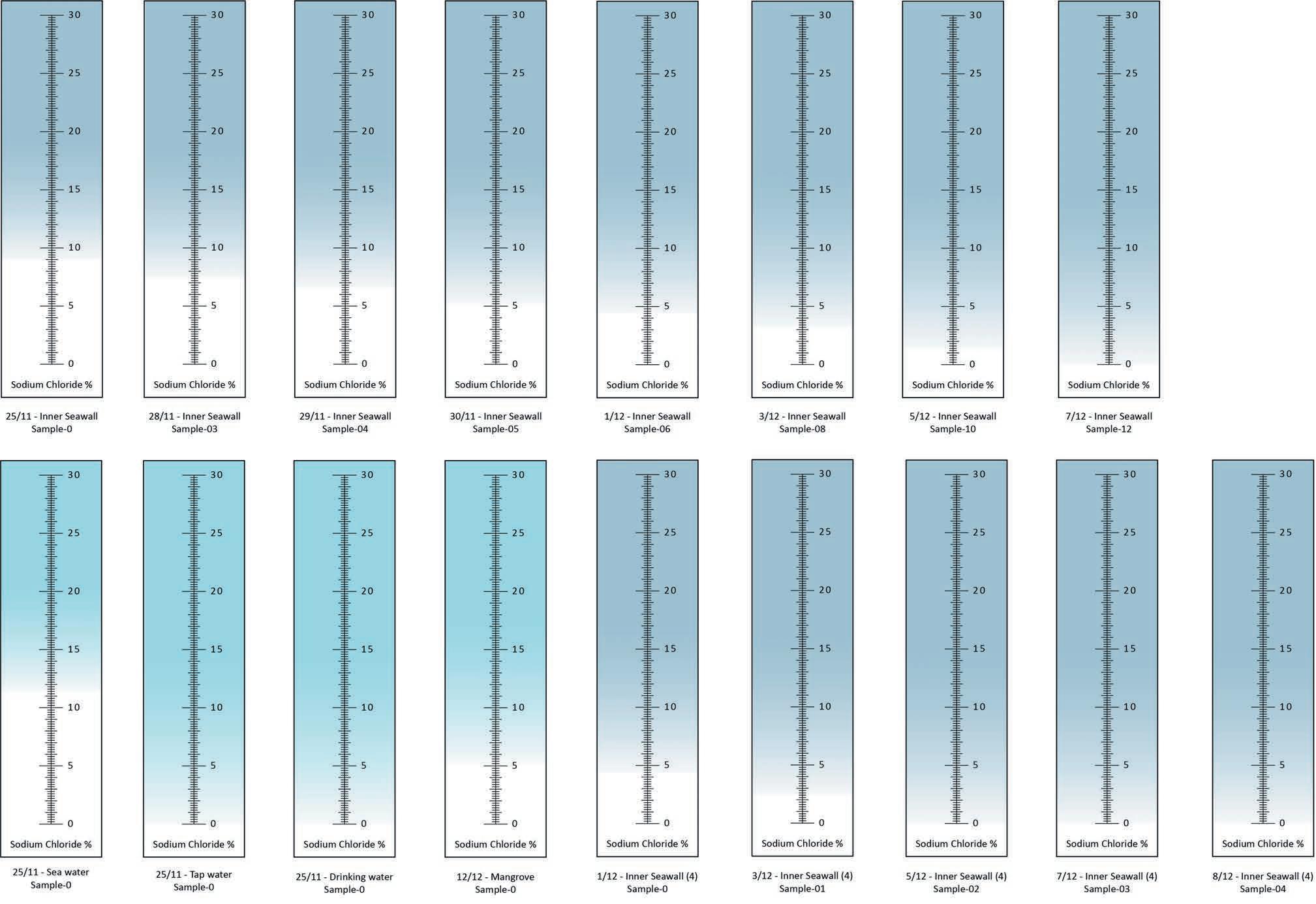

FIELDWORK fieldwork | WATER SAMPLES

FOUR MANGROVES

SINGLE MANGROVE

COCONUT WASTE

OUTER SEA WALL INNER SEA WALL

DRINKING WATER TAP WATER MANGROVE FOREST WATER

the hydroponic mangrove system | SCIENTIFIC TESTING/RESULTS

SCIENTIFIC TESTING

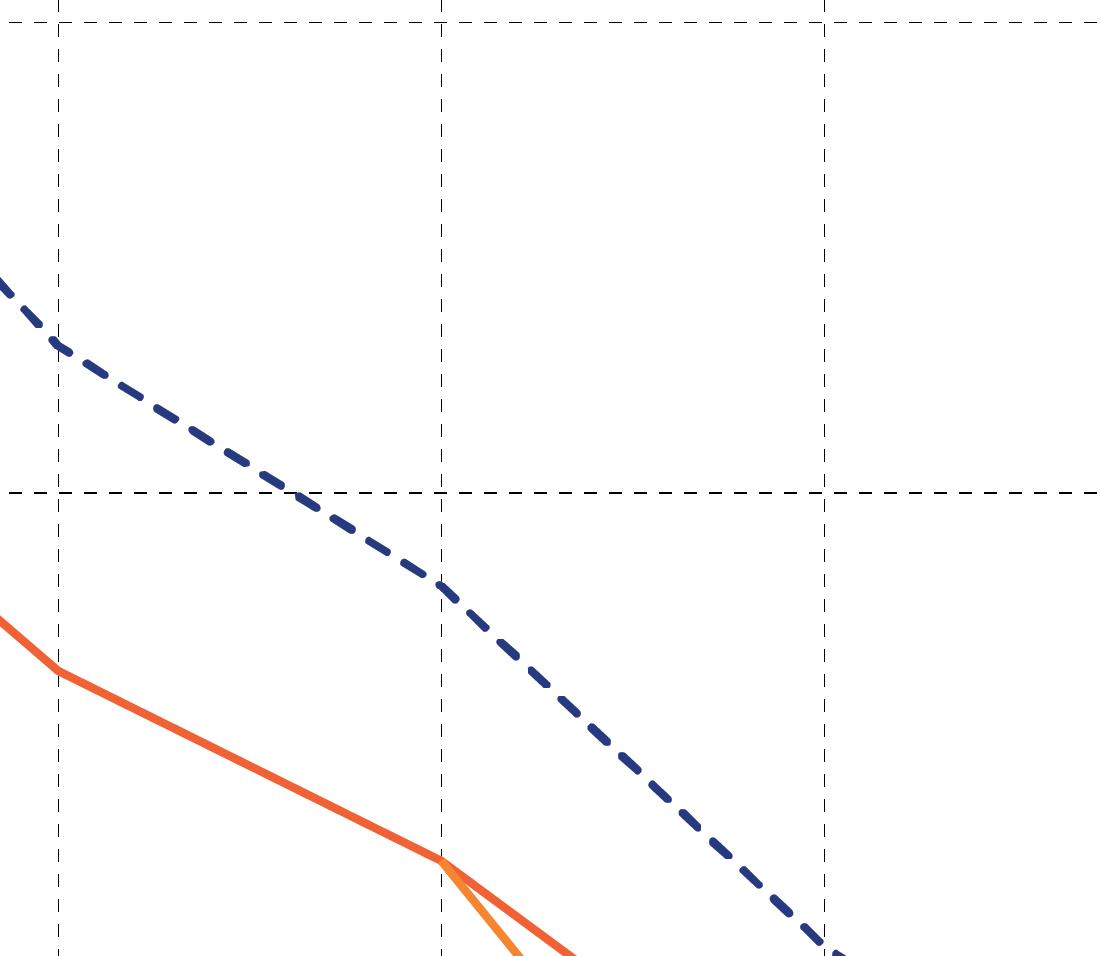

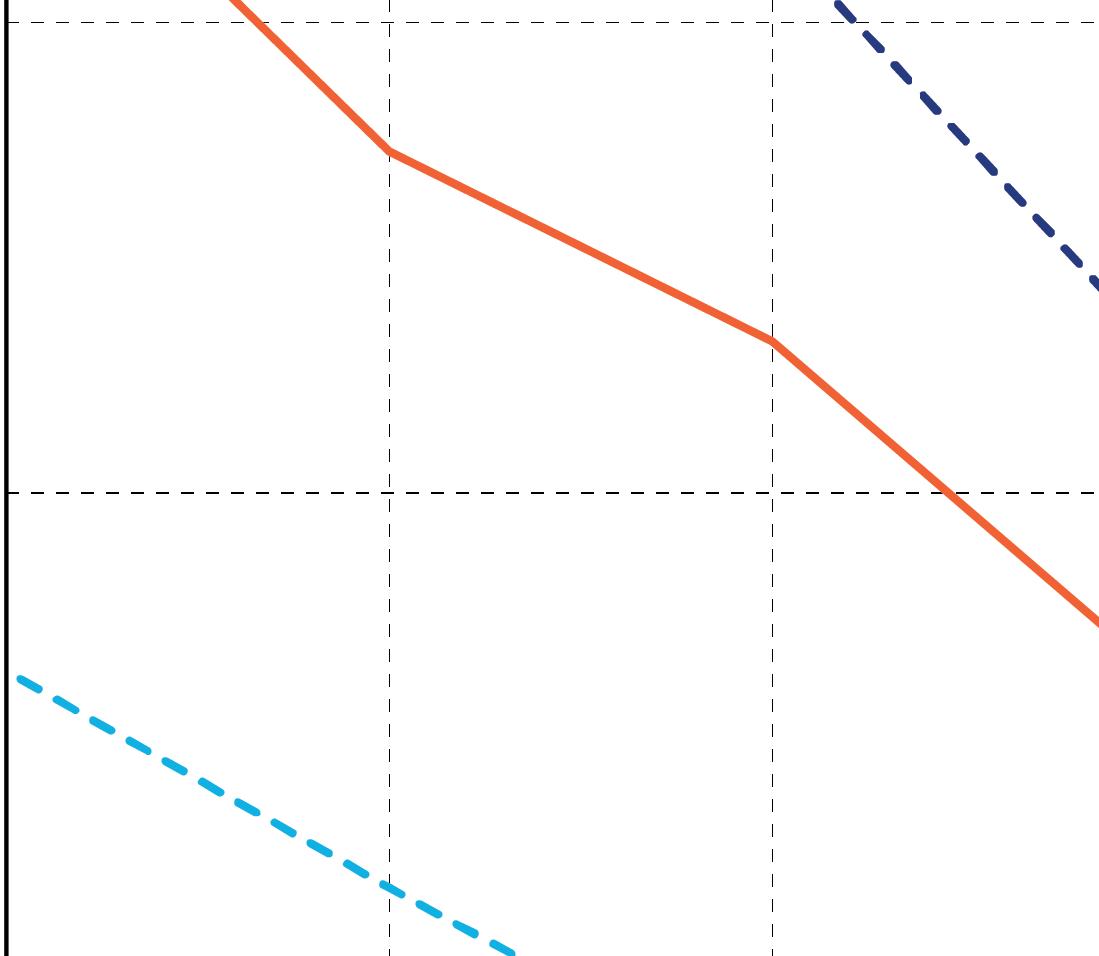

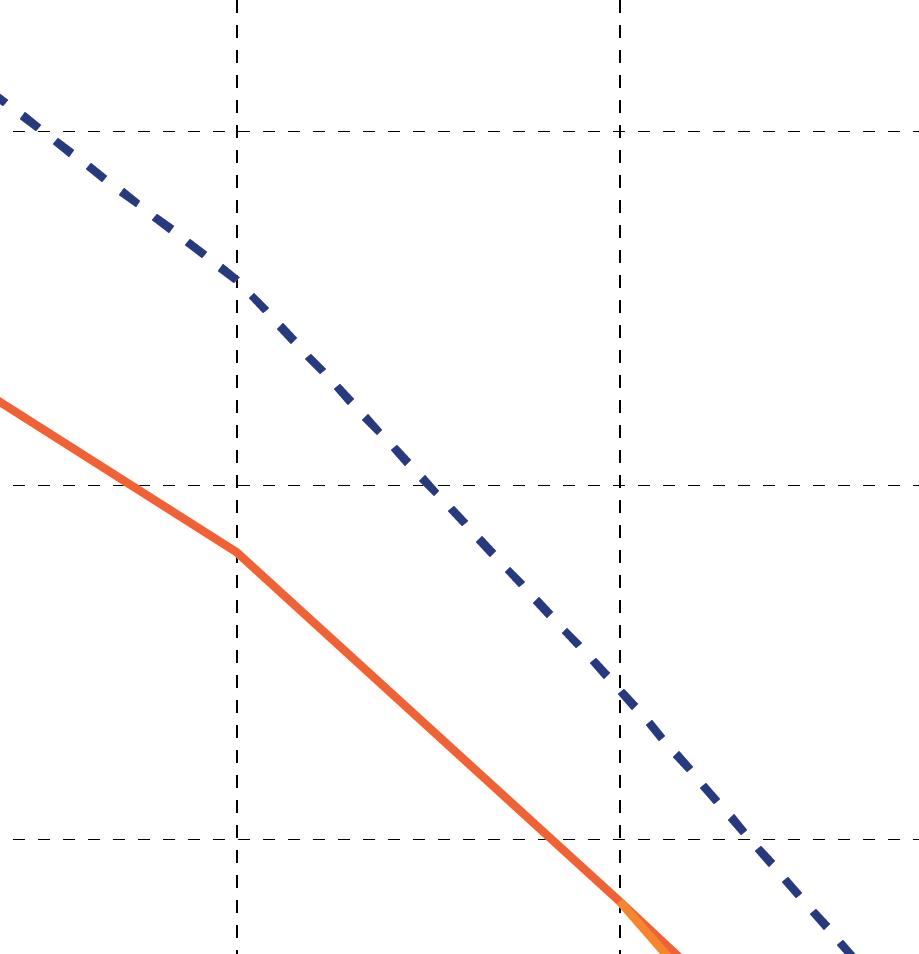

nutrient test | + FRESH COCONUT WASTE efficiency test | FOUR MANGROVES efficiency test | SINGLE MANGROVE

SCIENTIFIC RESULTS

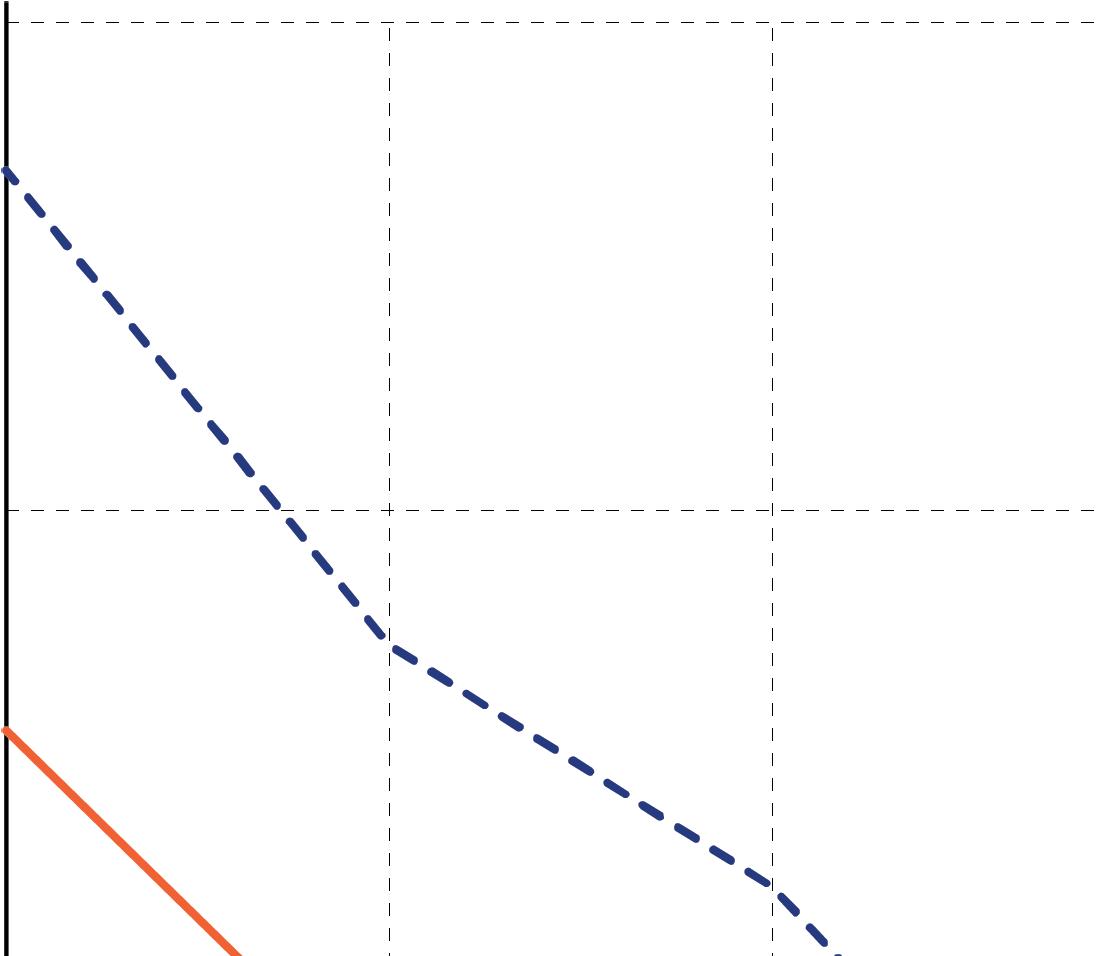

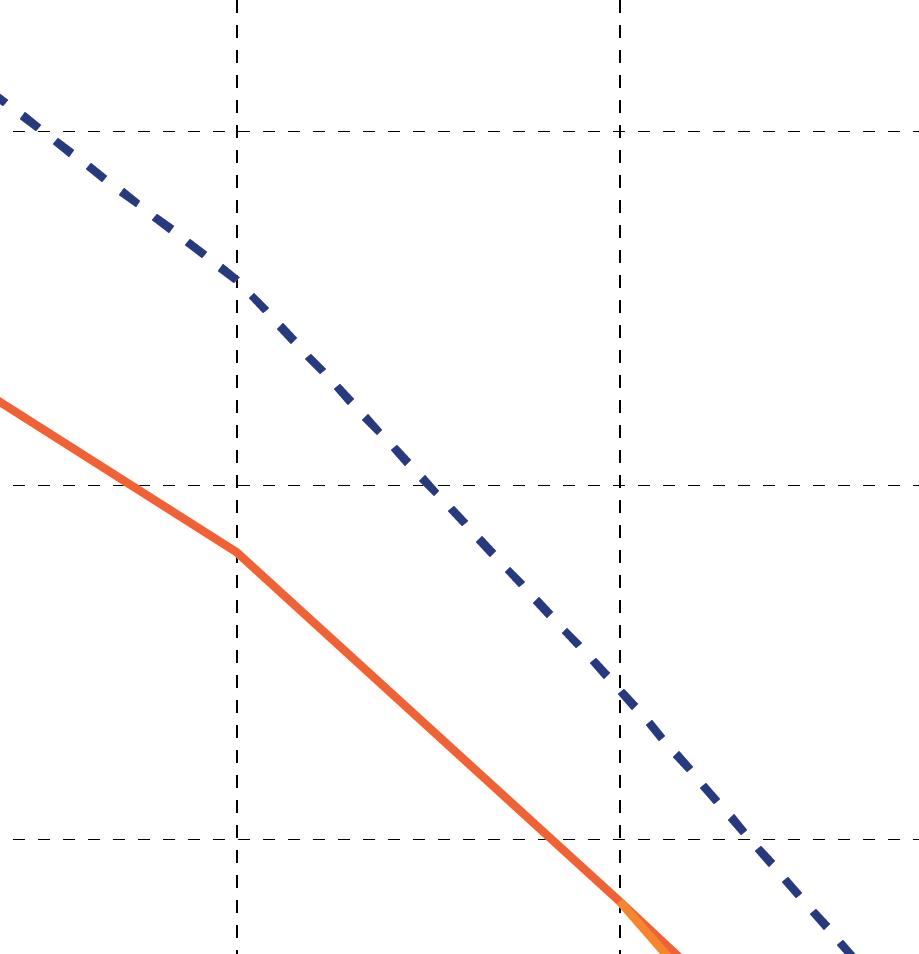

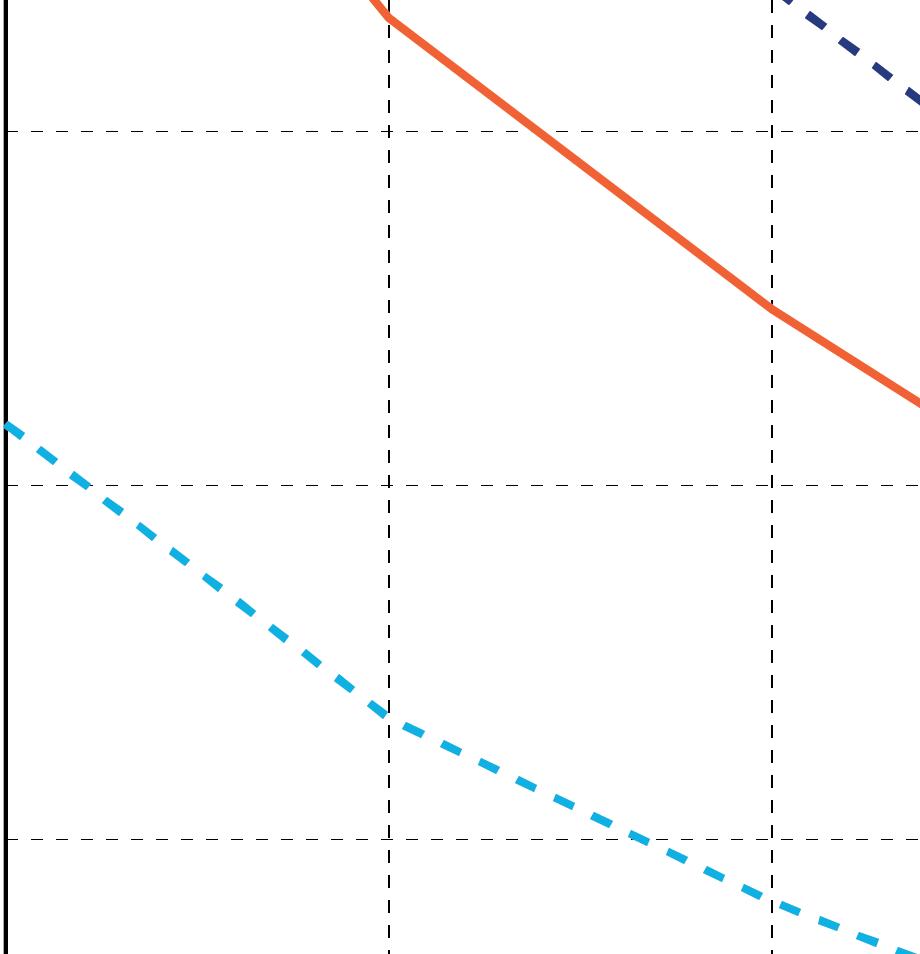

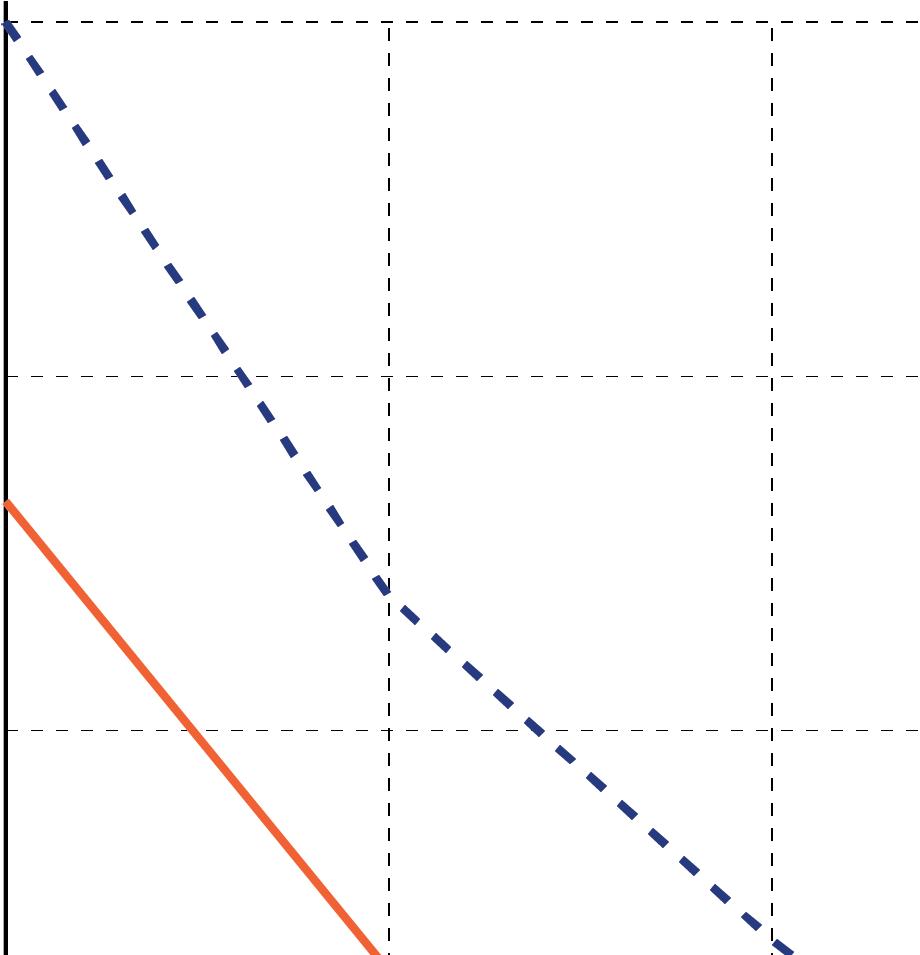

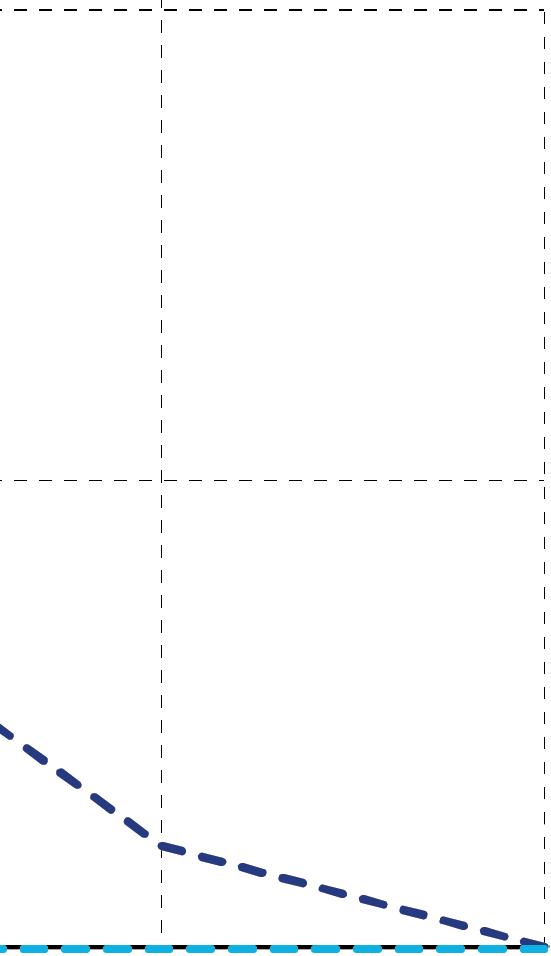

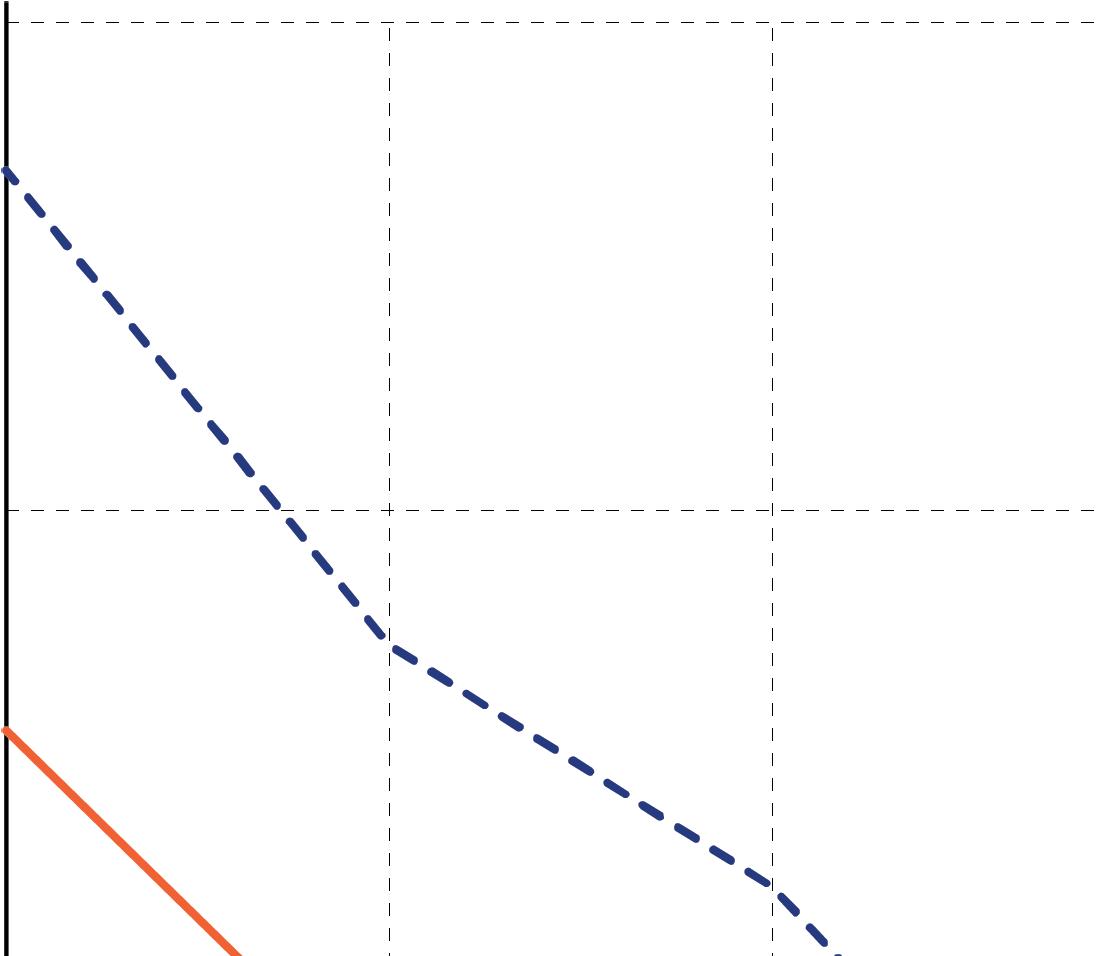

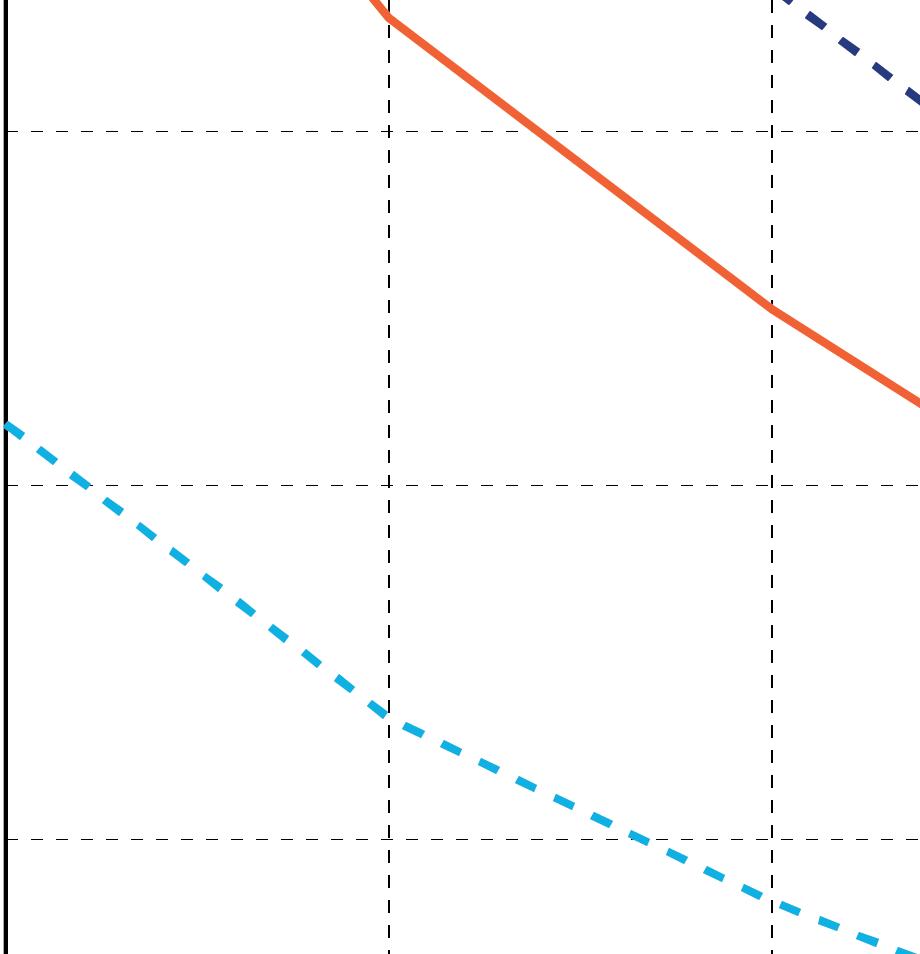

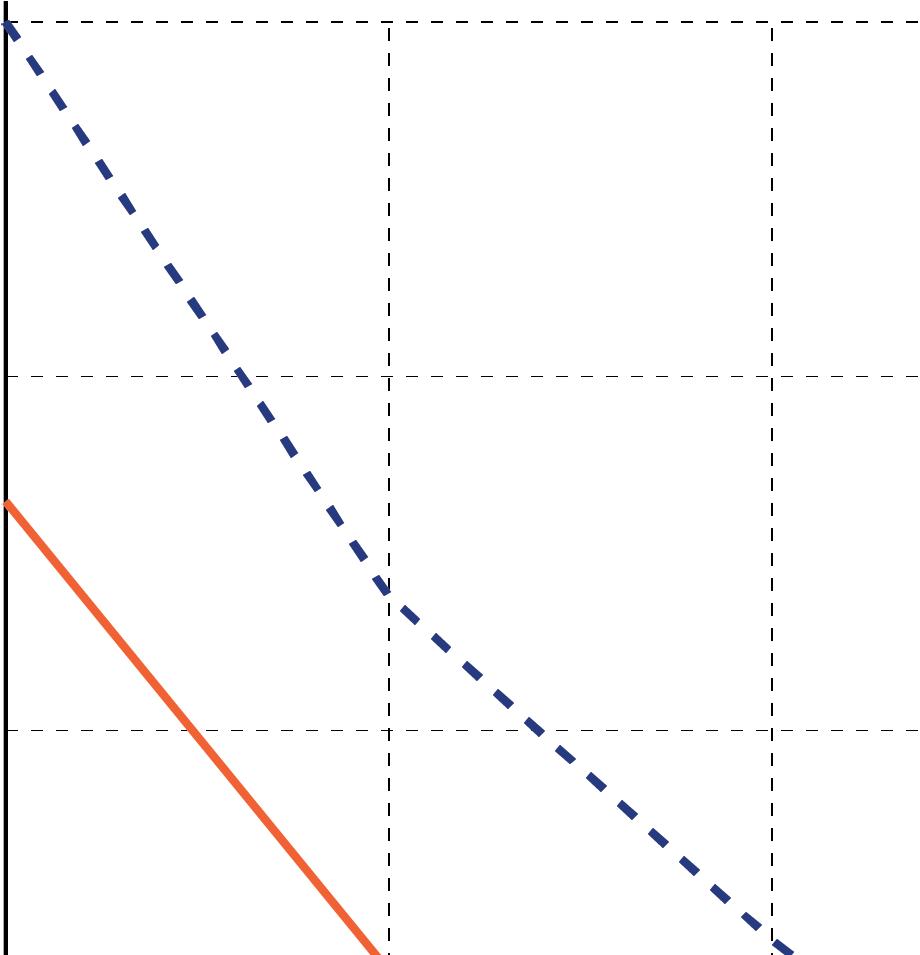

scientific results | SALINITY READINGS

PROJECTED

scientific results | SALINITY

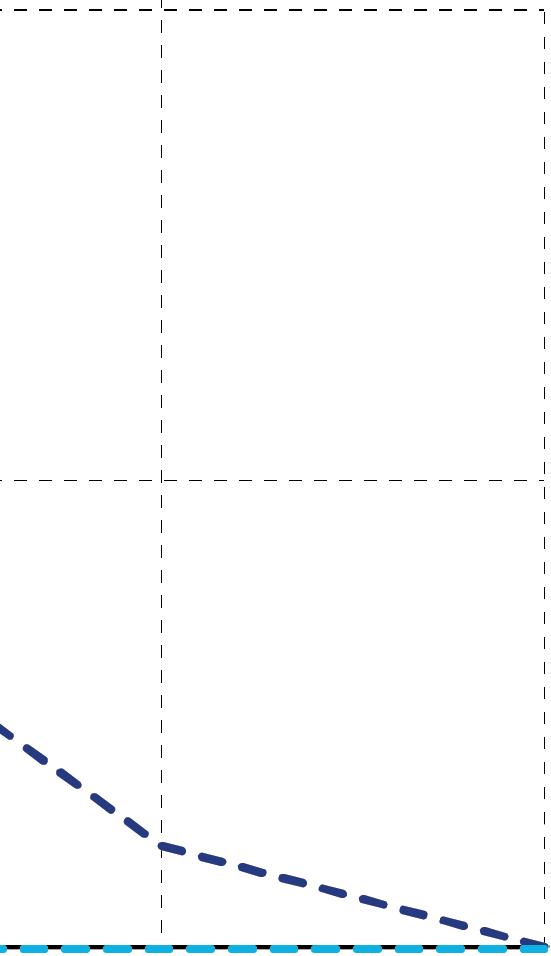

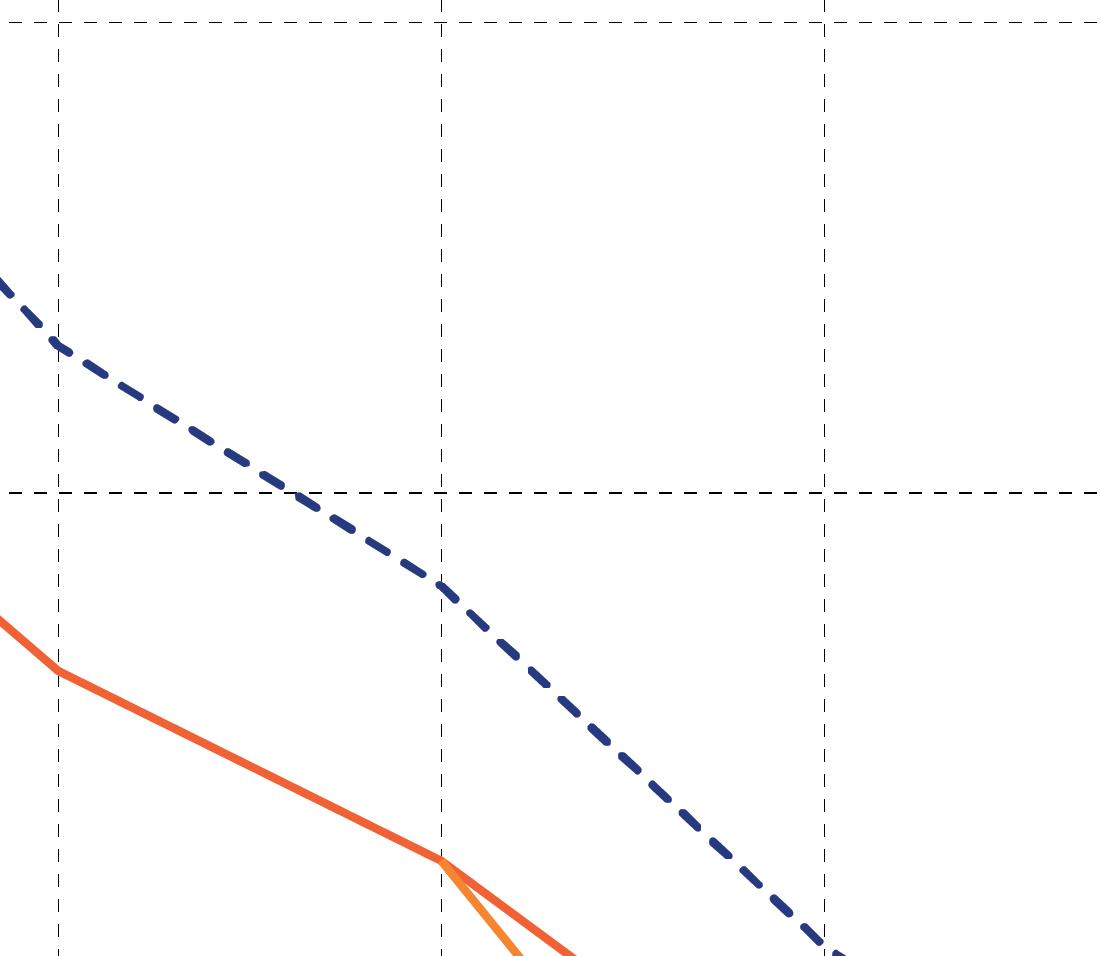

SCIENTIFIC RESULTS 12 8 10 6 4 2 0 NaCl (%) DAY 1 DAY 4 DAY 5 DAY 6 DAY 7 DAY 9 DAY 11 DAY 13 DAY 14 DAY 16 DAY 18

OUTER SEA WALL

MANGROVE

MANGROVES

MANGROVE FOREST

OUTER SEA WALL SINGLE MANGROVE FOUR MANGROVES PROJECTED MANGROVE FOREST NaCl (%) 0% DAY 9 DAY 11 DAY 13 DAY 18

SINGLE

FOUR

PROJECTED

PROJECTED

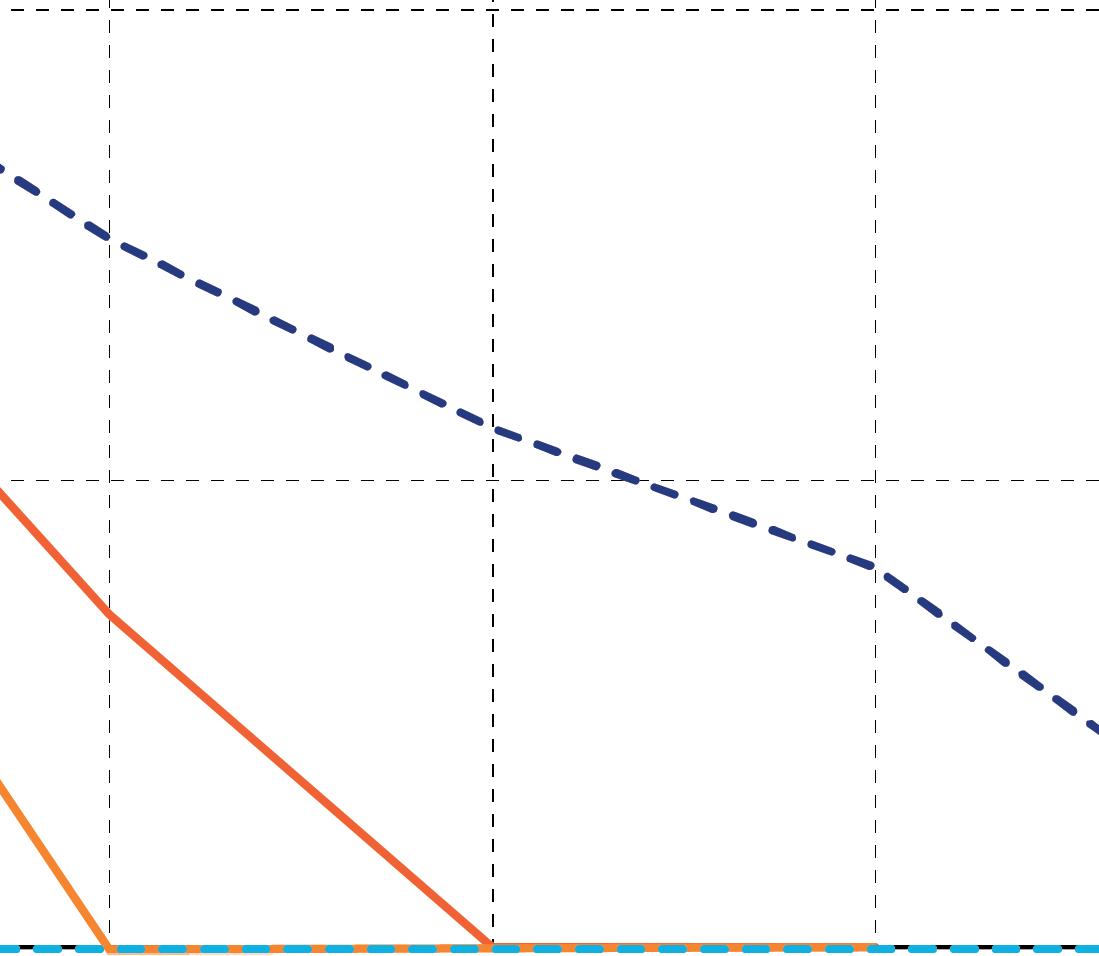

SCIENTIFIC RESULTS

PROJECTED OUTER SEA WALL

SINGLE MANGROVE

FOUR MANGROVES

PROJECTED MANGROVE FOREST

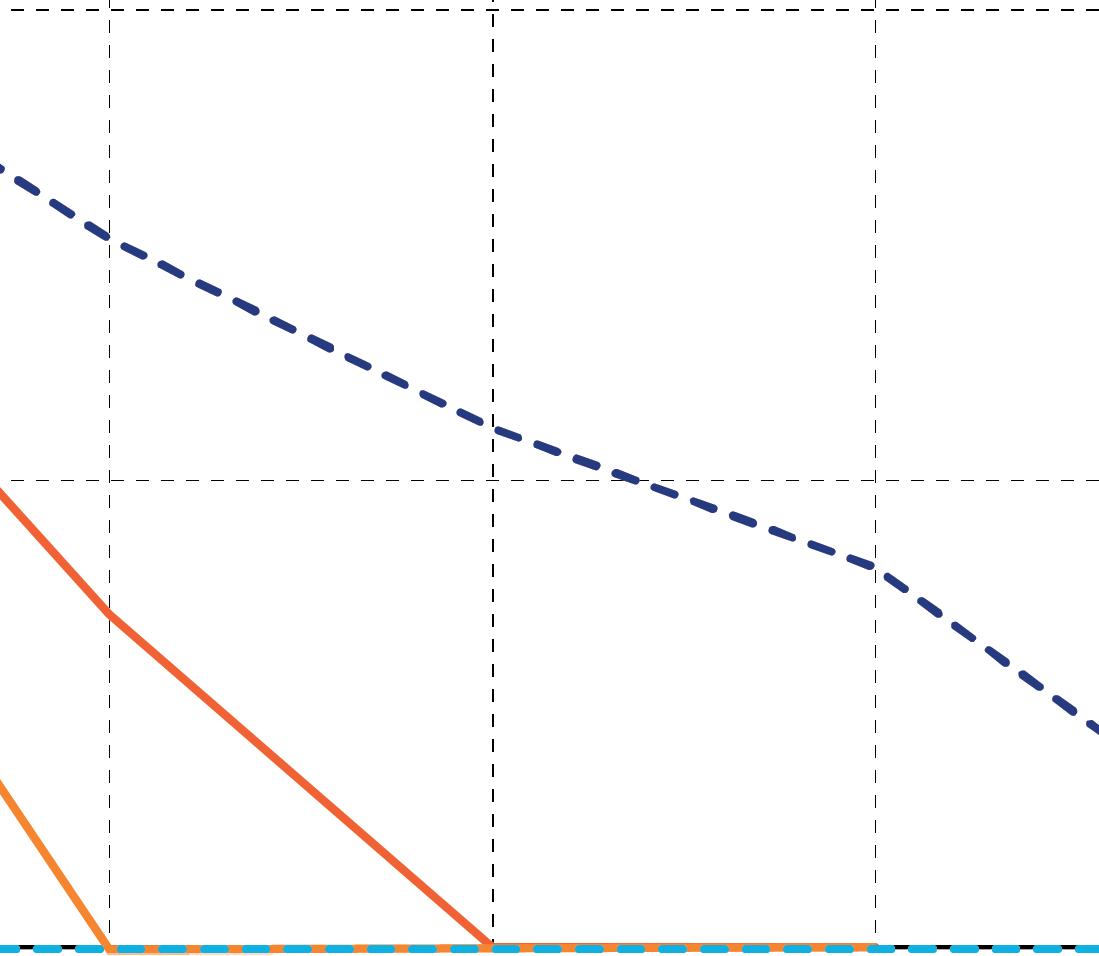

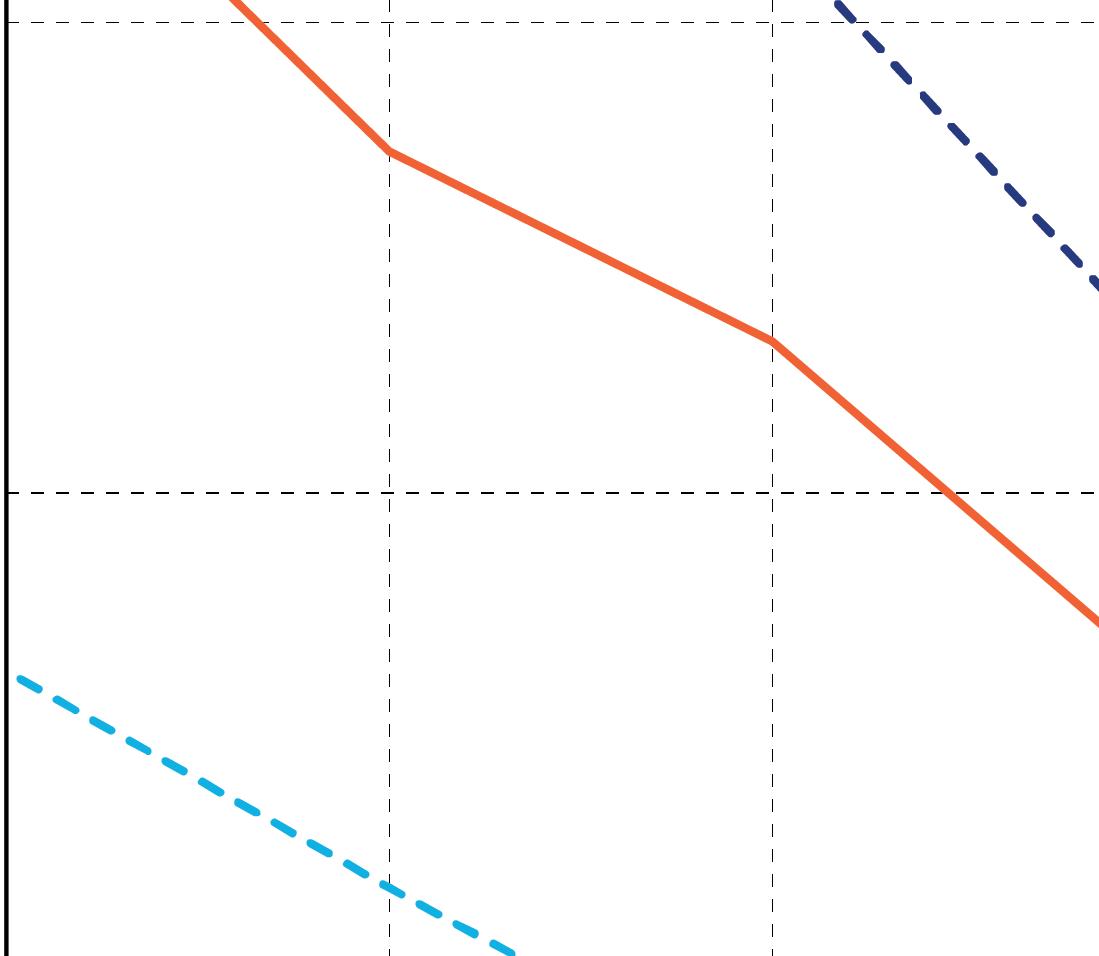

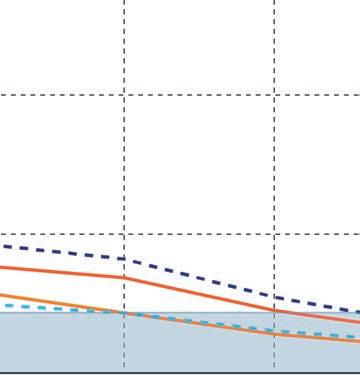

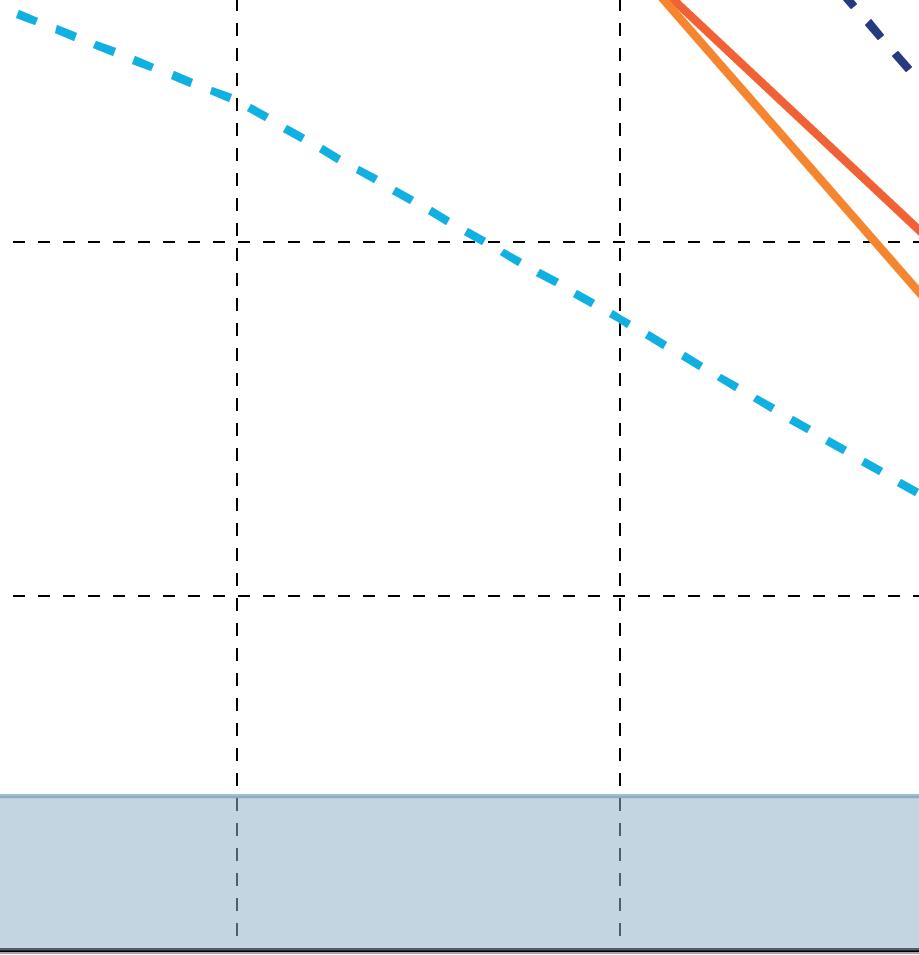

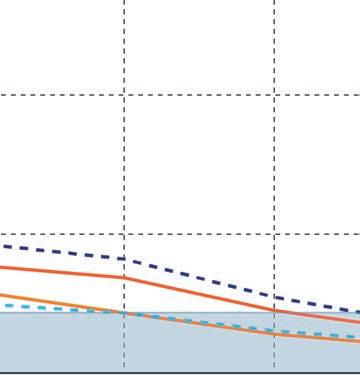

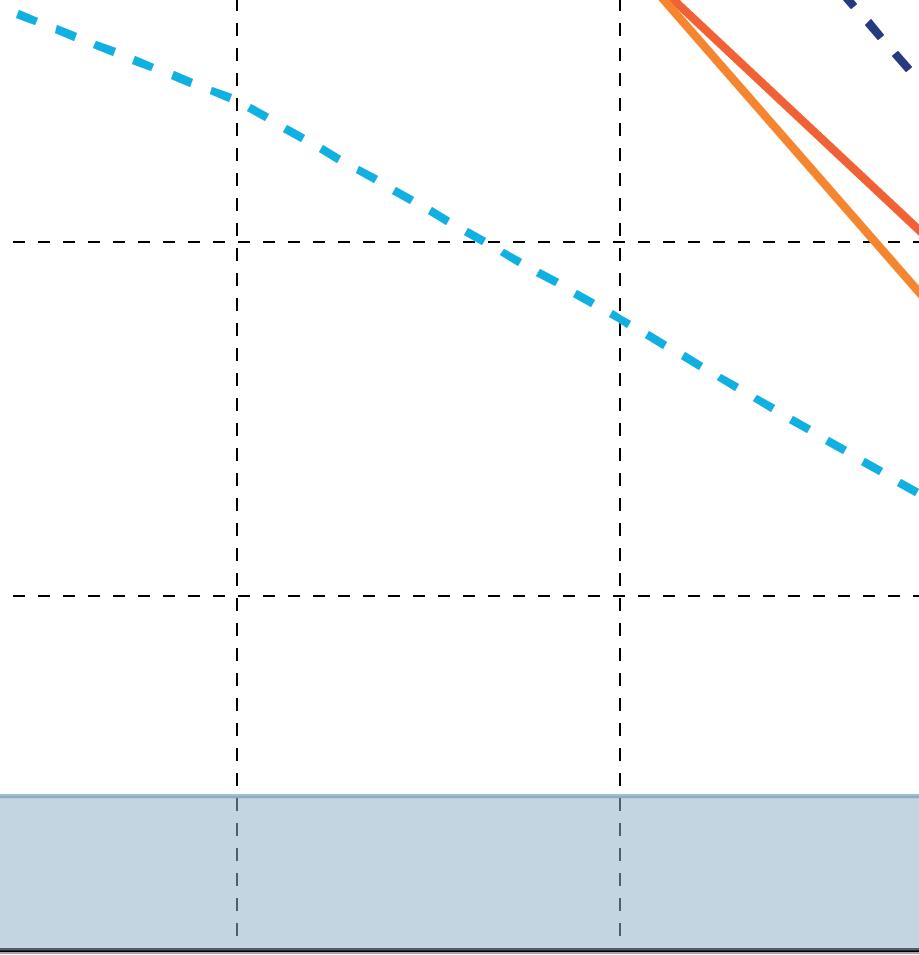

scientific results | TOTAL DISSOLVED SOLIDS

TDS value (ppm)

< 500 ppm

PROJECTED OUTER SEA WALL

SINGLE MANGROVE

FOUR MANGROVES

PROJECTED MANGROVE FOREST

500 ppm - acceptable tap water

TDS (ppm)

10000 6250 7500 8750 5000 3750 2500 1250 0 DAY 1 DAY 4 DAY 5 DAY 6 DAY 7 DAY 9 DAY 11 DAY 13 DAY 14 DAY 16 DAY 18 DAY 20

DAY 18 DAY 16 DAY 14 DAY 14

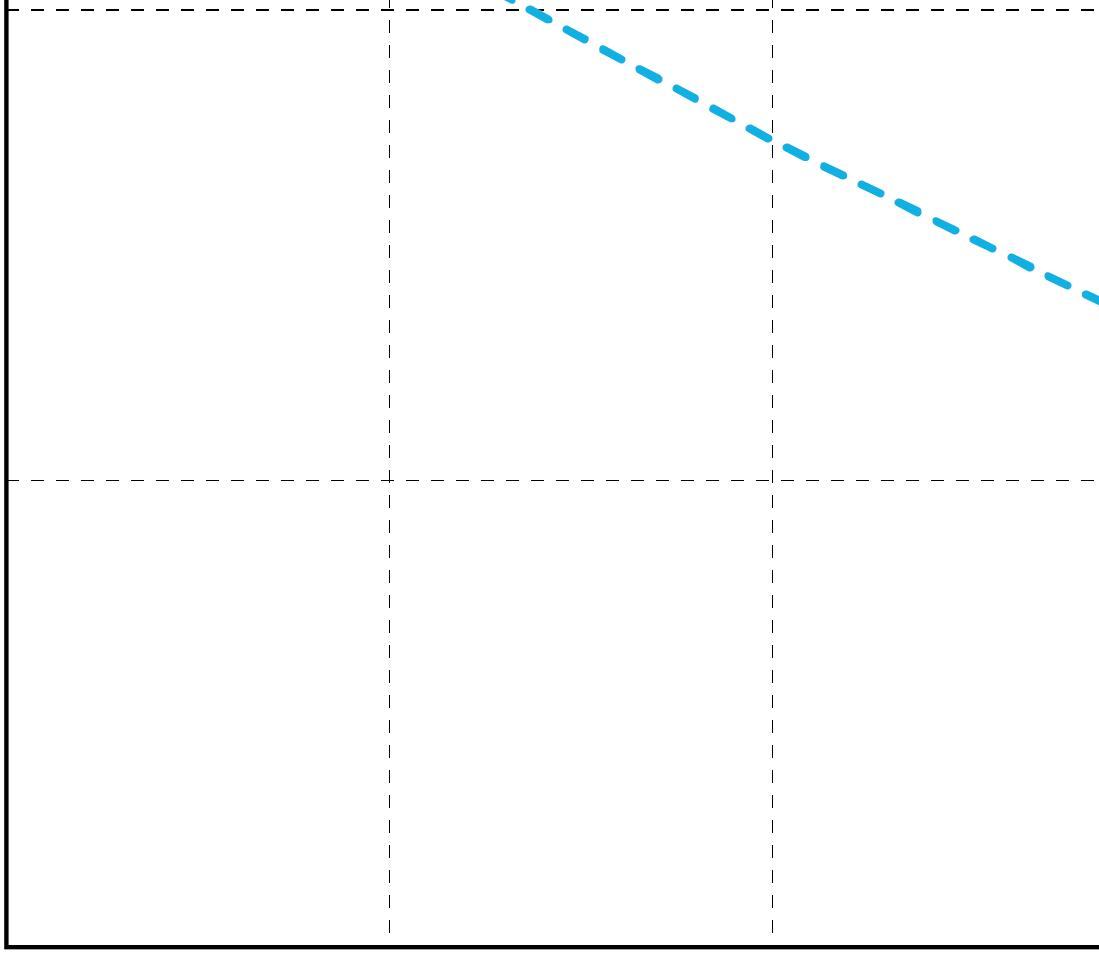

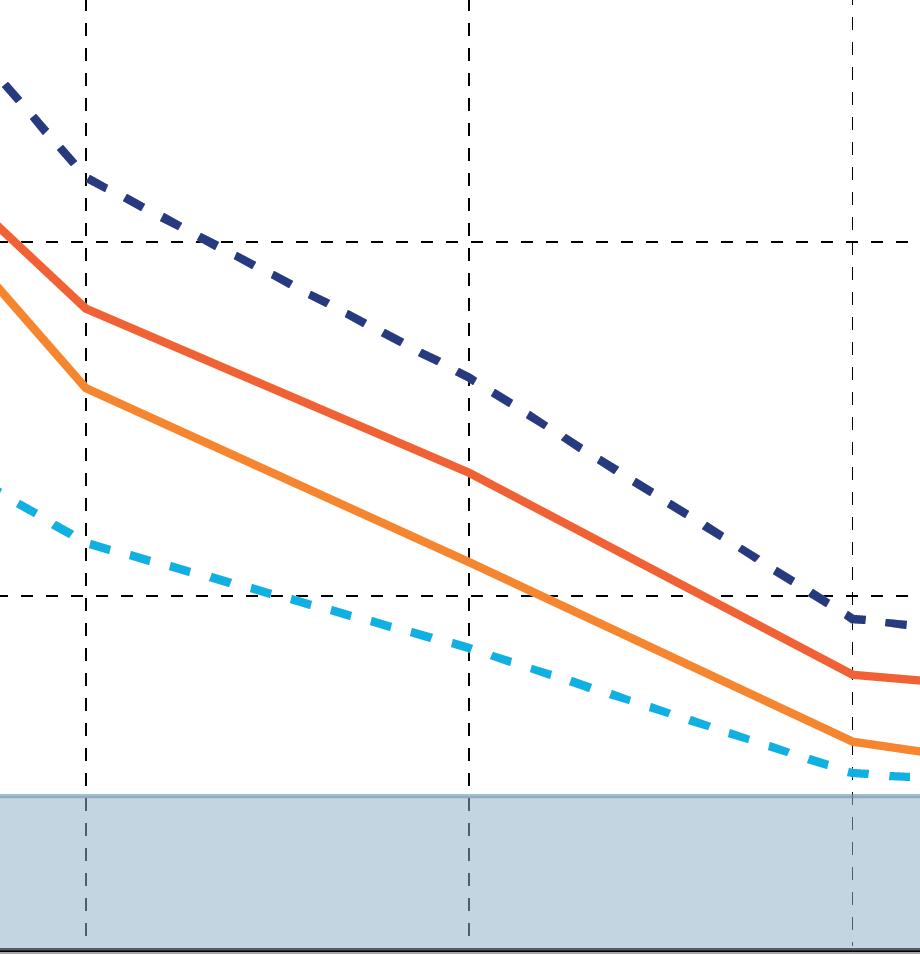

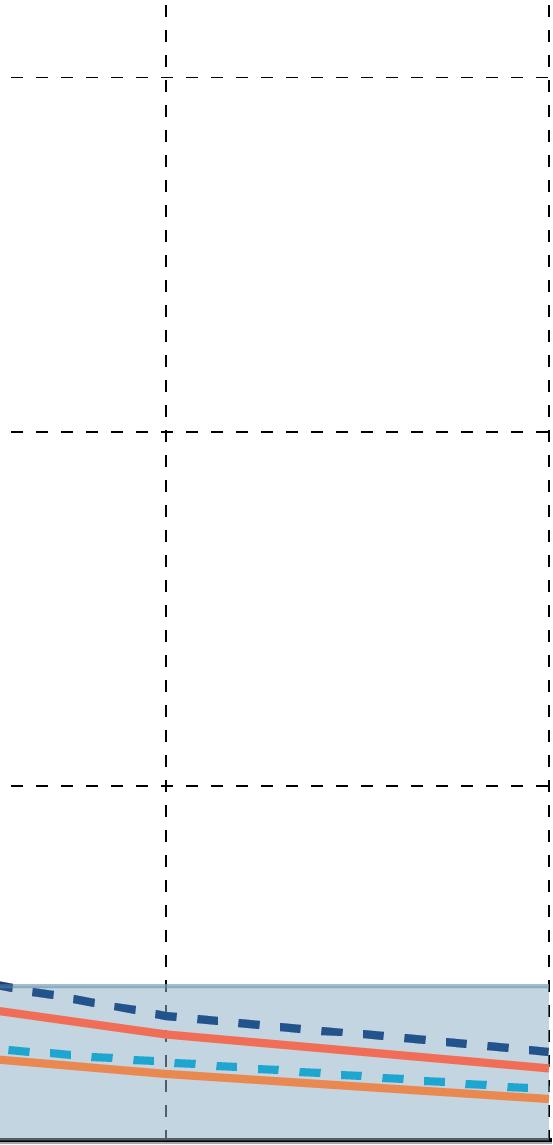

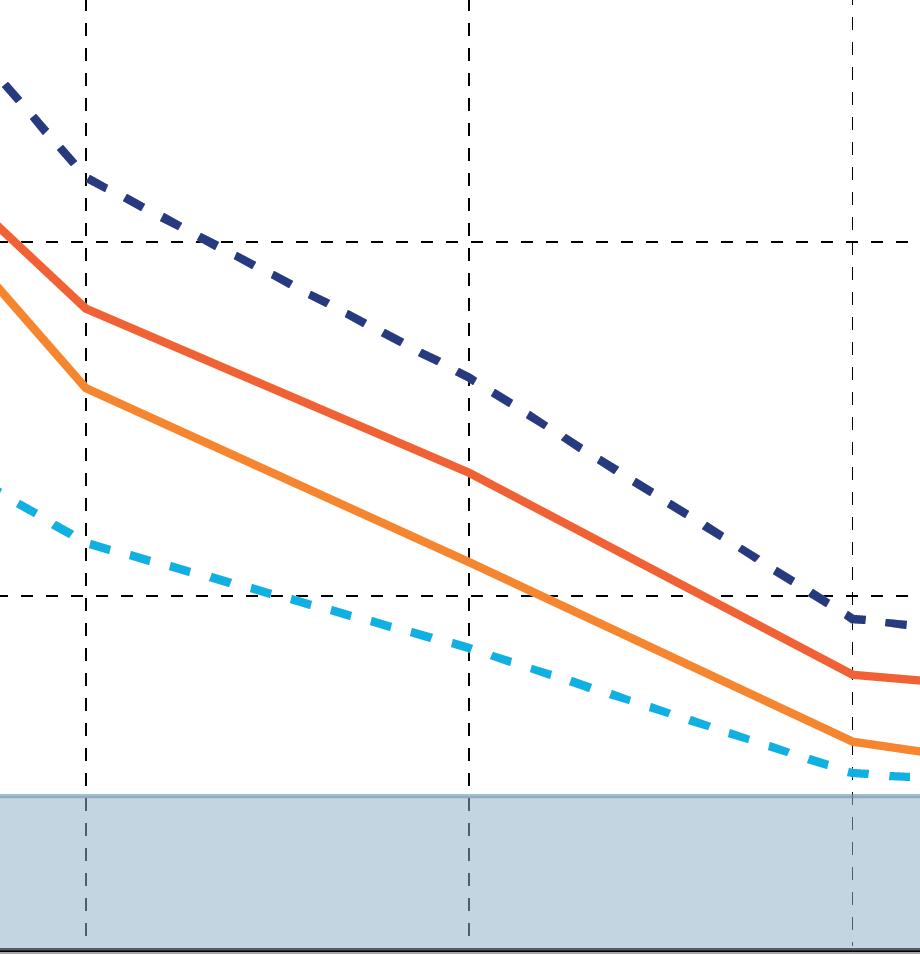

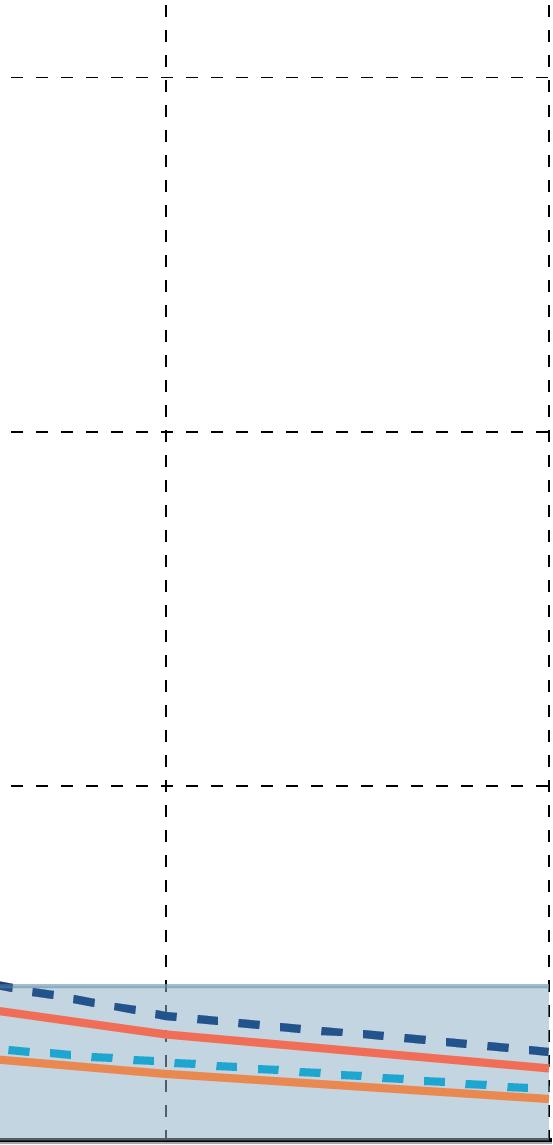

SCIENTIFIC RESULTS 34 20.4 27.2 13.6 6.8 0 Electrical Conductivity (us/cm) DAY 1 DAY 4 DAY 5 DAY 6 DAY 7 DAY 9 DAY 11 DAY 13 DAY 14 scientific results | ELECTRICAL CONDUCTIVITY SINGLE MANGROVE + FRESH COCONUT WASTE SINGLE MANGROVE + FRESH COCONUT WASTE EC (us/cm) increase NUTRIENTS PRESENT YES NO

the hydroponic mangrove system | ACKNOWLEDGEMENTS

MY FAMILY - FOR THE SUPPORT THROUGHT THE FIELDWORK PERIOD GRANDMA - FOR HELPING WITH SEWING THE WATER BAGS MR PAUNDRA - FOR GREAT INFORMATION ON MANGROVES MR RUBIMAN - FOR TRANSPORTATION

acknowledgements | LOCAL COLLABORATORS

MR PADYUMI - HELPING WITH DEPLOYMENT AND TRANSPORT MR AGUS - PROVIDING INFORMATION AND TAKING US AROUND MUARA BARU MR RESJATI - PROVIDING EXPERT KNOWLEDGE ON MANGROVES

ARTHUR - DRONE PILOT

ALEX - VIDEOGRAPHER KT- SUPPORT

MR AGUS

ARTHUR - DRONE PILOT

ALEX - VIDEOGRAPHER KT- SUPPORT

MR AGUS

ARCHITECTURE AND EXTREME ENVIRONEMENTS 2022/23

PROP ROOTS

PNEUMATOPHORES

PROP ROOTS

PNEUMATOPHORES

1. initial prototype exploded iso

2. initial float components

3. initial prototype module iso

1.

1.1. Coconut fibre pot

1.2. Plastic water collection chamber

1.3. Rubber seal

1.5. Valve

1.4. Silicone tube

1.6. Mesh

2.

3.

2.1. M6 bolt

2.2. M8 bolt

3.1. Parang joint

1. initial prototype exploded iso

2. initial float components

3. initial prototype module iso

1.

1.1. Coconut fibre pot

1.2. Plastic water collection chamber

1.3. Rubber seal

1.5. Valve

1.4. Silicone tube

1.6. Mesh

2.

3.

2.1. M6 bolt

2.2. M8 bolt

3.1. Parang joint

1. float components exploded iso

2. float joint connection exploded iso

1. float components exploded iso

2. float joint connection exploded iso

RAFIA ROPE

COCONUT FIBRE POT

COCONUT FIBRE ROPE

4.

4.1 40x40x50cm water bag

220gsm transparent tarpaulin

4.2 5cm tab with holes to attach to floats

220gsm transparent tarpaulin

4.3 Adjustable drawstring opening 5mm diameter rope

4.4 2cm diameter ring 200gsm transparent tarpaulin

4.5 coconut fibre rope

4.6 coconut fibre pot

4. Water bag section drawing

5. Water bag components

6. 1 module of floats and water bag

5.

6.

5.1 coconut fibre rope 8mm diameter

5.2 coconut fibre pot 15cm diameter

5.3 tarpaulin water bag 220gsm transparent

5.4 rope 5mm diameter

RAFIA ROPE

COCONUT FIBRE POT

COCONUT FIBRE ROPE

4.

4.1 40x40x50cm water bag

220gsm transparent tarpaulin

4.2 5cm tab with holes to attach to floats

220gsm transparent tarpaulin

4.3 Adjustable drawstring opening 5mm diameter rope

4.4 2cm diameter ring 200gsm transparent tarpaulin

4.5 coconut fibre rope

4.6 coconut fibre pot

4. Water bag section drawing

5. Water bag components

6. 1 module of floats and water bag

5.

6.

5.1 coconut fibre rope 8mm diameter

5.2 coconut fibre pot 15cm diameter

5.3 tarpaulin water bag 220gsm transparent

5.4 rope 5mm diameter

VACUUM FORM TEST USING 1MM THICK PLASTIC

COOLING THE PLASTIC

64 PLASTIC FLOATS CUT AND DRILLED

PLASTIC FLOATS BEFORE CUTTING

ILLIG VACUUM FORMING MACHINE

INDENTATION CAUSED BY USING HOLLOW MOULD

VACUUM FORM TEST USING 1MM THICK PLASTIC

COOLING THE PLASTIC

64 PLASTIC FLOATS CUT AND DRILLED

PLASTIC FLOATS BEFORE CUTTING

ILLIG VACUUM FORMING MACHINE

INDENTATION CAUSED BY USING HOLLOW MOULD

METAL LASER CUT - 50X50CM SHEET

SANDING ROUGH LASER CUT EDGES

SANDED PARANG JOINTS

4 FLOAT PARANG

2 FLOAT PARANG

3 FLOAT PARANG

METAL LASER CUT - 50X50CM SHEET

SANDING ROUGH LASER CUT EDGES

SANDED PARANG JOINTS

4 FLOAT PARANG

2 FLOAT PARANG

3 FLOAT PARANG

POWDER COATING PARANG JOINTS

BAKING TO SET THE POWDER COAT

DRYING AND COOLING THE COATED JOINTS

ONE TUB USED TO COAT JOINTS TWICE

POWDER COATING PARANG JOINTS

BAKING TO SET THE POWDER COAT

DRYING AND COOLING THE COATED JOINTS

ONE TUB USED TO COAT JOINTS TWICE

POTENTIAL SITE 3

POTENTIAL SITE 2 MUARA BARU (-6.1109280, 106.8063110)

FISHING NET HUB (-6.1047206, 106.8053232)

POTENTIAL SITE 1 TAMAN WISATA ALAM ANGKE KAPUK

POTENTIAL SITE 3

POTENTIAL SITE 2 MUARA BARU (-6.1109280, 106.8063110)

FISHING NET HUB (-6.1047206, 106.8053232)

POTENTIAL SITE 1 TAMAN WISATA ALAM ANGKE KAPUK

ATTACHING WATER BAGS TO FLOATS USING RAFIA ROPE

JOINING FLOATS IN SECTIONS INDOORS BEFORE GOING TO SITE

TRANSPORTING PROTOTYPE TO SITE

PUTTING THE WHOLE PROTOTYPE TOGETHER ON SITE

ATTACHING WATER BAGS TO FLOATS USING RAFIA ROPE

JOINING FLOATS IN SECTIONS INDOORS BEFORE GOING TO SITE

TRANSPORTING PROTOTYPE TO SITE

PUTTING THE WHOLE PROTOTYPE TOGETHER ON SITE

TYING THE COCONUT FIBRE POTS TO THE WATER BAGS

PROTOTYPE GOES INTO THE WATER

PLANTING THE MANGROVES

FILLING THE WATER BAGS WITH SEA WATER

TYING THE COCONUT FIBRE POTS TO THE WATER BAGS

PROTOTYPE GOES INTO THE WATER

PLANTING THE MANGROVES

FILLING THE WATER BAGS WITH SEA WATER

ARTHUR - DRONE PILOT

ALEX - VIDEOGRAPHER KT- SUPPORT

MR AGUS

ARTHUR - DRONE PILOT

ALEX - VIDEOGRAPHER KT- SUPPORT

MR AGUS