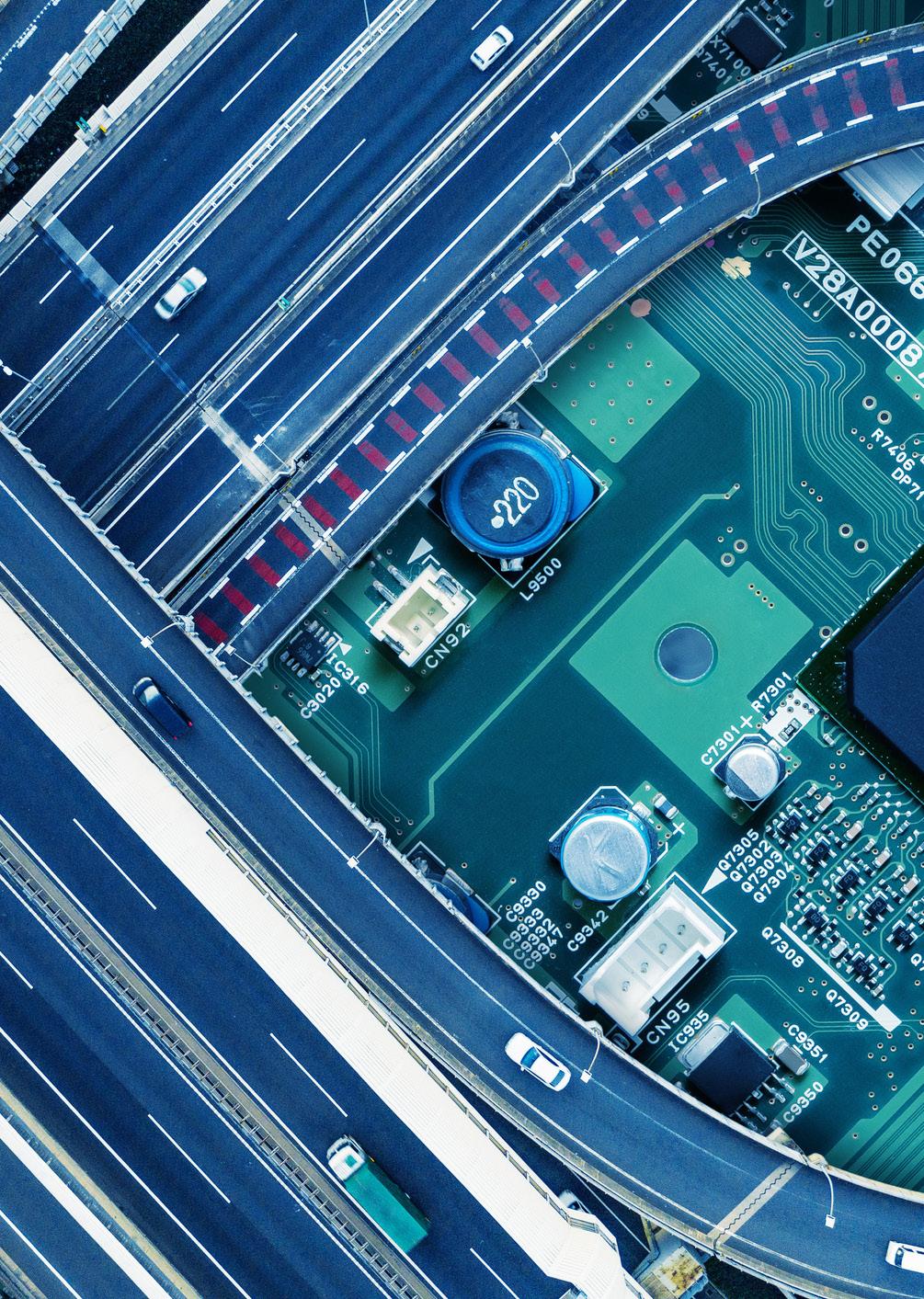

Expert Electronics Manufacturing from Design to Delivery

Expert Electronics Manufacturing from Design to Delivery

Founded in 2004, RTR Electronics Ltd. specializes in PCB assembly, BGA rework, PCB design & layout component kitting, and cable harness assembly, serving industries across Europe, North America, and Asia. With over 20 years of industry experience, RTR has become a trusted partner, delivering innovative solutions from concept to full-scale production.

Our team of skilled technicians and IPC-certified rework operators, led by a hardware engineer with decades of expertise, ensures high-quality results for industries such as semiconductors, medical devices, and more.

Located in Limerick, Ireland, our facility is strategically positioned near Shannon International Airport and major transport routes, enabling us to efficiently serve clients across Europe, North America, Asia, and beyond.

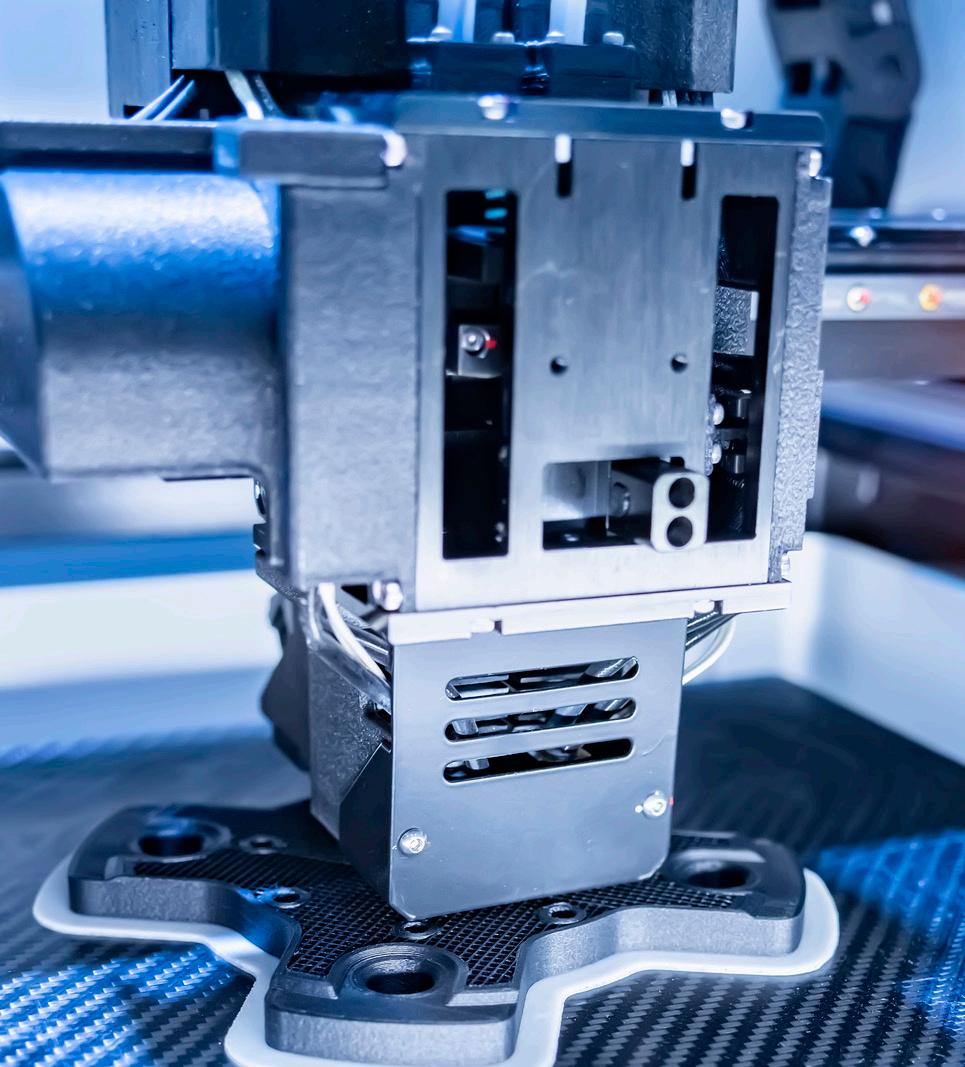

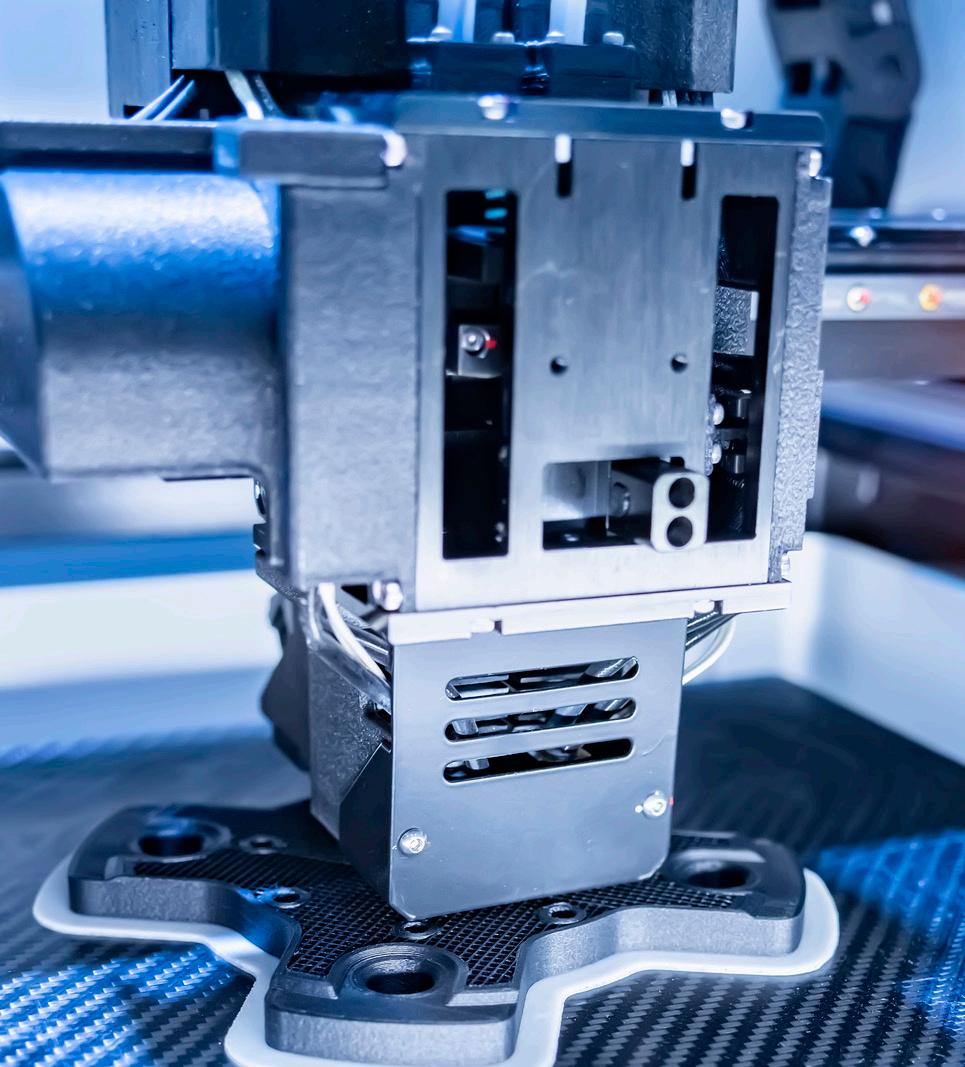

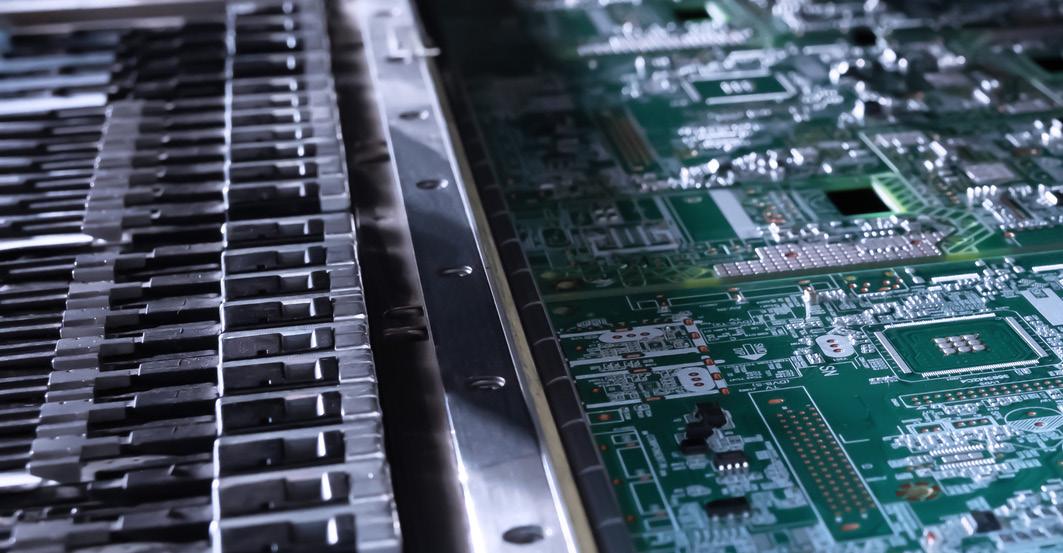

PCB Assembly - Our PCB Assembly Capabilities

PCB Assembly - Our PCB Assembly Capabilities

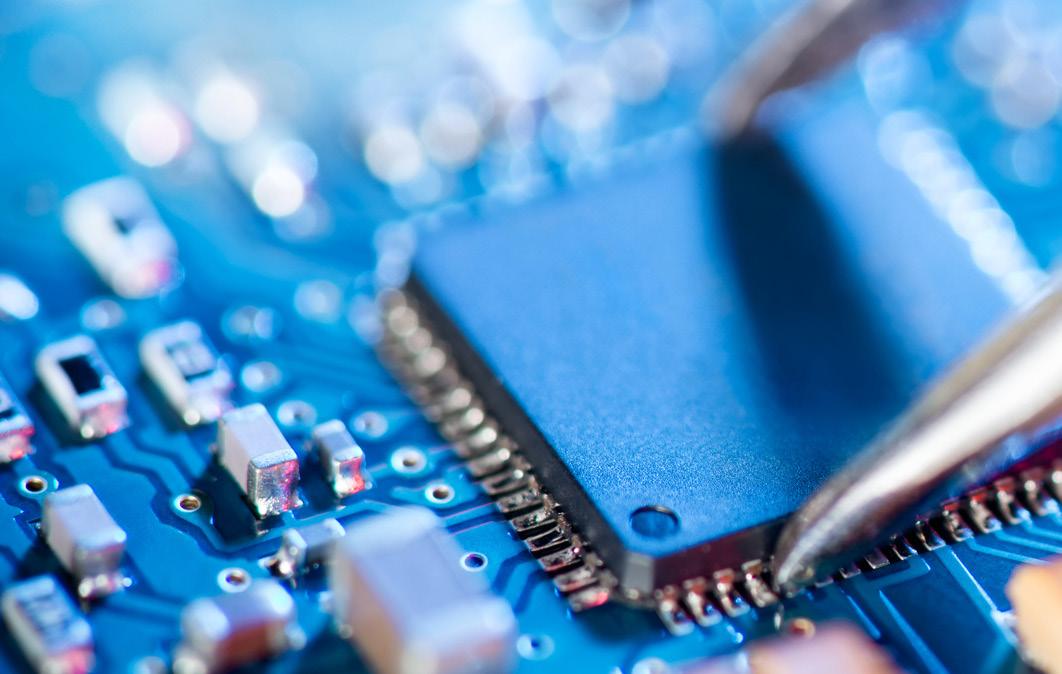

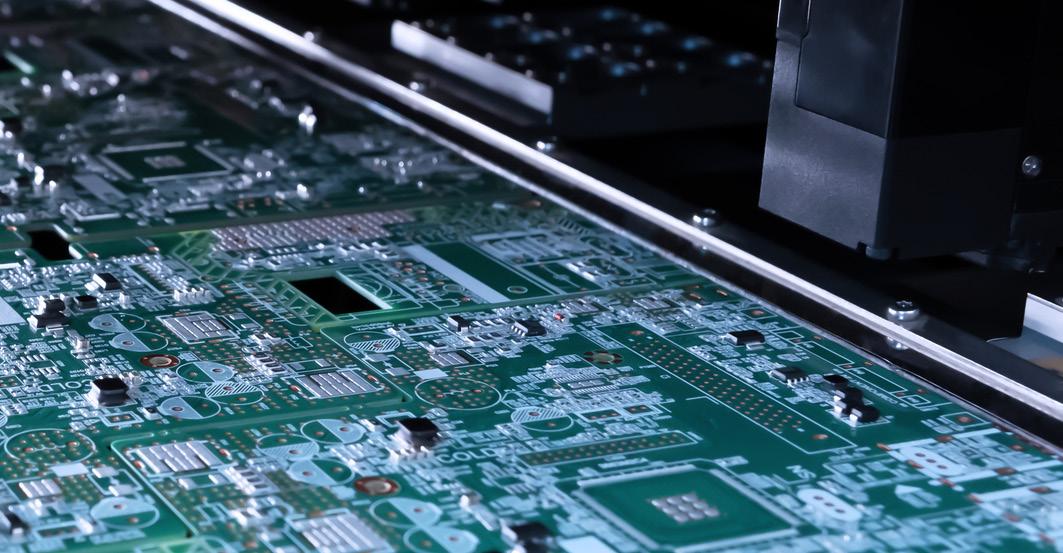

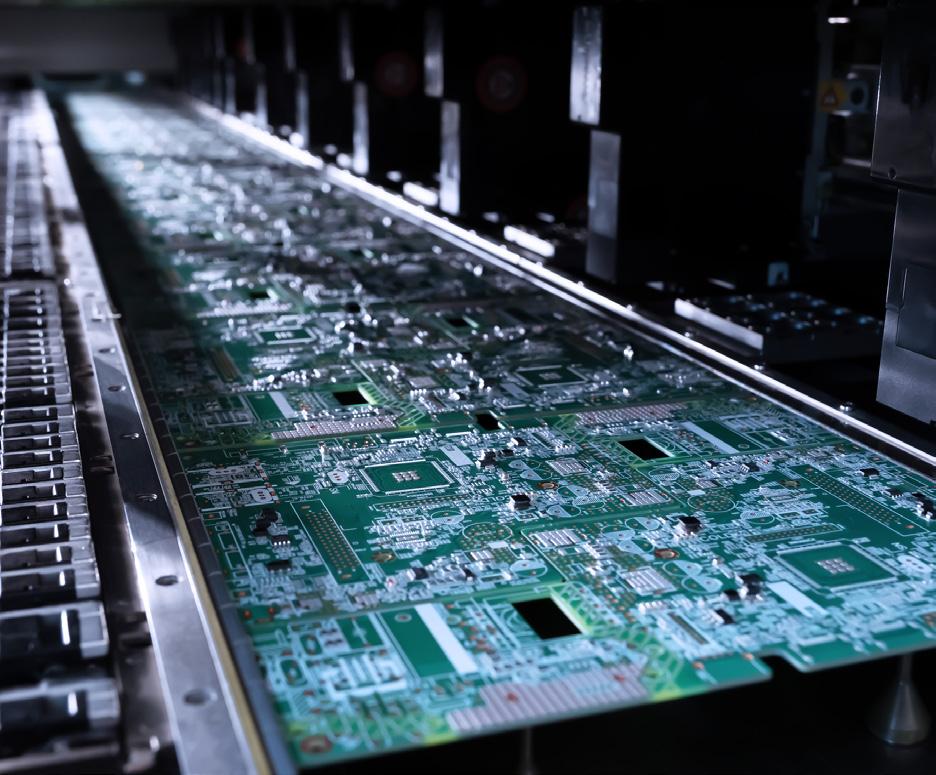

Surface Mount Technology (SMT) Assembly

High-speed, precision SMT placement for single or double-sided PCBs.

Automated Optical Inspection (AOI) & X-ray Inspection

Ensuring quality and accuracy at every stage.

BGA and Micro-BGA Assembly

Advanced rework and inspection for highdensity PCBs.

Reliable hand and automated throughhole soldering for robust connections. Through-Hole Assembly

Mixed Technology Assembly

Combining SMT and through-hole components for complex designs.

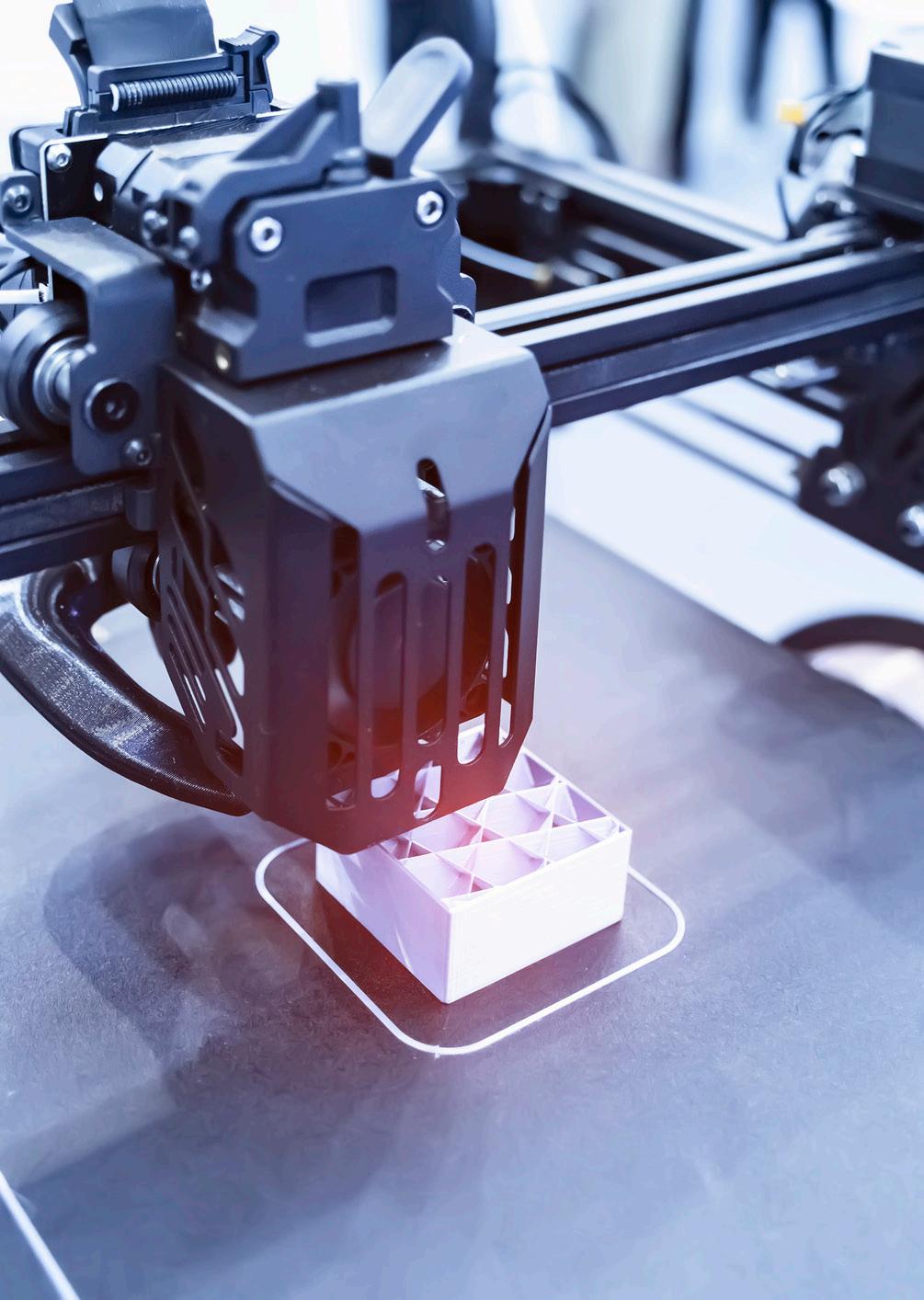

Rapid prototyping with seamless scaling to full production. Prototype to Production

Protection against harsh environmental conditions. Conformal Coating & Encapsulation

We work closely with you to design tailored cable assemblies that meet your exact specifications.

Our state-of-the-art equipment and skilled technicians ensure consistent quality and high reliability.

We adhere to IPC/WHMA-A-620 standards, guaranteeing top-tier performance.

We source high-quality wires, connectors, and shielding materials to match your environmental and electrical requirements

Every harness undergoes rigorous testing for electrical continuity, insulation resistance, and durability.

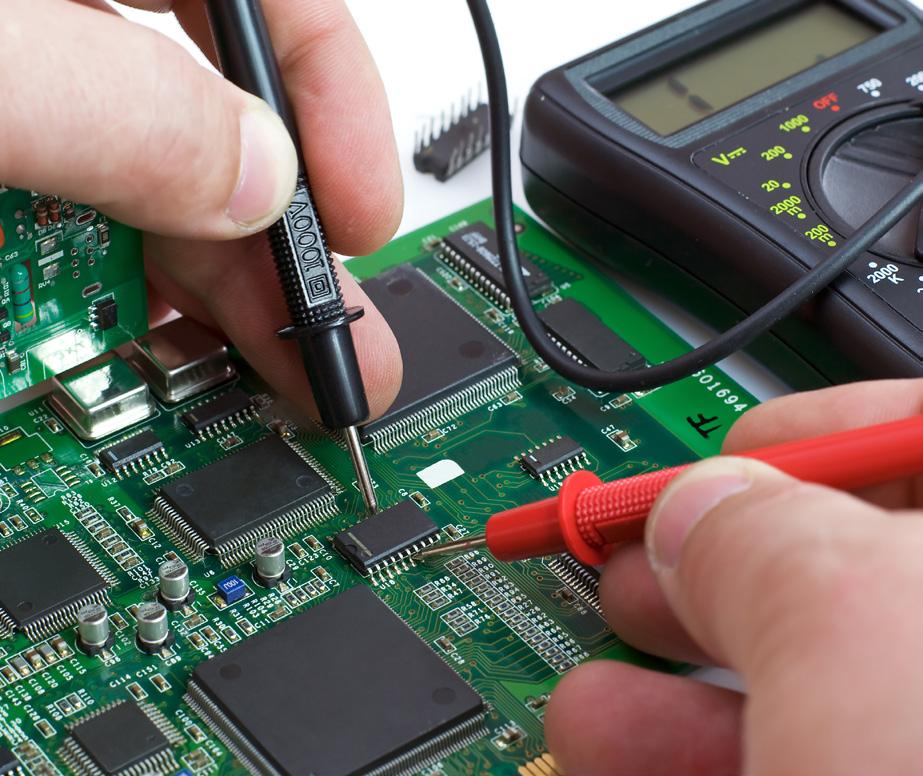

Precise removal, reballing, and re-installation of BGA components to restore functionality.

Expert repair and replacement of fine-pitch ICs, QFNs, BGAs, and other complex surface-mount and through-hole components.

Advanced imaging ensures proper solder joint integrity, minimizing defects and failures.

Restoration of damaged PCB pads, traces, and vias to maintain circuit functionality.

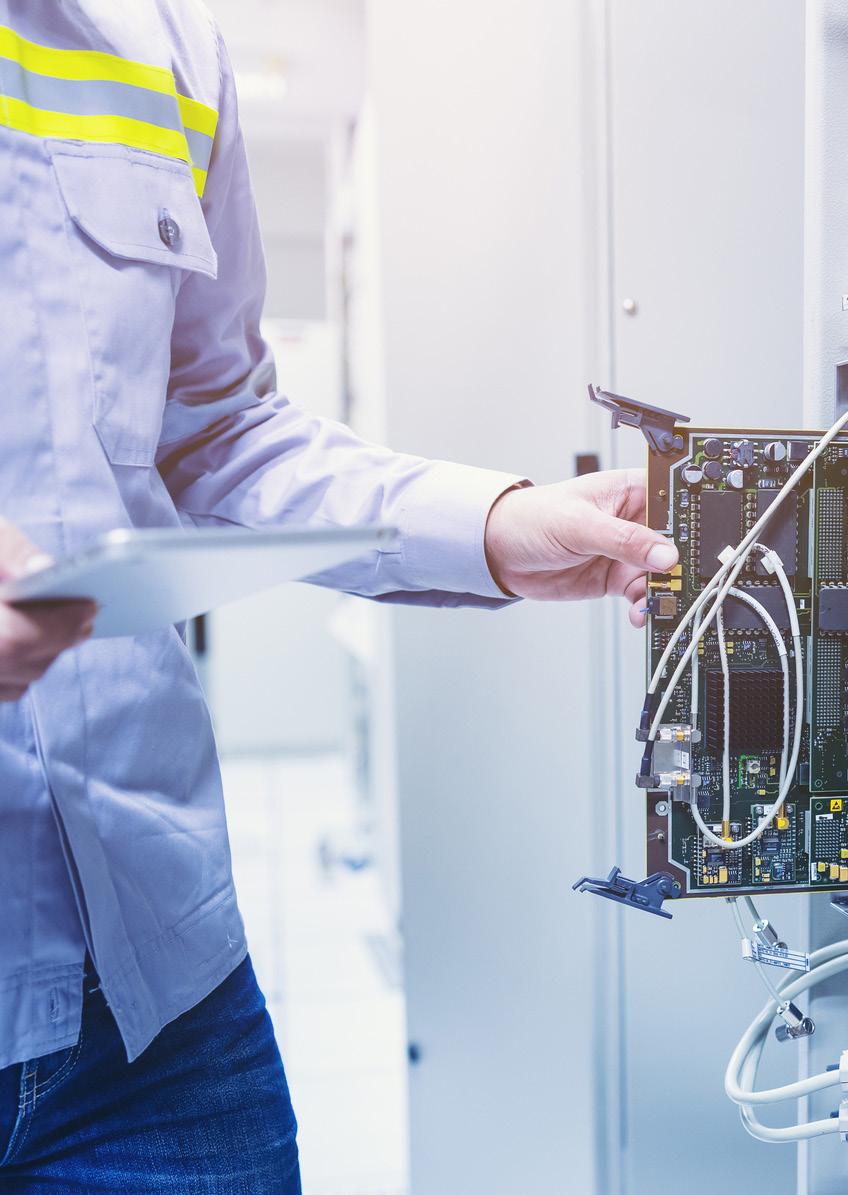

In today’s fast-paced electronics industry, efficiency and reliability are crucial. Our Electronics Repair, Re-manufacturing, and Testing Services provide a cost-effective solution to extend product life cycles, reduce electronic waste, and ensure optimal performance.

We specialize in diagnosing and repairing a wide range of electronic assemblies, from PCB-level component replacements to full system refurbishments. Our expert technicians use industry-leading tools to restore functionality, ensuring your products meet or exceed original specifications.

Our re-manufacturing services breathe new life into aging electronics. Whether it’s replacing outdated components, updating firmware, or enhancing system reliability, we help businesses maximize the value of their existing hardware while maintaining compliance with industry standards.

We employ rigorous testing protocols to verify performance, including:

Our advanced diagnostics and testing ensure that every repaired or re-manufactured unit meets high-quality standards before re-entering the supply chain.

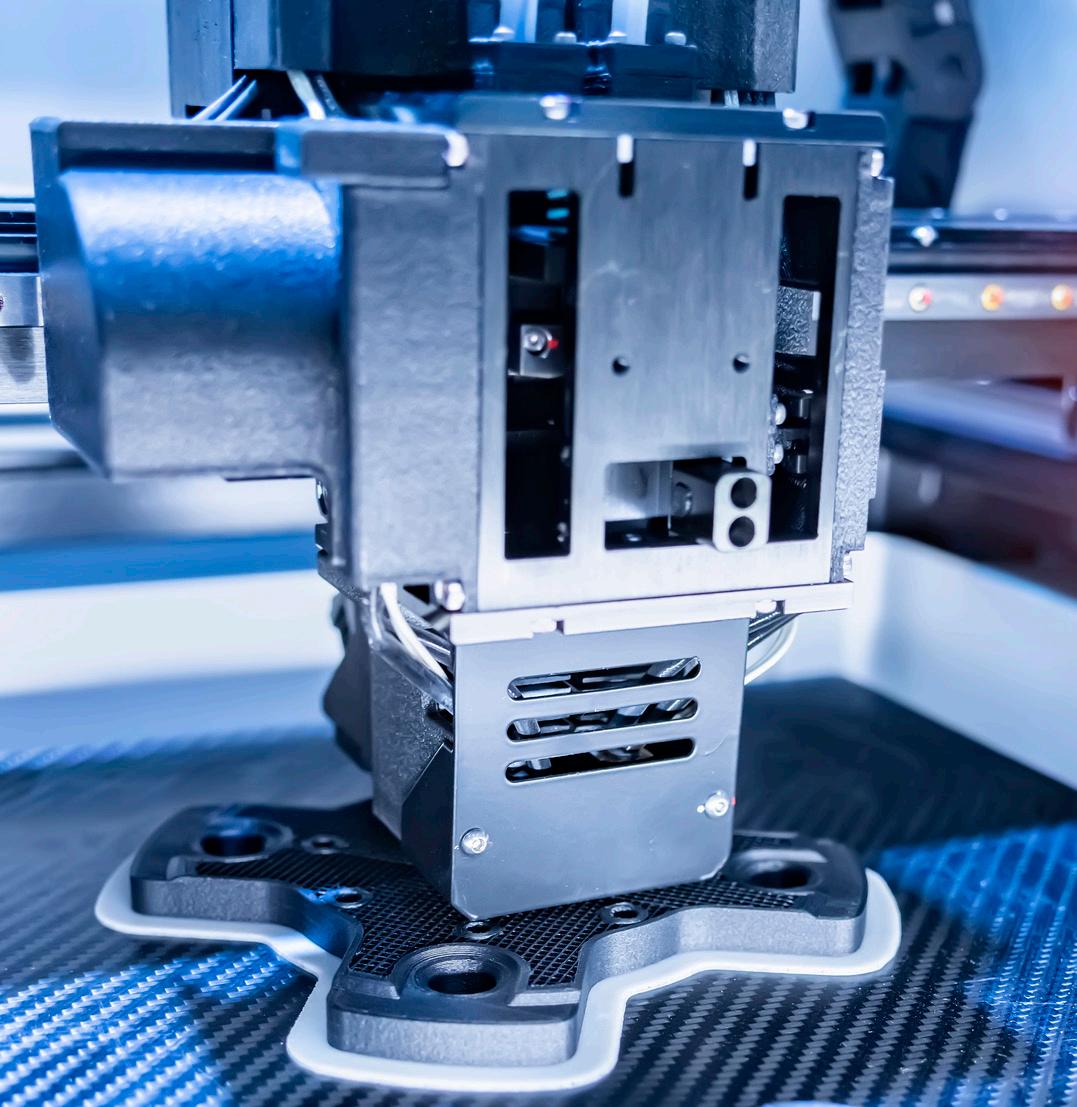

Complete turnkey solutions, from enclosure integration to final system assembly.

Precision wiring, custom cable assemblies, and interconnect solutions.

Installation of PCBs, power supplies, sensors, connectors, and mechanical components.

Comprehensive validation to ensure reliability and performance.

Sourcing, modifying, and assembling metal or plastic enclosures to match your specifications. & Finishing

Sourcing components, managing inventory, and delivering final products.

With years of industry experience and a commitment to quality, we tailor our box build services to meet your exact specifications while ensuring cost efficiency and rapid turnaround times. From concept to completion, we bring your product to life

Tailored PCB layouts and schematic design for optimal functionality and efficiency.

Rapid iterations to validate and refine designs before fullscale production.

Designed for manufacturability and testability, reducing production costs and improving yield.

Microcontroller and FPGA-based solutions for advanced applications.

Ensuring stable, low-noise designs that maximize efficiency.