Stainless Steel tube,pipe,coil Inspection service in cangzhou,wuxi city

Randomly selected samples

Samples were randomly taken from the mass product. Inspector will check the quality, the size, the weight, MTC etc.

Samples were randomly taken from the mass product. Inspector will check the quality, the size, the weight, MTC etc.

• The quality inspection methods of steel are written inspection, appearance inspection, physical and chemical inspection and non-destructive inspection.

• (1) Written inspection. The quality assurance data and test reports provided shall be reviewed and approved before they can be used.

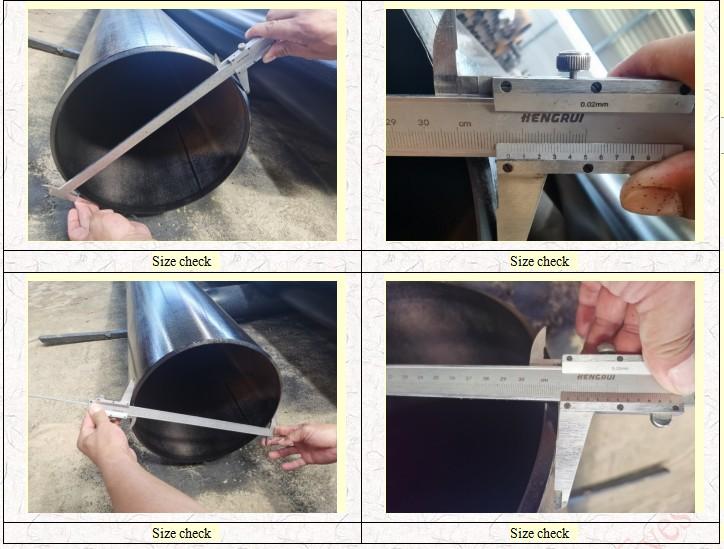

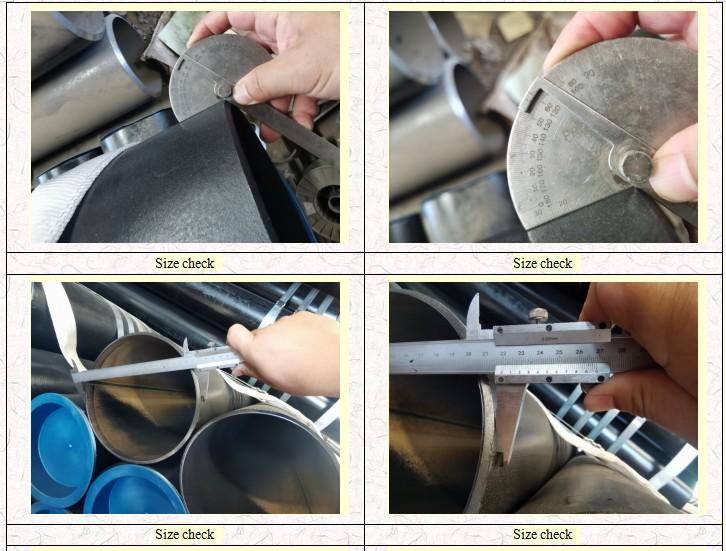

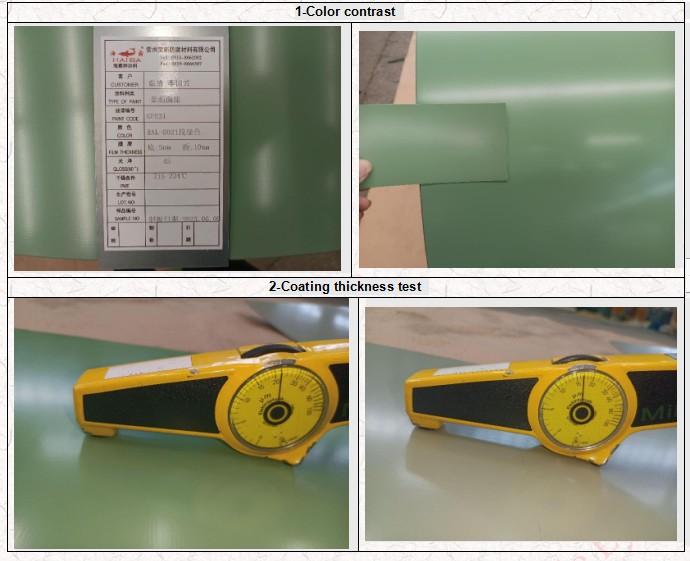

• (2) Appearance inspection. Visually inspect the material from the variety, specifications, marks, dimensions, etc., to see if there are quality problems.

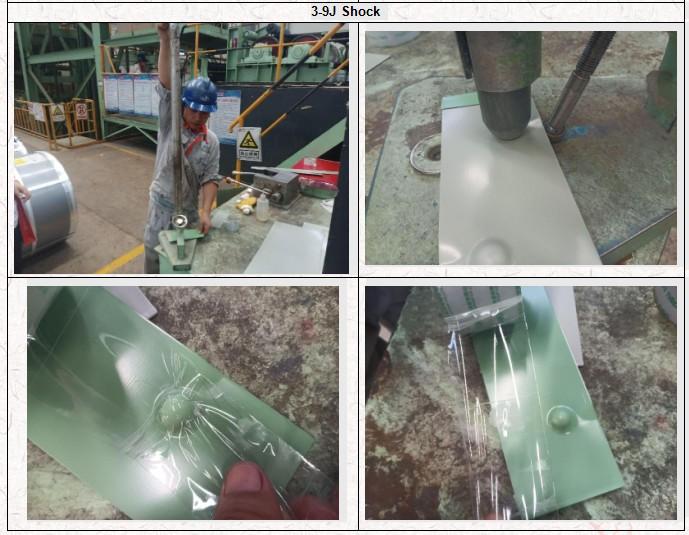

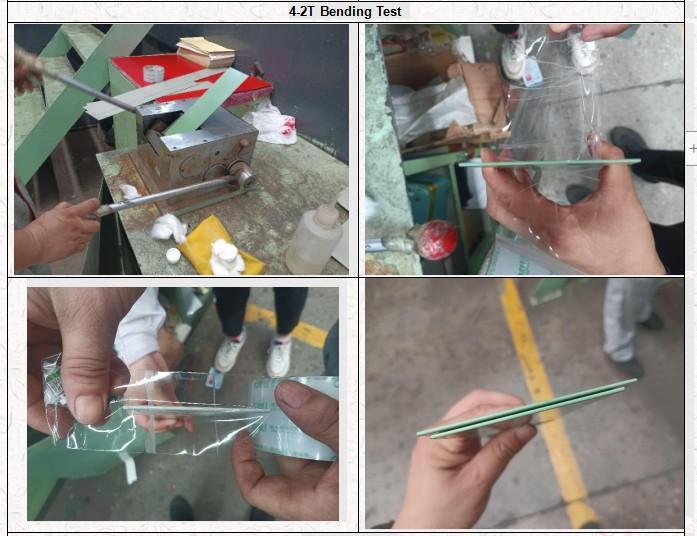

• (3) Physical and chemical test. With the help of test equipment and instruments, the chemical composition and mechanical properties of material samples are scientifically identified.

• (4) Non-destructive test. Under the premise of not destroying the material sample, ultrasonic wave, X-ray, surface flaw detector and so on are used for detection.

• Content of steel inspection

• The main contents of steel inspection include the following aspects.

• (1) The quantity and variety of steel shall be in accordance with the order contract.

• (2) The quality guarantee of the steel shall conform to the mark printed on the steel. Each batch of steel must have a material certificate provided by the manufacturer, indicating the furnace number, steel number, chemical composition and mechanical properties of the steel.

• Mechanical properties. The indicators of steel can be verified according to the provisions of the national standard.

• (3) Check the specifications and dimensions of the steel. The allowable deviation of various steel sizes can be checked with reference to the relevant national standards or standards.

• (4) Steel surface quality inspection. No matter flat steel, steel plate or section steel, its surface is not allowed to have scars, cracks, folding and delamination and other defects. Those with the above defects should be stacked separately for study and treatment. The corrosion depth of the steel surface shall not exceed 1/2 of the negative deviation value of its thickness.

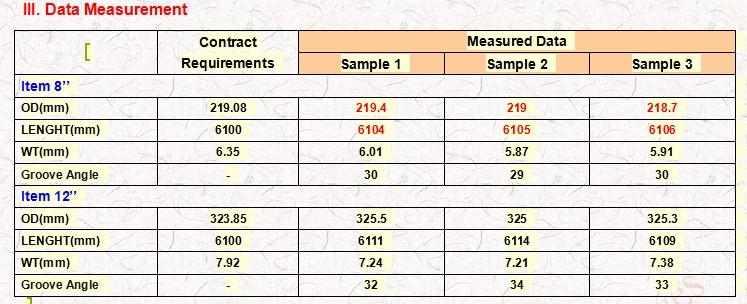

Measured data(Product size, Weight etc)

The report shows the situation at the inspection site. Check and verify that the goods meet the requirements of size, weight, packing and workmanship according to the information provided by customer. Work is good, function test is normal. After reading the report, customers can accurately judge whether the goods meet the requirements of the order.

Eagle Eyes Quality Inspection Co.,Ltd.

Eagle Eyes, Watch Your Quality All The Time!!!

Office: 0086-596-6718-300

Mobile:0086-150-5921-6291

Email: cs@china-qualityinspection.com

Website: https://www.china-quality-inspection.com

https://www.china-qualityinspection.com