Hello, I’m Kee Ting.

I believe that good design stems from an understanding of the human condition, and should be a smart response to its context. Combined with my passion in digital computation, I actively pursue designs that are cost-effective, efficient and elegant.

Work Experience

Mar 2022 - Present

Assistant Architect

ID Architects Pte Ltd

• Managed local projects including large and small food factories, a 16-storey office building in CBD and a landed house in varying phases, from design to completion.

• Conceptualised design and produced drawings for tender & construction with Revit and ArchiCAD.

• Prepared many authority submissions and am well-versed with local code requirements.

Sep 2020 - Apr 2021

Parametric Design Intern

Passage Projects

• Reduced construction cost and fabrication complexity of a complex geometry roof by parameterizing modules in Grasshopper, thereby cutting down the number of unique modules by 93%.

• Computationally analysed the deviation between the original design and proposed solution, to ensure adherence to engineering constraints.

• Built computational tools to streamline processes for design and structural analysis (e.g. Export Rhino/Grasshopper model to Oasys GSA).

• Produced 3D models, graphics and renders for design proposals.

Jan 2020

Front-End Developer Intern

Aural Aid Pte. Ltd.

• Built a web-based user interface that allows the creation and manipulation of polygons, calculation of attributes and cost estimations on the fly, and the export of generated information in a CSV file

• Programmed using JavaScript, HTML, CSS and Django (Python).

Jun 2019 - Aug 2019

Architecture Software Design Intern

Digital Blue Foam

• Learnt JavaScript on the job to contribute to the company’s code base.

• Created a code function that allows users to input freehand sketches as design constraints for the company’s building generation software.

• Interfaced with external APIs to generate geometric shapes for sun path visualisation.

• Researched and quantified attributes of a sustainable building, to incorporate into the product.

2020 - 2021

Education

Master of Architecture (Architecture and Sustainable Design)

Singapore University of Technology and Design (SUTD)

2017 - 2020

Bachelor of Science (Architecture and Sustainable Design)

Singapore University of Technology and Design (SUTD)

2015 - 2016

GCE ‘A’ Levels

Hwa Chong Institution

Awards

2019-2021

BCA-Industry iBuildSG Undergraduate Sponsorship

Sponsorship by Singapore’s Building Construction Authority

Nov 2015

Outstanding Award (Top Prize)

URA Challenge for the Urban and Built Environment (CUBE)

• Planned a designated area for enhanced liveability and connectivity in this national-scale workshop and competition organised by the Urban Redevelopment Authority.

Extra-Curricular Activities

Jan, Sep 2019

Design Participant

Workshop: Redesigning of Kindergarten in Rural Vietnam

• Surveyed the site’s architectural context, designed a preliminary concept with Vietnamese university students and presented to the partnering developer, Capitaland.

Jul 2017 - Sep 2017

Head of Logistics

PARK(ing) Day 2017

• Led a team of 3 to source and manage logistics for 7 design workshops which involved 8 secondary schools and polytechnics, and the main public event.

Oct 2014 - Apr 2017

Volunteer Leader and Sidewalker

Riding for the Disabled Association of Singapore

• Monitored and encouraged the weekly rehabilitation of the riders, who have disabilities like cerebral palsy, down’s syndrome and autism, through providing physical assistance and emotional encouragement.

Strong

Rhinoceros | Grasshopper (Python)

Adobe Illustrator | InDesign

Microsoft Powerpoint | Excel | Word

Familiar

Revit | ArchiCAD

Adobe Photoshop | Premiere Pro

Enscape

Languages

English and Chinese (spoken and written)

Python | Javascript

Travelling|Coding Music|Dance|Drawing

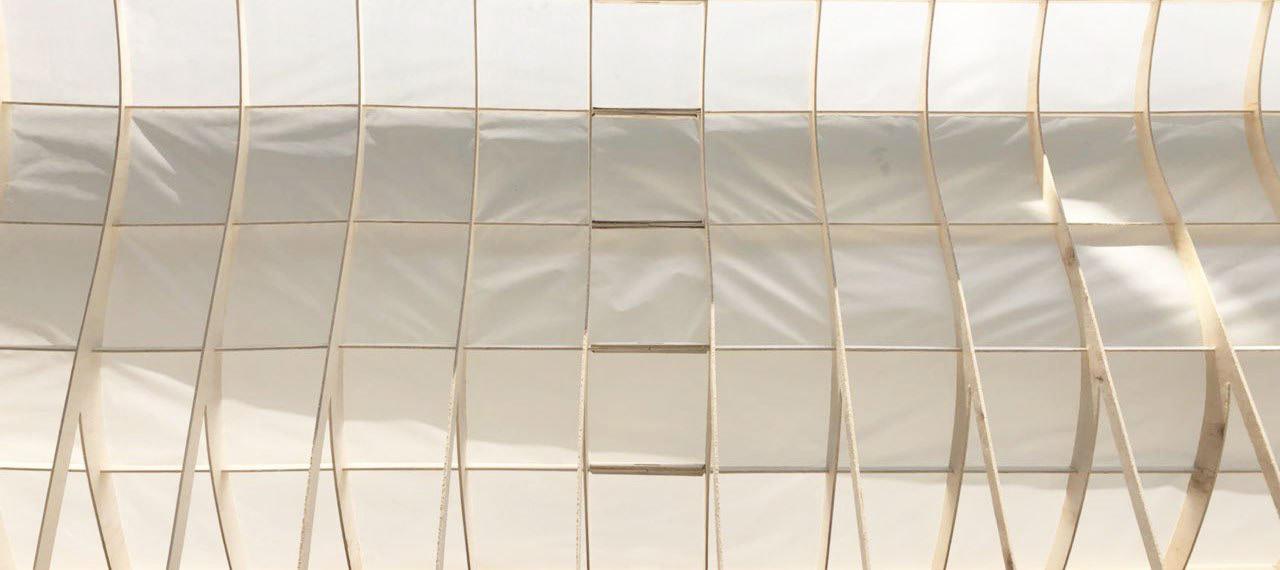

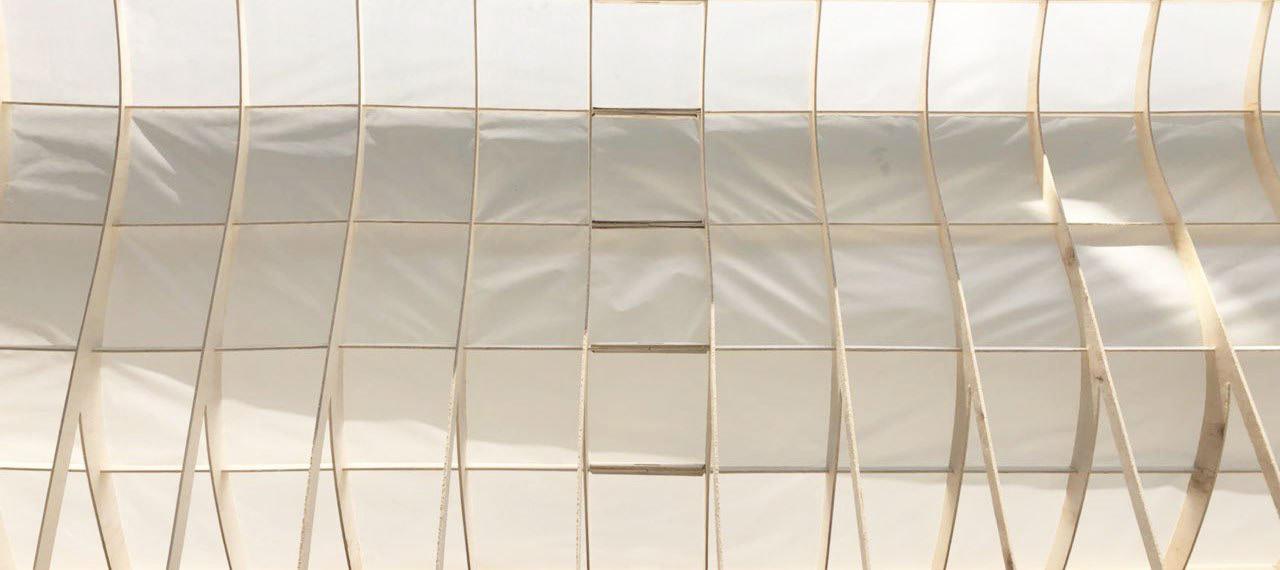

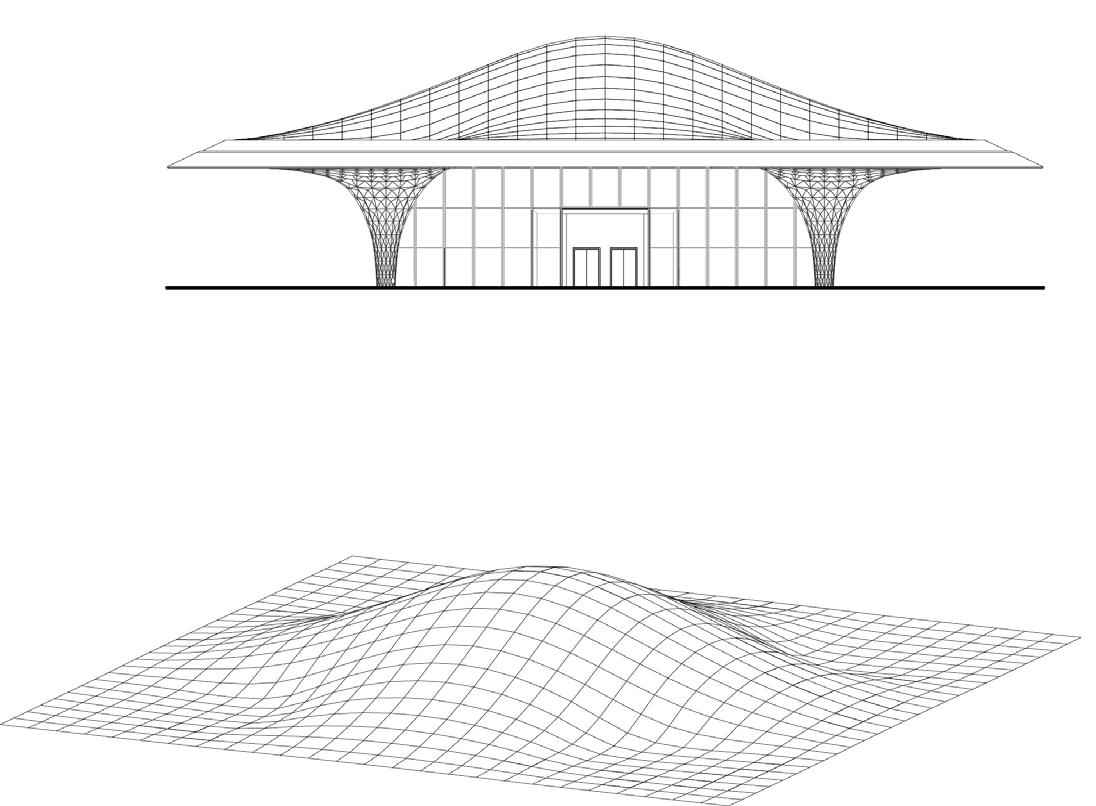

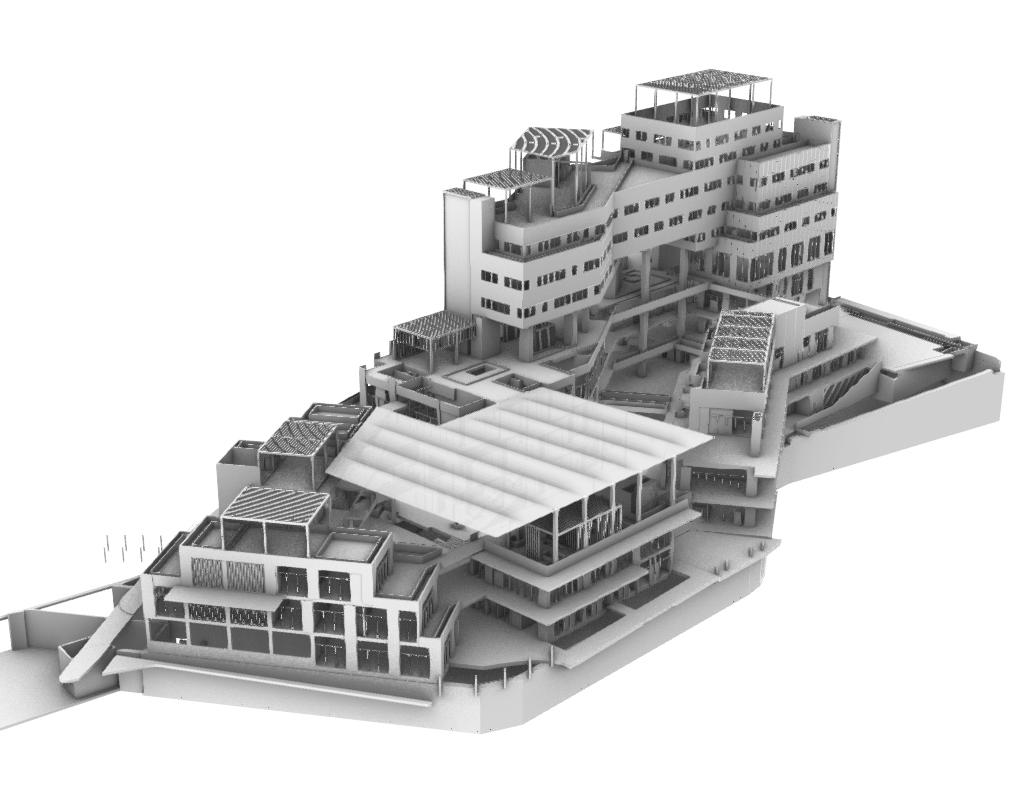

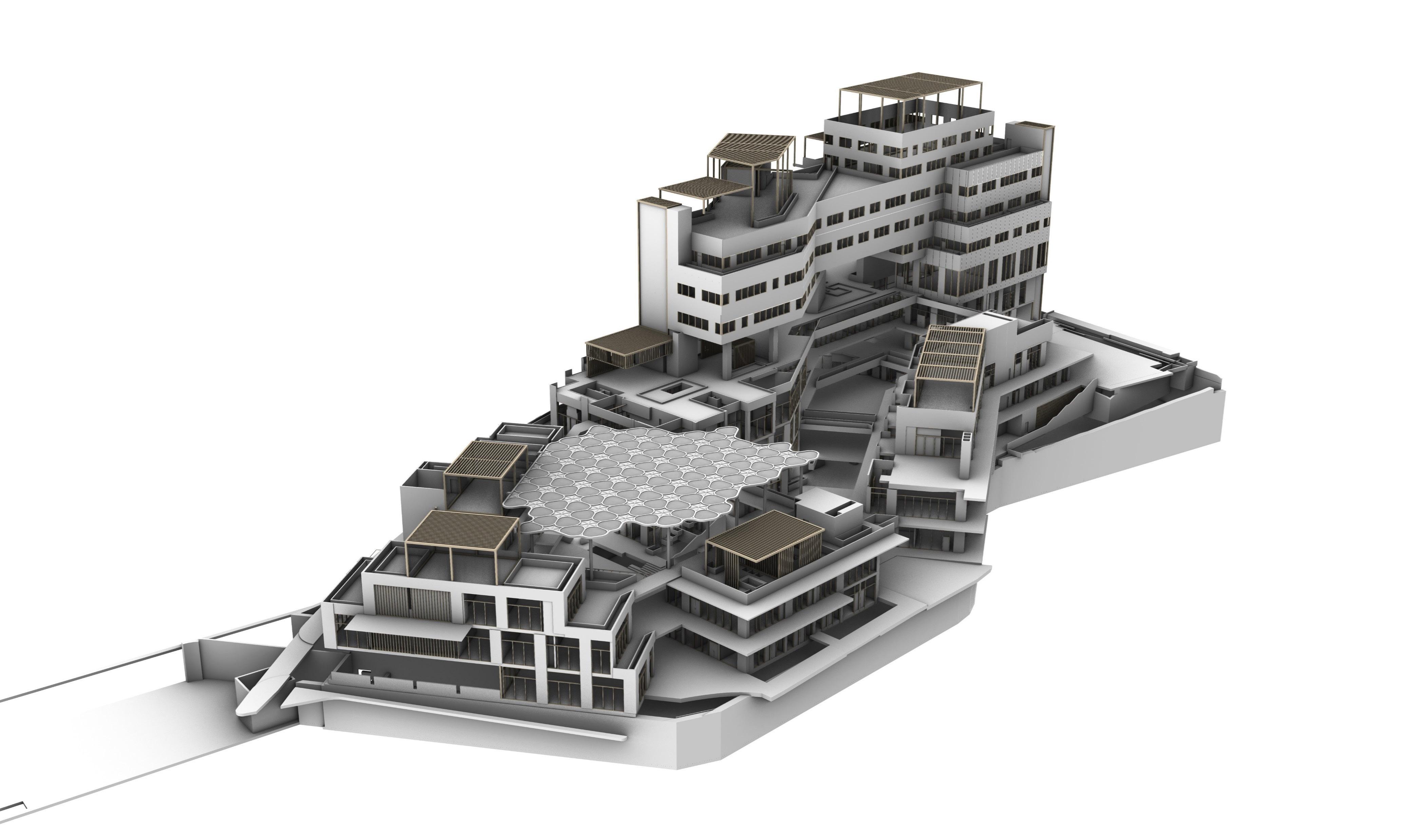

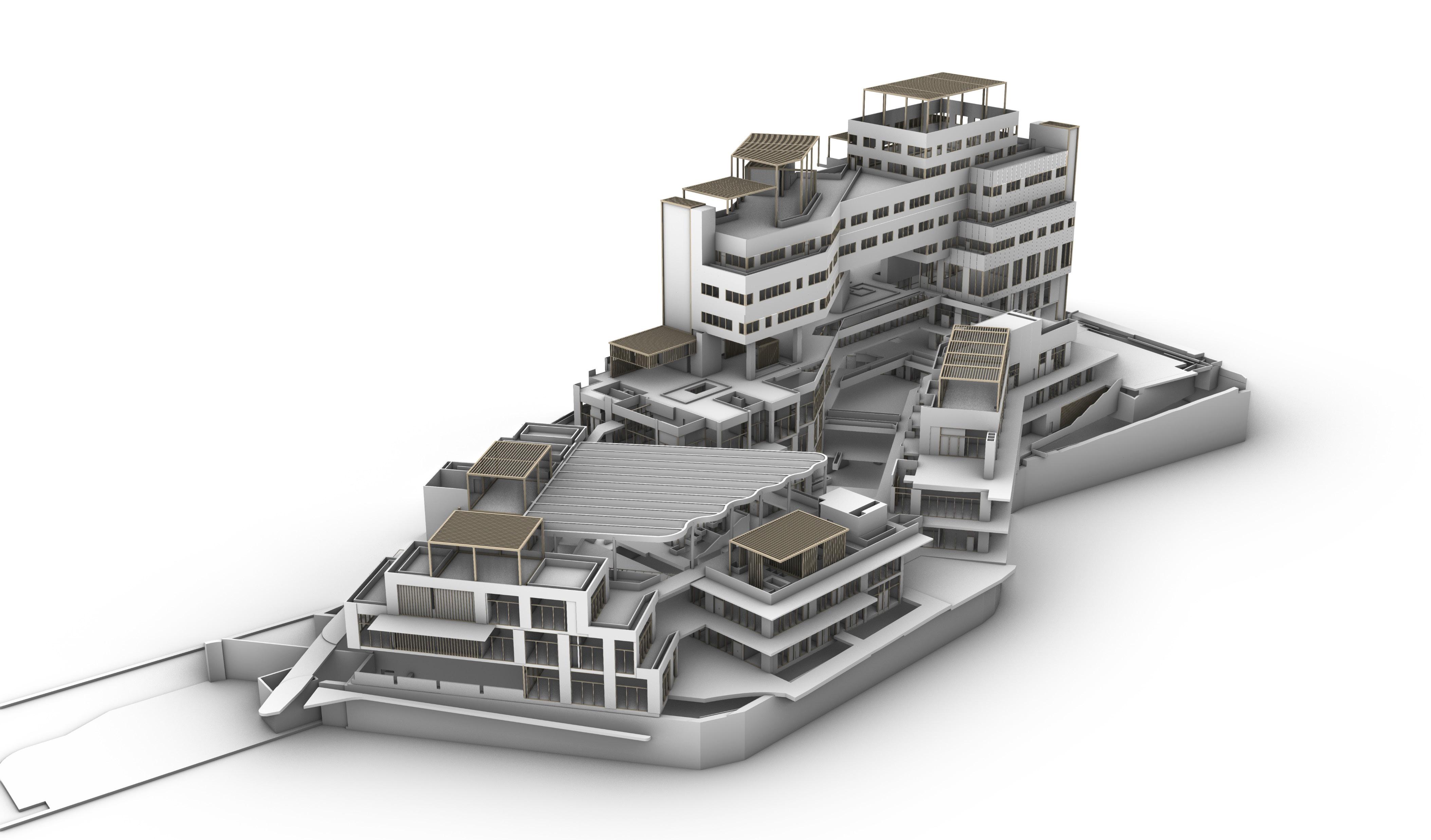

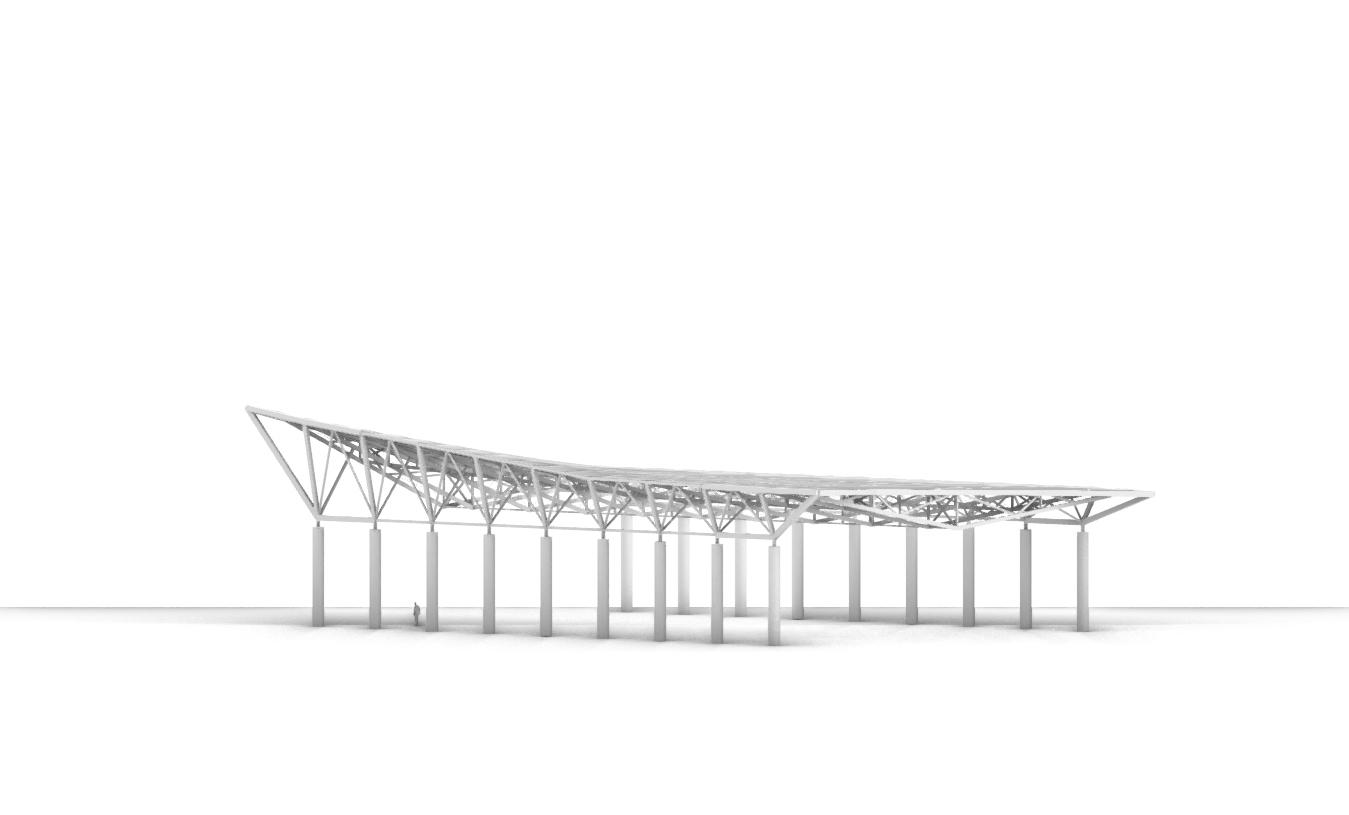

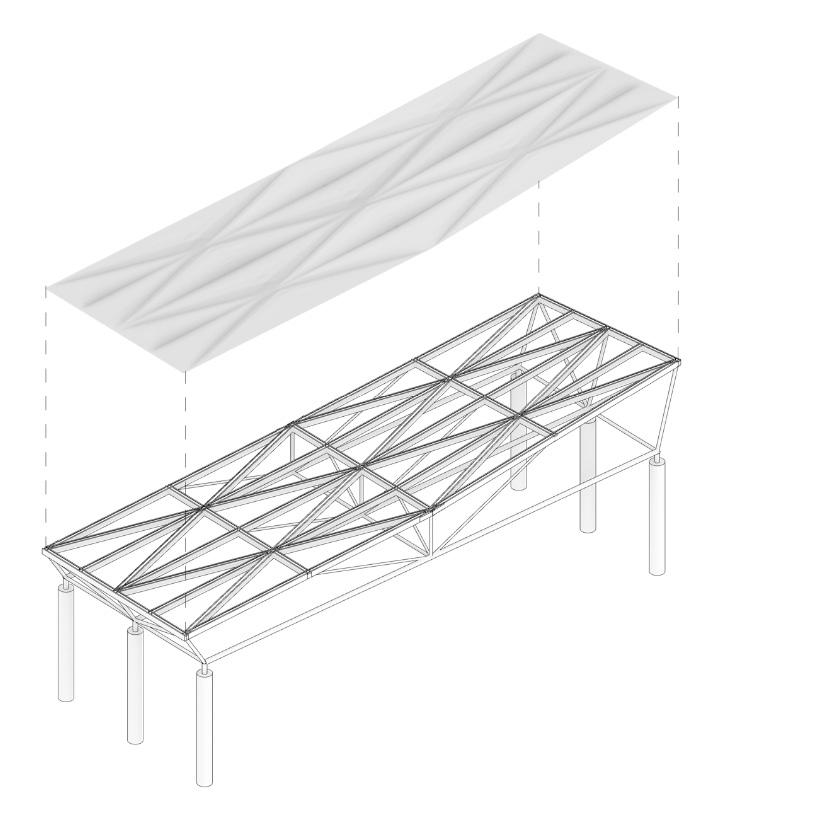

Cambodia Airport Roof

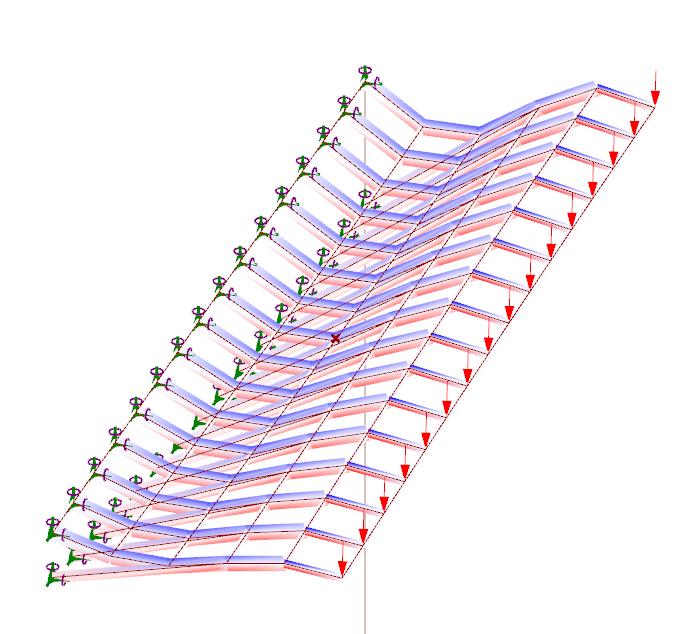

In my time at Passage Projects, I contributed significantly to the Value Engineering design proposal for a VVIP airport terminal in Cambodia. In particular, I reduced the number of unique modules in the roof by 90%, while retaining the design intent and adhering to engineering constraints.

Context

Base Design

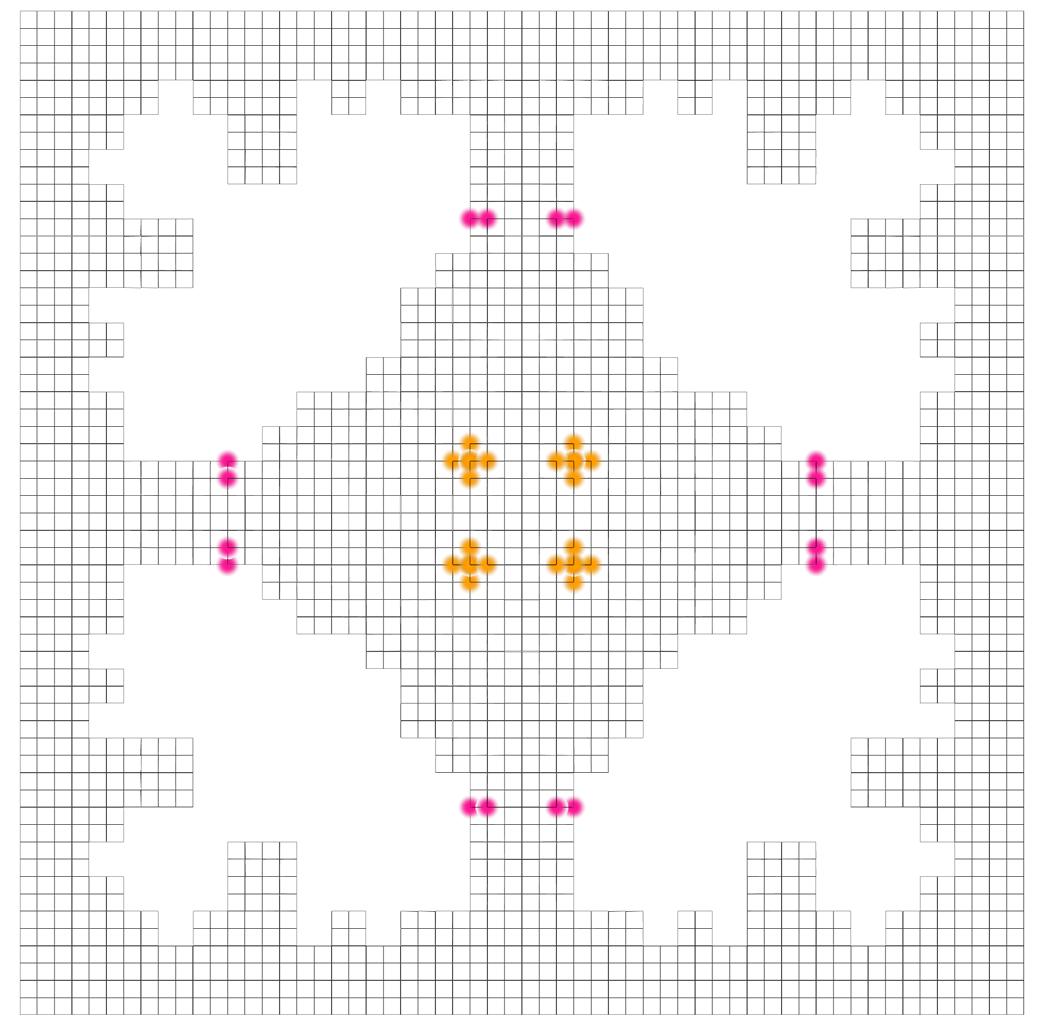

The original airport roof had a complicated soffit layer with over 500 unique pyramidshaped modules. To reduce cost of fabrication and improve craftsmanship, I explored various methods to reduce the number of modules.

Initial Approach

Initially, we tried the most straightforward approach - to reduce the entire roof to only 2 types of modules (either half a pyramid or a full pyramid). This was done by using a single curve to define the whole roof. However, due to the drastic change to the shape of the roof, this method was not further pursued.

2 Module - Layout

The shape of the roof drastically deviated from the original intent.

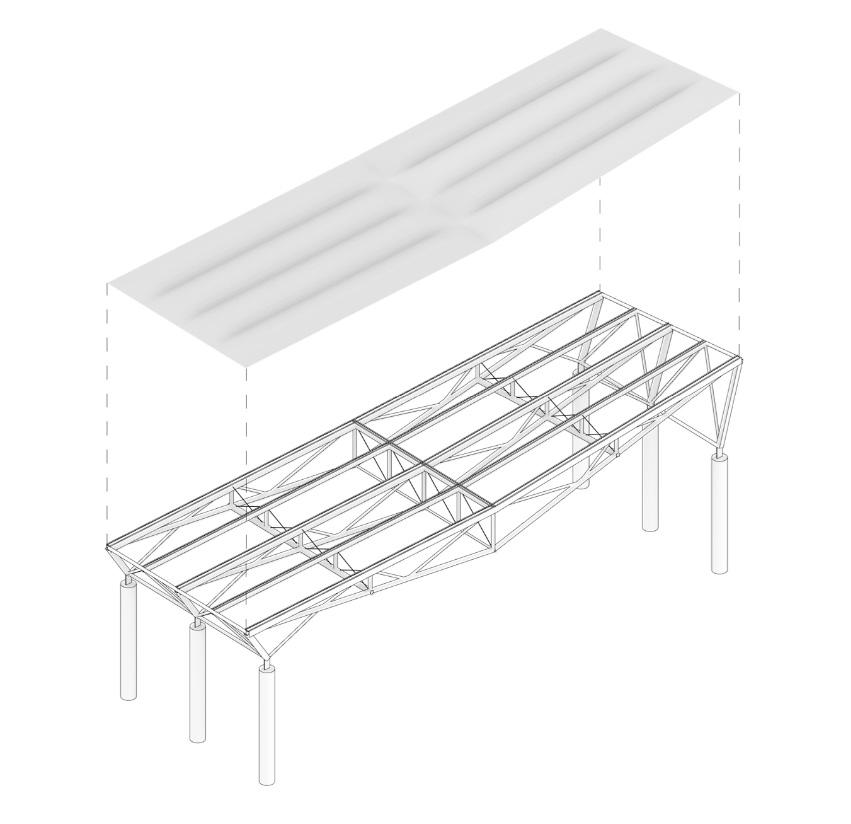

Space Frame Soffit Frame Pyramids (Soffit)Value Engineering Approach Rationalising Modules

Planarize Soffits

Creation of soffit Families

Architecture and ID

Architecture and

–Pyramids in one soffit frame are made identical, so joints are consistent and easier to fabricate

As the initial base design was done by another architect, I analysed the base model and adjusted it such that “families” of modules could be created, thereby reducing the numebr of unique modules by 93% (from 525 to 38).

Step 2) Analyse Implications of Planarisation

Plan View

Simplification of Roof Soffit Details

VE-002: Simplification of Roof Soffit Details

–Repeated modules improves craftsmanship, reduces cost

Creation of soffit Families

Creation of Soffit Frame Families

60% DD Soffit Frame

Base Quad

–Pyramids in one soffit frame are made identical, so joints are consistent and easier to fabricate

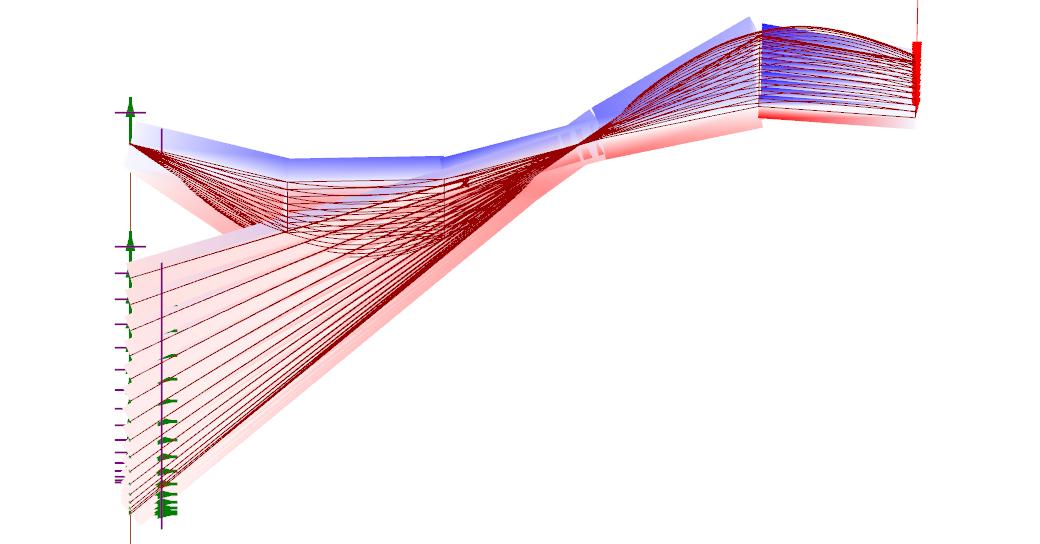

Individual pyramids and soffit frames are non-planar in 60% DD. As such, the size of each plate and angle of each joint is distinct from another. Unique modules are complicated and expensive to fabricate.

Planarization of soffit frames is proposed, so that the joints in each frame can be the same. This also allows the 4 pyramids in each soffit frame to be identical, reducing the number of unique modules to a quarter of the original design.

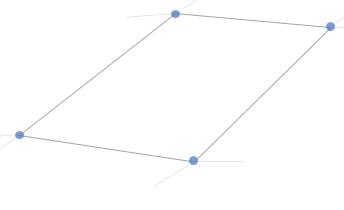

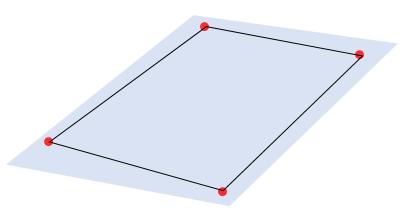

Step 1) Planarise Modules

–Pyramids in one soffit frame are made identical, so joints are consistent and easier to fabricate

Frame Families

Use average plane to planarize module

Proposed Planar Parallelogram

Soffit Frame

45

Implications

Planarize Soffits

Planarize Soffits

Averaging the plane of the soffit frame results in deviations in the shadow gap and creates a vertical gap between some soffit frames. Modules near the columns which deviate too much are removed from the modularization process (remain unchanged from 60% DD)

Individual pyramids and soffit frames are non-planar in 60% DD. As such, the size of each plate and angle of each joint is distinct from another. Unique modules are complicated and expensive to fabricate.

Individual pyramids and soffit frames are non-planar in 60% DD. As such, the size of each plate and angle of each joint is distinct from another. Unique modules are complicated and expensive to fabricate.

This proposal sees deviations in the shadow gap of ±7mm from the original size of 20mm, while the maximum vertical gap attained is 20mm. In the scale of the large roof, this deviation is deemed to be minimal.

Planarization of soffit frames is proposed, so that the joints in each frame can be the same. This also allows the 4 pyramids in each soffit frame to be identical, reducing the number of unique modules to a quarter of the original design.

Planarization of soffit frames is proposed, so that the joints in each frame can be the same. This also allows the 4 pyramids in each soffit frame to be identical, reducing the number of unique modules to a quarter of the original design.

Implications

Implications

Averaging the plane of the soffit frame results in deviations in the shadow gap and creates a vertical gap between some soffit frames. Modules near the columns which deviate too much are removed from the modularization process (remain unchanged from 60% DD)

Deviation Analysis

Deviation (Vertical Gap)

Averaging the plane of the soffit frame results in deviations in the shadow gap and creates a vertical gap between some soffit frames. Modules near the columns which deviate too much are removed from the modularization process (remain unchanged from 60% DD) Deviation Analysis Deviation (Vertical Gap)

This proposal sees deviations in the shadow gap of ±7mm from the original size of 20mm, while the maximum

Proposed Planar Parallelogram

Pyramid Base

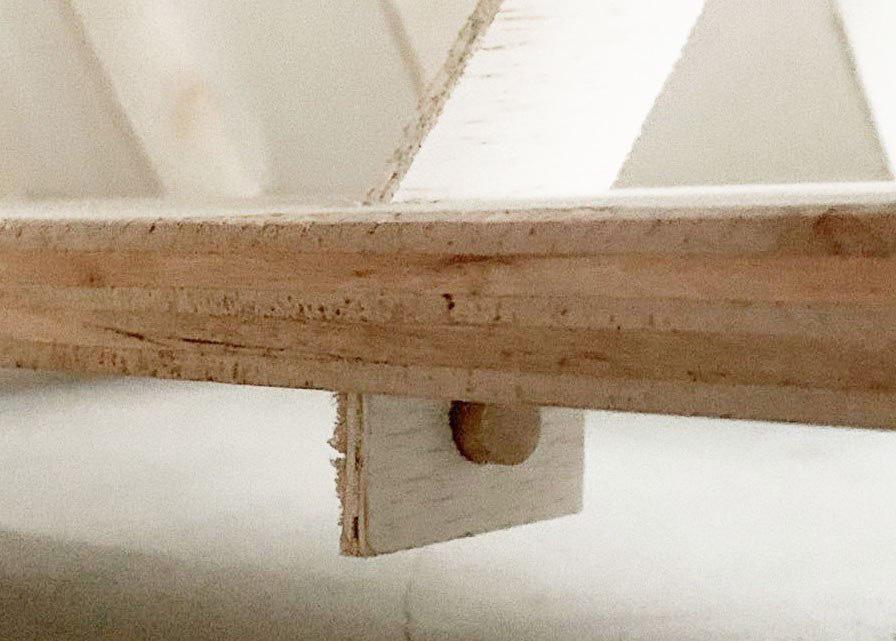

The original modules were not planar, resulting in an inevitable large volume of modules. First, I planarised the modules and adjusted the pyramids to be perpendicular to these planes. This also approximates each frame of 4 adjacent pyramids to be identical.

Deviation (Shadow Gap)

Due to the change in direction of pyramids, there was a +-7mm deviation from the originally consistent 20mm shadow gap between modules.

Deviation Analysis

Deviation (Vertical Gap)

15MM

15MM to 20MM

Vertical gap between adjacent pyramids

Deviation (Shadow Gap)

13MM to 15MM

Shadow gap size between adjacent pyramids

25MM to 27MM

Shadow gap size between adjacent pyramids

25MM to 27MM

13MM

Shadow gap size between adjacent pyramids

25MM to 27MM

Shadow gap size

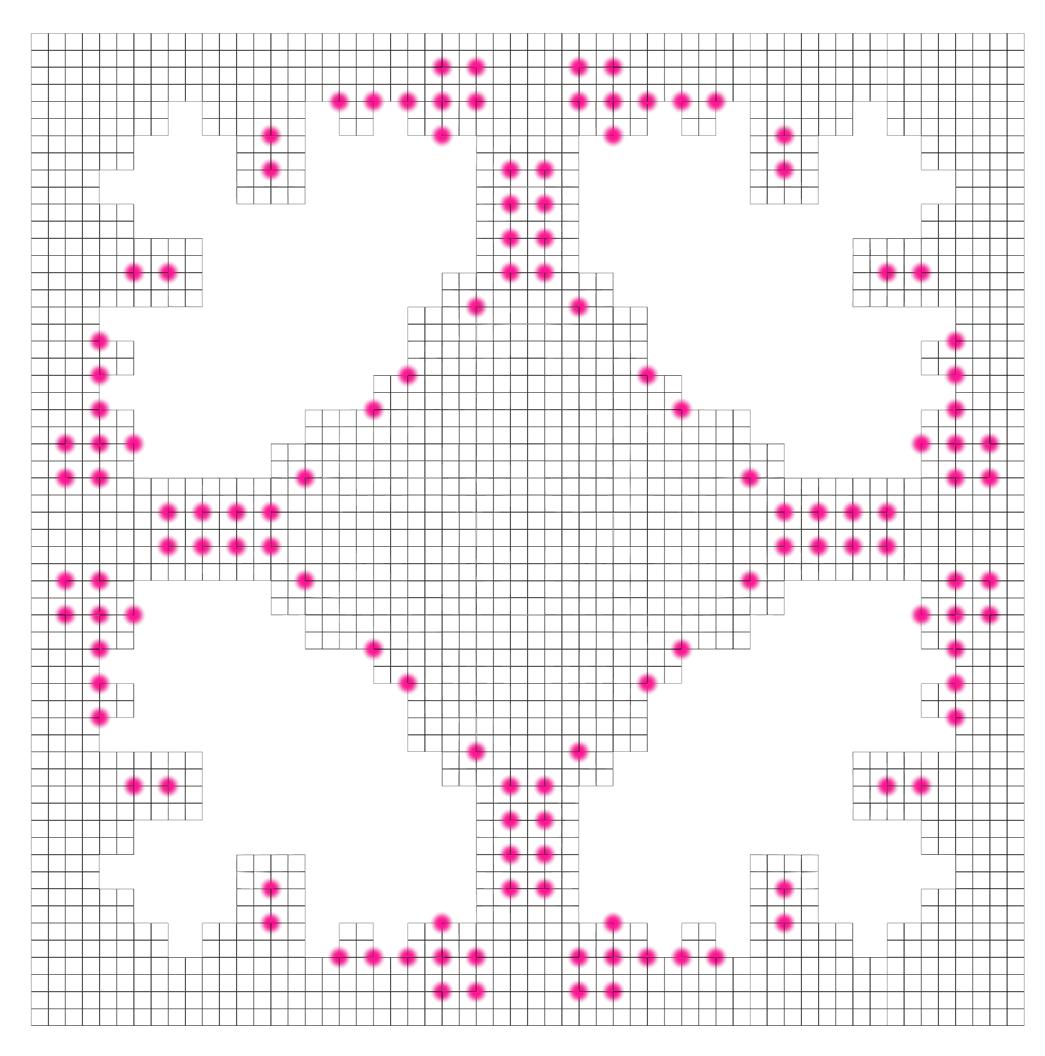

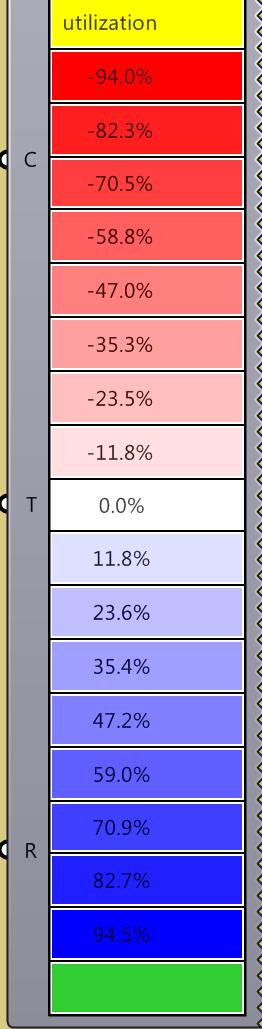

A Grasshopper tool was created to highlight deviations, colour-coding the deviations by userdefined values. In this case, it was deemed that the number of modules exceeding a +-5mm deviation was minimal, hence acceptable.

Step 3) Parameterise Modules & Approximate into Families

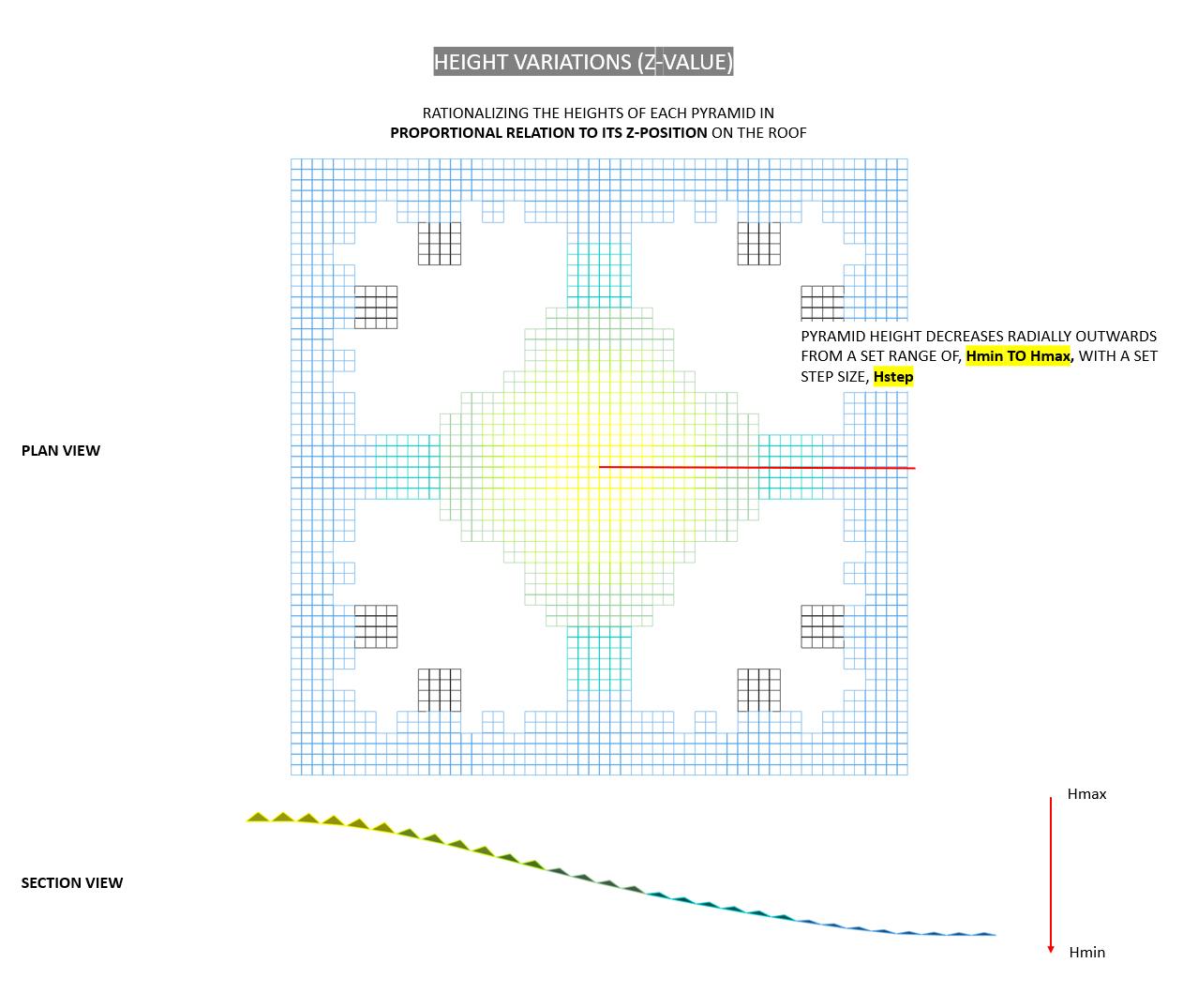

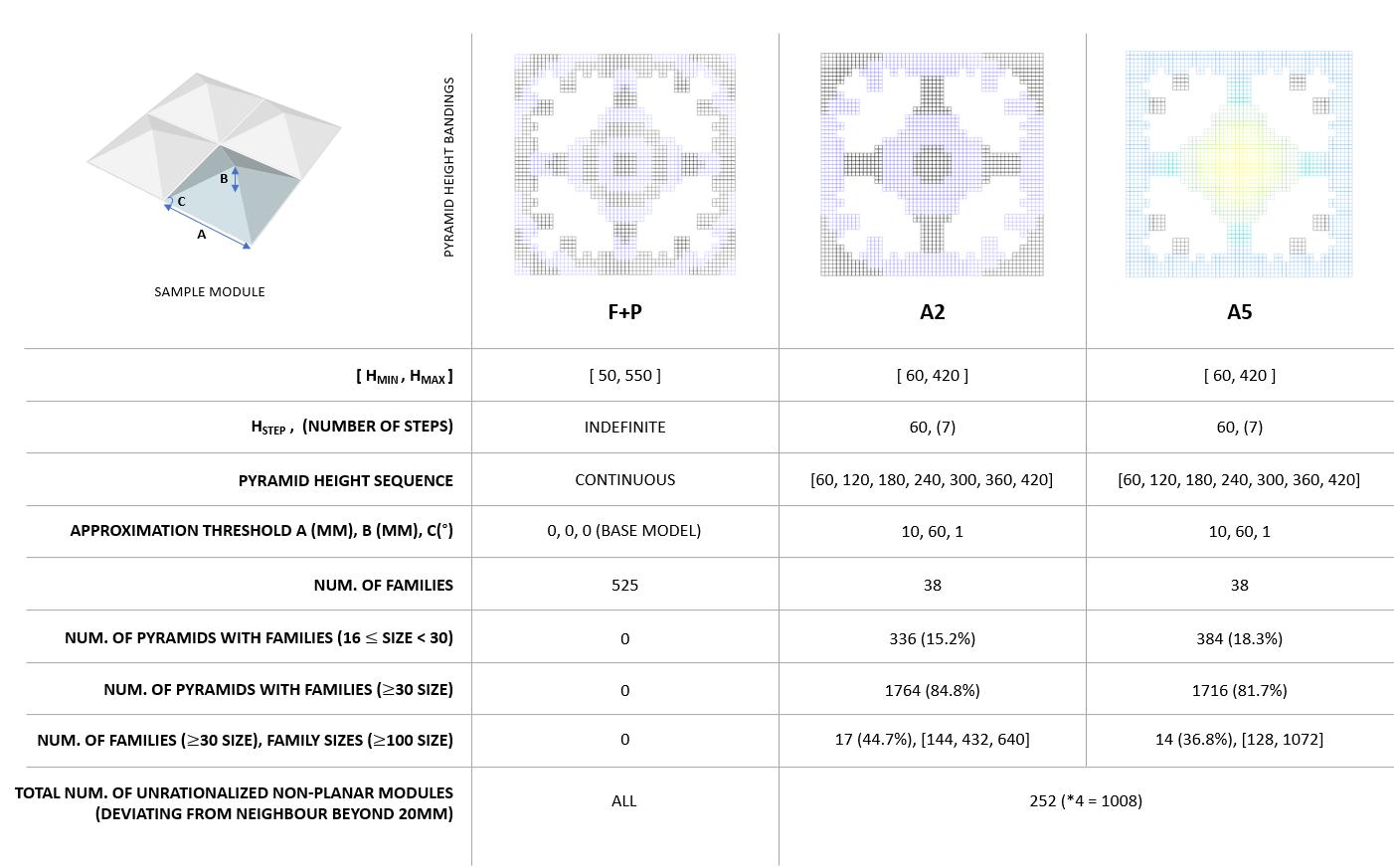

There are multiple parameters in the roof geometry, as set out as below. Each of these parameters are rounded off to a value (“thresholds of tolerance” that can be adjusted parametrically) and approximated into families of modules, to reduce the numebr of unique modules.

The height of the pyramids are set out in two different ways, producing two types of overall roof profile with slight difference in efficiency.

SETTING OUT OF THRESHOLDS:

Length of Pyramid Edges, L = NEAREST A mm

Height of Pyramids, H = Nearest B mm

Angle between Edges, X = Nearest C °

where A, B and C are thresholds that can be changed parametrically.

Base model: A = 10, B = 50, C = 1

Original Design

With this approach, the number of unique modules was reduced from 525 to 38 (93%), while retaining the design intent of the roof.

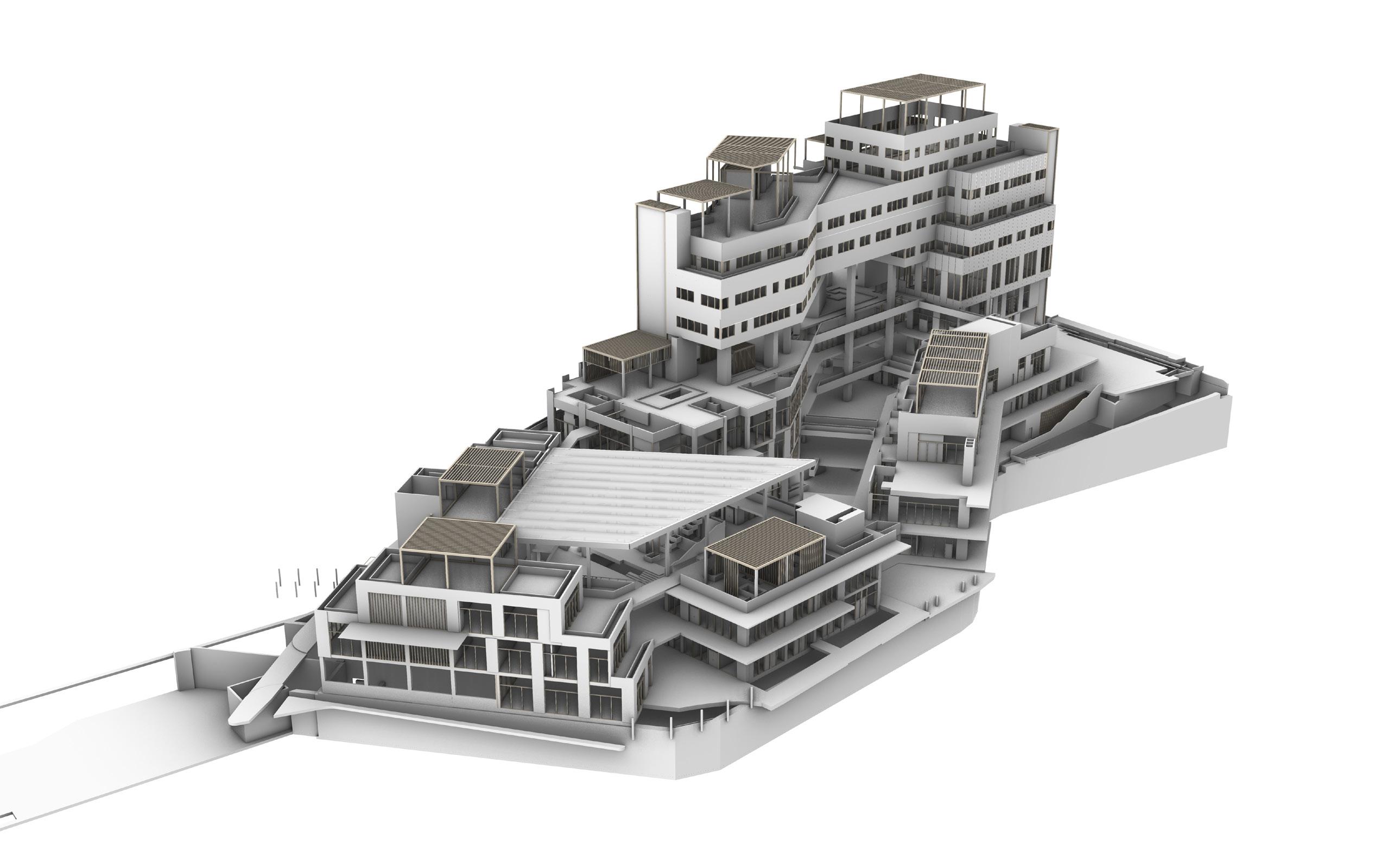

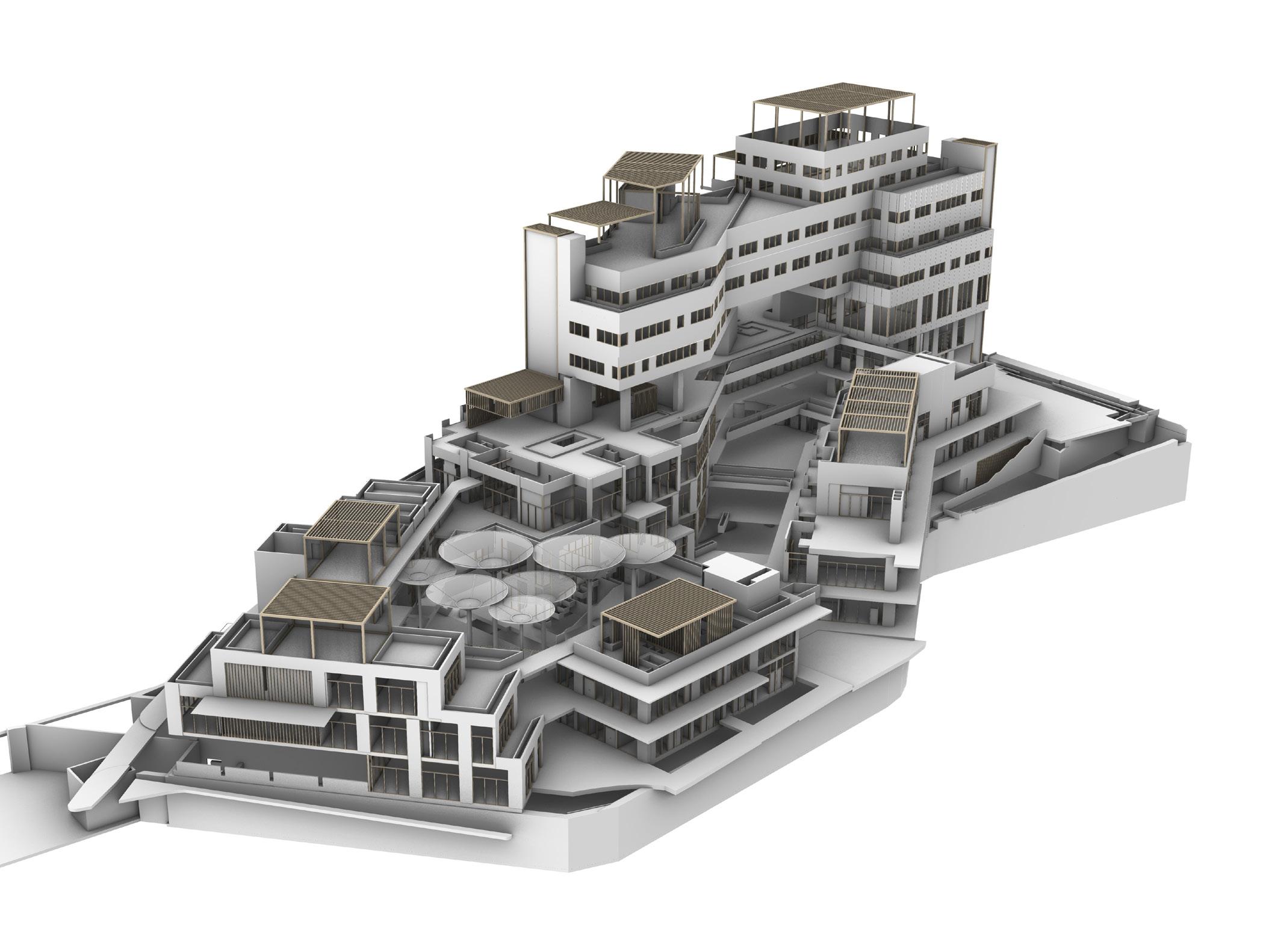

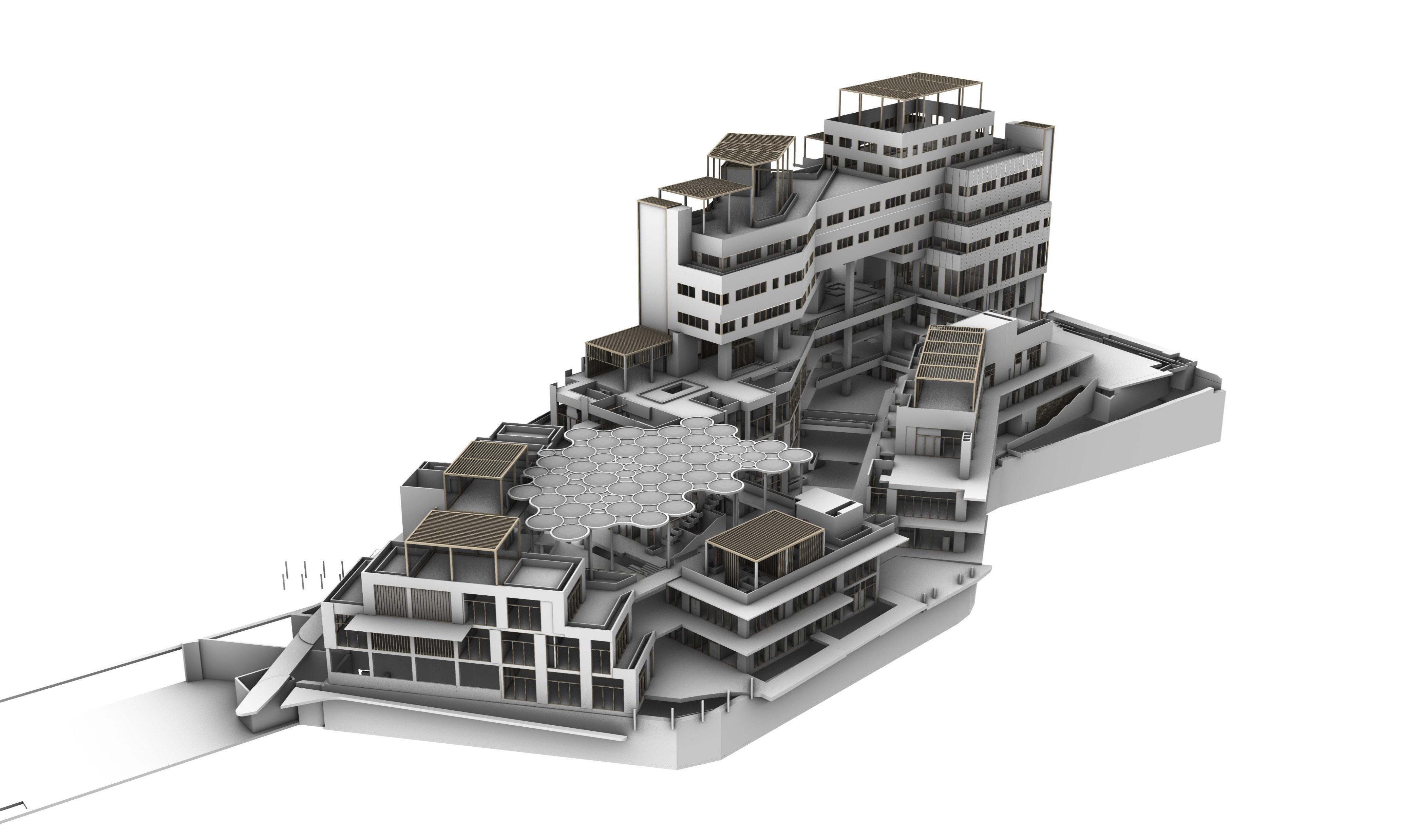

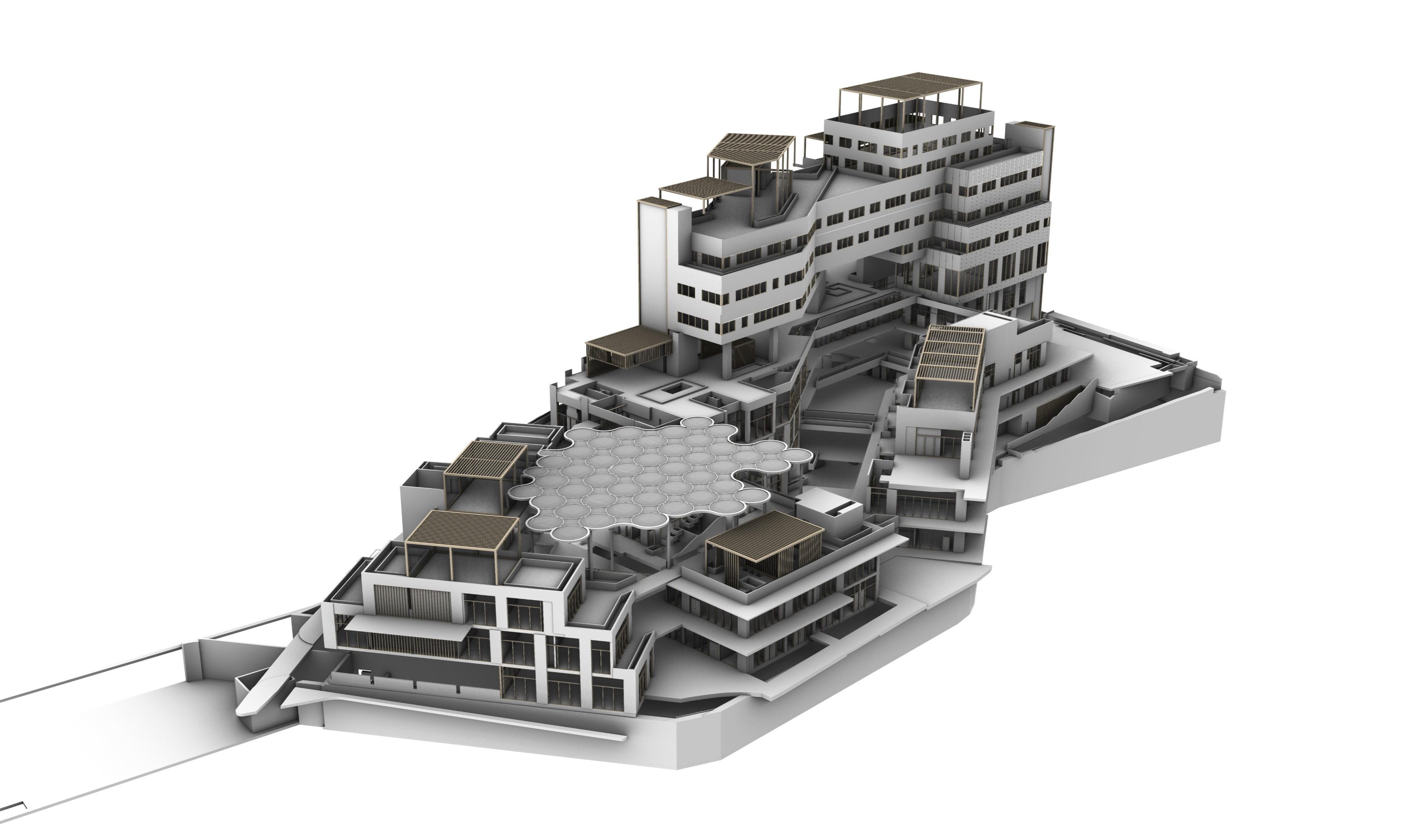

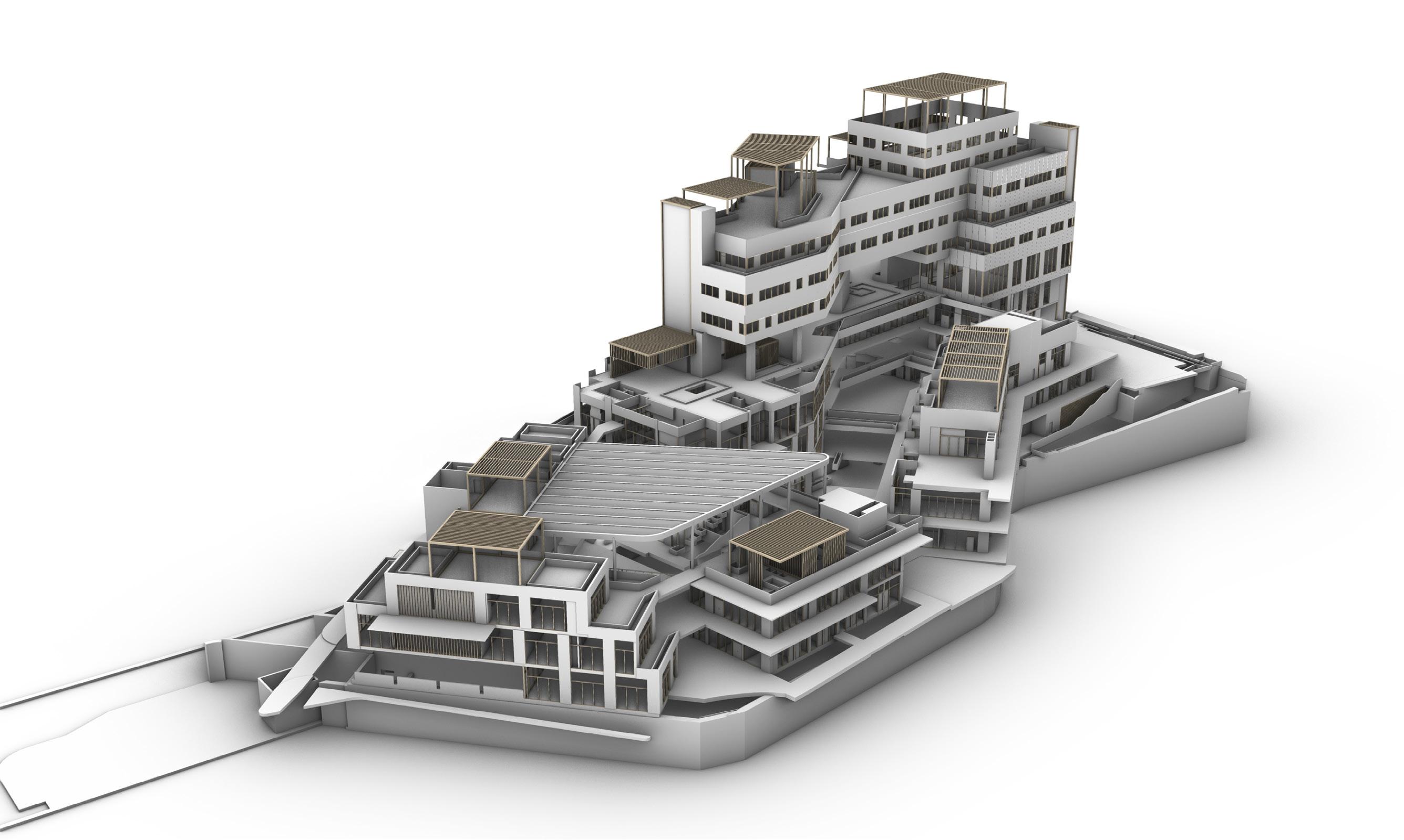

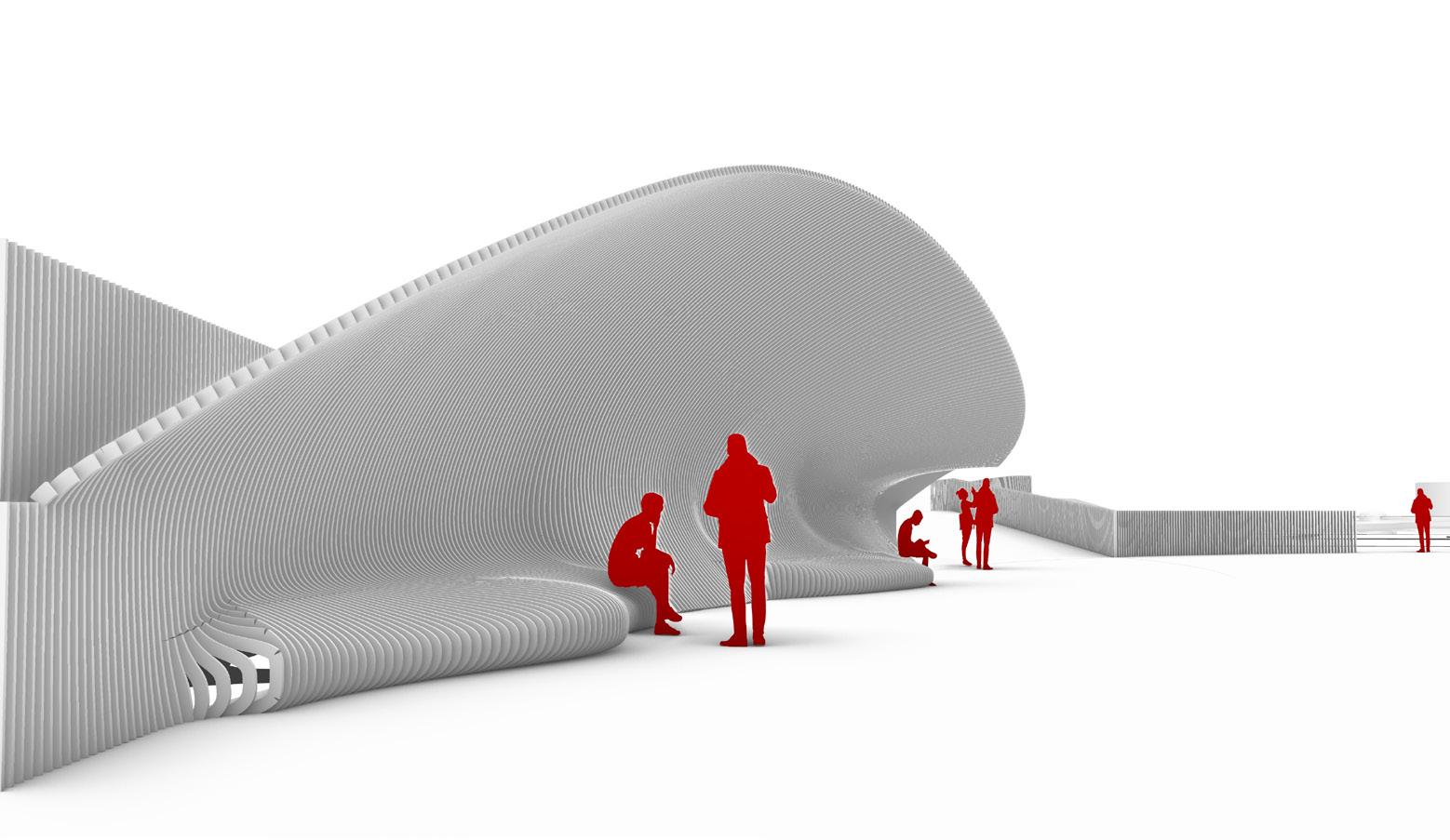

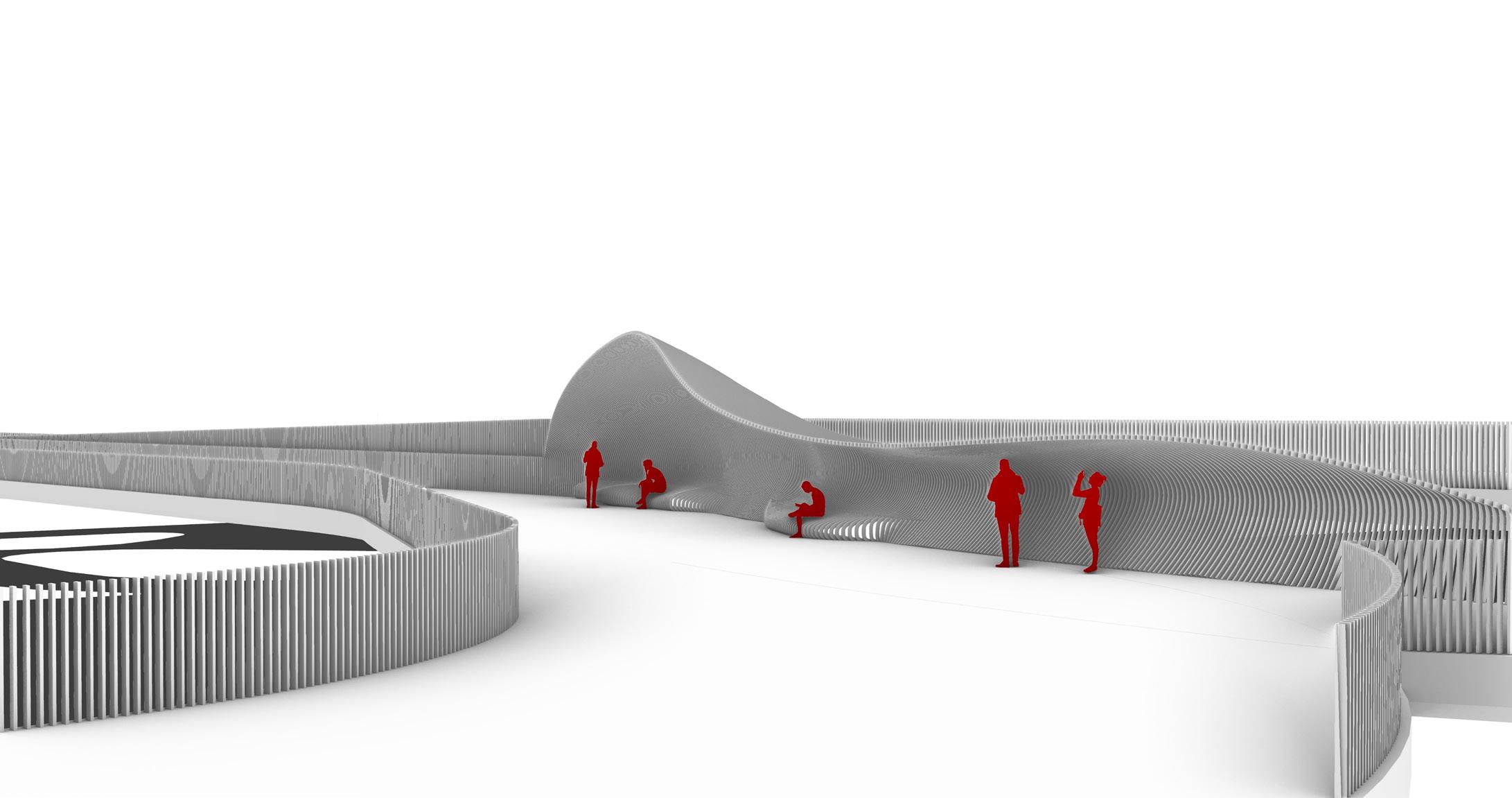

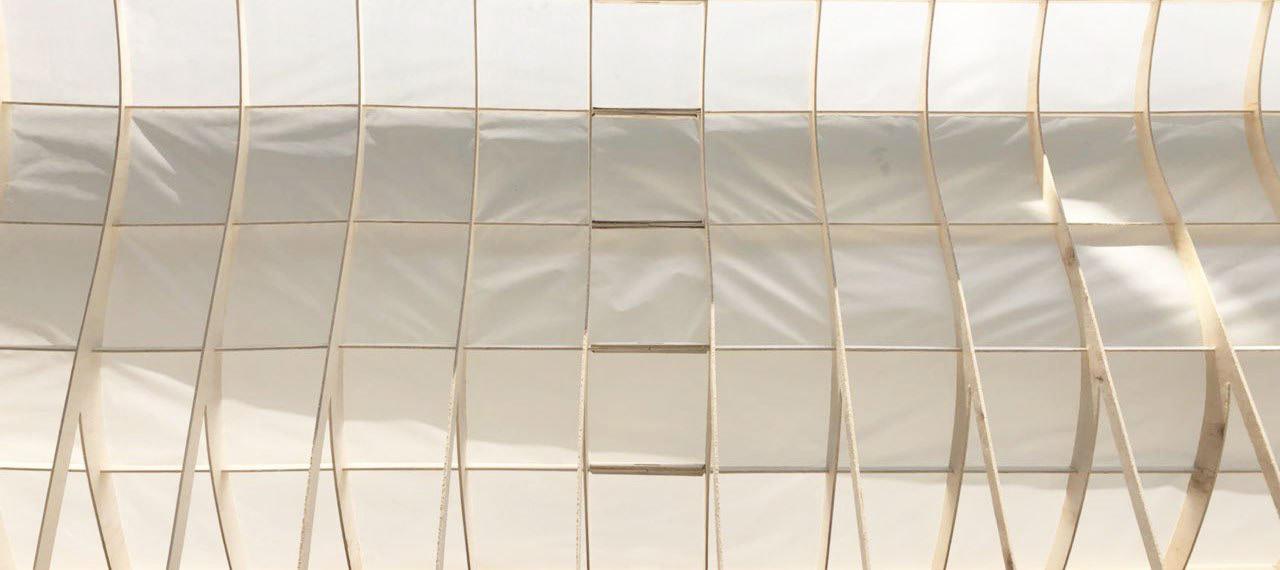

Canopy Form-Finding

A series of design iterations for a canopy was developed to shelter rain and sun from the central courtyard of a mixed-use development in Singapore. Each design stems from the base design brief, which requires the use of a steel frame structure to hold ETFE-cushions.

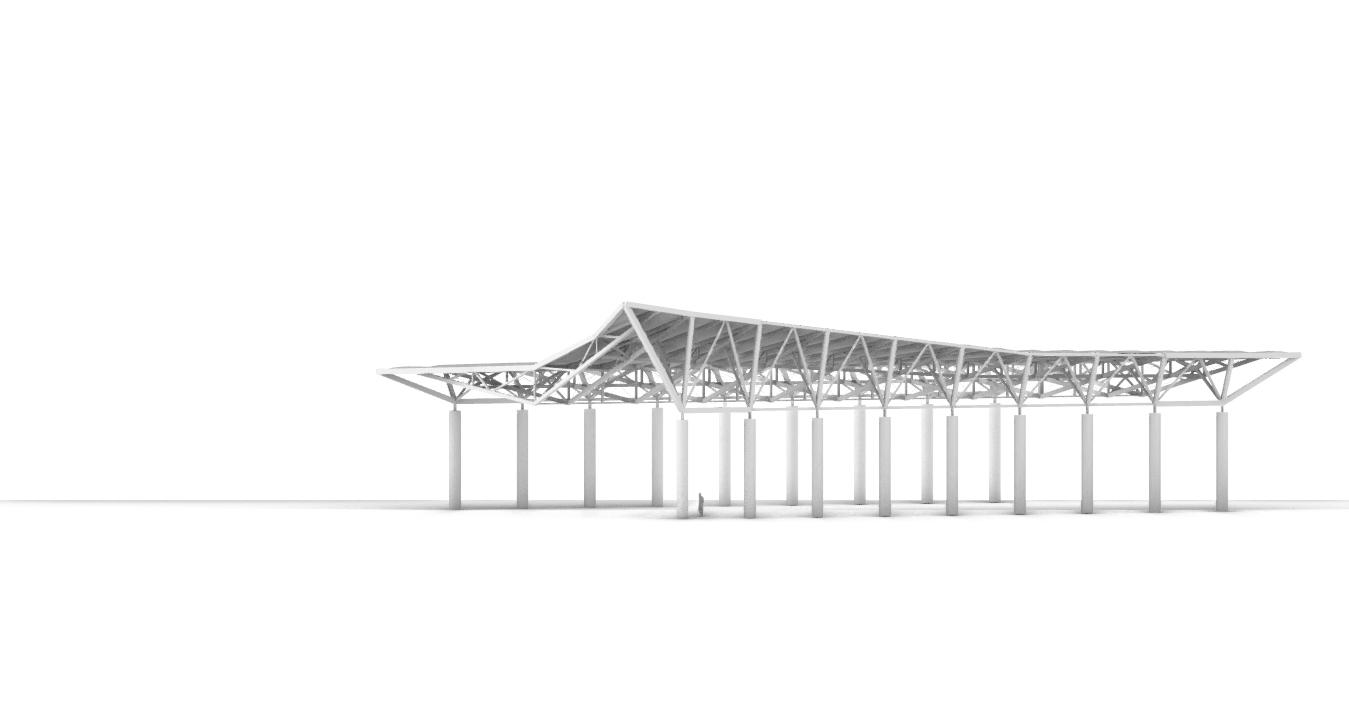

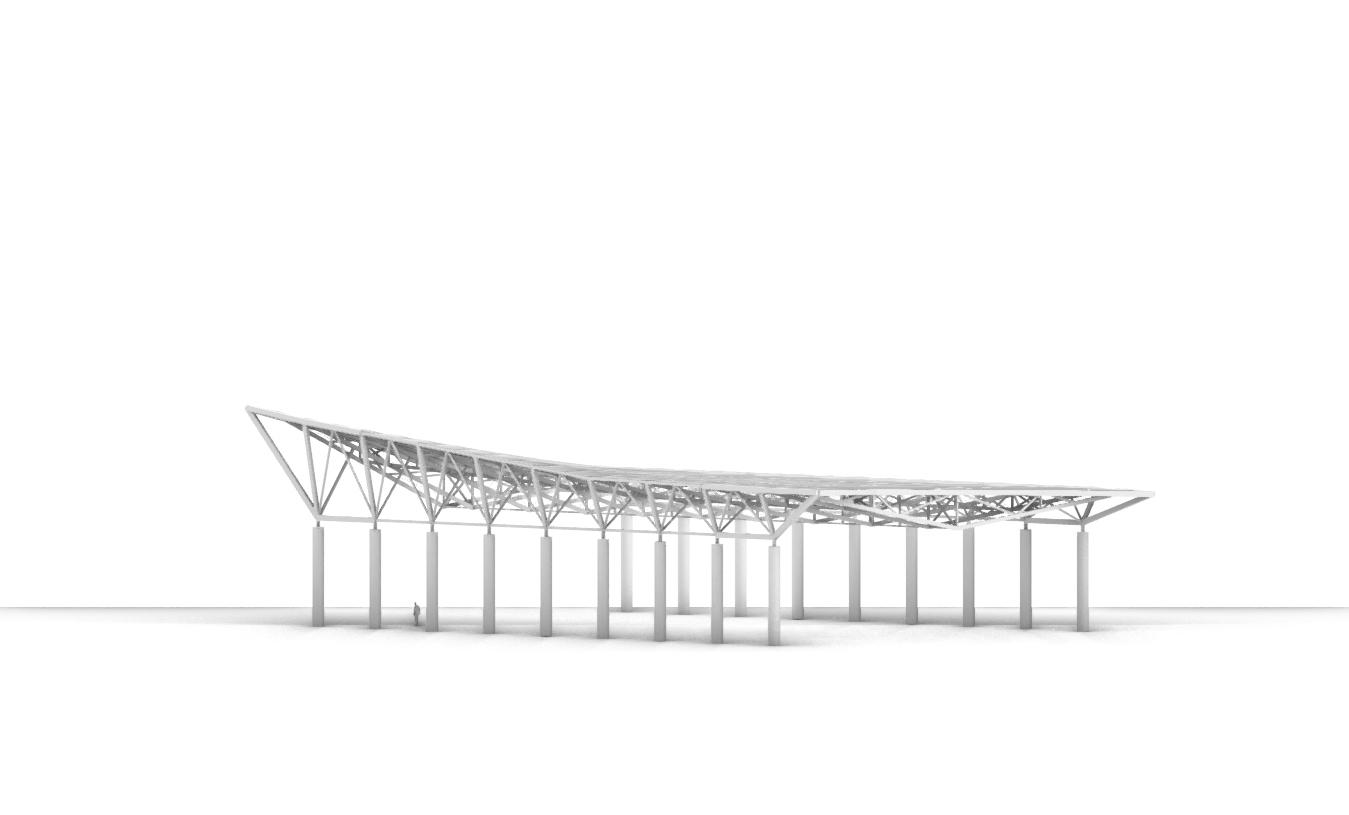

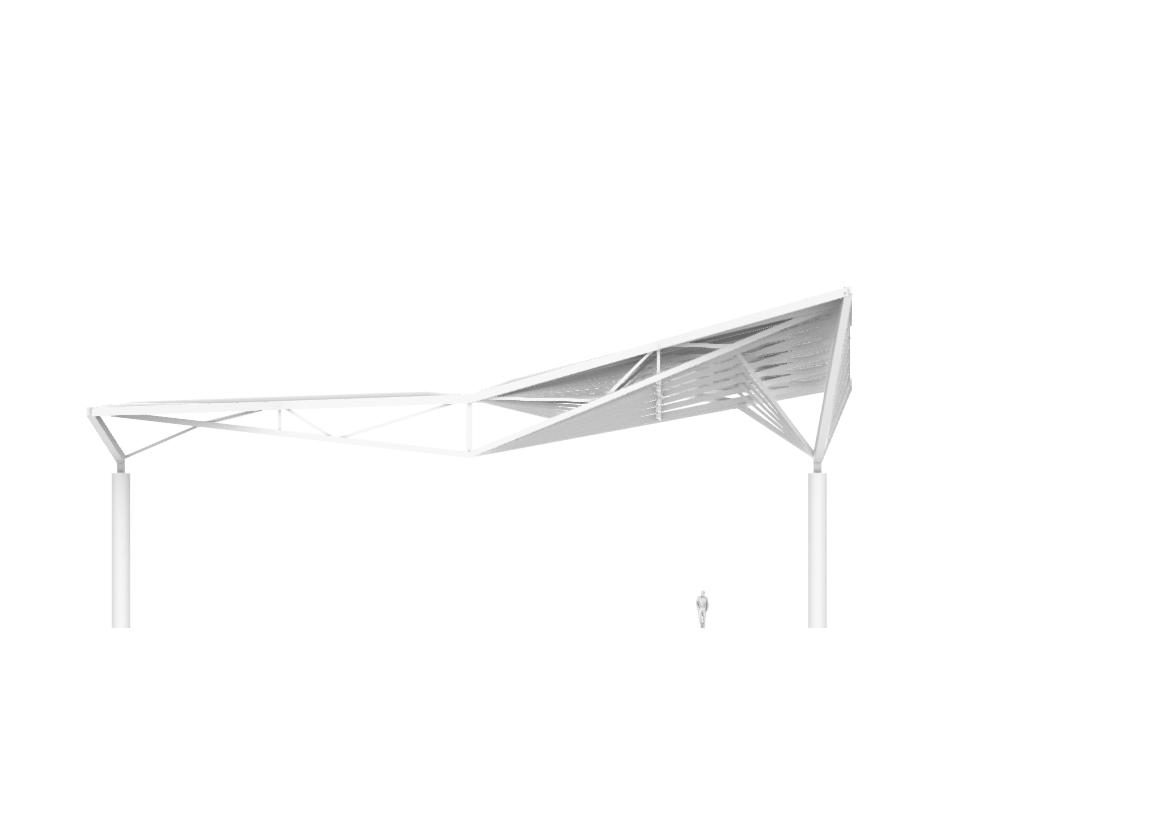

Kai Tak Sports Court

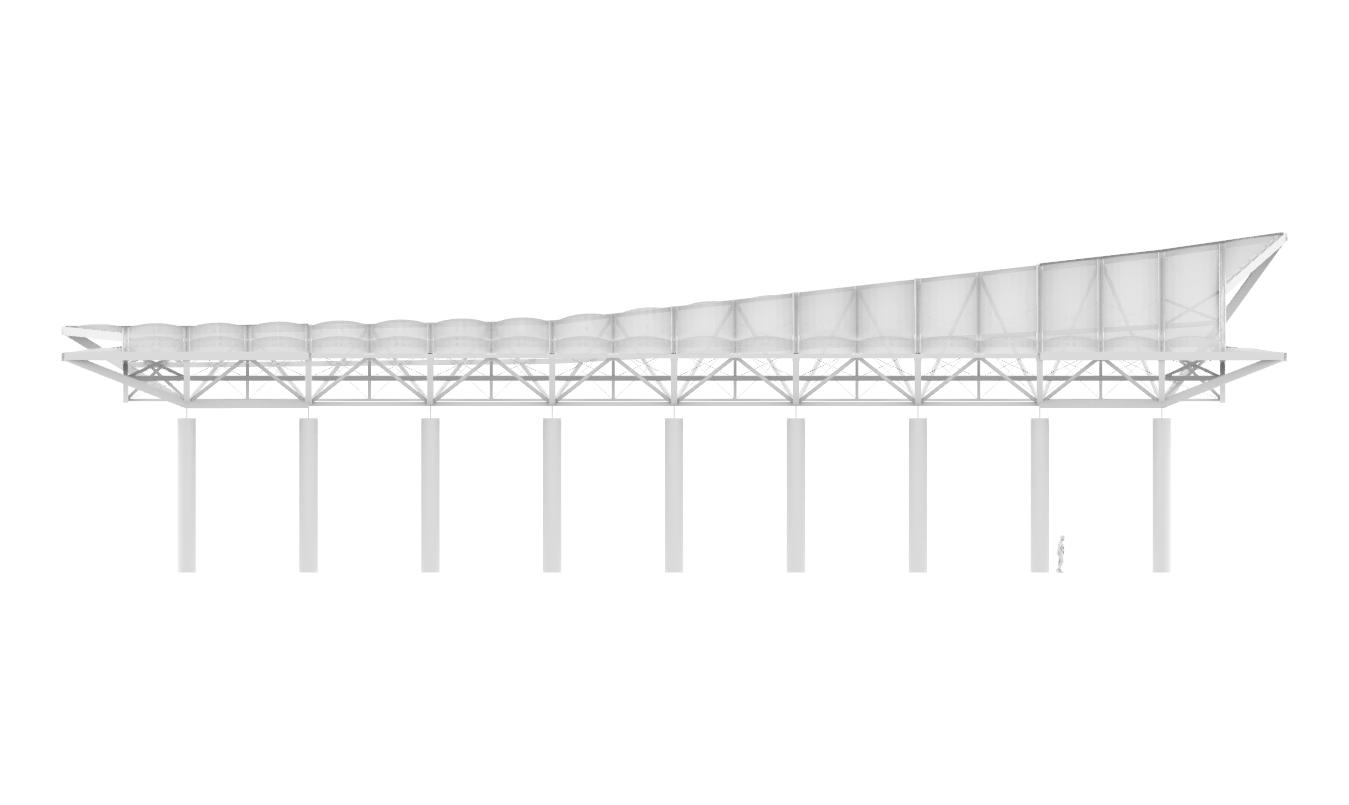

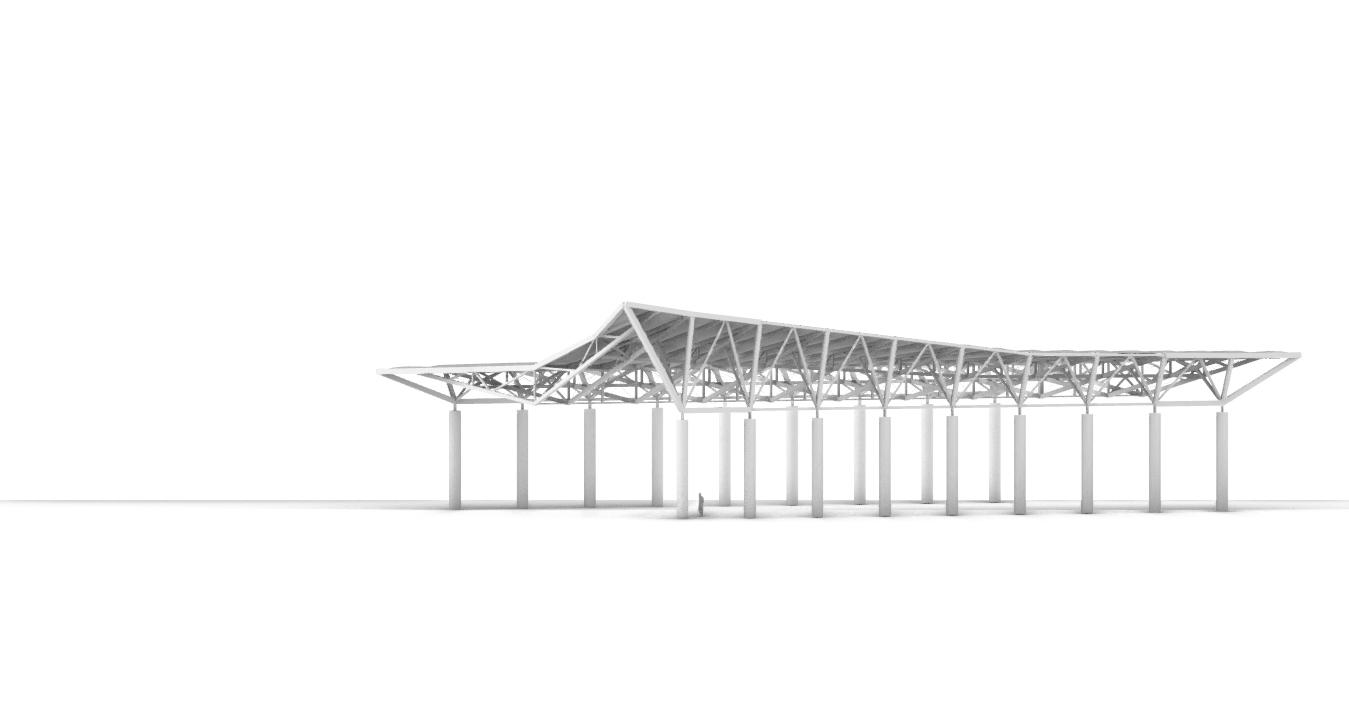

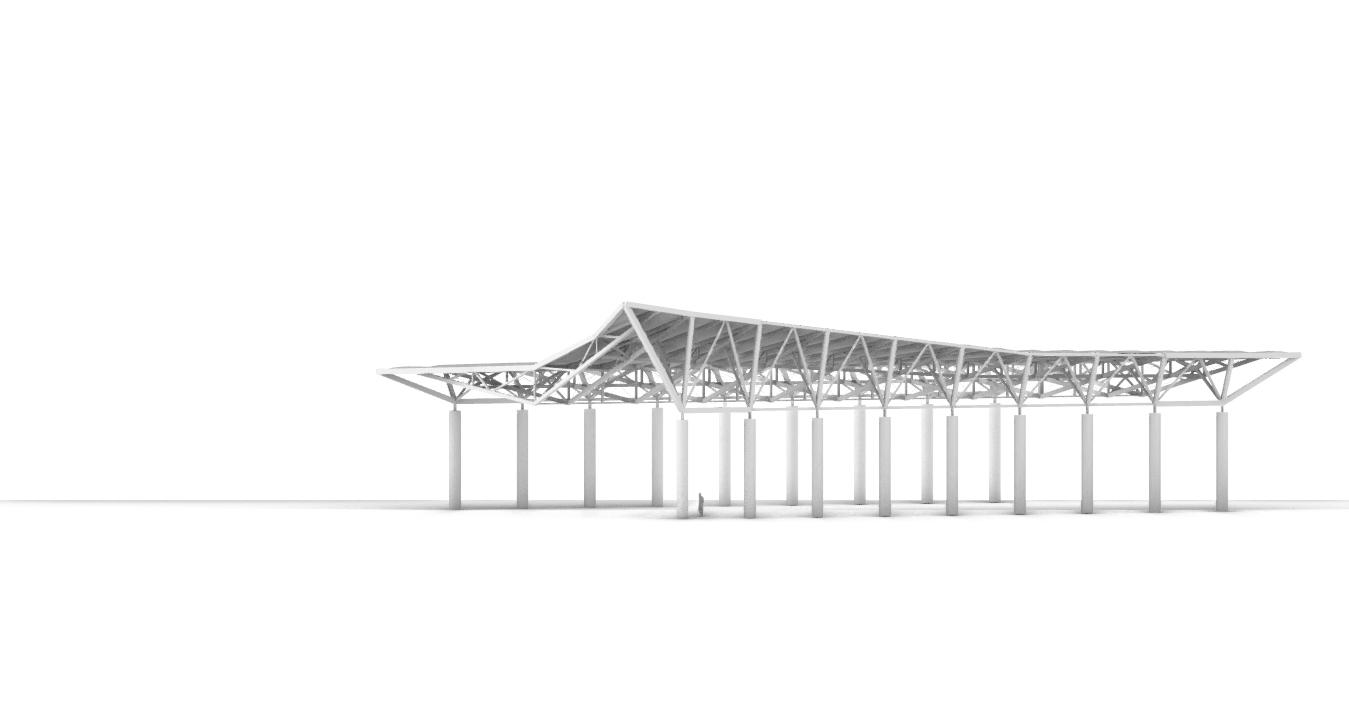

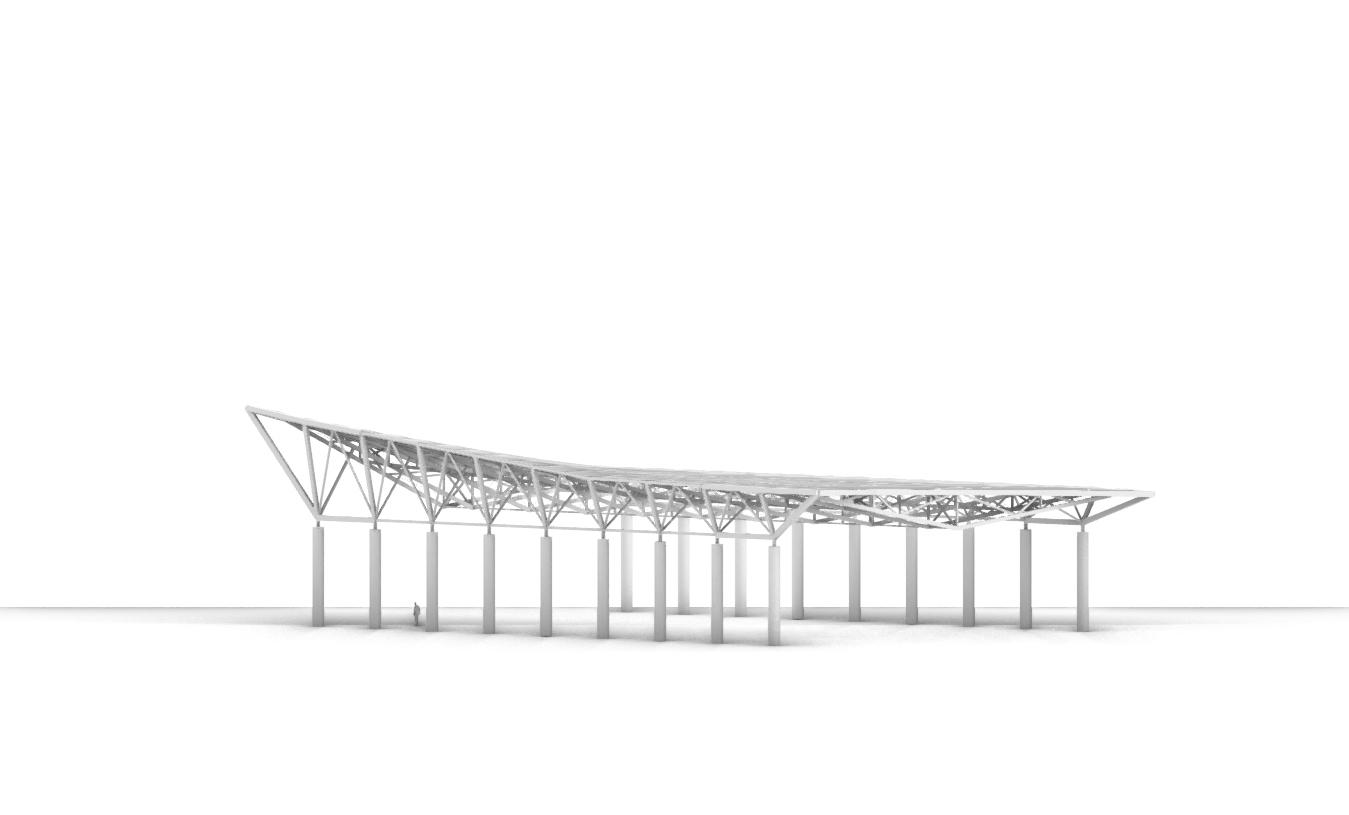

Structural design proposal for a sports court in Hong Kong. For this project, I modelled the proposal in Rhino and produced drawings and renders for presentation.

Front Elevation

Side Elevation

Front Elevation

Side Elevation

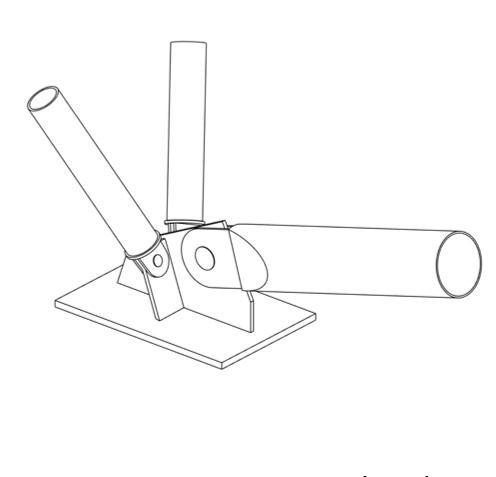

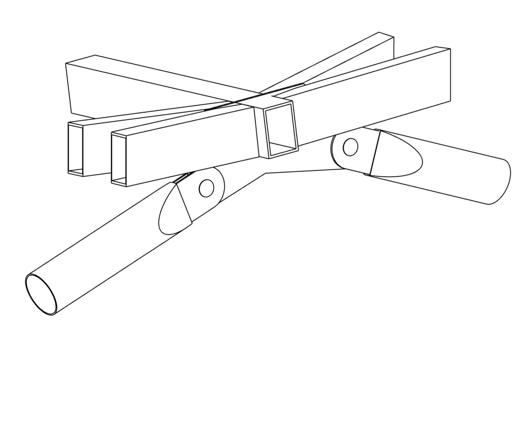

Connection at Spine Beam (Exploded View)

Connection to Edge Beam Connection to RC Pedestal Connection at Spine Beam

ETFE Cushion

Spine Beam

Main Beam

Primary Strut

Connection at Spine Beam (Exploded View)

Connection to Edge Beam Connection to RC Pedestal Connection at Spine Beam

ETFE Cushion

Spine Beam

Main Beam

Primary Strut

Base Scheme

Alternative Proposal: 3m Rectangular Cushions with print to replicate triangulation

Shenzhen Footbridge

As part of a urban planning project in Shenzhen, China, we proposed various structural profiles while incorporating public spaces for the elevated footbridge. Section

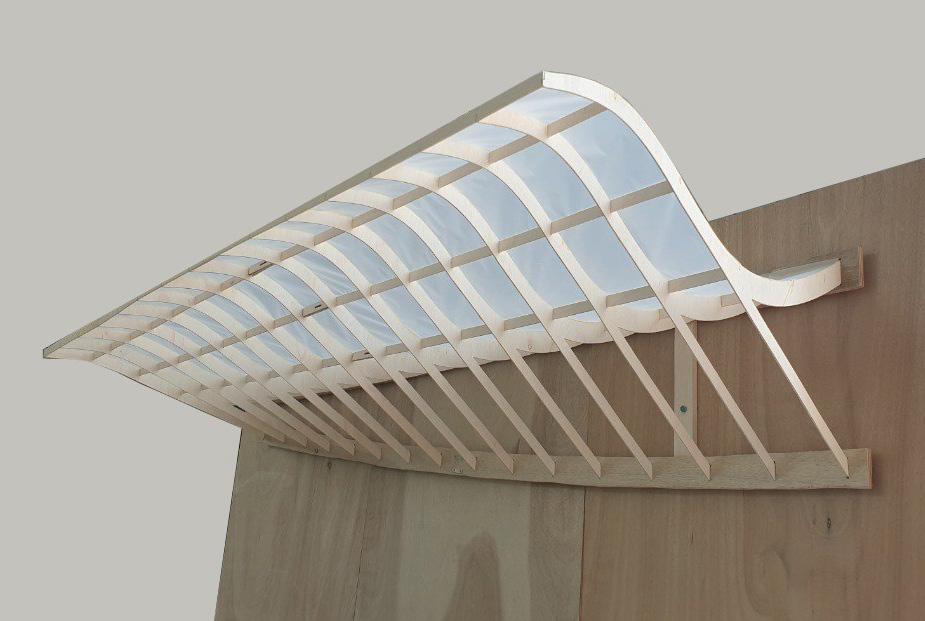

木 漏 れ 日

komorebi

Komorebi describes the poetic beauty of sunlight filtering through leaves. Seeking to design and fabricate a canopy that is subtle, elegant and structurally functional, we took inspiration from the simplicity of Komorebi.

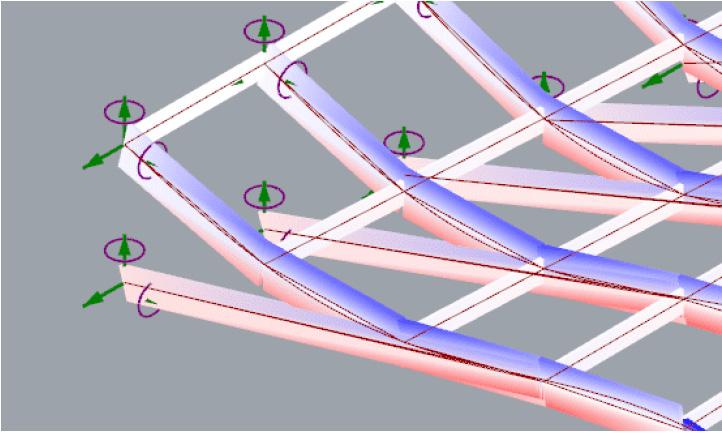

For this project, I designed a Grasshopper tool to parametrically generate a form for the canopy and used Karamba for structural analysis. This project was done in a team of 4, over the course of 6 weeks.

0.65cos(x+1.3) + 0.65sin(2.4y+6) -abs(0.3cos(1.2x+5)sin(6.5y+3.6) abs(cos(0.6x + 8.4) sin(2.5y + 2.6)) -abs(-0.51cos(3.3x+ 4.2)sin(6.4y+2.8) abs(-0.26cos(1.7x + 7.3)sin(6.2y+3.5)

Vertical Self & Live Loads

Total of 70kg vertical load spread across all points

Lateral Wind & Live Loads

Self loads are imposed by the weight of the materials. Vertical live loads factor for the possibility of the canopy being pulled from below or hung onto by users.

Point loads in the Karamba are modelled for the extreme scenario where only the edges of the canopy are pulled at.

Lateral live loads account for the possibility of the canopy being pushed in the horizontal direction by users.

Total of 1kg horizontal load spread across all points

There is little lateral live load expected, except for strong winds.

The Karamba model showed that there were additional tensional forces on the structure when the structure was not allowed to rotate freely from the back plank. Hence, to release tension in the structure, we introduced the loose hinge-dowel joint to allow rotation while fixing translation.

Without dowel joint (Rx fixed)

With dowel joint (Rx unfixed)

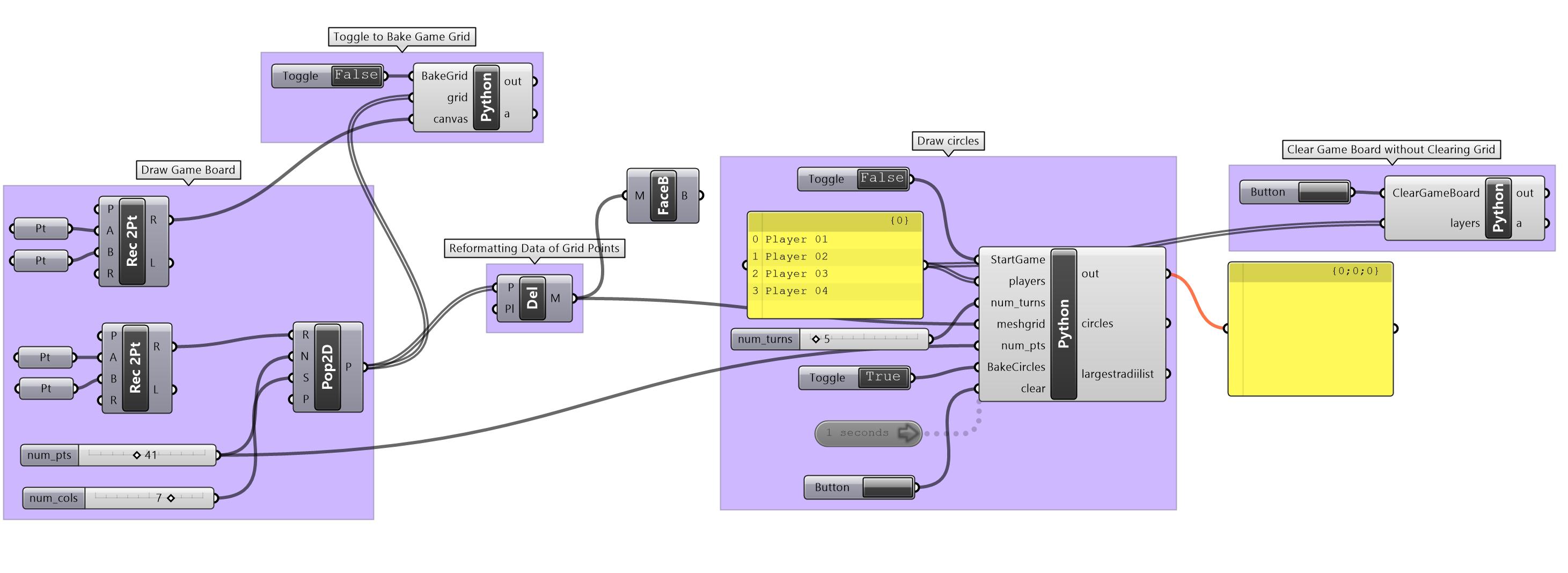

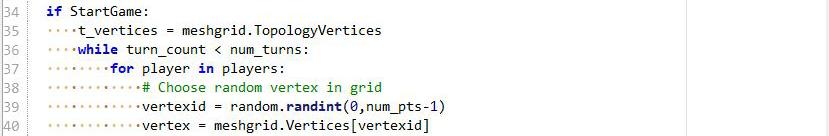

Circles Game

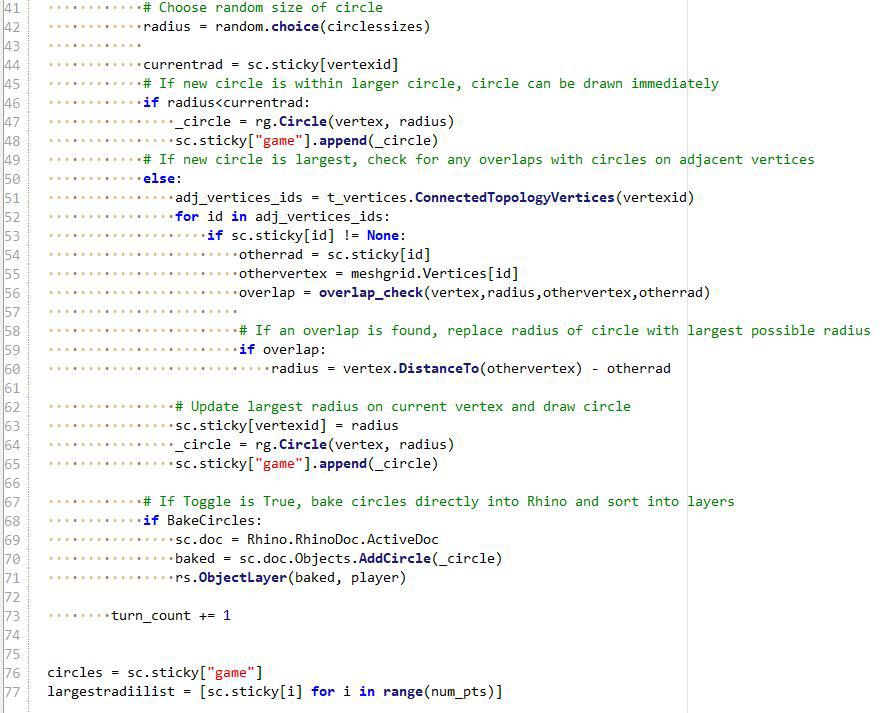

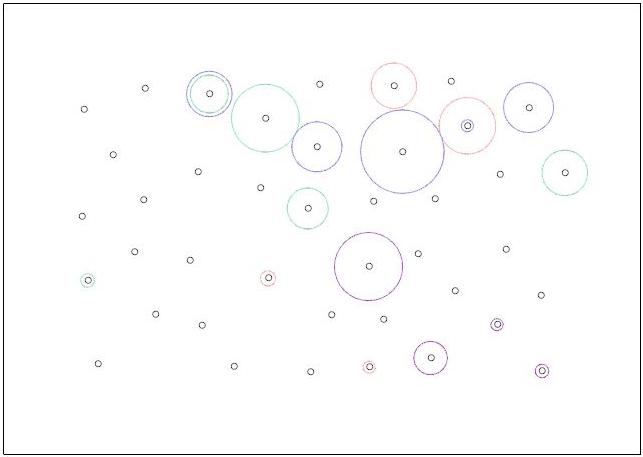

One of my first few Grasshopper projects, this code simulates a circle-drawing game to create a live artwork. When the programme runs, concentric circles are drawn onto points on a canvas over time. Depending on the changing parameters, different results are produced with varying paces of growth or arrangement of points. It can be exciting, intriguing, or simply therapeutic to watch.

Some things this project taught me was to create a memory system using sticky variables, and to access Rhino scriptcontext (to directly manipulate Rhino objects in Grasshopper, or automatically bake Grasshopper geometry into Rhino).

Thank