PUFoamSpraycontainerLoadingSupervision inqingdao,yantaishandong

•Containerloadinginspectionrequirements

•Supervisionistoloadtheproductintothecontainerunder supervision,andmeetthefollowingrequirements:

•(1)Theproductmeetstherequirements.

•Productcorrectness.

•Thenumberofcasesiscorrect.

•(2)Thecontainerissuitableforshipment.

•Thecontainerisundamagedandclean.

•Theplacementoftheproductinthecontainerissuitablefor transportation.

•Recordproductquantity,containernumber,andlocknumber.

2.Supervisetheinstallationprocess

1)Gettheinformationfromofficeandcontactthefactory.

2)Afterarrivingatthefactory,confirmwiththefactoryrepresentative whetherthecontainerhasarrivedatthefactory.Ifnot,furtherconfirm thearrivaltimeandinformtheoffice.

3)Checkproductsandcomparewithcustomerinformation.

4)Pumpingboxesandtakingphotos:stacking,outerboxes,shipping marks,products,thenumberofpumpingboxesissquarerootX0.6,at least5boxestomonitortheloadingprocess.

5)Checktheappearanceofthecontainer:nodamage,clearcontainer number,noerror.

6)Checktheinsideofthecontainer.

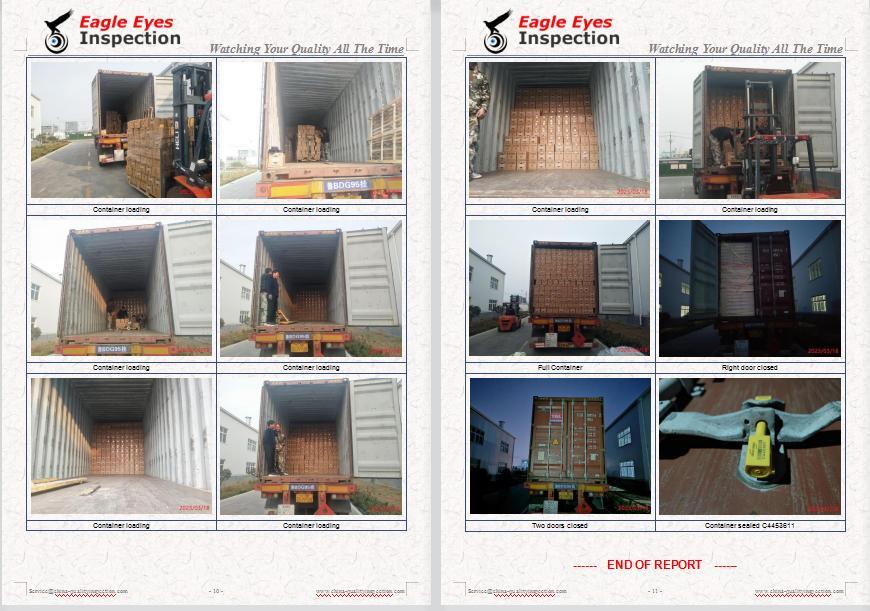

•Takephotosforlaodingprocess(40'containerasanexample).

•Empty

•Putaquarterin

•1/2loaded

•Putitin3/4

•100%loaded

•Closetherightdoor

•Twodoorsshut

•Oncelocked,thereshouldbeaclose-upofthelockposition

•Locknumbertobephotographed(close-up)

•Takeaclose-upoftherivetsofthelowercardslot(door)ofthelock positionoftheverticalrod(rightdoor)(especiallytoEastern Europeancountries)