About Andrew Pearson Glassworks

Located in Mount Airy, North Carolina, Andrew Pearson has been manufacturing unique glass products for architects, designers, and furniture manufacturers since 1989. While we are a source for all kinds of glass, we specialize in thick kiln glass and custom laminated glass in a wide variety of styles.

As leaders in technology and innovation, Andrew Pearson Glass pioneered processes such as UV bonding that are now considered market standards. Andrew Pearson was the first to bond metal to glass, and the first to modify stone cutting machinery to finish our stunning glass creations. That creativity is what keeps our products at the forefront of many architects, interior designers, and furniture designers alike.

Several years ago, we developed new fused glass technologies to create our line of thick glass products. With fine-tuned processes in place, we launched our countertop, vanity, and stair tread lines for commercial and residential applications.

Since all our glass products are fabricated by hand at our North Carolina factory, we are able to easily accommodate orders ranging from small tabletops to bar tops for large restaurants, to expansive wall panels for hotel lobbies. We encourage you to contact us so we can help you find a glass solution to your next design challenge.

For more information: www.AndrewPearsonGlass.com

At right: Our Fusion Glass is available with a variety of bottom textures. It used as table tops as well as countertops and backsplashes.

Front Page: An LED backlit bartop made from ¾-inch thick Crackle Glass. Like many of our luxury glass surfaces, Facet Glass is ideal for applications well beyond standard table tops.

Product Overview

Fusion Glass

Our large custom-built kilns fuse glass to glass, producing a very durable surface for daily use. Our thermoformed glass is both beautiful and unique, and available from ¾” to 2” thick with a variety of possible bottom textures. This, combined with the fact that glass is non-porous and so very easy to sanitize, makes them perfect for both residential and commercial applications like kitchens, bathrooms, furniture, restaurants, and conference rooms.

Fusion Glass tops on Bathroom Vanities

Available in a variety of styles, Charleston Forge Vanities feature ¾”-thick, backpainted Ultraclear Fuzion Glass tops with the Minimal texture facing up. There are a variety of standard backpaint colors available. The bases are made of steel and available in any metal finish. The cabinets are made with wood veneers which do better in high-humidity environments than solid wood. The sinks, available in three colors, are made of hammered aluminum and the glass is predrilled for the faucet. Three sizes of vanity are available, ranging from 24 inches to 70 inches wide. The 35-inchwide Watson Single Vanity is shown at left.

A 2-inch thick Fusion Glass countertop.

Mirrored Glass Backsplash

Laminated Glass

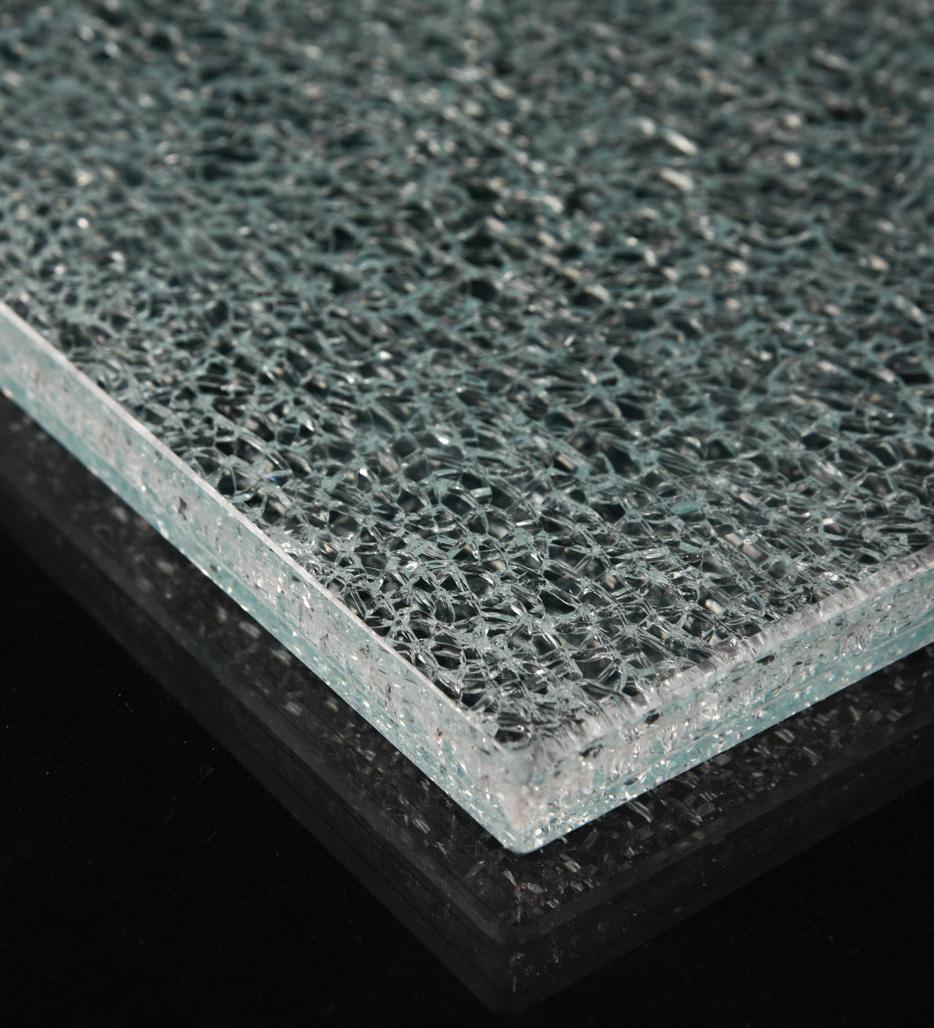

We seal fabric or paper between layers of glass through lamination to create a secure and permanent bond. Our skilled craftsmen can also safely crack the middle layer (seen at right) to create a unique and beautiful shimmering effect within the glass. Suitable for both residential and commercial applications like counter tops, backsplashes, furniture, and wall panels.

Back-Painted Glass

Add stunning color to your design project with our backpainted glass. Completely customizable and easy to clean, back-painted glass is an attractive and durable option in commercial and residential applications. We can match most major paint brand colors. We recommend using Starphire glass with back paint to get the closest match to the paint color.

Bonded Glass

We pioneered the use of UV lighting with super-strong adhesives to bond glass to glass and glass to metal. This application can be incorporated in many architectural projects. Entire tables can be made from glass bonded together to form a waterfall edge, or a metal puck can be bonded to the bottom surface of a table top to attach legs.

Custom Shapes, Holes, and Edges

Our artisan glass cutters have mastered the complexities of cutting all thicknesses of glass. We use our state-of-theart CNC machinery to cut and shape each order, then our edging machine applies the profile you desire. We can drill precise holes in glass and cut out virtually any shape or size to accommodate your design needs.

For more information

Please contact your local Charleston Forge sales representative or email us at glass@charlestonforge.com

Scan QR code to email us.