THE AWARDS ISSUE

OUTSTANDING COMPANIES RECOGNISED AT THE MANUFACTURING ASIA AWARDS 2023 AND ASIAN EXPORT AWARDS 2023

PUPUK KALTIM CEO TAKES PRIDE IN SNI-QUALITY PRODUCTS

WHAT ROLE DO FRONTLINE WORKERS PLAY IN TECH ADAPTION?

SILICON BOX BREAKS BOTTLENECK IN CHIPLET PACKAGING

AI ETHICS DEBATE SPURS IP RIGHTS DISCUSSION IN DESIGN MANUFACTURING

Issue No. 01 Manufacturing Asia

Display to 30 April 2025 S$5.90

About Us

Manufacturing Asia is the industry portal serving Asia’s dynamic manufacturing landscape. Each section carries a balance mix of articles which appeal to the C-level executives of large manufacturing companies in Asia.

Do reach out to us if you would like us to tell your story to our readers via print and online advertising or events.

PUBLISHER & EDITOR-IN-CHIEF Tim Charlton

EDITORIAL MANAGER Tessa Distor

PRINT PRODUCTION EDITOR Eleennae Ayson

PRODUCTION STAFF

Vincent Mariel Galang

Noreen Jazul

Lady Jo-An Llorin

Consuelo Marquez

Aulia Pandamsari

Ibnu Prabowo

Joanne Christine Ramos

Olivia Tirona

EDITORIAL RESEARCHER Angelica Rodulfo

GRAPHIC ARTISTS Simon Engracial

COMMERCIAL TEAM Janine Ballesteros

Jenelle Samantila Cristina Mae Posadas

ADVERTISING CONTACTS Shairah Lambat shairah@charltonmediamail.com

AWARDS Julie Anne Nuñez awards@charltonmediamail.com

ADMINISTRATION Eucel Balala accounts@charltonmediamail.com

EDITORIAL manufacturingasia@charltonmedia.com

SINGAPORE

101 Cecil St., #17-09 Tong Eng Building, Singapore 069533 +65 3158 1386

HONG KONG Room 1006, 10th Floor, 299 QRC, 287-299 Queen’s Road Central, Sheung Wan, Hong Kong +852 3972 7166

MIDDLE EAST

FDRK4467,Compass Building,Al Shohada Road, AL Hamra Industrial Zone-FZ, Ras Al Khaimah, United Arab Emirates

www.charltonmedia.com

Can we help?

Editorial Enquiries: If you have a story idea or press release, please email our news editor at manufacturingasia@charltonmedia.com. To send a personal message to the editor, include the word “Tim” in the subject line.

Media Partnerships: Please email manufacturingasia@charltonmedia.com with “Partnership” in the subject line.

For subscriptions, please email: subscriptions@charltonmedia.com

Retail Asia is published by Charlton Media Group. All editorial is copyright and may not be reproduced without consent. Contributions are invited but copies of all work should be kept as Retail Asia can accept no responsibility for loss. We will however take the gains.

Sold on newstands in Singapore, Malaysia, Hong Kong, London, and New York. Also out on https://manufacturing.asia/

**If you’re reading the small print you, may be missing the big picture caveat emptor

FROM THE EDITOR

Putting a premium on product safety and quality is central to PT Pupuk Kaltim’s industrial operations. CEO Budi Wahju Soesilo shares the concrete steps that Indonesia’s largest fertiliser manufacturer takes to ensure excellence. Read more on page 12.

Innovation and convenience also play critical roles in day-to-day operations. Kawan Lama’s new automation strategies, designed to reduce human errors, represent another facet of industry innovation. Turn to page 14 to learn more about their operations.

Meanwhile, through its proprietary fabrication method, Silicon Box can package chiplets with the shortest interconnections, leading the way in semiconductor integration whilst offering cost benefits to its partners. Learn more about this technology on page 16.

Recent technological advancements and environmental pressures have prompted manufacturers and exporters to reassess their operations. In recognition of those who have excelled, the Manufacturing Asia Awards and the Asian Export Awards celebrate significant achievements and contributions to Asia’s industrial growth. See pages 24 to 27 for a list of this year’s honorees. Congratulations to all!

Read on and enjoy.

Tim Charlton

Tim Charlton

Manufacturing Asia magazine is a proud media partner and host of the following events and expos:

MANUFACTURING ASIA 1

2 MANUFACTURING ASIA RETAIL SINGAPOREASIABUSINESS REVIEW | MARCH 2018 CONTENTS news on manufacturing, visit the website manufacturing.asia FIRST INTERVIEW SECTOR REPORT ANALYSIS 26 INTERVIEW EXCEPTIONAL COMPANIES LAUDED AT ASIAN EXPORT AND MANUFACTURING ASIA AWARDS OPINION TECH WATCH SILICON BOX BREAKS BOTTLENECK IN CHIPLET PACKAGING WITH SUB5-MICRON TECHNOLOGY 16 FACILITY WATCH 12 CEO INTERVIEW PUPUK KALTIM ADOPTS SNI TO BOOST MARKET TRUST Published by Charlton Media Group SINGAPORE: 101 Cecil St. #17-09 Tong Eng Building Singapore 069533 HONG KONG: Room 1006, 10th Floor 299 QRC, 287-299 Queen's Road Central, Sheung Wan, Hong Kong +852 3972 7166 MIDDLE EAST: FDRK4467,Compass Building,Al Shohada Road, AL Hamra Industrial Zone-FZ,Ras Al Khaimah, United Arab Emirates 06 What role do frontline workers play in tech? 07 Paper outpaces glass and metals in packaging industry 08 Overhead automation enhances safety at GlobalFoundries Singapore facility 10 Oliver Healthcare Packaging expands to Malaysia with 122,000 sqft facility 18 Talent scarcity slows growth in APAC semiconductor 20 Global steel sector abandons carbon capture efforts amidst growing inefficiencies 22 AI ethics debate spurs IP rights discussion in design manufacturing 14 New automation strategies cut down human errors at Kawan Lama Solution 24 SOLIDWORKS irons out its longterm strategy amidst evolving design and drafting industry 32 The Move to 5G: Enabling more resilient, event-driven supply chains in a new age of industrial manufacturing

Car Damage Detection With AI Technologies

The assessment of vehicle damage has historically been a time-consuming and labor-intensive process, necessitating the physical inspection by trained professionals.

At KBTG Labs, we recognize the inefficiencies in traditional inspection methods. Thus, our primary objective is to leverage internal AI R&D and engineering expertise to develop an automated system that revolutionizes vehicle damage assessment.

Our Car AI solution alleviates surveyors’ burdens by enabling end customers to capture a few photographs of their damaged vehicles. Then, the AI will automatically analyze and provide comprehensive damage evaluation results.

Since December 2021, our dedicated efforts have led to significant improvements in data processing within the auto insurance, auto repair, auto sales, and auto loan sectors.

The future of Car AI now resides at KBTG

For collaboration opportunities, please contact: co-innovation@kbtg.tech www.kbtg.tech

MANUFACTURING ASIA 3

News from manufacturing.asia

Daily news from Asia

MOST READ

India’s AI centres to drive significant growth in medical devices market

The Indian government has announced plans to establish three artificial intelligence (AI) centres of excellence in educational institutions as part of its “Make AI for India” and “Make AI work for India” initiatives, Finance Minister Nirmala Sitharaman said during the Union Budget for 2023-24 presentation.

Consumer electronics demand in Malaysia to slow down: analyst

The Malaysian consumer electronics demand will decelerate in 2023, which will affect tech manufacturing services firms, according to CGS-CIMB. “We downgrade our sector rating to Neutral from Overweight as we dial back our optimism to reflect these concerns,” said CGS-CIMB.

Broker predicts less competition for Indonesia’s cement industry in 2025

Industry 4.0 transformation in Malaysia is not just about convincing bosses in businesses to buy cutting-edge technology but also about investing in human capital, according to manufacturing experts in a panel discussion at the Industrial Transformation Asia Pacific 2022.

World’s largest chip maker braces for sales slowdown

Taiwan Semiconductor

Manufacturing Co. (TSMC), the world’s largest semiconductor manufacturer, saw its net profit rise 2.1% to NT$206.9b in the first quarter from NT202.7b a year earlier but the firm warned that sales will continue to slow down in the second quarter.

Broker sees easing competition for cement industry in Indonesia next year

SMGR announced that it would conduct a rights issue to acquire Semen Baturaja, and INTP announced that it signed a 3-year lease agreement to operate Semen Bosowa’s integrated plant in Maros. It is estimated that SMGR and INTP combined would have 83.2mtpa of integrated.

China’s BYD eyes EV production plant in Vietnam, says government

The planned factory will be used to manufacture and assemble EV units that will be sold in the country and the rest of Southeast Asia, according to Wang Chuanfu, founder, chairman and chief executive officer of BYD, during his meeting with Vietnamese deputy prime minister Tran Hong Ha on 5 May.

4 MANUFACTURING ASIA

INFORMATION TECHNOLOGY MARKET LABOUR INDUSTRIAL BUILDING & ENGINEERING

WATCH

PLANT

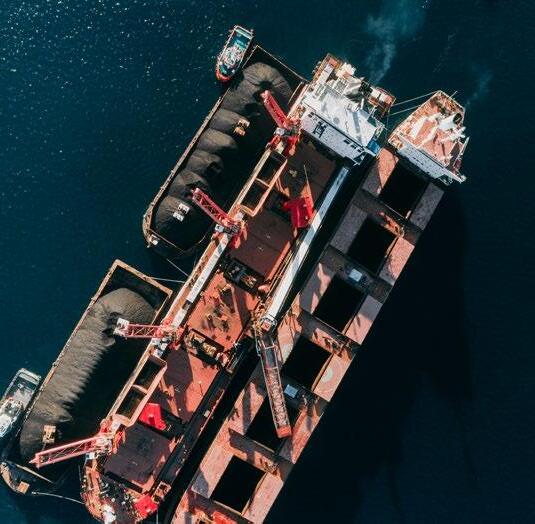

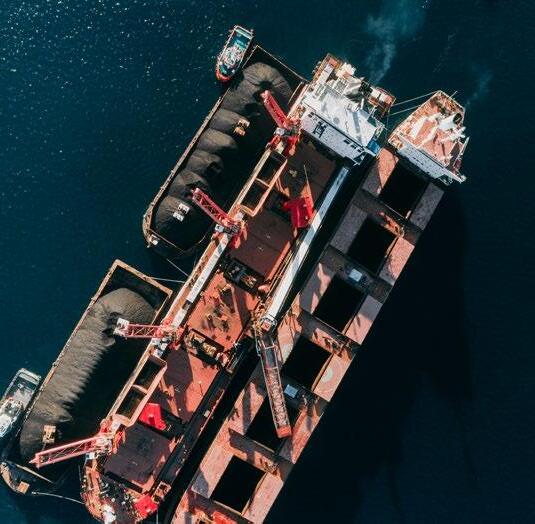

INDO’S SHIPYARDS REBOUND FROM HISTORIC DECLINES

Indonesia’s shipbuilding market has demonstrated resilience, achieving a 5% growth in 2023 despite a backdrop of historical declines and capturing 0.1% of the Asia-Pacific market share, according to a report by GlobalData.

Faced with intense competition from global giants like Huntington Ingalls and Samsung Heavy Industries, the sector is driven by significant R&D investments and innovation. However, it also confronts challenges such as high operational costs and material backlogs, which test the adaptability of market players.

Amidst these dynamics, Indonesian companies like PT. Batamec Shipyard and PT PAL Indonesia are advancing to secure and enhance their market positions.

R&D investment

Substantial R&D investments drive innovation, amplifying competitive pressures. Market dynamics, including government subsidies, vessel scrapping rates, and global seaborne trade volumes, significantly influence competitiveness.

UNCTAD’s Review of Maritime Transport reports a 2.4% increase in global maritime trade volume in 2023, further fueling market rivalry. Moreover, material backlog incurs significant storage expenses, hindering adaptability to market fluctuations. The Department of Scientific and Industrial Research notes shipyards’ substantial operating capital requirements during the building phase, typically ranging from 25-35% of the ship’s total cost, and further posing challenges for market entry.

What role do frontline workers play in tech?

When new technologies are introduced without consulting frontline workers, it often leads to frustration and resistance amongst the staff, undermining the effectiveness of these advancements. Involving these essential personnel from the outset not only smooths the transition but also harnesses their insights to enhance operational efficiency and technological integration, according to the World Economic Forum (WEF).

In a report, the WEF found that frontline workers in the industry appreciate employers who can effectively explain the benefits of and the rationale for introducing these technologies into their operations.

Hearing the plight of the workers during the decision-making process is also crucial to avoid making them feel ignored in a system that directly affects both the employees and the workflow.

For instance, in one of the interviews conducted, WEF said a factory that abruptly changed a perfectly working phone system in the production line without prior consultations with shopfloor workers only caused frustration among the employees.

“[The study] demonstrates how workers’ insights can be used to contribute to the process and thereby add value to companies, resulting in higher employee retention, improved employee satisfaction and a measurable return on investment (ROI) due to more efficient and effective technology introductions,” it stated.

Providing employees time and opportunity to explore and familiarise themselves with the new tech also goes a long way, according to WEF.

Demonstrations, training, support videos and even allowing them to take the devices home are just some of the initiatives manufacturers can employ to help workers be more confident handling the new technologies.

Employee buy-in

As the intended end-users, workers could also give helpful insights in assessing the risks and evaluating the effectiveness of the newly introduced tech, according to the study.

WEF also noted that managers have to guide workers at all stages of tech adoption, ensuring implementation timelines are clear and reasonable, and making sure effective support is available at all times to aid workers struggling with the tech.

After the introduction, workers were found to be open to providing feedback about the effectiveness as well as problems of the new system. All-hands meetings, follow-ups and online forms are some of the suggested methods to gather feedback from employees.

Acknowledging the contribution of the workers and rewarding excellent performance will also help keep employee morale up.

Central to an overall successful adoption is the continuity in utilising the technology. Having unsolved technical issues is one of the main reasons technologies are from the shop floor even though they are only adopted fairly recently.

In addition, supervisors can either coach or have one-to-one conversations to encourage workers to continue using the technology.

Moving forward, WEF said management and workers can work hand in hand in exploring new use cases for the installed technologies. It found that almost all interviewees talked about potential new use cases, new systems that could be applied, as well as points for improvement.

6 MANUFACTURING ASIA FIRST

Consulting with workers enables smoother adoption of new tech, WEF said

Valuing workers’ insights results in higher employee retention, improved employee satisfaction, and a measurable ROI

INDUSTRIAL

PROJECT

Paper outpaces glass and metals in packaging industry

The global packaging industry is witnessing a shift towards paper-based packaging, driven by its ease of manufacturing and sustainability advantages over glass and metals.

Saurabh Todi, Senior Research Analyst at Frost & Sullivan, said that paper recycling is increasingly gaining popularity as a sustainable alternative, with recycling rates in certain European countries reaching over 90%.

He explained that the key to paper’s rising dominance lies in its lower energy intensity in manufacturing compared to glass and metals,

coupled with its lightweight nature, resulting in reduced emissions per unit of packaging.

One of the major advantages of paper over plastics is its faster degradation rate and compostability. “Paper faces minimal sorting challenges, making it relatively easier to manufacture and recycle,” Todi noted. This ease of processing, along with growing consumer and regulatory pressures against single-use plastics, is bolstering the demand for paper packaging.

The trend is further reinforced by the impending merger of Smurfit Kappa and WestRock, set to create

the largest packaging company from a revenue standpoint. This merger, as assessed by Frost & Sullivan, signifies a major shift in the competitive landscape of the paper-based packaging industry.

“With a combined revenue of over $34b, this merger will not only form the largest paper packaging entity but also potentially the largest packaging company from a revenue perspective,” Todi said.

The merger, uniting Smurfit Kappa’s strong presence in Europe with WestRock’s footprint in the Americas, is expected to enhance the global competitiveness of the combined entity. This consolidation will create a significant gap between the new entity and its closest competitor, International Paper Company, which reports over $21 billion in revenue.

Regulation

Paper packaging is mainly impacted by regulations around unethical or unsustainable deforestation

As companies expand their presence in the paper packaging market, regulatory and industry standards around sustainability become increasingly crucial. “Paper packaging is mainly impacted by regulations around unethical or unsustainable deforestation, and the contamination and ecological impact it causes,” Todi remarked.

Certification programs like the Forest Stewardship Council (FSC) and the Program for the Endorsement of Forest Certification are essential for ensuring responsible forest management and sourcing practices.

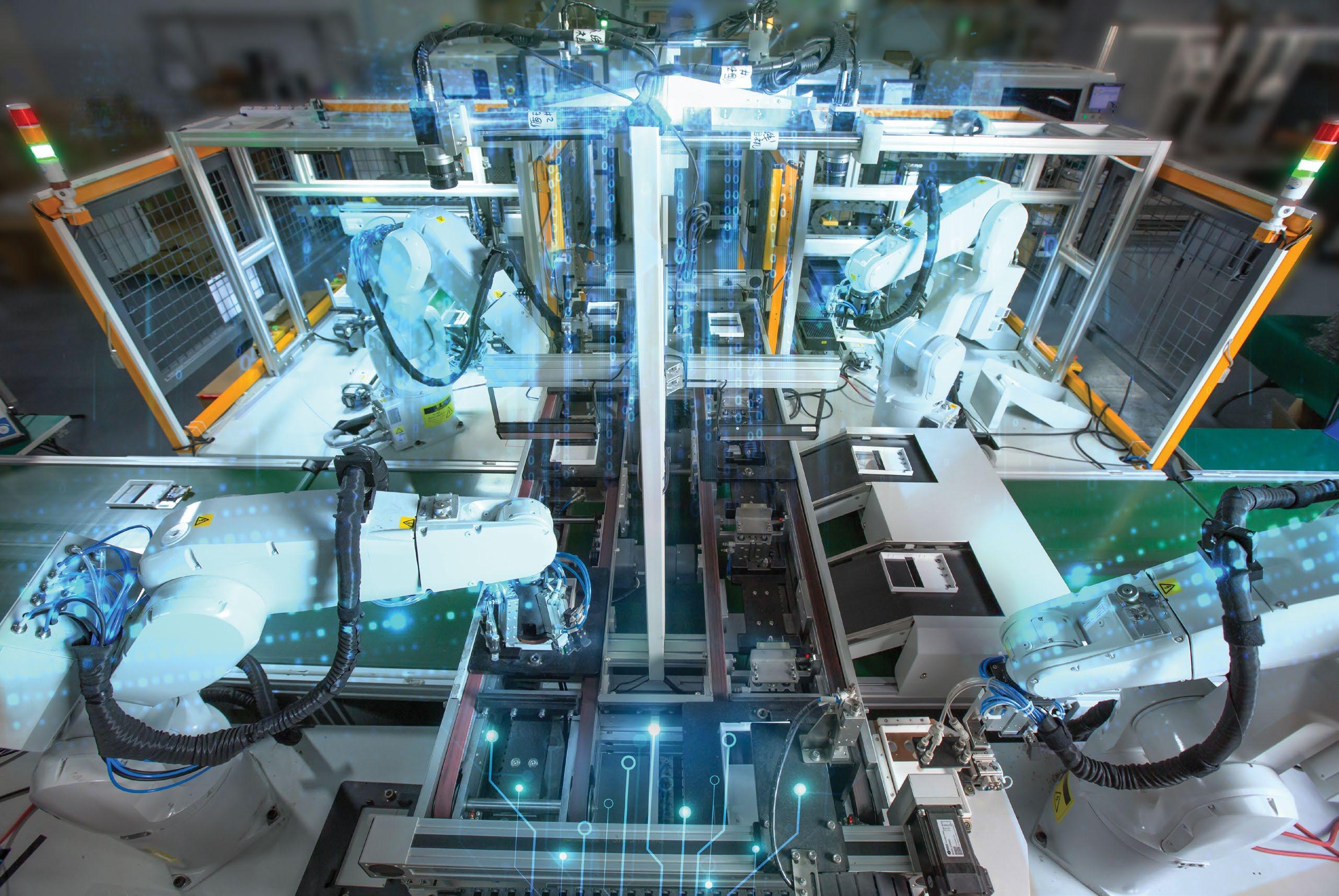

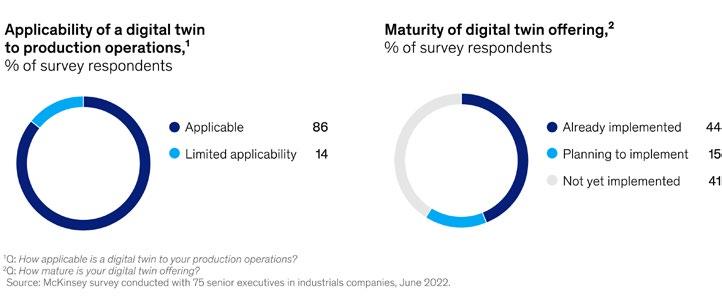

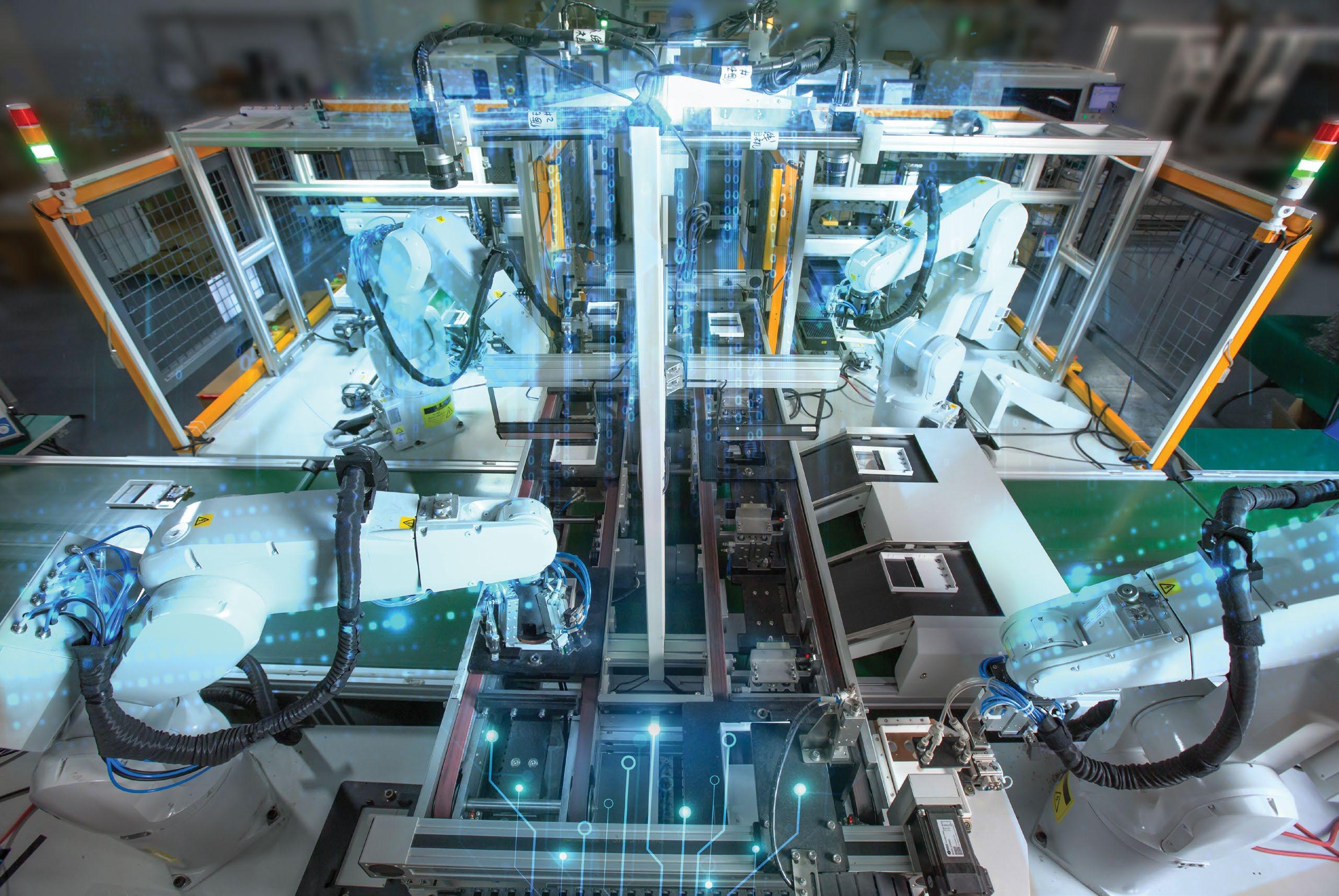

DIGITAL TWIN EMERGING AS A MUST-HAVE TOOL FOR MANUFACTURERS

As factories grapple with challenges like talent shortages and supply chain disruptions, McKinsey & Company emphasises the increasing need for digital twins. With the forthcoming integration of generative AI, digital twins are poised to become even more impactful, fundamentally transforming how manufacturers adapt to changes and strategise for the future.

A factory digital twin is a virtual replica of an existing or future factory floor that can simulate outcomes from real-time factory conditions, allowing companies to analyse, interact and test processes and layout changes in a virtual space.

From evaluating spatial parameters for assets such as clearances and employee movement within a cell to predicting production bottlenecks, uses of a digital twin vary depending on the requirements

and goals of each facility.

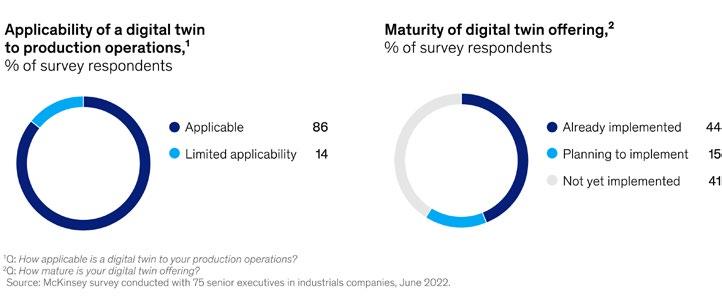

In a June 2022 survey, McKinsey found a whopping 86 percent of senior executives in the sector globally said digital twin is applicable in their production operations while nearly half, or 44% have already rolled out their own systems.

15% of the respondents were planning to implement and the rest still need to get started on that new tech.

Evolving with generative AI

McKinsey said that the digital twin tech will evolve further, and high-functioning AI models can make recommendations in real-time and even offer operators solutions to address supply chain disruptions.

“As these models and AI agents become more sophisticated and integrated, they will likely start to interact upstream to understand potential

MANUFACTURING ASIA 7 FIRST

A key benefit of paper over plastics is its quicker degradation and compostability

Applicability of digital twins

Source: McKinsey & Company

Saurabh Todi

RESEARCH

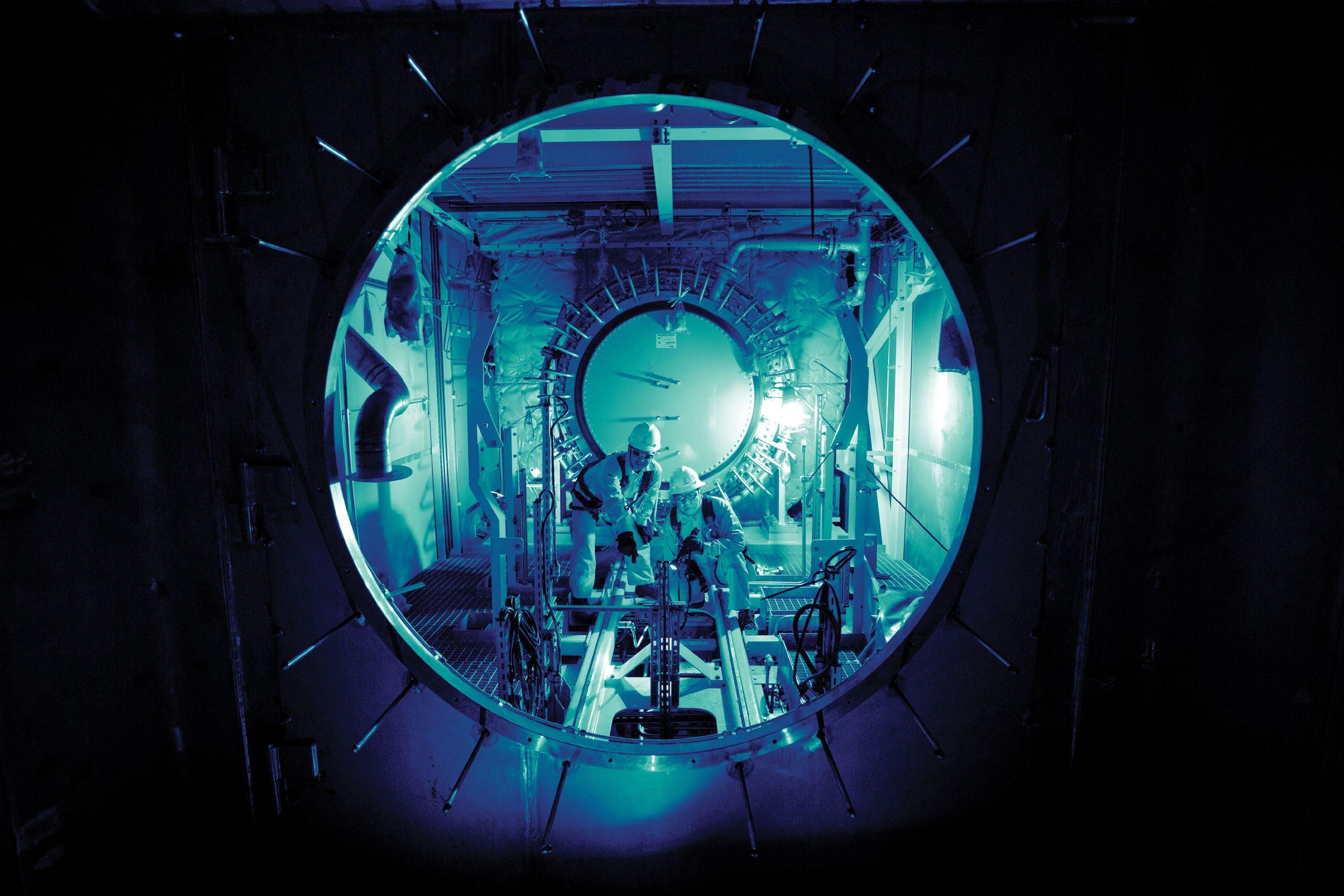

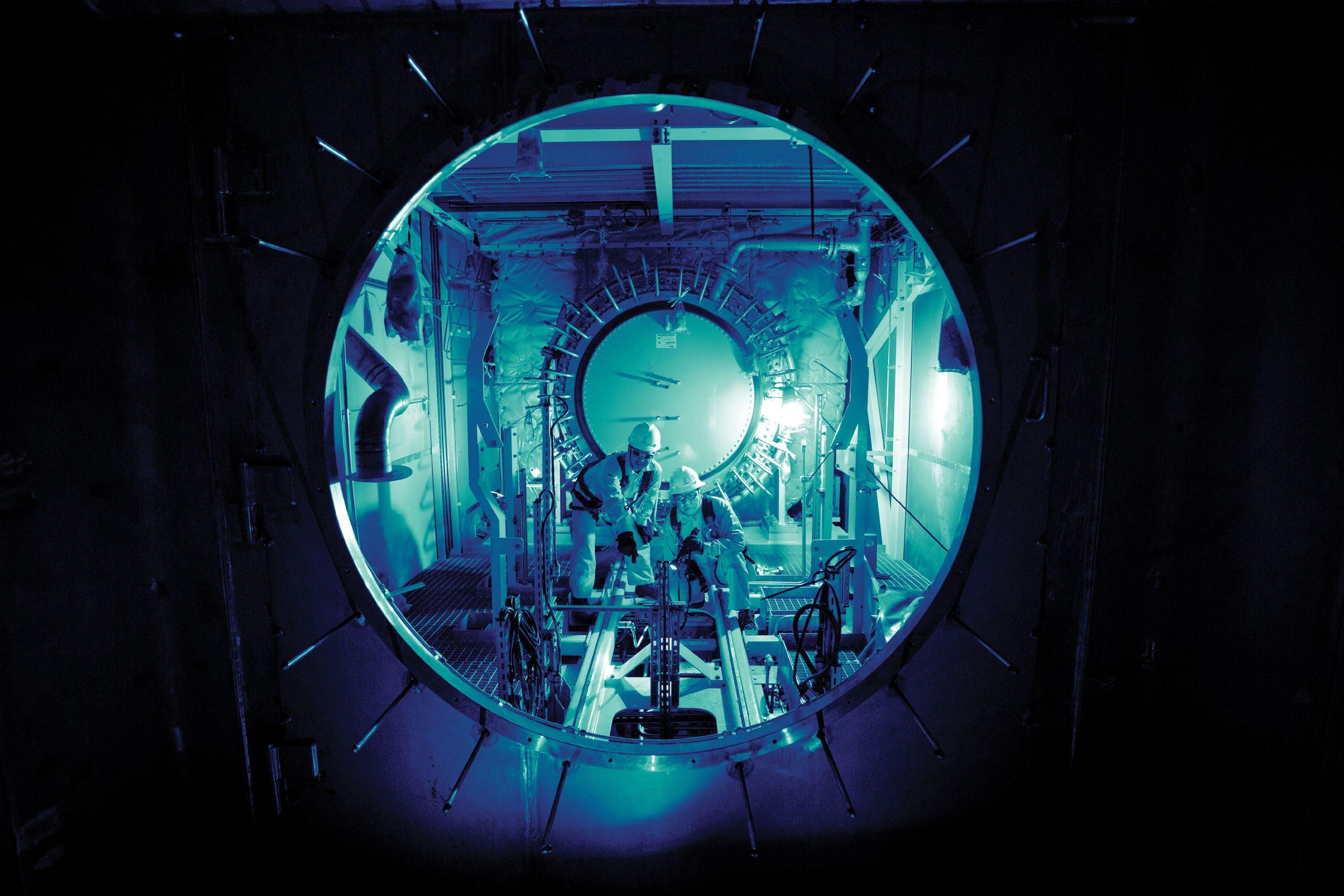

Overhead automation enhances safety at GlobalFoundries Singapore facility

GlobalFoundries’ system is capable of transporting wafers without requiring manual labour.

GlobalFoundries’ expanded factory in Singapore put up an advanced technology called an overhead automated material handling system. What it does is promote a safe working environment, pacifying concerns about the perceived hazards of manufacturing jobs that often deter potential talent.

Dan Steele, senior director of Global Environmental, Health Safety and Security Operations at GlobalFoundries Singapore, said they automated repetitive tasks by investing in robots, thereby freeing up employees from tedious work.

The overhead automated material handling system can perform 110,000 front-opening unified pod (FOUP) moves daily. “Much of manufacturing today has moved beyond the kind of labour-intensive, low-cost production that informs traditional stereotypes of manufacturing,” explained Steele in an interview with Manufacturing Asia

For further employee protection, Steele said the firm has invested in advanced detection capabilities for hazardous gases. The work environment is monitored on a real-time basis, and employees are promptly evacuated according to protocol if such gases are detected.

“Our gas detection limits are set at tighter restrictions far below the required level based on authority

guidelines,” Steele said. He said they also have an environmental safety team that conducts regular fire drills and emergency response training to prepare employees to respond to emergencies.

Near campus

The 23,000-square-meter expansion fabrication plant was built near the Global Foundries’ existing campus in Woodlands Wafer Fab Park.

“Being situated next to our existing facilities also enables us to easily tap into and share resources across fabs,” said GlobalFoundries Singapore Senior Vice President and General Manager Tan Yew Kong

“Choosing this location over setting up in a separate green field also aligns with our global expansion strategy and how we continue to build incremental capacity at our existing sites for greater economies of scale,” Tan shared with the magazine.

The company invested US$4 billion (S$5 billion) to set up the plant, which opened in September 2023. Over 1,000 high-value jobs will be opened, with 95% of the talent needed including equipment technicians, process technicians, and engineers.

8 MANUFACTURING ASIA

FACILITY WATCH: GLOBALFOUNDRIES

Dan Steele

SINGAPORE

MANUFACTURING ASIA 9

Oliver Healthcare Packaging expands to Malaysia with 122,000 sqft facility

This will be the manufacturing firm’s largest regional plant.

Oliver Healthcare Packaging announced plans to establish a new 122,000-square-foot manufacturing facility in Johor, Malaysia. It broke ground on February 2023 and will be completed by the end of 2024.

The company has positioned itself in Southeast Asia to target the large concentration of pharmaceutical and medical device companies operating in Singapore and Malaysia, its media release read.

The new manufacturing facility will operate ISO-7 and ISO-8 clean rooms to meet growing regulatory standards for medical packaging. It will produce pouches, lids, CleanCut cards, and roll stock.

“This site was strategically chosen to serve the large concentration of pharmaceutical and medical device companies that currently operate in Singapore and Malaysia,” said Michael Benevento, President and Chief Executive Officer of Oliver.

According to Oliver, this plant will emphasise sustainability throughout its manufacturing process. It plans to install solar panels to supplement and reduce dependency on local utilities.

“As a leading supplier of sterile barrier flexible packaging solutions, building our largest plant in Asia represents a significant milestone for us. This stateof-the-art facility will not only allow us to expand our production capacity, but also enable us to strengthen our capabilities to meet the growing demands of the biopharma, diagnostics, and medical device markets in Asia-Pacific,” said APAC general manager Kenneth De Muynck in his progress report.

Oliver also has a Technical Centre in Singapore where its research and development takes place, as well as manufacturing plants in the US, Europe, and China.

10 MANUFACTURING ASIA

MALAYSIA FACILITY WATCH: OLIVER HEALTHCARE PACKAGING

Michael Benevento

MANUFACTURING ASIA 11

Pupuk Kaltim adopts SNI to boost market trust

The leading fertiliser manufacturer pledges to ensure all products are SNI-compliant.

For key primary industries such as agribusiness, consumer confidence hinges on a public and reliable guarantee of the safety of chemicals used around people and the environment, making compliance with the Indonesian National Standard (SNI) crucial. Pupuk Kaltim believes that the Indonesian National Standard (SNI) plays a significant role in improving the company’s performance. They prioritise product quality to obtain the SNI label, making this standard an innate part of its ensuring product excellence in the free market.

Speaking to Manufacturing Asia, Budi Wahju Soesilo, the CEO of PT Pupuk Kaltim, asserted the crucial role of SNI for Indonesia’s largest fertiliser manufacturer.

“As someone responsible for ensuring the quality of products and services at PT Pupuk Kaltim, I have a strong commitment to implementing the Indonesian National Standard,” Soesilo said. “We realise that implementing standards is a crucial step to ensure that our products and operations meet or even exceed expectations, as well as ensuring the safety and reliability of our products.”

PT Pupuk Kaltim not only prioritises products with SNI certification but also implements various management systems that meet these standards. “By implementing and adhering to SNI standards, we are committed to providing high-quality products to our customers while maintaining the integrity and reputation of the company,” he said.

Concrete steps taken by PT Pupuk Kaltim include the implementation of ISO 9001:2015 certification and maintaining the quality of urea, NPK, and ammonia fertiliser products to meet SNI requirements.

The company has also adopted the Industry 4.0 framework through the implementation of Smart Production, a big databased system that enables the integration of operational data with pneumatic data and Distributed Control System (DCS).

Seal of safety

Compliance with the SNI is a must for all products intended to be distributed in the Indonesian market, whether they are produced locally or imported from external suppliers. The stringent application, assessment, and review process is developed to guarantee product safety and quality-both as a protection for the consumer and as a mark of reliability for the company, according to the Badan Standardisasi Nasional. Besides ensuring that the products are safe for use, these SNI stamps also weed out any counterfeit products from circulating in the market and prevent enduring damage to the environment. To date, there are 124 mandatory product categories subject to these tests, ranging from household items to industrial-grade chemicals.

Strong commitment

“SNI implementation is not only a crucial standard within the company but also a culture that we consistently apply,” Soesilo shared with the magazine. “We coordinate with the National Standardisation Agency (BSN) to raise awareness of quality standards at Pupuk Kaltim and its surrounding environment.”

PT Pupuk Kaltim has also set out a continuous evaluation and improvement system through its Standardisation Evaluation Study Team, which is formed every year to ensure product quality, Soesilo added.

Active involvement in the observance of National Quality Month is also part of the company’s efforts to support the implementation of SNI for all stakeholders.

“We are not only increasing consumer confidence but also enhancing the company’s competitiveness, both domestically and internationally,” Soesilo said.

SNI implementation is not only a crucial standard within the company but also a culture that we consistently apply

“We appreciate the programmes and services provided by BSN so far. In the future, we hope BSN can continue to improve its capacity to assess the conformity of products and services, thus protecting consumers and strengthening public confidence in Indonesian-made products,” he added.

The CEO concluded the magazine interview by affirming PT Pupuk Kaltim’s persistence in fortifying its role as a frontrunner in upholding superior standards, and yielding advantages not solely to the company but also to the broader industry and society.

12 MANUFACTURING ASIA

CEO INTERVIEW

Budi Wahju Soesilo, Pupuk Kaltim CEO

INDONESIA | by Ibnu Prabowo

MANUFACTURING ASIA 13

New automation strategies cut down human errors at Kawan Lama Solution

The company is aiming to capture a 30% market share in the industrial equipment sector in Indonesia.

To live the idea of being a leading manufacturer in the future, one must prioritise convenience in operations, especially for its workforce.

According to Vincent Mintarja, product director of Kawan Lama Solution, this future trend is why the two business entities within the Kawan Lama Group continually introduce innovative and high-tech solutions such as automation for raw material handling and packaging.

“In the future, there will be more convenience, and industries will no longer rely on conventional systems, such as manually moving flour. This convenience is not intended to eliminate jobs for operators but to reduce human errors,” Vincent told Manufacturing Asia

Established this year, Kawan Lama Solution is a merger of two business units under the Kawan Lama Group: PT Kawan Lama Sejahtera, which sells principal products like those from Mitutoyo and Nilfisk; and PT Krisbow Indonesia, which offers house brand products, such as imported household equipment labeled as Krisbow.

The two have automatically integrated their entire product lines and at present, Kawan Lama Solution represents a total of 100 principal brands. What makes perfect sense in this merger is that these two business entities complement each other.

“If customers require affordable products, we can offer Krisbow products,” Vincent shared with the magazine. “On the other hand, when they have a higher budget, we also provide products from principal brands.”

New technology solutions

Aiming to be a primary provider of equipment for both the engineering and commercial industries, Kawan Lama Solution has worked out its strategies to make innovation and convenience its distinct edge.

“To generate demand, what we do is create something new. For instance, we conduct research on which systems in factories are still manual, and from there, we offer technology to support them, transforming conventional processes into modern ones, making the factories interested,” said Vincent.

One of the new technologies introduced by Kawan Lama Solution is Material Transfer from Nilfisk, a manufacturing company from Denmark. Nilfisk offers an innovative solution for the automatic transfer of dry materials from one location to another. This reduces human contact in the pouring process, ensuring the cleanliness of processed products compared to manual pouring.

Additionally, this equipment reduces the potential for significant waste. For example, in the production of pharmaceutical tablets, raw material granules that are usually wasted can be reprocessed using the filters in this equipment, allowing the material to be reused. This equipment is not limited to the pharmaceutical industry but is also commonly used in the F&B sector.

Furthermore, Kawan Lama Solution offers a unique packaging solution from Youngsun that enhances

This convenience is not intended to eliminate jobs for operators but to reduce human errors

efficiency. “Kawan Lama Solution consistently brings products that are well-tested in the market and are premium and number one in their home country, such as Youngsun from China,” said Vincent.

The stretch feature in Youngsun’s wrapping machines claims to save up to 200%–300% in plastic wrapping usage. The automatic feature in the wrapping process also eliminates the potential for employee injuries during work. Youngsun’s wrapping machines operate at a speed of 80 packs per minute and are suitable for industries ranging from F&B to automotive.

Additionally, there is measurement equipment from Imada, which ensures precise measurements in the production process. This equipment can measure aspects like colour to ensure it matches the brand’s specifications. These days, the slightest difference in colours raises suspicion of being counterfeit products.

Moreover, there is a food texture measurement tool that can measure the thickness of items like bread to ensure it matches the desired specifications and maintains consistency between different product batches.

Precise measurements using this technology can reduce rework processes caused by inaccuracies in manual measurements. This measurement equipment is not only common in the F&B sector but is also used in other industries, such as shoe production.

14 MANUFACTURING ASIA INTERVIEW

Vincent Mintarja, product director of Kawan Lama Solution

INDONESIA | by Aulia Pandamsari

60 years pioneering toward sustainable water.

Toray Industries, Inc. has been developing Reverse Osmosis membranes since 1968. Today we o er a full lineup of membranes backed by our sixty years of experience. Our advanced membrane technologies and global operations ensure the success of any project.

At the Toray Group, we consider sustainability to be the most important global issue of the 21st century. Toray's Sustainability Vision for water treatment strives to achieve 3.5-fold water treated annually with our membranes by 2030 (compared to 2013). We will continue to provide advanced membrane technology such as RO membranes, further strengthen our technical services, and contribute to solving water problems worldwide.

HEADQUARTERS (TOKYO)

+81-3-3245-4540

ASIA PACIFIC

China : +86-10-8048-5216

Singapore : +65-6226-0525

South Korea : +82-2-3279-7000

MIDDLE EAST

Saudi Arabia : +971-4-392-8811

THE AMERICAS

California : +1-858-218-2360

EUROPE & SUB-SAHARAN AFRICA

Switzerland : +41-61-415-8710

Spain : +34-915-726-504

United Aarab Emirates : +971-4-392-8811

ROPURTM CSMTM

Toray RO

Materials Change Our Lives www.water.toray

Toray MBR Toray UF

TECH WATCH: CHIPLET PACKAGING

Silicon Box breaks bottleneck in chiplet packaging with sub-5-micron technology

The company’s technology reduces chiplet-based system packaging costs by up to 90%.

| by Noreen Jazul

In creating chips, designers have the propensity to prioritise manufacturing ease over performance. To eliminate any compromise, Singapore-based Silicon Box has come up with a chiplet integration technology that can expedite chiplet design cycles and reduce the cost of new devices.

Through its sub-5-micron technology proprietary fabrication method, Silicon Box has the “ability to package chiplets with the shortest interconnections,” leading the way for semiconductor integration whilst offering cost benefits to its partners.

Improved performance

Speaking to Manufacturing Asia, Dr. BJ Han, CEO and co-founder of Silicon Box, said that whilst the concept of chiplets is already well accepted across the industry, there is a bottleneck in advanced packaging capability and capacity.

“Our technology uses the shortest interconnections and the world’s first standardised large-format production for chiplet integration,” Dr. Han said. “Our approach has led to the highest electrical performance in terms of speed and bandwidth, the best thermal performance, and the highest reliability by eliminating material interfaces.”

By its own computation, Silicon Box has attained the improvement of electrical performance by over 50% and, at the same time, lowered power consumption by over 40%. This breakthrough is crucial because, as Dr. Han explained: “reducing thermal output means less power is required to cool the device, reducing energy use.”

To address the “missing link” in the “transformational movement towards chiplet adoption, Dr. Han co-founded Silicon Box with Dr. Sehat Sutardja and Weili Dai who were CEO and President at Marvell Technology Group, respectively.

“We are ‘box’-ing semiconductors in better ways!” said Dr. Han.

We are ‘box’-ing semiconductors in better ways!

Faster time to market

Apart from shortening the design cycle of chiplets and lowering new device costs, Silicon Box’s technology also allows faster-time-to-market for its partners involved in areas such as artificial intelligence (AI), data centres, electric vehicles (EVs), mobile, and wearables, according to Michael Han, head of business at Silicon Box.

“Our technology and manufacturing process lowers packaging costs for chiplet-based systems by up to 90%, whilst producing chips at high volume. This is because we are able to minimise the form factor of system packages, and manufacture in a large format,” he said.

Expansion plans

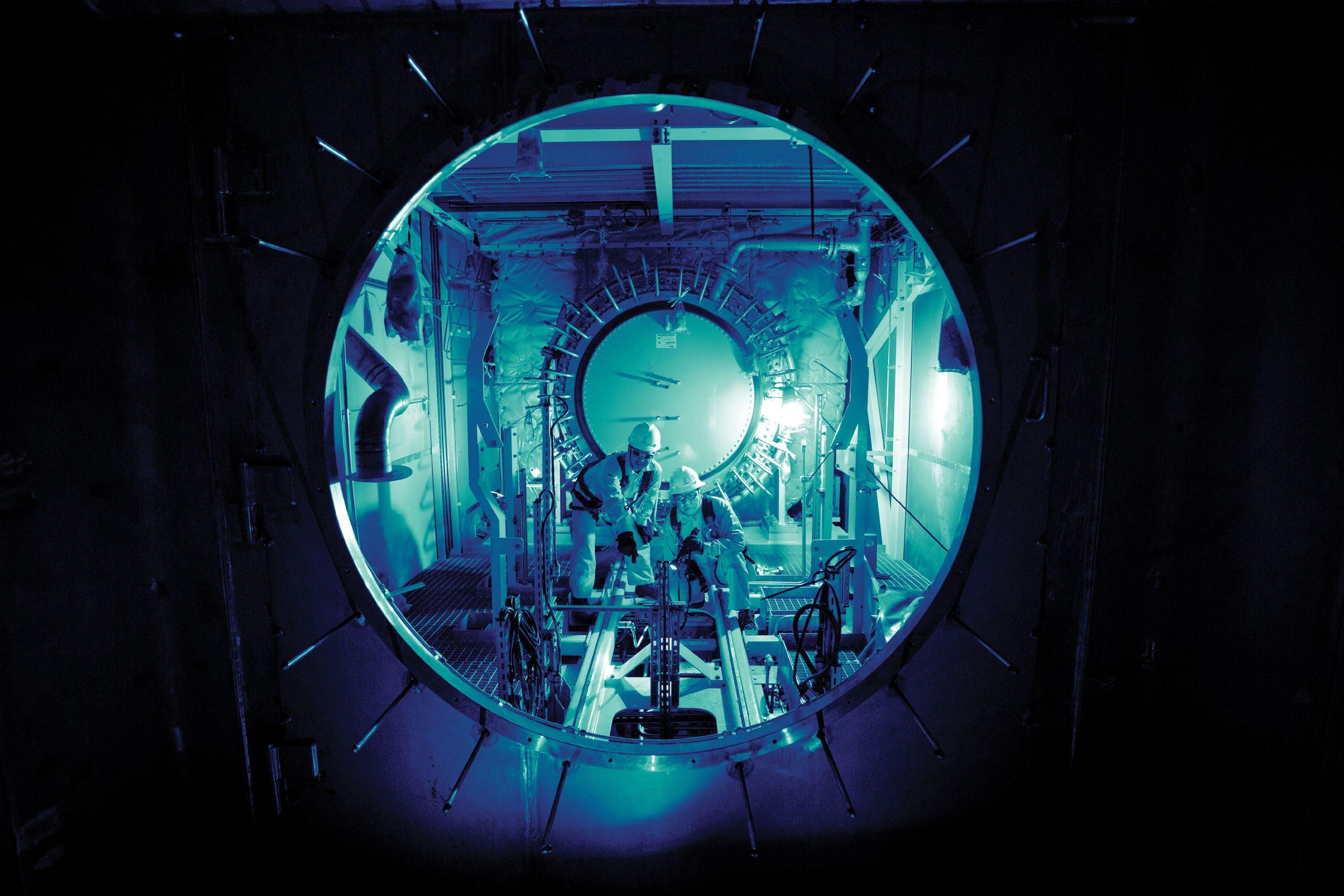

In July 2023, Silicon Box opened a 750,000 square feet semiconductor factory in Tampines.

“The factory houses a state-ofthe-art production line equipped to execute a one-of-a-kind, large-format fabrication method that improves the design cycle of chiplets,” he said.

Silicon Box business head said they are already working towards bringing the factory to full capacity and “exploring opportunities to replicate it in other locations” where there’s high demand for their services.

“Our technology can support a broad range of applications, and we have observed widespread interest and demand in our solutions, across different industries and the regions where they are based,” Michael said.

“We believe Silicon Box has catalysed greater creativity and enthusiasm in chiplet adoption to propel the semiconductor industry forward and to support the strategic silicon aspirations for diverse geopolitical blocs and industries,” he added.

Apart from expansion, Dr. Han told Manufacturing Asia that Silicon Box is also working on “the most advanced chiplet integration” particularly for AI, highperformance computing (HPC), mobile computing, data centres, electric vehicles, mobile devices, and wearables.

16 MANUFACTURING ASIA

The Silicon Box factory in Tampines (Photo from Silicon Box)

The

BJ Han

Michael Han

SINGAPORE

Whether you’re dealing with an increased workload or transitioning to low- and zero-emissions vehicles, we understand that having full visibility of your operations is key to running an efficient fleet. Manage all your fleet’s needs in one place with the Shell Card:

Manage your fuel and nonfuel-related purchases through a single, consolidated invoice.

Install charge points at your depot/ location or office. Reimburse your drivers for EV charging via the Shell Card.

Enhance security through chip, PIN and e-PIN features.

Access to our wide network of Shell sites for fuel and EV requirements.

Consolidate and collate your fleet’s data to create valuable operational insights, with Telematics.

Compensate for your fleet’s unavoidable emissions –to invests in independently approved, internationally recognised carbon compensation projects.

Your Shell Card can be managed via our online portal, Shell Fleet Hub, wherever you are.

Manage your fleet with one card and one invoice. Discover how the Shell Card can support your business: www.shell.com/fleetsolutions

MANUFACTURING ASIA 17

Talent gap slows growth in APAC semiconductor industry

Firms are investing in partnerships with universities and tech-based policies to boost STEM talent and training in the region.

Semiconductor companies across the Asia Pacific (APAC) region are doubling down on investments in talent development amidst a period of rapid technological advancement and a pressing shortage of skilled professionals.

To maintain a competitive edge and weather through these challenges, firms in the region are strategically focusing on employee career growth, skills enhancement, and the implementation of diverse strategic initiatives.

Talent development strategies

In Deloitte’s APAC Semiconductor Industry Trends report, over 90% of companies identified talent development as their primary investment focus to sustain industry growth and competitiveness.

The scarcity of qualified professionals, cited by 70% of respondents, leads to project delays and increased outsourcing costs.

Nearly 100% also emphasised the importance of providing clear career roadmaps, with 80% prioritising investment in skills development.

This aligns with the global sentiment highlighted in the 2024 KPMG Global Semiconductor Industry Outlook report, which sees

Over 90% of companies identified talent development as their primary investment focus

the shortage of skilled talent as the biggest industry challenge over the next three years.

To counteract this trend, semiconductor firms are implementing various strategies such as forging partnerships with universities to cultivate more STEM talent, reinforcing employee value propositions, offering remote work options, and providing enticing incentives like annual bonuses.

In Malaysia, for instance, the electronics and electrical sector boasts a workforce exceeding 600,000, supported by a robust educational system comprising 20 public and 53 private tertiary institutions, along with over 1,400 technical and vocational education and training colleges, according to EY’s report titled, “When the chips are down: ASEAN could be the answer to the semiconductor crunch.”

Nelson Samuel Wilson, consul and director at the Malaysian Investment Development Authority New York, explained that Malaysia’s position as a hub for advanced manufacturing and research and development is strengthened by its cost competitiveness and skilled talent pool.

In the Philippines, a highly skilled

and English-proficient labour force, with an average age of 24, also forms the backbone of the workforce.

Benedict Uy, Philippine Department of Trade and Industry Trade commissioner and director of the Philippine Trade and Investment Centre, New York, said initiatives such as innovation centres and technologybased policies are attracting top semiconductor companies.

Singapore, for its part, offers businesses access to skilled labour through various talent development schemes, including training grants and professional conversion programs, as noted by Jingxin Zheng, regional vice president for the Americas at the Singapore Economic Development Board.

APAC dominance

The APAC region accounted for a 57.6% share of the global semiconductor industry in 2022.

Amongst the top 15 global semiconductor companies, four hailed from APAC. China emerged as the world’s largest semiconductor equipment market, with the Chinese mainland and Taiwan accounting for 26% and 25% of global semiconductor equipment sales, respectively.

Geopolitical tensions such as the US-China trade war, RussiaUkraine war, and the South China Sea disputes, slow post-pandemic recovery, inflationary pressures, and demand fluctuations have collectively contributed to a slowdown in the region’s semiconductor market growth since 2021.

Still, nearly 50% of APAC semiconductor players remain optimistic, foreseeing accelerated market growth in the next three to five years. Many anticipate annual revenue growth exceeding 10%, with a focus on new product and solution development.

Future outlook

The global semiconductor market is anticipated to witness a surge of 13.1% in 2024, primarily fueled by a resurgence in downstream demand and sustained growth in the market for generative AI products and power discrete devices, according to Deloitte’s report.

18 MANUFACTURING ASIA

SECTOR REPORT: SEMICONDUCTORS

Benedict Uy

What do you see as the biggest issues facing the semiconductor industry over the next three years? Source: KPMG Global Semiconductor Industry Outlook Survey 2024 52% 1% 45% 30% 25% 24% 24% 20% 19% 17% 13% 10% Supply chain disruption Territorialism / The nationalization of semiconductor technology and intellectual propert y Talent risk (not enough skilled workers struggle for talent) Excess semiconductor production capacity High foundry cos t Increasing R&D cost s Government subsidies to localize investment in semiconductor s Semiconductor production capacity constraints Cyber security ASP erosion Other APAC

Nelson Samuel Wilson

MANUFACTURING ASIA 19

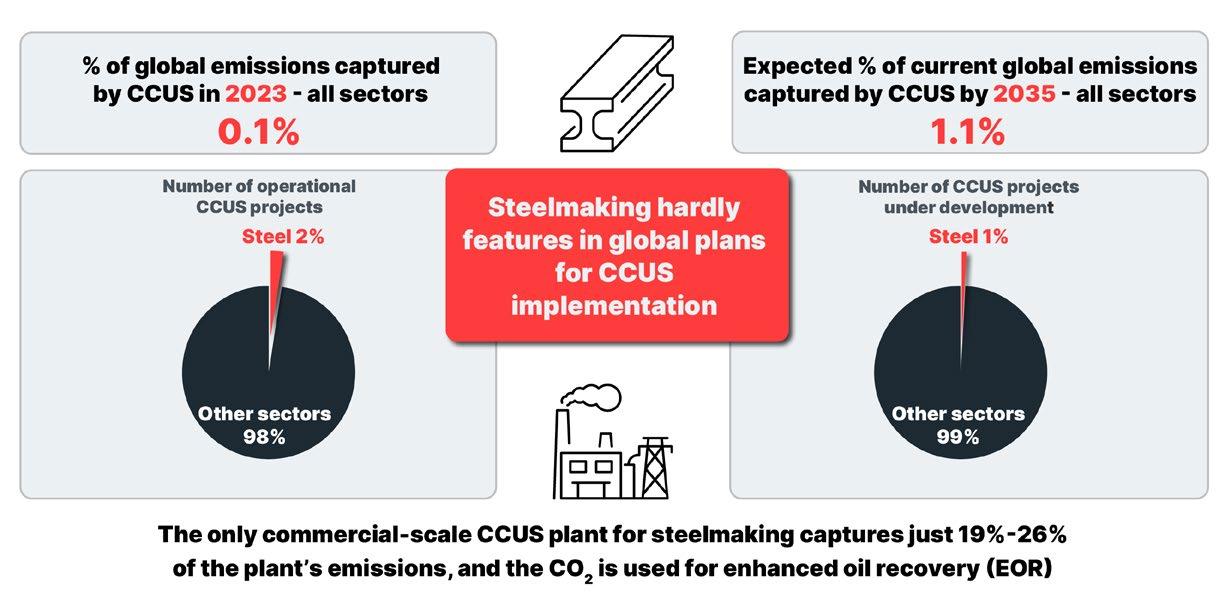

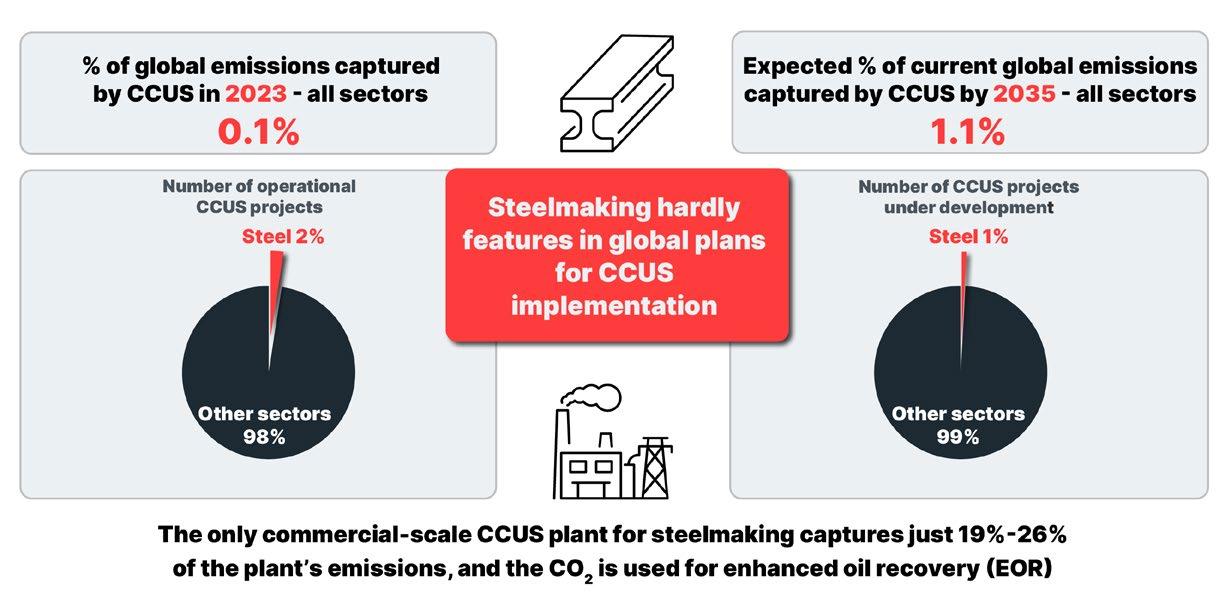

Global steel sector abandons carbon capture efforts amidst growing inefficiencies

The tech requires astronomical costs for installation, with no viable returns in sight.

Despite praises being sung as the next big thing in green tech investments, carbon capture utilisation and storage (CCUS) fails to live up to its promises to decarbonise the global steel industry.

Out of 13 large-scale CCUS projects implemented, five underperformed, two were suspended, one was mothballed, and two did not provide data that allowed performance to be assessed, the Institute for Energy Economics and Financial Analysis (IEEFA) revealed in its “Carbon Capture for Steel?” report, with figures supported by the Bloomberg New Energy Finance (BNEF).

Though the tech has been around for 50 years and given support during the 2023 COP28 climate conference, experts now question if capital should still be allocated for CCUS.

According to Simon Nicholas, lead analyst for the global steel sector at IEEFA, it may be time for investors to get involved.

“I think any investor in a steel company should be questioning that company if they are intending to put large amounts of capital into CCUS,” he told Manufacturing Asia in an interview. “I just don’t think it’s a good solution. Even the small scale, pilot scale projects we’ve seen in Europe have been expensive and captured very few emissions.”

High cost

Nicholas also said it looks “increasingly unrealistic that CCUS is going to evolve.”

One of the factors affecting the performance of CCUS is the cost of installing this technology. IEEFA noted that whilst the cost of alternatives – like renewable energy and battery storage – plunged, the price to implement carbon capture hardly reduced in 40 years.

The costly implementation of CCUS can be associated with the uniqueness of each project, Nicholas

If steel CCUS cannot advance in Europe where there is a significant carbon price, it cannot be expected to make headway in developing Asia, the seat of major steel demand growth

said. “There’s no turnkey solution, which you can fit to any project. Each project is different. It’s faced with different geology, different problems, different risks, different conditions, which makes it slow to implement and also keeps the cost high,” he explained to the magazine.

The expert said proponents have said what is needed is a significant carbon price. However, he noted that there is a significant carbon price in Europe which is not enough to encourage more projects on a commercial scale.

The IEEFA report also said that out of the combined 392 projects, only four are in the steel sector, including the operational Al Reyadah project in the United Arab Emirates. Three of these are for direct reduced ironbased (DRI) steel plants, not for blast furnace-based steelmaking which is the dominant and most carbonintensive process.

DRI-based steel making can run on green hydrogen with very low emissions, the report noted.

“If steel CCUS cannot advance in Europe where there is a significant carbon price, it cannot be expected to make headway in developing Asia, the seat of major steel demand growth,” the IEEFA pointed out.

Defining green steel

According to IEEFA, tighter definitions of what “green steel” it to be expected soon. This may put manufacturers implementing this technology at risk because steel produced this way may not be qualified as such.

Another risk they are likely to face is consumers not wanting coal involved in their supply chains at all.

Nicholas said the German steel industry has recently been setting their standard, but establishing a global one will be complicated.

“It’s hard to get one definition that covers all cases,” the IEEFA expert told Manufacturing Asia. “There will have to be quite a lot of legislation. We’ll probably see competing definitions, but then I imagine that one definition emerges as the benchmark at some point.”

Shifting to alternative IEEFA said that in the 2021 report of the International Energy Agency (IEA), titled “Net Zero by 2050: A Roadmap for the Global Energy Sector,” CCUS-equipped processes will make up 53% of global primary steel production in 2050. IEA’s Net Zero Emissions by 2050 Scenario said that 670m tonnes of CO2 would be captured from these processes.

20 MANUFACTURING ASIA SECTOR REPORT: STEEL

GLOBAL

Simon Nicholas

Carbon capture’s insignificant effect

Source: Bloomberg New Energy Finance, Global CCS Institute, IEEFA: Carbon capture for steel?

ANALYSIS: IP RIGHTS

AI ethics debate spurs IP rights discussion in design manufacturing

Industry experts from Dassault Systèmes say human creativity is irreplaceable.

The relationship between artificial intelligence (AI) and manufacturing emerges as a cornerstone of economic growth and technological advancement, especially at a time like Industry 4.0.

In an interview with Manufacturing Asia, Shrikanth Savant, director of Data Analysis and Science at Dassault Systèmes, said it is essential to understand the intricate dynamics of this fusion and the crucial role it plays in what’s known as Industry 4.0, a time marked by the digital revolution in manufacturing.

“We develop these tools that will help manufacturing design get better. So it’s not necessarily doing the task for them completely; it’s just reducing the tedium in the design process — as design is a fairly complex process,” said Savant. “And if we can integrate AI so that we can further reduce the tedium, I think this is something we would focus on working.”

AI as a design assistant

Building on the discussion of AI’s impact on manufacturing, the concept of generative design represents the cutting edge of innovation. Although still in its nascent stages, this approach synthesises user input with AI capabilities, empowering users to achieve their design goals at unprecedented speed and precision.

Savant also highlighted the beauty of AI’s role within 3D software platforms, saying that it acts as a supportive design assistant that streamlines the intricate process of designing without usurping user control. Also, central to this integration is the respectful treatment of data. Dassault Systèmes prioritises the development of AI models trained on proprietary data, ensuring customisation to meet user needs whilst respecting privacy and intellectual property rights.

Hype versus reality

In a media forum at the 25th 3DEXPERIENCE World in Dallas, Gian Paolo Bassi, senior vice

If we can integrate AI so that we can further reduce the tedium, I think this is something we would focus on working

president of 3DEXPERIENCE Works and customer role experience at Dassault Systèmes, and Manish Kumar, chief executive officer of SOLIDWORKS, shed light on the nuanced understanding needed to discern between AI hype and tangible advancements in CAD technologies.

“Because of ChatGPT, people have concluded that AI the same as generative AI. To me that is a misconception,” Kumar told the press.

Beyond ChatGPT

Kumar stressed that whilst generative AI garners significant attention, it represents only a segment of the broader AI landscape. He explained this distinction by recalling historical applications of AI in mundane tasks such as text recognition for postal services and highlighted the diverse functionalities encapsulated within the AI spectrum.

Moreover, Manish and his colleagues pointed out that the integration of AI into CAD software predates the current hype cycle. SOLIDWORKS, for instance, has been incorporating AI features for several years – 25 to be exact –including predictive commands and sketch auto-selection capabilities.

However, it was the recent surge in interest surrounding AI — catalysed in part by advancements in generative AI and large language

models like ChatGPT — that brought these capabilities to the forefront of industry discourse. Concerns about AI replacing human creativity were addressed, with a consensus emerging that whilst AI excels at data processing and pattern recognition, it cannot replicate the imaginative capacity unique to humans.

“Machines are very good at pattern recognition and transforming information from one place to another without changes, because humans are a disaster in a sense. If I tell you something and repeat that to another person, information could get lost,” explained Kumar.

A thought brought up during the discussion was the potential societal damage of overly relying on AI’s capabilities and overstepping one’s intellectual property (IP).

“We don’t see AI to give your users the final solution. AI will give multiple different ways or ideas to meet their specific needs. And when they try to evolve those ideas, they become copyright-protected or patentable, for that matter,” Kumar said.

“There is a philosophical aspect to the question: could AI become so dangerous to create reality? We have, at our disposal, technologies that wouldn’t be more dangerous than AI. Even if it does become dangerous, we are still able to contain it. I think the answer is always the same: it is the way we use technology,” Bassi reassured.

22 MANUFACTURING ASIA

AI acts as a supportive design assistant that streamlines the process without usurping user control (Photo from Dassault Systèmes)

Gian Paolo Bassi

Shrikant Savant

CEO INTERVIEW

SOLIDWORKS irons out its long-term strategy amidst evolving design and drafting industry

AI-driven capabilities are nothing new for the company with 29 years of experience.

The next three years lay out a period of growth for the product design and development services market, with manufacturers pushing a higher demand for advanced tools and software. The forecast for this specific market sets the compound annual growth rate (CAGR) at 10.9% between 2022 and 2027.

Fueling this growth projection are brands such as SOLIDWORKS, a unit of Dassault Systèmes that specialises in computer-aided design and drafting (CAD) software.

Speaking to Manufacturing Asia, SOLIDWORKS Chief Executive Officer Manish Kumar shared how he and his team are embarking on integrating artificial intelligence (AI) without disrupting creative rights — a strategic choice in research and development (R&D) and in meeting customer needs in the long-term.

Kumar also discusses the challenges in the short-term and how hands-on involvement of top executives ensures alignment in product development — mindful of security measures, must-have features, and future outlook.

Read on for the highlights of this exclusive sit-down with the SOLIDWORKS CEO.

As the CEO of SOLIDWORKS, how do you prioritise research and development efforts to stay ahead in the competitive CAD market?

SOLIDWORKS is part of Dassault Systèmes, and as part of that, we have a solid structure where we have teams and organisations whose job is to look into the industry trends. And that industry trend is fed into all the brands. SOLIDWORKS is one of the 13 brands of Dassault Systèmes, and we look at those trends and devise our strategy by looking at who our customers are, which market segments we serve, and what is most important to them. That defines our long-term strategy. Our short-term strategy is quite simple for the mainstream market. We look into what our users’ current needs are, what they are struggling with, and how we can serve them.

What are some key challenges SOLIDWORKS faces in integrating AI into its platform and engineering processes, and how do you address them? AI is nothing new for us. Even before AI became a household name, because of ChatGPT, we delivered AIdriven functionalities in SOLIDWORKS – which users are using in their day-to-day. SOLIDWORKS already had a structure in place, we already know, and we already know how to develop these. Now with ChatGPT getting more attention than before, we continue to say this: “AI is not new to SOLIDWORKS.” We are just more confident with delivering our services this year. However, there are many things in the pipeline that you will see a lot of AI-driven capabilities coming to our users.

How does SOLIDWORKS ensure the security and integrity of sensitive design data in its collaboration and product data management software?

SOLIDWORKS has only two flavours: with the cloud and on the cloud. Both are the very same SOLIDWORKS that people have been using in the past 29 years. But with every new licence of SOLIDWORKS, we give a licence to the platform so that people can have the option to save data to the platform. This enables people to have an option to save directly to the cloud platform or they can continue to save data wherever they were saving their files before.

Now with ChatGPT getting more attention than before, we continue to say this:’“AI is not new to SOLIDWORKS’

The reason why we are giving the two flavours is we are giving users an option to save data to the platform. And once the data is on the platform, then safety and security is our responsibility. If the data is on local premises, on your local hard drive hard disk or anywhere you want to keep it, the responsibility is in the user’s hands. With all these clients’ data on the platform, it needs to be extremely secure.

At SOLIDWORKS, we have a team of security experts who ensure that there are no loopholes in our firewall. We are part of a consortium called MITRE. Any vulnerability that is exposed, this organisation flags its partner members, making everyone aware of the threats. The moment the vulnerabilities are exposed, we immediately fix those in realtime – preventing any kind of attack.

24 MANUFACTURING ASIA

Manish Kumar, SOLIDWORKS CEO and R&D Vice President

GLOBAL | by Olivia Tirona

SCAN FOR FULL STORY

HKPC offers one-stop solutions and services to enterprises, including free consultations. By leveraging the New Industrialisation opportunities and utilising various substantial Government funding, HKPC works with enterprises to fulfil intelligent manufacturing and expand businesses.

Innovation and Technology Fund

Research and Development Cash Rebate Scheme (CRS)

Cash rebate equivalent to 40% of the local enterprise's eligible expenditure NO CEILING ON APPLICATION AMOUNT*

Maximum funding support: HK$15 MILLION All-round Support on Your Road to New Industrialisation Government

Re-industrialisation Funding Scheme (RFS)

Maximum funding support:

Reindustrialisation and Technology Training Programme (RTTP)

HK$500 THOUSAND

MANUFACTURING ASIA 25 For more details, contact us now: hkpcenq@hkpc.org (852) 2788 5678 The above information are for reference only. The announcement of related providers and implementation agents on the details of funding schemes shall prevail. *Projects amounting HK$30 million or above are approved by Legislative Council.

Funding

Funding Smart Solutions Smart

Government

Solutions with

Exceptional companies lauded at Asian Export and Manufacturing Asia Awards

The recent surge of technological innovations and growing environmental concerns have forced manufacturers and exporters to rethink their operational strategies as they continue to bounce back from the impacts of the previous global crises. Collaborative technologies are now presenting more opportunities for businesses in terms of providing real-time insights into the work processes and minimising friction points.

With the climate crisis being a definite issue that manufacturers and exporters have to navigate around, consumers’ attitude towards this is still going to largely affect how businesses thrive in these uncertain situations. Understanding their demands and habits are going to be key to remaining competitive.

Businesses that have become resilient and have worked on improving their operations with these factors in mind were amongst the standouts in the recently held Manufacturing Asia Awards and Asian Export Awards, held on 23 November 2023.

Manufacturing Asia Awards is an esteemed programme that

Asian ExportAwards 2023

Century Pacific Food, Inc

Philippines Excellence Award - Food

PLATINUM FRUITS

Thailand Supply Chain Initiative of the Year - Food

Pompous Sonthanhphat Limited (PSL Cashew)

Vietnam Export Product of the Year - Food

PT. Sampoerna Kayoe

Indonesia Sustainability Initiative of the Year - Wood Products

ManufacturingAsiaAwards 2023

Lee Kum Kee (Xinhui) Food Co., Ltd.

China Sustainable Manufacturing Initiative of the Year - Food

Millennium Group International Limited

Hong Kong Product Launch of the Year - Packaging

NCS Science Sdn Bhd

Malaysia Lean Manufacturing Initiative of the Year - Healthcare

PT Sasa Inti

Indonesia ESG Initiative of the Year - Food

Tyson Foods Malaysia

Malaysia Lean Manufacturing Initiative of the Year - Food

Malaysia Manufacturing Innovation of the Year - Food

Tyson International APAC Ltd.

Thailand Quality Control Initiative of the Year - Food

Vinda Malaysia Sdn. Bhd.

Malaysia Lean Manufacturing Initiative of the Year - Consumer Goods

Malaysia Manufacturing Innovation of the Year - Consumer Goods

ZTE

China Quality Control Initiative of the Year - Telecommunications

China Workforce Transformation of the Year - Telecommunications

celebrates innovation, efficiency, and outstanding achievements of game-changers in the heart of Asia’s industrial landscape, whilst the Asian Export Awards lauds the achievements of export companies that have maintained a strong presence in Asia and contributed to the region’s growth.

This year’s entries for both the awards programme were carefully evaluated by an esteemed panel of judges, including Richard Loi, Industrial Products & Construction Audit & Assurance Lead at Deloitte Southeast Asia, Atul Chandna, EY Asia-Pacific Supply Chain Leader; ASEAN Consumer Consulting Leader at EY, Chong Cheng Yuan, Partner & Industry Lead - Industrial Manufacturing Practice at RSM, Elayne Kuah, Director & Deputy Industry Lead - Industrial Manufacturing Practice at RSM, and Wu Hong Chiu, Partner, Head of Private Enterprise and Head of Infrastructure, Government, Healthcare & Manufacturing (Tax) at KPMG.

Congratulations to all the winners!

26 MANUFACTURING ASIA EVENT: MANUFACTURING ASIA AWARDS

Century Pacific Food, Inc

PLATINUM FRUITS

MANUFACTURING ASIA 27

PSL Cashew Lee Kum Kee (Xinhui) Food Co., Ltd.

Millennium Group International Limited

NCS Science Sdn Bhd

Tyson Foods Malaysia

Tyson International APAC Ltd.

Vinda Malaysia Sdn. Bhd.

ZTE

Platinum Fruits: Growing Together

Fruitfully

The company took home the Thailand Supply Chain Initiative of the Year - Food at the Asian Export Awards 2023.

Thailand is one of the world’s top fruit exporters. More than 2.94 million tonnes of fruits including the 4 Best Exotic Fruits – durian, longan, mangosteen, and coconut are shipped out of Thailand each year, at the value of BT172b. Amongst fruit and vegetable exporters in Thailand, Platinum Fruits ranks one of the top 5. Having been in the business for 3 decades, Platinum Fruits has placed quality and standards as our priority and never stopped exploring innovations to ensure mutual growth throughout the supply chain as guided by our vision and mission of “Growing Together Fruitfully”.

Growing: Driving the enterprise towards corporate goals by the avant-garde Management Team and staff that have innovation in mind.

Starting with the air shipment of durian and mangosteen to Taiwan under the “888” Brand in 1993, Platinum Fruits was established in 2010 and earned more than BT5,200m in revenue in 2022. Whilst products have been destined for markets across Asia and Europe, Platinum Fruits has set up 4 subsidiaries to support the fruit export business and create integrated services for agricultural

product shipments. All subsidiaries operate under international standards.

4 Subsidiaries

• 888 Fruits & Vegetables Co., Ltd. handles fruit and vegetable exports mainly to China, Taiwan and Europe.

• 888 Logistic Co., Ltd. operates a domestic and international container shipping business under ISO 9001: 2015 that encompasses a loading yard and Cold Chain service.

• Sky Shore Trading Co., Ltd. provides international shipping and customs clearance services with certification from the World Customs Organization.

• Sky Shore Depot Co., Ltd. caters a container yard service to multinational shipping companies.

Together: Building collaborative efforts that ensure a win-win opportunity for all involved parties in the supply chain, from employees to business partners,

suppliers, customers and farmers. China is the largest market for fruit exports from Thailand and is in high demand for “durian”. Platinum Fruits has gained trust following the ability to fix export troubles and ensure premium freshness and punctuality during the COVID-19 pandemic.

The successful business model was attributable to a collective effort. While Platinum Fruits truly understood the life cycle of durians, partners and suppliers provided insights into the specific preferences of Chinese consumers. With this knowledge, farmers ably churned out durians with the preferred taste and size.

Platinum Fruits has improved the logistics throughout the value chain. Quality assessment was conducted together with involved government agencies to ensure global standards. The Cold Chain logistics service was developed along with container yards for temperature control along the transportation route.

For freshness, all goods were handed over to buyers at the point where further distribution to spot markets could be done at speed. These efforts turned crisis into opportunity and have driven Platinum Fruits’ exports by 20%.

Fruitfully: Keeping in mind “Good Quality Product”, and enhance the quality of products and services at the premium level.

To meet customer preferences, Platinum Fruits has shared knowledge with farmers regarding soil nourishment, watering and fertilizer formulas and offered attractive prices. Our products are supplied by farmers with GAP and Global GAP certification; processed by factories certified for HACCP, GMP, GHP, DOA and Halal standards; and transported by a system that conserves freshness.

Confidence from partners, suppliers, customers and farmers is vital for business prosperity and transparencybased trust will lead Platinum Fruits and all involved parties towards a brighter future. The Asian Export Awards 2023: Supply Chain Initiative of the Year is another milestone that we have achieved.

Confidence from partners, suppliers, customers and farmers is vital for business prosperity and transparency-based trust will lead Platinum Fruits and all involved parties towards a brighter future

28 MANUFACTURING ASIA

THAILAND SUPPLY CHAIN INITIATIVE OF THE YEAR - FOOD

Mr Natakrit Eamskul, CEO, Platinum Fruits

SUMEET PURI

The Move to 5G: Enabling more resilient, event-driven supply chains in a new age of industrial manufacturing

The high-speed connectivity, low latency, and high bandwidth characteristics of 5G networks promise significant advancements in manufacturing and supply chain capabilities. For example, manufacturers on 5G networks will be able to connect billions of devices such as machine sensors and equipment, connected cars, and more with less network equipment, opening up a whole new world of applications and opportunities.

Some enterprises in Singapore are already eyeing 5G to re-engineer operations. Tuas Port, which will be the biggest port in the world once fully rolled out, is deploying a private 5G network to support 5G-enabled automated guide vehicles (AGVs) and Automated Cranes, while also exploring future use in Smart Grid5 and cargo handling operations.

The impending sunset on 3G networks offers the industry a widespread opportunity to revolutionise data-intensive processes, employ automated machinery, and establish real-time production and monitoring control – boosting the industry’s operations and service offerings.

But as the manufacturing industry embraces the full potential of 5G, the need for effectively managing and orchestrating real-time visibility across all levels of operations becomes paramount. The adoption of an event-driven operational framework – one that will be underpinned by an event-driven architecture (EDA) – will lay the foundation for a new era of agility and efficiency.

Unlocking opportunities unveiled by 5G in industrial manufacturing The advancements in 5G present both challenges and opportunities for manufacturers. By connecting more devices and sensors, huge waves of data are generated in near real-time, roughly 1000 times higher data volumes than are currently present on today’s mobile networks. The conventional architecture that funnels all data back to a centralised data centre will be insufficient for processing and responding rapidly to the ever-growing torrents of information delivered at 5G speed and satisfying end-user requirements.

This necessitates a change in how manufacturers architect their IT systems and manage their underlying infrastructure to deal with the extensive volume of real-time data. A faster, more capable, more bandwidth network backbone needs a complementing application data movement layer. A new approach is required to help manufacturers make the most of 5G – one that adopts EDA to allow them to reliably share data throughout the smart factory that spans edge, cloud and onpremise applications.

The role of an event mesh in 5G empowerment EDA – and by extension event mesh – is an application and integration architectural choice to fully leverage the 5G evolution. When networks become faster than disk, a radical shift in application development can bring about much better customer experience and insights into applications. We have already become accustomed to streaming music and movies, rather than downloading them, changing customer experience and insights in a never-before-seen way. This has also opened

SUMEET PURI Chief Technology Solutions Officer, Solace

SUMEET PURI Chief Technology Solutions Officer, Solace

a tremendous amount of business opportunities, while shutting down many businesses which did not see this shift coming.

For manufacturers to move at today’s speed of business, they must stream data from devices between the applications and microservices that process them in real-time so that insights can be gleaned and decisions made quickly. Take, for example, sensor data that indicates a faulty component on a machine. When that information is streamed in real-time, manufacturers can quickly schedule maintenance or repair work, ensuring that the problem is addressed with minimal production delays across the factory. In this case, the information exchanged between the sensor and application is called an event. This tag can also extend to any change, action or observation in a system that produces a notification. Other events can be more basic, such as a battery charge level threshold being met, or a periodic temperature reading from a sensor on a remote device.

Making use of the volume of events and the information in event streams requires an event-driven architecture, which promotes the production, detection, consumption of, and reaction to events. Adopting an event-driven approach to systems integration plays a crucial role in ensuring manufacturers effectively utilise 5G capabilities through timely, event-triggered interactions, which is particularly crucial given the intricacies of interconnected and data-intensive manufacturing operations. In this paradigm, manufacturers can plan how events are interpreted, transformed, published and subscribed, propagated across distributed networks so that the entire factory can be connected and reactive in real time.

Using event meshes

Complementing this, an event mesh acts as a communication layer that facilitates smooth data exchange among various applications and microservices, aiding in expediting decision-making. With an event mesh, manufacturers can easily allow events from one application to be published and then subscribed by any other application – no matter where these applications are deployed – with the scalability, performance, and security required to support today’s real-time applications. To make it more efficient for users, organisations such as GovTech have also developed an event catalogue that enables the discovery and sharing of event data, such as status updates or event streams in real-time, across both the Internet and Intranet.

Singapore-based PSA is one enterprise leveraging this evolution of 5G by becoming event driven. Most of the work at the port is performed by unmanned driverless vehicles, or AGVs, while creating new job opportunities. PSA plans to implement artificial intelligence, data analytics, robotics and other applications to bolster the nation’s maritime prominence.

The core of smart factory strategies is founded on a real-time event infrastructure that connects all elements, fostering end-to-end integration, event-driven processes, and heightened visibility across the global value chain. For high-tech manufacturers aiming to be competitive, implementing event-driven systems is imperative.

32 MANUFACTURING ASIA

OPINION

Tim Charlton

Tim Charlton

SUMEET PURI Chief Technology Solutions Officer, Solace

SUMEET PURI Chief Technology Solutions Officer, Solace